azbil公司及产品介绍

- 格式:pptx

- 大小:3.85 MB

- 文档页数:28

贝琪(阿折地平片)【药品名称】商品名称:贝琪通用名称:阿折地平片英文名称:Azelnidipine T ablets【成份】本品主要活性成份为:阿折地平。

化学名称:3-(1-二苯基甲基氮杂环丁基)-5-异丙基-2-氨基-1,4-二氢-6-甲基-4-(3-硝基苯基)-3,5-吡啶二羧酸酯。

化学结构式:分子式:C33H34N4O6分子量:582.65【适应症】本品适用于治疗高血压症,可单独使用,也可与其他抗高血压药物合用。

【用法用量】早餐后口服,一日一次。

成人的初始剂量为8mg每日一次,最大剂量为16mg每日一次。

剂量调整应根据患者个体反应进行。

一般的剂量调整应在7-14天后开始进行。

【不良反应】阿折地平在日本的临床研究提示,在总共1103例患者中共有159例(占14.4%)出现不良反应(自觉症状以及临床检查值异常)。

在383例65岁以上老年患者中有48例出现不良反应(占12.5%)。

在日本上市后的第4次安全性定期报告中,使用结果显示:5146例患者中有182例出现不良反应(包括临床检查值异常)(占3.5%)。

注:出现过敏时应停止给药。

【禁忌】下列患者禁用本品1.妊娠或可能妊娠的妇女。

2.对本品有过敏史的患者。

3.正在使用唑类抗真菌剂(伊曲康唑、咪康唑等)、HIV蛋白酶抑制剂(利托那韦、沙奎那韦、茚地那韦)的患者。

【注意事项】1.慎用1.严重肝功能不全的患者应慎用(因本品在肝脏中代谢)。

2.严重肾功能不全的患者应慎用(一般情况下,严重肾功能不全的患者伴随降压可能会导致肾功能减退)。

3.老年患者(见“老年用药”)。

2.重点注意事项1.据报道,突然停用钙拮抗剂时会使高血压病情加剧,停用本品时,应在医生的指导和密切观察下,缓慢减量直至安全停药。

2.给予本品时,很少数患者可能会出现血压过低,在此情形下应采取减量或停药等适当的措施。

3.因降压作用可能会出现头晕,因此高空作业、车辆驾驶、操作危险机械时应予注意。

No.CP-UM-5469C通訊控制器 CMC15G 多功能網關 使用說明書通訊連接篇POWER RUN CH1 RESET 1 2 CH 3 4ALM REC RS-232CLOADER USB CH2 11 12 13 1 2 EV 3 4 14 15 16 17 CH3RS-485CMC15G非常感謝您購買通訊控制器CMC15G。

本使用說明書中記述了安全、正確使用 CMC15G的必要事項。

對於承擔使用CMC15G的裝置的設計、維 護的工作人員請務必在閱讀理解本書的 基礎上使用。

此外,本使用說明書不只在安裝時,在 維護和故障維修時也是必不可少的。

請常備此手冊以供參考。

使用上的限制本産品是在一般設備上使用前提下開發、設計和製造的。

在有下列安全性要求的場合應用時,請在周全考慮了安全失效設計,冗餘設計及定期 維護檢查等系統和設備整體等的安全性的情況下使用。

・以人體保護爲目的的安全裝置 ・輸送設備的直接连接控制(運行停止等) ・航空設備 ・宇宙航天設備 ・原子能設備等 請勿把本産品用在與人身安全直接連接相關的用途上。

要求請確保把本使用說明書送到本産品使用者手中。

禁止擅自複印和轉載全部或部分本使用說明書的內容。

今後內容變更時恕不事先通知。

本使用說明書的內容,經過仔細審查校對,萬一有錯誤或遺漏,請向本 公司提出。

對客戶應用結果,本公司有不能承擔責任的場合,請諒解。

C 2007 Yamatake Corporation ALL RIGHTS RESERVED ○ⅰ本使用說明書的定位與CMC15G系列相關的使用說明書共有3冊。

請根據用途閱讀必要的使用說明書。

如果您手中無相關的使用說明書,請向本公司或代理店索取。

通訊控制器 CMC15G 多功能網關 資料編號 CP-UM-5463C 與CMC15G本體同包裝。

對安裝、設置上時的安全注意事項、安裝方法、電源、信號線接線等進行 說明。

通訊控制器 CMC15G多功能網關詳細篇 資料編號 CP-UM-5468C對本機的硬件及全部功能進行說明。

阿斯利康公司简介阿斯利康是全球领先制药公司,由前瑞典阿斯特拉公司和前英国捷利康公司于1999年合并而成。

阿斯利康在6大治疗领域为患者提供富于创新,卓有成效的医药产品,包括消化、心血管、肿瘤、中枢神经、麻醉和呼吸等,其中许多产品居于世界领先地位。

合并方简介阿斯特拉制药公司阿斯特拉是一家全球性制药公司,成立于1913年,总部位于瑞典的Södertälje。

公司从事制药产品的研究、发展、制造和销售,主要产品分为以下四大类:消化、心血管、呼吸和止疼。

在中枢神经领域也有一些产品。

公司还销售抗感染药等其它产品。

下属的阿斯特拉科技公司从事医疗设备的生产和销售。

合并时的主要产品· 消化类药物:洛赛克®(奥美拉挫)――全球销量最大的药品· 心血管类药物:倍他乐克®(酒石酸美托洛尔)、波依定®(非洛地平)、Ramace®(Ramipril)和Atacand®(双氢克尿噻)· 呼吸类药物:普米克®(布地奈德)、博利康尼®(硫酸特布他林)、雷诺考特®(布地奈德)和吸入剂推进装置· 麻醉类药物:赛罗卡因®(利多卡因)――全球销量最大的局部麻醉药1998年业绩· 销售总额为570亿瑞典克朗· 利润为160亿瑞典克朗· 研发费用为106亿瑞典克朗· 全球员工总数为22,000人捷利康集团股份有限公司1993年6月1日,帝国化学工业有限公司(简称ICI,成立于1926年)将旗下的三项业务(医药、农业化学和特种产品)剥离,组建了一家独立的公司——捷利康。

捷利康总部位于英国伦敦,从事医药、农业化学和特种化学品的研究、发展、制造和销售。

在医药方面主攻癌症、心血管、中枢神经系统、呼吸和麻醉等治疗领域。

捷利康在研发上有大量投入,拥有广泛的国际市场,强大的营销团队,和坚实的公共科学基础。

®®内部培训目录 企业简介、抗凝药概况、肝素类药物的演变和发展低分子肝素钙和低分子肝素钠的对比、赛博利基本信息低分子肝素钙作用机制、药理作用、作用特点、主要适应症低分子肝素钙适用科室、用法用量、市场分析、优势、营销策略企业简介深圳赛保尔生物药业有限公司是溢丰投资有限公司在华投资的高科技生物制药企业;公司拥有完善的现代化基因工程药物生产厂房、设施,和先进的生产技术、工艺设备。

生产规模在国内同行中名列前茅,产品出口东南亚国际市场,公司成为目前国内同类产品出口量最大的生产厂家。

公司于2007年获得“深圳高新技术企业”称号,2009年获国家“高新技术企业”称号,2010年获深圳市“劳动和谐关系企业”称号,公司生产的低分子肝素钙注射液(商品名:赛博利)获国家GMP和欧盟EMEA认证。

抗凝药概况抗凝药指在血栓形成前予以具有防止凝血,预防血栓形成的药物。

定义1、抑制凝血过程的药物:肝素类;2、抗维生素K药物:双香豆素,华法林;3、抗血小板药物:如阿司匹林等;4、降低血粘稠度的药物:低分子右旋糖酐5、丹参等活血化瘀的 中药分类肝素类药物的演变和发展分级或降解盐离子转换一系列化学工艺肝素:具有抗凝血功效,分子量15000道尔顿,最大副作用是出血,所以使用时需要不断检测。

低分子肝素:分子量小于8000道尔顿,同时具有抗血栓和抗凝血功效;使用过程中出血可能性小,不需要临床检测肝素钠:半衰期短,每天需多次注射.低分子肝素钠:皮下注射会出现出血点、淤青;且患者皮下注射会有疼痛感;大剂量使用,钠水储留,导致水肿。

低分子肝素钙:皮下注射后不减少细胞间毛细血管的钙胶质,也不改变血管通透性,基本上克服了皮下出血。

®赛博利低分子肝素钙注射液——产品基本信息通用名低分子肝素钙注射液商品名赛博利成分由肠粘膜获取的氨基葡聚糖(肝素)片段的钙盐药理低分子肝素钙是一种新型的抗凝血酶Ⅲ(ATⅢ)依赖性抗血栓形成药,其药理作用与普通肝素基本相似。

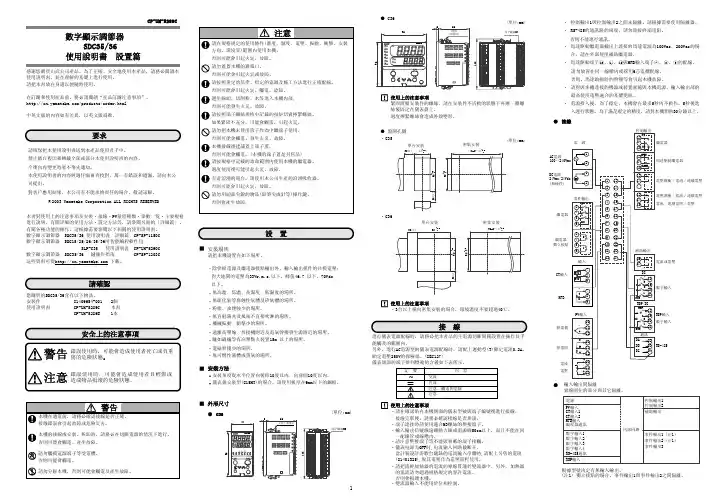

目 录要求请务必把本使用说明书送到本产品使用者手中。

禁止擅自复印和转载全部或部分本使用说明书的内容。

今后内容变更时恕不事先通知。

本使用说明书的内容,经过仔细审查校对,万一有错误或遗漏,请向本公司提出。

对客户应用结果,本公司有不能承担责任的场合,敬请谅解。

©2005 Yamatake Corporation ALL RIGHTS RESERVED在订货和使用时,请务必登入以下网站,仔细阅读“产品订购时的注意事项”。

/cn/products/order.html安全注意事項请确认本使用说明书的定位第1章 概 要 (1)第 2 章 安 装 (3)第 3章 接 线 (10)第 4章 调 整 (12)第 5 章 故障处理 (15)第 6 章 维护检查 (16)第 7章 规 格 (21)iii机壳安装螺丝维护套件1第1章概 要遮蔽器驱动用端子光电管单元标签热敏标签GF23第2章安 装●同时监视副烧嘴火焰及主烧嘴火焰的场合(连续点火、重复点火)请设定为监视副烧嘴火焰与主烧嘴火焰相交的范围。

●只监视主烧嘴火焰的场合(限时点火)请设定为主烧嘴火焰在低燃烧、高燃烧等任意燃烧状态下,都能监视火焰的最稳定部分。

特殊燃烧的场合,高燃烧与低燃烧分开监视,推荐用2台。

●副烧嘴火焰与主烧嘴火焰各自独立监视的场合(连续点火、重复点火)请勿把监视主烧嘴火焰的传感器误作副烧嘴火焰检测用。

当主烧嘴火焰的传感器作为副烧嘴火焰检测时,一旦主烧嘴断火,将不能进行断火检测,不能切断燃料。

●一个燃烧室中安装多个烧嘴的场合本机安装在每个烧嘴上时,请注意安装位置,以免会误检测到其他烧嘴火焰。

同时,当本机的光电管单元检测到火焰时,管内会产生放电现象。

通过这种放电,光电管单元放出紫外线,使用多个本机的场合,请作位置调整,以免检测到来自其他光电管单元的紫外线。

●冗余系统(重复监视)要提高系统的可靠性及尽量避免不必要的切断,建议重复监视。

可使用2套本机与烧嘴控制器的组合来监视1只烧嘴的火焰,构成冗余系统。

5th International Conference on Machinery, Materials and Computing Technology (ICMMCT 2017)A Study on Application of Cyber Physical System (CPS) in LimeProductionYouli ZhouDepartment of Bioinformatics Engineering, Yiyang Vocational & technical College, Yiyang Hunan,41300, ChinaKey words:Plaster, Automation, The configuration system.Abstract. Lime is important in the process of production of iron and steel materials, lime quality determines the quality of steel, lime production in China is much, but quality is not high, low efficiency, such as a direct result of the iron and steel production quality is not high. Automation so around this aspect research, in order to produce high quality white, produce high quality steel. Introduction and Scheme DesignAccepted Control System Scheme: CPS Automatic Control SystemFor purpose of the control system bidding scheme, we adopt the CPS automatic control system with AHC2001 hybrid controller as the core that is manufactured by Azbil Corporation and widely used for real-time control and monitoring of a 200,000 T/Y lime production equipment.(1) CPS system consists of control program assist—CPA; coordinating controller-AHC2001 hybrid multifunction controller.Control program assist (CPA) refers to graphic man-machine user interface running on Microsoft Windows NT/2000 operating system platform, of which the software attributes can be classified into engineer and operator. The attributes can be customized.(2) AHC2001 hybrid multifunction controller refers to high-precision controller developed by Azbil Corporation based on its longtime experience in the control field and with its controller technology that have been verified on spot.(3) The print server supports network printer. Hence, line-at-a-time printer and color ink jet printer both can realize print sharing via the network printer server. Line-at-a-time printer is usually used for print alarm records, while color ink jet for printing statements and copied images. Scheme Description and CPS ConfigurationScheme Description:The system handles four processes, i.e. loading, preheating, slewing and cooling. According to the drawings you provided: the abovementioned four parts are independent from each other in respect of control, and also coordinate with each other to constitute a whole control system to carry out the whole production process from loading to cooling.Based on the above information, we design a separate controller system for each of the abovementioned process, which are designed to realize data exchange via Ethernet. Between the host computer and all controllers, data exchange also is realized via Ethernet bus. The advantage of this is that the whole system follows a uniform data transmission protocol, so that data exchange is more convenient, flexible, transparent and faster. The connection diagram of each single system is as shown below:Specific configuration: 1 upper operation station, 1 engineer station. Engineer can use it for programming and configuration. The operation station is configured with operator attributor, which is for the use of operator.CPS system allows connection with the third party control system via serial interface and Ethernet interface.The print server supports network printer, so as to enable laser printer and color ink jet printer to realize network sharing as network printer, and visit client PC via the company’s information network to monitor historical information and batch processing.CPS DescriptionThe system has the features as below:Open architecture:For CPS, Microsoft Windows NT/2000 operating system is adopted. At the present stage, Windows NT/2000 is one of the operating systems of open architecture that are used most widely. It is convenient to connect P-LAN and a company LAN via TCP/IP protocol. The objects of other systems also can be switched in via OPC (OLE used for process control) or inset via DDE technology.Easy to operate and maintain:CPS is with a useful engineering tool developed by Azbil Corporation, which is not only used for the design of control strategy, but also for graphic and visual mode and creating engineering database/file for CPS system. SLPD-50 generates controller database that can be directly loaded in AHC2001 (coordinating controller).The database created with SLPD-50 is easy to modify, update and extend in the same manner online in future.Controller having been verified on spot:AHC2001 hybrid controller is used as the CPS controller, which can provide powerful logic block based on Boolean operation, text language of ST structure easy to use, regulation control function, and regulation calculation block with hybrid point technology.Hardware ComponentsCPA runs on personal computer: Pentium processor, 512MB SD RAM, CRT monitor: available sizes range from 17" to 21", with or without touch screen, mouse and QWERTY 101 keyboard.One or two printers can be connected to CPA via the parallel or serial channel of personal computer. Color printer, laser printer and line printer all can be used here.Digital multipurpose compact disc (CD) is a movable backup medium, which can be used for storing the whole engineering database and storing historical data for reference and analysis in future.Operation SecurityCPS system distinguish operator from engineer via password, in which different persons have different operating authorizations.Engineer’s Operating StationCoordination monitor station: CPA supports two types of operating characteristics: operator characteristic and engineer characteristic (also called universal characteristic). No new software needs to be installed in any engineering environment. If an engineer changes some control structures via CRT, the change will come into force immediately, and can be stored into the controller online.Operating MethodThere are three operating media used for CPA, i.e. 101 QWERTY keyboard, mouse and touch screen.In addition to mouse, operator also can realize operation via the touch screen of CRT. For group pictures and graphic pictures, operator can operate the set points, and control output via the up and down buttons on the screen of CRT.Graphic ImagesCPS system runs in Windows NT. Hence, bitmap units can be established. Moreover, the system has been installed with more than 60 graphic symbols. You can easily create new graphic symbols with the graphic editor. You can zoom in or out graphic symbols via the mouse. Every graphic symbol has its own attributes, such as color, size, use and function of defining users’ statement. Among the standard graphic symbols, bar graph, tendency chart and component diagram are created with OCX programming technique. The graphic pictures can be embedded and connected with other Windows applications, such as objects created with Microsoft Excel and Word, without affecting the image display function. The image types are as follows:Overview and Process Flow DiagramThe overview and process flow diagram shows the running state of devices, apparatuses and areas of the system, and the state, measured value, setting value, control mode (manual/automatic/cascade), and high or low level alarm and such information of procedure parameter variables, and can call out other images from the display block.Rotary Monitoring PictureThe rotary monitoring pictures are used for display and control the running state and the sending of operating instructions of devices of the rotary furnace.Trend PictureTrend picture shows the trend of any data marker of high way, and the trend record curve of eight variables in the same coordinate axis, in which parametric variables, colors and time intervals are available for users to select. Besides, the data axis can be zoomed in at random.Alarm ScreenThe alarm screen displays all procedure parameter alarms and hardware breakdown alarms in progress, can sequence the alarms in reversed chronological order, and differentiates the priority level and state of alarms via different colors. Unidentified alarms are flashing.Alarm contents cover:- Alarm time- Process variable name- Process variable description- Present value of process variable- Setting value of alarm- Engineering unit of process variable- Priority level of alarmProcess Flow Diagram ScreenThe graphic picture shows the images of process units, process flow diagram, schematic diagrams of equipment, line diagram, etc. Each picture shows letter and digital characters and graphic symbols. Usually, changeable colors, graphs and flashing are adopted to indicate different states of process variables. The value and state of all process variables are dynamically refreshed every second.Operator operates and adjusts related process variables in this screen.Bar GraphsBar graphs show the variation of process variables. For example, bar graph can be used to indicate the liquid level of tower vertically or horizontally. One screen can display 40-point horizontal or 64-point vertical bar graph.Report ScreenThe report screen displays and inquiries analog signal in the system and information of on/off state change of switch value, including label name, change state, change time, report, and record printing function.Reporting FunctionThe CPS system prints reports according to the pre-defined format. The collection and printing of report data can be conducted automatically in the user-defined interval or by means of event driven or by means of operator command.Report Type:- Class report- Daily report- Monthly reportRecord and Record Printing FunctionIn the case of change of alarm of any type, information, control parameter, control mode and operational attribute, CPS system will immediately start the printer for printing, and generate log database for future inquiry. The log record cannot be changed manually at will.This system provides a storage space larger than 100G. Hence, the historical data of alarm, information, operational instructions, historical trends and so on can be reserved longer than half a year. Besides, the abovementioned data can be automatically or manually transferred to external storage medium, such as CD, magnetic disk, MO, etc.System Maintenance ScreenSystem maintenance personnel can easily maintain the whole system via the system maintenance screen. From this screen, the maintenance personnel can observe the state of the whole system and the location and cause of system failure. The system maintenance screen contains the following contents: - System diagnosis picture- System maintenance picture- System working condition picture- Equipment status picture-AHC2001 Hybrid ControllerAHC2001 hybrid controller supports combinations of various types: control loop, logical function, sequential control, and I/O processing. Hence, users can combine the functions they desire most to address their application demands.I/O Processing- Input linearization/conversion to engineering unit- Multistage alarm- Input diagnosis- Output restriction and normalizationPV Calculation- Algorithm (accumulation, add-sub. multi-div. etc.)- Calculator function- Multistage alarmControl Calculation- Algorithm (PID-a, ra-PID, up-PID. etc.)- Initialization and track- SecurityLogical Control and Combination of Digit- Boole, timer and comparator- Input diagnosis and chain- Circuit disconnection alarm and chainSequential Control Programming- Parallel operation- Embedded exception handling- Batch order- Prescription data and intrinsic parametersSystem Diagnosis and Fault-tolerant CapabilityCPS system is provided with multiple diagnostic tools, and the diagnosis result can be displayed in multiple modes. Each AHC module is provided with an LED indicator for indicating its state. The contents to be indicated via the LED are:- Controller module (CPU module)Power/run/main LED and status display- Ethernet interface moduleRun/power LEDIn addition to LED indicator, the CPA also displays the system state, AHC state, and errors and realize confirmation.CPS is a system containing multiple CPUs, of which each module can independently fulfill its functions. Thus, any module with failure will not affect other modules.Print ServerIt can be realized to operate the historical database in the plant to automatically collect engineering operation data, and store the collected data as historical data for future use. Trend and status display can be realized via client software (correlation/backspace analysis, historical graphics, etc.), can connection to MS Excel/Access and browser software also can be realized.System CommunicationFor the communication, peer-to-peer digital communication system consisting of shielded twisted pair and switch is adopted, of which the transmission capacity reaches up to 10 Mbaud /100Mbaud. The switch is provided with 10BASE-T and 10BASE5 communication interfaces, which can meet information networking and management functions of a whole plant, and its communication protocol meets IEEE802.4, which can realize communication with equipment supporting TCP/IP protocol of a certain number that can meet the needs of LAN of a whole plant.Power Supply SystemRetention Time after Power Failure of Main AC Power SupplyRetention time after power failure under normal circumstances or in the case of full load: calculate according to the UPS capacity.DC24V Power SupplyExcept for digital output via electromagnetism value, all required DC24V is provided by the system. SoftwareWe will provide advanced, reliable and convenient system software. The software consists of software required by operating system, configuration, download, diagnosis and communication, as below:·Control and monitoring software SLPD-50This software is the latest software providing system configuration, application software download, system diagnosis and system communication and such functions, and also an indispensable software for project control system.·Application software CPAPoint configuration, logical chain, loop control scheme, sequential order program, image configuration and report, and so on manufactured in accordance with the needs of the buyer and the technological requirements.The abovementioned softwares are of the latest edition, and we can update software for users for free, provided that the base edition remains unchanged.System Configuration DescriptionControl Program Assist (CPA):1. Upper Operation Station: 1 sets- Pentium 4 2GMHz CPU- 40 GB HDD- 512MB memory- Mouse- 50X CD RW driver- QWERTY type 101 keyboardAmong the 2 sets, one is of universal attributes, that’s it supports both operator attributes and engineer attributes; and the other is of operator attributes, which is for operator use only.2. 19" color monitor: 1 set- Resolution ratio 1024*7683. Engineer keyboard: 1 set4. Concentrator: 1 set5. Operation desk: 1 nos.Printer and Printer Bench:1. Color ink jet printer * setReport printing and picture copying2. Line-at-a-time printer * setAlarm printingController Cabinet and Distributor1. AHC controller cabinet and distributer 1 coilBoth the controller and expander board are installed in the cabinet.Cables1. The company provides cables as below:- Communication cable (30 meters long for Ethernet network)- Extension cable: 3 meters long for installing in the cabinet to connect the controller to the expander board.- Peripheral cable of system (for printer).2. The required products that the company doesn’t provide include:- System cables other than the ones listed above- On-site I/O cable self-provided in the cabinet.Schematic Diagram of Control Network Composition Distribution Diagram of Upper Monitor System and ControllerCPS System and Network Structure DiagramSingle Line Diagram of Power DistributionSocketCPALine-at-a-time PrinterInk-jet PrinterOtherAHC2001 ControllerNoseplate CabinetSocketPDB Note 1: No illumination is provided in thecabinet.Note 2: The cabinet fan requires nodedicated power supply.ConclusionFor the whole set of the control system, we adopt a design idea of decentralized control and centralized management. For the host computer, an industrial personal computer is employed, so that the stability and reliability can be guaranteed in severe environment such as high temperature. Automatic control technology is an important product of the development of the computer age, whichneeds to be backed by strong comprehensive national strength and science and technology capability. This is also the goal of industrial development of our country. Presently, automatic control technology is almost used in all manufacturing, control and chemical enterprises, but we still have to import most hardware, software and systems from Europe, America and Japan. Therefore, cultivating and introducing technical talents have become the only way to improve China’s industrial production level.References[1]Wang Haijun. Evaluation of Reliability of Electric Automatization Control System of PowerPlant, Foreign Investment in China, 2012, (19).[2]Li Jing. Evaluation of Reliability of Electric Automatization Control System of Gangue PowerPlant, Energy and Energy Conservation, 2015, (1).[3]Song Wenkai. Humble Opinions on Application of Electric Automation Technology—CaseStudy of Huangling Mining Industry Gangue Electricity Generating Co., Ltd., China High-tech Enterprises, 2016, (1).[4]Li Chunguang. Application of Automation Technology in Electrical System of Power Plant,China High-tech Enterprises, 2014, (2).[5]Wang Hongying. Discussions on Reliability of Electric Automation System, Science &Technology Vision, 2014, (4).。