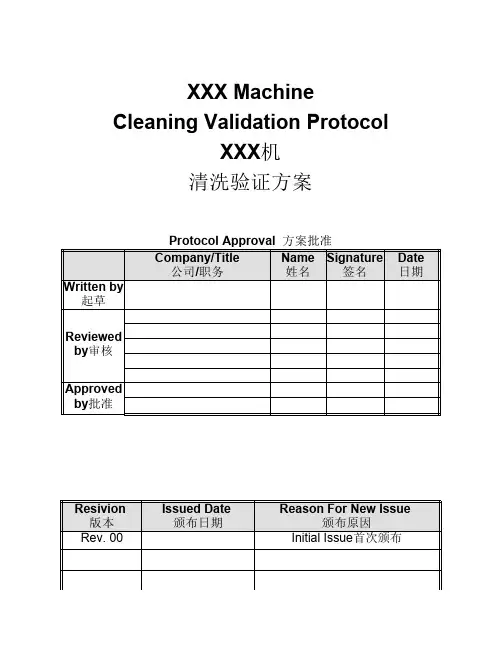

Cleaning validation(CV) protocol 清洁验证方案

- 格式:doc

- 大小:83.70 KB

- 文档页数:10

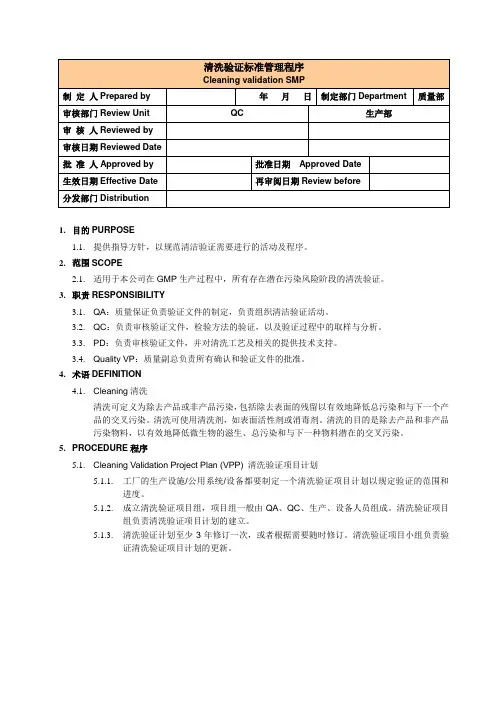

1.目的PURPOSE1.1.提供指导方针,以规范清洁验证需要进行的活动及程序。

2.范围SCOPE2.1.适用于本公司在GMP生产过程中,所有存在潜在污染风险阶段的清洗验证。

3.职责RESPONSIBILITY3.1.QA:质量保证负责验证文件的制定,负责组织清洁验证活动。

3.2.QC:负责审核验证文件,检验方法的验证,以及验证过程中的取样与分析。

3.3.PD:负责审核验证文件,并对清洗工艺及相关的提供技术支持。

3.4.Quality VP:质量副总负责所有确认和验证文件的批准。

4.术语DEFINITION4.1.Cleaning清洗清洗可定义为除去产品或非产品污染,包括除去表面的残留以有效地降低总污染和与下一个产品的交叉污染。

清洗可使用清洗剂,如表面活性剂或消毒剂。

清洗的目的是除去产品和非产品污染物料,以有效地降低微生物的滋生、总污染和与下一种物料潜在的交叉污染。

5.PROCEDURE程序5.1.Cleaning Validation Project Plan (VPP) 清洗验证项目计划5.1.1.工厂的生产设施/公用系统/设备都要制定一个清洗验证项目计划以规定验证的范围和进度。

5.1.2.成立清洗验证项目组,项目组一般由QA、QC、生产、设备人员组成。

清洗验证项目组负责清洗验证项目计划的建立。

5.1.3.清洗验证计划至少3年修订一次,或者根据需要随时修订。

清洗验证项目小组负责验证清洗验证项目计划的更新。

5.2.清洁验证的一般要求5.2.1.清洁程序通常应当进行验证,以证明清洁程序的有效性和重现性。

一般来说,清洁验证应当针对污染及物料易夹带给原料药质量带来最大风险的状况及步骤。

5.2.2.对于专用生产线或设备(指用于同一品种的生产),要求至少作连续3次的清洁验证。

对于专用生产线或一台非专用设备(指用于多品种生产),每种产品都必须做验证,且要求至少作3次的清洁验证。

5.2.3.设备使用完后应及时清洗,若使用放置一段时间才清洗,应对清洗效果进行评估或验证。

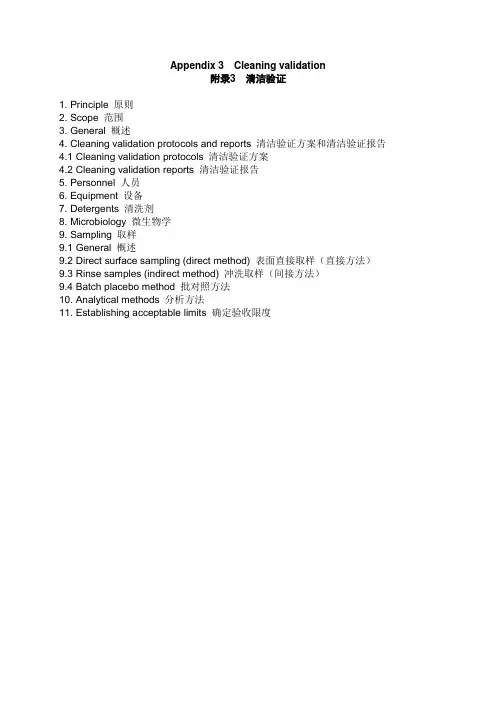

Appendix 3 Cleaning validation附录3 清洁验证1. Principle 原则2. Scope 范围3. General 概述4. Cleaning validation protocols and reports 清洁验证方案和清洁验证报告4.1 Cleaning validation protocols 清洁验证方案4.2 Cleaning validation reports 清洁验证报告5. Personnel 人员6. Equipment 设备7. Detergents 清洗剂8. Microbiology 微生物学9. Sampling 取样9.1 General 概述9.2 Direct surface sampling (direct method) 表面直接取样(直接方法)9.3 Rinse samples (indirect method) 冲洗取样(间接方法)9.4 Batch placebo method 批对照方法10. Analytical methods 分析方法11. Establishing acceptable limits 确定验收限度1. Principle 原则1.1 The objectives of good manufacturing practices (GMP) include the prevention ofpossible contamination and cross-contamination of pharmaceutical starting materials and products.GMP的目标包括了对药品起始物料和产品可能发生的污染和交叉污染进行预防。

1.2 Pharmaceutical products can be contaminated by a variety of substances suchas contaminants associated with microbes, previous products (both active pharmaceutical ingredients (API) and excipient residues), residues of cleaning agents, airborne materials, such as dust and particulate matter, lubricants and ancillary material, such as disinfectants, and decomposition residues from:许多物质都可能对药品造成污染,如微生物污染物、前个产品(包括活性药物成分API和辅料残留物)、清洗剂残留、空气物质如粉尘和颗粒物、润滑油和辅助材料如消毒剂、以及以下情况的分解产物:— product residue breakdown occasioned by, e.g. the use of strong acids and alkalis during the cleaning process; and如在清洁过程中使用强酸强碱引起的产品残留分解;和— breakdown products of the detergents, acids and alkalis that may be used as part of the cleaning process.可能用于清洁过程的洗涤剂、酸碱等的分解产物。

Objectives Cleaning ValidationCleaning Critical cleaning? Non-critical cleaning?Life Cycle ApproachCleaning validation Documented evidence(reports)Cleaning verification ●Documented evidenceQualification parts(1)Qualification parts(2) Qualification parts(3)Paradigm changeObjectives✓Cleaning processCleaning agent options ●Organic solventsDetergents Formulation disclosureCleaning parameters Cleaning parameters(cont.)Application methodsHow applyCommon steps●Pre-rinseCIP partsSpray devicesFixed (Sani-Matic)Rotating (Toftejorg)24CIP skidsFixed (CSI)Portable (CSI)Manual cleaning Manual issues●Control through…Design phase ●Identify and understandObjectives ✓Measuring effectiveness Residues measured●How selected?Key aspect of CV “Intersection”of two productsResidue limitsFor actives,dose-based calculationCare in terminology How low?In subsequent drug product“Default”limitsMaximum allowable carryover Limit per surface areaIn analytical test sampleIn units such asμg per swab orμg/mLOverall equation (0.001)(min.dose Act.A)(B.S.)(S.A.)Assessing protocol compliance●Most common approach is to make sureOther considerationsIndirect Contact Surfaces ●Indirect product contact surfaces are surfacesStill other considerations ●Are products dosed the sameLimit for microbes Calculations based on scientificallyVisual cleanness ●Include visual inspectionVisual cleanness alone●Based on European PIC/S guidance,someAnalytical methodSpecific methodSpecific methods(cont.)●Unequivocally measure targetWhy TOC acceptable?Non-specific methodsMeasure any species with aAnalytical method validation●Generally done for cleaning validationSwabsSwabs●Advantages56Swab pattern example Swabbing SOP●Swab(supplier and part no.)Number of swab sites Swab sampling locationsRinse sampling Two typesSeparate sampling rinse“Rinse”sampling ●AdvantagesReputation of rinse sampling ●“Bad name”because of misuse–Recovery studyAcceptable recovery How utilizeObjectivesEmphasis:scientific adequacy ✓Bulk biotech manufacture ChallengesDirty hold timeDirty hold time(2)●What?Clean hold time Clean hold time(2)●What done?Grouping strategies Grouping conditionsRepresentative product Representative limit Equipment groupingCV maintenance ●Must be similar typeRoutine monitoring during cleaning Change controlProcess deviations Regular reviewOther considerations Training recordsObjectives ✓。

CLEANING VALIDATION 清洁验证1 Cleaning validation should be performed in order to confirm the effectiveness of a cleaning procedure. The rationale for selecting limits of carry over of product residues, cleaning agents and microbial contamination should be logically based on the materials involved. The limits should be achievable and verifiable.清洁验证是为了确保清洁程序的有效性而进行的。

对于产品残留物清除、清洁剂和微生物污染的限度选择,理论上应该以相关原料为基础。

这些限度应该是可以达到的并且是可以被证实的。

2 Validated analytical methods having sensitivity to detect residues or contaminants should be used. The detection limit for each analytical method should be sufficiently sensitive to detect the established acceptable level of the residue or contaminant.应该使用经确认的、对于检测残留物或污染物具有灵敏度的分析方法。

每一种分析方法的检测限度应该足够灵敏来检测出符合可接受标准要求的残留物或污染物。

3 Normally only cleaning procedures for product contact surfaces of the equipment need to be validated. Consideration should be given to non-contact parts. The intervals between use and cleaning as well as cleaning and reuse should be validated. Cleaning intervals and methods should be determined.一般情况下,仅仅对于和产品接触的设备表面需要进行清洁验证。

设备的清洁验证概述

一、清洁验证的定义

清洁验证(Cleanroom Validation)是一种管理和验证有关设备、材

料和生产工艺的过程,旨在保证洁净室运行效果,维护洁净室封闭性,抑

制外部污染,保证洁净室内空气的质量和颗粒含量等。

二、清洁验证的目的

1、确保洁净室的空气清洁度达到符合规定的洁净标准;

2、为洁净室的操作和维护提供科学的具体指导,以实现高质量的生产;

3、定期进行清洁验证,可以使洁净室处于更加高效的运行状态,提

高生产效率;

4、清洁验证可以有效地提高产品的质量,为生产过程提供可靠的质

量保障,保证产品质量。

三、清洁验证的类型

1、性能验证:性能验证是指对洁净室、相关设备、材料等进行综合

评估的过程,主要包括:前期准备、空气灰尘测试和检测、测试空气的活

性氧测试、水蒸气测试、污染源控制测试、噪声测试等。

2、设备验证:设备验证是指对洁净室内的设备、工艺、制造工艺等

进行验证,目的是确保洁净室设备能够满足洁净室的空气质量要求,并保

证设备的安全可靠性。

3、污染源控制验证:污染源控制是指洁净室内的灰尘污染控制方案。

制药企业清洁验证和清洁确认取样中的一些注意事项6.4Additional Considerations其他注意事项Itis preferred to have a separate sampling SOP (apart from any specialinstructions in a cleaning validation protocol). This helps prevent “proceduredrift”, which might occur if the swabbing procedure text is just repeated inevery protocol. It also helps insure that the same sampling procedure is usedin recovery studies as in protocol execution, and thus simplifies training. Therinse sampling procedure may be the same procedure that is used for samplingwater systems, appropriately modified to cover sampling of process equipment.最好有一个单独取样的SOP(不同与清洁验证方案中任何特殊说明)。

这样可以避免“程序漂移”,如果在每个方案中重复擦拭取样程序的文字内容,则可能出现“程序飘移”。

这也有助于确保回收率研究采用与验证方案相同的取样程序,从而简化培训。

冲洗取样程序可同水系统取样程序相同,并适当修改以包含工艺设备的取样程序。

Inselecting sampling techniques, considerations should be given to thecompatibility of the sampling materials (such as vials, swabs, samplingsolutions) with each other, with the nature of the residue, and the nature ofthe analytical method. Furthermore, any requirement for cleaning or removing samplingmaterials from the sampled surface in a cleaning validation protocol should beaddressed in the design/selection of sampling methods, materials, andparameters.选择取样方法时,需要考虑取样材料(如瓶子,拭子,取样溶液)之间、取样材料与残留物特性以及分析方法之间的兼容性。

文件名称清洁验证管理规程文件编号起草:审核:审核:批准:年月日年月日年月日年月日颁发部门质量部生效日期年月日分发部门质量部存档、生产部、生产车间、QC、QA、设备部目的:设备容器具的清洗验证是证明按规定的清洗操作程序清洗后的设备和容器具,在使用该设备容器具进行生产药品时,没有来自上批/上品种产品及清洗过程所带来污染的风险,从而用该设备生产出来的药品是安全、纯净、有效的。

它是防止交叉污染的有效措施。

范围:本规程适用于与药品直接接触的设备、容器具和管道等。

责任:验证小组成员内容:1定义清洁验证Cleaning Validation:有文件和记录证明所批准的清洁规程能有效清洁设备,使之符合药品生产的要求;CIP在线清洁Cleaning in Place:通常指系统或较大型的设备在原安装位置不作拆卸及移动条件下的清洁工作;最差条件Worst Case:与理想条件对比,造成模拟产品清洁失败的最大可能的一种或者一系列的条件,包含标准操作规程中工艺和环境的上下限,这种条件不一定要导致产品或工艺的失败。

脏滞留时间Dirty Hold Time:生产后至清洁前的设备保存时间。

清洁有效期Clean Hold Time:清洁后至生产前的设备保存时间。

标的物Marker:一个产品或清洁剂的成分,作为分析物对产品或清洁剂总量进行定量。

半数致死量LD50:动物实验中导致50%死亡的剂量。

2清洁验证流程清洁验证的流程为:制定清洁SOP并培训→起草清洁验证方案(通过风险评估确定最差条件及验证策略)→确定标的物并制定可接受标准,开发并验证取样和检测方法→批准清洁验证方案并培训→执行验证程序(一般情况下连续三次)→完成验证报告→日常监控及变更→再验证。

3职责清洁验证是一个系统的工作,需要各部门的协同工作,验证小组主要由质量部、生产技术部、生产车间、设备部、研发部等其他可提供技术支持的部门组成。

QA:是清洁验证的组织者,主要负责起草清洁验证方案,组织验证过程的实施,以及验证过程出现的偏差处理和变更控制,并负责验证数据的汇总和完成清洁验证报告;QC:负责提供清洁验证中标的物分析方法验证工作,以及不同材质设备取样回收率试验,完成清洁验证的检测工作等;生产技术部:提供清洁验证的技术支持,负责提供生产工艺、审核清洁规程,协助QA完成清文件名称设备容器具清洁验证管理规程文件编号****洁验证方案、审核清洁验证报告等;设备部:提供清洁验证的技术支持,负责提供设备基本信息,协助QA完成清洁验证方案、审核清洁验证报告等;生产车间:提供设备、容器具等难清洁点,按照批准的清洁规程进行清洁,协助质量部门完成清洁验证;研发部等其他可提供技术支持的部门:提供相应技术支持,协助完成清洁验证。

Cleaningvalidation(CV)protocol清洁验证方案Cleaning validation(CV) protocol ofMixing tank、Storage tank、Transfer vehicle and Pipeline 配液罐、储液罐、移液车及其管道清洁验证方案Prepared by起草:Date日期:Reviewed by审阅:Date日期:Approved by批准:Date日期:Table of contents目录1.0 Summarize概述 (3)2.0 Purpose验证目的 (3)3.0 Responsibility验证职责 (3)3.1 Validation team验证小组 (3)3.2 Production department生产部 (4)3.3 Equipment department设备部 (4)3.4 Quality department质量部 (5)4.0 Validation scope验证范围 (5)5.0 Validation content验证内容 (5)5.1 Cleaning procedure清洗规程 (5)5.2 Sample Plan取样计划 (5)5.3 Test and Evaluation 测试和评估 (8)5.4 Re-validation and re-validation period拟定再验证及验证周期 (9)5.5 Conclusion 验证方案结论 (10)6.0 Approval of validation protocol验证方案最终批准 (10)1.0 Summarize概述: Mixing tank, storage tank, transfer vehicle and pipeline were used in alcohol wipe workshop for the 70% Isopropyl alcohol solution's storage and transporting. Because this system cleaning effect may affects the quality of theproduct, so we will perform a cleaning validation(CV) for this system. 配液罐、储液罐、移液车及其管道用于酒精擦片车间的药液配料、储存及药液运送,该系统的清洗效果直接影响到产品的质量,因此我们将对本系统进行一个清洁验证。

Cleaning validation(CV) protocol ofMixing tank、Storage tank、Transfer vehicle and Pipeline 配液罐、储液罐、移液车及其管道清洁验证方案Prepared by起草:Date日期:Reviewed by审阅:Date日期:Approved by批准:Date日期:Table of contents目录1.0 Summarize概述 (3)2.0 Purpose验证目的 (3)3.0 Responsibility验证职责 (3)3.1 Validation team验证小组 (3)3.2 Production department生产部 (4)3.3 Equipment department设备部 (4)3.4 Quality department质量部 (5)4.0 Validation scope验证范围 (5)5.0 Validation content验证内容 (5)5.1 Cleaning procedure清洗规程 (5)5.2 Sample Plan取样计划 (5)5.3 Test and Evaluation 测试和评估 (8)5.4 Re-validation and re-validation period拟定再验证及验证周期 (9)5.5 Conclusion 验证方案结论 (10)6.0 Approval of validation protocol验证方案最终批准 (10)1.0 Summarize概述: Mixing tank, storage tank, transfer vehicle and pipeline were used in alcohol wipe workshop for the 70% Isopropyl alcohol solution's storage and transporting. Because this system cleaning effect may affects the quality of the product, so we will perform a cleaning validation(CV) for this system. 配液罐、储液罐、移液车及其管道用于酒精擦片车间的药液配料、储存及药液运送,该系统的清洗效果直接影响到产品的质量,因此我们将对本系统进行一个清洁验证。

2.0 Purpose验证目的: Confirm cleaning procedure of mixing tank, storage tank, transfer vehicle and pipeline was reliability, to perform the cleaning procedure, right after a number of chemical pollution 确认配液罐、储液罐、移液车及其管道的清洗规程的可靠性,执行清洁程序后,不对后一批药液产生污染。

3.0 Responsibility验证职责:3.1 Validation team验证小组:3.1.1 Responsible for approval of protocol负责验证方案审批。

3.1.2 Responsible to coordinate the work of validation, ensure the implement of this protocol effectively.负责验证的协调工作以保证本验证方案规定项目的顺利实施。

3.1.3 Responsible for approval of validation report.负责验证报告的审批。

3.1.4 Responsible for signing and issue the certification of validation负责验证证书的发放。

3.1.5 Responsible for affirmed the period of validation负责验证周期的确认。

3.2 Production department生产部:3.2.1 Responsible for draft the protocol负责验证方案的起草。

3.2.2 Responsible for collected all validation data and submitted to the validation team. 负责收集各项验证记录,报验证小组。

3.2.3 If this protocol need to change because of specific cause, Equipment department should be responsible to fill 'the application and approval form of protocol change.若因特殊原因需变更原验证方案时,应负责填写“验证方案变更申请及批准书”,报验证小组批准。

3.2.4 Responsible for operation、cleaning and maintenance of equipment.负责设备的操作、清洗和维护保养。

3.2.5 Responsible for implement of this protocol.负责验证方案的实施。

3.2.6 Responsible for identified the re-validation period and protocol.负责拟定再验证方案及周期。

3.3 Equipment department设备部:3.3.1 Responsible for installing, adjusting the equipment and recording.负责设备的安装、调试并作好相应记录。

3.3.2 Responsible for the calibration of equipment and meter.负责仪器仪表的校正。

3.3.3 Responsible for providing mainly parameter of equipment.负责提供与设备有关的主要参数。

3.3.4 Responsible for assisting implement of this protocol.负责协助验证方案的实施。

3.4 Quality department质量部:3.4.1 The representative of Quality department should be involved in the approval of validation protocol and report.质量部负责人参与验证方案、验证报告的审阅。

3.4.2 Responsible for assisting the calibration of equipment and meter.负责协助仪器仪表的校正。

3.4.3 QA was responsible to supervise the validation process.QA对验证的过程实施监督。

4.0 Validation scope验证范围:Mixing tank, storage tank, transfer vehicle and pipeline 配液罐、储液罐、移液车及其管道清洗消毒验证.5.0 Validation content验证内容:5.1 Cleaning procedure清洗规程:5.1.1 According to YJ / SMP-PR-005 Daily cleaning procedure of Production equipment.按YJ/SMP-PR-005生产设备日常清洁和清洗指南操作。

Validate three continued lots.连续进行三个批次的验证。

5.1.2 The equipment operators should be trained and the training record should be finished and archived before they performed this procedure.在设备的操作人员执行清洁程序之前应该接受培训并完成培训记录及归档。

5.2 Sample Plan取样计划:5.2.1 Swab samples擦拭取样:5.2.1.1 sketch map of cotton棉签擦拭图:5.2.1.2 Worst case and sampling location最差条件和取样位置:Those location as following were not easy to be cleaned, so we will sample in those location.易进行清洗,因此在下列位置取样:Total 6 Sampling locations总共6个取样点:Table1表1:Part Name 部件名称Sample location取样位置Sample No.取样点编号Sample area取样面积(cm2)Mixing tank配液罐顶部喷淋装置后方 1 200底面搅拌浆遮挡处 2 200中部内表面 3 200 Storage tank储液罐顶部内表面 4 200中部内表面 5 200底部内表面 6 200Transfer vehicle移液车顶部内表面7 200 中部内表面8 200 底部内表面9 2005.2.2 Final Rinse samples淋洗水取样:Total 3 Sampling locations总共3个取样点:Part Name 部件名称Sample location取样位置Sample No.取样点编号Sample Volume取样体积(cm2)Mixing tank配液罐液体管道出口10 500(250*2)Storage tank储液罐液体管道出口11 500(250*2)Transfer vehicle移液车液体管道出口12 500(250*2)5.2.3 Hold time of cleaning 清洁保持时间:Conduct sample and testaccording to 5.2.1 at 1 week, 2 weeks, 3 weeks, 4 weeks after cleaningmixing tank, storage tank, transfer vehicle and pipeline placed in normalworkshop conditions. Because the concentration of Isopropyl alcohol will decrease as the storage time pass, the residue of isopropyl alcohol in first time is the highest; so microbial test was enough for this validation. Finally, we can determine the hold time of cleaned equipment according to the test results. 将清洁以后的配液罐、储液罐、移液车及其管道放置在车间正常环境中,至1周、2周、3周、4周。