铸造用英文翻译

- 格式:doc

- 大小:30.50 KB

- 文档页数:10

毕业设计(论文)外文翻译学生姓名:系别:机械工程系专业:机械设计制造及其自动化班级:学号:译文出处:Science and Technology Engl-ish for Mechanical EngineeringCasting、Forging and Welding1. CastingMetal casting is one of the oldest of all industries, both ancient and medieval history offering examples of the manufacture and use of casting. From simple axeheads poured from copper in open moulds some 5000 years age, casting in the pre-Christian world developed to a point at which elaborate bronze statuary could be produced in two-piece and cored moulds. By the end of the medieval period, decorated bronze and pewter casting had begun to be used in European church and domestic life.The widespread adoption of cast iron as engineering material awaited the success of Abraham Darby in 1790 in smelting in the coke blast furnace; this paved the way for the massive use of cast iron in construction during the years following the industrial revolution.Many foundries sprang up after the industrial revolution, the vast majority being for the manufacture of the cast iron then being used as a structural material. The quantity production of iron castings in the nineteenth century was not matched by a universal advance in quality and the engineering use of the products encountered more serious risks in a non-ductile material.Despite the skill of the molder in producing complex forms, there was little change in the metallurgical and engineering situation until the modern era brought a better understanding of the factors determining quality. With modern techniques of process control the rudimentary judgment of the operator could give way to objective measurements of metal temperature, molding material properties and other production variables. These improvements have been applied not only to cast iron but to a wide range of cast alloys.There are four basic casting methods: sand-casting, die-casting, investment-casting, and centrifugal casting.Sand-casting is the most widely used method employed in foundry. In this process, sand moulds are contained in metal molding boxes that have four sides but no top or bottom. During the molding operation the boxes are located togetherby pins so that they can be separated to remove the pattern, and replaced in the correct position before the metal is poured in. The boxes are clamped together, or the cope (top section) weighted down when pouring to prevent the cope from “floating away”from the drag (lower section) when the mould is full of molten metal. The sequence when molding the simple two-part mould to cast a bracket is illustrated as follows.At the first stage the pattern is seated on the moulding board. The pattern is covered with facing sand, which is a specially prepared sand of good quality, which can take a clean and smooth impression, and can resist the heat from the molten metal that will be in contact with it. The facing sand is backed up with molding sand, which is old facing sand from previous moulds. The molding sand is carefully rammed up so that it is fairly tight around the pattern to produce a good solid mould, yet permeable enough to allow the gases produced during casting to escape. The sand is finally leveled off.At the second stage the mould with the pattern still in position is inverted; the exposed sand lightly covered with parting sand, and the exposed pattern with facing sand.(The parting sand has no cohesion, and is introduced to permit a clean separation when the mould is opened up to remove the pattern .) The second molding box is located in position on the first box and filled with molding sand. Two or more plugs are introduced when the second box is being filled (these are removed later, leaving channels in the sand). One of these plugs is positioned to one side of the pattern. The sand is rammed up and leveled off.Now, at stage 3, to allow the pattern to be removed. This is done by screwing a bar with a threaded end into a suitable insert in the pattern, damping the sand around the pattern, and gently rapping the bar in all directions so that the pattern can be carefully withdrawn. To facilitate the removal of the pattern without scuffing the sides of the impression, all surfaces that lie in the direction of pattern removal are inclined slightly by a small amount (the draw angle).A groove called a gate is cut in the sand face to allow the channel producedby the plug that is outside the pattern to connect with the impression .The metal is poured through this channel (called the runner), and the gate prevents it from dropping straight into the impression and damaging it .The cross-section of the gate is slightly smaller than that of channel so that a full runner will always supply metal to the gate at a slight pressure.Finally, the mould is reassembled, carefully locating and securing the two sections. The top section is known as the cope, and the lower section is known as the drag. The sand in the cope is vented. These vents allow the sand to be rammed up more tightly at the earlier stages without the risk of gases being trapped in the molten metal and forming blowholes in the solid metal. A sand-feeding gate (also called a pouring or bowl) is added to make it easier to pour the metal into the runner. The molten metal is poured through the runner and the air will escape through the riser.The impression will be filled with molten metal when it is completely filled. Gases can escape through the runner and the riser, which also act as headers to supply the impression with more metal to compensate for the contraction of the metal when cooling in the molten state.2. ForgingForging is the plastic working of metal by means of localized compressive forces exerted by manual or power hammers, presses, or special forging machines. It may be done either hot or cold. however, when it is done cold, special names usually are given to the processes. Consequently, the terms“forging” usually implies hot forging done above the recrystallization temperature.Modern forging is a development form the ancient art practiced by the armor makers and the immortalized village blacksmith. High-powered hammers and mechanical presses have replaced the strong arm, the hammer, and the anvil and modern metallurgical knowledge supplements the art skill of the craftsman in controlling the heating and handling of the metal.Forge ability is the term used in the industry to denote a material relative resistance to deformation and its plasticity. While considerable disagreementexists as to precisely what characteristics the word “forge ability” should include, the term as used here is defined as the tolerance of a metal or alloy for deformation without failure, regardless of forging pressure requirements.Raw material used for forging is generally bar or billet stock hot rolled from ingots melted in open-hearth, electric arc, or vacuum arc furnace .other forms and shapes such as rolled slabs, plats, and stock produced by continuous casting techniques are occasionally used .for certain grades ,vacuum arc melting imparts better forge ability than does conventional arc melting . However, the major purpose of vacuum melting is the improvement of mechanical properties and cleanliness, not forging behavior.Equipment behavior influences the forging progress since it determines the feasibility of forging a part and affects the rate of deformation and the temperature conditions.The hammer is the most economical type of equipment for generating load and energy necessary to carry out a forging process, provided that the material being forged can support high deformation velocities. It is most commonly used hot forging equipment for repeated blows on the same workpiece and cannot be overloaded.There are various types of hammers: air-lift gravity drop hammers, power drop hammers, power drop hammers, Counterblow hammers ect. In a simple gravity drop hammer the upper ram is positively connected to a board, a belt, a chain or a piston. When forging the ram is lifted to a certain height and then dropped on the stock placed on the anvil. During the down stroke, the rain is accelerated by gravity and builds up the blow energy. The upstroke takes place immediately after the blow, the force necessary to ensure quick lift-up of the ram can be 3 to 5 times the ram weight. The operation principle of a power-drop hammer is similar to that of an air drop hammer. During the down stroke, in addition to gravity, the ram is accelerated by steam, cold air or hot air pressure. In an electro hydraulic gravity-drop hammer, the ram is lifted with oil pressure against an air cushion. The compressed air slows down the upstroke of the ram and contributes to its acceleration during the down stroke .thus; the electrohydraulic hammer also has a minor power hammer action.Press forging employs a slow squeezing action in deforming the plastic metal, as contrasted with the rapid-impact blows of a hammer. Hydraulic forging press is operated by large pistons driven by high-pressure hydraulic or hydrometric system. The squeezing action is carried completely to the center of the part being pressed, thoroughly working the entire section. These presses are the vertical type and may be either mechanically or hydraulically operated. The mechanical presses, which are faster operating and most commonly used, range in capacity from 5000 to 10000 tons.In the forging press a grater proportion of the total work put into the machine is transmitted to the metal than in a drop hammer. The machine and foundation absorb much of the impact of the drop hammer .press reduction of the metal is faster, and the cost of operation is consequently lower. most press forging s are symmetrical in shape ,having surfaces, which are quite smooth, and provide a closer tolerance than is obtained by a drop hammer .however ,drop forging can forge many parts of irregular and complicated shapes more economically. Forging presses are often used for sizing operations on parts made by other forging processes.For small forgings closed impression dies are used, and only one stroke of the ram is normally require to perform the forging operation .the maximum pressure is built up at the end of the stroke ,which forces the metal into shape .dies may be mounted as separate units, or all the cavities may be put into a single block. for small forgings individuals die units are more convenient .large ingots are now almost always forged with hydraulic presses instead of with steam hammers, since the work done by a press goes deeper. Further, the press can take a cooler ingot and can work to closer dimensions.The forging should be done at about the same temperature as rolling; the process improves the physical properties of the steel just as rolling does. In the final forging it is important not to have the steel too hot, for overheated steel will have poor mechanical properties when cooled. in heating for forging the temperature is usually judged by the eye, but where a large number of thesame patterns will be made, the pieces to be forged are heated in furnaces in which the temperature is indicated by pyrometers, and often is automatically controlled.3. weldingWelding techniques have become so versatile that it is difficult nowadays to define “welding”. Formerly welding was “the joining of metals by fusion”, that is, by melting, but this definition will no longer do. Welding was next defined as the “joining of metals by heat”, but this is not a proper definition either. Not only metals can be welded, so can many of the plastics. Furthermore several welding methods do not require heat. Every machinist is familiar with heatless welding method under some circumstances. Besides these, we can weld with sound and even with the famous laser. Faced with a diversity of welding methods that increase year by year, we must here adopt the following definition of welding:" welding is the joining of metals and plastics by methods that do not employ fastening devices”.There is also no uniform method of naming welding processes. Some processes are named according to the heat source or shielding method, other certain specialized processes are named after the type of joint produced. Examples are spot and butt welding. But an overall classification can not take account of this because the same type of joint may be produced by a variety of processes. Spot welding may be done by electric resistance, arc, or electron-beam processes and butt welding by resistance, flash or any of a number of other methods. Many welding processes are named depending on the heat applied, equipment used, and type of metal to be joined and the strength of the joint.Soldering is the process of joining two metals by a third metal to be applied in the molten state. Solder consists of tin and lead, while bismuth and cadmium are often included to lower the melting point. One of the important operations in soldering is that of cleaning the surface to be joined, this may be done by some acid cleaner. Soldering gives a satisfactory joint for light articles ofsteel, copper or brass, but the strength of soldering joint is rather less than a joint which is brazed, riveted or welded. These methods of metal are normally adopted for strong permanent joints.Pressure welding is known as the simplest method of welding two pieces of metal together. The ends of metal are heated to a while heat—for iron, the welding temperature should be about 1300℃—in a flame. At this temperature the metal becomes plastics. The ends are then presses or hammered together, and the joint is smoothed off. Care must be taken to ensure that the surfaces are thoroughly clean first, for dirt will weaken the weld. Moreover, the heating of iron or steel to a high temperature causes oxidation, and a film of oxide is formed on the heated surfaces. For this reasons, a flux is applied to the heated metal. At welding heat, the flux melts, and the oxide Particles are dissolved in it together with any other impurities which may be present. The metal surfaces are pressed together, and the flux is squeezed out from the center of the weld.Gas welding includes all the processes in which gases are used to obtain a hot flame. Those commonly used are acetylene, natural gas, and hydrogen in combination with oxygen. The maximum temperature developed by oxyhydrogen welding is 3600℉ (1980℃). Hydrogen is produced either by the electrolysis of water or by passing steam over coke. An oxyacetylene weld is produced by heating with a flame obtained from the combustion of oxygen and with or without the use of a filler metal. In most cases the joint is heated to a state of fusion, and as a rule, no pressure is used.Are welding is a process in which coalescence is obtained by heat produced from an electric arc. The electrode or filler metal is heated to a liquid state and deposited into the joint to make the weld. Contact is first made between the electrode and the work to create an electric circuit, and then, by separating the conductors, an arc is formed. The electric energy is converted into intense heat in the arc, which attains a temperature around 10 000°F (5500℃). Either direct or alternating current can be used for arc welding, direct current being preferred for most purposes. A d-c welder is simply a motor-generator set ofconstant-energy type, having the necessary characteristics to produce a stable arc. Arc welding uses commonly metal electrodes or carbon electrodes.Laser Welding is used because of laser’s high heat intensity. It can be operated in any transparent medium without contact with the workpiece, since the laser delivers its energy in the form of light. In welding, the power is delivered in pulses rather than as a continuous beam, the beam is focused on the workpiece and the intense heat produces a fusion weld. Laser welding is slow and is used only for special jobs involving small weldments. Its greatest use is found in the electronics industry.Explosion welding is a process that uses energy from the detonation of an explosive to join two pieces of metal. The explosion accelerates the pieces to a speed at which a metallic bond will form between them when they collide. The weld is produced in a fraction of a second without the addition of filler metal. This is essentially a room temperature process in that gross heating of the workpieces does not occur. The faying surfaces, however, are heated to some extent by the energy of the collision, and welding is accomplished through plastic flow of the metal on those surfaces. Welding takes place progressively as the explosion and the forces it creates advance from one end of the joint to the other. Deformation of the weldment varies with the type of joint. There may be no noticeable deformation at all in some weldments, and there is no loss of metal.译文:铸造、锻造和焊接1.铸造金属铸造是最古老的产业之一,远古时期和中世纪就有人使用和制造铸件了。

Casting、Forging and Welding1. CastingMetal casting is one of the oldest of all industries, both ancient and medieval history offering examples of the manufacture and use of casting. From simple axeheads poured from copper in open moulds some 5000 years age, casting in the pre-Christian world developed to a point at which elaborate bronze statuary could be produced in two-piece and cored moulds. By the end of the medieval period, decorated bronze and pewter casting had begun to be used in European church and domestic life.The widespread adoption of cast iron as engineering material awaited the success of Abraham Darby in 1790 in smelting in the coke blast furnace; this paved the way for the massive use of cast iron in construction during the years following the industrial revolution.Many foundries sprang up after the industrial revolution, the vast majority being for the manufacture of the cast iron then being used as a structural material. The quantity production of iron castings in the nineteenth century was not matched by a universal advance in quality and the engineering use of the products encountered more serious risks in a non-ductile material.Despite the skill of the molder in producing complex forms, there was little change in the metallurgical and engineering situation until the modern era brought a better understanding of the factors determining quality. With modern techniques of process control the rudimentary judgment of the operator could give way to objective measurements of metal temperature, molding material properties and other production variables. These improvements have been applied not only to cast iron but to a wide range of cast alloys.There are four basic casting methods: sand-casting, die-casting, investment-casting, and centrifugal casting.Sand-casting is the most widely used method employed in foundry. In this process, sand moulds are contained in metal molding boxes that have four sides but no top or bottom. During the molding operation the boxes are located togetherby pins so that they can be separated to remove the pattern, and replaced in the correct position before the metal is poured in. The boxes are clamped together, or the cope (top section) weighted down when pouring to prevent the cope from “floating away”from the drag (lower section) when the mould is full of molten metal. The sequence when molding the simple two-part mould to cast a bracket is illustrated as follows.At the first stage the pattern is seated on the moulding board. The pattern is covered with facing sand, which is a specially prepared sand of good quality, which can take a clean and smooth impression, and can resist the heat from the molten metal that will be in contact with it. The facing sand is backed up with molding sand, which is old facing sand from previous moulds. The molding sand is carefully rammed up so that it is fairly tight around the pattern to produce a good solid mould, yet permeable enough to allow the gases produced during casting to escape. The sand is finally leveled off.At the second stage the mould with the pattern still in position is inverted; the exposed sand lightly covered with parting sand, and the exposed pattern with facing sand.(The parting sand has no cohesion, and is introduced to permit a clean separation when the mould is opened up to remove the pattern .) The second molding box is located in position on the first box and filled with molding sand. Two or more plugs are introduced when the second box is being filled (these are removed later, leaving channels in the sand). One of these plugs is positioned to one side of the pattern. The sand is rammed up and leveled off.Now, at stage 3, to allow the pattern to be removed. This is done by screwing a bar with a threaded end into a suitable insert in the pattern, damping the sand around the pattern, and gently rapping the bar in all directions so that the pattern can be carefully withdrawn. To facilitate the removal of the pattern without scuffing the sides of the impression, all surfaces that lie in the direction of pattern removal are inclined slightly by a small amount (the draw angle).A groove called a gate is cut in the sand face to allow the channel producedby the plug that is outside the pattern to connect with the impression .The metal is poured through this channel (called the runner), and the gate prevents it from dropping straight into the impression and damaging it .The cross-section of the gate is slightly smaller than that of channel so that a full runner will always supply metal to the gate at a slight pressure.Finally, the mould is reassembled, carefully locating and securing the two sections. The top section is known as the cope, and the lower section is known as the drag. The sand in the cope is vented. These vents allow the sand to be rammed up more tightly at the earlier stages without the risk of gases being trapped in the molten metal and forming blowholes in the solid metal. A sand-feeding gate (also called a pouring or bowl) is added to make it easier to pour the metal into the runner. The molten metal is poured through the runner and the air will escape through the riser.The impression will be filled with molten metal when it is completely filled. Gases can escape through the runner and the riser, which also act as headers to supply the impression with more metal to compensate for the contraction of the metal when cooling in the molten state.2. ForgingForging is the plastic working of metal by means of localized compressive forces exerted by manual or power hammers, presses, or special forging machines. It may be done either hot or cold. however, when it is done cold, special names usually are given to the processes. Consequently, the terms“forging” usually implies hot forging done above the recrystallization temperature.Modern forging is a development form the ancient art practiced by the armor makers and the immortalized village blacksmith. High-powered hammers and mechanical presses have replaced the strong arm, the hammer, and the anvil and modern metallurgical knowledge supplements the art skill of the craftsman in controlling the heating and handling of the metal.Forge ability is the term used in the industry to denote a material relative resistance to deformation and its plasticity. While considerable disagreementexists as to precisely what characteristics the word “forge ability” should include, the term as used here is defined as the tolerance of a metal or alloy for deformation without failure, regardless of forging pressure requirements.Raw material used for forging is generally bar or billet stock hot rolled from ingots melted in open-hearth, electric arc, or vacuum arc furnace .other forms and shapes such as rolled slabs, plats, and stock produced by continuous casting techniques are occasionally used .for certain grades ,vacuum arc melting imparts better forge ability than does conventional arc melting . However, the major purpose of vacuum melting is the improvement of mechanical properties and cleanliness, not forging behavior.Equipment behavior influences the forging progress since it determines the feasibility of forging a part and affects the rate of deformation and the temperature conditions.The hammer is the most economical type of equipment for generating load and energy necessary to carry out a forging process, provided that the material being forged can support high deformation velocities. It is most commonly used hot forging equipment for repeated blows on the same workpiece and cannot be overloaded.There are various types of hammers: air-lift gravity drop hammers, power drop hammers, power drop hammers, Counterblow hammers ect. In a simple gravity drop hammer the upper ram is positively connected to a board, a belt, a chain or a piston. When forging the ram is lifted to a certain height and then dropped on the stock placed on the anvil. During the down stroke, the rain is accelerated by gravity and builds up the blow energy. The upstroke takes place immediately after the blow, the force necessary to ensure quick lift-up of the ram can be 3 to 5 times the ram weight. The operation principle of a power-drop hammer is similar to that of an air drop hammer. During the down stroke, in addition to gravity, the ram is accelerated by steam, cold air or hot air pressure. In an electro hydraulic gravity-drop hammer, the ram is lifted with oil pressure against an air cushion. The compressed air slows down the upstroke of the ram and contributes to its acceleration during the down stroke .thus; the electrohydraulic hammer also has a minor power hammer action.Press forging employs a slow squeezing action in deforming the plastic metal, as contrasted with the rapid-impact blows of a hammer. Hydraulic forging press is operated by large pistons driven by high-pressure hydraulic or hydrometric system. The squeezing action is carried completely to the center of the part being pressed, thoroughly working the entire section. These presses are the vertical type and may be either mechanically or hydraulically operated. The mechanical presses, which are faster operating and most commonly used, range in capacity from 5000 to 10000 tons.In the forging press a grater proportion of the total work put into the machine is transmitted to the metal than in a drop hammer. The machine and foundation absorb much of the impact of the drop hammer .press reduction of the metal is faster, and the cost of operation is consequently lower. most press forging s are symmetrical in shape ,having surfaces, which are quite smooth, and provide a closer tolerance than is obtained by a drop hammer .however ,drop forging can forge many parts of irregular and complicated shapes more economically. Forging presses are often used for sizing operations on parts made by other forging processes.For small forgings closed impression dies are used, and only one stroke of the ram is normally require to perform the forging operation .the maximum pressure is built up at the end of the stroke ,which forces the metal into shape .dies may be mounted as separate units, or all the cavities may be put into a single block. for small forgings individuals die units are more convenient .large ingots are now almost always forged with hydraulic presses instead of with steam hammers, since the work done by a press goes deeper. Further, the press can take a cooler ingot and can work to closer dimensions.The forging should be done at about the same temperature as rolling; the process improves the physical properties of the steel just as rolling does. In the final forging it is important not to have the steel too hot, for overheated steel will have poor mechanical properties when cooled. in heating for forging the temperature is usually judged by the eye, but where a large number of thesame patterns will be made, the pieces to be forged are heated in furnaces in which the temperature is indicated by pyrometers, and often is automatically controlled.3. weldingWelding techniques have become so versatile that it is difficult nowadays to define “welding”. Formerly welding was “the joining of metals by fusion”, that is, by melting, but this definition will no longer do. Welding was next defined as the “joining of metals by heat”, but this is not a proper definition either. Not only metals can be welded, so can many of the plastics. Furthermore several welding methods do not require heat. Every machinist is familiar with heatless welding method under some circumstances. Besides these, we can weld with sound and even with the famous laser. Faced with a diversity of welding methods that increase year by year, we must here adopt the following definition of welding:" welding is the joining of metals and plastics by methods that do not employ fastening devices”.There is also no uniform method of naming welding processes. Some processes are named according to the heat source or shielding method, other certain specialized processes are named after the type of joint produced. Examples are spot and butt welding. But an overall classification can not take account of this because the same type of joint may be produced by a variety of processes. Spot welding may be done by electric resistance, arc, or electron-beam processes and butt welding by resistance, flash or any of a number of other methods. Many welding processes are named depending on the heat applied, equipment used, and type of metal to be joined and the strength of the joint.Soldering is the process of joining two metals by a third metal to be applied in the molten state. Solder consists of tin and lead, while bismuth and cadmium are often included to lower the melting point. One of the important operations in soldering is that of cleaning the surface to be joined, this may be done by some acid cleaner. Soldering gives a satisfactory joint for light articles ofsteel, copper or brass, but the strength of soldering joint is rather less than a joint which is brazed, riveted or welded. These methods of metal are normally adopted for strong permanent joints.Pressure welding is known as the simplest method of welding two pieces of metal together. The ends of metal are heated to a while heat—for iron, the welding temperature should be about 1300℃—in a flame. At this temperature the metal becomes plastics. The ends are then presses or hammered together, and the joint is smoothed off. Care must be taken to ensure that the surfaces are thoroughly clean first, for dirt will weaken the weld. Moreover, the heating of iron or steel to a high temperature causes oxidation, and a film of oxide is formed on the heated surfaces. For this reasons, a flux is applied to the heated metal. At welding heat, the flux melts, and the oxide Particles are dissolved in it together with any other impurities which may be present. The metal surfaces are pressed together, and the flux is squeezed out from the center of the weld.Gas welding includes all the processes in which gases are used to obtain a hot flame. Those commonly used are acetylene, natural gas, and hydrogen in combination with oxygen. The maximum temperature developed by oxyhydrogen welding is 3600℉ (1980℃). Hydrogen is produced either by the electrolysis of water or by passing steam over coke. An oxyacetylene weld is produced by heating with a flame obtained from the combustion of oxygen and with or without the use of a filler metal. In most cases the joint is heated to a state of fusion, and as a rule, no pressure is used.Are welding is a process in which coalescence is obtained by heat produced from an electric arc. The electrode or filler metal is heated to a liquid state and deposited into the joint to make the weld. Contact is first made between the electrode and the work to create an electric circuit, and then, by separating the conductors, an arc is formed. The electric energy is converted into intense heat in the arc, which attains a temperature around 10 000°F (5500℃). Either direct or alternating current can be used for arc welding, direct current being preferred for most purposes. A d-c welder is simply a motor-generator set ofconstant-energy type, having the necessary characteristics to produce a stable arc. Arc welding uses commonly metal electrodes or carbon electrodes.Laser Welding is used because of laser’s high heat intensity. It can be operated in any transparent medium without contact with the workpiece, since the laser delivers its energy in the form of light. In welding, the power is delivered in pulses rather than as a continuous beam, the beam is focused on the workpiece and the intense heat produces a fusion weld. Laser welding is slow and is used only for special jobs involving small weldments. Its greatest use is found in the electronics industry.Explosion welding is a process that uses energy from the detonation of an explosive to join two pieces of metal. The explosion accelerates the pieces to a speed at which a metallic bond will form between them when they collide. The weld is produced in a fraction of a second without the addition of filler metal. This is essentially a room temperature process in that gross heating of the workpieces does not occur. The faying surfaces, however, are heated to some extent by the energy of the collision, and welding is accomplished through plastic flow of the metal on those surfaces. Welding takes place progressively as the explosion and the forces it creates advance from one end of the joint to the other. Deformation of the weldment varies with the type of joint. There may be no noticeable deformation at all in some weldments, and there is no loss of metal.译文:铸造、锻造和焊接1.铸造金属铸造是最古老的产业之一,远古时期和中世纪就有人使用和制造铸件了。

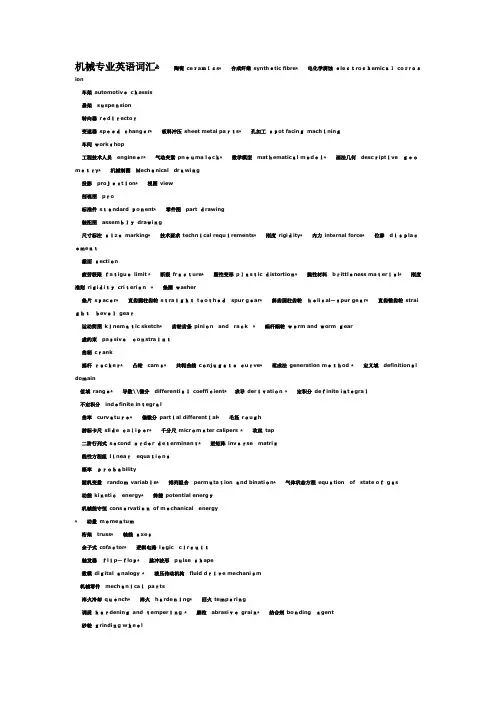

机械专业英语词汇ﻫ陶瓷ceramicsﻫ合成纤维synthetic fibreﻫ电化学腐蚀electrochemicalcorrosion车架automotivechassis悬架suspension转向器redirector变速器speedchangerﻫ板料冲压sheet metal partsﻫ孔加工spot facingmachining车间workshop工程技术人员engineerﻫ气动夹紧pneuma lockﻫ数学模型mathematical modelﻫ画法几何descriptivegeometryﻫ机械制图Mechanical drawing投影projectionﻫ视图view剖视图pro标准件standard ponentﻫ零件图part drawing装配图assemblydrawing尺寸标注sizemarkingﻫ技术要求technical requirementsﻫ刚度rigidityﻫ内力internal forceﻫ位移displacement截面section疲劳极限fatiguelimit ﻫ断裂fractureﻫ塑性变形plastic distortionﻫ脆性材料brittleness materialﻫ刚度准则rigiditycriterionﻫ垫圈washer垫片spacerﻫ直齿圆柱齿轮straighttoothedspur gearﻫ斜齿圆柱齿轮helical—spur gearﻫ直齿锥齿轮strai ghtbevelgear运动简图kinematic sketchﻫ齿轮齿条pinion and rackﻫ蜗杆蜗轮worm and worm gear虚约束passiveconstraint曲柄crank摇杆rackerﻫ凸轮camsﻫ共轭曲线conjugatecurveﻫ范成法generation method ﻫ定义域definitional domain值域rangeﻫ导数\\微分differentialcoefficientﻫ求导derivation ﻫ定积分definite integral不定积分indefinite integral曲率curvatureﻫ偏微分partial differentialﻫ毛坯rough游标卡尺slide caliperﻫ千分尺micrometer calipers ﻫ攻丝tap二阶行列式second order determinantﻫ逆矩阵inverse matrix线性方程组linearequations概率probability随机变量randomvariableﻫ排列组合permutation and binationﻫ气体状态方程equation of state ofgas 动能kineticenergyﻫ势能potential energy机械能守恒conservationof mechanical energyﻫ动量momentum桁架trussﻫ轴线axes余子式cofactorﻫ逻辑电路logic circuit触发器flip—flopﻫ脉冲波形pulse shape数模digital analogy ﻫ液压传动机构fluid drive mechanism机械零件mechanicalparts淬火冷却quenchﻫ淬火hardeningﻫ回火tempering调质hardeningand tempering ﻫ磨粒abrasivegrainﻫ结合剂bondingagent砂轮grinding wheel后角clearance angleﻫ龙门刨削planing主轴spindle主轴箱headstock卡盘chuckﻫ加工中心machining center车刀lathe tool车床latheﻫ钻削镗削boreﻫ车削turning磨床grinder基准benchmarkﻫ钳工locksmithﻫ锻forgeﻫ压模stamping焊weld拉床broaching machine拉孔broaching装配assembling铸造foundﻫ流体动力学fluid dynamics流体力学fluidmechanics加工machiningﻫ液压hydraulic pressure切线tangent机电一体化mechanotronics mechanical—electricalintegrationﻫ气压air pressure pneumatic pressure 稳定性stability介质mediumﻫ液压驱动泵fluid clutch液压泵hydraulic pumpﻫ阀门valve失效invalidation强度intensityﻫ载荷loadﻫ应力stress安全系数safty factorﻫ可靠性reliability螺纹thread螺旋helixﻫ键splineﻫ销pinﻫ滚动轴承rolling bearing滑动轴承slidingbearing弹簧springﻫ制动器arrester brakeﻫ十字结联轴节crossheadﻫ联轴器couplingﻫ链chainﻫ皮带strapﻫ精加工finishmachiningﻫ粗加工rough machiningﻫ变速箱体gearbox casingﻫ腐蚀rustﻫ氧化oxidationﻫ磨损wear 耐用度durability随机信号random signalﻫ离散信号discrete signalﻫ超声传感器ultrasonicsensorﻫ集成电路integrate circuit 挡板orificeplateﻫ残余应力residual stress套筒sleeve ﻫ扭力torsionﻫ冷加工coldmachining电动机electromotorﻫ汽缸cylinder过盈配合interference fit热加工hotwork摄像头CCD camera倒角rounding chamfer优化设计optimal designﻫ工业造型设计industrial moulding design有限元finiteelementﻫ滚齿hobbing插齿gear shapingﻫ伺服电机actuating motorﻫ铣床milling machine钻床drill machine镗床boring machine步进电机steppermotorﻫ丝杠screwrodﻫ导轨lead rail组件subassemblyﻫ可编程序逻辑控制器Programmable LogicController PLC电火花加工electricsparkmachiningﻫ电火花线切割加工electrical dischargewire - cuttingﻫ相图phase diagram 热处理heat treatmentﻫ固态相变solid statephase changes有色金属nonferrous metalﻫ陶瓷ceramicsﻫ合成纤维synthetic fibre电化学腐蚀electrochemical corrosion车架automotive chassisﻫ悬架suspensionﻫ转向器redirector变速器speed changer板料冲压sheet metalpartsﻫ孔加工spot facing machiningﻫ车间workshop工程技术人员engineerﻫ气动夹紧pneuma lock数学模型mathematical modelﻫ画法几何descriptivegeometry机械制图Mechanical drawing投影projection视图view剖视图pro标准件standard ponentﻫ零件图part drawing装配图assemblydrawing尺寸标注size markingﻫ技术要求technicalrequirements刚度rigidityﻫ内力internal force位移displacement截面section疲劳极限fatigue limitﻫ断裂fractureﻫ塑性变形plastic distortion脆性材料brittleness materialﻫ刚度准则rigidity criterion垫圈washerﻫ垫片spacer直齿圆柱齿轮straight toothed spur gear斜齿圆柱齿轮helical-spur gearﻫ直齿锥齿轮straight bevelgear ﻫ运动简图kinematicsketchﻫ齿轮齿条pinionand rack蜗杆蜗轮worm and worm gear虚约束passiveconstraintﻫ曲柄crank摇杆racker凸轮cams共轭曲线conjugate curveﻫ范成法generation method ﻫ定义域definitionaldomain值域range导数\\微分differential coefficientﻫ求导derivation ﻫ定积分definite integral不定积分indefinite integral曲率curvature偏微分partial differential毛坯roughﻫ游标卡尺slide caliperﻫ千分尺micrometer calipers ﻫ攻丝tap二阶行列式second order determinant逆矩阵inverse matrix线性方程组linear equations概率probability随机变量randomvariableﻫ排列组合permutation andbination气体状态方程equation ofstate ofgas动能kinetic energy势能potential energy机械能守恒conservation of mechanical energyﻫ动量momentumﻫ桁架trussﻫ轴线axesﻫ余子式cofactor逻辑电路logic circuitﻫ触发器flip—flop脉冲波形pulse shape数模digital analogy ﻫ液压传动机构fluid drive mechanism机械零件mechanical partsﻫ淬火冷却quenchﻫ淬火hardeningﻫ回火tempering调质hardening andtempering磨粒abrasivegrainﻫ结合剂bonding agent砂轮grinding wheelAssembly line 组装线Layout 布置图ﻫConveyer流水线物料板ﻫRivettable 拉钉机ﻫRivetgun拉钉枪Screwdriver 起子Pneumatic screwdriver 气动起子worktable工作桌ﻫOOBA开箱检查fit together组装在一起fasten锁紧(螺丝)ﻫfixture 夹具(治具)pallet 栈板barcode 条码barcode scanner条码扫描器fusetogether 熔合fuse machine热熔机ﻫrepair修理operator作业员ﻫQC品管ﻫsupervisor课长ME制造工程师MT制造生技cosmeticinspect 外观检查ﻫinner parts inspect内部检查thumb screw大头螺丝lbs、inch 镑、英寸EMI gasket 导电条ﻫfront plate 前板ﻫrear plate后板ﻫchassis基座bezel panel面板ﻫpower button电源按键resetbutton 重置键ﻫHi-pottest of SPS高源高压测试ﻫVoltageswitch ofSPS 电源电压接拉键ﻫsheet metal parts冲件plastic parts塑胶件ﻫSOP制造作业程序ﻫmaterial check list 物料检查表ﻫworkcell 工作间trolley 台车carton纸箱ﻫsub-line 支线leftfork 叉车personnel resource department 人力资源部production department生产部门ﻫplanning department企划部QC Section品管科ﻫstamping factory冲压厂ﻫpainting factory烤漆厂molding factory成型厂ﻫmon equipment常用设备uncoilerand straightener整平机ﻫpunching machine 冲床robot机械手ﻫhydraulic machine油压机ﻫlathe车床planer |plein|刨床ﻫmiller铣床grinder磨床linear cutting线切割electrical sparkle电火花welder电焊机ﻫstaker=revitingmachine铆合机position职务ﻫpresident董事长ﻫgeneral manager总经理ﻫspecial assistant manager特助factorydirector厂长department director部长deputy manager |=vice manager副理section supervisor课长deputysection supervisor =vice section superisor副课长ﻫgroup leader/supervisor组长line supervisor线长assistantmanager助理tomove, to carry, tohandle搬运ﻫbeput in storage入库pack packing包装to applyoil擦油ﻫto锉毛刺ﻫfinalinspection终检toconnect material接料to reversematerial翻料wet station沾湿台Tiana天那水cleaning cloth抹布ﻫto load material上料ﻫto unload material卸料ﻫto returnmaterial/stock to退料ﻫscrap ed |\\'skr?pid|报废ﻫscrape 、、v、刮;削ﻫdeficientpurchase来料不良manufactureprocedure制程deficient manufacturing procedure制程不良ﻫoxidation|\\' ksi\\’dei?n|氧化ﻫscratch刮伤ﻫdents压痕defectiveupsiding down抽芽不良defective to staking铆合不良embedded lump镶块ﻫfeeding is not in place送料不到位stamping-missing漏冲production capacity生产力education andtraining教育与训练proposalimprovement提案改善ﻫspare parts=buffer备件ﻫforklift叉车ﻫtrailer=long vehicle拖板车pound die合模ﻫdie locker锁模器pressure plate=plate pinch压板ﻫbolt螺栓administration/general affairs dept总务部automaticscrewdriver电动启子thicknessgauge厚薄规gauge(orjig)治具ﻫpower wire电源线ﻫbuzzle蜂鸣器defectiveproduct label不良标签ﻫidentifyingsheet list标示单ﻫlocation地点present members出席人员subject主题ﻫconclusion结论ﻫdecision items决议事项ﻫresponsible department负责单位pre-fixed finishing date预定完成日ﻫapprovedby / checked by / prepared by核准/审核/承办ﻫPCE assembly production schedulesheet PCE组装厂生产排配表model机锺ﻫwork order工令ﻫrevision版次ﻫremark备注productioncontrol confirmation生产确认ﻫchecked by初审ﻫapproved by核准ﻫdepartment部门ﻫstock age analysissheet 库存货龄分析表ﻫon—hand inventory现有库存ﻫavailable material良品可使用obsoletematerial良品已呆滞to beinspectedor reworked待验或重工total合计ﻫcause description原因说明ﻫpart number/P/N 料号ﻫtype形态item/group/class类别quality品质preparedby制表notes说明year-endphysical inventory difference analysis sheet 年终盘点差异分析表ﻫphysical inventory盘点数量ﻫphysicalcou nt quantity帐面数量difference quantity差异量ﻫcauseanalysis原因分析rawmaterials原料materials物料ﻫfinishedproduct成品ﻫsemi—finished product半成品packing materials包材ﻫgoodproduct/acceptedgoods/ accepted parts/good parts良品defective product/non-goodparts不良品disposedgoods处理品ﻫwarehouse/hub仓库ﻫon way location在途仓oversealocation海外仓ﻫspareparts physical inventorylist备品盘点清单spare molds location模具备品仓ﻫskid/pallet栈板toxmachine自铆机wire EDM线割ﻫEDM放电机ﻫcoil stock卷料sheet stock片料tolerance工差ﻫscore=groove压线ﻫcamblock滑块pilot导正筒trim剪外边ﻫpierce剪内边drag form压锻差ﻫpocket for the punchhead挂钩槽slug hole废料孔ﻫfeature die公母模expansion dwg展开图radius半径shim(wedge)楔子torch-flame cut火焰切割set screw止付螺丝form block折刀stop pin定位销roundpiercepunch=die button圆冲子shape punch=dieinsert异形子stock locater block定位块ﻫunder cut=scrapchopper清角ﻫactive plate活动板baffle plate挡块cover plate盖板ﻫmaledie公模ﻫfemale die母模groove punch压线冲子air—cushioneject—rod气垫顶杆spring—boxeject-plate弹簧箱顶板ﻫbushing block衬套ﻫinsert 入块ﻫclub car高尔夫球车ﻫcapability能力ﻫparame ter参数ﻫfactor系数ﻫphosphate皮膜化成ﻫviscosity涂料粘度alkalidipping脱脂ﻫmainmanifold主集流脉ﻫbezel斜视规blanking穿落模ﻫdejecting顶固模demagnetization去磁;消磁ﻫhigh-speedtransmission高速传递heat dissipation热传rack上料degrease脱脂ﻫrinse水洗alkalineetch龄咬ﻫdesmut剥黑膜D、I、rinse纯水次ﻫChromate铬酸处理Anodize阳性处理ﻫseal封孔revision版次ﻫpart number/P/N料号good products良品scraped products报放心品defective products不良品ﻫfinishedproducts成品disposed products处理品barcode条码ﻫflowchart流程表单assembly组装ﻫstamping冲压molding成型ﻫspareparts=buffer备品ﻫcoordinate座标dismantlethe die折模auxiliary fuction辅助功能poly-line多义线heater band加热片thermocouple热电偶sand blasting喷沙ﻫgrit砂砾ﻫderusting machine除锈机ﻫdegate打浇口dryer烘干机ﻫinduction感应ﻫinduction light感应光ﻫresponse=reaction=interaction感应ram连杆edge finder巡边器ﻫconcave凸convex凹ﻫshort射料不足nick缺口speck瑕疵shine亮班splay 银纹ﻫgasmark焦痕ﻫdelamination起鳞ﻫcold slug冷块blush 导色ﻫgouge沟槽;凿槽ﻫsatin texture段面咬花witnessline证示线ﻫpatent专利ﻫgrit沙砾ﻫgranule=peuet=grain细粒ﻫgrit maker抽粒机cushion缓冲magnalium镁铝合金magnesium镁金metal plate钣金ﻫlathe车mill锉ﻫplane刨grind磨ﻫdrill铝boring镗blinster气泡ﻫfillet镶;嵌边through-hole form通孔形式vollerpin formality滚针形式ﻫcam driver铡楔ﻫshank摸柄crank shaft曲柄轴augular offset角度偏差ﻫvelocity速度productiontempo生产进度现状torque扭矩spline=the multiplekeys花键ﻫquenching淬火ﻫtempering回火ﻫannealing退火ﻫcarbonization碳化ﻫtungstenhigh speedsteel钨高速得ﻫmoly high speed steel钼高速得ﻫorganic solvent有机溶剂ﻫbracket小磁导liaison联络单ﻫvolatile挥发性ﻫresistance电阻ion离子ﻫtitrator滴定仪ﻫbeacon警示灯coolant冷却液crusher破碎机阿基米德蜗杆Archimedeswormﻫ安全系数safetyfactor;factor of safetyﻫ安全载荷safe load凹面、凹度concavityﻫ扳手wrench ﻫ板簧flatleaf spring半圆键woodruff keyﻫ变形deformationﻫ摆杆oscillating bar摆动从动件oscillating followerﻫ摆动从动件凸轮机构cam with oscillatingfollower摆动导杆机构oscillating guide—bar mechanismﻫ摆线齿轮cycloidal gear摆线齿形cycloidaltooth profile摆线运动规律cycloidal motion摆线针轮cycloidal-pin wheelﻫ包角angleof contactﻫ保持架cageﻫ背对背安装back—to-back arrangementﻫ背锥back cone;normal coneﻫ背锥角back angleﻫ背锥距back conedistanceﻫ比例尺scaleﻫ比热容specificheat capacity闭式链closed kinematicchainﻫ闭链机构closed chain mechanism臂部arm变频器frequency convertersﻫ变频调速frequency control ofmotorspeed变速speedchangeﻫ变速齿轮change gear changewheelﻫ变位齿轮modifiedgearﻫ变位系数modificationcoefficientﻫ标准齿轮standard gear标准直齿轮standard spurgear表面质量系数superficial mass factorﻫ表面传热系数surface coefficient ofheat transferﻫ表面粗糙度surfaceroughnessﻫ并联式组合bination in parallel并联机构parallel mechanismﻫ并联组合机构parallel bined mechanismﻫ并行工程concurrent engineeringﻫ并行设计concurred design,CD不平衡相位phase angle ofunbalance不平衡imbalance (or unbalance)ﻫ不平衡量amountof unbalanceﻫ不完全齿轮机构intermittent gearing波发生器wavegenerator波数number of wavesﻫ补偿pensation参数化设计parameterizationdesign,PDﻫ残余应力residual stressﻫ操纵及控制装置operation control device槽轮Geneva wheelﻫ槽轮机构Genevamechanism;Maltesecrossﻫ槽数Genevanumerate槽凸轮groove camﻫ侧隙backlashﻫ差动轮系differential geartrain差动螺旋机构differential screw mechanismﻫ差速器differential常用机构conventional mechanism;mechanismin mon use车床latheﻫ承载量系数bearing capacity factorﻫ承载能力bearing capacity成对安装paired mounting尺寸系列dimension seriesﻫ齿槽tooth space齿槽宽spacewidth齿侧间隙backlashﻫ齿顶高addendum齿顶圆addendum circle齿根高dedendum齿根圆dedendum circleﻫ齿厚tooth thickness齿距circular pitchﻫ齿宽facewidth齿廓tooth profile齿廓曲线tooth curve齿轮gearﻫ齿轮变速箱speed—changing gearboxesﻫ齿轮齿条机构pinion andrackﻫ齿轮插刀pinion cutter;pinion-shap edshaper cutter齿轮滚刀hob,hobbingcutterﻫ齿轮机构gearﻫ齿轮轮坯blank齿轮传动系pinion unit齿轮联轴器gearcouplingﻫ齿条传动rack gearﻫ齿数toothnumber齿数比gearratio齿条rack齿条插刀rack cutter;rack—shapedshapercutter齿形链、无声链silentchain齿形系数formfactor齿式棘轮机构tooth ratchet mechanism插齿机gear shaperﻫ重合点coincident pointsﻫ重合度contact ratio冲床punch传动比transmissionratio,speedratio传动装置gearing;transmission gear传动系统driven systemﻫ传动角transmission angle传动轴transmissionshaftﻫ串联式组合bination inseriesﻫ串联式组合机构series bined mechanismﻫ串级调速cascade speedcontrol创新innovation creationﻫ创新设计creation design垂直载荷、法向载荷normalloadﻫ唇形橡胶密封lip rubber sealﻫ磁流体轴承magneticfluid bearing从动带轮drivenpulley从动件drivenlink,followerﻫ从动件平底宽度width offlat-face从动件停歇followerdwellﻫ从动件运动规律followermotionﻫ从动轮driven gear粗线bold lineﻫ粗牙螺纹coarsethread大齿轮gear wheelﻫ打包机packer打滑slippingﻫ带传动belt drivingﻫ带轮belt pulley带式制动器band brakeﻫ单列轴承single rowbearing单向推力轴承single-direction thrustbearing单万向联轴节single universal joint单位矢量unit vector当量齿轮equivalent spurgear;virtual gearﻫ当量齿数equivalent teethnumber;virtualnumberof teeth当量摩擦系数equivalent coefficientof frictionﻫ当量载荷equivalent loadﻫ刀具cutterﻫ导数derivative倒角chamferﻫ导热性conductionof heat导程leadﻫ导程角lead angleﻫ等加等减速运动规律parabolic motion;constant acceleration anddeceleration motionﻫ等速运动规律uniform motion;constantvelocity motion等径凸轮conjugate yokeradial camﻫ等宽凸轮constant-breadth camﻫ等效构件equivalent linkﻫ等效力equivalent forceﻫ等效力矩equivalentmoment offorce等效量equivalentﻫ等效质量equivalent mass等效转动惯量equivalentmoment ofinertia等效动力学模型dynamicallyequivalentmodelﻫ底座chassis低副lower pair点划线chain dottedline(疲劳)点蚀pittingﻫ垫圈gasketﻫ垫片密封gasket seal碟形弹簧belleville springﻫ顶隙bottom clearanceﻫ定轴轮系ordinarygear train;gear train with fixedaxesﻫ动力学dynamicsﻫ动密封kinematical sealﻫ动能dynamic energy动力粘度dynamic viscosity动力润滑dynamic lubrication动平衡dynamicbalanceﻫ动平衡机dynamicbalancing machine动态特性dynamic characteristicsﻫ动态分析设计dynamic analysis design动压力dynamic reaction动载荷dynamic load端面transverse plane端面参数transverse parametersﻫ端面齿距transversecircular pitchﻫ端面齿廓transverse tooth profileﻫ端面重合度transverse contact ratioﻫ端面模数transverse moduleﻫ端面压力角transverse pressureangle锻造forgeﻫ对称循环应力symmetrycirculatingstressﻫ对心滚子从动件radial (or in-line)rollerfollowerﻫ对心直动从动件radial (or in-line ) translatingfollowerﻫ对心移动从动件radial reciprocating followerﻫ对心曲柄滑块机构in—lineslider-crank(orcrank-slider)mechanismﻫ多列轴承multi—row bearingﻫ多楔带poly V—belt多项式运动规律polynomial motionﻫ多质量转子rotor withseveral massesﻫ惰轮idle gear额定寿命rating life额定载荷loadratingII级杆组dyadﻫ发生线generating line发生面generating plane法面normalplane法面参数normal parametersﻫ法面齿距normal circular pitch法面模数normal module法面压力角normal pressure angleﻫ法向齿距normal pitch法向齿廓normal toothprofileﻫ法向直廓蜗杆straight sided normal wormﻫ法向力normal forceﻫ反馈式组合feedback bining 反向运动学inverse(or backward)kinematicsﻫ反转法kinematic inversion反正切Arctanﻫ范成法generatingcutting仿形法form cuttingﻫ方案设计、概念设计conceptdesign, CDﻫ防振装置shockproof deviceﻫ飞轮flywheel飞轮矩momentof flywheel非标准齿轮nonstandardgear非接触式密封non-contact seal非周期性速度波动aperiodicspeedfluctuationﻫ非圆齿轮non-circular gearﻫ粉末合金powdermetallurgyﻫ分度线reference line; standardpitch lineﻫ分度圆reference circle;standard (cutting)pitch circle分度圆柱导程角lead angleatreferencecylinderﻫ分度圆柱螺旋角helix angle at reference cylinderﻫ分母denominatorﻫ分子n umeratorﻫ分度圆锥referencecone;standardpitch coneﻫ分析法analyticalmethodﻫ封闭差动轮系planetarydifferentialﻫ复合铰链poundhingeﻫ复合式组合pound bining复合轮系pound (orbined) gear train复合平带pound flat belt复合应力binedstress复式螺旋机构pound screw mechanism复杂机构plex mechanismﻫ杆组Assur group干涉interferenceﻫ刚度系数stiffness coefficient刚轮rigidcircularspline钢丝软轴wire soft shaft刚体导引机构bodyguidancemechanism刚性冲击rigid impulse(shock)ﻫ刚性转子rigidrotorﻫ刚性轴承rigidbearingﻫ刚性联轴器rigidcouplingﻫ高度系列height series 高速带highspeed beltﻫ高副higher pair格拉晓夫定理Grashoff`s lawﻫ根切undercuttingﻫ公称直径nominal diameterﻫ高度系列heightseriesﻫ功work工况系数application factorﻫ工艺设计technological designﻫ工作循环图working cycle diagram工作机构operation mechanism工作载荷external loads工作空间working space工作应力workingstress工作阻力effectiveresistance工作阻力矩effective resistance moment公法线mon normallineﻫ公共约束general constraintﻫ公制齿轮metric gearsﻫ功率powerﻫ功能分析设计function analyses designﻫ共轭齿廓conjugate profilesﻫ共轭凸轮conjugate cam构件link鼓风机blowerﻫ固定构件fixed link;frameﻫ固体润滑剂solid lubricant关节型操作器jointed manipulator惯性力inertia forceﻫ惯性力矩momentof inertia ,shaking momentﻫ惯性力平衡balance of shaking forceﻫ惯性力完全平衡full balance of shaking forceﻫ惯性力部分平衡partial balanceofshaking forceﻫ惯性主矩resultant momentof inertia惯性主失resultant vectorof inertia冠轮crowngearﻫ广义机构generationmechanismﻫ广义坐标generalized coordinate轨迹生成path generation轨迹发生器pathgeneratorﻫ滚刀hob滚道raceway滚动体rolling element滚动轴承rolling bearingﻫ滚动轴承代号rolling bearing identificationcode滚针needleroller滚针轴承needle roller bearingﻫ滚子rollerﻫ滚子轴承rollerbearingﻫ滚子半径radius of rollerﻫ滚子从动件roller follower滚子链rollerchainﻫ滚子链联轴器doubleroller chain couplingﻫ滚珠丝杆ballscrewﻫ滚柱式单向超越离合器roller clutch过度切割undercuttingﻫ函数发生器function generator函数生成functiongeneration ﻫ含油轴承oilbearingﻫ耗油量oil consumptionﻫ耗油量系数oil consumption factor赫兹公式H、Hertz equationﻫ合成弯矩resultant bendingmomentﻫ合力resultant force合力矩resultant moment of forceﻫ黑箱blackboxﻫ横坐标abscissa互换性齿轮interchangeablegears花键splineﻫ滑键、导键featherkey滑动轴承sliding bearing滑动率sliding ratioﻫ滑块sliderﻫ环面蜗杆toroid helicoids worm环形弹簧annular spring缓冲装置shocks; shock—absorber灰铸铁greycast iron回程return回转体平衡balance ofrotors混合轮系poundgear train积分integrate机电一体化系统设计mechanical-electricalintegration system design机构mechanismﻫ机构分析analysisof mechanism机构平衡balanceof mechanismﻫ机构学mechanism机构运动设计kinematicdesign of mechanism机构运动简图kinematic sketch of mechanismﻫ机构综合synthesis ofmechanism机构组成constitution of mechanismﻫ机架frame,fixedlink机架变换kinematic inversion机器machine机器人robot机器人操作器manipulator机器人学robotics技术过程techniqueprocess技术经济评价technical and economic evaluationﻫ技术系统technique system机械machineryﻫ机械创新设计mechanicalcreationdesign,MCDﻫ机械系统设计mechanical system design, MSD机械动力分析dynamic analysis ofmachinery机械动力设计dynamic designof machineryﻫ机械动力学dynamicsof machineryﻫ机械得现代设计modernmachinedesignﻫ机械系统mechanical systemﻫ机械利益mechanical advantage机械平衡balance of machineryﻫ机械手manipulator机械设计machinedesign;mechanicaldesignﻫ机械特性mechanical behavior机械调速mechanical speed governors机械效率mechanical efficiencyﻫ机械原理theory ofmachines andmechanismsﻫ机械运转不均匀系数coefficient ofspeed fluctuation机械无级变速mechanical steplessspeed changes基础机构fundamental mechanismﻫ基本额定寿命basic ratinglifeﻫ基于实例设计case-based design,CBD基圆base circleﻫ基圆半径radius of base circle基圆齿距base pitch基圆压力角pressureangle of base circle基圆柱base cylinder基圆锥base cone急回机构quick-return mechanism急回特性quick—return characteristics急回系数advance—toreturn-time ratio急回运动quick—return motion棘轮ratchet棘轮机构ratchetmechanism棘爪pawlﻫ极限位置extreme (or limiting)positionﻫ极位夹角crankanglebetween extreme(or limiting)positions计算机辅助设计puter aideddesign, CAD计算机辅助制造puter aided manufacturing,CAMﻫ计算机集成制造系统puter integrated manufacturing system,CIMSﻫ计算力矩fa ctored moment;calculation moment计算弯矩calculatedbending momentﻫ加权系数weightingefficient加速度acceleration加速度分析acceleration analysisﻫ加速度曲线accelerationdiagram尖点pointing; cuspﻫ尖底从动件knife—edge followerﻫ间隙backlash间歇运动机构intermittent motion mechanism减速比reductionratio减速齿轮、减速装置reductiongear减速器speed reducerﻫ减摩性anti—frictionquality渐开螺旋面involutehelicoidﻫ渐开线involute渐开线齿廓involute profileﻫ渐开线齿轮involute gear渐开线发生线generating line ofinvoluteﻫ渐开线方程involute equationﻫ渐开线函数involutefunction渐开线蜗杆involutewormﻫ渐开线压力角pressure angleof involute渐开线花键involute splineﻫ简谐运动simple harmonic motionﻫ键key键槽keyway交变应力repeated stressﻫ交变载荷repeated fluctuating loadﻫ交叉带传动cross-belt drive交错轴斜齿轮crossed helicalgearsﻫ胶合scoringﻫ角加速度angularaccelerationﻫ角速度angular velocity角速比angular velocity ratio角接触球轴承angular contact ball bearing角接触推力轴承angular contactthrust bearingﻫ角接触向心轴承angular contact radial bearingﻫ角接触轴承angularcontact bearing铰链、枢纽hingeﻫ校正平面correctingplane接触应力contact stress接触式密封contact seal阶梯轴multi—diametershaftﻫ结构structureﻫ结构设计structural design截面section节点pitch pointﻫ节距circular pitch;pitch ofteethﻫ节线pitch lineﻫ节圆pitchcircleﻫ节圆齿厚thickness on pitchcircleﻫ节圆直径pitchdiameter节圆锥pitchcone节圆锥角pitch coneangle解析设计analytical design紧边tight-sideﻫ紧固件fastener径节diametral pitch径向radialdirectionﻫ径向当量动载荷dynamic equivalentradial load径向当量静载荷static equivalentradial loadﻫ径向基本额定动载荷basicdynamic radial loadratingﻫ径向基本额定静载荷basic s tatic radial load tating径向接触轴承radial contact bearing径向平面radialplaneﻫ径向游隙radial internalclearance径向载荷radial loadﻫ径向载荷系数radial loadfactor径向间隙clearanceﻫ静力static force静平衡static balanceﻫ静载荷static load静密封static seal局部自由度passivedegree of freedomﻫ矩阵matrixﻫ矩形螺纹square threadedformﻫ锯齿形螺纹buttressthread formﻫ矩形牙嵌式离合器square-jaw positive-contactclutch绝对尺寸系数absolute dimensional factorﻫ绝对运动absolute motion绝对速度absolutevelocity均衡装置load balancing mechanismﻫ抗压强度pression strength开口传动open—belt driveﻫ开式链open kinematic chain开链机构openchain mechanism可靠度degree of reliabilityﻫ可靠性reliability可靠性设计reliability design,RDﻫ空气弹簧air springﻫ空间机构spatialmechanism空间连杆机构spatial linkageﻫ空间凸轮机构spatial camﻫ空间运动副spatial kinematic pair空间运动链spatial kinematicchain空转idleﻫ宽度系列width seriesﻫ框图block diagramﻫ雷诺方程Reynolds‘sequation ﻫ离心力centrifugalforce离心应力centrifugalstressﻫ离合器clutchﻫ离心密封centrifugal seal理论廓线pitchcurve理论啮合线theoreticalline of actionﻫ隶属度membership力forceﻫ力多边形force polygonﻫ力封闭型凸轮机构force—drive (orforce-closed) cam mechanismﻫ力矩momentﻫ力平衡equilibrium力偶coupleﻫ力偶矩moment of coupleﻫ连杆connecting rod,couplerﻫ连杆机构linkage连杆曲线coupler—curve连心线line ofcentersﻫ链chainﻫ链传动装置chain gearingﻫ链轮sprocket sprocket—wheel sprocketgear chainwhe el联组V带tight-up Vbelt联轴器couplingshaft couplingﻫ两维凸轮two-dimensionalcam临界转速critical speed六杆机构six-bar linkageﻫ龙门刨床doubleHaasplaner轮坯blank轮系gear trainﻫ螺杆screw螺距threadpitchﻫ螺母screwnut螺旋锥齿轮helical bevel gearﻫ螺钉screws螺栓boltsﻫ螺纹导程leadﻫ螺纹效率screwefficiencyﻫ螺旋传动power screwﻫ螺旋密封spiral sealﻫ螺纹thread (of a screw)ﻫ螺旋副helicalpair螺旋机构screw mechanismﻫ螺旋角helixangle螺旋线helix ,helicallineﻫ绿色设计greendesigndesign for environmentﻫ马耳她机构Genevawheel Geneva gearﻫ马耳她十字Maltesecross ﻫ脉动无级变速pulsating steplessspeed changes脉动循环应力fluctuatingcirculating stress脉动载荷fluctuating load铆钉rivet迷宫密封labyrinth sealﻫ密封seal密封带seal beltﻫ密封胶seal gumﻫ密封元件potted ponentﻫ密封装置sealing arrangementﻫ面对面安装face—to-face arr angement面向产品生命周期设计designfor product`s life cycle,DPLCﻫ名义应力、公称应力nominalstressﻫ模块化设计modulardesign, MDﻫ模块式传动系统modular systemﻫ模幅箱morphology boxﻫ模糊集fuzzy setﻫ模糊评价fuzzyevaluationﻫ模数module摩擦frictionﻫ摩擦角friction angle摩擦力friction force摩擦学设计tribology design, TDﻫ摩擦阻力frictional resistance摩擦力矩frictionmoment摩擦系数coefficient of friction摩擦圆friction circle磨损abrasion wear;scratching末端执行器end-effector目标函数objective function耐腐蚀性corrosion resistance ﻫ耐磨性wear resistance挠性机构mechanism with flexible elementsﻫ挠性转子flexiblerotor内齿轮internal gearﻫ内齿圈ringgearﻫ内力internal forceﻫ内圈inner ring能量energyﻫ能量指示图viscosityﻫ逆时针counterclockwise(or anticlockwise)ﻫ啮出engaging-out啮合engagement,mesh,gearing啮合点contactpointsﻫ啮合角working pressure angleﻫ啮合线lineof actionﻫ啮合线长度lengthof lineof action啮入engaging—inﻫ牛头刨床shaper凝固点freezing point;solidifyingpointﻫ扭转应力torsion stress扭矩momentof torqueﻫ扭簧helical torsion spring诺模图NomogramO形密封圈密封O ring seal盘形凸轮diskcamﻫ盘形转子disk—likerotor抛物线运动parabolic motionﻫ疲劳极限fatiguelimitﻫ疲劳强度fatigue strength偏置式offsetﻫ偏(心)距offset distance偏心率eccentricity ratioﻫ偏心质量eccentric massﻫ偏距圆offset circleﻫ偏心盘eccentric偏置滚子从动件offsetrollerfollowerﻫ偏置尖底从动件offsetknife—edge followerﻫ偏置曲柄滑块机构offsetslider—crank mechanism拼接matching评价与决策evaluation and decision频率frequencyﻫ平带flat belt平带传动flat belt drivingﻫ平底从动件flat-face followerﻫ平底宽度facewidthﻫ平分线bisector平均应力average stressﻫ平均中径mean screw diameterﻫ平均速度average velocityﻫ平衡balanceﻫ平衡机balancing machineﻫ平衡品质balancingqualityﻫ平衡平面correctingplaneﻫ平衡质量balancingmassﻫ平衡重counterweightﻫ平衡转速balancing speed平面副planar pair, flat pairﻫ平面机构planar mechanismﻫ平面运动副planarkinematicpairﻫ平面连杆机构planar linkageﻫ平面凸轮planarcamﻫ平面凸轮机构planar cammechanism平面轴斜齿轮parallelhelical gearsﻫ普通平键parallel keyﻫ其她常用机构othermechanisminmon use ﻫ起动阶段starting period启动力矩startingtorque气动机构pneumaticmechanism奇异位置singular position起始啮合点initial contact,beginningofcontact气体轴承gas bearing千斤顶jackﻫ嵌入键sunk key强迫振动forced vibration切齿深度depth of cutﻫ曲柄crank曲柄存在条件Grashoff`slaw曲柄导杆机构crank shaper (guide-bar)mechanism曲柄滑块机构slider-crank (orcrank-slider) mechanismﻫ曲柄摇杆机构crank-rocker mechanismﻫ曲齿锥齿轮spiral bevel gear 曲率curvature曲率半径radius of curvatureﻫ曲面从动件curved-shoe follower曲线拼接curvematchingﻫ曲线运动curvilinear motionﻫ曲轴crank shaftﻫ驱动力driving forceﻫ驱动力矩driving moment(torque)ﻫ全齿高whole depth权重集weightsets球ballﻫ球面滚子convex rollerﻫ球轴承ball bearingﻫ球面副spheric pair球面渐开线spherical involuteﻫ球面运动spherical motion球销副sphere—pin pair球坐标操作器polar coordinate manipulatorﻫ燃点spontaneous ignition热平衡heat balance;thermal equilibrium ﻫ人字齿轮herringbone gear冗余自由度redundant degree of freedom柔轮flexsplineﻫ柔性冲击flexible impulse; soft shockﻫ柔性制造系统flexible manufacturing system;FMSﻫ柔性自动化flexible automationﻫ润滑油膜lubricant film润滑装置lubricationdeviceﻫ润滑lubricationﻫ润滑剂lubricantﻫ三角形花键serration spline三角形螺纹V threadscrew三维凸轮three-dimensional cam三心定理Kennedy`s theoremﻫ砂轮越程槽grindingwheelgrooveﻫ砂漏hour-glass少齿差行星传动planetarydrive with smallteethdifference设计方法学design methodology设计变量designvariable设计约束design constraintsﻫ深沟球轴承deep groove ball bearingﻫ生产阻力productiveresistance升程rise升距lift实际廓线cam profileﻫ十字滑块联轴器double slider coupling; Oldham‘s couplingﻫ矢量vectorﻫ输出功output workﻫ输出构件o utput linkﻫ输出机构outputmechanism输出力矩output torque输出轴outputshaft输入构件input linkﻫ数学模型mathematic modelﻫ实际啮合线actual line ofaction双滑块机构double—slider mechanism,ellipsographﻫ双曲柄机构double crank mechanism双曲面齿轮hyperboloidgearﻫ双头螺柱studsﻫ双万向联轴节constant-velocity (or double) universal jointﻫ双摇杆机构double rockermechanism双转块机构Oldham couplingﻫ双列轴承doublerow bearingﻫ双向推力轴承double-direction thrustbearingﻫ松边slack-sideﻫ顺时针clockwiseﻫ瞬心instantaneouscenter死点dead pointﻫ四杆机构four—barlinkageﻫ速度velocityﻫ速度不均匀( 波动)系数coefficient of speed fluctuation速度波动speedfluctuation速度曲线velocity diagram速度瞬心instantaneous center of velocity塔轮step pulley踏板pedal台钳、虎钳vice太阳轮sun gear弹性滑动elasticity sliding motionﻫ弹性联轴器elastic coupling flexible coupling弹性套柱销联轴器rubber-cushioned sleeve bearing coupling套筒sleeve梯形螺纹acme thread formﻫ特殊运动链special kinematic chainﻫ特性characteristicsﻫ替代机构equivalent mechanism调节modulation,regulation调心滚子轴承self-aligning rollerbearing调心球轴承self—aligning ball bearingﻫ调心轴承self-aligning bearing调速speedgoverning调速电动机adjustable speedmotorsﻫ调速系统speed control system调压调速variable voltage control调速器regulator,governorﻫ铁磁流体密封ferrofluid seal停车阶段stopping phase停歇dwell同步带synchronous belt同步带传动synchronous belt driveﻫ凸得,凸面体convexﻫ凸轮camﻫ凸轮倒置机构inversecammechanismﻫ凸轮机构cam,cammechanism凸轮廓线cam profile凸轮廓线绘制layout of camprofile。

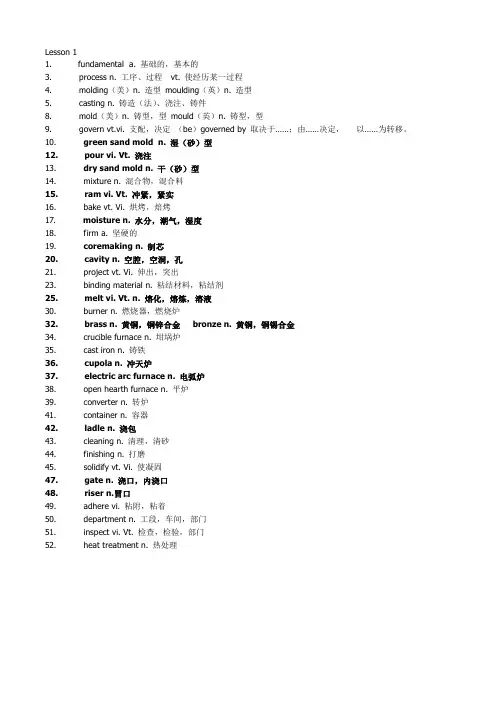

1. fundamental a. 基础的,基本的3. process n. 工序、过程vt. 使经历某一过程4. molding(美)n. 造型moulding(英)n. 造型5. casting n. 铸造(法)、浇注、铸件8. mold(美)n. 铸型,型mould(英)n. 铸型,型9. govern vt.vi. 支配,决定(be)governed by 取决于……;由……决定,以……为转移。

10. green sand mold n. 湿(砂)型12. pour vi. Vt. 浇注13. dry sand mold n. 干(砂)型14. mixture n. 混合物,混合料15. ram vi. Vt. 冲紧,紧实16. bake vt. Vi. 烘烤,焙烤17. moisture n. 水分,潮气,湿度18. firm a. 坚硬的19. coremaking n. 制芯20. cavity n. 空腔,空洞,孔21. project vt. Vi. 伸出,突出23. binding material n. 粘结材料,粘结剂25. melt vi. Vt. n. 熔化,熔炼,溶液30. burner n. 燃烧器,燃烧炉32. brass n. 黄铜,铜锌合金bronze n. 黄铜,铜锡合金34. crucible furnace n. 坩埚炉35. cast iron n. 铸铁36. cupola n. 冲天炉37. electric arc furnace n. 电弧炉38. open hearth furnace n. 平炉39. converter n. 转炉41. container n. 容器42. ladle n. 浇包43. cleaning n. 清理,清砂44. finishing n. 打磨45. solidify vt. Vi. 使凝固47. gate n. 浇口,内浇口48. riser n.冒口49. adhere vi. 粘附,粘着50. department n. 工段,车间,部门51. inspect vi. Vt. 检查,检验,部门52. heat treatment n. 热处理2. pack vt. 舂、紧,充填3. withdraw (withdrew,withdrawn)vt. 起出,取出5. riddle n.;vt. 筛,过筛6. screen n.;vt. 筛子,筛分8. unifomity n. 均匀性uniformly ad. 均匀地10. facing sand n. 面砂11. heat-resistant a. 耐热的13. collapse vi. 倒塌,毁坏14. excessive a. 过度的15. escape vi. 逸出16. cause vt.;n. 使产生,引起17. blow-hole n. 气孔18. cope n. 上型(箱)19. drag n. 下型(箱)20. boxlike a. 箱形的21. frame n. 框子22. flask n. 砂箱24. cheek n. 中型(箱)25. joint n.;vt. 连接面,接合面26. vent vt. 通气27. venthole n. 通气孔28. properly ad. 适当地,正确地29. permeability n. 透气性30. interior a. 内部的,里面的31. hard-baked a. 烘干,硬化32. insert vt. 放入 n. (pl.)金属型芯,内冷铁33. undercut n. (铸件上的)凹陷部分34. hollow n. 空穴,孔36. assembly n. 总装,组合件37. molten a. 熔融的38. downward ad. a. 向下39. runner n. 横浇道40. compensate vt. 补偿41. shrinkage n. 收缩,收缩量42. remove vt. 去掉,消除43. lug n. (箱)耳44. pin n. (合箱)销46. mold cavity n. 型腔47. parting surface n. 分型面48. pouring basin n. 浇口盆49. gate sprue n. 直浇道50. bottom board n. 底板51. cross-sectional view n. 剖面图2. non-ferrous a. 非铁(金属)的,有色(金属)的3. light-alloy a. 轻合金4. estimate n.;vt. 评价,判断5. fineness n. 细度,光洁度6. plasticity n. 可塑性7. bond n.;vt. 粘结,粘结力,粘结剂8. refractoriness n. 耐火性9. durability n. 耐久(用)性10. in different degrees 在不同程度上11. constituent n.;a. 成分,组成物12. grain n. 颗粒13. aluminium silicate n. 硅酸铝14. clay n. 粘土15. binder n. 粘结剂16. artificial a. 人工的,人造的17. greensand n. 湿砂18. impression n. 型腔,痕迹19. strickle n. 刮板21. proportioning n. 使成比例,配料,(按比例)配合22. hold together 结合23. fuse v. 熔化24. skin n. 表皮,外壳25. relate to 与……有关26. withstand (withstood)vt. 经得起,耐得住27. synthetic a.;n. 合成的,合成剂28. dig (dug,dug)vt. 挖掘,采掘29. pit n. 矿井,矿坑30. mix v. 混合31. relatively ad. 按比例的,相对地32. select vt. 选用,挑选33. nonthermosetting hydrocarbon resin 非热固性碳氢树脂34. bentonite n. 膨润土35. result from 由…引起,由于36. keep from 防止1. patternmaking n.模样制造2. pattern n. 模样3. patternmaker n. 木模工4. affect vt. 影响,对…起作用5. designing n., a. 设计(的)6. drafting n. 制图7. machining n. 机械加工8. be common to 为…所共有9. talk over 商量,讨论10. planning n. 设计,计划11. blueprint n. 蓝图,设计图12. visualize vt. 想象出,设想出13. preliminary a. 初步的14. cost n. 成本,费用15. order vt. 订货16. distortion n. 变形,挠曲17. location n. 位置18. allowance n. 余量19. parting line n. 分型线20. establish vt. 建立21. layout n. 放样图,设计图22. procedure n. 方法,(生产)过程23. decide upon = decide on 决定,选定,确定24. reproduction n. 复制品25. dress (dressed,drest)vt. 刨光,打磨26. edge n. 边,棱边,侧面27. square a. 方的;n. 角尺28. shrink rule n. 缩尺29. divider n. (pl.)两脚规,分规30. instrument n. 工具,装置31. pointed knife n. 尖刀32. tool n. 工具,刀具,机床33. accuracy n. 精度,准确度34. pattern allowance n. 模样余量,模样放尺35. take into account 考虑,重视36. drawing n. 图样37. check vt.;n. 校队,核对,开裂2. wear n.;vt. 磨损3. rapping n. 松模4. subsequent a. 继起的,后来的5. abrasive a.;n. 磨损的,摩擦的6. impervious a. 不能透过的,不渗水的7. alternately adv. 交替的8. damp a.;n. 潮湿的9. tear n. 撕裂,扯破10. plastic n. (常用pl.)塑料,合成树脂11. gypsum n. 石膏12. plaster n. 熟石膏13. exact a. 精确的,精密的14. undersize n. 尺寸过小,尺寸不足15. draft n. (起模)斜度16. machining provision n. 机械加工余量17. solid shrinkage n. 固态收缩18. freezing temperature n. 凝固温度19. contraction n. 收缩20. allow for 考虑到21. automatically ad. 自动地22. approximate a. 近似的,大约的23. malleable iron n. 可锻铸铁,马铁25. master pattern n. 母模26. draw (drew,drawn)vt. 起出(模样)27. vertical a. 垂直的28. taper vt.;n. 退拔,(起模)斜度29. inward a. 向内的30. mount vt. 固定,装配31. accuracy of finish n. 加工精度Lesson 61. skin-dried mold n. 表面干燥型2. air-dried mold n. 空气干燥铸型3. loam mold n. 泥型4. cement-boned mold n. 水泥砂型5. dry-sand core mold n. 组芯铸型6. investment mold n. 熔模铸型7. maintain vt. 维持,保持,维护10. softness n. 柔软(性,度)11. offer vt.;n. 提供,给予,产生12. resistance n. 阻力,抗(耐)……性13. crack n. ;vi. 开裂,裂纹14. favor=favour vt. ; n. 欢迎,赞成15. close vt. ; a. ; n. 合箱,关闭16. shake out n. (振动)落砂17. continuous cycle n. 连续循环,连续周期18. duration n. 持续时间19. majority n. 多数20. miscellaneous a. ;n. 各种的21. assemble vt. ;n. 装配,组合22. protection n. 保护,防护23. erosion n. 侵(腐)蚀,冲蚀24. corn flour n. 谷粉,玉米粉25. glutin n. 明胶26. molasses n. (废)糖浆27. linseed oil n. 亚麻油28. spray n. ;vt. 喷涂(料)29. gas torch n. 煤气喷灯30. portable a. 手提的,可携的,轻便的31. stove n. 炉子,烘炉32. infrared a. 红外线(的)33. backing sand 背砂,填充砂34. penetrate vt. 渗入Lesson 71. evolve vt. 放出,析出2. overnight ad. ;a. 在前一天晚上,隔夜3. oven n. 烘炉,加热室4. burner n. 燃烧器,喷灯5. charcoal n. 木炭6. circulate v. 循环,流通7. provide v. 供给,供应8. resist vt. 抵抗,耐,承受9. detail n. 细节,部分10. disadvantageous a. 不利的,有害的11. unusual a. 不平常的,独特的12. pattern plate n. 模板13. harden vt. 硬化14. sodium silicate n. 硅酸钠,水玻璃15. clay-free n. 无粘土的16. siliceous a. 含硅的,硅酸的17. carbon dioxide n. 二氧化碳18. promote vt. 促进,加速19. interfere vi. 妨碍,影响20. disintegration n. 溃散21. organic a. 有机的22. wood flour n. 木屑,木粉23. sand mixture n. 型砂24. delay vt. ;n. 耽误,延缓25. inadequate a. 不适宜的,不充分的26. portland cement n. 波特兰水泥(普通水泥)Lesson 81. gating system n. 浇注系统2. refer vt. 把…归类于,指(的是)3. passageway n. 通道4. pouring basin n. 浇口杯,浇口池5. strainer core n. 筛网芯片,撇渣芯,浇口滤片6. fulfill =fulfil vt. 实现,完成,达到7. be defined as ……的定义是,可称为8. be classified as 分成(为)……类9. parting-line gating n. 分型线浇注系统10. bottom gating n. 底注式浇注系统11. erosion n. 冲蚀,侵蚀12. turbulence n. 涡流,漩涡,紊流13. refractory tile pipe n. 耐火材料管14. horn gate n. 羊角浇口15. reversed horn gate n. 倒置羊角浇口16. top gating n. 顶注式浇注系统17. gradient n. 梯度18. directional solidification n. 定向凝固19. server as (for)起…作用,作为20. pencil gate n. 雨林浇口21. wedge gate n. 契形浇口22. choke n. 阻流口,节流口23. side gating n. 侧注式浇注系统24. slot n. 狭缝,隙缝25. step gate n. 阶梯浇口26. deliver vt. 供给,移交,交付27. function vi. ;n. 起作用,作用Lesson 91. satisfactory a. 满意的,(良)好的2. originally ad. 原来,最初3. hardness n. 硬度4. transport vt;n. 运输,输送5. (be)capable of –ing 能…,可以…,容许…6. smoothness n. 光滑度,平滑度7. wash n. 涂料8. coating n. 涂料,涂层9. impart vt. 给予,赋予10. collapsibility n.溃散性11. overstress vt.;n. 使…受(应)力过大,过应力,超载12. knock out 落砂,敲出,分离13. core print 型芯头(座)14. sharp sand n. 角形砂,纯砂15. pine-tree resin n. 松香16. cereal binder n. 谷类粘结剂17. dextrine = dextrin n. 糊精(C6H10O5)18. starch n. 淀粉Lesson 102. alloy n. 合金v. 合铸,熔合,熔成合成8. intentionally ad. 有意地,故意地9. blast n. v. 鼓风,(一股)气流10. blast furnace 高炉,鼓风炉11. nickle n. 镍12. chromium n. 铬13. molybdenum n. 钼14. graphite n. 石墨15. property n. 特性,性能16. mechanical property 机械性能17. metallurgical a. 冶金的,金相的18. distribution n. 分布,分布状态19. microscope n. 显微镜20. specimen n. 试样,样品,标本21. grind v. 磨光,磨快(过去式ground)22. polish v. 抛光,打光,发亮23. etch v. 侵蚀,腐蚀24. matrix n. 基体26. extend v. 延长,延伸,扩张27. ferrite n. 铁素体28. cementite n. 渗碳体29. pearlite n. 珠光体30. austenite n. 奥氏体31. steadite n. 斯氏体磷化物共晶体32. solution n. 溶解,溶液,熔体,解决(办法)33. solid solution 固溶体Lesson 111. white cast iron 白口铸铁2. malleable a. 有延展性的,可锻的3. malleable cast iron 球墨铸铁4. nodular a. 球粒状的5. nodular cast iron 球墨铸铁6. reminder n. 剩余物,剩下物7. chill n. a. v. 激冷,冷铁,冷铸,白口层8. rim n. 轮缘9. machining quality a. 机加工性能,被切削性10. forging n. 锻造,锻件11. ductility n. 韧性,延性12. separate v. 分离,析出13. temper v. n. 回火,搀和,加水混砂14. temper carton 退火碳15. interrupt v. 中断,阻碍16. implement n. 机具,农具17. agricultural implement 农具18. fitting n. a. 装配,配件,连接件19. pipe fitting 管接头,管配件20. instead of 代替,而不是21. in this respect 在这一点上,在这方面Lesson 121. primarily2. corrosion n. 腐蚀,侵蚀3. atmospheric a. 大气的,常压的4. exposure n. 暴露,照射5. plating n. 镀层,电镀,喷镀6. heat-treatable a. 可热处理的7. definite a. 确定的,一定的9. (be)prone to 易于,倾向于10. reaction a. 反应,反作用11. (be)liable to 易于…,有…倾向12. oxidation n. 氧化13. whilst =(while) conj. 当…时,而14. flux n. 熔剂,焊剂15. cover flux 覆盖剂16. cleanse vt. 去掉,清除17. oxide n. 氧化物18. to the extent of 到…程度19. aging = (ageing) n. 老化,时效20. self-aging 自然时效21. strain n. 应变,变形22. stability n. 稳定性23. titanium n. 钛24. in varying proportions 按不同的比例25. nonmagnetic a. 无磁的,非磁性的26. nonsparking a. 不产生火花的27. possess vt. 具有,拥有,占有30. equipment n. 设备,装备31. comparable with 可与…相比的,与…相类似的Lesson 132. specify vt. 规定8. impact resistance n. 抗冲击性9. wear resistance n. 耐磨性,磨损阻力10. acid resistance n. 耐酸性11. weldability n. 可焊性,焊接性12. rigidity n. 刚性,刚度13. deflection n. 挠曲,弯曲,挠度14. separately ad. 单独地15. identify vt. 识别,鉴定,验明16. yield strength n. 屈服强度17. ductility n. 韧性,可锻性,延性18. effectiveness n. 有效性19. with regard to 就…而论,对于,关于20. deoxidizer = deoxidiser n. 脱氧剂,还原剂21. soundness n. 完好的程度22. adversely ad. 相反地23. objectionable a. 有害的,不好的24. tolerate vt. 允许,承受Lesson 141. cylinder n. 圆柱体,汽缸2. shell n. 壳体,贝壳3. casing n. 箱,盒,壳,套4. lining n. 衬,衬里,内衬5. brick n. 砖vt. 砌砖6. windbox 风箱,风带7. encircle vt. 环绕,绕……行一周9. support vt. 支撑,支承10. leg n. 腿,脚,支柱11. hunge v. 铰接,用铰链结合;n. 铰链12. semicircular a. 半圆形的13. prop n. 撑杆,炉底撑杆14. remain vi. 剩下,余留15. coke n. 焦炭16. slag n. 炉渣,熔渣17. blower n. 鼓风机,风扇18. taphole 出铁孔19. spout n. 出铁槽,流槽,水落管20. float vi. 漂浮21. sighthole 观察孔22. charging door 加料门23. occupy vt. 占有,占据24. combustion n. 燃烧25. theoretical a. 理论上的26. boundary n. 边界,分界,界27. oxygen n. 氧28. eliminate vt. 除去,消除32. coke bed 底焦33. oxidize v. 使氧化34. influence n. 影响 vt. 影响,对…有作用35. regulate vt. 调整,调节36. efficiency n. 效率37. collect v. 收集,聚集38. preheat v. 预热39. stack n. 烟囱,炉身,堆40. represent v. 代表,意味,象征41. waste n. v. 废物,浪费,纱头,回丝 a. 无用的,废弃的Lesson 151. mass n. 物质,质量 a.大量的,集中的2. mass-production 大量(大批,成批)生产3. previous ad. 以前,预先4. backbreaking a. 累人的5. item n. 条,项,项目6. outstanding a. 显著的,突出的7. advantage n. 优点,有利条件8. dimensionally ad. 在尺寸方面11. fixture n. 夹具13. coordinate v. 配合,使同等14. coordinating n. 配套设备15. stationary a. 不动的,静止的16. permanent a. 永久的,恒定不变的17. foundation n. 基础,地基18. jolt v. ;n. 震击19. squeeze v. ;n. 压实20. piston n. 活塞21. combination n. 结合,组合22. tendency n. 倾向,趋势23. correct vt. 纠正,改正24. compress vt. 压缩25. compressed air 压缩空气26. source n. 源,源泉27. valve n. 阀28. knee valve n. 膝阀29. exhaust n. ;v. 排出30. port n. 口,港口31. cycle n. 循环,周期32. swing v. 回转,摇摆,摆动33. force vt. 迫使,推动;n. 力,力量34. diameter n. 直径Lesson 161. sand slinger n. 抛砂机2. throw vt. ;n. 掷,抛3. impact n. ;vt. 冲击4. mechanism n. 机构,机理5. impeller n. 叶轮6. blade n. 叶片vane n. 叶片8. endless bucket elevator 环形斗式提升机9. track n.;v. 轨道,跟踪10. bay n. 柱距,跨(度)12. centralized fingertrip control 中心按钮控制13. back and forth 前后,来回14. as compared with 与…比较15. aerate vt. 松砂16. provide with 装有,具备17. remote-contro station 遥控台18. visibility n. 能见度,视野,视界Lesson 171. gain ground 有进展2. in the order of 大约,按……次序3. enormous a. 巨大的4. fettling n. 清理,补炉5. none at all 一点也没有6. joint line 分型线7. feeder n. 冒口,补缩包8. dilation n. 扩大,膨胀9. bring about 引起、生产、导致10. ferrostatic head 铁水静压头11. dense a. 致密的12. uncommon a. 难得的、不平常的13. sophistication n. 采用先进技术14. associate vt. 联合be associated with 在…同时,与…有联系15. recover vt. 回收,复原16. expenditure n. 费用17. capital expenditure 基建费18. superior a. ;n. 优等的19. gradually ad. 逐渐20. short series 小批量21. jobbing n. 重复性很小的工作22. unsophisticated a. 不复杂的,简单的23. manual a. ;n. 手工的,手册24. assist vt.;n. 辅助25. lift vt. 起吊,提升26. rational a. 合理的27. criterion (复数criteria) n. (判断的)标准,准则28. prototype n. 原型,样机29. providing conj. (=provided)只要,如果30. delicate a. 精细的,易损的,脆弱的Lesson 181. scale n. 锈皮3. adequate a. 充分的,足够的,适当的5. stiff a. 硬的6. bristle n. (刷子等的)毛7. chisel n. 錾子,凿子8. barrel n. 筒,桶9. tumbling n. 清理滚筒10. rub v. 摩擦11. breakage n. 破裂,断裂12. absorb vt. 吸收,缓冲13. jet n. 气流,射流,水流14. velocity n. 速度15. cabinet n. 小室16. sand blast cabinet 喷砂室17. nozzle n. 喷嘴18. shatter v. 打碎,打破19. shatterproof glass 防震玻璃20. completion n. 完成,结束21. helmet n. 防护面具,头盔22. pneumatic a. 气动的,风动的23. pneumatic chipping hammer 风铲24. grinder n. 砂轮机,磨床25. pneumatic grinder 风动砂轮机26. centrifugal a. 离心的27. hopper n. 斗,仓28. storage hopper 贮存斗29. blade wheel 叶轮30. emery n. 金刚砂,磨光31. emery wheel 砂轮32. dust n. 灰尘33. dust-collecting device 击沉装置3. carbon n. 碳4. silicon n. 硅5. manganese n. 锰6. sulfur = (sulphur) n. 硫7. phosphorus n. 磷8. molybdenum n. 钼9. nickel n. 镍10. tungsten n. 钨11. vanadium n. 钒12. zirconium n. 锆13. calcium n. 钙14. silica n. 二氧化硅,石英。