塑胶模具寿命评估标准记录表

- 格式:xls

- 大小:31.00 KB

- 文档页数:1

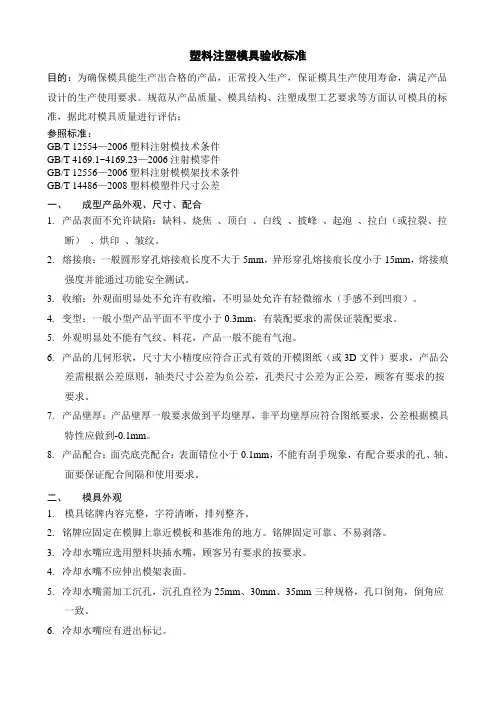

塑料注塑模具验收标准目的:为确保模具能生产出合格的产品,正常投入生产,保证模具生产使用寿命,满足产品设计的生产使用要求。

规范从产品质量、模具结构、注塑成型工艺要求等方面认可模具的标准,据此对模具质量进行评估;参照标准:GB/T 12554—2006塑料注射模技术条件GB/T 4169.1~4169.23—2006注射模零件GB/T 12556—2006塑料注射模模架技术条件GB/T 14486—2008塑料模塑件尺寸公差一、成型产品外观、尺寸、配合1.产品表面不允许缺陷:缺料、烧焦、顶白、白线、披峰、起泡、拉白(或拉裂、拉断)、烘印、皱纹。

2.熔接痕:一般圆形穿孔熔接痕长度不大于5mm,异形穿孔熔接痕长度小于15mm,熔接痕强度并能通过功能安全测试。

3.收缩:外观面明显处不允许有收缩,不明显处允许有轻微缩水(手感不到凹痕)。

4.变型:一般小型产品平面不平度小于0.3mm,有装配要求的需保证装配要求。

5.外观明显处不能有气纹、料花,产品一般不能有气泡。

6.产品的几何形状,尺寸大小精度应符合正式有效的开模图纸(或3D文件)要求,产品公差需根据公差原则,轴类尺寸公差为负公差,孔类尺寸公差为正公差,顾客有要求的按要求。

7.产品壁厚:产品壁厚一般要求做到平均壁厚,非平均壁厚应符合图纸要求,公差根据模具特性应做到-0.1mm。

8.产品配合:面壳底壳配合:表面错位小于0.1mm,不能有刮手现象,有配合要求的孔、轴、面要保证配合间隔和使用要求。

二、模具外观1.模具铭牌内容完整,字符清晰,排列整齐。

2.铭牌应固定在模脚上靠近模板和基准角的地方。

铭牌固定可靠、不易剥落。

3.冷却水嘴应选用塑料块插水嘴,顾客另有要求的按要求。

4.冷却水嘴不应伸出模架表面。

5.冷却水嘴需加工沉孔,沉孔直径为25mm、30mm、35mm三种规格,孔口倒角,倒角应一致。

6.冷却水嘴应有进出标记。

7.标记英文字符和数字应大于5/6,位置在水嘴正下方10mm处,字迹应清晰、美观、整齐、间距均匀。

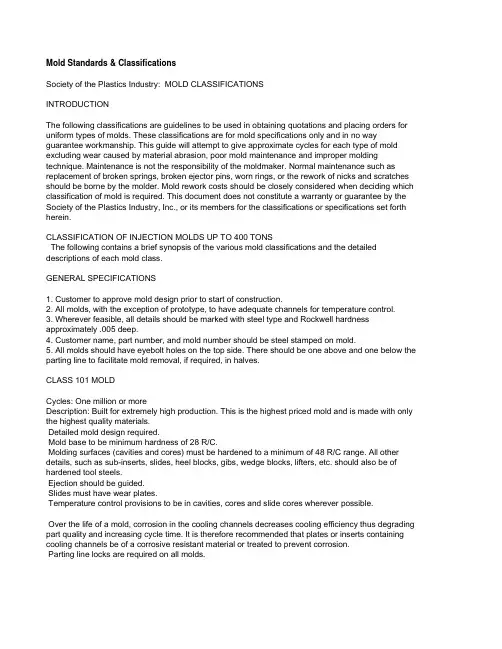

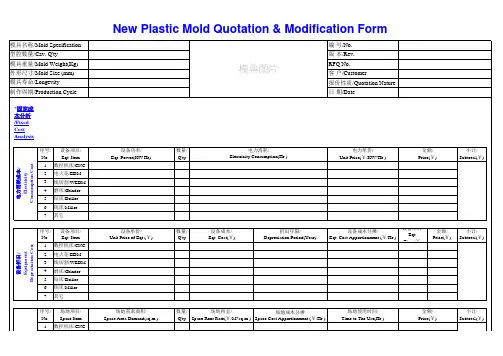

Mold Standards & ClassificationsSociety of the Plastics Industry: MOLD CLASSIFICATIONSINTRODUCTIONThe following classifications are guidelines to be used in obtaining quotations and placing orders for uniform types of molds. These classifications are for mold specifications only and in no way guarantee workmanship. This guide will attempt to give approximate cycles for each type of mold excluding wear caused by material abrasion, poor mold maintenance and improper molding technique. Maintenance is not the responsibility of the moldmaker. Normal maintenance such as replacement of broken springs, broken ejector pins, worn rings, or the rework of nicks and scratches should be borne by the molder. Mold rework costs should be closely considered when deciding which classification of mold is required. This document does not constitute a warranty or guarantee by the Society of the Plastics Industry, Inc., or its members for the classifications or specifications set forth herein.CLASSIFICATION OF INJECTION MOLDS UP TO 400 TONSThe following contains a brief synopsis of the various mold classifications and the detailed descriptions of each mold class.GENERAL SPECIFICATIONS1. Customer to approve mold design prior to start of construction.2. All molds, with the exception of prototype, to have adequate channels for temperature control.3. Wherever feasible, all details should be marked with steel type and Rockwell hardness approximately .005 deep.4. Customer name, part number, and mold number should be steel stamped on mold.5. All molds should have eyebolt holes on the top side. There should be one above and one below the parting line to facilitate mold removal, if required, in halves.CLASS 101 MOLDCycles: One million or moreDescription: Built for extremely high production. This is the highest priced mold and is made with only the highest quality materials.Detailed mold design required.Mold base to be minimum hardness of 28 R/C.Molding surfaces (cavities and cores) must be hardened to a minimum of 48 R/C range. All other details, such as sub-inserts, slides, heel blocks, gibs, wedge blocks, lifters, etc. should also be of hardened tool steels.Ejection should be guided.Slides must have wear plates.Temperature control provisions to be in cavities, cores and slide cores wherever possible.Over the life of a mold, corrosion in the cooling channels decreases cooling efficiency thus degrading part quality and increasing cycle time. It is therefore recommended that plates or inserts containing cooling channels be of a corrosive resistant material or treated to prevent corrosion.Parting line locks are required on all molds.CLASS 102 MOLDCycles: Not exceeding one millionDescription: Medium to high production mold, good for abrasive materials and/or parts requiring close tolerances. This is a high quality, fairly high priced mold.Detailed mold design required.Mold base to be minimum hardness of 28 R/C.Molding surfaces should be hardened to a 48 R/C range. All other functional details should be made and heat treated.Temperature control provisions to be directly in the cavities, cores, and slide cores wherever possible.Parting line locks are recommended for all molds.The following items may or may not be required depending on the ultimate production quantities anticipated. It is recommended that those items desired be made a firm requirement for quoting purposes:a. Guided Ejectionb. Slide Wear Platesc. Corrosive Resistant Temperature Control Channelsd. Plated CavitiesCLASS 103 MOLD*Cycles: Under 500,000Description: Medium production mold. This is a very popular mold for low to medium production needs; most common price range.Detailed mold design recommended.Mold base must be minimum hardness of 8 R/C.Cavity and cores must be 28 R/C or higher.All other extras are optional.CLASS 104 MOLD*Cycles: Under 100,000Description: Low production mold. Used only for limited production preferably with non-abrasive materials; low to moderate price range.Mold design recommended.Mold base can be of mild steel or aluminum.Cavities can be of aluminum, mild steel or any other agreed upon metal.CLASS 105 MOLDCycles: Not exceeding 500Description: Prototype only. This mold will be constructed in the least expensive manner possible to produce a very limited quantity of prototype parts.Molds may be constructed from cast metal or epoxy or any other material offering sufficient strength to produce minimum prototype pieces.。

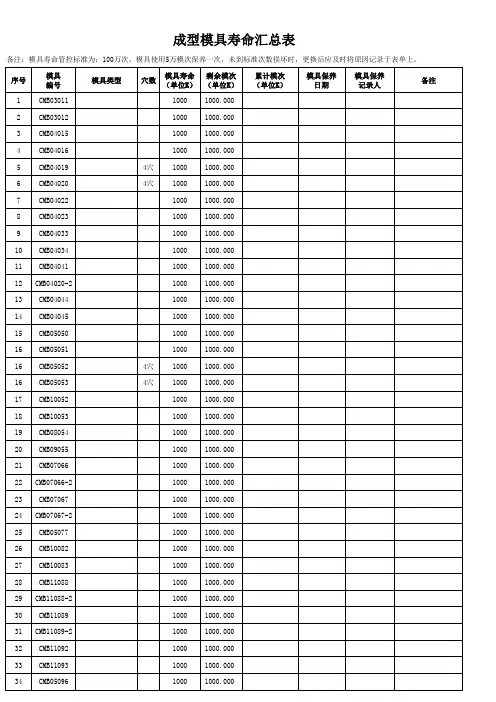

模具使用寿命标准表因各种因素而异,例如模具材料、模具结构、产品形状和尺寸、生产环境等。

以下是一些常见的模具使用寿命标准表,供您参考:

1.塑料模具使用寿命标准表:

●热流道系统:100万次以上

●大型注塑模具:30万次以上

●中小型注塑模具:10万次以上

●透明制品注塑模具:5万次以上

2.铝合金压铸模具使用寿命标准表:

●短周期模具:50万次以上

●中长周期模具:100万次以上

●长周期模具:200万次以上

3.冲压模具使用寿命标准表:

●钣金冲压模具:5-20万次

●塑性成形模具:20-50万次

●气动模具:100万次以上

需要注意的是,以上标准表只是一个大致的参考值,实际的模具使用寿命还需要根据具体情况进行评估。

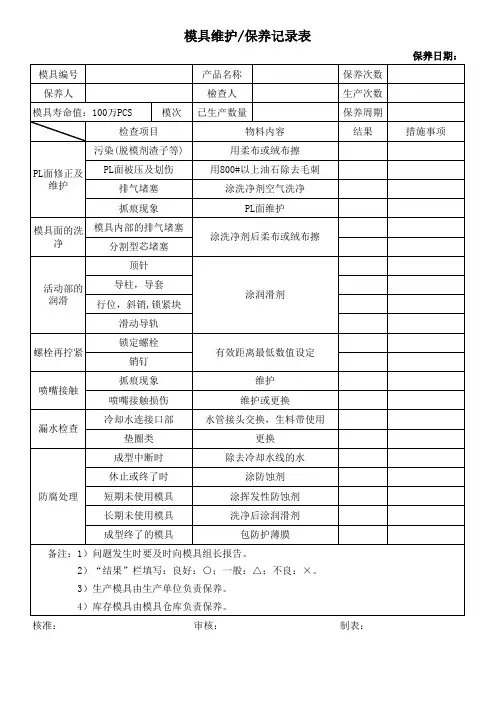

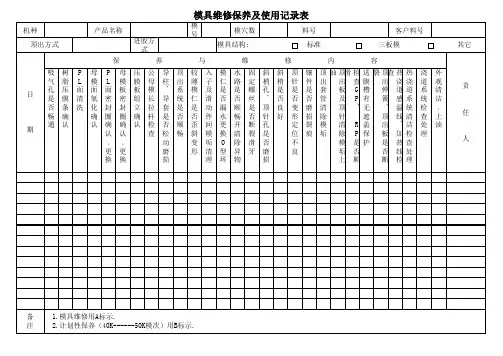

在使用模具时,应定期检查和保养模具,及时发现和解决问题,以延长模具的使用寿命。