TPA-13-6016中文资料

- 格式:pdf

- 大小:889.43 KB

- 文档页数:2

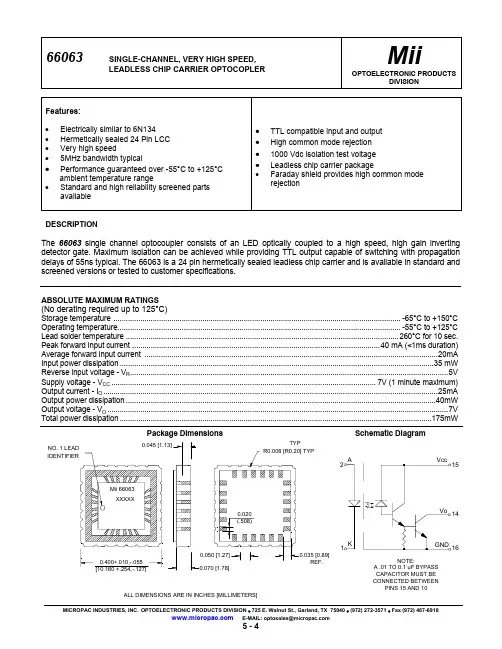

66063SINGLE-CHANNEL, VERY HIGH SPEED, LEADLESS CHIP CARRIER OPTOCOPLERMii OPTOELECTRONIC PRODUCTSDIVISIONFeatures:•Electrically similar to 6N134•Hermetically sealed 24 Pin LCC•Very high speed•5MHz bandwidth typical•Performance guaranteed over -55°C to +125°C ambient temperature range•Standard and high reliability screened parts available •TTL compatible input and output•High common mode rejection•1000 Vdc isolation test voltage •Leadless chip carrier package•Faraday shield provides high common mode rejectionDESCRIPTIONThe 66063 single channel optocoupler consists of an LED optically coupled to a high speed, high gain inverting detector gate. Maximum isolation can be achieved while providing TTL output capable of switching with propagation delays of 55ns typical. The 66063 is a 24 pin hermetically sealed leadless chip carrier and is available in standard and screened versions or tested to customer specifications.ABSOLUTE MAXIMUM RATINGS(No derating required up to 125°C)Storage temperature ...........................................................................................................................................-65°C to +150°C Operating temperature.........................................................................................................................................-55°C to +125°C Lead solder temperature ....................................................................................................................................260°C for 10 sec. Peak forward input current ........................................................................................................................40 mA (<1ms duration) Average forward input current ..............................................................................................................................................20mA Input power dissipation........................................................................................................................................................35 mW Reverse input voltage - V R. (5V)Supply voltage - V CC................................................................................................................................7V (1 minute maximum)66063 SINGLE–CHANNEL, VERY HIGH SPEED, LEADLESS CHIP CARRIER OPTOCOUPLER, ContinuedELECTRICAL CHARACTERISTICSOVER RECOMMENDED TEMPERATURE (T A = -55°C to +125°C) unless otherwise specifiedPARAMETERSYMBOLMIN TYP**MAXUNITSTEST CONDITIONSNOTEHigh Level Output Current I OH 5250µAV CC = 5.5V, V O = 5.5V,I F = 250 µA Low Level Output Voltage V OL 0.50.6VV CC = 5.5V, I F = 10mA,I OL (Sinking ) = 10mA 6High Level Supply Current I CCH 1828mAV CC = 5.5V, I F = 0(Both Channels )Low Level Supply Current I CCL 2636mA V CC = 5.5V, I F = 20mA(Both Channels )Input Forward VoltageV F 1.51.75V I F = 20mA, T A = 25°C Input Reverse Breakdown Voltage BV R 5VI R = 10µA, T A = 25°C Input-Output Insulation Leakage CurrentI I—O1.0µAV I-0 = 1000Vdc,Relative Humidity = 45%T A = 25°C, t = 5s.1Propagation Delay Time To High Output Levelt PLH 65100nsR L = 510Ω, C L = 15pF,I F = 13mA, T A = 25°C 2, 6Propagation Delay Time To Low Output Levelt PHL55100nsR L = 510Ω, C L = 15pF,I F = 13mA, T A = 25°C3, 6**All typical values are at V CC = 5V, T A = 25°CTYPICAL CHARACTERISTICSAT T A = 25°C, V CC = 5VPARAMETERSYMBOLMIN TYPMAX UNITSTEST CONDITIONSNOTEInput Capacitance C IN60pF V F = 0, f = 1MHzInput Diode Temperature Coefficient∆v F ∆T A-1.9mV/°CI F = 20mA Resistance (Input-Output)R I- O 1012ΩV I-O = 500V 1Capacitance (Input-Output)C I-O 1.7pF f = 1MHz 1Output Rise-Fall Time (10-90%)t r , t f 35ns R L = 510Ω, C L = 15pF,I F = 13mA6Common Mode Transient Immunity at High Output CM H100010000V/µsV CM = 10V (peak)V O (min.) = 2V,R L = 510Ω, I F = 0mA4Common Mode Transient Immunity at Low OutputCM L100010000V/µsV CM = 10V (peak)V O (max.) = 0.8V,R L = 510Ω, I F = 10mA5NOTES:1. Measured between pins 1 and 2 shorted together, and pins 10, 14 and 15 shorted together.2. The t PHL propagation delay is measured from the 6.5mA point on the trailing edge of the input pulse to the 1.5V point on the trailing edge of the outputpulse.3. The t PHL propagation delay is measured from the 6.5mA point on the leading edge of the input pulse to the 1.5V point on the leading edge of the outputpulse.4. CM H is the max. tolerable common mode transient to assure that the output will remain in a high logic state (i.e. V O > 2.0V).5. CM L is the max. tolerable common mode transient to assure that the output will remain in a low logic state (i.e. V O < 0.8V).6. It is essential that a bypass capacitor (.01 to 0.1µF, ceramic) be connected from pin 10 to pin 15.RECOMMENDED OPERATING CONDITIONSParameterSYMBOLMIN MAX UNITS Input Current, Low Level Each Channel I FL 0250µA Input Current, High Level Each Channel I FH 12.520mA Supply VoltageV CC 4.5 5.5V Fan Out (TTL Load) Each Channel N 6Operating TemperatureT A-55+125°C。

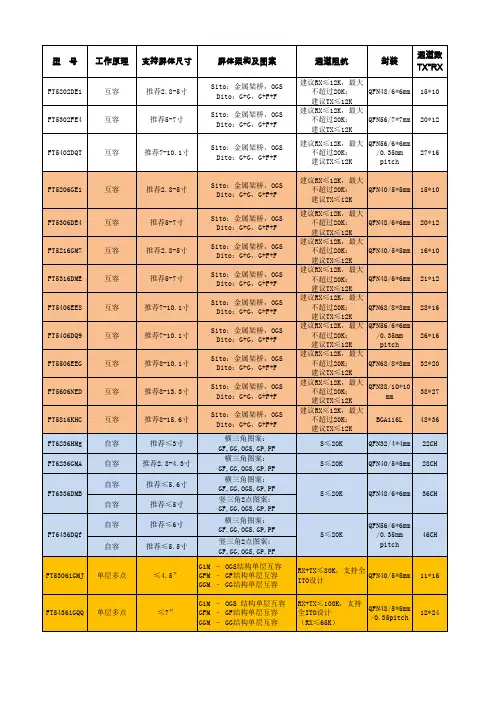

单通道触摸感应开关RH6016规格书Revision 0.32018-2-8 深圳芯派科技TEL:135 3045 2646 (唐生)ICQ:294 434 3362ICQ:294 435 3362目录1.简介 (3)2.特点 (3)3.封装引脚示意图及模式 (3)3.1引脚示意图 (3)3.2默认输出模式 (4)4.订购信息 (4)5.功能描述 (4)5.1输出有效电平配置(AHLB) (5)5.2快速/低功耗模式(LPMB) (5)5.3保持/同步模式(TOG) (5)5.4最大开启时间(MOT2MOT1) (5)6.应用电路图 (6)7.PCB设计注意事项 (6)8.电气参数 (7)8.1最大绝对额定值 (7)8.2DC电气参数 (7)9.封装信息(SOT23-6) (8)1.简介RH6016是一款内置稳压模块的单通道电容式触摸感应控制开关IC ,可以替代传统的机械式开关。

RH6016可在有介质(如玻璃、亚克力、塑料、陶瓷等)隔离保护的情况下实现触摸功能,安全性高。

RH6016内置高精度稳压、上电复位、低压复位、硬件去抖、环境自适应算法等多种有效措施,大大提高自身抗干扰性能。

RH6016可通过外部引脚配置成多种工作模式,可广泛应用于灯光控制、电子玩具、消费电子、家用电器等产品中。

2.特点∙工作电压:2.4V ~5.5V ∙待机平均电流小于10uA@3.0V ∙上电0.5s 快速初始化∙环境自适应功能,可快速应对先上电后覆盖介质、触摸上电等类似应用场景∙可靠的上电复位(POR)及低压复位(LVR)性能∙芯片内置去抖动电路,有效防止由外部噪声干扰导致的误动作∙可设置高/低电平有效输出、同步/保持模式、最大开启时间∙RH6016D ,NMOS 开漏输出∙RH6016C ,CMOS 输出∙封装形式:SOT23-63.封装引脚示意图及模式3.1引脚示意图图1RH6016C/RH6016D(SOT23-6)引脚示意图管脚名称RH6016CRH6016DI/O 描述VDD 55P 正电源AHLB 4-I-P L 输出高/低电平有效配置位TOG -4I-P L 同步/保持模式配置位GND 22P 地TCH 33I/O 触摸输入端口CS 11I/O 采样电容LPMB --I-P H 快速/低功耗模式配置位MOT1--I-P H 最大开启时间配置位1MOT2--I-P H最大开启时间配置位2OD-6OD NMOS开漏输出OC6-O CMOS输出I-P L/I-P H:带内部下拉/上拉电阻的CMOS输入OD:开漏输出O:CMOS输出I/O:CMOS输入/输出P:电源/地3.2默认输出模式SOT23-6(RH6016C)SOT23-6(RH6016D)OC引脚输出高有效可配置OD引脚输出低有效固定低功耗模式固定低功耗模式固定8s最大开启时间固定8s最大开启时间固定同步模式输出固定同步模式输出可配置可配置:指该封装上有相应模式的配置管脚引出,具体见5.功能描述。

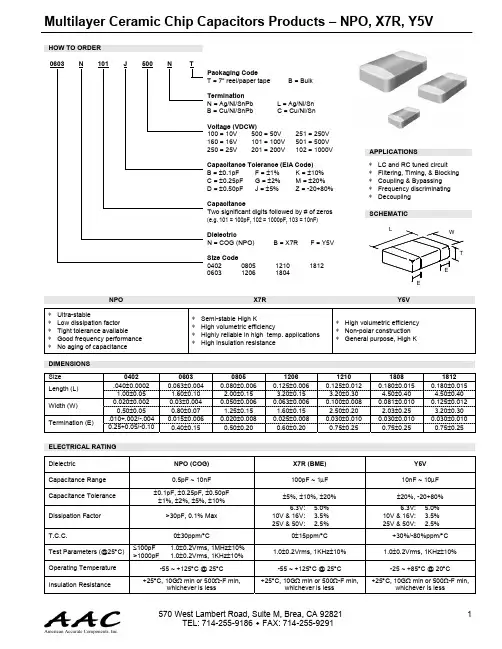

元器件交易网Multilayer Ceramic Chip Capacitors Products – NPO, X7R, Y5VHOW TO ORDER 0603 N 101 J 500 N T Packaging Code T = 7” reel/paper tape Termination N = Ag/Ni/SnPb B = Cu/Ni/SnPb B = Bulk L = Ag/Ni/Sn C = Cu/Ni/Sn 251 = 250V 501 = 500V 102 = 1000VVoltage (VDCW) 100 = 10V 500 = 50V 160 = 16V 101 = 100V 250 = 25V 201 = 200VAPPLICATIONS ∗ ∗ ∗ ∗ ∗ LC and RC tuned circuit Filtering, Timing, & Blocking Coupling & Bypassing Frequency discriminating DecouplingCapacitance Tolerance (EIA Code) B = ±0.1pF F = ±1% K = ±10% C = ±0.25pF G = ±2% M = ±20% Z = -20+80% D = ±0.50pF J = ±5% Capacitance Two significant digits followed by # of zeros (e.g. 101 = 100pF, 102 = 1000pF, 103 = 10nF) Dielectric N = COG (NPO) Size Code 0402 0805 0603 1206 B = X7R 1210 1804 F = Y5VSCHEMATICL WT1812EENPO ∗ ∗ ∗ ∗ ∗ Ultra-stable Low dissipation factor Tight tolerance available Good frequency performance No aging of capacitance ∗ ∗ ∗ ∗X7R Semi-stable High K High volumetric efficiency Highly reliable in high temp. applications High insulation resistanceY5V ∗ High volumetric efficiency ∗ Non-polar construction ∗ General purpose, High KDIMENSIONS Size Length (L) Width (W) Termination (E) 0402 .040±0.0002 1.00±0.05 0.020±0.002 0.50±0.05 .010+.002/-.004 0.25+0.05/-0.10 0603 0.063±0.004 1.60±0.10 0.03±0.004 0.80±0.07 0.015±0.006 0.40±0.15 0805 0.080±0.006 2.00±0.15 0.050±0.006 1.25±0.15 0.020±0.008 0.50±0.20 1206 0.125±0.006 3.20±0.15 0.063±0.006 1.60±0.15 0.025±0.008 0.60±0.20 1210 0.125±0.012 3.20±0.30 0.100±0.008 2.50±0.20 0.030±0.010 0.75±0.25 1808 0.180±0.015 4.50±0.40 0.081±0.010 2.03±0.25 0.030±0.010 0.75±0.25 1812 0.180±0.015 4.50±0.40 0.125±0.012 3.20±0.30 0.030±0.010 0.75±0.25ELECTRICAL RATING Dielectric Capacitance Range Capacitance Tolerance Dissipation Factor T.C.C. Test Parameters (@25°C) Operating Temperature Insulation Resistance ≤100pF >1000pF NPO (COG) 0.5pF ~ 10nF ±0.1pF, ±0.25pF, ±0.50pF ±1%, ±2%, ±5%, ±10% >30pF, 0.1% Max 0±30ppm/°C 1.0±0.2Vrms, 1MHz±10% 1.0±0.2Vrms, 1KHz±10% -55 ~ +125°C @ 25°C +25°C, 10GΩ min or 500Ω-F min, whichever is less X7R (BME) 100pF ~ 1µF ±5%, ±10%, ±20% 6.3V: 10V & 16V: 25V & 50V: 5.0% 3.5% 2.5% Y5V 10nF ~ 10µF ±20%, -20+80% 6.3V: 10V & 16V: 25V & 50V: 5.0% 3.5% 2.5%0±15ppm/°C 1.0±0.2Vrms, 1KHz±10% -55 ~ +125°C @ 25°C +25°C, 10GΩ min or 500Ω-F min, whichever is less+30%/-80%ppm/°C 1.0±0.2Vrms, 1KHz±10% -25 ~ +85°C @ 20°C +25°C, 10GΩ min or 500Ω-F min, whichever is less570 West Lambert Road, Suite M, Brea, CA 92821 TEL: 714-255-9186 FAX: 714-255-9291American Accurate Components, Inc.1元器件交易网10 Volts – 50 VoltsDIELECTRIC SIZE EIA Cap Code VDCW 0R5 0.5pF 1R0 1 1R2 1.2 1R5 1.5 1R8 1.8 2R2 2.2 2R7 2.7 3R3 3.3 3R9 3.9 4R7 4.7 5R6 5.6 6R8 6.8 8R2 8.2 100 10pF 120 12 150 15 180 18 220 22 270 27 330 33 390 39 470 47 560 56 680 68 820 82 101 100pF 121 120 151 150 181 180 221 220 271 270 331 330 391 390 471 470 561 560 681 680 821 820 102 1000pF 122 1200 152 1500 182 1800 222 2200 272 2700 332 3300 392 3900 472 4700 562 5600 682 6800 822 8200 103 .010µF 123 12000 153 15000 183 18000 223 22000 273 27000 333 33000 393 0.39µFMLCC Products – NPO TypeNPO 10 N N N N N N N N N N N N N N N N 0402 16 25 N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N 50 N N N N N N N N N N N N N N 10 S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S 0603 16 25 S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S 50 S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S S 10 A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A B B B B B B B B B B D D D D D D D D 0805 16 25 A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A B B B B B B B B B B B B B B B B B B B B D D D D D D D D D D D D 50 A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A B B B B B B B B B B D D D 10 1206 16 25 50 10 1210 16 25 50 10 1812 16 25 50B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B C C D D D D D D D GB B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B C C D D D D D D D GB B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B C CB B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B C CC C C C C C C C C C C C C C C C C C C C C C C C C C C C C CC C C C C C C C C C C C C C C C C C C C C C C C C C C C C CC C C C C C C C C C C C C C C C C C C C C C C C C C C C C CC C C C C C C C C C C C C C C C C C C C C C C C C C C C C CD D D D D D D D D D D D DD D D D D D D D D D D D DD D D D D D D D D D D D DD D D D D D D D D D D D D* Variations of size, capacitance, voltage, and 13” reel are available upon request.570 West Lambert Road, Suite M, Brea, CA 92821 TEL: 714-255-9186 FAX: 714-255-9291American Accurate Components, Inc.2元器件交易网100 Volts – 3000 VoltsMLCC Products – NPO TypeDIELECTRIC NPO EIA SIZE 0603 0805 1206 1210 CODE VDCW 100 100 200 250 500 100 200 250 500 1000 2000 100 200 250 500 1000 2000 100 200 0R5 0.5pF S A A A A B B B B B B 1R0 1 S A A A A B B B B B B 1R2 1.2 S A A A A B B B B B B 1R5 1.5 S A A A A B B B B B B 1R8 1.8 S A A A A B B B B B B 2R2 2.2 S A A A A B B B B B B 2R7 2.7 S A A A A B B B B B B 3R3 3.3 S A A A A B B B B B B 3R9 3.9 S A A A A B B B B B B 4R7 4.7 S A A A A B B B B B B 5R6 5.6 S A A A A B B B B B B 6R8 6.8 S A A A A B B B B B B 8R2 8.2 S A A A A B B B B B B 100 10pF S A A A A B B B B B B C C C C C C D D 120 12 S A A A A B B B B B B C C C C C C D D 150 15 S A A A A B B B B B B C C C C C C D D 180 18 S A A A A B B B B B B C C C C C C D D 220 22 S A A A A B B B B B B C C C C C C D D 270 27 S A A A A B B B B B B C C C C C C D D 330 33 S A A A A B B B B B B C C C C C C D D 390 39 S A A A A B B B B B B C C C C C C D D 470 47 S A A A A B B B B B B C C C C C C D D 560 56 S A A A A B B B B B C C C C C C D D D 680 68 S A A A B B B B B B C C C C C C D D D 820 82 S A A A B B B B B B C C C C C D D D 101 100pF S A A A C B B B B C C C C C C D D D 121 120 S A C C C B B B B C C C C C C D D D 151 150 S A C C D B B B B C C C C C D D D 181 180 S A D D B B B B C C C C C D D D 221 220 S A B B B B C C C C C D D D 271 270 S A B B B C C C C C C D D 331 330 S A B B B C C C C C D D D 391 390 B B B B C C C C C D D D 471 470 B B C C C C C C D D D 561 560 B B C C C C D D 681 680 B C C C C D D 821 820 B C C C C D D 102 1000pF B C C C C D D 122 1200 B C D D D D 152 1500 C C D D D D 182 1800 C C D D D D 222 2200 C D D D D 272 2700 C D D D D 332 3300 C D 392 3900 D 472 4700 D 562 5600 682 6800 822 8200 103 .010µF * Variations of size, capacitance, voltage, and 13” reel are available upon request. TAPE/REEL PACKAGE TYPE, QUANTITY, AND AVAILABILITY Thickness in mm A = 0.65 + 0.05/-0.15 B = 0.85 + 0.5/-0.15 C = 1.00 + 0.05/-0.15 D = 1.2 + 0.15 G = 1.60 + 0.05/-0.15 K = 2.00 + 0.2 M = 2.5 + 0.3 N = 0.5 + 0.05 S = 0.8 + 0.07 0402 Type Qty Paper 10K 0603 Type Qty Paper 4K 0805 Type Qty Paper 4K Paper 4K Plastic 3K Plastic 3K 1206 Type Qty Paper 4K Paper 4K Plastic 3K Plastic 3K Plastic 2K -1812 1808 250 500 1000 2000 3000 1000 2000 3000D D D D D D D D D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D D DD D D D DC C C C C C C C C C C C C K K K K K KC C C C C C C C C C C K K K K KC C C C C C C C C C C C C C1210 Type QtyPlastic Plastic Plastic Plastic Plastic -3K 3K 2K 2K 1K -1808 Type Qty Plastic 2K Plastic 2K Plastic 1K Plastic 1K -1812 Type Qty Plastic 1K Plastic 1K Plastic 1K Plastic 1K -570 West Lambert Road, Suite M, Brea, CA 92821 TEL: 714-255-9186 FAX: 714-255-9291American Accurate Components, Inc.3元器件交易网10 Volts – 50 VoltsMLCC Products – X7R TypeDIELECTRIC X7R SIZE 0402 0603 0805 EIA Cap Code VDCW 10 16 25 50 10 16 25 50 10 16 25 50 10 101 100pF N N N N S S S S B B B B 121 120 N N N N S S S S B B B B 151 150 N N N N S S S S B B B B 181 180 N N N N S S S S B B B B 221 220 N N N N S S S S B B B B B 271 270 N N N N S S S S B B B B B 331 330 N N N N S S S S B B B B B 391 390 N N N N S S S S B B B B B 471 470 N N N N S S S S B B B B B 561 560 N N N N S S S S B B B B B 681 680 N N N N S S S S B B B B B 821 820 N N N N S S S S B B B B B 102 1000pF N N N N S S S S B B B B B 122 1200 N N N N S S S S B B B B B 152 1500 N N N N S S S S B B B B B 182 1800 N N N N S S S S B B B B B 222 2200 N N N N S S S S B B B B B 272 2700 N N N S S S S B B B B B 332 3300 N N N S S S S B B B B B 392 3900 N N N S S S S B B B B B 472 4700 N N S S S S B B B B B 562 5600 N N S S S S B B B B B 682 6800 N N S S S S B B B B B 822 8200 N N S S S S B B B B B 103 N N S S S S B B B B B .010µF 123 .012 N N S S S S B B B B B 153 .015 N N S S S S B B B B B 183 .018 S S S S B B B B B 223 .022 S S S S B B B B B 273 .027 S S S S B B B B B 333 .033 S S S B B B B B 393 .039 S S S B B B B B 473 .047 S S S B B B B B 563 .056 S S S B B B B B 683 .068 S S S B B B B B 823 .082 S S B B B D B 104 S S B B B D B .100µF 154 .150 D D D C 184 .180 D D D C 224 .220 D D D C 334 .330 C 474 .470 684 .680 824 .820 105 1.00µF * Variations of size, capacitance, voltage, and 13” reel are available upon request. TAPE/REEL PACKAGE TYPE, QUANTITY, AND AVAILABILITY Thickness in mm A = 0.65 + 0.05/-0.15 B = 0.85 + 0.5/-0.15 C = 1.00 + 0.05/-0.15 D = 1.2 + 0.15 F = 1.40 + 0.05/-0.15 G = 1.60 + 0.05/-0.15 S = 0.8 + 0.07 N = 0.5 + 0.05 0402 – 0603 Type Quantity 0805 – 1206 Type Quantity Paper 4K/Reel Paper 4K/Reel Plastic 3K/Reel Plastic 3K/Reel Plastic 2K/Reel Plastic 2K/Reel Type 1210 Quantity Type 1808 Quantity Type 1812 Quantity1206 16 2550101210 16 2550101812 16 2550B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B C C C CB B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B C C C CB B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B C C CC C C C C C C C C C C C C C C C C C C C C C C C C C C C C C CC C C C C C C C C C C C C C C C C C C C C C C C C C C C C C CC C C C C C C C C C C C C C C C C C C C C C C C C C C C C C CC C C C C C C C C C C C C C C C C C C C C C C C C C C C C CD D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D D DD D D D D D D D D D D D D D D D D D D D D D D D D D D D D D DPlastic Plastic Plastic Plastic3K/Reel 3K/Reel 2K/Reel 2K/ReelPlastic Plastic Plastic Plastic3K/Reel 3K/Reel 1K/Reel 1K/ReelPlastic Plastic Plastic1K/Reel 1K/Reel 1K/ReelPaper Paper4K/Reel 10K/Reel570 West Lambert Road, Suite M, Brea, CA 92821 TEL: 714-255-9186 FAX: 714-255-9291American Accurate Components, Inc.4元器件交易网100 Volts – 3000 VoltsMLCC Products – X7R TypeDIELECTRIC X7R EIA SIZE 0603 0805 1206 1210 1812 1808 CODE VDCW 100 100 200 250 500 100 200 250 500 1000 1000 2000 100 200 250 500 1000 100 200 250 500 1000 2000 1000 1500 3000 101 100pF S B B B B 121 120 S B B B B 151 150 S B B B B 181 180 S B B B B B B B B B B B 221 220 S B B B B B B B B B B B 271 270 S B B B B B B B B B B B 331 330 S B B B B B B B B B B B 391 390 S B B B B B B B B B B B 471 470 S B B B B B B B B B B B D D C C C 561 560 S B B B B B B B B B B C D D C C C 681 680 S B B B B B B B B B B C D D C C C 821 820 S B B B B B B B B B G G D D C C C 102 1000pF S B B B B B B B B B G G C C C C C D D D D D D C C K 122 1200 S B B B B B B B B B G G C C C C C D D D D D D C C K 152 1500 S B B B B B B B B B G C C C C C D D D D D D C C 182 1800 S B B B B B B B B B G C C C C C D D D D D D C C 222 2200 S B B B B B B B B C G C C C C C D D D D D D C C 272 2700 S B B B B B B B D G C C C C C D D D D D D C D 332 3300 S B B B B B B B G G C C C C D D D D D D D C D 392 3900 S B B B B B B B G G C C C C D D D D D D C 472 4700 S B B B B B B B G G C C C C D D D D D D C 562 5600 S B B B B B G C C C C D D D D D D C 682 6800 S B B B B B G C C C C D D D D D D C 822 8200 S B B B B C C C C C D D D D D D 103 S B B B B C C C C C D D D D D D .010µF 123 .012 S B B B B C C C C D D D D 153 .015 S B B C C C C C C D D D D 183 .018 B B C C C C C C D D D D 223 .022 B C C C C C D D D D D 273 .027 B C C C C C D D D D 333 .033 B C C C D D D D 393 0.39 B C C C D D D D 473 .047 B C D D D D D D 563 .056 B C D D D 683 .068 C C D D D 823 .082 C C D D D 104 D C D D D .100µF 124 .120 D C D D D 154 .150 C D 184 .180 C D 224 .220 C D 334 .330 D 474 .470 D 684 .680 824 .820 105 1.00µF * Variations of size, capacitance, voltage, and 13” reel are available upon request. TAPE/REEL PACKAGE TYPE, QUANTITY, AND AVAILABILITY Thickness in mm A = 0.65 + 0.05/-0.15 B = 0.85 + 0.5/-0.15 C = 1.00 + 0.05/-0.15 D = 1.2 + 0.15 F = 1.40 + 0.05/-0.15 G = 1.60 + 0.05/-0.15 K = 2.00 + 0.2 S = 0.8 + 0.07 N = 0.5 + 0.05 0603-0805-1206 Type Quantity Paper 4K/Reel Paper 4K/Reel Plastic 3K/Reel Plastic 3K/Reel Plastic 2K/Reel Plastic 2K/Reel Type 1210 Quantity Type 1808 Quantity Type 1812 QuantityPlastic Plastic Plastic Plastic3K/Reel 3K/Reel 2K/Reel 2K/ReelPlastic Plastic Plastic Plastic Plastic3K/Reel 3K/Reel 1K/Reel 1K/Reel 1K/ReelPlastic Plastic Plastic Plastic1K/Reel 1K/Reel 1K/Reel 1K/Reel570 West Lambert Road, Suite M, Brea, CA 92821 TEL: 714-255-9186 FAX: 714-255-9291American Accurate Components, Inc.5元器件交易网10 Volts – 50 VoltsMLCC Products – Y5V TypeDIELECTRIC Y5V SIZE 0402 0603 0805 EIA Cap Code VDCW 10 16 25 50 10 16 25 50 10 16 25 50 10 103 N N N S S S S A A A A B .010µF 123 .012 N N N S S S S A A A A B 153 .015 N N N S S S S A A A A B 183 .018 N N N S S S S A A A A B 223 .022 N N N S S S S A A A A B 273 .027 N N N S S S S A A A A B 333 .033 N N N S S S S A A A A B 393 .039 N N N S S S S A A A A B 473 .047 N N N S S S S A A A A B 563 .056 N N S S S S A A A A B 683 .068 N N S S S S A A A A B 823 .082 N N S S S S A A A A B 104 N N S S S S A A A A B .100µF 154 .150 S S S S A A A A B 224 .220 S S S A A A A B 334 .330 S S B B B B 474 .470 S S B B B B 684 .680 S B B B 105 S B B C 1.00µF 155 1.50 C 225 2.20 C 335 3.30 D 475 4.75 D 106 10µF * Variations of size, capacitance, voltage, and 13” reel are available upon request.1206 16 25 B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B B C C C C C C D D D D50 B B B B B B B B B B B B B B B B B101210 16 2550101812 16 2550C C C C C C CC C C C C C CC C C C C C CC C C CD D D D D D DD D D D D D DD D D D D D DD D D D D D D100 Volts – 500 VoltsDIELECTRIC Y5V SIZE 0805 1206 1812 EIA Cap Code VDCW 100 200 250 500 100 200 250 500 100 200 250 103 B B B B B .010µF 123 .012 B B B B B 153 .015 B B B B B 183 .018 B B B B B 223 .022 B B B B B 273 .027 B B B B B 333 .033 B B B B B 393 .039 B B B B B 473 .047 B B B B 563 .056 B B B B 683 .068 B B B B 823 .082 B C C C 104 B C C C D D D .100µF 154 .150 C D D D 224 .220 C D D D 334 .330 D D D 474 .470 D D D * Variations of size, capacitance, voltage, and 13” reel are available upon request. TAPE/REEL PACKAGE TYPE, QUANTITY, AND AVAILABILITY Thickness in mm A = 0.65 + 0.05/-0.15 B = 0.85 + 0.5/-0.15 C = 1.00 + 0.05/-0.15 D = 1.2 + 0.15 F = 1.40 + 0.05/-0.15 G = 1.60 + 0.05/-0.15 K = 2.00+0.2mm S = 0.8 + 0.07 N = 0.5 + 0.05 0402 – 0603 Type Quantity 0805 – 1206 Type Quantity Paper 4K/Reel Paper 4K/Reel Plastic 3K/Reel Plastic 3K/Reel Plastic 2K/Reel Plastic 2K/Reel Type 1210 Quantity Type 1808 Quantity Type 1812 Quantity 500Plastic Plastic Plastic Plastic3K/Reel 3K/Reel 2K/Reel 2K/ReelPlastic Plastic Plastic Plastic3K/Reel 3K/Reel 1K/Reel 1K/ReelPlastic Plastic Plastic Plastic1K/Reel 1K/Reel 1K/Reel 1K/ReelPaper Paper4K/Reel 10K/Reel570 West Lambert Road, Suite M, Brea, CA 92821 TEL: 714-255-9186 FAX: 714-255-9291American Accurate Components, Inc.6元器件交易网MLCC Products – PackagingPACKAGING ON TAPE AND REEL Size 0603 0805 T (mm) 0.90~0.70 0.70~0.50 0.90~0.70 1.05~0.85 1.35~1.05 0.90~0.70 1.05~0.85 1.35~1.05 1.05~0.85 1.35~1.05 1.05~0.85 2.15~1.85 1.35~1.05 Tape Paper Tape Paper Tape Paper Tape Plastic Tape Plastic Tape Paper Tape Plastic Tape Plastic Tape Plastic Tape Plastic Tape Plastic Tape Plastic Tape Plastic Tape Quantity 4,000/Reel 4,000/Reel 4,000/Reel 3,000/Reel 3,000/Reel 4,000/Reel 3,000/Reel 3,000/Reel 3,000/Reel 3,000/Reel 3,000/Reel 1,000/Reel 1,000/ReelAREEL FOR TAPINGTaping is in accordance with EIA RS-481 or IEC 286-3TB* C N D1206 1210 1808 1812GUnit: mm Symbol DimensionA 178 ± 2.0N 50 minC 130 ± 0.5D 20 min.B 2.0±0.5G 10.0± 1.5T 14.9max1. PAPER TAPE DIMENSIONSt Feeding hole D A B Chip Capacitors Unlt:mm P P P Direction of FeedE2. PLASTIC TAPE DIMENSIONSChip pocket t Feeding hole D A B Chip Capacitors P Po PChip pocketEF WFWk Unlt:mmDirection of FeedPAPER TAPE W F E P1 P2 P0 ∅P t1 Dimensions in mm 8.0 ± 0.3 3.5 ± 0.05 1.75 ± 0.1 4.0 ± 0.1 2.0 ± 0.05 4.0 ± 0.1 1.5 + 0.1 –0 1.2 maximumPLASTIC TAPE W F E P1 P2 P0 ∅P t1 K Dimension in mm 8.0 ± 0.3 3.5 ± 0.05 1.75 ± 0.1 4.0 ± 0.1 2.0 ± 0.05 4.0 ± 0.1 1.5 + 0.1 –0 0.3 maximum 2.0 maximum570 West Lambert Road, Suite M, Brea, CA 92821 TEL: 714-255-9186 FAX: 714-255-9291American Accurate Components, Inc.7。

地址:电话:MA60系列智能型万能式断路器MB1,MB1L,MB1G,MB1F-63系列终端电器MB60,MB60Z系列塑壳断路器MA60系列智能型万能式断路器172022263338394345474853555759核心特点:全系列Icu=Ics最高可达150KA,满足更高保护需求国际领先的旋转式双断点结构,大大提升分断能力U型触头结构,限流效果更明显,确保产品的高可靠性精简尺寸,体积更小模块化脱扣器设计,全系列热磁脱扣器与智能脱扣器模块可互换外置漏电模块,方便用户更换及维护M B60系列塑壳断路器135产品总览MB1 系列微型断路器MA60 系列空气断路器MB60 系列塑壳断路器注:需选配C系列智能控制器注:需选配C系列智能控制器)125瞬间并联100A 250A 400A1600A 壳架电流3设计序号(3.4.5)高级型控制器代号CH 为壳架电流H以长九MB1和MB30系列断路器为执行器,壳架电流为63A 、125A 、250A 、630A 可选系列额定工作电流(A )设计代号企业产品型号执行器控制器类型(I 为简易型 为复合型)开关极数(2P 二极 3P 三极 4P 四极)注:转换开关本体为两工作位时,需将控制器设置为两段位自投自复/自投不自复可调,自投自复不可设置;;T BF-T1TBF-M1TBF-T2TBF-K1TBF-M1TBF-M1TBF -Z1T BF-T3T BF-T1T BF-M3隔离模块双回路监控探测器代号注:TBF-K1可测量两路漏电及两路温度,且必须与TBF-T1或TBF-T2配合使用。

温度传感器控制模块隔离模块组合式探测器K1MA40 系列MA40 系列M A 40 系列M A 450 系列MA450 系列注:1、合分电类型为内部附件的控制电压,合:合闸线圈,分:分励线圈,电:电动机储能机构,为必须选配附件。

2、用户极数选择3P+N 时需要加N相外接互感器。

MA 60 M - 4000 R3200 M / 3 FHVR NST + YU230 D1短路分断能力可选代号:M 标准型H 高分断型安装方式代号:FHHR :固定式上下水平 FHVR :固定式上平下竖 FVHR :固定式上竖下平 FVVR :固定式上下竖直 WHHR :抽屉式上下水平 WHVR :抽屉式上平下竖 WVHR :抽屉式上竖下平 WVVR :抽屉式上下竖直压脱扣器类型代号:空 不具备欠压脱扣器YU230 欠压脱扣器AC230V YU400 欠压脱扣器AC400V欠额定电流壳架等级额定电流可选代号:Inm =1600=2500=4000=6300Inm Inm Inm 智能控制器代号:M :Adaptcan 6A11基本型H :Adaptcan 6A12高级型极数代号:3: 3极4: 4极5: 3极+N (见注)合分电类型代号:(见注)NST 合分电AC230V DST 合分电DC230V OST 合分电AC400V 欠压延时时间代号:空 瞬时型D1 延时1s D3 延时3s D5 延时5s短路分断能力合分电类型欠压延时技术参数表技术参数表MA60 系列M A 60 系列技术参数表MA60 系列M A 60 系列MB60 MB60ZMB 60 S - 250 R 16 / 3 3 00 2 D A FF短路分断能力可选代号:S 标准型M 较高分断型H 高分断型壳架等级额定电流可选代号:Inm =250Inm =630额定电流脱扣方式代号:2:只有短路保护3:有短路,过载保护附件代号:“见附件表”用途代号:2 电机保护空 配电保护操作方式代号:D 电操Z 手操空 无安装方式代号:FF: 固定式,板前接线PR: 插入式,板后接线DR: 抽出式,板后接线注:250壳架无抽出式极数代号:3三极4四极::3极产品为空4极产品N极型式A :N 极直通,且不带保护B :N 极分断,且不带保护C :N 极分断,且带保护D :N 极直通,且带保护MB60 系列系列塑壳断路器MB60Z S - 250 R250 / 3 3 00 2 D A FF + 6B11 F0短路分断能力可选代号:S 标准型M 较高分断型H 高分断型额定电流脱扣方式代号:2:只有短路保护3:有过载和短路 保护操作方式代号:D 电动操作Z 手动操作机构空 无安装方式代号:FF: 固定式,板前接线PR: 插入式,板后接线DR: 抽出式,板后接线注:250壳架无抽出式附加功能代号:F0 基本型F1 组网型注:6B11才能选配 F1组网型附件壳架等级额定电流可选代号:Inm =250Inm =630极数代号:3 三极4 四极附件代号:“见附件表”用途代号:2 电动机保护空 配电保护电子脱扣器代号:6B11 基本型6B12 智能型3极产品为空4极产品N极型式A :N 极直通,且不带保护B :N 极分断,且不带保护C :N 极分断,且带保护D :N 极直通,且带保护电子脱扣器功能表MB60 系列M B 60Z 系列MB60 MB60Z 系列塑壳断路器技术参数表MB60 MB60Z 系列塑壳断路器MB 1F -63M B 60Z 系列附件代号MB60 MB60Z 系列塑壳断路器MB 1 F -63/4过欠压功能额定电流(32A 40A 50A 63A)MB 1F -63MB1,MB1L ,MB1G ,MB1F -63系列M B 1 系列M G 1 系列04代表4极接触器(不自带辅助触头) 65。

中国高新技术产品出口目录2003科学技术部对外贸易经济合作部财政部国家税务总局海关总署编制说明为实施科技兴贸战略,发挥科技优势,落实科技兴贸行动计划,促进我国高新技术产品出口,1999年科技部、外经贸部、财政部、国家税务总局和海关总署联合发布了2000版《中国高新技术产品出口目录》(以下简称《目录》)。

实践证明,《目录》对规范化、科学化管理高新技术产品出口,落实有关鼓励政策,优化出口商品结构,促进高新技术产品出口发挥了积极作用。

随着高新技术的快速发展和高新技术产品的更新换代,同时针对海关商品编号的调整和近年来《目录》在实际操作中存在的问题,科技部、外经贸部、财政部、国家税务总局和海关总署组织对2000版《目录》进行了修订和调整,形成了2003版《目录》。

2003版《目录》是在2000版《目录》的基础上,经企业申报和地方有关部门推荐,根据《目录》调整的原则和相关规定,经专家评审而确定。

本《目录》所列产品共计1875项。

本《目录》为便于有关部门操作、企业查询和报关便利,参照《海关报关实用手册》中商品编号排序实行新的排序方法,并进行了相应的分类。

其中部分产品按照《海关报关实用手册》细分到十位海关商品编号,同时对产品的界定提供了更为详细的描述,这为相关部门和企业落实相关政策提供了方便。

在《目录》的实际使用中,产品出口时,填报的《出口货物报关单》必须与《目录》上所列的海关商品编号、产品、汉字名称完全一致。

如《目录》中产品的海关商品编号与实际出口报关时归类的海关商品编号不一致,则以海关确定的商品编号为准。

《目录》中的产品在出口时应遵守国家有关出口管制的法律法规。

本《目录》将根据实际情况适时进行调整。

关于《中国高新技术产品出口目录》技术领域代码的说明为便于《目录》使用者了解产品所在的技术领域,本《目录》按照科技部确定的技术领域范围,将产品划分为九类,并用代码标识。

技术领域代码设立如下:01 ——电子信息02 ——软件03 ——航空航天04 ——光机电一体化05 ——生物医药和医疗器械06 ——新材料07 ——新能源和节能产品08 ——环境保护与地球海洋09 ——现代农业1345678910111215161819202122242528313435373941454647。

欧洲合金标准目录国家国家标准化组织网站欧洲合金标准目录编号中文名称英文名称CR 10316-2001 低合金钢的光辐射分析(常规法)发射光谱法的标准常规法制定指南Optical emission analysis of low alloy steels (routine method) - Guidelines for the preparation of standardroutine method for optical emission spectrometryCR 12471-2002 镍从直接和长期接触皮肤的物品的合金和镀层中释放的屏蔽试验Screening tests for nickel release from alloys and coatings in items that come into direct and prolonged contact withthe skinCR 12776-1997 铜和铜合金材料号分配和材料登记的规定和程序Copper and copper alloys - Provisions and procedures for the allocation of material numbers and registration of materialsCR 13388-1998 铜和铜合金组分和产品一览表Copper and copper alloys - Compendium of compositions and productsEN 10016-1-1994 拉制和/或冷轧用非合金钢棒第1部分:一般要求Non-alloy steel rod for drawing and/or cold rolling - Part 1: General requirementsEN 10016-2-1994 拉制和/或冷轧用非合金钢棒第2部分:一般用钢棒的特殊要求Non-alloy steel rod for drawing and/or cold rolling - Part 2: Specific requirements for general purposes rod EN 10016-3-1994 拉制和/或冷轧用非合金钢棒第3部分:沸腾和沸腾代用低碳钢棒的特殊要求Non-alloy steel rod for drawing and/or cold rolling - Part 3: Specific requirements for rimmed andrimmed substitute low carbon steel rodEN 10016-4-1994 拉制和/或冷轧用非合金钢棒第4部分:专用棒材的特殊要求Non-alloy steel rod for drawing and/or cold rolling - Part 4: Specific requirements for rod for specialapplicationsEN 10025-1993 热轧非合金结构钢制品交货技术条件Hot rolled products of non-alloy structural steels;technical delivery conditions (includes amendment A1:1993)EN 10028-2-2003 压力用途的钢板制品第2部分:具有规定的耐高温性能的非合金钢和合金钢Flat products made of steels for pressure purposes - Part 2: Non-alloy and alloy steels withspecified elevated temperature propertiesEN 10028-4-2003 压力用途的钢板制品第4部分:具有低温特性的镍合金钢Flat products made of steels for pressure purposes - Part 4: Nickel alloy steels with specified low temperaturepropertiesEN 10051-1997+A1-1997 非合金钢和合金钢连续热轧钢板材、薄板和带材规范尺寸和形状公差Continuously hot-rolled uncoated plate, sheet and strip of non-alloy and alloy steels -Tolerances on dimensions and shape (includes amendment A1:1997)EN 10083-2-1996+A1-1996 淬火钢和回火钢第2部分:非合金级钢交货技术条件Quenched and tempered steels - Part 2: Technical delivery conditions for unalloyed quality steels(includes Amendment A1:1996)EN 10090-1998 内燃机阀门用钢和合金Valve steels and alloys for internal combustion enginesEN 10095-1999 耐热钢和镍合金Heat resisting steels and nickel alloysEN 1011-4-2000 焊接金属材料焊接的推荐规范第4部分:铝和铝合金的电弧焊接Welding -Recommendations for welding of metallic materials - Part 4: Arc welding of aluminiumand aluminium alloysEN 10126-1995 半成品交货的冷轧非合金钢电工钢薄板和钢带Cold rolled electricalnon-alloyed steel sheet and strip delivered in the semi-processed stateEN 10165-1995 半成品交货的冷轧电工合金钢制薄板和带材Cold rolled electrical alloyedsteel sheet and strip delivered in the semi-processed stateEN 10210-1-1994 非合金及细晶粒结构钢的热轧结构空心型材交货技术条件Hot finished structural hollow sections of non-alloy and fine grain structural steels; part 1: technical deliveryrequirementsEN 10210-2-1997 非合金及细晶粒结构钢的热轧结构空心型材第2部分:公差、尺寸和截面特性Hot finished structural hollow sections of non-alloy and fine grain structural steels - Part 2:Tolerances, dimensions and sectional propertiesEN 10216-1-2002 压力用途的无缝钢管交货技术条件第1部分:有规定室温特性的非合金钢管Seamless steel tubes for pressure purposes - Technical delivery conditions - Part1: Non-alloy steel tubes with specified room temperature properties / Note: To beamended by EN 10216-1/prA1 (2003-07).EN 10216-2-2002 压力用途的无缝钢管交货技术条件第2部分:有规定高温特性的非合金及合金钢管Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2:Non-alloy and alloy steel tubes with specified elevated temperature properties / Note:To be amended by EN 10216-2/prA1 (2003-07).EN 10216-3-2002 压力用途的无缝钢管交货技术条件第3部分:合金细晶粒钢管Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 3: Alloy fine grain steel tubes /Note: To be amended by EN 10216-3/prA1 (2003-07).EN 10216-4-2002 压力用途的无缝钢管交货技术条件第4部分:有规定低温特性的非合金及合金钢管Seamless steel tubes for pressure purposes - Technical delivery conditions -Part 4: Non-alloy and alloy steel tubes with specified low temperature properties /Note: To be amended by EN 10216-4/prA1 (2003-07).EN 10217-1-2002 压力用途的焊接钢管交货技术条件第1部分:有规定室温特性的非合金钢管Welded steel tubes for pressure purposes - Technical delivery conditions - Part1: Non-alloy steel tubes with specified room temperature propertiesEN 10217-2-2002 压力用途的焊接钢管交货技术条件第2部分:有规定高温特性的电焊非合金及合金钢管Welded steel tubes for pressure purposes - Technical delivery conditions -Part 2: Electric welded non-alloy and alloy steel tubes with specified elevatedtemperature propertiesEN 10217-3-2002 压力用途的焊接钢管交货技术条件第3部分:合金细晶粒钢管Welded steel tubes for pressure purposes - Technical delivery conditions - Part 3: Alloy fine grain steel tubesEN 10217-4-2002 压力用途的焊接钢管交货技术条件第4部分:有规定低温特性的电焊非合金钢管Welded steel tubes for pressure purposes - Technical delivery conditions - Part4: Electric welded non-alloy steel tubes with specified low temperature propertiesEN 10217-5-2002 压力用途的焊接钢管交货技术条件第5部分:有规定高温特性的埋弧焊非合金及合金钢管Welded steel tubes for pressure purposes - Technical delivery conditions –Part 5: Submerged arc welded non-alloy and alloy steel tubes with specified elevatedtemperature propertiesEN 10217-6-2002 压力用途的焊接钢管交货技术条件第6部分:有规定低温特性的埋弧焊非合金钢管Welded steel tubes for pressure purposes - Technical delivery conditions - Part6: Submerged arc welded non-alloy steel tubes with specified low temperature propertiesEN 10219-1-1997 冷成型细晶粒钢和非合金钢的焊接结构空心型材第1部分:交货技术要求Cold formed welded structural hollow sections of non-alloy and fine grain steels - Part1: Technical delivery requirementsEN 10219-2-1997 冷成型细晶粒钢和非合金钢的焊接结构空心型材第2部分:公差、尺寸和截面特性Cold formed welded structural hollow sections of non-alloy and fine grain steels- Part 2: Tolerances, dimensions and sectional propertiesEN 10223-1-1997 栅栏用钢丝和钢丝制品第1部分:镀锌和镀锌合金的有刺钢丝Steel wire and wire products for fences - Part 1: Zinc and zinc-alloy coated steel barbed wireEN 10224-2002 输送液体(包括人类生活用水)用的非合金钢管和管件交货技术条件Non-alloy steel tubes and fittings for the conveyance of aqueous liquids including water for humanconsumption - Technical delivery conditionsEN 10244-2-2001 钢丝和钢丝制品钢丝上的非黑色金属外层第2部分:锌或锌合金镀层Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloycoatingsEN 10248-1-1995 非合金钢制热轧板堆第1部分:交货技术条件Hot rolled sheet piling of non alloy steels - Part 1: Technical delivery conditionsEN 10248-2-1995 非合金钢制热轧板堆第2部分:尺寸和形状公差Hot rolled sheet piling of non alloy steels - Part 2: Tolerances on shape and dimensionsEN 10249-1-1995 非合金钢制冷成型板堆第1部分:交货技术条件Cold formed sheet piling of non alloy steels - Part 1: Technical delivery conditionsEN 10249-2-1995 非合金钢制冷成型板堆第2部分:尺寸和形状公差Cold formed sheet piling of non alloy steels - Part 2: Tolerances on shape and dimensionsEN 10250-2-1999 一般工程用途的敞口钢模锻件第2部分:非合金钢和特殊钢Open die steel forgings for general engineering purposes - Part 2: Non-alloy quality andspecial steelsEN 10250-3-1999 一般工程用途的敞口钢模锻件第3部分:合金特殊钢Open die steel forgings for general engineering purposes - Part 3: Alloy special steelsEN 10257-1-1998 动力电缆或通信电缆铠甲用镀锌或锌合金的非合金钢电线第1部分:地面电缆Zinc or zinc alloy coated non-alloy steel wire for armouring either power cables ortelecommunication cables - Part 1: Land cablesEN 10257-2-1998 动力电缆或通信电缆铠甲用镀锌或锌合金的非合金钢电线第2部分:海底电缆Zinc or zinc alloy coated non-alloy steel wire for armouring either power cables ortelecommunication cables - Part 2: Submarine cablesEN 10264-2-2002 钢丝和钢丝制品绳用钢丝第2部分:一般用途绳用冷拔非合金钢丝Steel wire and wire products - Steel wire for ropes - Part 2: Cold drawn non alloy steel wire for ropesfor general applicationsEN 10264-3-2002 钢丝和钢丝制品绳用钢丝第3部分:重载用途圆形和成形非合金钢丝Steel wire and wire products - Steel wire for ropes - Part 3: Round and shaped non alloyed steel wire forhigh duty applicationsEN 10268-1998 冷成形用高屈服强度微合金钢的冷轧扁钢材交货一般条件Cold-rolled flat products made of high yield strength micro-alloyed steels for cold forming - General deliveryconditionsEN 10269-1999 规定高温和/或低温性能的紧固件用钢及镍合金Steels and nickel alloys forfasteners with specified elevated and/or low temperature propertiesEN 10296-1-2003 机械和一般工程用途的焊接圆形钢管交货技术条件第1部分:非合金钢管和合金钢管Welded circular steel tubes for mechanical and general engineering purposes - Technicaldelivery conditions - Part 1: Non-alloy and alloy steel tubesEN 10297-1-2003 机械和一般工程用途的无缝圆形钢管交货技术条件第1部分:非合金钢管和合金钢管Seamless circular steel tubes for mechanical and general engineering purposes- Technical delivery conditions - Part 1: Non-alloy and alloy steel tubesEN 10302-2002 抗蠕变钢、镍和钴合金Creep resisting steels, nickel and cobalt alloysEN 1057-1996 铜和铜合金在卫生和加热器中输送水和气体用无缝圆铜管Copper and copper alloys - Seamless, round copper tubes for water and gas in sanitary and heating applicationsEN 1092-3-2003 法兰及其连接按PN标注的管、阀门、配件及其附件用圆形法兰第3部分:铜合金法兰Flanges and their joints - Circular flanges for pipes, valves, fittings andaccessories PN designated - Part 3: Copper alloy flangesEN 1092-4-2002 法兰及其连接按PN标注的管、阀门、配件及其附件用圆形法兰第4部分:铝合金法兰Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PNdesignated - Part 4: Aluminium alloy flangesEN 1172-1996 铜和铜合金建筑用薄板和带材Copper and copper alloys - Sheet and strip for building purposesEN 1173-1995 铜和铜合金原料条件或回火名称Copper and copper alloys - Material condition or temper designationEN 1179-2003 锌和锌合金初级锌Zinc and zinc alloys - Primary zincEN 12019-1997 锌和锌合金光学发射分光光度测定法Zinc and zinc alloys - Optical emission spectrometric analysisEN 12020-1-2001 铝和铝合金合金EN AW-6060和EN AW-6063的精密压制型材第1部分:检验与交货技术条件Aluminium and aluminium alloys - Extruded precision profiles in alloysEN AW-6060 and EN AW-6063 - Part 1: Technical conditions for inspection and deliveryEN 12020-2-2001 铝和铝合金合金EN AW-6060和EN AW-6063的精密压制型材第2部分:尺寸与形状公差Aluminium and aluminium alloys - Extruded precision profiles in alloys ENAW-6060 and EN AW-6063 - Part 2: Tolerances on dimensions and formEN 12060-1997 锌和锌合金取样方法规范Zinc and zinc alloys - Method of sampling - Specifications EN 1213-1999 建筑物阀门建筑物内便携式供水用的铜合金断流阀试验和要求Building valves - Copper alloy stopvalves for potable water supply in buildings - Tests and requirementsEN 12163-1998 铜和铜合金一般用途的棒材Copper and copper alloys - Rod for general purposesEN 12164-1998+A1-2000 铜和铜合金供快速切削用的棒材Copper and copper alloys - Rod for free machining purposesEN 12165-1998 铜和铜合金已加工和未加工的锻坯Copper and copper alloys - Wrought and unwrought forging stockEN 12166-1998 铜和铜合金一般用途的线材Copper and copper alloys - Wire for general purposesEN 12167-1998 铜及铜合金一般用途的型材和扁棒材Copper and copper alloys - Profiles and rectangular bar for general purposesEN 12168-1998+A1-2000 铜和铜合金用于非加工目的的空心棒材Copper and copper alloys - Hollow rod for free machining purposesEN 12258-1-1998 铝和铝合金术语和定义第1部分:通用术语Aluminium and aluminium alloys - Terms and definitions - Part 1: General termsEN 12258-3-2003 铝和铝合金术语和定义第3部分:废料Aluminium and aluminium alloys - Terms anddefinitions - Part 3: ScrapEN 12288-2003 工业用阀铜合金闸阀Industrial valves - Copper alloy gate valvesEN 12373-1-2001 铝和铝合金阳极氧化第1部分:铝上装饰和保护阳极氧化膜的测定方法Aluminium and aluminium alloys - Anodizing - Part 1: Method for specifying decorative andprotective anodic oxidation coatings on aluminiumEN 12373-10-1998 铝和铝合金阳极氧化第10部分:用磨擦喷射试验机测定阳极氧化膜的平均比耐磨性Aluminium and aluminium alloys - Anodizing - Part 10: Measurement of mean specificabrasion resistance of anodic oxidation coatings using an abrasive jet test apparatus EN 12373-11-2000 铝和铝合金阳极氧化第11部分:20°、45°、60°或85°角处测量阳极氧化膜在的镜面反射率和镜面光泽度Aluminium and aluminium alloys - Anodizing - Part 11:Measurement of specular reflectance and specular gloss of anodic oxidation coatingsat angles of 20? 45? 60?or 85?国际标准分类号:25.220.2077.120.10英文标准名称:Aluminium and aluminium alloys - Anodizing - Part11: Measurement of specular reflectance and specular gloss of anodicoxidation coatings at angles of 20? 45? 60?or 85?EN 12373-12-2000 铝和铝合金阳极氧化第12部分:用积分球仪测量铝表面的反射特性Aluminium and aluminium alloys - Anodizing - Part 12: Measurement of reflectance characteristics ofaluminium surfaces using integrating-sphere instrumentsEN 12373-13-2000 铝和铝合金阳极氧化第13部分:用测角光度仪或滤色测角光度仪测量铝表面的反射特性Aluminium and aluminium alloys - Anodizing - Part 13: Measurement ofreflectance characteristics of aluminium surfaces using a goniophotometer or anabridged goniophotometerEN 12373-14-2000 铝和铝合金阳极氧化第14部分:阳极氧化膜成象清晰度的目测座标比例尺法Aluminium and aluminium alloys - Anodizing - Part 14: Visual determination of imageclarity of anodic oxidation coatings - Chart scale methodEN 12373-15-2000 铝和铝合金阳极氧化第15部分:阳极氧化膜抗形变破裂性的评定Aluminium and aluminium alloys - Anodizing - Part 15: Assessment of resistance of anodic oxidationcoatings to cracking by deformationEN 12373-16-2001 铝和铝合金阳极氧化第16部分:薄阳极氧化膜的连续性检验硫酸铜试验Aluminium and aluminium alloys - Anodizing - Part 16: Check of continuity of thinanodic oxdation coatings; Copper sulfate testEN 12373-17-2001 铝和铝合金阳极氧化第17部分:电击穿电压的测定Aluminium and aluminium alloys - Anodizing - Part 17: Determination of electric breakdown potentialEN 12373-18-2001 铝和铝合金阳极氧化第18部分:点蚀评定铝用检定系统图表法Aluminium and aluminium alloys - Anodizing - Part 18: Rating system for the evaluation of pittingcorrosion; Chart methodEN 12373-19-2001 铝和铝合金阳极氧化第19部分:点蚀评定铝用检定系统网格法Aluminium and aluminium alloys - Anodizing - Part 19: Rating system for the evaluation of pittingcorrosion; Grid methodEN 12373-2-1998 铝和铝合金阳极氧化第2部分:阳极氧化膜单位面积质量(表面密度)的测定重量分析法Aluminium and aluminium alloys - Anodizing - Part 2: Determination of mass perunit area (surface density) of anodic oxidation coatings - Gravimetric methodEN 12373-3-1998 铝和铝合金阳极氧化第3部分:阳极氧化膜厚度的测定分束显微镜无损测量Aluminium and aluminium alloys - Anodizing - Part 3: Determination of thickness ofanodic oxidation coatings - Non-destructive measurement by split-beam microscope EN 12373-4-1998 铝和铝合金阳极氧化第4部分:通过事先经酸处理的染斑试验估计封闭后阳极氧化膜吸收能力的损失Aluminium and aluminium alloys - Anodizing - Part 4: Estimation ofloss of absorptive power of anodic oxidation coatings after sealing by dye spot test withprior acid treatmentEN 12373-5-1998 铝和铝合金阳极氧化第5部分:用导纳测量法评定封闭阳极氧化膜的质量Aluminium and aluminium alloys - Anodizing - Part 5: Assessment of quality of sealed anodicoxidation coatings by measurement of admittanceEN 12373-6-1998 铝和铝合金阳极氧化第6部分:通过测量事发未经酸处理的磷酸/铬酸中浸泡后的质量损失评定封闭阳极氧化膜Aluminium and aluminium alloys - Anodizing - Part 6:Assessment of quality of sealed anodic oxidation coatings by measurement of the loss ofmass after immersion in phosphoric acid/chromic acid solution without prior acidtreatmentEN 12373-7-2002 铝和铝合金阳极氧化第7部分:通过测量事发经酸处理的磷酸/铬酸中浸泡后的质量损失评定封闭阳极氧化膜的Aluminium and aluminium alloys - Anodizing - Part 7:Assessment of quality of sealed anodic oxidation coatings by measurement of the lossof mass after immersion in phosphoric acid/chromic acid solution with prior acidtreatmentEN 12373-8-1998 铝和铝合金阳极氧化第8部分:着色阳极氧化膜可比耐紫外光和耐热色牢固度的测定Aluminium and aluminium alloys - Anodizing - Part 8: Determination of the comparativefastness to ultra-violet light and heat of coloured anodic oxidation coatingsEN 12373-9-1998 铝和铝合金阳极氧化第9部分:用磨擦轮磨损试验机测定阳极氧化膜耐磨性和耐磨系数Aluminium and aluminium alloys - Anodizing - Part 9: Measurement of wearresistance and wear index of anodic oxidation coatings using an abrasive wheel weartest apparatusEN 12384-1999 铜和铜合金带材弹性弯曲极限的测定Copper and copper alloys - Determination of spring bending limit on stripEN 12392-2000 铝和铝合金锻制品压力设备生产用制品的特殊要求Aluminium and aluminium alloys - Wrought products - Special requirements for products intended for the production ofpressure equipmentEN 12402-1999 铅和铅合金分析用取样方法Lead and lead alloys - Methods of sampling for analysis EN 12420-1999 铜和铜合金锻件Copper and copper alloys - ForgingsEN 12421-1998 镁和镁合金纯镁Magnesium and magnesium alloys - Unalloyed magnesiumEN 12438-1998 镁和镁合金铸造阳极用镁合金Magnesium and magnesium alloys - Magnesium alloys for cast anodesEN 12441-1-2001 锌和锌合金化学分析第1部分:锌合金中铝的测定滴定法Zinc and zinc alloys - Chemical analysis - Part 1: Determination of aluminium in zinc alloys; Titrimetric method EN 12441-2-2001 锌和锌合金化学分析第2部分:锌合金中镁的测定火焰原子吸收光谱法Zinc and zinc alloys - Chemical analysis - Part 2: Determination of magnesium in zinc alloys;Flame atomic absorption spectrometric methodEN 12441-3-2001 锌和锌合金化学分析第3部分:铅、镉和铜的测定火焰原子吸收光谱法Zinc und zinc alloys - Chemical analysis - Part 3: Determination of lead, cadmium and copper;Flame atomic absorption spectrometric methodEN 12441-4-2003 锌和锌合金化学分析第4部分:用分光光度法测定锌合金中的铁Zinc and zinc alloys- Chemical analysis - Part 4: Determination of iron in zinc alloys; SpectrophotometricmethodEN 12441-5-2003 锌和锌合金化学分析第5部分:用分光光度法测定原生锌中的铁Zinc and zinc alloys - Chemical analysis - Part 5: Determination of iron in primary zinc; SpectrophotometricmethodEN 12441-6-2003 锌和锌合金化学分析第6部分:用原子吸收光谱法测定铝和铁Zinc and zinc alloys - Chemical analysis - Part 6: Determination of aluminium and iron-Flame atomic absorptionspectrometric methodEN 12449-1999 铜和铜合金通用无缝圆管Copper and copper alloys - Seamless, round tubes for general purposesEN 12450-1999 铜和铜合金无缝圆铜毛细管Copper and copper alloys - Seamless, round copper capillary tubesEN 12451-1999 铜和铜合金热交换器用无缝圆管Copper and copper alloys - Seamless, round tubes for heat exchangersEN 12452-1999 铜和铜合金热交换器用轧制翅片无缝管Copper and copper alloys - Rolled, finned, seamless tubes for heat exchangersEN 12482-1-1998 铝和铝合金一般用重轧坯料第1部分:热轧重轧坯料规范Aluminium and aluminium alloys - Reroll stock for general applications - Part 1: Specifications for hot rolled rerollstockEN 12482-2-1998 铝和铝合金一般用重轧坯料第2部分:冷轧重轧坯料规范Aluminium and aluminium alloys - Reroll stock for general applications - Part 2: Specifications for cold rolled rerollstockEN 12487-2000 金属的防腐蚀铝和铝合金上清洗和非清洗的铬酸盐转化镀层Corrosion protection of metals - Rinsed and non-rinsed chromate conversion coatings on aluminium andaluminium alloysEN 12501-2-2003 金属材料的防腐泥土中可能出现的腐蚀第2部分:低合金和非合金的钢铁材料Protection of metallic materials against corrosion - Corrosion likelihood in soil - Part 2:Low alloyed and non alloyed ferrous materialsEN 12508-2000 金属和合金的防腐表面处理、金属和其它无机涂层词汇Corrosion protection of metals and alloys - Surface treatment, metallic and other inorganic coatings - Vocabulary EN 12536-2000 焊接消耗品非合金钢和抗蠕变钢气焊用焊条分类Welding consumables - Rods for gas welding of non alloy and creep-resisting steels - ClassificationEN 1254-1-1998 铜和铜合金管件第1部分:低温焊接或纤焊接到铜管上的毛细管用端头管件Copper and copper alloys - Plumbing fittings - Part 1: Fittings with ends for capillary soldering orcapillary brazing to copper tubesEN 1254-2-1998 铜和铜合金管件第2部分:铜管用压接端头管件Copper and copper alloys - Plumbing fittings - Part 2: Fittings with compression ends for use with copper tubesEN 1254-3-1998 铜和铜合金管件第3部分:塑料管用压接端头管件Copper and copper alloys - Plumbing fittings - Part 3: Fittings with compression ends for use with plastics pipesEN 1254-4-1998+AC-1999 铜和铜合金管件第4部分:带有与毛细管端接或压接端头的管件Copper and copper alloys - Plumbing fittings - Part 4: Fittings combining other end connections withcapillary or compression endsEN 1254-5-1998 铜和铜合金管件第5部分:纤焊到铜管的毛细管用短端头管件Copper and copper alloys - Plumbing fittings - Part 5: Fittings with short ends for capillary brazing to coppertubesEN 12548-1999 铅和铅合金电缆铍和护套用铅合金铸锭Lead and lead alloys - Lead alloy ingots for electric cable sheathing and for sleevesEN 12588-1999 铅和铅合金建筑物用铅轧皮Lead and lead alloys - Rolled lead sheet for building purposesEN 12659-1999 铅和铅合金铅Lead and lead alloys - LeadEN 12735-1-2001 铜和铜合金空调和制冷用无缝圆铜管第1部分:管道系统用管子Copper and copper alloys - Seamless, round copper tubes for air conditioning and refrigeration - Part 1:Tubes for piping systemsEN 12735-2-2001 铜和铜合金空调和制冷用无缝圆铜管第2部分:设备用管子Copper and copper alloys - Seamless, round copper tubes for air conditioning and refrigeration - Part 2:Tubes for equipmentEN 12844-1998 锌和锌合金铸件规范Zinc and zinc alloys - Castings - SpecificationsEN 12861-1999 铜与铜合金废料Copper and copper alloys - ScrapEN 12862-2000 可运输气瓶可移动再充式焊接铝合金气瓶的设计和结构规范Transportable gas cylinders - Specification for the design and construction of refillable transportable welded aluminiumalloy gas cylindersEN 12893-2000 铜和铜合金螺旋拉伸数的测定Copper and copper alloys - Determination of spiral elongation numberEN 12938-1999 铅锡锑合金的分析方法用原子光谱法测定合金及杂质元素含量Methods for the analysis of pewter - Determination of alloying and impurity element contents by atomicspectrometryEN 1301-1-1997 铝和铝合金拉制线材第1部分:检查和交货的技术条件Aluminium and aluminium alloys - Drawn wire - Part 1: Technical conditions for inspection and deliveryEN 1301-2-1997+AC-1998 铝和铝合金拉制线材第2部分:机械性能Aluminium and aluminium alloys - Drawn wire - Part 2: Mechanical propertiesEN 1301-3-1997 铝和铝合金拉制线材第3部分:尺寸和公差Aluminium and aluminium alloys - Drawn wire - Part 3: Tolerances on dimensionsEN 13086-2000 铅和铅合金氧化铅Lead and lead alloys - Lead oxidesEN 13147-2001 铜和铜合金窄带材边界区域中残余应力的测定Copper and copper alloys - Determination of residual stresses in the border area of slit stripEN 13148-2001 铜和铜合金热浸镀锡带材Copper and copper alloys - Hot-dip tinned stripEN 13195-1-2002 铝和铝合金海洋设备(造船、海运和海上设备)用锻造和浇铸产品Aluminium and aluminium alloys - Wrought and cast products for marine applications (shipbuilding,marine and offshore) - Part 1: SpecificationsEN 13283-2002 锌和锌合金再生锌Zinc and zinc alloys - Secondary zincEN 13347-2002 铜和铜合金焊接和黄铜焊用棒和线Copper and copper alloys - Rod andwire for welding and braze weldingEN 13348-2001 铜和铜合金医用气体或真空用无缝圆铜管Copper and copper alloys - Seamless, round copper tubes for medical gases or vacuumEN 13349-2002 铜和铜合金带实心覆盖层的预绝缘铜管Copper and copper alloys - Pre-insulated copper tubes with solid coveringEN 13599-2002 铜和铜合金电气用途的铜板、铜片和铜条Copper and copper alloys - Copperplate, sheet and strip for electrical purposesEN 13600-2002 铜和铜合金电气用途的无缝铜管Copper and copper alloys - Seamlesscopper tubes for electrical purposesEN 13601-2002 铜和铜合金常规电气用途的铜棒、铜条和铜线Copper and copper alloys -Copper rod, bar and wire for general electrical purposesEN 13602-2002 铜和铜合金用于制造导电体的拉制圆铜线Copper and copper alloys - Drawn,round copper wire for the manufacture of electrical conductorsEN 13603-2002 铜和铜合金评估电气用途拉制圆铜线上的保护锡镀层的试验方法Copper and copper alloys - Test methods for assessing protective tin coatings on drawn round copper wire forelectrical purposesEN 13604-2002 铜和铜合金电子管、半导体器件和真空设备用高导电率铜产品Copper and copper alloys - Products of high conductivity copper for electronic tubes, semiconductor devices andvacuum applicationsEN 13605-2002 铜和铜合金电气用途的铜型材和型线材Copper and copper alloys - Copperprofiles and profiled wire for electrical purposesEN 13828-2003 建筑物阀门建筑物中饮用水供水用手动铜合金及不锈钢球阀试验和要求Building valves - Manually operated copper alloy and stainless steel ball valves for potable water supply inbuildings - Test and requirementsEN 1386-1996 铝和铝合金梯级金属板规范Aluminium and aluminium alloys - Tread plate - SpecificationsEN 13920-1-2003 铝和铝合金废料第1部分:一般要求、取样和试验Aluminium and aluminium alloys - Scrap - Part 1: General requirements, sampling and testsEN 13920-10-2003 铝和铝合金废料第10部分:由用过的铝饮料罐组成的废料Aluminium and aluminium alloys - Scrap - Part 10: Scrap consisting of use aluminium beverage cansEN 13920-11-2003 铝和铝合金废料第11部分:包括铝-铜散热器在内的废料Aluminium and aluminium alloys - Scrap - Part 11: Scrap consisting of aluminium-copper radiatorsEN 13920-12-2003 铝和铝合金废料第12部分:由单一合金组成的废料Aluminium and aluminium alloys - Scrap - Part 12: Turnings consisting of one single alloyEN 13920-13-2003 铝和铝合金废料第13部分:由两种或多种合金组成的混合切屑Aluminium and aluminium alloys - Scrap - Part 13: Mixed turnings consisting of twoor more alloysEN 13920-14-2003 铝和铝合金废料第14部分:消费品铝包装生产的废料Aluminium and aluminium alloys - Scrap - Part 14: Scrap from post-consumer aluminiumpackagingsEN 13920-15-2003 铝和铝合金废料第15部分:消费品铝包装产生的去涂层铝废料Aluminium and aluminium alloys - Scrap - Part 15: Decoated aluminium scrap frompost-consumer aluminium packagingsEN 13920-16-2003 铝和铝合金废料第16部分:由浮渣、碎屑、铸锭的金属物组成的废料Aluminium and aluminium alloys - Scrap - Part 16: Scrap consisting of skimmings, drosses, spills andmetallicsEN 13920-2-2003 铝和铝合金废料第2部分:纯铝废料Aluminium and aluminium alloys -Scrap - Part 2: Unalloyed aluminium scrapEN 13920-3-2003 铝和铝合金废料第3部分:线头和缆绳Aluminium and aluminium alloys -Scrap - Part 3: Wire and cable scrapEN 13920-4-2003 铝和铝合金废料第4部分:由单一锻压合金组成的废料Aluminium and aluminiumalloys - Scrap - Part 4: Scrap consisting of one single wrought alloyEN 13920-5-2003 铝和铝合金废料第5部分:由同一系列的两种或多种锻压合金组成的废料Aluminium and aluminium alloys - Scrap - Part 5: Scrap consisting of two or more wrought alloysof the same seriesEN 13920-6-2003 铝和铝合金废料第6部分:由两种或多种锻压合金组成的废料Aluminium and aluminium alloys - Scrap - Part 6: Scrap consisting of two or more wrought alloysEN 13920-7-2003 铝和铝合金废料第7部分:由铸锭组成的废料Aluminium and aluminiumalloys - Scrap - Part 7: Scrap consisting of castingsEN 13920-8-2003 铝和铝合金废料第8部分:由铝分离工艺必经的切岁程序中产生的非铁质材料组成的废料Aluminium and aluminium alloys - Scrap - Part 8: Scrap consisting of non-ferrousmaterials from shredding processes destined to aluminium separation processesEN 13920-9-2003 铝和铝合金废料第9部分:非铁质碎料的铝分离工艺所产生的废料Aluminium and aluminium alloys - Scrap - Part 9: Scrap from aluminium separation processes ofnon-ferrous shredded materialsEN 13957-2003 铝合及铝合金一般用途挤压圆形、蛇形管规范Aluminium and aluminium alloys - Extruded round, coiled tube for general applications - SpecificationEN 13958-2003 铝及铝合金一般用途冷拉圆形、蛇形管规范Aluminium and aluminium alloys - Cold drawn round, coiled tube for general applications - SpecificationEN 1396-1996 铝和铝合金一般用途的盘绕涂层薄板和带材规范Aluminium and aluminium alloys - Coil coated sheet and strip for general applications - SpecificationsEN 13981-1-2003 铝及铝合金铁路结构用产品,检验和交货技术条件第1部分:挤压产品Aluminium and aluminium alloys - Products for structural railway applications; Technical conditionsfor inspection and delivery - Part 1: Extruded productsEN 14057-2003 铅及铅合金废料术语和定义Lead and lead alloys - Scraps - Terms and definitions EN 1412-1995 铜和铜合金欧洲编号系统Copper and copper alloys - European numbering systemEN 14121-2003 铝及铝合金电工用铝片、铝带和铝板Aluminium and aluminium alloys - Aluminium sheet, strip and plate for electrotechnical applicationsEN 1503-4-2002 阀门阀体、阀帽和阀套用材料第3部分:欧洲标准规定的铜合金Valves - Materials for bodies, bonnets and covers - Part 4: Copper alloys specified in European StandardsEN 1559-4-1999 铸造交货的技术条件第3部分:铝合金铸件的附加要求Founding - Technicalconditions of delivery - Part 4: Additional requirements for aluminium alloy castingsEN 1559-5-1997 铸造交货的技术条件镁合金铸件的附加要求Founding - Technical conditionsof delivery - Part 5: Additional requirements for magnesium alloy castingsEN 1559-6-1998 铸造交货的技术条件锌合金铸件附加要求Founding - Technical conditions of delivery - Part 6: Additional requirements for zinc alloy castingsEN 1592-1-1997 铝和铝合金HF接缝焊接管第1部分:检验和交货技术条件Aluminium and aluminium alloys - HF seam welded tubes - Part 1: Technical conditions for inspection and delivery EN 1592-2-1997 铝和铝合金HF接缝焊接管第2部分:机械性能Aluminium and aluminiumalloys - HF seam welded tubes - Part 2: Mechanical propertiesEN 1592-3-1997 铝和铝合金HF接缝焊接管第3部分:圆形管的尺寸和形状公差Aluminium and aluminium alloys - HF seam welded tubes - Part 3: Tolerances on dimensions and formfor circular tubesEN 1592-4-1997 铝和铝合金HF接缝焊接管第4部分:方形、矩形和异形管的尺寸和形状公差Aluminium and aluminium alloys - HF seam welded tubes - Part 4: Tolerances on dimensions andform for square, rectangular and shaped tubesEN 1597-1-1997 焊料试验方法第1部分:镍和镍合金钢中完全焊接金属试验样品用试件Welding consumables - Test methods - Part 1: Test piece for all-weld metal test specimens insteel, nickel and nickel alloysEN 1652-1997 铜和铜合金一般用途的平板、薄板材、带材和圆形材Copper and copper alloys - Plate, sheet, strip and circles for general purposesEN 1653-1997+A1-200 铜和铜合金锅炉、压力容器和蓄热水器用的平板、薄板材和圆形材Copper and copper alloys - Plate, sheet and circles for boilers, pressure vessels and hot water storageunitsEN 1654-1997+AC-2003 铜和铜合金弹簧和连接器用带材Copper and copper alloys - Strip for springs and connectorsEN 1655-1997 铜和铜合金符合性声明Copper and copper alloys - Declarations of conformityEN 1668-1997 焊接耗材非合金和细晶粒钢的惰性气体保护钨极焊用焊条焊丝和熔敷分类Welding consumables - Rods, wires and deposits for tungsten inert gas welding of non alloy and finegrain steels - ClassificationEN 1669-1996 铝及铝合金试验方法薄板材和带材的耳子试验Aluminium and aluminium alloys - Test methods - Earing test for sheet and stripEN 1676-1996 铝及铝合金重熔用的合金锭规范Aluminium and aluminium alloys - Alloyed ingots for remelting - SpecificationsEN 1706-1998 铝及铝合金铸件化学成分和机械性能Aluminium and aluminium alloys - Castings - Chemical composition and mechanical propertiesEN 1715-1-1997 铝和铝合金拉制件第1部分:检验和交货的一般要求及技术条件Aluminium and aluminium alloys - Drawing stock - Part 1: General requirements and technical conditionsfor inspection and deliveryEN 1715-2-1997+AC-1998 铝和铝合金拉制坯料第2部分:电气应用的特殊要求Aluminium and aluminium alloys - Drawing stock - Part 2: Specific requirements for electrical applications EN 1715-3-1997+AC-1998 铝和铝合金拉制坯料第3部分:机械应用的特殊要求(包括焊接) Aluminium and aluminium alloys - Drawing stock - Part 3: Specific requirements for mechanical uses(excluding welding)EN 1715-4-1997 铝和铝合金拉制坯料第4部分:焊接应用的特殊要求Aluminium and aluminium alloys - Drawing stock - Part 4: Specific requirements for welding applicationsEN 1753-1997+AC-1997 镁和镁合金镁合金锭和铸件Magnesium and magnesium alloys - Magnesium alloy ingots and castingsEN 1754-1997 镁和镁合金镁和镁合金氧化极、铸锭和铸件命名体系Magnesium and magnesium alloys - Magnesium and magnesium alloy anodes, ingots and castings - Designation systemEN 1758-1997 铜及铜合金引线架用带材Copper and copper alloys - Strip for lead framesEN 1759-3-2003 法兰及其接头管材、阀门、管件及附件用已命名种类的圆形法兰第2部分:铜合金法兰Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, classdesignated - Part 3: Copper alloy flangesEN 1759-4-2003 法兰及其接头管材、阀门、管件及附件用已命名种类的圆形法兰第4部分:铝合金法兰Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, classdesignated - Part 4: Aluminium alloy flangesEN 1774-1997 锌和锌合金铸造用合金铸锭和铸液Zinc and zinc alloys - Alloys for foundry purposes - Ingot and liquid。

英语:欧洲技术认证组织EOTA目录前言7参考8第一部分:介绍101前页111。

1法律依据111.2ETA指导的状态112适用范围132。

1适用范围132。

2用途类型152。

3假定条件153术语163.1通用术语与缩写163.2特殊术语与缩写163。

3注释19第二部分:适用性评测指南21总注214工件要求,以及工件与预应力系统特征属性的关系234。

0综述234。

1系统机械阻力与稳定性29第I部分:对所有预应力系统的必要要求294。

1.1—I抗静荷载力294。

1。

2—I抗疲劳力294。

1。

3—I转移结构负载294.1。

4-I摩擦系数294.1.5—I偏差/偏离(极限)294.1.6—I安装(如管填充)的实用性与可靠性29第II部分:对可选用途类型与新型预应力系统的补充要求29 (a)可复原钢筋:4。

1。

6-II(a)安装(如管填充)的实用性与可靠性30(b)可替换钢筋:4。

1.6-II(b)安装(如管填充)的实用性与可靠性30(c)低温应用:4.1.1—II(c)抗静荷载力30(d)配备塑料管道的内部粘结钢筋:4.1.6—II(d)安装(如管填充)的实用性与可靠性30 (e)压缩钢筋:4。

1。

6-II(e)安装(如管填充)的实用性与可靠性30 (f)绝缘钢筋:4.1。

6—II(f)安装(如管填充)的实用性与可靠性30(g)结构钢材钢筋与复合结构外部钢筋:4。

1.3—II(g)转移结构负载30(h)砖石建筑结构内部粘结钢筋,非粘结与/或外部钢筋:4。

1。

3-II(h)转移结构负载30(i)木材结构建筑内部无粘结钢筋,与/或外部钢筋:4.1。

3-II(i)转移结构负载31(k)新型系统:4.1。

6—II(k)安装(如管填充)的实用性与可靠性31 4.2火灾安全314。

3卫生、健康与环境314。

4使用安全314。

5噪音隔离314.6能源经济与保热314。

7操作性能相关方面315验证方法325.0综述325。

中国振华(集团)新云电子元器件有限责任公司片式固体电解质钽电容器规格书提供客户: 立 创型号规格:CA45-A-16v-10uf-K片式固体电解质钽电容器规格书1. 产品特点该产品为模压封装、片式引出,具有密封性好、重量轻、电性能优良、稳定可靠等特点。

适用于移动通讯、摄像机、程控交换机、计算机、汽车电子等各种电子设备的表面贴装直流或脉动电路。

2. 产品订货编码示例CA45- A - 16V - 10μF - K型号壳号额定电压标称电容量电容量偏差K:±10%M:±20%3. 产品外形及尺寸:见图1及表1图1 外形图表1 电容器的外形尺寸4.电性能参数4.1 工作温度范围:-55℃~125℃,额定温度:85℃;当大于85℃时,施加类别电压使用;4.2 标称电容量允许偏差(25℃,100Hz):±10%、4.3 主要电性能参数:见表24.4 执行标准:Q/MM82A-2010表2 电性能参数表5.标志5.1标志内容(1)正极标识及厂标(2)标称容量(3)额定电压6. 产品外观质量6.16.2 产品标志:应清晰、完整、正确;无重影、漏打等现象。

7.包装7.1 产品编带的尺寸及卷绕方向:见图3、图4、表5、表6。

7.2包装数量:编带2000只/盘,每4盘装一小盒,每小盒数量10000只。

7.3产品内外包装盒应无破损,料盘、小盒及外包装箱上应有相应物料标识单,标识应清楚、准确。

7.4每批产品应附产品合格证,内容包括产品型号、规格、壳号、容量级别、数量、生产批号及执行标准等。

8.典型试验要求:见表7表7 典型试验要求续表79 限用物质要求本产品所含限用物质符合2002/95/EC RoHS 指令。

10 应用指南10.1室温电性能的测量10.1.1 电容量(C)和损耗角正切(tg δ)的测量●测量频率:100Hz 。

●施加电压:直流偏压: U -=2.20 -1.0V ;交流电压(有效值)的范围:U ~=1.00-0.5V 。