ISO-TS16949:2009质量管理体系中英文对照版

- 格式:doc

- 大小:516.50 KB

- 文档页数:74

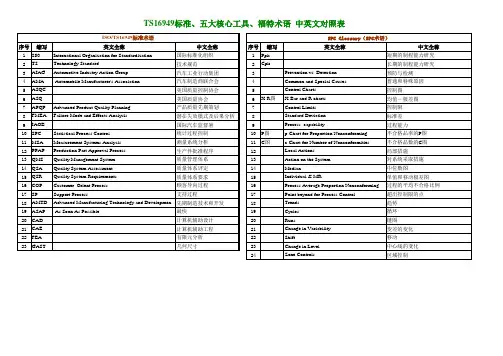

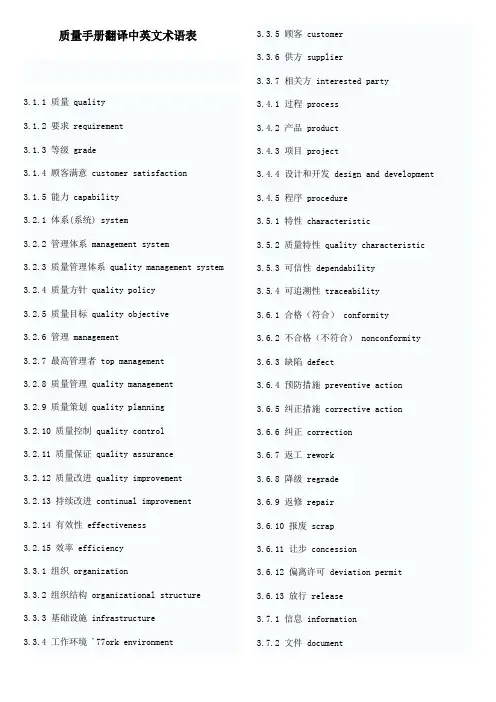

质量手册翻译中英文术语表3.1.1质量quality3.1.2要求requirement3.1.3等级grade3.1.4顾客满意customer satisfaction3.1.5能力capability3.2.1体系(系统)system3.2.2管理体系management system3.2.3质量管理体系quality management system 3.2.4质量方针quality policy3.2.5质量目标quality objective3.2.6管理management3.2.7最高管理者top management3.2.8质量管理quality management3.2.9质量策划quality planning3.2.10质量控制quality control3.2.11质量保证quality assurance3.2.12质量改进quality improvement3.2.13持续改进continual improvement3.2.14有效性effectiveness3.2.15效率efficiency3.3.1组织organization3.3.2组织结构organizational structure3.3.3基础设施infrastructure3.3.4工作环境'77ork environment 3.3.5顾客customer3.3.6供方supplier3.3.7相关方interested party3.4.1过程process3.4.2产品product3.4.3项目project3.4.4设计和开发design and development 3.4.5程序procedure3.5.1特性characteristic3.5.2质量特性quality characteristic 3.5.3可信性dependability3.5.4可追溯性traceability3.6.1合格(符合)conformity3.6.2不合格(不符合)nonconformity 3.6.3缺陷defect3.6.4预防措施preventive action3.6.5纠正措施corrective action3.6.6纠正correction3.6.7返工rework3.6.8降级regrade3.6.9返修repair3.6.10报废scrap3.6.11让步concession3.6.12偏离许可deviation permit3.6.13放行release3.7.1信息information3.7.2文件document3.7.3规范specification3.7.4质量手册quality manual3.7.5质量计划quality plan3.7.6记录record3.8.1客观证据objective evidence3.8.3试验test3.8.4验证verification3.8.5确认validation3.8.6鉴定过程qualification process3.8.7评审review3.9.1审核audit3.9.2审核方案audit programme3.9.3审核准则audit criteria3.9.4审核证据audit evidence3.9.5审核发现audit findings3.9.6审核结论audit conclusion3.9.7审核委托方audit client3.9.8受审核方auditee3.9.9审核员auditor3.9.10审核组audit team3.9.11技术专家technical expert3.9.12能力competence3.10.1测量控制体系measurement control system 3.10.2测量过程measurement process3.10.3计量确认metrological confirmation3.10.4测量设备measuring equipment3.10.5计量特性metrological characteristic 3.10.6计量职能metrological function Aaudit3.9.1审计audit client 3.9.7客户审计audit conclusion3.9.6审计结论audit criteria3.9.3审计标准audit evidence3.9.4审计证据audit findings3.9.5audit programme3.9.2审计大纲audit team3.9.10审计团队auditee3.9.8auditor3.9.9Ccapability3.1.5characteristic3.5.1concession3.6.11conformity3.6.1continual improvement3.2.13 correction3.6.6corrective action3.6.5customer 3.3.5customer satisfaction3.1.4 competence3.9.12Ddefect3.6.3dependability 3.5.3design and development3.4.4deviation permit3.6.12document 3.7.2Eeffectiveness 3.2.14efficiency3.2.15Ggrade3.1.3Iinformation3.7.1infrastructure3.3.3inspection3.8.2interested party3.3.7Mmanagement3.2.6management system3.2.2 measurement control system3.10.1 measurement process 3.10.2 measuring equipment 3.10.4 metrological characteristic3.10.5 metrological confirmation3.10.3 metrological function3.10.6Nnonconformity 3.6.2Oobjective evidence3.8.1客观证据organization3.3.1organizational structure3.3.2Ppreventive action3.6.4 procedure3.4.5process3.4.1product3.4.2project3.4.3Qqualification process3.8.6 quality3.1.1quality assurance3.2.11quality characteristic3.5.2 quality control3.2.10quality improvement 3.2.12 quality management3.2.8quality management system3.2.3 quality manual3.7.4quality objective3.2.5quality plan 3.7.5quality planning3.2.9质量计划quality policy3.2.4Rrecord3.7.6记录regrade3.6.8release3.6.13放行repair3.6.9requirement3.1.2review3.8.7rework3.6.7返工Sscrap3.6.10specification 3.7.3supplier 3.3.6供应商system3.2.1系统Ttechnical expert<audit>3.9.11技术出口test3.8.3测试top management3.2.7高层管理traceability3.5.4可塑性Vvalidation3.8.5verification3.8.4验证Wwork environment3.3.4工作环境质量管理体系基础和术语Quality management syst ems--Fundamentals and vocabulary质量管理和质量保证标准第2部分:GB/T19001、GB /T19002和GB/T19003实施通用指南Quality mana gement and quality assurance standards--Part 2:Generic guidelines for the application of GB /T19001、GB/T19002and GB/T19003质量管理和质量保证标准第3部分:GB/T19001在计算机软件开发、供应、安装和维护中的使用指南Qu ality management and quality assurance standard s--Part3:Guidelines for the application of GB/T19001to the development,supply,installa tion and maintenance of computer software质量管理和质量保证标准第4部分:可信性大纲管理指南Quality management and quality assurance s tandards--Part4:Guide to dependability prog ramme management质量管理体系要求Quality management systems--Requirements质量管理体系业绩改进指南Quality management sy stems--Guidelines for performance improvement s质量管理和质量体系要素第2部分:服务指南Quali ty management and quality system elements--Pa rt2:Guidelines for services质量管理和质量体系要素第3部分:流程性材料指南Quality management and quality system elements --Guidelines for processed materials质量管理和质量体系要素第4部分:质量改进指南Q uality management and quality system elements--Guidelines for quality improvement质量管理质量计划指南Quality management--Gui delines for quality plans质量管理项目管理质量指南Quality management--Guidelines to quality in project management 质量管理技术状态管理指南Quality management--Guidelines for configuration management质量体系审核指南审核Guidelines for auditing q uality systems--Part1:Auditing质量体系审核指南质量体系审核员的评定准则Guide lines for auditing quality systems--Part2:Q ualification criteria for quality systems audit ors质量体系审核指南审核工作管理Guidelines for au diting quality systems--Part3:Management of audit programmes测量设备的质量保证要求第一部分:测量设备的计量确认体系Quality assurance requirements for mea suring equipment Part1:Metrological confirmat ion system for measuring equipment测量设备的质量保证第2部分:测量过程控制指南Q uality assurance for measuring equipment--Par t2:Guidelines for control of measurement proc esses质量手册编制指南Guidelines for developing qual ity manuals质量经济性管理指南Guidelines for managing the economics of quality质量管理培训指南Quality management--Guideli nes for trainingEnglish Chinesereceipt(入厂)接受,验收,进货handling搬运packaging包装storage保存protection保护comparison比较identification标识replacement of identification mark标识标志更换maintenance of identification标识的保持records of identification control标识控制记录tender标书normative document标准文件supplemental补充nonconforming product不合格品control of nonconforming product不合格品控制control procedure of nonconforming products不合格品控制程序tendency of nonconformance不合格倾向purchasing采购verification of purchased product采购的产品验证purchasing process采购过程purchasing control procedure采购控制程序purchasing information采购信息reference standard参照标准reference instructions参照细则stockhouse仓库measurement,analysis and improvement测量,分析和改进measurement result测量结果control procedure of monitoring and measuring d evices测量设备控制程序planning策划preservation of product产品保护control procedure for maintenance,replacement and records of product identification产品标识的保持,更换及记录控制程序procedure for product identification and tracea bility产品标识和可追溯性程序conformity of product产品的符合性monitoring and measurement of product产品的监督和测量product plan产品方案control procedure for product preservation产品防护控制程序method of product release产品放行方法conformity of product,product conformity产品符合性product realization产品实现planning of product realization产品实现策划product characteristics产品特性input to product requirements产品要求的输入product status产品状态final acceptance of product产品最后验收procedure程序program documents程序文件continual improvement持续改进procedure for continual improvement of quality management system持续改进质量体系程序adequacy充分性storage location存放地点agency personnel代理人员submission of tenders递交标书adjustment调整,调节statutory and regulatory requirements法律法规要求rework,vt返工repair,vt返修subcontractor分承包方annex附录improvement改进improvement actions改进措施on-the-job training岗位技能培训responsibility of individual department and pos t各部门,各岗位职责change identification更改标记change order number更改单编号process sheets工艺单process specification工艺规程procedure(process card)工艺规程(工艺卡) process characteristics工艺特性Job Description Format工种描述单work environment工作环境impartiality公正性functional requirements功能要求supplier供方supplier evaluation procedure供方评价程序supplier provided special processes供方提供的特殊过程verification at supplier's premises供方现场验证supply chain供应链criteria for supplier selection,evaluation and re-evaluation供应商选择、评估和再评估准则communication沟通customer顾客customer property顾客财产control procedure for customer property顾客财产控制程序customer feedback顾客反馈Customer Service Contact Form顾客服务联系表customer communications顾客沟通customer satisfaction顾客满意statistical analysis of customer satisfaction 顾客满意度统计分析customer complaint顾客投诉identification of customer requirements顾客要求的识别management review管理评审records from management review管理评审记录management review control procedure管理评审控制程序management representative管理者代表management responsibility管理职责specified limits of acceptability规定的可接受界限specified use规定的用途process过程complexity of processes过程的复杂性monitoring and measurement of processes过程的监视和测量operation of process过程的运行status of processes过程的状态process approach过程方法process controls过程控制process control documents过程控制文件process performance过程业绩appropriateness合适性changes to contractor合同的更改contract review control procedure合同评审控制程序internet sales互联网销售environmental conditions环境条件monogram pragram requirements会标纲要要求type of activities活动类型infrastructure基础建设infrastructure基础设施fundamentals and vocabulary基础与词汇control of records记录控制technical specificaion技术规范process trace sheet加工跟踪单monitoring and measurement监视和测量monitoring and measuring device监视和测量装置control of monitoring and measuring devices监视和测量装置控制check method检查方法frequency of checks检查频次calibration status检定状态inspection and test control procedure检验和试验控制程序identification procedure for inspection and tes t status检验和试验状态标识程序inspection witness point检验见证点inspection hold point检验停止点buildings建筑物delivery交付post-delivery activities交付后的活动delivery activities交付活动interface接口acceptance of contract or orders接受合同或定单type of medium介质类型experience经验correction action纠正措施Corrective action response time纠正措施答复时间,纠正措施响应时间management procedure for corrective actions纠正措施管理程序corrective action response times纠正措施响应时间development activity开发活动traceability mark可追溯性标志objectivity客观性Customer Service Log客户服务记录簿control feature控制特性,控制细节control features控制细则periodic assessment of stock库存定期评估justification理由routine例程,惯例,常规质量职能分配表论证范围internal communication内部沟通internal audit内部审核internal audit procedure内部审核程序internally controlled standard内控标准internal audit内审results of internal and external audits内外部审核结果competence能力training培训training needs培训需要evaluate评价records of the results of the review评审结果的记录review output评审输出review input评审输入Purchase Requisition请购单authority权限validation确认concession让步human resources人力资源job training of personnel人员岗位培训qualification of personnel人员资格equipment control procedure设备控制程序device type设备类型order of design changes设计更改通知单design and development control procedure设计和开发控制程序design and development设计开发design and development planning设计开发策划control of design and development changes设计开发更改控制design and development review设计开发评审design and development validation设计开发确认design and development outputs设计开发输出design and development inputs设计开发输入design and development verification设计开发验证design validation设计确认design documentation设计文件编制design acceptance criteria设计验收准则design verification设计验证audit program审核大纲conduct of audits审核行为audit criteria审核准则production process control生产过程控制production process control procedure生产过程控制程序production and service provision生产和服务提供control of production and service provision生产和服务提供的控制validation of processes for production and serv ice provision生产和服务提供过程的确认production order生产令identification and traceability识别和可追溯性identification and traceability maintenance and replacement识别和可追溯性维护与替换invalidate使失效market survey市场调研suitability适宜性scope适用范围controlled condition受控状态terms and definitions术语与定义analysis of data数据分析sequence顺序transfer of ownership所有权转移system document体系文件statistical technique统计方法outsource(vt)a process外包过程external source外部来源documents of external origin外来文件outsource,vt外协unique identification唯一的标识maintenance维护Document Change Control文件更改控制Request For Document Change(RDC)文件更改需求单control of documents文件控制documentation requirements文件要求enquiry问询,询价field nonconformity analysis现场不符合分析relevance相关性interaction相互作用detail design详细设计,详图设计,零件设计,施工设计sales department销售部sales contract销售合同checklist校验表,一览表,检查一览表calibration校准submission of action plans行动计划的递交documented procedures形成文件的程序documented statement形成文件的声明performance requirements性能要求licensee responsibilities许可证持有者责任acceptance criteria验收准则verification arrangement验证安排verification results验证结果customer focus以客户为关注点,以客户为焦点awareness意识introduction引言,概述,介绍normative references引用标准application应用visit to user用户访问review of requirements related to the product 有关产品的要求评审competent有能力的effectiveness有效性determination of requirements related to the pr oduct与产品有关的要求的确定customer-related processes与顾客有关的过程preventive action预防措施management procedure for preventive actions预防措施管理程序planned results预期的结果intended use预期的用途procedure for competence,knowledge and trainin g of personnel员工能力,知识和培训程序personnel training procedure员工培训程序supporting services支持性服务functions职能部门responsibility职责assignment of responsibility职责分工workmanship制造工艺manufacturing acceptance criteria制造验收准则quality policy质量方针quality programs质量纲领quality management system质量管理体系quality management system planning质量管理体系策划performance of the quality management system质量管理体系业绩quality plan质量计划quality records质量记录quality objectives质量目标quality audit质量审核quality manual质量手册quality problem handling form质量问题处理单quality requirements质量要求allocation table of quality responsibilities质量职能分配表availability of resources资源的可获得性resource management资源管理allocation of resources资源配置provision of resources资源提供general requirements总要求,一般要求constituent part组成部件organization组织continual improvement of the organization组织的持续改进size of organization组织的规模Organizational Diagram组织机构图final acceptance最终验收work instructions作业指导书。

ts16949 汽车配件管理体系英语【引言】随着全球化进程的不断推进,汽车产业在国际市场的竞争愈发激烈。

为了在市场中脱颖而出,我国企业纷纷开始关注国际质量管理体系标准,以提升产品质量和企业竞争力。

其中,TS16949作为汽车行业的质量管理体系标准,越来越受到企业重视。

本文将围绕TS16949汽车配件管理体系,介绍相关英语词汇,并结合实用场景进行分析,以帮助读者更好地理解和应用这一标准。

【TS16949简介】TS16949,全称为“Technical Specification 16949”,是由国际汽车工作组织(IATF)制定的汽车行业质量管理体系标准。

自2002年发布以来,已成为全球范围内汽车零部件供应商的质量管理规范。

1.起源与发展TS16949起源于1994年的美国汽车制造商联合制定的一套质量管理体系标准,经过多年的发展与完善,现已成为全球汽车行业的通用标准。

2.主要内容与目标TS16949主要内容包括:组织结构、人员培训、过程控制、客户满意度、内部审核、纠正与预防措施等。

其目标是确保企业提供安全、高质量的产品,以满足客户需求。

【汽车配件管理体系英语词汇】在理解和应用TS16949标准时,掌握相关的英语词汇至关重要。

以下列举了一些管理体系相关词汇,以供参考:1.管理体系词汇- Management System:管理体系- Quality Management System(QMS):质量管理体系- Environmental Management System(EMS):环境管理体系- Occupational Health and Safety Management System (OHSMS):职业健康安全管理体系2.质量管理体系相关词汇- Quality Policy:质量政策- Quality Objectives:质量目标- Customer Focus:客户导向- Continuous Improvement:持续改进3.生产与供应链管理相关词汇- Production Planning:生产计划- Material Requirements Planning(MRP):物料需求计划- Supply Chain Management(SCM):供应链管理- Just-In-Time(JIT):准时制生产【实用场景与案例分析】以下场景与案例分析将帮助读者更好地理解TS16949在实际中的应用:1.零部件供应商管理体系认证一家零部件供应商希望进入国际汽车市场,需通过TS16949认证。

TECHNICAL ISO/TS SPECIFICATION 16949质量管理体系-汽车生产件和相关服务件组织应用ISO 9001:2008的特别要求Quality management systems -Particular requirements for the applicationof ISO 9001:2008 for automotive productionand relevant service part organizationsReference numberISO/TS 16949:2009 (E)© ISO 2009ContentsForewordRemarks for certificationIntroduction0.1 General总则0.2 Process approach过程方法0.3 Relationship with ISO 9004 与ISO 9004的关系0.3.1 IATF Guidance to ISO/TS 16949:2002 IATF关于ISO/TS 16949:2002的指南0.4 Compatibility with other management systems与其他管理体系的相容性0.5 Goal of this Technical Specification本技术规范的目标1 Scope范围1.1 General总则1.2 Application应用2 Normative reference规范性引用文件3 Terms and definitions术语和定义3.1Terms and definitions for the automotive industry汽车行业的术语和定义4 Quality management system 质量管理体系4.1 General requirements 总要求4.1.1 General requirements – Supplemental 总要求-补充4.2 Documentation requirements 文件要求4.2.1 General总则4.2.2 Quality manual质量手册4.2.3 Control of documents 文件控制4.2.3.1 Engineering specifications 工程规范4.2.4 Control of records 记录控制4.2.4.1 Records retention 记录保存5 Management responsibility管理职责5.1 Management commitment管理承诺5.1.1 Process efficiency过程效率5.2 Customer focus以顾客为关注焦点5.3 Quality policy 质量方针5.4 Planning策划5.4.1 Quality objectives质量目标5.4.1.1 Quality objectives – Supplemental 质量目标-补充5.4.2 Quality management system planning质量管理体系策划5.5 Responsibility, authority and communication职责权限与沟通5.5.1 Responsibility and authority 职责和权限5.5.1.1 Responsibility for quality质量职责5.5.2 Management representative管理者代表5.5.2 1 Customer representative顾客代表5.5.3 Internal communication内部沟通5.6 Management review管理评审5.6.1 General总则5.6.1.1 Quality management system performance 质量管理体系绩效5.6.2 Review input 评审输入5.6.2.1 Review input – Supplemental 评审输入-补充5.6.3 Review output评审输出6 Resource management 资源管理6.1 Provision of resources资源提供6.2 Human resources人力资源6.2.1 General总则6.2.2 Competence, awareness and training and awareness 能力、意识和培训和意识6.2.2.1 Product design skills 产品设计技能6.2.2.2 Training 培训6.2.2.3 Training on the job 岗位培训6.2.2.4 Employee motivation and empowerment 员工激励和授权6.3 Infrastructure 基础设施6.3.1 Plant, facility and equipment planning 工厂、设施和设备策划6.3.2 Contingency plans 应急计划6.4 Work environment 工作环境6.4.1 Personnel safety to achieve conformity to product quality requirements与实现产品质量要求符合性相关的人员安全6.4.2 Cleanliness of premises 生产现场的清洁7 Product realization 产品实现7.1 Planning of product realization产品实现的策划7.1.1 Planning of product realization – Supplemental 产品实现的策划-补充7.1.2 Acceptance criteria 接收准则7.1.3 Confidentiality 保密7.1.4 Change control 更改控制7.2 Customer-related processes 与顾客有关的过程7.2.1 Determination of requirements related to the product与产品有关的要求的确定7.2.1.1 Customer-designated special characteristics 顾客指定的特殊特性7.2.2 Review of requirements related to the product与产品有关的要求的评审7.2.2.1 Review of requirements related to the product - Supplemental与产品有关的要求的评审-补充7.2.2.2 Organization manufacturing feasibility 组织制造可行性7.2.3 Customer communication 顾客沟通7.2.3.1 Customer communication – Supplemental顾客沟通-补充7.3 Design and development 设计和开发7.3.1 Design and development planning 设计和开发策划7.3.1.1 Multidisciplinary approach 多方论证方法7.3.2 Design and development inputs 设计和开发输入7.3.2.1 Product design input 产品设计输入7.3.2.2 Manufacturing process design input 制造过程设计输入7.3.2.3 Special characteristics 特殊特性7.3 3 Design and development outputs 设计和开发输出7.3.3.1 Product design outputs – Supplemental 产品设计输出-补充7.3.3.2 Manufacturing process design output制造过程设计输出7.3.4 Design and development review 设计和开发评审7.3.4.1 Monitoring 监视7.3.5Design and development verification设计和开发验证7.3.6 Design and development validation 设计和开发确认7.3.6.1 Design and development validation –Supplemental设计和开发确认-补充7.3.6.2 Prototype programme 样件计划7.3.6.3 Product approval process 产品批准过程7.3.7 Control of design and development changes 设计和开发更改的控制7.4 Purchasing 采购7.4.1 Purchasing process 采购过程7.4.1.1 Regulatory conformity法规的符合性7.4.1.2 Supplier quality management system development供方质量体系的开发7.4.1.3 Customer-approved sources 顾客批准的供货来源7.4.2 Purchasing information采购信息7.4.3 Verification of purchased product采购产品的验证7.4.3.1 Incoming product quality conformity to requirements 进货产品质量要求的符合性7.4.3.2 Supplier monitoring 对供方的监视7.5 Production and service provision 生产和服务提供7.5.1 Control of production and service provision 生产和服务提供的控制7.5.1.1 Control plan 控制计划7.5.1.2 Work instructions 作业指导书7.5.1.3 Verification of job set-ups 作业准备的验证7.5.1.4 Preventive and Predictive maintenance 预防性和预见性维护7.5.1.5 Management of production tooling 生产工装的管理7.5.1.6 Production scheduling 生产计划7.5.1.7 Feedback of information from service服务信息反馈7.5.1.8 Servicing agreement with customer与顾客的服务协议7.5.2 Validation of processes for production and service provision生产和服务提供过程的确认7.5.2.1 Validation of processes for production and service provision - Supplemental生产和服务提供过程的确认-补充7.5.3 Identification and traceability 标识和可追溯性7.5.3.1 Identification and traceability - Supplemental标识和可追溯性-补充7.5.4 Customer property顾客财产7.5.4.1 Customer-owned production tooling 顾客所有的生产工装7.5.5 Preservation of product产品防护7.5.5.1 Storage and inventory贮存和库存7.6 Control of monitoring and measuring devices equipment监视和测量装置设备的控制7.6.1 Measurement system analysis测量系统分析7.6.2 Calibration/Verification records校准/检定(验证)记录7.6.3 Laboratory requirements实验室要求7.6.3.1 Internal laboratory内部实验室7.6.3.2 External laboratory 外部实验室8 Measurement, analysis and improvement 测量、分析和改进8.1 General总则8.1.1 Identification of statistical tools 统计工具的确定8.1.2 Knowledge of basic statistical concepts 基本统计概念只是8.2 Monitoring and measurement测量和监视8.2.1 Customer satisfaction顾客满意8.2.1.1 Customer satisfaction - Supplemental顾客满意-补充8.2.2 Internal audit 内部审核8.2.2.1 Quality management system audit 质量管理体系审核8.2.2.2 Manufacturing process audit制造过程审核8.2.2.3 Product audit产品审核8.2.2.4 Internal audit plans内部审核计划8.2.2.5 Internal auditor qualification内审核员资格8.2.3 Monitoring and measurement of processes过程的监视和测量8.2.3.1 Monitoring and measurement of manufacturing processes制造过程的监视和测量8.2.4 Monitoring and measurement of product产品的监视和测量8.2.4.1 Layout inspection and functional testing全尺寸检验和功能试验8.2.4.2 Appearance items外观项目8.3 Control of nonconforming product不合格品控制8.3.1 Control of nonconforming product- Supplemental不合格品控制-补充8.3.2 Control of reworked product返工产品的控制8.3.3 Customer information顾客信息8.3.4 Customer waiver顾客特许8.4 Analysis of data数据分析8.4.1 Analysis and use of data数据的分析和使用8.5 Improvement改进8.5.1 Continual improvement持续改进8.5.1.1 Continual improvement of the organization组织的持续改进8.5.1.2 Manufacturing process improvement制造过程改进8.5.2 Corrective action纠正措施8.5.2.1 Problem solving解决问题8.5.2.2 Error-proofing防错8.5.2.3 Corrective action impact纠正措施影响8.5.2.4 Rejected product test/analysis拒收产品的试验/分析8.5.3 Preventive action预防措施Annex A (normative) Control Plan附录A (规范性附录) 控制计划A.1 Phases of the control plan/控制计划的阶段A.2 Elements of the control plan/控制计划的要素BibliographyNOTE In this table of contents, ISO9001:2008 headings are normal type face, IATF headings are in italicsForeword前言ISO(the International Organization for Standardization)is a worldwide federation of national standards bodies(ISO member bodies). The work of preparing International Standards is normally carried out through ISO technical committees. Each member body interested in a subject for which a technical committee has been established has the right to be represented on that committee. International organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical Commission(IEC) on all matters of electrotechnical standardization.国际标准化组织(ISO)是由各国标准化机构(ISO成员机构)组成的世界性的联合会。

TS16949汽车业质量管理体系标准国际标准化组织(ISO)于2002年3月公布了一项行业性的质量体系要求,它的全名是“质量管理体系—汽车行业生产件与相关服务件的组织实施ISO9001:2000的特殊要求”,英文为ISO/TS16949。

我们从实践角度出发,在背景、目标与意义、内容三方面,对该质量管理体系要求作简要介绍。

ISO/TS16949的背景和动态为了协调国际汽车质量系统规范,由世界上主要的汽车制造商及协会于1996年成立了一个专门机构,称为国际汽车工作组International Automotive Task Force (IATF) 。

IATF的成员包括了国际标准化组织质量管理与质量保证技术委员会(ISO/TC176),意大利汽车工业协会(ANFIA),法国汽车制造商委员会(CCFA)和汽车装备工业联盟(FIEV),德国汽车工业协会(VDA),汽车制造商如宝马(BMW),克莱斯勒(Daimler Chrysler),菲亚特(Fiat),福特(Ford),通用(General Motors),雷诺(Renault)和大众(Voldswagen)等。

IATF对3个欧洲规范VDA6.1(德国),VSQ(意大利),EAQF(法国)和QS-9000(北美)进行了协调,在和ISO9001:2000版标准结合的基础上,在ISO/TC176的的认可下,制定出了ISO/TS16949 :2002 这个规范。

2002年3月1日,ISO与IATF公布了国际汽车质量的技术规范ISO/TS16949:2002,这项技术规范适用于整个汽车产业生产零部件与服务件的供应链,包括整车厂,2002年版的ISO/TS16949已经生效,并展开认证工作。

在2002年4月24号,福特,通用和克莱斯勒三大汽车制造商在美国密歇根州底特律市召开了新闻发布会,宣布对供应厂商要采取的统一的一个质量体系规范,这个规范就是ISO/TS16949。

ISO/TS16949:2009技术规范TECHNICAL SPECIFICATION质量管理体系—汽车生产件及相关服务件组织应用ISO9001:2008的特殊要求Quality management systems —Particular requirements for the application of ISO 9001:2008 for automotive production and relevant service part organizations目录Contents前言Foreword (7)有关认证的说明Remarks for certification…………………………………………………9引言Introduction……………………………………………………………………………10 0.1总则General (10)0.2过程方法Process approach………………………………………………………………1 10.3与ISO 9004的关系Relationship with ISO 9004………………………………………1 30.4与其他管理体系的相容性Compatibility with other management systems……………1 40.5本技术规范的目的Goal of this Technical Specification………………………………1 5 1范围Scope (16)1.1总则General (16)1.2应用Application…………………………………………………………………………17 2引用标准Normative reference……………………………………………………………17 3术语和定义Terms and definitions…………………………………………………………18 3.1汽车行业术语和定义Terms and definitions for the automotive industry………………18 4质量管理体系Quality management system………………………………………………20 4.1总要求General requirements (20)4.1.1总要求—补充General requirements—Supplemental…………………………………2 1 4.2文件要求Documentation requirements…………………………………………………2 1 4.2.1 总则General (21)4.2.2 质量手册Quality manual (22)4.2.3文件控制Control of documents………………………………………………………2 2 4.2.3.1工程规范Engineering specifications (23)4.2.4记录控制Control of records (23)4.2.4.1记录保存Records retention (24)5管理职责Management responsibility (24)5.1管理承诺Management commitment……………………………………………………5.1.1过程效率Process efficiency (24)5.2以顾客为关注焦点Customer focus (24)5.3质量方针Quality policy (25)5.4策划Planning (25)5.4.1质量目标Quality objectives (25)5.4.1.1质量目标—补充Quality objectives—Supplemental………………………………2 5 5.4.2质量管理体系的策划Quality management system planning…………………………2 6 5.5职责、权限与沟通Responsibility, authority and communication...........................2 6 5.5.1职责和权限Responsibility and authority (26)5.5.1.1质量职责Responsibility for quality…………………………………………………2 6 5.5.2管理者代表Management representative………………………………………………27 5.5.2.1顾客代表Customer representative…………………………………………………27 5.5.3内部沟通Internal communication……………………………………………………27 5.6管理评审Management review (27)5.6.1总则General……………………………………………………………………………27 5.6.1.1质量管理体系绩效Quality management system performance……………………28 5.6.2评审输入Review input (28)5.6.2.1评审输入—补充Review input—Supplemental……………………………………28 5.6.3评审输出Review output………………………………………………………………29 6资源管理Resource management…………………………………………………………29 6.1资源提供Provision of resources…………………………………………………………29 6.2人力资源Human resources………………………………………………………………29 6.2.1总则General……………………………………………………………………………30 6.2.2能力、培训和意识Competence, training and awareness……………………………30 6.2.2.1产品设计技能Product design skills…………………………………………………6.2.2.2培训Training…………………………………………………………………………3 1 6.2.2.3岗位培训 (31)6.2.2.4员工的激励Employee motivation and empowerment………………………………3 1 6.3基础设施Infrastructure…………………………………………………………………3 1 6.3.1工厂、设施和设备策划Plant, facility and equipment planning………………………3 2 6.3.2应急计划Contingency plans (32)6.4工作环境Work environment……………………………………………………………3 2 6.4.1为达成产品要求符合性的人员安全Personnel safety to achieve conformity product requirements…………………………………………………………………………………3 2 6.4.2生产现场的清洁Cleanliness of premises (32)7产品实现Product realization………………………………………………………………3 3 7.1产品实现的策划Planning of product realization………………………………………3 3 7.1.1产品实现的策划—补充Planning of product realization—Supplemental……………34 7.1.2接收准则Acceptance criteria…………………………………………………………3 4 7.1.3保密性Confidentiality…………………………………………………………………3 4 7.1.4更改控制Change control………………………………………………………………3 4 7.2与顾客有关的过程Customer-related processes…………………………………………3 4 7.2.1与产品有关的要求的确Determination of requirements related to the product………3 5 7.2.1.1顾客指定的特殊特性Customer-designated special characteristics…………………3 5 7.2.2与产品有关的要求的评审Review of requirements related to the product…………3 5 7.2.2.1与产品有关的要求的评审—补充Review of requirements related to the produc—Supplemental…………………………………………………………………………………3 6 7.2.2.2组织制造可行性Organization manufacturing feasibility…………………………3 67.2.3.1顾客沟通—补充Customer communication—Supplemental………………………37 7.3设计和开发Design and development……………………………………………………37 7.3.1设计和开发策划Design and development planning…………………………………37 7.3.1.1多方论证方法Multidisciplinary approach…………………………………………37 7.3.2设计和开发输入Design and development inputs……………………………………38 7.3.2.1产品设计输入Product design input…………………………………………………38 7.3.2.2制造过程设计输入Manufacturing process design input……………………………39 7.3.2.3特殊特性Special characteristics……………………………………………………39 7.3.3设计和开发输出Design and development outputs……………………………………39 7.3.3.1产品设计输出—补充Product design outputs—Supplemental……………………40 7.3.3.2制造过程设计输出Manufacturing process design output…………………………40 7.3.4设计和开发评审Design and development review……………………………………4 1 7.3.4.1监视Monitoring (41)7.3.5设计和开发验证Design and development verification………………………………4 2 7.3.6设计和开发确认Design and development validation (42)7.3.6.1设计和开发确认—补充Design and development validation—Supplemental……4 2 7.3.6.2样件计划Prototype programme……………………………………………………4 2 7.3.6.3产品批准过程Product approval process (43)7.3.7 设计和开发更改的控制Control of design and development changes………………4 3 7.4 采购Purchasing (43)7.4.1采购过程Purchasing process…………………………………………………………4 4 7.4.1.1法规符合性Regulatory conformity…………………………………………………4 4 7.4.1.2供方质量管理体系开发Supplier quality management system development……7.4.1.3顾客批准的供方Customer-approved sources………………………………………4 4 7.4.2采购信息Purchasing information……………………………………………………4 5 7.4.3采购产品的验证Verification of purchased product…………………………………4 5 7.4.3.1进货产品对要求的符合性Incoming product conformity to requirements…………4 5 7.4.3.2对供方监视Supplier monitoring……………………………………………………4 6 7.5 生产和服务提供Production and service provision……………………………………4 6 7.5.1生产和服务提供的控制Control of production and service provision………………4 6 7.5.1.1控制计划Control plan………………………………………………………………47 7.5.1.2作业指导书Work instructions………………………………………………………47 7.5.1.3作业准备验证Verification of job setups……………………………………………47 7.5.1.4预防性和预见性维护Preventive and predictive maintenance……………………48 7.5.1.5生产工装的管理Management of production tooling………………………………48 7.5.1.6生产计划Production scheduling……………………………………………………49 7.5.1.7服务信息反馈Feedback of information from service………………………………49 7.5.1.8与顾客的服务协议Service agreement with customer………………………………49 7.5.2生产和服务提供过程的确认Validation of processes for production and service provision (49)7.5.2.1生产和服务提供过程的确认—补充Validation of processes for production and service provision—Supplemental……………………………………………………………50 7.5.3标识和可追溯性Identification and traceability………………………………………50 7.5.3.1标识和可追溯性—补充Identification and traceability–Supplemental……………50 7.5.4顾客财产Customer property…………………………………………………………5 17.5.5.产品防护Preservation of product……………………………………………………5 1 7.5.5.1贮存和库存Storage and inventory…………………………………………………5 1 7.6监视和测量设备的控制Control of monitoring and measuring equipment……………5 2 7.6.1测量系统分析Measurement system analysis…………………………………………5 3 7.6.2校准/验证记录Calibration/verification records………………………………………5 3 7.6.3实验室要求Laboratory requirements…………………………………………………5 3 7.6.3.1内部实验室Internal laboratory………………………………………………………5 3 7.6.3.2外部实验室External laboratory……………………………………………………5 4 8测量、分析和改进Measurement, analysis and improvement……………………………5 4 8.1总则General (55)8.1.1统计工具的确定Identification of statistical tools……………………………………5 5 8.1.2基础统计概念知识Knowledge of basic statistical concepts………………………5 5 8.2 监视和测量Monitoring and measurement……………………………………………5 5 8.2.1顾客满意Customer satisfaction………………………………………………………5 5 8.2.1.1顾客满意—补充Customer satisfaction—Supplemental……………………………5 6 8.2.2内部审核Internal audit (56)8.2.2.1质量管理体系审核Quality management system audit……………………………57 8.2.2.2制造过程审核Manufacturing process audit…………………………………………57 8.2.2.3产品审核Product audit………………………………………………………………57 8.2.2.4内部审核计划Internal audit plans…………………………………………………57 8.2.2.5内审员资格Internal auditor qualification (57)8.2.3.1制造过程的监视和测量Monitoring and measurement of manufacturing p r o c e s s e s58 8.2.4产品的监视和测量Monitoring and measurement of product…………………………59 8.2.4.1全尺寸检验和功能试验Layout inspection and functional testing…………………59 8.2.4.2外观项目Appearance items…………………………………………………………60 8.3不合格品控制Control of nonconforming product………………………………………60 8.3.1不合格品控制—补充Control of nonconforming product—Supplemental…………6 1 8.3.2返工产品的控制Control of reworked product………………………………………6 1 8.3.3顾客通知Customer information………………………………………………………6 1 8.3.4顾客特许Customer waiver……………………………………………………………6 1 8.4数据分析Analysis of data (61)8.4.1数据分析和使用Analysis and use of data……………………………………………6 2 8.5改进Improvement (62)8.5.1持续改进Continual improvement……………………………………………………6 2 8.5.1.1组织的持续改进Continual improvement of the organization………………………6 2 8.5.1.2制造过程的改进Manufacturing process improvement……………………………6 2 8.5.2纠正措施Corrective action……………………………………………………………6 3 8.5.2.1解决问题的方法Problem solving (63)8.5.2.2防错Error-proofing…………………………………………………………………6 3 8.5.2.3纠正措施影响Corrective action impact……………………………………………6 3 8.5.2.4拒收产品的试验/分析Rejected product test/analysis………………………………6 3 8.5.3预防措施Preventive action……………………………………………………………6 4 附录A控制计划Annex A (normative) Control plan………………………………………参考文献Bibliography………………………………………………………………………67前言Foreword国际标准化组织(ISO)是由各国标准化机构(ISO成员机构)组成的世界性联合会。