Chapter_10

- 格式:pdf

- 大小:754.33 KB

- 文档页数:20

第十章可持续旅游发展规划CHAPTER 10 Planning for Sustainable Tourism一、可持续旅游:一种发展哲学可持续性(sustainability)的概念第一次引起公众的注意是自1980年3月一份题为《世界保护战略》的刊出而起(IUCN, 1980)。

而“可持续发展”(sustainable development)的号召则在1987年的世界环境与发展委员会的年度报告中提出(WCED, 1987)。

(一)可持续旅游概念之形成“可持续旅游”又译为“永续旅游”。

1993年,一本名为《Journal of Sustainable Tourism (可持续旅游)》的刊物在英国诞生,标志着持续发展思潮已在旅游研究领域形成规模(谢彦君,1994)。

目前对可持续旅游的概念尚未形成统一概念,但1990年在加拿大温哥华举行的全球持续发展大会(Globe’90国际大会)旅游组行动策划委员会(1994)会议上,形成了一个《旅游持续发展行动战略》。

该次会议文件对可持续旅游的概念所作的表述较为全面,它提出了可持续旅游应符合以下5个目标(Var, 1991):(1)增进人们对旅游所产生的环境效应与经济效应的理解,强化其生态意识;(2)促进旅游的公平发展;(3)改善旅游接待地区的生活质量;(4)向旅游者提供高质量的旅游经历;(5)保护未来旅游开发赖以存在的环境质量。

1991年9月20多名国际上知名的生态旅游研究者聚会加拿大阿尔伯塔省卡尔加里市,着重探讨了生态旅游问题。

自此以后可持续旅游的理念逐渐流行,有关论著也随着出现(Nelson, Butler and Wall, 1993; Stabler, 1997; Wahab and Pigram, 1997; Hunter, 1997; Hall and Lew, 1998)。

1996年9月,为了响应联合国《21世纪议程》提出的可持续发展理念及其行动计划,世界旅游组织、世界旅游理事会、地球理事会联合制定了《关于旅行与旅游业的21世纪议程:迈向环境可持续发展》,并于1997年6月在联合国大会第九次特别会议上发布。

PART IIANSWERS TO END-OF-CHAPTER QUESTIONSCHAPTER 10: WAREHOUSING MANAGEMENT10-1. Why does warehousing exist in a supply chain?A key reason for warehousing is because patterns of production and consumption do not coincide and warehousing serves to match different rates or volumes of flow. Sometimes, larger quantities of goods are purchased than can be consumed in a short period of time and warehousing space is needed to store the surplus product. There is also a supply aspect of warehousing in the sense that a producer might purchase additional supplies in response to anticipated shortages.10-2. Explain the four ways that warehousing facilitates the regrouping function. Regrouping involves rearranging the quantities of products as they move through the supply chain, and it takes four forms: accumulating (also referred to as bulk-making), allocating (also referred to as bulk-breaking), assorting, and sorting. Accumulating involves bringing together similar stocks from different sources whereas allocating involves breaking larger quantities into smaller quantities. Assorting refers to building up a variety of different products for resale to particular customers whereas sorting out refers to separating products into grades and qualities desired by different target markets.10-3. Distinguish among warehouses, distribution centers, fulfillment centers, and cross-docking facilities.Warehouses emphasize the storage of products, and their primary purpose is to maximize the use of storage space. In contrast, distribution centers emphasize the rapid movement of products through a facility and thus attempt to maximize throughput (the amount of product entering and leaving a facility in a given time period). Fulfillment centers represent a special type of distribution center that is focused on e-commerce orders. The increased emphasis on time reduction in supply chains has led to the growth of cross docking, which can be defined as the process of receiving product and shipping it out the same day or overnight, without putting it into storage.10-4. Discuss the disadvantages to public warehousing.Perhaps the biggest drawback to public warehousing is the potential lack of control by the user. For example, sometimes public warehousing doesn’t have the space ava ilability required by the user; even if space is available, users may have little say in where their goods are stored. Moreover, some public warehousing is not open 24 hours a day, meaning that prospective users may not be able to access their products as needed or that users may need to tailor their operations to fit those of the public warehouse.10-5. What are the advantages and disadvantages of private warehousing?As for advantages, private warehousing offers users a great deal of control over their storage needs. More specifically, private warehouses can be constructed to meet user specifications, and companies can also control product placement within a facility. In addition, private warehousing offers access to products when an organization needs or wants them.One disadvantage to private warehousing is that it is characterized by high fixed costs—which necessitates high and steady demand volumes. In addition, a high fixed cost alternative becomes less attractive in times of high interest rates because it is costlier to secure the necessary financing. Private warehousing may also reduce an organization’s flexibility with respect to responding to changes in the external environment.10-6. Discuss why contract warehousing is a preferred alternative for many organizations. Contract warehousing simultaneously mitigates the negative aspects and accentuates the positive aspects of public and private warehousing. For instance, contract warehousing allows a company to focus on its core competencies, with warehousing management provided by experts. Contract warehousing also tends to be more cost effective than private warehousing, with potentially the same degree of control because key specifications can be included in the relevant contract.10-7. How does multiclient warehousing mix attributes of public and contract warehousing?Whereas contract warehousing is generally dedicated to just one customer and public warehousing may be used by any number of customers, a limited number of customers (at least two, but no more than one dozen) utilize a multiclient facility. In a similar fashion, the services in a multiclient facility are more differentiated than those in a public facility but less customized than would be found in a contract warehousing.10-8. Explain how common sense can be helpful in terms of warehousing design.One common-sense piece of advice is that prior to designing a warehousing facility, the quantity and character of goods to be handled must be known. For example, the design of fulfillment centers for online orders should explicitly incorporate key attributes of online commerce such as small orders sizes, the necessity to store limited quantities of SKUs, and intense peaks in demand, among others.Another common-sense piece of advice is that it is important for an organization to know the purpose to be served by a particular facility because the relative emphasis placed on the storage and distribution functions affects space layout. For instance, a facility that emphasizes rapid movement with limited time in storage should be configured to facilitate the flow of product into and out of it.10-9. In terms of warehousing design, give examples of trade-offs involving space, labor, and mechanization.Spaciousness may not always be advantageous because the distances that an individual or machine must travel in the storing and retrieving functions are increased. Moreover, unused space is excess capacity, and excess capacity costs money. Alternatively, cramped conditions can lead to inefficiencies such as the product damage that can be caused by forklift puncture and movement bottlenecks caused by inefficient aisle width.10-10. Distinguish between fixed and variable slot locations. How might they affect warehousing design?A fixed slot location refers to a situation where each SKU has one or more permanent slots assigned to it whereas a variable slot location involves empty slots being assigned to products based on space availability. Fixed slot location can provide stability in order picking in the sense that a company should always know where a specific SKU is located; however, this may result in low space utilization. Although variable slot location generally results in more efficient space utilization, it requires a near-perfect information system because there must be flawless knowledge of each product’s location.10-11. Discuss the trade-offs associated with order-picking versus stock-replenishing functions.Organizations must decide whether workers who pick outgoing orders and those who are restocking storage facilities should work at the same time or in the same area. When order pickers and stock replenishers are allowed to work in the same area, fewer managerial personnel may be needed but it may also lead to congestion due to the number of workers in a relatively limited space. One suggestion is for the two sets of workers to use different aisles for their activities, but this requires a superior information system.10-12. Explain the relevance of aisle width in warehouse design.As aisle space increases, the storage capacity of a facility decreases; for example, narrow aisles can store 20–25 percent more product than conventional aisles. However, it is easier to operate mechanical equipment in wider aisles, and wider aisles reduce the chances of accidents and product damage. In addition, narrower aisles require specialized storage and handling equipment, and this equipment is more expensive than less specialized equipment.10-13. Discuss some key considerations associated with warehouse automation. Warehouse automation refers to utilizing mechanical or electronic devices to substitute for human labor, and key considerations involve noticeable improvement in warehousing effectiveness and efficiency. An organization should first assess whether it is ready forautomation, because automation can be complex, expensive, and disruptive to day-to-day operations. If an organization is ready for automation, then it’s important to evaluate how the automation will support the organization’s logistics system.10-14. What are some potential nonstorage space needs that might impact warehousing design?The text mentions 12 potential nonstorage needs, such as an area where transport drivers and operators can wait while their equipment is loaded or unloaded. Any combination of these 12 needs is acceptable.10-15. How can warehousing productivity be improved without significant investment in technology or equipment?One suggestion for improving warehousing productivity involves a review of existing procedures and practices to identify the tasks that are creating the largest inefficiencies without adding to or upgrading present technology or equipment. Organizations can also examine their facility layouts; long horizontal runs and frequent backtracking could be symptoms of layout problems. Something as basic as adding cross aisles could reduce the length of horizontal runs as well as the length of backtracking. Another low-cost suggestion for improving warehousing productivity is to play music, if conditions permit; research suggests that worker productivity increases when music is playing.10-16. What is OSHA’s role in warehousing safety?OSHA is the Occupational Safety and Health Administration, an agency of the U.S. federal government that has responsibilities for industrial safety practices, and OSHA inspectors make frequent visits to industrial workplaces to ensure regulatory compliance. OSHA has paid special attention to forklift operations and equipment; only trained and certified warehousing employees are permitted to operate a forklift, and forklift operators must be recertified every three years. OSHA also provides suggestions for improving warehousing safety, such as prohibiting employees from jumping from dock plate to dock plate.10-17. Discuss how fires are a constant threat in warehousing.Fires are a constant threat in warehousing in part because many materials used for packaging are highly flammable. In addition, although plastic pallets last longer, are cleaner, and are less likely to splinter than wooden pallets, they tend to be a greater fire risk. High-rise facilities are more susceptible to fires because the vertical spaces between stored materials serve as flues and help fires burn.10-18. What is a hazardous material? What design elements should be considered when storing hazardous materials?A hazardous material (hazmat) is any item or agent (biological, chemical, physical) that has the potential to cause harm to humans, animals, or the environment, either by itself or through interactions with other factors. Buildings that store hazmat often have specially constructed areas so that materials can be contained in the case of an accident. Likewise, these facilities may have walls and doors that can withstand several hours of intense fire. It’s also important for a hazmat storage facility to have proper sprinkling systems as well as excellent ventilation.10-19. Discuss how warehousing security can be enhanced by focusing on people, facilities, and processes.With respect to people, a starting point might be determining if a facility even has a formal hiring process. As for facilities, experts recommend a combination of overt (e.g., closed-circuit television systems) and covert (e.g., unannounced security audits) surveillance methods. Finally, with respect to processes, the more times a shipment is handled, the greater the opportunities for loss and/or damage.10-20. How are cleanliness and sanitation issues relevant to warehousing operations? Warehousing cleanliness and sanitation are extremely important in many industries, such as the foodservice industry where clean and sanitary warehouses reduce the likelihood of foodborne illnesses. Moreover, clean and sanitary facilities have a positive impact on employee safety, morale, and productivity while also reducing employee turnover.PART IIICASE SOLUTIONSCASE 10-1: MINNETONKA WAREHOUSEQuestion 1: For each of the four work team sizes, calculate the expected number of trucks in the queue to be unloaded.Question 2: For each of the four work team sizes, calculate the expected time in the queue—that is, the expected time a truck has to wait in line to be unloaded.Question 3: For each of the four work team sizes, what is the probability that a truck cannot be unloaded immediately?Question 4: Which of the four work team sizes results in the lowest cost to Wayne?Question 5: Wayne is also considering rental of a forklift to use in truck unloading. A team of only two would be needed, but the hourly cost would be $38 per hour ($28 for the workers and $10 for the forklift). The two workers could unload a truck in 5 minutes. Should Wayne rent the forklift?A two-person crew and a forklift will cost $38 per hour. Compare this with the answers in Question 4; Wayne should adopt a two-man crew and use a forklift.Question 6: Disregard your answer to Question 5. Labor negotiations are coming up, and Wayne thinks he can get the union to give way on the work rule that prohibits warehouse workers on the unloading dock from being given other assignments when they are not unloading trucks. How much would Wayne save in unloading dock costs if he could reassign warehouse workers to other tasks when they are not unloading trucks, assuming that he has picked a good team of workers and each worker works 8 hours a day?From the printouts, we must determine how much “idle time” there is with th e present system. This depends in part upon the crew size. For a crew of four, for example, 24 minutes per hour is spent unloading trucks and the rest is idle time. Therefore, Wayne could get 36 minutes of work per hour of work elsewhere out of each worker. At $14 per hour, this is worth $8.40 ($14/hour times 0.6 hours). In theory, Wayne could save up to $8.40 per worker per hour assuming he could assign them to other tasks where the pay rates were the same.。

简爱第10章读书笔记Jane Eyre Chapter 10 marks a significant turning point in the story as Jane's life takes a new direction. This chapter explores the aftermath of Jane's traumatic experience at Lowood School and her journey towards finding independence and self-empowerment. It delves into the complexities of Jane's character and her growing sense of agency as she navigates a world that is often cruel and unjust.简爱第10章标志着故事发生重要转折,简的生活走向了新的方向。

这一章探索了简在洛伍德学校的创伤经历后,她寻找独立和自我赋权之路。

它深入探讨了简的性格复杂性,以及在一个常常残酷和不公正的世界中,她日益增长的主动性。

Jane's experiences at Lowood had a profound impact on her, shaping her worldview and strengthening her resilience. Despite facing adversity and cruelty, Jane emerges from her ordeal with a renewed sense of purpose and determination. This resilience is evident in her interactions with others, as she stands up for herself and asserts her worth in the face of societal norms that seek to diminish her sense of self-worth.简在洛伍德的经历对她产生了深远影响,塑造了她的世界观,并增强了她的逆境适应能力。

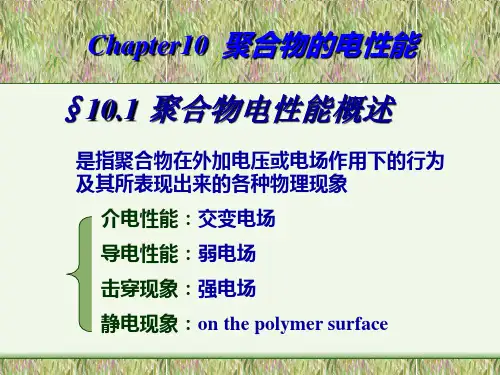

Chapter 10 Language and Computer1. 计算机语言学计算机语言学可以看作是应用语言学的分支,即通过计算机处理人类语言。

计算机语言包括:对语言数据的分析,建立一个序列,通过它,语言学习者可以获得各种语法规律或某一特定词项的出现频率;人工语言的电子生成和人类语言的自动识别;它也包括不同自然语言之间的自动翻译和语篇处理;人与计算机的交流。

2. CAI, CAL & CALL2.1. CAI:计算机辅助教学,就是在教学过程中使用计算机。

2.2. CAL:计算机辅助学习,强调在教和学两方面使用计算机,通过学生自己的推理和和实践,帮助学习者达到教学目标。

2.3. CALL:计算机辅助语言学习,如果说CAI,和CAL是处理一般的教和学,那么CALL是用来处理语言教学的。

它特别是指将计算机运用到第二语言或外语的教学中去。

3. 机器翻译&人工翻译3.1. 定义机器翻译是指使用机器将语篇从一种自然语言翻译至另一种自然语言。

机器翻译可分为两类:不需要辅助的和需要辅助的。

3.2. 机器翻译&人工翻译在新世纪之初,很明显,机器翻译和人工翻译能够且将会相对协调地同时存在。

我们仍旧需要那些人工翻译者所作出的贡献。

当翻译不得不讲究“可发行”质量时,机器翻译和人工翻译都具有各自的作用。

对语篇翻译来说,在对输出的质量要求不高的地方,机器翻译是一种理想的解决方法。

对信息的一对一交换而言,人工翻译家可能总是会有作用的。

至于口语翻译,一定会是人工翻译者的市场。

4. 计算机语料库4.1. 语料库(corpus)A collection of linguistic data, either compiled as written texts or as a transcription of recorded speech. The main purpose of a corpus is to verify a hypothesis about language--- for example, to determine how the application of a particular sound, word, or syntactic construction varies.语料库是一个语言数据的集合,可以有书面文本构成,也可以由录音言语的转写本构成。