关于斜拉桥的中英文翻译

- 格式:doc

- 大小:87.50 KB

- 文档页数:13

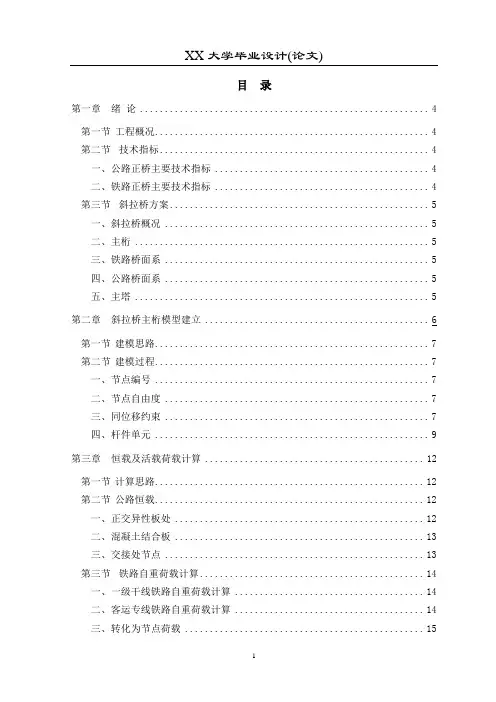

目录第一章绪论 (4)第一节工程概况 (4)第二节技术指标 (4)一、公路正桥主要技术指标 (4)二、铁路正桥主要技术指标 (4)第三节斜拉桥方案 (5)一、斜拉桥概况 (5)二、主桁 (5)三、铁路桥面系 (5)四、公路桥面系 (5)五、主塔 (5)第二章斜拉桥主桁模型建立 (6)第一节建模思路 (7)第二节建模过程 (7)一、节点编号 (7)二、节点自由度 (7)三、同位移约束 (7)四、杆件单元 (9)第三章恒载及活载荷载计算 (12)第一节计算思路 (12)第二节公路恒载 (12)一、正交异性板处 (12)二、混凝土结合板 (13)三、交接处节点 (13)第三节铁路自重荷载计算 (14)一、一级干线铁路自重荷载计算 (14)二、客运专线铁路自重荷载计算 (14)三、转化为节点荷载 (15)第四节活载荷载计算 (15)一、公路活载 (15)二、铁路活载 (16)第四章斜拉索初张力确定 (18)第一节拉索初张力确定思路 (18)第二节拉索初张力确定 (18)一、恒载索力 (18)二、活载索力 (20)三、拉索初张力 (23)第五章斜拉桥结构内力分析 (25)第一节恒载内力 (25)一、确定控制断面 (25)二、恒载作用下跨中断面内力 (25)三、恒载作用下支座处断面内力 (26)第二节公路桥面横向分布系数计算 (26)一、汽车荷载横向分布计算 (26)二、求弹性支承的刚度系数 (26)三、建立横梁模型 (27)四、用移动荷载法求影响线 (27)五、确定最不利桁架 (28)六、求中桁的横向分布系数 (28)第三节公路桥面横向分布系数计算 (29)一、计算方法 (29)二、求横向分布系数 (29)三、确定最不利桁架 (30)第四节活载内力分析 (31)一、分析思路 (31)二、求汽车活载下的内力 (31)三、求列车活载下的内力 (32)第六章结构验算 (34)第一节内力检算 (34)一、上弦杆件检算 (34)二、下弦杆件检算 (35)第二节疲劳检算 (36)一、上弦杆件21单元疲劳检算 (36)二、下弦杆件117单元疲劳检算 (37)第三节刚度检算 (38)一、中桁上弦控制节点(40)的垂直挠度值 (38)二、中桁下弦控制节点(119)的垂直挠度值 (38)三、刚度检算 (38)第七章性能评价 (39)一、恒载内力 (39)二、活载内力 (39)三、结构刚度 (39)四、不妥之处 (39)结束语 (40)致谢 (41)参考文献 (42)附录 (43)1.英文文献及翻译2.斜拉桥总图3.主桁杆件截面图4.斜拉桥主塔图第一章绪论第一节工程概况这个公铁两用江山大桥位于火星江山二桥下游9.5km处的这个分汊河段上,北岸为江岸区谌家矶,南岸为青山区建十路,大桥横越江山,连通太阳,土星两镇。

桥梁工程中英文对照外文翻译文献BRIDGE ENGINEERING AND AESTHETICSEvolvement of bridge Engineering,brief reviewAmong the early documented reviews of construction materials and structu re types are the books of Marcus Vitruvios Pollio in the first century B.C.The basic principles of statics were developed by the Greeks , and were exemplifi ed in works and applications by Leonardo da Vinci,Cardeno,and Galileo.In the fifteenth and sixteenth century, engineers seemed to be unaware of this record , and relied solely on experience and tradition for building bridges and aqueduc ts .The state of the art changed rapidly toward the end of the seventeenth cent ury when Leibnitz, Newton, and Bernoulli introduced mathematical formulatio ns. Published works by Lahire (1695)and Belidor (1792) about the theoretical a nalysis of structures provided the basis in the field of mechanics of materials .Kuzmanovic(1977) focuses on stone and wood as the first bridge-building materials. Iron was introduced during the transitional period from wood to steel .According to recent records , concrete was used in France as early as 1840 for a bridge 39 feet (12 m) long to span the Garoyne Canal at Grisoles, but r einforced concrete was not introduced in bridge construction until the beginnin g of this century . Prestressed concrete was first used in 1927.Stone bridges of the arch type (integrated superstructure and substructure) were constructed in Rome and other European cities in the middle ages . Thes e arches were half-circular , with flat arches beginning to dominate bridge wor k during the Renaissance period. This concept was markedly improved at the e nd of the eighteenth century and found structurally adequate to accommodate f uture railroad loads . In terms of analysis and use of materials , stone bridgeshave not changed much ,but the theoretical treatment was improved by introd ucing the pressure-line concept in the early 1670s(Lahire, 1695) . The arch the ory was documented in model tests where typical failure modes were considere d (Frezier,1739).Culmann(1851) introduced the elastic center method for fixed-e nd arches, and showed that three redundant parameters can be found by the us e of three equations of coMPatibility.Wooden trusses were used in bridges during the sixteenth century when P alladio built triangular frames for bridge spans 10 feet long . This effort also f ocused on the three basic principles og bridge design : convenience(serviceabili ty) ,appearance , and endurance(strength) . several timber truss bridges were co nstructed in western Europe beginning in the 1750s with spans up to 200 feet (61m) supported on stone substructures .Significant progress was possible in t he United States and Russia during the nineteenth century ,prompted by the ne ed to cross major rivers and by an abundance of suitable timber . Favorable e conomic considerations included initial low cost and fast construction .The transition from wooden bridges to steel types probably did not begin until about 1840 ,although the first documented use of iron in bridges was the chain bridge built in 1734 across the Oder River in Prussia . The first truss completely made of iron was in 1840 in the United States , followed by Eng land in 1845 , Germany in 1853 , and Russia in 1857 . In 1840 , the first ir on arch truss bridge was built across the Erie Canal at Utica .The Impetus of AnalysisThe theory of structures ,developed mainly in the ninetheenth century,foc used on truss analysis, with the first book on bridges written in 1811. The Wa rren triangular truss was introduced in 1846 , supplemented by a method for c alculating the correcet forces .I-beams fabricated from plates became popular in England and were used in short-span bridges.In 1866, Culmann explained the principles of cantilever truss bridges, an d one year later the first cantilever bridge was built across the Main River in Hassfurt, Germany, with a center span of 425 feet (130m) . The first cantilever bridge in the United States was built in 1875 across the Kentucky River.A most impressive railway cantilever bridge in the nineteenth century was the Fir st of Forth bridge , built between 1883 and 1893 , with span magnitudes of 1 711 feet (521.5m).At about the same time , structural steel was introduced as a prime mater ial in bridge work , although its quality was often poor . Several early exampl es are the Eads bridge in St.Louis ; the Brooklyn bridge in New York ; and t he Glasgow bridge in Missouri , all completed between 1874 and 1883.Among the analytical and design progress to be mentioned are the contrib utions of Maxwell , particularly for certain statically indeterminate trusses ; the books by Cremona (1872) on graphical statics; the force method redefined by Mohr; and the works by Clapeyron who introduced the three-moment equation s.The Impetus of New MaterialsSince the beginning of the twentieth century , concrete has taken its place as one of the most useful and important structural materials . Because of the coMParative ease with which it can be molded into any desired shape , its st ructural uses are almost unlimited . Wherever Portland cement and suitable agg regates are available , it can replace other materials for certain types of structu res, such as bridge substructure and foundation elements .In addition , the introduction of reinforced concrete in multispan frames at the beginning of this century imposed new analytical requirements . Structures of a high order of redundancy could not be analyzed with the classical metho ds of the nineteenth century .The importance of joint rotation was already dem onstrated by Manderla (1880) and Bendixen (1914) , who developed relationshi ps between joint moments and angular rotations from which the unknown mom ents can be obtained ,the so called slope-deflection method .More simplification s in frame analysis were made possible by the work of Calisev (1923) , who used successive approximations to reduce the system of equations to one simpl e expression for each iteration step . This approach was further refined and integrated by Cross (1930) in what is known as the method of moment distributi on .One of the most import important recent developments in the area of anal ytical procedures is the extension of design to cover the elastic-plastic range , also known as load factor or ultimate design. Plastic analysis was introduced with some practical observations by Tresca (1846) ; and was formulated by Sa int-Venant (1870) , The concept of plasticity attracted researchers and engineers after World War Ⅰ, mainly in Germany , with the center of activity shifting to England and the United States after World War Ⅱ.The probabilistic approa ch is a new design concept that is expected to replace the classical determinist ic methodology.A main step forward was the 1969 addition of the Federal Highway Adim inistration (FHWA)”Criteria for Reinforced Concrete Bridge Members “ that co vers strength and serviceability at ultimate design . This was prepared for use in conjunction with the 1969 American Association of State Highway Offficials (AASHO) Standard Specification, and was presented in a format that is readil y adaptable to the development of ultimate design specifications .According to this document , the proportioning of reinforced concrete members ( including c olumns ) may be limited by various stages of behavior : elastic , cracked , an d ultimate . Design axial loads , or design shears . Structural capacity is the r eaction phase , and all calculated modified strength values derived from theoret ical strengths are the capacity values , such as moment capacity ,axial load ca pacity ,or shear capacity .At serviceability states , investigations may also be n ecessary for deflections , maximum crack width , and fatigue .Bridge TypesA notable bridge type is the suspension bridge , with the first example bu ilt in the United States in 1796. Problems of dynamic stability were investigate d after the Tacoma bridge collapse , and this work led to significant theoretica l contributions Steinman ( 1929 ) summarizes about 250 suspension bridges bu ilt throughout the world between 1741 and 1928 .With the introduction of the interstate system and the need to provide stru ctures at grade separations , certain bridge types have taken a strong place in bridge practice. These include concrete superstructures (slab ,T-beams,concrete b ox girders ), steel beam and plate girders , steel box girders , composite const ruction , orthotropic plates , segmental construction , curved girders ,and cable-stayed bridges . Prefabricated members are given serious consideration , while interest in box sections remains strong .Bridge Appearance and AestheticsGrimm ( 1975 ) documents the first recorded legislative effort to control t he appearance of the built environment . This occurred in 1647 when the Cou ncil of New Amsterdam appointed three officials . In 1954 , the Supreme Cou rt of the United States held that it is within the power of the legislature to de termine that communities should be attractive as well as healthy , spacious as well as clean , and balanced as well as patrolled . The Environmental Policy Act of 1969 directs all agencies of the federal government to identify and dev elop methods and procedures to ensure that presently unquantified environmenta l amentities and values are given appropriate consideration in decision making along with economic and technical aspects .Although in many civil engineering works aesthetics has been practiced al most intuitively , particularly in the past , bridge engineers have not ignored o r neglected the aesthetic disciplines .Recent research on the subject appears to lead to a rationalized aesthetic design methodology (Grimm and Preiser , 1976 ) .Work has been done on the aesthetics of color ,light ,texture , shape , and proportions , as well as other perceptual modalities , and this direction is bot h theoretically and empirically oriented .Aesthetic control mechanisms are commonly integrated into the land-use re gulations and design standards . In addition to concern for aesthetics at the sta te level , federal concern focuses also on the effects of man-constructed enviro nment on human life , with guidelines and criteria directed toward improving quality and appearance in the design process . Good potential for the upgrading of aesthetic quality in bridge superstructures and substructures can be seen in the evaluation structure types aimed at improving overall appearance .Lords and lording groupsThe loads to be considered in the design of substructures and bridge foun dations include loads and forces transmitted from the superstructure, and those acting directly on the substructure and foundation .AASHTO loads . Section 3 of AASHTO specifications summarizes the loa ds and forces to be considered in the design of bridges (superstructure and sub structure ) . Briefly , these are dead load ,live load , iMPact or dynamic effec t of live load , wind load , and other forces such as longitudinal forces , cent rifugal force ,thermal forces , earth pressure , buoyancy , shrinkage and long t erm creep , rib shortening , erection stresses , ice and current pressure , collisi on force , and earthquake stresses .Besides these conventional loads that are ge nerally quantified , AASHTO also recognizes indirect load effects such as fricti on at expansion bearings and stresses associated with differential settlement of bridge components .The LRFD specifications divide loads into two distinct cate gories : permanent and transient .Permanent loadsDead Load : this includes the weight DC of all bridge components , appu rtenances and utilities, wearing surface DW nd future overlays , and earth fill EV. Both AASHTO and LRFD specifications give tables summarizing the unit weights of materials commonly used in bridge work .Transient LoadsVehicular Live Load (LL) Vehicle loading for short-span bridges :considera ble effort has been made in the United States and Canada to develop a live lo ad model that can represent the highway loading more realistically than the H or the HS AASHTO models . The current AASHTO model is still the applica ble loading.桥梁工程和桥梁美学桥梁工程的发展概况早在公元前1世纪,Marcus Vitrucios Pollio 的著作中就有关于建筑材料和结构类型的记载和评述。

我的家乡景洪英语作文50字带翻译My hometown is in the beautiful and rich Jinghong City, Xishuangbanna Prefecture, where the trees are shaded and the flowers and fruits are fragrant in all seasons.My family lives on the bank of the beautiful Lancang River. There are two bridges beside the river. There is also a bridge at the hydropower station. These three bridges are the bridges that enter our city. The three bridges are cable-stayed bridges, arch bridges and pillar bridges.In Jinghong, you can only see crowds during festivals. In Shanghai, it seems like a festival at any time, no matter how remote the place is, there is always a sea of =people and lively.I love my hometown, I love Jinghong翻译:我的家乡在美丽富饶的西双版纳州景洪市,这里四季都绿树成阴、花果飘香。

我家就住在美丽的澜沧江畔,江旁边有两座大桥,在水电站呢,还有一座大桥。

这三座大桥是进入我们城市的桥,这三座大桥分别是斜拉桥、拱桥和支柱桥。

在景洪,只有在过节时才能看到人山人海的景象。

Unit6 BridgeSectionI Talking Face to Face1. IntroductionA designer is a person who designs. More formally, a designer is an agent that "specifies the structural properties of a design object".[1] In practice, anyone who creates tangible or intangible objects, such as consumer products, processes, laws, games and graphics, is referred to as a designer.Ask students to read dialogue and then make dialogues according to the task.2. Explaining some words and expressions in the dialogue:Dialogue one:It’s said that……:据说……Cable-stayed bridge: 斜拉桥It’s no doubt that……:毫无疑问……Authorities:当局Locate: vt. 使……坐落于……Experienced: adj. 富有经验的Dialogue two:In the heart of……:在……的中心Head:v. (向特定方向)出发Transfer: v. 换车,转车SectionII Maintaining a sharp eyePassage1 Bridge IntroductionImportant words1. Innovation n.1). 革新,改革,创新[U] innovatinge.g. The innovation of air travel during this century has made the world seem smaller. 本世纪空中旅行的革新使世界似乎变小了。

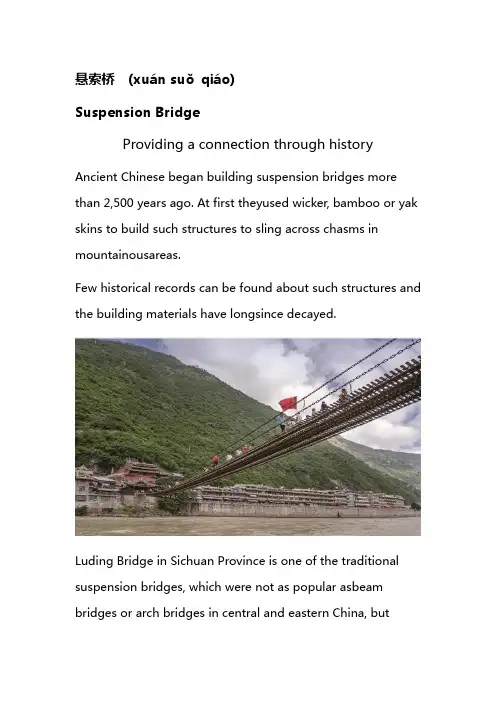

悬索桥(xuán suǒqiáo)Suspension BridgeProviding a connection through history Ancient Chinese began building suspension bridges more than 2,500 years ago. At first theyused wicker, bamboo or yak skins to build such structures to sling across chasms in mountainousareas.Few historical records can be found about such structures and the building materials have longsince decayed.Luding Bridge in Sichuan Province is one of the traditional suspension bridges, which were not as popular asbeam bridges or arch bridges in central and eastern China, butwidely built in the mountainous area ofwestern China. However, there are records of a bamboo suspension bridge built in the third century BC by LiBing (302–235 BC), a famous engineer. Located near today's Chengdu, capital of SichuanProvince. It is said this bamboo bridge was in use for more than 600 years.Iron chain suspension bridges first appeared in China during the T ang Dynasty (618–907 AD), butsuch bridges still in existence today were mostly built during the Ming Dynasty (1368–1644).In 1430, Thangtong Gyalpo (1385–1464), a great Tibetan Buddhist, architect and creator ofTibetan opera, built an iron chain bridge spanning the Yarlung Tsangpo River south of Lhasa,capital of the Tibetan Autonomous Region today. Boasting a central span of 137 meters, it was the suspension bridge with the longestunsupported span in the world at that time. The bridge's wooden plank walkway hung fromvertical poles and the planks were bound together with twisted willow and strips of yak hide.According to legends, Gyalpo, known as the "Buddha of Iron Bridges" at his time, built a total of58 iron chain suspensionbridges in his whole lifetime.The structure of Tibetan architect Thangtong Gyalpo's iron chain bridge on the Yarlung Tsangpo RiverAnother ancient iron chain suspension bridge with detailed historical records in China was theJihong Bridge, spanning the Lancang River in southwest China's Yunnan Province.It was once called the "First Bridge in Southwest China" as it sat on an ancient path leading toIndia and Myanmar.The iron chain link bridge was built in 1475, replacing a bamboo structure.With a total length of 113.4 meters and a width of 3.7 meters, the bridge was built with 18 thickiron chains and featured a span of 57.3 meters.However, the ancient bridge was washed away by floods in 1986.Another masterpiece of historic suspension bridges is the Luding Bridge. Built in 1706 in thesouthwest China's Sichuan Province, the 103-meter-long and 3-meter-wide bridge is made from13 thick iron chains with a total weight of more than 40 tons.The bridge was long regarded as a key link in connecting Sichuan Province and the Tibetanregion. But it is today also known for a fierce battle fought there by the Chinese CommunistParty-led Red Army in May 1935 against Kuomintang allied local warlords during its famous LongMarch to reach its bases in northern China.In 1961, the bridge was listed among the first batch of key cultural relics of the country and putunder state protection. Today it is a popular tourist attraction drawing throngs of visitors everyday.Though suspension bridges were not as popular as beam bridges or arch bridges in ancientChina, in the past several decades, the country has built many world-class suspension bridges tomeet its needs for modernization.The Xihoumen Bridge was built in 2009 on the Zhoushan Archipelago in east China's Zhejiang Province, witha main span of 1,650 meters.They include the Xihoumen Bridge built in 2009 on the Zhoushan Archipelago in east China'sZhejiang Province, with a main span of 1,650 meters; the Runyang Yangtze River Bridge built in2005 in east China's Jiangsu Province, with a main span of 1,490 meters; the Fourth NanjingYangtze Bridge build in 2012 also in Jiangsu Province, with a main span of 1,418 meters; and theJiangyin Yangtze River Bridge built in 1999 also in Jiangsu Province, with a main span of 1,385meters.All the four above are among the top 10 suspension bridges in the world today in terms of the length of their main spans.Pictorial dictionary·吊桥(diào qiáo) drawbridgeIn Chinese, the term diaoqiao may mean either a suspension bridge or a drawbridge. Asuspension bridge can also be called xuansuoqiao in Chinese, but the drawbridge doesn't haveanother common alias.Also, unlike in other parts of the world, where the term drawbridge may refer to a number ofmovable bridges, such as bascule bridge, vertical-lift bridge and swing bridge, in ancient China adrawbridge was used almost exclusively of the bridge installed in front of a city wall gate andspanning a surroundingmoat.Such city moat drawbridges were mostly made of wood and could be raised —particularly toprevent invading troops from entering the city.Many Chinese historians and architects believe that the first drawbridges appeared in Chinaduring the Spring and Autumn Period (770–476 BC), together with the city moat.。

附录A译文桥梁桥梁是人类征服空间的象征。

当日落时你在太平洋中看到深红色网格的金门大桥时,或者耀武扬威的在深谷上滑翔,你会感到惊奇并钦佩它们建造者的艺术。

它们是人类在追求更好更自由的世界,移除堡垒的决心的持久的证明。

他们的设计和建筑计划是像在梦里一样的想象,但是构想和决心都还不够,各种力如重力等的具体数据必须靠数学模型精确计算,这需要艺术的灵感和工匠的技术。

科学关于材料和结构的行为的知识已经明显地扩大,并且计算技术现在可广泛便捷地应用在操作复杂的理论,工程师们实际上在过去十年已经彻底改革桥设计和建设方法。

这些发展应用于短、中、长跨桥。

对于耐久的桥,最普通的材料就是用钢筋和混凝土。

不同种类的桥都是用这些材料的。

木材都是用于水上的暂时的建筑,木制短跨度桥不可设置在水平面下,现在美国已经在实验一些铝制的短跨度桥。

一座桥的主要部分可以据说是“基础”和“上层建筑”。

因为在很多桥里没有清楚的在这两个之间划分,这个划分被仅仅为了方便起见在这里使用。

基础的一般要素是桥台和墩台,它们经常分别建造基础,例如混凝土扩展基础,这些基础是基础的一部分。

偶尔有些基础是桩基础,桩伸到水平线以上,顶部有桩帽,这样可以支持主要的上部结构。

这种形式经常被用来做长的、低的、跨水的结构。

附录B英文文献BridgesBridges are great symbols of mankind’s conquest of space. The sight of the crimson tracery of the Golden Gate Bridge against a setting sun in the Pacific Ocean, or the atch of the Garabit Biaduct soaring triumphantly above the deep gorge. F ills one’s heart with wonder and admiration for the art of their builders[11]. They are the enduring expressions of mankind’s determination to remove all barriers in its pursuit of a better and freer world. Their design and building schemes are conceived in dream-like bisions. But vision and determination are not enough. All the physical forces of nature and gravity must be understood with mathematical precision and such forces have to be resisted by manipulating the right materials in the right pattern. This requires both the inspiration of an artist and the skill of an artisan.Scientific knowledge about materials and structural behavior has expanded tremendously, and computing techniques are now widely available to manipulate complex theories in innumerable ways very quickly. Engineers have virtually revolutionized bridge design and construction methods in the past decade. The advances apply to short-medium and long-span bridges.For permanent bridge,the most commonly used materials are steel and concrete. Bridge of many different type are built with these materials,used singly or in combination. Timber may be used for temporary above-water construction, for the elements of a structure that lie below the waterline (particularly timber pile s), or for short-span bridges located on secondary roads. A few short-span aluminum bridges have been built in the United States on an experimental basis.The principal portions of a bridge may be said to be the “substructure” and the “superstructure.” This division is used here simply for convenience, since in many bridges there is no clear dividing lint between the two.Common elements of the substructure are abutments (usually at the bridge ends) and piers (between the abutments).Piers and abutments often rest on separately constructed foundations such as concrete spread footings or groups of bearing piles; these foundations are part of the substructure. Occasionally a bridge substructure comprises a series of pile bents in which the piles extend above the waterline and are topped by a pile cap that, in turn, supports the major structural elements of the superstructure. Such bents often are used in arepetitive fashion as part of along, low, over-water crossing.In recent years, the dividing lines between short-medium and long-span bridge have blurred somewhat. Currently, spans of 20 to 100 ft (6.1 to 30.5m) are regarded as short by many designers, who have developed many standardized designs to handle these spans economically.Medium spans range up to, per-haps, 400ft (121.9m) in modern bridge practice, depending on the organization involved and the materials used. Long spans range up to 4000ft (1219.2m) or more, but a clear span above 1000ft (304.8m)is comparatively rare.。

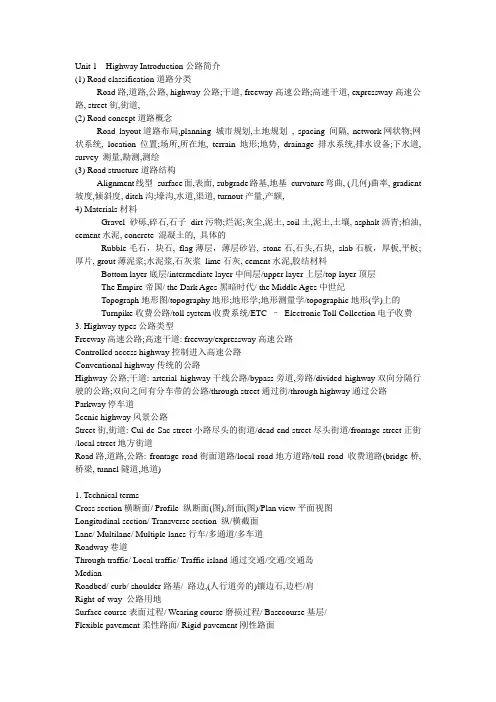

Unit 1 Highway Introduction公路简介(1) Road classification道路分类Road路,道路,公路, highway公路;干道, freeway高速公路;高速干道, expressway高速公路, street街,街道,(2) Road concept道路概念Road layout道路布局,planning 城市规划,土地规划, spacing 间隔, network网状物;网状系统, location位置;场所,所在地, terrain 地形;地势, drainage排水系统,排水设备;下水道, survey 测量,勘测,测绘(3) Road structure道路结构Alignment线型surface面,表面, subgrade路基,地基curvature弯曲, (几何)曲率, gradient 坡度,倾斜度, ditch沟;壕沟,水道,渠道, turnout产量,产额,4) Materials材料Gravel 砂砾,碎石,石子dirt污物;烂泥;灰尘,泥土, soil土,泥土,土壤, asphalt沥青;柏油, cement水泥, concrete 混凝土的, 具体的Rubble毛石,块石, flag薄层,薄层砂岩, stone石,石头,石块, slab石板,厚板,平板;厚片, grout薄泥浆;水泥浆,石灰浆lime石灰, cement水泥,胶结材料Bottom layer底层/intermediate layer中间层/upper layer上层/top layer顶层The Empire帝国/ the Dark Ages黑暗时代/ the Middle Ages中世纪Topograph地形图/topography地形;地形学;地形测量学/topographic地形(学)上的Turnpike收费公路/toll system收费系统/ETC –Electronic Toll Collection电子收费3. Highway types公路类型Freeway高速公路;高速干道: freeway/expressway高速公路Controlled access highway控制进入高速公路Conventional highway传统的公路Highway公路;干道: arterial highway干线公路/bypass旁道,旁路/divided highway双向分隔行驶的公路;双向之间有分车带的公路/through street通过街/through highway通过公路Parkway停车道Scenic highway风景公路Street街,街道: Cul-de-Sac street小路尽头的街道/dead end street尽头街道/frontage street正街/local street地方街道Road路,道路,公路: frontage road街面道路/local road地方道路/toll road 收费道路(bridge桥,桥梁, tunnel隧道,地道)1. Technical termsCross section横断面/ Profile 纵断面(图),剖面(图)/Plan view平面视图Longitudinal section/ Transverse section 纵/横截面Lane/ Multilane/ Multiple lanes行车/多通道/多车道Roadway巷道Through traffic/ Local traffic/ Traffic island通过交通/交通/交通岛MedianRoadbed/ curb/ shoulder路基/ 路边,(人行道旁的)镶边石,边栏/肩Right-of-way 公路用地Surface course表面过程/ Wearing course磨损过程/ Basecourse基层/Flexible pavement柔性路面/ Rigid pavement刚性路面Cohesion凝聚力/ cohesive有粘着力的;凝聚性的;有结合力的Roadbase基层/ Subbase基层Crack/ Break/ Stress/ Distress裂纹/打破/压力/痛苦,窘迫的Modulus of elasticity弹性模量2. Main points1 Geometric Cross Section on Highway几何截面的公路上1.1 Lane巷1.2 Median位数1.3 Outer separation外部分离1.4 Roadbed路基1.5 Roadside路边1.6 Roadway巷1.7 Shoulder肩1.8 Travel way旅行方式Unit 4 Asphalt and Mix Asphalt沥青和沥青混合Technical termsMix/ mixture/ compound混合/混合物/复合Petroleum石油/ crude oil原油/ gasoline汽油/ diesel柴油/ gas可燃气;煤气;沼气/ petrol汽油Bitumen沥青/ bituminous 沥青的;含沥青的/ pitch搭(帐篷);扎(营)/asphalt沥青/ asphaltum沥青/ tar焦油;柏油,沥青Hydrocarbon碳氢化合物/ hydrau液Destructive distillation破坏性蒸馏Disulfate硫酸盐Emulsify乳化/ emulsion乳胶;乳状液/Dilute稀释/ diluents稀释剂/solvent有溶解力的/ cutter stock刀具的库存Oxygen氧,氧气/ oxidize使氧化/ oxidation 氧化(作用)/ oxidization 氧化/ dioxide二氧化物/ hydrogen氢/ sulphur硫磺Waterproof不透水的,防水的Acid/ alkalis/ salt/ alcohol酸/碱/盐/酒精Liquid/ fluid/ liquor/ liquefy液/液/液/液化Semi-solid半固态/ hard-brittle solid硬脆性固体/ water-thin liquidBinder粘结剂,捆缚(或包扎)用具;绳索,带子/ sticky粘的;涂有粘胶物质的;泥泞的/ viscous粘的/ adhesive粘的;粘着的;有粘性的/ viscosity粘质;粘性Hard-surface硬地/ hard-face硬面/ hard-surfaced road坚硬的路Tack coat粘结层Cut-back asphalt稀释沥青Penetration. 针入度Versatility多样化的/ flexibility易曲性;适应性,灵活性;弹性/ durability耐久性/ ability能力;能耐/ capacity 容量, 能力,才能,接受能力,理解力/ compactability紧/Rigidity 坚硬;严格;刚直;死板/ strength强度;(酒等的)浓度/ hardness硬性;硬度/ elastic 有弹性的,有弹力的/ rigid坚硬的;坚固的;不易弯曲的/ modules of elasticity弹性模数/Cold temperature cracking低温开裂/ warm temperature rutting高温车辙Performance 履行;实行;完成,演出/ grade等级;级别;阶段/ Performance Grading性能分级(PG)Aggregate使聚集Bin (贮藏谷物等的)箱子,容器,仓/ dryer干燥剂,催干剂/ pug mill练泥机/ drum鼓状物;圆桶/ tank (贮水,油,气等的)柜,罐,箱,槽latex乳汁;乳胶sulphur extended asphalt硫磺沥青混合料sulphur dioxide二氧化硫hydrogen sulphide硫化氢1. Technical termsStability 稳定,稳定性/ stabilize 使稳定,使稳固/availability有效;有益;可利用性/ available 可利用的,可得到的/Sense 感觉;意识;观念/ sensitivity敏感性;感受性Solubility 可溶性, 溶解度/ soluble 可溶解的/ solution溶解,解答;解决(办法); /Rutting车辙/ rust锈,铁锈;(脑子等的)迟钝;(能力等的)荒废/ tar焦油;柏油,沥青Roadstone石马路By-product副产品/ coke 焦,焦炭,焦煤/ coal gas 煤气/ kerosene煤油,火油Residue 残余,剩余,滤渣,残余物/ residual残留的;剩余的/ remain剩下,余留strengthen 加强;增强;巩固/ strength 力,力量, 强度/ deformation 毁坏;变形/ deform 使变形/ reform 改革,革新,改良elastic有弹性的,有弹力的/elasticity 弹性;弹力/plastic可塑的,塑性的/plasticity 可塑性;适应性;柔软性/chipping碎屑permanent永久的,永恒的;永远的, 固定性的;常在的/ temporary 临时的;暂时的,一时的poise使平衡;使平稳/ Dyne达因/ Newton 牛顿stiffness劲度/ stiff 硬的,僵直的,僵硬的/ stress压力;紧张;应力/ strain拉紧;拖紧;伸张/ fatigue疲劳,劳累Deduce演绎,推论/ deduction 扣除,减除,推论;演绎(法/ composition 构成;构图;成分penetration test渗透测试/ softening point test软化点试验/ ring and ball test环和球试验internal diameter 内部直径/ external diameter外部直径sample样品,样本;例子,实例/ water bath水浴arbitrary反复无常的,任性多变的;独断的,专制的/ pragmatic 实际的;实干的/ pragmatism 实用主义/fluidity 流动性;流状;易变(性)/ segregate分离/ susceptibility敏感性/ susceptible 敏感的, rheology流变学/ rheological 流变rolled asphalt碾压沥青synthetic polymer 合成聚合物/ additive附加的epoxy resin环氧树脂impart to传授/ deter威慑住,吓住;使断念/ deterrent 威慑的;遏制的container terminal集装箱码头/ airfield apron机场停机坪Unit 5 Cement and Concrete水泥和混凝土A. Technical termsCement水泥,胶结材料/ chalk粉笔/ matrix矩阵Cementitious 水泥Calcium钙/ calciferous钙/Lime石灰/ limestone石灰石Silica 硅土,二氧化硅/ silicate硅酸盐Aluminium铝/ alumina氧化铝/ aluminate铝sinter烧结coarse clinker粗水泥熟料calcium aluminate 铝酸钙/ calcium silicate硅酸钙hydrate水合物/ cure治疗/Work工作/ workable 可使用的,可运转的/ workability可使用性Shrinkage收缩/ swell膨胀/ swellable膨胀/ swellability溶胀strain拉紧;拖紧;伸张grout薄泥浆;水泥浆constituent组织/ ingredient成分/ component组成Thermal热的;热量的/ thermal coefficient of expansion热膨胀热系数Compressive strength抗压强度/ tensile strength拉伸强度Compressive压缩/ tensile 拉伸Reinforce加固/ reinforcing bar钢筋/ reinforced concrete钢筋混凝土Stiffness劲度Vulnerable脆弱的Efflorescence 风化/ weather天气/ weathering气候Column 柱/ volume体积/Pressure vessel压力容器1. Technical termsPrestress预应力Crew船员Contract 合同/ contractor承包商Resident engineer驻地工程师Inspector检查员Structural member结构构件Steel strand钢绞线Bridge girder桥主梁Pier cap墩帽Deck slab甲板Pretensioning先张法/ post-tensioning后张法Precast预制/ cast -in-place就地浇Box girder箱梁Predetermined stress预定压力Stretch拉伸/ relax 放松/ shorten 缩短/ induce诱导Duct 输送管;导管/ conduit导水管,导管/ pipe管,导管,输送管/ tube 管;筒/ canal管,道/ vessel 容器Anchor 锚/ Anchorage锚具corrosion腐蚀;侵入rebar钢筋/ reel卷轴tarpaulin 防水油布condense压缩/ condensation冷凝require要求/ requisite必要/ prerequisite不可缺的;事先需要的uniform 制服/ uniformity统一vary使多样化/ various不同的;各种各样的,形形色色的/ variable / variationcamber deflection 上弯翘起挠度creep蠕变Standard Specification 标准规范/ Sampling Guide取样指南Couple一双(对)/ coupler联结器Stir搅拌/ stirrup镫筋,箍筋/Web网络/ flange凸缘/ rib肋,肋骨/ side form形式Flimsy脆弱的Galvanize strip steel 镀锌带钢/ sheet steel钢片Weld焊接;熔接;锻接,使结合/ seam 缝;接缝,缝合处,接合口;裂缝Helical螺旋/helically螺旋形的/ helicopter直升飞机Contra-flexure反向弯曲/ parabolic curve抛物曲线Uplift隆起的Wobble摆动/ twist扭转;扭弯;旋转/ spall破碎Case事实,实例,案件/ Encase装箱Increment增加;增加量;增额Slack松弛的,不紧的;不严的Pressure gauge压力表/ load cell负载单元/ stretcher担架/ dynamometer动力计;力量计;握力计Dead end 尽头;困境/ stressing end强调结束Elongation measurement伸长测量法Spliced strand拼接链Tendon筋腱、预应力钢索、钢筋束Inject注射/ eject 逐出,轰出;喷射,吐出/ injection /ejectionVent通风孔,排气孔/ slut邋遢女子/ inlet valve入口阀Unit 6 Measuring Technology and Equipment测量技术及设备A. Technical termsSurvey测量/ surveyor测量员Horizontal/vertical/plumb/slope/ plan/plane垂直/水平/垂直/倾斜/计划/飞机Elevation高程Odometer 测距仪Circumference 圆周;周长/ circle圆/ circulate流通;传播/ circular 圆Tape带子,线带Tacheometry 视距测量Stadia 视距Theodolite /transit 经纬仪Rod 测杆、标尺Telescope望远镜Topographic survey地形测量Topographic mapping地形测绘Hydrographic mapping水文图Electronic distance measurement(EDM)电子距离测量Terrain地形;地势Electromagnetic电磁(体)的Velocity/speed速度/速度Band传送带;带,细绳Infrared/ ultraviolet 红外/紫外Module/ modulate模块/调节Passive/ active/ positive/ negative 被动/主动/积极/消极Perpendicular/ parallel 垂直/平行Clinometer / abney 测斜仪/水准仪Sextant六分仪/ sexagesimal 六十分数Compass界线;周围,圆规Protractor 量角器Unit 8 The Subgrade Design and Construction Technology路基设计与施工技术A. Technical termsUppermost / top soil 最上面/土壤Embankment / excavation路堤/挖掘Fill / cut填充/切割Foundation建立,创办;基础;基本原则Organic / inorganic / organ / organization有机/无机/机关/组织Imported soil / borrow sources进口/借用来源Dense / density / condense密/密度/凝结Moisture content含水量Classification分类;分级Differ / different / difference / differentiate不同的/不同/不同/分化Cobble / gravel / sand / silt / clay卵石/砾/砂/泥/粘土Fine grained soil细粒土Dry mass / dry matter干质量/干物质Semi-weathered半风化In-situ在原处;在原位置Infer推断Resilient modulus 回弹模量Manual 手的;手工的;用手操作的;体力的Backcalculate 反演计算Overlay覆盖;铺在...上面;镀;压倒Prototype原型;标准;模范Frost冰冻/ thaw融化,融解/ heave举起,拉起, /Guide / guidance / guideline指导/指南/指导方针Expansive soil 膨胀土Bentonitic shale 膨胀土页岩Soil modifier土壤改良剂Culvert阴沟;地下电缆管道;涵洞桥Form / formulate / formulation / formula形式/制定/公式化;规划;构想/公式Title——Highway Subgrade Construction公路路基施工1. Technical termsExcavation挖掘;开凿Borrow pit借土坑Sidestep回避Borrow ditch借沟Dispose / disposal处理/处置Surplus material剩余材料Approach接近,靠近Conforming / nonconforming material合格/不合格材料Top soil / superficial coatTurf 草皮土壤/表层stake mark危险标记subgrade edge路基边缘top of slope / foot of slope顶坡/坡脚berm 便道peg 桩facility 设施silt 泥沙,淤泥/ scour 冲刷permeable有渗透性的;可穿过的/ torrent 急流earthwork 土方量over-excavation挖blast 爆炸,爆破/ fetch soil 取土transverse 横向的;横断的;横切的/ longitudinal excavation纵向开挖hauling牵引backfill 回填self-dumper 自卸车segment / segmental部分;线段side wall侧壁rock filling填石/ borrow filling 借方填筑compaction machine压实机/ rolling passes碾压cut off切断;中断provided 以...为条件;假如(that)bench长凳;长椅;法官席;法官;法庭tamp / tamper 夯具Unit 9 Pavement Design and Construction Technology 路面设计与施工技术A. Technical termsSkid / skidding 打滑/集材/拖曳Free-draining自由排水Standing water站在水Imported/treated material进口/处理材料Platform平台,台Bound/unbound material绑定/绑定材料Bitumen-based material沥青基材料Unbound granular material松散颗粒材料Ingress入口Regular / Regularity /regulate定期/规律/调节Permeable / impermeable / permeability 渗透/渗透/渗透impermeability不渗透性Texture组织,结构,质地Tolerance忍耐,忍耐力;宽容,宽大Deep-seated 根深蒂固/由来已久/顽固的Remedy / remedial / diagnose药物/治疗/诊断Propagate / Propagation / propaganda路床面宣传/传播/宣传Formation 形态,结构Deem 认为Clear-cut 轮廓鲜明的/ 清晰的/ 皆伐Onset 开始Design life设计寿命Roadwork道路工程Discount折扣;打折扣1. Technical termsMacadam碎石Impetus 动力/推动Rubble瓦砾Avenue / street / road 路/街/路Stone Matrix Asphalt (SMA) 沥青玛蹄脂碎石混合料Sprayer喷雾器Gritting machine 铺砂机Mixing plant搅拌设备Spreader散布者;(涂奶油用的)奶油刀Paver摊铺机Roller 滚动物;滚柱;滚筒;滚轴Road binder道路粘合剂Guss asphalt/concrete 摊铺地沥青/混凝土Stone quarry 采石场Wear and tear磨损Unit 10 Highway Alignment Design 公路线形设计A. Technical termsHorizontal/vertical alignment水平/垂直对齐Configuration. 结构;表面配置Safe operating speed安全操作速度Sight distance视距Highway capacity / traffic volume公路容量/交通量tangent正切;切线Superelevation 超高Rate of grade change速度等级变化Horizontal/vertical curve 水平/垂直曲线criteria(判断、批评的)标准,准则,尺度simple circular curve简单的圆曲线spiral transition curve 螺旋缓和曲线compound curve 复合曲线sharp curve锐曲线sharp/slight curvature 急剧的;锋利的;尖的/轻微弯曲swept path扫路centerline. 中线runoff决赛;终投票outline外形;轮廓minimum curve radii最小曲线半径long / length / lengthen长/长度/延长reverse curve 反向曲线superelevation transition超高过渡providing / provided (that) 假如…urban / suburban / rural城市/郊区/农村stopping/passing sight distance停止/超车视距multiple decision point多个决策点sight line瞄准线middle ordinate 中距/正矢no-passing zone禁区1. Technical termsGrade line分数线Crest/sag vertical curve嵴/凹形竖曲线Auxiliary lane辅助车道Maximum/minimum grade最高/最低等级Detrimental有害的warp使变形;使弯曲;Standpoint观点Climbing lane爬坡车道Offset补偿;抵消Ramp exit gore匝道出口高尔Headlight beam前照灯光束Encroach侵犯Ponding water积水Water table地下水位Pavement box路面盒Prism棱柱(体),角柱(体)Balance point平衡点Unit 14 Bridge Introduction 桥梁简介A. Technical termsPipeline / cycle track / pedestrian管道/周期轨道/行人Superstructure / substructure上层建筑/结构Single storey building单层建筑物Handrail扶手/ guardstone守护石Bearing 关系,关联;举止,风度;体态Plan view平面视图Pier墩,墩/abutment桥墩;桥基;桥台;毗邻;接界处/wingwall翼墙/approach接近,靠近/apron 裙板Rivetment 固结Masonry石造工程;石造建筑Retaining wall挡土墙Subsoil / Earthfill地基/填土Well foundation 井筒基础Footpath小径,(乡间)小路Parapet wall 栏杆、女儿墙Topple 倾覆Buckle 受弯屈服Arch bridge 拱桥/Three Gorge三峡/ span墩距;跨度slab bridge / 板桥T-beam T梁bow string girder bridge 弓弦梁桥suspension bridge吊桥Cable-stayed bridge斜拉桥steel bridge桥梁钢rainbow bridge彩虹桥Niagara river 尼亚加拉河Shutter百叶窗;活动遮板Head room头部空间Tie beam系梁Thrust用力推;刺;插;塞;挤出(路)Arch rib 拱肋Suspender / stay吊带/保持Tower塔;塔楼;高楼Orthotropic deck正交异性桥面Continuous girder连续梁Three-dimensional三维Stiffening girder加劲梁Transverse/longitudinal/radial bracing横向/纵向/径向支撑Moment of inertia转动惯量Truss bridge桁架桥Rigid frame bridge刚构桥Axial force轴向力Portal frame门架Clearance清除,清扫;出空;空地;空隙Spandrel braced arch 腹拱、肩拱Trussed arch桁架拱桥1. Technical termsInclement恶劣的Investigation / FBI调查/调查局Reconnaissance侦察;勘察;事先考查Feasibility可行性;可能性Right angle直角Erosion侵蚀;腐蚀Whirl / cross current / scour旋转/交叉电流/冲刷render给予,提供;使得,使成为inerodable strata地层High Flood Level(HFL)高水位Discharge排出(液体,气体等);允许...离开;释放;解雇Waterway航道Pier thickness桥墩厚度High flood大洪水Current meter电流表Velocity rod流速杆Free board自由板Catchment area汇水盆地,汇水区域Watershed转折点;关键时刻;流域Boring 钻孔、钻探Rainfall降雨,下雨;降雨量Span墩距;跨度Culvert涵洞桥Ordinary Flood Level(OFL)普通洪水水位Low Water Level(LWL)低水位Afflux 雍水Head room头部空间Viaduct 高架桥Trestled bent栈桥弯曲Causeway 漫水桥Submersible潜水Cross-drainage横向排水Temporary/ permanent bridge临时/永久性桥Deck/through/semi-through bridge上/下/中承式桥Formation 建造、路床面Pony小马;小型的东西Headway进展Vertical lift bridge 垂直升降桥Bascule bridge开合式桥Swing bridge 旋开式桥Box/pipe/arch culvert盒/管/拱涵Cast iron铸铁;生铁Bearing capacity承载能力Earth cushion地垫Unit 15 Bridge Superstructure桥梁上部结构A. Technical termsWeight limit重量限制supplier供应者Span Arrangement跨径布置Bridge Project Manager大桥项目经理Redundant多余的,过剩的specification 规格;明细单;详细计划书Fracture critical骨折的关键Collapse倒塌;崩溃,瓦解Ability / Inability能力/能力Bolt螺栓stringer纵梁;纵桁span / single-span / multi-span跨度/单跨/连栋continuous spans连续跨越steel/concrete superstructure bridge钢筋混凝土桥梁rolled beam 辊压梁cover plate盖板welded plate girder焊接板梁box girder 箱梁truss扎,捆,缚,绑;用构架支撑cable stayed斜拉tied arch 系杆拱桥vertical/inclined web垂直/斜腹板top/bottom flange plate顶部/底部法兰盘hollow rectangular/trapezoidal section空心的矩形/梯形截面aesthetics美学torsional resistance扭阻力curved bridge曲线桥stringer / floor beam斯特林格/地板梁top/bottom chord顶部/底部和弦vertical/diagonal member垂直/斜成员lateral/sway bracing侧/斜撑axial load/force轴向载荷/力量concrete deck / steel girder混凝土桥面/钢大梁Box beam箱梁Strongback定位板Fabricate / fabrication / fabricator制造/生产/制造Balanced cantilever平衡悬臂Strain gage应变计Homogeneity / non-homogeneity 均匀/非均匀性Erratic 不定、无规律的Deflection偏斜;偏向;挠曲;偏度;挠度Mid-span / middle span / side span跨中/ 中跨/ 边跨Yield出产;结出(果实);产生(效果,收益等)Non-linearity非线性的Prescribe规定,指定Limiting strain极限应变flexure弯曲;弯曲部分,曲率neutral axis中性轴centroid距心lever arm杠杆臂resultant compression/tension/force/load由此产生的压缩/拉伸/ /载荷equivalent stress block等效应力块investigation / FBI调查/调查局under-reinforced / over-reinforced少筋/ 超筋stress intensity应力强度product产品,产物;产量;出产nomenclature学术用语;术语表Unit 16 Bridge Substructure桥梁下部结构A. Technical termsCap-and column type pier柱式墩帽Strut 支撑、加固T-type pierT型Hammerhead pier锤头码头Taper逐渐减少;逐渐变弱Rectangular/oval column矩形或椭圆柱Wall type pier墙式墩Strut and tie model拉压杆模型footing(稳固的)地位;基础single column/multi-column单/多列concentrated load集中荷载wall abutment墙台caisson 沉箱gutter 槽stepped/terraced wall configuration加强/梯田壁配置stub abutment直式桥台integral abutment整体式桥台wingwall 翼墙bridge seat 桥座backwall 背墙stem柄,把,杆approach slab 搭板contour轮廓;轮廓线;外形;结构1. Technical termsSpread footing扩展基础Cofferdam 围堰Negative skin friction / downdrag force负摩/下拉荷载力Friction pile摩擦桩End bearing pile端承桩Drilled caisson钻孔灌注Constructibility可构成性Embedment嵌入Casing箱;盒Confinement curbing约束控制Wire mesh basket 网笼Gabion 枝条筐streambed河床Unit 20 ——Construction Management and Cost Estimate 施工组织与概预算A. Technical termsSchedule 进度表Event / task / action /activity活动/任务/行动/活动Ultimate disposition 最后安排Expense / expenditure / cost费用/费用/成本Recast重铸Uncertainty不确定;不确信;易变;不可靠Production rate / productivity生产效率/生产力Gantt chart / bar chart甘特图表/图表Superimpose叠加Critical Path Method (CPM)关键路径法Critical task关键任务Logic diagram逻辑图Superintendent监督人,监管者Activity-on-the-arrow (AOA)活动箭Activity-on-the-node (AON)节点活动Dummy activity 虚拟工序Early start time / late start time开始时间早/晚开始时间Early finish time / late finish time最早完成时间/最晚完成时间Double line / bold line / color highlighted line / dash line双行线/颜色/大胆突出线/虚线Float / total float / free float 浮动/总时差/自由浮动interfering float 时差Preceding activity / succeeding activity前面的活动/后继活动Title——Construction Cost Estimate 建筑成本预算1. Technical termsBreakdown故障,损坏,崩溃;破裂Parameter / parametric参数/参数Direct/indirect cost直接/间接成本Finance / budget财务/预算Craftman钱包Scheme / schematic计划/方案Unit cost/price单位成本/价格Lump sum总金额Site visit网站访问Checklist核对用的清单Take-off脱下;移去;起飞;休假Overhead / profit / bond费用/利润/债券Escalation / contingence升级/偶然Shift 转移;替换,推卸Craft行业,职业Ownership and operating cost所有权和经营成本Dozer / bulldozer推土机/推土机Vendor 卖主Tax税;税金Markup 售价Similarity / dissimilarity相似/相异Unit 21 Tendering and Contract 投标与合同A. Technical termsTender敏感的,嫩的;柔软的;温柔的,体贴的Bid / bidder招标投标Agreement同意,一致;协定,协议Bond结合力;联结,联系Insurance保险;保险契约Makeup补足;编造;组成Owner / architect / designer / supplier / party业主/建筑师/设计师/供应商/派对Public agency / private company公共部门/私营公司Responsibility职责,任务;义务,负担General/special/technical provision一般/特殊/技术discretion判断力;辨别力;谨慎,考虑周到addenda补遗;追加;附加物Title——Types of construction contracts and bonds建筑合同和担保的类型1. Technical termsNegotiation / renegotiation协商/谈判Arctic / Antarctic北极/南极Cost plus a fixed fee成本加固定费用Cost plus a percentage成本加百分比Incentive刺激;鼓励;动机Thrifty 节约Innovation革新,改革,创新Compensate补偿,赔偿;酬报Procure 获得、实施Popular / popularity / population流行/流行/人口Recoup 收回surety / obligee担保/债权人forfeiture 没收、罚金penal / penalty刑法/处罚underwrite / constraint认购/约束default 违约option选择;选择权;选择自由lien 扣留权、留置权。

桥梁设计外文翻译文献桥梁设计外文翻译文献(文档含中英文对照即英文原文和中文翻译) 原文:A Bridge For All CenturiesAn extremely long-and record setting-main span was designed for the second bridge to across the Panama Canal in order to meet the owner’s requirement that no piers be placed in the water.Because no disruption of canal traffic was permitted at any time,the cable-stayed bridge of cast-in-place cancrete was carefully constructed using the balanced-cantilever method.In 1962 ,the Bridge of Americas(Puente de las America) opened to traffic,serving as the only fixed link across the Panama Canal .The bridge was designed to carry 60,000 vehicles per day on four lanes, but it has beenoperating above its capacity for many years.Toalleviate bottlenecks on the route that the bridge carries over the canal-the Pan-AmericanHighway(Inter-American Highway)-and promotegrowth on the western side of Panama,the country’s Ministry of Public Works(Ministerio de Obras Publicas,or MOP )decided to build a new highway systerm linking the northern part of Panama City,on the eastern side of the canal, to the town of Arraijan,located on the western side of the canal.The Centennial Bridge –named to commemorate 100 years of Panamanian independence-has noe been constructed and, when opend, will carry six lanes of traffic. This cable-stayed bridge of cast-in-place cancrete features a main span of 420m,the longest such span for this type of bridge in the Western Hemisphere.In 200 the MOP invited international bridge design firms to compete for the design of the crossing, requesting a two-package proposal:one techinical, the other financial. A total of eight proposals were received by December 2000 from established bridge design firms all over the world. After short-listing three firms on the basis of the technical merits of their proposals, the MOP selected T.Y.Lin International, of San Francisco, to prepare the bridge design and provide field construction support based on the firm’s financial package.The Centennial Bridge desige process was unique and aggressive,incorporating concepts from the traditional design/build/bid method, the design/build method , and the sa-called fast-track design process.T o complete the construction on time-that is ,within just 27 months-the design of the bridge was carried out to a level of 30 percent before construction bidding began, in December 2001.The selected contractor-the Wiesbaden,Germany,office of Bilfinger Berger,AG-was brought on board immediately after being selected by the MOP ,just as would be the case in a fast-track approach. The desige of the bridge was then completed in conjunction with construction , a process that id similan to desige/build.The design selected by the client features two single-mast towers,each supporting two sets of stay cables that align in one vertical plane.Concrete was used to construct both the towers and the box girder deck,as well as the approach structures.The MOP , in conjunction with the Panama Canal Authority,established the following requirements for the bridge design :A 420m,the minimum length for the main span to accommodate the recently widened Gaillard Cut,a narrow portion of the canal crossing the Continental Divide that was straightened and widened to 275m in 2002;A navigational envelope consisting of 80m of vertical clearance and 70mof horizontal clearance to accommodate the safe passage of a crane of World War 11 vintage-a gift from the /doc/e5324711c381e53a580216fc700abb 68a982ad21.html ernment that is used by the Panama Canal Authority to maintain the canal gates and facilities;A roadway wide enough to carry six lanes of traffic, three in each direction;A deck able to accommodate a 1.5m wide pedestrian walkway;A design that would adhere to the American Association of State Highway and Transportation Official standard for a 100-year service life and offer HS-25 truck loading;A structure that could carry two 0.6m dianeter water lines;A construction method that would not cross the canal at any time or interrupt canal operationa in any way.Because of the bridge’s long main span and the potential for strong seismic activity in the area,no single building code covered all aspects of the project.Therefore the team from T.Y. Lin International determinded which portions of several standard bridge specifications were applicable and which were not.The following design codes were used in developing the design criteria for the bridge,it is standard specifications for highway bridge ,16th ed,1996It was paramount that the towers of the cable-stayed structucture be erected on land to avoid potential ship collision and the need to construct expensive deep foundation in water. However, geological maps and boring logs produced during the preliminary design phrase revealed that the east and west banksof the canal, where the towers were to be located, featured vastly different geologicaland soil conditions. On the east side of the canal, beneath shallow layers of overburden that rangs in consistency from soft to hard, lies a block of basalt ranging from medium hard to hard with very closely spaced joint.The engineers determined that the basalt would provide a competent platform for the construction of shallow foundation for tower, piers, and approach structures on this side of bridge.The west side, however,featured the infamous Cucaracha Formation, which is a heterogeneous conglomerate of clay shale with inclusions of sandstone, basalt,and ash that is prone to landslide. As a sudsurface stratum the Cucaracha Formation is quite stable,but it quickly erodes when exposed to the elements. The engineers determined that deep foundations would therefore be needed for the western approach structure,the west tower,and the western piers.Before a detailed design of the foundationa could be developed,a thorough analysis of the seismic hazards at the site was required,The design seismic load for the project was developed on the basis of a probabilistic seismic hazard assessment that considered the conditions at the site.Such an assessment establishes the return period for a given earthquake and the corresponding intensity of ground shaking in the horizontal directtion in terms of an acceleration response spectrum.The PSHA determined two dominant seismic sources: a subduction source zone associated with the North Panama Deformed Belt capable of producing a seimic event as strong as 7.7MW,and the Rio Gatun Fault, capable of producing an event as strong as 6.5MW.The 7.7MW NPDB event was used as the safety evluationearthquake,that is,the maximum earthquake that could strike without putting the bridge out of service.The damage to the bridge would be minor but would require some closures of the bridge.The 6.5MWRio Gatun Fault event was used as the foundational evaluation earthquake,a lower-level temblor that would cause minimal damage to the bridge and would not require closures.For the FEE load case,the SEE loading was scaled back by two-thirds.The FEE is assumed to have a peak acceleration of 0.21g and a return period of 500 years; the probability that it will be exceeded within 50 years is 10 pencent and within 100 years,18 persent.The SEE is assumed to have a peak acceleration of 1.33g and a return period of 2,500 years;the probability that it will be exceeded within 50 years is 2 pencent and within 100 years,4 persent.Because of uncertainty about the direction from which the seismic waves would approach the site, a single response spectrum-a curve showing the mathematically computed maximum response of a set of simple damped harmonic oscillators of different natural frequencies to a particular earthquake ground acceleration-was used to characterize mitions in two mutually orthogonal directions in the horizontal plane.To conduct a time-history analysis of the bridge’s multiple supports,a set of synthetic motions with three components-longitudinal,transverse,and vertical-was developd using an iterative technique.Recorded ground motions from an earthquake in Chile in 1985 were used as “seed”motions for the sythesis process.A time delay estimate-that is,an estimate of the time it would take for the motions generated by the SEEand FEE earthquakes to travel from one point to the next-was create using theassumed seismic wave velocity and the distance between the piers of the /doc/e5324711c381e53a580216fc700abb 68a982ad21.html ing an assumed was velocity of approximately 2.5km/s,a delay on the order of half a second to a secondis appropriate for a bridge 1 to 2km long.Soil-foundation interaction studies were performed to determine the stiffness of the soil and foundation as well as the seismic excitation measurement that would be used in the dynamic analyses.The studieswere conducted by means of soil-pile models using linear and nonlinear soil layera of varying depths.The equivalent pile lengths in the studies-that is, the lengths representing the portions of a given pile that would actually be affected by a given earthquake-induced ground motion-ranged from2to10m.In such a three-dimensional model,there are six ways in which the soil can resist the movement of the lpile because of its stiffness:throngh axial force in the three directions and through bending moments in three directions.Because the bridge site contains so many layers of varying soil types,each layer had to be represented by a different stiffness matrix and then analyzed.Once the above analyses were completed,the T.Y.Lin International engineers-taking into consideration the project requirements developedby the owener-evaluated several different concrete cable-stayed designs.A number of structural systems were investigated,the main variables,superstructure cross sections,and the varying support conditions described above.The requirement that the evevation of the deck be quite high strongly influenced the tower configuration.For the proposeddeck elevation of more than 80m,the most economical tower shapes included single-and dual-mast towers as well as “goa l post”towers-that is,a design in which the two masts would be linked to each other by crossbeams.Ultimately the engineers designd the bridge to be 34.3m wide with a 420mlong cable-stayd main span,two 200mlong side spans-one on each side of the main span-and approach structures at the ends of the side spans.On the east side there is one 46m long concrete approach structure,while on the west side there are three,measuring 60,60,and 66m,for a total bridge length of 1,052m.The side spans are supported by four piers,referred to,from west to east,as P1.P2,P3,and P4.The bridge deck is a continuous single-cell box girder from abutment to abutment; the expansion joints are located at the abutments only. Deck movements on the order of 400 mm are expected at these modular expansion joints Multidirectional pot bearings are used at the piers and at the abutments to accommodate these movements.The deck was fixed to the two towers to facilitate the balanced-cantilevermethod of construction and to provide torsional rigidity and lateral restraint to the deck.. Transverse live loads, seismic loads, and wind loads are proportionally distributed to the towers and the piers by the fixity of the deck to the towers and by reinforced-concrete shear keys located at the top of P1, P3, and P4. The deck is allowed to move longitudinally over the abutments and piers. The longitudinal, seismic, live, and temperature loads are absorbed by what is known as portal frame structural behavior, whereby the towers and the deck form a portal-much like the frame of a door in a building-that acts in proportion to therelative stiffness of the two towers.As previously mentioned, the presence of competent basalt on the east side of the site meant that shallow foundations could be used there; in particular, spread footings were designed for the east tower, the east approach structure, and the east abutment. The west tower, the west approach structure, and the western piers (P2 and P3), however, had to be founded deep within the Cucaracha Formation. A total of 48 cast-in-drilled-hole (CIDH) shafts with 2 m outer diameters and lengths ranging from 25 to 35 m were required. A moment curvature analysis was performed to determine the capacity of the shafts with different amounts of longitudinal steel rebar. The results were plotted against the demands, and on the basis of the results the amount of required longitudinal reinforcing steel was determined to be 1 percent of the amount of concrete used in the shafts. The distribution of the longitudinal reinforcing steel was established by following code requirements, with consideration also given to the limitations of constructing CIDH piles with the contractor’s preferred method, which is the water or slurry displacement method.A minimum amount of transverse steel had to be determined for use in the plastic regions of the shaft-that is, those at the top one-eighth of eighth of each shaft and within the shaft caps, which would absorb the highest seismic demands. Once this amount was determined, it was used as the minimum for areas of the shafts above their points of fixity where large lateral displacements were expected to occur. The locations of the transverse steel were then established by following code requirements and by considering the construction limitations of CIDH piles. The transverse steel was spiral shaped.Even though thief foundation designs differed, the towers themselves were designed to be identical. Each measures 185.5 m from the top of its pile cap and is designed as a hollow reinforced-concrete shaft with a truncated elliptical cross section (see figure opposite). Each tower’s width in plan varies along its height, narrowing uniformly from 9.5 m at the base of the tower to 6 m at the top. In the longitudinal direction, each pylon tapers from 9.5 m at the base to about 8 m right below the deck level, which is about 87 m above the tower base. Above the deck level the tower’s sections vary from 4.6 m just above the deck to 4.5 m at the top. Each tower was designed with a 2 by 4 m opening for pedestrian passage along the deck, a design challenge requiring careful detailing.The towers were designed in a accordance with the latest provisions of the ATC earthquake design manual mentioned previously (ATC-32). Owing to the portal frame action along the b ridge’s longitudinal axis, special seismic detailing was implemented in regions with the potential to develop plastic hinges in the event of seismic activity-specifically, just below the deck and above the footing. Special confining forces and alternating open stirrups-with 90 and 135 degree hooks-within the perimeter of the tower shaft.In the transverse direction, the tower behaves like a cantilever, requiring concrete-confining steel at its base. Special attention was needed at the joint between the tower and the deck because of the central-plane stay-cable arrangement, it was necessary to provide sufficient torsional stiffness and special detailing at the pier-to-deck intersection. This intersection is highly congested with vertical reinforcing steel, the closely spaced confining stirrups of the tower shaft, and the deck prestressing andreinforcement.The approach structures on either side of the main span are supported on hollow reinforced-concrete piers that measure 8.28 by 5 m in plan. The design and detailing of the piers are consistent with the latest versions of the ATC and AASHTO specifications for seismic design. Capacity design concepts were applied to the design of the piers. This approach required the use of seismic modeling with moment curvature elements to capture the inelastic behavior of elements during seismic excitation. Pushover analyses of the piers were performed to calculate the displacement capacity of the piers and to compare them with the deformations computed in the seismic time-history analyses. To ensure an adequate ductility of the piers-an essential feature of the capacity design approach-it was necessary to provide adequate concrete-confining steel at those locations within the pier bases where plastic hinges are expected to form.The deck of the cable-stayed main span is composed of single-cell box girders of cast-in-place concrete with internal, inclined steel struts and transverse posttensioned ribs, or stiffening beams, toward the tops. Each box girder segment is 4.5 m deep and 6 m long. To facilitate construction and enhance the bridge’s elegant design, similar sizes were used for the other bridge spans. An integral concrete overlay with a thickness of 350 mm was installed instead of an applied concrete overlay on the deck. In contrast to an applied overlay, the integral overlay was cast along with each segment during the deck erection. Diamond grinding equipment was used to obtain the desired surface profile and required smoothness. The minimum grinding depth was 5 mm.A total of 128 stay cables were used, the largest comprising83 monostrands. All cables with a length of more than 80 m were equipped at their lower ends with internal hydraulic dampers. Corrosion protection for the monostrands involved galvanization of the wires through hot dipping, a tight high-density polyethylene (HDPE) sheath extruded onto each strand, and a special type of petroleum wax that fills all of the voids between the wires.The stays are spaecd every 6 m and are arranged in a fan pattern.They are designed to be stressed from the tower only and are anchored in line with a continuous stiffening beam at the centerline of the deck.The deck anchorage system is actually a composite steel frame that encapsulates two continous steel plates that anchor the stays and transfer the stay forces in a continuous and repetitive system-via shear studs-throuthout the extent of the cable-supported deck (see figure above).A steel frame was designed to transfer the stays’horizontal forces to the box girders through concrete-embedded longitudinal steel plates and to transfer the boxes’ vertical forces directly through the internal steel struts.This innovative and elegant load transfer system made rapid construction of the concrete deck segments-in cycles of three to five days-possible.In addition to the geotechnical and seismic analyses,several structural analyses were performed to accurately capture the behavior of this complex bridge.For the service-load analysis,which includes live,temperature,and wind loads,the engineers used SAP2000, a computer program created and maintained by Computers &Structrures,Inc.(CSI), of Berkeley, California.This program was selected for its ability to easily model the service loads and to account for tridimensional effects.For correct SAP2000 modeling,it was necessary to define a set of initial stresses on the cables, deck, and tower elements to capture the state of the structure at the end of construction.For the calculation of those initial stresses, a series of iterations on the basic model were performed to obtain the stay forces in the structure that balance both the bridges’s self-weight and the superimposed dead loads. Once the correct cable stiffness and stress distribution were obtained, all subsequent service-load analyses were performed to account for the geometric stiffness and P-deltaeffects, which consider the magnitude of an applied load (P) versus the displacement(delta).The seismic analysis of the structure was conducted using the SADSAP structural analysis program, also a CSI product, based on the differences in seismic motions that will be experienced at the different piers based on their distance from one another.This sophisticated program has the capability to model inelastic behavior in that flexural plastic hinges can readily be simulated.Plastic hinge elements were modeled at varous locations along the structure where the results from a preliminary response spectrum analysis in SAP2000 indicated that inelastic behavior might be expected.The time-history records pertaining to the site were used in conjunction with the SADSAP model to botain a performace-based design of the piers and towers and to verifh the design of several deck stctions.As previously mentioned,the construction contractor was brought on board earl y in the process;the company’s bid of $93 million was accepted and the project was awarded in March 2002.To guarantee unimpeded canal traffic,the bridge had to be constructed without the use of the canal waters.To accomplish this, the cast-in-place main-pain superstructure was erected using the balanced-cantilever method.Form travelers were usedto accomplish this, and they were designed in such a way that they could be used as an integral part of the pier tables’falsework.After assembly on the ground, two 380 Mg form travelers were raised independently into the pier table casting position and connected to each other.After an initial learning period, the contractor was able to achieve a four-day cycle for the casting of the cantilevered deck segments, an achievement that greatly enhanced the ability of the team to construct the project on time.Once the side-span and mai-span closures were cast, the travelers had to be removed from locations adjacent to the towers rather than over water so as to avoid any influence on canal traffic.To save time, the towers approach structure, and piers were built simultaneously.The approach viaducts were designed and built using the span-by-span erection method by means of an underslung suupport truss.The east viaduct span was built first and the support truss was then removed and transferred to the west side so that it could be used to build the three spans of the west viaduct, one span at a time.The bridge construction was completeed in Auguse 2004 at a cost of approximately $2,780 per square meter.Its opening awaits the completion of the rest of the highway it serves.跨越世纪之桥1962年,横跨巴拿马运河的美国大桥作为仅有的固定连接开放交通车。