(完整word版)单元机组主控系统(中英对照翻译)

- 格式:doc

- 大小:29.01 KB

- 文档页数:2

妙文翻译公司翻译样稿One concept – the whole system for all functions一个概念–具有所有功能的整体系统Power units动力单元The power unit is the heart of the turbine, supplying the power necessary to operate pitch, yaw and braking systems and providing backup in case of power failure, ensuring a safe stop with no risk of damage.Our hydraulic power units are designed with reliabilty, ease of maintenance and a wide operating temperature range in mind.动力单元是风轮机的心脏,为浆距、偏航和制动系统的运行提供必要的电力,并在断电时提供备用措施,保证安全停止,无损坏危险。

我们的液压动力单元在设计时充分考虑了可靠性、维护方便性及宽温度范围。

Added life寿命增加Parker filtration technology extends the life and increases the reliability of wind turbines by using environmental solutions.In addition to a wide range of hydraulic filters, lube filters and reservoir accessories, Parker offers you the global leader in fluid condition monitoring with the Laser CM portable particle counter.A comprehensive range of quality products to cover all your needs!通过应用环境条件解决方案,Parker过滤技术延长了风轮机的寿命并提高了可靠性。

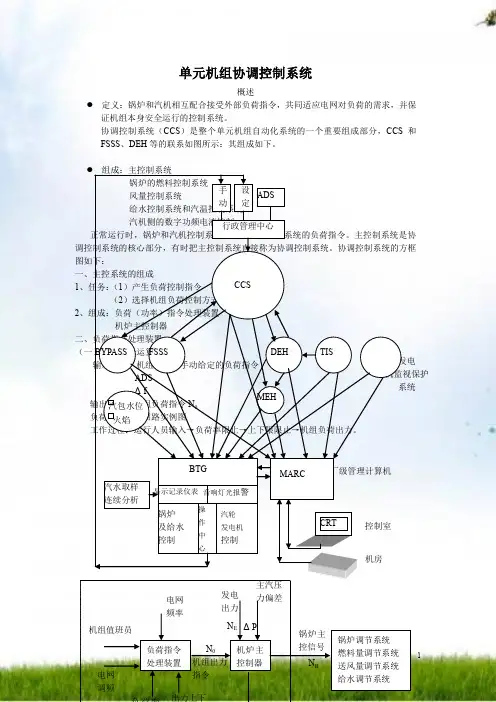

单元机组协调控制系统概述●定义:锅炉和汽机相互配合接受外部负荷指令,共同适应电网对负荷的需求,并保证机组本身安全运行的控制系统。

协调控制系统(CCS)是整个单元机组自动化系统的一个重要组成部分,CCS和FSSS、DEH等的联系如图所示:其组成如下。

(二)机组最大可能出力运算回路 ● 定义:考虑各种辅机的运行状况而计算出的机组出力。

● 机组最大可能出力运算回路原理图 (三)机组的允许最大负荷运算回路 ● 定义:考虑锅炉燃烧器等不可测故障时,使锅炉的实际出力达不到机组功率指令N 0的要求,而设置的机组负荷运算回路,简称返航回路。

● 返航回路的工作过程: (1)正常运行:N 允许=N 最大,4接通6 (2)大于5%的燃烧率,积分器2的输出为机组允许最大负荷信号。

运算过程示意图如下:图3 机组最大可能出力运算回路原理图图4 机组允许最大负荷运算过程示意图 U 2、U 3U 4、U 6分别为积分器2、反向器3、偏置器4和6的输出信号 τ0出现6%燃烧率偏差τ1监控器31动作时间,切换器5将燃烧率偏差信号直接送入偏置器4 τ2燃烧率偏差信号=1%,机组允许最大负荷信号停止下降,机组稳定 τ3、故障排除,燃烧率偏差信号<1%,积分器输入为正值,直至允许最大出力等于最大 (出力变化率限止) MW AM R .LMT ∑ ≯≮ ΔH/L f(x)P ± AM CPTR (计算机方式) (热应力控制) CPTR MW H/A 运行人员要求负荷指令 增 减 a a →跟踪方式c 负荷急 减警报 A B Δf(频率偏差) 增 减 出力下限值 出力上限值 机组负荷指令1、主控系统组成:负荷指令运算回路;机炉主控制器2、工作方式:7种● 基本方式(BASE )● 锅炉跟随1方式(BLR FLW1)● 锅炉跟随2方式(BLR FLW2)● 汽机跟随1方式(TURB FLW1)● 汽机跟随2方式(TURB FLW1) ● 以锅炉跟随为基础的协调控制方式(COORD BF )● 以汽机跟随为基础的协调控制方式(COORD TF ) (一)负荷指令运算回路(LDC(Load Demand Computer))结构原理1、功能:将各种负荷要求加工成机组实际可以接收的指令。

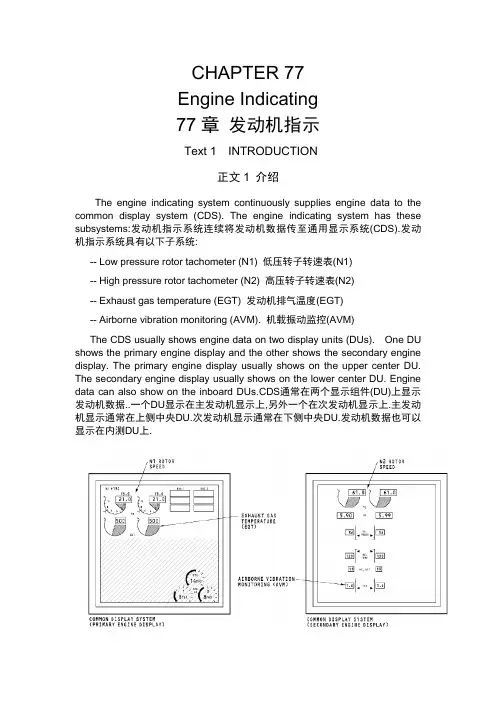

单元77(中英⽂对照版)CHAPTER 77Engine Indicating77章发动机指⽰Text 1 INTRODUCTION正⽂1 介绍The engine indicating system continuously supplies engine data to the common display system (CDS). The engine indicating system has these subsystems:发动机指⽰系统连续将发动机数据传⾄通⽤显⽰系统(CDS).发动机指⽰系统具有以下⼦系统:-- Low pressure rotor tachometer (N1) 低压转⼦转速表(N1)-- High pressure rotor tachometer (N2) ⾼压转⼦转速表(N2)-- Exhaust gas temperature (EGT) 发动机排⽓温度(EGT)-- Airborne vibration monitoring (AVM). 机载振动监控(AVM)The CDS usually shows engine data on two display units (DUs). One DU shows the primary engine display and the other shows the secondary engine display. The primary engine display usually shows on the upper center DU. The secondary engine display usually shows on the lower center DU. Engine data can also show on the inboard DUs.CDS通常在两个显⽰组件(DU)上显⽰发动机数据..⼀个DU显⽰在主发动机显⽰上,另外⼀个在次发动机显⽰上.主发动机显⽰通常在上侧中央DU.次发动机显⽰通常在下侧中央DU.发动机数据也可以显⽰在内测DU上.Text 2 Related Components正⽂2相关部件The engine indicating system shows these parameters for each engine:发动机指⽰系统显⽰每个发动机的以下参数:-- Low pressure rotor speed (N1)低压转⼦转速(N1)-- High pressure rotor speed (N2)⾼压转⼦转速(N2)-- Exhaust gas temperature (EGT) 排⽓温度(EGT)-- Engine vibration. 发动机振动Electronic Engine Control 发动机电⼦控制The electronic engine control (EEC) receives an analog input from these engine sensors:发动机电⼦控制(EEC)从以下发动机传感器接收模拟输⼊:-- N1 speed sensor N1转速传感器-- N2 speed sensor N2转速传感器-- EGT probes (T49.5). EGT探头(T49.5)The EEC changes the analog signals to digital signals. The EEC sends the digital signals on an ARINC 429 data bus to the display electronics units (DEU)s.EEC将模拟信号转换为数字信号..EEC将信号从ARINC429数据汇流条⾄电⼦显⽰组件(DEU).Airborne Vibration Monitoring Signal Conditioner 机载振动监控信号调节器The airborne vibration monitoring (AVM) signal conditioner calculates and monitors vibration levels of each engine.机载振动监控(AVM)信号调节器计算和监控每个发动机的振动⽔平.The AVM signal conditioner receives analog input from these engine sensors: AVM信号调节器从以下发动机传感器接收模拟输⼊:-- N1 speed sensor N1转速传感器-- N2 speed sensor N2转速传感器-- Number 1 bearing vibration sensor 1号轴承振动传感器-- Fan frame compressor case vertical vibration (FFCCV) sensor.风扇结构压⽓机机匣垂⾯(FFCCV)振动传感器The DEUs and the flight data acquisition unit (FDAU) receive AVM information through an ARINC 429 data bus.DEU和飞⾏数据采集组件从通过ARINC429数据汇流条接收AVM信息DEUs DEUThe DEUs use digital input from the EEC to show these engine parameters on the common display system (CDS):DEU利⽤来⾃EEC的信号输⼊来在通⽤显⽰系统(CDS)上显⽰以下发动机参数:-- N1-- N2-- EGT.The DEUs use their analog N1 and N2 signals as alternate inputs when the EEC does not have electrical power. EGT shows only when the EEC has electrical power.DEU在EEC未通电时使⽤模拟的N1和N2信号作为备份输⼊.EGT只有在发动机通电时才能显⽰.Text 3 ENGINE TACHOMETER SYSTEM正⽂3 发动机转速计系统The engine tachometer system supplies the engine low pressure rotor (N1) and the engine high pressure rotor (N2) speed signals to these components:发动机转速计系统将发动机低压转速和发动机⾼压转速信号送⼊以下部件: -- Electronic engine control (EEC)发动机电⼦控制(EEC)-- Display electronics units (DEUs) 电⼦显⽰组件(DEUs)-- Engine airborne vibration monitoring (AVM) signal conditioner.发动机机载振动监控(AVM)信号调节器General Description概述The EEC receives two analog signals from each speed sensor. The EEC changes these analog signals to digital signals.EEC从每个转速传感器接收模拟信号,EEC将这些模拟信号转换为数字信号The EEC uses the two signals for channel A and channel B operation. Each channel sends data to each DEU on an ARINC 429 data bus.EEC使⽤这两个信号以进⾏A,B通道操作.每个通道将数据送⼊ARINC 429数据汇流条上的每个DEU. Usually, the DEUs use input from the EEC to show N1 and N2 on the common display system (CDS). The DEUs can also use input directly from the speed sensors to show N1 and N2.DEU通常使⽤来⾃EEC的输⼊来在CDS上显⽰N1和N2。

画面一casting platform (2)一.Ladle turrent 大包转台 (2)dle turrent大包转台 (2)B.旋转驱动 (2)二.Ladle cover manipulator包盖机械操作手 (3)A.Status ok状态正常 (3)B.Swivel valve旋转阀 (3)C.Lifting valve提升阀 (3)三.Ladle weighting 大包承重 (3)四.Ladle slide gate大包滑动水口 (4)dle slide gate大包滑动水口 (4)B.Enable operation操作使能 (4)五.Ladle slag detection下渣检测 (4)六.Tundish temperature 中包温度 (5)七.Tundish cars中包车 (5)八.Tundish weight中包称重 (6) weigh cast position浇注位时净重 (6)B.System ready系统准备就绪 (6)九.SENEC水口 (6)A.SENCE on水口开 (6)B.Distance lowered to top of mold与结晶器顶部的顶部距离降低 (6)十.Mold level control结晶器液位控制 (7)十一.Mold width adjustment结晶器调宽 (7)十二.Mold oscillator结晶器震动 (7)十三.Mold espert 结晶器专家 (8)十四.mold powder feeder 结晶器保护渣喂入系统 (8)画面二.casting platform 浇注平台 (8)画面三.Strand overview 流总览 (8)画面四.Operation modes操作模式 (9)1.Maintenance 维护模式 (9)2.Inset插入模式 (9)3.Jog mode 点动模式 (10)4.Check mode 检查模式 (10)5.prepare to cast mode 浇注模式准备 (11)6.cast mode 浇注模式 (11)7.Clear mode 尾坯模式 (12)画面七.primary cooling face 一次冷却面 (12)1.mold cooling faces 结晶器冷却面 (12)A.Loose side 大面 (12)B.fixed side 固定面 (13)C.Left side 左侧 (13)D.Right side 右侧 (13)E.Mold level sensor flow measurement ok 结晶器液位传感器流量测量正常 (13)画面八.spray cooling common 气雾冷却 (13)1. Spray cooling common 气雾冷却 (13)2.Strand1 一流 (13)3.strand2 (同上)二流 (14)4.图上单词 (14)画面九.Primary cooling faces-common 一次冷却面 (14)1.Mold cooling common 结晶器冷却水 (14)2.mold cooling-strand1 一流结晶器冷却水 (14)画面十.Closed machine cooling 闭路机冷却水 (15)画面十一.Spray cooling water 气雾冷却水 (15)1.strand 1 一流 (15)A. Spray cooling water 气雾冷却水 (15)B.Spray cooling air 气雾冷却空气 (15)C.air controller(zone2-4/5-8/9-10空气控制器) (15)D.emergency cooling事故冷却水 (16)2.strand 2 (同上)二流 (16)画面十二.ASTC-segment clamping扇形段轻压下 (16)其他.element 元素名称 (17)画面一casting platform一.Ladle turrent 大包转台dle turrent大包转台dle turrent ok大包转台正常2.Emergency drive selected选择事故驱动3.Emergency turn active事故旋转启动dle locked大包上锁5.Turn collision released旋转碰撞释放dle exchange active大包更换启动7.Synchronisation同步的跟踪系统8.Encoder ok编码器正常B.旋转驱动1.Drive ready驱动准备就绪2.Emergency stop事故急停3.Main drive selected ok主驱动选择正常4.Drive enable驱动使能5.Move active移动启动6.Turn brake open旋转抱闸打开7.Drive fault驱动故障8.Load position接包位9.Casting position浇注位二.Ladle cover manipulator包盖机械操作手A.Status ok状态正常Emergency stop 事故急停Cover包盖Collision active碰撞启动Position位置Emergency tralve valve enable事故行走阀使能Emergency lift valve enable事故提升阀使能B.Swivel valve旋转阀Swivel drive ok旋转驱动正常C.Lifting valve提升阀Arm 1叉臂1三.Ladle weighting 大包承重Weighting processor称重处理器Tare not done arm叉臂皮重称量未完成Ladle in cast position大包在浇注位Ladle open time 大包打开时间Ladle in load position 大包在接包位Ladle gross weight大包毛重Ladle open大包打开Ladle net weight大包净重Tare done in cast浇注位皮重称量完成Ladle tare weight大包皮重Ladle not done in cast浇注位皮重称量未完成Tare done皮重称量完成Steel net weight钢水净重Cover tare weight ladle包盖皮重Load cells cooling压缩空气冷却风四.Ladle slide gate大包滑动水口dle slide gate大包滑动水口Emergency close on OS2 not active主控室事故未关闭Emergency close on OS5 not active大包转台事故关闭未启动Emergency close on LC116 not active事故关闭未启动Emergency procedure not active事故程序未启动Emergency accumulator pressture ok事故蓄能器压力正常Working pressure ok工作压力正常Pressure line open压力管线打开Hydraulie ok液压正常Arm in cast or area叉臂在浇注位或空区Tundish in cast area中包车在浇注位Tundish weight actual中包实际重量Tundish weight setpoint中包重量设定值B.Enable operation操作使能Pressure release压力释放Open valve大开阀Close valve关闭阀Fast open valve快速打开阀Fast close valve快速关闭阀Ready to work in cast position浇注位准备就绪Ready to auto自动模式准备就绪Auto mode自动模式Auto close active自动关闭模式启动LSG selected选择大包滑动水口五.Ladle slag detection下渣检测Automatic close of LSG in cast of slag alarm on下渣检测报警时滑动水口自动关闭Ready准备就绪Active启动Fault故障Ladle slag detect alarm下渣检测报警Acture sensor signal measuring fault实际传感器信号测量故障Automatic on自动化启动Actual sensor signal实际传感器信号Sensor signal alarm limit传感器信号报警极限六.Tundish temperature 中包温度Sporadic systerm ready偶测系统准备就绪Sporadic measurement progress偶测进程Measured temperature测量温度Last sporadic measurement最后一次偶测Continuous temperature measurement连续测温Continuous temperature in cast area浇注区的连续测温Continuous measurement TC1 ready中包车1连续测温准备就绪Continuous measurement TC1 in progress中包车1连续测温正在进行Continuous measurement TC2 ready 中包车2连续测温准备就绪Continuous measurement TC2 in progress中包车2连续测温正在进行七.Tundish cars中包车Collision protection碰撞保护Emergency stop事故急停Emergency run active事故运行驱动Tundish lopsided LS s171中包倾斜S171Emergency cast position S111事故浇注位S111Emergency preheat position S112事故预热位S112Tundish lifted (LS S122)中包提升Collision protection lift提升碰撞保护Collision protection travel运行碰撞保护Synchronization LS S101同步极限开关Lift ready提升准备Lifting collision LS S101提升碰撞Lifting collision released提升碰撞释放Lopsided released倾斜释放Lifting cvlinders synchronized提升液压缸同步Auto elevation action自动提升启动SENEC on水口开Cylinder 1 position液压缸1位Average elevation匀速提升Shifting forward向前位移Shifting backward 向后位移Drive ready驱动准备Main drive selected选择主驱动Travel collision released行走释放碰撞Brake opened抱闸打开Position位置八.Tundish weight中包称重 weigh cast position浇注位时净重Tundish not raisedTundish in cast area中包未提升Tundish no movement中包未移动Weighting processor ok称重处理器正常Weighting stable称重稳定B.System ready系统准备就绪Weighting processor ok称重处理器正常Tare done皮重称量完成Tundish weight above max max中包称重重量超高Tundish weight above max中包称重重量高Weight in range称重重量在范围内Tundish weight below min中包称重重量超低Tundish weight below min min中包称重重量超低Tundish net weight中包净重Tundish tare weight 中包皮重Tundish gross weight中包毛重九.SENEC水口A.SENCE on水口开Expire time循环时间Immersion depth strand 1一流侵入深度Average elevation of tundish car中包车匀速上升B.Distance lowered to top of mold与结晶器顶部的顶部距离降低Upper limit for SENEC movement水口移动距离上限Lower limit for SENEC movement水口移动距离下限Actual nozzle length实际水口长度SENEC expire time水口循环时间Step hight设定高度Step cycle time minutes设定循环时间十.Mold level control结晶器液位控制Mole模式Actual实际Setpoint设定值Actual stopper position实际塞棒位置Setpoint stopper position塞棒位设定值Stopper syetem ok塞棒系统正常Min one of the alarms is active至少一个报警启动Min one of the faults is active至少一个故障启动Min one of the warning is active至少一个警告启动十一.Mold width adjustment结晶器调宽Mold ok结晶器正常Decrease cast speed to set value降低浇注速度到设定值Cast speed setpoint浇注速度设定值Stop caster停止铸机Decrease negative strip factor降低负滑脱系数Mode模式Adjustment buffer status调节缓冲器状况Mode width结晶器宽度Left taper左侧锥面Left taper pere 左面锥度Right taper右面锥面Right taper pere右面锥度Alarm active报警启动Warning active警报启动Fault active故障启动Mold thickness结晶器厚度十二.Mold oscillator结晶器震动Mold模式Actual non sinus实际非正弦Frequency频率Alarm active报警启动Strok震动Fault active故障启动Strok SP振幅设定值Waring active 警报启动十三.Mold espert 结晶器专家Cold calibration active 冷态调节启动Alarm active 发生真报警Watchdog ok 看门狗正常Status 浇注状态Speed reduction 速度减少十四.mold powder feeder 结晶器保护渣喂入系统Ready 准备就绪Running 运行Container ok装保护渣Feeding rate喂入速度画面二.casting platform 浇注平台Preheater ready 预热器准备就绪Preheater feeder ok 预热器状态良好Preheater heating on 预热器加热开Measurement fault 测量故障Heating time 加热时间Heating temperature 加热温度Ladle shroud pressure 大包水口压力Tundish car 1中包车1Setpoint设定值Actual 实际值画面三.Strand overview 流总览Strand tracking 跟踪准备就绪Dummy bar tracking active 引锭杆跟踪启动Hot strand 1/2tracking active 热流1/2追踪启动Event tracking 1/2/3/4/5 acting 事件追踪1/2/3/4/5启动Dummy bar successfully synchronized 引锭杆同步成功Hot strand 1/2 successfully synchronized 热流1/2同步成功Hot strand 1/2 end tranking active 热流1/2尾坯追踪启动Stop drives due to synchronization fault pulse 由于同步脉冲故障停止驱动Dummy bar tracking encoder in contact found 引锭杆追踪编码器在应用Dummy bar tracking encoder in group found 引锭杆追踪编码器在组中Hot strand 1/2 tracking encoder in contact found热流1/2追踪编码器在应用Hot strand 1/2 tracking encoder in group found热流1/2追踪编码器在组中Ladle boundary 大包分界线DB heat tracking 引锭杆头追踪DB tail tracking 引锭杆尾部追踪Tracking value to be displayed in status line 追踪数值显示在数据线上Actual实际值Previous 前一个值Strand length流长度Moved length移动长度Residual length 剩余长度End of cast 浇注结束画面四.Operation modes操作模式1.Maintenance 维护模式Withdrawal drives stopped 拉矫机驱动停止2.Inset插入模式Mold oscillate stopped结晶器震动停止Mold width at miximum 结晶器宽度到最大值Segments 1-4 ready 扇形段1-4准备就绪Withdrawal drives remote selected远程选择拉矫机驱动Withdrawal drives ready 拉矫机驱动准备就绪Withdrawal drives stopped segment1-4 1-4扇形段拉矫机驱动停止Pinch roll 1-4 open 夹紧辊1-4打开Dummy bar hoist not lowered 引锭杆卷扬未下降Dummy bar guide lowered 引锭杆导向下降Dummy bar disconnection roll lowered 脱引锭辊下降Dummy bar car in mold position 引锭杆车在结晶位Dummy bar car ready 引锭杆车准备就绪Lubrication system segment and mold and bender 扇形段、结晶器、弯曲段润滑系统开Segment and tunout hydraulic 扇形段和出坯液压Strand tracking system ready 流跟踪系统准备就绪Emergency stops push buttons healthy 急停按钮状态正常Hot strand has cleared segment 4 前4段无热坯Dummy bar centering done 引锭杆对中完成Maintenance or clear or check selected 选择检修、尾坯、检查模式3.Jog mode 点动模式Mold oscillation stopped 结晶器震动停止Segments1-4 resdy 扇形段1-4准备就绪Withdrawal drives remote selected 远程选择拉矫机驱动Withdrawal drives ready拉矫机驱动准备就绪Withdrawal drives stopped segments1-4 stopped 扇形段1-4拉矫机驱动停止Pinch roll segment 1-2 closed with dummy bar pressure扇形段1-2主动辊以引锭杆压力压下Lubrication system segments and mold and bender on扇形段、结晶器、弯曲段润滑系统开Segment and runout hydraulic 扇形段和出坯液压Strand tracking system ready 流跟踪系统准备就绪Hot strand has cleared segment 扇形段无热坯Emergency stops push buttons healthy 急停按钮状态正常Insert selected 选择插入模式4.Check mode 检查模式Mold oscillator stopped 结晶器震动停止Mold width at maximum 结晶器宽度到最大ASTC all segment ready 所有扇形段准备就绪Withdrawal drives remote selected 远程选择拉矫机驱动Withdrawal drives ready 拉矫机驱动准备就绪Withdrawal drives stopped 拉矫机驱动停止Pinch roll segment 1-2-3 closed with dummy bar pressure扇形段1-2-3主动辊以引锭杆压力压下Pinch roll 4-14 open 夹紧辊4-14 打开Dummy bar hoist ready 引锭杆卷扬准备就绪Dummy bar hoist not lowered 引锭杆卷扬未下降Dummy bar hoist auto selected 选择引锭杆卷扬自动模式Dummy bar be guide lowered 引锭杆导向下降Dummy bar guide auto selected 引锭杆向导自动模式Dummy bar disconnection roll lowered 脱引锭辊下降Lubrication system segments on 扇形段润滑系统开Segments and runout hydraulic 扇形段和出坯液压Strand tracking system ready 流跟踪系统准备就绪Emergency stops push buttons healthy 急停按钮状态正常Torch approach table ready 火焰接近辊台准备就绪Torch approach table auto selected 选择火焰接近辊台自动模式Jog or maintenance selected 选择点动或维护模式5.prepare to cast mode 浇注模式准备mold oscillator stopped 结晶器震动停止segment 1-4 ready 扇形段1-4 准备就绪Pinch roll segment 1-2-3 closed with dummy bar pressure扇形段1-2-3主动辊以引锭杆压力压下Casting platform hydraulic 浇注平台液压Segment and runout hydraulic 扇形段和出坯液压Strand tracking system ready 流跟踪系统准备就绪‘Emergency stops push buttons healthy 急停按钮正常Casting not in progress 浇注未完成Maintenance or jog or cast selected 选择维护、点动浇注模式6.cast mode 浇注模式Steam exhaust fans 1-2 ready and running 排风扇1,2准备就绪并运行Width adjustable mold ready 结晶器调宽准备就绪Mold clamped 结晶器夹紧Mold oscillator ready 结晶器震动准备就绪Mold oscillator stopped 结晶器震动器停止Mold oscillator remote selected 远程选择结晶器震动器Mold level measurement system healthy 结晶器液位测量系统状态正常ASTC all segment ready 所有扇形段准备就绪Pinch roll segment 1-2-3 closed with dummy bar pressure扇形段1-2-3主动辊以引锭杆压力压下Pinch roll 4-5 open 主动辊4-5打开Withdrawal drives remote selected 远程选择拉矫机驱动Withdrawal drives ready 拉矫机驱动准备就绪Withdrawal drives rolls1-5 stopped 拉矫机驱动1-5停止Dummy bar hoist ready 引锭杆卷扬准备就绪Dummy bar hoist not lowered 引锭杆卷扬未下降Dummy bar hoist auto selected 选择引锭杆卷扬自动模式Dummy bar be guide lowered 引锭杆导向下降Dummy bar disconnection roll lowered 脱引锭辊下降Torch cutting machine ready 火焰切割机准备就绪Torch tables ready辊台准备就绪All lubrication systems on 所有润滑系统开Main hydraulic system on 主液压系统开Tundish stopper hydraulic 中包塞棒液压Oscillator and WAM hydraulic 震动和调宽液压Segment and runout hydraulic 扇形段和出坯液压Mold cooling ready 结晶器冷却水准备就绪‘Spray cooling ready 二冷水准备就绪Closed machine cooling ready and on 闭路机冷水准备就绪并打开Low voltage power distribution healthy 低压电源配电柜状态良好USV system healthy USV系统装填良好Emergency stops push buttons healthy 急停按钮状态良好Strand tracking system ready 流追踪系统准备就绪Operation mold prepare to cast active 操作模式浇注启动7.Clear mode 尾坯模式Start of cast event occurred 浇注时间发生启动Clear end of cast active 浇注启动尾坯模式结束Operation mode cast active 操作模式浇注启动画面七.primary cooling face 一次冷却面1.mold cooling faces 结晶器冷却面A.Loose side 大面Flow in range 流量在范围内Temperature inrange 温度在范围内Temperature measurement ok 温度测量正常Delta temperature in range 温差在范围内B.fixed side 固定面C.Left side 左侧D.Right side 右侧E.Mold level sensor flow measurement ok 结晶器液位传感器流量测量正常Mold level sensor flow above lower limit 结晶器液位传感器流量在低限上Inlet hand valve opened手动阀入口打开Outlet hand valve opened 手动阀出口打开画面八.spray cooling common 气雾冷却1. Spray cooling common 气雾冷却Inlet preasure in range 入口压力在范围内Inlet preasure measurement ok入口压力测量正常Emergency cooling not active 事故冷却水未启动Emergency tank ok 事故水箱正常Emergency tank level measurement ok 事故水箱液位测量正常2.Strand1 一流Supply ready 供给准备就绪Spray cooling strand 1 ready 一流气雾冷却水准备就绪Emergency inlet shut-off valve closed J001 事故截止阀入口关闭Emergency inlet shut-off not fault J001 事故截止阀无故障Emergency inlet hand valveopened-Z1 1260 事故手动阀入口打开3.strand2 (同上)二流4.图上单词Tank refilling valve 水箱再充满阀Emergency water supply 事故水供给Water treatment plant 水处理站Drain to scale flume 排放到水槽Runout area cooling torch cutting machine 切割区冷却水火焰切割机Process air for mist cooling 气雾冷却空气画面九.Primary cooling faces-common 一次冷却面1.Mold cooling common 结晶器冷却水Inlet preasure in range 入口压力在范围内Inlet preasure measurement ok入口压力测量正常Emergency cooling not active 事故冷却水未启动Emergency tank ok 事故水箱正常Emergency tank level measurement ok 事故水箱液位测量正常WTP ump ready and running 泵准备就绪并运行2.mold cooling-strand1 一流结晶器冷却水Supply ready 供给准备就绪Spray cooling strand 1 ready 一流气雾冷却水准备就绪Emergency inlet shut-off valve closed J001事故截止阀入口打开Emergency inlet shut-off not fault J001 事故截止阀无故障Emergency inlet hand valveopened-Z1 1260 事故手动阀入口打开3.Mold cooling-strand2 二流结晶器冷却水4.Closed machine cooling common闭路机冷却水画面十.Closed machine cooling 闭路机冷却水All roller flow in range所有辊流量在范围内All roller flow measurement ok所有辊流量测量正常All bearing flow in range所有轴承流量在范围内All bearing flow measurement ok所有轴承流量测量正常画面十一.Spray cooling water 气雾冷却水1.strand 1 一流A. Spray cooling water 气雾冷却水Flow measurement ok 流量测量正常Flow deviation in range 流量偏差在范围内Scale flume hand valve open Z1255 水槽手阀打开Backwash filter not clogged 回洗过滤器未堵塞TCM shut-off valve not fault J1201 火焰切割机冷却水截止阀无故障TCM flow in range 火焰切割机冷却水在范围内TCM flow measurement ok 火焰切割机冷却水测量正常Zone 9XR shut-off valve not fault 9区右侧截止阀无故障Zone 9XR flow in range 9区右侧流量在范围内Zone 9XR flow measurement ok 9区右侧流量测量正常Zone 9XL flow in range 9区左侧流量在范围内Zone 9XLflow measurement ok 9区左侧流量测量正常B.Spray cooling air 气雾冷却空气Pressure in range 压力在正常范围内Pressure measurement ok 压力测量正常Pressure deviation in range 压力偏差在范围内C.air controller(zone2-4/5-8/9-10空气控制器)SP 设定值Quality 质量Level1/21级2级Deviation 偏差Min sp 最小设定值Position 位置Max sp 最大设定值Manual 手动Dev h 偏差高Operator操作员Dev hh 偏差高高Master 主控制器Emerg pos 事故位Simulate 模拟V alve position 阀位D.emergency cooling事故冷却水2.strand 2 (同上)二流画面十二.ASTC-segment clamping扇形段轻压下No communication between master and segments controllers 主控制器和扇形段控制器间无通讯The temperature at the segment controller exceeds the warning level 扇形段控制器温度超过设定值At least one position sensor dose not transmit actual gap position 至少有一个位置传感器不能传送实际辊缝值The emergency stop push button is pressed 已拍急停Freeze by tolerance1 公差1 产生制动Segment controller in manual modes 扇形段控制器在手动模式Individual freezer 单个制动Pressure positioning压力Segment not calibration 扇形段未校验Wrong parameter 错误参数Soft clamping active 轻压下启动Setpoint gap inner入口辊缝设定值Setpoint gap outer 出口辊缝设定值Actual gap inner left side 入口左侧实际辊缝值Actual gap inner right side 入口右侧实际辊缝值Actual gap outer left side 出口左侧实际辊缝值Actual gap outer right side 出口右侧实际辊缝值其他.element 元素名称Unit 显示值的单位Movement conditions移动条件Registry sever 重启服务器System observer 系统监视服务器Show grade specification显示钢种特殊成分Strand aborted 流失败。

机舱设备主海水冷却泵MAIN COOL. S. W. P.惰气装置洗涤冷却水泵INERT GAS UNIT SCRUBER C.W.P 舱底、压载、消防总用泵BILGE/B./FIRE GEN. S. PUMP洗舱泵TANK CLEANING PUMP燃油输送泵F.O. TRANSF. PUMP柴油输送泵D.O. TRANSF. PUMP舱底水油水分离器BILGE OIL W. SEPERATOR辅锅炉给水泵FEED PUMP FOR EXH. GAS BOILER 辅机滑油分油机供给泵FEED PUMP FOR A/E L.O. PUR主机滑油分油机供给泵FEED PUMP FOR M/E L.O. PUR艉管滑油泵STERN TUBE L.O. PUMPCPP液压油动力单元CPP HYD OIL POWER UNIT油渣泵SLUPGE PUMP主滑油泵MAIN L.O. PUMP空冷机清洁泵AIR COOLER CLEAN PUMP空冷机清洁柜AIR COOLER CLEAN TK.滑油输送泵L.O. TRANSF. PUMP造水机喷射器泵F.W. GEN. EJECT. PUMP甲板水封海水泵DECK SEAL S.W. PUMP中央冷却器CENTER COOLER接地装置EARTHING DEVICE日用舱底泵DAIL Y BILGE PUMP附加电流阴极保护箱ADDITIONAL CA THODE PROTECT防海生物控制箱MGPS CONTROL BOX柴油分油机供给泵FEED PUMP FOR D.O. PUR主机MAIN ENGINE发动机A/E主机滑油自清滤器M/E L.O. AUTO FILTER主机缸套水预热泵PREHEAT PUMP FOR CL YDINER WA TER OF M/E 控制空气干燥器CONTROL AIR DRYER空压机滑油柜AIR COMPR. L.O. TK.主空压机MAIN AIR COMPRESSOR主机滑油冷却器M/E L.O. COOLER造水机F.W. GENERATOR主机缸套水预热器M/E JACKET W. PREHEATER低温淡水冷却泵L.T.F.W. PUMP辅机柴油供给泵A/E D.O. SUPPLY PUMP辅锅炉燃油加热器F.O. HEATER FOR AUX. BLR辅锅炉燃油单元F.O. UNIT FOR AUX. BLR主辅机燃油供油单元F.O. SUPPL Y UNIT FOR A/E&M/E燃油分油机F.O. PURIFIER柴油分油机D.O. PURIFIER主滑油分油机MAIN L.O. PURIFIER辅机滑油分油机A/E L.O. PURIFIER分油机室抽风机FAN FOR PUR. ROOM大气冷凝器ATMOS. CONDENSER凝水柜及检油箱CONDENSATE TK&INSPECT TK. 生活污水处理装置SEW AGE TREATMENT UNIT辅空气瓶AUX AIR RESERVOIRCPP液压油储藏柜CPP HYD OIL STORAGE TK.分油机清洁池WASH BASIN IN PURIFIEK ROOM 发电机预热单位A/E PREHEAT UNIT应急空压机EMEGENY COMPRESSOR阴极保护控制箱MICC CONTROL UNIT主海水泵变频器MSP STARTER焚烧炉INCINERATOR辅锅炉AUX BOILER冷藏压缩机PROV REF. COMPRESSOR热水柜HOTW. HYDR. TK. UNIT淡水压力柜F. W. PRESS. TK.艉管滑油重力柜STERNTUBE GRA VTTY. OIL TK. 主配电板MAIN SWITCH BOARD汽缸油输送泵CYL OIL TRANS. PUMP集控室CONSOLE焚烧炉柴油D.O. TK. FOR INCINERATOR焚烧炉日用柜WASTE OIL SERV. TK. INCIN焚烧炉沉淀柜WASTE OIL SETTLNG TK INCINERATOR主机排气阀阀杆研磨机M/E EXHVGRIND MACHINE FOR V ALVE SPINDLE 日用淡水消毒器DOMESTIC F.W. STERILIZED工作空气瓶WORK AIR RESERVIOR电工试验板ELEC. TEST PANEL虎钳VICE工作台WORK BENCH机舱行车CRANE OF E/R饮水机FOUNTAIN变压器TRANSFORMER备用缸盖SPARE CYL. COVER备用活塞SPARE DISTON汽缸油测量柜CYL. OIL MEASURE TK.备用排气阀NO.1 SPARE EXH. V.电焊机WELDER电焊机工作台WELDER TABLE车床LATHE砂轮机GRINDER工作台WORKING BENCH立式钻床VERTICAL DRILLER空调压缩机AIR COND. REF. COMP.WORK AIR COMP.硬化滤器REHARDENING FILTER工作空气干燥器WORK AIR DRYER机修间抽风机FAN FOR WORK ROOM冷藏压缩机制冷备用瓶REF. BOTTLE FOR REF. COMP.主机油头试验台TEST PLATFORM FOR M/E F.O. NOZZLE辅机油头试验台TEST PLATFORM FOR A/E F.O. NOZZLE油头架F.O.V. SHELL机修间空调机组AIR COND. UNIT WORKSHOP排气阀阀座研磨机M/E EXH. V. GRIND. MACHINE(FOR V ALVE CAGE) 主机备用汽缸套SPARE M/E CYLINDER LINER污水收集柜SEW AGE COLLECT TK.集控室空调机组AIR COND UNITOR E.C.R.焚烧炉污油驳运泵INCINERATOR SLUDGE OIL TRANSF. PUMP淡水增压泵F.W. COOLING BOOST PUMP防火布帘CURTAIN FOR WELDING氧气乙炔开关箱OXY/ACETYL. SWITCH BOX遥控蝶阀阀动力液压油柜REMOTE BUTT.V.POWER HYD. OIL. TANK.遥控蝶阀动力站REMOTE BUTT. V. POWER UNIT主机雨水收集柜A/E SOOT COLLECTION TANK辅机雨水收集柜A/E SOOT COLLECTION TANK淡水膨胀水箱F. W. EXPAIN. TK.AUX. BOILER FAN艉管滑油储存柜STERN TUEBE STORE TK.锅炉控制板BOILER CONTR. PANEL废气锅炉EXHAUST GAS BOILER辅机消音器A/E SIL ENCER机舱风机FAN IN ENGINE ROOM辅锅炉火星熄灭器SPARK ARRESTER OF AUX. BOILER废气锅炉火星熄灭器SPARK ARRESTER OF EXHAUST GAS BOILER 焚烧炉火星熄灭器SPARK ARRESTER OF INCINERATOR。

CHAPTER 77Engine Indicating77章发动机指示Text 1 INTRODUCTION正文1 介绍The engine indicating system continuously supplies engine data to the common display system (CDS). The engine indicating system has these subsystems:发动机指示系统连续将发动机数据传至通用显示系统(CDS).发动机指示系统具有以下子系统:-- Low pressure rotor tachometer (N1) 低压转子转速表(N1)-- High pressure rotor tachometer (N2) 高压转子转速表(N2)-- Exhaust gas temperature (EGT) 发动机排气温度(EGT)-- Airborne vibration monitoring (AVM). 机载振动监控(AVM)The CDS usually shows engine data on two display units (DUs). One DU shows the primary engine display and the other shows the secondary engine display. The primary engine display usually shows on the upper center DU. The secondary engine display usually shows on the lower center DU. Engine data can also show on the inboard DUs.CDS通常在两个显示组件(DU)上显示发动机数据..一个DU显示在主发动机显示上,另外一个在次发动机显示上.主发动机显示通常在上侧中央DU.次发动机显示通常在下侧中央DU.发动机数据也可以显示在内测DU上.Text 2 Related Components正文2相关部件The engine indicating system shows these parameters for each engine:发动机指示系统显示每个发动机的以下参数:-- Low pressure rotor speed (N1)低压转子转速(N1)-- High pressure rotor speed (N2)高压转子转速(N2)-- Exhaust gas temperature (EGT) 排气温度(EGT)-- Engine vibration. 发动机振动Electronic Engine Control 发动机电子控制The electronic engine control (EEC) receives an analog input from these engine sensors:发动机电子控制(EEC)从以下发动机传感器接收模拟输入:-- N1 speed sensor N1转速传感器-- N2 speed sensor N2转速传感器-- EGT probes (T49.5). EGT探头(T49.5)The EEC changes the analog signals to digital signals. The EEC sends the digital signals on an ARINC 429 data bus to the display electronics units (DEU)s.EEC将模拟信号转换为数字信号..EEC将信号从ARINC429数据汇流条至电子显示组件(DEU).Airborne Vibration Monitoring Signal Conditioner 机载振动监控信号调节器The airborne vibration monitoring (AVM) signal conditioner calculates and monitors vibration levels of each engine.机载振动监控(AVM)信号调节器计算和监控每个发动机的振动水平.The AVM signal conditioner receives analog input from these engine sensors: AVM信号调节器从以下发动机传感器接收模拟输入:-- N1 speed sensor N1转速传感器-- N2 speed sensor N2转速传感器-- Number 1 bearing vibration sensor 1号轴承振动传感器-- Fan frame compressor case vertical vibration (FFCCV) sensor.风扇结构压气机机匣垂面(FFCCV)振动传感器The DEUs and the flight data acquisition unit (FDAU) receive AVM information through an ARINC 429 data bus.DEU和飞行数据采集组件从通过ARINC429数据汇流条接收AVM信息DEUs DEUThe DEUs use digital input from the EEC to show these engine parameters on the common display system (CDS):DEU利用来自EEC的信号输入来在通用显示系统(CDS)上显示以下发动机参数:-- N1-- N2-- EGT.The DEUs use their analog N1 and N2 signals as alternate inputs when the EEC does not have electrical power. EGT shows only when the EEC has electrical power.DEU在EEC未通电时使用模拟的N1和N2信号作为备份输入.EGT只有在发动机通电时才能显示.Text 3 ENGINE TACHOMETER SYSTEM正文3 发动机转速计系统The engine tachometer system supplies the engine low pressure rotor (N1) and the engine high pressure rotor (N2) speed signals to these components:发动机转速计系统将发动机低压转速和发动机高压转速信号送入以下部件: -- Electronic engine control (EEC)发动机电子控制(EEC)-- Display electronics units (DEUs) 电子显示组件(DEUs)-- Engine airborne vibration monitoring (AVM) signal conditioner.发动机机载振动监控(AVM)信号调节器General Description概述The EEC receives two analog signals from each speed sensor. The EEC changes these analog signals to digital signals.EEC从每个转速传感器接收模拟信号,EEC将这些模拟信号转换为数字信号The EEC uses the two signals for channel A and channel B operation. Each channel sends data to each DEU on an ARINC 429 data bus.EEC使用这两个信号以进行A,B通道操作.每个通道将数据送入ARINC 429数据汇流条上的每个DEU.Usually, the DEUs use input from the EEC to show N1 and N2 on the common display system (CDS). The DEUs can also use input directly from the speed sensors to show N1 and N2.DEU通常使用来自EEC的输入来在CDS上显示N1和N2。

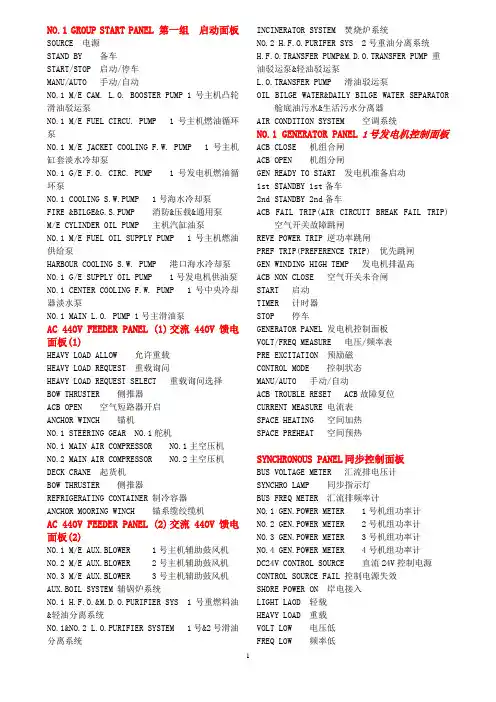

NO.1 GROUP START PANEL 第一组启动面板SOURCE 电源STAND BY 备车START/STOP 启动/停车MANU/AUTO 手动/自动NO.1 M/E CAM. L.O. BOOSTER PUMP 1号主机凸轮滑油驳运泵NO.1 M/E FUEL CIRCU. PUMP 1号主机燃油循环泵NO.1 M/E JACKET COOLING F.W. PUMP 1号主机缸套淡水冷却泵NO.1 G/E F.O. CIRC. PUMP 1号发电机燃油循环泵NO.1 COOLING S.W.PUMP 1号海水冷却泵FIRE &BILGE&G.S.PUMP 消防&压载&通用泵M/E CYLINDER OIL PUMP 主机汽缸油泵NO.1 M/E FUEL OIL SUPPLY PUMP 1号主机燃油供给泵HARBOUR COOLING S.W. PUMP 港口海水冷却泵NO.1 G/E SUPPLY OIL PUMP 1号发电机供油泵NO.1 CENTER COOLING F.W. PUMP 1号中央冷却器淡水泵NO.1 MAIN L.O. PUMP 1号主滑油泵AC 440V FEEDER PANEL (1) 交流440V馈电面板(1)HEAVY LOAD ALLOW 允许重载HEAVY LOAD REQUEST 重载询问HEAVY LOAD REQUEST SELECT 重载询问选择BOW THRUSTER 侧推器ACB OPEN 空气短路器开启ANCHOR WINCH 锚机NO.1 STEERING GEAR NO.1舵机NO.1 MAIN AIR COMPRESSOR NO.1主空压机NO.2 MAIN AIR COMPRESSOR NO.2主空压机DECK CRANE 起货机BOW THRUSTER 侧推器REFRIGERATING CONTAINER 制冷容器ANCHOR MOORING WINCH 锚系缆绞缆机AC 440V FEEDER PANEL (2) 交流440V馈电面板(2)NO.1 M/E AUX.BLOWER 1号主机辅助鼓风机NO.2 M/E AUX.BLOWER 2号主机辅助鼓风机NO.3 M/E AUX.BLOWER 3号主机辅助鼓风机AUX.BOIL SYSTEM 辅锅炉系统NO.1 H.F.O.&M.D.O.PURIFIER SYS 1号重燃料油&轻油分离系统NO.1&NO.2 L.O.PURIFIER SYSTEM 1号&2号滑油分离系统INCINERATOR SYSTEM 焚烧炉系统NO.2 H.F.O.PURIFER SYS 2号重油分离系统H.F.O.TRANSFER PUMP&M.D.O.TRANSFER PUMP 重油驳运泵&轻油驳运泵L.O.TRANSFER PUMP 滑油驳运泵OIL BILGE WATER&DAILY BILGE WATER SEPARATOR 舱底油污水&生活污水分离器AIR CONDITION SYSTEM 空调系统NO.1 GENERATOR PANEL 1号发电机控制面板ACB CLOSE 机组合闸ACB OPEN 机组分闸GEN READY TO START 发电机准备启动1st STANDBY 1st备车2nd STANDBY 2nd备车ACB FAIL TRIP(AIR CIRCUIT BREAK FAIL TRIP)空气开关故障跳闸REVE POWER TRIP 逆功率跳闸PREF TRIP(PREFERENCE TRIP) 优先跳闸GEN WINDING HIGH TEMP 发电机排温高ACB NON CLOSE 空气开关未合闸START 启动TIMER 计时器STOP 停车GENERATOR PANEL 发电机控制面板VOLT/FREQ MEASURE 电压/频率表PRE EXCITATION 预励磁CONTROL MODE 控制状态MANU/AUTO 手动/自动ACB TROUBLE RESET ACB故障复位CURRENT MEASURE 电流表SPACE HEATING 空间加热SPACE PREHEAT 空间预热SYNCHRONOUS PANEL 同步控制面板BUS VOLTAGE METER 汇流排电压计SYNCHRO LAMP 同步指示灯BUS FREQ METER 汇流排频率计NO.1 GEN.POWER METER 1号机组功率计NO.2 GEN.POWER METER 2号机组功率计NO.3 GEN.POWER METER 3号机组功率计NO.4 GEN.POWER METER 4号机组功率计DC24V CONTROL SOURCE 直流24V控制电源CONTROL SOURCE FAIL 控制电源失效SHORE POWER ON 岸电接入LIGHT LAOD 轻载HEAVY LOAD 重载VOLT LOW 电压低FREQ LOW 频率低1BUS SHORT CIR.TRIP 汇流排短路断路EMER GEN VOL TEST 应急机组电压测试ESB BUS BLACKOUT 应急配电板失电SYN MEASURE 同步表ACB CLOSE 机组合闸ACB OPEN 机组分闸NO.1 GEN GOVERNOR 1号发电机调速器LOW/OFF/RAISE 降低/关/升高SHORT CIR. TROUBLE RESET 断路故障失效复位FLICKER STOP 停止闪烁BUZZER STOP 停止蜂鸣LAMP TEST 试灯STAND BY GEN SELECTION 发电机备车选择D/G CONTROL SELECTION 柴油发电机控制部位选择LOCAL CONTROL/ECR PMCS(ENGINE CONTROL ROOM POWER MANAGEMENT CONTROL SYSTEM)机旁控制/集控室电源操作控制系统SHAFT GENERATOR PANEL 轴带发电机控制面板S/G SYSTEM VOLT 轴带发电机系统电压S/G SYSTEM FREQUENTCY 轴带发电机系统频率S/G SYSTEM CURRENT 轴带发电机系统电流ACB CLOSE 机组合闸ACB OPEN 机组分闸S/G SYS VOLT ABNORMAL 轴带发电机系统电压不正常S/G SYS FREQ ABNORMAL 轴带发电机系统频率不正常S/G VOLT ABNORMAL 轴带发电机电压不正常RUN 运行READY TO START 准备启动START IN PROCESS 正在启动TIMER 计时器LIGHT FAULT 轻载故障HEAVY FAULT 重载故障M/E SLOW WAITING 主机慢转等待CONTROL POWER 控制电源LOCAL 机旁REMOTE 遥控START 启动ACB TROUBLE RESET 机组合闸故障复位STOP 停车ACB MODE SELECT 机组合闸状态选择MANU/OFF/AUTO 手动/关/自动S/G SYSTEM VOLT 轴带发电机系统电压S/G CONTROL&COND POWER 轴带发电机控制电源&补偿器电源S/G SYSTEM CURRENT 轴带发电机系统电流SPACE HEATING 加热SPACE PREHEAT 预热AC 220V FEEDER PANEL 交流220V馈电板LIGHT FOR E/R 机舱照明LIGHTING FOR CAP.&BOAT&MAIN DECK驾驶台甲板照明(船长层甲板照明)&艇甲板照明&主甲板照明LIGHTING FOR OUTSIDE 外部照明LIGHTING FOR CARGO HOLD 起货照明NAVIGATION&SIGNAL LIGHT 航行&信号灯SUEZ CANAL SEARCHLIGHT SUEZ运河探照灯LIGHTING FOR FRT.DECK 前甲板照明LIGHTING FOR AFT.DECK 后甲板照明ELCECTRIC TEST BOARD 电力试验面板BATTERY CHARGING UNIT 蓄电池充电单元MAIN TRANSFORMER 主变压器SHORE POWER SUPPLY 岸电供给蓄电池充放电板VOLTAGE MEASURE 电压测量CURRENT MEASURE 电流测量AIR-BREAK SWITCH 电源开关NAV./INNER COMM.DC 24V DIS.BOX 航行/船内通讯24V分电单元MAIN ENGINE REMOTE CONTROL SYSTEM 主机遥控LOUD-SPEAKER 扩音机FIRE ALARM 火警E/R MONITOR RACKS 机舱监控台ESB ALARM POWER SUPPLY 主配电板报警电源ENGINEER CALL UNIT 轮机员呼叫装置GENERAL ALARM 通用报警NO.2 GROUP START PANEL 第2组启动控制面板SOURCE 电源STAND BY 备车START/STOP 启动/停车MANU/AUTO 手动/自动M/E JACKET F.W.PREHEATING PUMP 主机缸套淡水预热泵NO.2 M/E FUEL OIL SUPPLY PUMP 2号主机燃油供给泵2HARBOUR CENTER COOLING F.W. PUMP 港口中央冷却器淡水泵NO.2 G/E F.O.SUPPLY PUMP 2号发电机燃油供给泵NO.2 CENTER COOLING F.W.PUMP 2号中央冷却器淡水泵NO.2 MAIN L.O.PUMP 2号主滑油泵NO.2 M/E CAM L.O.BOOSTER PUMP 2号主机凸轮滑油增压泵NO.2 M/E FUEL CIRCU. PUMP 2号主机燃油循环泵NO.2 M/E JACKET COOLING F.W.PUMP 2号主机缸套冷却器淡水泵NO.2 G/E F.O.CIRC. PUMP 2号发电机燃油循环泵NO.2 COOLING S.W.PUMP 2号冷却器海水泵FIRE &BILGE&BALLAST PUMP 消防&舱底&压载泵EMERG.GEN.PANEL 应急发电机控制面板TIMER 计时器INS MEASURE 绝缘检测VOLT MEASURE 电压表CURRENT MEASURE 电流表INS LOW 绝缘性能低EMER.GEN TEST 应急电机测试ACB CLOSE 机组合闸ACB OPEN 机组分闸PRE EXCITATION 预励磁START/STOP 启动/停车MODE SELECTION 状态选择AUTO/TEST/MANU 自动/测试/手动MAIN SWITCHBOARD FEED INDICATOR 主配电板馈电指示AUX.AIR COMPRESSOR 辅助空气压缩机EMERG.FIRE PUMP 应急消防泵LIFE BOAT 救生艇NO.2 STEERING GEAR 2号舵机EMERG.TRANSFORMER 应急变压器NAVIGATION EQUIPMENT 航行设备RADIO EQUIPMENT 无线电设备MAIN SWITCHBOARD FEED 主配电板LOCAL PANEL控制箱BOILER SYSTEM 锅炉系统STEAM PRESSURE 蒸汽压力FUEL OIL FLOW 燃油流量COMBUSTION AIR FLOW 燃烧空气流量O2 CONTENT IN EXHAUST GAS 废气中氧气含量NO.1 FEED WATER PUMP RUNNING NO.1 伺服水泵运行NO.1 FEED WATER PUMP TROUBLE NO.1 伺服水泵故障NO.1 FEED WATER PUMP START/OFF/STAND BY NO.1 伺服水泵起/停/备车NO.1 FUEL OIL PUMP RUNNING NO.1 燃油泵运行NO.1 FUEL OIL PUMP TROUBLE NO.1 燃油泵故障NO.1 FUEL OIL PUMP START/OFF/STAND BY NO.1 燃油泵起/停/备车NO.2 FEED WATER PUMP RUNNING NO.2 伺服水泵运行NO.2 FEED WATER PUMP TROUBLE NO.2 伺服水泵故障NO.2 FEED WATER PUMP START/OFF/STAND BY NO.2 伺服水泵起/停/备车NO.2 FUEL OIL PUMP RUNNING NO.2 燃油泵运行NO.2 FUEL OIL PUMP TROUBLE NO.2 燃油泵故障NO.2 FUEL OIL PUMP START/OFF/STAND BY NO.2 燃油泵起/停/备车PARAMETER CONTROLLERS 参数控制器WATER LEVEL 水位FUEL OIL PRESSURE 燃油压力FUEL OIL TEMPERATURE 燃油温度ATOMIZING STEAM PRESSURE 雾化蒸汽压力MASTER STEAM PRESSURE 主蒸汽压力AIR/OIL COMBUSTION 空气/燃油燃烧比PARAMETER MEASURE 参数测量PARAMETER SETTING 参数设定FEED WATER VALVE POSITION 供给水阀位置INCREASE/DECREASE/ENTER/OFF/SETUP 增加/减少/确定/关/设定SOURCE 通电IGNITION 燃烧SIREN 警报器WATER LEVEL HIGH 水位高WATER LEVEL LOW 水位低STEAM PRESSURE LOW 蒸汽压力低STEAM PRESSURE HIGH 蒸汽压力高COMBUSTION AIR FAN 助燃空气送风机FUEL OIL VALVE 燃油阀ATOMIZING STEAM VALVE 雾化蒸汽阀DRAIN STEAM VALVE 排气阀STEAM PURGE VALVE 蒸汽放气阀OIL TEMPERATURE HIGH 油温高OIL TEMPERATURE LOW 油温低HIGH SALINITY IN FEED WATER 供给水盐度高FAN FAILURE 风机故障BURNER ON/OFF 燃烧器开/关HEAVEY OIL/DIESEL OIL 重油/柴油3FIRE BUTTON 点火按钮BURNER NOZZLE 燃烧器喷嘴EMER.STOP 应急停炉HIGH FOG DENSITY 高雾气密度LOW OIL PRESSURE 低油压LOW COMBUSTION AIR PRESSURE 低燃烧空气压力BLOW OUT 熄火EXH.GAS BOILER/AUX.BOILER/PARALLEL OPERATION 辅锅炉/废气锅炉/并联操作AUTO/MANU 自动/手动RESET 复位HORN STOP 消声LAMP TEST 指示灯试验FLAME FAILURE 点火失败LOW ATOMIZING STEAM PRESSURE 雾化蒸汽压力低EXHAUST GAS TEMP. HIGH 废气温度高FIRE IN THE WINDBOX 风箱着火DOMESTIC SEWAGE TREATMENT 生活污水处理系统SCRAPER 刮削器AIR 空气CLEAN WATER DISCHARGE TANK 清水排出箱CHLORIC JET PUMP 氯气喷射泵FLOCCULANTJET PUMP 凝聚剂喷射泵PRES TANK 压力柜CIRCULATING PUMP 循环泵EXPANSION TANK 膨胀水箱SEWAGE WATER INLET 生活污水入口EXHAUST HOLE 排气口GRINDING PUMP 粉碎泵PRETREAMENT TANK 预处理箱CLEAN WATER PUMP 清水泵DRAIN WATER PUMP 排水泵DISCHARGED WATER PUMP 出水口PRESS TANK PRESSURE 压力柜压力DRAIN WATER PUMP START 排出泵起动CHLORIC JET PUMP START 氯气喷射泵起动FLOCCULANT JET PUMP START 凝聚剂喷射泵起动CIRCULATING PUMP START 循环泵起动GRINDING PUMP START 粉碎泵起动CLEAN WATER PUMP START 清水泵起动SCRAPER START 刮淤泥器起动PRETREAMENT TANK LEVEAL ALARM 预处理柜液位警报DRAIN WATER PUMP STOP 排出泵停止CHLORIC JET PUMP STOP 氯气喷射泵停止FLOCCULANT JET PUMP STOP 凝聚剂喷射泵停止CIRCULATING PUMP STOP 循环泵停止GRINDING PUMP STOP 粉碎泵停止CLEAN WATER PUMP STOP 清水泵停止SCRAPER STOP 刮淤泥器停止LAMP TEST 指示灯试验OIL WATER SEPARATER 油水分离器OIL CONTENT INDICATOR 油浓度监控报警器VACUUM PRESS METER 真空压力计TEMPERATURE CONIROL METER 温度控制表TO BILGE WATER TANK 到舱底柜SOURCE 电源指示灯COMPLETE PUMP START/STOP 配套泵起动/停止DISCHARGED OIL MODE CONTROL MANU/AUTO 排油控制模式手动/自动OIL CONTENT INDICATOR TEST 油份浓度监控器测试LAMP TEST 指示灯试验OIL LEVEL MONITOR 油位监视器ELECTRIC-HEATER 电加热器COMPRESSED AIR 压缩空气SAFETY VALVE 安全阀FROM BILGE WATER TANK 来自检测口DISCHARGED WATER OUTLET 排水口OIL OUTLET 出油口SAMPLE COCK 取样阀BILGE WATER TANK 舱底柜SLUDGE TANK 渣油柜INLET FILTER 内置滤器TO OIL CONTENT INDICATOR 到油份浓度监控器CLEAN WATER 清水BILGE WATER TANK 舱底柜AIR SUPPLY SYSTEM 压缩空气系统NO.1 AIR COMPRRESSOR CURRENT NO.1 空压机电流NO.2 AIR COMPRRESSOR CURRENT NO.2 空压机电流RUNNING/STRAT 运行/起动STOP 停止DELOAD 卸载GROUP ALARM UNIT 组合报警单元汽船报警二氧化碳报警机舱火灾报警机械故障报警联络报警4车令报警人身伤亡事故报警SOURCE 电源RUNNING 运行AIR TEMP.HIGH 空气温度高COOLING WATER TEMPERATURE HIGH 冷却水温度高OIL LOW PRESS 油压低OVERLOAD 过载LOCAL/REMOTE 机旁/遥控AUTO/STOP/MANU 自动/停/手动LUBE.OIL SEPARATOR 滑油分油机HEATER 加热器START/STOP 起动/停止SLUDGE DISCHARGE 排渣SLUDGE DISCHARGE FAULT 排渣故障RESET 复位START/STOP HEATER 起/停加热器START/STOP SEPERATOR 起/停分油机SLUDGE DISCHARGE 排渣TT1 LOW OIL TEMPERATURE TT1 低油温TT2 HIGH OIL TEMPERATURE TT2 高油温XS1 VIBRATION/EMERGENCY STOP XS1 震动/应急停止PS41 HIGH OIL PRESSURE PS41 高油压PS41 LOW OIL PRESSURE PS41 低油压MT4 WATER TRANSDUCER MT4 水分传感器MV1 OIL TO SEPERATOR MV1 进油口MV10 CONDITIONING WATER MV10 置换水MV10A DISPLACEMENT MV10A 置换MV15 BOWL OPENING WATER MV15 补偿水MV16 BOWL CLOSING WATER MV16 操作水SEPERATOR MOTOR CURRENT 分油机马达电流SEPERATOR MOTOR RUNNING 分油机马达运行中FEED OIL PUMP RUNNING 滑油供应泵运行中MOTOR ON/OFF 马达开/关FEED OIL PUMP ON/OFF 滑油供应泵开/关RESET 复位MAIN SWITCH 主开关LAMP TEST 指示灯试验H.F.O/M.D.O SEPARATOR 燃油分油机HEATER 加热器START/STOP 起动/停止SLUDGE DISCHARGE 排渣SLUDGE DISCHARGE FAULT 排渣故障RESET 复位START/STOP HEATER 起/停加热器START/STOP SEPERATOR 起/停分油机SLUDGE DISCHARGE 排渣TT1 LOW OIL TEMPERATURE TT1 低油温TT2 HIGH OIL TEMPERATURE TT2 高油温XS1 VIBRATION/EMERGENCY STOP XS1 震动/应急停止PS41 HIGH OIL PRESSURE PS41 高油压PS41 LOW OIL PRESSURE PS41 低油压MT4 WATER TRANSDUCER MT4 水分传感器MV1 OIL TO SEPERATOR MV1 进油口MV10 CONDITIONING WATER MV10 置换水MV10A DISPLACEMENT MV10A 置换MV15 BOWL OPENING WATER MV15 补偿水MV16 BOWL CLOSING WATER MV16 操作水SEPERATOR MOTOR CURRENT 分油机马达电流SEPERATOR MOTOR RUNNING 分油机马达运行中FEED OIL PUMP RUNNING 燃油供应泵运行中MOTOR ON/OFF 马达开/关FEED OIL PUMP ON/OFF 燃油供应泵开/关RESET 复位MAIN SWITCH 主开关LAMP TEST 指示灯试验START/STOP SYSTEM FOR NO.1 AUX. ENGINE NO.1 柴油发电机系统起/停控制箱READY FOR START 准备启动ENGINE RUNNING 运行中COOLING WATER TEMP.HIGH 冷却水温度高LUBE.OIL PRESS.LOW 滑油压力低CHARGE AIR TEMP.HIGH 排气温度高OVERSPEED 超速OIL MIST HIGH 油雾温度高STOP 停车START 启动LOCAL/REMOTE 机旁/遥控EMERGENCY STOP 应急停车RESET 复位LAMP TEST 指示灯试验PRELUBE.PUMP STARTER 预供油泵启动器POWER ON 电源接通PUMP RUNNING 泵运行中PUMP TRIPPED 泵过载MAIN SWITCH 主开关OFF/ ON /AUTO 关/开/自动RESET 复位INCINERATOR 焚烧炉FAN 送风机DIESEL TANK 燃油柜DIESEL PUMP 燃油泵DISTRIBUTION PUMP 分流泵5CIRCULATING PUMP 循环泵DISPERSE PUMP 粉碎泵SLUDGE TANK 污油柜SOURCE 加料FAN START 风机启动DISPERSE PUMP START 粉碎泵启动CIRCULATING PUMP START 循环泵启动DISTRIBUTION PUMP START 分流泵启动DIESEL PUMP START 燃油泵启动FIRE 燃烧IGNITION 点火FAN STOP 风机停止DISPERSE PUMP STOP 粉碎泵停止CIRCULATING PUMP STOP 循环泵停止DISTRIBUTION PUMP STOP 分流泵停止DIESEL PUMP STOP 燃油泵停止LAMP TEST 指示灯试验BRIDGE 驾控台延伸报警单元车钟记录打印机玻璃盖NO.1 BILGE FIRE&G/S PUMP NO.1 舱底消防&通用海水泵EM'cy FIRE PUMP 应急消防泵EM'cy STOP "应急停止(停油,停风)"SPEED LOG 速度记录START AIR PRESSURE 起动空气压力RUDDER ANGLE INDICATOR 舵角指示器M/E RPM 主机转速EMERGENCY TELEGRAPH 应急电报机CONTROL SYSTEM FAILURE 控制系统失效LAOD SYSTEM FAILURE 负载控制失效LOW HYDRAULIC OIL PRESSURE 低液压油油压LOW HYDRAULIC OIL LEVEL 低液压油油位HIGH OIL TEMPERATURE 高油温HIGH DRIVE MOTOR TEMPERATURE 主驱动马达高温HIGH DRIVE MOTOR TEMP TRIPPED 驱动马达高温保护停机DRIVE MOTOR OVERLOAD 主驱动马达过载HIGH STEP-UP TRANSFORMER TEMP 渐变变压器高温HIGH AUTO TRANSFORMER TEMP 自动变压器高温RESET/TEST/POWER/ALARM 复位/测试/通电/报警器侧推器操纵板BOW THRUSTER UNIT 侧推器单元PORT/STARB. 左舵/右舵IN COMM. 等待指令HYDR.RUN 液压运行IN SERV. 运行OVERLOAD 过载LAMP TEST 指示灯试验HYDR.START 液压起动EMER.STOP 应急停止START REQU. 起动询问主机遥控板EMER.STOP 应急停车ENGINE TELEGRAPH UNIT 主机联络单元SUBTELEGRAPH MODE 车令模式FEW/STAND BY/AT SEA 完车/备车/在海上CONTROL LOCATION 控制权限EMERGENCY/CONTROL ROOM/BRIDGE 应急/控制室/驾驶台TELEGRAPH STATUS 电报机状态NEW COMMAND/WRONG WAY/RCS NOT READY 新指令/错误/控制系统未准备好SYSTEM 系统LAMP TEST/SOUND OFF/INTERNAL FAILURE 指示灯试验/消声/内部故障舵机运行状态及报警板FAILURE HYDR.PUMP NO.1 NO.1液压泵失效FAILURE FEEDER EMER.CONTROL NO.1 NO.1液压泵应急伺服器失效OVERLOAD HYDR.PUMP NO.1 NO.1液压泵过载LOW OIL LEVEL 低油位FAILURE HYDR.PUMP NO.2 NO.2液压泵失效FAILURE FEEDER EMER.CONTROL NO.2 NO.2液压泵应急伺服器失效OVERLOAD HYDR.PUMP NO.2 NO.2液压泵过载PHASE FAILURE NO.1 NO.1液压泵相位错误HYDRAULIC LOCKING NO.1 NO.1液压泵液压锁定OIL FILTER CLOGGED NO.1 NO.1液压油滤器阻塞GREASING PUMP FAILURE 注脂泵失效PHASE FAILURE NO.2 NO.2液压泵相位错误HYDRAULIC LOCKING NO.2 NO.2液压泵液压锁定OIL FILTER CLOGGED NO.2 NO.2液压油滤器阻塞HYDR.PUMP ON NO.1 NO.1液压泵开LOW SERVO OIL PRESSURE NO.1 NO.1液压泵工作油油压低HIGH OIL TEMPERATURE 高油温HYDR.PUMP ON NO.2 NO.2液压泵开LOW SERVO OIL PRESSURE NO.2 NO.2液压泵工作油油压低ALARM ACCEPTANCE 回复警报FAILURE SAFEMATICRUDDER TORQUE REDUCED 舵叶扭矩降低6LAMP TEST 指示灯试验NO.1 STEERING PUMP NO.1 操纵泵开/关STEERING PUMP SYSTEM PANEL 操纵泵系统控制板主机遥控安全报警板START AIR PR. 起动空气压力COMMAND RPM 指令转速ENGINE RPM 主机转速AHEAD/ASTERN 正车/倒车DOWN/UP/TEST 低/高/测试DOWN/UP 低/高LOWER/RAISE/ENTER 降低/增加/确定ALARM 报警器SAFETY FUNCTIONS/OTHER ALARMS 安全功能/其它警报SHD NONE CANCEL 故障停机未取消M/E L.O.PRESS.LOW 主机滑油压力低START FAILURE 起动失败CONTROL ROOM PANEL FAILURE 集控室控制板失效SHD CANCEL ABLE 故障停机可取消SLD CANCEL ABLE 故障减速可取消START BLOCK 起动受阻SAFETY SYSTEM FAILURE 安全系统失败SHD ACTIVE 故障停车激活SLD ACTIVE 故障减速激活ENGINE NOT READY 主机未准备好TELEGRAPH FAILURE 车钟失灵OVERSEED 超速EMER.STOP 应急停止SYSTEM FAILURE 系统失效GOVERNOR FAILURE 控制器失效INDICATION 指示盘SETPOINT LIMITER/STATE 设定限制/状态MANUAL RPM LIMIT 手动转速限制ROUGH SEA LIMIT 恶劣气候航行限制STARTING 起动中SLOW TURNING 慢转起动LAOD UP 重载LOAD DOWN 轻载REPEAT START 重复起动START TOO LONG 起动时间太长ACCELERACTION LIMIT 加速限制START SETPOINT LIMIT 发火转速限制CRASH ASTERN 紧急倒车START AIR PRESSURE LOW 起动空气压力低CRITICAL RPM LIMIT 严格转速限制LOAD PROGRAM 加载STOPPING 停车HANDLE MATCH 手柄操作CANCEL FUNCITIONS 取消功能CANCEL SHD 取消故障停车CANCEL SLD 取消故障减速CANCEL LIMITATION 取消限制CANCEL LAOD PROGRAM 取消程序负荷CANCEL SLOW TURNING 取消慢转OTHER FUNCTIONS 其它功能EL.SHAFT WARNING RESET 轴带机故障ROUGH SEA 恶劣天气航行LAMP TEST 指示灯试验COMMIS LOCK 通讯故障RESET/SOUND OFF/ALARM ACKN. 复位/消声/应答警报STATUS/WARNING 状态/警告SYST.OP. 系统操作码I/O SIM. 输入/输出模拟RECEIVE/TRANSMIT 接收/发送POW.FAIL 电源故障COMMUN. 通讯故障MEMORY 内存故障IN./OUT. 输入/输出故障FAIL SAFE 安保系统故障COMMAND POSITION 指令位置PORT BRIDGE WING 左侧桥楼ENGINE ROOM 机舱BRIDGE 驾驶台STARB.BRIDGE WING 右侧桥楼SIMULATOR REMOTE CONTROL SYSTEM 远程控制系统BRIDGE UNIT 驾驶台单元集控台M.E.FUEL INDEX 主机燃油指数M.E.TURBO CHARGER 1RPM 主机涡轮增压器1RPM M.E.TURBO CHARGER 2RPM 主机涡轮增压器2RPM M.E.TURBO CHARGER 3RPM 主机涡轮增压器3RPM 进出港备车前准备工作(1)机舱自上而下巡回检测一圈(2)开MDO电动泵(3)加开一台副机(4)关右低位海底阀(港)(5)停造水机(进港)(6)检查锅炉放自动状态(进港)(7)主机准备转集控室控制(进港)BASIC ALRAM PANEL 常用警报面板BRIDGE CONTROL 驾驶室控制E.C.R.CONTROL 集控室控制7EMERG CONTROL 机旁控制/集控室操作FUEL CAM AHEAD 燃油凸轮正车位TURNING GEAR DISENGAGED 盘车机脱开MAIN START VALVE IN SERVICE 主启动阀开启GOVERNOR ENGAGED 调速器开启FUEL CAM ASTERN 燃油凸轮倒车位TURNING GEAR ENGAGED 盘车机合上MAIN START VALVE BLOCKED 主启动阀关闭START AIR DISTRIB.BLOCKED 空气分配器关闭LIMITERSIN GOVERNOR CANCELLED 取消加速限制AUX.BLOWER1 RUN 辅助鼓风机1工作AUX.BLOWER2 RUN 辅助鼓风机2工作AUX.BLOWER3 RUN 辅助鼓风机3工作SLOW TURNING 慢转AUX.BLOWER1 STOP 辅助鼓风机1停车AUX.BLOWER2 STOP 辅助鼓风机2停车AUX.BLOWER3 STOP 辅助鼓风机3停车LAMP TEST 指示灯试验AUX.BLOWER 辅助鼓风机AUTO/STOP/MANU 自动/停车/手动INDICATING PANEL 显示面板MAIN ENGINE TORQUE METER 转矩计SELECTION 选择RPM/TORQUE/SHAFT POWER 转速/转矩/轴功率POWER ON/OFF 电源开/关M/E REVOLUTION COUNTER 主机转数计M/E RUNNING HOUR 主机运转时间M/E RPM 主机转速DOPPLER SPEED LOG INDICATION 航速表RUDDER ANGLE INDICATION 舵角显示LIGHT COLUMN PANEL 显示灯专栏面板E/R GROUP ALARM INDICATION PANEL 机舱组报警显示面板SHUT DOWN/LOOP FAIL/OP CODE/CANCEL 停车/循环失效/操作码/取消OVERSEED 超速LUB.OIL TO MAIN BEARING AND THRUST BEARING LP.NONF CANCELLABLE 主轴承的滑油/推力轴承的滑油低压取消CAMSHAFT LUB.OIL INLET LOW PRESSURE CANCELLABLE 凸轮轴滑油内部压力低取消THRUST BEARING SEGMENT HIGH TEMPERATURE CANCELLABLE 推力轴承部件高温取消FRESH COOLING WATER INLET PRESSURE LOW CANCELLABLE 淡水冷却器内部压力低取消SLOW DOWN 降速LUB.OIL(SYSTEM OIL) TEMPERATURE HIGHCANCELLABLE 系统内部滑油温度高取消PISTON COOL.OIL OUTLET TEMPERATURE HIGH CANCELLABLE 活塞冷却油外部高温取消PISTON COOL.OIL OUTLET NO FLOW CANCELLABLE 活塞冷却油断流取消PISTON COOL.OIL INLET PRESSURE LOW CANCELLABLE 活塞冷却油内部压力低取消LUB.OIL TO MAIN BEARING AND THRUST BEARING PRESS.LOW CANCELLABLE 流到主轴承的滑油与推力轴承的压力低取消THRUST BEARING SEGMENT TEMPERATURE HIGH CANCELLABLE 推力轴承部件部件高温取消LUB.OIL TO CAMSHAFT TEMPERATURE HIGH CANCELLABLE 到凸轮轴滑油内部高温取消SLOW DOWN 降速CYLINDER LUBRICATORS NO FLOW CANCELLABLE 汽缸润滑油断流取消FRESH COOLING WATER INLET PRESSURE LOW CANCELLABLE 淡水冷却器内部低压取消JACKET COOL.WATER OUTLET TEMPERATURE HIGH CANCELLABLE 缸套冷却水外部高温取消SCAVENGE AIR FIRE TEMPERATURE HIGH CANCELLABLE 扫气箱着火高温取消EXH.GAS AFTER CYLINDER TEMP.DEVIATION FROM AVERAGE CANCELLABLE 排气温度偏离平均值取消OIL MIST DENSITY HIGH CANCELLABLE 油雾密度高取消LUB.OIL INLET TO TURBOCHARGE PRESSURE LOW CANCELLABLE 到透平增压机滑油内部压力低取消ALARM 报警EMERGENCY STOP SW. 应急停车开关SHUT DOWN 停机SLOW DOWN 降速SHUT DOWN CANCELLED 取消停车SLOW DOWN CANCELLED 取消降速CRITICAL RPM 危险转速WRONG ROTATION 转向错误RPM DETECTOR FAIL 转速监测失效LOOP FAIL EMERG.STOP SW. 应急停车开关失效EMERGENCY STOP VALVE ACTIVATED 应急停车阀激活RPM-DETECTOR SYSTEMS 转速监测系统STATUS/WARNING 级别SYST.OPERATION 系统操作I/O SIMULATE I/O加强RECEIVE/TRANSMIT 接收/发送WARNING 警告8INT.POWER FAIL 内部失电COMMUNICATION 对话MEMORY 记忆INPUT/OUTPUT 输入/输出FAILSAFT 危险OP.CODE/PARAMETER/VALUE 操作码/参数/数值UP/DOWN LOWER/RAISE 上/下降低/升高输入/测试CHANGE LOCK/OPEN 转变锁住/开启RESET 复位SOUND OFF 消音/ALARM ACKN. 警报应答SLOW DOWN 降速M.E.SAFETY SYSTEM UNIT 主机安全保护系统单元BRIDGE/SIMULATION 驾控/仿真STOP 停车AHEAD CMD/ASTERN CMD 正车令/倒车令START BLOCK 启动闭锁ABOVE REVERSING LEVEL 反转转速点START SETP. 发火转速AHEAD S.V./ASTERN S.V./STOP GOV. 正车电磁阀/倒车电磁阀/停车电磁阀.LIMITER 取消调速器限制ABOVE START LEVEL 高于启动转速REPEATED START NO.2 第二次重复启动SLOW TURNING S.V./START S.V./STOP S.V. 慢转电磁阀/启动电磁阀/停车电磁阀REPEATED START NO.1 第一次重复启动SETPOINT LIMITER 设定限制AHEAD ROTATION/ASTERN ROTATION 正转/倒转STATE 状态START INHIBITED 启动闭锁READY FOR START 准备启动SLOW TURNING 慢转STARTING 启动RUNNING 运行CRASH ASTERN 紧急反转STOPPING 停车ENGINE TRIPPED 故障停机SETPOINT LIMITER 设定限定MANUAL RPM 手动转速LOAD PROGRAM 负荷程序ACCELERACTION 加速CRITICAL RPM 临界转速SLOW DOWN 故障减速MINIMUM RPM 最低稳定转速START SETPOINT 发火转速设定START FAIL/BLOCK 启动失败/闭锁3 FAIL STARTS 3次启动失败START TOO LONG 启动时间过长SLOW TURNING FAIL 慢转启动失败START AIR PRESS.LOW 启动空气压力低RPM DETECTOR FAIL 转速传感器故障ENGINE TRIPPED 主机故障停机ENGINE NOT READY 主机备车未完成ENGINE NOT READY 主机备车故障GOVERNOR NOT CONN. 调速器未连接ST.AIR VALVE BLOCKED 启动空气阀闭锁ST.AIR DISTR. BLOCKED 启动空气分配器闭锁TURNING GERA ENGAGED 盘车机闭锁AUX.BLOWER FAILURE 辅助鼓风机故障SYSTEM WARNING 系统报警BRIDGE PANEL FAIL 驾控面板故障TELEGRAPH FAIL 车钟故障SAFETY SYSTEM FAIL 安保系统故障GOVERNOR FAIL 调速器失灵LIMITATION CANCELLED 限制取消LOAD PROGR.CANCELLED 负荷程序取消SLOW TURNING CANCELLED 慢转取消SYSTEM FAIL 系统故障RPM DET.SYSTEM 1 FAIL 转速检测系统1故障RPM DET.SYSTEM 2 FAIL 转速检测系统2故障SOLENOID VALVE LOOPFAIL 电磁阀故障CONTROL POS.MISSING 控制位置错失I/O COMMIS.OP.CODE I/O通讯操作码RESET 复位SOUND OFF/ALARM ACKN./START BLOCK 消音/报警确认/启动闭锁COMMAND POS. 控制位置BRIDGE CONTR./ENGINE ROOM CONTR. 驾驶台控制/集控室控制STATUS 状态SYS.OPERATION 系统操作I/O SIMULATE I/O仿真RECEIVE/TRANSMIT 接收/发送WARNING 报警INT.POWER FAIL 电源故障COMMUNICATION 通讯MEMORY 内存INPUT/OUTPUT 输入/输出FAILSAFT 安保故障OP.CODE/PARAMETER/VALUE 操作码/参数/值UP/DOWN LOWER/RAISE ENTER/TEST 加/减确认/试验SYSTEM OP.CODES 系统操作码955 BRIDGE COMMAND 55 驾驶台车令56 RPM SETPOING 56 转速设定57 ENGINE RPM 57 转速58 START AIR PRESSURE 58 启动空气压力59 SYSTEM 59 系统CHANGE LOCK/OPEN 转换闭锁/打开M.E.REMOTE CONTROL SYSTEM 主机遥控系统板主机进出港机动操作注意事项1)进港备车,进行机动操作时即取消驾控转集控."2)由海速降至港速前进三的操作过程,不得少于10分钟.""3)主机出港加速时的操作应循序渐进,谨慎操作.""4)自港速前进三加速至海速100RPM的操作过程,不得少于30分钟."5)主机定速、结束机动操作时方可驾控. HARBOUR SPEED TABLE 港口速度表格全速/半速/慢速/最低转速最低转速/慢速/半速/全速FULL AHEAD 全速正车/前进三HALF AHEAD 半速正车/前进二SLOW AHEAD 慢速正车/前进一DEAD SLOW AHEAD 微速正车/微速前进FULL ASTERN 全速倒车/后退三HALF ASTERN 半速倒车/后退二SLOW ASTERN 慢速倒车/后退一DEAD SLOW ASTERN 微速倒车/微速后退F/W/E(finished with engine )完车STAND BY 备车FOR MANUAL CONTROL ONLY 仅供手动操作SLOW TURNING/NORMAL/CANCEL.OF LIMITERS 慢转/正常/取消限制REMOTE CONTROL/C/R CONTROL 遥控控制/机旁控制启动车钟EMER.STOP 应急停车ENGINE TELEGRAPH UNIT 机器电报面板SUBTELEGRAPH MODE 附属电报模式FWE/STAND BY/AT SEA 完车/备车/在海上FEW LOOP ABNORMAL 完车重复不正常CONTROL AIR NOT VENTED 控制空气未被泄放SAFETY AIR NOT VENTED 安全空气未被泄放START VAL.NOT BLOCKED 启动阀没有阻塞CONTROL LOCATION 操作面板EMERGENCY/CONTROL ROOM/BRIDGE 应急/控制室/驾驶台TELEGRAPH STATUS 电报级别NEW COMMAND/WRONG WAY/RCS NOT READY 新命令/错误方式/遥控系统没有准备SYSTEM 系统LAMP TEST/SOUND OFF/INTERNAL FAILURE 试灯/消音/内部失效联络车钟船钟M.E.F.O.VISCOSITY CONTROLLER 主机燃油粘度控制器MODE 模式NORMAL/IDLE/SETPOINT/TEST/CALIBRATE/SELFTEST 正常/空载/局点/测试/校准/自测STATUS 状态REGULATOR ON/START/STOP/RPM LIMIT ON/FUEL LIMIT ON/OTHER 调节器开/起动/停/转速限制开/燃油限制开/其它ALARM 警报LOW VOLTAGE/RPM DETECT. FAIL 低压/转速检测失效IN-DATA ERROR/OUT-DATA ERROR 当前错误/以往错误SYSTEM IN TEST/OTHER 测试系统中/其它PARAMETER 参数1.MODE SELECT 1.模式选择2.RPM COMMAND 2.转速指令3.RPM MEASURED 3.所测转速4.GENERAL INFORMATION 4.大体情况5.SCAV.AIR PRESSURE 5.扫气空气压力6.MAIN.RPM LIMIT 6.手动转速限制7.MAIN.FUEL LIMIT 7.手动燃油限制8.RPM DEADBAND 8.极限转速9.OTHER STATUS 9.其它状态10.OTHER ALARM 10.其他警报LAMP TEST/RESET/DOWN/UP 指示灯试验/复位/低/高DIGITAL GOVERNOR UNIT 数字控制器单元CONTROL MODES 控制模式CONST FUEL/ROUGH SEA/FUEL SETPOINT 常油量/恶劣气候航行/燃油设定DATA VALUE/REGULATOR 数值/调节器SAVE/DOWN/UP 保存/低/高TEST 测试MODE 模式NORMAL/IDLE/TEST/CALIBRATE/SELF TEST 正常/空载/测试/校准/自测STATUS 状态SERVO ON/MANUAL CONTR./EXTERNAL STOP 伺服机构开/手动控制/外部停止10SERVO BLOCKED/OTHER 伺服机构卡住/其它ALARM 警报LOW VOLTAGE/FEEDBACK FAIL 低压/反馈失效IN-DATA ERROR/SERVO AMPL FAIL 当前错误/伺服机构放大器失效SYSTEM IN TEST/OTHER 测试系统中/其它PARAMETER 参数1.MODE SELECT 1.模式选择2.FUEL COMMAND 2.燃油指令3.FUEL OUTPUT 3.燃油输出4.SERVO DEVIATION OUTP. 4.伺服机构输出偏差5.SERVO DEADBAND 5.伺服机构断带6.GENERAL INFORMATION 6.总体去7.FEEDBACK FAIL 7.反馈失效8.IN-DATA ERROR 8.当前错误9.OTHER STATUS 9.其它状态10.OTHER ALARM 10.其他警报LAMP TEST/RESET/DOWN/UP 指示灯试验/复位/低/高TEST 测试SERVO ON/DEACTIVATE SERVO 伺服机构开/伺服机构失效DATA VALUE/ACTUATOR 数据值/执行器CHANGE LOCK/OPEN 变化锁定/开SAVE/DOWN/UP 保存/低/高TEST 测试SET/FUEL/AUTO 设定/燃油/自动SELECT/INLET/OUTLET 选择/入口/出口MDO/HFO 轻柴油/重燃油A/E FUEL OIL CHANGE OVER&INDICATION 辅机燃油转换和指示板BOILER FUEL O.TEMP. 锅炉燃油温度BOILER STEAM PRESS. 锅炉蒸汽压力BOILER WATER LEVEL 锅炉水位BOILER RUNNING 锅炉运行中BOILER EMER.STOP 锅炉应急停M.E.L.O.INLET PRESS. 主机滑油进口压力M.E.F.O.PRESS. 主机燃油压力M.E.PISTON L.O.PRESS. 主机活塞滑油压力M.E.CAM.L.O.PRESS. 主机凸轮轴滑油压力NO.1 MAIN AIR RESERVOIR PRESS. NO.1主空气瓶气压NO.2 MAIN AIR RESERVOIR PRESS. NO.2主空气瓶气压M.E.SCAVENGE AIR PRESS. 主机扫气压力M.E.F.C.W.INLET PRESS. 主机冷却水入口压力M.E.STARTING AIR PRESS. 主机起动空气压力M.E.CONTROL AIR PRESS. 主机控制空气压力M.E.SAFETY AIR PRESS. 主机安全空气压力M.E.L.O.INLET TEMP. 主机滑油入口油温INCINERATOR RUNNING 焚烧炉运行中AUX.BILGE PUMP RUNNING/START 辅舱底泵运行/起动NO.1 E/R FAN SUPPLY RUNNING/START 机舱NO.1送气风机运行/起动NO.1 E/R FAN EXHAUST RUNNING/START 机舱NO.1排气风机运行/起动NO.2 E/R FAN SUPPLY RUNNING/START 机舱NO.2送气风机运行/起动NO.2 E/R FAN EXHAUST RUNNING/START 机舱NO.2排气风机运行/起动E/R PUMP EMER.STOP 机舱油泵应急停BOW THRUSTER POWER ON 侧推器通电MAIN AIR COMPR.NO.1 RUNNING NO.1主空气压缩机运行MAIN AIR COMPR.NO.2 RUNNING NO.2主空气压缩机运行STEERING GEAR NO.1 RUNNING NO.1舵机运行INCINERATOR EMER.STOP 焚烧炉应急停AUX.BILGE PUMP STOP 辅舱底泵停NO.1 E/R FAN STOP 机舱NO.1风机停NO.2 E/R FAN STOP 机舱NO.2风机停E/R FAN EMER.STOP 机舱风机应急停LAMP TEST 指示灯试验MAIN AIR COMPR.NO.1 MANU./AUTO. NO.1主空气压缩机手动/自动MAIN AIR COMPR.NO.2 MANU./AUTO. NO.2主空气压缩机手动/自动STEERING GEAR NO.2 RUNNING NO.2舵机运行模拟屏FROM AIR RECEIV. 来自空气瓶START AIR VALVE 启动空气阀FROM L.O. 来自滑油STORAGE TANK 贮存柜L.O PRE-PUMP 预滑油泵L.O COOLER 滑油冷却器HT.FW.COOLER 高温淡水冷却器FROM M/E 来自主机TO M/E 到主机L.O.PURIFIER 滑油分油机L.O.SPILL.TANK 滑油溢油柜L.O.CLEAN.TANK 滑油清洁柜F.O.SPILL.TANK 燃油溢油柜L.O.CIRC.TANK 滑油循环柜F.O.TRANS.PUMP 燃油输驳运泵FROM.D.O.TANK 来自柴油日用柜11L.O.CIRC.TANK 滑油循环柜F.O.PURIFIER 燃油分油机SLUDGE TANK 污油柜L.O.TRANS.PUMP 滑油驳运泵L.O.STORAGE TANK 滑油贮存柜L.O.CIRC.TANK 滑油循环柜F.O.SET.TANK 燃油沉淀柜D.O.PURIFIER 柴油分油机D.O.FEED.PUMP 柴油供油泵F.O.FEED.PUMP 燃油供油泵F.O.SERV.TAMK 燃油日用柜D.O.SERV.TAMK 柴油日用柜CYL.O.SERV.TAMK 气缸油日用柜BOILER.D.O.SERV.TAMK 锅炉柴油日用柜BOILER.F.O.SERV.TAMK 锅炉燃油日用柜DONKEY.BOILER 辅锅炉BLOWER 鼓风机STEAM PRESS 蒸汽压力EXH.GAS BOILER 废气锅炉BURNER 燃烧器DRAIN V. 泄放阀F.W.PUMP 淡水泵CAM L.O BOOSTER PUMP 凸轮滑油增压泵TURNING GEAR 盘车机DISENGAGE/ENGAGE 脱开/合上SHAFT GEN. 轴带发电机FROM L.O.STORAGE TANK 来自滑油储存柜M/E L.O.CIRC.TANK 主机滑油循环柜TO L.O.TRANS.PUMP 到滑油驳运泵M/E START.V 主机起动阀TO PISTON 到活塞TO BEARING 到轴承HOT WELL 热水井M/E R.P.M 主机转速CONTROL AIR PRESS 控制空气压力M/E START AIR PRESS 主机起动空气压力JACKET W.INLET TEMP. 缸套水进口温度L.O.AUTO FILTER 滑油自清滤器TO SLUDGE TANK 到污油柜FROM A/E 来自副发电机L.O.FITER OUT PRESS 滑油滤器出口压力MAIN L.O.PUMP 主滑油泵M/E L.O.PRESS 主机滑油压力M/E L.O.INLET TEMP. 主机滑油进口温度M/E F.O.SERV.TANK 主机燃油日用柜F.O.SET.TANK 燃油沉淀柜BOILER F.O.SEV.TANK 锅炉燃油日用柜M/E L.O.CIRC.TANK 主机滑油循环柜L.O.STORAGE TNK 滑油储存柜STEAM FOLLOW TUBE TANK 蒸汽伴随管柜F.O.SPILL TANK 燃油溢油柜12。

CHAPTER 8080章发动机起动系统Text 1 Engine Starting正文1 发动机起动The engine starting system uses pneumatic power to turn the engine’s N2 rotor during a start or motor procedure. Pneumatic power comes from one of these sources:发动机起动系统在起动或者运动程序时利用气动能量来转动N2转子.气动能量来自于以下之一:-- APU 辅助动力装置(APU)-- Pneumatic ground equipment 地面气源装置-- Opposite engine. 另一侧发动机These components control the engine start system: 以下部件控制发动机起动系统:-- Flight compartment switches 驾驶舱开关-- Display electronics unit (DEU) 电子显示组件(DEU)-- Electronic engine control (EEC). 发动机电子控制(EEC)The engine starting system operates on the ground and in flight.发动机起动系统在地面在空中均可运行.The engine starting system uses these airplane and engine systems or components:发动机起动系统使用以下飞机和发动机系统或部件-- Pneumatic power 气源系统-- Electrical power 电源系统-- Flight compartment switches 驾驶舱开关-- Engine fuel control system 发动机燃油控制系统-- Engine control system. 发动机控制系统-- Common display system (CDS). 通用显示系统(CDS)Engine Start Switch发动机起动开关You put the engine start switch to the GRD position to turn the engine with the starter. The switch automatically moves to the OFF position at starter cutout.将发动机起动开关置于GRD位以在起动机作用下转动发动机.当起动机关断时开关自动移至OFF位When electrical and pneumatic power is available, this happens when you put the switch to the GRD position:当电源和气源可用时,将开关置于GRD位会发生以下情况:-- Electronic engine control (EEC) receives a start signal EEC接收到一个起动信号-- APU receives an engine start signal APU收到一个发动机起动信号-- Start valve opens and the pneumatic starter turns the engine. 起动杆打开,气动起动机使发动机转动.The crew uses the FLT position to start the engine in flight when the starter is not necessary.机组人员使用FLT位以在空中不需用起动机就可起动发动机.The CONT position supplies continuous ignition. CONT位提供连续点火. Start Valve and StarterThe start valve opens to supply power to the starter. Usually, this valve opens when you put the engine start switch to the GRD position. The start valve position shows on the engine display. You can manually open the valve. The starter turns the engine N2 rotor through the engine accessory gearbox (AGB).起动活门开启以给起动机供应能量.通常这个活门在讲发动机启动开关置于GRD位时开启.起动活门的位置在发动机显示上显示.可人工开启此活门.起动机通过发动机的辅助齿轮箱(AGB)来转动N2转子.EEC EECThe EEC protects the engine during start. The EEC shuts off fuel supply to the engine when it finds the engine parameters are out of limits during a start.EEC在起动时保护发动机.当EEC发现在起动时发动机参数超出限制就会关断发动机的燃油供应Display Electronics Units (DEUs) 电子显示组件(DEUs)The DEUs are components of the common display system (CDS). The DEUs monitor N2 and let the engine start switch go back to the OFF position at starter cutout.DEU是CDS的部件.DEU监控N2,在起动机关断时使起动开关回至OFF位.CHAPTER 74 Ignition74章点火系统Text 2 General Introduction正文2 一般介绍The ignition systems supply electrical sparks in the combustion chamberfor combustion. Each engine has two ignition systems that operate independently. The ignition system usually operates manually. However, the ignition systems operate automatically when the electronic engine control (EEC) sees a possible engine flameout condition.点火系统为燃烧室提供电火花以供燃烧.每个发动机具有两个相互独立工作的点火系统.点火系统通常人工运行.但是,当EEC发现有可能熄火的情况下点火系统会自动运行.You use ignition during these times:在以下情况下会进行点火-- Ground start 地面起动--Takeoff and landings 起飞和着陆--In-flight (during heavy turbulence or bad weather) 飞行中(在强颠簸或坏天气时)--In-flight start. 飞行中起动Text 2 Components正文2 部件Each engine has a right and a left ignition system. These are the components of each ignition system:每个发动机均有左右点火系统.以下为每个点火系统的部件-- Ignition exciter 点火激励器-- Ignition lead 点火器导线-- Air manifold 空气总管-- Spark igniter 火花点火器The left ignition system is located on the left hand side, connected to the lower ignition exciter. 左点火系统位于左手位与下侧点火激励器相连接The right ignition system is located on the right hand side, connected to the upper ignition exciter.右点火系统位于右手位,与上侧点火激励器相连接Text 3 Control正文3 控制These components control ignition:以下部件控制点火--Start levers 起动杆--Start switches 起动开关--Ignition selector switch 点火选择开关--Electronic engine control (EEC).发动机电子控制(EEC)The start lever controls ignition system power to the EEC. The start switch and the ignition selector switch supply inputs to the EEC. The EEC uses these inputs to supply power to the ignition exciters. The ignition exciters supply power to the spark igniters.起动杆控制送入EEC的点火系统能量.起动开关和和点火选择开关将输入送入EEC.EEC利用这些输入给点火激励器供应能量.点火激励器给火花点火器提供能量The engine starting system also uses the switch positions for control.发动机起动系统利用开关位置进行控制.Text 4 Electrical Power正文4 电能The engine 1 ignition systems receive 115v ac from ac transfer bus 1 and the ac standby bus. The EEC has internal switches that control the 115v ac to the ignition exciters. The ignition exciters change the 115v ac input to a dc voltage of approximately 15,000 to 20,000v for the spark igniters. The spark igniters give a spark for combustion. The ignition systems of engine 2 receive ac power from ac transfer bus 2 and the ac standby bus1号发动机点火系统从1号交流转换汇流条和交流备用汇流条接收115V交流电..EEC具有内部开关控制进入点火激励器的115V交流电.点火激励器将115V交流输出转换为供火花点火器使用的大约15000到20000V直流电..火花激励器为燃烧提供电火花,2号发动机的点火系统从2号交流转换汇流条和交流备份汇流条接收电能.Text 5 Ignition Lead Cooling正文5 点火导线冷却Each spark igniter has its own ignition lead. Each ignition lead goes into an air manifold at the 6:00 position at the aft end of the fan case. Booster air (low pressure compressor exhaust air) decreases the temperature of the lead. It comes out of the spark igniter end of the ignition lead to cool the spark igniter. The cooling air for the lead is necessary because the copper wire increases its resistance with the temperature. So a hot lead decreases the igniter current and consequently the energy of the igniter spark.每个火花点火器均具有自己的点火导线.每个点火导线进入风扇机匣后端6点钟位置的空气总管.增压器空气(低压压气机排气)降低导线的温度.空气从点火导线的火花点火器端流出以冷却火花点火器.导线的冷却空气是必要的因为铜线的电阻会随着温度增加而增大.所以过热的导线会降低点火电流进而会降低电火花的能量.Questions to the text:正文问题1. How is the ignition lead cooled?点火导线怎样进行冷却?2. Where is the cooling air from?冷却空气从哪里来?3. Why is the cooling air necessary?为什么冷却空气是必要的?4. What will happen if the lead becomes hot?当导线变热时会发生什么情况?。

火电厂火电厂火电厂火电厂、、、、热电厂各系统中英文对照热电厂各系统中英文对照热电厂各系统中英文对照热电厂各系统中英文对照1111Quality and nuclear safety related system(完全与质量和核安全相关系统)Partially quality and nuclear safety related system(部分与质量和核安全相关系统)Quality related system(与质量相关系统)Non quality related system(与质量无关系统)A Feedwater Supply(供水系统)ABP Low Pressure Feedwater Heater(低压给水加热器系统)ACO Feedwater Heaters Drain Recovery(给水加热器疏水回收系统)ADG Feedwater Deaerating Tank and Gas Stripper(给水除氧器系统)ADS LV AC Network 380V(ET Buiding)/低压交流电源380V系统(ET厂房)AET Feedwanter Pump Turbine Gland(主给水泵汽机轴封系统)AGM Moter Driven Feedwater Pump Lubrication(电动主给水泵润滑系统)AGR Feedwater Pump Turbine Lubrication and Control Fluid(主给水泵汽机润滑油及调节油系统)AHP High Pressure Feedwataer Heater(高压给水加热器系统) ory System(汽机监视系统)APA Moter-Driven Feedwater Pump(电动主给水泵系统)2222APD Start-up Feedwater System(启动给水系统)APG Steam Generator Blowdown(蒸汽发生器排污系统)APP Turbine-Driven Feedwater Pump(汽动主给水泵系统)APU Feedwater Pump Turbine Drain(主给水泵汽机疏水系统)ARE Feedwater Flow Control(给水流量控制系统)ASG Auiliary Feedwater (辅助给水系统)ATE Condensate Polishing Plant(凝结水净化处理系统)C Condenser(Condensation-Vacuum-Circulating Water)/凝汽器(冷凝-真空-循环水)CAR Turbine Exhaust Water Spraying(汽机排汽口喷淋系统)CET Turbine Gland(汽机轴封系统)CEX Condensate Extraction(凝结水抽取系统)CFI Circulating Water Filtraation(循环水过滤系统)CGR Circulating Water Pump Lubrication(循环水泵润滑系统)CPA Cathodic Protection(阴极保护系统)CRF Circulating Water(循环水系统)3333CTE Circulating Water Treatment(循环水处理系统)CVI Condenser Vacuum(凝汽器真空系统)D Ventilation-Handling Equipment-Communications-Elighting(通风-吊装设备-通讯-照明)DAA BOP Elevator System(BOP电梯系统)DAI Nuclear Island Building Elevators(核岛厂房电梯)DAM Turbine Hall Elevators(汽机厂房电梯)DEG Nuclear Island Chilled Water (核岛冷冻水系统)DEL Electrical Building Chilled Water(电气厂房冷冻水系统)DMA BOP Handling Equipment(AC Building)/BOP吊装设备(AC厂房)DME Main Swithchyard Handling Equipment(主开关站吊装设备)DMH Miscellaneous Hoists and Lifting Equipment in BOP Buildingsand Area(BOP厂房和BOP区域内的各种吊装设备DMK Fuel Building Handling Equipment(核燃料厂房吊装设备)DMM Turbine Hall Mechanical Handling Equipment(汽机厂房机械吊装设备)DMN Nuclear Auxiliary Building Handling Equipment(核辅助厂房吊装设备)4444DMP Circulating Water Pumping Station Handling Equipment (循环水泵站吊设备)DMR Reactor Building Handling Equipment(反应堆厂房吊装设备)DMW Handling Equipment for Reactor Building Gantry andPeripheral Rooms(反应堆厂房外部龙门架及其外围厂房吊装设备) DNB BOP Building&Area Normal Lighting(BOP厂房和区域内正常照明系统)DNK Fuel Buildings Normal Lighting(核燃料厂房正常照明系统)DNL Electrical Building Nomal Lighting(电气厂房正常照明系统)DNM Turbine Hall Normal Lighting(汽机厂房正常照明系统)DNN Nuclear Auxiliray Building Normal Lighting(核辅助厂房正常照明系统)DNP Circulating Water Pumping Station Normal Lighting(循环水泵房正常照明系统)DNQ Waste Auxiliary Building Normal Lighting(核废料辅助厂房正常照明系统)DNR Reactor Building Normal Lighting(反应堆厂房正常照明系统)DSB BOP Building&Area Emergency Lighting(BOP厂房和区域内应急照明系统)DSI Site Security System(厂区保安系统)DSK Fuel Buildings Emergency Lighting(核燃料厂房应急照明系统)5555DSL Electrical Building Emergency Lighting (电气厂房应急照明系统)DSM Turbine Hall Emergency Lighting(汽机厂房应急照明系统)DSN Nuclear Auxiliray Building Emergency Lighting(核辅助厂房应急照明系统)tem(汽机监视系统)DSP Circulating Water Pumping Station Emergency Lighting(循环水泵房应急照明系统)DSQ Waste Auxiliary Building Emergency Lighting(核废料辅助厂房应急照明系统)DSR Reactor Building Emergency Lighting(反应堆厂房应急照明系统)DTL Closed-Circuit Television(闭路电视系统)DTV Site Communication(厂区通讯系统)DVC Control Room Air Conditioning(主控制室空调系统)DVE Cable Floor Ventilation (电缆层通风系统)DVF Electrical Building Smoke Exhaust(电气厂房排烟系统)DVG Auxiliary Feedwater Pump Room Ventilation(辅助给水泵房通风系统)DVH Charging Pump Room Emergency Ventilation(上充泵房应急通风系统)DVI Component Cooling Room Ventilation(设备冷却水房间通风系统)DVK Fuel Building Ventilation(核燃料厂房通风系统)6666DVL Electrical Building Main Ventilation(电气厂房主通风系统)DVM Turbine Hall Vetilation(汽机厂房通风系统)DVN Nuclear Auxiliry Building Ventilation?房应急照明系统)统)DVP Circulating Water Pumping Station Ventilation (循环水泵通风系统)DVQ Waste Auxiliary Building Ventilation (废物辅助厂房通风系统)DVS Safety Injection and Containment Spray Pump Motor RoomVentilation(安全注入和安全喷林泵电机通风系统)DVT Demineralization Plant VentilationDVV Auxiliary Boiler and Compressor Building Ventilation(辅助锅炉和空压机厂房通风系统)DVW Peripheral Rooms Ventilation (安全壳环廊房间通风系统)DVX Lubricating Oil Transfer Plant Building Ventilation(润滑油输送装置厂房通风系统)DW A Hot Workshop and Warehouse Ventilation(热机修车间和仓库通风系统)DWB RestaurantVentilation (SA餐厅通风系统)DWC Trainning Center Ventilation (EA Building)/培训中心通风系统DWD Security Building Ventilation(保安楼通风系统)7777DWE Main Swithchyard Ventilation(主开关站通风系统)DWM EC Building Ventilation System(EC厂房暖通空调系统)ets(集中控制模拟量机柜)DWL Hot Laundry Ventilation(热洗衣房通风系统)DWM Emergency Center Ventilation System(应急中心通风系统/EM楼)DWN Site Laboratory Ventilation(厂区实验室通风系统/AL实验室)DWQ Garge & Laundry Ventilation(车库和洗衣房通风系统(AG/EL)厂房)DWS Essential ServiceWater Pumping Station Ventilation(重要厂用水泵站通风系统/PX泵站)DWT Archive & Documentation Center Ventilation(AD Building )/文档中心通风系统(AD楼)DWU Fire Fighting Training CenterV entilation(消防培训中心通风系统/EB楼)DWV Oil Storage Area V entilation (FC Building)/油料仓库通风系统(FC厂房)DWX Compressors Building Ventilation System(ZC Building)/空压机房通风系统(ZC厂房)DWY Electrochlorination Plant Ventilation(制氯站通风系统)DWZ Hydrogen Production Plant Ventilation(制氢站通风系统)8888E ContainmentEAS Containment Spray(安全壳喷淋系统)lation System(EC厂房暖通空调?rEAU Containment Instrumentation(安全壳仪表系统)EBA Containment Sweeping Ventilation(安全壳换气通风系统)EPP Containment Leakage Monitoring(安全壳泄漏监测系统)ETY Containment Atmosphere Monitoring(安全壳大气监测系统)EVC Reactor Pit Ventilation(反应堆堆坑通风系统)EVF Containment Cleanup(安全壳内空气净化系统)EVR Containment Continuous Ventilation(安全壳连续通风系统)G Turbine Generator(汽轮发电机)GCA Turbine and Feedheating Plant Preservation DuringOutage(汽机和给水加热装置停运期间的保养系统)GCT Turbine Bypass(汽机旁路系统)GEV Power Transmission(输电系统)GEW Main Swithchyard-EHV Switchgear(主开关站-超高压配电装置)GEX Generator Excitation and V oltage Regulation(发电机励磁和电压调节系统)9999GFR Turbine Control Fluid(汽机调节系统)GGR Turbine Lubrication Jaching and Turning(汽机润滑、顶轴和盘车系统)GHE Generator Seal Oil(发电机密封油系统)GME Turbine Supervisory System(汽机监视系统) GPA Generator and Power Transmission Protection(发电机和输电保护系统)GPV Turbine Steam and Drain(汽机蒸汽和疏水系统)GRE Turbine Governing(汽机调节系统)GRH Generator Hydrogen Cooling(发电机氢气冷却系统)GRV Generator Hydrogen Supply(发电机氢气供应系统)GSE Turbine Protection(汽机保护系统)GSS Moisture Separator Water(汽水分离再热器系统)GST Stator Cooling Water(发电机定子冷却水系统)GSY Grid Synchronization and Connection(同步并网系统)GTH Turbine Lube Oil Treatment(汽机润滑油处理系统)GTR TurbineGenerator Remote Control(汽轮发电机远程控制系统)10101010J Fire Protection(Detection-Fire Fighting)/消防(探测-火警)JDT Fire Detection(火警探测系统)JPD Fire Fighting Water Distribution(消防水分配系统)JPH Turbine Oil Tank Fire Protection(汽机油箱消防系统)JPI Nuclear Island Fire Protection (核岛消防系统)JPL Electrical Building Fire Protection(电气厂房消防系统)JPP Fire Fighting Water Production(消防水生产系统)JPS Mobile & Portable Fire Fighting Equipment(移动式和便携式消防设备)JPT Transformers Fire Protection(变压器灭火系统)JPU Site Fire Fighting Water Distribution(厂区消防水分配系统)JPV DieselGenerator Fire Protection(柴油发电机灭火系统)K Instrumentation and Control(仪表和控制)KBS Thermocouple Cold Junction Boxes(热电偶冷端盒系统)KCO Common Control Cabinets for Conventional Island(常规岛共用控制机柜)KDO Test Data Acquisition(试验数据采集系统)11111111KIR Loose Parts and Vibration Monitoring(松动部分和振动监测系统)KIS Seisimic Instrumentation(地震仪表系统)KIT Centralized Data Processing(集中数据处理系统)KKK Site and Building Access Control(厂区和办公楼出入监督系统)KKO Energy Metering and Perturbography(电度表和故障录波仪)KLP 500KV Line Protection 500KV (线路保护系统)KME Test Instrumentation(试验仪表系统)KPR Remote Shutdown Panel (应急停堆盘系统)KRG General Control Analog Cabinets(集中控制模拟量机柜)?房应急照明系统)KRS Site Radiation and Meteorological Monitoring(厂区辐射与气象检测系统)KRT Plant Radiation Monitoring (电厂辐射监测系统)KSA Alarm Processing(报警处理系统)KSC Main Control Room(主控制室系统)KSN Nulear Auxiliary Building-Local Control Panels and Boards(核辅助厂房-就地控制屏和控制盘)12121212KSU Security Building Control Desk(应急保安控制台系统)KZC Controlled Area Access Monitoring(控制区出入监测系统)L Electrical System(电气系统)LAA Uninterrupted 230V DC Power System(LNE)Inverter Power Supply/230V 不间断直流电源系统、逆变系统(电气厂房LNE)LAB Turbine Generator Continuous Lubrication Pump Power Supply/汽轮机不间断润滑油泵电源系统(汽机厂房)常?JPD Fire Fightin_。

单元机组主控系统Master Control System of Unit Plant单元机组主控系统一般设置有四种运行方式:即汽轮机手动控制,锅炉手动控制的基本方式(BASE方式);以锅炉为基础的汽轮机跟随方式(TF方式);以汽轮机为基础的锅炉跟随方式(BF方式)和汽轮机一锅炉综合功率控制的协调控制方式(CCS方式)。

四种运行方式之间的切换必须是平稳无扰动的。

操作员可根据机组的运行情况进行选择。

一般情况下,机组适宜在滑压控制方式和CCS方式下运行。

事故工况时,则通常选择在TF方式和定压方式下运行。

The master control system of the unit plant generally provides four modes of operation, including the base mode of steam turbine manual control and boiler manual control; the boiler-based turbine following mode (TF mode); the steam turbine-based boiler following mode (BF mode), and the Coordinated Control System (CCS) mode of steam turbine-boiler integrated power control. Switching amongst the four modes must be smooth without disturbance. The operator may make choices based on the unit running conditions. Under normal circumstances, the unit is suitable to operate in the sliding pressure control mode and the CCS mode. In accident conditions, it will usually run in the TF mod and the constant pressure mode.单元机组主控系统的前三种运行方式的根本区别在于对功率和主汽压力的控制处理上。

在单元机组中,汽轮机进汽压力是反映机、炉能量平衡和机组运行稳定的重要指标。

The fundamental difference between the first three modes of the master control system of the unit plant lies in the control and treatment of power and main steam pressure. In the unit plant, the inlet steam pressure of the steam turbine is an important indicator to reflect energy balance of the unit and the furnace as well as the unit running stability.BF方式:汽轮机接受负荷指令,调节功率,能快速响应负荷要求;锅炉负责调节主汽压力,维持主汽压力的稳定,但由于锅炉动态响应慢,因此动态过程中主汽压波动大。

特点:可以利用锅炉蓄热提高经济性,但主汽压波动大,影响机组的安全运行。

BF mode: the steam turbine accepts load demand, adjusts the power and is able to quickly respond to load requirements; the boiler is responsible for regulating the main steam pressure and maintaining the stability of the main steam pressure. However, the main steam pressure will greatly fluctuate in the dynamic process due to slow dynamic response of the boiler. Features: boiler heat storage can be taken advantage of to improve the economy, but great fluctuations of the main steam pressure will affect safe operation of the unit.TF方式:锅炉接受负荷指令,调节功率,满足负荷要求,汽轮机负责调节主汽压力,但锅炉动态响应慢,因此,负荷响应能力差。

其特点:由于汽轮机负责调节主汽压力,因而主汽压力稳定,但会产生附加蓄热,机组经济性下降。

TF mode: the boiler accepts load demand, adjusts the power and meets the load requirements; the steam turbine is responsible for regulating the main steam pressure. However, the load response capacity is poor due to slow dynamic response of the boiler. Features: the main steam pressure isstable as the steam turbine is responsible for regulating the main steam pressure, but the unit economy will decline due to the generation of additional heat storage.协调控制方式(CCS)较好地解决机组的负荷适应性与稳定性这一对矛盾。

协调控制系统的一个重要思想,就在于蓄能的合理利用和补偿:利用锅炉的蓄能,同时要防止利用的无限性;补偿蓄能,动态超调锅炉的能量输入。

The CCS mode can better solve the contradiction between the unit’s load adaptability and stability. Rational utilization and compensation of energy storage is an important idea of the coordinated control system: to make use of the boiler energy storage but prevent unlimited use; to compensate energy storage and dynamically over-shoot the boiler energy input.单元主控中的锅炉主控制器相当于负荷指令处理回路与燃烧控制系统之间的接口,它产生的锅炉指令作为锅炉子控制系统的定值信号,通过该回路可以将经过修正的机组负荷指令信号传送到风量控制回路及燃料控制回路,以协调锅炉出力与负荷指令的匹配关系。

该主控回路既可以工作在自动方式,也可以工作在手动方式,均能够相应地完成单元机组在各种工况下的控制功能。

The boiler master controller in the unit master is equivalent to the interface between the load demand processing loop and the combustion control system. It generates boiler demands as the set signal of the boiler sub-control system. This loop can send modified load demand signal of the unit to the air volume control loop and the fuel control loop, so as to coordinate the matching relation between boiler output and load demand. The master control loop is able to complete the unit’s control functions in different operating conditions either in automatic mode or manual mode.单元主控中的汽轮机主控制器的任务是接受机组负荷指令,经各种运算及运行方式的切换,最终产生汽轮机负荷指令的步进增/减信号。

汽轮机主控回路相当于负荷指令处理回路与DEH系统之间的接口,通过DEH系统改变汽轮机调节汽门开度,使进入汽轮机的蒸汽量与机组的负荷指令相适应,从而协调机炉之间的能量需求。

The master controller of the steam turbine of the unit master is responsible for receiving load demands of the unit and ultimately generating the stepping increment / decrement signal of load demands of the steam turbine by switching between different methods of calculation and modes of operation. The master control loop of the steam turbine is equivalent to the interface between the load demand processing loop and the DEH system. The DEH system changes the adjustable valve opening of the steam turbine so that the amount of steam entering the steam turbine adapts to the unit’s load demand, thereby coordinating the energy demand between the unit and the boiler.单元主控还设有辅机故障减负荷(Run Back,简称RB)和机组快速甩负荷(Fast Cut Back.简称FCB)工况的负荷指令控制回路,机组迫升/迫降负荷指令控制回路和增闭锁/减闭锁负荷指令控制回路。