Damping-characteristics-of-unreinforced,-glass-and-carbon-fiber-reinforced-nylon-6-6-spur-gears_2006

- 格式:pdf

- 大小:351.85 KB

- 文档页数:7

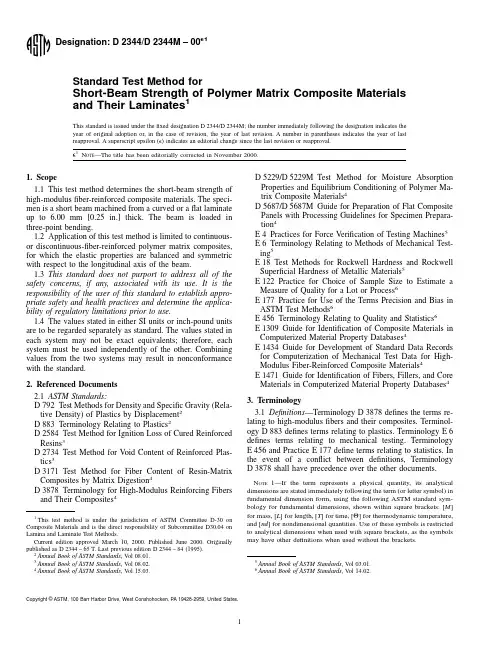

3.2Definitions of Terms Specific to This Standard:3.2.1balanced laminate ,n —a continuous fiber-reinforcedlaminate in which each +u lamina,measured with respect to thelaminate reference axis,is balanced by a –u lamina of the samematerial (for example,[0/+45/–45/+45/–45/0]).3.2.2short-beam strength ,n —the shear stress as calculatedin Eq 1,developed at the specimen mid-plane at the failureevent specified in 11.6.3.2.2.1Discussion —Although shear is the dominant appliedloading in this test method,the internal stresses are complexand a variety of failure modes can occur.Elasticity solutions byBerg et al (1)7,Whitney (2),and Sullivan and Van Oene (3)have all demonstrated inadequacies in classical beam theory indefining the stress state in the short-beam configuration.Thesesolutions show that the parabolic shear-stress distribution aspredicted by Eq 1only occurs,and then not exactly,on planesmidway between the loading nose and support points.Awayfrom these planes,the stress distributions become skewed,withpeak stresses occurring near the loading nose and supportpoints.Of particular significance is the stress state local to theloading nose in which the severe shear-stress concentrationcombined with transverse and in-plane compressive stresseshas been shown to initiate failure.However,for the moreductile matrices,plastic yielding may alleviate the situationunder the loading nose (1)and allow other failure modes tooccur such as bottom surface fiber tension (2).Consequently,unless mid-plane interlaminar failure has been clearly ob-served,the short-beam strength determined from this testmethod cannot be attributed to a shear property,and the use ofEq 1will not yield an accurate value for shear strength.3.2.3symmetric laminate ,n —a continuous fiber-reinforcedlaminate in which each ply above the mid-plane is identicallymatched (in terms of position,orientation,and mechanicalproperties)with one below the mid-plane.3.3Symbols :b —specimen width.CV —sample coefficient of variation (in percent).F sbs —short-beam strength.h —specimen thickness.n —number of specimens.P m —maximum load observed during the test.x i —measured or derived property for an individual specimenfrom the sample population.x ¯—sample mean (average).4.Summary of Test Method4.1The short-beam test specimens (Figs.1-4)are center-loaded as shown in Figs.5and 6.The specimen ends rest ontwo supports that allow lateral motion,the load being appliedby means of a loading nose directly centered on the midpointof the test specimen.5.Significance and Use5.1In most cases,because of the complexity of internalstresses and the variety of failure modes that can occur in thisspecimen,it is not generally possible to relate the short-beam strength to any one material property.However,failures are normally dominated by resin and interlaminar properties,and the test results have been found to be repeatable for a given specimen geometry,material system,and stacking sequence (4).5.2Short-beam strength determined by this test method can be used for quality control and process specification purposes.It can also be used for comparative testing of composite materials,provided that failures occur consistently in the same mode (5).5.3This test method is not limited to specimens within the range specified in Section 8,but is limited to the use of a loading span length-to-specimen thickness ratio of 4.0and a minimum specimen thickness of 2.0mm [0.08in.].6.Interferences 6.1Accurate reporting of observed failure modes is essen-tial for meaningful data interpretation,in particular,the detec-tion of initial damage modes.7.Apparatus 7.1Testing Machine ,properly calibrated,which can be operated at a constant rate of crosshead motion,and which the error in the loading system shall not exceed 61%.The load-indicating mechanism shall be essentially free of inertia7Boldface numbers in parentheses refer to the list of references at the end of thisstandard.N OTE 1—Drawing interpretation per ANSI Y14.5-1982and ANSI/ASM B46.1-1986.N OTE 2—Ply orientation tolerance 60.5°relative to –B–.FIG.1Flat Specimen Configuration(SI)lag at the crosshead rate used.Inertia lag may not exceed 1%of the measured load.The accuracy of the testing machine shallbe verified in accordance with Practices E 4.7.2Loading Nose and Supports ,as shown in Figs.5and 6,shall be 6.00-mm (0.250-in.)and 3.00-mm (0.125-in.)diametercylinders,respectively,with a hardness of 60to 62HRC,asspecified in Test Methods E 18,and shall have finely groundsurfaces free of indentation and burrs with all sharp edgesrelieved.7.3Micrometers —For width and thickness measurements,the micrometers shall use a 4-to 5-mm (0.16-to 0.2-in.)nominal diameter ball interface on an irregular surface such asthe bag side of a laminate and a flat anvil interface on machinededges or very smooth tooled surfaces.A micrometer or caliperwith flat anvil faces shall be used to measure the length of thespecimen.The accuracy of the instrument(s)shall be suitablefor reading to within 1%of the sample dimensions.For typicalsection geometries,an instrument with an accuracy of 60.002mm (60.0001in.)is desirable for thickness and width mea-surement,while an instrument with an accuracy of 60.1mm(60.004in.)is adequate for length measurement.7.4Conditioning Chamber ,when conditioning materials atnonlaboratory environments,a temperature/vapor-level-controlled environmental conditioning chamber is required thatshall be capable of maintaining the required temperature towithin 63°C (65°F)and the required vapor level to within63%.Chamber conditions shall be monitored either on an automated continuous basis or on a manual basis at regular intervals.7.5Environmental Test Chamber ,an environmental test chamber is required for test environments other than ambient testing laboratory conditions.This chamber shall be capable of maintaining the test specimen at the required test environment during the mechanical test method.8.Sampling and Test Specimens 8.1Sampling —Test at least five specimens per test condi-tion unless valid results can be gained through the use of fewer specimens,as in the case of a designed experiment.For statistically significant data,consult the procedures outlined in Practice E 122.Report the method of sampling.8.2Geometry :8.2.1Laminate Configurations —Both multidirectional and pure unidirectional laminates can be tested,provided that there are at least 10%0°fibers in the span direction of the beam (preferably well distributed through the thickness),and that the laminates are both balanced and symmetric with respect to the span direction of the beam.8.2.2Specimen Configurations —Typical configurations for the flat and curved specimens are shown in Figs.1-4.For specimen thicknesses other than those shown,the following geometries are recommended:Specimen length =thickness 36Specimen width,b =thickness 32.0N OTE 2—Analysis reported by Lewis and Adams (6)has shown that a width-to-thickness ratio of greater than 2.0can result in a significant width-wise shear-stress variation.8.2.2.1For curved beam specimens,it is recommended that the arc should not exceed 30°.Also,for these specimens,the specimen length is defined as the minimum chord length.8.3Specimen Preparation —Guide D 5687/D 5687M pro-vides recommended specimen preparation practices and should be followed where practical.8.3.1Laminate Fabrication —Laminates may be hand-laid,filament-wound or tow-placed,and molded by any suitable laminating means,such as press,bag,autoclave,or resin transfer molding.8.3.2Machining Methods —Specimen preparation is impor-tant for these specimens.Take precautions when cutting specimens from the rings or plates to avoid notches,undercuts,rough or uneven surfaces,or delaminations as a result of inappropriate machining methods.Obtain final dimensions by water-lubricated precision sawing,milling,or grinding.The use of diamond tooling has been found to be extremely effective for many material systems.Edges should be flat and parallel within the specified tolerances.8.3.3Labeling —Label the specimens so that they will be distinct from each other and traceable back to the raw material,in a manner that will both be unaffected by the test method and not influence the test method.9.Calibration 9.1The accuracy of all measuring equipment shall have certified calibrations that are current at the time of use of theequipment.N OTE 1—Drawing interpretation per ANSI Y14.5-1982and ANSI/ASME B46.1-1986.N OTE 2—Ply orientation tolerance 60.5°relative to –B–.FIG.2Flat Specimen Configuration (InchPound)10.Conditioning10.1Standard Conditioning Procedure —Unless a differentenvironment is specified as part of the test method,conditionthe test specimens in accordance with Procedure C of TestMethod D 5229/D 5229M,and store and test at standardlaboratory atmosphere (2363°C (7365°F)and 50610%relative humidity).11.Procedure11.1Parameters to Be Specified Before Test :11.1.1The specimen sampling method and coupon geom-etry.11.1.2The material properties and data-reporting formatdesired.N OTE 3—Determine specific material property,accuracy,and data-reporting requirements before test for proper selection of instrumentation and data-recording equipment.Estimate operating stress levels to aid in calibration of equipment and determination of equipment settings.11.1.3The environmental conditioning test parameters.11.1.4If performed,the sampling test method,coupon geometry,and test parameters used to determine density and reinforcement volume.11.2General Instructions :11.2.1Report any deviations from this test method,whether intentional or inadvertent.11.2.2If specific gravity,density,reinforcement volume,or void volume are to be reported,then obtain these samples from the same panels as the test samples.Specific gravityandN OTE 1—Drawing interpretation per ANSI Y14.5-1982and ANSI/ASM B46.1-1986.N OTE 2—Ply orientation tolerance 60.5°relative to –A–.FIG.3Curved Specimen Configuration(SI)density may be evaluated by means of Test Methods D 792.V olume percent of the constituents may be evaluated by one ofthe matrix digestion procedures of Test Method D 3171,or forcertain reinforcement materials such as glass and ceramics,bythe matrix burn-off technique of Test Method D 2584.V oidcontent may be evaluated from the equations of Test MethodD 2734and are applicable to both Test Methods D 2584andD 3171.11.2.3Condition the specimens as required.Store the speci-mens in the conditioned environment until test time,if the testenvironment is different from the conditioning environment.11.2.4Following final specimen machining and any condi-tioning,but before testing,measure and record the specimenwidth and thickness at the specimen midsection and thespecimen length to the accuracy specified in 7.3.11.3Speed of Testing —Set the speed of testing at a rate of crosshead movement of 1.0mm (0.05in.)/min.11.4Test Environment —If possible,test the specimen under the same fluid exposure level as that used for conditioning.However,if the test temperature places too severe requirements upon the testing machine environmental chamber,test at a temperature with no fluid exposure control.In this case,a restriction must be placed upon the time from removal of the specimen from the conditioning chamber until test completion to inhibit nonrepresentative fluid loss from the specimen.Record any modifications to the test environment and specimen weight change after removal from conditioning until test completion.11.4.1Monitor the test temperature by placing an appropri-ate thermocouple at specimen mid-length to be located ontheN OTE 1—Drawing interpretation per ANSI Y14.5-1982and ANSI/ASME B46.1-1986.N OTE 2—Ply orientation tolerance 60.5°relative to –A–.FIG.4Curved Specimen Configuration (InchPound)underside of the beam.11.5Specimen Insertion —Insert the specimen into the testfixture,with the toolside resting on the reaction supports asshown in Fig.5or Fig.6.Align and center the specimen suchthat its longitudinal axis is perpendicular to the loading noseand side supports.Adjust the span such that the span-to-measured thickness ratio is 4.0to an accuracy of 60.3mm(0.012in.).The loading nose should be located equidistantbetween the side supports to within 60.3mm (0.012in.).Boththe loading nose and side supports should overhang thespecimen width by at least 2mm (0.08in.)at each side.In thecase of the flat laminate test,each specimen end shouldoverhang the side support centers by at least the specimenthickness.11.6Loading —Apply load to the specimen at the specifiedrate while recording data.Continue loading until either of thefollowing occurs:11.6.1A load drop-off of 30%,11.6.2Two-piece specimen failure,or11.6.3The head travel exceeds the specimen nominal thick-ness.11.7Data Recording —Record load versus crosshead dis-placement data throughout the test method.Record the maxi-mum load,final load,and the load at any obvious discontinui-ties in the load-displacement data.11.8Failure Mode —Typical failure modes that can be identified visually are shown in Fig.7.However,these may be preceded by less obvious,local damage modes such as transply cracking.Record the mode and location of failure,if possible identifying one or a combination of the modes shown.12.Calculation 12.1Short-Beam Strength —Calculate the short-beam strength using Eq 1as follows:F sbs 50.753P m b 3h (1)where:F sbs =short-beam strength,MPa (psi);P m =maximum load observed during the test,N (lbf);b =measured specimen width,mm (in.),and h =measured specimen thickness,mm (in.).12.2Statistics —For each series of test methods,calculate the average value,standard deviation,and coefficient of varia-tion (in percent)for each property determined asfollows:FIG.5Horizontal Shear Load Diagram (CurvedBeam)FIG.6Horizontal Shear Load Diagram (FlatLaminate)x 5~(i –1n x i !/n (2)s n –15Œ~(i 51nx i 2–n ~x !2!/~n –1!(3)CV 51003s n –1/x(4)where:x ¯=sample mean (average);s n–1=sample standard deviation;CV =sample coefficient of variation,%;n =number of specimens;and x i =measured or derived property.13.Report13.1Report the following information,or references point-ing to other documentation containing this information,to themaximum extent applicable (reporting of items beyond thecontrol of a given testing laboratory,such as might occur withmaterial details or panel fabrication parameters,shall be theresponsibility of the requester):N OTE 4—Guides E 1309,E 1434,and E 1471contain data reportingrecommendations for composite materials and composite materials me-chanical testing.13.1.1This test method and revision level or date of issue.13.1.2Whether the coupon configuration was standard orvariant.13.1.3The date and location of the test.13.1.4The name of the test operator.13.1.5Any variations to this test method,anomalies noticedduring testing,or equipment problems occurring during testing.13.1.6Identification of the material tested including:mate-rial specification,material type,material designation,manufac-turer,manufacturer’s batch or lot number,source (if not from manufacturer),date of certification,expiration of certification,filament diameter,tow or yarn filament count and twist,sizing,form or weave,fiber areal weight,matrix type,prepreg matrix content,and prepreg volatiles content.13.1.7Description of the fabrication steps used to prepare the laminate including:fabrication start date,fabrication end date,process specification,cure cycle,consolidation method,and a description of the equipment used.13.1.8Ply orientation and stacking sequence of the lami-nate.13.1.9If requested,report density,volume percent rein-forcement,and void content test methods,specimen sampling method and geometries,test parameters,and test results.13.1.10Average ply thickness of the material.13.1.11Results of any nondestructive evaluation tests.13.1.12Method of preparing the test specimen,including specimen labeling scheme and method,specimen geometry,sampling method,and coupon cutting method.13.1.13Calibration dates and methods for all measurements and test equipment.13.1.14Details of loading nose and side supports including diameters and material used.13.1.15Type of test machine,alignment results,and data acquisition sampling rate and equipment type.13.1.16Dimensions of each test specimen.13.1.17Conditioning parameters and results.13.1.18Relative humidity and temperature of the testing laboratory.13.1.19Environment of the test machine environmental chamber (if used)and soak time at environment.13.1.20Number of specimens tested.13.1.21Speed oftesting.FIG.7Typical Failure Modes in the Short BeamTest13.1.22Maximum load observed during the test,for eachspecimen.13.1.23Load-displacement curves for each specimen.13.1.24Failure mode of each specimen,identified if pos-sible from Fig.7.14.Precision and Bias14.1Precision —The data required for the development of aprecision statement is not currently available for this testmethod.14.2Bias —Bias cannot be determined for this test method as no acceptable reference standard exists.15.Keywords 15.1composite materials;resin and interlaminar properties;short-beam strengthREFERENCES(1)Berg,C.A.,Tirosh,J.,and Israeli,M.,“Analysis of Short BeamBending of Fiber Reinforced Composites,”in Composite Materials:Testing and Design (Second Conference),ASTM STP 497,ASTM,1972,pp.206-218.(2)Whitney,J.M.,and Browning,C.E.,“On Short-Beam Shear Tests forComposite Materials,”Experimental Mechanics ,V ol 25,1985,pp.294-300.(3)Sullivan,J.L.,and Van Oene,H.,“An Elasticity Analysis for theGenerally and Specially Orthotropic Beams Subjected to ConcentratedLoads,”Composites Science and Technology ,V ol 27,1986,pp.182-191.(4)U.S.Department of Transportation,Federal Aviation Administration,“Test Methods for Composites a Status Report:V olume III Shear Test Methods,”Report No.DOT/FAA/CT-93/17,III,FAA Technical Cen-ter,Atlantic City,1993.(5)Cui,W.,Wisnom,M.R.,and Jones,M.,“Effect of Specimen Size on Interlaminar Shear Strength of Unidirectional Carbon Fibre-Epoxy,”Composites Engineering ,V ol 4,No.3,1994,pp.299-307.(6)Adams,D.F.and Lewis,E.Q.,“Current Status of Composite Material Shear Test Methods,”SAMPE ,V ol 31,No.6,1994,pp.32-41.The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this ers of this standard are expressly advised that determination of the validity of any such patent rights,and the risk of infringement of such rights,are entirely their own responsibility.This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and if not revised,either reapproved or withdrawn.Your comments are invited either for revision of this standard or for additional standards and should be addressed to ASTM Headquarters.Your comments will receive careful consideration at a meeting of the responsible technical committee,which you may attend.If you feel that your comments have not received a fair hearing you should make your views known to the ASTM Committee on Standards,at the address shown below.This standard is copyrighted by ASTM,100Barr Harbor Drive,PO Box C700,West Conshohocken,PA 19428-2959,United States.Individual reprints (single or multiple copies)of this standard may be obtained by contacting ASTM at the above address or at 610-832-9585(phone),610-832-9555(fax),or service@ (e-mail);or through the ASTM website().。

Designation:D790–07Standard Test Methods forFlexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials1This standard is issued under thefixed designation D790;the number immediately following the designation indicates the year of original adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.A superscript epsilon(e)indicates an editorial change since the last revision or reapproval.This standard has been approved for use by agencies of the Department of Defense.1.Scope*1.1These test methods cover the determination offlexural properties of unreinforced and reinforced plastics,including high-modulus composites and electrical insulating materials in the form of rectangular bars molded directly or cut from sheets, plates,or molded shapes.These test methods are generally applicable to both rigid and semirigid materials.However,flexural strength cannot be determined for those materials that do not break or that do not fail in the outer surface of the test specimen within the5.0%strain limit of these test methods. These test methods utilize a three-point loading system applied to a simply supported beam.A four-point loading system method can be found in Test Method D6272.1.1.1Procedure A,designed principally for materials that break at comparatively small deflections.1.1.2Procedure B,designed particularly for those materials that undergo large deflections during testing.1.1.3Procedure A shall be used for measurement offlexural properties,particularlyflexural modulus,unless the material specification states otherwise.Procedure B may be used for measurement offlexural strength only.Tangent modulus data obtained by Procedure A tends to exhibit lower standard deviations than comparable data obtained by means of Proce-dure B.1.2Comparative tests may be run in accordance with either procedure,provided that the procedure is found satisfactory for the material being tested.1.3The values stated in SI units are to be regarded as the standard.The values provided in brackets are for information only.1.4This standard does not purport to address all of the safety concerns,if any,associated with its use.It is the responsibility of the user of this standard to establish appro-priate safety and health practices and determine the applica-bility of regulatory limitations prior to use.N OTE1—These test methods are not technically equivalent to ISO178.2.Referenced Documents2.1ASTM Standards:2D618Practice for Conditioning Plastics for TestingD638Test Method for Tensile Properties of PlasticsD883Terminology Relating to PlasticsD4000Classification System for Specifying Plastic Mate-rialsD4101Specification for Polypropylene Injection and Ex-trusion MaterialsD5947Test Methods for Physical Dimensions of Solid Plastics SpecimensD6272Test Method for Flexural Properties of Unrein-forced and Reinforced Plastics and Electrical Insulating Materials by Four-Point BendingE4Practices for Force Verification of Testing Machines E691Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method2.2ISO Standard:3ISO178Plastics—Determination of Flexural Properties of Rigid Plastics3.Terminology3.1Definitions—Definitions of terms applying to these test methods appear in Terminology D883and Annex A1of Test Method D638.4.Summary of Test Method4.1A bar of rectangular cross section rests on two supports and is loaded by means of a loading nose midway between the supports.A support span-to-depth ratio of16:1shall be used unless there is reason to suspect that a larger span-to-depth ratio may be required,as may be the case for certain laminated materials(see Section7and Note7for guidance).1These test methods are under the jurisdiction of ASTM Committee D20on Plastics and are the direct responsibility of Subcommittee D20.10on Mechanical Properties.Current edition approved Sept.1,2007.Published October2007.Originally approved st previous edition approved in2003as D790–03.2For referenced ASTM standards,visit the ASTM website,,or contact ASTM Customer Service at service@.For Annual Book of ASTM Standards volume information,refer to the standard’s Document Summary page on the ASTM website.3Available from American National Standards Institute(ANSI),25W.43rd St., 4th Floor,New York,NY10036,.*A Summary of Changes section appears at the end of this standard. Copyright©ASTM International,100Barr Harbor Drive,PO Box C700,West Conshohocken,PA19428-2959,United States.4.2The specimen is deflected until rupture occurs in the outer surface of the test specimen or until a maximum strain (see 12.7)of5.0%is reached,whichever occurs first.4.3Procedure A employs a strain rate of 0.01mm/mm/min [0.01in./in./min]and is the preferred procedure for this test method,while Procedure B employs a strain rate of 0.10mm/mm/min [0.10in./in./min].5.Significance and Use5.1Flexural properties as determined by these test methods are especially useful for quality control and specification purposes.5.2Materials that do not fail by the maximum strain allowed under these test methods (3-point bend)may be more suited to a 4-point bend test.The basic difference between the two test methods is in the location of the maximum bending moment and maximum axial fiber stresses.The maximum axial fiber stresses occur on a line under the loading nose in 3-point bending and over the area between the loading noses in 4-point bending.5.3Flexural properties may vary with specimen depth,temperature,atmospheric conditions,and the difference in rate of straining as specified in Procedures A and B (see also Note 7).5.4Before proceeding with these test methods,reference should be made to the ASTM specification of the material being tested.Any test specimen preparation,conditioning,dimensions,or testing parameters,or combination thereof,covered in the ASTM material specification shall take prece-dence over those mentioned in these test methods.Table 1in Classification System D 4000lists the ASTM material speci-fications that currently exist for plastics.6.Apparatus6.1Testing Machine —A properly calibrated testing ma-chine that can be operated at constant rates of crosshead motion over the range indicated,and in which the error in the load measuring system shall not exceed 61%of the maximum load expected to be measured.It shall be equipped with a deflection measuring device.The stiffness of the testing machine shall be such that the total elastic deformation of the system does not exceed 1%of the total deflection of the test specimen duringtesting,or appropriate corrections shall be made.The load indicating mechanism shall be essentially free from inertial lag at the crosshead rate used.The accuracy of the testing machine shall be verified in accordance with Practices E 4.6.2Loading Noses and Supports —The loading nose and supports shall have cylindrical surfaces.The default radii of the loading nose and supports shall be 5.060.1mm [0.19760.004in.]unless otherwise specified in an ASTM material specification or as agreed upon between the interested parties.When the use of an ASTM material specification,or an agreed upon modification,results in a change to the radii of the loading nose and supports,the results shall be clearly identified as being obtained from a modified version of this test method and shall include the specification (when available)from which the modification was specified,for example,Test Method D 790in accordance with Specification D 4101.6.2.1Other Radii for Loading Noses and Supports —When other than default loading noses and supports are used,in order to avoid excessive indentation,or failure due to stress concen-tration directly under the loading nose,they must comply with the following requirements:they shall have a minimum radius of 3.2mm [1⁄8in.]for all specimens.For specimens 3.2mm or greater in depth,the radius of the supports may be up to 1.6times the specimen depth.They shall be this large if significant indentation or compressive failure occurs.The arc of the loading nose in contact with the specimen shall be sufficiently large to prevent contact of the specimen with the sides of the nose.The maximum radius of the loading nose shall be no more than four times the specimen depth.6.3Micrometers —Suitable micrometers for measuring the width and thickness of the test specimen to an incremental discrimination of at least 0.025mm [0.001in.]should be used.All width and thickness measurements of rigid and semirigid plastics may be measured with a hand micrometer with ratchet.A suitable instrument for measuring the thickness of nonrigid test specimens shall have:a contact measuring pressure of 2562.5kPa [3.660.36psi],a movable circular contact foot 6.3560.025mm [0.25060.001in.]in diameter and a lower fixed anvil large enough to extend beyond the contact foot in all directions and being parallel to the contact foot within 0.005mm [0.002in.]over the entire foot area.Flatness of foot and anvil shall conform to the portion of the Calibration section of Test Methods D 5947.7.Test Specimens7.1The specimens may be cut from sheets,plates,or molded shapes,or may be molded to the desired finished dimensions.The actual dimensions used in Section 4.2,Cal-culation,shall be measured in accordance with Test Methods D 5947.N OTE 2—Any necessary polishing of specimens shall be done only in the lengthwise direction of the specimen.7.2Sheet Materials (Except Laminated Thermosetting Ma-terials and Certain Materials Used for Electrical Insulation,Including Vulcanized Fiber and Glass Bonded Mica):7.2.1Materials 1.6mm [1⁄16in.]or Greater in Thickness —For flatwise tests,the depth of the specimen shall be the thickness of the material.For edgewise tests,the width of theTABLE 1Flexural StrengthMaterial Mean,103psiValues Expressed in Units of %of 103psi V r A V R B r C R D ABS9.99 1.59 6.05 4.4417.2DAP thermoset 14.3 6.58 6.5818.618.6Cast acrylic 16.3 1.6711.3 4.7332.0GR polyester19.5 1.43 2.14 4.05 6.08GR polycarbonate 21.0 5.16 6.0514.617.1SMC26.04.767.1913.520.4AV r =within-laboratory coefficient of variation for the indicated material.It is obtained by first pooling the within-laboratory standard deviations of the test results from all of the participating laboratories:Sr =[[(s 1)2+(s 2)2...+(s n )2]/n]1/2then V r =(S r divided by the overall average for the material)3100.BV r =between-laboratory reproducibility,expressed as the coefficient of varia-tion:S R ={S r 2+S L 2}1/2where S L is the standard deviation of laboratory means.Then:V R =(S R divided by the overall average for the material)3100.Cr =within-laboratory critical interval between two test results =2.83V r .DR =between-laboratory critical interval between two test results =2.83V R.specimen shall be the thickness of the sheet,and the depth shall not exceed the width(see Notes3and4).For all tests,the support span shall be16(tolerance61)times the depth of the beam.Specimen width shall not exceed one fourth of the support span for specimens greater than3.2mm[1⁄8in.]in depth.Specimens3.2mm or less in depth shall be12.7mm[1⁄2 in.]in width.The specimen shall be long enough to allow for overhanging on each end of at least10%of the support span, but in no case less than6.4mm[1⁄4in.]on each end.Overhang shall be sufficient to prevent the specimen from slipping through the supports.N OTE3—Whenever possible,the original surface of the sheet shall be unaltered.However,where testing machine limitations make it impossible to follow the above criterion on the unaltered sheet,one or both surfaces shall be machined to provide the desired dimensions,and the location of the specimens with reference to the total depth shall be noted.The value obtained on specimens with machined surfaces may differ from those obtained on specimens with original surfaces.Consequently,any specifi-cations forflexural properties on thicker sheets must state whether the original surfaces are to be retained or not.When only one surface was machined,it must be stated whether the machined surface was on the tension or compression side of the beam.N OTE4—Edgewise tests are not applicable for sheets that are so thin that specimens meeting these requirements cannot be cut.If specimen depth exceeds the width,buckling may occur.7.2.2Materials Less than1.6mm[1⁄16in.]in Thickness—The specimen shall be50.8mm[2in.]long by12.7mm[1⁄2in.] wide,testedflatwise on a25.4-mm[1-in.]support span.N OTE5—Use of the formulas for simple beams cited in these test methods for calculating results presumes that beam width is small in comparison with the support span.Therefore,the formulas do not apply rigorously to these dimensions.N OTE6—Where machine sensitivity is such that specimens of these dimensions cannot be measured,wider specimens or shorter support spans,or both,may be used,provided the support span-to-depth ratio is at least14to1.All dimensions must be stated in the report(see also Note5).7.3Laminated Thermosetting Materials and Sheet and Plate Materials Used for Electrical Insulation,Including Vulcanized Fiber and Glass-Bonded Mica—For paper-base and fabric-base grades over25.4mm[1in.]in nominal thickness,the specimens shall be machined on both surfaces to a depth of25.4mm.For glass-base and nylon-base grades, specimens over12.7mm[1⁄2in.]in nominal depth shall be machined on both surfaces to a depth of12.7mm.The support span-to-depth ratio shall be chosen such that failures occur in the outerfibers of the specimens,due only to the bending moment(see Note7).Therefore,a ratio larger than16:1may be necessary(32:1or40:1are recommended).When laminated materials exhibit low compressive strength perpendicular to the laminations,they shall be loaded with a large radius loading nose(up to four times the specimen depth to prevent premature damage to the outerfibers.7.4Molding Materials(Thermoplastics and Thermosets)—The recommended specimen for molding materials is127by 12.7by3.2mm[5by1⁄2by1⁄8in.]testedflatwise on a support span,resulting in a support span-to-depth ratio of16(tolerance 61).Thicker specimens should be avoided if they exhibit significant shrink marks or bubbles when molded.7.5High-Strength Reinforced Composites,Including Highly Orthotropic Laminates—The span-to-depth ratio shall be cho-sen such that failure occurs in the outerfibers of the specimens and is due only to the bending moment(see Note7).A span-to-depth ratio larger than16:1may be necessary(32:1or 40:1are recommended).For some highly anisotropic compos-ites,shear deformation can significantly influence modulus measurements,even at span-to-depth ratios as high as40:1. Hence,for these materials,an increase in the span-to-depth ratio to60:1is recommended to eliminate shear effects when modulus data are required,it should also be noted that the flexural modulus of highly anisotropic laminates is a strong function of ply-stacking sequence and will not necessarily correlate with tensile modulus,which is not stacking-sequence dependent.N OTE7—As a general rule,support span-to-depth ratios of16:1are satisfactory when the ratio of the tensile strength to shear strength is less than8to1,but the support span-to-depth ratio must be increased for composite laminates having relatively low shear strength in the plane of the laminate and relatively high tensile strength parallel to the support span.8.Number of Test Specimens8.1Test at leastfive specimens for each sample in the case of isotropic materials or molded specimens.8.2For each sample of anisotropic material in sheet form, test at leastfive specimens for each of the following conditions. Recommended conditions areflatwise and edgewise tests on specimens cut in lengthwise and crosswise directions of the sheet.For the purposes of this test,“lengthwise”designates the principal axis of anisotropy and shall be interpreted to mean the direction of the sheet known to be stronger inflexure.“Cross-wise”indicates the sheet direction known to be the weaker in flexure and shall be at90°to the lengthwise direction.9.Conditioning9.1Conditioning—Condition the test specimens at236 2°C[73.463.6°F]and5065%relative humidity for not less than40h prior to test in accordance with Procedure A of Practice D618unless otherwise specified by contract or the relevant ASTM material specification.Reference pre-test con-ditioning,to settle disagreements,shall apply tolerances of 61°C[1.8°F]and62%relative humidity.9.2Test Conditions—Conduct the tests at2362°C[73.46 3.6°F]and5065%relative humidity unless otherwise specified by contract or the relevant ASTM material specifica-tion.Reference testing conditions,to settle disagreements, shall apply tolerances of61°C[1.8°F]and62%relative humidity.10.Procedure10.1Procedure A:10.1.1Use an untested specimen for each measurement. Measure the width and depth of the specimen to the nearest 0.03mm[0.001in.]at the center of the support span.For specimens less than2.54mm[0.100in.]in depth,measure the depth to the nearest0.003mm[0.0005in.].These measure-ments shall be made in accordance with Test Methods D5947.10.1.2Determine the support span to be used as described in Section7and set the support span to within1%of the determinedvalue.10.1.3Forflexuralfixtures that have continuously adjust-able spans,measure the span accurately to the nearest0.1mm [0.004in.]for spans less than63mm[2.5in.]and to the nearest 0.3mm[0.012in.]for spans greater than or equal to63mm [2.5in.].Use the actual measured span for all calculations.For flexuralfixtures that havefixed machined span positions,verify the span distance the same as for adjustable spans at each machined position.This distance becomes the span for that position and is used for calculations applicable to all subse-quent tests conducted at that position.See Annex A2for information on the determination of and setting of the span.10.1.4Calculate the rate of crosshead motion as follows and set the machine for the rate of crosshead motion as calculated by Eq1:R5ZL2/6d(1) where:R=rate of crosshead motion,mm[in.]/min,L=support span,mm[in.],d=depth of beam,mm[in.],andZ=rate of straining of the outerfiber,mm/mm/min[in./ in./min].Z shall be equal to0.01.In no case shall the actual crosshead rate differ from that calculated using Eq1,by more than610%.10.1.5Align the loading nose and supports so that the axes of the cylindrical surfaces are parallel and the loading nose is midway between the supports.The parallelism of the apparatus may be checked by means of a plate with parallel grooves into which the loading nose and supports willfit when properly aligned(see A2.3).Center the specimen on the supports,with the long axis of the specimen perpendicular to the loading nose and supports.10.1.6Apply the load to the specimen at the specified crosshead rate,and take simultaneous load-deflection data. Measure deflection either by a gage under the specimen in contact with it at the center of the support span,the gage being mounted stationary relative to the specimen supports,or by measurement of the motion of the loading nose relative to the supports.Load-deflection curves may be plotted to determine theflexural strength,chord or secant modulus or the tangent modulus of elasticity,and the total work as measured by the area under the load-deflection curve.Perform the necessary toe compensation(see Annex A1)to correct for seating and indentation of the specimen and deflections in the machine.10.1.7Terminate the test when the maximum strain in the outer surface of the test specimen has reached0.05mm/mm [in./in.]or at break if break occurs prior to reaching the maximum strain(Notes8and9).The deflection at which this strain will occur may be calculated by letting r equal0.05 mm/mm[in./in.]in Eq2:D5rL2/6d(2) where:D=midspan deflection,mm[in.],r=strain,mm/mm[in./in.],L=support span,mm[in.],andd=depth of beam,mm[in.].N OTE8—For some materials that do not yield or break within the5% strain limit when tested by Procedure A,the increased strain rate allowed by Procedure B(see10.2)may induce the specimen to yield or break,or both,within the required5%strain limit.N OTE9—Beyond5%strain,this test method is not applicable.Some other mechanical property might be more relevant to characterize mate-rials that neither yield nor break by either Procedure A or Procedure B within the5%strain limit(for example,Test Method D638may be considered).10.2Procedure B:10.2.1Use an untested specimen for each measurement.10.2.2Test conditions shall be identical to those described in10.1,except that the rate of straining of the outer surface of the test specimen shall be0.10mm/mm[in./in.]/min.10.2.3If no break has occurred in the specimen by the time the maximum strain in the outer surface of the test specimen has reached0.05mm/mm[in./in.],discontinue the test(see Note9).11.Retests11.1Values for properties at rupture shall not be calculated for any specimen that breaks at some obvious,fortuitousflaw, unless suchflaws constitute a variable being studied.Retests shall be made for any specimen on which values are not calculated.12.Calculation12.1Toe compensation shall be made in accordance with Annex A1unless it can be shown that the toe region of the curve is not due to the take-up of slack,seating of the specimen,or other artifact,but rather is an authentic material response.12.2Flexural Stress(s f)—When a homogeneous elastic material is tested inflexure as a simple beam supported at two points and loaded at the midpoint,the maximum stress in the outer surface of the test specimen occurs at the midpoint.This stress may be calculated for any point on the load-deflection curve by means of the following equation(see Notes10-12):s f53PL/2bd2(3) where:s=stress in the outerfibers at midpoint,MPa[psi],P=load at a given point on the load-deflection curve,N [lbf],L=support span,mm[in.],b=width of beam tested,mm[in.],andd=depth of beam tested,mm[in.].N OTE10—Eq3applies strictly to materials for which stress is linearly proportional to strain up to the point of rupture and for which the strains are small.Since this is not always the case,a slight error will be introduced if Eq3is used to calculate stress for materials that are not true Hookean materials.The equation is valid for obtaining comparison data and for specification purposes,but only up to a maximumfiber strainof5%in the outer surface of the test specimen for specimens tested by the procedures described herein.N OTE11—When testing highly orthotropic laminates,the maximum stress may not always occur in the outer surface of the test specimen.4 Laminated beam theory must be applied to determine the maximum tensile stress at failure.If Eq3is used to calculate stress,it will yield an apparent strength based on homogeneous beam theory.This apparent strength is highly dependent on the ply-stacking sequence of highly orthotropic laminates.N OTE12—The preceding calculation is not valid if the specimen slips excessively between the supports.12.3Flexural Stress for Beams Tested at Large Support Spans(s f)—If support span-to-depth ratios greater than16to 1are used such that deflections in excess of10%of the support span occur,the stress in the outer surface of the specimen for a simple beam can be reasonably approximated with the following equation(see Note13):s f5~3PL/2bd2!@116~D/L!224~d/L!~D/L!#(4) where:s f,P,L,b,and d are the same as for Eq3,andD=deflection of the centerline of the specimen at the middle of the support span,mm[in.].N OTE13—When large support span-to-depth ratios are used,significant end forces are developed at the support noses which will affect the moment in a simple supported beam.Eq4includes additional terms that are an approximate correction factor for the influence of these end forces in large support span-to-depth ratio beams where relatively large deflec-tions exist.12.4Flexural Strength(s fM)—Maximumflexural stress sustained by the test specimen(see Note11)during a bendingtest.It is calculated according to Eq3or Eq4.Some materials that do not break at strains of up to5%may give a load deflection curve that shows a point at which the load does not increase with an increase in strain,that is,a yield point(Fig.1, Curve B),Y.Theflexural strength may be calculated for these materials by letting P(in Eq3or Eq4)equal this point,Y.12.5Flexural Offset Yield Strength—Offset yield strength is the stress at which the stress-strain curve deviates by a given strain(offset)from the tangent to the initial straight line portion of the stress-strain curve.The value of the offset must be given whenever this property is calculated.N OTE14—This value may differ fromflexural strength defined in12.4. Both methods of calculation are described in the annex to Test Method D638.12.6Flexural Stress at Break(s fB)—Flexural stress at break of the test specimen during a bending test.It is calculated according to Eq3or Eq4.Some materials may give a load deflection curve that shows a break point,B,without a yield point(Fig.1,Curve a)in which case s fB=s fM.Other materials may give a yield deflection curve with both a yield and a break point,B(Fig.1,Curve b).Theflexural stress at break may be calculated for these materials by letting P(in Eq 3or Eq4)equal this point,B.12.7Stress at a Given Strain—The stress in the outer surface of a test specimen at a given strain may be calculated in accordance with Eq3or Eq4by letting P equal the load read from the load-deflection curve at the deflection corresponding to the desired strain(for highly orthotropic laminates,see Note11).12.8Flexural Strain,e f—Nominal fractional change in the length of an element of the outer surface of the test specimen at midspan,where the maximum strain occurs.It may be calculated for any deflection using Eq5:e f56Dd/L2(5) where:e f=strain in the outer surface,mm/mm[in./in.],D=maximum deflection of the center of the beam,mm [in.],L=support span,mm[in.],andd=depth,mm[in.].12.9Modulus of Elasticity:12.9.1Tangent Modulus of Elasticity—The tangent modu-lus of elasticity,often called the“modulus of elasticity,”is the ratio,within the elastic limit,of stress to corresponding strain. It is calculated by drawing a tangent to the steepest initial straight-line portion of the load-deflection curve and using Eq 6(for highly anisotropic composites,see Note15).E B5L3m/4bd3(6)4For a discussion of these effects,see Zweben,C.,Smith,W.S.,and Wardle,M. W.,“Test Methods for Fiber Tensile Strength,Composite Flexural Modulus and Properties of Fabric-Reinforced Laminates,“Composite Materials:Testing and Design(Fifth Conference),ASTM STP674,1979,pp.228–262.N OTE—Curve a:Specimen that breaks before yielding.Curve b:Specimen that yields and then breaks before the5%strain limit.Curve c:Specimen that neither yields nor breaks before the5%strain limit.FIG.1Typical Curves of Flexural Stress(ßf)Versus FlexuralStrain(ef)where:E B =modulus of elasticity in bending,MPa [psi],L =support span,mm [in.],b =width of beam tested,mm [in.],d =depth of beam tested,mm [in.],andm =slope of the tangent to the initial straight-line portion of the load-deflection curve,N/mm [lbf/in.]of deflec-tion.N OTE 15—Shear deflections can seriously reduce the apparent modulusof highly anisotropic composites when they are tested at low span-to-depth ratios.4For this reason,a span-to-depth ratio of 60to 1is recommended for flexural modulus determinations on these composites.Flexural strength should be determined on a separate set of replicate specimens at a lower span-to-depth ratio that induces tensile failure in the outer fibers of the beam along its lower face.Since the flexural modulus of highly anisotropic laminates is a critical function of ply-stacking sequence,it will not necessarily correlate with tensile modulus,which is not stacking-sequence dependent.12.9.2Secant Modulus —The secant modulus is the ratio of stress to corresponding strain at any selected point on the stress-strain curve,that is,the slope of the straight line that joins the origin and a selected point on the actual stress-strain curve.It shall be expressed in megapascals [pounds per square inch].The selected point is chosen at a prespecified stress or strain in accordance with the appropriate material specification or by customer contract.It is calculated in accordance with Eq 6by letting m equal the slope of the secant to the load-deflection curve.The chosen stress or strain point used for the determination of the secant shall be reported.12.9.3Chord Modulus (E f )—The chord modulus may be calculated from two discrete points on the load deflection curve.The selected points are to be chosen at two prespecified stress or strain points in accordance with the appropriate material specification or by customer contract.The chosen stress or strain points used for the determination of the chord modulus shall be reported.Calculate the chord modulus,E f using the following equation:E f 5~s f 22s f 1!/~e f 22e f 1!(7)where:s f 2and s f 1are the flexural stresses,calculated from Eq 3or Eq 4and measured at the predefined points on the loaddeflection curve,and e f 2ande f 1are the flexural strain values,calculated from Eq 5and measured at the predetermined points on the load deflection curve.12.10Arithmetic Mean —For each series of tests,the arithmetic mean of all values obtained shall be calculated to three significant figures and reported as the “average value”for the particular property in question.12.11Standard Deviation —The standard deviation (esti-mated)shall be calculated as follows and be reported to two significant figures:s 5=~(X 22nX¯2!/~n 21!(8)where:s =estimated standard deviation,X =value of single observation,n =number of observations,andX ¯=arithmetic mean of the set of observations.13.Report13.1Report the following information:13.1.1Complete identification of the material tested,includ-ing type,source,manufacturer’s code number,form,principal dimensions,and previous history (for laminated materials,ply-stacking sequence shall be reported),13.1.2Direction of cutting and loading specimens,when appropriate,13.1.3Conditioning procedure,13.1.4Depth and width of specimen,13.1.5Procedure used (A or B),13.1.6Support span length,13.1.7Support span-to-depth ratio if different than 16:1,13.1.8Radius of supports and loading noses,if different than 5mm.When support and/or loading nose radii other than 5mm are used,the results shall be identified as being generated by a modified version of this test method and the referring specification referenced as to the geometry used.13.1.9Rate of crosshead motion,13.1.10Flexural strain at any given stress,average value and standard deviation,13.1.11If a specimen is rejected,reason(s)for rejection,13.1.12Tangent,secant,or chord modulus in bending,average value,standard deviation,and the strain level(s)used if secant or chord modulus,13.1.13Flexural strength (if desired),average value,and standard deviation,13.1.14Stress at any given strain up to and including 5%(if desired),with strain used,average value,and standard devia-tion,13.1.15Flexural stress at break (if desired),average value,and standard deviation,13.1.16Type of behavior,whether yielding or rupture,or both,or other observations,occurring within the 5%strain limit,and13.1.17Date of specific version of test used.TABLE 2Flexural ModulusMaterial Mean,103psiValues Expressed in units of %of 103psi V r A V R B r C R D ABS338 4.797.6913.621.8DAP thermoset 485 2.897.188.1520.4Cast acrylic 81013.716.138.845.4GR polyester816 3.49 4.209.9111.9GR polycarbonate 1790 5.52 5.5215.615.6SMC195010.913.830.839.1AV r =within-laboratory coefficient of variation for the indicated material.It is obtained by first pooling the within-laboratory standard deviations of the test results from all of the participating laboratories:Sr =[[(s 1)2+(s 2)2...+(s n )2]/n ]1/2then V r =(S r divided by the overall average for the material)3100.BV r =between-laboratory reproducibility,expressed as the coefficient of varia-tion:S R ={S r 2+S L 2}1/2where S L is the standard deviation of laboratory means.Then:V R =(S R divided by the overall average for the material)3100.Cr =within-laboratory critical interval between two test results =2.83V r .DR =between-laboratory critical interval between two test results =2.83V R.。

船用舷窗和矩形窗钢化安全玻璃非破坏性强度试验冲压法GB 3385-821 对象和使用范围本标准为执行ISO1095的舷窗玻璃和ISO3254的矩形窗玻璃规定了钢化安全玻璃非破坏性强度试验方法。

2 引用标准ISO 48硫化橡胶硬度测定法〔硬度为30~85IRHD〕ISO 1095 船用舷窗钢化安全玻璃ISO 3254 船用矩形窗钢化安全玻璃3 试验装置试验装置如图1所示的适当型式:a、A型:用于公称尺寸等于和大于250mm的舷窗玻璃和各种尺寸的矩形窗玻璃。

b、B型:用于公称尺寸200mm的舷窗玻璃。

建筑玻璃可见光透射比、太阳光直接透射比、太阳能总透射比、紫外线透射比及有关窗玻璃参数的测定GB/T 2680-94本标准参照采用国际标准ISO 9050-1990? 建筑玻璃——可见光透射比、太阳光直接透射比、太阳能总透射比、紫外线透射比及有关窗玻璃参数的测定?1 主题内容与适用范围本标准规定了建筑玻璃可见光透射〔反射〕比、太阳光直接透射〔反射、吸收〕比、太阳能总透射比、紫外线透射〔反射〕比、半球辐射率和遮蔽系数的测定条件和计算公式。

2 测定条件2.1 试样2.1.1 一般建筑玻璃和单层窗玻璃构件的试样,均采用同材质玻璃的切片。

钠钙硅硼玻璃化分析方法GB/T 1549-94Methods of chemical analysis of Sada-lime-alumina and borosilicate glass1 主题内容与适用范围本标准规定了钠钙硅铝硼玻璃的化学分析方法。

本标准适用于钠钙硅铝硼玻璃如中碱玻璃、无碱玻璃及类似组成玻璃的化学分析。

2 引用标准GB 1347 钠钙硅玻璃化学分析方法3 一般规定3.1 对同一测定对象,有些规定了不同的测定方法,可根据实际情况任选一种。

有争议时,以I法为仲裁法。

3.2 化学分析用的天平应准确至0.0001g;天平与砝码应定期进行检定。

“ 恒重〞系指连续两次称重之差不大于0.0002g。

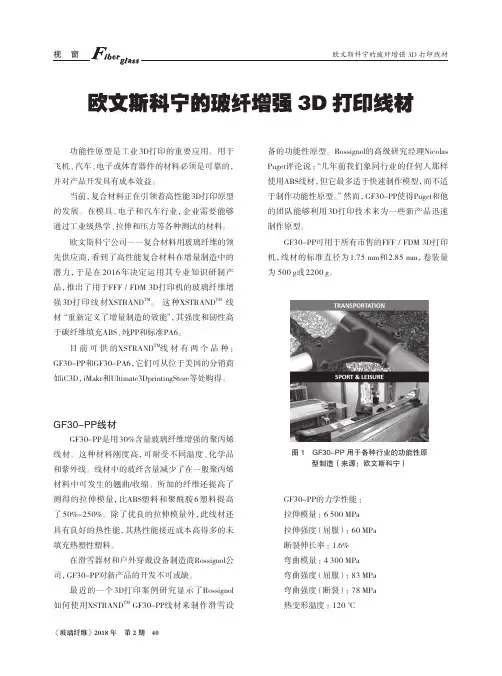

《玻璃纤维》2018年 第2期 40欧文斯科宁的玻纤增强3D 打印线材功能性原型是工业3D打印的重要应用。

用于飞机、汽车、电子或体育器件的材料必须是可靠的,并对产品开发具有成本效益。

当前,复合材料正在引领着高性能3D打印原型的发展。

在模具、电子和汽车行业,企业需要能够通过工业级热学、拉伸和压力等各种测试的材料。

欧文斯科宁公司――复合材料用玻璃纤维的领先供应商,看到了高性能复合材料在增量制造中的潜力,于是在2016年决定运用其专业知识研制产品,推出了用于FFF / FDM 3D打印机的玻璃纤维增强3D打印线材XSTRAND TM 。

这种XSTRAND TM 线材“重新定义了增量制造的效能”,其强度和韧性高于碳纤维填充ABS、纯PP和标准PA6。

目前可供的XSTRAND TM 线材有两个品种:GF30-PP和GF30-PA6,它们可从位于美国的分销商如iC3D,iMakr和Ultimate3DprintingStore等处购得。

GF30-PP线材GF30-PP是用30%含量玻璃纤维增强的聚丙烯线材。

这种材料刚度高,可耐受不同温度、化学品和紫外线。

线材中的玻纤含量减少了在一般聚丙烯材料中可发生的翘曲/收缩。

所加的纤维还提高了测得的拉伸模量,比ABS塑料和聚酰胺6塑料提高了50%-250%。

除了优良的拉伸模量外,此线材还具有良好的热性能,其热性能接近成本高得多的未填充热塑性塑料。

在滑雪器材和户外穿戴设备制造商Rossignol公司,GF30-PP对新产品的开发不可或缺。

最近的一个3D打印案例研究显示了Rossignol 如何使用XSTRAND TM GF30-PP线材来制作滑雪设备的功能性原型。

Rossignol的高级研究经理Nicolas Puget评论说:“几年前我们象同行业的任何人那样使用ABS线材,但它最多适于快速制作模型,而不适于制作功能性原型。

” 然而,GF30-PP使得Puget和他的团队能够利用3D打印技术来为一些新产品迅速制作原型。

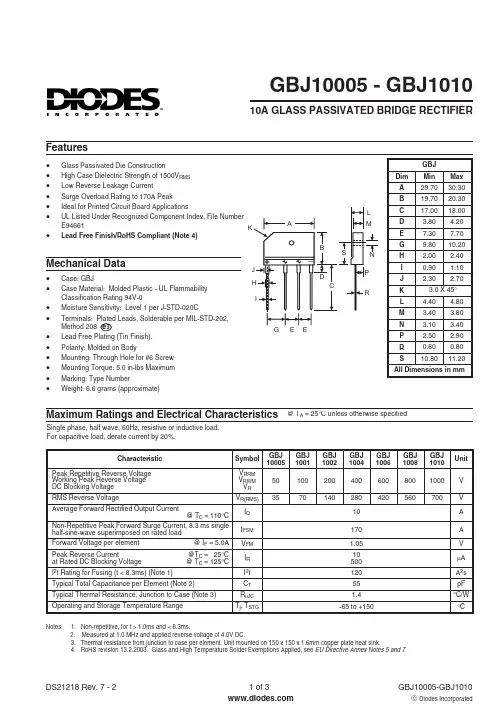

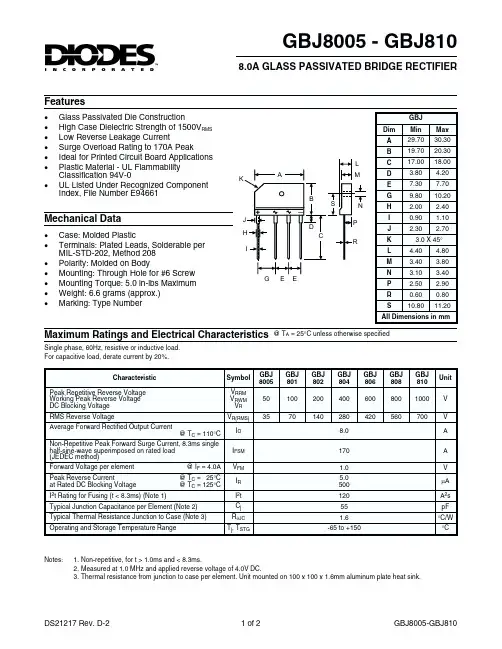

e 3Features·Glass Passivated Die Construction ·High Case Dielectric Strength of 1500V RMS ·Low Reverse Leakage Current ·Surge Overload Rating to 170A Peak ·Ideal for Printed Circuit Board Applications·UL Listed Under Recognized Component Index, File Number E94661·Lead Free Finish/RoHS Compliant (Note 4)Single phase, half wave, 60Hz, resistive or inductive load.For capacitive load, derate current by 20%.Maximum Ratings and Electrical Characteristics@ T A = 25°C unless otherwise specifiedGBJ10005 - GBJ101010A GLASS PASSIVATED BRIDGE RECTIFIER·Case:GBJ·Case Material: Molded Plastic - UL Flammability Classification Rating 94V-0·Moisture Sensitivity: Level 1 per J-STD-020C·Terminals: Plated Leads,Solderable per MIL-STD-202,Method 208·Lead Free Plating (Tin Finish).·Polarity: Molded on Body·Mounting: Through Hole for #6 Screw ·Mounting Torque: 5.0 in-lbs Maximum ·Marking: Type Number·Weight: 6.6 grams (approximate)Mechanical DataNotes: 1. Non-repetitive, for t > 1.0ms and < 8.3ms.2. Measured at 1.0 MHz and applied reverse voltage of 4.0V DC.3. Thermal resistance from junction to case per element. Unit mounted on 150 x 150 x 1.6mm copper plate heat sink.4.RoHS revision 13.2.2003. Glass and High Temperature Solder Exemptions Applied, see EU Directive Annex Notes 5 and 7.0.010.11.0100.40.81.21.61.8V ,INSTANTANEOUS FORWARD VOLTAGE (V)Fig.2Typical Forward Characteristics (per element)F I ,I N S T A N T A N E O U S F O R W A R D C U R R E N T (A )F4080120160180110100I ,P E A K F O R W A R D S U R G E C U R R E N T (A )F S M NUMBER OF CYCLES AT 60HzFig.3Maximum Non-Repetitive Surge Current101001110100C ,T O T A L C A P A C I T A N C E (p F )T V ,REVERSE VOLTAGE (V)Fig.4Typical Total Capacitance,Per ElementR 0.11.010100100020406080100120140PERCENT OF RATED PEAK REVERSE VOLTAGE (%)Fig.5Typical Reverse Characteristics24681012255075100125150I ,A V E R A G E R E C T I F I E D C U R R E N T (A )O T ,CASETEMPERATURE (C)Fig.1Forward Current Derating CurveC °Ordering Information(Note 5)Notes: 5. For packaging details, visit our website at /datasheets/ap2008.pdf.IMPORTANT NOTICEDiodes Incorporated and its subsidiaries reserve the right to make modifications,enhancements,improvements,corrections or other changes without further notice to any product herein.Diodes Incorporated does not assume any liability arising out of the application or use of any product described herein;neither does it convey any license under its patent rights,nor the rights of others.The user of products in such applications shall assume all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on our website,harmless against all damages.LIFE SUPPORTDiodes Incorporated products are not authorized for use as critical components in life support devices or systems without the expressed written approval of the President of Diodes Incorporated.。

AdvisoryU.S. Departmentof TransportationCircularFederal AviationAdministrationDate: 9/8/09 AC No: 20-107BSubject: COMPOSITE AIRCRAFTSTRUCTUREInitiated by: AIR-100 Change:1 Purpose of this Advisory Circular ACThis AC sets forth an acceptable means, but notthe only means of showing compliance with the provisions of Title 14 of the Code of FederalRegulations 14 CFR parts 23, 25, 27, and 29 regarding airworthiness type certificationrequirements for composite aircraft structures involving fiber reinforced materials, e.g., carbonand glass fiber reinforced plasticsGuidance information is also presented on the closely relateddesign, manufacturing, and maintenance aspectsThe informationcontained herein is forguidance purposes and is not mandatory or regulatory in nature2 To Whom this AC AppliesThe audience of this AC may include applicants,certificate/approval holders, parts manufacturers, material suppliers, maintenance, and repairorganizations3CancellationAC 20-107A, Composite Aircraft Structure, dated April 25, 1984, is cancelled4. Related Regulations and GuidanceThe material contained herein applies to normal,utility, acrobatic, commuter, and transport category aircraft type certificated under Civil AviationRegulations CARs 3, 4b, 6, 7; and 14 CFR parts 23, 25, 27, 29; and it is produced incompliance with 14 CFR part 21, §§ 21.125, or 21.143 as may be appropriateThe sections of14 CFR, parts 23, 25, 27, and 29 applicable to each paragraph of this AC are listed in Appendix1Other supporting guidance relevant to the AC is also provided in Appendix 15Generala. The procedures outlined in this AC provide guidancematerial for composite structures,particularly those that are essential in maintaining the overall flight safety of the aircraft “criticalstructure” as defined in Appendix 2, and are considered acceptable to the FAA for showingcompliance with certification requirements of civil composite aircraftThis circular is publishedto aid in the evaluation of certification programs for composite applications and to reflect thecurrent status of composite technologyIt is expected that this circular will be modified 9/8/09 AC 20-107Bperiodically to reflect the continued evolution of composite technology and the data collectedfrom service experience and expanding applicationsb. There are factors unique to the specific composite materials and processes used for agiven applicationFor example, the environmental sensitivity, anisotropic properties, andheterogeneous nature of composites can make the determination of structural failure loads,modes, and locations difficultThe reliability of such evaluation depends on repeatablestructural details created by scaled manufacturing or repair processesThe extent of testingand/or analysis may differ for a structure depending upon the criticality to flight safety, expectedservice usage, the material and processes selected, the design margins, the failure criteria, thedatabase and experience with similar structures, and on other factors affecting a particularstructureIt is expected that these factors will be considered when interpreting this AC for useon a specific applicationc. Definitions of terms used in this AC can be found in Appendix 26. Material and Fabrication DevelopmentAll composite materials and processes used instructures are qualified through enough fabrication trials and tests to demonstrate a reproducibleand reliable designOne of the unique features of composite construction is the degree of careneeded in the procurement and processing of composite materialsThe final mechanicalbehavior of a given composite material may vary greatly depending on the processing methodsemployed to fabricate production partsSpecial care needs to be taken in controlling both thematerials being procured and how the material is processed once delivered to the fabricationfacilityRegulatory requirements in 14 CFR, parts 2X, §§ 2x.603 and 2x.605 specify the need toprocure and process materials under approved material and process specifications that control thekey parameters governing performance14 CFR, parts 2X, §§ 2x.609 and 2x.613 outlines a needto protect structures against the degradation possible in serviceThey also require that the designaccount for any changes in performance e.g., environmental and variability effects permitted bymaterial and process specificationsa. Material and Process Control 1 Specifications covering material, material processing, and fabrication procedures areestablished to ensure a basis for fabricating reproducible and reliable structureMaterialspecifications are required to ensure consistent material is being procured, and batch acceptancetesting or statistical process controls are used to ensure materialproperties do not drift over timeSpecifications covering processing procedures should be developed to ensure that repeatable andreliable structure is being manufacturedThe means of processing qualification and acceptancetests defined in each material specification should be representative of the expected applicablemanufacturing processThe process parameters for fabricating test specimens should match theprocess parameters used in manufacturing actual production parts as closely as possibleBothtest and production parts must conform to material and process specifications 2 Once the fabrication processes have been established, changes should not occurunless additional qualification, including testing of differences is completed refer to AppendixPage 2 9/8/09 AC 20-107B3It is important to establish processing tolerances; material handling and storage limits; andkey characteristics, which can be measured and tracked to judge part quality 3 Material requirements identified in procurement specifications should be based on thequalification test results for samples produced using the related process specificationsQualification data must cover all properties important to the control of materials composites andadhesives and processes used for production of composite structureCarefully selectedphysical, chemical, and mechanical qualification tests are used to demonstrate the formulation,stiffness, strength, durability, and reliability of materials and processes for aircraft applicationsIt is recommended that material suppliers work closely with airframe manufacturers to properlydefine material requirements 4 To provide an adequate design database, environmental effects on critical propertiesof the material systems and associated processes should be establishedIn addition to testing inan ambient environment, variables should include extreme service temperature and moisturecontent conditions and effects of long-term durabilityQualification tests for environmentaleffects and long-term durability are particularly important when evaluating the materials,processes, and interface issues associated with structural bonding refer to paragraph 6.c forrelated guidance 5 Key characteristics and processing parameters will be monitored for in-processquality controlThe overall quality control plan required by the certifying agency should involveall relevant disciplines, i.e., engineering, manufacturing, and quality controlA reliable qualitycontrol system should be in place to address special engineering requirements that arise inindividual parts or areas as a result of potential failure modes, damage tolerance and flaw growthrequirements, loadings, inspectability, and local sensitivities to manufacture and assembly 6 The discrepancies permitted by the specifications should also be substantiated byanalysis supported by test evidence, or tests at the coupon, element or subcomponent levelFornew production methods, repeatable processes should be demonstrated at sufficient structuralscale in a way shown to be consistent with the material and process qualification tests anddevelopment of the associated specificationsThis will requireintegration of the technical issuesassociated with product design and manufacturing details prior to a large investment in structuraltests and analysis correlationIt will also ensure the relevance of quality control proceduresdefined to control materials and processes as related to the product structural details 7 The FAA does not generally certify materials and processesHowever, the materialsand processes may be accepted as part of a particular aircraft product certificationAppropriatecredit may be given to organizations using the same materials and processes in similarapplications subject to substantiation and applicabilityIn some cases, material and processinginformation may become part of accepted shared databases used throughout the industryNewusers of shared qualification databases must control the associated materials and processesthrough proper use of the related specifications and demonstrate their understanding byperforming equivalency sampling tests for key propertiesMaterials and processes used intechnical standard order TSO articles or authorizations must also be qualified and controlledPage 3 9/8/09 AC 20-107Bb. Manufacturing Implementation 1 Process specifications and manufacturing documentation are needed to control composite fabrication and assemblyThe environment and cleanliness of facilities are controlledto a level validated by qualification and proof of structure testingRaw and ancillary materialsare controlled to specification requirements that are consistent with material and processqualificationsParts fabricated meet the production tolerances validated in qualification, designdata development, and proof of structure testsSome key fabrication process considerationsrequiring such control include material handling and storage; laminate layup and bagging orother alternate process steps for non-laminated material forms and advanced processes; matingpart dimensional tolerance control; part cure thermal management; machining and assembly;cured part inspection and handling procedures; and technician training for specific material,processes, tooling and equipment 2 Thorough manufacturing records are needed to support parts acceptance andallowable discrepancies defects, damage and anomaliesSubstantiating data is needed tojustify all known defects, damage and anomalies allowed to remain in service without rework orrepairManufacturing records are also needed for all substantiated design and process changes 3 New suppliers of parts for previously certified aircraft products are qualified bymanufacturing trials and quality assessments to ensure equivalent production and repeatabilitySome destructive inspection of critical structural details is needed for manufacturing flaws thatare not end item inspectable and require process controls to ensure reliable fabricationc. Structural BondingBonded structures include multiple interfaces e.g., composite-to-composite, composite-to-metal, or metal-to-metal, where at least one of the interfaces requiresadditional surface preparation prior to bondingThe general nature of technical parameters thatgovern different types of bonded structures are similarA qualified bonding process isdocumented after demonstrating repeatable and reliable processing steps such as surfacepreparationIt entails understanding the sensitivity of structural performance based uponexpected variation permitted per the processCharacterization outside the process limits isrecommended to ensure process robustnessIn the case of bonding composite interfaces, aqualified surface preparation of all previously cured substrates is needed to activate their surfacefor chemical adhesionAll metal interfaces in a bonded structure also have chemically activatedsurfaces created by a qualified preparation processMany technical issues for bonding requirecross-functional teams for successful applicationsApplications require stringent process controland a thorough substantiation of structural integrity 1 Many bond failures and problems in service have been traced to invalid qualificationsor insufficient quality control of production processesPhysical and chemical tests may be usedto control surface preparation, adhesive mixing, viscosity, and cureproperties e.g., density,degree of cure, glass transition temperatureLap shear stiffness and strength are commonmechanical tests for adhesive and bond process qualificationShear tests do not provide areliable measure of long-term durability and environmental degradation associated with poorbonding processes i.e., lack of adhesionSome type of peel test has proven more reliable forevaluating proper adhesionWithout chemical bonding, the so-called condition of a “weakPage 4 9/8/09 AC 20-107Bbond” exists when the bonded joint is either loaded by peel forces or exposed to the environmentover a long period of time, or bothAdhesion failures, which indicate the lack of chemicalbonding between substrate and adhesive materials, are considered an unacceptable failure modein all test typesMaterial or bond process problems that lead to adhesion failures are solvedbefore proceeding with qualification tests 2 Process specifications are needed to control adhesive bonding in manufacturing andrepairA “process control mentality,” which includes a combination of in-process inspectionsand tests, has proven to be the most reliable means of ensuring the quality of adhesive bondsThe environment and cleanliness of facilities used for bonding processes are controlled to a levelvalidated by qualification and proof of structure testingAdhesives and substrate materials arecontrolled to specification requirements that are consistent with material and bond processqualificationsThe bonding processes used for production and repair meet tolerances validatedin qualification, design data development, and proof of structure testsSome key bondfabrication process considerations requiring such control include material handling and storage;bond surface preparation; mating part dimensional tolerance control; adhesive application andclamp-up pressure; bond line thickness control; bonded part cure thermal management; curedpart inspection and handling procedures; and bond technician training for specific material,processes, tooling, and equipmentBond surface preparation and subsequent handling controlsleading up to the bond assembly and cure must be closely controlled in time and exposure toenvironment and contamination 3 14 CFR § 23.573a sets forth requirements for substantiating the primary compositeairframe structures, including considerations for damage tolerance, fatigue, and bonded jointsAlthough this is a small airplane rule, the same performance standards are normally expectedwith transport and rotorcraft category aircraft via special conditions and issue papers a For any bonded joint, § 23.573a5 states in part: "the failure of which wouldresult in catastrophic loss of the airplane, the limit load capacity must be substantiated by one ofthe following methods?i The imum disbonds of each bonded joint consistent with thecapability to withstand the loads in paragraph a3 of this section must be determined byanalysis, tests, or bothDisbonds of each bonded joint greater than this must be prevented bydesign features; or ii Proof testing must be conducted on eachproduction article that willapply the critical limit design load to each critical bonded joint; or iii Repeatable and reliablenon-destructive inspection techniques must be established that ensure the strength of each joint." b These options do not supersede the need for a qualified bonding process andrigorous quality controls for bonded structuresFor example, fail safety implied by the firstoption is not intended to provide adequate safety for the systematic problem of a bad bondingprocess applied to a fleet of aircraft structuresInstead, it gives fail safety against bondingproblems that may occasionally occur over local areas e.g., insufficient local bond contactpressure or contaminationPerforming static proof tests to limit load, which is the secondoption, may not detect weak bonds requiring environmental exposure and time to degradebonded joint strengthThis issue should be covered by adequately demonstrating that qualifiedbonding materials and processes have long-term environmental durabilityFinally, the thirdoption is open for future advancement and validation of non-destructive inspection NDIPage 5 9/8/09 AC 20-107Btechnology to detect weak bonds, which degrade over time and lead to adhesion failuresSuchtechnology has not been reliably demonstrated at a production scale to date 4 Adhesion failures found in production require immediate action to identify thespecific cause and isolate all affected parts and assemblies for dispositionAdhesion failuresdiscovered in service require immediate action to determine the cause, to isolate the affectedaircraft, and to conduct directed inspection and repairDepending on the suspected severity ofthe bonding problem, immediate action may be required to restore the affected aircraft to anairworthy conditiondEnvironmental ConsiderationsEnvironmental design criteria should be developed thatidentify the critical environmental exposures, including humidity and temperature, to which thematerial in the application under evaluation may be exposedService data e.g., moisture contentas a function of time in service can be used to ensure such criteria are realisticIn addition, thepeak temperatures for composite structure installed in close proximity to aircraft systems thatgenerate thermal energy need to be identified for worst-case normal operation and system failurecasesEnvironmental design criteria are not required where existing data demonstrate that。

国外机车前风挡玻璃抗冲击测试标准解析及应对策略随着机车运输行业的不断发展,对于机车前风挡玻璃的品质和安全性要求也越来越高。

在机车运输当中,机车前风挡玻璃往往承担着很大的安全责任,因此对于其抗冲击的能力也提出了更高的要求。

本文将从国外机车前风挡玻璃抗冲击测试的标准出发,针对其测试标准所存在的问题进行分析,并提出应对策略。

目前国外机车前风挡玻璃的抗冲击测试标准主要有FMVSS-205、ECE-R43等标准。

1. FMVSS-205标准FMVSS-205标准是美国机动车安全标准的一部分,是对于机动车上玻璃的要求。

该标准对于前挡风玻璃的抗冲击能力进行了测试,包括静态荷载、动态荷载、钱带荷载等。

其中静态荷载测试是将铝合金气枕椅上的一吨重的钢球垂直落下,检查玻璃是否破碎。

动态荷载测试则是模拟车辆行驶路面上的颠簸和碰撞情况,通过将钢球从不同高度落下来进行测试。

钱带荷载测试则是模拟车辆在高速公路上行驶时的强风荷载,并对玻璃进行测试。

2. ECE-R43标准ECE-R43标准是欧洲经济委员会采用的对于汽车前挡风玻璃的要求标准。

该标准将对前挡风玻璃进行耐冲击测试,包括钢球试验和弹珠试验。

钢球试验是测试玻璃能否承受一定速度和重量的钢球的撞击,弹珠试验则是测试玻璃能否承受一定速度和射程的金属球的撞击。

二、存在问题虽然国外机车前风挡玻璃抗冲击的测试标准相对严格,但是仍然存在以下几个问题:1. 国内乃至国际之间抗冲击测试标准缺乏统一性。

目前不同国家、不同地区对于机车前风挡玻璃的抗冲击测试标准要求不一,缺乏统一标准,这给机车运输行业带来了不必要的麻烦和混乱。

2. 部分测试标准存在不足。

FMVSS-205标准在测试过程中只测试了前挡风玻璃的抗冲击能力,而对于侧窗玻璃的测试较为薄弱,这与实际使用中的安全需要还有一定差距。

同时,ECE-R43标准的测试方法也有待完善,因为无法对于玻璃碎片的飞溅情况进行预先控制。

三、应对策略针对存在的问题,我们可以从以下几个方面进行应对:1. 推进国际化标准建设,制定统一的抗冲击测试标准。

第50卷第6期2022年6月同济大学学报(自然科学版)

JOURNALOFTONGJIUNIVERSITY(NATURALSCIENCE)

Vol.50No.6

Jun.2022

论文拓展介绍

S32001双相型不锈钢高温力学性能试验楼国彪1,2,杨未1,陈武龙1,陶宇超1,王美南3(1.同济大学土木工程学院,上海200092;2.同济大学土木工程防灾国家实验室,上海200092;3.远大可建科技有限公司,湖南长沙430121)

摘要:对S32001双相型不锈钢进行了高温稳态拉伸试验研究,得到了高温下初始弹性模量、名义屈服强度、抗拉强度、断后伸长率等主要力学性能指标及其变化规律;利用试验数据研究了Rasmussen模型和Gardner模型的适用性,并基于Rasmussen模型提出了S32001不锈钢硬化指数的计算公式,

建立了高温下不锈钢材料本构关系表达式;对比分析了S32001不锈钢与其他种类不锈钢及Q235B结构钢的高温力

学性能。研究表明,S32001不锈钢的屈服强度和极限强度随温度升高下降,600℃时低于常温时的50%,但高温下材料强度明显高于S30408不锈钢,具有更加优越的抗火性能。该研究结果可用于结构受火性能研究和抗火设计。

关键词:双相型不锈钢;力学性能;本构关系;高温中图分类号:TU511.3文献标志码:A

ExperimentalInvestigationonMechanicalPropertiesofS32001DuplexStainlessSteelatElevatedTemperatures

LOUGuobiao1,2,YANGWei1,CHENWulong1,TAO

Yuchao1,WANGMeinan3

(1.CollegeofCivilEngineering,TongjiUniversity,Shanghai200092,China;2.StateKeyLaboratoryforDisasterReductioninCivilEngineering,TongjiUniversity,Shanghai200092,China;3.BroadSustainableBuilding,Changsha430121,Hunan,China)

材料科学与工程专业英语匡少平课后翻译答案精编W O R D版IBM system office room 【A0816H-A0912AAAHH-GX8Q8-GNTHHJ8】Alloy合金applied force作用力amorphous materials不定形材料artificial materials人工材料biomaterials生物材料biological synthesis生物合成biocompatibility生物相容性brittle failure脆性破坏carbon nanotub e碳纳米管carboxylic acid羟酸critical stress临近应力dielectric constant介电常数clay minera l粘土矿物cross-sectional area横截面积critical shear stress临界剪切应力critical length临界长度curing agent固化剂dynamic or cyclic loading动态循环负载linear coefficient of themal expansio n性膨胀系数electromagnetic radiation电磁辐射electrodeposition电极沉积nonlocalizedelectrons游离电子electron beam lithography电子束光刻elasticity 弹性系数electrostation adsorption静电吸附elastic modulus弹性模量elastic deformation弹性形变elastomer弹性体engineering strain工程应变crystallization 结晶fiber-optic光纤维Ethylene oxide环氧乙烷fabrication process制造过程glass fiber玻璃纤维glass transition temperature 玻璃化转变温度heat capacity热熔Hearing aids助听器integrated circuit集成电路Interdisplinary交叉学科intimate contact密切接触inert substance惰性材料implant移植individual application个体应用deformation局部形变mechanical strength机械强度mechanical attrition机械磨损Mechanical properties力学性Materials processing材料加工质mechanical behavior力学行为magnetic permeability磁导率magnetic hybrid technique混合技术induction磁感应mass per unit of volume单位体积质量monomer identity单体种类molecular mass分子量microsphere encapsulation technique微球胶囊技术macroscopical宏观的naked eye 肉眼nonlocalized nanoengineered materials纳米材料nanostructured materials纳米结构材料nonferrous metal有色金属线nucleic acid核酸nanoscale纳米尺度Nanotechnology纳米技术nanobiotechnology纳米生物技术nanocontact printing纳米接触印刷optical property光学性质optoelectronic device光电设备oxidation degradation 氧化降解piezoelectric ceramics压电陶瓷Relative density相对密度stiffnesses刚度sensor传感材料semiconductors半导体specific gravity比重shear 剪切Surface tention表面张力self-organization自组装static loading静载荷stress area应力面积stress-strain curves应力应变曲线sphere radius球半径submicron technique亚微米技术substrate衬底supramolecalar超分子sol-gel method溶胶凝胶法thermal/electrical conductivity 热/点导率thermoplastic materials热塑性材料Thermosetting plastic热固性塑料thermal motion热运动toughness test韧性试验tension张力torsion扭曲Tensile Properties拉伸性能Two-dimentional nanostructure二维纳米结构Tissue engineering组织工程transplantation of organs器官移植the service life使用寿命the longitudinal direction纵向the initial length of the materials初始长度the acceleration gravity重力加速度the normal vertical axis垂直轴the surface to volume ratio 比表面密度the burgers vector伯格丝矢量the mechanics and dynamics of tissues 组织力学和动力学phase transformation temperature相转变温度plastic deformation塑性形变Pottery陶瓷persistence length余晖长度polymer synthesis聚合物合成Polar monomer记性单体polyelectrolyte高分子电解质pinning point钉扎点plasma etching 等离子腐蚀pharmacological acceptability药理接受性pyrolysis高温分解ultrasonic treatment超射波处理yield strength屈服强度vulcanization硫化1-1:直到最近,科学家才终于了解材料的结构要素与其特性之间的关系。