Draft New Recommendation M.3108.2 TMN MANAGEMENT SERVICES FOR DEDICATED AND RECONFIGURABLE

- 格式:pdf

- 大小:182.58 KB

- 文档页数:52

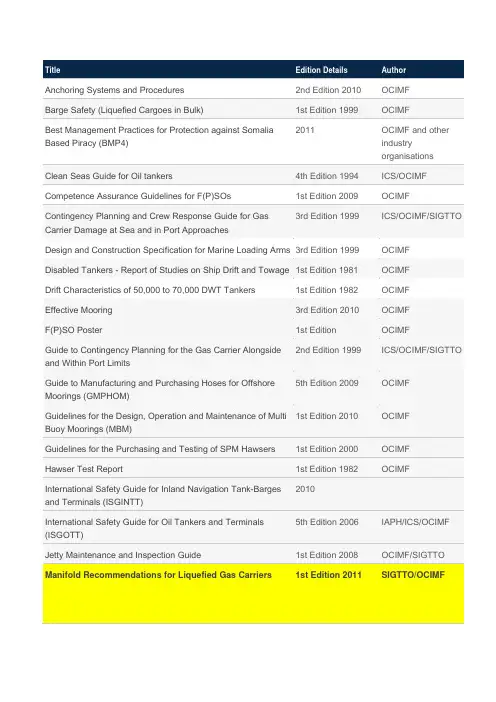

Anchoring Systems and Procedures2nd Edition 2010 OCIMF Barge Safety (Liquefied Cargoes in Bulk)1st Edition 1999 OCIMFBest Management Practices for Protection against Somalia Based Piracy (BMP4) 2011 OCIMF and otherindustryorganisationsClean Seas Guide for Oil tankers4th Edition 1994 ICS/OCIMFCompetence Assurance Guidelines for F(P)SOs1st Edition 2009 OCIMFContingency Planning and Crew Response Guide for GasCarrier Damage at Sea and in Port Approaches3rd Edition 1999 ICS/OCIMF/SIGTTO Design and Construction Specification for Marine Loading Arms3rd Edition 1999 OCIMFDisabled Tankers - Report of Studies on Ship Drift and Towage1st Edition 1981 OCIMFDrift Characteristics of 50,000 to 70,000 DWT Tankers1st Edition 1982 OCIMFEffective Mooring3rd Edition 2010 OCIMFF(P)SO Poster1st Edition OCIMFGuide to Contingency Planning for the Gas Carrier Alongsideand Within Port Limits2nd Edition 1999 ICS/OCIMF/SIGTTOGuide to Manufacturing and Purchasing Hoses for OffshoreMoorings (GMPHOM)5th Edition 2009 OCIMFGuidelines for the Design, Operation and Maintenance of MultiBuoy Moorings (MBM)1st Edition 2010 OCIMF Guidelines for the Purchasing and Testing of SPM Hawsers1st Edition 2000 OCIMFHawser Test Report1st Edition 1982 OCIMF International Safety Guide for Inland Navigation Tank-Bargesand Terminals (ISGINTT)2010International Safety Guide for Oil Tankers and Terminals(ISGOTT)5th Edition 2006 IAPH/ICS/OCIMF Jetty Maintenance and Inspection Guide1st Edition 2008 OCIMF/SIGTTO Manifold Recommendations for Liquefied Gas Carriers1st Edition 2011 SIGTTO/OCIMFMarine Terminal Management and Self Assessment (MTMSA)1st Edition 2012 OCIMFMarine Terminal Operator Competence and Training Guide(MTOCT)1st Edition 2013 OCIMF Mooring Equipment Guidelines (MEG3)3rd Edition 2008 OCIMFOffshore Loading Safety Guidelines with special relevance toharsh weather zones1st Edition 1999 OCIMF Offshore Vessel Management and Self Assessment (OVMSA)1st Edition 2012 OCIMF Peril at Sea and Salvage A Guide for Masters (ebook only)5th Edition 1998 ICS/OCIMF Piracy and Armed Robbery Against Ships.1st Edition 2000 OCIMF Prevention of Oil Spillage Through Pumproom Sea Valves2nd Edition 1991 ICS/OCIMF Recommendations for Equipment Employed in the BowMooring of Conventional Tankers at Single Point Moorings4th Edition 2007 OCIMFRecommendations for Oil Tanker Manifolds and AssociatedEquipment4th Edition 1991 OCIMFSafe Transfer of Liquefied Gas in an Offshore Environment(STOLGOE)1st Edition 2010 OCIMF Ship to Ship Service Provider Management1st Edition 2011 OCIMFShip to Ship Transfer Guide for Petroleum, Chemicals and Liquefied Gases 1st Edition 2013 OCIMF, CDI, ICS,SIGTTOSingle Point Mooring Maintenance and Operations Guide2nd Edition 1995 OCIMFSPM Hose System Design Commentary (ebook only)2nd Edition 1993 OCIMF Survival Craft - A Seafarers' Guide1st Edition 2009 OCIMFTandem Mooring and Offloading Guidelines for ConventionalTankers at F(P)SO Facilities1st Edition 2009 OCIMFTanker Management and Self Assessment - A Best PracticeGuide for Vessel Operations2nd Edition 2008 OCIMFThe Use of Large Tankers in Seasonal First-Year Ice andSevere Sub-Zero Conditions1st Edition 2010 OCIMF。

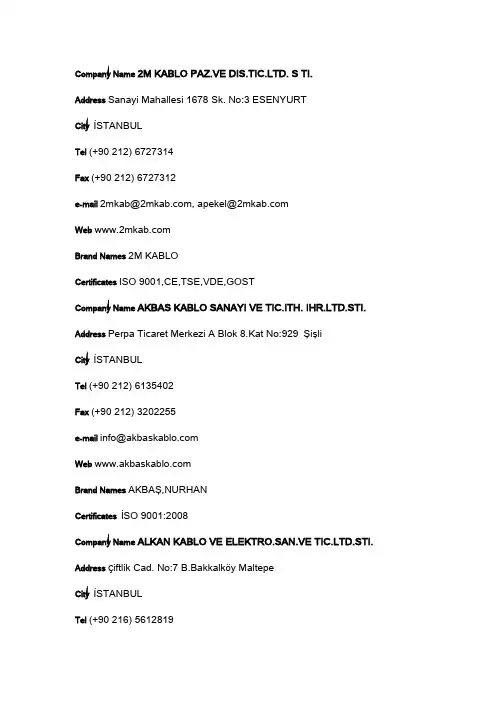

Company Name 2M KABLO PAZ.VE DIS.TIC.LTD. S TI.Address Sanayi Mahallesi 1678 Sk. No:3 ESENYURTCity İSTANBULTel (+90 212) 6727314Fax (+90 212) 6727312e-mail ***************,****************Web Brand Names 2M KABLOCertificates ISO 9001,CE,TSE,VDE,GOSTCompany Name AKBAS KABLO SANAYI VE TIC.ITH. IHR.LTD.STI. Address Perpa Ticaret Merkezi A Blok 8.Kat No:929 ŞişliCity İSTANBULTel (+90 212) 6135402Fax (+90 212) 3202255e-mail *******************Web Brand Names AKBAŞ,NURHANCertificates İSO 9001:2008Company Name ALKAN KABLO VE ELEKTRO.SAN.VE TIC.LTD.STI. Address Çiftlik Cad. No:7 B.Bakkalköy MaltepeCity İSTANBULTel (+90 216) 5612819Fax (+90 216) 5615575e-mail *********************Web Brand Names PHILIPS-OSRAM-GENERAL ELECTRIC-SIEMENS-VIKO Insulated wire, cableHS Code 8544Updated at 23th November 2011Company Name ALUÇRA KABLO SAN.VE TİC.LTD. ŞTİ.Address Isıso Sanayi Sit. F blok No:14 HadımköyCity İSTANBULTel (+90 212) 6728939Fax (+90 212) 6230282e-mail *****************Web Brand Names AKSKABLOCertificates TSECompany Name AR-EL KABLO PLASTİK SAN.VE TİC.LTD.ŞTİ. Address Organize Sanayi Bölgesi 28.Cad. No:16 MelikgaziCity KAYSERİTel (+90 352) 3221900Fax (+90 352) 3221904e-mail **************.trWeb .trBrand Names AR-ELCertificates ISO, OHSAS, VDE, TSECompany Name ARTAR KABLO SAN.VE TIC.LTD.STIAddress Şair Ziya Paşa Caddesi No:10/A PK:34420 KaraköyCity İSTANBULTel (+90 212) 2434437Fax (+90 212) 2513695e-mail *******************.trWeb .trBrand Names ARTARCertificates ISO, TSEInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name ATOM KABLO SAN.VE TIC.A.SAddress Feneryolu Cemil Topuzlu Cad. Türkiye İşBankasıBlokları,E Blok D:8 KadıköyCity İSTANBULTel (+90 216) 4670440Fax (+90 216) 4670439e-mail *************.trWeb .trBrand Names ATOM KABLOCertificates ISO 9001:2008,TSECompany Name BASKAR KABLO IMALATI VE TIC. LTD STI.Address İçerenköy Yolu Cad. Keyap San.Sitesi E-2 Blok No:82 YukarıDudullu City İSTANBULTel (+90 216) 4205940Fax (+90 216) 3138776e-mail *********************Web Brand Names SIMH-OCertificates ISO, TSE, VDECompany Name BEMKA KABLO VE ELEKTRIK MALZEM ELERI SAN. TIC. LTD.STI.Address Alkop San.Sitesi C-2 Blok No:3-4 EsenyurtCity İSTANBULTel (+90 212) 8861929Fax (+90 212) 8861949e-mail *****************Web Brand Names BEMKACertificates ISO, TSE, VDEInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name BORSAN ELEKT.MALZ.İML.SAN.TİC.LTD.ŞTİ.Address Org.SanBulvar No:34 KutlukentCity SAMSUNTel (+90 362) 2665925Fax (+90 362) 2666194e-mail *******************.trWeb .trCompany Name DE-KA ELEKTROTEKNİK SAN.VE TİC A.Ş.Address Akse Mah. Fevzi Çakmak Cad. No:140 41420 ÇayırovaCity KOCAELİTel (+90 262) 7436060Fax (+90 262) 7442918e-mail **************Web Brand Names DETA ELOKTRO TEKNİKCertificates TSE, RD, HAR, ASTA, İRAMCompany Name DEMAS KABLO SANAYI VE TICARET A.S.Address Boya Vernik Organize Sanayi Bölgesi Tem Kuzey Yanyol BatıCaddesi No:12 TuzlaCity İSTANBULTel (+90 216) 5930770Fax (+90 216) 5930771e-mail ********************.trWeb .trBrand Names DEMKA, DEMAŞKABLO, HİTİTCertificates TSE,TSEN,İSOInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name DENİZLİKABLO SAN.VE TIC.LTD. STI.City DENİZLİTel (+90 258) 2692666Fax (+90 258) 2691893e-mail ************************Web Brand Names DENİZLİKABLOCompany Name DORTLER KABLO SANAYI TICARET LTD.STI. City TOKATTel (+90 356) 2752703Fax (+90 356) 2756729e-mail **********************.trWeb .trBrand Names DÖRTLER KABLOCertificates TSE,ISO,GOST,CECompany Name ECS-ELEKTRİK ENJEKSİYON VE KABLO SİST.SAN.TİC.A.Ş. Address NOSAB 206. Sokak No:7/2 NilüferCity BURSATel (+90 224) 4111015Fax (+90 224) 4111017e-mail **********************Web Brand Names ECSKABLEM,ECSCertificates TSE, İSO:9001:2000Insulated wire, cableHS Code 8544Updated at 23th November 2011Company Name ELCAB KABLO PROFIL SAN.TIC. LTD.STI.Address Atatürk Mah. Yıldırım Beyazıt Cad. Hayat Sok. No:5 Boğazköy-ArnavutköyCity İSTANBULTel (+90 212) 6852094Fax (+90 212) 6850280e-mail *********************Web Brand Names ELCABCertificates ISO, CE, VDECompany Name ELKI ELEKTRIK KABLO SANAYI VE TICARET A.S.Address Yenidoğan Mah. Ferhatpasa Cad. Şehit Naci Cakar Sok. No:2 TopçularBayrampaşaCity İSTANBULTel (+90 212) 6135313Fax (+90 212) 5653075e-mail ******************Web Brand Names IRMAK KABLOCertificates TSE, ISO, CE, VDECompany Name ERSE KABLO IMALATI SAN.TIC.LTD STI.Address Perpa Ticaret Merkezi A Blok Kat 2 No : 9/0023 34384 OkmeydanıCity İSTANBULTel (+90 212) 3202680Fax (+90 212) 3202684e-mail ***********************.trWeb .trBrand Names ERSE KABLOCertificates ISO, VDE, GOST, CE, TSEInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name ETABIR BIRTAS KABLO SAN.VE DIS TIC.LTD.STI.Address Bankalar, Şair Ziya Paşa Caddesi Topçuoğlu Han No: 42City İSTANBULTel (+90 212) 2931664Fax (+90 212) 2430500e-mail ********************Web Certificates ISO, VDE, CE, GOSTCompany Name FOKABEKS KABLO VE SISTEMLERI LTD.STI.Address 38.ADA , ATA 3/3 PLAZA, KAT:6, DAIRE: 60 , ATASEHIR 34758 City İSTANBULTel (+90 216) 4569139Fax (+90 216) 4569141e-mail ****************Web Brand Names FOCABEXCompany Name G.M.S.KABLO SAN.VE TIC.LTD.STIAddress Gümüşsuyu Cad. BirtaşSan. Sit. No:61/77 Maltepe/TopkapıCity İSTANBULTel (+90 212) 5777235Fax (+90 212) 6124237e-mail *********************Web Brand Names GMSCertificates TSE, ISO, VDE, TSHInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name HAS ÇELİK VE HALAT SAN.TİC.A.ŞAddress Erciyes mah Hes caddesi No :11 HacılarCity KAYSERİTel (+90 352) 4421640Fax (+90 352) 4421644e-mail *******************************************.trWeb .trBrand Names HASÇELİK, HAS-ALCertificates TSE, ISO, CECompany Name HASTEL KABLO ELEK.INS.MAK. IM.TAAH.TIC.VE SAN.LTD.STI.Address Emekyemez mahallesi Okçu Musa Cad. GüneşHan No: 24 Kat: 5 BeyoğluCity İSTANBULTel (+90 212) 2386823Fax (+90 212) 2386902e-mail ********************Web Brand Names HASTEL KABLOCertificates TSE, ISO, VDE, GOST, CECompany Name HEDEF KABLO ELEKTRIK PL.TIC.VE SAN.A.S. Address Organize Sanayi Bölgesi.20.Cad.No:15 38070City KAYSERİTel (+90 352) 3211474Fax (+90 352) 3211766e-mail *******************.trWeb .trBrand Names HEDEF KABLOCertificates TSE, TÜV, ISO 9001:2008Insulated wire, cableHS Code 8544Updated at 23th November 2011Company Name KABEL KABLO ELEMANLARI SANAYI VE TICARET A.S. Address OSB.11.Cad.No:14 26110City ESKİŞEHİRTel (+90 222) 2361130Fax (+90 222) 2360880e-mail ***************.trWeb .trBrand Names KILIÇOĞLUCertificates TS EN ISO-9002Company Name KABTEK KABLO INS.SAN.VE TIC. LTD.STI.Address Alipaşa mevkii Sanayi 12. Sokak No:7 SilivriCity İSTANBULTel (+90 212) 7165330Fax (+90 212) 7165344e-mail ******************Web Brand Names KABTEKCertificates TSE,VDE,ISO 9001:2008, TUV, GOST, HARMONİZE MARKA KULLANMA BELGESİCompany Name KABUKÇU KABLO SAN.VE TIC.KOLL. ŞTI. MUSTAFA KABUKCUVE ORT.Address BOZBURUN MAH.7067 SK.NO:1 MERKEZCity DENİZLİTel (+90 258) 3715957Fax (+90 258) 3711436e-mail *******************Web Brand Names HİSARKABLOCertificates İSO 9001-11001,TSEInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name LAPP KABLO SANAYI VE TICARET LTD.STI.Address Atatürk BulvarıAyanoğlu İşMerkezi No:1/1 34758 AtaşehirCity İSTANBULTel (+90 216) 4565699Fax (+90 216) 4565687e-mail *************.trWeb .trBrand Names ÖLFLEX, HITRONİC, UNITRONIC, EPİC, SKİNTOP, SİLVYN, FLEXİMARK, ETHERLİNECertificates ISO 9001Company Name LEONI KABLO VE TEKNOLOJİLERİSAN.VE TİC.LTD.ŞTİ. Address Bursa Serbest Bölgesi Hisar Mevki Liman Yolu PK:16600City BURSATel (+90 224) 5248900Fax (+90 224) 5248960e-mail **************.trWeb .trBrand Names LEONİCertificates ISO 14001Company Name MAKSAN KABLO SANAYI VE TICARET LTD.STI. Address Yolcuzade Iskender cd. No:66-68 Kat:4 Sishane 80020City İSTANBULTel (+90 212) 2359152Fax (+90 212) 2533793e-mail ***************Web Brand Names MAKSAN KABLOInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name MASS KABLO YATIRIM VE TIC.A.S. Address Barbaros BulvarıNo:59 Preveze Han 34353 BeşiktaşCity İSTANBULTel (+90 212) 2615163Fax (+90 212) 2581656e-mail ******************.trWeb .trBrand Names MASS,DEMİRERCertificates ISO 14001,ISO 18001Company Name MEKSAN KABLO SAN.VE TIC. LTD.STI. Address Alipaşa Mah.Sanayi 36.Sok.No:2 SilivriCity İSTANBULTel (+90 212) 7361300Fax (+90 212) 7361333e-mail ********************Web Brand Names MEKSANCertificates TS-EN-ISO 9001:2000Company Name MURAT TICARET KABLO SANAYİAŞ.Address İnegöl Organize San.Bölgesi 4.Cad.No:28 İnegölCity BURSATel (+90 224) 7148182Fax (+90 224) 7148187e-mail *********************Web Certificates ISO 9001:2000, ISO 9001:2008, TS-EN 14000, ISO/TS 16949:2009, TSE,ISO 16949:2002, ISO 14001Insulated wire, cableHS Code 8544Updated at 23th November 2011Company Name MUSTAFA CARKIT KABLO SAN. IC VE DIS TIC.LTD.STI Address HacıeyüplüMh.Akça Cd.No:157 Üçler / DenizliCity DENİZLİTel (+90 258) 3710030Fax (+90 258) 3720014e-mail *******************************Web Brand Names CMKCertificates BASECCompany Name NERGIZ KABLO VE PLASTIK SANAYI VE TICARET LTD.STI. Address TaşocağıCad.No:13/15 Kat:2 Çağlayan P.K.34403City İSTANBULTel (+90 212) 2240110Fax (+90 212) 2246315e-mail ***************************.trWeb .trBrand Names NERGİZ KABLOCertificates EN ISO 9001:2000,TSE,EN 50214,CECompany Name OREN KABLO PAZ. VE TIC.LTD.STIAddress Perpa Ticaret Merkezi A Blok Kat:11 No:1483 PK: 34384 OkmeydanıCity İSTANBULTel (+90 212) 2204800Fax (+90 212) 2205021e-mail ******************Web Brand Names ÖRENKABLOCertificates TSE. İSO, TSEK, CE, GOSTInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name OZGUN KABLO VE ELEKTRIK MALZ. SAN.TIC.A.S.Address Şekerpınar Mah. Fevzi Çakmak Cad. Menekşe Sok. No:6 PK:41435 City KOCAELİTel (+90 262) 6580979Fax (+90 262) 6580984e-mail *******************Web Brand Names ÖZGÜNCertificates ISO 9001, 14001, OHSAS 18001, VDE,UKRASEPROCompany Name OZLER KABLO İÇ DIŞTİC SAN A.ŞAddress PELİTLİKÖYÜ GEBZECity KOCAELİTel (+90 262) 7515200Fax (+90 262) 7515205e-mail ********************.trWeb .trBrand Names ÖZLERKABLOCertificates TSE,BAZEKCompany Name OZ-PA KABLO IC VE DIS PAZ. INSAAT SANAYI TIC.LTD.STI. Address Pelitli KöyüÇoğrul Deresi Çardak Bayırı1/1 41490 Gebze KOCAELİCity KOCAELİTel (+90 262) 7515201Fax (+90 262) 7515205e-mail ********************.trWeb .trInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name PAMUKKALE KABLO SAN.TİC.A.Ş.Address EGS Bussiness Park Plaza B1 Blok Kat:16 No:463 Yeşilköy City İSTANBULTel (+90 212) 4653812Fax (+90 212) 4655383e-mail *********.trWeb .trBrand Names PAMUKKALEKABLOCertificates TSE, İSO, BASECCompany Name PEKTAS KABLO VE PVC GRANUL SAN TIC.LTD.STI. Address Sanayi Mah. Çinçin Deresi Cad. No:127 Güngören/İstanbul City İSTANBULTel (+90 212) 6444955Fax (+90 212) 5399529e-mail ********************Web Company Name PENTA KABLO VE TEL.SAN.DIS.TIC .LTD.STI.Address Bebek Cevdetpaşa Caddesi Günaydın ÇıkmazıGünaydın Sitesi B blok D.2BebekCity İSTANBULTel (+90 212) 2570648Fax (+90 212) 2576937e-mail ********************Web Brand Names PENTAInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name SENA KABLO SANAYI VE TICARET LTD.STI.Address Izmir Asfalti Bozburun mah. Salihaga Koyu Yolu No:10City DENİZLİTel (+90 258) 3710567Fax (+90 258) 3713817e-mail ******************.trWeb .trBrand Names SENAKABLOCertificates TSE, HAR, ISO 9001Company Name SEVAL KABLO AYDINLATMA CIHAZLARI İTHALATİHRACAT.SAN.VE TIC.A.S.Address HacıeyüplüMah.3119 Sokak No:5 ÜçlerCity DENİZLİTel (+90 258) 3710455Fax (+90 258) 3715406e-mail *************************Web Brand Names SEVALKABLOCertificates TSE İSO,CE,BAZECCompany Name SIEMENS SAN.VE TİC.A.Ş.Address Yakacık Cad. No :111 31870 KartaLCity İSTANBULTel (+90 216) 4593085Fax (+90 216) 4592136e-mail *************************Web .trBrand Names SİEMENSCertificates TSE, CE, ISO 9001Insulated wire, cableHS Code 8544Updated at 23th November 2011Company Name TEDUM KABLO FIS DONANIM SAN.VE TIC.A.S. Address Akçaburgaz Mah. 87. Sok. No :6 EsenyurtCity İSTANBULTel (+90 212) 8865075Fax (+90 212) 8865076e-mail ***************Web .trBrand Names TEDÜMCertificates TSE, VDECompany Name TEM KABLO DONANIMLARI SAN.VE T IC.LTD.ŞTI. Address Yeni Sakarya Caddesi 246 / A 54200 ErenlerCity SAKARYATel (+90 264) 2413107Fax (+90 264) 2413215e-mail *****************Web Certificates ISO 9001:9008Company Name TUMKA KABLO SANAYI A.S.Address Ömerli Mah. Ilgaz Sk. No:7 Arnavutköy HadımköyCity İSTANBULTel (+90 212) 7982006Fax (+90 212) 7982117e-mail ********************.trWeb .trCertificates TSE,İSOInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name TURKUAZ KABLO TAAHHUT TIC.VE SAN.A.S. Address Balçık köyüMezarlık Sok . No :47 GebzeCity KOCAELİTel (+90 262) 7513100Fax (+90 262) 7513090e-mail *********************Web Brand Names TURKUAZ KABLOCertificates TSE 3930, ISO 14001, ISO 9001Company Name TÜRK PRYSMIAN KABLO VE SİSTEML.A.Ş. Address Ömerbey Mah. Bursa AsfaltıCad. No:51 Mudanya City BURSATel (+90 224) 2703000Fax (+90 224) 2703030e-mail *****************Web Brand Names AFUMEXCertificates TSE, İSOCompany Name UNAL KABLO DIS.TIC.LTD.STI.Address Şair Ziyapaşa Cd. Laleli Çeşme Sk. No:18 Karaköy-İSTANBUL City İSTANBULTel (+90 212) 2433589Fax (+90 212) 2456521e-mail ******************Web Brand Names ÜNALKABLOCertificates HAR, CE, İSO, TSE, TÜV, ROSHInsulated wire, cableHS Code 8544Updated at 23th November 2011Company Name UNKA KABLO SAN. VE TIC. A.S.Address Dr. Fazıl küçük cad. Sdite yolu No :16 ÜmraniyeCity İSTANBULTel (+90 216) 6341440Fax (+90 216) 6341444e-mail ******************.trWeb .trCertificates ISO 9001Company Name UNTEL KABLOLARI SANAYI VE TICARET A.S. Address Dr. Fazıl küçük cad. Üntel Sok. No :26 34768 ÜmraniyeCity İSTANBULTel (+90 216) 6342577Fax (+90 216) 6340677e-mail **************.trWeb .trCertificates ISO 9000:2008, TSE, CE, RİNA, LOTVEGASTERCompany Name YILMAZ KABLO SAN A.Ş.Address BANKALAR CADDESİ21 KARAKÖY BEYOĞLU - İSTANBUL City İSTANBULTel (+90 212) 5446828Fax (+90 212) 5678124e-mail ***************Web Insulated wire, cableHS Code 8544Updated at 23th November 2011Company Name YILMAZLAR KABLO VE ELEKTRIK SANAYI VE TICARET LTD.STI.Address Gebze OSB Molla Fenari Yolu, belediye asfaltıŞantiye yolu No: 20 PelitliGebzeCity KOCAELİTel (+90 262) 7514268Fax (+90 262) 7513949e-mail *******************Web Brand Names YILKA KABLO Certificates TSE, ISO。

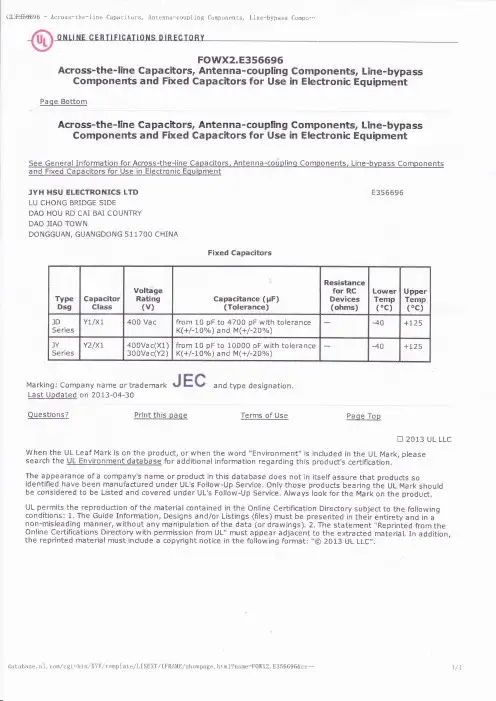

ENEC LICENCELicence No. ENEC-00656Page 1/Date of Issue 2013-07-05Certification ManagerJan-Erik StorgaardThe product and production sites listed on the License comply with the ENEC requirement and the UL Global Service Agreement,with reference to Terms and Conditions for the ENEC mark.The Owner of the License is entitled to use the ENEC 15(as shown in annex 1)for the products listed on the License and manufactured at the production site listed.UL has to be informed in writing about any changes to the product or production site in accordance with the Term and Conditions of the ENEC mark.Certification Body UL International Demko A/S, Borupvang 5A, DK-2750Ballerup, Denmark, Tel. +45 44 85 65 65,info.dk@Licence Holder JYH HSU ELECTRONICS LTDLU CHONG BRIDGE SIDEDAO HOU RD CAI BAI COUNTRYDAO JIAO TOWNDONGGUAN, 511700 GUANGDONG ChinaManufacturer JYH HSU ELECTRONICS LTDLU CHONG BRIDGE SIDEDAO HOU RD CAI BAI COUNTRYDAO JIAO TOWNDONGGUAN, 511700 GUANGDONG ChinaProduction site JYH HSU ELECTRONICS LTDLU CHONG BRIDGE SIDEDAO HOU RD CAI BAI COUNTRYDAO JIAO TOWNDONGGUAN, 511700 GUANGDONG ChinaCertification Mark See Annex 1Certified Product Fixed Capacitors For Electromagnetic Interference SuppressionAnd Connection To The Supply Mains, Ceramic TypeModelJD seriesTrademarkRated Voltage / Frequency400Vac, 50/60Hz Rated Current / PowerX1 / Y1; 10 ~ 4700 pF, 40/125/21C, Capacitance tolerance K(±10%) or M(±20%)Insulation Class-Degree of protection (IP)-Tested acc. toEN 60384-14:2005Test Report No.CAP-12CA42327-A-1 issued on 2013-06-26AdditionalAnnex 1 to Licence No.ENEC-00656Annex of the form of the MarkCertification Body The product and production sites listed on the License comply with the ENEC requirement and the UL Global ServiceAgreement,with reference to Terms and Conditions for the ENEC mark.The Owner of the License is entitled to use theENEC 15(as shown in annex 1)for the products listed on the License and manufactured at the production site listed.ULhas to be informed in writing about any changes to the product or production site in accordance with the Term andConditions of the ENECmark.* Identification number of the Certification BodySize of the mark:The size of the mark may be reduced on the condition thatit remains legible and that the ratio b/a=1,7 is keptRef. Certif. No.US-21902-ULCB TEST CERTIFICATECERTIFICAT D'ESSAI OC ProductProduitFixed Capacitors For Electromagnetic Interference Suppression And Connection To The Supply Mains, Ceramic Type Name and address of the applicantNom et adresse du demandeur JYH HSU ELECTRONICS LTD LU CHONG BRIDGE SIDEDAO HOU RD CAI BAI COUNTRYDAO JIAO TOWNDONGGUAN, 511700 GUANGDONG ChinaName and address of the manufacturer Nom et adresse du fabricant JYH HSU ELECTRONICS LTDLU CHONG BRIDGE SIDEDAO HOU RD CAI BAI COUNTRYDAO JIAO TOWNDONGGUAN, 511700 GUANGDONG ChinaName and address of the factory Nom et adresse de l'usine Note: When more than one factory, please report on page 2Note: Lorsque il y plus d'une usine, veuillez utiliser la 2ème pageJYH HSU ELECTRONICS LTDLU CHONG BRIDGE SIDEDAO HOU RD CAI BAI COUNTRYDAO JIAO TOWNDONGGUAN, 511700 GUANGDONG ChinaAdditional Information on page 2Ratings and principal characteristicsValeurs nominales et caractéristiques principalesX1 / Y1, 400Vac, 50/60Hz; 10 ~ 4700 pF, 40/125/21C, Capacitance tolerance K(±10%) or M(±20%)Trademark (if any)Marque de fabrique (si elle existe)Type of Manufacturer's Testing Laboratories usedType de programme du laboratoire d'essaisconstructeurModel / Type Ref.Ref. De typeJD series Additional information (if necessary may also bereported on page 2)Les informations complémentaires (si nécessaire,,peuvent être indiqués sur la 2ème pageAdditionally evaluated to EN 60384-14:2005; National Differences specified in the CB Test Report. Additional Information on page 2A sample of the product was tested and foundto be in conformity withUn échantillon de ce produit a été essayé et a étéconsidéré conforme à laIEC 60384-14(ed.3)As shown in the Test Report Ref. No. which formspart of this CertificateComme indiqué dans le Rapport d'essais numéro deréférence qui constitue partie de ce Certificat CAP-12CA42327-A-1 issued on 2013-06-26This CB Test Certificate is issued by the National Certification BodyCe Certificat d'essai OC est établi par l'Organisme National de CertificationUL (US), 333 Pfingsten Rd IL 60062, Northbrook, USAUL (Demko), Borupvang 5A DK-2750 Ballerup, DENMARKUL (JP), Marunouchi Trust Tower Main Building 6F, 1-8-3 Marunouchi, Chiyoda-ku, Tokyo 100-0005, JAPANUL (CA), 7 Underwriters Road, Toronto, M1R 3B4 Ontario, CANADAFor full legal entity names see /ncbnamesDate: 2013-07-05Signature:Jolanta M. WroblewskaFestkondensator zur Unterdrückung elektromagnetischer Störungen, geeignet für Netzbetrieb Fixed capacitor for electromagnetic interference suppression and connection to the supply mainsTyp(en) / Type(s):JDKapazitätsklasse undX1 und/and Y1-unterklasseCapacity Class and subclassBemessungsspannungAC 400 V Rated voltageTemperaturcharakteristikY5P Temperature characteristicBemessungskapazität10 pF, 12 pF, 15 pF, 18 pF, 20 pF, 22 pF, 25 pF, 27 pF,Rated capacitance 30 pF, 33 pF, 36 pF, 39 pF, 47 pF, 50 pF, 56 pF, 62 pF,68 pF, 75 pF, 82 pF100 pF, 150 pF, 220 pF, 270 pF, 330 pF470 pF, 560 pF, 680 pF, 1000 pFTemperaturcharakteristikY5U oder/or Y5V Temperature characteristicBemessungskapazität1000 pF 1500 pF 2200 pF Rated capacitance3300 pF 3900 pF 4700 pF Klimakategorie40/085/21Climatic categoryKategorie der passivenC EntflammbarkeitPassive flammability categoryGrenzabweichung derY5P ± 10 % (K)BemessungskapazitätY5U ± 20 % (M)Tolerance of rated capacitanceY5V ± 20 % (M)Name und Sitz des Genehmigungs-Inhabers / Name and registered seat of the Certificate holder Jyh Chung Electronic Co., Ltd., No. 40, Lane 221, Ren Hau Rd., TA LI CITY, TAICHUNG HSIEN,TAIWANAktenzeichen / File ref.letzte Änderung / updated Datum / Date 2189700-4670-0002 / 130663 / FG32 / BT 2010-05-282001-07-11Dieses Blatt gilt nur in Verbindung mit Blatt 1 des Zeichengenehmigungsausweises Nr. 137027.This supplement is only valid in conjunction with page 1 of the Certificate No. 137027.Fortsetzung siehe Blatt 3 /continued on page 3Name und Sitz des Genehmigungs-Inhabers / Name and registered seat of the Certificate holderJyh Chung Electronic Co., Ltd., No. 40, Lane 221, Ren Hau Rd., TA LI CITY, TAICHUNG HSIEN, TAIWANAktenzeichen / File ref.letzte Änderung / updated Datum / Date 2189700-4670-0002 / 130663 / FG32 / BT2010-05-282001-07-11 Dieses Blatt gilt nur in Verbindung mit Blatt 1 des Zeichengenehmigungsausweises Nr. 137027.This supplement is only valid in conjunction with page 1 of the Certificate No. 137027.Weitere Einzelheit(en)Anlage Nr. 1 bis 7Further detail(s)Enclosure No. 1 to 7_____________________________________________________________________ VDE Prüf- und Zertifizierungsinstitut GmbHVDE Testing and Certification InstituteFachgebiet FG32Section FG32Festkondensator zur Unterdrückung elektromagnetischer Störungen, geeignet für Netzbetrieb Fixed capacitor for electromagnetic interference suppression and connection to the supply mainsFertigungsstätte(n)Place(s) of manufactureReferenz/ReferenceJyh Chung Electronic Co., Ltd.30001378No. 40, Lane 221, Ren Hau Rd.TA LI CITY, TAICHUNG HSIENTAIWANReferenz/Reference JEC Company30019605Chen Wu District, Hou Jie Town523942 DONGGUAN CITYGuangdongCHINAReferenz/Reference JYH HSU ELECTRONICS LTD.30019606Lu Chong Bridge Side, Dao Hou Rd.Cai Bai Country523185 DAO JIAO TOWN, DONGGUANGuangdongCHINA VDE Prüf- und Zertifizierungsinstitut GmbHVDE Testing and Certification InstituteFachgebiet FG32Section FG32Name und Sitz des Genehmigungs-Inhabers / Name and registered seat of the Certificate holder Jyh Chung Electronic Co., Ltd., No. 40, Lane 221, Ren Hau Rd., TA LI CITY, TAICHUNG HSIEN,TAIWANAktenzeichen / File ref.letzte Änderung / updated Datum / Date 2189700-4670-0002 / 130663 / FG32 / BT 2010-05-282001-07-11Dieses Beiblatt ist Bestandteil des Zeichengenehmigungsausweises Nr. 137027.This supplement is part of the Certificate No. 137027.Name und Sitz des Genehmigungs-Inhabers / Name and registered seat of the Certificate holderJyh Chung Electronic Co., Ltd., No. 40, Lane 221, Ren Hau Rd., TA LI CITY, TAICHUNG HSIEN,TAIWANAktenzeichen / File ref.letzte Änderung / updated Datum / Date 2189700-4670-0002 / 130663 / FG32 / BT2010-05-282001-07-11 Dieses Blatt gilt nur in Verbindung mit Blatt 1 des Zeichengenehmigungsausweises Nr. 137027.This supplement is only valid in conjunction with page 1 of the Certificate No. 137027. Genehmigung zum Benutzen des auf Seite 1 abgebildeten markenrechtlich geschützten Zeichens desVDE:Grundlage für die Benutzung sind die Allgemeinen Geschäftsbedingungen (AGB) des VDE Prüf- und Zertifizierungsinstitut GmbH. Das Recht zur Benutzung erstreckt sich nur auf die bezeichnete Firma mit den genannten Fertigungsstätten und die oben aufgeführten Produkte mit den zugeordneten Bezeichnungen. Die Fertigungsstätte muss so eingerichtet sein, dass eine gleichmäßige Herstellung der geprüften und zertifizierten Ausführung gewährleistet ist.Die Genehmigung ist so lange gültig wie die VDE-Bestimmungen gelten, die der Zertifizierung zu-grunde gelegen haben, sofern sie nicht auf Grund anderer Bedingungen aus der Prüf- und Zertifizierungsordnung (PM102) zurückgezogen werden muss.Der Gültigkeitszeitraum einer VDE-GS-Zeichengenehmigung kann auf Antrag verlängert werden. Bei gesetzlichen und / oder normativen Änderungen kann die VDE-GS-Zeichengenehmigung ihre Gültigkeit zu einem früheren als dem angegebenen Datum verlieren.Produkte, die das Biozid Dimethylfumarat (DMF) enthalten, dürfen gemäß der Kommissionsent-scheidung 2009/251/EG nicht mehr in den Verkehr gebracht oder auf dem Markt bereitgestellt werden.Der VDE-Zeichengenehmigungsausweis wird ausschließlich auf der ersten Seite unterzeichnet. Approval to use the legally protected Mark of the VDE as shown on the first page:Basis for the use are the gerneral terms and conditions of the VDE Testing and Certification Institute. The right to use the mark is granted only to the mentioned company with the named places of manufacture and the listed products with the related type references. The place of manufacture shall be equipped in a way that a constant manufacturing of the certified construction is assured.The approval is valid as long as the VDE specifications are in force , on which the certification is based on, unless it is withdrawn accordiProcedure (PM102).The validity period of a VDE-GS-Mark Approval may be prolonged on request. In case of changes in legal and / or normative requirements, the validity period of a VDE-GS-Mark Approval may be shortened.Products containing the biocide dimethylfumarate (DMF) may not be marketed or made available on the EC market according to the Commission Decision 2009/251/EC.The approval is solely signed on the first page。

2To order, visit or call 1.800.932.5000Nonsterile Gowning ProcedureGown RemovalStep 4 - In order:• Hood - Hang in controlled environ-ment.• Remove Goggles or Safety Glasses. • Mask - Usually discarded after each change.• Bouffant/Hair Net - Usually discard-ed after each change.• Shoe Covers - Usually discarded after each change.• Gloves - It is recommended that gloves be discarded after each change.Step 3If coverall is to be used again, either hang it in a controlled environment or prepare for storage.Step 2If boots are to be used again, store them separately from other garment components, either downwind or in a proper container.Step 1 - In order:If two pairs of gloves are worn,remove boots, then discard top pair of gloves. If only one pair of gloves is worn, remove gloves last. It is recom-mended that gloves be discarded after each change.The above are recommendations only. Gowning procedures may vary by location.3To order, visit or call 1.800.932.5000Sterile Gowning ProcedureGown UpStep 1 - In order:• Bouffant/Hair Net - Contain all hair.• Shoe Covers.• Wash hands thoroughly using bactericidal soap and dry thoroughly.• Don first pair of sterile gloves following aseptic technique by touch-ing only the inside of the gloves. Sanitize.• Sanitize gloves after donning each article, if required.Step 2Put sterile boots or high-top shoe covers on using aseptic technique.The first boot donned can now be placed in the “clean” side of gown-ing area. Don second boot and place the other foot in the “clean” side of gowning area.Step 3• Sterile Hood - Ensure snug fit and proper neck seal.• Sterile Mask - Adjust for a snug facial fit. May be worn over or under hood.• Sterile Coveralls - Carefully remove coverall from package by holding the inside neck area. Unfold garment while preventing it from touching the floor, your clothes or bench. Don using aseptic technique. Tuck coverall legs into boots.• Goggles or Safety Glasses - Adjust for a snug facial fit.Step 4Perform a final inspection in gowning room mirror prior to entry into the sterile cleanroom.Complete gowning steps by aseptically donning second pair of sterile gloves over the first pair, making sure the cuffs are securely over the sleeves.Gown RemovalStep 1Enter gowning area from cleanroom and head directly to the “exit gown room” (preferred method). If no “exit gown room” is available,go directly to the “nonclean” side, usually divided by a bench and/or line.Step 2Remove items in reverse order of gowning procedure and discard.The above are recommendations only. Gowning procedures may vary by location.4To order, visit or call 1.800.932.5000Table of ContentsSupplies . . . . . .14-15Caps/Hoods/Masks . . . .5-6Coveralls . . . . . . . .8-9Gloves . . . . . . . .10-11Shoe/Boot Covers . . .12-13Eyewear . . . . . . . . . .75Caps/Hoods/MasksTo order, visit or call 1.800.932.50006Caps/Hoods/MasksTo order, visit or call 1.800.932.50007EyewearTo order, visit or call 1.800.932.5000Lens Coating Cat. No. Each Box of 10Ultra-dura 89009-112 5.9053.91Uvextra89009-1146.6260.43Antifog Lens14222-5108.96BlueWhite 89032-912 6.75VermillionBlack/Gray89032-9026.758CoverallsTo order, visit or call 1.800.932.5000Sizing Chart for Products Listed AboveCoveralls9To order, visit or call 1.800.932.5000Sizing Chart for Products Listed Above10GlovesTo order, visit or call 1.800.932.5000Gloves11To order, visit or call 1.800.932.500029PH2Y72PL90500.0012Shoe/Boot CoversTo order, visit or call 1.800.932.5000Shoe/Boot Covers13To order, visit or call 1.800.932.500014SuppliesTo order, visit or call 1.800.932.5000Blue 87003-436179.95White87003-434179.95Spiral Size, cm (in.)Location Cat. No.Each 7.6 x 12.7 (3 x 5)Top 12345-03610.8114 x 21.6 (51/2x 81/2)Side 12345-04010.8121.6 x 27.9 (81/2x 11)Side12345-04212.92VWR PureStep Adhesive MatsMultilayered floor mats remove dirt and dust from foot traffic and rmation.Dimensions, L x W, cm (in.)Cat. No.Case of 866 x 114.3 (26 x 45)87004-052231.2591.4 x 114.3 (36 x 45)87004-076325.60DescriptionCat. No.Each Case of 12Tubular Knit Mop Head33502-72826.36274.96Tubular Knit Mop Head, Sterile 33502-730—309.98Tubular Knit Mop Head, Ribbed 33502-73242.54443.87Stainless Steel Two-Piece Handle, 68310-014176.87—152.4 cm (60") LongSupplies15To order, visit or call 1.800.932.5000VWR ®Cleanroom Polyester Knitted WipersLightweight, economical knitted wipers for spill control and general wiping in Class 100 environments, and cleaning sensitive surfaces. Feature 100%continuous-filament polyester construction for high absorbency, ultralow par-ticle generation, and low extractable levels. Cleanroom-laundered to ultra-clean for rigorous wiping with minimal fiber and particle release. Packed in solvent-safe, Bag-Within-A-Bag ®packaging.Dimensions, cm (in.)Cat. No.Pack of 15022.9 x 22.9 (9 x 9)14004-91646.38Dimensions, cm (in.)Cat. No.Pack of 7522.9 x 22.9 (9 x 9)47751-45817.9022.9 x 22.9 (9 x 9)21914-75828.4322.9 x 22.9 (9 x 9)21913-21438.350307 15M Lit. No. 923891.888.VWR.LINEVWR can answer your questions regarding product applications, product specifications,manufacturer recommendations, and regulatory compliance information. Any questions concerning the occupational health and safety of your workers can be directed to our staff.You can contact VWR's Technical Resource Center for a quick response to your Safety and Controlled Environment questions at 1-888-VWR-LINE (1-888-897-5463), Option 4.Once Connected...Push 4for Safety and Controlled EnvironmentsVWR Technical Resource Center。

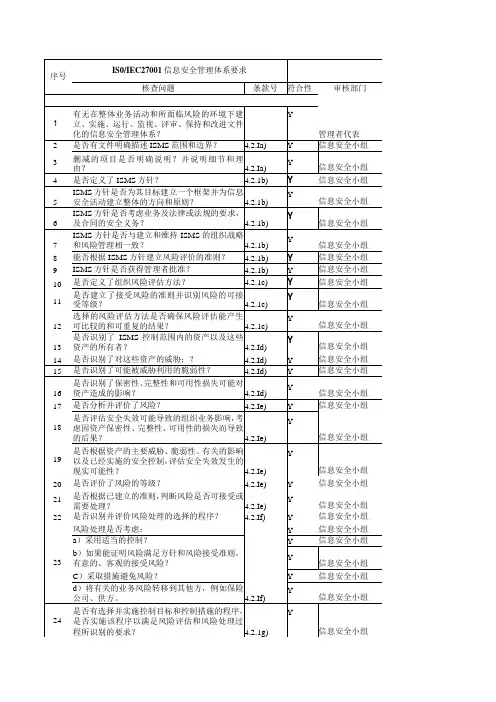

备注序号IS0/IEC27001信息安全管理体系要求4 组织是否对所有的与信息处理设施有关的信息和资产指定"所有者”?A.7.1.2Y5是否识别与信息系统或服务相关的资产的合理使用规则,并将其文件化,并予以实施?A.7.1.3Y物流中心 管理者是否通过明确导向、可证实的承诺、信息安全职责的分配来积极支持组织内的信息安Y物流中心9 是否对新的信息处理设施规定并实施管理授权过程?A.6.1.4Y 物流中心 W 反映组织信息保护需求的保密或不泄密协议的要求是否被识别并定期对其进行评审? Λ.6.1.5 Y 物流中心 11 与相关的权威机构的适当联系是否被保持? A.6.1.6 Y 物流中心 12与专业的相关团体或其他安全专家论坛或专业协会的适当联系是否被保持? A.6.1.7Y 物流中心 13组织管理信息安全的方法及其实施情况(如控制目标和控制措施、策略、过程和信息安全的程序)是否根据策划的时间间隔,或者是当安全实施发生重大变化时进行了独立评审? A.6.1.8 Y物流中心 14 是否识别由外部相关方参与商业过程而对组织信息资产和信息处理设施造成的风险?并在批准外部相关方访问信息资产和信息处理设施前实施适当的控制? Λ.6.2.1 Y 物流中心15在批准顾客访问组织信息或资产前,是否处理所有己识别的安全要求? A.6.22 Y 物流中心 16 与第三方签订的涉及组织信息或信息处理设施或信息处理设施附加部件和服务的访问、处理、沟通或管理的协议,是否包含或涉及所有已识别的安全要求?A.6.2.3Y物流中心17对每一个信息系统和组织而言,法律条文、行政法规及合同内容所规定的所有相关要求,以及满足这些要求的组织方法,是否加以明白地界定、文件化并保持更新? Λ.15.1.1 Y物流中心18是否实行适当的程序,以确保在具有知识产权的产品和私有软件产品时,能符合法律、法规和合同条款的要求? A151.2Y 物流中心20 数据保护和隐私是否确保符合相是否的法律法规要求,适用时也是否满足合同条款的要求? Λ.15.1.4 Y物流中心21 是否阻止用户把信息处理设备用于未经授权的目的? A.15J15 Y 物流中心密码控制措施的使用要与所有的相关协定、法律Y 物流中心是否定期检查信息系统是否符合安全运行标Y 物流中心 26 是否保护对信息系统审核工具的访问,防止任何可能的误用或者危害? A.15.3.2 Y 物流中心27 是否明确识别所有资产,并建立和保持《重要资产清单》? Λ.7.11 Y 营销中心 组织是否对所有的与信息处理设施有关的信息Y 营销中心 30 是否明确识别所有资产,并建立和保持《重要资产清单》? A.7.1.1 Y 行政中心 31 组织是否对所有的与信息处理设施有关的信息和资产指定〃所有者“? A.7.1.2 Y 行政中心 32 是否识别与信息系统或服务相关的资产的合理使用规则,并将其文件化,并予以实施? A.7.1.3 Y 行政中心 33 是否根据其价值、法律要求、敏感度以及对组织的关键程度,对信息进行分类? A.7.2.1 Y 行政中心 34是否依据组织采纳的分类方案制定并实施一系列适当的信息标识和处理程序? Λ.7.2.2 Y 行政中心 35是否依据组织的信息安全方针规定员工、合作方以及第三方用户的安全任务和责任,并将其文件Y行政中心363738管理者是否要求员工、合作方以及第三方用户依据建立的方针和程序来应用安全? Aa21Y 行政中心39组织的所有员工,适当时还包括合作方和第三方用户,是否接受适当的意识培训并定期向它们传达组织更新的方针和程序,以及工作任务方面的新情况? A.8.2.2Y行政中心40对造成安全破坏的员工是否有一个正式的惩戒过程? A.8.2.3Y行政中心41执行工作终止或工作变化的职责是否清晰的定义和分配? A.8.3.1Y行政中心42所有员工、合作方以及第三方用户是否在他们的聘用期限、合同或协议终止时归还他们负责的所有组织资产? A.8.3.2Y行政中心43所有员工、合作方以及第三方用户对信息和信息处理设施的访问权是否在其聘用期限、合同或协议终止时删除,或根据变化作相是否的调整? A.8.3.3Y行政中心44是否使用安全周界(墙、刷卡出入的大门或者人工接待前台)保护包含信息及信息处理设施的区域? A.9.1.1Y营销中心45是否通过适当进入管理措施保护安全区域,确保只有得到授权的用户才能访问? A.9.1.2Y营销中心46办公室、房间和设施的物理安全措施是否被设计并应用? A.9.1.3Y营销中心47防范火灾、水灾、地震、爆炸、社会动荡,以及其它形式的自然或人为灾害的物理安全控制是否被设计并应用? A.9.1.4Y营销中心48安全区的物理保护和原则是否被设计并应用? A.9.1.5Y营销中心49是否对交付和存储设施的访问地点以及其它未经授权的人员可能访问到的地点进行控制,可能的话,是否与信息处理设施隔离,以避免未经授权的访问? A.9.1.6Y营销中心50设备是否被定位或保护,以降低来自环境威胁和危害的风险,以及未经授权的访问机会? A.9.2.1Y营销中心51是否对设备加以保护使其免于电力中断或者其它电力异常的影响? A.9.2.2Y营销中心52是否保护传输数据和辅助信息服务的电缆和通讯线路,使其免于截取或者破坏? A.9.2.3Y营销中心53设备是否得到正确的维护,以确保其持续有效性和完整性? A.9.2.4Y营销中心54考虑到在组织场所外工作的风险,安全是否应用到场所外设备?Λ.9.2.5Y营销中心55包含储存媒体的设备的所有项目是否进行检查,以确保在处置之前将所有敏感数据和许可软件都被清除或者覆盖掉? A.9.2.6Y营销中心56在未经授权的情况下,设备、信息或软件是否带到场所外?Λ,9.27Y营销中心57操作程序是否被文件化、保持,并且在用户需要时可用?Λ.10.1.1Y营销中心58是否控制对信息处理设备和系统的变更? A.10.1.2Y营销中心符合符合符合符合符合蒋符合符合符合符合符合俞符合符合。

公司管理中的英文缩写分类:发布时间: 2011/9/19 12:52:16阅读(5084) | 评论(0)推荐1.MM --- Materials Management:物料管理2. CMM --- Component Module Move:零组件(乡村包围城市);系统组装(火车头火车头工业驱动供应链);整合供应链(运筹物流, ERP, VMI, SFC … )3. ECMMS$ --- Engineering Component Module Move Service Dollars:?工程?(研究开发);?零组件?(乡村包围城市);?系统组装(火车头火车头工业驱动供应链);?整合供应链?(运筹物流, ERP, VMI, SFC … ) ;?服务,?代收钱4. Forecast ---?客户需求预测5. WO --- Work Order = PO --- Production Order:?生产工令6. MRP --- Material Requirement Planning:?物料需求计划7. VPO --- Vendor Purchase Order:?供货商采购订单8. MAWB --- Master Air Waybill:?空运主提单9. HAWB --- House Air Waybill:?小提单10. B / L --- Bill of Loading:?海运提单11. Consignee:?收货者12. ETD --- Estimated to Departure:?预计出发13. MIN / MAX --- Minimum and Maximum:?最小量与最大量14. VPO Burning:?向供货商采购货的平衡量15. VMI --- Vendor Management Inventory:?供货商免费存放,?在距离客户组装地2小时车程内, 3天到2周之库存16. VDPS --- Vendor Daily Planning Schedule:?供货商日生产排配17. ETA --- Estimated to Arrival:?预计到达时间18. Stock Level:?库存水准19. WO / PO Consumption --- Work Order / Production Order Consumption:?工令消耗20. BO Replenish --- Back Order Replenish:?订单欠交补货21. VMSA Burning --- Vendor Managed Stock Area Burning:?供货商管理库存平衡22. Pull Back:?由后往前拉23. Pipeline:?物流供应链中的库存24. ERP – SAP --- Enterprise Resource Planning / System Application Productin Process:?企业资源规划及生产应用管制操作系统25. SFC --- Shop Floor Control:?现场车间管制操作系统26. MOQ --- Minimum Order Quantity:?最小订购量27. MSQ --- Maximum Supply Quantity:?最大供应量28. Where Use Report:?零件共同使用报表28. Where Use Report:?零件共同使用报表29. EXW-EX??Works:?工厂交货价30. RTV- Return to vendor:?退货31.RMA-Return Material Approval?退货验收32.ETA-Estimated Time of Arrival?预计到港时间33.ETD-Estimated Time of Departure?预计离港时间ERP专业词汇1 ABM Activity-based Management?基于作业活动管理2 AO Application Outsourcing?应用程序外包3 APICS American Production and Inventory Control Society,Inc?美国生产与库存管理协会4 APICS Applied Manufacturing Education Series?实用制造管理系列培训教材5 APO Advanced Planning and Optimization?先进计划及优化技术6 APS Advanced Planning and Scheduling?高级计划与排程技术7 ASP Application Service/Software Provider?应用服务/软件供应商8 ATO Assemble To Order?定货组装9 ATP Available To Promise?可供销售量(可签约量)10 B2B Business to Business?企业对企业(电子商务)11 B2C Business to Consumer?企业对消费者(电子商务)12 B2G Business to Government?企业对政府(电子商务)13 B2R Business to Retailer?企业对经销商(电子商务)14 BIS Business Intelligence System?商业智能系统15 BOM Bill Of Materials?物料清单16 BOR Bill Of Resource?资源清单17 BPR Business Process Reengineering?业务/企业流程重组18 BPM Business Process Management?业务/企业流程管理19 BPS Business Process Standard?业务/企业流程标准20 C/S Client/Server(C/S)\Browser/Server(B/S)?客户机/服务器\浏览器/服务器21 CAD Computer-Aided Design?计算机辅助设计22 CAID Computer-Aided Industrial Design?计算机辅助工艺设计23 CAM Computer-Aided Manufacturing?计算机辅助制造24 CAPP Computer-Aided Process Planning?计算机辅助工艺设计25 CASE Computer-Aided Software Engineering?计算机辅助软件工程26 CC Collaborative Commerce?协同商务27 CIMS Computer Integrated Manufacturing System?计算机集成制造系统28 CMM Capability Maturity Model?能力成熟度模型29 COMMS Customer Oriented Manufacturing Management System?面向客户制造管理系统30 CORBA Common Object Request Broker Architecture?通用对象请求代理结构31 CPC Collaborative Product Commerce?协同产品商务32 CPIM Certified Production and Inventory Management?生产与库存管理认证资格33 CPM Critical Path Method?关键线路法34 CRM Customer Relationship Management?客户关系管理35 CRP capacity requirements planning?能力需求计划36 CTI Computer Telephony Integration?电脑电话集成(呼叫中心)37 CTP Capable to Promise?可承诺的能力38 DCOM Distributed Component Object Model?分布式组件对象模型39 DCS Distributed Control System?分布式控制系统40 DMRP Distributed MRP?分布式MRP41 DRP Distribution Resource Planning?分销资源计划42 DSS Decision Support System?决策支持系统43 DTF Demand Time Fence?需求时界44 DTP Delivery to Promise?可承诺的交货时间45 EAI Enterprise Application Integration?企业应用集成46 EAM Enterprise Assets Management?企业资源管理47 ECM Enterprise Commerce Management?企业商务管理48 ECO Engineering Change Order?工程变更订单49 EDI Electronic Data Interchange?电子数据交换50 EDP Electronic Data Processing?电子数据处理51 EEA Extended Enterprise Applications?扩展企业应用系统52 EIP Enterprise Information Portal?企业信息门户53 EIS Executive Information System?高层领导信息系统54 EOI Economic Order Interval?经济定货周期55 EOQ Economic Order Quantity?经济订货批量(经济批量法)56 EPA Enterprise Proficiency Analysis?企业绩效分析57 ERP Enterprise Resource Planning?企业资源计划58 ERM Enterprise Resource Management?企业资源管理59 ETO Engineer To Order?专项设计,按订单设计60 FAS Final Assembly Schedule?最终装配计划61 FCS Finite Capacity Scheduling?有限能力计划62 FMS Flexible Manufacturing System?柔性制造系统63 FOQ Fixed Order Quantity?固定定货批量法64 GL General Ledger?总账65 GUI Graphical User Interface?图形用户界面66 HRM Human Resource Management?人力资源管理67 HRP Human Resource Planning?人力资源计划68 IE Industry Engineering/Internet Exploration?工业工程/浏览器69 ISO International Standard Organization?国际标准化组织70 ISP Internet Service Provider?互联网服务提供商71 ISPE International Society for Productivity Enhancement?国际生产力促进会72 IT/GT Information/Group Technology?信息/成组技术73 JIT Just In Time?准时制造/准时制生产74 KPA Key Process Areas?关键过程域75 KPI Key Performance Indicators?关键业绩指标76 LP Lean Production?精益生产77 MES Manufacturing Executive System?制造执行系统78 MIS Management Information System?管理信息系统79 MPS Master Production Schedule?主生产计划80 MRP Material Requirements Planning?物料需求计划81 MRPII Manufacturing Resource Planning?制造资源计划82 MTO Make To Order?定货(订货)生产83 MTS Make To Stock?现货(备货)生产84 OA Office Automation?办公自动化85 OEM Original Equipment Manufacturing?原始设备制造商86 OPT Optimized Production Technology?最优生产技术87 OPT Optimized Production Timetable?最优生产时刻表88 PADIS Production And Decision Information System?生产和决策管理信息系统89 PDM Product Data Management?产品数据管理90 PERT Program Evaluation Research Technology?计划评审技术91 PLM Production Lifecycle Management?产品生命周期管理92 PM Project Management?项目管理93 POQ Period Order Quantity?周期定量法94 PRM Partner Relationship Management?合作伙伴关系管理95 PTF Planned Time Fence?计划时界96 PTX Private Trade Exchange?自用交易网站97 RCCP Rough-Cut Capacity Planning?粗能力计划98 RDBM Relational Data Base Management?关系数据库管理99 RPM Rapid Prototype Manufacturing?快速原形制造100 RRP Resource Requirements Planning?资源需求计划101 SCM Supply Chain Management?供应链管理102 SCP Supply Chain Partnership?供应链合作伙伴关系103 SFA Sales Force Automation?销售自动化104 SMED Single-Minute Exchange Of Dies?快速换模法105 SOP Sales And Operation Planning?销售与运作规划106 SQL Structure Query Language?结构化查询语言107 TCO Total Cost Ownership?总体运营成本108 TEI Total Enterprise Integration?全面企业集成109 TOC Theory Of Constraints/Constraints managemant?约束理论/约束管理110 TPM Total Productive Maintenance?全员生产力维护111 TQC Total Quality Control?全面质量控制112 TQM Total Quality Management?全面质量管理113 WBS Work Breakdown System?工作分解系统114 XML eXtensible Markup Language?可扩展标记语言115 ABC Classification(Activity Based Classification) ABC分类法116 ABC costing?作业成本法117 ABC inventory control ABC?库存控制118 abnormal demand?反常需求119 acquisition cost ,ordering cost?定货费120 action message?行为/活动(措施)信息121 action report flag?活动报告标志122 activity cost pool?作业成本集123 activity-based costing(ABC)?作业基准成本法/业务成本法124 actual capacity?实际能力125 adjust on hand?调整现有库存量126 advanced manufacturing technology?先进制造技术127 advanced pricing?高级定价系统128 AM Agile Manufacturing?敏捷制造129 alternative routing?替代工序(工艺路线)130 Anticipated Delay Report?拖期预报131 anticipation inventory?预期储备132 apportionment code?分摊码133 assembly parts list?装配零件表134 automated storage/retrieval system?自动仓储/检索系统135 Automatic Rescheduling?计划自动重排136 available inventory?可达到库存137 available material?可用物料138 available stock?达到库存139 available work?可利用工时140 average inventory?平均库存141 back order?欠交(脱期)订单142 back scheduling?倒排(序)计划/倒序排产143 base currency?本位币144 batch number?批号145 batch process?批流程146 batch production?批量生产147 benchmarking?标杆瞄准(管理)148 bill of labor?工时清单149 bill of lading?提货单150 branch warehouse?分库151 bucketless system?无时段系统152 business framework?业务框架153 business plan?经营规划154 capacity level?能力利用水平155 capacity load?能力负荷156 capacity management?能力管理157 carrying cost?保管费158 carrying cost rate?保管费率159 cellular manufacturing?单元式制造160 change route?修改工序161 change structure?修改产品结构162 check point?检查点163 closed loop MRP?闭环MRP164 Common Route Code(ID)?通用工序标识165 component-based development?组件(构件)开发技术166 concurrent engineering?并行(同步)工程167 conference room pilot?会议室模拟168 configuration code?配置代码169 continuous improvement?进取不懈170 continuous process?连续流程171 cost driver?作业成本发生因素172 cost driver rate?作业成本发生因素单位费用173 cost of stockout?短缺损失174 cost roll-up?成本滚动计算法175 crew size?班组规模176 critical part?急需零件177 critical ratio?紧迫系数178 critical work center?关键工作中心179 CLT Cumulative Lead Time?累计提前期180 current run hour?现有运转工时181 current run quantity?现有运转数量182 customer care?客户关怀183 customer deliver lead time?客户交货提前期184 customer loyalty?客户忠诚度185 customer order number?客户订单号186 customer satisfaction?客户满意度187 customer status?客户状况188 cycle counting?周期盘点189 DM Data Mining?数据挖掘190 Data Warehouse?数据仓库191 days offset?偏置天数192 dead load?空负荷193 demand cycle?需求周期194 demand forecasting?需求预测195 demand management?需求管理196 Deming circle?戴明环197 demonstrated capacity?实际能力198 discrete manufacturing?离散型生产199 dispatch to?调度200 DRP Distribution Requirements Planning?分销需求计划201 drop shipment?直运202 dunning letter?催款信203 ECO workbench ECO工作台204 employee enrolled?在册员工205 employee tax id?员工税号206 end item?最终产品207 engineering change mode flag?工程变更方式标志208 engineering change notice?工程变更通知209 equipment distribution?设备分配210 equipment management?设备管理211 exception control?例外控制212 excess material analysis?呆滞物料分析213 expedite code?急送代码214 external integration?外部集成215 fabrication order?加工订单216 factory order?工厂订单217 fast path method?快速路径法218 fill backorder?补足欠交219 final assembly lead time?总装提前期220 final goods?成品221 finite forward scheduling?有限顺排计划222 finite loading?有限排负荷223 firm planned order?确认的计划订单224 firm planned time fence?确认计划需求时界225 FPR Fixed Period Requirements?定期用量法226 fixed quantity?固定数量法227 fixed time?固定时间法228 floor stock?作业现场库存229 flow shop?流水车间230 focus forecasting?调焦预测231 forward scheduling?顺排计划232 freeze code?冻结码233 freeze space?冷冻区234 frozen order?冻结订单235 gross requirements?毛需求236 hedge inventory?囤积库存237 in process inventory?在制品库存238 in stock?在库239 incrementing?增值240 indirect cost?间接成本241 indirect labor?间接人工242 infinite loading?无限排负荷243 input/output control?投入/产出控制244 inspection ID?检验标识245 integrity?完整性246 inter companies?公司内部间247 interplant demands?厂际需求量248 inventory carry rate?库存周转率249 inventory cycle time?库存周期250 inventory issue?库存发放251 inventory location type?仓库库位类型252 inventory scrap?库存报废量253 inventory transfers?库存转移254 inventory turns/turnover?库存(资金)周转次数255 invoice address?发票地址256 invoice amount gross?发票金额257 invoice schedule?发票清单258 issue cycle?发放周期259 issue order?发送订单260 issue parts?发放零件261 issue policy?发放策略262 item availability?项目可供量263 item description?项目说明264 item number?项目编号265 item record?项目记录266 item remark?项目备注267 item status?项目状态268 job shop?加工车间269 job step?作业步骤270 kit item?配套件项目271 labor hour?人工工时272 late days?延迟天数273 lead time?提前期274 lead time level?提前期水平275 lead time offset days?提前期偏置(补偿)天数276 least slack per operation?最小单个工序平均时差277 line item?单项产品278 live pilot?应用模拟279 load leveling?负荷量280 load report?负荷报告281 location code?仓位代码282 location remarks?仓位备注283 location status?仓位状况284 lot for lot?按需定货(因需定量法/缺补法)285 lot ID?批量标识286 lot number?批量编号287 lot number traceability?批号跟踪288 lot size?批量289 lot size inventory?批量库存290 lot sizing?批量规划291 low level code?低层(位)码292 machine capacity?机器能力293 machine hours?机时294 machine loading?机器加载295 maintenance ,repair,and operating supplies?维护修理操作物料296 make or buy decision?外购或自制决策297 management by exception?例外管理法298 manufacturing cycle time?制造周期时间299 manufacturing lead time?制造提前期300 manufacturing standards?制造标准301 master scheduler?主生产计划员302 material?物料303 material available?物料可用量304 material cost?物料成本305 material issues and receipts?物料发放和接收306 material management?物料管理307 material manager?物料经理308 material master,item master?物料主文件309 material review board?物料核定机构310 measure of velocity?生产速率水平311 memory-based processing speed?基于存储的处理速度312 minimum balance?最小库存余量313 Modern Materials Handling?现代物料搬运314 month to date?月累计315 move time , transit time?传递时间316 MSP book flag MPS登录标志317 multi-currency?多币制318 multi-facility?多场所319 multi-level?多级320 multi-plant management?多工厂管理321 multiple location?多重仓位322 net change?净改变法323 net change MRP?净改变式MRP324 net requirements?净需求325 new location?新仓位326 new parent?新组件327 new warehouse?新仓库328 next code?后续编码329 next number?后续编号330 No action report?不活动报告331 non-nettable?不可动用量332 on demand?急需的333 on-hand balance?现有库存量334 on hold?挂起335 on time?准时336 open amount?未清金额337 open order?未结订单/开放订单338 order activity rules?订单活动规则339 order address?订单地址340 order entry?订单输入341 order point?定货点342 order point system?定货点法343 order policy?定货策略344 order promising?定货承诺345 order remarks?定货备注346 ordered by?定货者347 overflow location?超量库位348 overhead apportionment/allocation?间接费分配349 overhead rate,burden factor,absorption rate?间接费率350 owner's equity?所有者权益351 parent item?母件352 part bills?零件清单353 part lot?零件批次354 part number?零件编号355 people involvement?全员参治356 performance measurement?业绩评价357 physical inventory?实际库存358 picking?领料/提货359 planned capacity?计划能力360 planned order?计划订单361 planned order receipts?计划产出量362 planned order releases?计划投入量363 planning horizon?计划期/计划展望期364 point of use?使用点365 Policy and procedure?工作准则与工作规程366 price adjustments?价格调整367 price invoice?发票价格368 price level?物价水平369 price purchase order?采购订单价格370 priority planning?优先计划371 processing manufacturing?流程制造372 product control?产品控制373 product family?产品系列374 product mix?产品搭配组合375 production activity control?生产作业控制376 production cycle?生产周期377 production line?产品线378 production rate?产品率379 production tree?产品结构树380 PAB Projected Available Balance?预计可用库存(量)381 purchase order tracking?采购订单跟踪382 quantity allocation?已分配量383 quantity at location?仓位数量384 quantity backorder?欠交数量385 quantity completion?完成数量386 quantity demand?需求量387 quantity gross?毛需求量388 quantity in?进货数量389 quantity on hand?现有数量390 quantity scrapped?废品数量391 quantity shipped?发货数量392 queue time?排队时间393 rated capacity?额定能力394 receipt document?收款单据395 reference number?参考号396 regenerated MRP?重生成式MRP397 released order?下达订单398 reorder point?再订购点399 repetitive manufacturing?重复式生产(制造) 400 replacement parts?替换零件401 required capacity?需求能力402 requisition orders?请购单403 rescheduling assumption?重排假设404 resupply order?补库单405 rework bill?返工单406 roll up?上滚407 rough cut resource planning?粗资源计划408 rounding amount?舍入金额409 run time?加工(运行)时间410 safety lead time?安全提前期411 safety stock?安全库存412 safety time?保险期413 sales order?销售订单414 scheduled receipts?计划接收量(预计入库量/预期到货量) 415 seasonal stock?季节储备416 send part?发送零件417 service and support?服务和支持418 service parts?维修件419 set up time?准备时间420 ship address?发运地址421 ship contact?发运单联系人422 ship order?发货单423 shop calendar?工厂日历(车间日历)424 shop floor control?车间作业管理(控制)425 shop order , work order?车间订单426 shrink factor?损耗因子(系数)427 single level where used?单层物料反查表428 standard cost system?标准成本体系429 standard hours?标准工时430 standard product cost?标准产品成本431 standard set up hour?标准机器设置工时432 standard unit run hour?标准单位运转工时433 standard wage rate?标准工资率434 status code?状态代码435 stores control?库存控制436 suggested work order?建议工作单437 supply chain?供应链438 synchronous manufacturing?同步制造/同期生产439 time bucket?时段(时间段)440 time fence?时界441 time zone?时区442 top management commitment?领导承诺443 total lead time?总提前期444 transportation inventory?在途库存445 unfavorable variance, adverse?不利差异446 unit cost?单位成本447 unit of measure?计量单位448 value chain?价值链449 value-added chain?增值链450 variance in quantity?量差451 vendor scheduler,supplier scheduler?采购计划员/供方计划员452 vendor scheduling?采购计划法453 Virtual Enterprise(VE)/ Organization?虚拟企业/公司454 volume variance?产量差异455 wait time?等待时间456 where-used list?反查用物料单457 work center capacity?工作中心能力458 workflow?工作流459 work order?工作令460 work order tracking?工作令跟踪461 work scheduling?工作进度安排462 world class manufacturing excellence?国际优秀制造业463 zero inventories?零库存464?465 Call/Contact/Work/Cost center?呼叫/联络/工作/成本中心466 Co/By-product?联/副产品467 E-Commerce/E-Business/E-Marketing?电子商务/电子商务/电子集市468 E-sales/E-procuement/E-partner?电子销售/电子采购/电子伙伴469 independent/dependent demand?独立需求/相关需求件470 informal/formal system?非/规范化管理系统471 Internet/Intranet/Extranet?互联网/企业内部网/企业外联网472 middle/hard/soft/share/firm/group ware?中间/硬/软/共享/固/群件473 pegging/kitting/netting/nettable?追溯(反查)/配套出售件/净需求计算474 picking/dispatch/disbursement list?领料单(或提货单)/派工单/发料单475 preflush/backflush/super backflush?预冲/倒冲法/完全反冲476 yield/scrap/shrinkage (rate)?成品率/废品率/缩减率477 scrap/shrinkage factor?残料率(废品系数)/损耗系数478?479 costed BOM?成本物料清单480 engineering BOM?设计物料清单481 indented BOM?缩排式物料清单482 manufacturing BOM?制造物料清单483 modular BOM?模块化物料清单484 planning BOM?计划物料清单485 single level BOM?单层物料清单486 summarized BOM?汇总物料清单487?488 account balance?账户余额489 account code?账户代码490 account ledger?分类账491 account period?会计期间492 accounts payable?应付账款493 accounts receivable?应收账款494 actual cost?实际成本495 aging?账龄496 balance due?到期余额497 balance in hand?现有余额498 balance sheet?资产负债表499 beginning balance?期初余额500 cash basis?现金收付制501 cash on bank?银行存款502 cash on hand?现金503 cash out to?支付给504 catalog?目录505 category code?分类码506 check out?结帐507 collection?催款508 cost simulation?成本模拟509 costing?成本核算510 current assets?流动资产511 current liabilities?流动负债512 current standard cost?现行标准成本513 detail?明细514 draft remittance?汇票汇出515 end of year?年末516 ending availables?期末可供量517 ending balance?期末余额518 exchange rate?汇率519 expense?费用520 financial accounting?财务会计521 financial entity?财务实体522 financial reports?财务报告523 financial statements?财务报表524 fiscal period?财务期间525 fiscal year?财政年度526 fixed assets?固定资产527 foreign amount?外币金额528 gains and loss?损益529 in balance?平衡530 income statement?损益表531 intangible assets?无形资产532 journal entry?分录533 management accounting?管理会计534 manual reconciliation?手工调账535 notes payable?应付票据536 notes receivable?应收票据537 other receivables?其他应收款538 pay aging?付款账龄539 pay check?工资支票540 pay in?缴款541 pay item?付款项目542 pay point?支付点543 pay status?支付状态544 payment instrument?付款方式545 payment reminder?催款单546 payment status?付款状态547 payment terms?付款期限548 period?期间549 post?过账550 proposed cost?建议成本551 simulated cost?模拟成本552 spending variance,expenditure variance?开支差异553 subsidiary?明细账554 summary?汇总555 tax code?税码556 tax rate?税率557 value added tax?增值税558?559 as of date , stop date?截止日期560 change lot date?修改批量日期561 clear date?结清日期562 date adjust?调整日期563 date available?有效日期564 date changed?修改日期565 date closed?结束日期566 date due?截止日期567 date in produced?生产日期568 date inventory adjust?库存调整日期569 date obsolete?作废日期570 date received?收到日期571 date released?交付日期572 date required?需求日期573 date to pull?发货日期574 earliest due date?最早订单完成日期575 effective date?生效日期576 engineering change effect date?工程变更生效日期577 engineering stop date?工程停止日期578 expired date?失效日期,报废日期579 from date?起始日期580 last shipment date?最后运输日期581 need date?需求日期582 new date?新日期583 pay through date?付款截止日期584 receipt date?收到日期585 ship date?发运日期586?587 allocation?已分配量588 alphanumeric?字母数字589 approver?批准者590 assembly?装配(件)591 backlog?未结订单/拖欠订单592 billing?开单593 bill-to?发票寄往地594 bottleneck?瓶颈资源595 bulk?散装596 buyer?采购员597 component?子件/组件598 customer?客户599 delivery?交货600 demand?需求601 description?说明602 discrete?离散603 ergonomics?工效学(人类工程学) 604 facility?设备、功能605 feature?基本组件/特征件606 forecast?预测607 freight?运费608 holidays?例假日609 implement?实施610 ingredient?配料、成分611 inquire?查询612 inventory?库存613 item?物料项目614 job?作业615 Kanban?看板616 level?层次(级)617 load?负荷618 locate?定位619 logistics?后勤保障体系;物流管理620 lot?批次621 option?可选件622 outstanding?逾期未付623 overhead?制造费用624 override?覆盖625 overtime?加班626 parent?双亲(文件)627 part?零件628 phantom?虚拟件629 plant?工厂,场所630 preference?优先权631 priority?优先权(级)632 procurement?采购633 prototyping?原形测试634 queue?队列635 quota?任务额,报价636 receipt?收款、收据637 regeneration?全重排法638 remittance?汇款639 requisition?请购单640 returned?退货641 roll?滚动642 routing?工艺线路643 schedule?计划表644 shipment?发运量645 ship-to?交货地646 shortage?短缺647 shrink?损耗648 spread?分摊649 statement?报表650 subassembly?子装配件651 supplier?供应商652 transaction?事务处理653 what-if?如果怎样-将会怎样654?655 post-deduct inventory transaction processing?后减库存处理法656 pre-deduct inventory transaction processing?前减库存处理法657 generally accepted manufacturing practices?通用生产管理原则658 direct-deduct inventory transaction processing?直接增减库存处理法659 Pareto Principle?帕拉图原理660 Drum-buffer-rope?鼓点-缓冲-绳子661?663 Open Database Connectivity?开放数据库互连664 Production Planning?生产规划编制?665 Work in Process?在制品?666 accelerated cost recovery system?快速成本回收制度667 accounting information system?会计信息系统?668 acceptable quality kevel?可接受质量水平?669 constant purchasing power accounting?不买够买力会计670 break-even analysis?保本分析671 book value?帐面价值672 cost-benefit analysis?成本效益分析673 chief financial office?财务总监674 degree of financial leverage?财务杠杆系数675 degree of operating leverage?经济杠杆系数676 first-in , first-out?先进先出法?677 economic lot size?经济批量?678 first-in ,still-here?后进先出法679 full pegging?完全跟踪?680 linear programming?线性规划?681 management by objective?目标管理?682 value engineering?价值工程?683 zero based budgeting?零基预算684 CAQ computer aided quality assurance?计算机辅助质量保证? 685 DBMS database management system?数据库管理系统?686 IP Internet Protocol?网际协议?687 TCP Transmission Control Protocol?传输控制协议?689?690 API Advanced Process Industry?高级流程工业691 A2A Application to Application?应用到应用(集成)692 article?物品693 article reserves?物品存储694 assembly order?装配订单695 balance-on-hand-inventory?现有库存余额696 bar code?条形码697 boned warehouse?保税仓库698 CPA Capacity Requirements Planning?能力需求计划699 change management?变革管理700 chill space?冷藏区701 combined transport?联合运输702 commodity inspection?进出口商品检验703 competitive edge?竞争优势704 container?集装箱705 container transport?集装箱运输706 CRP Continuous Replenishment Program?连续补充系数707 core competence?核心才能708 cross docking?直接换装709 CLV Customer Lifetime Value?客户生命周期价值710 CReM Customer Relationship Marketing?客户关系营销711 CSS Customer Service and Support?客户服务和支持712 Customer Service Representative?客户服务代表713 customized logistics?定制物流714 customs declaration?报关715 cycle stock?经常库存716 data cleansing?数据整理717 Data Knowledge and Decision Support?数据知识和决策支持718 data level integration?数据层集成719 data transformation?数据转换720 desktop conferencing?桌面会议721 distribution?配送722 distribution and logistics?分销和后勤723 distribution center?配送中心724 distribution logistics?销售物流725 distribution processing?流通加工726 distribution requirements?分销量727 DRP distribution resource planning?配送/分销资源计划728 door-to-door?门到门729 drop and pull transport?甩挂运输730 DEM Dynamic Enterprise Module?动态企业建模技术731 ECR Efficient Consumer Response?有效顾客反应732 e-Government Affairs?电子政务733 EC Electronic Commerce?电子商务734 Electronic Display Boards?电子公告板735 EOS Electronic order system?电子订货系统736 ESD Electronic Software Distribution?电子软件分发737 embedding?插入738 employee category?员工分类739 empowerment?授权740 engineering change effect work order?工程变更生效单741 environmental logistics?绿色物流742 experiential marketing?直效行销(又称体验行销)743 export supervised warehouse?出口监管仓库744 ERP Extended Resource Planning?扩展资源计划745 field sales/cross sale/cross sell?现场销售/交叉销售/连带销售746 franchising?加盟连销权747 FCL Full Container Load?整箱货748 Global Logistics Management?全球运筹管理749 goods collection?集货750 goods shed?料棚751 goods shelf?货架752 goods stack?货垛753 goods yard?货场754 handing/carrying?搬运755 high performance organization?高绩效组织756 inland container depot?公路集装箱中转站757 inside sales?内部销售758 inspection?检验759 intangible loss?无形消耗760 internal logistics?企业物流761 international freight forwarding agent?国际货运代理762 international logistics?国际物流763 invasive integration?侵入性集成764 joint distribution?共同配送765 just-in-time logistics?准时制物流766 KM Knowledge Management?知识管理767 lead (customer) management?潜在客户管理768 learning organization?学习型组织769 LCL less than container load?拼装货770 load balancing?负载平衡771 loading and unloading?装载772 logistics activity?物流活动773 logistics alliance?物流联盟774 logistics center?物流中心775 logistics cost?物流成本776 logistics cost control?物流成本管理777 logistics documents?物流单证778 logistics enterprise?物流企业779 logistics information?物流信息780 logistics management?物流管理781 logistics modulus?物流模数782 logistics network?物流网络783 logistics operation?物流作业784 LRP Logistics Resource Planning?物流资源计划785 logistics strategy?物流战略786 logistics strategy management?物流战略管理787 logistics technology?物流技术788 MES Manufacture Execute System?制造执行系统789 mass customization?大规模定制790 NPV Net Present Value?净现值791 neutral packing?中性包装792 OLAP On-line Analysis Processing?联机/在线分析系统793 OAG Open Application Group?开放应用集成794 order picking?拣选795 outsourcing?外包796 package/packaging?包装797 packing of nominated brand?定牌包装798 palletizing?托盘包装799 PDA Personal Digital Assistant?个人数据助理800 personalization?个性化801 PTF Planning time fence?计划时界802 POS Point Of Sells?电子收款机803 priority queuing?优先排队804 PBX Private Branch Exchange?专用分组交换机805 production logistics?生产物流806 publish/subscribe?发布/订阅807 quality of working life?工作生活品质808 Quick Response?快速反映809 receiving space?收货区810 REPs Representatives?代表或业务员811 return logistics?回收物流812 ROI Return On Investment?投资回报率813 RM Risk Management?风险管理814 sales package?销售包装815 scalability?可扩充性816 shipping space?发货区817 situational leadership?情境领导818 six sigma?六个标准差819 sorting/stacking?分拣/堆拣。