工程施工组织设计外文翻译

- 格式:doc

- 大小:56.00 KB

- 文档页数:10

第八章各分部分项工程的施工方案Chapter 8 Construction Scheme of Subprojects8.1 土建施工方案8.1 Civil Engineering Construction Scheme8.1.1 工程测量8.1.1 Engineering Surveying1)测量概述1) Measurement Overview为满足工程施工特点,该工程的测量控制网按照“从整体到局部,高精度控制低精度”的原则,由高到低设置三级控制网,各级控制网相互衔接,统一为整体系统。

In order to meet the characteristics of construction, the survey control networks of the project have three levels from high to low in accordance with the principle “From the whole to the part; High precision controls low precision”. Control networks at all levels should be connected, thus forming the overall system.1、测量注意事项1. Measurement Considerations建筑物占地面积超大,这对轴线控制网的布设和投测带来难度,需要充分利用高精度电子全站仪进行轴线控制网的布设及细部测量放线,钢尺作为辅助;轴线投测时,仪器要架设在建筑物两端,以减少投测误差。

As the buildings occupy a large area, which brings difficulty to the layout design and measurement of the axis control network, the electronic total station with high precision should be used to lay the network and do detailed survey with steel rulers as assistive devices. When transfer of building lines is conducted, instruments should be erected on both ends of the buildings to minimize measuring errors.2、测量前准备工作2. Preparations before measurement(1)、测量仪器检定:本工程使用的所用测量仪器及工具(包括专业分包的测量仪器)均应经国家计量单位检校合格并在有效时间之内。

第1篇In the field of engineering construction, there are numerous specialized terms and phrases that are essential for effective communication among professionals. Here are some commonly used construction English terms, categorized by their functions and applications.1. Planning and Design- Blueprint: A detailed technical drawing or plan of a building or structure.- Architectural design: The process of creating the overall design of a building.- Structural engineering: The application of scientific and mathematical principles to design and construct buildings and bridges.- Civil engineering: The professional practice of designing, building, and maintaining infrastructure such as roads, bridges, and water supply systems.2. Materials and Tools- Concrete: A building material made from cement, sand, aggregate, and water.- Reinforcement: Materials such as steel bars or mesh used to strengthen concrete structures.- Screwdriver: A tool used for turning screws.- Wrench: A tool used for turning nuts and bolts.3. Construction Processes- Foundation: The base upon which a building is constructed.- Excavation: The process of removing soil and rock from a site to prepare it for construction.- Concrete pouring: The process of placing concrete in a formwork and allowing it to harden.- Backfilling: The process of filling an excavation with soil or other materials.4. Safety and Regulations- Hard hat: A safety helmet worn to protect the head from falling objects.- Safety goggles: Eye protection worn to prevent eye injuries.- Personal protective equipment (PPE): Safety equipment worn to protect workers from hazards.- OSHA: The Occupational Safety and Health Administration, a U.S. federal agency responsible for ensuring safe and healthful working conditions.5. Quality Control- Quality assurance: The systematic approach to ensuring that the quality of a product or service meets the required standards.- Inspection: The process of examining a construction project to ensure that it meets the specified requirements.- Defect: A flaw or imperfection in a construction project.- Warranty: A guarantee from the contractor or manufacturer that a product or service will perform as specified.6. Estimation and Cost Management- Bid: A proposal submitted by a contractor to perform a construction project.- Cost estimate: An approximation of the total cost of a construction project.- Change order: A document that describes the modifications made to a construction project and their impact on the cost and schedule.- Budget: A financial plan that outlines the expected costs of a construction project.7. Project Management- Project manager: The person responsible for planning, executing, and closing a project.- Construction schedule: A timeline that outlines the sequence of activities and their durations.- Progress report: A document that provides an update on the status of a construction project.- Handover: The process of transferring a completed construction project to the client.These are just a few examples of the many construction English termsthat are essential for effective communication and collaboration in the field of engineering construction. By familiarizing yourself with these terms, you can improve your understanding of construction projects and contribute to their successful completion.第2篇In the field of engineering construction, there are numerous terms and phrases that are commonly used to describe various aspects of the construction process. Here are some of the most commonly used English terms in engineering construction:1. Project: The overall plan or undertaking that involves the construction of a building, road, bridge, or any other type of structure.2. Contractor: The person or company responsible for the planning, execution, and completion of the construction project.3. Architect: The professional who designs the building or structure, taking into account the client's requirements, regulations, and budget constraints.4. Engineer: The professional responsible for the technical aspects of the construction project, including the design, planning, and supervision of the construction work.5. Construction site: The location where the construction work is taking place.6. Foundation: The structure that supports the weight of the building or structure.7. Superstructure: The part of the building or structure that is above the foundation, including walls, floors, and roofs.8. Substructure: The part of the building or structure that is below the ground level, including the foundation and basement.9. Frame: The structural framework that provides support for thebuilding or structure.10. Columns: Vertical structural members that provide support for the roof and floors.11. Beams: Horizontal structural members that support the weight of the roof and floors.12. Slabs: Flat, horizontal surfaces that form the floors and roofs of the building.13. Masonry: The construction of walls using bricks, blocks, or stones.14. Concrete: A mixture of cement, aggregates, and water that is used to form the foundation, walls, and floors of a building.15. Reinforcement: The steel bars or mesh that is embedded in concrete to provide additional strength and support.16. Plumbing: The installation of water supply, drainage, and sanitation systems in a building.17. Electrical: The installation of electrical systems, including wiring, lighting, and power outlets.18. HVAC: Heating, ventilation, and air conditioning systems thatprovide comfort and maintain air quality in a building.19. Demolition: The process of tearing down or removing an existing structure to make way for a new one.20. Excavation: The process of removing soil or rock from a construction site to create a foundation or to make room for the structure.21. Grading: The process of leveling the ground to create a smooth and even surface for the construction work.22. Backfilling: The process of filling the excavated area with soil or other materials to support the foundation.23. Piling: The process of driving piles into the ground to provide support for the foundation.24. Underpinning: The process of reinforcing the foundation of anexisting building to ensure its stability.25. Waterproofing: The process of applying a waterproofing material to prevent water from entering the building.These are just a few of the many terms and phrases used in engineering construction. Understanding these terms is essential for anyone involved in the construction industry, whether they are architects, engineers, contractors, or construction workers. By familiarizing themselves with these terms, they can better communicate with each other and ensure that the construction project is completed successfully.第3篇1. Construction Site - 施工现场2. Project Manager - 项目经理3. Construction Worker - 施工工人4. Engineer - 工程师5. Supervisor - 监工6. Blueprint - 工程图纸7. Construction Plan - 施工方案8. Building Permit - 建筑许可证9. Foundation - 基础10. Foundation Laying - 基础施工11. Concrete - 混凝土12. Reinforcement - 钢筋13. Cement - 水泥14. Bricks - 砖块15. Tiles - 地砖16. Roofing - 屋面工程17. Flooring - 地面工程18. Electrical Wiring - 电路布线19. Plumbing - 给排水工程20. HVAC - 供暖、通风和空调21. Painting - 涂装22. Decorative Work - 装饰工程23. Construction Equipment - 施工设备24. Crane - 起重机25. Excavator - 挖掘机26. Bulldozer - 推土机27. Backhoe - 反铲挖掘机28. Dump Truck - 自卸车29. Forklift - 挂车30. Concrete Mixer - 混凝土搅拌机31. Paver - 摊铺机32. Drill - 钻机33. Hammer - 锤子34. Saw - 锯子35. Wrench - 扳手36. Screwdriver - 螺丝刀37. Level - 水准仪38. Tape Measure - 卷尺39. Safety Helmet - 安全帽40. Safety Glasses - 安全眼镜41. Hard Hat - 安全帽42. High Visibility Vest - 高可见性背心43. Fall Protection Gear - 高处作业安全装备44. Personal Protective Equipment (PPE) - 个人防护装备45. Construction Schedule - 施工进度表46. Construction Progress - 施工进度47. Work Order - 工作指令48. Change Order - 变更指令49. Inspection Report - 检查报告50. Construction Contract - 施工合同These are some common English vocabulary terms used in engineering construction. Familiarizing yourself with these terms can help you communicate effectively with project managers, engineers, and construction workers. Whether you are a professional in the construction industry or simply interested in learning more about it, understanding these terms will enhance your knowledge and skills in the field.。

bim施工组织设计外文文献BIM(BuildingInformationModeling)是一种基于建筑信息模型的数字化设计和施工方法。

在BIM的支持下,建筑施工团队可以更加高效地协作和管理项目。

本文将介绍一些与BIM施工组织设计相关的外文文献。

1. “BIM-based Construction Organization Design using the Analytic Hierarchy Process” by Y.H. Wang and C. Lu 本文提出了一种基于层次分析法的BIM施工组织设计方法。

该方法可以帮助建筑施工团队在BIM模型中制定施工组织方案,并通过对各种方案进行分析和比较,选出最优的施工组织方案。

该方法可以提高施工过程的效率和质量。

2. “BIM-enabled construction planning and organization design” by H. Li and Y. Lu本文介绍了一种基于BIM的施工规划和组织设计方法。

该方法可以通过BIM模型中的空间、时间和资源信息,制定施工计划和组织方案。

该方法可以提高施工效率和质量,并降低项目成本。

3. “BIM-enabled construction organization design for prefabrication projects” by Y. Lu and H. Li本文介绍了一种针对预制建筑项目的BIM施工组织设计方法。

该方法可以通过BIM模型中的构件信息,制定优化的施工组织方案。

该方法可以提高预制建筑项目的效率和质量,并减少施工时间和成本。

4. “Applying BIM to Construction Organization Design” byR. A. Issa and F. Olawale本文介绍了BIM在施工组织设计中的应用。

作者通过案例研究,阐述了BIM在施工组织设计中的优势和挑战。

施工组织设计摘要中英Title: Summary of Construction Organizational DesignIntroduction:Construction organizational design plays a crucial role in the success of any construction project. It involves the planning, coordination, and implementation of various activities to ensure the project is completed efficiently and effectively. In this article, we will provide a summary of key considerations in construction organizational design.1. Project Scope and Objectives1.1 Clearly define the project scope and objectives: It is essential to have a clear understanding of the project's scope and objectives before designing the construction organization. This will help in determining the required resources, timelines, and budget for the project.1.2 Identify key deliverables: Identify the key deliverables of the project and break them down into smaller tasks. This will help in assigning responsibilities to different team members and ensuring that all tasks are completed on time.1.3 Establish a communication plan: Develop a communication plan to ensure that all team members are on the same page regarding the project scope, objectives, and deliverables. Regular communication will help in avoiding misunderstandings and delays.2. Team Structure and Roles2.1 Define team structure: Determine the hierarchy and reporting structure within the construction organization. Clearly define the roles and responsibilities of each team member to avoid confusion and ensure accountability.2.2 Allocate resources effectively: Allocate resources such as manpower, equipment, and materials based on the project requirements. Ensure that resources are utilized efficiently to avoid wastage and delays.2.3 Foster teamwork: Encourage collaboration and teamwork among team members to promote a positive work environment. Establish clear channels of communication and provide support to team members to enhance productivity.3. Risk Management3.1 Identify potential risks: Conduct a thorough risk assessment to identify potential risks that may impact the project. This will help in developing strategies to mitigate risks and ensure project success.3.2 Develop a risk management plan: Develop a risk management plan that outlines the steps to be taken in case of any unforeseen events. This plan should include contingency measures and emergency response procedures.3.3 Monitor and evaluate risks: Continuously monitor and evaluate risks throughout the project lifecycle. Regularly review the risk management plan and make adjustments as needed to address any new risks that may arise.4. Quality Control4.1 Establish quality standards: Define quality standards and benchmarks that need to be met throughout the project. Implement quality control measures to ensure that the project meets these standards.4.2 Conduct regular inspections: Conduct regular inspections and audits to monitor the quality of work being done. Address any issues or deficiencies immediately to maintain the quality of the project.4.3 Provide training and support: Provide training and support to team members to ensure that they have the necessary skills and knowledge to maintain quality standards. Encourage continuous improvement and feedback to enhance the overall quality of the project.5. Project Monitoring and Evaluation5.1 Implement a monitoring system: Implement a monitoring system to track the progress of the project against the established timelines and milestones. This will help in identifying any delays or issues early on and taking corrective action.5.2 Evaluate project performance: Evaluate the performance of the project based on key performance indicators such as cost, schedule, and quality. Use this information to make informed decisions and improve future projects.5.3 Conduct post-project review: Conduct a post-project review to assess the overall success of the project and identify areas for improvement. Document lessons learned and best practices to apply to future projects.Conclusion:Construction organizational design is a complex and multifaceted process that requires careful planning and execution. By considering key factors such as project scope, team structure, risk management, quality control, and project monitoring, construction organizations can ensure the success of their projects. Effective organizational design will lead to improved efficiency, productivity, and overall project outcomes.。

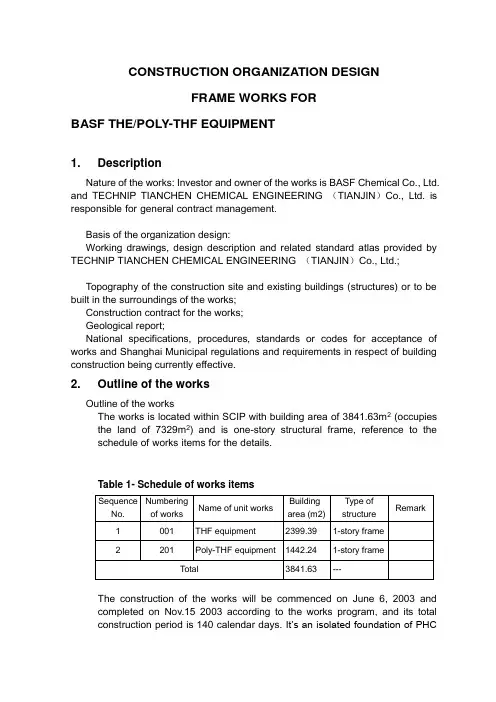

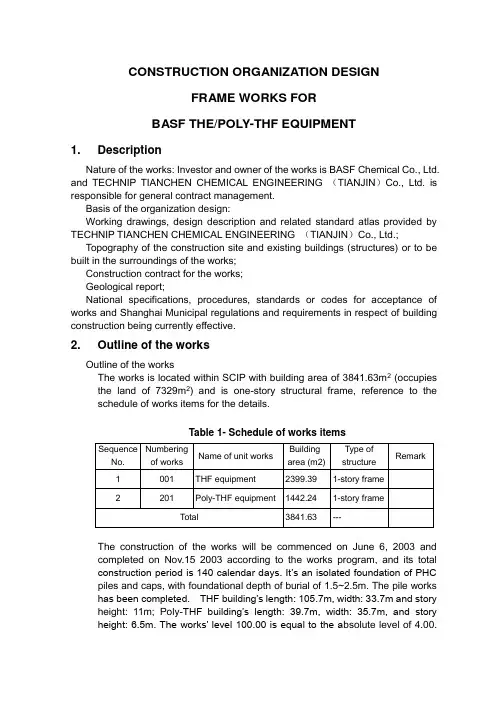

CONSTRUCTION ORGANIZATION DESIGNFRAME WORKS FORBASF THE/POLY-THF EQUIPMENT1. DescriptionNature of the works: Investor and owner of the works is BASF Chemical Co., Ltd. and TECHNIP TIANCHEN CHEMICAL ENGINEERING (TIANJIN)Co., Ltd. is responsible for general contract management.Basis of the organization design:Working drawings, design description and related standard atlas provided by TECHNIP TIANCHEN CHEMICAL ENGINEERING (TIANJIN)Co., Ltd.;Topography of the construction site and existing buildings (structures) or to be built in the surroundings of the works;Construction contract for the works;Geological report;National specifications, procedures, standards or codes for acceptance of works and Shanghai Municipal regulations and requirements in respect of building construction being currently effective.2. Outline of the worksOutline of the worksThe works is located within SCIP with building area of 3841.63m2 (occupies the land of 7329m2) and is one-story structural frame, reference to the schedule of works items for the details.Table 1- Schedule of works itemsThe construction of the works will be commenced on June 6, 2003 and completed on Nov.15 2003 according to the works program, and its total construction period is 140 calendar days. It’s an isolated foundation of PHCpiles and caps, with foundational depth of burial of 1.5~2.5m. The pile works has been completed. THF building’s length: 105.7m, width: 33.7m and story height: 11m; Poly-THF building’s length: 39.7m, width: 35.7m, and s tory height: 6.5m. The works’ level 100.00 is equal to the absolute level of 4.00.All concrete for the works shall be commercial C30/C40 concrete.Site conditionThe construction site of the works is wide, power, water supply and drainage have provided, and the leveling has been completed, it has been get ready for commencement. Temporary power supply for construction has been solved through providing generator by the contractor as well as temporary water supply has been also connected to the site.Construction arrangementConstruction organization managementProject methods will be conducted for the construction and we will establish a Project Department in charge of performing the contract in all respects, organizing, inducting managing, coordinating and controlling the construction.The project Dept. will take scientific management, crack and highly effective team as well as reasonable structure as its principle to form a strong construction team for the works’ construction, meanwhile, accept the supervisions of owner and supervisors so to ensure the time and quality of the construction.A project responsible system will be conducted for all works in respect ofproduction, technology, quality, cost and safety, with dynamic management and optimized combination in system. We intends to take corresponding measures as follows in the construction organization and arrangement:3.1.1 In order to ensure the completion of the works in time, except preparation ofmaster program, sectional operation program will be worked out based thereon to control the construction progresses of sectional or sub-item works, organize labors in earnest, arrange overtime work and allocate labors as necessary to the extent that the construction progress is ensured without suspension and holdup in the work, and initiatives of all participates in the construction will be fully given play to, and the construction assigned us by the owner will be completed on or before the specified time.3.1.2 Stress on planning management, properly work out month, week and daywork plans, set up a reliable materials and supporting system to the extent that the supply can be ensured and the transportation meets any requirement.3.1.3 Fully use commercial concrete for the structure of the works, properlycoordinate with concrete suppliers, improve planning and allocation to ensure the construction demands, conduct transaction in the commercial concrete management market and conclude and sign contract in relation thereto.3.1.4 Organization structure on the site: Establish a Project Management Dept. andconduct Project Manager’s responsible system, set up a construction a technology section, a safety inspection section, a materials section, a financial & budget section, a supporting section under the dept. and uniformly directed by the Project manager. Functions of all sections (see attached management network of organization structure on the site hereinafter) as follows:Technology section: Jointly review workshop drawings, preparing construction methods, detailing drawing, formwork and reinforcement, implementing construction measurement and sorting out technical data, telling the operation sections for sectional or sub-item works of the detailed requirements, solving the technical issues occurred in the construction and organize the construction in accordance with the workshop drawings, related National Codes, Procedures and regulations.Quality inspection section: Be familiar to construction specifications, procedures and standards for quality inspection, performing quality acceptance work in taking-handing-over of all working operations, inspect and supervise the quality of the materials delivered to the site and construction quality on the site. Define the quality target of the works and conduct a quality assessment among all sections.Safety inspection section: Be familiar to safety operation procedures and labor protection ordinance, take the responsibility for safety and civilization inspection in the construction process and put forward opinions for rectification.Materials section: Shall be familiar to the performance and quality requirements of the materials, prepare materials procurement and supply plans, buy corresponding construction materials in time per required by the works, take good care of the materials such as storage, positioned stackingetc, timely provide documentation information in respect of the quality of the materials to technology Section.Financial & budget section: properly take the responsibility for examining and calculating the cost for the works, statistics of the quantity of the works, payment collection, alternation of the construction budget etc.Supporting section: Shall be responsible for living and logistics work, site security, site cleaning and maintaining work.Various operational groups will be set up for organizing labors per trade for the works such as carpenter group, steel bender group, scaffolding work group, concrete group, masonry group, installation group etc. to operate under coordination and unified direction.3.1.5 Organization of construction management staffs as Figure 1 hereunder:Figure 1 Options for main construction technologiesEarthworks: Adopt heavy excavation with lope for most of the excavation of foundation pit, adopt steel plate pile enclosure protection for partial deep foundation, lower water level with well-point. Excavated mainly with machines and associated with human power to trim the bottom, and provide trucks for transporting and stacking the soil within the site.Rebar works: Fabricate and process rebar works o the site, adopt both flashing butt weld and arc weld for the horizontal joints of rebar, mainly handling them with manpower within the site. Use electro slag pressing weld for vertical rebar joints.Formwork: Spliced with plywood (thickness: 18) and supported it with 48 steel pipe for formwork.Concrete works: Use commercial concrete and pour it through pump with pumping truck for the whole works.Scaffolding works: We use steel pipe scaffolding of ground type and with couplers.Vertical transportation: We mainly use derrick for the transportation and provide it with a 16t mobile crane when installing roof rebar.Construction sequences:3.3.1 Key construction sequences: Pit enclosure protection lower waterlevel through well-points earthwork excavation beddinglayer and cutting pipes binding rebar and setting formwork forfoundation poring concrete (cure) for foundation backfillingupper-structure roof structure equipment foundation andthe foundation at level 100.00 operated synchronically post-pourconcrete belt.3.3.2 Concrete of footing beam of the foundation of THF/Poly-THF is planned tobe poured first to the bottom of the bedding slab, backfill after formwork removed, lay bottom formwork of filling slab and pour concrete.3.3.3 Horizontal construction section of THF equipment will be divided into 2 flowsections as post-pouring belt and operated crossly. It shall not require dividing into flow sections because the area for Poly-THF equipment is small.Schedule of fabrication of test cubes (reference to table 2 for the detail):selves first, and report it to Quality Section to double check after the works qualified.24 hours prior notify owner and quality supervisor in writing for joint-acceptance after the double check, and properly record the inspection. It shall operate the next operation sequence only after the works accepted as qualified. Acceptance schedule for concealed works (reference to Table 3 for the detail):The works is a exclusive concrete frame structure, ensuring its verticality and correct axis is a key work, technical re-check system must be conducted therefore to avoid technical errors. All technical staffs at any level, sectional and group leaders shall honestly and strictly carry out the re-check system, properly make records in respect of the check, conduct double check and acceptance section by section, time by time based on the requirements of the progress to the extent that each sub-item works is re-checked when it constructed, without omission and no substitution of each other, technical chief shall not sign the technical double check records and next course shall not be begun if the works not being accepted. Schedule of technical re-check (reference to Table 4 for the detail):4. Quality PlanTechnical managementAfter received the drawings, organize related staffs and all professionals to properly joint-review the drawings, timely solve the problems found in the drawings and specially assign persons to responsible for the management and negotiation work.Specially assign persons to take responsibility for preparing construction organization design, organization design for single item works and newtechnological cards, strictly carry out the rules in respect of review, approval. Alternation and inspection based on the practice of construction to the extent that the works can be executed only after related methods or plans made.In addition to preparing construction organization and technology scheme, organize staffs and labors to study them and properly conduct telling the technical details as well as the working post training.Organize the work of processing, ordering and detailing drawings, uniformly manage processing and ordering materials at home and abroad, perform the double check in relation thereto.During the construction, seriously accumulate technical information, and define the filing items, copies and standards. Timely collect data and prepare files of completion as required by National major project.Stress on inspection, test and handling work of raw materials, factory’s certificate, permit and certificates of site double check.Stress on technical control in special process.Stress on control of measurement, setting out and level control as well as the observation of settlement and communication.Technical protection measures for finished products.Quality controlBreakdown the target of construction quality control, define quality target of unit, sectional and sub-item works.Perfectly establish a quality control system to the extent that post liability system can be put into practice, the duty assigned to each person and an examining system can be implemented.Establish a leading group for good quality creating activities.Highlight standards of quality acceptance, conduct the rule of quality sample first and the system of together accepting and determining by tree parties-Party A, Party B and Supervisor.Focus on the quality of pile foundation treatment, butt weld of rebar, concrete pouring and the main structure works.Set up a quality control group for the quality control of special process, and properly conduct quality control work such as plan, execution, inspection, conclusion, improvement etc. applying PDCN circulation principle to the extent that enable the whole process always under a stable control.Collect information, and conduct comparison and analysis with computerinformation managerial program for submission, jointly study and decision to improve the works’ quality.Conduct a system of self-inspection, mutual inspecting and taking-handing-over acceptance, and report to the supervisor for his acceptance of the concealed works.Strictly carryout the Chief engineer’s signature of instructions for concrete pouring etc.Periodically or temporarily invite related specialist to direct on the site.After the completion, we will assign a special group conduct a revisit the owner and general contractor and service and provide service on calls.Fulfilling and ensuring measures for quality target4.3.1 Quality target of the works: ensure the qualified ratio of the works as 100%.4.3.2 Quality ensuring systemPlace the works in our company’s list of major and key works.Place the quality of the works in the plan of creation of good quality.Establish a quality control and good quality creation groups leaded byCompan y’s Chief Engineer, Manager of Engineering Dept., ProjectManager, Project Engineer and Technical officer.Conduct monthly and temporary inspection by company, weeklyinspection organized by the project dept., quality contr oller’s monthlyinspection, group’s self-inspection, mutual inspection andtaking-handing-over inspections.Conduct QC group’s activities for settling technical problems in respect ofquality to improve works quality and eliminate common quality defects.Fully apply ISO 9002 Quality System to conduct process control andacceptance certification work.Obey owner and supervisor’s instructions on the site.Breakdown the duties to each person, clearly define the division of workand establish reward and fine regulations level by level, adopt amplerewards and grievous penalty system.Works Quality Ensuring System (reference to Figure 2 for the detail):Figure 2 Management Structure Network on the siteEnsuring measures for qualityQuality control of mobilizationConduct education of quality consciousness in earnest to the extent that all staffs and operators firmly establish the subjective thought of “Quality First”, and clearly know the quality target of the w orks.Workout corresponding detailed rules and regulations on good qualitycreation plan.Work out ensuring measures for special quality.Work out quality control and quality inspecting plans for key operation sequences.Optimize the construction organization design and work out operational guiding book for sectional and sub-item works.Conduct joint-review of the drawings, study technical standards in all respects, construction specifications, operational procedures and construction organization design, as well as technical exchanges and control work in earnest.Make sure of the resources of the raw materials and ensure the supply and transportation.Quality control in the processTelling the technical and quality requirements in detail prior to execute any sequences to the extent that any operators clearly know the operational technology, and the quality purpose can be realized.All construction sequences must implement acceptance specifications fo r building works and related regulations on works’ quality currently in force.The quality of all raw materials, finished and semi-finished products shall be in accordance with the acceptance specifications of related national authorities and the stipulations in relation thereto referred to in the tender documents, and stress on the protection of the same products.Perfectly conduct construction diary work, timely deal with conformation sheet for all alternated works and well collect and manage the technical information of all kinds.Strictly conduct ‘Three-inspection System” for sub-item works, fix person and post and construct with tags and signboard, timely and properly conduct acceptance and assessment work of quality-class, key sequences will conduct TQC activities.Concealed works must be accepted as qualified in accordance with the regulations and the next sequence can be started thereafter.Actively conduct quality control in all aspects, establish a quality ensuring system and adopt standardized working procedures in the construction.Prompt self-inspection by groups, mutual inspection and handing-taking-over inspection.As for decoration works, it will adopt a sample leaded rule, can the works of large area be constructed only after the sample being confirmed.Actively prompt to use new technology and techniques.Quality control of procurementPrepare materials procurement plan as required by the project, the materials procured shall be noted with their names, quantities, sizes, delivery date to the site, delivery ways, name of suppliers, standards for test and verification mode.Conduct assessment of qualified sub-contractors and suppliers, assess their ensuring capability for equal quality, social credit. Qualified subcontractors and suppliers for this project will be selected from our name list of the qualified, and conduct period and unscheduled adjust of the assessment of them.When the client requires to verify the supplied materials or equipment, procurement dept. must provide related certificate of quality and test report, owner’s verification shall not release us from the liabilities for prov iding qualified goods and nor eliminate owner’s rejection of the goods.Control of identification of productsIdentifications of products delivered to the site shall include: name of dealer, manufacturer, name, quantity and size and type of the products, test report, defects liability sheet, date of production and certificate of quality etc.Products identifications shall be recorded in storing register and card after qualified goods received into store.Identifications of construction process (storage, sectional and sub-item works).Each product or products of each lot shall have exclusive identification so to ensure its trace-ability.Control of test and inspectionConduct inspection and test when goods delivered to the site, inspect its quality assurance, quality certificate, test report, as for special materials, specially nominate a person or persons to inspect them through sampling and the method as required.Materials not be inspected and tested shall not be processed or incorporated into the works.Process inspection and testSectional and sub-item works must be inspected and tested in accordance with the acceptance specifications, design and functional requirements in t he process, those haven’t been inspected and tested or not qualified works shall not start next sequence of the works.Final inspection and testPrior to conduct final inspection of unit works, Project Dept. willorganize related departments to conduct test-run of ventilation,power and water supply system, test on system commissioning andrecords.Our company will assess the inspection and confirm the quality classof the final inspection, and test in accordance with inspectionassessment criteria of building and installation works, report them toquality supervisory authorities after the same reviewed, confirmed byGeneral Manager and Chief Engineer with comp any’s seal, productsfailed to pass the review and conformation shall not be delivered foruse.Aimed measures for quality controlWe will work out aimed quality ensuring measures in different construction sages based on our great deal of practices and incorporating with the actual conditions.Quality ensuring measures for rebar works (reference to Figure 3 for the detail):Figure 31) General measuresForeman must tell the operators the detailed sequences,methods and requirements of rebar prior to the construction,double check rebar’s size and q uantity and position at any time.Omission of ring clips at nodal points of beam and column shallbe strictly prohibited and size of rebar in complicated positionsshall be specially pay attention to.Inspection must be conducted to inspect rebar of upper andlower courses of basement bottom slab and the support ofcantilever structure whether are firm and reliable after rebarbinding work completed.The thickness of rebar protection course shall be complying todesign drawings. Numbers of the rebar joints in the samesection shall conform to the requirements of specifications.Strictly control the inserting position of rebar for columns to avoiddisplacement of rebar and its size not conform to designdrawings. Cement grout at the foot must be clearly removedprior to bind rebar of columns, and pat attention to its verticalityof vertical rebar, horizontal and clips shall not be bound underinclined conditions. Make a contracting clip on the insertingrebar to link them together so to avoid any displacement or bent.Strictly control the height of negative rebar of slab surfaceespecially the overhanging position, set rebar split heads andgang-board to avoid rebar being lowered due to stepping on it.Acceptance sheet shall be separately issued for overhangingstructure.Rebar in the works shall not be alternated without authorization,if it surely needs adjustment based on the actual conditions, itmust be approved by designer and technical departments, andtechnical confirmation sheet shall be issued.Bent and deformed rebar shall be rectified prior to use it, oil andmud on rebar shall be clearly removed.Rebar shall be bound firm at the center and both ends of thelapped position; All contacting points of beam’s main rebar andclips shall be bound form with wire, except all cross-points ofrebar of wall and floor slabs bearing forces in both directionsshall be bound firm, the medial positions shall be bound inalternated form like winter-sweet.Except the lapped binding and anchoring of rebar shall conformto the specifications, they shall also meet the designedanti-seismic requirements. If it requires leaving holes, for built-inparts and pipelines in rebar binding, and interrupted rebar shallbe cut therefore, reinforcement coil shall be set accordingdrawings and solve the related problems with related persons.Moving, removing and cutting without authorization shall bestrictly prohibited.Specially assign a person or persons to monitor when pourconcrete and rectify the deviations may occur at any time.Acceptance sheet must have signature of Quality Officer. Qualityanalysis meeting shall be holed in respect of the construction ofeach stage to find the defects and put forward measures forrectifying them. Assist supervisors in acceptance of unit worksand carefully rectify the defects so to ensure the quality of theworks. Starting the next sequence can be conducted only afterthe current sequence works being accepted.2) Electric arc weldingPreparation prior to the welding.Clean the edges of welding joints (oil, rust, dew etc.);Inspect welding materials (electrode, flux whether conform tothe requirements);Technical documents (drawings and technology etc.);Welding equipment etc.2 tension test pieces shall be fabricated under the sameconditions prior to welding rebar. Official welding can bepermitted only when the test result greater than the tensionstrength of rebar of same kind. Mainly conduct visualinspection of welded joints after the welding, the jointsrequire flat and smooth surface, without cracks, no clearundercut, concave, wart, cramped cinder and air hole. Clearsound can be heard from welded joints when bit them withsmall hammer. Dimensions and deviation of defects shallconform to “Specifications of Rebar Welding and Acceptance(JGH18-96)”.Electro slag hyperbaric weldingOperators must have operation certificates, and welding flux must bedry over heat prior to the welding. Check operational rebar fixtures atany time and release of the fixtures after the weld shall not be tooearly. Select suitable welding current and conducting time based onthe diameters of rebar. Stress on self-inspection of the sequencesand record it well. The end of rebar shall be even, its rust removed,as for rebar being butt jointed in vertical axis, especially the edgejoints of upper and lower rebar shall be aligned, bent at the joint notexceed 2 degrees, axis deviation at the joint not exceed o.1 d, andnot exceed 2 mm. After the weld, there will be an even weld at thejoint, no cracks, no observable defects like burn on the surface.Where the displacement of rebar at a joint exceeds the specifiedstandard, it shall be re-welded. Meanwhile, in order to make up theloss in length in the welding, the length of rebar may be 5 cmextended (that is 1-2d), the joints shall be visually checked one byone, and shall sample a group (3 pieces) from similar joints of 300each course for test.Ensuring network for quality of formwork (reference to Figure 4 for the detail):Figure 4Poor or good fabrication of formwork will directly relate to the quality of concrete. We will use small steel formwork and plywood (9-layers) for beams, columns and walls, and the control of installing deviation shall be in accordance with the enterprise’s standards.Before the formwork construction, configuration design for supporting system and formwork shall be conducted first, work out the arranging diagram. Person in charge of detailing drawings and foreman must tell the group persons the detailed requirements in respect of supporting and arrangement of formwork, operation sequences, assembling and removing methods. Formwork and its fittings delivered to the site shall be inspected and sorted and counted in accordance with the regulations and quantity, all those not qualified shall not be used.Processed steel formwork for round column shall be pre-assembled on the ground, its plan dimension, flatness and connecting points shall be checked, and only the qualified can be used.Axis position and sectional dimension shall be correctly controlled in the installation of the formwork, and the spliced joints shall be tight. The joints of 1mm shall be sealed with suitable materials or tinplate, if the span exceeds 4m, an arch of 0.3% shall be formed.Water stopping steel plate of basement shall be strictly executed in accordance with the drawings, fixed with welding rebar to ensure a correct position and level of the whole steel plate.Supporting system of formwork must be horizontally flat and vertically straight with firm supporting points, fasteners and bolts must be fastened, and assemble formwork strictly in accordance with the arranging diagram. Specially assign a person or persons to check the formwork’s supports,bolts, fasteners and column clips etc., and rectify it timely if any defectfound.Positions of holes and built-in parts etc. shall be correct. Propose toconduct numbering on the detailed drawings to avoid omission or beingmiss-placed. It shall be firmly installed and close the formwork afterchecked and found no error.Platform support of formwork must be set up strictly in accordance withdesign drawings to the extent that down part and upper part, in and outpart are uniform.Uniformly remove the formwork in accordance with the required strengthreferred to in “ Construction Acceptance Specifications” and designstipulations. Formwork shall not be removed without consent of relatedtechnical departments, and foreman of carpenters shall double-check itcourse by course. Conduct pressure test on test piece if necessary whenremoving the formwork for fabricated concrete piece to ensure its qualityand safety.Formwork shall be often trimmed and repaired and brush the separatingagent, and keep its leanness and flatness if it is used circularly.4.5.3 Ensuring network for quality of concrete works (reference to Figure 5 for the detail):Figure 5。

施工方案的英文翻译怎么写概述施工方案(Construction Plan)是对工程项目的具体落实、实施过程和步骤进行详细描述的计划文档。

在国际工程项目中,施工方案通常需要提供英文版本。

本文将介绍如何正确、准确地翻译施工方案的英文版本,旨在帮助工程相关人员解决在翻译过程中遇到的问题,并提供一些翻译技巧和注意事项。

翻译流程1. 熟悉原文在进行翻译之前,首先要彻底理解施工方案的原文内容。

对于专业术语和特定行业的名词要有一定的了解,以确保在翻译过程中准确传达原文的意思。

2. 词汇翻译在翻译施工方案时,需要正确翻译其中的专业术语和行业名词。

以下是一些建议的翻译策略:•直接翻译:对于一些普遍使用的术语和名词,可以直接翻译为相应的英文词汇。

•解释翻译:对于一些特定的术语和名词,可以使用解释翻译的方法,即在翻译时同时给出其英文含义。

•拼音翻译:对于一些中文专业术语和名词,可以使用其拼音作为英文译名。

3. 句子结构和语法调整中文和英文在句子结构和语法上存在一定的差异。

在翻译时需要注意调整句子结构和语法,以使翻译后的文档符合英文的表达习惯。

以下是一些常见的调整方法:•主动语态和被动语态:在涉及到动作的描述中,中文通常使用主动语态,而英文更常用被动语态。

在翻译时可以根据上下文和语义调整语态。

•时态转换:中文中的动词时态灵活,而英文时态相对固定。

在翻译时需要根据上下文和语义确定正确的时态。

•并列结构:中文中常使用“和”、“与”等词语连接并列的句子成分,而英文通常使用逗号或者连接词(如and、or)来表示并列关系。

4. 格式调整在进行施工方案翻译时,需要调整格式以符合英文文档的排版习惯。

以下是一些常见的格式调整要点:•标题和副标题:对于中文标题和副标题,可以直接使用英文进行翻译,保持整体文档的一致性。

•缩进和段落:在英文文档中,通常使用缩进和空行来分隔不同的段落和层级。

在翻译时需要注意适当添加缩进和空行,使文档结构清晰。

施工组织设计英文参考文献以下是关于施工组织设计的英文参考文献,供您参考:1. C.J. Anumba, J.E. Bouchlaghem, and R.J. Evbuomwan (1997). The integration of process planning with 3D CAD models for construction project management. Robotics andComputer-Integrated Manufacturing, 13(1), 47-57.2. M.A. Becerik-Gerber, and K.L. Rice (2010). Construction informatics in the 21st century: a review and outlook. Automation in Construction, 19(7), 829-835.3. A. Chao-Duivis, and H.S.M. Schoenmakers (2012). Planning and control of construction projects: a systems approach based on fuzzy logic and simulation. Automation in Construction, 22, 217-225.4. J. Fan, and X. Li (2010). Application of BIM technology in construction project management. Journal of Computing in Civil Engineering, 24(3), 236-243.5. E. Kheradmand, and M.R. Nikakhtar (2012).Multi-objective optimization of construction site layout using genetic algorithms. Automation in Construction, 26, 85-91.6. M. Liao, Y. Luo, and S. Wu (2011). A system dynamics model for construction project management. Automation in Construction, 20(2), 107-114.7. G. Shen, and J. Liu (2004). Integrating case-based reasoning and rule-based reasoning for construction project management decision support. Automation in Construction, 13(1), 11-23.8. T. Tezel, and I. Aziz (2008). Building information modeling (BIM) adoption and implementation for architectural practices. Structural Survey, 26(1), 7-25.9. J. Wang, Y. Wang, and X. Zhang (2010). Construction project management using building information modeling (BIM) in China. Proceedings of the 2010 International Conference on Construction & Real Estate Management, 924-928.10. L. Yi, and L. Chan (2009). A fuzzy set approach for construction project risk assessment and control. Automation in Construction, 18(6), 731-736.以上文献涵盖了施工组织设计中的多个方面,包括计划与控制、BIM技术应用、风险评估与控制等。

CONSTRUCTION ORGANIZATION DESIGNFRAME WORKS FORBASF THE/POLY-THF EQUIPMENT1. DescriptionNature of the works: Investor and owner of the works is BASF Chemical Co., Ltd. and TECHNIP TIANCHEN CHEMICAL ENGINEERING (TIANJIN)Co., Ltd. is responsible for general contract management.Basis of the organization design:Working drawings, design description and related standard atlas provided by TECHNIP TIANCHEN CHEMICAL ENGINEERING (TIANJIN)Co., Ltd.;Topography of the construction site and existing buildings (structures) or to be built in the surroundings of the works;Construction contract for the works;Geological report;National specifications, procedures, standards or codes for acceptance of works and Shanghai Municipal regulations and requirements in respect of building construction being currently effective.2. Outline of the worksOutline of the worksThe works is located within SCIP with building area of 3841.63m2 (occupies the land of 7329m2) and is one-story structural frame, reference to the schedule of works items for the details.Table 1- Schedule of works itemsThe construction of the works will be commenced on June 6, 2003 and completed on Nov.15 2003 according to the works program, and its total construction period is 140 calendar days. It’s an isolated foundation of PHC piles and caps, with foundational depth of burial of 1.5~2.5m. The pile works has been completed. THF building’s length: 105.7m, width: 33.7m and story height: 11m; Poly-THF building’s length: 39.7m, width: 35.7m, and story height: 6.5m. The works’ level 100.00 is equal to the a bsolute level of 4.00.All concrete for the works shall be commercial C30/C40 concrete.Site conditionThe construction site of the works is wide, power, water supply and drainage have provided, and the leveling has been completed, it has been get ready for commencement. Temporary power supply for construction has been solved through providing generator by the contractor as well as temporary water supply has been also connected to the site.3. Construction arrangementConstruction organization managementProject methods will be conducted for the construction and we will establish a Project Department in charge of performing the contract in all respects, organizing, inducting managing, coordinating and controlling the construction.The project Dept. will take scientific management, crack and highly effective team as well as reasonable structure as its principle to form a strong construction team for the works’ construction, meanwhile, accept the supervisions of owner and supervisors so to ensure the time and quality of the construction.A project responsible system will be conducted for all works in respect ofproduction, technology, quality, cost and safety, with dynamic management and optimized combination in system. We intends to take corresponding measures as follows in the construction organization and arrangement:3.1.1 In order to ensure the completion of the works in time, except preparation ofmaster program, sectional operation program will be worked out based thereon to control the construction progresses of sectional or sub-item works, organize labors in earnest, arrange overtime work and allocate labors as necessary to the extent that the construction progress is ensured without suspension and holdup in the work, and initiatives of all participates in the construction will be fully given play to, and the construction assigned us by the owner will be completed on or before the specified time.3.1.2 Stress on planning management, properly work out month, week and daywork plans, set up a reliable materials and supporting system to the extent that the supply can be ensured and the transportation meets any requirement.3.1.3 Fully use commercial concrete for the structure of the works, properlycoordinate with concrete suppliers, improve planning and allocation to ensure the construction demands, conduct transaction in the commercial concrete management market and conclude and sign contract in relation thereto.3.1.4 Organization structure on the site: Establish a Project Management Dept. andconduct P roject Manager’s responsible system, set up a construction a technology section, a safety inspection section, a materials section, a financial & budget section, a supporting section under the dept. and uniformly directed by the Project manager. Functions of all sections (see attached management network of organization structure on the site hereinafter) as follows:Technology section: Jointly review workshop drawings, preparing construction methods, detailing drawing, formwork and reinforcement, implementing construction measurement and sorting out technical data, telling the operation sections for sectional or sub-item works of the detailed requirements, solving the technical issues occurred in the construction and organize the construction in accordance with the workshop drawings, related National Codes, Procedures and regulations.Quality inspection section: Be familiar to construction specifications, procedures and standards for quality inspection, performing quality acceptance work in taking-handing-over of all working operations, inspect and supervise the quality of the materials delivered to the site and construction quality on the site. Define the quality target of the works and conduct a quality assessment among all sections.Safety inspection section: Be familiar to safety operation procedures and labor protection ordinance, take the responsibility for safety and civilization inspection in the construction process and put forward opinions for rectification.Materials section: Shall be familiar to the performance and quality requirements of the materials, prepare materials procurement and supply plans, buy corresponding construction materials in time per required by the works, take good care of the materials such as storage, positioned stacking etc, timely provide documentation information in respect of the quality of the materials to technology Section.Financial & budget section: properly take the responsibility for examining and calculating the cost for the works, statistics of the quantity of the works, payment collection, alternation of the construction budget etc.Supporting section: Shall be responsible for living and logistics work, site security, site cleaning and maintaining work.Various operational groups will be set up for organizing labors per trade for the works such as carpenter group, steel bender group, scaffolding work group, concrete group, masonry group, installation group etc. to operateunder coordination and unified direction.3.1.5 Organization of construction management staffs as Figure 1 hereunder:Figure 1 Options for main construction technologiesEarthworks: Adopt heavy excavation with lope for most of the excavation of foundation pit, adopt steel plate pile enclosure protection for partial deep foundation, lower water level with well-point. Excavated mainly with machines and associated with human power to trim the bottom, and provide trucks for transporting and stacking the soil within the site.Rebar works: Fabricate and process rebar works o the site, adopt both flashing butt weld and arc weld for the horizontal joints of rebar, mainly handling them with manpower within the site. Use electro slag pressing weld for vertical rebar joints.Formwork: Spliced with plywood (thickness: 18) and supported it with 48 steel pipe for formwork.Concrete works: Use commercial concrete and pour it through pump with pumping truck for the whole works.Scaffolding works: We use steel pipe scaffolding of ground type and with couplers.Vertical transportation: We mainly use derrick for the transportation and provide it with a 16t mobile crane when installing roof rebar.Construction sequences:3.3.1 Key construction sequences: Pit enclosure protection lower waterlevel through well-points earthwork excavation bedding layer and cutting pipes binding rebar and setting formwork for foundation poring concrete (cure) for foundation backfilling upper-structure roof structure equipment foundation and the foundation at level 100.00 operated synchronically post-pour concrete belt.3.3.2 Concrete of footing beam of the foundation of THF/Poly-THF is planned tobe poured first to the bottom of the bedding slab, backfill after formwork removed, lay bottom formwork of filling slab and pour concrete.3.3.3 Horizontal construction section of THF equipment will be divided into 2 flowsections as post-pouring belt and operated crossly. It shall not require dividing into flow sections because the area for Poly-THF equipment is small.Schedule of fabrication of test cubes (reference to table 2 for the detail):selves first, and report it to Quality Section to double check after the works qualified.24 hours prior notify owner and quality supervisor in writing for joint-acceptance after the double check, and properly record the inspection. It shall operate the next operation sequence only after the works accepted as qualified. Acceptance schedule for concealed works (reference to Table 3 for the detail):The works is a exclusive concrete frame structure, ensuring its verticality and correct axis is a key work, technical re-check system must be conducted therefore to avoid technical errors. All technical staffs at any level, sectional and group leaders shall honestly and strictly carry out the re-check system, properly make records in respect of the check, conduct double check and acceptance section by section, time by time based on the requirements of the progress to the extent thateach sub-item works is re-checked when it constructed, without omission and no substitution of each other, technical chief shall not sign the technical double check records and next course shall not be begun if the works not being accepted. Schedule of technical re-check (reference to Table 4 for the detail):4. Quality PlanTechnical managementAfter received the drawings, organize related staffs and all professionals to properly joint-review the drawings, timely solve the problems found in the drawings and specially assign persons to responsible for the management and negotiation work.Specially assign persons to take responsibility for preparing construction organization design, organization design for single item works and new technological cards, strictly carry out the rules in respect of review, approval. Alternation and inspection based on the practice of construction to the extent that the works can be executed only after related methods or plans made.In addition to preparing construction organization and technology scheme, organize staffs and labors to study them and properly conduct telling the technical details as well as the working post training.Organize the work of processing, ordering and detailing drawings, uniformly manage processing and ordering materials at home and abroad, perform the double check in relation thereto.During the construction, seriously accumulate technical information, and define the filing items, copies and standards. Timely collect data and prepare files of completion as required by National major project.Stress on inspection, test and handling work of raw materials, factory’s certificate, permit and certificates of site double check.Stress on technical control in special process.Stress on control of measurement, setting out and level control as well as the observation of settlement and communication.Technical protection measures for finished products.Quality controlBreakdown the target of construction quality control, define quality target of unit, sectional and sub-item works.Perfectly establish a quality control system to the extent that post liability system can be put into practice, the duty assigned to each person and an examiningsystem can be implemented.Establish a leading group for good quality creating activities.Highlight standards of quality acceptance, conduct the rule of quality sample first and the system of together accepting and determining by tree parties-Party A, Party B and Supervisor.Focus on the quality of pile foundation treatment, butt weld of rebar, concrete pouring and the main structure works.Set up a quality control group for the quality control of special process, and properly conduct quality control work such as plan, execution, inspection, conclusion, improvement etc. applying PDCN circulation principle to the extent that enable the whole process always under a stable control.Collect information, and conduct comparison and analysis with computer information managerial program for submission, jointly study and decision to improve the works’ quality.Conduct a system of self-inspection, mutual inspecting and taking-handing-over acceptance, and report to the supervisor for his acceptance of the concealed works.Strictly carryout the Chief engineer’s signature of instructions for concrete pouring etc.Periodically or temporarily invite related specialist to direct on the site.After the completion, we will assign a special group conduct a revisit the owner and general contractor and service and provide service on calls.Fulfilling and ensuring measures for quality target4.3.1 Quality target of the works: ensure the qualified ratio of the works as 100%.4.3.2 Quality ensuring system(1) Place the works in our company’s list of major and key works.(2) Place the quality of the works in the plan of creation of good quality.(3) Establish a quality control and good quality creation groups leaded byCompany’s Chief Engineer, Manager of Engineering Dept., ProjectManager, Project Engineer and Technical officer.(4) Conduct monthly and temporary inspection by company, weeklyinspection organized by the project dept., qualit y controller’s monthlyinspection, group’s self-inspection, mutual inspection andtaking-handing-over inspections.(5) Conduct QC group’s activities for settling technical problems in respect ofquality to improve works quality and eliminate common quality defects.Fully apply ISO 9002 Quality System to conduct process control andacceptance certification work.(6) Obey owner and supervisor’s instructions on the site.(7) Breakdown the duties to each person, clearly define the division of workand establish reward and fine regulations level by level, adopt amplerewards and grievous penalty system.(8) Works Quality Ensuring System (reference to Figure 2 for the detail):Figure 2 Management Structure Network on the siteEnsuring measures for qualityQuality control of mobilization(1) Conduct education of quality consciousness in earnest to the extent thatall staffs and operators firmly establish the subjective thought of “Quality First”, and clearly know the quality target of the works.(2) Workout corresponding detailed rules and regulations on good qualitycreation plan.(3) Work out ensuring measures for special quality.(4) Work out quality control and quality inspecting plans for key operationsequences.(5) Optimize the construction organization design and work out operationalguiding book for sectional and sub-item works.(6) Conduct joint-review of the drawings, study technical standards in allrespects, construction specifications, operational procedures and construction organization design, as well as technical exchanges and control work in earnest.(7) Make sure of the resources of the raw materials and ensure the supplyand transportation.Quality control in the process(1) Telling the technical and quality requirements in detail prior to executeany sequences to the extent that any operators clearly know the operational technology, and the quality purpose can be realized.(2) All construction sequences must implement acceptance specificationsfor building works and related regulations on works’ quality currently in force.(3) The quality of all raw materials, finished and semi-finished products shallbe in accordance with the acceptance specifications of related national authorities and the stipulations in relation thereto referred to in the tender documents, and stress on the protection of the same products.(4) Perfectly conduct construction diary work, timely deal with conformationsheet for all alternated works and well collect and manage the technical information of all kinds.(5) Strictly conduct ‘Three-inspection System” for sub-item works, fix personand post and construct with tags and signboard, timely and properly conduct acceptance and assessment work of quality-class, key sequences will conduct TQC activities.(6) Concealed works must be accepted as qualified in accordance with theregulations and the next sequence can be started thereafter.(7) Actively conduct quality control in all aspects, establish a quality ensuringsystem and adopt standardized working procedures in the construction.(8) Prompt self-inspection by groups, mutual inspection andhanding-taking-over inspection.(9) As for decoration works, it will adopt a sample leaded rule, can the worksof large area be constructed only after the sample being confirmed.(10) Actively prompt to use new technology and techniques.Quality control of procurement(1) Prepare materials procurement plan as required by the project, thematerials procured shall be noted with their names, quantities, sizes, delivery date to the site, delivery ways, name of suppliers, standards for test and verification mode.(2) Conduct assessment of qualified sub-contractors and suppliers, assesstheir ensuring capability for equal quality, social credit. Qualified subcontractors and suppliers for this project will be selected from our name list of the qualified, and conduct period and unscheduled adjust of the assessment of them.(3) When the client requires to verify the supplied materials or equipment,procurement dept. must provide related certificate of quality and test report, owner’s verification shall not release us from the liabilities for providing qualified goods and nor eliminate owner’s rejection of the goods.Control of identification of products(1) Identifications of products delivered to the site shall include: name ofdealer, manufacturer, name, quantity and size and type of the products, test report, defects liability sheet, date of production and certificate of quality etc.(2) Products identifications shall be recorded in storing register and cardafter qualified goods received into store.(3) Identifications of construction process (storage, sectional and sub-itemworks).(4) Each product or products of each lot shall have exclusive identificationso to ensure its trace-ability.Control of test and inspection(1) Conduct inspection and test when goods delivered to the site, inspect itsquality assurance, quality certificate, test report, as for special materials, specially nominate a person or persons to inspect them through sampling and the method as required.Materials not be inspected and tested shall not be processed or incorporated into the works.(2) Process inspection and testSectional and sub-item works must be inspected and tested in accordance with the acceptance specifications, design and functional requirements in the process, those haven’t been inspected and tested or not qualified works shall not start next sequence of the works.(3) Final inspection and test1) Prior to conduct final inspection of unit works, Project Dept. willorganize related departments to conduct test-run of ventilation,power and water supply system, test on system commissioning andrecords.2) Our company will assess the inspection and confirm the quality classof the final inspection, and test in accordance with inspectionassessment criteria of building and installation works, report them toquality supervisory authorities after the same reviewed, confirmed byGeneral Manager and Chief Engineer with company’s seal, productsfailed to pass the review and conformation shall not be delivered foruse.Aimed measures for quality controlWe will work out aimed quality ensuring measures in different construction sages based on our great deal of practices and incorporating with the actual conditions.Quality ensuring measures for rebar works (reference to Figure 3 for the detail):Figure 31) General measuresa. Foreman must tell the operators the detailed sequences,methods and requirements of rebar prior to the construction,double check rebar’s size and quantity and position at any time.Omission of ring clips at nodal points of beam and column shallbe strictly prohibited and size of rebar in complicated positionsshall be specially pay attention to.b. Inspection must be conducted to inspect rebar of upper andlower courses of basement bottom slab and the support ofcantilever structure whether are firm and reliable after rebarbinding work completed.c. The thickness of rebar protection course shall be complying todesign drawings. Numbers of the rebar joints in the samesection shall conform to the requirements of specifications.d. Strictly control the inserting position of rebar for columns to avoiddisplacement of rebar and its size not conform to designdrawings. Cement grout at the foot must be clearly removedprior to bind rebar of columns, and pat attention to its verticalityof vertical rebar, horizontal and clips shall not be bound underinclined conditions. Make a contracting clip on the insertingrebar to link them together so to avoid any displacement or bent.e. Strictly control the height of negative rebar of slab surfaceespecially the overhanging position, set rebar split heads andgang-board to avoid rebar being lowered due to stepping on it.Acceptance sheet shall be separately issued for overhangingstructure.f. Rebar in the works shall not be alternated without authorization,if it surely needs adjustment based on the actual conditions, itmust be approved by designer and technical departments, andtechnical confirmation sheet shall be issued.g. Bent and deformed rebar shall be rectified prior to use it, oil andmud on rebar shall be clearly removed.h. Rebar shall be bound firm at the center and both ends of thelapped position; All contacting points of beam’s main rebar andclips shall be bound form with wire, except all cross-points ofrebar of wall and floor slabs bearing forces in both directionsshall be bound firm, the medial positions shall be bound inalternated form like winter-sweet.i. Except the lapped binding and anchoring of rebar shall conformto the specifications, they shall also meet the designedanti-seismic requirements. If it requires leaving holes, for built-inparts and pipelines in rebar binding, and interrupted rebar shallbe cut therefore, reinforcement coil shall be set accordingdrawings and solve the related problems with related persons.Moving, removing and cutting without authorization shall bestrictly prohibited.j. Specially assign a person or persons to monitor when pour concrete and rectify the deviations may occur at any time.k. Acceptance sheet must have signature of Quality Officer. Quality analysis meeting shall be holed in respect of the construction ofeach stage to find the defects and put forward measures forrectifying them. Assist supervisors in acceptance of unit worksand carefully rectify the defects so to ensure the quality of theworks. Starting the next sequence can be conducted only afterthe current sequence works being accepted.2) Electric arc weldingA. Preparation prior to the welding.Clean the edges of welding joints (oil, rust, dew etc.);Inspect welding materials (electrode, flux whether conform tothe requirements);Technical documents (drawings and technology etc.);Welding equipment etc.B. 2 tension test pieces shall be fabricated under the sameconditions prior to welding rebar. Official welding can bepermitted only when the test result greater than the tensionstrength of rebar of same kind. Mainly conduct visualinspection of welded joints after the welding, the jointsrequire flat and smooth surface, without cracks, no clearundercut, concave, wart, cramped cinder and air hole. Clearsound can be heard from welded joints when bit them withsmall hammer. Dimensions and deviation of defects shallconform to “Specifications of Rebar Welding an d Acceptance(JGH18-96)”.3) Electro slag hyperbaric weldingOperators must have operation certificates, and welding flux must be dry over heat prior to the welding. Check operational rebar fixtures at any time and release of the fixtures after the weld shall not be too early. Select suitable welding current and conducting time based on the diameters of rebar. Stress on self-inspection of the sequences and record it well. The end of rebar shall be even, its rust removed, as for rebar being butt jointed in vertical axis, especially the edge joints of upper and lower rebar shall be aligned, bent at the joint not exceed 2 degrees, axis deviation at the joint not exceed o.1 d, and not exceed 2 mm. After the weld, there will be an even weld at the joint, no cracks, no observable defects like burn on the surface.Where the displacement of rebar at a joint exceeds the specifiedstandard, it shall be re-welded. Meanwhile, in order to make up theloss in length in the welding, the length of rebar may be 5 cmextended (that is 1-2d), the joints shall be visually checked one byone, and shall sample a group (3 pieces) from similar joints of 300each course for test.Ensuring network for quality of formwork (reference to Figure 4 for the detail):Figure 4(1) Poor or good fabrication of formwork will directly relate to the quality ofconcrete. We will use small steel formwork and plywood (9-layers) for beams, columns and walls, and the control of installing deviation shall be in accordance wit h the enterprise’s standards.(2) Before the formwork construction, configuration design for supportingsystem and formwork shall be conducted first, work out the arranging diagram. Person in charge of detailing drawings and foreman must tell the group persons the detailed requirements in respect of supporting and arrangement of formwork, operation sequences, assembling and removing methods. Formwork and its fittings delivered to the site shall be inspected and sorted and counted in accordance with the regulations and quantity, all those not qualified shall not be used.(3) Processed steel formwork for round column shall be pre-assembled onthe ground, its plan dimension, flatness and connecting points shall be checked, and only the qualified can be used.(4) Axis position and sectional dimension shall be correctly controlled in theinstallation of the formwork, and the spliced joints shall be tight. The joints of 1mm shall be sealed with suitable materials or tinplate, if the span exceeds 4m, an arch of 0.3% shall be formed.(5) Water stopping steel plate of basement shall be strictly executed inaccordance with the drawings, fixed with welding rebar to ensure a correct position and level of the whole steel plate.(6) Supporting system of formwork must be horizontally flat and verticallystraight with firm supporting points, fasteners and bolts must be fastened, and assemble formwork strictly in accordance with the arranging diagram.Specially assign a person or persons to check the formwork’s supports, bolts, fasteners and column clips etc., and rectify it timely if any defect found.(7) Positions of holes and built-in parts etc. shall be correct. Propose toconduct numbering on the detailed drawings to avoid omission or being miss-placed. It shall be firmly installed and close the formwork after checked and found no error.(8) Platform support of formwork must be set up strictly in accordance withdesign drawings to the extent that down part and upper part, in and out part are uniform.(9) Uniformly remove the formwork in accordance with the required strengthreferred to in “ Construction Acceptance Specifications” and design stipulations. Formwork shall not be removed without consent of related technical departments, and foreman of carpenters shall double-check it course by course. Conduct pressure test on test piece if necessary when removing the formwork for fabricated concrete piece to ensure its quality and safety.(10) Formwork shall be often trimmed and repaired and brush the。

施工专业英语词汇施工专业英语词汇ilxyonline编辑积分: 571发帖: 338于2006-08-0913:48施工construct; execution; construction; execution of works 施工安装图construction and erection drawing 施工安装用的机械及工具machines and tools for construction and erection 施工标桩construction stake 施工布置图construction plan 施工步骤construction procedure; construction steps 施工测量construction survey 施工程序construction program; execution programme for works 施工程序网络图project network 施工贷款construction loan 施工单位construction organization; builder 施工道路construction road okok.or g施工地点job location 施工吊车construction hoist 施工定额construction norm 施工队construction team 施工方法job practice 施工方式form of construction work 施工费用construction cost 施工缝construction joint 施工工程construction work 施工工程师construction engineer; operating engineer 施工工程学construction engineering 施工工期construction period 施工工种construction trade 施工规模scope of construction item; size of construction 施工荷载construction loads; working load 施工合同construction contract 施工机械construction machinery 施工机械费cost of constructor's mechanical plant 施工机械化mechanization of building operation; mechanization of construction 施工机械化系数coefficient of construction mechanization 施工技术财务计划financial plan for construction technology 施工计划construction plan; construction program(me)施工监督supervision of construction; supervision; monitoring 施工检查inspection of construction 施工检查员construction inspector 施工阶段construction stage; construction phase 施工进度construction progress 施工进度表schedule of construction; schedule of operations;work-schedule 施工进度计划detailed construction schedule; construction schedule 施工经济学construction economics 施工经理construction manager 施工经验construction experience 施工卷扬机builder's hoist; builder's winch okok.or g施工临时螺栓construction bolt 施工流水作业法construction streamline method 施工面积floor space under construction 施工平面图construction plan 施工期construction period 施工起重机construction hoist 施工企业construction enterprises 施工前阶段preconstruction stage 施工区construction area 施工缺陷constructional deficiency 施工人员constructor; builder 施工设备plant for construction; construction equipment 施工设计detail design; detailed engineering 施工水平仪builder's level 施工说明general des cription of construction 施工说明书construction specifications 施工图设计construction documents design 施工图设计阶段construction documents design phase; construction documents phase 施工图预算working drawing estimate 施工文件construction documents (包括施工图及说明)施工误差construction error 施工现场fabricating yard; job location 施工详图detail of construction; construction detail; working drawing 施工项目project under construction; construction item 施工项目编号construction item reference number 施工效率efficiency of construction 施工性能workability 施工许可证builder's licence 施工验收技术规范technical code for work and acceptance 施工依据manufacture bases 施工营业执照builder's licence 施工预算construction estimate 施工执照building permit 施工准备preliminary work for construction; preparations for construction 施工准备计划preparatory plan 施工总平面图overall construction site plan 施工总则general conditions of construction 施工组织设计construction management pla n 施工作业计划work element construction program 项目subject of entry; item 项目报告project paper 项目编制阶段project preparation phase 项目标记project mark 项目财务估价project financial evaluation 项目采购project purchasing 项目成本project cost; item cost 项目筹备融通资金project preparation facility (PPF)项目贷款project finance; project-financing loan; project loan 项目单menu 项目的拟订project formulation 项目的所有者owner of the project 项目的总投标价值total tender value of project 项目发展周期project development cycle 项目范围scope of project 项目方案project alternatives 项目分隔符item separation symbol 项目分类classification of items 项目分配allocation of items 项目分析item analysis 项目工程师project engineer 项目工程师负责制project engineer system 项目管理project management 项目管理人project manager 项目号item number 项目核对法check list (市场调查技术之一)项目核准权projects approval authority okok.or g项目后评价post project evaluation 项目后评价和后继行动post project evaluation and followup 项目划分segregation of items 项目化组织projectized organization 项目环境生态评价environmental appraisal of a project 项目货款额度project line 项目技术评价project technology evaluation 项目计划project plan 项目计划设计图project planning chart 项目记录item record 项目加权item weighting 项目检验回归曲线item-test regression curve 项目建设费用cost of project implementation 项目建设进度表project implementation scheduling okok.or g项目建议书proposals for the projects 项目经济估价project economic evaluation; economic evaluation of a okok.or gproject 项目经理project manager 项目矩阵组织project matrix organization 项目控制project control 项目块entry block 项目历史history of project 项目目标管理project management by objectives 项目拟订project formulation 项目匹配法matching item 项目评估project appraisal; project evaluation 项目评估法Project Evaluation and Review Technique 项目企业经济评价enterprise's economic appraisal of a project 项目删除deletion of items 项目上端item top 项目社会评价project's social value appraisal 项目设备project equipment 项目设计item design 项目设计工程师负责制project engineer responsibility system 项目生产project production 项目说明item des cription 项目说明书specification of an item 项目投资时期investment phase of a project 项目图与布置图project charts and layouts 项目网络法project network technique okok.or g项目网络分析project network analysis okok.or g项目文件item file 项目小组project group; project team organiztion 项目行item line 项目修理通知单item repairing order 项目选择project selection 项目训练法project training 项目研究编目item study listing 项目研究小组project team 项目一次采购法project purchasing 项目一览表itemized schedule 项目预算program budget; project budget 项目预算编制program budgeting 项目政治评价political appraisal of a project 项目支助业务project supporting services 项目执行project implementation 项目执行情况审计报告project performance audity report (PPAR)项目指标project indicators 项目转移item advance 项目资金筹措project financing。