Chapter9-ELIDGrindingwithLappingKinematics.pdf

- 格式:rtf

- 大小:4.21 MB

- 文档页数:62

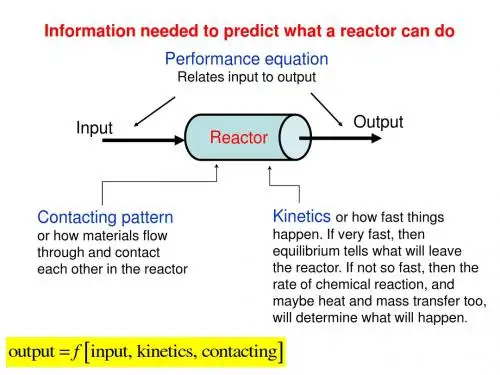

Chapter 9:Natural ConvectionYoav PelesDepartment of Mechanical, Aerospace and Nuclear Engineering Rensselaer Polytechnic InstituteCopyright ©The McGraw-Hill Companies, Inc. Permission required for reproduction or display.ObjectivesWhen you finish studying this chapter, you should be able to:•Understand the physical mechanism of natural convection,•Derive the governing equations of natural convection, and obtain the dimensionless Grashof number by nondimensionalizing them,•Evaluate the Nusselt number for natural convection associated with vertical, horizontal, and inclined plates as well as cylinders andspheres,•Examine natural convection from finned surfaces, and determine the optimum fin spacing,•Analyze natural convection inside enclosures such as double-pane windows, and•Consider combined natural and forced convection, and assess the relative importance of each mode.Viscous Force Buoyancy ForceggZo o m i n dy dtPSubstituting Eqs. 9–8 and 9–9 into Eq. 9–7 andconservation of )1dx dy ⋅⋅The flow regime in natural convection is Buoyancy forceViscous forceEmpiricalcorrelations1010 for Nuavgg L c=0.3 mβ ≈1 / Tk = 0.026 W/m-K0.2530.252.714 2.714opts LS L LS Ra Ra ⎛⎞==⎜⎟⎝⎠(9-32)WL 量 (T s =constant) :255.54)(Ra ; )]([714.2])([714.2s 25.025.04====LSS S LS Ra SLS Ra SS opt s s opt (9-31)Nu = h S opt / k = 1.307量= Q = h (2nLH) (T s –T ∞)(9-34)(9-33)n = 數T ∞enclosure, the fluid adjacent to the hotterenclosure•Gr /Re 2 < 0.1 : natural convection is negligible .•Gr /Re2 > 10 : forced convection is negligible .•0.1 < Gr /Re 2 <10 : forced and natural convection arenot negligible .hot isothermal verticalplate。

Modeling Flows in Moving Zones 在运动参考系中的流动问题求解需要使用可动单元区域。

单元区域的运动可以认为是依附于运动参考系的单元区域的运动。

由此,很多包含运动部件的问题可以在fluent中得到解决。

9.1 Overview of Moving Zone Approachesfluent中的moving cell zone这一强大的特性可以求解计算区域或者部分计算区域是运动的。

可求解问题如下:Flow in a (single) rotating f.rameModel flows in turbo machinery, mixing tanks, and related devices:在这种情况下,因为转子或者叶轮周期性的掠过求解域,相对惯性参考系来讲,流动是不稳定的。

然而。

在不考虑静止部件的情况下,取于旋转部件一起运动的一个计算域,那么相对这个旋转参考系来讲,流动就是稳定的了。

但是如果除了旋转部件,静止部件也要考虑的话,上面的处理方法就不大可能。

比如在涡轮机械中的叶轮和转子靠的很近。

Fluent提供了三种方法解决:The multiple reference frame (MRF) modelThe mixing plane modelThe sliding mesh model前面两种假设流动是稳定的,转子-定子的作用是近似的平均,用在where the rotor-stator interaction is weak or an approximate solution for the system is desired.滑移网格模型假设流动是不稳定的,Rotor-stator interaction is strong and a more accurate simulation of the system is desired9.2 Flow in a Rotating Reference Framefluent一般在惯性参考系中建立模型,但是它能在加速参考系中建立模型,在这种情况下,坐标系的加速度包含在运动方程中。

Chapter 9 ELID Grinding with Lapping Kinematics

Ahmed Bakr Khoshaim*, Zonghua Xu† and Ioan D. Marinescu‡ *The University of Mecca, Saudi Arabia; †MIME Dept., University of Toledo, Toledo, Ohio; ‡The University of Toledo, Toledo, Ohio

9.1 INTRODUCTION Grinding is one of the most important abrasive processes. It is used to perform smooth and precise dimensions and surfaces. Usually, the material removal rate from the workpiece is low in grinding operations compared to that in milling or other cutting operations. However, it is considered effective for brittle materials. Finishing operations have a long history. Since the Stone Age, people were rubbing stones to create sharp edges. Also, the Egyptians had an amazing machining process for cutting large rocks, such as in the pyramids. Modern machining started in the nineteenth century [1]. In grinding, a grinding wheel with a number of abrasives adhered to it is used. The abrasives come in small pieces and in irregular shapes. In addition to the ability to resist chemical reaction caused by the lubricating fluid, the bond material should be strong enough to overcome the grinding forces and temperature. Many types of grinding wheels offer different configurations for different grinding operation conditions [2].

Abrasives and Wheel Types Abrasives can be either conventional or superabrasives. Conventional wheels are cheaper than superabrasives wheels. On the other hand, superabrasives wheels are made with more expensive materials, and therefore, only a small part of the wheel is made by the superabrasives material where the rest can be made with metal. Conventional abrasives can be aluminum oxide (Al2O3) or silicon carbide (SiC). On the contrary, superabrasives can be either cubic boron nitride (CBN) or diamond. These last two are the hardest materials, which give them the ability to machine other hard materials. The hardness can be cited as Knoop hardness. For example, diamond hardness is 6500 kg/cm3, and CBN is 4500 kg/cm3. These levels are high compared to SiC and Al2O3 at 2500 and

Handbook of Ceramics Grinding and Polishing. http://dx.doi.org/10.1016/B978-1-4557-7858-4.00011-X 394 Copyright © 2015 Elsevier Inc. All rights reserved. ELID Grinding with Lapping Kinematics Chapter | 9 395 1370–2260 kg/cm3, respectively [3]. The abrasives can be either small in size for better surface-finish roughness or large in size for higher material removal rate. The abrasives have the ability to fracture into pieces. This characteristic is called friability, which makes the abrasives self-sharpening. Very high friability and very low friability are undesirable. Very high friability makes the abrasives so soft that they are quite fragile. Low friability prevents the abrasives from breaking and sharpening themselves again, which will lead the abrasives to become dull. These abrasives have been made in the industry due to the amount of impurities in natural materials, which affects the reliability. The abrasives grain sizes are to be considered small compared to machining tools or inserts [4]. The six grinding wheel properties include the type of coating, the kind of dressing, the method and precision of balancing, the type of resin, the abrasives grit size, and the grain formula [5]. Grinding wheels come in a variety of types and sizes. They can be produced in many shapes, including straight, cylinder, straight cup, flaring cup, depressed center, and mounted. Both conventional and superabrasives wheels use different bond types. The two sheared bond types are vitrified and resinoid. A vitrified bond consists of ceramic bond mixed with the abrasives and shaped to the desired grinding wheel shape. Then, it is heated gradually to 1300 °C to allow the ceramic to create strong structure. Finally, it is cooled slowly and tested. Consequentially, in resinoid bonding, organic compounds are used and mixed with the abrasives, compressed, and shaped at a lower temperature of about 175 °C [3]. Metal-bonded grinding wheels have some advantages over the resin- and ceramic-bonded wheels, because metal-bonded wheels have high hardness and possess high heat conduction. Also, metal-bonded wheels have a high bondage capability, which gives the wheel a high holding ability for abrasives [6]. Sometimes, if the operation undergoes vibrations, but at the same time metal bond is needed for its electrical conductivity, a metal-resin-bonded grinding wheel can be used. Usually, this line of grinding wheels has a mixture of metal and resin bonds with a ratio of metal to resin at 7:3 [7]. Other types of bonds, including silicate, rubber, elastic, epoxy, and oxychloride, are also on the market and are manufactured by select manufacturers. Grinding wheels typically have a standard coding, or marking system, for wheels to show their properties. For instance, we may find this code on a grinding wheel: 30A 46 H 6 V XX. The A in the code indicates that the wheel is made out of aluminum oxide Al2O3 abrasives. Different letters indicate different abrasives (e.g., C = SiC, D = diamond, Z = zirconia). The number 46 is the grain size, which ranges typically from 4 (coarse) to 500 or more (fine). H is the grade, which ranges from A (soft) to Z (hard). The harder the wheel is, the better the finishing and stronger the abrasives holding, hence, the longer the wheel life. On the other hand, the softer the wheel, the faster the cutting ability. The number 6 is the structure or the number of spaces between the bond and the abrasives grains. The structure is on a scale of 1–15, where the grains are dense at 1 and open at 15, V is the bond type (vitrified) (e.g., M = metal, R = rubber,