模具 外文翻译 英文文献 模具的发展与趋势

- 格式:doc

- 大小:118.00 KB

- 文档页数:27

注塑模具工艺中英文对照资料外文翻译文献附录2Integrated simulation of the injection molding process withstereolithography moldsAbstract Functional parts are needed for design verification testing, field trials, customer evaluation, and production planning. By eliminating multiple steps, the creation of the injection mold directly by a rapid prototyping (RP) process holds the best promise of reducing the time and cost needed to mold low-volume quantities of parts. The potential of this integration of injection molding with RP has been demonstrated many times. What is missing is the fundamental understanding of how the modifications to the mold material and RP manufacturing process impact both the mold design and the injection molding process. In addition, numerical simulation techniques have now become helpful tools of mold designers and process engineers for traditional injection molding. But all current simulation packages for conventional injection molding are no longer applicable to this new type of injection molds, mainly because the property of the mold material changes greatly. In this paper, an integrated approach to accomplish a numerical simulation of injection molding into rapid-prototyped molds is established and a corresponding simulation system is developed. Comparisons with experimental results are employed for verification, which show that the present scheme is well suited to handle RP fabricated stereolithography (SL) molds.Keywords Injection molding Numerical simulation Rapid prototyping1 IntroductionIn injection molding, the polymer melt at high temperature is injected into the mold under high pressure [1]. Thus, the mold material needs to have thermal and mechanical properties capable of withstanding the temperatures and pressures of the molding cycle. The focus of many studies has been to create theinjection mold directly by a rapid prototyping (RP) process. By eliminating multiple steps, this method of tooling holds the best promise of reducing the time and cost needed to createlow-volume quantities of parts in a production material. The potential of integrating injection molding with RP technologies has been demonstrated many times. The properties of RP molds are very different from those of traditional metal molds. The key differences are the properties of thermal conductivity and elastic modulus (rigidity). For example, the polymers used in RP-fabricated stereolithography (SL) molds have a thermal conductivity that is less than one thousandth that of an aluminum tool. In using RP technologies to create molds, the entire mold design and injection-molding process parameters need to be modified and optimized from traditional methodologies due to the completely different tool material. However, there is still not a fundamental understanding of h ow the modifications to the mold tooling method and material impact both the mold design and the injection molding process parameters. One cannot obtain reasonable results by simply changing a few material properties in current models. Also, using traditional approaches when making actual parts may be generating sub-optimal results. So there is a dire need to study the interaction between the rapid tooling (RT) process and material and injection molding, so as to establish the mold design criteria and techniques for an RT-oriented injection molding process.In addition, computer simulation is an effective approach for predicting the quality of molded parts. Commercially available simulation packages of the traditional injection molding process have now become routine tools of the mold designer and process engineer [2]. Unfortunately, current simulation programs for conventional injection molding are no longer applicable to RP molds, because of the dramatically dissimilar tool material. For instance, in using the existing simulation software with aluminum and SL molds and comparing with experimental results, though the simulation values of part distortion are reasonable for the aluminum mold, results are unacceptable, with the error exceeding 50%. The distortion during injection molding is due to shrinkage and warpage of the plastic part, as well as the mold. For ordinarily molds, the main factor is the shrinkage and warpage of the plastic part, which is modeled accurately in current simulations. But for RP molds, the distortion of the mold has potentially more influence, which have been neglected in current models. For instance, [3] used a simple three-step simulation process to consider the mold distortion, which had too much deviation.In this paper, based on the above analysis, a new simulation system for RP molds is developed. The proposed system focuses on predicting part distortion, which is dominating defect in RP-molded parts. The developed simulation can be applied as an evaluation tool for RP mold design and process opti mization. Our simulation system is verified by an experimental example.Although many materials are available for use in RP technologies, we concentrate on usingstereolithography (SL), the original RP technology, to create polymer molds. The SL process uses photopolymer and laser energy to build a part layer by layer. Using SL takes advantage of both the commercial dominance of SL in the RP industry and the subsequent expertise base that has been developed for creating accurate, high-quality parts. Until recently, SL was primarily used to create physical models for visual inspection and form-fit studies with very limited func-tional applications. However, the newer generation stereolithographic photopolymers have improved dimensional, mechanical and thermal properties making it possible to use them for actual functional molds.2 Integrated simulation of the molding process2.1 MethodologyIn order to simulate the use of an SL mold in the injection molding process, an iterative method is proposed. Different software modules have been developed and used to accomplish this task. The main assumption is that temperature and load boundary conditions cause significant distortions in the SL mold. The simulation steps are as follows:1T he part geometry is modeled as a solid model, which is translated to a file readable by the flow analysis package.2Simulate the mold-filling process of the melt into a pho topolymer mold, which will output the resulting temperature and pressure profiles.3Structural analysis is then performed on the photopolymer mold model using the thermal and load boundary conditions obtained from the previous step, which calculates the distortion that the mold undergo during the injection process.4If the distortion of the mold converges, move to the next step. Otherwise, the distorted mold cavity is then modeled (changes in the dimensions of the cavity after distortion), and returns to the second step to simulate the melt injection into the distorted mold.5The shrinkage and warpage simulation of the injection molded part is then applied, which calculates the final distor tions of the molded part.In above simulation flow, there are three basic simulation mod ules.2. 2 Filling simulation of the melt2.2.1 Mathematical modelingIn order to simulate the use of an SL mold in the injection molding process, an iterativemethod is proposed. Different software modules have been developed and used to accomplish this task. The main assumption is that temperature and load boundary conditions cause significant distortions in the SL mold. The simulation steps are as follows:1. The part geometry is modeled as a solid model, which is translated to a file readable by the flow analysis package.2. Simulate the mold-filling process of the melt into a photopolymer mold, which will output the resulting temperature and pressure profiles.3. Structural analysis is then performed on the photopolymer mold model using the thermal and load boundary conditions obtained from the previous step, which calculates the distortion that the mold undergo during the injection process.4. If the distortion of the mold converges, move to the next step. Otherwise, the distorted mold cavity is then modeled (changes in the dimensions of the cavity after distortion), and returns to the second step to simulate the melt injection into the distorted mold.5. The shrinkage and warpage simulation of the injection molded part is then applied, which calculates the final distortions of the molded part.In above simulation flow, there are three basic simulation modules.2.2 Filling simulation of the melt2.2.1 Mathematical modelingComputer simulation techniques have had success in predicting filling behavior in extremely complicated geometries. However, most of the current numerical implementation is based on a hybrid finite-element/finite-difference solution with the middleplane model. The application process of simulation packages based on this model is illustrated in Fig. 2-1. However, unlike the surface/solid model in mold-design CAD systems, the so-called middle-plane (as shown in Fig. 2-1b) is an imaginary arbitrary planar geometry at the middle of the cavity in the gap-wise direction, which should bring about great inconvenience in applications. For example, surface models are commonly used in current RP systems (generally STL file format), so secondary modeling is unavoidable when using simulation packages because the models in the RP and simulation systems are different. Considering these defects, the surface model of the cavity is introduced as datum planes in the simulation, instead of the middle-plane.According to the previous investigations [4–6], fillinggoverning equations for the flow and temperature field can be written as:where x, y are the planar coordinates in the middle-plane, and z is the gap-wise coordinate; u, v,w are the velocity components in the x, y, z directions; u, v are the average whole-gap thicknesses; and η, ρ,CP (T), K(T) represent viscosity, density, specific heat and thermal conductivity of polymer melt, respectively.Fig.2-1 a–d. Schematic procedure of the simulation with middle-plane model. a The 3-D surface model b The middle-plane model c The meshed middle-plane model d The display of the simulation result In addition, boundary conditions in the gap-wise direction can be defined as:where TW is the constant wall temperature (shown in Fig. 2a).Combining Eqs. 1–4 with Eqs. 5–6, it follows that the distributions of the u, v, T, P at z coordinates should be symmetrical, with the mirror axis being z = 0, and consequently the u, v averaged in half-gap thickness is equal to that averaged in wholegap thickness. Based on this characteristic, we can divide the whole cavity into two equal parts in the gap-wise direction, as described by Part I and Part II in Fig. 2b. At the same time, triangular finite elements are generated in the surface(s) of the cavity (at z = 0 in Fig. 2b), instead of the middle-plane (at z = 0 in Fig. 2a). Accordingly, finite-difference increments in the gapwise direction are employed only in the inside of the surface(s) (wall to middle/center-line), which, in Fig. 2b, means from z = 0 to z = b. This is single-sided instead of two-sided with respect to the middle-plane (i.e. from the middle-line to two walls). In addition, the coordinate system is changed from Fig. 2a to Fig. 2b to alter the finite-element/finite-difference scheme, as shown in Fig. 2b. With the above adjustment, governing equations are still Eqs. 1–4. However, the original boundary conditions inthe gapwise direction are rewritten as:Meanwhile, additional boundary conditions must be employed at z = b in order to keep the flows at the juncture of the two parts at the same section coordinate [7]:where subscripts I, II represent the parameters of Part I and Part II, respectively, and Cm-I and Cm-II indicate the moving free melt-fronts of the surfaces of the divided two parts in the filling stage.It should be noted that, unlike conditions Eqs. 7 and 8, ensuring conditions Eqs. 9 and 10 are upheld in numerical implementations becomes more difficult due to the following reasons:1. The surfaces at the same section have been meshed respectively, which leads to a distinctive pattern of finite elements at the same section. Thus, an interpolation operation should be employed for u, v, T, P during the comparison between the two parts at the juncture.2. Because the two parts have respective flow fields with respect to the nodes at point A and point C (as shown in Fig. 2b) at the same section, it is possible to have either both filled or one filled (and one empty). These two cases should be handled separately, averaging the operation for the former, whereas assigning operation for the latter.3. It follows that a small difference between the melt-fronts is permissible. That allowance can be implemented by time allowance control or preferable location allowance control of the melt-front nodes.4. The boundaries of the flow field expand by each melt-front advancement, so it is necessary to check the condition Eq. 10 after each change in the melt-front.5. In view of above-mentioned analysis, the physical parameters at the nodes of the same section should be compared and adjusted, so the information describing finite elements of the same section should be prepared before simulation, that is, the matching operation among the elements should be preformed.Fig. 2a,b. Illustrative of boundary conditions in the gap-wise direction a of the middle-plane model b of thesurface model2.2.2 Numerical implementationPressure field. In modeling viscosity η, which is a function of shear rate, temperature and pressure of melt, the shear-thinning behavior can be well represented by a cross-type model such as:where n corresponds to the power-law index, and τ∗ characterizes the shear stress level of the transition region between the Newtonian and power-law asymptotic limits. In terms of an Arrhenius-type temperature sensitivity and exponential pressure dependence, η0(T, P) can be represented with reasonable accuracy as follows:Equations 11 and 12 constitute a five-constant (n, τ∗, B, Tb, β) representation for viscosity. The shear rate for viscosity calculation is obtained by:Based on the above, we can infer the following filling pressure equation from the governing Eqs. 1–4:where S is calculated by S = b0/(b−z)2η d z. Applying the Galerkin method, the pressure finite-element equation is deduced as:where l_ traverses all elements, including node N, and where I and j represent the local node number in element l_ corresponding to the node number N and N_ in the whole, respectively. The D(l_) ij is calculated as follows:where A(l_) represents triangular finite elements, and L(l_) i is the pressure trial function in finite elements.Temperature field. To determine the temperature profile across the gap, each triangular finite element at the surface is further divided into NZ layers for the finite-difference grid.The left item of the energy equation (Eq. 4) can be expressed as:where TN, j,t represents the temperature of the j layer of node N at time t.The heat conduction item is calculated by:where l traverses all elements, including node N, and i and j represent the local node number in element l corresponding to the node number N and N_ in the whole, respectively.The heat convection item is calculated by:For viscous heat, it follows that:Substituting Eqs. 17–20 into the energy equation (Eq. 4), the temperature equation becomes:2.3 Structural analysis of the moldThe purpose of structural analysis is to predict the deformation occurring in the photopolymer mold due to the thermal and mechanical loads of the filling process. This model is based on a three-dimensional thermoelastic boundary element method (BEM). The BEM is ideally suited for this application because only the deformation of the mold surfaces is of interest. Moreover, the BEM has an advantage over other techniques in that computing effort is not wasted on calculating deformation within the mold.The stresses resulting from the process loads are well within the elastic range of the mold material. Therefore, the mold deformation model is based on a thermoelastic formulation. The thermal and mechanical properties of the mold are assumed to be isotropic and temperature independent.Although the process is cyclic, time-averaged values of temperature and heat flux are used for calculating the mold deformation. Typically, transient temperature variations within a mold have been restricted to regions local to the cavity surface and the nozzle tip [8]. The transients decay sharply with distance from the cavity surface and generally little variation is observed beyond distances as small as 2.5 mm. This suggests that the contribution from the transients to the deformation at the mold block interface is small, and therefore it is reasonable to neglect the transient effects. The steady state temperature field satisfies Laplace’s equation 2T = 0 and the time-averaged boundary conditions. The boundary conditions on the mold surfaces are described in detail by Tang et al. [9]. As for the mechanical boundary conditions, the cavity surface is subjected to the melt pressure, the surfaces of the mold connected to the worktable are fixed in space, and other external surfaces are assumed to be stress free.The derivation of the thermoelastic boundary integral formulation is well known [10]. It is given by:where uk, pk and T are the displacement, traction and temperature,α, ν represent the thermal expansion coefficient and Poisson’s ratio of the material, and r = |y−x|. clk(x) is the surfacecoefficient which depends on the local geometry at x, the orientation of the coordinate frame and Poisson’s ratio for the domain [11]. The fundamental displacement ˜ulk at a point y in the xk direction, in a three-dimensional infinite isotropic elastic domain, results from a unit load concentrated at a point x acting in the xl direction and is of the form:where δlk is the Kronecker delta function and μ is the shear modulus of the mold material.The fundamental traction ˜plk , measured at the point y on a surface with unit normal n, is:Discretizing the surface of the mold into a total of N elements transforms Eq. 22 to:where Γn refers to the n th surface element on the domain.Substituting the appropriate linear shape functions into Eq. 25, the linear boundary element formulation for the mold deformation model is obtained. The equation is applied at each node on the discretized mold surface, thus giving a system of 3N linear equations, where N is the total number of nodes. Each node has eight associated quantities: three components of displacement, three components of traction, a temperature and a heat flux. The steady state thermal model supplies temperature and flux values as known quantities for each node, and of the remaining six quantities, three must be specified. Moreover, the displacement values specified at a certain number of nodes must eliminate the possibility of a rigid-body motion or rigid-body rotation to ensure a non-singular system of equations. The resulting system of equations is assembled into a integrated matrix, which is solved with an iterative solver.2.4 Shrinkage and warpage simulation of the molded partInternal stresses in injection-molded components are the principal cause of shrinkage and warpage. These residual stresses are mainly frozen-in thermal stresses due to inhomogeneous cooling, when surface layers stiffen sooner than the core region, as in free quenching. Based onthe assumption of the linear thermo-elastic and linear thermo-viscoelastic compressible behavior of the polymeric materials, shrinkage and warpage are obtained implicitly using displacement formulations, and the governing equations can be solved numerically using a finite element method.With the basic assumptions of injection molding [12], the components of stress and strain are given by:The deviatoric components of stress and strain, respectively, are given byUsing a similar approach developed by Lee and Rogers [13] for predicting the residual stresses in the tempering of glass, an integral form of the viscoelastic constitutive relationships is used, and the in-plane stresses can be related to the strains by the following equation:Where G1 is the relaxation shear modulus of the material. The dilatational stresses can be related to the strain as follows:Where K is the relaxation bulk modulus of the material, and the definition of α and Θ is:If α(t) = α0, applying Eq. 27 to Eq. 29 results in:Similarly, applying Eq. 31 to Eq. 28 and eliminating strain εxx(z, t) results in:Employing a Laplace transform to Eq. 32, the auxiliary modulus R(ξ) is given by:Using the above constitutive equation (Eq. 33) and simplified forms of the stresses and strains in the mold, the formulation of the residual stress of the injection molded part during the cooling stage is obtain by:Equation 34 can be solved through the application of trapezoidal quadrature. Due to the rapid initial change in the material time, a quasi-numerical procedure is employed for evaluating the integral item. The auxiliary modulus is evaluated numerically by the trapezoidal rule.For warpage analysis, nodal displacements and curvatures for shell elements are expressed as:where [k] is the element stiffness matrix, [Be] is the derivative operator matrix, {d} is the displacements, and {re} is the element load vector which can be evaluated by:The use of a full three-dimensional FEM analysis can achieve accurate warpage results, however, it is cumbersome when the shape of the part is very complicated. In this paper, a twodimensional FEM method, based on shell theory, was used because most injection-molded parts have a sheet-like geometry in which the thickness is much smaller than the other dimensions of the part. Therefore, the part can be regarded as an assembly of flat elements to predict warpage. Each three-node shell element is a combination of a constant strain triangular element (CST) and a discrete Kirchhoff triangular element (DKT), as shown in Fig. 3. Thus, the warpage can be separated into plane-stretching deformation of the CST and plate-bending deformation of the DKT, and correspondingly, the element stiffness matrix to describe warpage can also be divided into the stretching-stiffness matrix and bending-stiffness matrix.Fig. 3a–c. Deformation decomposition of shell element in the local coordinate system. a In-plane stretchingelement b Plate-bending element c Shell element3 Experimental validationTo assess the usefulness of the proposed model and developed program, verification is important. The distortions obtained from the simulation model are compared to the ones from SL injection molding experiments whose data is presented in the literature [8]. A common injection molded part with the dimensions of 36×36×6 mm is considered in the experiment, as shown in Fig. 4. The thickness dimensions of the thin walls and rib are both 1.5 mm; and polypropylene was used as the injection material. The injection machine was a production level ARGURY Hydronica 320-210-750 with the following process parameters: a melt temperature of 250 ◦C; an ambient temperature of 30 ◦C; an injection pressure of 13.79 MPa; an injection time of 3 s; and a cooling time of 48 s. The SL material used, Dupont SOMOSTM 6110 resin, has the ability to resist temperatures of up to 300 ◦C temperatures. As mentioned above, thermal conductivity of the mold is a major factor that differentiates between an SL and a traditional mold. Poor heat transfer in the mold would produce a non-uniform temperature distribution, thus causing warpage that distorts the completed parts. For an SL mold, a longer cycle time would be expected. The method of using a thin shell SL mold backed with a higher thermal conductivity metal (aluminum) was selected to increase thermal conductivity of the SL mold.Fig. 4. Experimental cavity modelFig. 5. A comparison of the distortion variation in the X direction for different thermal conductivity; where “Experimental”, “present”, “three-step”, and “conventional” mean the results of the experimental, the presented simulation, the three-step simulation process and the conventional injection molding simulation, respectively.Fig. 6. Comparison of the distortion variation in the Y direction for different thermal conductivitiesFig. 7. Comparison of the distortion variation in the Z direction for different thermal conductivitiesFig. 8. Comparison of the twist variation for different thermal conductivities For this part, distortion includes the displacements in three directions and the twist (the difference in angle between two initially parallel edges). The validation results are shown in Fig.5 to Fig. 8. These figures also include the distortion values predicted by conventional injection molding simulation and the three-step model reported in [3].4 ConclusionsIn this paper, an integrated model to accomplish the numerical simulation of injection molding into rapid-prototyped molds is established and a corresponding simulation system is developed. For verification, an experiment is also carried out with an RPfabricated SL mold.It is seen that a conventional simulation using current injection molding software breaks down for a photopolymer mold. It is assumed that this is due to the distortion in the mold caused by the temperature and load conditions of injection. The three-step approach also has much deviation. The developed model gives results closer to experimental.Improvement in thermal conductivity of the photopolymer significantly increases part quality. Since the effect of temperature seems to be more dominant than that of pressure (load), an improvement in the thermal conductivity of the photopolymer can improve the part quality significantly.Rapid Prototyping (RP) is a technology makes it possible to manufacture prototypes quickly and inexpensively, regardless of their comp lexity. Rapid Tooling (RT) is the next step in RP’s steady progress and much work is being done to obtain more accurate tools to define the parameters of the process. Existing simulation tools can not provide the researcher with a useful means of studying relative changes. An integrated model, such as the one presented in this paper, is necessary to obtain accurate predictions of the actual quality of final parts. In the future, we expect to see this work expanded to develop simulations program for injection into RP molds manufactured by other RT processes.References1. Wang KK (1980) System approach to injection molding process. Polym-Plast Technol Eng 14(1):75–93.2. Shelesh-Nezhad K, Siores E (1997) Intelligent system for plastic injection molding process design. J Mater Process Technol 63(1–3):458–462.3. Aluru R, Keefe M, Advani S (2001) Simulation of injection molding into rapid-prototyped molds. Rapid Prototyping J 7(1):42–51.4. Shen SF (1984) Simulation of polymeric flows in the injection molding process. Int J Numer Methods Fluids 4(2):171–184.5. Agassant JF, Alles H, Philipon S, Vincent M (1988) Experimental and theoretical study of the injection molding of thermoplastic materials. Polym Eng Sci 28(7):460–468.6. Chiang HH, Hieber CA, Wang KK (1991) A unified simulation of the filling and post-filling stages in injection molding. Part I: formulation. Polym Eng Sci 31(2):116–124.7. Zhou H, Li D (2001) A numerical simulation of the filling stage in injection molding based on a surface model. Adv Polym Technol 20(2):125–131.8. Himasekhar K, Lottey J, Wang KK (1992) CAE of mold cooling in injection molding using a three-dimensional numerical simulation. J EngInd Trans ASME 114(2):213–221.9. Tang LQ, Pochiraju K, Chassapis C, Manoochehri S (1998) Computeraided optimization approach for the design of injection mold cooling systems. J Mech Des, Trans ASME 120(2):165–174.10. Rizzo FJ, Shippy DJ (1977) An advanced boundary integral equation method for three-dimensional thermoelasticity. Int J Numer Methods Eng 11:1753–1768.11. Hartmann F (1980) Computing the C-matrix in non-smooth boundary points. In: New developments in boundary element methods, CML Publications, Southampton, pp 367–379.12. Chen X, Lama YC, Li DQ (2000) Analysis of thermal residual stress in plastic injection molding. J Mater Process Technol 101(1):275–280.13. Lee EH, Rogers TG (1960) Solution of viscoelastic stress analysis problems using measured creep or relaxation function. J Appl Mech 30(1):127–134.14. Li Y (1997) Studies in direct tooling using stereolithography. Dissertation, University of Delaware, Newark, DE..。

Figure 1. Organization of the IKEM Project2 Intelligent Mold Design ToolThe mold design tool in its basic form is a Visual Basic application taking input from a text file that contains information about the part and a User Input form. The text file contains information about the part geometry parsed from a Pro/E information file. The input is used to estimate the dimensions of mold and various other features.2.1 Literature ReviewDesign of molds is another stage of the injection molding process where the experience of an engineer largely helps automate the process and increase its efficiency. The issue that needs attention is the time that goes into designing the molds. Often, design engineers refer to tables and standard handbooks while designing a mold, which consumes lot of time. Also, a great deal of time goes into modeling components of the mold in standard CAD software. Differentresearchers have dealt with the issue of reducing the time it takes to design the mold in different ways. Koelsch and James have employed group technology techniques to reduce the mold design time. A unique coding system that groups a class of injection molded parts, and the tooling required ininjection molding is developed which is general and can be applied to other product lines.A software system to implement the coding system has also been developed. Attempts were also directed towards the automation of the mold design process by capturing experience and knowledge of engineers in the field. The development of a concurrent mold design system is one such approach that attempts to develop a systematic methodology for injection mold design processes in a concurrent engineering environment. The objective of their research was to develop a mold development process that facilitates concurrent engineering-based practice, andFigure 2. Organization of the Mold Design Module.While most of the input, like the number of cavities, cavity image dimensions, cycle time are based on the client specifications, other input like the plasticizing capacity, shots per minute etc., can be obtained from the machine specifications. The output of the application contains mold dimensions and other information, which clearly helps in selecting the standard mold base from catalogs. Apart from the input and output, the Figure 2 also shows the various modules that produce the final output.2.5 Framing rulesAt this stage, the expert’s knowledge is represented in the form of multiple If-Then statements. The rules may be representations of both qualitative and quantitative knowledge. By qualitative knowledge, we mean deterministic information about a problem that can be solved computationally. By qualitative we mean information that is not deterministic, but merely followed as a rule based on previous cases where the rule has worked. A typical rule is illustrated below:If Material = “Acetal” AndRunner Length <= 3 AndRunner Length > 0 ThenRunner Diameter =0.062End IfWhen framing the rules it is important that we represent the information in a compact way while avoiding redundancy, incompleteness and inconsistency. Decision tables help take care of all the above concerns by checking for redundancy and comprehensive expression of the problem statement. As an example, in the process of selecting an appropriate mold base, the size of mold base depends on the number of cavities and inserts. To ensure that all possible combinations of。

外文原文Abstract:Die designing is a demanding and hard work.To design a separate die for each product is time consuming and expensive task.This paper presents an idea of sets of standard reference dies.it gives a concept of flexible die designing using a reference standard die designed in a popular commercial CAD/CAM software—Pro/Engineer.Rather than designing a separate die for each part,just update the die design by selecting the die dimensions as required.The use of this concept will prove to reduce time and cost of product in manufacturing industry.Key words:die;flexible die designing system ;standardization;Pro/E;secondary developmentAt present, the industrial developed countries and regions in the mold industry has been gradually standardize and serialization. In China, although the majority die within the enterprises have business standards, but generally not high degree of standardization, standardization of stamping die in the die-limited parts of the parts. To achieve real savings stamping die design time and shorten the processing cycle, cost savings, reduce design and manufacturing staff workload purposes, it needs to develop a flexible stamping die design system. At the same time, stamping die serialization of the scope of standardization and can not be confined to die-part of the fixed panels, boards, the top plate unloading device commonly used components such as stamping or even die structure, we should achieve serialization and standardization.As CAD / CAM technology in the design and manufacture die in the course of extensive application, it should first be standardized stamping die from the CAD system began. Some large-scale commercialization of the CAD / CAM software, such as Pro / E, UG, and so on. Have developed a specialized injection mold design package. And stamping die design for the special software, users need to be developed.l The application tools Pro / E in stamping die design flexibility in the system developmentPro / Engineer by the United States has developed a set of PTC CAD / cAM / CAE software. Pro / E using a single database And feature-based, the design parameters of the model, provides users with 1 The development is very convenient for stamping die flexible system of tools juice1.1 Family TableFanaily Fable known as the Family Table, the structure used to create the same or similar parts of the size and characteristics of the standardized database tables, is devoted to the establishment of a standard parts library tool. The use of the formerfirst family table to create a generic representation of the components (the generic), according to the need to target and then added to the family table a series of management.Family sheet management can be the object of a size (dimension), features (feature), parameters (parameter) and assembly parts (component), and so on.A family table can have multiple levels, that is a generic parts can contain multiple sub-components (instance, also known as examples), and each Instance can contain their own Sub Instance. Discharge screw (stripper-bolt) the family table structure as shown in Figure 1.Figure 1 Family Table hierarchy1.2 RelationsRelations (relations) between mathematics and procedures, including grammar, and its main role is to be part or assembly of the relevance of the data by size symbols, and other parameters of grammar (syntax) to establish mathematical formula to meet the design requirements. Pro / E system of relations can be found in Sketch, Feature, Part and in the Assembly. Simple sentence, judgement and sentence is to establish relations of common format. Simple sentence that a simple mathematical relationship between the size of direct response associated situation. The use of simple format, such as d6 = L. BP 1 2 * d3. Judgement on the sentence for certain occasions, by specifying conditions to express design intent, grammar structure: "IF… ENDIF" or "IF… ELSE… ENDIF" in the "ELSE… ENDIF" between conditional statements can be multi-nested. Relations in the standardization and flexible stamping die design system in the building process plays a very important role, it has decided to parts of the geometric shape and characteristics of relations between the digital Xiao, partsrelations between the assembly and parts assembly in the presence of middle - A number of features.1.3 Pro/ProgramPro / Program (program) is the Pro / E of a procedural tool, similar to its grammar VBA and Office software in the Macro (Acer). When users use of Pro / engineer to design .The product of various kinds of information to document the format will be recorded. Through the Pro / Progran document editing, can be achieved on the characteristics of the hide, delete and re-order the assembly of components to add and replacement operation. These features stamping dies for the establishment of standard parts library, standards and flexible design structure of the system is very useful.Program files in the structure can be broadly classified into the title, set of parameters relationship, to add features (parts) and updating the quality attributes, such as five parts. In "INPUT… END INPUT" Xiao located between the parameters of the "RE1 ATIONS… ENDREALATIONS" relations between the various add in the "ADD… END ADD" and added features (part module) or parts (assembly module). Pro / Program provides three types of parameters: NUMBER (numerical) STRING (string) and YES-NO (it).2. Standards moldbase of the development2.1 Standards moldbase Classification and organizationsDie-stamping die is an important part. The typical model-there are three types: rear-guided-mode (back pillar sets), the middle-guided-mode (center pillar sets) and the guided-mode-angle (diagonal pillarsets). Each type of die-also includes a variety of specifications. According to Die boundary demarcation size, rear-guided, in a L ×B-22 specifications, D0 specifications 6 (L = B), middle-guided, in the nine-D0 specifications, the guided-mode-Kok L × B specifications 7 [2-3].In order to facilitate the management and data calls, the standard mode of the directory of the best-established in the Pro / E installation directory. As three categories-the larger structural differences, it may die-the root of the establishment of three other subdirectories, each subdirectory contains all the component parts-mode, and each type of parts can be adopted Pro / E Software for the family table, and toolssuch as the establishment of standard procedures for the database.2.2 Standards moldbase library buildingDie-stamping die from the main mode on the Block (upper.shoe), nder-Block (1 ower.shoe), I. column (guide.pillar) and I. Case (guidebushing), and other components. In order to make structural integrity of mold, can also die stalk (shank) assembly to die-in. Here are rear-die I.Establishment of the standard method.First of all the various components to create three-dimensional model, and then the standard manual data in the table a series of symbolic dimension added to the group on January 1 Editor (can also use Excel for editing). Add in the size of symbols, Size will be the best symbol to revise the manual and the size of the same symbol. Because people can not distinguish between Table Capitalization is, when both the same size letters, proposed to use capital letters to distinguish between pairs of characters, such as that for the d D, and D that will become a DD.Standard on two-Block: When the L ×B> 200 mm ×160 mn-i have installed Boss, and when L × B is less than or equal to the scope of non-installation of Boss, shown in Figure 2. Determine whether Boss in two ways: one way is to use Family Table, will generate the Boss Extrude Offset two characteristics and the way to Feature added to the family table, and in these two characteristics of the list Enter in the "Y" or "N", to determine the specifications of a certain mode on the Block, whether these two features; Another method is to find these two features in the Pro / Program in the location and characteristics of the process to add Extrude His statement before the judge "IF L> 200 1 B> 160", adding the Offset characteristics of the procedures used "END IF" the end of judgement.Figure2. die on the ground in two types2.3 The establishment of Standards moldbase forIn Pro / Assembly in the same module can be generated by the use of family die-standard database. Family structure in the assembly, when selected COrnponent, select the mode of all the parts-and enter a different group in the table-model specifications required by the standards of sub-components of the name, as shown in Figure 3.Figure 3 rear-guided, in the standard mode of Family TableCommon mode handles four types: pressure-in-stalk, the flange-stalk, Screw-mode and floating stems die stalk. If the four types of module assembly to handle all the common-mode model (Figure 3 in the assembly only two kinds), in the group table by the need to enter the module handles parts of the name, set the parameters of INPUT, with Regenerate Called when the parameters of renewable order to choose the mode of different types of handles. Of course, people can also die of the table do not have to handle characters with "N" to curb, as shown in Figure 3-mode system is used in this method.3 The development of standard stamping die3.1 The typical combination of stamping dieStamping die in the larger structural differences and establish flexible stamping die design systems using the best combination of the typical mold. Use of combinations to determine the structure of the typical mold of the structure, and thus determine the composition of the various components die sizes and assembly relations. Commonly used combination of stamping die typical structure: a fixed combinationof unloading, Tanya unloading combinations, composite model portfolio, such as plate-portfolio. Mold can not be separated from the structure of ISO standardization of parts, in the Pro / Engineer Dies in the standardization of parts can be used in the design of the bottom-up approach can also be used top-down design.3.2 die in the process of assembling data transferBecause of complicated, so stamping die by the standardization of the factors to consider-Modulus than standardized by many more factors to consider, one of the most important factor is the size of the correlation between the components. In the mold of a standard combination, assembly and components, parts and components between the need for data transmission, and in the Pro / Assembly can be very easy to achieve this objective.3.2.1 by the assembly of components to the data transferPro / Program can use the assembly EXECUTE statement will be down the parameters in a sub-assembly or parts delivery, the use of syntax is as follows: EXECUTE PART / ASSEMBLY file name components or sub-assembly of the parameters in the assembly of = END EXECUTE EXECUTE statement parameters can not leapfrog data transmission, not by the assembly to sub-assembly of components in the direct transmission of data.3.2.2 data transfer between the componentsWhen added to the assembly of components are in a Id, it can complete the assembly of components between the data transfer. Id assembly of components, can be used in the menu RELATIONs Session Id command to query. Figure 4 is the combination of Tanya discharge standards in the spring of unloading assembly diagram. As assembly to die in the spring have a pre-compression and thus the length of its assembly (Hs) are no longer equal to the length of freedom (H.). In determining H, you can use the following mathematical relationship:Hs:38= L:32一tbp:0In this way can always guarantee equal to the length of spring assembly from the surface to Dianban discharge board under the surface height, thus eliminating the relevant parts were replaced after the size of Laws. In the design of this mold is very practical, because the mold assembly in a similar situation there are many. Again, in determining the discharge screw on the seat-hole diameter (dI34), they can use thefollowing mathematical relationship:d134:8=D:32+2This Id, established by the mathematical relationship between the need to use Regenerate order to take effect, so different parts on the size of the location of as little as possible in this way, so as not to die in the initial call model will appear at the wrong result will be displayed. But if the parts in between and parameters to transfer data, the location of the various components of size parameters to create a mathematical relationship, the trouble can be avoided.3.2.3 standard replacement partsFamily Table used to establish the standard parts can lookup. inst Replacement statement. Lookup inst allows users to find the standard parts that match the sub-components, if not find the results, then return to a generic [4 J.Lookup.inst :lookup inst(generic—name,match-mode,paramnamel,match—valuel,param-name2,match—value2…)One match. preferred mode of three, representing different meanings: one is to find parameters of less than or equal to find the value of components; parameter values 0 to find an exact match to find value of the sub-components; to find parameters of greater than or equal to find value The sub-components.3.3 structure of the assemblyDie parts to complete the establishment and rationalize the assembly relations between the components, you can generate mold assembly model. Figure 5 for the development of the author Tanya unloading combination of specifications for the 200 mm × 160 mm of die structure (omit all the characteristics of thread).3.4 stamping die callStamping die in the Pro / Assembly call directly, but also can be used Pro / TOOLKIT development of visual user interface to call. Pro / TOOLKIT Pro Ecuador is the second development system software package, its main purpose is to allowusers or third parties through the expansion of C code Pro / E function, based on the development of Pro / E system of application modules to meet user Special needs. Pro/T00LKIT use of the UI dialog, the menu VC + + and Visual Interface technology, designed to facilitate flexible and practical stamping die design system for interactive interface. Use interface called the structure of various stamping dies, the choice of different specifications of the parts, enter a different parameters to determine sheet parameters as well as their positioning in the mold, and further in the system design punch, die and other structures, Thus greatly enhance the efficiency of stamping die design.4 ConclusionSince stamping process a wide range of complex processes, and the shape of various parts die, stamping dies in achieving standardization and development of flexible design system and the process is very complicated, but flexible stamping die design system of stamping die CAD is to improve the level of the cornerstones . Pro / E powerful components, the assembly of the criteria for the establishment of the functions of stamping dies for the standardization and flexible design of the feasibility of developing systems to provide a strong guarantee. In the development of flexible design system, should ingenious application of Pro / E software provided by an effective tool, considering the different types of standard structural composition of the assembly relations. Between the parts and components meet requirements of size structure changes, and the best use RELATIONS Pro / Program prepared by the mathematical relations systems and procedures to increase the flexibility and practicality. Die flexible design and application development system to avoid a mold designers unnecessary duplication of labor, so that the programme will focus on the concept, process optimization, and other creative work, thus mold the rapid design and production standards have a practical application Significance.外文资料翻译译文摘要:模具设计是一个苛刻的辛勤工作。

模具行业英语Mold making is an intricate art that requires precision and a keen eye for detail. The process begins with a design, which is then meticulously crafted into a mold that can withstand the pressures of manufacturing.In the world of molds, materials are carefully selected to ensure the durability and functionality of the final product. Metals like steel and aluminum are popular choices due to their strength and heat resistance.The molding process itself is a symphony of heat and pressure. Molten materials are poured into the mold, taking shape as they cool and solidify. This transformation is a testament to the craftsmanship involved in the industry.Advancements in technology have revolutionized the mold-making industry. Computer-aided design (CAD) and computer-aided manufacturing (CAM) have streamlined the process, allowing for more complex and precise molds to be created.Sustainability is a growing concern in the industry, with efforts being made to reduce waste and energy consumption. Eco-friendly materials and processes are increasingly sought after to minimize the environmental impact.Quality control is paramount in the mold industry. Each mold is inspected for any imperfections that could affect thefinal product. This attention to detail ensures that only the highest quality molds are used in production.Training and education are vital for those entering the mold-making field. Apprenticeships and specialized courses provide the necessary skills and knowledge to excel in this specialized industry.The future of the mold industry is promising, with innovations in materials and technology driving its growth. As products become more sophisticated, so too does the need for molds that can meet these evolving demands.。

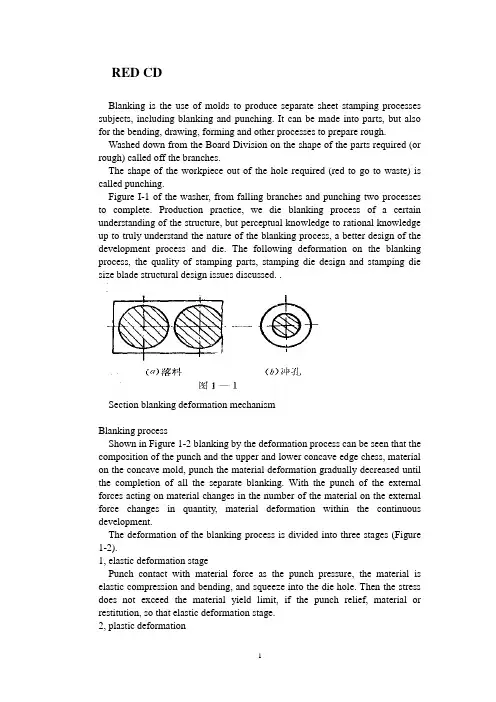

RED CDBlanking is the use of molds to produce separate sheet stamping processes subjects, including blanking and punching. It can be made into parts, but also for the bending, drawing, forming and other processes to prepare rough. Washed down from the Board Division on the shape of the parts required (or rough) called off the branches.The shape of the workpiece out of the hole required (red to go to waste) is called punching.Figure I-1 of the washer, from falling branches and punching two processes to complete. Production practice, we die blanking process of a certain understanding of the structure, but perceptual knowledge to rational knowledge up to truly understand the nature of the blanking process, a better design of the development process and die. The following deformation on the blanking process, the quality of stamping parts, stamping die design and stamping die size blade structural design issues discussed. .Section blanking deformation mechanismBlanking processShown in Figure 1-2 blanking by the deformation process can be seen that the composition of the punch and the upper and lower concave edge chess, material on the concave mold, punch the material deformation gradually decreased until the completion of all the separate blanking. With the punch of the external forces acting on material changes in the number of the material on the external force changes in quantity, material deformation within the continuous development.The deformation of the blanking process is divided into three stages (Figure 1-2).1, elastic deformation stagePunch contact with material force as the punch pressure, the material is elastic compression and bending, and squeeze into the die hole. Then the stress does not exceed the material yield limit, if the punch relief, material or restitution, so that elastic deformation stage.2, plastic deformationPunch to pressure, the stress reaches the yield limit of material, some metal is squeezed into the die hole, producing plastic shear deformation, are shining maggot cut surface. For convex, concave feel there is room between the depression, it is the plastic shear deformation is also accompanied by the bending and stretching.3, fault isolation stageMaterials continue to increase external and internal stress increasing, convex, because the incision die stress concentration, shear strength over the first internal stress, micro-crack appears. Mold continuing under pressure, convex, concave mold cavities of the micro-crack edge to the material constantly within the share capital, then pulled off material separation. Such as convex, concave die gap was reasonable, the upper and lower crack coincide with each other. ' Stress and strainFurther analysis of blanking time of stress and strain state of deformation zone and help to the understanding of the blanking process. Die and punch in the edge of the joint line to take 'cell body, "whose stress-strain diagram shown in Figure 1-3. Can be seen from the figure, it seemsMetal fracture line AB that is cutting edge on-line) at 45 degrees. The main uranium direction I was pulling stress and tensile deformation, tensile stress the goldIs a fiber elongation; its vertical axis 2 is the compression stress direction and compressive deformation, the fiber extrusion pressure; in the tangential direction of the stress and strain is very small, negligible; and principal stress direction at 45. Direction to the direction of maximum shear stress between the punch and die clearance, elongation and tear off the metal, resulting in broken fracture surface roughness, and with a burr.The process can also blanking blanking force deformation curves of the figure is confirmed. Figure 2-9 (materials), is punching a 3 mm thick material punching power and punch of the curve. Can be seen from the diagram:In the process of blanking blanking force size is constantly changing. AB section of the equivalent of punching the elastic deformation stage, BC Section for the plastic deformation stage. When the material internal stress to shear strength began to crack when the material, CD segment for the crack propagation until the material isolated rupture in order teams, DE Dan launch materials introduced die mouth piece.Cut section ofSee Figure 2-10The deformation process of blanking the red plant parts are not smooth vertical section, the section has three areas, namely, with rounded corners, bright band and the fault zone.Rounded band is in the process of blanking the beginning of plastic deformation. Since the bending and stretching metal fibers formed, soft material than hard Branch rounded large.Light zone is the second phase of deformation produced plastic shear deformation of metal forming, has a smooth vertical surface, bright band of the entire cross section of 1 / 2 to 1 / 3 of the light bandwidth of soft materials, hard materials with a narrow bright . With the mechanical properties of materials, space, mold structural changes.Fault is equivalent to the third stage of the blanking process, mainly due to the role of tensile stress, the continuous expansion of China cracks down payments second fiber extension, so a very rough surface is not smooth, and there Liaoduo. In the section on the same punch with these characteristics, but the distribution of the three regions opposite position and blanking.Blanking addition to drag a section of rough dimensions, there are points dome curved, not flat, face a burr, so blanking requirements apply only to an Blanking.Section Drawing gapBlanking time requires not only the shape of call times out of line drawing parts, there should be a certain quality requirements, quality of stamping pieces is cut surface quality, dimensional accuracy and form error. Cut surface should be flat, smooth, no crack and tear, mezzanine and other defects, glitches small parts, the surface should be flat as possible, that is a small vaulted arch, size, degree of precision required to ensure the drawings do not exceed the tolerance range.Factors that affect the quality of stamping pieces range from the actual production that, convex, concave die gap size and power uniformity, pattern edge state, the mold structure and manufacturing precision, quality materials, and so on all affect Na blanking. However, we must find out which plays a decisive role in the quality of the blanking factor. Gap is a.Section 1 on the quality of blankingComparison of straight, smooth, and no burr. In this case, the quality of parts that is a good cross section.When the gap is too hours of up and down the crack does not coincide with each other. . . .When the gap is too large cracks do not overlap. . . . (See 2-11)If the gap uneven distribution of local spikes. . . Uneven wear, increased, so clearance is not only to use reasonable and die on the manufacture and adjustment of space even when the guarantee.2. Gap on the Dimensional AccuracyBlanking Stamping dimensional accuracy refers to the actual size and nominal size of the margin, the difference is smaller the higher the precision.difference between living in two areas packet error, one blanking punch or die with the size of the deviation, one mold itself create bias.Blanking and convex, die size deviation was mainly due to:Workpiece (waste) from the concave mold release, as caused by elastic recovery. Deviation may be positive, it could be negative.Factors affecting the value of this deviation are:1, convex, concave mold gap. Big gap. . . Tensile obvious effect, elastic recovery materials and parts to drop less than the die size, punching pieces. . Small gap. . .2, material properties. Material properties and dimensional accuracy of packages since it will then determine the material properties of its material form in the amount of blanking. Outline of the elastic deformation of the soft small amount of elastic recovery after blanking also small, so the workpiece accuracy. Hard steel elastic recovery greater precision on the lower parts.3, workpiece shape and size. Workpiece thickness and shape of post degree only-J also have an impact, thin elastic recovery of material punching shield large,-t pieces of low accuracy. The more complex the shape of the workpiece, die and create and adjust the gap when the more difficult to ensure uniform, so the greater the size of deviations.See Figure 2-134. Blade-like quality video straight to the section noon5. Gap on the impact of blanking forceThe smaller the gap, blanking deformation area of the higher hydrostatic pressure, the greater the material change Kang force. Blanking force, the greater the contrary, when the gap increases, lower resistance, blanking force alsodecreases, but the value is not reduced (see Figure 2-14)Life on the sidelines of the impact of mold (see materials abbreviated talk)Section III to determine clearance punch and dieThus, convex and concave clearance on blanking die quality morning, punching power, tool life has a great impact, so the mold design - will select a reasonable gap to ensure Blanking section of good quality punching required is small, high-die life. But the difference of quality, precision, blanking force requirements in many aspects of cooperation were identified gap is not limited to the same - a value, but close to each other, taking into account the deviationof model county manufacturing and use of wear and tear,Therefore, production is often to select an appropriate range of reasonable space, as long as the gap falls within this range can be out of good parts, the scope of the minimum value, said minimum clearance Zmin reasonably small. Most reasonable position that the biggest gap Zmax. At least a reasonable gap Z Mi n can be with the board perpendicular to the section, without a significant glitch. In the largest gap Zmax "section can still be satisfied with the quality: just not with the board vertical. Taking into account the die wear and tear during use to increase the gap, so when the design and manufacture a new model to use the smallest reasonable space ZminReasonable methods to determine gap calculated with the experience to determine and French.One theory to define the lawTheory to define the main basis for the law is to ensure that cracks coincide in order to get a good cross section. Group 1 began the process of blanking the instantaneous crack q triangles from the graph we can find space z AB cType in: A, - convex molded into the depth; β - the maximum shear stress direction and the angle between the vertical;Can be seen from the above formula, gap z and the material thickness t, the relative cut into the depth h. / T and the crack orientation day. Relevant, but to another with the material properties and β is related to the more rigid material, h. / T smaller. Therefore, we can see from the style, the main factors affecting thevalue gap is the material properties and thickness. The more rigid material more thick, the necessary and reasonable value of the larger gap. Table 1-3 for the popular press materials, h. / T and β approximation.A variety of materials h. / T and β value is still no accurate determination of value, and. Production is not convenient to use this method, so widely used empirical formula with the graph method.Second, the experience to determine methodsExperience to determine the nature of law is based on the material and thickness, press-type to determineThe formula: K-factor related with the material properties. t - thickness ofmaterial.Soft materials such as 08, l0, brass, copper Z = (0.08-0.1) tIn hardwood Section: A3, A 4,20,25. Z = (0.1-0.I 2) tHard materials such as A5, 50 ... ... and so Z = (0.1-0.14) tLower limit of thin materials which take.Third, the chart methodIn addition, you can directly determine the space look-up table values (such as teaching materials 2-3,2-4,2-5 table) Table 2-5 is the former Ministry of Machinery Industry, "blanking clearance," Technical Guidance Document (JB/z271-86 ) recommended clearance value.Over the past China's general information on using Soviet gap value, from the use of the experience, the gap value is generally small. One reason for this is the classification space is not used according to the characteristics of production, the other is only as the main basis for precision stamping parts, without considering the King and the chess section with a life of quality and other important factors, so many problems exist in production. For example: Wear + blanking force. . .Therefore, in practice, in addition to special requirements of the workpiece outside the vertical section, as far as possible large gap.In addition, my experience in practice should:(1) z-punching to take the value of bigger than expected drop.(2) red holes get bigger when the z value, to prevent broken punch.(3) Carbide Die z value should be 30% larger than the steel.(4)J die orifice is cone-shaped than straight smaller z value.(5) high-speed stamping dies easily when the heat, f value should get bigger.(6) when the punch and die wall thin. To prevent cracking up, should be enlarged punching z.IV Size Calculation of Cutting EdgeDie edge dimensions and tolerances directly affect the dimensional accuracy of Blanking, also is sufficient to guarantee a reasonable gap. Therefore, the correct calculation of the mold edge mold design dimensions and tolerances are small - the work of great importance.Dimensions and tolerances in calculating the cutting edge should follow the following principles:1. Taking into account the drop size depends on the materials and parts die size, while punching pieces depends on the size of the punch dimensions of the blanking die design should be to die as the base is difficult to stay in the punch on the gap; Design Punching model should be based on the punch as the base, orange on the gap left in the concave. (There is a taper section, and the big end blanking parts die size = size, empty pieces of red punch small end size = size)2. Taking into account the wear and tear will foot a larger die, the punch size decreases, in order to ensure the life of mold, the basic blanking die size should be taken close to or equal to the minimum limit of size of the workpiece; Piercing Punch basic dimensions shall be taken as close to the or equal to the maximum limit of size of workpiece, using the smallest reasonable gap value.3. Sampling edge of manufacturing tolerances, the workpiece should be to ensure the accuracy and timeliness based clearance requirements. At the same time easy to mold manufacturing tolerance is too large, then out of the parts may be disqualified, or one can guarantee a reasonable gap; too small. And to die is difficult to mold manufacturing costs.Accuracy and precision blanking dies relationship tableSpecial Note: If the size of the workpiece is not marked tolerance. I T14 without tolerances according to class to deal with, and die according to I D 11 manufacturing (non-graphic parts). Or by I T 6-7 class manufacturing (for round parts).Mold processing method according to the different calculation methods aredivided into two kinds of edge1. Separate punch and die machiningSeparate processing: refers to the punch and die are processed separately by the respective drawings, mold the size of the gap processed by guarantee. Therefore, to calculate and mark out the punch and die dimensions and tolerances. This method is suitable for round or shape of a simple piece.(1) Blanking Die Blanking piece size based degree d, according to the above principles, first determine the small scale and then reduce the die size in order to ensure a reasonable punch clearance. Knife-edge part of the incidence graph of the size shown.Edge blanking die size is calculated as follows:(2) The punching die set punching size of d. (Standard tolerance) calculated according to the principles of the punch first determine the size. Further increasing the die size in order to ensure a reasonable minimum edge clearance associated with some of the dimensions in Figure 2-13 (b) below.Red edge aperture size is calculated as follows:Symbol meaning:X-tolerance zone offset factor, the purpose is to avoid all bias limit most blanking size (other omitted)Its value and accuracy of the workpiece.Tolerance band offset coefficient of 2-7 x to be investigated, or obtained by the following relationsWorkpiece accuracy of IT10 above: x = 1Workpiece accuracy of IT11 ~ 13: x = 1.75Fine piece head IT14: x = 0.5In order to ensure a reasonable space, mold manufacturing tolerances must meet the following conditionsConvex, concave mold separate processing advantages are: convex, concavemold with interchangeable, easy to mold batch processing.Convex, concave mold separate processing disadvantage: in order to ensure a reasonable gap. Require higher levels of mold manufacturing tolerances, mold making more difficult.(Based on the use of examples to explain -6,2-7 table)2. Punch and die with the processingFor complex shapes or thin material workpiece. In order to facilitate mold, should be used with the process. This method is first processed basis documents (when blanking die, punch when the punch), and then base the actual size of the Huai items to do with the other documents (when blanking punch, punch when punch), and then base the actual size of the Huai items to do with the other documents (when blanking punch, punch die when), in another space on the revised smallest reasonable value. Therefore, when used with the process, simply reference documents marked size and tolerance, another mark only basic dimensions. And marked "punch-foot small scale only by the actual preparation of the die to ensure the single gap" (blanking time); or "die size of the actual size of the preparation by the punch to ensure the side gap.." (When punching ). With the process, the base parts of the manufacturing tolerance 6f (or long) is no longer limited by the gap value, or even appropriate to enlarge manufacturing tolerances, so relatively easy to manufacture molds. Most factories have recently used this combined approach. Benchmark parts manufacturing tolerances generally preferable to A / 4For some the shape of complex stamping parts. For each part of the size of the different nature of the wear law is different, it must be a specific analysis. Calculated separately.Figure 2-20a for the blanking parts and die size ,2-20b for the punching pieces and punch size, in these two diagrams: A class size is worn larger size, such size should be charged formula feed die size (2 • 2) calculation, B Class size is worn by people of such small size scale should be punching punch size formula (2-4) calculation; C Class size is worn the same size, of such size, the size of the workpiece in the middle of the basic dimensions as the mold, and then standard deviation can be symmetrical, the specific formula as follows:V blanking forceCutting edge technology, including separation of materials needed forpunching power and discharge power, pushing pieces of power and top pieces of power. After blanking. Washed down the workpiece (or waste) as elastic recovery and expansion will be within the infarct in the die hole. Similarly, the scrap piece〕〔or out of the hole on the elastic contraction because of tight coupling on the punch. ? Called the discharge power;? Named top material (pieces) force;? Called push material (pieces of) force.The purpose of calculating power stamping process is it?Reasonable choice is to press tonnage. (Of course choose not to consider the tonnage presses, as well as tables, press structure... Shut height, etc.) Select press when you press and public pressure (N) must make a big or equal to the total pressure during blankingFirst, the calculation of punching forceFlat blade used in production Die Blanking, the blanking force can be calculated as follows;K-safety factor, and generally the skin = 1.3. It takes into account mold edge wear and blunting the punch and the die gap is uneven material thickness deviation of the performance factors, such as Ko.Blanking of high strength material or thick material and large size parts, the need to force a larger punch. If the blanking press more than the tonnage of the existing plant, it is necessary to reduce the blanking force.1. Heating blankingMaterial shear strength in the heated state decreased significantly, which can reduce the blanking force. However, heating the material will produce oxide, will be deformation, therefore applied only to thick or the surface quality and precision of less demanding jobs. Lower τ2. Ladder arrangement blanking punchIn the multi-blanking punch in the punch made of different degrees south, a ladder Boubou set (Figure 2-18), will enable each punch the maximum blanking force of wood come together. Thereby reducing the total blanking force. Punch height difference between the thickness determined by: t <3mm, h = tt> 3mm h = 0.5tWhen the punch by step layout 'symmetrically as possible. At the same time should do a small punch shorter, longer doing big punch, so to avoid a small punch side material flow because the pressure caused by tilt or break situation.3. Oblique incision Die Blanking Figure 2-u-shaped cloth ladder A model aimed Knife-edge blanking level, the entire flat edge on the contact sheet to the rather oblique knife edge blanking die, because edge is inclined, not simultaneously cut into the knife-edge blanking time, but gradually punching material, so very dry by punching a small section of the post. Thus lower. Second, the calculation of other blanking forceMany factors affect these forces, mainly the mechanical properties and thickness, die gap, the workpiece shape and size and lubrication conditions. The effects of these factors is very complex to quantify accurately reflect the size of these forces is difficult. Therefore, the general experience with the following formula:Fx = KF (K look-up table 2-10)The overall strength based on the actual die stamping process concrete analysis of the structure.外文资料译文冲裁冲裁是利用模具使板科产生分离的冲压工序,包括落料与冲孔。

国内外模具技术的现状及发展趋势国内外模具技术的现状及发展趋势摘要:本文叙述了模具技术在国民经济中的重要性,介绍了各行业模具的现状及发展方向;文中强调指出了两个关键问题——模具材料和模具标准——是持续发展模具技术的重大策略。

中国模具技术,则是依据着国际模具市场的发展趋势,转变着模具品牌产品的发展规模,不断的提高着模具设计水平,迎合着模具企业的经济发展需求,也会进一步的推动着模具技术发展。

关键词:发展趋势、现状、模具技术、塑料模具、模具CAD/CAM Abstract:This paper was narrated the importance of the mould technology in the national economy.It was introduced the present situation and development direction of all trade and professions on the mould and die.It was indicated emphatically two questions of the crux一一mould materials and mould standard——developing continuous ly the great tactics on the progress of the mould technology. China mold technology, according to the international mold is the development trend of the market, the brand product change mould the development sc ale, and constantly improve the level of the die design, catering to the needs of the mould enterprise economic development, will further promote the development of the mould technology.一、引言模具是工业生产的基础工艺装备,国民经济的五大支拄产业机械、电子、汽车、石化、建筑都要求模具工业发展与之相适应。

中英文资料对照外文翻译英文:Design and Technology of the Injection Mold1、3D solid model to replace the center layer modelThe traditional injection molding simulation software based on products of the center layer model. The user must first be thin-walled plastic products abstract into approximate plane and curved surface, the surface is called the center layer. In the center layer to generate two-dimensional planar triangular meshes, the use of these two-dimensional triangular mesh finite element method, and the final result of the analysis in the surface display. Injection product model using3D solid model, the two models are inconsistent, two modeling inevitable. But because of injection molding product shape is complex and diverse, the myriads of changes from athree-dimensional entity, abstraction of the center layer is a very difficult job, extraction process is very cumbersome and time-consuming, so the design of simulation software have fear of difficulty, it has become widely used in injection molding simulation software the bottleneck.HSCAE3D is largely accepted3D solid / surface model of the STL file format. Now the mainstream CAD/CAM system, such as UG, Pro/ENGINEER, CATIA and SolidWorks, can output high quality STL format file. That is to say, the user can use any commercial CAD/CAE systems to generate the desired products3D geometric model of the STL format file, HSCAE3D can automatically add the STL file into a finite element mesh model, through the surface matching and introduction of a new boundary conditions to ensure coordination of corresponding surface flow, based on3D solid model of analysis, and display of three-dimensional analysis results, replacing the center layer simulation technology to abstract the center layer, and then generate mesh this complicated steps, broke through system simulation application bottlenecks, greatly reducing the burden of user modeling, reduces the technical requirement of the user, the user training time from the past few weeks shorter for a fewhours. Figure 1 is based on the central layer model and surface model based on 3D solid / flow analysis simulation comparison chart.2、Finite element, finite difference, the control volume methodsInjection molding products are thin products, products in the thickness direction of size is much smaller than the other two dimensions, temperature and other physical quantities in the thickness direction of the change is very large, if the use of a simple finite element and finite difference method will cause analysis time is too long, can not meet the actual needs of mold design and manufacturing. We in the flow plane by using finite element method, the thickness direction by using finite difference method, were established and plane flow and thickness directions corresponding to the size of the grid and coupling, while the accuracy is guaranteed under the premise of the calculation speed to meet the need of engineering application, and using the control volume method is solved. The moving boundary problem in. For internal and external correspondence surface differences between products, can be divided into two parts the volume, and respectively formed the control equation, the junction of interpolation to ensure thatthe two part harmony contrast.3、Numerical analysis and artificial intelligence technologyOptimization of injection molding process parameters has been overwhelming majority of mold design staff concerns, the traditional CAE software while in computer simulation of a designated under the conditions of the injection molding conditions, but is unable to automatically optimize the technical parameters. Using CAE software personnel must be set to different process conditions were multiple CAE analysis, combined with practical experience in the program were compared between, can get satisfactory process scheme. At the same time, the parts after the CAE analysis, the system will generate a large amount of information about the project ( product, process, analyzes the results ), which often results in a variety of data form, requiring the user to have the analysis and understanding of the results of CAE analysis ability, so the traditional CAE software is a kind of passive computational tools, can provide users with intuitionistic, effective engineering conclusion, to software users demand is too high, the influence of CAE system in the larger scope of application and popularization. In view of the above, HSCAE3D software in the original CAE system based on accurate calculationfunction, the knowledge engineering technology is introduced the system development, the use of artificial intelligence is the ability of thinking and reasoning, instead of the user to complete a large number of information analysis and processing work, directly provide guiding significance for the process of conclusions and recommendations, effectively solve the CAE of the complexity of the system and the requirements of the users of the contradiction between, shortening of the CAE system and the distance between the user, the simulation software by traditional " passive" computational tools to " active" optimization system. HSCAE3D system artificial intelligence technology will be applied to the initial design, the results of the analysis of CAE interpretation and evaluation, improvement and optimization analysis of3 aspects.译文:注塑模具设计的技术1.用三维实体模型取代中心层模型传统的注塑成形仿真软件基于制品的中心层模型。