starch with a slow digestion property produced by altering it

- 格式:pdf

- 大小:190.49 KB

- 文档页数:8

食品化学-碳水化合物A卷一名词解释20分斯特勒克降解——在二羰基化合物存在下,氨基酸可发生脱羧,脱胺作用,成为少一个碳的醛,羰基化合物则转移到二羰基化合物上。

焦糖化作用——糖类在没有氨基化合物存在的情况下,加热到其熔点以上的温度时,因糖发生脱水与降解,也会发生褐变反应,这种作用称为焦糖化作用。

淀粉糊化——-淀粉在水中经加热后出现膨润现象继续加热,成为溶液状态的现象。

淀粉老化——经过糊化的-淀粉在室温或低于室温下放置后,会变得不透明甚至凝结而沉淀,这现象称为老化二选择题60分1.以下为核糖分子的结构式是(A)ABCD 2.下列反应能产生香味物质的是(D)A阿姆德瑞分子重排B果糖基胺脱胺C羰氨缩合D斯特勒克降解3.以下各项中对美拉德反应无影响的因子是(D)ApH值B温度C金属离子D酶浓度4.相对甜度最高的是(B)A蔗糖B果糖C葡萄糖D麦芽糖5.淀粉在下列条件下易老化的是(B)A含水量小于10%B温度在2~40C之间CpH小于4DpH大于116.加入下列物质褐变速度最快的是(C)A木糖B半乳糖C核糖D葡萄糖的缩合产物不能进一步生成(C) 7.亚硫酸根抑制美拉德反应是因为其与醛,R-NH2AHMF与还原酮B果糖基氨C薛夫碱与N-葡萄糖基氨D果糖基氨与2-氨基-2-脱氧葡萄糖8.制造蜜饯时,不能使用的糖是(C)A果糖B果葡糖浆C蔗糖D淀粉糖浆9.以下糖类中糖尿病人可以食用的是(B)A葡萄糖B木糖醇C山梨糖D蔗糖10.在烘烤中着色最快的糖是(A)A果糖B葡萄糖C蔗糖D麦芽糖11.在相同浓度下,加入下列哪种糖能使雪糕最不易起冰粒(B) A蔗糖B葡萄糖C麦芽糖D葡麦糖浆12.以下哪种淀粉属于物理变形淀粉(D)Aβ—淀粉B糊化淀粉C氧化淀粉D预糊化淀粉13.以下不属于淀粉老化原理应用的是(D)A.粉丝的生产B.油炸方便面加工C.速煮米饭加工D.肉糜制品14.在汤团皮中添加5%左右的什么可以起粘结剂作用?(A)A酯化淀粉B氧化淀粉C酸变性淀粉D预糊化淀粉15.LM果胶必须在什么存在情况下形成凝胶?(D)A糖B酸C适当pH值D二价阳离子三是非题(要求解释原因)10分1.糖浓度只有在70%以上才能抑菌,故通常利用高浓度的果糖来保存食品.答:是的.糖浓度只有在70%以上才能抑制大多数微生物的生长,而在室温条件(20O C)下,只有果糖的浓度可以达到70%,其它糖的溶解度都低于70%,故通常利用高浓度的果糖来保存食品.2.淀粉都能令碘液变色。

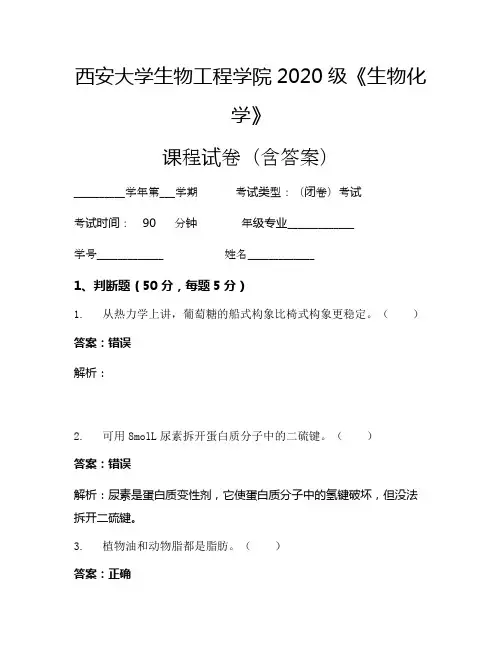

西安大学生物工程学院2020级《生物化学》课程试卷(含答案)__________学年第___学期考试类型:(闭卷)考试考试时间:90 分钟年级专业_____________学号_____________ 姓名_____________1、判断题(50分,每题5分)1. 由1g粗酶制剂经纯化后得到10mg电泳纯的酶制剂,则酶的比活力较原来提高了100倍。

()答案:错误解析:2. 组成多糖的大多数单糖是L型。

()答案:错误解析:组成多糖的大多数单糖是D型。

3. 镰状细胞贫血症患者红细胞内的2,3BPG的浓度通常比正常人高。

()解析:4. DDNA代表细胞内DNA的基本构象,在某些情况下,还会呈现A型、Z型和三股螺旋的局部构象。

()答案:正确解析:5. αD葡萄糖和αD半乳糖结构很相似,它们是差向异构体。

()答案:正确解析:6. 多数寡聚蛋白质分子其亚基的排列是对称的,对称性是蛋白质分子四级结构的最重要的性质之一。

()答案:正确解析:7. 所谓肽单位就是指组成蛋白质的氨基酸残基。

()解析:肽单位又称肽基,是肽链主链上的重复结构,是由参与肽键催生主链的氮原子、碳原子和它们的4个代替成分羰基氧原子、酰胺氢原子和两个毗邻的α碳原子组成单位名称的一个平面单位。

8. 所有的酶都含有辅基或辅酶。

()[中山大学2018研]答案:错误解析:不是所有的酶都内含辅基或辅酶,单纯复合物只有蛋白质而不含有辅因子,如脲酶、淀粉酶和一些养份等。

9. DNA核蛋白及RNA核蛋白可用0.14molL NaCl溶液抽提出来。

()答案:错误解析:DNA核蛋白及RNA核蛋白一般用1molL NaCl抽提。

10. 植物油和动物脂都是脂肪。

()答案:正确解析:2、名词解释题(25分,每题5分)1. 增色效应[华中农业大学2017;上海交通大学2018研;暨南大学2019研]答案:增色效应是指由于DNA变性引起溶液的紫外高异吸收作用增强的效应。

1472药剂学(本)一、单项选择题阿司匹林水溶液的pH值下降说明其主要发生( )B.水解包合物是由主分子和客分子构成的()B. 分子胶囊包衣的目的不包括()C. 加快药物的溶出速度不具有助悬作用的辅料是()B. 吐温-80不属于软膏剂的质量检查项目的是()。

D.硬度不属于注射剂的优点是( )。

D.可迅速终止药物作用茶碱在乙二胺存在下溶解度由1:120 增大至1:5,乙二胺的作用是() D. 助溶肠溶包衣材料是( )。

E.羟丙甲基纤维素酞酸酯常用的增塑剂是()A. 丙二醇常用的致孔剂是( )蔗糖对喷雾剂的叙述错误的是( )。

C.抛射药液的动力是压缩状态的抛射剂对于易水解的药物,通常加入乙二醇、丙醇增加稳定性,其原因是( )A.介电常数较小粉末直接压片的助流剂是()C. 微晶纤维素复方碘溶液中加入碘化钾的作用是( )。

D.助溶高分子溶液剂中加入大量电解质可导致( ) C.盐析关于包合物的错误表述是( )。

D.包合物具有靶向作用关于空胶囊和硬胶囊剂的说法,错误的是()。

C.空胶囊的规格号数越大,容积也越大关于亲水性胶体叙述错误的是( )。

B.明胶﹑琼脂溶液具有触变性质关于热原的错误表述是( )。

B.致热能力最强的是革兰阳性杆菌所产生的热原关于糖浆剂的说法错误的是( )。

D.热熔法适于对热不稳定或挥发性药物制备糖浆剂关于液体制剂特点的表述正确的是()B.药物分散度大,吸收快,药效发挥迅速关于凝胶剂的叙述正确的是( )。

凝胶剂是指药物与适宜的辅料制成的均一.混悬或乳状稠厚液体或半固体制剂关于脂质体特点和质量要求的说法,正确的是()脂质体为被动靶向制剂,在其载体上结合抗体,糖脂等也可使其具有特异性靶向性含碳酸氢钠和有机酸的颗粒是()A. 泡腾颗粒混悬剂中加入少量电解质可作为()C. 絮凝剂与反絮凝剂经皮给药制剂基本组成不包括()C. 隔离层可用作片剂的崩解剂是()D. 低取代羟丙基纤维素可作栓剂水溶性基质的是()。

食品生物化学一单项选择题3脂类的氧化、美拉德反应、维生素的分解等反应速率最大的水分活度为(D)A0.2~0.3 B0.4~0.5 C0.6~0.7 D0.7~0.99对低水分活度最敏感的菌类是(B)A霉菌B细菌C酵母菌D干性霉菌10水分多度在(C)时,微生物变质以细菌为主A0.62以上 B 0.71以上 C 0.88以上D0.91以上13要保持干燥食品的理想性质,水分活度不能超过(C)A0.1~0.2 B0.2~0.3 C0.3~0.5 D0.6~0.71.下列哪种糖无还原性?BA.麦芽糖B.蔗糖C.阿拉伯糖D.木糖E.果糖5.下列哪种糖不是还原糖:CA.葡萄糖B.半乳糖C.蔗糖D.麦芽糖E.核糖9.下列哪个是蔗糖经蔗糖酶水解的产物:BA.葡萄糖+葡萄糖B.果糖+葡萄糖C.半乳糖+葡萄糖D.果糖+半乳糖E.半乳糖+半乳糖12.关于糖类生理功能的叙述下列哪个是错误的EA.供能B.构成细胞成分C.参与特殊功能—抗体等D.转变成脂肪和α-酮酸E.维持酶的活性19.自然界中最甜的糖是:EA.蔗糖B.葡萄糖C.果糖D.乳糖E.麦芽糖3、组成蛋白质的基本单位是:(A)A L-α-氨基酸B D-α-氨基酸C L-β-氨基酸D L.D-α-氨基酸5、除了八种必需氨基酸外,婴儿特殊需要的必需氨基酸是(C)A、色氨酸B、亮氨酸C、组氨酸D、酪氨酸7、下面能与茚三酮溶液发生反应并呈黄色的有(C)A、色氨酸B、亮氨酸C、脯氨酸D、酪氨酸9、在加工脱水猪肉时,干燥前先调节肉的pH,使其远离蛋白质等电点,复水时较易嫩化,这主要是利用了蛋白质的(A)A、水化作用B、乳化性质C、起泡性质D、胶凝作用10、新鲜的猪肉在很高的压力下都不能把其中的水分压挤出来,这主要是(D)A、水化作用B、乳化性质C、起泡性质D、胶凝作用11、食品卫生中的利用乙醇消毒灭菌和加热蒸煮杀菌,是利用了蛋白质的(C)A、水化作用B、乳化性质C、变性作用D、胶凝作用12、使肌肉呈红色的蛋白质是(C)A 、肌溶蛋白B、肌粒蛋白C、肌红蛋白D、肌球蛋白13、小麦蛋白中缺乏(B),并不是一种良好蛋白质来源,需要与其他蛋白质配合。

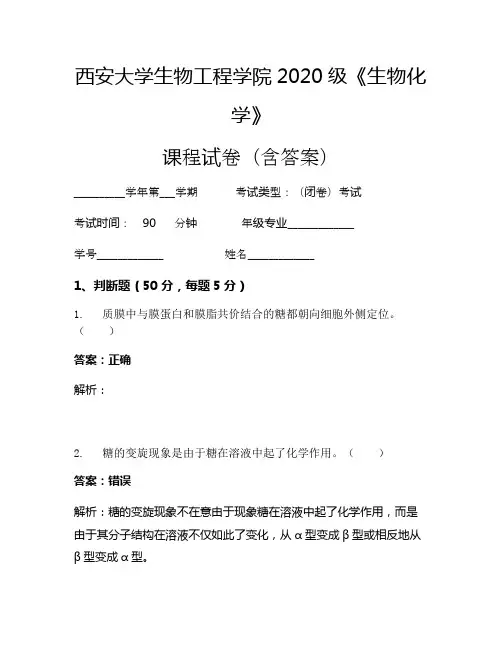

西安大学生物工程学院2020级《生物化学》课程试卷(含答案)__________学年第___学期考试类型:(闭卷)考试考试时间:90 分钟年级专业_____________学号_____________ 姓名_____________1、判断题(50分,每题5分)1. 质膜中与膜蛋白和膜脂共价结合的糖都朝向细胞外侧定位。

()答案:正确解析:2. 糖的变旋现象是由于糖在溶液中起了化学作用。

()答案:错误解析:糖的变旋现象不在意由于现象糖在溶液中起了化学作用,而是由于其分子结构在溶液不仅如此了变化,从α型变成β型或相反地从β型变成α型。

3. 就已有文献资料来看,核酶(ribozyme)不符合催化剂概念。

()答案:错误解析:4. 当底物处于饱和水平时,酶促反应的速度与酶浓度成正比。

()。

答案:正确解析:5. 酶的Kcat型抑制剂比Km型抑制剂专一性更强。

()。

答案:正确解析:6. 基因表达的最终产物都是蛋白质。

()答案:错误解析:基因表达的产物可以是蛋白质或RNA。

7. DNA分子中含有等摩尔数的A、G、C、T。

()答案:错误解析:8. 真核生物成熟mRNA的两端均带有游离的3′OH。

()答案:正确解析:真核生物成熟mRNA的5′为帽子结构即,因此5′端也是3′OH。

9. DNA核蛋白及RNA核蛋白可用0.14molL NaCl溶液抽提出来。

()答案:错误解析:DNA核蛋白及RNA核蛋白一般用1molL NaCl抽提。

10. 自然界中只存在右手螺旋的DNA双螺旋。

()答案:错误解析:2、名词解释题(25分,每题5分)1. 鞘糖脂(glycosphingolipid)答案:鞘糖脂(glycosphingolipid)是指单糖或寡糖的糖链与神经酰胺C1上的羟基以糖苷键相连而形成的化合物,主要包括脑苷脂和神经节苷脂。

解析:空2. 亲和层析、离子交换层析答案:(1)特异是指利用共价连接有亲和层析配体的层析介质分离蛋白质混合物中能特异结合配体的目的蛋白或底物其他分子的层析技术。

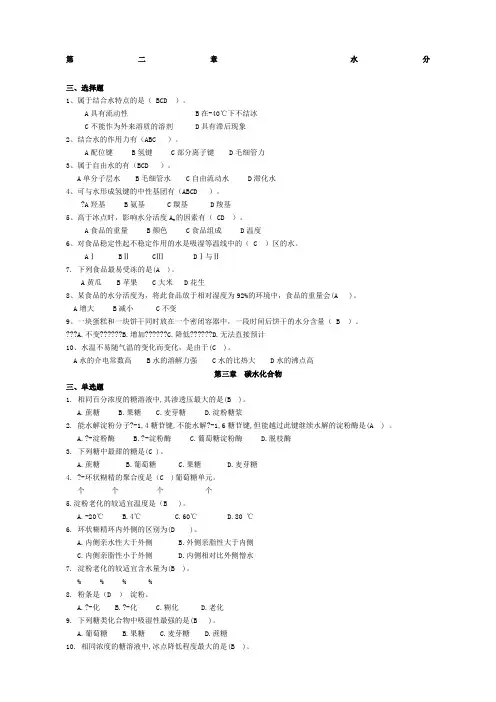

第二章水分三、选择题1、属于结合水特点的是( BCD )。

A具有流动性 B在-40℃下不结冰C不能作为外来溶质的溶剂 D具有滞后现象2、结合水的作用力有(ABC )。

A配位键 B氢键 C部分离子键 D毛细管力3、属于自由水的有(BCD )。

A单分子层水 B毛细管水 C自由流动水 D滞化水4、可与水形成氢键的中性基团有(ABCD )。

?A羟基 B氨基 C羰基 D羧基5、高于冰点时,影响水分活度A w的因素有( CD )。

A食品的重量 B颜色 C食品组成 D温度6、对食品稳定性起不稳定作用的水是吸湿等温线中的( C )区的水。

AⅠ BⅡ CⅢ DⅠ与Ⅱ7. 下列食品最易受冻的是(A )。

A黄瓜 B苹果 C大米 D花生8、某食品的水分活度为,将此食品放于相对湿度为92%的环境中,食品的重量会(A )。

A增大 B减小 C不变9、一块蛋糕和一块饼干同时放在一个密闭容器中,一段时间后饼干的水分含量( B )。

???A.不变??????B.增加??????C.降低??????D.无法直接预计10、水温不易随气温的变化而变化,是由于(C )。

A水的介电常数高 B水的溶解力强 C水的比热大 D水的沸点高第三章碳水化合物三、单选题1. 相同百分浓度的糖溶液中,其渗透压最大的是(B )。

A.蔗糖B.果糖C.麦芽糖D.淀粉糖浆2. 能水解淀粉分子?-1,4糖苷键,不能水解?-1,6糖苷键,但能越过此键继续水解的淀粉酶是(A ) 。

A.?-淀粉酶B.?-淀粉酶C.葡萄糖淀粉酶D.脱枝酶3. 下列糖中最甜的糖是(C )。

A.蔗糖B.葡萄糖C.果糖D.麦芽糖4. ?-环状糊精的聚合度是(C )葡萄糖单元。

个个个个5.淀粉老化的较适宜温度是(B )。

A.-20℃B.4℃C.60℃D.80 ℃6. 环状糊精环内外侧的区别为(D )。

A.内侧亲水性大于外侧B.外侧亲脂性大于内侧C.内侧亲脂性小于外侧D.内侧相对比外侧憎水7. 淀粉老化的较适宜含水量为(B )。

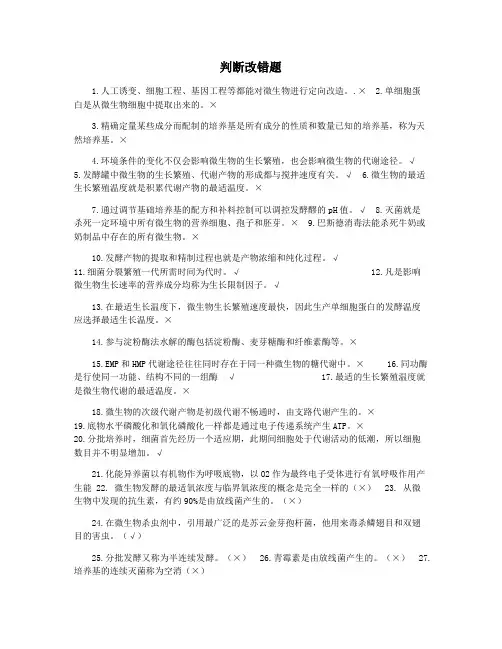

判断改错题1.人工诱变、细胞工程、基因工程等都能对微生物进行定向改造。

.×2.单细胞蛋白是从微生物细胞中提取出来的。

×3.精确定量某些成分而配制的培养基是所有成分的性质和数量已知的培养基,称为天然培养基。

×4.环境条件的变化不仅会影响微生物的生长繁殖,也会影响微生物的代谢途径。

√5.发酵罐中微生物的生长繁殖、代谢产物的形成都与搅拌速度有关。

√6.微生物的最适生长繁殖温度就是积累代谢产物的最适温度。

×7.通过调节基础培养基的配方和补料控制可以调控发酵醪的pH值。

√ 8.灭菌就是杀死一定环境中所有微生物的营养细胞、孢子和胚芽。

× 9.巴斯德消毒法能杀死牛奶或奶制品中存在的所有微生物。

×10.发酵产物的提取和精制过程也就是产物浓缩和纯化过程。

√11.细菌分裂繁殖一代所需时间为代时。

√ 12.凡是影响微生物生长速率的营养成分均称为生长限制因子。

√13.在最适生长温度下,微生物生长繁殖速度最快,因此生产单细胞蛋白的发酵温度应选择最适生长温度。

×14.参与淀粉酶法水解的酶包括淀粉酶、麦芽糖酶和纤维素酶等。

×15.EMP和HMP代谢途径往往同时存在于同一种微生物的糖代谢中。

× 16.同功酶是行使同一功能、结构不同的一组酶√ 17.最适的生长繁殖温度就是微生物代谢的最适温度。

×18.微生物的次级代谢产物是初级代谢不畅通时,由支路代谢产生的。

×19.底物水平磷酸化和氧化磷酸化一样都是通过电子传递系统产生ATP。

×20.分批培养时,细菌首先经历一个适应期,此期间细胞处于代谢活动的低潮,所以细胞数目并不明显增加。

√21.化能异养菌以有机物作为呼吸底物,以O2作为最终电子受体进行有氧呼吸作用产生能 22. 微生物发酵的最适氧浓度与临界氧浓度的概念是完全一样的(×) 23. 从微生物中发现的抗生素,有约90%是由放线菌产生的。

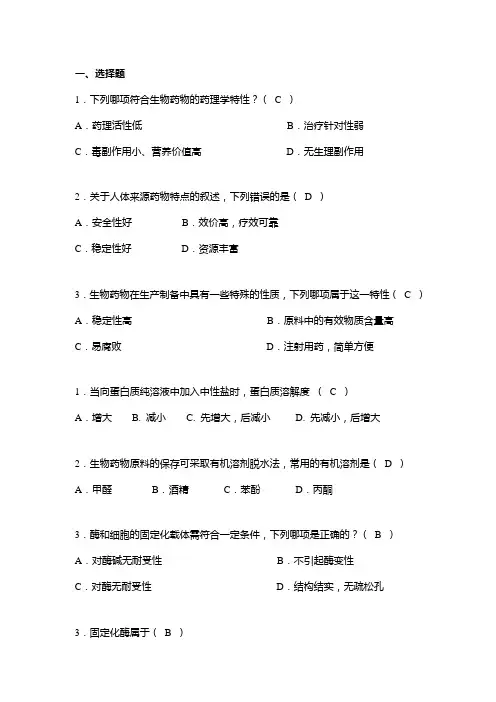

一、选择题1.下列哪项符合生物药物的药理学特性?(C )A.药理活性低B.治疗针对性弱C.毒副作用小、营养价值高D.无生理副作用2.关于人体来源药物特点的叙述,下列错误的是(D )A.安全性好B.效价高,疗效可靠C.稳定性好D.资源丰富3.生物药物在生产制备中具有一些特殊的性质,下列哪项属于这一特性(C )A.稳定性高B.原料中的有效物质含量高C.易腐败D.注射用药,简单方便1.当向蛋白质纯溶液中加入中性盐时,蛋白质溶解度(C )A.增大 B. 减小 C. 先增大,后减小 D. 先减小,后增大2.生物药物原料的保存可采取有机溶剂脱水法,常用的有机溶剂是(D )A.甲醛B.酒精C.苯酚D.丙酮3.酶和细胞的固定化载体需符合一定条件,下列哪项是正确的?(B )A.对酶碱无耐受性B.不引起酶变性C.对酶无耐受性D.结构结实,无疏松孔3.固定化酶属于(B )A.天然酶B.修饰酶C.天然酶或修饰酶D.细胞产生的酶4.固定化酶的最大特点是:(A )A.既有生物催化剂功能,又有固相催化剂特性B.有生物催化剂功能,无固相催化剂特性C.无生物催化剂功能,只有固相催化剂特性D.既无生物催化剂功能,又无固相催化剂特性5.下面哪一种药物属于多糖类生物药物(C )A、洛伐他汀B、干扰素C、肝素D、细胞色素C6.能用于防治血栓的酶类药物有(D )A、SODB、胰岛素C、L-天冬酰胺酶D、尿激酶7.下列哪项是采用固定化酶技术的优点?(D )A.反应后,底物与产物易于分开,易于纯化B.反应条件易于控制,可实现转化反应的不连续性C.酶的利用效率高,单位酶催化底物量减少,用酶量减少D.比水溶性酶更适合于多酶反应1.目前分离的1000多种抗生素,约2/3产自(B )A、真菌B、放线菌C、细菌D、病毒2.属于生物次级代谢产物的药物是(B )A.维生素B.抗生素C.核苷酸D.氨基酸3.下面不属于抗生素的一般生产方法的为(D )A.生物合成法B.化学合成法C.生物化学合成法D.物理合成法4.在菌种保藏方法中,保藏期为1~6个月的是(A )A.斜面保藏法B.石蜡油封藏法C.砂土管保藏法D.冷冻干燥保藏法5.在菌种保藏方法中,适合于菌种长期保存的方法为(D )A.斜面保藏法B.石蜡油封藏法C.砂土管保藏法D.冷冻干燥保藏法。

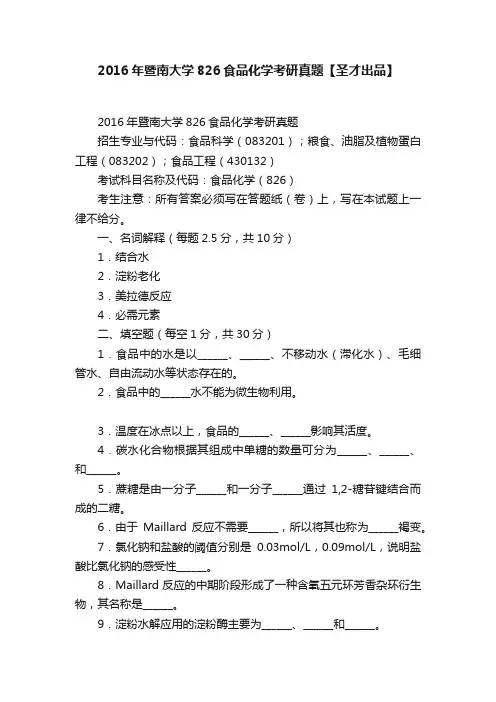

2016年暨南大学826食品化学考研真题【圣才出品】2016年暨南大学826食品化学考研真题招生专业与代码:食品科学(083201);粮食、油脂及植物蛋白工程(083202);食品工程(430132)考试科目名称及代码:食品化学(826)考生注意:所有答案必须写在答题纸(卷)上,写在本试题上一律不给分。

一、名词解释(每题2.5分,共10分)1.结合水2.淀粉老化3.美拉德反应4.必需元素二、填空题(每空1分,共30分)1.食品中的水是以______、______、不移动水(滞化水)、毛细管水、自由流动水等状态存在的。

2.食品中的______水不能为微生物利用。

3.温度在冰点以上,食品的______、______影响其活度。

4.碳水化合物根据其组成中单糖的数量可分为______、______、和______。

5.蔗糖是由一分子______和一分子______通过1,2-糖苷键结合而成的二糖。

6.由于Maillard反应不需要______,所以将其也称为______褐变。

7.氯化钠和盐酸的阈值分别是0.03mol/L,0.09mol/L,说明盐酸比氯化钠的感受性______。

8.Maillard反应的中期阶段形成了一种含氧五元环芳香杂环衍生物,其名称是______。

9.淀粉水解应用的淀粉酶主要为______、______和______。

10.纤维素是以______为骨架的,半纤维素又是以______为骨架。

11.下列糖中最甜的糖是______。

(蔗糖、葡萄糖、果糖、麦芽糖)12.相同浓度的糖溶液中,冰点降低程度最大的是______。

(蔗糖、葡萄糖、麦芽糖、淀粉糖浆)13.焙烤食品表皮颜色的形成主要是由于食品化学反应中的______引起的。

(非酶褐变反应、糖的脱水反应、脂类自动氧化反应、酶促褐变反应)14.下列脂酸脂中必需脂肪酸是______。

(软脂酸、亚油酸、油酸、豆蔻酸)15.食品中的蛋白质通过消化器官可以水解为简单的营养成分______。

西安大学生物工程学院2020级《生物化学》课程试卷(含答案)__________学年第___学期考试类型:(闭卷)考试考试时间:90 分钟年级专业_____________学号_____________ 姓名_____________1、判断题(50分,每题5分)1. 从热力学上讲,葡萄糖的船式构象比椅式构象更稳定。

()答案:错误解析:2. 可用8molL尿素拆开蛋白质分子中的二硫键。

()答案:错误解析:尿素是蛋白质变性剂,它使蛋白质分子中的氢键破坏,但没法拆开二硫键。

3. 植物油和动物脂都是脂肪。

()答案:正确解析:4. 溶液的pH可以影响氨基酸的等电点。

()答案:错误解析:氨基酸的等电点是指氨基酸所带净电荷为零时溶液的pH,溶液的pH并不影响氨基酸的等电点。

5. 多核苷酸链内共价键的断裂叫变性。

()答案:错误解析:6. DNA是生物遗传物质,RNA则不是。

()答案:错误解析:DNA和RNA都是生命遗传物质。

7. 寡聚酶一般是指由多个相同亚基组成的酶分子。

()答案:错误解析:8. 两个核酸样品A和B,如果A的OD260OD280大于B的OD260OD280,那么A的纯度大于B的纯度。

()答案:错误解析:核酸样品的纯度可以根据样品的OD260OD280的比值判断,纯的DNA样品OD260OD280=1.8,纯的RNA样品OD260OD280=2.0。

9. 大多数蛋白质的主要带电基团是由它N端的氨基和C端的羧基组成。

()答案:错误解析:蛋白质分子所带的电荷主要来自带电荷班莱班县的侧链基团。

10. 酶的反竞争性抑制作用的特点是Km值变小,Vmax也变小。

()[华中农业大学2017研]答案:正确解析:加入竞争性抑制剂后才,Vmax不变,Km变大;加入非竞争性抑制剂后,Km值不变,Vmax变小;加入反竞争性拮抗剂后,Km及Vmax都变小。

2、名词解释题(25分,每题5分)1. 生物膜的相变温度[暨南大学2019研]答案:相变温度是指由单一类型磷脂构成的脂双层的热吸收曲线峰顶对应的温度。

淀粉的消化:在活体内和体外,描述低聚糖或葡萄糖释放的特征的动力学模型摘要:我们给出了淀粉消化的动力学的概述,强调了体外研究,运用了各种数学模型和来分析数据。

这篇综述的观点是建立在没有凝胶的淀粉上(其中颗粒是完整的,且没有膨胀),适合喂养家畜,作为一些人的食物。

哺乳动物的消化系统用了一个复杂但很有秩序的系列过程来降解和吸收各自日常饮食中的营养物质。

包括咀嚼和搅拌的机械作用贯穿整个肠胃中的每个小分段,还有分泌物中的生物化学成分,包含有酸、缓冲液和水解酶。

为了完成模型的复杂过程,在体外做了许多模拟消化的尝试。

在体外用纯净的酶催化水解(分别简化)的表述已经证明很困难,就像淀粉颗粒复杂的结构导致酶催化作用需要符合不方便的动力学。

用糖水解酶类消化淀粉的敏感性依赖一系列的因素,包括淀粉颗粒的结构,制备的方法,淀粉的天然活性和分子力。

在一个淀粉颗粒中,分支结构,分子大小,分子重量分布和结晶度,可能都会影响淀粉颗粒的物理性质,这些控制消化。

淀粉的特性如溶解度,纤维质、脂肪、蛋白质的存在都影响消化的速率。

关键词:淀粉葡糖甘酶a-淀粉酶淀粉消化水解动力学模型产物抑制作用速消化淀粉淀粉时间可分辨的1H核的磁性共振1.引言淀粉的消化不是一个简单独立的化学过程。

其进程一定程度上可由几个不同的量的来确定。

这几个量因为催化水解所需的酶和发生的反应不同而不同,包括淀粉的分解率以及葡萄糖和各种低聚糖的生成率。

了解影响淀粉水解的因素的最好方式是通过下面的因果相关的机械性的过程,其模式如下:生物合成→产生和加工过程→淀粉和包含淀粉的物质的结构→消化特性。

也就是说,生物合成控制着淀粉的产生及其结构。

其结构由一些变量(Buleon, Colonna, Planchot,&Tang,2009;Smith,2007)(昼夜温度、水的供应等)和糊化等过程决定。

需要注意的是,这些箭头所标示的因果关系不会影响上述过程的进行。

由于某个特殊的植物品种可随机产生更多的快速分解的淀粉,可以看出植物的多样性和快速消化率之间存在一定的相互关系,但这个过程不是随机的(Copeland et al.,2009)。

中国农业大学——生物化学考试试题《生物化学》复习一≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌≌一、填空题1、在电场中蛋白质不迁移的pH叫做。

2、1913年Michaelis和Menten提出与酶促反应速度关系的数学方程式。

即米-曼氏方程式,简称米氏方程式。

3、TPP的中文名称是,其功能部位在噻唑环上。

4、催化果糖-6-磷酸C-1磷酸化的酶是。

5、脂肪酸生物合成的限速反应步骤是由催化的。

6、 CoQ是电子传递链中惟一的组分。

7、增加溶液的离子强度能使某种蛋白质的溶解度增高的现象叫做。

8、tRNA的氨基酸臂上含有特殊的结构。

9、维生素D3是由其前体经紫外线照射转变而成。

10、在糖无氧酵解中,唯一的氧化发生在分子上。

11、尿素循环中产生的鸟氨酸和两种氨基酸不是蛋白质氨基酸。

12、因为核酸分子具有,所以在260nm处有吸收峰,可用紫外分光光度计测定。

13、α-酮戊二酸在大多数转氨酶催化的反应中具有汇集的作用。

14、在哺乳动物体内由8分子乙酰CoA合成1分子的软脂酸,总共需要消耗分子的NADPH。

15、以RNA为模板合成DNA的酶叫作。

16、大多数蛋白质中氮的含量较恒定,平均为 %。

17、核苷酸的主要合成途径为。

19、痛风是因为体内产生过多造成的。

20、黄嘌呤氧化酶既可以使用黄嘌呤又可以使用作为底物。

二、解释概念题1、退火:2、氧化磷酸化:3、脂肪酸的β-氧化:4、转氨基作用:5、磷氧比值(P/O):三、判断题【】1、利用双缩脲反应可以确定蛋白质的水解程度。

【】2、tRNA分子中用符号Ψ表示假尿嘧啶。

【】3、在任何条件下,酶的Km值都是常数。

【】4、生食胡萝卜可以有效地补充维生素A。

【】5、沿糖酵解途径简单逆行,可从丙酮酸等小分子前体物质合成葡萄糖。

【】6.酶的抑制剂可以引起酶活力下降或消失,但并不引起酶变性。

【】7.用双倒数作图法可求出别构酶的Km值。

一、名词解释(共10分,每题1分)1.滞后效应2.改性淀粉3.必需氨基酸(并举一例)4.助氧化剂5.定向酯交换6.蛋白质的二级结构7.维生素原8.生物可利用性9.助色团10.沙氏AH/B生甜团学说二、填空题(共10分,每空0.5分)生变化。

三、判断题(共5分,每题1分)1.水分活度越低,食品的稳定性越好。

2.过氧化值是衡量油脂氧化程度的指标,过氧化值越低,说明油脂氧化程度越低。

3.蛋白质食品经适当热处理后,营养价值提高。

4.纤维素不能被人体消化,故无营养价值。

5.果蔬类食品富含有机酸,故为酸性食品。

四.简答题(共15分,每题3分)1.试从糖的结构说明为何糖具有亲水性?并解释为何很纯并结晶完好的糖完全不吸湿?2.一般化学反应的温度系数Q10仅为1-2,而蛋白质的变性温度系数可达600,为什么?据此说明高温短时灭菌的原理。

3.试述过氧化值并用化学方程式表示碘量法测过氧化值的原理。

4.试述苹果、土豆去皮后变褐的机理,如何抑制褐变?5.米、面精制后,对食品营养价值的影响如何?为什么?五、论述题(10分)一种含油脂12%的甜点,在25℃和相对湿度68%的环境中达到稳定时,试计算这种食品的Aw;若在35℃下保存一个月,试就其稳定性加以讨论。

(Aw的温度系数为0.005/℃)(提示:应全面考虑食品中各种营养素的稳定性)一、名词解释(共20分,每题2分)1.体相水2.麦拉德反应3.必需脂肪酸(并举一例)4.固体脂肪指数(SFI)5.蛋白质的等电点6.强化7.必需元素(并举2例)8.光谱红移9.气味的阈值10.回味(风味回复)二、填空题(共20分,每空0.5分)三、判断题:下列说法完全正确则打√,不完全正确则打×,并写出正确说法。

(共20分,每题0.5~1.5分)1.常压烘干法(105℃)能完全除去结合水。

2.影响食品稳定性的水主要是水分吸附等温线Ⅲ区的水。

3.工业制硬糖一般选转化糖和果葡糖浆。

4.直链淀粉形成的糊比支链淀粉糊稳定。

西安大学生物工程学院2020级《生物化学》 课程试卷(含答案) __________学年第___学期 考试类型:(闭卷)考试 考试时间: 90 分钟 年级专业_____________ 学号_____________ 姓名_____________ 1、判断题(50分,每题5分) 1. 疏水蛋白质的折叠伴随着多肽链熵的增加。( ) 答案:错误 解析:疏水蛋白质翻转时,环境的熵增加,而多肽链的增益是减少的。 2. 具有对底物分子切割功能的都是蛋白质。( ) 答案:错误 解析:已经发现一些RNA具有催化能力,可以催化自我拼接等反应 3. 在氯化铯密度超离心时,下列各组分的沉降速度是RNA>闭环形质粒DNA>开环及线形DNA>蛋白质。( )

答案:正确 解析:

4. Tm是DNA的一个重要特性,其定义为:使DNA双螺旋90解开时所需要的温度。( )[湖南农业大学2015研]

答案:错误 解析:Tm是使DNA双螺旋只须一半解开时所可能需要的温度。 5. HIV蛋白酶与胃蛋白酶一个主要的差别是后者的活性中心位于一个单一的亚基上,而前者的活性中心由两个亚基参与构建。( )

答案:正确 解析:

6. 氧化酶都含有细胞色素。( ) 答案:错误 解析:

7. 杂交双链是指DNA双链分开后两股单链的重新结合。( ) 答案:错误 解析:

8. Ca2+的信使作用必须通过钙调蛋白来完成。( ) 答案:错误 解析:Ca2+的信使作用是通过钙调蛋白来完成的,但也有通过其他蛋白质作用的,比如通过PKC或其他钙离子传感器蛋白(Ca2+sensors)。

9. 脂肪的皂化价高表示含低相对分子质量的脂酸少。( ) 答案:错误 解析:脂肪钙质的皂化价与其相对分子质量成反比,皂化价愈相比高表示含低相对分子质量的脂酸愈多。

10. 激素与靶细胞中特异受体的结合亲和力很高,但大多是一种可逆反应。( )

答案:正确 解析:

2、名词解释题(25分,每题5分) 1. 外肽酶[武汉大学2014研] 答案:外肽酶又称肽链端解酶,或端解酶,是蛋白水解酶几种,可催化多肽链末端肽键水解,游离末端氨基酸。根据其所剪切肽链末端为氨基或羧基端又可分为氨基肽酶和羧基肽酶。此外,还包括催化二肽水解的二肽酶,从多肽链末端剪切二肽的二肽基肽酶。

StarchwithaSlowDigestionPropertyProducedbyAlteringItsChainLength,BranchDensity,andCrystallineStructure

ZIHUAAO,SENAYSIMSEK,GENYIZHANG,MAHESHVENKATACHALAM,BRADLEYL.REUHS,ANDBRUCER.HAMAKER*

WhistlerCenterforCarbohydrateResearchandDepartmentofFoodScience,PurdueUniversity,WestLafayette,Indiana47907-2009

Thehypothesisofincreasingthebranchdensityofstarchtoreduceitsdigestionratethroughpartialshorteningofamylopectinexteriorchainsandthelengthofamylosewasinvestigated.Starchproductspreparedusing-amylase,-amylaseandtransglucosidase,maltogenicR-amylase,andmaltogenicR-amylaseandtransglucosidaseshowedsignificantreductionofrapidlydigestedstarchby14.5%,29.0%,19.8%,and31.0%withaconcomitantincreaseofslowlydigestedstarchby9.0%,19.7%,5.7%,and11.0%,respectively.Theresistantstarchcontentincreasedfrom5.1%to13.5%intreatedstarches.Thetotalcontentsoftheprebioticsisomaltose,isomaltotriose,andpanose(Isomaltooli-gosaccharides)were2.3%and5.5%,respectively,for-amylase/transglucosidase-andmaltogenicR-amylase/transglucosidase-treatedstarches.Themolecularweightdistributionofenzyme-treatedstarchesandtheirdebranchedchainlengthdistributions,analyzedusinghigh-performancesize-exclusionchromatographywithmultianglelaserlightscatteringandrefractiveindexdetection(HPSEC-MALLS-RI)andHPSEC-RI,showeddistinctlydifferentpatternsamongstarcheswithdifferentenzymetreatments.Alargerproportionoflowmolecularweightfractionsappearedinstarchestreatedadditionallywithtransglucosidase.Allenzyme-treatedstarchesshowedamixtureofB-andV-typeX-raydiffractionpatterns,and1HNMRspectrashowedasignificantincreaseofR-1,6linkages.Both

theincreaseofthestarchbranchdensityandthecrystallinestructureinthetreatedstarcheslikelycontributetotheirslowdigestionproperty.

KEYWORDS:Starch;slowdigestionproperty;branchdensity;prebioticfunction;-amylase;maltogenicr-amylase;transglucosidase;1HNMR

INTRODUCTIONStarchisthemainglycemiccarbohydrateinstarchyfoods.Accordingtotherateandextentofstarchdigestioninvitro,starchhasbeenclassifiedintothreemajorfractions(1):(1)rapidlydigestiblestarch,theportionofstarchdigestedwithinthefirst20minofincubation,(2)slowlydigestiblestarch,theportionofstarchdigestedfrom20to120min,and(3)resistantstarch,theremainingportionthatcannotbefurtherdigested.Ahighlysignificantpositivecorrelationbetweentheglycemicindex(GI)andrapidlydigestiblestarchwasreported(2).GIisdefinedastheincrementalareaundertheglucoseresponsecurveafterastandardamountofcarbohydratefromatestfoodisconsumedrelativetothatofacontrolfood(glucoseorwhitebread)(3).ThehumanphysiologicalconsequencesofGIhavebeenrelatedtodiabetes,prediabetes,cardiovasculardisease,andobesity(4).HighGImealspromotedfatdepositioninmice,resultinginalmosttwicethebodyfatofthoseconsuminglowGImeals(5).Inobeseteenagers,therapidabsorptionofglucoseafterconsumptionofhighGImealsinducedasequenceof

hormonalandmetabolicchangesthatwererelatedtoexcessivefoodintake(6).LowGImealsdecreasednonfastingplasmaglucose,plasmatriacylglycerols,andadipocytevolumeinrats(7)andprolongedsatietyinobeseadolescents(8).Starchwithaslowdigestionpropertywouldprovideforextendedglucose(energy)releasealongwithalowglycemicresponseand,thus,mayhavecommercialapplicationasahealthyingredientofprocessedfoods.Therearenocommercialslowlydigestiblestarch-basedproductsavailableinthecurrentfoodmarkettoourknowledge.Itisknownthatstarchiscomposedoftwodistincttypesofmacromolecules:amyloseandamylopectinwithmolecularweightsof104to106and107to108,respectively.Amylose,a

polymerofR-D-glucopyranosylunitsmainlycombinedbyR-1,4linkages,isdefinedasessentiallyalinearmolecularchain.AmylopectinisaverylargebranchedpolymerconsistingoflinearR-1,4-linkedD-glucopyranosylchainsconnectedbyR-1,6branchlinkages,thelattercomprising4.0-5.5%ofthetotallinkages(9).ThechainsofamylopectinaredescribedasA,B,andCchains(10).TheAchainsarelinkedonlythroughtheirreducingterminitoC6ofaglucoseunitofotherchains.TheB

chainsarelinkedinthesameway,buttheBchainhasatleast*Towhomcorrespondenceshouldbeaddressed.Phone:(765)494-

5668.Fax:(765)494-7953.E-mail:hamakerb@purdue.edu.

10.1021/jf063123xCCC:$37.00©xxxxAmericanChemicalSocietyPAGEEST:7.7PublishedonWeb05/08/2007