HXYR-5(空气预热器吹灰器) 说明书(中英文)

- 格式:doc

- 大小:1.15 MB

- 文档页数:27

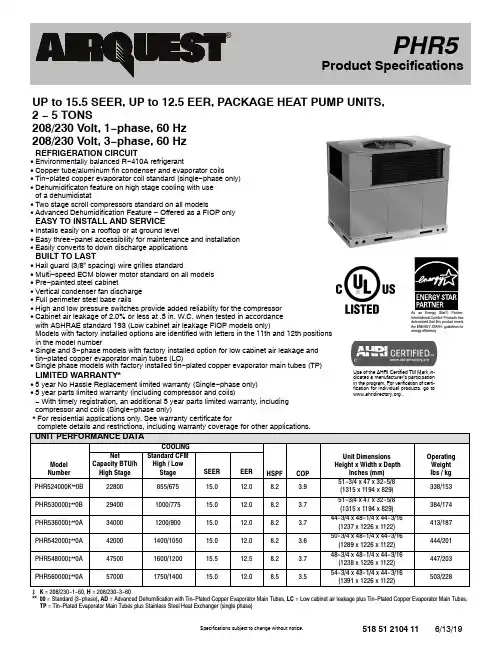

Use of the AHRI Certified TM Mark in-dicates a manufacturer’s participation in the program. For verification of certi-fication for individual products, go to .As an Energy Star ® P artner,International Comfort Products has determined that this product meets the ENERGY STAR ® guidelines for energy efficiency.518 51 2104 11 6/13/19Specifications subject to change without notice.UP to 15.5 SEER, UP to 12.5 EER, PACKAGE HEAT PUMP UNITS, 2 − 5 TONS208/230 Volt, 1−phase, 60 Hz 208/230 Volt, 3−phase, 60 HzREFRIGERATION CIRCUIT•Environmentally balanced R −410A refrigerant•Copper tube/aluminum fin condenser and evaporator coils•Tin −plated copper evaporator coil standard (single −phase only)•Dehumidificaton feature on high stage cooling with use of a dehumidistat•Two stage scroll compressors standard on all models•Advanced Dehumidification Feature − Offered as a FIOP only EASY TO INSTALL AND SERVICE•Installs easily on a rooftop or at ground level•Easy three −panel accessibility for maintenance and installation •Easily converts to down discharge applicationsBUILT TO LAST•Hail guard (3/8” spacing) wire grilles standard•Multi −speed ECM blower motor standard on all models •Pre −painted steel cabinet•Vertical condenser fan discharge •Full perimeter steel base rails•High and low pressure switches provide added reliability for the compressor •Cabinet air leakage of 2.0% or less at .5 in. W.C. when tested in accordance with ASHRAE standard 193 (Low cabinet air leakage FIOP models only)Models with factory installed options are identified with letters in the 11th and 12th positions in the model number•Single and 3−phase models with factory installed option for low cabinet air leakage and tin −plated copper evaporator main tubes (LC)•Single phase models with factory installed tin −plated copper evaporator main tubes (TP)LIMITED WARRANTY*•5 year No Hassle Replacement limited warranty (Single −phase only)•5 year parts limited warranty (including compressor and coils)− With timely registration, an additional 5 year parts limited warranty, including compressor and coils (Single −phase only)* For residential applications only. See warranty certificate forcomplete details and restrictions, including warranty coverage for other applications.UNIT PERFORMANCE DATAModel Number COOLING HSPF COP Unit Dimensions Height x Width x DepthInches (mm)Operating Weight lbs / kg NetCapacity BTU/h High StageStandard CFM High / Low Stage SEER EER PHR524000K**0B 22800855/67515.012.08.2 3.951-3/4 x 47 x 32-5/8(1315 x 1194 x 829)338/153PHR530000‡**0B 294001000/77515.012.08.2 3.751-3/4 x 47 x 32-5/8(1315 x 1194 x 829)384/174PHR536000‡**0A 340001200/90015.012.08.2 3.744-3/4 x 48-1/4 x 44-3/16(1237 x 1226 x 1122)413/187PHR542000‡**0A 420001400/105015.012.08.2 3.650-3/4 x 48-1/4 x 44-3/16(1289 x 1226 x 1122)444/201PHR548000‡**0A 475001600/120015.512.58.2 3.748-3/4 x 48-1/4 x 44-3/16(1238 x 1226 x 1122)447/203PHR560000‡**0A570001750/140015.012.08.53.554-3/4 x 48-1/4 x 44-3/16(1391 x 1226 x 1122)503/228‡K = 208/230-1-60, H = 208/230-3-60**00 = Standard (3-phase), AD = Advanced Dehumification with Tin-Plated Copper Evaporator Main Tubes, LC = Low cabinet air leakage plus Tin-Plated Copper Evaporator Main Tubes, TP = Tin-Plated Evaporator Main Tubes plus Stainless Steel Heat Exchanger (single phase)MODEL NOMENCLATUREMODEL SERIES 123,45,67,8,91011,12131415 P H R536000K000 A or B1P = PackageH = Heat PumpR5 = Mainline TIER24 = 24,000 BTUH = 2 Tons30 = 30,000 BTUH = 2.5 Tons36 = 36,000 BTUH = 3 Tons42 = 42,000 BTUH = 3.5 Tons48 = 48,000 BTUH = 4 Tons60 = 60,000 BTUH = 5 Tons NOMINAL CLG CAPACITY000 = no factory heat NOMINAL HTG BTUH (input)K = 208/230−1−60H = 208/230−3−60VOLTAGE00 = No optionsAD = Advanced Dehumidification plus Tin−Plated Copper Evap Main TubesLC = Low Cabinet Air Leakage plus Tin−Plated Copper Evap Main TubesTP = Tin−Plated Evaporator Main Tubes FACTORY INSTALLED OPTIONS0 = Standard FEATURE CODESales Model DigitEngineering DigitUNIT SPECIFICATIONSUNIT SIZE243036424860 NOMINAL CAPACITY (ton)22-1/233-1/245SHIPPING WEIGHT lb. SHIPPING WEIGHT (kg)347157393178420191466212462210511232COMPRESSORS Quantity Scroll 1REFRIGERANT (R-410A)Quantity lb Quantity (kg)8.23.711.25.111.05.014.66.612.05.414.86.7REFRIGERANT METERING DEVICE TXV, Indoor TXV ORIFICE - OUTDOOR COILID (in.) ID (mm).032 (2)0.81 (2).035 (1) .038 (1).89 (1) .97 (1).042 (2)1.07 (2).042 (2)1.07 (2).042 (2)1.07 (2).052 (2)1.32 (2)OUTDOOR COILRows...Fins/in. Face Area (sq ft)1 (21)18.82 (21)18.82 (21)13.62 (21)19.42 (21)17.52 (21)23.3OUTDOOR FANNominal Cfm Diameter in.Diameter (mm) Motor Hp (Rpm)210024609.61/12 (800)250024609.61/8 (810)300026660.41/5 (810)300026660.41/5 (810)330026660.41/5 (810)360026660.41/5 (810)INDOOR COILRows...Fins/in. Face Area (sq ft)3 (17)3.73 (17)3.73 (17)4.73 (17)4.73 (17)5.74 (17)5.7INDOOR BLOWERNominal Low Stage Cooling Airflow(Cfm)Nominal High Stage Cooling Airflow(Cfm)Size in.Size (mm.)Motor HP (RPM)67585510x10254x2541/2 (1050)775100010x10254x2541/2 (1050)900120011x10279.4x2543/4 (1000)1050140011x10279.4x2543/4 (1075)1200160011x10279.4x2541.0 (1075)1400175011x10279.4x2541.0 (1075)HIGH−PRESSURE SWITCH (psig) Cut−out Reset (Auto)650 +/− 15 420 +/− 25LOW−PRESSURE SWITCH (psig) cut−out Reset (auto)20 +/− 5 45 +/− 5RETURN-AIR FILTERS†}Throwaway Size in. Throwaway Size (mm)20x20x1508x508x2520x24x1508x610x2524x30x1610x762x2524x36x1610x914x25{ Required filter sizes shown are based on the larger of the AHRI (Air Condi-tioning Heating and Refrigeration Institute) rated cooling airflow or the heatingairflow velocity of 300 ft/minute for throwaway type or 450 ft/minute for high−ca-pacity type. Air filter pressure drop for non−standard filters must not exceed 0.08in. W.C.}If using accessory filter rack refer to the filter rack installation instructions forcorrect filter sizes and quantity.2518 51 2104 11Specifications subject to change without notice.A−WEIGHTED SOUND POWER LEVEL (dBA)Model PHR5Sound Ratings (dBA)TYPICAL OCTAVE BAND SPECTRUM (dBA without tone adjustment) 1252505001000200040008000246877656563575248 306970666765585654 36736463.5686865.560.552.5 42716462656663.559.552.5 487459.565706764.560.552.5 6073686366666559.552.5 NOTE: Tested in accordance with AHRI Standard 270−1995 (not listed in AHRI).OPTIONS AND ACCESSORIESITEM DESCRIPTIONFACTORYINSTALLEDOPTIONFIELDINSTALLEDACCESSORYCoil Options Base unit with tin plated indoor coil hairpins XCompressor Start Kit Compressor Start Kit assists compressor start−up by providing additional starting torque onsing phase units only.XCorporate Thermostats Thermostats provide control for the system heating, cooling and dehumidication functions.X Crankcase Heater Crankcase Heater provides anti−floodback protection for low−load cooling applications.XEconomizerVertical Economizer with solid state controls and barometric relief dampers includes filterracks and provide outdoor air during cooling and reduce compressor operation.X Horizontal Economizer with solid state controls and barometric relief dampers includes filterracks and provide outdoor air during cooling and reduce compressor operation.XElectric Heaters Electric Heat Supplement XFilter Rack Filter Rack features easy installation, serviceability, and high−filtering performance forvertical applications. Includes 1−in. filter.X XFlat Roof Curb14−in. (356 mm) Flat Roof Curb is available for roof mounted applications.XLow Ambient Kit Low Ambient Kit (Motormaster II Control) allows the use of mechanical cooling down tooutdoor temperatures as low as 0°F (−18C) when properly installed.XManual Outside Air Damper Manual Outside Air Damper includes hood and filter rack with adjustable damper blade forup to 25% outdoor air.XSquare−to−Round Duct Transition Kit Square−to−Round Duct Transition Kit enable 24−48 size units to be fitted to 14 in (356mm). round ductwork.XLow Cabinet Air Leakage Cabinet air leakage of 2.0% or less at .5 in. W.C. when tested in accordance with ASHRAEstandard 193.XDual Point Electric Heaters Allows you to power the electric heater and unit contactor separately by having two indi-vidual field power supply circuits connected respectively.XAdvanced DehumidificationPackage Standard unit with tin plated indoor coil hairpins and a dedicated DEHUM features thatenables owner controlled dehumidification..XSpecifications subject to change without notice.518 51 2104 113UNIT AIRFLOW − DRY COIL AIR DELIVERY* − HORIZONTAL AND DOWNFLOW DISCHARGE WITHOUT ADVANCED DEHUMIDIFICATION (AD) FIOPUNIT PHR5MOTORSPEEDWIRECOLOREXTERNAL STATIC PRESSURE (IN. W.C.)0.10.20.30.40.50.60.70.80.9 1.0PHR524Low1BlueCFM777692583465318---------------BHP0.090.100.100.110.12---------------Med-Low PinkCFM877779698598519410------------BHP0.120.120.130.140.150.15------------Medium2RedCFM904841769705628522372---------BHP0.160.170.170.180.190.190.20---------Med-High OrangeCFM1229117111051049980913838775679516BHP0.280.300.300.310.320.330.330.340.340.33 High BlackCFM12911206114210811017951888823753668BHP0.310.320.330.340.340.350.360.360.370.37PHR530Low BlueCFM777692583465318---------------BHP0.090.100.100.110.12---------------Med-Low1PinkCFM831765670586466299------------BHP0.110.120.120.130.130.14------------Medium2RedCFM113910691012937870786724626512381BHP0.220.230.240.240.250.260.260.270.270.28 Med-High OrangeCFM1229117111051049980913838775679516BHP0.280.300.300.310.320.330.330.340.340.33 High BlackCFM1531146013821301120911141003890764629BHP0.530.520.500.480.460.440.420.400.370.35PHR536Low BlueCFM1097971823747669636558513456412BHP0.120.110.100.110.120.130.130.140.150.16 Med-Low1PinkCFM934864810745698649571525486428BHP0.100.100.110.120.130.140.140.150.160.17 Medium2RedCFM125111981149110410661017970932892839BHP0.190.210.210.230.240.250.260.270.280.29 Med-High OrangeCFM1451141513721327128712491212116811301094BHP0.290.300.310.32248.590.350.360.370.380.39 High BlackCFM1466142313841343130812631219118311451106BHP0.300.310.330.340.350.360.370.380.400.41PHR542Low BlueCFM1097971823747669636558513456412BHP0.120.110.100.110.120.130.130.140.150.16 Med-Low1PinkCFM10761026972918872827771714666611BHP0.130.140.150.150.170.180.180.200.210.22 Medium RedCFM125111981149110410661017970932892839BHP0.190.210.210.230.240.250.260.270.280.29 Med-High2OrangeCFM1451141513721327128712491212116811301094BHP0.290.300.310.32248.590.350.360.370.380.39 High BlackCFM1633159015521518148314441406137213401303BHP0.410.430.440.450.470.480.490.500.510.53PHR548Low1BlueCFM127112291177112110661027974942887839BHP0.190.200.210.230.240.250.260.270.280.29 Med-Low PinkCFM13401299124011911139109110501001952895BHP0.220.230.240.250.260.280.290.300.310.32 Medium2RedCFM1686165016171576154415031468143313931356BHP0.420.440.450.460.480.490.510.520.530.55 Med-High OrangeCFM1854183717811784172016981655162515781532BHP0.560.570.600.590.620.630.640.660.670.67 High BlackCFM1934190018551815177817371695165616061528BHP0.590.610.620.640.650.670.680.700.700.68PHR560Low BlueCFM11821137110210531012966920868830783BHP0.210.220.230.240.250.260.270.280.300.31 Med-Low1PinkCFM1454140513641316128112341198114711051056BHP0.340.350.360.370.380.400.410.420.430.45 Medium2RedCFM1818177017311693165716211579154615051436BHP0.560.570.590.600.620.630.640.660.670.66 Med-High OrangeCFM1881184918181793176317291679161015231479BHP0.670.690.700.710.720.730.730.710.680.65 High BlackCFM2138208420251967189318291754167815911475BHP0.980.950.930.900.860.840.800.760.740.68* Air delivery values are without air filter and are for dry coil (See PHR5−A WetCoil Pressure Drop table).1 Factory−shipped low stage cooling speed.2 Factory−shipped high stage cooling speed.Note: Deduct field−supplied air filter pressure drop and wet coil pressure drop toobtain external static pressure available for ducting.Shaded areas indicate acceptable Dehum. Speeds (Dehum. Mode is High Stage Only, 208/230 VAC Models Only).4518 51 2104 11Specifications subject to change without notice.UNIT AIRFLOW − DRY COIL AIR DELIVERY − HORIZONTAL AND DOWNFLOW DISCHARGE WITH ADVANCED DEHUMIDIFICATION (AD) FIOPUNIT SIZECFM ADJUSTPIN SELECT LO PIN NOM PIN HI PIN EXTERNAL STATICPRESSURE RANGE0.0 − 0.390.4 − 0.690.7 − 1.00.0 − 0.390.4 − 0.690.7 − 1.00.0 − 0.390.4 − 0.690.7 − 1.0PHR524000KAD0B1HIGHSTAGECOOLING770795790855885875940975965 COOLING WITHDEHUMIDIFY610615570675685635745755700LOWSTAGECOOLING610610570675680635745750700 COOLING WITHDEHUMIDIFY475470360530520401585570440PHR530000KAD0B1HIGHSTAGECOOLING905935935100510401040110511451145 COOLING WITHDEHUMIDIFY715740725795820803875900885LOWSTAGECOOLING715740730795820810875900890 COOLING WITHDEHUMIDIFY555555485615615540675675595PHR536000KAD0A1HIGHSTAGECOOLING106011001095117512201215129513401335 COOLING WITHDEHUMIDIFY845880875940975970103510751065LOWSTAGECOOLING835850845930945940102510401035 COOLING WITHDEHUMIDIFY675685670750760745825835820PHR542000KAD0A1HIGHSTAGECOOLING124012651275137514051414151515451555 COOLING WITHDEHUMIDIFY101010401015112011551125123012701240LOWSTAGECOOLING970975965107510851070118511951175 COOLING WITHDEHUMIDIFY785790790870880875955970965PHR548000KAD0A1HIGHSTAGECOOLING144514501445160516101605176517701765 COOLING WITHDEHUMIDIFY115511701255128513001395141514301535LOWSTAGECOOLING109511051095121512251215133513501335 COOLING WITHDEHUMIDIFY880890875975990970107510901065PHR560000KAD0A1HIGHSTAGECOOLING156515701555174017451725191519201900 COOLING WITHDEHUMIDIFY127012801280141014241420155015651560LOWSTAGECOOLING125012651260139014051400153015451540 COOLING WITHDEHUMIDIFY101510151015112511301125124012451240NOTE:Field−supplied air filter and wet coil pressure drop will minimally affect air delivery values.Continuous Fan CFM is 50% of High Stage Cooling Airflow.WET COIL PRESSURE DROP (IN. W.C.)Unit SizeStandard CFM (SCFM) 6007008009001000110012001300140015001600170018001900200021002200240.030.040.050.060.07300.060.070.070.080.09360.060.070.080.090.100.11420.070.080.090.100.110.110.120.12480.030.040.080.080.100.110.140.150.16 600.080.100.110.140.150.160.16 ECONOMIZER WITH 1−IN. FILTER PRESSURE DROP (IN. W.C.)Filter Size in. (mm)ClgTonsStandard CFM (SCFM) 6007008009001000110012001300140015001600170018001900200021002200600−1400CFM12x20x1+12x20x1 (305x508x25+305x508x25)2.0,2.5−−0.090.140.160.180.250.280.3−−−−−−−−1200−1800 CFM16x24x1+14x24x1 (406x610x25+356x610x25)3.0,3.5−−−−−−0.100.110.120.130.140.160.16−−−−1500−2200 CFM 16x24x1+18x24x1 (406x610x25+457x610x25)4.05.0−−−−−−−−−0.150.170.180.200.210.220.230.23Specifications subject to change without notice.518 51 2104 115FILTER PRESSURE DROP TABLE (IN. W.C.)Filter Size in. (mm)ClgTonsStandard CFM (SCFM) 6007008009001000110012001300140015001600170018001900200021002200600−1400CFM12x20x1+12x20x1 (305x508x25+305x508x25)2.0,2.50.030.050.060.080.100.110.130.140.16−−−−−−−−1200−1800 CFM16x24x1+14x24x1 (406x610x25+356x610x25)3.0,3.5−−−−−−0.070.080.090.090.100.110.12−−−−1500−2200 CFM 16x24x1+18x24x1 (406x610x25+457x610x25)4.05.0−−−−−−−−−0.040.060.080.100.110.130.140.15ELECTRIC HEAT PRESSURE DROP TABLES (IN. W.C.)Small Cabinet: 24−30STATICSTANDARD CFM (SCFM) 50060070080090010001100120013001400150016005 kW0.000.000.000.000.000.000.000.000.020.040.060.07 10 kW0.000.000.000.000.000.020.040.060.070.090.100.11 15 kW0.000.000.000.020.040.060.080.100.120.140.160.18 20 kW0.000.000.020.040.060.080.090.110.130.150.170.19LARGE CABINET: 36−60STATICSTANDARD CFM (SCFM) 1100120013001400150016001700180019002000210022002300240025005 kW0.000.000.000.010.020.030.040.050.060.070.080.090.100.110.12 10 kW0.000.000.010.020.030.040.050.060.070.080.090.100.110.120.13 15 kW0.000.020.030.040.050.060.070.080.090.100.110.120.130.140.15 20 kW0.020.030.040.050.060.070.080.090.100.110.120.130.140.150.16 MINIMUM AIRFLOW FOR SAFE ELECTRIC HEATER OPERATION (CFM)SIZE243036424860 Cfm85010001200140016001750 MULTIPLICATION FACTORSHEATER kW RATING VOLTAGE DISTRIBUTION V/3/60MULTIPLICATION FACTOR2402002082302400.690.750.921.006518 51 2104 11Specifications subject to change without notice.ELECTRICAL DATA − WITHOUT ADVANCED DEHUMIDIFICATION (AD) FIOPUNIT NOMINAL VOLTAGE RANGE COMPRESSOR OFM IFMELECTRIC HEAT POWER SUPPLYNOMINALkW FLA MCA MOCP MIN MAX RLA LRA FLA FLAPHR524000K208/230-1-6019725311.758.30.6 4.1-/--/-19.330 3.8/518.1/20.842/45.345/50 5.4/7.225.9/3051.7/56.860/60 7.5/1036.1/41.764.5/71.570/80PHR530000K208/230-1-6019725313.473.00.9 4.1-/--/-21.830 3.8/518.1/20.844.4/47.545/50 5.4/7.225.9/3054.1/59.360/60 7.5/1036.1/41.766.9/73.970/80 11.3/1554.2/62.589.5/99.990/100PHR530000H208/230-3-601972539.058.00.9 4.1-/--/-16.320 3.8/510.4/1229.3/31.330/35 7.5/1020.8/24.142.3/46.445/50 11.3/1531.2/36.155.3/61.460/70PHR536000K208/230-1-6019725315.383.0 1.2 6.0-/--/-26.340 3.8/518.1/20.849/52.350/60 5.4/7.225.9/3058.7/63.860/70 7.5/1036.1/41.771.5/78.580/80 11.3/1554.2/62.594.1/104.5100/110PHR536000H208/230-3-6019725311.673.0 1.2 6.0-/--/-21.730 3.8/510.4/1234.7/36.735/40 7.5/1020.8/24.147.7/51.850/60 11.3/1531.2/36.160.7/66.870/70PHR542000K208/230-1-6019725320.496.0 1.2 6.0-/--/-32.745 3.8/518.1/20.855.3/58.760/60 5.4/7.225.9/3065.1/70.270/80 7.5/1036.1/41.777.8/84.880/90 11.3/1554.2/62.5100.5/110.8110/125 15/2072.2/83.3123/136.8125/150PHR542000H208/230-3-6019725314.288.0 1.2 6.0-/--/-2535 3.8/510.4/1238/4040/40 7.5/1020.8/24.151/55.160/60 11.3/1531.2/36.164/70.170/80 15/2041.4/47.976.7/84.880/90PHR548000K208/230-1-6019725321.2104.0 1.27.6-/--/-35.350 3.8/518.1/20.857.9/61.360/70 5.4/7.225.9/3067.7/72.870/80 7.5/1036.1/41.780.4/87.490/90 11.3/1554.2/62.5103.1/113.4110/125 15/2072.2/83.3125.6/139.4150/150PHR548000H208/230-3-6019725314.083.1 1.27.6-/--/-26.340 3.8/510.4/1239.3/41.340/45 7.5/1020.8/24.152.3/56.460/60 11.3/1531.2/36.165.3/71.470/80 15/2041.4/47.978.1/86.280/90PHR560000K208/230-1-6019725328.8152.9 1.27.6-/--/-44.860 3.8/518.1/20.867.4/70.870/80 5.4/7.225.9/3077.2/82.380/90 7.5/1036.1/41.789.9/96.990/100 11.3/1554.2/62.5112.6/122.9125/125 15/2072.2/83.3135.1/148.9150/150PHR560000H208/230-3-6019725316.2110.0 1.27.6-/--/-29.140 3.8/510.4/1242.1/44.145/45 7.5/1020.8/24.155.1/59.260/60 11.3/1531.2/36.168.1/74.270/80 15/2041.4/47.980.8/88.990/90LEGENDFLA= Full Load AmpsLRA = Locked Rotor AmpsMCA= Minimum Circuit AmpacityMOCP= Maximum Overcurrent ProtectionRLA =Rated Load AmpsSpecifications subject to change without notice.518 51 2104 117ELECTRICAL DATA − WITH ADVANCED DEHUMIDIFICATION (AD) FIOPUNIT NOMINALVOLTAGERANGE COMPRESSOR OFM IFMELECTRIC HEAT POWER SUPPLYNOMINALkW FLA MCA MOCP MIN MAX RLA LRA FLA FLAPHR524000KAD0B1208/230−1−6019725311.758.30.67.7−/−−/−19.530 3.8/518.1/20.842/45.545/50 5.4/7.225.9/3051.9/5760/60 7.5/1036.1/41.764.7/71.770/80PHR530000KAD0B1208/230−1−6019725313.4730.97.7−/−−/−2230 3.8/518.1/20.844.6/4845/50 5.4/7.225.9/3054.3/59.560/60 7.5/1036.1/41.767.1/74.170/80 11.3/1554.2/62.589.7/100.190/110PHR536000KAD0A1208/230−1−6019725315.383 1.29.6−/−−/−27.140 3.8/518.1/20.849.8/53.150/60 5.4/7.225.9/3059.5/64.660/70 7.5/1036.1/41.772.3/79.380/80 11.3/1554.2/62.594.9/105.3100/110PHR542000KAD0A1208/230−1−6019725320.496 1.29.6−/−−/−33.545 3.8/518.1/20.856.1/59.560/60 5.4/7.225.9/3065.9/7170/80 7.5/1036.1/41.778.6/85.680/90 11.3/1554.2/62.5101.3/111.6110/125 15/2072.2/83.3123.8/137.6125/150PHR548000KAD0A1208/230−1−6019725321.2104 1.212.8−/−−/−36.850 3.8/518.1/20.859.4/62.860/70 5.4/7.225.9/3069.2/74.370/80 7.5/1036.1/41.781.9/88.990/90 11.3/1554.2/62.5104.6/114.9110/125 15/2072.2/83.3127.1/140.9150/150PHR560000KAD0A1208/230−1−6019725328.8152.9 1.212.8−/−−/−46.360 3.8/518.1/20.868.9/72.370/80 5.4/7.225.9/3078.7/83.880/90 7.5/1036.1/41.791.4/98.4100/100 11.3/1554.2/62.5114.1/124.4125/125 15/2072.2/83.3136.6/150.4150/175LEGENDFLA= Full Load AmpsLRA = Locked Rotor AmpsMCA= Minimum Circuit AmpacityMOCP= Maximum Overcurrent ProtectionRLA =Rated Load Amps8518 51 2104 11Specifications subject to change without notice.A06564 AHRI* CAPACITIESCOOLING CAPACITIES AND EFFICIENCIESUnit Model NominalTonsStandard CFM(High / Low Stage)Net CoolingCapacities - Btuh(High Stage)EER @A**SEER†242855 / 67522,80012.015.0 302-1/21000 / 77529,40012.015.0 3631200 / 90034,00012.015.0 423-1/21400 / 105042,00012.015.0 4841600 / 120047,50012.515.5 6051750 / 140057,00012.015.0LEGENDdB−Sound Levels (decibels)db—Dry BulbSEER—Seasonal Energy Efficiency Ratiowb—Wet BulbCOP−Coefficient of Performance* Air Conditioning, Heating & Refrigeration Institute.**At “A” conditions−80_F (26.7_C) indoor db/67_F (19.4_C) indoor wb & 95_F (35_C) outdoor db.{ Rated in accordance with U.S. Government DOE Department of Energy test procedures and/or AHRI Standards 210/240.Notes:1. Ratings are net values, reflecting the effects of circulating fan heat.Ratings are based on:Cooling Standard: 80°F (26.7_C) db, 67°F wb (19.4_C) indoor entering−air temperature and 95°F db (35_C) outdoor entering−air temperature.2. Before purchasing this appliance, read important energy cost and efficiency information available from AHRI .Unit Model Heating Capacity(BTUH) @ 47_F(8.3_C)COP @ 47_F(8.3_C)Heating Capacity(BTUH) @ 17_F(8.3_C)COP @ 17_F(8.3_C)HSPF Heating Cd2423,400 3.912,200 2.38.20.25 3030,000 3.716,200 2.38.20.25 3634,000 3.717,200 2.38.20.25 4242,000 3.624,000 2.58.20.25 4847,500 3.726,000 2.38.20.25 6057,000 3.532,400 2.48.50.25Specifications subject to change without notice.518 51 2104 119Specifications subject to change without notice.518 51 2104 1110P H R 524 E X T E N D E D C O O L I N G P E R F O R M A N C E − L O W C O O LC O NDE N S E R E N T E R I N G A I R T E M P E R A T U R E S d e gF , D r y B u l b 75 (23.8_C )85 (29.4_C )95 (35_C )105 (40.5_C )115 (46.1_C )E N T E R I N G I N D O O R T E M P E R A T U R E − d e gF , W e t B u l b C F M 576263††6772576263††6772576263††6772576263††6772576263††6772525M B h †18.1518.6118.9420.3222.2317.6517.9318.2519.5521.3816.9517.0417.3718.6320.3816.0016.0316.1717.5519.2714.9815.0014.8616.2218.06S /T ‡1.000.940.750.720.531.000.960.760.740.541.000.990.780.760.551.001.000.800.780.561.001.000.840.810.57A M P S *4.594.584.574.544.505.185.185.175.155.125.855.855.845.845.826.626.626.626.616.627.517.517.527.507.51H I P R 268269270273278310311311315321355355356361367405405406410418462462461466472L O P R 130133134143154135137138147158140141143152163145145146156168150150148159173675M B h †19.6419.8519.7621.2023.1719.0419.0718.9820.3322.2218.2818.3118.0119.3121.1117.3617.3816.8018.1419.9116.2416.2715.4216.7918.61S /T ‡1.000.950.810.790.571.001.000.840.810.581.001.000.860.840.591.001.000.890.870.611.001.000.940.910.63A M P S *4.614.614.614.584.535.225.215.225.195.155.905.905.905.885.876.676.676.676.676.677.577.577.587.567.58H I P R 271272272275280314314313317323360360359363369410410408413420466466463468474L O P R 140141140149160145145144153164150150148157169155156151161173160160153164178700M B h †19.8520.1119.8621.3223.2919.2319.2619.0720.4422.3318.4618.4918.0919.3921.2017.5417.5616.8818.2219.9816.4116.4415.4916.8718.68S /T ‡1.000.930.830.800.571.001.000.850.820.591.001.000.880.850.601.001.000.910.890.621.001.000.950.920.64A M P S *4.624.614.624.584.545.225.225.225.205.165.905.905.915.895.876.686.686.686.686.687.587.587.597.577.59H I P R 272273272275280314314314318323361361359364369411411408413420466467464468475L O P R 141143141150161146146144154165151152148158170157157152162174162162154165178P H R 524 E X T E N D E D C O O L I N G P E R F O R M A N C E − H I G H C O O LC O NDE N S E R E N T E R I N G A I R T E M P E R A T U R E S d e gF , D r y B u l b 75 (23.8_C )85 (29.4_C )95 (35_C )105 (40.5_C )115 (46.1_C )C F ME N T E R I N G I N D O O R T E M P E R A T U R E − d e gF , W e t B u l b 576263††6772576263††6772576263††6772576263††6772576263††6772700M B h †21.4922.1622.5224.1726.4120.8821.3421.7023.2725.4320.1720.4220.7622.2624.3519.3419.3919.7221.1623.1618.3518.3818.4719.9421.88S /T ‡1.000.910.730.710.521.000.930.750.720.531.000.960.760.740.541.001.000.780.760.551.001.000.800.780.56A M P S *6.616.646.666.736.827.317.337.357.427.528.108.118.138.218.329.029.029.039.139.2510.1310.1310.1310.2310.36H I P R 287288289294300331332333339345379380381387394432432433440448490490491497506L O P R 125129131140151130132134143155134136138147159139140141150162144144144154166855M B h †22.8723.0523.3225.0127.3122.1822.2122.4024.0226.2421.3821.4221.4022.9325.0620.4920.5220.2621.7323.7919.4619.4818.9720.4322.43S /T ‡1.000.970.780.750.551.001.000.800.770.561.001.000.820.790.571.001.000.840.820.581.001.000.870.850.60A M P S *6.756.766.776.846.937.457.457.467.537.638.248.248.248.328.429.179.179.159.249.3610.2810.2810.2410.3410.46H I P R 290291292296302335335335341347384384383389397437437436442450495495493499508L O P R 134134135145156138138139148160142142142151163147147145155167152152148158171900M B h †23.2723.6323.5325.2427.5522.5522.5822.5924.2226.4521.7321.7621.5623.1125.2520.8120.8420.4121.9023.9419.7619.7919.1020.5722.57S /T ‡1.000.940.790.770.561.001.000.810.790.571.001.000.840.810.581.001.000.860.840.591.001.000.890.870.61A M P S *6.806.816.816.886.977.497.497.497.577.668.298.298.278.358.469.219.229.189.289.3910.3210.3210.2810.3710.50H I P R 291292292297303336336336341348385385384390397438438436443451497497494500509L O P R 136138137146158140140140149161145145143152165149149146156168154154149159172S e e L e g e n d a n d N o t e s o n P a g e 15.。

吹灰器操作说明1.吹灰器控制箱指示灯显示说明:(1)各吹灰器正常运行指示为相应台数绿色指示(2)吹灰器限位故障指示为相应台数脉冲闪烁红色指示(3)吹灰器运行超时故障为相应台数红色常亮指示和故障指示灯红色显示(4)吹灰器运行过载故障为相应台数红色常亮指示;故障指示灯红色显示,报警电铃工作(5)当正常吹灰时,蒸汽温度或者压力低于设定值,相应指示为绿色脉冲显示。

2.吹灰器控制箱操作流程首先旋动三相检测旋钮,检查三相电源是否正常,若正常按下电源启动按钮相应电源指示灯亮,然后按下试灯按钮检查各指示灯是否正常,(试灯指示为3秒)各步骤操作完毕后等待下一步操作。

连锁开关在断开位置:连锁开关在断开位置时,吹灰器和蒸汽保证系统之间没有连锁,即蒸汽温度和压力不连锁到吹灰器运行过程,保证系统的三个阀门可以单独动作,需要启动哪个就启动那个。

(1)手动运行过程:按下手动启停按钮相应手动指示灯亮,按下需要运行吹灰器的启动按钮,吹灰器开始运行。

(2)自动运行过程:按下自动按钮相应指示灯亮,吹灰器按着程序一台台运行下去,(3)退出运行过程:若有的吹灰器由于某种原因不需要运行,可以对此或多台吹灰器进行退出系统运行。

过程为:吹灰器控制上手动和自动都没有运行,按下退出按钮相应指示灯亮。

然后按下不需要运行的吹灰器按钮对应的红色指示灯亮。

在吹灰器正常运行自动的状态下系统会直接跳过退出的吹灰器(1)消警复位:吹灰器设置了多项保护措施:运行超时、电机过载、限位故障。

可以对上述描述的故障进行复位,假如按下消警复位后对应吹灰器显示灯为脉冲闪烁。

说明吹灰器本体上的限位没有完全脱开,这一问题表示吹灰器本体上阀门没有关闭,或者限位没有自行复位,消除这一问题可以通过下面操作对其进行复位操作:吹灰器控制箱的手动和自动都关闭,按住对应此故障显示的吹灰器,吹灰气就会工作自动退回起始位置。

等吹灰器到达位置后自动停止,按下消警复位按钮闪烁指示灭。

连锁开关在连锁位置:连锁开关在连锁位置时,不管是手动运行或者自动运行,蒸汽保证系统首先自动运行。

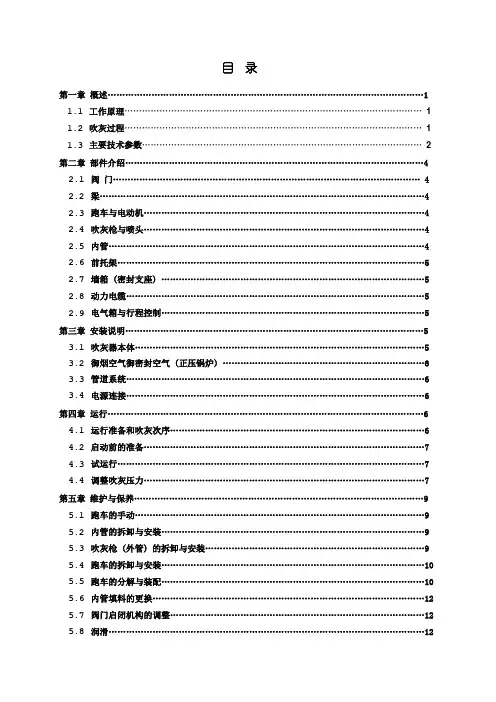

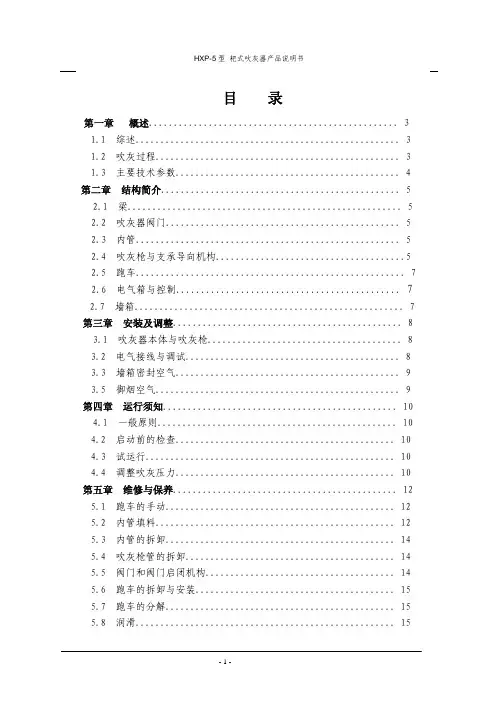

目录第一章概述 (1)1.1工作原理 (1)1.2吹灰过程 (1)1.3主要技术参数 (2)第二章部件介绍 (4)2.1阀门 (4)2.2梁 (4)2.3跑车与电动机 (4)2.4吹灰枪与喷头 (4)2.5内管 (4)2.6前托架 (5)2.7墙箱(密封支座) (5)2.8动力电缆 (5)2.9电气箱与行程控制 (5)第三章安装说明 (5)3.1吹灰器本体 (5)3.2御烟空气御密封空气(正压锅炉) (6)3.3管道系统 (6)3.4电源连接 (6)第四章运行 (6)4.1运行准备和吹灰次序 (6)4.2启动前的准备 (7)4.3试运行 (7)4.4调整吹灰压力 (7)第五章维护与保养 (9)5.1跑车的手动 (9)5.2内管的拆卸与安装 (9)5.3吹灰枪(外管)的拆卸与安装 (9)5.4跑车的拆卸与安装 (10)5.5跑车的分解与装配 (10)5.6内管填料的更换 (12)5.7阀门启闭机构的调整 (12)5.8润滑 (12)第一章概述HXC-5型长伸缩吹灰器(图1)利用蒸汽或压缩空气吹扫锅炉受热面--主要是过热器,再热器及省煤器上的积灰和结渣,也可用来清除炉顶和管式空气预热器的积灰,以提高锅炉热效率,保证锅炉满负荷,长周期安全正常运行。

1.1 工作原理从伸缩旋转的吹灰枪端部的喷嘴(一般是两个)中,喷出压缩空气或蒸汽持续冲击、吹扫,清除掉受热面的积灰和结渣是本吹灰器的工作原理。

每个喷嘴的运动轨迹是一条螺旋线(图3),螺旋线的导程,由吹灰器行程和吹灰要求决定(本吹灰器的基本导程约100mm)。

图3 喷嘴吹扫轨迹图1.2吹灰过程吹灰器停用时,除枪管上的喷头部分在炉墙保护套里外,其余部分均在炉墙之外,电动机和跑车位于靠近阀门的终止位臵。

电源接通后,电机驱动跑车沿着箱式梁的两侧的导轨向前运动,吹灰枪一边旋转一边进入炉内,当吹灰枪进入炉内一定距离后,跑车上的撞销拨动阀门开启机构,打开阀门,吹灰开始;跑车继续前进,将吹灰枪旋进炉膛,当跑车前进到最前端(行程终点)时,前行程开关动作,电动机反转,跑车带动反向旋转的枪管以与前进时不同的吹灰轨迹后退,退至喷嘴接近炉墙时,跑车上的撞销关闭阀门,吹灰停止。

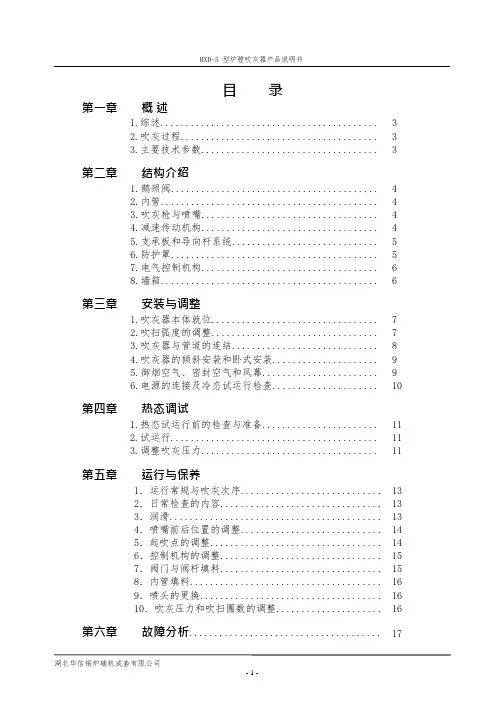

第一章目录概述1.综述 (3)2.吹灰过程 (3)3.主要技术参数 (3)第二章结构介绍1.鹅颈阀 (4)2.内管 (4)3.吹灰枪与喷嘴 (4)4.减速传动机构 (4)5.支承板和导向杆系统 (5)6.防护罩 (5)7.电气控制机构 (6)8.墙箱 (6)第三章安装与调整1.吹灰器本体就位 (7)2.吹扫弧度的调整 (7)3.吹灰器与管道的连结 (8)4.吹灰器的倾斜安装和卧式安装 (9)5.御烟空气、密封空气和风幕 (9)6.电源的连接及冷态试运行检查 (10)第四章热态调试1.热态试运行前的检查与准备 (11)2.试运行 (11)3.调整吹灰压力 (11)第五章运行与保养1.运行常规与吹灰次序 (13)2.日常检查的内容 (13)3.润滑 (13)4.喷嘴前后位置的调整 (14)5.起吹点的调整 (14)6.控制机构的调整 (15)7.阀门与阀杆填料 (15)8.内管填料 (16)9.喷头的更换 (16)10.吹灰压力和吹扫圈数的调整 (16)第六章故障分析 (17)插图目录☞图1: HXD-5 型炉膛吹灰器总图☞图2: HXD-5 型炉膛吹灰器安装及接口尺寸图☞图3:驱动销、螺纹管与前支承☞图4:电动机控制盒和减速箱☞图5.:棘爪和导向杆的装配间隙☞图6:吹灰圈数的调整机构☞图7:小于 3600 的吹灰☞图8:吹灰压力的调整☞图9:喷嘴伸缩调整机构☞图10:阀门弹簧的装、拆☞图11:内管填料的装填☞图12:HXD-5 型炉膛吹灰器电气接线图第一章概述1.综述HXD-5 型炉膛吹灰器主要用于清除锅炉水冷壁上的结灰和结渣。

HXD-5 型炉膛吹灰器采用单喷嘴前行到位后定点旋转吹灰。

根据结灰(或结渣)的性质和锅炉不同部位的吹灰要求,本吹灰器的吹扫弧度、吹扫圈数和吹灰压力都可进行调整,以期达到最理想的吹灰效果。

2.吹灰过程HXD-5 型炉膛吹灰器为电动吹灰器,可近操、远操和程控。

吹灰时,按下启动按钮,电源接通,减速传动机构驱动前端大齿轮顺时针方向转动,大齿轮带动喷头、螺纹管及后部的凸轮同方向转动。

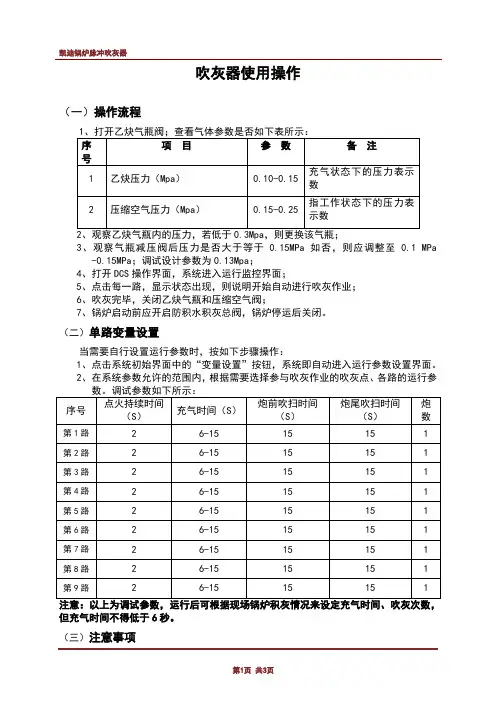

吹灰器使用操作(一)操作流程1、打开乙炔气瓶阀;查看气体参数是否如下表所示:序号项目参数备注1 乙炔压力(Mpa)0.10-0.15 充气状态下的压力表示数2 压缩空气压力(Mpa)0.15-0.25 指工作状态下的压力表示数2、观察乙炔气瓶内的压力,若低于0.3Mpa,则更换该气瓶;3、观察气瓶减压阀后压力是否大于等于0.15MPa如否,则应调整至0.1 MPa-0.15MPa;调试设计参数为0.13Mpa;4、打开DCS操作界面,系统进入运行监控界面;5、点击每一路,显示状态出现,则说明开始自动进行吹灰作业;6、吹灰完毕,关闭乙炔气瓶和压缩空气阀;7、锅炉启动前应开启防积水积灰总阀,锅炉停运后关闭。

(二)单路变量设置当需要自行设置运行参数时,按如下步骤操作:1、点击系统初始界面中的“变量设置”按钮,系统即自动进入运行参数设置界面。

2、在系统参数允许的范围内,根据需要选择参与吹灰作业的吹灰点、各路的运行参数。

调试参数如下所示:序号点火持续时间(S)充气时间(S)炮前吹扫时间(S)炮尾吹扫时间(S)炮数第1路 2 6-15 15 15 1 第2路 2 6-15 15 15 1 第3路 2 6-15 15 15 1 第4路 2 6-15 15 15 1 第5路 2 6-15 15 15 1 第6路 2 6-15 15 15 1 第7路 2 6-15 15 15 1 第8路 2 6-15 15 15 1 第9路 2 6-15 15 15 1注意:以上为调试参数,运行后可根据现场锅炉积灰情况来设定充气时间、吹灰次数,但充气时间不得低于6秒。

(三)注意事项1、控制柜电源在正常情况下应始终保持开启状态;2、乙炔稳压减压模块及空气稳压减压模块已调好,不可擅动(即乙炔稳压阀和空气稳压阀不需要调节);3、乙炔气瓶周围5米内严禁明火;4、应经常检查乙炔胶管及其接嘴处、乙炔气瓶及其减压阀是否漏气;5.当发现乙炔瓶内压力低于0.3MPa时应及时更换。

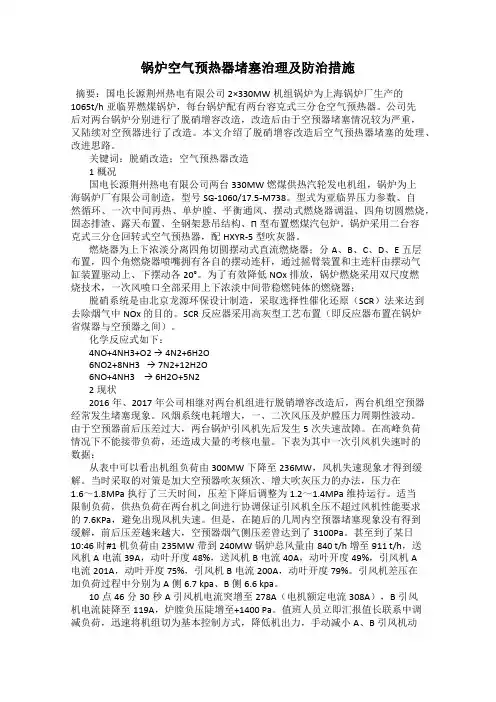

锅炉空气预热器堵塞治理及防治措施摘要:国电长源荆州热电有限公司2×330MW机组锅炉为上海锅炉厂生产的1065t/h亚临界燃煤锅炉,每台锅炉配有两台容克式三分仓空气预热器。

公司先后对两台锅炉分别进行了脱硝增容改造,改造后由于空预器堵塞情况较为严重,又陆续对空预器进行了改造。

本文介绍了脱硝增容改造后空气预热器堵塞的处理、改进思路。

关键词:脱硝改造;空气预热器改造1概况国电长源荆州热电有限公司两台330MW燃煤供热汽轮发电机组,锅炉为上海锅炉厂有限公司制造,型号SG-1060/17.5-M738。

型式为亚临界压力参数、自然循环、一次中间再热、单炉膛、平衡通风、摆动式燃烧器调温、四角切圆燃烧,固态排渣、露天布置、全钢架悬吊结构、Π型布置燃煤汽包炉。

锅炉采用二台容克式三分仓回转式空气预热器,配HXYR-5 型吹灰器。

燃烧器为上下浓淡分离四角切圆摆动式直流燃烧器;分A、B、C、D、E五层布置,四个角燃烧器喷嘴拥有各自的摆动连杆,通过摇臂装置和主连杆由摆动气缸装置驱动上、下摆动各20°。

为了有效降低NOx排放,锅炉燃烧采用双尺度燃烧技术,一次风喷口全部采用上下浓淡中间带稳燃钝体的燃烧器;脱硝系统是由北京龙源环保设计制造,采取选择性催化还原(SCR)法来达到去除烟气中NOx的目的。

SCR反应器采用高灰型工艺布置(即反应器布置在锅炉省煤器与空预器之间)。

化学反应式如下:4NO+4NH3+O2 → 4N2+6H2O6NO2+8NH3 → 7N2+12H2O6NO+4NH3 → 6H2O+5N22现状2016年、2017年公司相继对两台机组进行脱销增容改造后,两台机组空预器经常发生堵塞现象。

风烟系统电耗增大,一、二次风压及炉膛压力周期性波动。

由于空预器前后压差过大,两台锅炉引风机先后发生5次失速故障。

在高峰负荷情况下不能接带负荷,还造成大量的考核电量。

下表为其中一次引风机失速时的数据:从表中可以看出机组负荷由300MW下降至236MW,风机失速现象才得到缓解。

HXYR-5型回转式空气预热器用吹灰器产品说明书湖北华信机械发展有限公司第一章 概 述1.1综述HXYR-5型吹灰器是以蒸汽或空气作为吹灰介质,专门用于吹扫回转式空气预热器受热面积灰的吹灰器(见图1)。

HXYR-5型吹灰器的吹灰枪管、枪管上的喷 嘴口径及布置间距根据不同的空预器和安装要 求专门设计。

运行时,吹灰枪管只作伸缩运动, 而回转式空预器作旋转运动,因此,每个喷嘴 的吹灰轨迹是数圈阿基米德螺旋线,几个喷嘴 一起,完成对整个空气预热器的吹扫(见图3)。

喷嘴喷出的气流有一定扩散角,喷射覆盖面宽 度随喷嘴到空预器扇形板的距离不同而变化。

通常,喷嘴距扇形板的距离为200毫米时,覆 盖面宽约64毫米,而当距离为300毫米时,覆盖面可达95毫米。

图3 HXYR-5型吹灰器的吹灰轨迹在确定HXYR-5吹灰器的运行速度(即吹灰枪管的运行速度)时,必须根据空预器的旋转速度和喷嘴到扇形受热面的距离,合理地选定吹灰器的运行速度。

当空预器旋转一周时,喷嘴的前进距离必须小于其喷射覆盖面的宽度。

例如,当喷嘴距受热面300毫米时,空预器每旋转一周,吹灰枪管前进约75毫米。

这样,每圈螺旋线形吹扫覆盖面有足够的重叠量,以确保吹灰效果。

1.2吹灰过程吹灰器可近操、远操和程控。

按下启动按钮,电源接通、跑车前移,与之拴接的吹灰枪管亦同时前移。

随即,跑车操纵凸轮机构,开启阀门,吹灰开始。

当跑车前进至触及前端行程开关时,跑车退回,并使吹灰枪缩回,退至近终点时,阀门关闭,吹灰停止。

在整个吹灰过程中,吹灰枪匀速前进、后退,空气预热器匀速转动,在空预器的受热面上留下了阿基米德螺旋线形的吹灰轨迹。

最后,跑车触动后端行程开关,跑车停止,吹灰器完成了一次吹灰过程。

当需要单程吹灰时,可在吹灰器退回时,关闭空预器吹灰管道上的电动阀。

这样,吹灰器自身的阀门虽未关闭,但由于汽源丧失,使吹灰器在退回的过程中并未吹灰。

当用压缩空气吹灰时,要有足够大的空气储罐,并要求在管道上装上压力表,用来监视吹灰时的压力,以防压力过低而达不到吹灰效果。

烟气加热器GGH用全伸缩式吹灰器Jetblower 安装、运行与维修手册目录1前言 (4)2/1.吹灰设备技术数据表 (5)3吹灰设备运行要求 (8)4吹灰设备冷态调试 (9)5吹灰设备热态调试 (10)6吹灰装置日常维护和保养. (10)7吹灰器空气密封墙箱 (11)8吹灰器润滑表 (12)9吹灰器安装说明 (14)10吹灰器总体描述 (16)11内/外管组件的装配和拆卸 (20)12现场替换高压水喷嘴 (21)13Jetblower全伸缩吹灰器图 GH-0 (22)14喷嘴装配图 K22588 (23)15吹灰器本体阀门 (25)16本体阀门图GH-2-0 (30)17吹灰器电机齿轮箱 (32)18齿轮箱图 K20695 (35)19吹灰器行走箱组件 (图 K20220) (36)20高压水软管托架组件 (图见GH-8-0 GH-9-0) (37)21横轴组件 (图见K21685) (38)221”链条张紧机构(图见 K22545) (39)231/2”链条张紧机构 (见图K20217) (39)24行走箱图 K20220 (41)25高压水软管托架图GH-8-0 GH-9-0 (42)26横轴图K21685 (43)27张紧机构 K20217 K22545 (45)28编码器 (47)29密封风机 (54)30压力变送器 (59)31高压水过滤器 (71)32流量开关 (77)33ASCO 电磁阀 (78)34限位开关 (83)1前言回目录本公司生产的烟气加热器用全伸缩式吹灰器是按照正常工况条件下,采用严格的技术要求和公差控制来设计、制造的,保证吹灰器能可靠、有效地运行。

通过采用本说明书所介绍的方法对吹灰器进行定期检查和维修,定期润滑和更换密封填料能保证吹灰器处于最佳工作性能和保持工作寿命。

当吹灰器运行时,可以同时参照本说明书和所提供的组件图。

如遇到本说明书没有涉及到的任何技术问题,可按下面的地址进行联系:中国上海杨树浦路2200号上海克莱德贝尔格曼机械有限公司电话:0086-021-65396385传真:0086-021-65661886备件:我们通过精密制造来保证提供的备件具有完全互换性。

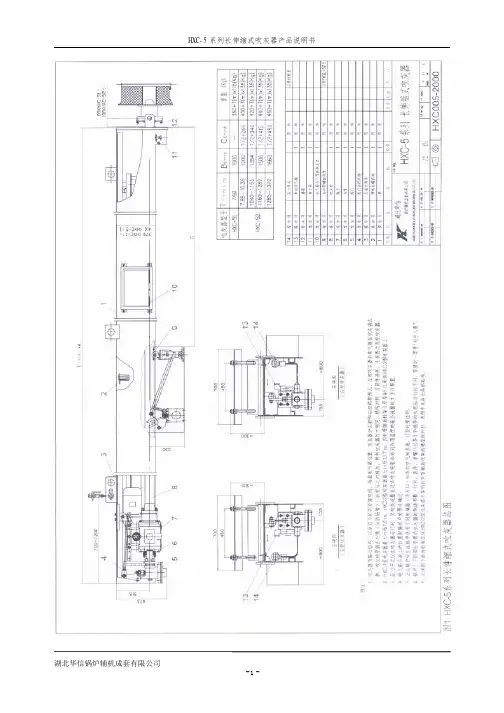

HRC-5型长伸缩式吹灰器使用说明书武汉华瑞机电设备成套工程有限公司目录第一章前言1.1概述1.2工作原理1.3主要技术参数第二章部件介绍2.1跑车与电动机2.2吹灰器阀门2.3梁2.4墙箱2.5动力电缆2.6内外管辅助托架2.7前托架2.8内管2.9吹灰枪与喷头2.10电气箱与行程控制2.11螺旋线相位变化机构(选用)第三章安装说明3.1吹灰器本体3.2风幕和密封空气3.3管道系统3.4阀门垫片和阀门冷凝水排泄管3.5御烟空气3.6电源连接第四章运行4.1运行前准备和吹灰秩序4.2启动前的准备4.3试运行4.4吹灰压力调整第五章维修与保养5.1跑车的手动5.2内管填料5.3内、外管的拆卸5.4阀门和阀门启闭机构5.5跑车的拆卸与安装5.6跑车的分解5.7跑车的装配和蜗轮蜗杆的调整5.8螺旋线相位变化机构的更换5.9HRC-51型吹灰器弹性电缆的更换5.10HRC-52型吹灰器弹性电缆的更换5.11润滑插图目录图1、HRC-5系列吹灰器总图图2、HRC-5系列吹灰器安装及接口尺寸图图3、喷嘴吹扫轨迹图图4、轮系图图5、前托轮的调整图6、螺旋线相位变化机构(左侧)图7、吹灰压力的调整图8、跑车后视图图9、内管填料的装填方向图10、内管安装图图11、阀门启闭机构的调整图12、跑车分解图图13、蜗轮蜗杆的装配调整程序图14、螺旋线相位变化机构的安装图15、HRC-51型吹灰器弹性电缆的更换图16、HRC-52型吹灰器弹性电缆的更换图17、润滑点图18、吹灰器电气接线图图1图2第一章前言1.1概述HRC-5系列长伸缩式吹灰器,根据行程不同,分别为HRC-51型和HRC-52型两种吹灰器(见图1)。

主要用于吹扫锅炉受热面上的积灰和结渣。

主要用在清除过热器、再热器及省煤器上的积灰和结渣,也可用来清除炉顶和管式空气预热器的积灰。

1.2工作原理A.清扫原理从伸缩旋转的吹灰枪管端部的一个或几个喷嘴中,喷出压缩空气或蒸汽持续冲击、清洗受热面是本吹灰器的工作原理。

目录第一章概述 (3)第二章结构介绍 (4)2.1阀门 (4)2.2空心轴 (4)2.3吹灰枪 (4)2.4减速传动机构与弓形板 (4)2.5电气控制箱 (4)2.6炉墙接口装置 (4)2.7吹灰枪管的炉内支承 (5)第三章安装与调整 (7)3.1确定吹灰器的安装部位 (7)3.2吹灰枪管的炉内支承 (7)3.3墙箱就位 (7)3.4吹灰枪管的安装和与吹灰器本体的对接 (7)3.5吹灰器的固定和与管道的连结 (8)3.6吹灰器的倾斜安装和卧式安装 (8)3.7御烟空气、密封空气和风幕 (8)3.8凸轮切割、安装及吹灰方位的调整 (9)3.9润滑 (9)3.10电源的连接及冷态调试 (9)第四章热态调试 (11)4.1试运行 (11)4.2调整吹灰压力 (11)第五章运行须知 (13)5.1低负荷时的吹灰 (13)5.2吹灰器的运行操作 (13)5.3快装锅炉的吹灰 (13)5.4停炉时,吹灰效果的检查 (14)5.5影响吹灰效果的因素 (14)第六章维修与保养 (15)6.1润滑 (15)6.2阀门 (15)6.3阀杆填料 (15)6.4空心轴填料 (16)6.5枪管的校直 (16)6.6枪管与支承托板的焊接 (17)第七章故障分析 (18)插图目录图1HXG-5型固定旋转式吹灰器总图图2HXG-5型固定旋转式吹灰器安装及接口尺寸图图3炉墙接口装置图4枪管切割尺寸图图5吹灰角度与凸轮弧长对照表图6吹灰压力的调整图7手动操作图8更换阀门弹簧图9支承托板及枪管焊接示意图图10HXG-5型固定旋转式吹灰器电气接线图第一章概述HXG-5型固定旋转式吹灰器(见图1)主要用来吹扫锅炉管道受热面的积灰。

HXG-5型固定旋转式吹灰器边旋转边吹灰,其转动由电动装置提供,吹灰角度由凸轮控制。

吹扫圈数由控制箱控制。

前端大齿轮上装有切制好的凸轮,大齿轮顺时针方向转动(从后端看)时,凸轮控制启动臂,开启和关闭阀门,为吹灰枪管提供吹灰介质。

HXDJ-5型多介质吹灰器产品说明书湖北华信锅炉辅机成套有限公司2006年7月HXDJ-5型 多介质吹灰器产品说明书湖北华信锅炉辅机成套有限公司2目 录一、系统简介 (3)二、吹灰器的工作原理和吹灰过程 (4)三、主要技术参数 (5)四、吹灰器结构 (6)五、高压泵站、吹灰管道系统及安装 (8)六、吹灰器的安装与调试 (9)七、吹灰系统的运行 (11)八、吹灰器的日常维护 (12)九、故障分析……………………………………………………………13 附:高压布置说明书(供参考)插图目录HXDJ-5型多介质吹灰器总图(半伸缩式)HXDJ-5型多介质吹灰器总图(全伸缩式)本吹灰器原型号、名称为: C305-DJ 型 长伸缩式吹灰器,现改为 HXDJ-5型 多介质吹灰器, 特此说明HXDJ-5型多介质吹灰器产品说明书一、系统简介HXDJ-5型多介质伸缩式吹灰器,用于清除脱硫设备的烟气加热器(GGH)上的结灰和石膏结垢,也用于清除沉积在脱销空气预热器(SCR)上的硫酸铵等各种盐垢和结灰。

运行中,吹灰器及时清除其热交换面上的结灰和结垢,对保证相关热交换设备的正常运行具有重要意义。

吹灰器可以是全伸缩式,也可以是半伸缩式。

半伸缩式实际使用较多。

吹灰器的吹灰介质为过热蒸汽(或压缩空气),低压水和高压水:过热蒸汽(或压缩空气)的吹扫为两种热交换设备运行时经常使用的吹灰方式。

压缩空气由于其压力和流量的参数限制,其吹灰效果较过热蒸汽差得多。

因此,在条件允许时,尽可能使用过热蒸汽吹灰。

高压水冲洗为在线冲洗,在运行需要时投入。

低压水冲洗为离线冲洗。

即停炉时大水量冲洗,根据结灰和结垢的具体情况投用。

低压水离线冲洗一般只用在GGH的冲洗上。

本清洁装置主要由四部分组成:1、吹灰器本体:每台热交换设备一般上、下各布置一台吹灰器。

2、吹灰管道系统:过热蒸汽(或压缩空气)和低压水(一般只用在GGH上)共用一套管道系统。

高压水单独用一套管道系统。

矿产资源开发利用方案编写内容要求及审查大纲

矿产资源开发利用方案编写内容要求及《矿产资源开发利用方案》审查大纲一、概述

㈠矿区位置、隶属关系和企业性质。

如为改扩建矿山, 应说明矿山现状、

特点及存在的主要问题。

㈡编制依据

(1简述项目前期工作进展情况及与有关方面对项目的意向性协议情况。

(2 列出开发利用方案编制所依据的主要基础性资料的名称。

如经储量管理部门认定的矿区地质勘探报告、选矿试验报告、加工利用试验报告、工程地质初评资料、矿区水文资料和供水资料等。

对改、扩建矿山应有生产实际资料, 如矿山总平面现状图、矿床开拓系统图、采场现状图和主要采选设备清单等。

二、矿产品需求现状和预测

㈠该矿产在国内需求情况和市场供应情况

1、矿产品现状及加工利用趋向。

2、国内近、远期的需求量及主要销向预测。

㈡产品价格分析

1、国内矿产品价格现状。

2、矿产品价格稳定性及变化趋势。

三、矿产资源概况

㈠矿区总体概况

1、矿区总体规划情况。

2、矿区矿产资源概况。

3、该设计与矿区总体开发的关系。

㈡该设计项目的资源概况

1、矿床地质及构造特征。

2、矿床开采技术条件及水文地质条件。