ASTM D1037-99 Particle Board Prop

- 格式:pdf

- 大小:480.03 KB

- 文档页数:30

pom材质标准

POM(聚甲醛)是一种工程塑料,也被称为聚氧化甲烯。

POM材质的标准通常是根据不同国际标准或行业标准来制定的。

以下是几种常见的POM材质标准:

1. ISO标准:ISO 9988-1996是国际标准化组织(ISO)制定的POM材料的规范。

该标准规定了POM材料的物理性能、化学性能、热性能等方面的要求。

2. ASTM标准:ASTM D6778-18是美国材料和测试协会(ASTM)制定的POM材料的标准规范。

该标准规定了POM

材料的物理性能、化学性能、热性能等方面的要求。

3. JIS标准:JIS K6772是日本工业标准(JIS)制定的POM材

料的标准规范。

该标准规定了POM材料的物理性能、化学性能、热性能等方面的要求。

此外,还有一些行业标准或企业自行制定的POM材质标准,

主要是根据特定应用或行业需求来确定POM材料的性能要求。

需要根据具体应用需求选择合适的POM材料,并参考相应标

准来评估材料的性能。

次,即把精力集中于生产过程产品 的质量控制。

我们不是不要抽样检 验,而是不要单纯的抽样检验,我 们要把抽样检验多次地应用于原 料、半成品、各工序的检验和控 制,结合其它数理统计的质量控 制,真正把产品不合格品率控制在 可接收范围内,这就是统计质量管 理方法。

世界上先进国家的质量管理发 展史分为三个阶段,20 世纪20 年 代~40年代的以最终产品检验为主 的检验质量管理模式,之后是以生 产过程控制为主的统计质量管理模 式,最后是20世纪60年代~70年代 逐步进入全面质量管理模式。

我国 的质量管理以前可以说长期处于最低级的检验质量管理模式,自20世 注册,并严格要求按他们规定的GMP 生产工艺进行生产,每批罐头出口 时还必须附有五种关键工序的原始 记录供审查。

我想他们的这种管理 和控制质量的方法,要比我们高明 得多。

通过上面我们的模拟实验和理 论分析,除了少数缺陷分布有均匀 性的产品外,大多数产品按我国现 行的抽样标准抽检,误判率在20% 或30%以上。

也许有人要问,这种 情况你们的检验工作如何能顺利进 行?应当说,长期的实践迫使人们 采取了一定的补救措施。

如出口检 验部门历年来执行的检验员驻厂制 度和对企业及生产工艺的监督管理 等一系列措施。

加之企业摄于国外 的验收和口岸的查验,而在生产和《欧洲中密度纤维板工业标 准》(EMB 第三版1995)有关甲醛 释放量的规定:甲醛释放量(穿孔值) A 级:≤9.0mg/100g B 级:>9.0~≤40.0mg/100g 规定的穿孔值应是两种情况之一:在企业内部的产品质量控制情 况下,经常性的检测并有足够数量 的检测结果符合规定的限量值;在 外部监控的情况下,至少是3张板 子的平均值符合规定的限量值,且 单个值不能超过限量值的10%。

规 定的穿孔值只适用于板子的含水率 为 6.5%时。

当中密度纤维的含水率 不同时,穿孔值还应乘以系数F,F 值由下式计算确定:当板子的含水率h 为4%≤h ≤9% 时:纪90 年代以来受到世界潮流的影 响,全国形成了学习全面质量管理 的热潮,按照国外某些评论即是欲 跨越统计质量管理阶段而直接进入 全面质量管理阶段。

泡沫塑料及相关国家标准概述泡沫塑料是一种轻质、柔软、具有良好隔热性能的塑料材料。

它由许多由气泡组成的薄膜组成,这些气泡可以在制造过程中形成或通过添加发泡剂产生。

泡沫塑料广泛应用于各个领域,包括建筑、包装、交通工具等。

泡沫塑料的制造过程主要包括聚合物原料的融合和发泡两个步骤。

首先,将聚合物原料加热至熔融状态,并添加适量的发泡剂和其他添加剂。

然后,将熔融聚合物注入模具中,并在注入过程中加入高压气体,使熔融聚合物膨胀形成气泡。

最后,将泡沫塑料冷却固化并从模具中取出。

泡沫塑料有许多种类,其中最常见的是聚苯乙烯泡沫(EPS)和聚氨酯泡沫(PU)。

聚苯乙烯泡沫是一种具有轻质、坚固和优良隔热性能的泡沫塑料,广泛应用于建筑保温、包装和艺术品制作等领域。

聚氨酯泡沫是一种具有良好弹性和抗冲击性能的泡沫塑料,常用于座椅和垫子等产品中。

为了确保泡沫塑料的质量和安全性,许多国家都制定了相关的国家标准。

以下是一些主要国家对泡沫塑料的标准概述:1.中国国家标准:中国国家标准GB/T6343-2023《泡沫塑料材料》规定了泡沫塑料的分类、要求、试验方法和包装标志等内容。

该标准适用于建筑、包装、交通工具以及其他相关领域中的泡沫塑料制品。

2.美国国家标准:美国国家标准ASTMC578-19《泡沫塑料绝热板材规范》规定了泡沫塑料绝热板材的要求和试验方法。

该标准对聚苯乙烯泡沫、聚氨酯泡沫和聚异氰酸酯(PIR)泡沫等绝热板材进行分类和评估。

4.日本国家标准:日本国家标准JISA9512:2023《保温材料—泡沫结构材料》规定了泡沫结构材料的分类、要求和试验方法。

该标准适用于聚苯乙烯泡沫、聚氨酯泡沫等泡沫结构材料。

以上仅是几个国家关于泡沫塑料的国家标准的概述,不同国家对泡沫塑料的标准可能有所不同。

这些标准的制定旨在保证泡沫塑料制品的质量和安全性,促进泡沫塑料在各个领域的应用。

同时,制定和遵守这些标准还有助于减少对环境的负面影响,并提高产品的可持续发展性。

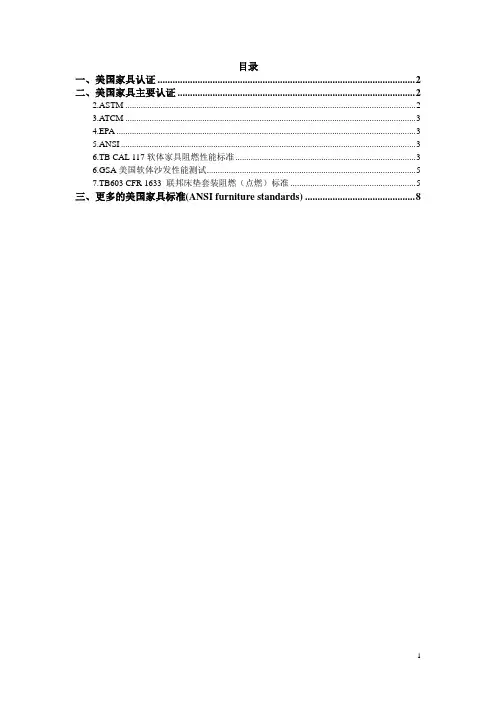

目录一、美国家具认证 (2)二、美国家具主要认证 (2)2.ASTM (2)3.ATCM (3)4.EPA (3)5.ANSI (3)6.TB CAL 117软体家具阻燃性能标准 (3)6.GSA美国软体沙发性能测试 (5)7.TB603 CFR 1633 联邦床垫套装阻燃(点燃)标准 (5)三、更多的美国家具标准(ANSI furniture standards) (8)一、美国家具认证二、美国家具主要认证1.BIFMA认证BIFMA是美国办公家具制造商协会(The Business and Institutional Furniture Manufacturer's Association)的英文简称。

作为信息资源中心和办公家具工业代表,BIFMA为北美洲办公家具制造工业提供专业且广泛的贸易发展机会。

BIFMA标准因内容全、技术严格而闻名,赢得世界的广泛认可。

BIFMA5.1-5.7分别针对办公椅、文件柜、沙发、办公桌\台、嵌板屏风及小型的办公和家用家具的测试内容与方法作了详尽的描述。

BIFMA5.1对于办公椅的测试有:椅背强度测试、五爪强度测试、沙包自由落体冲击测试、旋转测试摆动机构疲劳性测试、椅座疲劳性冲击测试、稳定性测试、扶手强度测试、椅背疲劳性测试、脚轮、五爪疲劳性测试、椅腿强度测试、脚踏板疲劳性测试等,且其严酷程度远高于其他同类标准BIFMA认证产品涵盖办公桌椅、文件柜等办公家具。

1. BIFMA x 5.1 - 2002 Office chairs : tests 办公椅测试2. BIFMA X 5.2 - 1997 Lateral files : tests 文件柜测试(宽度>深度)3. BIFMA X 5.3 - 1997 Vertical files - tests 文件柜测试(深度>宽度)4. BIFMA X5.4 - 1997 Lounge seating - tests 长沙发测试5. BIFMA X 5.5 - 1998 Desk/table products - tests 桌子测试6. BIFMA X 5.6 - 2003 Panel systems - tests 屏风系统测试7. ANSI/SOHO S6.5 - 2001 Small office/home office furniture - tests SOHO家具测试2.ASTMASTM美国试验与材料协会,目前共制定了48个家具标准,重点为以下4个方面:A. 家具安全标准:包括安装在自行车前后的儿童座椅、豆袋椅、弹簧床、婴儿床、婴儿栏杆小床、床铺、便携式钩接式座椅、婴儿浴室座椅、婴儿被垫、柜、门柜和橱柜、未成年人用弹跳座椅、高脚椅等家具的安全技术规范;B. 家具阻燃标准:包括软垫、装饰性家具部件、床垫等的阻燃性能。

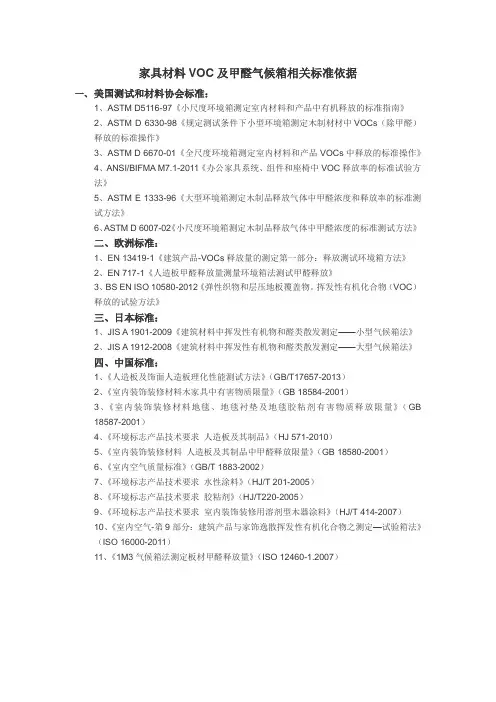

家具材料VOC及甲醛气候箱相关标准依据一、美国测试和材料协会标准:1、ASTM D5116-97《小尺度环境箱测定室内材料和产品中有机释放的标准指南》2、ASTM D 6330-98《规定测试条件下小型环境箱测定木制材材中VOCs(除甲醛)释放的标准操作》3、ASTM D 6670-01《全尺度环境箱测定室内材料和产品VOCs中释放的标准操作》4、ANSI/BIFMA M7.1-2011《办公家具系统、组件和座椅中VOC释放率的标准试验方法》5、ASTM E 1333-96《大型环境箱测定木制品释放气体中甲醛浓度和释放率的标准测试方法》6、ASTM D 6007-02《小尺度环境箱测定木制品释放气体中甲醛浓度的标准测试方法》二、欧洲标准:1、EN 13419-1《建筑产品-VOCs释放量的测定第一部分:释放测试环境箱方法》2、EN 717-1《人造板甲醛释放量测量环境箱法测试甲醛释放》3、BS EN ISO 10580-2012《弹性织物和层压地板覆盖物。

挥发性有机化合物(VOC)释放的试验方法》三、日本标准:1、JIS A 1901-2009《建筑材料中挥发性有机物和醛类散发测定——小型气候箱法》2、JIS A 1912-2008《建筑材料中挥发性有机物和醛类散发测定——大型气候箱法》四、中国标准:1、《人造板及饰面人造板理化性能测试方法》(GB/T17657-2013)2、《室内装饰装修材料木家具中有害物质限量》(GB 18584-2001)3、《室内装饰装修材料地毯、地毯衬垫及地毯胶粘剂有害物质释放限量》(GB18587-2001)4、《环境标志产品技术要求人造板及其制品》(HJ 571-2010)5、《室内装饰装修材料人造板及其制品中甲醛释放限量》(GB 18580-2001)6、《室内空气质量标准》(GB/T 1883-2002)7、《环境标志产品技术要求水性涂料》(HJ/T 201-2005)8、《环境标志产品技术要求胶粘剂》(HJ/T220-2005)9、《环境标志产品技术要求室内装饰装修用溶剂型木器涂料》(HJ/T 414-2007)10、《室内空气-第9部分:建筑产品与家饰逸散挥发性有机化合物之测定—试验箱法》(ISO 16000-2011)11、《1M3气候箱法测定板材甲醛释放量》(ISO 12460-1.2007)。

Designation:D1037–99StandardTestMethodsforEvaluatingPropertiesofWood-BaseFiberandParticlePanelMaterials1

ThisstandardisissuedunderthefixeddesignationD1037;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.

ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.INTRODUCTIONThetestmethodspresentedhereinhavebeendevelopedandarepresentedtoservetwodistinctpurposes.Theyaredividedintotwoparts,PartsAandB,dependingonthepurposeforwhichtheyareintended.Thechoicebetweenaparticulartestmethodanditsalternativeshouldbemadewithafullunderstandingoftheintendedpurposeofeach,becausevaluesobtainedfromtestsmay,insomecases,differ.Ofthetestmethodspresentedinbothparts,somehavebeeningenerallyaccepteduseformanyyears,somearemodificationsandrefinementsofpreviouslydevelopedtestmethods,andsomearemorerecentdevelopments.Wheretestmethodsaresuitableformorethanoneofthepurposes,theyaredelineatedinPartA,butnotrepeatedinPartB.Itistheintentthatreferencetotheappropriatesectionofthetestmethodshallsufficeinspecificationsdevelopedforthedifferentmaterials.PartA.GeneralTestMethodsforEvaluatingtheBasicPropertiesofWood-BaseFiberandParticlePanelMaterials—PartAisforuseinobtainingbasicpropertiessuitableforcomparisonstudieswithothermaterialsofconstruction.TheserefinedtestmethodsareapplicableforthispurposetoallmaterialscoveredbyDefinitionsD1554.PartB.AcceptanceandSpecificationTestMethodsforHardboard—PartBisforspecificuseinspecificationsforprocurementandacceptancetestingofhardboard.Thesetestmethodsaregenerallyemployedforthosepurposesintheindustry.Byconfiningtheirintendeduseasindicated,ithasbeenpossibletoachieveadequateprecisionofresultscombinedwitheconomyandspeedintesting,whicharedesirableforspecificationuse.

PARTA—GENERALTESTMETHODSFOREVALUATINGTHEBASICPROPERTIESOFWOOD-BASEFIBERANDPARTICLEPANELMATERIALS

1.Scope1.1Thesetestmethodscoverthedeterminationofthepropertiesofwood-basefiberandparticlepanelmaterialsasfollows:

SectionsSizeandAppearanceofBoards7-10StrengthProperties:StaticBending11-20TensileStrengthParalleltoSurface21-27TensileStrengthPerpendiculartoSurface28-33CompressionStrengthParalleltoSurface34-40

FastenerHoldingTests:

LateralNailResistanceTest41-46NailWithdrawalTest47-53Nail-HeadPull-ThroughTest54-60DirectScrewWithdrawalTest61-67HardnessTest68-73HardnessModulusTest74-80ShearStrengthinthePlaneoftheBoard81-86Glue-LineShearTest(BlockType)87-90FallingBallImpactTest91-95AbrasionResistancebytheU.S.NavyWearTester96-99MoistureTests:WaterAbsorptionandThicknessSwell-ing100-107LinearVariationwithChangeinMoistureContent108-111AcceleratedAging112-118CuppingandTwisting119MoistureContentandSpecificGravity120–121InterlaminarShear122-129EdgewiseShear130-136Compression-ShearTest137-146

1ThesetestmethodsareunderthejurisdictionofASTMCommitteeD-7on

WoodandarethedirectresponsibilityofSubcommitteeD07.03onPanelProducts.CurrenteditionapprovedApril10,1999.PublishedJuly1999.OriginallypublishedasD1037–49.LastpreviouseditionD1037–96a.

1Copyright©ASTMInternational,100BarrHarborDrive,POBoxC700,WestConshohocken,PA19428-2959,UnitedStates.1.2Thereareacceptedbasictestproceduresforvariousfundamentalpropertiesofmaterialsthatmaybeusedwithoutmodificationforevaluatingcertainpropertiesofwood-basedfiberandparticlepanelmaterials.ThesetestmethodsareincludedelsewhereintheAnnualBookofASTMStandards.ThepertinentonesarelistedinTable1.Afewofthetestmethodsreferencedareforconstructionwherethewood-basematerialsoftenareused.1.3Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Themetricequivalentsofinch-poundunitsmaybeapproximate.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyproblems,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:C273TestMethodforShearTestinFlatwisePlaneofFlatSandwichConstructionsorSandwichCores2D143MethodsofTestingSmallClearSpecimensofTim-ber3D905TestMethodforStrengthPropertiesofAdhesiveBondsinShearbyCompressionLoading4D1554DefinitionsofTermsRelatingtoWood-BaseFiberandParticlePanelMaterials3D3501MethodsofTestingPlywoodinCompression3

3.SignificanceandUse3.1Thesetestmethodscoversmall-specimentestsforwood-basefiberandparticlepanelmaterialsthataremadetoprovide:3.1.1Dataforcomparingthemechanicalandphysicalpropertiesofvariousmaterials,3.1.2Datafordeterminingtheinfluenceonthebasicprop-ertiesofsuchfactorsasrawmaterialandprocessingvariables,post-treatmentsofpanels,andenvironmentalinfluences,and3.1.3Dataformanufacturingcontrol,productresearchanddevelopment,andspecificationacceptance.