PCB Roadmap-2009

- 格式:pdf

- 大小:252.51 KB

- 文档页数:1

比亚迪微电子公司2010年5月 比亚迪股份有限公司比亚迪微电子公司简介比亚迪微电子成立于2003年3月为国内外市场提供有竞争力的研发和产品解决方案 支持比亚迪集团的垂直整合战略,为集团提供所需 产品资源 致力于手机,汽车,新能源市场比亚迪微电子目前有超过1500名员工其中有百分之七十为研发工程师 占地25,000平米专注于半导体产品的研发和生产CMOS 图像传感器和处理芯片 电源管理芯片 功率场效应管 IGBT 芯片和模组 电流传感器 触控芯片和触摸板 音频系列芯片 瞬态电压抑制二极管CMOS图像传感器用于摄像手机 CMOS Image Sensors for Video phone电阻式/电容式多点触摸控制芯片用于手机触摸屏 Resistive/ Capacitive Multi-touch Controller for touch panel消噪芯片用于通话环境噪声抑制 Ambient Noise Suppression IC for phone conversation电容式按键触摸控制芯片用于手机按键导航键 Capacitive Touch Key Controller for touch key and touch navigationD/AB类音频功放用于驱动手机喇叭 Class D/AB Audio Power Amplifier for driving speaker低压MOSFET用于手机充电管理 LV MOSFET for charge management AC-DC及光耦用于手机充电适配器 AC-DC and photocoupler for adapter 5V/12V单向双向(低电容)ESD保护器件 低压MOSFET、单节锂电池保护芯片 5V/12V Uni- / Bi-direction (Low Capacitance) 用于手机电池保护 ESD Protector LV MOSFET & 1-cell Li+ Battery protection IC for Battery cell protect circuit电阻式/电容式多点触摸控制芯片 用于笔记本触摸屏 Resistive/ Capacitive Multi-touch Controller for Notebook touch panelD/AB类音频功放用于笔记本立体扬声器驱动 Class D/AB Audio Power Amplifier for driving Notebook stereo speaker消噪芯片用于通话环境噪声抑制 Ambient Noise Suppression IC for phone conversationCMOS图像传感器用于笔记本 CMOS Image Sensors for Notebook 高压MOSFET、AC-DC 、光耦、功率因数 校正器用于适配器 HV MOSFET,AC-DC, photocoupler & PFC Controller for adapter电容式按键触摸控制芯片用于笔记本按键控制 Capacitive Touch Key Controller for Notebook touch key controlLDO用于笔记本 LDO for Notebook触摸板模组用于笔记本,支持多点触摸 Touch Pad Module for Notebook, support multi-touch降压DC/DC用于笔记本 Step-down DC/DC for Notebook低压MOSFET、双节/多节电池保护芯片、电 量计用于笔记本电池保护 LV MOSFET,2-cell/Multi-cell Battery 5V/12V单向双向(低电容) Protector IC & Gas Gauge for Notebook ESD保护器件 5V/12V Uni- / Bi-direction (Low Capacitance) ESD ProtectorMOS管、马达驱动用于车身直流马达驱动 高压MOSFET用于点火线圈驱动 MOSFET, Motor Driver for DC Motor HV MOSFET for Ignition coil drivers低频发射芯片用于智能无钥匙系统 Keyless LF Transmitter IC for auto倒车雷达系统 Car Reversing Aid SystemsDC-DC 用于车载DVD 电阻式/电容式多点触控芯片用于车载GPS DC-DC for P-DVD Resistive/ Capacitive Multi-touch Controller for GPSCMOS图像传感器用于倒车系统 CMOS Image Sensor for Car Reversing Systems电容式按键触摸控制芯片用于汽车按键控制 Capacitive Touch Key Controller for Automotive touch key control高压MOSFET用于燃料喷射器驱动 HV MOSFET for Fuel injector drivers高压MOS管用于HID灯 HV MOSFET for HID光耦用于电池管理系统 Photocoupler for Battery management system高压MOSFET用于电动助力转向系统 HV MOSFET for Electric power steering大功率TVS管用于汽车浪涌保护 HP TVS for surge discharging比亚迪微电子各部门及产品分布总览总经理办公室其它部门产品一部产品二部产品三部研发部财务部 运营部 品质部 制造部 设计服务部 工程应用部 技术市场部 业务发展部 人力资源部 总经办 综合办功率场效应管 锂电保护芯片 充电器芯片 DC/DC 芯片 LDO/Motor 芯片 LED 驱动芯片 IGBT 芯片及模组 电量计 电源管理单元VGA 1/8” VGA 1/10” 2MP 1/4” 5MP 1/3.2” VGA PAL/NTSC电阻式多点触摸控制芯片 电容式触摸屏控制芯片 电容式触摸按键控制芯片 触摸板模组 AB/D类音频功放 净音IC TVS PFC 控制芯片 全系列LED 驱动芯片 汽车相关IC多媒体控制芯片 车载 MCU 车载光耦模块 电流传感器比亚迪微电子客户群比亚迪微电子产品三部概况Number of Employee : 239 Organization of Product Dept. IIIDept. III Manager Neil YangLine 1Line 2Line 3Line 4Line 5Line 6OtherTouch key Controller, Touch screen Controller, Touch-pad controllerKeyless Transmitter, Keyless Transceiver, RF IC, MEMS MICAudio Power Amplifier (Class AB\D), Ambient Noise Cancellation ICTouch PadTVS Diode, ESD Protectors, Motor driver, CRAS controllerPFC, LED driverAE科 FAE 科 NPI 科 市场开发科 综合管理科产品三部主要产品展示Resistive Multi-touch ControllerCapacitive Touch Panel ControllerCapacitive Touch Key ControllerTouch Pad ModuleAudio Power AmplifierPure Sound IC for Ambient Noise SuppressionTVSPFCTouchpad产品线概况员工人数Number of Employee : 33Product Manager: 1人 Project Manager: 1人 Product Marketing Manager:1人 Software Engineer:15人 Hardware Engineer:5人 Field applcation Engineer:5人 Test Engineer :5人120 100 80Touchpad产品线人员规划10060 60 40 20 20 0 33Series of Products :BTPSXXXXX、 BTPSXXXXX…年份2009 2010 2011 2012Our Strength:Proprietary sensor ic completely Design in-house Excellence cost performance In time technical support Customization Service Shorter lead time Trustworthy partner--TSMCTouch Pad IntroductionThe BYD Touchpad is an enhanced version of the Finger-Sensing. It supports normal mouse operations. including: Tap Double-Tap Tap& Drag Movement Button WheelFeaturesCapacitive type XP/Vista/Win7 PS/2®and IIC interface Provides smooth and reliable finger detection Low fatigue pointing action Low power consumption Configurable device mounting orientation Light weight Optimized parametersNaming RuleB TP S 6740 D N 2 U A1 2 3 4 5 6 7 8 9ID1 2 3 4 5 6 7 8 9ContentManufacturer Products Touch Type Dimension Pin Description Color of Mylar Button QTY Connector Orientation Version Number B: BYDInterpretationTP: Touchpad S: Single-touch M: Multi-touch 67mm × 40mm D: different R: red W: white… N: none2: two button U: up D: down A: version one B: version twoProduct ListPart NumberBTPS7740DN2UA BTPS6740DN2UA BTPS5440DN2UA BTPS8442DN2NA BTPS6030DN2UA BTPS6549DN2UA BTPS6034DN2UA BTPS7442DN2UA BTPS10861DN2UA BTPS8644DN2UA BTPS4833DN2UAWidth (mm) & Height (mm) & PCB Thickness (mm)77.2± 0.25; 40.1± 0.25; 0.91±0.15 67.0± 0.25; 40.0± 0.25; 0.91±0.15 53.5± 0.25; 39.8± 0.25; 0.91±0.15 84.0± 0.25; 42.0± 0.25; 0.91±0.15 60.0± 0.25; 29.7± 0.25; 0.91±0.15 65.0± 0.25; 49.0± 0.25; 0.91±0.15 60.4± 0.25; 34.2± 0.25; 0.91±0.15 73.9± 0.25; 41.9± 0.25; 0.91±0.15 108.0± 0.25; 61.0± 0.25; 0.91±0.15 84.4± 0.25; 43.8± 0.25; 0.91±0.15 48.0± 0.25; 32.5± 0.25; 0.91±0.15DescriptionSingle Touch Single Touch Single Touch Single Touch Single Touch Single Touch Single Touch Single Touch Single Touch Single Touch Single TouchCompatible ModuleSynaptics TM-01059 Synaptics TM-00450 Synaptics TM-00336 Synaptics TM-00268 Synaptics TM-01134 Synaptics TM-41B Synaptics TM-01198 Synaptics TM-00378 Synaptics TM-01100 Synaptics TM-01152 Synaptics TM-01058We provide customized serviceGesturesThe choice of human-computer InteractionTouch Pad GesturesSingle Touch Basic Mouse FunctionsMulti Touch Various ExperienceTouchPad RoadmapMP DevelopingMult-TouchMPSingle-TouchMPQ3Q4Q1Q2Q320092010Our TargetDesire to Market Share Target CustomerOtherBYD Synaptics……Thank you !。

单片式OBU生产计划设计方案(自建工厂)版本:编制:时间:目录一、设计目标 (3)二、设计要求 (3)三、资源需求 (4)四、时间安排 (7)五、管理模式 (10)六、风险控制 (10)一、设计目标实现单片式OBU的稳定批量生产,日产能达到10000片,月度最大产能达到300000片,开工率达到90%,出厂合格率达100%。

建立完善的生产工艺及质量管控体系,培养一支具备一定技术能力的专业化生产队伍,实现在管理、制造和品控等方面的不断提升,为企业创造更大的价值。

单片式OBU生产分为备料、制板、贴片、组装和测试包装等环节,其中制板为外协生产,即PCB板在生产中作为特殊物料。

二、设计要求安全要求:生产所需各项内容均需符合国家的各项法律法规要求,符合ISO9001质量体系要求,符合对人员安全防护要求,符合环境保护要求,符合防火防灾要求。

产能要求:计划产能:10000片/班,300000片/月,3600000片/年;极限月产能888片/月。

生产开工率90%。

质量要求:出厂合格率100%,生产合格率99.5%。

产品质量作为生产的根本,必须建立严格的可执行的质量品控体系,并在生产中不断完善,从而保证产品质量达标,客户满意。

品控从备料开始,严把进料关,从源头控制产品质量;对外协厂要建立品控档案,并定期对其评价;对生产过程建立生产加品控的管理模式,树立“质量是生产出来的”质量意识,每道工序不合格不转序,品控具备一票否决权;产品库由品控负责,严格做好成品库、半成品库和非品库的区分和管理。

成本要求:生产部负责生产成本控制,但是降低成本绝不是以牺牲产品质量为代价。

产品生产成本务必在可控范围内,每批次上浮不得超过1%。

三、资源需求1.场地需求:安装功能不同,将场地划分为车间、库房、办公三类场所,各类场所均需按照要求安装摆放消防设施,预留安全通道和安全门。

生产车间考虑设备重量和震动等因素将位置设置在一楼,其它各场所根据需求进行装修。

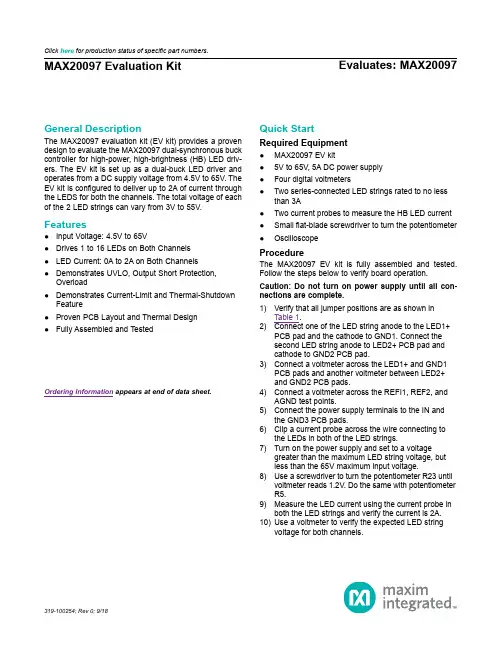

Evaluates: MAX20097MAX20097 Evaluation Kit General DescriptionThe MAX20097 evaluation kit (EV kit) provides a proven design to evaluate the MAX20097 dual-synchronous buck controller for high-power, high-brightness (HB) LED driv-ers. The EV kit is set up as a dual-buck LED driver and operates from a DC supply voltage from 4.5V to 65V. The EV kit is configured to deliver up to 2A of current through the LEDS for both the channels. The total voltage of each of the 2 LED strings can vary from 3V to 55V.Features●Input Voltage: 4.5V to 65V●Drives 1 to 16 LEDs on Both Channels ●LED Current: 0A to 2A on Both Channels ●Demonstrates UVLO, Output Short Protection,Overload ●Demonstrates Current-Limit and Thermal-ShutdownFeature ●Proven PCB Layout and Thermal Design ●Fully Assembled and Tested319-100254; Rev 0; 9/18Ordering Information appears at end of data sheet.Quick StartRequired Equipment●MAX20097 EV kit●5V to 65V, 5A DC power supply ●Four digital voltmeters●Two series-connected LED strings rated to no less than 3A●Two current probes to measure the HB LED current ●Small flat-blade screwdriver to turn the potentiometer ●OscilloscopeProcedureThe MAX20097 EV kit is fully assembled and tested. Follow the steps below to verify board operation. Caution: Do not turn on power supply until all con-nections are complete.1)Verify that all jumper positions are as shown in Table 1.2)Connect one of the LED string anode to the LED1+PCB pad and the cathode to GND1. Connect the second LED string anode to LED2+ PCB pad and cathode to GND2 PCB pad.3)Connect a voltmeter across the LED1+ and GND1PCB pads and another voltmeter between LED2+and GND2 PCB pads.4)Connect a voltmeter across the REFI1, REF2, andAGND test points.5)Connect the power supply terminals to the IN andthe GND3 PCB pads.6)Clip a current probe across the wire connecting tothe LEDs in both of the LED strings.7)Turn on the power supply and set to a voltagegreater than the maximum LED string voltage, but less than the 65V maximum input voltage.8)Use a screwdriver to turn the potentiometer R23 untilvoltmeter reads 1.2V. Do the same with potentiometer R5.9)Measure the LED current using the current probe inboth the LED strings and verify the current is 2A.10)Use a voltmeter to verify the expected LED stringvoltage for both channels.Click here for production status of specific part numbers.Table 1. MAX20097 EV Kit Jumper DescriptionsJUMPER SHUNTPOSITION DESCRIPTIONJ1Closed(Default)Use the resistive divider to set the LED current on LED2+ string Open Use the external power supply on REFI2 to set the LED2+ current.J2Closed(Default)Single power supply input for both the buck controllersOpen Powers up the LED2+ controller separately through IN2 and GND4 PCB pads.J3Open External PWM pulse generator to be applied on DIM2 test point.1-2(Default)DIM2 pulled up to V CC for 100% PWM dimming.2-3DIM2 input is GND and LED2+ string is disabled.J41-2 (Default)IN power supply connected to the IN pin of the device.2-3IN pin of the device shorted to V CC and external voltage between 4.5V to 5.5V can be forced onVCC test point.J5Open External PWM pulse generator to be applied on DIM1 test point 1-2(Default)DIM1 pulled up to V CC for 100% PWM dimming.2-3DIM1 input is GND and LED1+ string is disabled.J6Closed(Default)Use the resistive divider to set the LED current on LED1+ string. Open Use the external power supply on REFI1 to set the LED current.J7Closed(Default)V CC and V IO shortedJ15Closed(Default)Pull FLTB to V CC through 10kΩ resistorDetailed DescriptionThe MAX20097 is a dual-channel, high-voltage, synchro-nous N-channel high-current buck LED drivers. The device uses a proprietary average current mode control scheme to regulate the inductor current. This control method does not require any control loop compensation while maintaining nearly constant switching frequency. Inductor current sense is achieved by sensing the current in the bottom switching device. The MAX20097 integrates 2 fully synchronous buck controllers. The devices operate over a wide input range of 4.5V to 65V. The device is designed for high-frequency operation and can operate as high as 1MHz.Analog Dimming Control (REFI1, REFI2)The EV kit demonstrates the analog dimming feature of the device. R22 and R23 form a resistor-divider between V CC and AGND and sets the voltage on REFI1 pin. R22 is a 10kΩ resistor and R23 is a 10kΩ potentiometer, with the wiper shorted to the high side of the potentiometer. Using a flat-blade screwdriver, turn the wiper-adjustment pin clockwise to increase the voltage on the REFI1 input. Turn the wiper-adjustment pin counterclockwise to decrease the voltage on the REFI input. The REFI1 input allows for analog dimming of the LED string connected between LED1+ and GND1. A REFI1 input voltage of 0.2V or less turns off the LED driver. A REFI1 input volt-age between 0.2V and 1.2V provides linear dimming of the LED string. A REFI input voltage greater than 1.2V sets the LED string current to maximum current (based on the current-sense resistor). The analog dimming on channel 2 is controlled by the resistive-divider formed by R3 and R4 (potentiometer). Follow the same procedure as described for REFI1.Alternatively, the analog dimming input can be set with an external power supply. Remove the shunt on J6 and connect an external power supply directly to the REFI1 test point to perform analog dimming on LED1+ string. Remove the shunt on J1 and connect an external power supply directly to the REFI2 test point to perform analog dimming on LED2+ string. Pulse-Dimming Inputs (DIM1, DIM2)The EV kit demonstrates the PWM dimming feature of the MAX20097. Remove the shunt on J5. Connect a PWM sig-nal to the DIM1 test point. Vary the duty cycle to increase or decrease the intensity of the LED1+ string. The DIM1 and DIM2 inputs of the device have a 2V (max) rising threshold and a 0.8V (min) falling threshold and are com-patible with 3.3V and 5V logic-level signals. Remove the shunt on J3 for PWM dimming on LED2+ string. Connect a PWM signal to the DIM2 test point. Vary the duty cycle to increase or decrease the intensity of the LED2+ string. Fault IndicatorThe EV kit demonstrates the fault-protection features of the device, which include short-LED, open-LED, and overtemperature protection. The FLTB output is an open-drain, active-low fault indicator.Current Monitor OutputThe EV kit also demonstrates the current monitor output feature of the device. The IOUTV1 and IOUTV2 test points output a voltage which is a measure of the LED current. Refer to the MAX20096/MAX20097 data sheet for the equation relating to the IOUTV1 and IOUTV2 volt-age as well as the LED current.External V CC InputThe EV kit also demonstrates operation of the device with an external V CC input. In this case, the internal LDO is not used. Move the shunt on J4 to pins 2-3. In this case, IN and V CC pins of the device are shorted together. Apply an external power supply between 4.6V and 5.5V on the VCC test point to allow switching of the device. Separate Power Supply InputsThe second (LED2+) buck controller can be driven with a separate power supply, if needed. Removing the shunt on J2 enables to do this. Connect the second power supply between IN2 and GND4 PCB pads.#Denotes RoHS compliant.Ordering InformationPART TYPEMAX20097EVKIT#EV KitMAX20097 EV Kit Bill of MaterialsITEM QTY REF DES MAXINV MFG PART #MANUFACTURER VALUE DESCRIPTION COMMENTS19IN, IN2, AGND,GND1-GND4, LED1+,LED2+01-9020BUSS20AWG-009020 BUSS WEICO WIRE MAXIMPADEVK KIT PARTS;MAXIM PAD; WIRE; NATURAL;SOLID; WEICO WIRE; SOFTDRAWN BUS TYPE-S; 20AWG22C1, C2820-0001U-CA96CGA4J3X7R1H105M125AB TDK1UF CAPACITOR; SMT (0805); CERAMIC CHIP; 1UF; 50V;TOL=20%; TG=-55 DEGC TO +125 DEGC; TC=X7R; AUTO36C2, C6, C14, C16,C23, C2720-000U1-DA52CGA3E2X7R1H104K080AE TDK0.1UFCAPACITOR; SMT (0603);CERAMIC CHIP; 0.1UF; 50V;TOL=10%; TG=-55 DEGC TO +125DEGC; TC=X7R; AUTO; SOFTTERMINATION44C3, C12, C18, C2620-1000P-CA80CGA3E2C0G2A102J080AA TDK1000PF CAPACITOR; SMT (0603); CERAMIC CHIP; 1000PF; 100V; TOL=5%; TG=-55 DEGC TO +125 DEGC; TC=C0G; AUTO52C4, C2020-0001U-CA22CGA3E1X7R1V105K TDK1UF CAPACITOR; SMT (0603); CERAMIC CHIP; 1UF; 35V;TOL=10%; TG=-55 DEGC TO +125 DEGC; TC=X7R; AUTO64C9, C11, C17, C2120-004U7-CA59CGA6M3X7S2A475K200AE TDK 4.7UF CAPACITOR; SMT (1210); CERAMIC CHIP; 4.7UF; 100V; TOL=10%; TG=-55 DEGC TO +125 DEGC; TC=X7S; AUTO72C10, C1920-00U22-BA63CGA3E3X7R1H224K080AB;GCM188R71H224KA49TDK; MURATA0.22UFCAPACITOR; SMT (0603);CERAMIC CHIP; 0.22UF; 50V;TOL=10%; TG=-55 DEGC TO +125DEGC; TC=X7R; AUTO81C1320-002U2-CA73CGA3E1X7R0J225K080AC TDK 2.2UF CAPACITOR; SMT (0603); CERAMIC; 2.2UF; 6.3V; TOL=10%; TG=-55 DEGC TO +125 DEGC; TC=X7R; AUTO91C1520-000U1-CA82CGA4J2X7R2A104K125AA TDK0.1UF CAPACITOR; SMT (0805); CERAMIC CHIP; 0.1UF; 100V; TOL=10%; TG=-55 DEGC TO +125 DEGC; TC=X7R; AUTO102D1, D430-1N4448WS7F-001N4448WS-7-F DIODES INCORPORATED1N4448WS-7-F DIODE; SWT; SOD-323; PIV=75V; IF=0.5A114D2, D3, D5, D630-B18013F-00B180-13-F DIODES INCORPORATED B180-13-F DIODE; SCH; SCHOTTKY BARRIER RECTIFIER; SMA; PIV=80V; IF=1A128VCC, DIM1, DIM2,FLTB, REFI1, REFI2,IOUTV1, IOUTV202-TPCOMP5007-005007KEYSTONE N/ATEST POINT; PIN DIA=0.125IN;TOTAL LENGTH=0.35IN; BOARDHOLE=0.063IN; WHITE;PHOSPHOR BRONZE WIRESILVER PLATE FINISH;RECOMMENDED FOR BOARDTHICKNESS=0.062IN; NOT FORCOLD TEST135J1, J2, J6, J7, J1501-PCC02SAAN2P-21PCC02SAAN SULLINS PCC02SAAN CONNECTOR; MALE; THROUGH HOLE; BREAKAWAY; STRAIGHT THROUGH; 2PINS; -65 DEGC TO +125 DEGC143J3-J501-PCC03SAAN3P-21PCC03SAAN SULLINS PCC03SAAN CONNECTOR; MALE; THROUGH HOLE; BREAKAWAY; STRAIGHT THROUGH; 3PINS; -65 DEGC TO +125 DEGC152L1, L250-0047U-S44A MSS1278T-473ML COILCRAFT47UH INDUCTOR; SMT;FERRITE BOBBIN CORE; 47UH; TOL=+/-20%; 5.4AMAX20097 EV Kit Bill of Materials (continued)ITEM QTY REF DES MAXINV MFG PART #MANUFACTURER VALUE DESCRIPTION COMMENTS164Q1-Q490-BUK9Y10780E-21BUK9Y107-80E NXP BUK9Y107-80E TRAN; N-CHANNEL 80V;107MOHM LOGIC LEVEL MOSFET; NCH; LFPAK; PD-(37W); I-(11.8A); V-(80V)172R1, R2480-0453K-24ERJ-3EKF4533V PANASONIC453K RESISTOR; 0603; 453K OHM; 1%; 100PPM; 0.10W; THICK FILM184R2, R3, R21, R2580-024K9-24CRCW060324K9FK VISHAY DALE24.9K RESISTOR; 0603; 24.9K OHM; 1%; 100PPM; 0.10W; THICK FILM195R4, R14, R22,R29, R3080-0010K-24CRCW060310K0FK;ERJ-3EKF1002VISHAY DALE; PANASONIC10KRESISTOR; 0603; 10K; 1%;100PPM; 0.10W; THICK FILM202R5, R2380-0010K-39A3296W-1-103LF BOURNS10K RESISTOR; THROUGH-HOLE-RADIAL LEAD; 3296 SERIES; 10K OHM; 10%; 100PPM; 0.5W; SQUARE TRIMMING POTENTIOMETER; 25 TURNS; MOLDER CERAMIC OVER METAL FILM212R6, R2080-000R1-CA25RUW3216FR100SAMSUNG ELECTRONICS0.1RESISTOR; 1206; 0.1 OHM; 1%; 150PPM; 1W; THICK FILM228R7, R8, R10, R16,R18, R19, R31, R3280-0000R-27CRCW06030000ZS;MCR03EZPJ000; ERJ-3GEY0R00VISHAY DALE/ROHM/PANASONICRESISTOR; 0603; 0 OHM; 0%;JUMPER; 0.10W; THICK FILM234R11-R13, R1580-004R7-19CRCW06034R70FN VISHAY DALE 4.7RESISTOR; 0603; 4.7 OHM; 1%; 100PPM; 0.10W; THICK FILM241U100-SAMPLE-01MAX20097AHI+MAXIM MAX20097AHI+EVKIT PART-IC; DRV;DUAL CHANNEL HIGH VOLTAGE BUCK LED DRIVER WITH SPI INTERFACE; PACKAGE OUTLINE: 21-0066; PACKAGE CODE: U28-1; TSSOP28251PCB N/A MAX20097EVK MAXIM PCB PCB:MAX20097EVK-TOTAL8828N/A N/A N/A OPENTOTAL10PACKOUT (These are purchased parts but not assembled on PCB and will be shipped with PCB)ITEM QTY REF DES MAXINV MFG PART #MANUFACTURER VALUE DESCRIPTION COMMENTS TOTAL0Figure 1. MAX20097 EV Kit SchematicFigure 2. MAX20097 EV Kit Component Placement Guide—Component SideFigure 3. MAX20097 EV Kit PCB Layout—Top LayerFigure 4. MAX20097 EV Kit PCB Layout—Inner Layer 1Figure 5. MAX20097 EV Kit PCB Layout—Inner Layer 2Figure 6. MAX20097 EV Kit PCB Layout—Bottom Layer3.20 3.20Maxim Integrated cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim Integrated product. No circuit patent licenses are implied. Maxim Integrated reserves the right to change the circuitry and specifications without notice at any time.Revision HistoryREVISION NUMBERREVISION DATE DESCRIPTIONPAGES CHANGED9/18Initial release—For pricing, delivery, and ordering information, please visit Maxim Integrated’s online storefront at https:///en/storefront/storefront.html.。

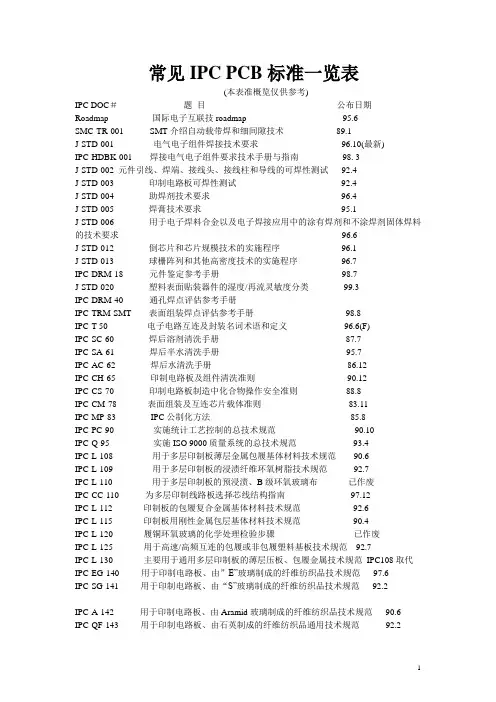

常见IPC PCB标准一览表(本表准概览仅供参考)IPC DOC#题目公布日期Roadmap 国际电子互联技roadmap 95.6SMC-TR-001 SMT介绍自动载带焊和细间隙技术89.1J-STD-001 电气电子组件焊接技术要求96.10(最新)IPC-HDBK-001 焊接电气电子组件要求技术手册与指南98. 3J-STD-002 元件引线、焊端、接线头、接线柱和导线的可焊性测试92.4J-STD-003 印制电路板可焊性测试92.4J-STD-004 助焊剂技术要求96.4J-STD-005 焊膏技术要求95.1J-STD-006 用于电子焊料合金以及电子焊接应用中的涂有焊剂和不涂焊剂固体焊料的技术要求96.6J-STD-012 倒芯片和芯片规模技术的实施程序96.1J-STD-013 球栅阵列和其他高密度技术的实施程序96.7IPC-DRM-18 元件鉴定参考手册98.7J-STD-020 塑料表面贴装器件的湿度/再流灵敏度分类99.3IPC-DRM-40 通孔焊点评估参考手册IPC-TRM-SMT 表面组装焊点评估参考手册98.8IPC-T-50 电子电路互连及封装名词术语和定义96.6(F)IPC-SC-60 焊后溶剂清洗手册87.7IPC-SA-61 焊后半水清洗手册95.7IPC-AC-62 焊后水清洗手册86.12IPC-CH-65 印制电路板及组件清洗准则90.12IPC-CS-70 印制电路板制造中化合物操作安全准则88.8IPC-CM-78 表面组装及互连芯片载体准则83.11IPC-MP-83 IPC公制化方法85.8IPC-PC-90 实施统计工艺控制的总技术规范90.10IPC-Q-95 实施ISO 9000质量系统的总技术规范93.4IPC-L-108 用于多层印制板薄层金属包履基体材料技术规范90.6IPC-L-109 用于多层印制板的浸渍纤维环氧树脂技术规范92.7IPC-L-110 用于多层印制板的预浸渍、B级环氧玻璃布已作废IPC-CC-110 为多层印制线路板选择芯线结构指南97.12IPC-L-112 印制板的包履复合金属基体材料技术规范92.6IPC-L-115 印制板用刚性金属包层基体材料技术规范90.4IPC-L-120 履铜环氧玻璃的化学处理检验步骤已作废IPC-L-125 用于高速/高频互连的包履或非包履塑料基板技术规范92.7IPC-L-130 主要用于通用多层印制板的薄层压板、包履金属技术规范IPC108取代IPC-EG-140 用于印制电路板、由”E”玻璃制成的纤维纺织品技术规范97.6IPC-SG-141 用于印制电路板、由“S”玻璃制成的纤维纺织品技术规范92.2IPC-A-142 用于印制电路板、由Aramid玻璃制成的纤维纺织品技术规范90.6 IPC-QF-143 用于印制电路板、由石英制成的纤维纺织品通用技术规范92.2IPC-CF-148 用于印制板的涂敷环氧树脂的金属98.9 IPC-MF-150 用于印制线路的金属箔92.8 IPC-CF-152 用于印制线路板的复合金属材料技术规范98.3 IPC-FC-203 扁平电缆、圆导体、接地面技术规范85.7 IPC-FC-210 扁平连接器地下电缆性能技术规范85.9 IPC-FC-213 扁平地下电话电缆技术规范84.9 IPC-FC-217IPC-FC-218B接插件、电气扁平电缆类型通用技术规范91.5 IPC-FC-219 航空用密封环境下扁平电缆接插件84.5 IPC-FC-220 非屏蔽扁平电缆、扁平接插件技术规范85.7 IPC-FC-221 用于扁平电缆的扁平铜导体技术规范84.5 IPC-FC-222 非屏蔽扁平电缆圆导体技术规范91.5 IPC-FC-225 扁平电缆设计指南85.10 IPC-FC-231 用于柔性印制线路的柔性基体绝缘材料95.10 IPC-FC-232 用于柔性印制线路和柔性连接膜覆盖板涂镀粘接剂95.10 IPC-FC-233 参考232IPC-FC-241 用于制造柔性印制线路的柔性包履金属绝缘材料95.10 IPC-RF-245 刚柔印制电路板性能技术规范87.4 IPC-D-249 单、双面柔性印制电路板设计标准87.1 IPC-FC-250A 单、双面柔性印制线路技术规范86.9 IPC-FA-251 单面和双面柔性电路指南92.2 IPC-D-275 刚性印制电路板和刚性印制电路板组件设计标准96.4 IPC-RB-276 刚性印制电路板规格和性能技术规范92.3 IPC-D-279 可靠的表面组装技术印制电路板组件设计指南96.7 IPC-D-300 印制电路板尺寸和公差84.1 IPC-D-310 照相工具生成和测量技术指南91.6 IPC-A-311 照相工具生成及使用工艺控制指南96.3 IPC-D-316 采用软基板的微波电路板设计指南95.5 IPC-D-317 采用高速技术的电子封装设计指南95.1 IPC-HF-318 微波终端产品电路板的检验和测试91.12 IPC-D-319 刚性单面和双面印制电路板设计标准87.1 IPC-D-320A 印制电路板、刚性、单面和双面、终端产品标准81.3 IPC-SD-320B 刚性单面和双面印制电路板性能技术规范86.11 IPC-D-322 参照标准板尺寸选择印制线路板尺寸指南91.9 IPC-MC-324 金属芯电路板性能技术规范88.10 IPC-D-325 印制电路板、组件和支持图文件技术要求95.5 IPC-D-326 制造印制电路板组件资料技术要求91.4 IPC-D-330 设计指南手册IPC-PD-335 电子封装手册89.12 IPC-NC-349 布线器计算机数字控制格式化85.8 IPC-D-350 用数字形式描述印制电路板92.7 IPC-D-351 用数字形式描述印制电路板图85.8 IPC-D-352 用数字对式印制电路板的电子设计数据描述85.8IPC-D-354 数字形式印制电路板图库格式描述87.2IPC-D-355 用数字形式描述印制电路板组装95.1IPC-D-356 用数字形式测试的裸板电气性能资料98.1IPC-AM-361 用于加工艺印制电路板的刚性基板技术规范82.1(作废)IPC-MB-380 模制互连器件指南90.10IPC-D-390 自动设计指南88.2IPC-C-406 表面组装接插件设计和应用指南90.1IPC-CI-408 非焊接表面贴装接插件设计和应用指南94.1IPC-BP-421 压装的刚性印制电路板底板通用技术规范90.4IPC-D-422 压装刚性印制电路板底板设计指南82.9IPC-DW-424 密封分立线互连电路板通用技术规范95.1IPC-DW-425 分立线路板设计与终端产品技术要求90.5IPC-DW-426 分立线路组装技术规范87.12IPC-TR-460 印制线路板波峰焊接故障检测表84.2IPC-TR-461 厚薄涂层的可焊性评价79.3IPC-TR-462 为长期保存而涂履保护涂层的印制线路板的可焊性评价87.10IPC-TR-464 用于可焊性评价的加速老化87.12IPC-TR-465-1 关于蒸气老化温度控制稳定性的循环测试93IPC-TR-465-2 蒸气老化时间和温度对可焊性测试结果的影响93IPC-TR-465-3 关于替代涂饰蒸汽老化评价96.7IPC-TR-466 润湿平衡标准重量比较测试95.4IPC-TR-467 ANSI/J-STD-001附件D的支持数据和数字举例96.10IPC-TR-468 影响印制电路板绝缘电阻性能的因素79.3IPC-TR-470 多层互连线路板的热特性74.1IPC-TR-474 分立线路技术综观79.3IPC-TR-476 如何避免电子硬件中金属膨胀问题74.1IPC-TR-480 多层IV 循环测试程序阶段I的结果75.9IPC-TR-481 多层V 循环测试程序的结果81.4IPC-TR-483 薄层压板的尺寸稳定性测试椀?/FONT>1 阶段报告国际循环测试程序86.4 IPC-TR-484 IPC铜箔延展性循环研究的结果86.4IPC-TR-485 IPC铜箔脆性强度测试循环研究结果85.3IPC-TR-549 印制线路板上的斑点73.11IPC-TR-551 印制板电子元件组装和互连的质量评价93.7IPC-DR-570 直径为1/8英寸的硬质合金钻头印制板总技术规范84.4IPC-DR-572 印制电路板钻孔指南88.4IPC-TR-576 加工艺评价77.9IPC-TR-578 引线边缘制造技术报告84.9IPC-TR-579 印制线路板小直径镀履通孔的循环可靠性评估88.9IPC-TR-580 清洗和清洁度测试程序第1阶段测试结果89.10IPC-TR-581 IPC第3 阶段控制气氛焊接研究94.8IPC-TR-582 IPC第3 阶段免洗助焊剂研究94.11IPC-A-600 印制电路板的可接受性(检验标准) 95.8IPC-QE-605A 印制电路板质量评价手册99.2IPC-SS-605 印制电路板质量评价IPC-A-610 电子组件的检验标准95.8IPC-QE-615 组装质量评估手册93.3IPC-SS-615 组装质量评估93.3IPC-AI-640 未贴装元件的厚膜混装基板的自动检测用户指南87.1IPC-AI-641 焊点自动检测用户指南87.1IPC-AI-642 原理图、内层、未贴装元件的PWB自动检测用户指南88.10IPC-OI-645 光学检测仪器标准93.10IPC-TM-650 测试方法手册IPC-ET-652 未贴装元件的印制电路板的电气测试规则和技术要求90.10IPC-QL-653 检验/测试印制电路板、元件、材料的设备鉴定97.11IPC-MI-660 原材料来料检测手册84.2IPC-R-700C 印制电路板和组件的改型、返工、返修指南88.1IPC-TA-720 层压板技术评估手册IPC-TA-721 多层电路板技术评估手册IPC-TA-722 焊接技术评估IPC-TA-723 表面组装技术评估手册IPC-TA-724 净化间技术评估IPC-PE-740 印制电路板制造和组装故障检测指南97.12IPC-CM-770 印制电路板元件贴装96.1IPC-SM-780 表面组装元件的封装和互连88.3IPC-SM-782 表面组装设计和焊盘图形标准96.10 IPC-EM-782 表面组装设计和焊盘分布图形95.12 IPC-SM-784 COB技术应用指南90.11IPC-SM-785 表面贴装焊点连接的快速可靠性测试指南92.11 IPC-SM-786 潮湿气氛/再流感应ICs的特性化和处理步骤95.1IPC-MC-790 多芯片模块技术应用指南92.8IPC-S-804 印制线路板的可焊性测试方法87.1IPC-S-805 元件引线和端点的可焊性测试85.1IPC-MS-810 高容量显微薄片指南93.10 IPC-S-815 焊接电子互连件的通用技术要求87.12 IPC-S-816 SMT工艺指南和清单93.7IPC-SM-817 绝缘表面贴装胶的通用技术要求89.11 IPC-SF-818 用于电子组件焊接的助焊剂通用技术要求91.12IPC-SP-819 用于电子工业的焊膏通用技术要求和测试方法88.10IPC-AJ-820 组装和连接手册96.8IPC-CA-821 导热粘接剂通用技术要求95.1IPC-CC-830 用于印制电路板组件的电子绝缘化合物的鉴定和性能98.10IPC-SM-839 施用焊料掩膜前后的清洗指南90.4IPC-SM-840 用于印制电路板的永久性聚合物涂层的鉴定与性能96.1IPC-H-855 混合微电路设计指南82.10 IPC-D-859 厚膜多层混合电路设计标准89.12 IPC-HM-860 多层混合电路技术规范87.1IPC-TF-870 聚合物厚膜印制电路板的鉴定和性能89.11 IPC-ML-910 被275替代IPC-D-949 刚性多层印制电路板设计标准87.1IPC-ML:-950 刚性多层印制电路板性能技术规范86.11IPC-ML-960 用于多层印制电路板的批量层压面板的鉴定与性能技术规范94.7IPC-ML-975 用于多层印制线路板的终端产品技术规范69.9IPC-ML-990 柔性多层线路性能技术规范72.9IPC-1402 混合微电路设计指南82.10IPC-1710 印制电路板制造者的鉴定曲线(MQP)的OEM标准97.12IPC-1720 组装鉴定曲线(AQP) 96.7IPC-1730 胶合机鉴定曲线(LQP) 98.1IPC-2141 可控阻抗电路板与高速逻辑设计90.4IPC-2221 印制电路板通用标准98.2IPC-2222 刚性有机印制电路板部分设计标准98.2IPC-2223 柔性印制电路板分段设计标准98.11IPC-3406 表面组装用导电胶规则96.7IPC-3408 各向异性导电粘接剂膜通用技术要求96.11IPC-4101 刚性及多层印制板的基体材料技术规范97.12IPC-4110 用于印制电路板非纺织物纤维素纸技术规范与特征化方法98.8IPC-4130 非纺织物”E”玻璃纤维板技术规范与特征化方法98.9IPC-6011 印制电路板通用性能技术规范96.7IPC-6012 刚性印制电路板的鉴定与性能技术规范96.7IPC-6013 柔性印制电路板的鉴定与性能技术规范98.11IPC-6015 有机多芯片模块(MCM-L)组装及互连结构的鉴定与性能技术规范98.2IPC-6018 微波终端产品电路板检验与测试98.1IPC/JPCA-6202 单双面柔性印制线路板性能指导手册99.2IPC-7711 电子组件返修98.4IPC-7721 印制电路板和电子组件的返修与改型98.4IPC-9201 表面绝缘电阻手册96.7IPC-9501 评价电子元件的PWB仿真组装工艺95.7 公布IPC-9504 评价非IC元件的仿真组装工艺98.6 度量图98.4片式元件图98.8鸥翼形元件图98.8J形引线元件图98.8。

整合性混合訊號解決方案PCB布局及工业设计指南SigmaTel D -主要應用註釋2004 年 9 月 0.4 版_____________________________________________________________正式產品文檔2004 年 9 月 28 日______________________________________________________________________________________________________________5-PCBLO-1.0-051303© 2001 年 SigmaTel 股份有限公司版權所有,保留一切權利。

本文件全部內容均受版權法保護,未經 SigmaTel, Inc. 明示的書面同意不得複製。

本文件所包含的 SigmaTel、SigmaTel 徽標及其組合均為 SigmaTel, Inc. 的商標。

本出版物使用的其他產品名稱均僅用於辨識目的,可能是其各自所屬公司的商標或註冊商標。

本文件內容與 SigmaTel, Inc. 產品一道提供。

SigmaTel, Inc. 已盡最大努力確保本文所含資訊的準確性和可靠性。

但是,SigmaTel, Inc. 對本出版物內容的準確性和完整性不做任何明示或暗示的保證,並按「概不保證」原則提供本出版物。

SigmaTel, Inc. 保留隨時更改技術規格和產品說明的權利。

並保留隨時停止生產或更改其產品的權利,對此無須事先通知。

SigmaTel, Inc. 不承擔因任何產品或電路的應用或使用而產生的任何責任,並明確表示不承擔任何及所有責任,包括但不僅限於特殊、連帶或意外損壞。

PCB布局及工业设计指南SigmaTel D -主要應用註釋修訂記錄修訂日期說明原版發佈0.2 01/28/041. 在所有頁面上添加了以毫米和密爾為單位的尺寸。

0.3 02/05/042. 添加了有關 DCDC_GND 引腳接地的進一步闡釋。

目 录题 目IPC-SC-60A锡焊后溶剂清洗手册IPC-SA-61锡焊后半水溶剂清洗手册IPC-AC-62A 锡焊后水溶液清洗手册IPC-CH-65A 印制板及组装件清洗导则IPC-FC-234 单面和双面印制电路压敏胶粘剂组装导则IPC-D-279 高可靠表面安装印制板组装件技术设计导则IPC-A-311 照相版制作和使用的过程控制IPC-D-316 高频设计导则IPC-D-317A 采用高速技术电子封装设计导则IPC-C-406 表面安装连接器设计及应用导则IPC-CI-408 使用无焊接表面安装连接器设计及应用导则IPC-TR-579 印制板中小直径镀覆孔可靠性评价联合试验IPC-A-600F 中文版 印制板验收条件IPC-QE-605A 印制板质量评价IPC-A-610C 中文版 印制板组装件验收条件IPC-ET-652 未组装印制板电测试要求和指南IPC-PE-740A 印制板制造和组装的故障排除IPC-CM-770D 印制板元件安装导则IPC-SM-780 以表面安装为主的元件封装及互连导则IPC-SM-782A 表面安装设计及连接盘图形标准(包括修订1和2)IPC-SM-784 芯片直装技术实施导则IPC-SM-785 表面安装焊接件加速可靠性试验导则IPC-SM-786A 湿度/再流焊敏感集成电路的特性分级与处置程序IPC-CA-821 导热胶粘剂通用要求IPC-SM-839 施加阻焊前及施加后清洗导则IPC-1131 印制板印制造商用信息技术导则IPC/JPCA-2315 高密度互连与微导通孔设计导则IPC-4121 多层印制板用芯板结构选择导则(代替IPC-CC-110A)IPC/JPCA-6801 积层/高密度互连的术语和定义、试验方法与设计例IPC-7095 球栅阵列的设计与组装过程的实施IPC-7525 网版设计导则IPC-7711 电子组装件的返工IPC-7721 印制板和电子组装的修复与修正IPC-7912 印制板和电子组装件的DPMO(每百万件缺陷数)和制造指数的计算IPC-9191 实施统计过程控制(SPC)的通用导则IPC-9201 表面绝缘电阻手册IPC-9501 电子元件的印制板组装过程模拟评价(集成电路预处理)IPC-9502 电子元件的印制板组装焊接过程导则IPC-9503 非集成电路元件的湿度敏感度分级IPC-9504 非集成电路元件的组装过程模拟评价(非集成电路元件预处理)J-STD-012 倒装芯片及芯片级封装技术的应用J-STD-013 球栅阵列及其它高密度封装技术的应用IPC/EIA J-STD-026倒装芯片用半导体设计标准IPC/EIA J-STD-028倒装芯版面及芯片凸块结构的性能标准IPC/JEDEC J-STD-035非气密封装电子元件用声波显微镜IPC-HDBK-001 已焊接电子组装件的要求手册与导则IPC-T-50F 电子电路互连与封装术语和定义IPC-L-125A 高速高频互连用覆箔或未覆箔塑料基材规范IPC-DD-135 多芯片组件内层有机绝缘材料的鉴定试验IPC-EG-140 印制板用经处理E玻璃纤维编织物规范(包括修改1及修改2)IPC-SG-141 印制板用经处理S玻璃纤维织物规范IPC-A-142 印制板用经处理聚芳酰胺纤维编织物规范IPC-QF-143 印制板用经处理石英(熔融纯氧化硅)纤维编织物规范IPC-CF-148A 印制板用涂树脂金属箔IPC-CF-152B 印制线路板复合金属材料规范IPC-FC-231C 挠性印制线路用挠性绝缘基底材料(包括规格单修改)IPC-FC-232C 挠性印制线路和挠性粘结片用涂粘接剂绝缘薄膜(包括规格单修改)IPC-FC-241C 制造挠性印制线路板用挠性覆箔绝缘材料(包括规格单修改)IPC-D-322 使用标准在制板尺寸的印制板尺寸选择指南IPC-MC-324 金属芯印制板性能规范IPC-D-325A 印制板、印制板组装件及其附图的文件要求IPC-D-326 制造印制板组装件的资料要求IPC-NC-349 钻床和铣床用计算机数字控制格式IPC-D-356A 裸基板电检测的数据格式IPC-DW-424 封入式分立布线互连板通用规范IPC-DW-425A 印制板分立线路的设计及成品要求(包括修改1)IPC-DW-426 分立线路组装规范IPC-OI-645 目视光学检查工具标准IPC-QL-653A 印制板、元器件及材料检验试验设备的认证IPC-CA-821 导热粘接剂通用要求IPC-CC-830A 印制板组装件用电绝缘复合材料的鉴定与性能(包括修改1)IPC-SM-840C 永久性阻焊剂的鉴定及性能(包括修改1)IPC-D-859 厚膜多层混合电路设计标准IPC-HM-860 多层混合电路规范IPC-TF-870 聚合物厚膜印制板的鉴定与性能IPC-ML-960 多层印制板用预制内层在制板的鉴定与性能规范IPC-1902/IEC 60097印制电路网格体系IPC-2221 印制板设计通用标准(代替IPC-D-275)(包括修改1)IPC-2222 刚性有机印制板设计分标准(代替IPC-D-275)IPC-2223 挠性印制板设计分标准(代替IPC-D-249)IPC-2224 PC卡用印制电路板分设计分标准IPC-2225 有机多芯片模块(MCM-L)及其组装件设计分标准IPC-2511A 产品制造数据及其传输方法学的通用要求IPC-2524 印制板制造数据质量定级体系IPC-2615 印制板尺寸和公差IPC-3406 表面贴装导电胶使用指南IPC-3408 各向异性导电胶膜的一般要求IPC-4101 刚性及多层印制板用基材规范IPC/JPCA-4104 高密度互连(HDI)及微导通孔材料规范IPC-4110 印制板用纤维纸规范及性能确定方法IPC-4130E 玻璃非织布规范及性能确定方法IPC-4411 聚芳基酰胺非织布规范及性能确定方法IPC-DR-570A,IPC-4562,IPC6016印制线路用金属箔(代替IPC-MF-150F)IPC-6011 中文版 印制板通用性能规范(代替IPC-RB-276)IPC-6012A中文版 刚性印制板的鉴定与性能规范(包括修改1)IPC-6013 挠性印制板的鉴定与性能规范(包括修改1)IPC-6015 有机多芯片模块(MCM-L)安装及互连结构的鉴定与性能规范IPC-6016 高密度互连(HDI)层或印制板的鉴定与性能规范IPC-6018 微波成品印制板的检验和测试(代替IPC-HF-318A)IPC/JPCA-6202 单双面挠性印制板性能手册J-STD-001C 电气与电子组装件锡焊要求IPC/EIA J-STD-002A元件引线、端子、焊片、接线柱及导线可焊性试验J-STD-003 印制板可焊性试验(代替IPC-S-804A)J-STD-004 锡焊焊剂要求(包括修改1)J-STD-005 焊膏技术要求(包括修改1)J-STD-006电子设备用电子级锡焊合金、带焊剂及不带焊剂整体焊料技术要求(包括修改1)IPC/JEDEC J-STD-020A非密封固态表面贴装器件湿度/再流焊敏感度分类IPC/JEDEC J-STD-033对湿度、再流焊敏感表贴装器件的处置、包装、发运和使用IPC PCB标准概览IPC DOC# 题 目公布日期Roadmap 国际电子互联技术roadmap 95.6SMC-TR-001 SMT介绍自动载带焊和细间隙技术 89.1J-STD-001 电气电子组件焊接技术要求 96.10(最新)IPC-HDBK-001 焊接电气电子组件要求技术手册与指南 98. 3J-STD-002 元件引线、焊端、接线头、接线柱和导线的可焊性测试 92.4J-STD-003 印制电路板可焊性测试 92.4J-STD-004 助焊剂技术要求 96.4J-STD-005 焊膏技术要求 95.1J-STD-006 用于电子焊料合金以及电子焊接应用中的涂有焊剂和不涂焊剂固体焊料的技术要求 96.6J-STD-012 倒芯片和芯片规模技术的实施程序 96.1J-STD-013 球栅阵列和其他高密度技术的实施程序 96.7IPC-DRM-18 元件鉴定参考手册 98.7J-STD-020 塑料表面贴装器件的湿度/再流灵敏度分类 99.3IPC-DRM-40 通孔焊点评估参考手册 IPC-TRM-SMT 表面组装焊点评估参考手册 98.8IPC-T-50 电子电路互连及封装名词术语和定义 96.6(F)IPC-SC-60 焊后溶剂清洗手册 87.7IPC-SA-61 焊后半水清洗手册 95.7IPC-AC-62 焊后水清洗手册 86.12IPC-CH-65 印制电路板及组件清洗准则 90.12IPC-CS-70 印制电路板制造中化合物操作安全准则 88.8IPC-CM-78 表面组装及互连芯片载体准则83.11IPC-MP-83 IPC公制化方法85.8IPC-PC-90 实施统计工艺控制的总技术规范 90.10IPC-Q-95 实施ISO 9000质量系统的总技术规范93.4IPC-L-108 用于多层印制板薄层金属包履基体材料技术规范 90.6IPC-L-109 用于多层印制板的浸渍纤维环氧树脂技术规范 92.7IPC-L-110 用于多层印制板的预浸渍、B级环氧玻璃布 已作废IPC-CC-110 为多层印制线路板选择芯线结构指南 97.12IPC-L-112 印制板的包履复合金属基体材料技术规范 92.6IPC-L-115 印制板用刚性金属包层基体材料技术规范 90.4IPC-L-120 履铜环氧玻璃的化学处理检验步骤 已作废IPC-L-125 用于高速/高频互连的包履或非包履塑料基板技术规范 92.7IPC-L-130 主要用于通用多层印制板的薄层压板、包履金属技术规范 IPC108取代IPC-EG-140 用于印制电路板、由”E”玻璃制成的纤维纺织品技术规范 97.6IPC-SG-141 用于印制电路板、由“S”玻璃制成的纤维纺织品技术规范 92.2IPC-A-142 用于印制电路板、由Aramid玻璃制成的纤维纺织品技术规范90.6IPC DOC# 题 目公布日期IPC-QF-143 用于印制电路板、由石英制成的纤维纺织品通用技术规范 92.2IPC-CF-148 用于印制板的涂敷环氧树脂的金属 98.9IPC-MF-150 用于印制线路的金属箔 92.8IPC-CF-152 用于印制线路板的复合金属材料技术规范 98.3IPC-FC-203 扁平电缆、圆导体、接地面技术规范 85.7IPC-FC-210 扁平连接器地下电缆性能技术规范 85.9IPC-FC-213 扁平地下电话电缆技术规范84.9IPC-FC-217 IPC-FC-218B 接插件、电气扁平电缆类型通用技术规范 91.5IPC-FC-219 航空用密封环境下扁平电缆接插件 84.5IPC-FC-220 非屏蔽扁平电缆、扁平接插件技术规范 85.7IPC-FC-221 用于扁平电缆的扁平铜导体技术规范 84.5IPC-FC-222 非屏蔽扁平电缆圆导体技术规范 91.5IPC-FC-225 扁平电缆设计指南 85.10IPC-FC-231 用于柔性印制线路的柔性基体绝缘材料 95.10IPC-FC-232 用于柔性印制线路和柔性连接膜覆盖板涂镀粘接剂 95.10IPC-FC-233 参考 232IPC-FC-241 用于制造柔性印制线路的柔性包履金属绝缘材料 95.10IPC-RF-245 刚柔印制电路板性能技术规范 87.4IPC-D-249 单、双面柔性印制电路板设计标准87.1IPC-FC-250A 单、双面柔性印制线路技术规范 86.9IPC-FA-251 单面和双面柔性电路指南 92.2IPC-D-275 刚性印制电路板和刚性印制电路板组件设计标准 96.4IPC-RB-276 刚性印制电路板规格和性能技术规范 92.3IPC-D-279 可靠的表面组装技术印制电路板组件设计指南 96.7IPC-D-300 印制电路板尺寸和公差84.1IPC-D-310 照相工具生成和测量技术指南 91.6IPC-A-311 照相工具生成及使用工艺控制指南 96.3IPC-D-316 采用软基板的微波电路板设计指南 95.5IPC-D-317 采用高速技术的电子封装设计指南 95.1IPC-HF-318 微波终端产品电路板的检验和测试 91.12IPC-D-319 刚性单面和双面印制电路板设计标准 87.1IPC-D-320A 印制电路板、刚性、单面和双面、终端产品标准 81.3IPC-SD-320B 刚性单面和双面印制电路板性能技术规范 86.11IPC-D-322 参照标准板尺寸选择印制线路板尺寸指南 91.9IPC-MC-324 金属芯电路板性能技术规范 88.10IPC-D-325 印制电路板、组件和支持图文件技术要求 95.5IPC-D-326 制造印制电路板组件资料技术要求 91.4IPC-D-330 设计指南手册 IPC-PD-335 电子封装手册 89.12IPC DOC# 题 目公布日期IPC-NC-349 布线器计算机数字控制格式化 85.8IPC-D-350 用数字形式描述印制电路板 92.7IPC-D-351 用数字形式描述印制电路板图 85.8IPC-D-352 用数字对式印制电路板的电子设计数据描述 85.8IPC-D-354 数字形式印制电路板图库格式描述 87.2IPC-D-355 用数字形式描述印制电路板组装 95.1IPC-D-356 用数字形式测试的裸板电气性能资料 98.1IPC-AM-361 用于加工艺印制电路板的刚性基板技术规范 82.1(作废)IPC-MB-380 模制互连器件指南 90.10IPC-D-390 自动设计指南 88.2IPC-C-406 表面组装接插件设计和应用指南 90.1IPC-CI-408 非焊接表面贴装接插件设计和应用指南 94.1IPC-BP-421 压装的刚性印制电路板底板通用技术规范 90.4IPC-D-422 压装刚性印制电路板底板设计指南 82.9IPC-DW-424 密封分立线互连电路板通用技术规范 95.1IPC-DW-425 分立线路板设计与终端产品技术要求 90.5IPC-DW-426 分立线路组装技术规范 87.12IPC-TR-460 印制线路板波峰焊接故障检测表 84.2IPC-TR-461 厚薄涂层的可焊性评价 79.3IPC-TR-462 为长期保存而涂履保护涂层的印制线路板的可焊性评价 87.10 IPC-TR-464 用于可焊性评价的加速老化 87.12IPC-TR-465-1 关于蒸气老化温度控制稳定性的循环测试 93IPC-TR-465-2 蒸气老化时间和温度对可焊性测试结果的影响 93IPC-TR-465-3 关于替代涂饰蒸汽老化评价 96.7IPC-TR-466 润湿平衡标准重量比较测试 95.4IPC-TR-467 ANSI/J-STD-001附件D的支持数据和数字举例 96.10IPC-TR-468 影响印制电路板绝缘电阻性能的因素 79.3IPC-TR-470 多层互连线路板的热特性 74.1IPC-TR-474 分立线路技术综观 79.3IPC-TR-476 如何避免电子硬件中金属膨胀问题 74.1IPC-TR-480 多层 IV 循环测试程序阶段I的结果 75.9IPC-TR-481 多层 V 循环测试程序 的结果 81.4IPC-TR-483 薄层压板的尺寸稳定性测试椀?/FONT>1 阶段报告国际循环测试程序 86.4IPC-TR-484 IPC铜箔延展性循环研究的结果 86.4IPC-TR-485 IPC铜箔脆性强度测试循环研究结果 85.3IPC-TR-549 印制线路板上的斑点 73.11IPC-TR-551 印制板电子元件组装和互连的质量评价 93.7IPC-DR-570 直径为1/8英寸的硬质合金钻头印制板总技术规范 84.4IPC-DR-572 印制电路板钻孔指南 88.4IPC-TR-576 加工艺评价 77.9IPC DOC# 题 目 公布日期IPC-TR-578 引线边缘制造技术报告 84.9IPC-TR-579 印制线路板小直径镀履通孔的循环可靠性评估 88.9IPC-TR-580 清洗和清洁度测试程序第1阶段测试结果 89.10IPC-TR-581 IPC第3 阶段控制气氛焊接研究 94.8IPC-TR-582 IPC第3 阶段免洗助焊剂研究 94.11IPC-A-600 印制电路板的可接受性(检验标准) 95.8IPC-QE-605A 印制电路板质量评价手册 99.2IPC-SS-605 印制电路板质量评价 IPC-A-610 电子组件的检验标准 95.8IPC-QE-615 组装质量评估手册 93.3IPC-SS-615 组装质量评估 93.3IPC-AI-640 未贴装元件的厚膜混装基板的自动检测用户指南 87.1IPC-AI-641 焊点自动检测用户指南 87.1IPC-AI-642 原理图、内层、未贴装元件的PWB自动检测用户指南 88.10 IPC-OI-645 光学检测仪器标准 93.10IPC-TM-650 测试方法手册 IPC-ET-652 未贴装元件的印制电路板的电气测试规则和技术要求 90.10 IPC-QL-653 检验/测试印制电路板、元件、材料的设备鉴定 97.11IPC-MI-660 原材料来料检测手册 84.2IPC-R-700C 印制电路板和组件的改型、返工、返修指南 88.1IPC-TA-720 层压板技术评估手册 IPC-TA-721 多层电路板技术评估手册 IPC-TA-722 焊接技术评估 IPC-TA-723 表面组装技术评估手册 IPC-TA-724 净化间技术评估 IPC-PE-740 印制电路板制造和组装故障检测指南 97.12IPC-CM-770 印制电路板元件贴装 96.1IPC-SM-780 表面组装元件的封装和互连 88.3IPC-SM-782 表面组装设计和焊盘图形标准 96.10IPC-EM-782 表面组装设计和焊盘分布图形 95.12IPC-SM-784 COB技术应用指南 90.11IPC-SM-785 表面贴装焊点连接的快速可靠性测试指南 92.11IPC-SM-786 潮湿气氛/再流感应ICs的特性化和处理步骤 95.1IPC-MC-790 多芯片模块技术应用指南 92.8IPC-S-804 印制线路板的可焊性测试方法 87.1IPC-S-805 元件引线和端点的可焊性测试 85.1IPC-MS-810 高容量显微薄片指南 93.10IPC-S-815 焊接电子互连件的通用技术要求 87.12IPC-S-816 SMT工艺指南和清单 93.7IPC-SM-817 绝缘表面贴装胶的通用技术要求 89.11IPC-SF-818 用于电子组件焊接的助焊剂通用技术要求 91.12IPC DOC# 题 目 公布日期IPC-SP-819 用于电子工业的焊膏通用技术要求和测试方法 88.10IPC-AJ-820 组装和连接手册 96.8IPC-CA-821 导热粘接剂通用技术要求 95.1IPC-CC-830 用于印制电路板组件的电子绝缘化合物的鉴定和性能 98.10 IPC-SM-839 施用焊料掩膜前后的清洗指南 90.4IPC-SM-840 用于印制电路板的永久性聚合物涂层的鉴定与性能 96.1IPC-H-855 混合微电路设计指南 82.10IPC-D-859 厚膜多层混合电路设计标准 89.12IPC-HM-860 多层混合电路技术规范 87.1IPC-TF-870 聚合物厚膜印制电路板的鉴定和性能 89.11IPC-ML-910 被275替代IPC-D-949 刚性多层印制电路板设计标准 87.1IPC-ML:-950 刚性多层印制电路板性能技术规范 86.11IPC-ML-960 用于多层印制电路板的批量层压面板的鉴定与性能技术规范 94.7IPC-ML-975 用于多层印制线路板的终端产品技术规范 69.9IPC-ML-990 柔性多层线路性能技术规范 72.9IPC-1402 混合微电路设计指南 82.10IPC-1710 印制电路板制造者的鉴定曲线(MQP)的OEM标准 97.12IPC-1720 组装鉴定曲线(AQP) 96.7IPC-1730 胶合机鉴定曲线(LQP) 98.1IPC-2141 可控阻抗电路板与高速逻辑设计 90.4IPC-2221 印制电路板通用标准 98.2IPC-2222 刚性有机印制电路板部分设计标准 98.2IPC-2223 柔性印制电路板分段设计标准 98.11IPC-3406 表面组装用导电胶规则 96.7IPC-3408 各向异性导电粘接剂膜通用技术要求 96.11IPC-4101 刚性及多层印制板的基体材料技术规范 97.12IPC-4110 用于印制电路板非纺织物纤维素纸技术规范与特征化方法 98.8 IPC-4130 非纺织物”E”玻璃纤维板技术规范与特征化方法 98.9IPC-6011 印制电路板通用性能技术规范 96.7IPC-6012 刚性印制电路板的鉴定与性能技术规范 96.7IPC-6013 柔性印制电路板的鉴定与性能技术规范 98.11IPC-6015 有机多芯片模块(MCM-L)组装及互连结构的鉴定与性能技术规范 98.2IPC-6018 微波终端产品电路板检验与测试 98.1IPC/JPCA-6202 单双面柔性印制线路板性能指导手册 99.2IPC-7711 电子组件返修 98.4IPC-7721 印制电路板和电子组件的返修与改型 98.4IPC-9201 表面绝缘电阻手册 96.7IPC-9501 评价电子元件的PWB仿真组装工艺 95.7IPC DOC# 题 目 公布日期IPC-9504 评价非IC元件的仿真组装工艺 98.6 度量图 98.4 片式元件图 98.8 鸥翼形元件图 98.8 J形引线元件图 98.8。

追溯过去自从1987年以来,每当工业需要有关焊盘图形尺寸和容差方面的信息时,总是依照表面贴装设计和焊盘图形标准IPC-SM-782。

1993年曾对该标准的修订版A进行了一次彻底修正,接着1996年对新的片式元件进行了修正,到1999年又对引脚间距小于1.0 mm的BGA 元件进行了修正,该文件向用户提供了表面贴装焊盘的合适尺寸、形状和容差,以保证这些焊点的焊缝满足要求,同时可供检验与测试。

该文件还努力紧跟新元件系列的不断推出和元件密度向更高方向发展的趋势,IPC确认其范例交换是有序的。

走入未来2005年2月,IPC发布了期待已久的IPC-SM-782A的替代标准IPC-7351——表面贴装设计和焊盘图形标准通用要求。

IPC-7351不只是一个强调新的元件系列更新的焊盘图形的标准,如方型扁平无引线封装QFN (Quad Flat No-Lead)和小外型无引线封装SON (Small Outline No-Lead);还是一个反映焊盘图形方面的研发、分类和定义——这些建立新的工业CAD数据库的关键元素——的全新变化的标准。

您想要它多小?IPC-7351 的基本概念紧紧围绕着三个焊盘图形几何形状的变化,所设计的这三个新的具体应用的焊盘图形几何形状的变化,支持各种复杂度等级的产品;而IPC-SM-782只是一个对已有元件提供单个焊盘图形的推荐技术标准。

IPC-7351认为要满足元件密度、高冲击环境和对返修的需求等变量的要求,只有一个焊盘图形推荐技术标准是不够的;因此,IPC-7351为每一个元件提供了如下的三个焊盘图形几何形状的概念,用户可以从中进行选择:密度等级A:最大焊盘伸出——适用于高元件密度应用中,典型的像便携/手持式或暴露在高冲击或震动环境中的产品。

焊接结构是最坚固的,并且在需要的情况下很容易进行返修。

密度等级B:中等焊盘伸出——适用于中等元件密度的产品,提供坚固的焊接结构。

密度等级C:最小焊盘伸出——适用于焊盘图形具有最小的焊接结构要求的微型器件,可实现最高的元件组装密度。

Electrical Integration GuideSL1204-06-50200 – April 2009 – Initial Revision RevisionGPS Applications Using SL1206 and SL1204 Active AntennasABSTRACTGPS Navigation systems requiring superior performance typically use an active antenna, consisting of an antenna and a high performance Low Noise Amplifier. An electrical guideline is presented, for the integration of Sarantel’s active antennas.INTRODUCTIONThe Sarantel GeoHelix® active GPS Antennas are designed to operate with GPS receivers from many manufacturers. The active design using the standard SL1200-GeoHelix® -P2 antenna, helps the designer to achieve high performance and robust antenna solutions with significantly reduced development time in “otherwise difficult to achieve” GPS applications. The antenna module can be fully embedded in the housing or the enclosure can include an external protective radome for applications where an external antenna is required.The active antenna module’s electrical circuitry is contained underneath the soldered metal can. The major elements include a quadrifilar helix antenna, high temperature plastic support, Low Noise Amplifier (LNA) and the protective antenna Radome or sleeve. The device has been designed and tuned to receive the L1 band GPS satellites at a frequency of 1575.42MHz. The Sarantel GeoHelix® active antenna has an inbuilt radio frequency filtering characteristic that significantly reduces the out-of-band interfering signals but the GeoHelix®active also contains additional filtering in order to increase the signal suppression outside the GPS band.Sarantel ‘s active antennas offer the following advantages for difficult GPS environments and Applications:•High Gain and Low Noise Figure•Low current consumption•Low profile dimensions•Small PCB footprint•Shielded Low Noise AmplifierTYPICAL PARAMETERSGain Typ [dBi] NF LNA[dB]3dB BeamwidthSupply Voltage[V]Current[mA]SL1206 25 1.2 135° 2.8 – 3.6 13 SL1204 18 0.8 135° 1.8 – 3.6 3.3SL1204-06-50200 – April 2009 – Initial RevisionSL1206 AND SL1204 IN TYPICAL GPS APPLICATIONSThe SL1206 (GeoHelix®-S) and SL1204 (GeoHelix®-M) are active components with LNA incorporated into the device and hence need an electrical power source for their operation. There are two ways to provide the necessary electrical power for the LNA. One way is to directly connect the active antenna to an existing DC source in the final device via a choke inductor. This configuration is independent from the GPS receiver module so may require power control logic (or a power switch circuit) in order to prevent unnecessary power consumption when the receiver module is not in use. Placing additional supervisory circuit can be avoided by simple using the receiver module DC bias line to switch the supply to the active antenna. Alternatively, and the easiest way is to bias the LNA by using a GPS receiver module with active antenna support feature. The majority of the GPS receivers can provide the necessary DC power from their antenna input pins to the LNA. This allows the active antenna to connect directly to the receiver and no additional components or PCB layout changes are required between the active antenna and the receiver module. Most receiver modules incorporate a standard or optional antenna supervision circuitry which can supply 20-50mA bias current at their antenna input pins and also automatically detects the current and shuts down the bias voltage immediately if there is a short circuit at the antenna pin. The majority of the applications use the active antennas soldered directly to the motherboard but connecting it to the receiver via coaxial cable is also an option.Biasing the SL1206Using the SL1206 active antenna requires a power source of 3.0V-3.3V DC and a current of 13mA. Figure 1 shows a typical biasing method for the SL1206 using an available DC supply source from other circuitry within the device. The SRF of the choke inductor should be considered for this application. The inductor should be chosen so the SRF is near the GPS frequency. The C1 capacitor value is not critical and can be selected between 18pF and100pF. It is not necessary to add C1 if the receiver has its own internal DC block capacitor, please refer to the receiver module or chipset manufacturer’s documentation.The total area occupied by the active antenna’s PCB is 20.5mm x 14.6mm. ArrayFigure 1In Figure 2 a standard connection to the GPS receiver is shown. The receiver module provides the DC bias voltage through the 50 Ohm PCB transmission line or cable.Figure 2Biasing the SL1204Supply voltage for the SL1204 is 1.8V to 3.6V DC with typical current consumption 3.4mA. The typical receiver “independent” bias circuit is shown in Figure 3. Most GPS receiver modules incorporate a SAW filter therefore additional filtering is not necessary. An external SAW filter can be connected between the active antenna and the receiver if there is no GPS band pass filter (SAW or Dielectric filter) present in the receiver module or if a GPS chip is being used. Refer to the receiver module or chipset datasheet for guidance on whether this is required. Components L1 and C1 have the same functions as described earlier in this document. SAW filters generally have maximum rated DC voltage 0V...7V which needs to be considered and will determine whether the DC block capacitor (C1) is necessary.The total area occupied by the SL1204 active antenna’s PCB is 10.3mm x 11.0mm.Figure 3A schematic of a receiver directly providing the bias voltage for the SL1204 active antenna can be seen in Figure 4.Figure 4Bill of MaterialsTable 1 Comp. Name Value Package Function ManufacturerC122pF1GRM1555 series0402 DC block MurataC21nFGRM1555 series0402 RF block MurataL147nH2LQG15HS series0402 Bias feed MurataSAW SAFEB1G57KB0F00 1.4mm x 1.1mm Band pass filter Murata 1: between 18pF and 100pF, 2: between 39nH and 56nHThe component values listed in the table above can be sourced from many other manufacturers but other component parameters should be considered (for example SRF for L1 or RoHS compliance)PCB LAYOUTIn order to establish a good signal path between the active antenna and the receiver, general RF layout rules needs to be considered during the PCB design. Regarding trace widths, an online PCB calculator or RF design software can be used in order to find the trace widths for a given PCB stack-up. The track between the active antenna and receiver should be designed to be 50 Ohms. Placing the components as close as possible is also a preferred method to minimize the loss along the RF signal path.The recommended layouts (in gerber format) for the four different bias circuit configurations can be downloaded from Sarantel’s website.SL1204-06-50200 – April 2009 – Initial RevisionIMPORTANT NOTICEThe SL1206 and SL1204 incorporates active ESD protective circuits, however the Active Antennas contain active circuitry which has some sensitivity to damage by electrostatic discharge (ESD). Sarantel recommend using standard ESD precautions handling the antenna unit.REVISION LOGVersion Release Date Description1.0 APRIL 2009 Initial revisionIntegration Guides: /technology/technicalnotesMore InformationFor technical support: /contact/For samples: https:///Other questions and comments: /contact/Copyright © by SARANTELSarantel Ltd.Unit 2, Wendel PointRyle Drive, Park Farm SouthWellingboroughNN8 6BAUK+44 1933 670560*****************。