纺织品行业及贸易外文文献翻译资料

- 格式:doc

- 大小:73.50 KB

- 文档页数:10

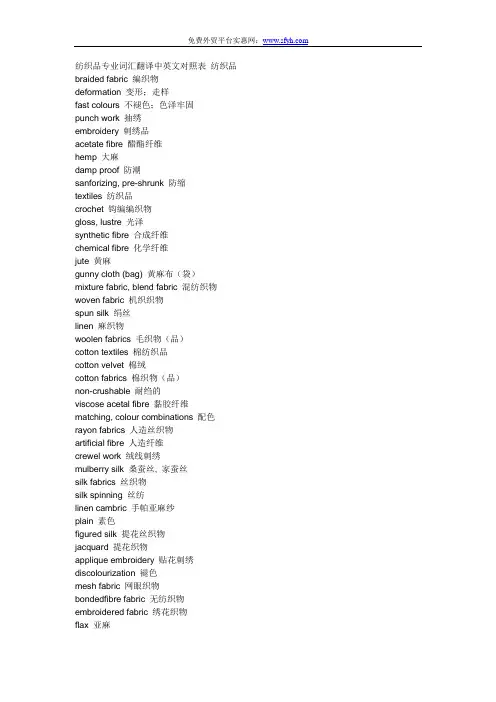

纺织品专业词汇翻译中英文对照表纺织品braided fabric 编织物deformation 变形;走样fast colours 不褪色;色泽牢固punch work 抽绣embroidery 刺绣品acetate fibre 醋酯纤维hemp 大麻damp proof 防潮sanforizing, pre-shrunk 防缩textiles 纺织品crochet 钩编编织物gloss, lustre 光泽synthetic fibre 合成纤维chemical fibre 化学纤维jute 黄麻gunny cloth (bag) 黄麻布(袋)mixture fabric, blend fabric 混纺织物woven fabric 机织织物spun silk 绢丝linen 麻织物woolen fabrics 毛织物(品)cotton textiles 棉纺织品cotton velvet 棉绒cotton fabrics 棉织物(品)non-crushable 耐绉的viscose acetal fibre 黏胶纤维matching, colour combinations 配色rayon fabrics 人造丝织物artificial fibre 人造纤维crewel work 绒线刺绣mulberry silk 桑蚕丝, 家蚕丝silk fabrics 丝织物silk spinning 丝纺linen cambric 手帕亚麻纱plain 素色figured silk 提花丝织物jacquard 提花织物applique embroidery 贴花刺绣discolourization 褪色mesh fabric 网眼织物bondedfibre fabric 无纺织物embroidered fabric 绣花织物flax 亚麻linen yarn 亚麻纱knitting 针织knitwear 针织品hosiery 针织物textile fabric 织物ramee, ramie 苎麻tussah silk 柞蚕丝服装---clothes 衣服,服装wardrobe 服装clothing 服装habit 个人依习惯.身份而着的服装ready-made clothes, ready-to-wear clothes 成衣garments 外衣town clothes 外衣double-breasted suit 双排扣外衣suit 男外衣dress 女服tailored suit 女式西服everyday clothes 便服three-piece suit 三件套trousseau 嫁妆layette 婴儿的全套服装uniform 制服overalls 工装裤rompers 连背心的背带裤formal dress 礼服tailcoat, morning coat 大礼服evening dress 夜礼服dress coat, tails 燕尾服,礼服nightshirt 男式晚礼服dinner jacket 无尾礼服(美作:tuxedo)full dress uniform 礼服制服frock coat 双排扣长礼服gown, robe 礼袍tunic 长袍overcoat 男式大衣coat 女大衣topcoat 夹大衣fur coat 皮大衣three-quarter coat 中长大衣dust coat 风衣mantle, cloak 斗篷poncho 篷却(南美人的一种斗篷)sheepskin jacket 羊皮夹克pelisse 皮上衣jacket 短外衣夹克anorak, duffle coat 带兜帽的夹克,带风帽的粗呢大衣hood 风帽scarf, muffler 围巾shawl 大披巾knitted shawl 头巾,编织的头巾fur stole 毛皮长围巾muff 皮手筒housecoat, dressing gown 晨衣(美作:duster) short dressing gown 短晨衣bathrobe 浴衣nightgown, nightdress 女睡衣pyjamas 睡衣裤(美作ajamas)pocket 衣袋lapel (上衣)翻领detachable collar 假领,活领wing collar 硬翻领,上浆翻领V-neck V型领sleeve 袖子cuff 袖口buttonhole 钮扣孔shirt 衬衫blouse 紧身女衫T-shirt 短袖圆领衫,体恤衫vest 汗衫(美作:undershirt)polo shirt 球衣middy blouse 水手衫sweater 运动衫short-sleeved sweater 短袖运动衫roll-neck sweater 高翻领运动衫round-neck sweater 圆领运动衫suit, outfit, ensemble 套服twinset 两件套,运动衫裤jerkin 猎装kimono 和服ulster 一种长而宽松的外套jellaba, djellaba, jelab 带风帽的外衣cardigan 开襟毛衣mac, mackintosh, raincoat 橡胶雨衣trousers 裤子jeans 牛仔裤short trousers 短裤knickers 儿童灯笼短裤knickerbockers 灯笼裤plus fours 高尔夫球裤,半长裤braces 裤子背带(美作:suspenders)turnup 裤角折边,挽脚breeches 马裤belt 裤带skirt 裙子divided skirt, split skirt 裙裤underskirt 内衣underwear, underclothes 内衣裤underpants, pants 内衣裤(美作:shorts)briefs 短内裤,三角裤panties 女短内裤knickers 女半短内裤,男用灯笼短裤brassiere, bra 乳罩corselet 紧身胸衣stays, corset 束腰,胸衣waistcoat 背心slip, petticoat 衬裙girdle 腰带stockings 长袜suspenders 袜带(美作:garters)suspender belt 吊袜腰带(美作:garter belt) socks 短袜tights, leotard 紧身衣裤handkerchief 手帕bathing trunks 游泳裤bathing costume, swimsuit, bathing suit 游泳衣bikini 比基尼泳衣apron 围裙pinafore (带护胸)围裙shoe 鞋sole 鞋底heel 鞋后跟lace 鞋带moccasin 鹿皮鞋patent leather shoes 黑漆皮鞋boot 靴子slippers 便鞋sandal 凉鞋canvas shoes, rope soled shoes 帆布鞋clog 木拖鞋galosh, overshoe 套鞋tie 领带(美作:necktie)bow tie 蝶形领带cravat 领巾cap 便帽hat 带沿的帽子bowler hat 圆顶硬礼帽top hat 高顶丝质礼帽Panama hat 巴拿马草帽beret 贝蕾帽peaked cap, cap with a visor 尖顶帽broad-brimmed straw hat 宽边草帽headdress 头饰turban 头巾natural fabric 天然纤维cotton 棉silk 丝wool 毛料linen 麻synthetic fabric 混合纤维acryl 压克力polyester 伸缩尼龙nylon 尼龙worsted 呢料cashmere 羊毛patterns 花样tartan plaid 格子花(美作:tartan) dot 圆点花stripe 条纹flower pattern 花纹花样veil 面纱颜色---pink 粉红色salmon pink 橙红色baby pink 浅粉红色shocking pink 鲜粉红色brown 褐色, 茶色beige 灰褐色chocolate 红褐色, 赭石色sandy beige 浅褐色camel 驼色amber 琥珀色khaki 卡其色maroon 褐红色moss green 苔绿色emerald green 鲜绿色olive green 橄榄绿blue 蓝色turquoise blue 土耳其玉色cobalt blue 钴蓝色, 艳蓝色navy blue 藏青色, 深蓝色, 天蓝色aquamarine blue 蓝绿色red 红色scarlet 绯红, 猩红mauve 紫红wine red 葡萄酒红purple, violet 紫色lavender 淡紫色lilac 浅紫色antique violet 古紫色pansy 紫罗兰色white 白色off-white 灰白色ivory 象牙色snowy white 雪白色oyster white 乳白色gray 灰色charcoal gray 炭灰色smoky gray 烟灰色misty gray 雾灰色End==wedoliya提供==End++感谢:Handson提供++Begin==Handson提供==Begin 服装专业词汇[分享] 服装专业词汇A 色牢度试验项目COLOUR FASTNESS TESTS皂洗牢度washing摩擦牢度rubbing/crocking汗渍牢度perspiration干洗牢度drycleaning光照牢度light水渍牢度water氯漂白chlorine bleach spotting非氯漂白non-chlorine bleach漂白bleaching实际洗涤(水洗一次)actual laundering (one wash) 氯化水chlorinated water含氯泳池水chlorinated pool water海水sea-water酸斑acid spotting碱斑alkaline spotting水斑water spotting有机溶剂organic solvent煮呢potting湿态光牢度wet light染料转移dye transfer热(干态)dry heat热压hot pressing印花牢度print durability臭氧ozone烟熏burnt gas fumes由酚类引起的黄化phenolic yellowing唾液及汗液saliva and perspiration B 尺寸稳定性(缩水率)及有关试验项目(织物和成衣)DIMENSIONAL STABILITY (SHRINKAGE) AND RELATED TESTS (FABRIC & GARMENT)皂洗尺寸稳定性dimensional stability to washing (washing shrinkage)洗涤/手洗后的外观appearance after laundering / hand wash热尺寸稳定性dimensional stability to heating熨烫后外观appearance after ironing商业干洗稳定性dimensional stability to commercial drycleaning (drycleaning shrinkage) 商业干洗后外观(外观保持性)appearance after commercial drycleaning (appearance retention)蒸汽尺寸稳定性dimensional stability to steaming松弛及毡化dimensional stabilty to relaxation and felting缝纫线形稳定性dimensional stability for sewing thread C 强力试验项目STRENGTH TESTS拉伸强力tensile strength撕破强力tear strength顶破强力bursting strength接缝性能seam properties双层织物的结合强力bonding strength of laminated fabric涂层织物的粘合强力adhesion strength of coated fabric单纱强力single thread strength缕纱强力lea strength钩接强力loop strength纤维和纱的韧性tenacity of fibres and yarn D 织物机构测试项目FABRIC CONSTRUCTION TESTS织物密度(机织物) threads per unit length (woven fabric construction)织物密度(针织物) stitch density (knittted fabric)纱线支数counts of yarn纱线纤度(原样)denier counts as received织物幅宽fabric width织物克重fabric weight针织物线圈长度loop length of knitted fabric纱线卷曲或织缩率crimp or take-up of yarn割绒种类type of cut pile织造种类type of weave梭织物纬向歪斜度distortion in bowed and skewed fabrics (report as received and after one wash)圈长比terry to ground ratio织物厚度fabric thickness E 成分和其他分析试验项目COMPOSITION AND OTHER ANALYTICAL TESTS纤维成分fibre composition染料识别dyestuff identification靛蓝染料纯度purity of indigo含水率moisture content可萃取物质extractable matter填充料和杂质含量filling and foreign matter content淀粉含量starch content甲醛含量formaldehyde content甲醛树脂presence of formaldehyde resin棉丝光度mercerisation in cottonPH值PH value水能性absorbance F 可燃性试验项目FLAMMABILITY TESTS普通织物的燃烧性能flammability of general clothing textiles布料的燃烧速率(45。

外文文献原稿和译文原稿Introduction2010,Risks in Global MarketWhere there’s an opportunity,there’s a risk.Traders always face risks in any market,from the richest countries to the least developed economies. And as the global economic crisis changed markets,some risks for international trades might have been unveiled or worsened.The risks,which derive from the diversity and vicissitude of market structures,jurisdictions,commerce rules, cultures,languages,and even psychosociological factors,may exist in any sector and stage of the trade process,such as destination marketing,customs clearance,financial support,debts and solvencies,and adherence to WTO rules.A report by the Ministry of Commerce of China specified the risks of investing and doing business in many countries.Zhou Mi,an expert on the research panel,argued that the global market is undergoing a wave of restructuring and rebalancing because consumption in developed countries has waned and the emerging economies will accordingly wield greater influence in the world economy.The newest updates of this report will reveal more specifics, and some of them are listed here in advance.A senior manager from Ernst& Young analyzes the effect that corporate reshaping could have on customs clearance.China Export&Credit Insurance Corporation evaluates the risk factors in the financial systems and debt structures of some important markets.An expert from China’s Economic Diplomacy defines some risks created by WTO rules and offers advice on how to handle the risks.译文介绍2010年,在全球市场的风险那里是一个机会,还有一个风险。

Interlaced 交织Blended 混纺Brushed 磨毛Coated ,涂层lamination:覆膜Bleached 漂白Greige坯布Embossed 压花Flame-proof阻燃整理Water-proof 防水Mercerized 丝光Dyed染色Enzymes wash 酵素洗Printed 印花Lettered 印字Starched 上浆Ecru finishing 本色整理Sand washing 砂洗Scraping the color 刮色Gold stamping /hot silver 烫金/银Soft finishing 柔软整理Singeing 烧毛Mercerizing&bleaching 丝光漂Water preshrinking 预缩纺织品专业词汇翻译中英文对照表纺织品[转]纺织品专业词汇翻译中英文对照表纺织品braided fabric 编织物deformation变形;走样fast colours不褪色;色泽牢固punch work 抽绣embroidery 刺绣品acetate fibre醋酯纤维hemp大麻damp proof 防潮sanforizing, pre-shrunk 防缩textiles纺织品crochet钩编编织物gloss, lustre 光泽synthetic fibre 合成纤维chemical fibre 化学纤维jute 黄麻gunny cloth (bag)黄麻布(袋)mixture fabric, blend fabric 混纺织物woven fabric机织织物spun silk 绢丝linen麻织物woolen fabrics 毛织物(品)cotton textiles 棉纺织品cotton velvet 棉绒cotton fabrics 棉织物(品)non-crushable 耐绉的viscose acetal fibre 黏胶纤维matching, colourcombinations 酉己色rayon fabrics人造丝织物artificial fibre 人造纤维crewel work绒线刺绣mulberry silk桑蚕丝,家蚕丝silk fabrics 丝织物silkspinning 丝纺linen cambric手帕亚麻纱plain素色figured silk提花丝织物jacquard提花织物applique embroidery 贴花刺绣discolourization 褪色meshfabric网眼织物bondedfibrefabric 无纺织物embroidered fabric 绣花织物flax亚麻linen yarn亚麻纱knitting 针织knitwear 针织品hosiery 针织物textile fabric 织物ramee, ramie 苎麻tussahsilk 柞蚕丝月艮装 --clothes衣服,服装wardrobe月艮装clothing月艮装habit个人依习惯.身份而着的服装ready-made clothes, ready-to-wear clothes 成衣garments夕卜衣town clothes 夕卜衣double-breasted suit 双排扣夕衣suit男外衣dress女服tailored suit女式西服everyday clothes 便月艮three-piece suit 三件套trousseau 嫁妆layette婴儿的全套服装uniform制月艮overalls工装裤rompers连背心的背带裤formal dress 礼服tailcoat, morning coat 大礼服evening dress夜礼月服dress coat, tails 燕尾服,礼服nightshirt男式晚礼服dinner jacket无尾礼服(美作仙*3~。

纺织行业摘要文献资料范文纺织行业摘要文献资料范文本文将对纺织行业的发展现状、趋势、问题以及解决方案进行探讨。

纺织行业作为国民经济的支柱产业,在全球范围内都具有重要的地位。

然而,随着技术的进步和全球化竞争的加剧,纺织行业面临着许多挑战和机遇。

1. 发展现状纺织行业在过去几十年中取得了长足的发展,成为了全球产业链中的重要环节。

中国是世界上最大的纺织品生产和出口国家,拥有庞大的劳动力和完善的供应链体系。

然而,随着工资和原材料成本的上升,中国的竞争力逐渐减弱,一些新兴市场如印度和孟加拉国也开始崭露头角。

另外,随着科技的发展,纺织行业也面临着应对数字化和自动化的挑战。

许多企业已经开始引入智能制造和物联网技术,提高生产效率和产品质量。

2. 行业趋势2.1 环保意识的提高随着全球环境问题的加剧,消费者对环保产品的需求日益增加。

因此,纺织行业需要提高环保标准,减少对环境的污染。

一些企业已经开始采用可再生材料、节能设备和环保工艺来生产纺织品。

2.2 新材料的应用纺织行业的创新主要依赖于新材料的研发和应用。

高性能纤维、功能性纺织材料和智能纺织品等新材料的应用将为行业带来新的机遇和挑战。

这些材料可以在服装、家居和工业等领域发挥重要作用。

2.3 个性化需求的增强消费者的个性化需求日益增强,他们更加注重穿着的舒适性、风格和特色。

因此,纺织行业需要向个性化定制和柔性生产转变,以满足不同消费者的需求。

3. 面临的问题3.1 人工成本上升随着劳动力成本的上升,纺织企业需要进一步提高生产效率,降低生产成本。

这加速了传统劳动密集型纺织企业向自动化生产的转型。

3.2 研发投入不足目前,中国纺织行业的研发投入相对较低,创新能力有待提高。

纺织企业需要加大对新材料和技术的研发投入,提高产品附加值和竞争力。

3.3 环境污染问题传统纺织生产方式对环境造成了很大的污染。

纺织企业需要加强环境保护意识,改善生产工艺,减少对环境的影响。

4. 解决方案4.1 提高生产效率纺织企业可以引入智能制造和物联网技术,提高生产效率和生产线的灵活性。

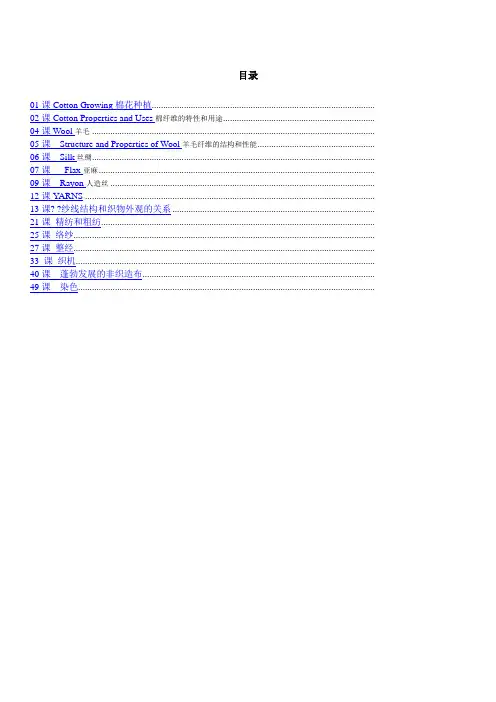

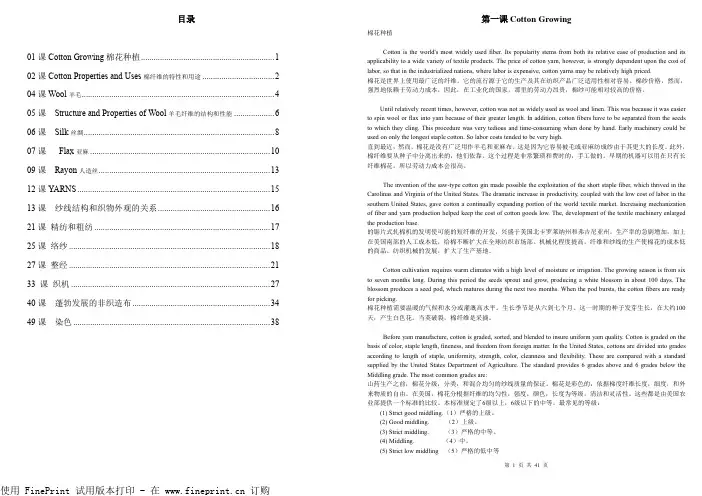

目录01课Cotton Growing棉花种植................................................................................................. 02课Cotton Properties and Uses棉纤维的特性和用途.................................................................. 04课Wool羊毛 ........................................................................................................................... 05课Structure and Properties of Wool羊毛纤维的结构和性能................................................... 06课Silk丝绸........................................................................................................................... 07课Flax亚麻........................................................................................................................ 09课Rayon人造丝 ................................................................................................................... 12课YARNS .............................................................................................................................. 13课? ?纱线结构和织物外观的关系 ........................................................................................ 21课精纺和粗纺....................................................................................................................... 25课络纱................................................................................................................................... 27课整经...................................................................................................................................33 课织机.................................................................................................................................. 40课蓬勃发展的非织造布..................................................................................................... 49课染色.................................................................................................................................第一课Cotton Growing棉花种植Cotton is the world's most widely used fiber. Its popularity stems from both its relative ease of production and its applicability to a wide variety of textile products. The price of cotton yarn, however, is strongly dependent upon the cost of labor, so that in the industrialized nations, where labor is expensive, cotton yarns may be relatively high priced.棉花是世界上使用最广泛的纤维。

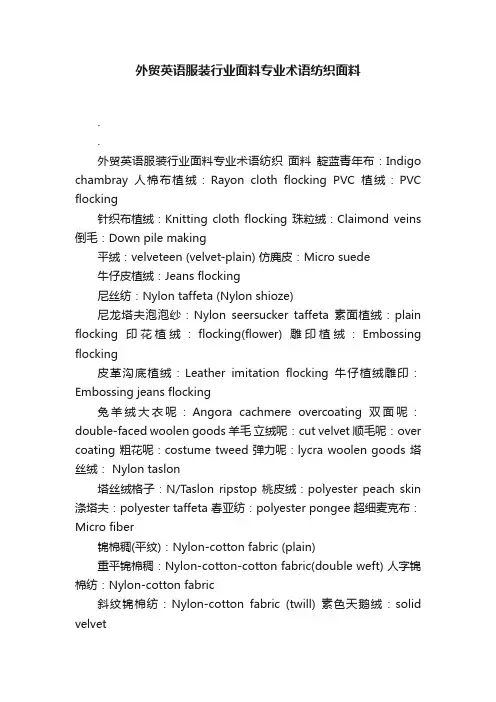

外贸英语服装行业面料专业术语纺织面料..外贸英语服装行业面料专业术语纺织面料靛蓝青年布:Indigo chambray 人棉布植绒:Rayon cloth flocking PVC 植绒:PVC flocking针织布植绒:Knitting cloth flocking 珠粒绒:Claimond veins 倒毛:Down pile making平绒:velveteen (velvet-plain) 仿麂皮:Micro suede牛仔皮植绒:Jeans flocking尼丝纺:Nylon taffeta (Nylon shioze)尼龙塔夫泡泡纱:Nylon seersucker taffeta 素面植绒:plain flocking 印花植绒:flocking(flower) 雕印植绒:Embossing flocking皮革沟底植绒:Leather imitation flocking 牛仔植绒雕印:Embossing jeans flocking兔羊绒大衣呢:Angora cachmere overcoating 双面呢:double-faced woolen goods 羊毛立绒呢:cut velvet 顺毛呢:over coating 粗花呢:costume tweed 弹力呢:lycra woolen goods 塔丝绒: Nylon taslon塔丝绒格子:N/Taslon ripstop 桃皮绒:polyester peach skin 涤塔夫:polyester taffeta 春亚纺:polyester pongee 超细麦克布:Micro fiber锦棉稠(平纹):Nylon-cotton fabric (plain)重平锦棉稠:Nylon-cotton-cotton fabric(double weft) 人字锦棉纺:Nylon-cotton fabric斜纹锦棉纺:Nylon-cotton fabric (twill) 素色天鹅绒:solid velvet抽条磨毛天鹅绒:Rib fleece velvet 雪花天鹅绒:melange velvet 轧花天鹅绒:ginning velvet 粒粒绒布:pellet fleece velvet 麻棉混纺布:linen/cotton blended fabric 麻棉交织布:linen/cotton mixed fabric 素色毛巾布:solid terry 蚂蚁布:fleece in one side 素色卫衣布:solid fleece 鱼网布:fleece彩条汗布:color-stripes single jersey T/R 弹力布:T/R bengalineT/C 色织格子布:T/C solid check fabric 弹力仿麂皮:Micro suede with spandex T/R 仿麂皮:T/R Micro suede仿麂皮瑶粒绒复合布:100%polyester micro suede bounding with polar fleece仿麂皮针织布复合:100% polyester bounding with knitting micro suede fabric仿麂皮羊羔绒复合布:100% polyester micro suede bounding with lamb fur 蜡光缎:cire satine全消光尼丝纺:Full dull nylon taffeta 半消光尼丝纺:semi-dull nylon taffeta 亮光尼龙:Trilobal nylon全消光塔丝隆:Full dull nylon taslan 全消光牛津布:full dull nylon oxford 尼龙格:Nylon rip-stop 塔丝隆格:Taslan rip-stop 哑富迪:Full dull Micro polyester pongee 全消光春亚纺:Full dull polyester pongee 春亚纺格子:polyester pongee rip-stop 全消光涤纶桃皮绒:Full dull polyester peach 宽斜纹桃皮绒:Big twill polyester peach 涤锦复合桃皮绒:poly/nylon peach 涤纶格子:polyester taffeta rip-stop 涤纶蜂巢塔丝隆:polyester honey taslan全消光涤纶低弹牛津布:Full dull poly textured oxford 涤锦交织桃皮绒:Nylon/polyester inter-woven peachREVERSE SIDE 反面RE-WASHING 返洗READY-TO-WEAR 成衣蒸化(aging)自动筛网印花(automatic screen printing)满地印花(blotch print)烂花印花(burn —out prints)涪烘(curing)..直接印花(direct prints)拔染印花(discharge prints)干法印花(dry prints)双面印花(duplex prints)静电荷(electrostatic charge)静电植绒(electrostatic flocking)按特殊要求印花(engineered print)叠印 (fall on)平板(flatbed)植绒印花(flock printing)植绒(flocking)半色调或中间色调(halftone)手工筛网印花(hand screen printing)热转移印花(heat--transfer printing)喷射印花(jet printing)机械植绒(mechanical flocking)罩印(over print)印花色浆(print paste)印花对花准确/对花不准(print register /off register) 对花(registration)防染印花(resist printing)滚筒印花(roller printing)圆形筛网印花或圆网印花(rotary screen printing)筛网印花(screen printing)打样(strike off)热转移印花(thermal transfer printing)经纱印花(warp prints)湿罩干印花(wet —On —dry)湿罩湿印花(wet —On —wet)湿法印花(wet prints)制作精巧 skillful manufacture工艺精良 sophisticated technology最新工艺 latest technology加工精细 finely processed设计精巧 deft design造型新颖 modern design造型优美 beautiful design设计合理 professional design造型富丽华贵 luxuriant in design结构合理 rational construction款式新颖 attractive design款式齐全 various styles式样优雅 elegant shape花色入时 fashionable patterns任君选择 for your selection五彩缤纷 colorful.. 色彩艳丽beautiful in colors色泽光润color brilliancy色泽素雅delicate colors瑰丽多彩pretty and colorful洁白透明pure white and translucence 洁白纯正purewhiteness品质优良excellent quality(high quality) 质量上乘superior quality质量稳定stable quality质量可靠reliable quality品种繁多wide varieties规格齐全complete in specifications保质保量quality and quantity assured性能可靠dependable performance操作简便easy and simple to handle使用方便easy to use经久耐用durable in use以质优而闻名well-known for its fine quality数量之首The king of quantity质量最佳The queen of quality信誉可靠reliable reputation闻名世界world-wide renowm久负盛名to have a long standing reputation誉满中外to enjoy high reputation at home and abroad历史悠久to have a long history畅销全球selling well all over the world深受欢迎to win warm praise from customers增白:WHITE / SNOW WHITE特黑:BLACK / JET BLACK奶白:IVORY/ECRU/OFF WHITE/CREAM大红:RED紫红:BORDEAUX/WINE紫色:BURGUNDY/PLUM/VIOLET/PURPLE绿色:GREEN灰色:GREY玉色:OYSTER/PEACH黄色:YELLOW卡其:KAHKI雪青:LILAC古铜色:BROWN梅红:FUSCHIA墨绿:CHARCOAL豆绿:OLIVE藏青:NAVY/BLUE天蓝:SKY BLUE粉红:PINK..米色: BEIGE橘黄: ORANGE驼色: CAMEL[color=Orange][size=2]产品包装方面: [/size][/color] 卷杆: RILLING/WINDING散装: LOOSE PACKING编织袋: WEAVING BAG纸箱: CARTON木箱: WODEN CASE中性包装: NEUTRAL PACKING单幅卷杆: ROLLED ON TUBES IN OPEN WIDTH双幅卷杆: DOUBLE FOLDED ON ROLLS双幅折板: DOUBLE FOLDED ON BOARD腰封: PAPER TAPES纸管: TUBE吊牌: LABLE / HANG TAG唛头: SHIPPING MARK船样: SHIPPING SAMPLE塑料袋: POLY BAG匹长: ROLL LENGTH拼匹: ROLL WITH SEWING / ROLL WITH JOIN 拼箱: LCL整箱: FCL出口包装: EXPORT PACKING涂银: SILVER烫金: GOLD PRINT磨毛: BRUSHED起皱: CRINKED/ CREPED硬挺: STIFFENING抗静电: ANTI-STATIC抗起球: ANTI-PILLING防羽绒: DOWN PROOF防霉: ANTI-FUNGUS免烫: WASH AND WEAR砂洗: STONE WASHED阻燃: FLAM RETARDANT环保染色: AZO FREE / NO AZO防水: W/P ( WATER SHRINKAGE )里料: LINING面料:FABRIC平纹: TAFFETA斜纹: TWILL缎面: SATIN / CHARMEUSE绡: LUSTRINE提花: JACQUARD烂花: BURNT-OUT春亚纺:PONGEE格子:CHECK条子:STRIPE双层:DOUBLE –LAYER双色:TWO –TONE花瑶:FAILLE弹力布:SPANDEX/ELASTIC/STREC/LYCRA 牛仔布:JEANET 牛津布:OXFORD帆布:CAMBRIC涤棉:P/C涤捻:T/R白条纺:WHITE STRIPE黑条纺:BLACK STRIPE空齿纺:EMPTY STRIPE人字锦棉纺:Nylon-cotton fabric斜纹锦棉纺:Nylon-cotton fabric (twill)麻棉混纺布:linen/cotton blended fabric麻棉交织布:linen/cotton mixed fabric涤纶:PLOYESTER锦纶:NYLON/POLYAMIDE醋酸:ACETATE棉:COTTON 人棉:RAYON人丝:VISCOSE仿真丝:IMITATED SILK FABRIC真丝:SILK氨纶:SPANDEX/ELASTIC/STREC/LYCRA 长丝:FILAMENT 短纤:SPUN黑丝:BLACK YARN原纱、本色纱:gray yarn坯布、本色布:gray fabric纺纱:spinning纱支:yarn count经纱:warp纬纱:weft经密:ends per inch纬密:picks per inch织物结构:fabric construction布宽:fabric width单幅:single width双幅:double width天然纤维:natural fiber复合纤维:conjugated yarn长纤维:filament.短纤维:cut staple,spun混纺纱:blended yarn交织:cross weave被子:Quilt; Duvet(充羽毛、绒制成的)被壳:Comforter Shell传统式枕套:Pillow Sham开口式枕套:Pillow Case靠垫:Cushion帷幔:Valance窗帘:Curtain闺枕:Boudoir Pillow圆抱枕:Neck Roll被单:Bed Sheet包被单:Sheet床单:Flat Sheet床罩:Fitted Sheet; Bed Skirt枕巾:Pillow T owel桌布:Tablecloth盖毯:Throw毛毯:Woolen Blanket毛巾毯:Towel Blanket睡袋:Sleeping bag; Fleabag home textil家纺bedding 床上用品quilt 被子comforter胖被duvet cove被套quilt cover 被套comforter shell被壳sheet set床单套flat sheet床单套fitted sheet 床垫套pillowcase 西式枕(美)sham 中式枕(美)housewife pillowcase西式枕(英)oxford pillowcase中式枕(英)university 大学bed skirt床裙petti skirt床裙(加拿大)mattress床垫(toss) pillow 靠垫/抱枕cushion cover 靠垫壳breakfast cushion 早餐枕bumper床帷子table cloth台布.placemat 盘垫runner长条doily杯垫oval椭圆的oblong长方的square正方的round圆的kitchen厨房oven mitt微波炉手套pot holder锅垫hotpot火锅window 窗window treatment 窗上用品panel大窗帘drapery大窗帘tieback绑带tier小窗帘valance帘头swag三角帘sca**窗幔*scot valance倒三角帘shade遮光帘blind遮光帘Accessory附件trimming饰边tassel 吊苏fringe排苏button扣子stud暗扣zipper拉链thread线rayon人丝线metallic thread金属线tape带子ribbon丝带,缎带lace蕾丝,花边cord线绳twist粗绳elastics松紧带sequin亮片bead 珠子label标签care label水洗标sewn-in label水洗标woven label织标printed label印刷标签.***** sticker不干胶纸帖law label法律标barcode条形码carton label箱帖carton纸箱swing tag 吊牌hang tag吊牌master carton外箱inner carton内箱vinyl bag PVC袋handle 提手gusset加高folding board垫板insert 彩卡package包装case pack装箱数shipping mark唛头main mark主唛side mark 侧唛container集装箱seal number封号dimension尺寸measurement尺寸design 设计designer设计者style风格description描述ricrac水浪带association协会store 商店department store 百货公司speciality store专卖店discount store折扣店supermarket 超市chain store连锁店importer进口商exporter出口商vendor卖主,供应商agency代理商manufacturer制造商,厂商supplier供货方factory工厂mill工厂retailer零售商[/size][/color] 纺织原料textile raw materials 天然纤维natural fibre.化学纤维chemical fibre植物纤维vegetable fibre纺织纤维textile fibre人造纤维man made fibre动物纤维animal fibre罗纹针织物rib knit fabric双反面针织物purl fabric长毛绒针织物high pile knitted fabric提花针织物jacquard knitted fabric多梳栉经编针织物multi-ba* **bric树脂衬resin interlining麻布胸衬breast canvas树脂领衬resin collar interlining绒布胸衬breast fleece热熔衬fusible interlining粘合衬adhesive-bonded interlining双面粘合衬double-faced adhesive interlining 无纺布衬non-woven interlining无纺粘合衬non-woven adhesive interlining 有纺粘合衬adhesive woreninterlinging黑炭衬hair interlining马尾衬horsehair interlining化纤衬chemical fibre interlining 针织衬knitted interlining2.填料棉花cotton人造棉artificial cotton喷胶棉polyester wadding丝棉silk wadding腈纶棉acrylic staple fibre羽绒down3.线、扣、拉链线thread棉线cotton thread丝线silk thread尼龙线nylon thread装饰线ornamental thread钮button四目扣four-hole button装饰纽扣decorative button 异形扣special-shaped button 塑料扣plastic button玻璃扣glass button子母扣,四合扣snap button 拉链zipper尼龙拉链nylon zipper.涤纶拉链polyester zipper双头拉链zipper with double sliders装饰带fashion tape罗纹rib家纺英语的专业术语(中英文对照)产品色彩风格/Color and style of the products产品结构分类/Product structure classification套件主题/ themes of each set产品生产规格/ Production specification专卖店陈列/ stand alone displaying产品需求比例/Proportion of products demand产品风格Style of the products典雅CLASSIC精致FANCY舒适ELEGANT春夏产品色彩Main color of the products in Spring and summer秋冬产品色彩Main color of the products in autumn and winter产品高贵色彩COLORS FOR HIGH-END PRODUCTS9-儿童类9-children’s sets 10-夏凉产品10-summer household products印花/ Print Programs绣花/ Embroidered Programs 提花/ Jacquard Programs蕾丝/ Lace Programs婚庆/ Wedding Sets盖被绣花Fully embroidered throws 枕边绣花Embroidered pillow cases 被面绣花Embroidered duvet covers被套:duvet cover有边枕套:pillow shame无边枕套:pillow case床单:sheet床裙:bed skirt盖被:throw被芯:duvet睡衣:pajamas抱枕:cushion小件产品:basic set里料lining面料fabric平纹taffeta斜纹twill牛仔布jeanet牛津布oxford帆布cambric.涤棉P/C涤捻T/R白条纺white stripe 黑条纺black stripe 涤纶polyester 锦纶nylon/polyamide 醋酸acetate棉cottonretailer零售商wholesale*批发商**bric面料cotton棉布polyester涤Linen亚麻ramie苎麻silk真丝mulberry silk桑蚕丝dupioni双宫绸linen/viscose麻粘布percale高纱支sateen缎纹布satin佳丽缎sheer透明面料voile薄纱organdy薄纱organza硬纱taffeta塔夫绸corduroy灯芯绒faux suede麂皮绒velvet天鹅绒sew缝cut 剪finish整理iron整烫ruffle 自由折box pleat对脸折seam 接缝seam allowance缝头hem卷边face/front 面back/reverse底filling/batting/wadding 填充物棉子needle针opening/closure开口button closure纽扣封口zipper closure 拉链封口.hidden zipper暗拉链flange飞边scallop荷叶边layout布局scatter分散的horizontal水平的vertical垂直的cuff/.hem西式枕的复边programme项目project项目order订单purchase order(P.O.)订单negotiate谈判approve/confirm确认production生产bulk production 批量生产mass production大规模生产manager经理general manager总经理director董事,主管flight航班forwarder货代consolidator集运公司、人inspection检验audit审查,验厂list一览表,清单namelist名单cost成本price价格quote报价quotation报价quota配额duty税freight运费commission佣金distribution center配货中心review查看shipping出运delivery发货register注册cubic meter立方米square meter平方米foot英尺inch英寸centimeter厘米file文件.attachment附件catalogue目录warehouse仓库standard标准quality质量quantity数量team/group组,队sample样品comment意见change/amend更改exclusive专门logo标志picture/photo图片finish后处理pre-treatment前处理content成分bleach漂白width 幅宽fabric weight面料克重construction组织结构screen网(平网/圆网印花)mercerize 丝光sanding 磨光soften 柔软seersucker 泡泡纱wash 水洗launder.(动词) 洗涤laundry.(名词)水洗woven 梭织的,机织的knit 针织的hand wash手洗dry clean 干洗machine wash 机洗flammability 阻燃性appearance retention 外观持久性dimension stability 尺寸稳定性[/size][/color association协会store 商店department store 百货公司speciality store专卖店discount store折扣店supermarket 超市chain store连锁店importer进口商exporter出口商vendor卖主,供应商.. agency代理商manufacturer制造商,厂商supplie*供货方**ctory工厂mill工厂.。

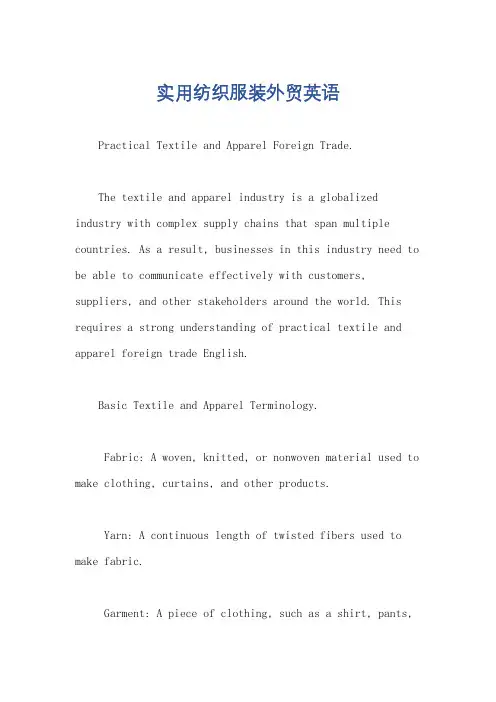

实用纺织服装外贸英语Practical Textile and Apparel Foreign Trade.The textile and apparel industry is a globalized industry with complex supply chains that span multiple countries. As a result, businesses in this industry need to be able to communicate effectively with customers, suppliers, and other stakeholders around the world. This requires a strong understanding of practical textile and apparel foreign trade English.Basic Textile and Apparel Terminology.Fabric: A woven, knitted, or nonwoven material used to make clothing, curtains, and other products.Yarn: A continuous length of twisted fibers used to make fabric.Garment: A piece of clothing, such as a shirt, pants,or dress.Accessories: Items that are worn with garments, such as belts, scarves, and jewelry.Textile manufacturing: The process of creating fabric from raw materials.Apparel manufacturing: The process of creating garments from fabric.Foreign trade: The exchange of goods and services between countries.Essential English Phrases for Textile and Apparel Foreign Trade.Can you provide me with a sample of the fabric?What is the minimum order quantity?What is the lead time for production?What are the payment terms?What is the shipping method?Can you provide me with a certificate of origin?I would like to place an order for [quantity] units of [product].I would like to request a quote for [product].I have a question about the product specifications.I am interested in becoming a distributor for your products.Common Challenges in Textile and Apparel Foreign Trade.Language barriers: Textile and apparel businesses often deal with customers and suppliers who speak different languages. This can lead to misunderstandings andcommunication errors.Cultural differences: Textile and apparel businesses need to be aware of the cultural differences that exist between different countries. This can affect everything from the way products are designed to the way they are marketed.Government regulations: Textile and apparel businesses need to comply with the government regulations of the countries in which they operate. This can include regulations on product safety, environmental protection, and labor standards.Currency fluctuations: Textile and apparel businesses need to be aware of the risks associated with currency fluctuations. This can affect the cost of goods and services, as well as the profitability of businesses.Tips for Success in Textile and Apparel Foreign Trade.Learn the basics of textile and apparel terminology.This will help you to communicate effectively with customers, suppliers, and other stakeholders.Develop strong communication skills. This includes the ability to write clear and concise emails, make presentations, and negotiate contracts.Be aware of cultural differences. This will help you to avoid misunderstandings and build strong relationships with customers and suppliers.Stay up-to-date on government regulations. This will help you to comply with the law and avoid costly penalties.Manage currency risks. This will help you to protect your business from the effects of currency fluctuations.Conclusion.Textile and apparel foreign trade is a complex and challenging business. However, by following the tips above, you can increase your chances of success. With a strongunderstanding of practical textile and apparel foreign trade English, you can build strong relationships with customers and suppliers around the world.。

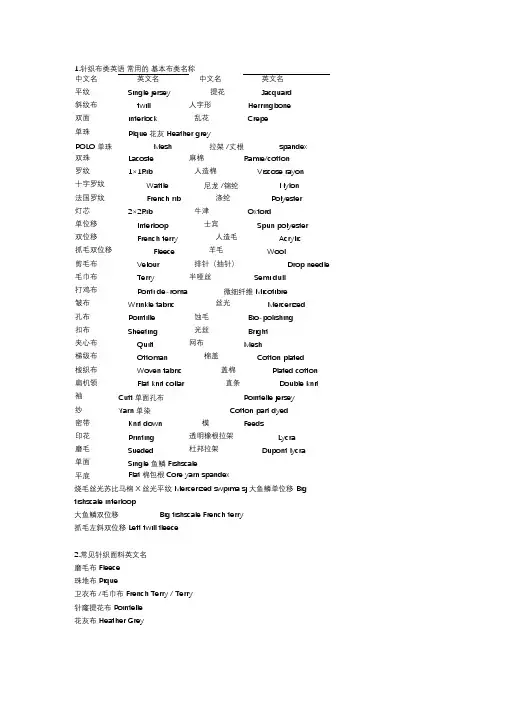

1.针织布类英语常用的基本布类名称中文名英文名中文名英文名平纹Single jersey 提花Jacquard斜纹布twill 人字形Herringbone双面interlock 乱花Crepe单珠Plque 花灰Heather greyPOLO 单珠Mesh 拉架/丈根spandex双珠Lacoste 麻棉Ramie/cotton罗纹1×1Rib 人造棉Viscose rayon十字罗纹Waffle 尼龙/锦纶Nylon法国罗纹French rib 涤纶Polyester灯芯2×2Rib 牛津Oxford单位移Interloop 士宾Spun polyester双位移French terry 人造毛Acrylic抓毛双位移Fleece 羊毛Wool剪毛布Velour 排针(抽针)Drop needle 毛巾布Terry 半哑丝Semi dull打鸡布Ponti de-roma 微细纤维Micofibre皱布Wrinkle fabric 丝光Mercerized孔布Pointille 蚀毛Bio-polishing扣布Sheeting 光丝Bright夹心布Quilt 网布Mesh梯级布Ottoman 棉盖Cotton plated梭织布Woven fabric 盖棉Plated cotton扁机领Flat knit collar 直条Double knit袖Cuff 单面孔布Pointelle jersey纱Yarn 单染Cotton part dyed密带Knit down 模Feeds印花Printing 透明橡根拉架Lycra磨毛Sueded 杜邦拉架Dupont lycra单面Single 鱼鳞Fishscale平底Flat 棉包根Core yarn spandex烧毛丝光苏比马棉X 丝光平纹Mercerized swpima sj 大鱼鳞单位移Big fishscale interloop大鱼鳞双位移Big fishscale French terry抓毛左斜双位移Left twill fleece2.常见针织面料英文名磨毛布Fleece珠地布Pique卫衣布/毛巾布French Terry / Terry针窿提花布Pointelle花灰布Heather Grey印花布Prints双面布Interlock罗纹布Rib 精英外贸论坛/b 提花布Jacquard斜纹布Twill Knit 精英外贸论坛平纹布Jersey剪毛布Velour氨纶布Lycra十字布Waffle / Popcorn丝光布Mercerized色织布Yarn Dyed梯级布Ottoman面料缩写:C :Cotton 棉W :Wool 羊毛M :Mohair 马海毛S :Silk 真丝J :Jute 黄麻L :linen 亚麻Ly :lycra 莱卡Ram :Ramine 苎麻Hem :Hemp 大麻T :Polyester 涤纶WS :Cashmere 羊绒N :Nylon 锦纶(尼龙)A :Acrylic 腈纶Tel :Tencel 天丝,是Lyocell 莱赛尔纤维的商品名La :Lambswool 羊羔毛Md :Model 莫代尔CVC :chief value of cotton 涤棉倒比(涤含量低于60%以下)Ms :Mulberry silk 桑蚕丝R :Rayon 粘胶纤维缩写:纤维名称天然纤维丝麻人造纤维粘胶纤维醋酯纤维三醋酯纤维铜氨纤维富强纤维蛋白纤维缩写代号SLRCACTACVPPolynosicPROT纽富纤维合成纤维碳纤维聚苯硫醚纤维聚缩醛纤维酚醛纤维弹性纤维聚醚酮纤维预氧化腈纶改性腈纶维纶聚乙烯醇缩乙醛纤维氨纶硼纤维含氯纤维高压型阳离子可染聚酯纤维常压沸染阳离子可染纤维聚乳酸纤维聚对苯二甲酸丙二醇酯纤维聚对苯二甲酸丁二醇酯纤维聚萘二甲酸乙二醇酯纤维聚乙烯、聚丙烯共混纤维氯纶聚对本二氧杂环已酮纤维弹性二烯纤维同位芳香族聚酰胺纤维对位芳香族聚酰胺纤维芳砜纶聚酰亚胺纤维超高强高模聚乙烯纤维Newcell CF PPS POM PHE PEA PEEK PANOF MAC PVAL PVB PU EF CL CDP ECDP PLAPTT PBT PEN ESPvoPDSEDPPT PPTA PDSTA PiCHMW-PE其他金属纤维玻璃纤维MTF GE产品包装方面:卷杆:RILLING/WINDING 散装:LOOSE PACKING 编织袋:WEAVING BAG 纸箱:CARTON 木箱:WODEN CASE 中性包装:NEUTRAL PACKING 单幅卷杆:ROLLED ON TUBES IN OPEN WIDTH 双幅卷杆:DOUBLE FOLDED ON ROLLS 双幅折板:DOUBLE FOLDED ON BOARD 腰封:PAPER TAPES 纸管:TUBE 吊牌:LABLE / HANG TAG 唛头:SHIPPING MARK 船样:SHIPPING SAMPLE 塑料袋:POLY BAG 匹长:ROLL LENGTH 拼匹:ROLL WITH SEWING / ROLL WITH JOIN 拼箱:LCL 整箱:FCL 出口包装:EXPORT PACKING 产品检验及标准方面质量标准:QUALITY STANDARD ( OEKO-TEX STANDARD 100 、ISO9002 、SGS 、ITS 、AATCC 、M&S ) 客检:CUSTOMER INSPECTION 台板检验:TABLE INSPECTION 经向检验:LAMP INSPECTION 色牢度:COLOR FASTNESS 皂洗色牢度:WASHING COLOR FASTNESS 摩擦色牢度:RUBBING/ CRICKING COLOR FASTNESS 光照色牢度:LIGHT COLOR FASTNESS 汗渍色牢度:PERSPIRATION COLOR FASTNESS 水渍色牢度:WATER COLOR FASTNESS 氯漂白色牢度:CHLORINE BLEACH COLOR FASTNESS 尺寸稳定性:DIMENSIONAL STABILITY 外观持久性:APPEARANCE RETENTION 拉伸强度:TENSILE STRENGTH 撕破强度:TEAR STRENGTH 接缝滑裂:SEAM SLIPPAGE 抗起毛起球性:PILLING RESISTANCE 耐磨性:ABRASION RESISTANCE 拒水性:WATER REPELLENCY 抗水性:WATER RESISTANCE 织物密度:THREAD PER INCH/STICH DENSITY 纱支:YARN COUNT 克重:WEIGHT产品疵点方面:疵点:DEFECT/FAULT 经柳:STREAKY WARP 断经:BROKEN END 急经:RIGHT END 粗纬:COARSE PICKS 粗经:COARSE END 断纬:BROKEN PICKS 纬斜:SKEWING/SLOPE 横档:FILLING BAR 污迹:STAIN/DIRT 异型丝:GOAT/FOREING YARN 破洞:HOLE 色花:SHADE VARIATION/COLOR DIFFERENCE/COLOR DIVIATION 色柳:COLOR STRIPE 渗色:COLOR BLEEDING 褪色:COLOR FADING/DISCOLOR 擦伤:SCRATCH/BARASION/WINCH MARK 松板印:MOIRE EFFECTS 折痕:CREASE MARK整理方面染色前整理:PREMINARY FINISHE ( PFP ,PFD ) 退浆:DESIZING染色:DYEING 固色:COLOR FIXING 后整理:AFTER FINISH / AFTER TREATMENT 热定型:HEAT SETTING 树脂整理:RESIN FINISH 切割:CUT 轧花:EMBOSSED/LOGOTYPE 涂层:COATING( PVC 、PU 、PA ) 涂白:WHITE PIGMENT 涂银:SILVER 烫金:GOLD PRINT 磨毛:BRUSHED 起皱:CRINKED/ CREPED 轧泡:BUBBLED 丝光:MERCERIZED 硬挺:STIFFENING 抗静电:ANTI-STATIC 抗起球:ANTI-PILLING 防羽绒:DOWN PROOF 防霉:ANTI-FUNGUS 免烫:WASH AND WEAR 砂洗:STONE W ASHED 阻燃:FLAM RETARDANT 环保染色:AZO FREE / NO AZO 防水:W/P ( WATER SHRINKAGE )拒水:W/R ( WATER REPELLENT ) 缩水:W/S ( WATER SHRINKAGE ) 印花:PRINTING 涂料印花:COAT PRINTING 拔染印花:DISCHARGE PRINTING 平网印花:PLATE SCREAM PRINTING 圆网印花:ROTARY SCREAM PRINTING 转移印花:TRANSFER PRINTING 烂花:BURN OUT 模版印花:BLOCK PRINTING 纸版印花:PAPER STENCIL设备方面麦克贝思电脑配色系统:MACBETH “ CLOR –EYE ” COMPUTER COLOR –MATCHING SYSTEM电脑配液系统:“ RAPID –DOSER ” LABORTEX –LABORATORY DOSING SYSTEMVERIVIDE 对色灯箱:VERIVIDE COLOR ASSESMENT CABINET打样:LAB DIPS 大货生产:BULK PRODUCTION 精练机:DESIZING MACHINE折幅机:CREASING MACHINE 卷染:JIG DYEING 溢流染色:JET OVERFLOW DYEING/BLEED DYEING 轧染:PAD DYEING 定型机:SET-STRECHING/STENTER FRAME染料方面碱性染料:BASIC DYES 酸性染料:ACID DYES 活性染料:REACTIVE DYES分散染料:DISPERSE DYES 阳离子染料:CATION DYES 还原染料:直接染料:VAT DYES DIRECT DYES 硫化染料:SULPHUR DYES 非偶氮染料:AZO FREE DYES原料方面涤纶:PLOYESTER 锦纶:NYLON/POL YAMIDE 醋酸:ACETATE 棉;COTTON 人棉:RAYON 人丝:VISCOSE 仿真丝:IMITATED SILK FABRIC 真丝:SILK 氨纶:SPANDEX/ELASTIC/STREC/L YCRA 长丝:FILAMENT 短纤:SPUN 黑丝:BLACK YARN 阳离子:CATION 三角异形丝:TRIANGLE PROFILE 空气变形丝:AIR-JET TEXTURING Y ARN 超细纤维:MICRO –FIBRIC 全拉伸丝:FDY ( FULL DRAWN YARN ) 预取向丝:POY ( PREORIENTED YARN ) 拉伸变形丝:DTY ( DRAW TEXTURED Y ARN ) 牵伸加捻丝:DT( DRWW TWIST )woven fabric -- 织布、织物gray yarn -- 原纱、本色纱gray fabric -- 坯布、本色布spinning -- 纺纱yarn count -- 纱支warp -- 经纱weft -- 纬纱ends per inch -- 经密picks per inch -- 纬密fabric construction -- 织物结构fabric width -- 布宽single width -- 单幅double width -- 双幅cutting length -- 切断长度irregular roll length -- 不定匹长natural fiber -- 天然纤维conjugated yarn -- 复合纤维filament -- 长纤维cut staple,spun -- 短纤维blended yarn -- 混纺纱cross weave -- 交织twist yarn -- 捻纱left twist -- S 捻、左手捻right twist -- Z 捻、右手捻tight twist yarn -- 强捻纱soft twist yarn -- 弱捻纱yarn dyeing -- 原纱染色fabric dyeing -- 匹染hank dyeing -- 绞纱染色direct dyeing -- 直接染色plain -- 平纹twill -- 斜纹satin -- 缎纹stripe -- 条纹check,plaid -- 格纹jacquard -- 提花dobby -- 双臂花式织double faced jacquard -- 双面异色花纹atural fibre -- 自然vegetable fibre -- 植物animal fibre-- 动物mineral fibre-- 矿物cotton fibre-- 棉bast fibre -- 麻asbestos fibre-- 石棉glass fibre -- 玻璃chemical fibre;man-made fibre -- 化学synthetic fibre -- 合成artificial fibre -- 人造regenerated fibre -- 再生specialty fibre -- 特种micro fibre -- 超细elastane fibre;spendex fibre -- 弹性viscose fibre;rayon fibre -- 粘胶cellulose acelate fibre;acetate fibre;acetate -- 醋酯,醋酸polyester fibre -- 聚酯,涤纶polyamide fibre -- 聚酰胺,锦纶。

Lesson Nine九课Rayon人造丝Rayon is composed of cellulose. Like cotton it is a polymer. The difference in degree of polymerization between cotton and rayon accounts for some of the variance in physical properties between the two.粘胶纤维是由纤维素。

像棉花是一种聚合物。

对于一些在两个物理性能之间的差异在棉花和人造丝的帐户之间的聚合程度的差异。

Other causes for the difference between rayon and cotton include the difference in the degree of crystallinity, 60 percent for cotton and 40 percent for rayon, and differences in hydrogen bonding as evidenced by the infrared spectrum of native cellulose and regenerated cellulose.人造纤维和棉之间的差异的其他原因包括在不同的结晶度,为棉花和人造丝百分之40百分之60,和氢键的差异证明了天然纤维素的红外光谱和再生纤维素。

The mechanisms of formation for natural celluloses are significantly different from man's ability to reform cellulosic structures found in nature. Rayon is structurally different from cotton molecularly, morphologically, and in relation to chain length. Contaminants of various types from the pulp and other materials used in the process introduce significant differences to rayon that are not present in cotton. These differences result in significant differences in properties between cotton and rayon. As a consequence of the technological developments for regeneration of cellulose by man, a much wider range of fiber properties is obtainable from the man-made regenerated cellulose fibers than is possible from native celluloses such as cotton.对天然纤维素的形成机制是人类进行改革的能力在自然界中发现的纤维素结构差异显著。

目录01课Cotton Growing棉花种植 (1)02课Cotton Properties and Uses棉纤维的特性和用途 (2)04课Wool羊毛 (4)05课Structure and Properties of Wool羊毛纤维的结构和性能 (6)06课 Silk丝绸 (8)07课 Flax亚麻 (10)09课 Rayon人造丝 (13)12课YARNS (15)13课纱线结构和织物外观的关系 (16)21课精纺和粗纺 (17)25课络纱 (18)27课整经 (21)33 课织机 (27)40课蓬勃发展的非织造布 (34)49课染色 (38)第一课Cotton Growing棉花种植Cotton is the world's most widely used fiber. Its popularity stems from both its relative ease of production and its applicability to a wide variety of textile products. The price of cotton yarn, however, is strongly dependent upon the cost of labor, so that in the industrialized nations, where labor is expensive, cotton yarns may be relatively high priced.棉花是世界上使用最广泛的纤维。

它的流行源于它的生产及其在纺织产品广泛适用性相对容易。

棉纱价格,然而,强烈地依赖于劳动力成本,因此,在工业化的国家,那里的劳动力昂贵,棉纱可能相对较高的价格。

Until relatively recent times, however, cotton was not as widely used as wool and linen. This was because it was easier to spin wool or flax into yam because of their greater length. In addition, cotton fibers have to be separated from the seeds to which they cling. This procedure was very tedious and time-consuming when done by hand. Early machinery could be used on only the longest staple cotton. So labor costs tended to be very high.直到最近,然而,棉花是没有广泛用作羊毛和亚麻布。

文献出处:Sukumar N, Gnanavel P, Ananthakrishnan T. Effect of Seams on Drape of Fabrics [J]. African Research Review, 2009, 3(3):62-72.原文Effect of Seams on Drape of FabricsSukumar ;Gnanavel. P. , Ananthakrishnan, T.AbstractDrape of the fabric is its ability to hang freely in graceful folds when some area of it is supported over a surface and the rest is unsupported. Drape is a unique property that allows a fabric to be bent in more than in one direction, When two-dimensional fabric are converted to three-dimensional garment form. In the present study, the effects of sewing of different seam were selected on different fabric and their behaviors were studied. In this study drape of ten fabrics are analyzed with three types of seams and three stitch densities. Sample without seam is a control sample and drape of seamed samples are compared with control sample to analyze the drape behavior of seamed fabrics. This paper presents a fundamental drape analysis of seamed fabrics using drape meter. Drape behavior is determined in terms of drape coefficient. The effect of seams on the drape coefficient and Drape profile has been made. Drape coefficients significantly differs between the fabrics and also between the seam stitch density combinations. Investigating drape on seamed fabrics can improve fabric end use application.Key words: drape, computer aided design, seam, stitch densityIntroductionDrape is an important property that decides the gracefulness of any garment as it is relates to aesthetics of garments (Kaushal Raj sharma and B.K. Behera. 2005). The mechanical properties of fabrics were first studied during the late 19th century by German researchers working on developing airships (Postle, 1998). Drape ability has been regarded as a quantitative characteristic of cloth, and several devices as well as virtual systems have been developed to measure it (Booth, 1968; Jeong, 1998; Stylios and Wan, 1999). Instruments for measuring drape ability have been developed by Chu et al.(1950) and later by Cusick (1965, 1968) using a parallel light source that reflects the drape shadow of a circular specimen from hanging disc into a piece of ring paper at present numerous instruments, ranging from a simple cantilever bending tester to a dynamic drape tester developed for measuring fabric drape. During recent years, the investigation of fabric drape has attracted the attention of many researchers because of the attempts to realize the clothing Computer aided design (CAD) system by introducing the fabric properties, in which fabric drape is the key element. It is obvious that fabrics have to be sewn together for a garment to be formed. The seams of a garment affect the fabric drape greatly (Matsudaira, M. and Yang, M. 2000). It is unrealistic to realize the appearance of a garment system without the consideration of seams and the methods of assembling of fabrics into garments (Jinlian Hu et al, 1997).When a fabric is draped; it can bend in one or more directions. Curtains and drapes usually bend in one direction, whereas garments and upholstery exhibit acomplex three-dimensional form with double curvature. Hence, fabric drape is a complex mathematical problem involving large deformations under low stresses (Postle, 1993).A plain seam the most typical seam found extensively in apparel is the simplest type in which a single row of lock stitches joins two pieces of fabrics together. Thus, investigating the effect of a plain seam on fabric drape has a significant value for both the textile and clothing industries. The quantified drapeability of a fabric into a dimensionless value called a “Drape coefficient”, which is defined as the percent of the area from an angular ring of fabric covered by a vertical projection of the draped fabric (Brand R.H.1964). “Drape co efficient (DC)” the m ain parameter used to quantify fabric drape (Narahari Kenkare and Traci May-Plumlee. 2005). Though useful, it is insufficient to characterize complex forms such as garments. Stylios and Zhu, 1997 considered that the drape coefficient by itself did not capture the full aesthetic quality of the drape of a fabric.Drape profile of fabrics with seams provide guidance for garment designs and producers in the apparel industry and improve the understanding of drape properties corresponding to different seam features (Fourt.L and Hollies.N.R.S.1970). Furthermore, we expect that the results will be useful in predicting garment drape with clothing CAD systems.Different types of seams are used in garment making and also wide stitch densities are employed. Once the fabric is joined with seams possibly its drape configuration would vary.The product range of textile industry has extended to the garments. Mass production of operational systems and automated sewing is making more and more presence, it is very essential to understand to the change in properties the fabric under goes once it is seamed. This study is an attempt to understand the effects of seams on the drape of fabrics, which is one of key characteristics for apparels and certain draperies.Types of SeamThe types of seams were selected and in each type, three stitch densities were employed. Fabrics were sewn along the warp and weft direction on a 35cm square side. Control sample for the test is a piece with no seams. This resulted in 9 treatment combinations.(1) Plain Seam (S1)This is the most common seam used in the garment industry. This is easy to make and pliable. It is normally suitable for all types of garments. And, it is suitable for curved locations like armhole. To make this seam we have to place two pieces of fabrics to be joined together right sides facing, matching the seam lines, and we should stitch the seam exactly on the seam line.(2) Welt Seam (S2)For constructing this, we should stitch the plan seam and press both seam allowances to one si de. Then the inside seam allowance is trimmed to ”. Then top stitching is done on the right side of the garment by catching the wider seam allowance. This type is normally used on heavy coats.(3) French seam (S3)The French seam is stitched twice once from the right side and once from the wrong side. It is the classic seam for sheers and looks best if the finished width is” or less. To form this seam, with wrong sides of the fabric together, we should stitch 3/8” from the edge on the right side of the fabr ic. The seam allowance in trimmed to 1/8” and the seam is pressed well. Then the right sides are folded together with stitched line exactly on the edge of the fold and pressed again. Then the stitches are made” from the fold.ConclusionA study on effect of seams on the drape coefficient Drape profile is been made. Three types of seams namely three stitch densities 5, 4 and 3 per centimeter has been employed. Ten fabric verities containing different fibres weaves are analyzed. Drape coefficients significantly differs between the fabrics also between the seam stitch density combination.The Drape Coefficient alone may not give a clean idea of real drape. For this purpose the drape profiles were generated with the help of radii measures. The drape profile has clearly indicating shapes that takes place with the seams put on. Seamed fabrics have generally shown more stabilized pattern compared to control samples.Sateen weave followed by BHC MAT weave has shown highly symmetrical patterns. The seam has markedly improved drape profile of honeycomb fabric. Polyester, Polyester/Viscous fabrics have registered better drape profiles than Polyester/Cotton fabrics. Both the cotton gray casement has shown agreeable drapeprofiles.译文接缝对面料褶皱效果的影响库马尔;甘拉维尔;安娜斯克里斯兰摘要褶皱是服装面料的一个内在特性,这使得它能够优雅地挂在服装面料的表面,特别是当面料的有些区域需要用到褶皱的时候。

Levi Strauss and AnnounceBan on SandblastingAs a commitment to the health and safety of workers across the apparel industry, Levi Strauss & Co. and Hennes & Mauritz AB (H&M) announced plans to implement a global ban on sandblasting in all of their future product lines. The two companies are encouraging others to join this ban in a move toward eliminating sandblasting as an industry practice Sandblasting is one of a number of finishing techniques used to create a worn look for denim and other apparel. When sandblasting is performed, proper safeguards, such as those used by Levi Strauss & Co. and H&M suppliers, must be in place to protect workers from potentially serious harm resulting from exposure to crystalline silica (a compound found in sand). But there are some factories in the apparel industry-often linked to counterfeit operations-which do not apply the same safeguards, putting workers' health at risk.we've implementedrigorous standards forsandblasting in our ownsupply chain but wedecided that the best wayto help ensure noworker-in any garmentfactory-faces the risksassociated with exposureto crystalline silica is tomove to end sandblasting industry-wide, said David Love, Senior Vice President and Chief Supply Chain Officer at Levi Strauss & Co. We're proud to join with H&M in a commitment to apparel workers world-wide and we urge other companies to join us in ending this practice.“H&M has had health and safety requirements for sandblasting for several years. Like all other Code of Conduct requirements, monitoring of sandblasting practices has been part of our extensive Full Audit Programme. At the same time, securing that these standards are being observed by all of oursuppliers and their subcontractors has proven too difficult. Inorder to make certain that no worker producing denim garments for H&M risks his or her health, we have decided to quit purchasing and retailing sandblasted produc ts,” said Karl Gunnar Fagerlin, Production Manager at H&M.Effective immediately, Levi Strauss & Co. and H&M will not place any new orders for sandblasted product and as of December 31, 2010, Levi Strauss & Co. and H&M will no longer have any active production that uses this finishing technique. The ban includes, but is not limited to, the use of aluminum oxide, aluminum silicate, silicon carbide, copper slag and garnet for abrasive blasting.翻译:李维·史特劳斯和Hennes & Mauritz(瑞典连锁服饰品牌)宣布禁止对服装喷砂技术的使用作为对整个服装行业工人的健康和安全的承诺,利维斯特劳斯公司和Hennes&Mauritz(H&M)的公司宣布计划实施一个全球性的计划———对其未来的所有产品禁止使用晶体硅喷砂。

进出口贸易外文翻译文献(文档含英文原文和中文翻译)China’s Competitive Performance: A Threat To East Asian Manufactured Exports?There is growing concern in Southeast and East Asia about the competitive threat posed by China’s burgeoning exports, exacerbated by its accession to the WTO. The threat is not confined to labor-intensive products but spans the whole technological and skill range. At the same time, China is rapidly raising its imports from the region, and it is not clear whether its burgeoning exports will damage it s neighbors. We examine the dimensions of China’s competitive threat in the 1990s, benchmarking competitive performance by technology and market, and finds that market share losses are so far mainly in low technology products, with Japan being the most vulnerable market. We analyze market share changes and highlight product groups that are directly or indirectly exposed to a competitive threat. We examine intra-regional trade and find that China and its neighbors are raising high technology exports in tandem: the nature of theinternational production systems involved lead to complementarily rather than confrontation. China is thus acting as an engine of export growth for its neighbors in terms of direct trade. However, this will change as China moves up the value chain and takes on the activities that have driven East Asian export growth.IntroductionConcern about China’s competitive threat is widespread (in developed economies like US as well as developing ones like Mexico), but is strongest in East and So utheast Asia. China’s burgeoning exports–backed by cheap and productive labor, a large stock of technical manpower, huge and diversified industrial sector, attractiveness to foreign investors, pragmatic use of industrial policy, and, now, freer access to world markets under WTO – lead to apocalyptic visions of export losses.2 China is most threatening to neighbors that rely primarily on low wages for their export advantage. However, as it upgrades its export structure, the more advanced economies (Singapore, Hong Kong, Korea and Taiwan) also fear for their competitiveness. The current hollowing out of their low-end manufacturing may soon extend to complex production, design, development and related services. Domestic markets are also threatened by China, but so far most attention seems to have been on exports.Offsetting this threat are the promise of the giant Chinese market (WTO accession is only one of several initiatives to liberalize regional trade) and the potential for collaboration with it in exporting to the rest of the world. Trade within the East Asian region is flourishing. China is a growing importer from the region of natural resources that it does not possess. It is also raisin g imports of manufactured products. Its advanced neighbors are selling it sophisticated consumer and producer goods, and using it as a base for processing exports to third countries. The multinational companies (MNCs) that now account for around half of Chinese exports (and far more of its high technology exports, UNCTAD,2002) are incorporating China into production systems spanning the region (‘fragmentation’ and‘segmentation’ are used to describe this phenomenon3), so promoting considerable intra-firm trade with other regional bases. China’s own enterprises are likely t o specialize with respect to regional counterparts and so raise intra-industry trade in differentiated products. Perhapsworryingly for competitors in other regions, such integration can lead China to complement regional competitiveness as a whole, rather than substitute its exports for those of its neighbors.It is difficult to assess, however, whether complementarily between China and the regional economies will fully offset its competitive threat. The dynamics and complexity of the interactions make it impossible to quantify the outcome, even to predict broad directions. The basic issue is whether China’s higher wage neighbors can move into more advanced export activities or functions rapidly enough to permit continued export expansion. If they can, they can continue with export-led growth. If they cannot, they will suffer export deceleration and/or a shift in specialization towards primary products or slow-growing segments of manufactured exports. The outcome, in other words, will depend on the relative growth of technological and other capabilities in Chinese and regional enterprises, with the former having such advantages as lower wages, larger scale economies, greater industrial depth, pools of technical skill and a proactive government. However, as East Asian countries differ widely in these factors (Lall, 2001), they face different kinds and intensity of competitive threat. The nature of the threat depends, moreover, on the organization of the production and marketing system: independent local firms are likely to compete more directly than affiliates of the same MNC spread over different countries in an integrated system.This paper does not try to measure China’s competitive threat or its effects, but to map relative export performance in the 1990s by technology and destination and so assess where the threat appears most intense. We focus on major East Asian exporters5 and on exports to third markets, but we also analyses complementarities between China and East Asia, particularly in electronics, the re gion’s largest export and the one where MNC systems dominate. As the 1990s predate China’s WTO accession, we do not go into the implications of this accession; however, the analysis of competitive trends has implications for the evolution of future trade by the region as liberalization grows.Background on Chinese export performanceChinese manufactured exports grew by 16.9% per annum over 1990-2000, compared to 6.4% for the world, 12.0% for all developing countries and 10.3%for the rest of East Asia. Its share of world manufactured exports rose from 1.7% to 4.4% over the decade and continued rising rapidly. 6 Thus, by 2002 China accounted for 5.1% of world merchandise exports; it was then the fifth largest exporter (after USA, Germany, Japan and France, an d ahead of the UK). China’s share of developing world manufactured exports rose from 11% to 20% over the 1990s and of the East Asian region excluding China from 18.7% to 41.8%. Its export gains (see below) spanned the entire technological spectrum, and were most dynamic in the complex end of the range, in products that have recently driven the export growth of the rest of East Asia.This export surge is likely to be sustained for some time to come. China has ‘spare capacity’ in that its per capita exports are still relatively small,7 wages are much lower than in its main neighbors and it has large reserves of cheap and disciplined labor (though drawing it into exports will involve the cost of building links with the interior).8 More importantly, its advantages are not static (confined to cheap labor); they are upgrading rapidly. China is investing heavily in technology and advanced skills; for example, the share of the relevant age group enrolled in tertiary education rose from 9 percent in 1997 to 13 percent in 2000 (UNESCO website). It is exploiting the scale offered by its giant market to become competitive in capital-intensive activities beyond the reach of many neighbors. It is using its diverse industrial base to deepen local content. It is drawing in export-oriented FDI at an impressive rate, using its market attractions to induce investors to raise local R&D and linkages; till now it has been able to impose performance requirements of the type soon to be banned under WTO rules.WTO accession may constra in China’s ability to use industrial policy (Nolan, 2001) but it will also open up new export opportunities, particularly in textiles and garments.9 Accession may also enhance its domestic competitiveness: it will improve the investment climate for FDI, make imported inputs cheaper (for enterprises outside special export regimes) and induce faster restructuring of domestic enterprises (Ianchovichinaetal, 2003, and Lemoyne and Unal-Kesenci, 2002).Market share changes in major developed country marketsWe analyze market shares of China and its neighbors in three major markets: Japan, the US and West Europe, according to technology categories (Annex Table 1). In terms of value, the most important market for China in 2000 is the US ($49 billion), followed by Japan ($36 billion) and West Europe ($38 billion). However, the rest of the world is almost as large a destination for Chinese exports as these together ($106 billion in 2000) and within this the rest of East Asia is larger than any major OECD market by itself ($74.6 billion).The competitive position of each country can be analyzed in terms of the market share in 1990 and 2000 and the change over the decade. The annex table shows the following:Total manufactured exports: China does best in Japan, followed at some distance by the US. In common with most neighbors, its market share gain is weakest in West Europe. Korea loses market shares in both Japan and US, while Taiwan loses only in the US. Hong Kong’s loses market shares in all markets, particularly in the US and Japan. Like Taiwan, Singapore loses only in the US. The new Tigers gain share in all markets. With the exception of Indonesia, with a rather tepid performance, the others all gain most share in the Japanese market. Resource based products: China again leads the region in terms of market share increases, with a pattern similar to that for total exports. However, Korea has a large gain in Japan, in contrast to Taiwan and Singapore, which lose shares; the latter two also lose in the US. Thailand is a big gainer in Japan while Indonesia and the Philippines lose out in the US. Low technology products: China’s massive market share gains are again concentrated in Japan. The four mature Tigers generally suffer losses in market share, but Singapore sees an increase in Japanese market share. The best overall performance among the new Tigers is by Indonesia.Medium technology products: While the Chinese pattern of success recurs, the new Tigers make significant gains in Japan and Korea incurs a significant loss. Taiwan and Singapore suffer losses in the US market. High technology exports: Taiwan again diverges from Korea in its performance in Japan, the former showing the second largest gain in the group (after China) and the latter the largest loss. In the US market, the situation is reversed, with Singapore joiningTaiwan in losing market shares. Among the new Tigers, Malaysia and the Philippines are the big gainers in Japan, but the other two also benefit significantly. The Philippines is the second largest winner in the group in the US market. In sum, China’s main market share gains in the developed world are concentrated in Japan (though the US accounts for a larger dollar value of export growth). This is also true of its neighbors with the exceptions of Korea and Indonesia (Hong Kong was an all-round loser). To the extent that we can interpret market share changes to be causally related to China’s export surge, it would seem that the mature Tigers suffered the most from Chinese competition. The largest such loss is in low technology products, which is to be expected, but this not take into account the growth of LT exports by Korea and Taiwan to China. The relatively low gains by the lower-income new Tigers in LT may also reflect the impact of Chinese competition – without the offsetting increase in exports of intermediates to China.ConclusionsChina’s export surge has raised grave concerns in the region. While some of the apocalyptic predictions may have been overdone, it is certainly possible that rapid export growth by such a massive entrant will adversely affects export growth in its neighbors. As this analysis shows,however, the outcome is complex. For a start, the rise in China’s exports is matched by that in its imports – within the region its import growth outpaces its export growth. With appropriate restructuring of activities to match new competitive needs, its neighbors should be able to maintain high rates of export growth.There are two main drivers of regional exports to China. The first is to meet its burgeoning demand for imported products: primary products and resource-based manufactures that it cannot produce capital goods and intermediates for domestic -oriented production and more sophisticated consumer goods than its industry can currently provide. The second is to meet the needs of its export industries. This has two components: ‘processing’ activity in special economic zones that use imported inputs for export activities, and other exporters that also need imports. Processing activity is increasingly organized as part of integrated production systems, particularly its high technology segments, thoughsome domestic oriented industries are also being plugged into this system as they realize scale and learning economies and become globally competitive. Both drivers are likely to continue into the foreseeable future, though their composition will change as Chinese and regional capabilities develop.中国竞争力的表现:是对东亚制成品出口的威胁吗?越来越多的东南亚和东亚地区关注中国出口的迅速增长所带来的竞争威胁,中国加入WTO后,更加剧了这种情况。

纺织品专业词汇翻译中英文对照1. 纤维•中文:纤维•英文:Fiber2. 棉花•中文:棉花•英文:Cotton3. 麻•中文:麻•英文:Flax 4. 丝绸•中文:丝绸•英文:Silk 5. 羊毛•中文:羊毛•英文:Wool 6. 涤纶•中文:涤纶•英文:Polyester 7. 尼龙•中文:尼龙•英文:Nylon 8. 腈纶•中文:腈纶•英文:Acrylic 9. 聚酯纤维•中文:聚酯纤维•英文:Polyester Fiber 10. 人造纤维•中文:人造纤维•英文:Rayon11. 粘胶纤维•中文:粘胶纤维•英文:Viscose Fiber 12. 锦纶•中文:锦纶13. 涤纶纤维•中文:涤纶纤维•英文:Polyester Fiber 14. 梳棉•中文:梳棉•英文:Combed Cotton 15. 纱线•中文:纱线16. 织造•中文:织造•英文:Weaving 17. 绗缝•中文:绗缝•英文:Hemming 18. 织物•中文:织物19. 缝纫•中文:缝纫•英文:Sewing 20. 瓦状织物•中文:瓦状织物•英文:Tiles Fabric 21. 苫布•中文:苫布22. 孔雀绒•中文:孔雀绒•英文:Velvet 23. 绒布•中文:绒布•英文:Flannel 24. 卡其布•中文:卡其布25. 雪纺•中文:雪纺•英文:Chiffon 26. 真丝•中文:真丝•英文:Silk 27. 拉架•中文:拉架•英文:Tenter 28. 贴布•中文:贴布•英文:Interlining 29. 面料•中文:面料•英文:Fabric 30. 整理•中文:整理•英文:Finishing 31. 防水•中文:防水•英文:Waterproof 32. 防火•中文:防火•英文:Fireproof 33. 可拆洗•中文:可拆洗•英文:Removable and Washable 34. 花型•中文:花型•英文:Pattern35. 纤维混纺•中文:纤维混纺•英文:Blended Fiber36. 雾化•中文:雾化37. 打毛•中文:打毛•英文:Napping 38. 硅洗•中文:硅洗•英文:Silicon Wash 39. 染色•中文:染色40. 印花•中文:印花•英文:Printing41. 双面织物•中文:双面织物•英文:Double-sided Fabric 42. 时装•中文:时装43. 设计•中文:设计•英文:Design 44. 布料•中文:布料•英文:Cloth 45. 色差•中文:色差•英文:Color Difference 46. 织造工艺•中文:织造工艺•英文:Weaving Technique 47. 网眼织物•中文:网眼织物•英文:Mesh Fabric48. 纱线密度•中文:纱线密度•英文:Thread Count49. 染色差异•中文:染色差异•英文:Dyeing Difference50. 亚麻•中文:亚麻•英文:Linen以上是纺织品专业词汇的中英文对照表。

第二课棉纤维的性能及其应用内容提要:本文从吸水性、强度、耐用性等方面来描述棉纤维。

并在课文的最后,介绍了棉纤维的应用。

棉纤维的性能棉纤维的性能和应用课文翻译:吸湿性和良好的吸湿排汗性能使棉纤维的成为一种更舒适的纤维。

棉纤维具有较高的吸水性能,是由于其纤维素的亲水的羟基基团。

当水进入棉纤维内部,纤维发生溶胀,其截面变得更圆。

受潮后的亲水性能和溶胀使棉花可以吸收其重量约四分之一的水。

这意味着,在炎热的天气里,身体的汗会被棉织品吸收,并沿棉纱传送到织物的外表面并蒸发到空气中。

因此,(棉纤维的这种性质)可帮助身体维持其温度。

不幸的是,棉花的亲水性使得它容易受到水渍。

如在咖啡或葡萄汁的水溶性色素会随着水渗入纤维;当水分蒸发,着色剂被困在纤维内部。

棉织品是他们容易起皱并很难除皱,也许是它们的主要缺点。

棉纤维的刚度可以降低织物的抗起皱能力。

当纤维弯曲到一种新的形态,纤维素大分子内发生一些氢键断裂和分子滑动以减少纤维内部应力。

在新的位置氢键重组,所以当外力去除后,纤维保持了这一形状。

氢键的断裂和重组保持了皱纹,因而若要消除皱纹,需要熨烫。

棉纤维具有中等强度,是具有良好的耐磨性和尺寸稳定性,能够抵抗日常的酸,碱和有机溶剂。

但由于它是一种天然物质,容易受昆虫,霉菌和真菌的攻击。

最突出的是棉花在潮湿的环境下有霉烂的倾向。

棉花抗太阳光和热,但是直接长期暴露于强烈的阳光下棉纤维会泛黄,并最终降解。

煤气烘燥也可使棉织品变黄。

颜色的变化是纤维素和氧或氮氧化物之间的化学反应,尤其在热空气中。

为使棉花保留其白度较长时间,需用滴水晾干或在电干燥器中干燥。

另一感兴趣的事实是,棉纱湿强度大于干强度。

这是由于纤维内部宏观和微观结构。

当水被吸收,纤维溶胀,其截面变得更圆。

通常这种大量的外来物质的吸收会导致内部应力较高,导致纤维弱化。

然而,棉纤维吸水导致内部应力减少。

在内部应力减小的情况下,肿胀的纤维变得更强。

同时,在纱线溶胀纤维之间挤得更紧,增强了纱线内部纤维摩擦力。

目录01课Cotton Growing棉花种植 (1)02课Cotton Properties and Uses棉纤维的特性和用途 (2)04课Wool羊毛 (4)05课Structure and Properties of Wool羊毛纤维的结构和性能 (6)06课 Silk丝绸 (8)07课 Flax亚麻 (10)09课 Rayon人造丝 (13)12课YARNS (15)13课纱线结构和织物外观的关系 (16)21课精纺和粗纺 (17)25课络纱 (18)27课整经 (21)33 课织机 (27)40课蓬勃发展的非织造布 (34)49课染色 (38)第一课Cotton Growing棉花种植Cotton is the world's most widely used fiber. Its popularity stems from both its relative ease of production and its applicability to a wide variety of textile products. The price of cotton yarn, however, is strongly dependent upon the cost of labor, so that in the industrialized nations, where labor is expensive, cotton yarns may be relatively high priced.棉花是世界上使用最广泛的纤维。

它的流行源于它的生产及其在纺织产品广泛适用性相对容易。

棉纱价格,然而,强烈地依赖于劳动力成本,因此,在工业化的国家,那里的劳动力昂贵,棉纱可能相对较高的价格。

Until relatively recent times, however, cotton was not as widely used as wool and linen. This was because it was easier to spin wool or flax into yam because of their greater length. In addition, cotton fibers have to be separated from the seeds to which they cling. This procedure was very tedious and time-consuming when done by hand. Early machinery could be used on only the longest staple cotton. So labor costs tended to be very high.直到最近,然而,棉花是没有广泛用作羊毛和亚麻布。