Three-parameter AVO inversion with PP and PS data using offset binning

- 格式:pdf

- 大小:743.72 KB

- 文档页数:22

第25卷第4期2007年7月物理测试P hysics Examination and T estingV ol.25,No.4July 2007作者简介:张 滨(1978),女,硕士生; E -mail:b inzhang@ ; 修订日期:2006-11-14关于用U PS 测量功函数张 滨, 孙玉珍, 王文皓(中国科学院金属研究所分析测试部,辽宁沈阳110016)摘 要:详细介绍了紫外光电子谱(U P S)测量功函数的原理与实验方法,测量了金属镍、银和IT O 靶材的功函数,并对测量方法和误差进行了讨论,表明这个方法更适用于测量功函数变化。

关键词:功函数;U P S中图分类号:O433.1 文献标识码:A 文章编号:1001-0777(2007)04-0021-03Work Function Measurements Using UPSZH NA G Bin, SU N Yu -zhen, WANG Wen -hao(Institut e o f M etal R esear ch,Chinese A cademy o f Sciences,Sheny ang 110016,L iaoning ,China)Abstract:T he pr inciple and method of measur ing o n the w ork funct ion using U PS w ere intr oduced in details.T he w or k funct ion of N i,A g and IT O tar get w as measured,and measuring method and er ror s w ere discussed.It was show that this metho d is av ailable t o measur e on change o f wo rk functio n.Key words:w ork function;U P S功函数是材料的重要物理参数,无论是功能材料还是结构材料,都离不开功函数这个物理量。

Trans. Nonferrous Met. Soc. China 22(2012) 1064í1072Correlation between welding and hardening parameters offriction stir welded joints of 2017 aluminum alloyHassen BOUZAIENE, Mohamed-Ali REZGUI, Mahfoudh AYADI, Ali ZGHALResearch Unit in Solid Mechanics, Structures and Technological Development (99-UR11-46),Higher School of Sciences and Techniques of Tunis, TunisiaReceived 7 September 2011; accepted 1 January 2011Abstract: An experimental study was undertaken to express the hardening Swift law according to friction stir welding (FSW) aluminum alloy 2017. Tensile tests of welded joints were run in accordance with face centered composite design. Two types of identified models based on least square method and response surface method were used to assess the contribution of FSW independent factors on the hardening parameters. These models were introduced into finite-element code “Abaqus” to simulate tensile tests of welded joints. The relative average deviation criterion, between the experimental data and the numerical simulations of tension-elongation of tensile tests, shows good agreement between the experimental results and the predicted hardening models. These results can be used to perform multi-criteria optimization for carrying out specific welds or conducting numerical simulation of plastic deformation of forming process of FSW parts such as hydroforming, bending and forging.Key words: friction stir welding; response surface methodology; face centered central composite design; hardening; simulation; relative average deviation criterion1 IntroductionFriction stir welding (FSW) is initially invented and patented at the Welding Institute, Cambridge, United Kingdom (TWI) in 1991 [1] to improve welded joint quality of aluminum alloys. FSW is a solid state joining process which was therefore developed systematically for material difficult to weld and then extended to dissimilar material welding [2], and underwater welding [3]. It is a continuous and autogenously process. It makes use of a rotating tool pin moving along the joint interface and a tool shoulder applying a severe plastic deformation [4].The process is completely mechanical, therefore welding operation and weld energy are accurately controlled. B asing on the same welding parameters, welding joint quality is similar from a weld to another.Approximate models show that FSW could be successfully modeled as a forging and extrusion process [5]. The plastic deformation field in FSW is compared with that in metal cutting [6í8]. The predominant deformation during FSW, particularly in vicinities of thetool, is expected to be simple shear, and parallel to the tool surface [9]. When the workpiece material sticks to the tool, heat is generated at the tool/workpiece contact due to shear deformation. The material becomes in paste state favoring the stirring process within the thermomechanically affected zone, causing a large plastic deformation which alters micro and macro structure and changes properties in polycrystalline materials [10].The development of the mechanical behavior model, of heterogeneous structure of the welded zone, is based on a composite material approach, therefore it must takes into account material properties associated with the different welded regions [11]. The global mechanical behavior of FSW joint was studied through the measurement of stress strain performed in transverse [12,13] and longitudinal [14] directions compared with the weld direction. Finite element models were also developed to study the flow patterns and the residual stresses in FSW [15]. B ased on all these models, numerical simulations were performed in order to investigate the effects of welding parameters and tool geometry on welded material behaviors [16] to predict the feasibility of the process on various shape parts [17].Corresponding author: Mohamed-Ali REZGUI; E-mail: mohamedali.rezgui@ DOI: 10.1016/S1003-6326(11)61284-3Hassen BOUZAIENE, et al/Trans. Nonferrous Met. Soc. China 22(2012) 1064í1072 1065 However, the majority of optimization studies of theFSW process were carried out without being connectedto FSW parameters.In the present study, from experimental andmodeling standpoint, the mechanical behavior of FSWaluminum alloy 2017 was examined by performingtensile tests in longitudinal direction compared with theweld direction. It is a matter of identifying the materialparameters of Swift hardening law [18] according to theFSW parameters, so mechanical properties could bepredicted and optimized under FSW operating conditions.The strategy carried out rests on the response surfacemethod (RSM) involving a face centered centralcomposite design to fit an empirical models of materialparameters of Swift hardening law. RSM is a collectionof mathematical and statistical technique, useful formodeling and analysis problems in which response ofinterest is influenced by several variables; its objective isto optimize this response [19]. The diagnostic checkingtests provided by the analysis of variance (ANOV A) suchas sequential F-test, Lack-of-Fit (LoF) test, coefficient ofdetermination (R2), adjusted coefficient of determination(2adjR) are used to select the adequacy models [20].2 Experimental2.1 Welding processThe aluminum alloy 2017 chosen for investigationhas good mechanical characteristics (Table 1), excellentmachinability and formability, and is mostly used ingeneral mechanics applications from high strengthsuitable for heavy-duty structural parts.Table 1 Mechanical properties of aluminum alloy 2017Ultimate tensile strength/MPaYieldstrength/MPaElongation/%Vickershardness427 276 22 118 The experimental set up used in this study was designed in Kef Institute of Technology (Tunisia). A 7.5 kW powered universal mill (Momac model) with 5 to 1700 r/min and welding feed rate ranging from 16 to 1080 mm/min was used. Aluminum alloy 2017 plate of6 mm in thickness was cut and machined into rectangular welding samples of 250 mm×90 mm. Welding test was performed using two samples in butt-configuration, in contact along their larger edge, fixed on a metal frame which was clamped on the machine milling table.To ensure the repeatability of the FSW process, clamping torque and flatness surface of the plates to be welded are controlled for each welding test. At the end of welding operation, around 80 s are respected before the withdrawal of the tool and the extracting of the welded parts. In this experimental study, we purpose to screen theeffects of three operating factors, i.e. tool rotational speed N, tool welding feed F and diameter ratio r, on hardening parameters from Swift’s hardening law such as strength coefficient (k), initial yield strain (İ0) and hardening exponent (n). The ratio (r=d/D) of pin diameter (d) to shoulder diameter (D), is intended to optimize the tool geometry [21í23]. The welding tool is manufactured from a high alloy steel (Fig. 1).Fig. 1 FSW tool geometry (mm)Preliminary welding tests were performed to identify both higher and lower levels of each considered factors. These limits are fixed from visual inspections of the external morphology and cross sections of the welded joints with no macroscopic defects such as surface irregularities, excessive flash, and lack of penetration or surface-open tunnels. However, among these limits one is not sure to have a safe welded joint so often, but they show great potential on defect avoidance. Figure 2 shows some external macroscopic defects observed beyond the limit levels established for each factor. Table 2 lists the processing factors as well as levels assigned to each, and Table 3 shows the fixed levels for other factors needed to success the welding tests.A face centered central composite design, which comes under the RSM approach, with three factors was used to characterize the nature of the welded joints by determining hardening parameters. In this design the star points are at the center of each face of the factorial space (Į=±1), all factors are run at three levels, which are í1, 0, +1 in term of the coded values (Table 4). The experiment plan has been run in random way to avoid systematic errors.2.2 Tensile testsThe tensile tests are performed on a Testometric’s universal testing machines FSí300 kN. The tensile test specimens (ASME E8Mí04) proposed for characterizing the mechanical behavior of the FSW joint, were cut inHassen BOUZAIENE, et al/Trans. Nonferrous Met. Soc. China 22(2012) 1064í10721066Fig. 2 Types of macroscopic defectsTable 2 Levels for operating parameters for FSW processFactorLow level (í1) Center point (0) High level(+1)N /(r·min í1) 653 910 1280 F /(mm·min í1)67 86 109r /%33 39 44Table 3 Welding parametersPin height/ mm Shoulder diameter/ mm Small diameter pin/mm Tool’s inclination angle/(°) Penetrationdepth of shoulder/mm5.3 18 4 30.78longitudinal direction compared with the weld direction, so that active zone is enclosed in the central weld zone (Fig. 3). Figure 4 shows the tensile specimens after fracture.Ultimately, it is a matter of experimental evaluation of hardening parameters of the behavior of FSW joints (k , İ0, n ) according to Swift’s hardening law:n k )(p 0H H V (1)These parameters are required to identify the plastic deformation aptitude of the FSW joints. They are also needed for numerical simulations of forming operations on welded plates. The hardening parameters have been calculated by least square method (LSM) from the stressüstrain curves data. Table 4 shows the experimental design as well as dataset performance characteristics according to the FSW parameters of aluminum Alloy 2017.3 Experimental results3.1 Development of mathematical modelsAlthough the basic principles of FSW are very simple, it involves complex phenomena related to thermo-mechanical and metallurgical transformation that causes strong microstructural heterogeneities in the welded zone. From an energy standpoint, welding process is generated by converting mechanical energy provided by FSW tool into other types of energy such as heat, plastic deformation and microstructural transformations. The nonlinear character of these different dissipation forms can justify research for nonlinear prediction models whose accuracy generally depends on the order of the models relating the responses to welding parameters. For this reason, we chose the RSM which is helpful in developing a suitable approximation for the true functional relationships between quantitative factors (x 1, x 2, Ă, x k ) and the response surface or response functions Y (k , İ0, n ) that may characterize the nature of the welded joints as follows:r 21),,,(e x x x f Y k (2)Hassen BOUZAIENE, et al/Trans. Nonferrous Met. Soc. China 22(2012) 1064í10721067Table 4 Face centered central composite design for FSW of aluminum alloy 2017Factors levelCoded Actual Hardening parameterTypeStandard orderN F r N /(r·m í1)F /(mm·min í1)r /% k /MPan İ0/%1 í1 í1 í165367 33629.7 0.3296 0.00202 1 í1 í1 1280 67 33 654.7 0.4514 0.0035 3 í1 1 í1 653109 33 587.8 0.3712 0.0025 4 1 1 í1 1280 109 33 689.2 0.4856 0.00555 í1 í1 1 653 67 44 642.3 0.4524 0.00256 1 í1 1128067 44 218.6 0.2447 0.0015 7 í1 1 1 653 109 44 685.5 0.4885 0.0035 Factorialdesign8 1 1 1 1280 109 44 332.5 0.3405 0.00209 0 0 0 91086 39 624.9 0.4257 0.0025 10 0 0 0 910 86 39 639.9 0.4292 0.0025 11 0 0 0 910 86 39 640.9 0.4011 0.0020 Center point12 0 0 0 910 86 39 598.6 0.3960 0.0023 13 í1 0 0 653 86 39 690.6 0.4748 0.0027 14 1 0 0 128086 39 505.6 0.3909 0.0030 15 0 í1 091067 39499 0.3317 0.001716 0 1 0 910 109 39 545.6 0.4157 0.0026 17 0 0 í1 910 86 33 672.1 0.4385 0.0027 Star point18 0 019108644 509.7 0.41750.0019Fig. 3 Tensile test specimens (ASME E8Mí04) cut in longitudinal direction compared with weld direction (mm)Fig. 4 Tensile specimens after fractureThe residual error term (e r ) measures theexperimental errors. Such relationship was developed as quadratic polynomial under multiple regression form [19,20]:¦¦¦ r 20e x x b x b x b b Y j i ij i ii i i (3)where b 0 is an intercept or the average of response; b i , b ii , and b ij represent regression coefficients. For the three factors, the selected polynomial could be expressed as:2332222113210r b F b N b r b F b N b b YFr b Nr b NF b 231312 (4)In applying the RSM, the independent variable Y was viewed as surface to which a mathematical model was fitted. The adequacy of the developed model was tested using the analysis of variance (ANOV A) which quantifies the amount of variation in a process and determines if it is significant or is caused by random noise.3.2 Mathematic model of hardening parametersTable 5 lists the coefficients of the best linear regression models. All selected parameters (N , F , r ) for k and İ0 are statistically significant (P-value less than 0.05) at the 95% confidence level. However, for the response n , the term b 3r having a P-value=0.0654>0.05 is not statistically significant at the 95% confidence level even though the term b 13Nr is statistically significant. Consequently, b 3(r ) is kept in the model to improve the Lack-of-Fit test (Table 6). Furthermore, only theHassen BOUZAIENE, et al/Trans. Nonferrous Met. Soc. China 22(2012) 1064í10721068Table 5 Coefficients of regression models for hardening parametersStrength coefficient (k) Hardeningcoefficient(n) Initial yield strain (İ0) CoefficientEst. SEP-value Est SE P-valueEst/10í4 SE/10í4 P-value b0 610.39,48<10í4 0.422 0.0073 <10-4 22.8 1.010 <10-4 b1 í83.58.48<10í4 í0.020 0.0065 0.0091 2.30 0.912 0.0267 b2 19.68.480.0410.0290.00650.00084.900.9120.0002b3 í84.58.48<10í4 í0.013 0.0065 0.0654 í4.80 0.912 0.0002 b11 5.561.3670.0009b22 í61.812.720.0005í0.0310.00980.009b33b12b13 í112.99.48<10í4 í0.074 0.0073 <10-4 -8,75 1.010 <10-4 b23R2 95.90% 92.38% 92.84%2adjR 94.19% 89.21% 89.86% SE of est. 30.7 0.021 2.9×10í4Est: Estimate; SE: Standard Error; SE of est.: Standard error of estimateTable 6 ANOV A for hardening parametersk n İ0Source of variationSS Df P-Value SS Df P-Value SS/10í7 Df P-Value Model 263946.0 5 <10í4 0.062357 5 <10í4 129.324 5 <10í4Residual 11296.4 12 0.005140912 9.97 12Lack-of-Fit 10130.4 9 0.2065 0.00428669 0.3678 8.295 9 0.3723 Pure error 1166.07 3 0.0008543 3 1.675 3 Total correction 275243.017 0.06749817 139.294 17 DW-value 1.31 1.42 2.26DW: Durbin-Watson statistic; SS: Sum of squares; D f: Degree of freedominteraction (Nír) is statistically significant on the three responses (Fig. 5). According to the adjusted R2 statistic, the selected models explain 94.19%, 89.21% and 89.86% of the variability in k, n and İ0 respectively.The ANOV A (Table 6) for the hardening parameter shows that all models (k, n, İ0) represent statistically significant relationships between the variables in each model at the 99% confidence level (P-value<10í4). The Lack-of-Fit test confirms that these models (k, n, İ0) are adequate to describe the observed data (P-value>0.05) at the 95% confidence level. The DW statistic test indicates that there is probably not any serious autocorrelation in their residuals (DW-value>1.4). The normal probability plots of the residuals suggest that the error terms, for these models, are indeed normally distributed (Fig. 6). The response surface models in terms of coded variables (Eqs. (5)í(7)) are shown in Fig. 7.k=610.3–83.5 N+19.6 F–84.5 r –61.8 F2–112.9 Nr(5) n=0.422–0.020 N+0.029 F–0.013 r–0.031 F2–0.074 Nr(6) İ0=22.8+2.3 N+4.90 F–4.80 r+5.56 N2–8.75 Nr(7) Fig. 5 Interaction plots of Nír (rotational speedídiameter ratio): (a) Strength coefficient k; (b) Hardening coefficient n;(c) Initial yield strain İ0Hassen BOUZAIENE, et al/Trans. Nonferrous Met. Soc. China 22(2012) 1064í1072 1069Fig. 6 Normal probability plots for residual: (a) Strength coefficient k; (b) Hardening coefficient n; (c) Initial yield strain İ04 Validation of identified modelsValidation tests of the identified models were performed through comparative study between the experimental models (EM) of tensile tests and the computed responses given by numerical simulations of the same tests (Fig. 8). The computed responses, expressed in the form of tension and elongation, wereFig. 7 Response surfaces plots: (a) Strength coefficient k;(b) Hardening coefficient n; (c) Initial yield strain İ0 established by examining welded joints having an elastoplastic behavior in accordance with the Swift hardening law (Eq. (1)). These computed responses were deduced from the numerical simulations using the finite element code Abaqus/Implicit, in which the introduced elastoplastic behavior was obtained from the least square hardening models (LSHM) (Table 4) and the response surface hardening models (RSHM) (Table 5). The highest deviations (<10%), between EM and computed response, were recorded with the RSHM. Increasing deviations, as shown in Fig. 8, is due to the effect of combining damage with plastic strains accumulatedHassen BOUZAIENE, et al/Trans. Nonferrous Met. Soc. China 22(2012) 1064í10721070Fig. 8 Relationship between tension and elongation: Confrontation between experimental model (EM), and computed responses (LSHM, RSHM) for three experimental testsduring the onset of localized necking.The relative average deviation criterion (EM/LSHM ]) between the experimental data and the numerical predictions of tensions, was used to assess the quality of the identified models.¦¸¸¹·¨¨©§'' '2exp num exp exp/num )()()(1i i i L F L F L F N] (8)where N is the number of experimental measurements,F exp (ǻL i ) and F num (ǻL i ) are respectively the experimental and predicated tensions relating to the i-th elongation ǻL i . Figure 9 illustrates that the relative average deviation of EM/LSHM (EM/LSHM ]) ranges between 1.64% and 6.75% while the relative average deviation of EM/RSHM (EM/RSHM ]) ranges between 4.52% and 9.32%.Fig. 9 Distribution of relative average deviations for most representative experimental testsFor the deviation within limits fluctuating between 4.52% and 6.75% the estimated models (LSHM and RSHM) are comparable. This applies particularly to welded joints characterized by a strength coefficient (k ), ranging from 520 to 610 MPa and a hardening exponent (n ) ranging between 0.30 and 0.45.5 DiscussionIn this study we evaluated, using RSM, the effect of FSW parameters such as tool rotational speed, welding feed rate and diameter ratio of pin to shoulder on the plastic deformation aptitudes of welded joints. The performed analysis highlights the incontestable significant effects of rotational speed (N ), welding feed rate (F ) and the interaction (Nír ) between rotational speed and diameters ratio on hardening parameters (k , n , İ0) according to Swift law. The established models show that tool diameter ratio has a linear effect only on (k ) and (İ0), it does not have any quadratic effect. They also show that rotational speed has a quadratic effect solely on (İ0); while welding feed rate has a quadratic effect on both (k ) and (n ).In addition, numerical simulation of tensile tests of welded joints has been made possible through the predictive models (LSHM and RSHM) of Swift’s hardening parameters. To judge whether the models represent correctly the data, a comparative study between the experimental response and the computed response, expressed in terms of tension-elongation, was carried out. It was found that the relative average deviation betweenHassen BOUZAIENE, et al/Trans. Nonferrous Met. Soc. China 22(2012) 1064í1072 1071experimental model and numerical models is less than 9.5% in all cases.Moreover, correlation between welding and hardening parameters provided has many benefits. The correlation relationships can solve inverse problem relating to optimal choice of parameters linked up with the desired welded joints properties to produce welds having tailor-made mechanical properties. The correlation predictions offer the possibility to identify the behavior of friction stir welded joints necessary for finite element simulations of various forming processes while minimizing experimental cost and time. Ultimately, understanding correlations can be useful for studies on reliability of welded assemblies in service life expectancy.6 Conclusions1) Rotational speed and welding feed rate are the factors that have greater influence on hardening parameters (k, n, İ0), followed by diameter ratio that has no influence on the hardening coefficient (n).2) The numerical models RSHM were compared with those through LSHM and confronted to the experimental results. Indeed, within the limit of a relative average deviation of about 9.3%, between the experimental model and numerical models expressed in terms of tension-elongation, the validity of these models is acceptable.3) The predictive models of work-hardening coefficients, established taking into account the FSW parameters, have made possible the numerical simulation of tensile tests of FSW joints. These results can be used to perform multi-criteria optimization for producing welds with specific mechanical properties or conducting numerical simulation of plastic deformation of forming process of friction stir welded parts such as hydroforming, bending and forging.References[1]THOMAS W M, NICHOLAS E D, NEEDHAM J C, MURCH M G,TEMPLE-SMITH P, DAWES C J. Friction stir butt welding,PCT/GB92/ 02203 [P]. 1991.[2]XUE P, NI D R, WANG D, XIAO B L, MA Z Y. Effect of friction stirwelding parameters on the microstructure and mechanical propertiesof the dissimilar AlíCu joints[J]. Materials Science and EngineeringA, 2011, 528: 4683í4689.[3]LIU H J, ZHANG H J, YU L. Effect of welding speed onmicrostructures and mechanical properties of underwater friction stirwelded 2219 aluminum alloy [J]. Materials and Design, 2011, 32:1548í1553.[4]MISHRA R S, MA Z Y. Friction stir welding and processing [J].Materials Science and Engineering R, 2005, 50: 1í78.[5]ARB EGAST W J. A flow-partitioned deformation zone model fordefect formation during friction stir welding [J]. Scripta Materialia,2008, 58: 372í376.[6]LEWIS N P. Metal cutting theory and friction stir welding tooldesign [M]. NASA Faculty Fellowship Program Marshall SpaceFlight Center, University of ALABAMA, NASA/MSFC Directorate:Engineering (ED-33), 2002.[7]ARB EGAST W J. Modeling friction stir welding joining as ametalworking process, hot deformation of aluminum alloys III [C].San Diego: TMS Annual Meeting, 2003: 313í327.[8]ARTHUR C N Jr. Metal flow in friction stir welding [R]. NASAmarshall space flight center, EM30. Huntsville, AL 35812.[9]FONDA R W, B INGERT J F, COLLIGAN K J. Development ofgrain structure during friction stir welding [J]. Scripta Materialia,2004, 51: 243í248.[10]NANDAN R, DEBROY T, BHADESHIA H K D H. Recent advancesin friction stir weldingüProcess, weldment structure and properties[J]. Progress in Materials Science, 2008, 53: 980í1023.[11]LOCKWOOD W D, TOMAZ B, REYNOLDS A P. Mechanicalresponse of friction stir welded AA2024: Experiment and modeling[J]. Materials Science and Engineering A, 2002, 323: 348í353. [12]SALEM H G, REYNOLDS A P, LYONS J S. Microstructure andretention of superplasticity of friction stir welded superplastic 2095sheet [J]. Scripta Materialia, 2002, 46: 337í342.[13]LOCKWOOD W D, REYNOLDS A P. Simulation of the globalresponse of a friction stir weld using local constitutive behavior [J].Materials Science and Engineering A, 2003, 339: 35í42.[14]SUTTON M A, YANG B, REYNOLDS A P, YAN J. B andedmicrostructure in 2024–T351 and 2524-T351 aluminum friction stirwelds, Part II. Mechanical characterization [J]. Materials Science andEngineering A, 2004, 364: 66í74.[15]ZHANG H W, ZHANG Z, CHEN J T. The finite element simulationof the friction stir welding process [J]. Materials Science andEngineering A, 2005, 403: 340í348.[16]ZHANG Z, ZHANG H W. Numerical studies on controlling ofprocess parameters in friction stir welding [J]. Journal of MaterialsProcessing Technology, 2009, 209: 241í270.[17]B UFFA G, FRATINI L, SHIVPURI R. Finite element studies onfriction stir welding processes of tailored blanks [J]. Computers andStructures, 2008, 86: 181í189.[18]SWIFT H W. Plastic instability under plane stress [J]. Journal of theMechanics and Physics of Solids, 1952, 1: 1í18.[19]MONTGOMERY D C. Design and analysis of experiments [M].Fifth Edition. New York: John Wiley & Sons, 2001: 684.[20]MYERS R H, MONTGOMERY D C, ANDERSON-COOK C M.Response surface methodology: Process and product optimizationusing designed experiment [M]. 3rd Edition. New York: John Wiley& Sons, 2009: 680.[21]VIJAY S J, MURUGAN N. Influence of tool pin profile on themetallurgical and mechanical properties of friction stir welded Al–10% TiB2 metal matrix composite [J]. Materials and Design,2010, 31: 3585í3589.[22]ELANGOV AN K, BALASUBRAMANIAN V. Influences of tool pinprofile and tool shoulder diameter on the formation of friction stirprocessing zone in AA6061 aluminum alloy [J]. Materials andDesign, 2008, 29: 362í373.[23]PALANIVEL R, KOSHY MATHEWS P, MURUGAN N.Development of mathematical model to predict the mechanicalproperties of friction stir welded AA6351 aluminum alloy [J]. Journalof Engineering Science and Technology Review, 2011, 4(1): 25í31.Hassen BOUZAIENE, et al/Trans. Nonferrous Met. Soc. China 22(2012) 1064í107210722017䪱 䞥 ⛞ ⛞⹀ ⱘ ㋏Hassen BOUZAIENE, Mohamed-Ali REZGUI, Mahfoudh AYADI, Ali ZGHALBesearch Unit in Solid Mechanics, Structures and Technological Development (99-UR11-46),Higher School of Sciences and Techniques of Tunis, Tunisia㽕˖ 2017䪱 䞥䖯㸠 ⛞ ˈ㸼䗄Swift⹀ 㾘 DŽ䞛⫼䴶 䆒䅵 ⊩䖯㸠⛞ ⱘ Ԍ 偠䆒䅵DŽ䞛⫼ Ѣ ѠЬ⊩ 䴶⊩ⱘ2⾡ 䆘Ԅ ⛞ ⛞ ㋴ ⹀ ⱘ DŽ䞛⫼ 䰤 Abaqus ⛞ Ԍ⌟䆩㒧 DŽⳌ 㒧 㸼 ˈ 偠㒧 㒧 䕗 DŽ䖭ѯ㒧 㛑⫼Ѣ 偠 Ⳃ Ӭ ˈ 㸠 ԧ⛞ ⛞ 䳊ӊ 䖛Ё ⱘ ˈ ⎆ ǃ 䬏䗴DŽ䬂䆡˖ ⛞ ˗ 䴶 ⊩˗䴶 Ё 䆒䅵˗⹀ ˗ ˗Ⳍ(Edited b y LI Xiang-qun)。

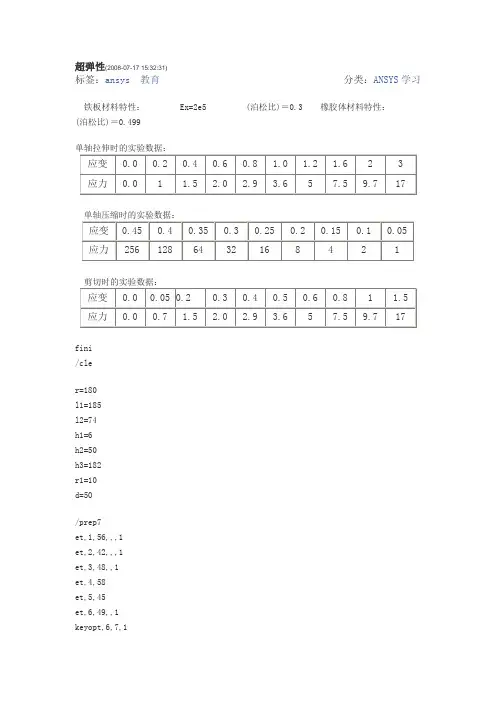

超弹性(2008-07-17 15:32:31)标签:ansys教育分类:ANSYS学习铁板材料特性:Ex=2e5 (泊松比)=0.3 橡胶体材料特性:(泊松比)=0.499fini/cler=180l1=185l2=74h1=6h2=50h3=182r1=10d=50/prep7et,1,56,,,1et,2,42,,,1et,3,48,,1et,4,58et,5,45et,6,49,,1keyopt,6,7,1keyopt,3,7,1r,1,10000,,0.5rect,0,l1,0,h1rect,0,l2,0,h2cyl4,0,h3,r,-90,,0 aovlap,allasel,s,loc,y,0,h1asel,r,loc,x,0,l2 aadd,allallsasel,s,loc,y,h1,h3 aadd,allallslsel,s,loc,x,0lsel,r,loc,y,0,h1lcom,allallslsel,s,loc,x,0lsel,r,loc,y,h1,h3 lcom,allallslsel,s,loc,y,h1lsel,r,loc,x,0,l2lcom,allallslsel,s,loc,y,h1,h2lsel,r,loc,x,l2*get,line1,line,,num,max allslsel,s,loc,x,l2,l1lsel,r,loc,y,h2,h3*get,line2,line,,num,max allslfillt,line1,line2,r1 allsal,1,4,3asel,s,loc,y,h1,h3 aadd,allallslsel,s,loc,x,l2,l1lsel,r,loc,y,h1+0.1,h3-0.1 lcom,allallslsel,s,loc,x,l2,l1lsel,r,loc,y,h1+0.1,h3-0.1 *get,line3,line,,num,max allskl,line3,0.12lsel,s,loc,x,0lsel,r,loc,y,h1,h3*get,line4,line,,num,max kl,line4,0.4kl,line4,0.7allslstr,5,7lstr,13,8asel,s,loc,y,h1,h3lsel,s,,,3,4asbl,all,allallsasel,s,loc,y,h1,h3aatt,1,1,1asel,s,loc,y,0,h1aatt,2,1,2allslesize,3,,,10lesize,8,,,12,2lesize,7,,,6lesize,12,,,1lesize,19,,,8mshkey,1amesh,5amesh,3amesh,2amesh,1amesh,6allslsel,s,,,19nsll,s,1cm,targ,nodeallslsel,s,,,6nsll,s,1cm,cont1,nodelsel,s,,,8nsll,s,1nsel,r,loc,y,h1,130 cm,cont2,nodeallscmsel,s,cont1 cmsel,a,cont2!cmsel,a,cont3cm,cont,nodeallstype,3mat,1real,1gcgen,cont,targallssave,hypelastic,db resume,hypelastic,db mp,nuxy,1,0.499 mp,ex,2,2e5mp,nuxy,2,0.3m=1.95m1=2.03n=1.05*dim,strn,,10,3*dim,strss,,10,3*dim,const,,5*dim,calc,,30*dim,sortss,,30*dim,sortsn,,30*dim,ffx,table,30,2*dim,ecalc,table,100*dim,xval,table,100strn(1,2)=-0.45,-0.4,-0.35,-0.3,-0.25,-0.2,-0.15,-0.1,-0.05strss(1,2)=-256,-128,-64,-32,-16,-8,-4,-2,-1*do,i,1,9strss(i,2)=strss(i,2) *mstrn(i,2)=strn(i,2)*m1*enddostrn(1,1)=0.0,0.2,0.4,0.6,0.8,1.0,1.2,1.6,2,3strss(1,1)=0.0,1,1.5,2.0,2.9,3.6,5,7.5,9.7,17strn(1,3)=0.0,0.05,0.2,0.3,0.4,.5,.6,.8,1,1.5strss(1,3)=0.0,0.7,1.5,2.0,2.9,3.6,5,7.5,9.7,17*do,i,1,10strss(i,3)=strss(i,3)* n*enddotb,mooney,,,,1*mooney,strn(1,1),strss(1,1),,const(1),calc(1),sortsn(1),sortss(1) *vfun,ffx(1,1),copy,sortss(1)*vfun,ffx(1,2),copy,calc(1)*vplot,strn(1),ffx(1),2*eval,1,2,const(1),-0.2,0,xval(1),ecalc(1)*vplot,xval(1),ecalc(1)fini/soluallsnsel,s,loc,y,0d,all,all,0allsnsel,s,loc,x,0d,all,ux,0d,all,uz,0allsnsel,s,loc,y,h3d,all,ux,0d,all,uz,0d,all,uy,-dallsantype,staticnlgeom,onnropt,,,onoutpr,all,alloutres,all,allautots,ontime,1deltim,0.03,0.01,0.3cnvtol,f,,0.02,2lnsrch,onpred,onallssolvefiniansys-Beam3二维弹性单元特性翻译工程应力与真实应力(2008-07-31 13:47:36)标签:ansys教育分类:ANSYS学习fini/cle/PREP7ET,1,plane182KEYOPT,1,3,1R,1,0.001, , , , , ,MP,EX,1,2.1E11 ! STEELMP,NUXY,1,0.3TB,BKIN,1,1 ! DEFINE NON-LINEAR MATERIAL PROPERTY FOR STEEL TBTEMP,0TBDATA,1,210e6,8.6e9BLC4,0, ,0.03,0.03NUMCMP,ALLAESIZE,1,0.003,allsamesh,allnsel,s,loc,y,0nsel,a,loc,y,0.05d,all,uynsel,s,loc,y,0.03nsel,a,loc,y,0.08D,all, ,0.00009,, , ,Uy ! if >0.00003 material is yield;alls/SOLUNLGEOM, ON!According small strain theory 0.005 cause 0.3%= (0.00009/0.03) strain; but if we trun NLGEOM ON, the strain is 0.2996%=ln(1+0.00009/0.03)NSUBST, 40, 100, 40OUTRES, ALL, 1SOLVE/POST1SET, LASTPLNSOL, EPTO,Y, 0,1.0 ! the max total strain value is 0.2996%/repl/POST26RFORCE, 2, 22, f, y, FY_2PLVAR, 2ANSOL,4,22,EPEL,y,EPELy_2ANSOL,5,22,EPPL,y,EPPLy_4ANSOL,6,22,S,y,Sy_4ADD,7,4,5, , , , ,1,1,1,/AXLAB,X, DEFLECTION/AXLAB,Y, Stress/GRID,1XVAR,7PLVAR,6超级大变形(2008-07-15 15:56:19)标签:ansys分类:ANSYS学习fini/cle/PREP7lsize=600hsize=24l=135e-3h=6e-3p=-10e-3!定义单元!ET,1,VISCO108ET,1,SHELL181ET,2,MASS21KEYOPT,2,1,0KEYOPT,2,2,0KEYOPT,2,3,2KEYOPT,1,1,0KEYOPT,1,2,0KEYOPT,1,3,0KEYOPT,1,5,0KEYOPT,1,6,0KEYOPT,1,7,0KEYOPT,1,8,0KEYOPT,1,9,0KEYOPT,1,11,0!实常数R,1,0.3e-3, , , , , , !板厚RMORE, , , ,RMORERMORE, ,R,2,(5.3e-3)/(hsize-1), !集中质量!定义材料MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,1,,2.06e11MPDATA,PRXY,1,,0.3 MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,DENS,1,,7900!板尺寸BLC4,p, ,l,h!单元大小LESIZE,1, , ,lsize, , , , ,1LESIZE,2, , ,hsize, , , , ,1 MSHAPE,0,2DMSHKEY,1AMESH,1TYPE,2REAL,2nsel,s,loc,x,l+pnsel,r,extnsel,u,loc,y,0nsel,u,loc,y,h*get,n_min,node,,num,minn_num=n_min*do,i,1,hsize-1E,n_numn_num=ndnext(n_num)*enddo!约束DL,4,,ALLEPLOTallssave!求解/SOLUANTYPE,4 !瞬态大变形TRNOPT,FULLLUMPM,0NLGEOM,1NSUBST,20,100,10 !子步数OUTRES,ERASEOUTRES,esol,LASTOUTRES,nsol,LASTAUTOTS,1lnsrch,1PRED,ONSSTIF,1KBC,0!cnvtol,f,0.05,,, !收敛容差!cnvtol,u,0.05,,,!冲击波加载J=1*do,i,1.1e-5,1.1e-3,1.1e-4 !载荷步数可在此改time,iacel,,,9810*sin(2854.5*i) !冲击波形lswrite,jj=j+1*enddo*do,i,1.1e-3+1e-3,30e-3,1e-3 !载荷步数可在此改time,iNSUBST,50,100,10acel,,,-361.94*sin(108.7*(i-1.1e-3)) !冲击波形lswrite,jj=j+1*enddoacel,,,0*do,i,30e-3+1e-3,0.05,1e-3 !载荷步数可在此改time,iNSUBST,50,100,10lswrite,jj=j+1*enddoj=j-1save!求解lssolve,1,J,1,Ansys疲劳算例(2008-02-22 13:38:45)标签:ansys 教育! ***************环境设置***************/units,si/title, Fatigue analysis of cylinder with flat head! ***************参数设定***************Di=1000 ! 筒体内径t=20 ! 筒体厚度hc=nint(4*sqrt(Di/2*t)/10)*10 ! 模型中筒体长度tp=60 ! 平板封头厚度r1=10 ! 平板封头外测过渡圆弧半径r2=10 ! 平板封头内侧应力释放槽圆弧半径exx=2e5 ! 材料弹性模量mu=0.3 ! 材料泊松比p1=2 ! 最高工作压力p3=2.88 ! 水压试验压力n1=2e4 ! 最高/最低压力循环次数n2=5 ! 水压试验次数! ***************前处理***************/prep7et,1,82 ! 设定单元类型keyopt,1,3,1 ! 设定周对称选项mp,ex,1,exx ! 定义材料弹性模量mp,nuxy,1,mu ! 定义材料泊松比! ******* 建立模型*******k,1,0,0 ! 定义关键点k,2,Di/2+t,,k,3,Di/2+t,-(tp+hc)k,4,Di/2,-(tp+hc)k,5,Di/2,-tpk,6,Di/2-r2,-tp ! 定义应力释放槽圆弧中心关键点k,7,0,-tpl,1,2 ! 生成线l,2,3l,3,4l,4,5l,5,7l,7,1LFILLT,1,2,r1 ! 生成外测过渡圆弧al,all ! 生成子午面CYL4, kx(6),ky(6), r2,180 ! 生成应力释放槽面域ASBA,1,2 ! 面相减wprot,,,90 ! 旋转工作平面wpoff,,,kx(6)-3*r2 ! 移动工作平面asbw,all ! 用工作平面切割子午面wprot,,90 ! 旋转工作平面wpoff,,,tp+r2 ! 移动工作平面asbw,all ! 用工作平面切割子午面esize,5 ! 设定单元尺寸MSHKEY,1 ! 设定映射剖分amesh,1 ! 映射剖分面1amesh,3 ! 映射剖分面3esize,2 ! 设定单元尺寸MSHKEY,0 ! 设定自由剖分amesh,4 ! 自由剖分面4fini ! 退出前处理! ***************求解***************/solu ! 筒体端部施加轴向约束dl,3,,uy ! 筒体端部施加轴向约束dl,6,,symm ! 平板封头对称面施加对称约束time,1 ! 载荷步1lsel,s,,,8 ! 选择内表面各线段lsel,a,,,11,13lsel,a,,,15cm,lcom1,line ! 生成内表面线组件SFL,all,PRES,p1, ! 内表面施加内压alls ! 全选solve ! 求解fini ! 退出求解器! ***************后处理***************/post1 ! 进入后处理FTSIZE,1,2,2, ! 设定疲劳评定的位置数、事件数及载荷数FP,1,1e1,2e1,5e1,1e2,2e2,5e2 ! 根据疲劳曲线输入S-N数据FP,7,1e3,2e3,5e3,1e4,2e4,5e4FP,13,1e5,2e5,5e5,1e6, ,FP,19, ,FP,21,4000,2828,1897,1414,1069,724FP,27,572,441,331,262,214,159FP,33,138,114,93.1,86.2, ,FP,39, ,! ****** 水压试验循环******fs,4760,1,1,1,0,0,0,0,0,0 ! 储存节点4760对应其第一载荷的应力set,1,last ! 读入第一载荷步数据FSNODE,4760,1,2 ! 储存节点4760对应其第二载荷的应力fe,1,n2,p3/p1 ! 设定事件循环次数及载荷比例系数! ****** 最高/最低压力循环******fs,4760,2,1,1,0,0,0,0,0,0 ! 储存节点4760对应其第一载荷的应力set,1,last ! 读入第一载荷步数据FSNODE,4760,2,2 ! 储存节点4760对应其第二载荷的应力FE,2,n1,1, ! 设定事件循环次数及载荷比例系数FTCALC,1 ! 进行疲劳计算(并记录使用系数)fini!~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~计算结果如下:PERFORM FATIGUE CALCULATION AT LOCATION 1 NODE 0*** POST1 FATIGUE CALCULATION ***LOCA TION 1 NODE 4760事件1:****** 水压试验循环******EVENT/LOADS 1 1 AND 1 2PRODUCE ALTERNA TING SI (SALT) = 285.16(应力幅值)CYCLES USED/ALLOWED = 5.000/7779(实际循环数/许用循环数)= PARTIAL USAGE (局部损伤)=0.00064事件2:****** 最高/最低压力循环******EVENT/LOADS 2 1 AND 2 2PRODUCE ALTERNA TING SI (SALT) = 198.03 WITH TEMP = 0.0000CYCLES USED/ALLOWED = 0.2000E+05/ 0.2541E+05 = PARTIAL USAGE = 0.78719CUMULATIVE FATIGUE USAGE = 0.78784注意:285/198=P3/P1,应力与载荷成线性关系节点4760的S1,S3分别为:395,-1.2;应力幅值=(S1-S3)/2=(395-(-1.2))/2198对应的许用循环数0.2541E+05是通过S-N(214->20000 ,159->50000)曲线插值出来的.下面的命令流进行的是一个简单的二维焊接分析, 利用ANSYS单元生死和热-结构耦合分析功能进!行焊接过程仿真, 计算焊接过程中的温度分布和应力分布以及冷却后的焊缝残余应力。

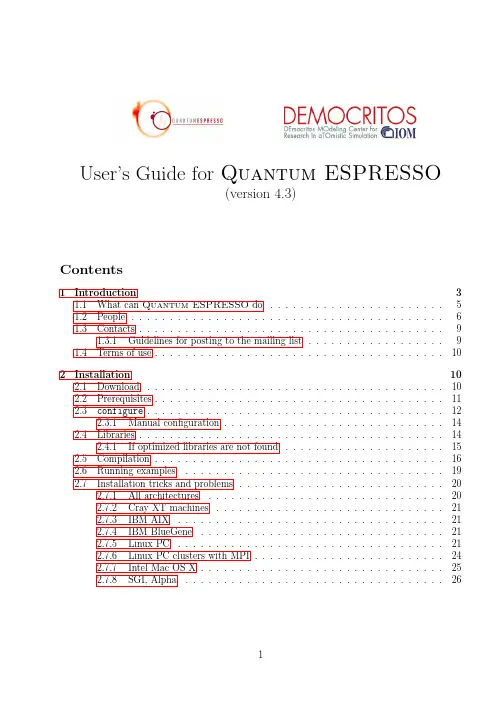

User’s Guide for Quantum ESPRESSO(version4.3)Contents1Introduction31.1What can Quantum ESPRESSO do (5)1.2People (6)1.3Contacts (9)1.3.1Guidelines for posting to the mailing list (9)1.4Terms of use (10)2Installation102.1Download (10)2.2Prerequisites (11)2.3configure (12)2.3.1Manual configuration (14)2.4Libraries (14)2.4.1If optimized libraries are not found (15)2.5Compilation (16)2.6Running examples (19)2.7Installation tricks and problems (20)2.7.1All architectures (20)2.7.2Cray XT machines (21)2.7.3IBM AIX (21)2.7.4IBM BlueGene (21)2.7.5Linux PC (21)2.7.6Linux PC clusters with MPI (24)2.7.7Intel Mac OS X (25)2.7.8SGI,Alpha (26)3Parallelism273.1Understanding Parallelism (27)3.2Running on parallel machines (27)3.3Parallelization levels (28)3.3.1Understanding parallel I/O (30)3.4Tricks and problems (31)4Using Quantum ESPRESSO334.1Input data (33)4.2Datafiles (34)4.3Format of arrays containing charge density,potential,etc (34)4.4Pseudopotentialfiles (35)5Using PWscf355.1Electronic structure calculations (36)5.2Optimization and dynamics (37)5.3Direct interface with CASINO (38)6NEB calculations40 7Phonon calculations427.1Single-q calculation (42)7.2Calculation of interatomic force constants in real space (43)7.3Calculation of electron-phonon interaction coefficients (43)7.4Distributed Phonon calculations (44)8Post-processing448.1Plotting selected quantities (44)8.2Band structure,Fermi surface (45)8.3Projection over atomic states,DOS (45)8.4Wannier functions (45)8.5Other tools (46)9Using CP469.1Reaching the electronic ground state (48)9.2Relax the system (48)9.3CP dynamics (50)9.4Advanced usage (52)9.4.1Self-interaction Correction (52)9.4.2ensemble-DFT (53)9.4.3Free-energy surface calculations (55)9.4.4Treatment of USPPs (55)10Performances5610.1Execution time (56)10.2Memory requirements (57)10.3File space requirements (58)10.4Parallelization issues (58)11Troubleshooting5911.1pw.x problems (59)11.2Compilation problems with PLUMED (66)11.3Compilation problems with YAMBO (67)11.4PostProc (67)11.5ph.x errors (68)12Frequently Asked Questions(F AQ)6912.1General (69)12.2Installation (69)12.3Pseudopotentials (70)12.4Input data (71)12.5Parallel execution (72)12.6Frequent errors during execution (72)12.7Self Consistency (73)12.8Phonons (75)1IntroductionThis guide covers the installation and usage of Quantum ESPRESSO(opEn-Source Packagefor Research in Electronic Structure,Simulation,and Optimization),version4.3.The Quantum ESPRESSO distribution contains the following core packages for the cal-culation of electronic-structure properties within Density-Functional Theory(DFT),using a Plane-Wave(PW)basis set and pseudopotentials(PP):•PWscf(Plane-Wave Self-Consistent Field).•CP(Car-Parrinello).It also includes the following more specialized packages:•NEB:energy barriers and reaction pathways through the Nudged Elastic Band method.•PHonon:phonons with Density-Functional Perturbation Theory.•PostProc:various utilities for data postprocessing.•PWcond:ballistic conductance(http://people.sissa.it/~smogunov/PWCOND/pwcond.html).•GIPAW(Gauge-Independent Projector Augmented Waves):EPR g-tensor and NMR chem-ical shifts().•XSPECTRA:K-edge X-ray adsorption spectra.•vdW:(experimental)dynamic polarizability.•GWW:(experimental)GW calculation using Wannier functions(/).•TD-DFPT:calculations of spectra using Time-Dependent Density-Functional PerturbationTheory(see TDDFPT/README for a list of reference papers).The following auxiliary codes are included as well:•PWgui:a Graphical User Interface,producing input datafiles for PWscf.•atomic:a program for atomic calculations and generation of pseudopotentials.•QHA:utilities for the calculation of projected density of states(PDOS)and of the free energy in the Quasi-Harmonic Approximation(to be used in conjunction with PHonon).•PlotPhon:phonon dispersion plotting utility(to be used in conjunction with PHonon).A copy of required external libraries are included:•iotk:an Input-Output ToolKit.•BLAS and LAPACKFinally,several additional packages that exploit data produced by Quantum ESPRESSO or patch some Quantum ESPRESSO routines can be installed as plug-ins:•Wannier90:maximally localized Wannier functions(/),writ-ten by A.Mostofi,J.Yates,Y.-S Lee.•WanT:quantum transport properties with Wannier functions(),originally written by A.Ferretti,A Calzolari and M.Buongiorno Nardelli.•YAMBO:electronic excitations within Many-Body Perturbation Theory:GW and Bethe-Salpeter equation(),originally written by A.Marini.•PLUMED:calculation of free-energy surface through metadynamicsM.Bonomi et al,m.180,1961(2009)(http://merlino.mi.infm.it/~plumed/PLUMED).This guide documents PWscf,NEB,CP,PHonon,PostProc.The remaining packages have sepa-rate documentation.The Quantum ESPRESSO codes work on many different types of Unix machines,in-cluding parallel machines using both OpenMP and MPI(Message Passing Interface).Running Quantum ESPRESSO on Mac OS X and MS-Windows is also possible:see section2.2.Further documentation,beyond what is provided in this guide,can be found in:•the pw forum mailing list(pw forum@).You can subscribe to this list,browse and search its archives(links in /contacts.php).See section1.3,“Contacts”,for more info.•the Doc/directory of the Quantum ESPRESSO distribution,containing a detailed description of input data for most codes infiles INPUT*.txt and INPUT*.html,plus and a few additional pdf documents•the Quantum ESPRESSO web site:;•the Quantum ESPRESSO Wiki:/wiki/index.php/Main Page.People who want to contribute to Quantum ESPRESSO should read the Developer Manual: Doc/developer man.pdf.This guide does not explain the basic Unix concepts(shell,execution path,directories etc.) and utilities needed to run Quantum ESPRESSO;it does not explain either solid state physics and its computational methods.If you want to learn the latter,you should read a good textbook,such as e.g.the book by Richard Martin:Electronic Structure:Basic Theory and Practical Methods,Cambridge University Press(2004).See also the“Learn”section in the Quantum ESPRESSO web site;the“Reference Papers”section in the Wiki.All trademarks mentioned in this guide belong to their respective owners.1.1What can Quantum ESPRESSO doPWscf can currently perform the following kinds of calculations:•ground-state energy and one-electron(Kohn-Sham)orbitals;•atomic forces,stresses,and structural optimization;•molecular dynamics on the ground-state Born-Oppenheimer surface,also with variable cell;•macroscopic polarization andfinite electricfields via the modern theory of polarization (Berry Phases).•the modern theory of polarization(Berry Phases).•free-energy surface calculation atfixed cell through meta-dynamics,if patched with PLUMED.All of the above works for both insulators and metals,in any crystal structure,for many exchange-correlation(XC)functionals(including spin polarization,DFT+U,nonlocal VdW functionas,hybrid functionals),for norm-conserving(Hamann-Schluter-Chiang)PPs(NCPPs) in separable form or Ultrasoft(Vanderbilt)PPs(USPPs)or Projector Augmented Waves(PAW) method.Non-collinear magnetism and spin-orbit interactions are also implemented.An imple-mentation offinite electricfields with a sawtooth potential in a supercell is also available.NEB calculates reaction pathways and energy barriers using the Nudged Elastic Band(NEB) and Fourier String Method Dynamics(SMD)methods.Note that these calculations are no longer performed by the pw.x executable of PWscf.Also note that NEB with Car-Parrinello Molecular Dynamics is currently not implemented.PHonon can perform the following types of calculations:•phonon frequencies and eigenvectors at a generic wave vector,using Density-Functional Perturbation Theory;•effective charges and dielectric tensors;•electron-phonon interaction coefficients for metals;•interatomic force constants in real space;•third-order anharmonic phonon lifetimes;•Infrared and Raman(nonresonant)cross section.PHonon can be used whenever PWscf can be used,with the exceptions of DFT+U,nonlocal VdW and hybrid PP and PAW are not implemented for higher-order response calculations.See the header offile PH/phonon.f90for a complete and updated list of what PHonon can and cannot do.Calculations,in the Quasi-Harmonic approximations,of the vibra-tional free energy can be performed using the QHA package.PostProc can perform the following types of calculations:•Scanning Tunneling Microscopy(STM)images;•plots of Electron Localization Functions(ELF);•Density of States(DOS)and Projected DOS(PDOS);•L¨o wdin charges;•planar and spherical averages;plus interfacing with a number of graphical utilities and with external codes.CP can perform Car-Parrinello molecular dynamics,including variable-cell dynamics,and free-energy surface calculation atfixed cell through meta-dynamics,if patched with PLUMED.1.2PeopleIn the following,the cited affiliation is either the current one or the one where the last known contribution was done.The maintenance and further development of the Quantum ESPRESSO distribution is promoted by the DEMOCRITOS National Simulation Center of IOM-CNR under the coor-dination of Paolo Giannozzi(Univ.Udine,Italy)and Layla Martin-Samos(Democritos)with the strong support of the CINECA National Supercomputing Center in Bologna under the responsibility of Carlo Cavazzoni.The PWscf package(which included PHonon and PostProc in earlier releases)was origi-nally developed by Stefano Baroni,Stefano de Gironcoli,Andrea Dal Corso(SISSA),Paolo Giannozzi,and many others.We quote in particular:•Matteo Cococcioni(Univ.Minnesota)for DFT+U implementation;•David Vanderbilt’s group at Rutgers for Berry’s phase calculations;•Ralph Gebauer(ICTP,Trieste)and Adriano Mosca Conte(SISSA,Trieste)for noncolinear magnetism;•Andrea Dal Corso for spin-orbit interactions;•Carlo Sbraccia(Princeton)for NEB,Strings method,for improvements to structural optimization and to many other parts;•Paolo Umari(Democritos)forfinite electricfields;•Renata Wentzcovitch and collaborators(Univ.Minnesota)for variable-cell molecular dynamics;•Lorenzo Paulatto(Univ.Paris VI)for PAW implementation,built upon previous work by Guido Fratesi(ano Bicocca)and Riccardo Mazzarello(ETHZ-USI Lugano);•Ismaila Dabo(INRIA,Palaiseau)for electrostatics with free boundary conditions;•Norbert Nemec and Mike Towler(U.Cambridge)for interface with CASINO.For PHonon,we mention in particular:•Michele Lazzeri(Univ.Paris VI)for the2n+1code and Raman cross section calculation with2nd-order response;•Andrea Dal Corso for USPP,noncollinear,spin-orbit extensions to PHonon.For PostProc,we mention:•Andrea Benassi(SISSA)for the epsilon utility;•Dmitry Korotin(Inst.Met.Phys.Ekaterinburg)for the wannier ham utility.The CP package is based on the original code written by Roberto Car and Michele Parrinello. CP was developed by Alfredo Pasquarello(IRRMA,Lausanne),Kari Laasonen(Oulu),Andrea Trave,Roberto Car(Princeton),Nicola Marzari(Univ.Oxford),Paolo Giannozzi,and others. FPMD,later merged with CP,was developed by Carlo Cavazzoni,Gerardo Ballabio(CINECA), Sandro Scandolo(ICTP),Guido Chiarotti(SISSA),Paolo Focher,and others.We quote in particular:•Manu Sharma(Princeton)and Yudong Wu(Princeton)for maximally localized Wannier functions and dynamics with Wannier functions;•Paolo Umari(Democritos)forfinite electricfields and conjugate gradients;•Paolo Umari and Ismaila Dabo for ensemble-DFT;•Xiaofei Wang(Princeton)for META-GGA;•The Autopilot feature was implemented by Targacept,Inc.Other packages in Quantum ESPRESSO:•PWcond was written by Alexander Smogunov(SISSA)and Andrea Dal Corso.For an introduction,see http://people.sissa.it/~smogunov/PWCOND/pwcond.html•GIPAW()was written by Davide Ceresoli(MIT),Ari Seitsonen (Univ.Zurich),Uwe Gerstmann,Francesco Mauri(Univ.Paris VI).•PWgui was written by Anton Kokalj(IJS Ljubljana)and is based on his GUIB concept (http://www-k3.ijs.si/kokalj/guib/).•atomic was written by Andrea Dal Corso and it is the result of many additions to the original code by Paolo Giannozzi and others.Lorenzo Paulatto wrote the PAW extension.•iotk(http://www.s3.infm.it/iotk)was written by Giovanni Bussi(SISSA).•XSPECTRA was written by Matteo Calandra(Univ.Paris VI)and collaborators.•VdW was contributed by Huy-Viet Nguyen(SISSA).•GWW was written by Paolo Umari and Geoffrey Stenuit(Democritos).•QHA amd PlotPhon were contributed by Eyvaz Isaev(Moscow Steel and Alloy Inst.and Linkoping and Uppsala Univ.).•TD-DFPT written by Stefano Baroni(SISSA),Ralph Gebauer(ICTP),Baris Malcioglu, Dario Rocca,Brent Walker.Other relevant contributions to Quantum ESPRESSO:•Brian Kolb and Timo Thonhauser(Wake Forest University)implemented the vdW-DF and vdW-DF2functionals,with support from Riccardo Sabatini and Stefano de Gironcoli (SISSA and DEMOCRITOS);•Andrea Ferretti(MIT)contributed the qexml and sumpdos utility,helped withfile formats and with various problems;•Hannu-Pekka Komsa(CSEA/Lausanne)contributed the HSE functional;•Dispersions interaction in the framework of DFT-D were contributed by Daniel Forrer (Padua Univ.)and Michele Pavone(Naples Univ.Federico II);•Filippo Spiga(ano Bicocca)contributed the mixed MPI-OpenMP paralleliza-tion;•The initial BlueGene porting was done by Costas Bekas and Alessandro Curioni(IBM Zurich);•Gerardo Ballabio wrote thefirst configure for Quantum ESPRESSO•Audrius Alkauskas(IRRMA),Uli Aschauer(Princeton),Simon Binnie(Univ.College London),Guido Fratesi,Axel Kohlmeyer(UPenn),Konstantin Kudin(Princeton),Sergey Lisenkov(Univ.Arkansas),Nicolas Mounet(MIT),William Parker(Ohio State Univ), Guido Roma(CEA),Gabriele Sclauzero(SISSA),Sylvie Stucki(IRRMA),Pascal Thibaudeau (CEA),Vittorio Zecca,Federico Zipoli(Princeton)answered questions on the mailing list, found bugs,helped in porting to new architectures,wrote some code.An alphabetical list of further contributors includes:Dario Alf`e,Alain Allouche,Francesco Antoniella,Francesca Baletto,Mauro Boero,Nicola Bonini,Claudia Bungaro,Paolo Cazzato, Gabriele Cipriani,Jiayu Dai,Cesar Da Silva,Alberto Debernardi,Gernot Deinzer,Yves Ferro, Martin Hilgeman,Yosuke Kanai,Nicolas Lacorne,Stephane Lefranc,Kurt Maeder,Andrea Marini,Pasquale Pavone,Mickael Profeta,Kurt Stokbro,Paul Tangney,Antonio Tilocca,Jaro Tobik,Malgorzata Wierzbowska,Silviu Zilberman,and let us apologize to everybody we have forgotten.This guide was mostly written by Paolo Giannozzi.Gerardo Ballabio and Carlo Cavazzoni wrote the section on CP.Mike Towler wrote the PWscf to CASINO subsection.1.3ContactsThe web site for Quantum ESPRESSO is /.Releases and patches can be downloaded from this site or following the links contained in it.The main entry point for developers is the QE-forge web site:/.The recommended place where to ask questions about installation and usage of Quantum ESPRESSO,and to report bugs,is the pw forum mailing list:pw forum@.Here you can receive news about Quantum ESPRESSO and obtain help from the developers and from knowledgeable users.Please read the guidelines for posting,section1.3.1!You have to be subscribed in order to post to the pw forum list.NOTA BENE:only messages that appear to come from the registered user’s e-mail address,in its exact form,will be accepted.Messages”waiting for moderator approval”are automatically deleted with no further processing(sorry,too much spam).In case of trouble,carefully check that your return e-mail is the correct one(i.e.the one you used to subscribe).Since pw forum averages∼10message a day,an alternative low-traffic mailing list,pw users@,is provided for those interested only in Quantum ESPRESSO-related news,such as e.g.announcements of new versions,tutorials,etc..You can subscribe(but not post)to this list from the Quantum ESPRESSO web site(“Contacts”section).If you need to contact the developers for specific questions about coding,proposals,offers of help,etc.,send a message to the developers’mailing list:user q-e-developers,address .1.3.1Guidelines for posting to the mailing listLife for subscribers of pw forum will be easier if everybody complies with the following guide-lines:•Before posting,please:browse or search the archives–links are available in the”Contacts”page of the Quantum ESPRESSO web site:/contacts.php.Most questions are asked over and over again.Also:make an attempt to search the available documentation,notably the FAQs and the User Guide.The answer to most questions is already there.•Sign your post with your name and affiliation.•Choose a meaningful subject.Do not use”reply”to start a new thread:it will confuse the ordering of messages into threads that most mailers can do.In particular,do not use ”reply”to a Digest!!!•Be short:no need to send128copies of the same error message just because you this is what came out of your128-processor run.No need to send the entire compilation log fora single error appearing at the end.•Avoid excessive or irrelevant quoting of previous messages.Your message must be imme-diately visible and easily readable,not hidden into a sea of quoted text.•Remember that even experts cannot guess where a problem lies in the absence of sufficient information.•Remember that the mailing list is a voluntary endeavour:nobody is entitled to an answer, even less to an immediate answer.•Finally,please note that the mailing list is not a replacement for your own work,nor is it a replacement for your thesis director’s work.1.4Terms of useQuantum ESPRESSO is free software,released under the GNU General Public License. See /licenses/old-licenses/gpl-2.0.txt,or thefile License in the distribution).We shall greatly appreciate if scientific work done using this code will contain an explicit acknowledgment and the following reference:P.Giannozzi,S.Baroni,N.Bonini,M.Calandra,R.Car,C.Cavazzoni,D.Ceresoli,G.L.Chiarotti,M.Cococcioni,I.Dabo,A.Dal Corso,S.Fabris,G.Fratesi,S.deGironcoli,R.Gebauer,U.Gerstmann,C.Gougoussis,A.Kokalj,zzeri,L.Martin-Samos,N.Marzari,F.Mauri,R.Mazzarello,S.Paolini,A.Pasquarello,L.Paulatto, C.Sbraccia,S.Scandolo,G.Sclauzero, A.P.Seitsonen, A.Smo-gunov,P.Umari,R.M.Wentzcovitch,J.Phys.:Condens.Matter21,395502(2009),/abs/0906.2569Note the form Quantum ESPRESSO for textual citations of the code.Pseudopotentials should be cited as(for instance)[]We used the pseudopotentials C.pbe-rrjkus.UPF and O.pbe-vbc.UPF from.2Installation2.1DownloadPresently,Quantum ESPRESSO is only distributed in source form;some precompiled exe-cutables(binaryfiles)are provided only for PWgui.Stable releases of the Quantum ESPRESSO source package(current version is4.3)can be downloaded from this URL:/download.php.Uncompress and unpack the core distribution using the command:tar zxvf espresso-X.Y.Z.tar.gz(a hyphen before”zxvf”is optional)where X.Y.Z stands for the version number.If your version of tar doesn’t recognize the”z”flag:gunzip-c espresso-X.Y.Z.tar.gz|tar xvf-A directory espresso-X.Y.Z/will be created.Given the size of the complete distribution,you may need to download more packages and to unpack them following the same procedure(they will unpack into the same directory).Plug-ins such as YAMBO or PLUMED should instead be downloaded into subdirectory archive but NOT UNPACKED OR UNCOMPRESSED:command make will take care of this during installation.Occasionally,patches for the current version,fixing some errors and bugs,may be distributed as a”diff”file.In order to install a patch(for instance):cd espresso-X.Y.Z/patch-p1</path/to/the/diff/file/patch-file.diffIf more than one patch is present,they should be applied in the correct order.Daily snapshots of the development version can be downloaded from the developers’site :follow the link”Quantum ESPRESSO”,then”SCM”.Beware:the develop-ment version is,well,under development:use at your own risk!The bravest may access the development version via anonymous CVS(Concurrent Version System):see the Developer Manual(Doc/developer man.pdf),section”Using CVS”.The Quantum ESPRESSO distribution contains several directories.Some of them are common to all packages:Modules/sourcefiles for modules that are common to all programsinclude/files*.h included by fortran and C sourcefilesclib/external libraries written in Cflib/external libraries written in Fortranextlibs/archive of external libraries LAPACK,BLAS and iotkinstall/installation scripts and utilitiespseudo/pseudopotentialfiles used by examplesupftools/converters to unified pseudopotential format(UPF)examples/sample input and outputfilesDoc/general documentationarchive/contains plug-ins in.tar.gz formwhile others are specific to a single package:PW/PWscf:sourcefiles for scf calculations(pw.x)pwtools/PWscf:sourcefiles for miscellaneous analysis programstests/PWscf:automated testsNEB/PWneb:sourcefiles for NEB calculations(neb.x)PP/PostProc:sourcefiles for post-processing of pw.x datafilePH/PHonon:sourcefiles for phonon calculations(ph.x)and analysisGamma/PHonon:sourcefiles for Gamma-only phonon calculation(phcg.x)D3/PHonon:sourcefiles for third-order derivative calculations(d3.x)PWCOND/PWcond:sourcefiles for conductance calculations(pwcond.x)vdW/VdW:sourcefiles for molecular polarizability calculation atfinite frequency CPV/CP:sourcefiles for Car-Parrinello code(cp.x)atomic/atomic:sourcefiles for the pseudopotential generation package(ld1.x) atomic doc/Documentation,tests and examples for atomicGUI/PWGui:Graphical User Interface2.2PrerequisitesTo install Quantum ESPRESSO from source,you needfirst of all a minimal Unix envi-ronment:basically,a command shell(e.g.,bash or tcsh)and the utilities make,awk,sed. MS-Windows users need to have Cygwin(a UNIX environment which runs under Windows) installed:see /.Note that the scripts contained in the distribution assume that the local language is set to the standard,i.e.”C”;other settings may break them. Use export LC ALL=C(sh/bash)or setenv LC ALL C(csh/tcsh)to prevent any problem when running scripts(including installation scripts).Second,you need C and Fortran-95compilers.For parallel execution,you will also needMPI libraries and a“parallel”(i.e.MPI-aware)compiler.For massively parallel machines,orfor simple multicore parallelization,an OpenMP-aware compiler and libraries are also required.Big machines with specialized hardware(e.g.IBM SP,CRAY,etc)typically have a Fortran-95compiler with MPI and OpenMP libraries bundled with the software.Workstations or “commodity”machines,using PC hardware,may or may not have the needed software.If not,you need either to buy a commercial product(e.g Portland)or to install an open-source compiler like gfortran or g95.Note that several commercial compilers are available free of charge under some license for academic or personal usage(e.g.Intel,Sun).2.3configureTo install the Quantum ESPRESSO source package,run the configure script.This is ac-tually a wrapper to the true configure,located in the install/subdirectory.configure will(try to)detect compilers and libraries available on your machine,and set up things accordingly. Presently it is expected to work on most Linux32-and64-bit PCs(all Intel and AMD CPUs)and PC clusters,SGI Altix,IBM SP machines,NEC SX,Cray XT machines,Mac OS X,MS-Windows PCs.It may work with some assistance also on other architectures(see below).Instructions for the impatient:cd espresso-X.Y.Z/./configuremake allSymlinks to executable programs will be placed in the bin/subdirectory.Note that both Cand Fortran compilers must be in your execution path,as specified in the PATH environment variable.Additional instructions for special machines:./configure ARCH=crayxt4r for CRAY XT machines./configure ARCH=necsx for NEC SX machines./configure ARCH=ppc64-mn PowerPC Linux+xlf(Marenostrum)./configure ARCH=ppc64-bg IBM BG/P(BlueGene)configure Generates the followingfiles:install/make.sys compilation rules andflags(used by Makefile)install/configure.msg a report of the configuration run(not needed for compilation)install/config.log detailed log of the configuration run(may be needed for debugging) include/fft defs.h defines fortran variable for C pointer(used only by FFTW)include/c defs.h defines C to fortran calling conventionand a few more definitions used by CfilesNOTA BENE:unlike previous versions,configure no longer runs the makedeps.sh shell scriptthat updates dependencies.If you modify the sources,run./install/makedeps.sh or type make depend to updatefiles make.depend in the various subdirectories.You should always be able to compile the Quantum ESPRESSO suite of programs without having to edit any of the generatedfiles.However you may have to tune configure by specifying appropriate environment variables and/or command-line ually the tricky part is toget external libraries recognized and used:see Sec.2.4for details and hints.Environment variables may be set in any of these ways:export VARIABLE=value;./configure#sh,bash,kshsetenv VARIABLE value;./configure#csh,tcsh./configure VARIABLE=value#any shellSome environment variables that are relevant to configure are:ARCH label identifying the machine type(see below)F90,F77,CC names of Fortran95,Fortran77,and C compilersMPIF90name of parallel Fortran95compiler(using MPI)CPP sourcefile preprocessor(defaults to$CC-E)LD linker(defaults to$MPIF90)(C,F,F90,CPP,LD)FLAGS compilation/preprocessor/loaderflagsLIBDIRS extra directories where to search for librariesFor example,the following command line:./configure MPIF90=mpf90FFLAGS="-O2-assume byterecl"\CC=gcc CFLAGS=-O3LDFLAGS=-staticinstructs configure to use mpf90as Fortran95compiler withflags-O2-assume byterecl, gcc as C compiler withflags-O3,and to link withflag-static.Note that the value of FFLAGS must be quoted,because it contains spaces.NOTA BENE:do not pass compiler names with the leading path included.F90=f90xyz is ok,F90=/path/to/f90xyz is not.Do not use environmental variables with configure unless they are needed!try configure with no options as afirst step.If your machine type is unknown to configure,you may use the ARCH variable to suggest an architecture among supported ones.Some large parallel machines using a front-end(e.g. Cray XT)will actually need it,or else configure will correctly recognize the front-end but not the specialized compilation environment of those machines.In some cases,cross-compilation requires to specify the target machine with the--host option.This feature has not been ex-tensively tested,but we had at least one successful report(compilation for NEC SX6on a PC). Currently supported architectures are:ia32Intel32-bit machines(x86)running Linuxia64Intel64-bit(Itanium)running Linuxx8664Intel and AMD64-bit running Linux-see note belowaix IBM AIX machinessolaris PC’s running SUN-Solarissparc Sun SPARC machinescrayxt4Cray XT4/5machinesmacppc Apple PowerPC machines running Mac OS Xmac686Apple Intel machines running Mac OS Xcygwin MS-Windows PCs with Cygwinnecsx NEC SX-6and SX-8machinesppc64Linux PowerPC machines,64bitsppc64-mn as above,with IBM xlf compilerppc64-bg IBM BlueGeneNote:x8664replaces amd64since v.4.1.Cray Unicos machines,SGI machines with MIPS architecture,HP-Compaq Alphas are no longer supported since v.4.3.Finally,configure rec-ognizes the following command-line options:。