Transport-of-terrestrial-organic-matter-in-the-Ogoou-deep-sea-turbidite-system-Gabon-_2011

- 格式:pdf

- 大小:1.68 MB

- 文档页数:12

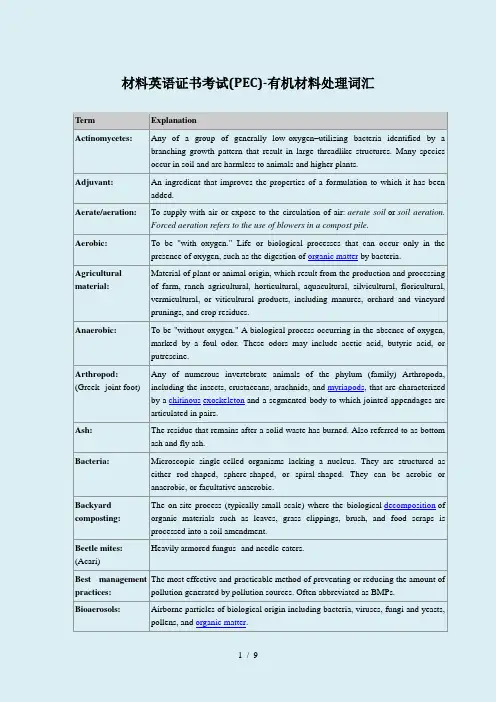

材料英语证书考试(PEC)-有机材料处理词汇Term ExplanationActinomycetes:Any of a group of generally low-oxygen–utilizing bacteria identified by a branching growth pattern that result in large threadlike structures. Many speciesoccur in soil and are harmless to animals and higher plants.Adjuvant:An ingredient that improves the properties of a formulation to which it has been added.Aerate/aeration:To supply with air or expose to the circulation of air: aerate soil or soil aeration.Forced aeration refers to the use of blowers in a compost pile.Aerobic:To be "with oxygen." Life or biological processes that can occur only in the presence of oxygen, such as the digestion of organic matter by bacteria.Agricultural material:Material of plant or animal origin, which result from the production and processing of farm, ranch agricultural, horticultural, aquacultural, silvicultural, floricultural, vermicultural, or viticultural products, including manures, orchard and vineyard prunings, and crop residues.Anaerobic:To be "without oxygen." A biological process occurring in the absence of oxygen, marked by a foul odor. These odors may include acetic acid, butyric acid, orputrescine.Arthropod: (Greek--joint foot) Any of numerous invertebrate animals of the phylum (family) Arthropoda, including the insects, crustaceans, arachnids, and myriapods, that are characterized by a chitinous exoskeleton and a segmented body to which jointed appendages are articulated in pairs.Ash:The residue that remains after a solid waste has burned. Also referred to as bottom ash and fly ash.Bacteria:Microscopic single-celled organisms lacking a nucleus. They are structured as either rod-shaped, sphere-shaped, or spiral-shaped. They can be aerobic oranaerobic, or facultative anaerobic.Backyard composting:The on-site process (typically small scale) where the biological decomposition of organic materials such as leaves, grass clippings, brush, and food scraps is processed into a soil amendment.Beetle mites:(Acari)Heavily armored fungus- and needle-eaters.Best management practices:The most effective and practicable method of preventing or reducing the amount of pollution generated by pollution sources. Often abbreviated as BMPs.Bioaerosols:Airborne particles of biological origin including bacteria, viruses, fungi and yeasts, pollens, and organic matter.Bioassay:Appraisal of the biological activity of a substance by testing its effect on an organism and comparing the result with some agreed standard.Biodiversity:The variability among living organisms on Earth, including the variability within and between species and within and between ecosystems.Biofiltration:The harnessing of natural processes for volatile organic compounds (VOC) and odor control. Example: an air stream is passed through a biofiltercontaining microorganisms, which metabolize the VOCs, turning them into carbondioxide and water.Bioremediation:The use of plants or microorganisms to clean up contamination and pollution or to solve other environmental problems, and return the environment to its originalcondition.Biosolids:The nutrient-rich organic byproduct material resulting from the treatment of sewage sludge and wastewater.CAFO:Combined animal feeding operation (CAFO). Animal feeding operations (AFOs) are livestock-raising operations, such as hog, cattle and poultry farms, whichconfine and concentrate animal populations and their wastes. CAFO is the largestcategory of AFO with greater than 1,000 "animal units" and is a significantcontributor to the pollution of waters in the U.S.Casing layer: A moist layer of peat moss mixed with a small amount of calcium carbonate that growers apply over mycelium to retain moisture and provide a growing surface formushrooms.Catchment:a) A catching or collecting of water, especially rainwater, b) A structure, such as a basin or reservoir, used for collecting or draining water, c) The amount of watercollected in such structure, d) A catchment area.Cellobiose: A disaccharide obtained by the hydrolysis of cellulose by cellulase. Formula: C12H22O11Cellulase:Any enzyme that converts cellulose to the disaccharide cellobiose.Cellulose:The main substance in the cell walls of plants, which is used in making paper, artificial fibers, and plastics.Chitin, (pronounced ktin):Main component of the cell walls of arthropods, found in the outer skeleton of insects, crabs, and lobsters and in the internal structures of other invertebrates.CNMP:Comprehensive Nutrient Management Plan is a conservation plan that is unique to animal feeding operations and which incorporates environmental practices to utilizeanimal manure and organic by-products as a beneficial resource to ensure that bothproduction and natural resource protection goals are achieved.Co-composting:The process of blending biosolids with manure or other green waste materials to produce compost. Co-composting includes both the active and curing phases of thecomposting process.Compaction:In soil, compaction occurs when weight of grazing animals/livestock or heavymachinery compresses the soil. The soil then is less able to absorb water.Compost:The product resulting from the decomposition of organic material. Material used to make compost includes landscape trimmings, agricultural crop residues, paper pulp,food scrap, wood chips, manure, and biosolids. These are typically referred to asfeedstock.Composting:The biological decomposition process of organic materials such as leaves, garden waste, coffee grounds, grass clippings, brush, and food waste into a soilamendment.Construction and demolition waste:Waste from building materials such as rubble, lumber, wire, sheet metal, and miscellaneous metal parts.Conversion technology:Term used for the technologies that convert unwanted organic materials into high-value products such as energy, alternative fuels, solvents, and other products.Cover crop: A crop, such as clover, planted between periods of regular crop production to control weeds, prevent soil erosion, and provide humus or nitrogen to the soil.Crown:The junction of root and stem, usually at the level of the ground.Decomposer:An organism that feeds on and breaks down organic materials into simpler chemical compounds.Decomposition:The process by which organic materials chemically break down into simpler compounds.Dewatering:Removal of water from solid waste and sludge via mechanical or thermal means.Disaccharide:Any of a class of sugars, such as maltose, lactose, and sucrose, having two linked monosaccharide units per molecule.Ecosystem:All the living things in an area and the way they affect each other and the environment.Exoskeleton:An external supportive covering of an animal such as a crab or insect (as an arthropod).Feedstock:The raw material used for chemical or biological processes. For example, feedstock used for making compost could include grass clippings, leaves, food scraps, planttrimmings, straw, and animal bedding.Foliage:The leaves of plants or trees.Food material:Material acquired for animal or human consumption, is separated from the municipal solid waste stream, and does not meet the definition of “agriculturalmaterial.”Food scraps:All excess food, including surplus, spoiled, or unsold food such as vegetables and culls (lower quality vegetables or trimmings such as onion peels or carrot tops), aswell as plate scrapings. Food scraps also are commonly called food remnants, foodresiduals, or food waste.Food waste:Refers to all surplus food scraps. The term has fallen out of favor with somecomposters, who prefer to view this material as a resource rather than as wastematerial. However, this term is interchangeable with food scraps.Food Web:The totality of interacting food chains within an ecosystem.Fulvic acid: A yellow to yellow-brown humic substance that is soluble in water under all pH conditions.Fungi:Saprophytic and parasitic plants that lack chlorophyll and include molds, rusts, mildews, smuts, and mushrooms.Grasscycling:The natural recycling of grass by leaving clippings on the lawn when mowing.Grass clippings will quickly decompose, returning valuable nutrients to the soil.Green material:Green material includes, but is not limited to, yard trimmings, untreated wood wastes, natural fiber products, and construction and demolition wood waste. Greenmaterial does not include food material, biosolids, mixed solid waste, materialprocesses from commingled collection, wood containing lead-based paint or woodpreservative, and mixed construction or mixed demolition debris.Green waste: A term used to refer to urban landscape waste generally consisting of leaves, grass clippings, weeds, yard trimmings, wood waste, branches and stumps, home gardenresidues, and other miscellaneous organic materials.Hazardous Waste:This includes radioactive substances, toxic chemicals, explosives, biological waste(e.g. from hospitals), and flammable waste.Heavy Metals: A commonly hazardous waste that can damage organisms at low concentrations, including cadmium, mercury, and lead, and which can be found in the waste streamin batteries, televisions, paints, and ink.Homopteran:Any of an order or suborder of insects (as cicadas, aphids, and scale insects) that have sucking mouthparts, able to pierce plant tissue and suck liquid out.Humic Acid:Any of various organic acids obtained from humus.Humus:The organic component of soil formed by the decomposition of animal or vegetable matter.Hydrolysis: A catch-all term for any reaction in which the water molecule is split.Hyphae:The plural of hypha, which is any of the filaments that constitute the body (mycelium) of a fungus.Industrial sludge:Sludge from factories, manufacturing facilities, and refineries. This type does not include any subtypes. For example, this type includes paper pulp sludge and watertreatment filter cake sludge.Inoculate:To implant microorganisms onto or into a culture medium.Inorganic matter:Refers to non-living source such as rocks, minerals or sand, of nonbiological origin.Integrated pest management (IPM):Integrated pest management (IPM) is an ecosystem-based strategy that focuses on long-term prevention of pests or their damage through a combination of techniques such as biological control, habitat manipulation, modification of cultural practices,and use of resistant varieties. Pesticides are used only after monitoring indicatesthey are needed according to established guidelines, and treatments are made withthe goal of removing only the target organism.Invertebrate:An organism lacking a spinal column.Laminarinase: A polysaccharide that is found in various brown algae and yields only glucose on hydrolysis.Leachate: A water that has percolated through a solid waste, such as a landfill.Leftovers:In terms of food scraps or food waste, may refer to food prepared in excess that has not been served but may be collected for a human food donation or recoveryprogram. Leftovers can also refer to plate scrapings that are not appropriate forhuman consumption.Lerp Psyllid: A plant-moisture sucking homopterans in the insect family Psyllidae. Redgum lerp psyllid nymphs (immature) form a cover called a "lerp," which is a small white,hemispherical cap composed of solidified honeydew and wax. The UC BerkeleyBiological Control of the Red Gum Lerp Psyllid page provides additionalinformation on Lerp Psyllid.Lignin: A complex polymer, the chief non-carbohydrate constituent of wood that binds to cellulose fibers and hardens and strengthens the cell walls of plants.Manure:Agricultural material and means accumulated herbivore or avian excrement. This includes feces and urine, and any bedding material, spilled feed, or soil that ismixed with feces or urine.Mesophilic: (Gr.--Cold loving) Describes bacteria which are active in the temperature range between 40-110 degrees Fahrenheit, but thrive between 70-90 degrees Fahrenheit. Most of the decomposition that takes place in a compost pile is mesophilic.Methane: A gas created naturally in marshes and bogs, as well as landfills. Considered a potent greenhouse gas.Microbial spore suspensions:Microscopically visible particles dispersed throughout a less dense liquid from which they are easily filtered but not easily settled because of system viscosity or molecular interactions.Microorganisms:Microscopic living organisms that digest organic material through metabolic activity.Mold: A superficial (often woolly) fungus that grows especially on damp or decaying organic matter or on living organisms.Monosaccharides: A sugar that is not decomposable to simpler sugars by hydrolysis. The simplest form of sugar.Morphology:The form and structure of an organism or any of its partsMulch: A layer of organic material that is spread over the bare surface of soil to block the loss of moisture and to discourage the growth of weeds. Typically applied aroundplants to minimize moisture evaporation. Mulch is the term for non-composted materials, such as shredded or chipped bark.Municipal organicmaterials:Organic materials generated by residential, business, institutional, and agricultural sources, which are then collected and sent to city and county waste facilities.Municipal solid waste (MSW): Garbage. Refuse with the potential for energy recovery; includes residential, commercial, and institutional wastes.Means the material part of the municipal solid waste stream and is mixed with or contains nonorganic, processed industrial materials, or plastics. Compostable material that contains mixed demolition or mixed construction debris shall be considered mixed solid waste.Mycelium:The body of a fungus, composed of many threads of tissue. Mushrooms do not reproduce by seed, but by spores. The spores germinate to produce threadlikestructures known as hyphae. Collectively, a mass of hyphae are known as themycelium.Myriapoda:Any of a group of arthropods having the body made up of numerous similar segments nearly all of which bear true jointed legs and including the millipedes andcentipedes.Native plant:The native plants of a given area are those that grew there prior to European contact. Native plants have co-evolved with animals, fungi, and microbes to form acomplex network of relationships. These plants are the foundation ofnative ecosystems, or natural communities.Nematode:Any un-segmented worm of the class Nematoda, having a tough outer cuticle. The group includes free-living forms and disease-causing parasites, such as thehookworm and filaria.Also called: nematode worm, roundwormNitrates: A compound containing nitrogen and oxygen that can exist in the atmosphere or in water and that can have harmful effects on humans and animals at highconcentrations.Non-Aerated:No air or circulation of air.Nonpoint source pollution:Diffuse discharges of waste throughout the natural environment which are a major cause of water pollution. Difficult to pinpoint physically, but can be classified by type: urban runoff, agriculture, mining, septic tank leach fields, and silviculture.Organic matter:Material that comes from organisms that were once alive, or derived from or produced through the biological activity of a living thing.Old corrugatedcontainer (OCC):A fabricated container made from linerboard placed around a corrugated medium.Parasite:An organism that inhabits a living host in a symbiotic relationship, for existence or support. Typical examples include hookworms, tapeworms, and some mites. Inplants, a parasitic plant is one that gets its sustenance from an established hostplant.Pathogen:Any organism or infectious agent, capable of causing disease or infection. In the composting process, (found in animal waste material), pathogens are killed by thehigh temperatures (131 degrees Fahrenheit or higher for three days).Phyllosphere:The three-dimensional micro-environmental space surrounding a leaf.Phylloxera:Scientific Name: Daktulosphaira vitifoliae--a tiny aphid-like insect that feeds on Vitis vinifera grape roots, stunting growth of vines or killing them.Phylum: A series of animals or plants genetically connected by one or more fundamental characteristics that set them apart from all other animals and plants and forming aprimary category of the animal or plant kingdom.Phytophthoracinnamomi:A destructive parasitic fungi causing root rot in plants.Phytophthora ramorum:A newly identified plant pathogen that causes Sudden Oak Death in a variety of hosts.Polysaccharide: A carbohydrate that can be decomposed by hydrolysis into two or more molecules of monosaccharides especially: any of the more complex carbohydrates (ascellulose, starch, or glycogen).Postconsumer food scraps:Food that has been served to diners but is not eaten; also called plate scrapings. This may include vegetables, salad dressings, sauces, cheese, meat, and bones, as well as nonfood items, such as napkins. If the nonfood items are not separated from the food, these and other nonfood contaminants like straws, cups, and plastic utensils will become a part of this blend.Preconsumer food scraps:Preconsumer scraps may include food processing wastes such as vegetable culls, brewery by-products, coffee grounds, or kitchen preparation wastes. Restaurants, for example, often cut off inedible portions of vegetables in food preparation. This can include carrot tops, potato peels, lettuce leaves, broccoli stems, or similar scraps.Protozoa:Unicellular or single-celled animals which have varied morphology and physiology, and often complex life cycles. Represented in almost every kind of habitat.Psychrophilic: (Gr.--Warmth loving) Describes bacteria which are active in a low temperature range (below 65 degrees Fahrenheit), but thrive around 55 degrees Fahrenheit.Putrescine:Produced by the breakdown of amino acids as organisms break down.Rendering:Related to animal waste, a process that breaks down and converts animal tissue intoa usable commodity. Rendering operations can make edible products such ascanned pet food, or non-edible products like bone meal.Rhizome:An underground, horizontal plant stem that produces shoots above and roots below, and is distinguished from a true root in possessing buds, nodes, and usuallyscale-like leaves. Examples of plants with underground rhizomes include gingerand bamboo; plants with rhizomes that grow above ground include some irisspecies and ferns.Rhizosphere:The below-ground area that surrounds the root surface of plants, where root secretions occur and microorganisms consume sugars released by the roots.Saprophages:Also known as detritus feeders. Refers to organism that contributes to decomposition, obtaining food by absorbing dissolved organic material.Side dressing:The application of fertilizer or organic matter around a plant, the material being left on the soil surface rather than being dug in. Also known as top dressing.Silviculture:The care and cultivation of forest trees; forestry.Soil amendment: A material, such as organic matter or sand, mixed into soil to improve growing conditions.Soil biology:The study of the organisms and their activity in soil, this includes bacteria, worms, fungi, and nematodes.Soil food web: A group of plants, soil, organic matter, and organisms that thrive within a system.Soluble:Susceptible to being dissolved in or as if in a liquid and especially water.Spawn:The term used for the combination of mycelium and substrate is spawn. This can be thought of as the vegetative part of the mushroom.Stolon: A horizontal stem at or just below the surface of the ground that roots at the nodes and produces new plants. Also called "runners."Substrate:Any combination of materials that provide support, water retention, aeration, or nutrient retention for plant growth. In this instance, substrate is compost into whichmushroom spawn is distributed.Sudden Oak Death:A disease infecting oaks and several other ornamental plants that were noticed in recent years in coastal California and a small geographic area of Oregon. The United States Department of Agriculture website provides additional information on Phytophthora ramorum.Textiles:Items made of thread, yarn, fabric, or cloth. This includes clothes, fabric trimmings, draperies, and all natural and synthetic cloth fibers. This does not include cloth-covered furniture, mattresses, leather shoes, leather bags, or leather belts.Thatch: A mat of undercomposed plant material (as grass roots) accumulated next to the soil in a grassy area (as a lawn)Thermophilic: (Gr.--Heat loving)Heat-loving, applied especially to certain bacteria requiring high temperatures for normal development.Tilth:The condition of soil or land that has been tilled, especially with respect to suitability for promoting plant growth.Tire: A pneumatic tire or solid tire manufactured for use on any type of motor vehicle.Trommel: A revolving cylindrical sieve used for screening or sizing compost and mulch.Vector Control:Related to rats, insects, birds, and vermin. Methods used to control and reduce therisk of exposure to these pests that may transmit disease pathogens to humans.Vermicomposting:The process whereby worms feed on slowly decomposing materials (e.g., vegetable scraps) in a controlled environment to produce a nutrient-rich soil amendment.Additional terms for the soil amendment are worm castings or worm manure. Thismaterial is rich in nutrients and is an excellent soil conditioner. Species typicallyused for vermicomposting include Red Wigglers and European nightcrawlers.Volatile Organic Compound (VOC):Carbon-containing compounds that evaporate into the air (with a few exceptions). VOCs contribute to the formation of smog and/or may themselves be toxic. VOCs often have an odor. Typical liquids that release VOCs include gasoline, diesel fuel, pesticides, cleaning supplies, glues, and solvents used in paints.Watershed:The total land area that contributes water from rain or snowmelt down to a body of water, such as a river, reservoir, wetland, stream, lake, or ocean. Synonymous withdrainage area, drainage basin, and catchment.Wood-overs:Also called compost-overs, these are large, woody parts of the compost pile that have not completely broken down and will not pass through a minus one-halfinch trommel screen.Wood waste:Solid waste consisting of wood pieces or particles which are generated from the manufacturing or production of wood products, harvesting, processing, or storageof raw wood materials, or construction and demolition activities.Xeriscaping:The practice of landscaping with slow-growing, drought-tolerant plants to eliminate the need for irrigation and lower the need for water consumption.Yard trimmings:Wastes generated from the maintenance or alteration of public, commercial or residential landscapes including, but not limited to, yard clippings, leaves, treetrimmings, prunings, brush, and weeds.。

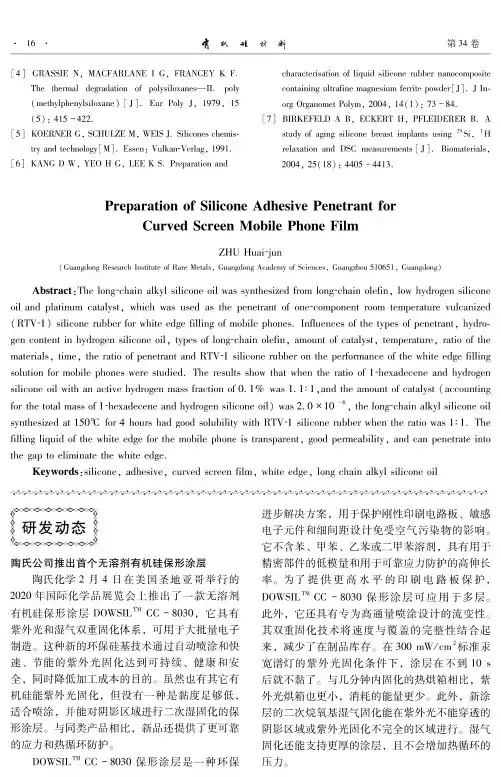

第34卷)4]GRASSIE N,MACFARLANE I G,FRANCEY K F.The thermal degradation of polysiloxanes一II.poly (methylphenylsiloxane))J].Eua Poly J,1979,15(5):415-422.)5]KOERNER G,SCHULZE M,WEIS J.Silicones chemis-ty and technology)M].Essen:Vulkan-Verlaa,1991. )6]KANG D W,YEO H G,LEE K S.Preparation andcharacterisation of liquid silicone rubbee nanocomposite containiny ultrafine magnesium ferrite powder[J].J In-ory Oryanomet Polym,2004,14(1):73-84.)7]BIRKEFELD A B,ECKERT H,PFLEIEERER B.A study of aging silicone breast implantr usiny29Si,1H relaxation and DSC measurement)J].Biomaterials, 2004,25(18):4405-4413.Preparation of Silicone Adhesive Penetrant forCurved Screen Mobile Phone FilmZHU Huai-jun(Guangdong Research Institute of Rare Metals,Guangdong Academy of Sciences,Guangzhou510651,Guangdong)Abstract:The long-chain alkyl silicone oil was synthesized from long-chain olefin,low hydrooen silicone oil and plainum catalyse,which was used as the penetrani of onevomponent room temperature vulconized (RTV-1)silicone rubbea la white edge filling of mobiie phones.Ineuences of the types of penetrani,hydragen ooneeneln hydeogen slolooneolo,eypesoioong c ohaln ooeiln,amouneoioaeaoyse,eempeeaeuee,eaelooiehe maeealais,elme,eheaaelooipeneeaaneand RTV1slilooneaubbeaon ehepeaioamanoeoiehewhleeedgeil i lng soiuelon ioamobliephonesweaeseudled.Theaesuiesshowehaewhen eheaaelooi1c h eaadeoeneand hydaogen silicone oil with an activv hydrooen mass fraction of0.1%was1.1:1,and the amount of catalyse(accounting fo the totai mass of1-hexadecene and hydrooen silicone oii)was2.0Z106,the long-chain alkyl silicone oil synthesized at150°C fo4houra had good solubility with RTV-silicone rubbea when the ratio was1:1.The filling liquid of the white edge for the mobiie phone is transparent,good permeabilita,and con penetrate inta the gap ta eeminte the white edge.Keywords:silicone,adhesivv,curved screen film,white edge,long chain alkyl silicone oilI研发动态I^^000000000000000陶氏公司推出首个无溶剂有机硅保形涂层陶氏化学2月4日在美国圣地亚哥举行的2020年国际化学品展览会上推出了一款无溶剂有机硅保形涂层DOWSII™CC-8030,它具有紫外光和湿气双重固化体系,可用于大批量电子制造。

不通氧553硅的成分英文回答:Non-fluorinated 553 silicone is a type of silicone polymer that does not contain any fluorine atoms in its structure. It is typically composed of a repeating chain of siloxane units (-Si-O-Si-) with various organic groups attached to the silicon atoms. The most common organic groups used in the synthesis of non-fluorinated 553silicone are methyl (-CH3) and phenyl (-C6H5) groups.The composition of non-fluorinated 553 silicone can vary depending on the specific application for which it is intended. For example, silicones used in the aerospace industry may have different compositions than those used in medical devices. However, the general composition of non-fluorinated 553 silicone can be represented as follows:[Si(CH3)2-O]n[Si(C6H5)2-O]m.where n and m are integers that represent the relative proportions of methyl and phenyl groups in the polymer chain.中文回答:无氟553硅胶是一种结构中不含任何氟原子的硅氧烷聚合物。

第 49 卷第 12 期2021 年 6 月广 州 化 工Guangzhou Chemical Industry Vol. 49 No. 12Jun. 2021制备及性能研究**基金项目:近海流域环境测控治理福建省高校重点实验室开放课题(编号S1-KF1806)。

第一作者:陈玉(1979-),女,硕士,专业方向:天然高分子。

陈玉,郭津(福建技术师范学院材料与环境工程学院,福建福清350300)摘 要:采用单因素实验研究了玉米淀粉与PVA 质量比、增塑剂添加量、交联剂添加量对复合膜性能的影响,并通过正交实验进行优化,确定了制备复合膜的较优工艺条件。

结果表明,在交联反应温度70 t 、交联反应时间30 min 、干燥时间3 h 、干 燥温度80 t 、玉米淀粉:PVA 质量比6: 4、甘油添加量15% ,氯化钙添加量2%时,复合膜的各项性能较佳。

在最佳工艺条件下 制备的复合膜的各项性能分别为拉伸强度23. 66 MPa 、断裂伸长率101.4%、透光率25.5%、吸水率41.9%。

关键词:玉米淀粉、聚乙烯醇、复合膜、交联、甘油、氯化钙中图分类号:O69; TQ613文献标志码:A 文章编号:1001-9677(2021)012-0037-05Preparation and Properties of Calcium Chloride Cross-linkedStarch/Polyvinyl Alcohol Composite Films *CHEN Yu , GUO Jin(School of Materials and Environmental Engineering , Fujian Polythchnic Normal University ,Fujian Fuqing 350300 , China)Abstract : The effects of the mass ratio of corn starch to PVA , the amount of plasticizer and crosslinker on theproperties of the composite films were studied by single factor experiment. The orthogonal experiment was used to optimize and the better technological conditions for the preparation of the composite film were determined. The results showed that the properties of the composite films were better when the cross linking reaction temperature was 70 t , the cross linking reaction time was 30 min , the drying time was 3 h , the drying temperature was 80 t , the mass ratio of corn starch to PVA was 6:4, the amount of glycerol was 15% , and the amount of calcium chloride was 2% . The properties of the composite film prepared by this process were as follows : tensile strength was 23. 66 MPa , elongation at break was 101. 4% , transmittance was 25. 5% , water absorption was 41. 9%.Key words : corn starch ; polyvinyl alcohol ; composite film ; cross-linking ; glycerol ; calcium chloride随着近年来绿色发展理念的提出,开发新型生物可降解材 料已变得迫切需要,以淀粉、纤维素、壳聚糖等生物资源为原 料制备可降解生物薄膜,不仅能解决石油化工资源的紧缺,还 能促进农产品的加工利用,符合国家提出的保护生态环境、节 约自然资源的可持续发展战略[1-2]。

2Discover innovative technologyThe use of silicon-based technologies in the coatings market has evolved over the decades, allowing formulators to create differentiated, high-performance protective and decorative coatings.Silicone resins and resin intermediates have found utility in heat-resistant paint and industrial, marine and protective coatings (1950s); coil coatings (1970s); and, most recently, hybrid resin systems (1990s), creating interpenetrating silicone-organic resins with attributes of both chemistries for premium topcoat finishes.Paint and coating formulations incorporating DOWSIL™ silicone resins and resin intermediates exhibit improved resistance to:• Temperature • Moisture • Corrosion• Electrical discharge • WeatheringWith excellent compatibility with many organic resins, silicone resins can provide a wide range of film and performance properties for many high-value applications.2 3 410 11 11Applications• Barbecue Grills • Woodstoves • Fireplace Inserts • Automotive Mufflers • Heat Exchangers• Lighting Fixtures • Cookware• Ceramic Composites • Bakeware• Offshore Rigs • Wind Turbines • Bridges • Tank Farms • Stadiums• Ships • Refineries• Chemical Processing • Amusement Park RidesHigh temperature Weathering3The chemistry of silicone resinsSilicone resins are polymers comprised of a siloxane (silicon–oxygen) lattice with at least some portion comprised of the silicate (SiO 4/2) or silsesquioxane (R-SiO 3/2) structures, where R represents various alkyl or aryl organic groups (most commonly methyl or phenyl). In comparison to organic resins (with their carbon-carbon backbone), silicone resins exhibit greaterresistance to thermal and radiation degradation. The durability of silicone resins is attributed to the bond strength between silicon and oxygen (108 vs. 82.6 kcal/mole for the carbon-carbon bond), transparency to visible and ultraviolet light, and the inherent partially oxidized structure. Evidence supporting this stability claim can be found beneath our feet. The silicon-oxygen bond is the most abundant chemical bond on earth.With the addition of organic substituents (see “Degree of substitution” in tables 2-4), the siloxane polymer becomes more linear, modifying the physical properties (e.g., flexibility) and performance. The attachment of phenyl to the silicone backbone contributes organic compatibility, toughness and longer thermal stability at moderate temperatures (250°C). In comparison, methyl groups provide fast cure, thermal shock resistance and lower weight loss at extreme temperatures (see “Silicon dioxide content” in tables 2-4).Silicone resins can be produced by hydrolyzing mixtures of chlorosilanes or alkoxy silanes to form highly reactive silanol groups:RSiCl 3 + 3H 2O RSi(OH)3 + 3HCl RSi(OR’)3 + 3H 2O RSi(OH)3 + 3R’OHwhich initially condense to form oligomeric siloxane structures:2 RSi(OH)3 RSi(OH)2 - O - SiR(OH)2 + H 2OFurther condensation occurs to form three-dimensional siloxane lattices. Driving the condensation by applying heat and catalysis increases molecular weight and improves physical properties (see DOWSIL™ RSN-0805 Resin, DOWSIL™ RSN-0806Resin, and DOWSIL™ RSN-0808 Resin) but increases polymer viscosity and solvent-loading requirements.Similarly, where application performance requires, the silanol and alkoxy functionality can be reacted with hydroxyl groups on organic resins (e.g., polyesters) to form silicone-organic hybrid resins with performance improvements proportionate to the level of siloxane modification (see table 1). Cold-blends of silicone and organic resins require lower additions of application solvent but rely on hotter and longer thermal curing schedules to drive copolymerization and complete cure.Along with selecting the appropriate silicone resin, the choice of other formulation components plays a critical role in coating performance.4Selecting a resin binder systemThe first step in creating a coating prototype is to define the application performance demands and the potential resin binder system. Thermal, chemical and radiation exposure along with required cure schedule and needed physical properties all influence the choice of resin binder.While silicone resin will contribute to the paint’s thermal, chemical and UV radiation resistance, some performance attributes and physical properties will benefit from combinations of silicone and organic binders.• Hardness: Phenolics and melamines • Air-dry: Acrylics• Corrosion resistance: Epoxies • Toughness: AlkydsThe level of silicone utilization in a paint formulation is dictated by the severity of the application performance requirements and can range from a minimum of 15% to as high as 100% of the resin binder system (see table 1).Performance temperature range 1Resin type % SiliconePigment121-204°C (250- 400°F)Silicone-modified organic 15-50All pigments204-316°C (400-600°F)Silicone-modified organic 15-50Leafing aluminumOrganic-modified silicone 51-90All pigments316-427°C (600-800°F)Organic-modified silicone 51-90Black iron oxide, leafing aluminumSilicone100All pigments427-538°C (800-1,000°F)Silicone 100Black iron oxide, leafing aluminum538-760°C(1,000-1,400°F)Silicone 100CeramicTable 1: Resin system selection11,000 hours minimum5Choosing a silicone resinDow offers a diverse line of silicone resins and resinintermediates. Silicone resins are, themselves, good film-formers. Whereas resin intermediates are intended forblending with other silicone, or organic resins to create a film with the required balance of performance properties. Solvent-based, solventless liquid and solid flake options are available, allowing formulators to meet a wide range of performance and regulatory requirements and to achieve the best balance of performance, compliance and economy.Choosing which DOWSIL™ product to use is influenced primarily by two factors: organic compatibility and desired film hardness.Softer, more flexible resins are recommended for coatingformulations required to withstand the thermal expansion and contraction associated with heated metal. Rigid resins provide excellent hot hardness for exposed painted surfaces prone to nicks and scrapes.A third consideration is the level of residual silicon dioxide produced during the pyrolysis of the resins. As silicone resins oxidize, the remaining silicon dioxide ash reacts with pigments and fillers to create the metalo-silica composite, which provides long-term thermal stability – but this attribute must be balanced with other film properties, particularly flexibility.Figures 1 and 2 provide the means by which to select a DOWSIL™ resin for your coating prototype.It is possible that a single resin may not meet the specific needs of your application. In general, DOWSIL™ resins have good intercompatibility and can be blended together at any ratio to achieve a balance of properties. However, resins with a phenyl:methyl ratio below 1:1 tend to be less compatible with organic resin systems. Laboratory testing of resin mixtures should be conducted prior to commercial use.Figure 1: Resin property comparisonRelative pendulum hardnessO r g a n i c c o m p a t i b i l i t y1Estimated hardness-15 525 45 65 85 105 12521.510.5Figure 2: Decision tree for selecting a DOWSIL™ Resin Is the intended coating...YES6Solvent-based resins from DowDow delivers silicone resin solutions that can be used alone,or in combination with organic resins or other silicone resins.They vary in resin content, organic compatibility and molecularweight, allowing formulators to design coatings to meet specific application requirements:• High-temperature coatings where low VOCcontent is required• Maintenance paints for improved UV durability• Colored baking enamels for wood-burningstoves, space heaters, etc.• As an additive to improve the flow-out and initialgloss of epoxy coatingsTable 2: Characteristics and properties of solvent-based resins from DowDOWSIL™RSN-0805 Resin DOWSIL™RSN-0806ResinDOWSIL™RSN-0808ResinDOWSIL™RSN-0840ResinFunctionality Silanol Silanol Silanol Silanol Silanol Silanol Silanol Silanol content13331113 Silicon dioxide content148526448525752 Degree of substitution2 1.6 1.4 1.3 1.6 1.4 1.5 1.4 Phenyl:Methyl ratio 1.1:1 1.2:10.4:1 1.1:1 1.2:10.6:1 1.2:1 Molecular weight3 (1,000)2-72-72-7200-300200-300200-3002-7Resin solids, %by weight4 by volume 8074807460515042504150426051Solvent Xylene Toluene Toluene Xylene Toluene/xyleneXylene TolueneViscosity, centipoise2008003012515012520 Specific gravity 1.12 1.14 1.07 1.01 1.02 1.01 1.06 VOC5, g/L (lb/gal)228 (1.9)228 (1.9)431 (3.6)503 (4.2)515 (4.3)503 (4.2)431 (3.6) Flash point – Closed cup, °C (°F)27 (81)7 (45)7 (45)27 (81)7 (45)27 (81)7 (45)1Percent by weight2Organic groups attached per silicon atom3Weight average40.5 g/1 hr/110°C (230°F)5Volatile organic content, EPA Reference Method 247Flake Resins from DowDOWSIL™ flake resins deliver silicone technology concentrated in dry, pourable flakes, which can either be solvated or used as neat polymers in powder coatings or composites or combined with “softer” solvated silicone resins to improve hardnessand reduce VOCs. The flakes also can be cold-blended or copolymerized with organic polymers to improve thermal and weathering resistance.• High-temperature powder coatings for barbecue grills• Mica board composites• Ceramic firings• Silicone-alkyd copolymers for protectiveand marine paint• Silicone-polyester copolymers for coil coatings• DOWSIL™ RSN-0217 Flake Resin, DOWSIL™ RSN-0233 Flake Resin and DOWSIL™ RSN-0255 Flake Resin aresuitable for applications regulated byFDA 21 CFR 175.300DOWSIL™ RSN-0233 Flake ResinDOWSIL™RSN-0249Flake ResinDOWSIL™RSN-0255Flake ResinDOWSIL™RSN-6018ResinIntermediateFunctionality Silanol Silanol Silanol Silanol Silanol Silanol Silanol content1665556 Silicon dioxide content1475155636250 Degree of substitution2 1.0 1.2 1.15 1.15 1.05 1.0 Phenyl:Methyl ratio All phenyl 2.0:1 1.3:10.6:10.84:1 2.7:13 Molecular weight4 (1,000) 1.5-2.52-42-42-4 2.5-4.5 1.5-2.5Resin solids, %by weight5999999999999 Tg (°C)654947415648 Specific gravity 1.34 1.33 1.32 1.3 1.22 1.31 Flash point – Closed cup, °C (°F)138 (280)138 (280)138 (280)138 (280)138 (280)138 (280) Table 3: Characteristics and properties of flake resins from Dow1Percent by weight2Organic groups attached per silicon atom3Phenyl:Propyl Ratio4Weight average50.5 g/1 hr/110°C (230°F)8Alkoxy resins and intermediates from Dow The unique reactivity of the silylalkoxy group provides this class of materials with a broad array of utility in the coatings market.• “Polysiloxane” epoxy and acrylate hybrid topcoats• Reacted with unsaturated polyesters, oil-free alkyds and other hydroxyl-bearing organic resins forflexible, weather-resistant coil coatings• DOWSIL™ 5314 Intermediate is used for modification of acrylic and other alkaline pH resin emulsions• Silicone-polyester copolymers made with DOWSIL™ 3074 Intermediate are suitable for applications regulated by FDA21 CFR 175.300• Blended with other silicone resins to reduce VOCs• When catalyzed with titanates, DOWSIL™ US-CF-2403 Resin can be formulated into ambienttack-free coatingsDOWSIL™ 3037 IntermediateDOWSIL™3074 IntermediateDOWSIL™5314IntermediateFunctionality Methoxy Methoxy Methoxy Methoxy Methoxy Methoxy content1362815-1815-1835Silicon dioxide content189********Degree of substitution21 1.05 1.7 1.3 1.3 Phenyl:Methyl ratio All Methyl All Methyl0.25:1 1.0:1 3.3:1 Molecular weight3 (1,000)0.740.8-1.31-1.5Monomer Blend Resin solids, %by weight4647282-8582-8565 Viscosity, centipoise2520014120 1.87 Specific gravity 1.15 1.11 1.07 1.16 1.04Flash point – Closed cup, °C (°F)39 (102)39 (102)106 (223)120 (248)28 (83) Suitable for FDA 21 CFR 175.300No No No Yes NoTable 4: Characteristics and properties of alkoxy resins and intermediates from Dow1Percent by weight2Organic groups attached per silicon atom3Weight average4Cured resin solids, delivered solventless9CatalystsSilanol-functional resins will heat-cure without the addition of catalyst, but the addition of metallic driers (e.g., zinc, iron or cobalt octoate) will accelerate the rate of cure. T ypical catalyst level is 0.1 to 0.2% metal on resin solids.DOWSIL™ RSN-0805 Resin, DOWSIL™ RSN-0806 Resin and DOWSIL™ RSN-0808 Resin are supplied pre-catalyzed. Silylalkoxy resins require the addition of a hydrolysis or condensation catalyst to promote full-cure properties. T ypical use level is 0.5-3% on resin solids, depending on the resin, desired cure profile, and final performance requirements.Leaching of metals (e.g., iron or lead) from unlined storage containers can catalyze the condensation of silicone resins and cause a viscosity increase or gelation.ApplicationFilm thickness varies depending upon application and specific formulation, but typical high temperature paints are appliedat film thicknesses ranging from three to four mils (75 to 100 microns). Thicker films can result in delamination.Curing schedulesCoatings formulated with silanol-functional silicone resins typically require thermal curing to achieve optimum film properties, but curing cycles vary depending upon the level of silicone content and the cure chemistry of other primary components. A typical cure for a 100% silicone resin system is 30 minutes at 232°C (450°F) or 60 minutes at 204°C (400°F). For silicone-organic blends in which silicone is not the primary component, follow the cure recommendation for the primary resin.Solvents and thinnersThe resins described in this selection guide can be solvated with aromatic hydrocarbons (e.g., toluene and xylene), most ketones, esters, acetates and chlorinated solvents.Aliphatic hydrocarbons (e.g., VM&P Naphtha and mineral spirits) are reasonable diluents but should be combined with stronger solvents.Glycol ethers and alcohols (e.g., butanol), at low levels (<5%), improve resin stability.Pigments and fillersTraditional pigments used with organic binder systems can be employed with silicone resins for those applications exposed to low or moderate heat (121 to 204°C [250 to 400°F]). For higher temperatures, only heat-stable inorganic pigments should be utilized. Consideration also should be given to weather and chemical exposure. Leafing aluminum pastes and metal oxides, particularly iron and titanium, are useful. Hydroxyl reactivity on the pigment surface reacts with the silicone resin during curing and pyrolysis to form metalo-silicone composites. Typical pigment-to-binder ratios range from 0.6 to 1.0.Unreactive pigments (carbon black) and fillers (calcium carbonate) should be used sparingly (<10%), as these materials do not integrate into the composite structure and will detract from long-term performance.Reactive (hydroxyl-bearing) reinforcing fillers (e.g., silica, mica or wollastonite [2 to 20 weight % loading]) can improve the physical properties and long-term durability of a coating.Other formulation components10Product information and technical supportOur website, , gives you immediateaccess to:• Product samples• Product literature and technical data sheets• Technical articles• Customer and technical service• The name of a Dow distributor near youMore than materials ... solutionsAvailable worldwide, the products listed in this guide meetthe majority of global industry requirements. However, they represent only a portion of Dow’s total resin technology offering. Our extended product line includes options designed especially to meet the needs of your local market. Contact Dow for tailored recommendation.LimitationsThese products are neither tested nor represented as suitable for medical or pharmaceutical uses.Your global connectionAt home or abroad – wherever your business takes you– you will find the product supply, customer service and technical support you need to succeed available locally from Dow.Whether you are facing a challenge that could benefit from Dow’s international business and market experience or you need a reliable, local source of supply for innovative paints, inks and coatings solutions, contact your Dow representative. Product samples, technical information and assistance also are available online at .11Images: Cover - dow_43820930741; Page 2 - dow_40075909467, dow_40422314371; Page 3 - dow_40458252925; Page 4 - dow_40370458984; Page 7 - dow_40440228436; Page 8 - dow_40388857165; Page 9 - dow_40145783269PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND SAFETY DATA SHEETS AND CONTAINERLABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. THE SAFETY DATA SHEET IS AVAILABLE ON THE DOW WEBSITE AT , OR FROM YOUR DOW SALES APPLICATION ENGINEER, OR DISTRIBUTOR, OR BY CALLING DOW CUSTOMER SERVICE.NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.®™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow© 2023 The Dow Chemical Company. All rights reserved.2000024822-5539Form No. 25-799-01-0523 S2DStorage and shelf lifeDOWSIL™ silicone resins should be stored at room temperature in sealed containers, away from heat and open flame. DOWSIL™ solid flake products should be stored below 22°C (72°F).Refer to individual products’ technical data sheets orcontact Dow for the shelf life (from date of manufacture) of the DOWSIL™ resins and intermediates discussed in this brochure.Handling precautionsProduct safety information required for safe use is not included. Before handling, read product and safety data sheets and container labels for safe use, physical and health hazard information. The material safety data sheet is available on the Consumer Solutions website at . You also can obtain a copy from your local Dow sales representative or distributor.When working with DOWSIL™ silicone resins formulated with flammable solvents, the following safety precautions should be taken:• Keep away from heat and open flame • Use only with adequate ventilation • Avoid prolonged breathing of vapor • Avoid prolonged or repeated skin contact • Avoid eye contactDOWSIL™ solid flake resins are electrically nonconductive and, like plastic in particle form, can generate static charges during transfer operations. For this reason, proper precautions should be taken to safely dissipate any charges possibly generated, particularly when solvents or solvent vapors are present. These two important cautions are detailed as follows:1. The flake itself will generate an electrical potential, andthe user should maintain adequate safeguards to properly handle it. The vessel into which the flake is being poured should be grounded along with the platform on which the operator stands.2. Avoid the presence of ignitable materials during the transferoperation. If possible, have an inert atmosphere in the kettle and keep the solvent vapor content of the surrounding area at safe levels by providing adequate building area ventilation.Important information on storage, handling and flammability。

环五聚二甲基硅氧烷纯度英文回答:I am a chemist and I will answer your question about the purity requirements for cyclic pentamethylsiloxane, also known as D5. Purity is an important aspect in the chemical industry as it directly affects the quality and performance of the final product. In the case of D5, its purity is crucial for various applications such as personal care products, pharmaceuticals, and industrial processes.To determine the purity of D5, several analytical techniques can be employed. One common method is gas chromatography (GC), which separates and quantifies the different components in a sample. By comparing the peak areas of impurities to that of the main compound, thepurity of D5 can be calculated. Another technique is nuclear magnetic resonance (NMR) spectroscopy, which provides information about the molecular structure and composition of a compound. By analyzing the NMR spectrum ofD5, any impurities present can be identified and quantified.In terms of purity requirements, it depends on the specific application of D5. For example, in personal care products like shampoos and lotions, high purity D5 is desired to ensure the product is safe for use on the skin.In this case, a purity of 99% or higher may be required. On the other hand, in industrial processes where D5 is used as a solvent or intermediate, a slightly lower purity may be acceptable, such as 95% or higher.Maintaining high purity levels can be challenging as impurities can come from various sources such as raw materials, reaction by-products, or contaminants during storage and handling. Therefore, it is important to implement strict quality control measures throughout the manufacturing process. This includes using high-quality starting materials, optimizing reaction conditions, and implementing effective purification techniques.Let me give you an example to illustrate the importance of purity in personal care products. Imagine you are usinga shampoo that contains D5 with impurities. Theseimpurities can cause skin irritation or allergic reactions. However, if the D5 used in the shampoo is of high purity,it will be gentle on the skin and provide a pleasant experience during use. This is why purity is crucial inthis application.中文回答:我是一名化学家,我将回答你关于环五聚二甲基硅氧烷(也称为D5)纯度要求的问题。

酸碱质子理论凡是能给出质子的分子或离子称为酸(完整版)实用资料(可以直接使用,可编辑完整版实用资料,欢迎下载)酸碱质子理论:凡是能给出质子的分子或离子称为酸,凡是能接受质子的分子或离子称为碱。

如:HCl 为酸,-Cl 为碱。

酸碱质子理论只能局限于包含质子的放出和质子的接受。

各类溶液pH 值的求算:在弱酸(碱)溶液中,若加入含有相同离子的一种强电解质时,常时酸碱平衡移向生成分子的一方,是电离度大大下降。

另外,溶液浓度的变化和盐效应等对酸碱平衡也有一定的影响。

缓冲溶液的组成:由弱酸与共轭碱(或弱碱与共轭酸)构成的体系,具有缓冲溶液的性质。

缓冲原理:由于缓冲体系中存在着弱酸(或弱碱)的离解平衡,且共轭酸碱的浓度都是较大的,因此加入H +或OH -时,只是使平衡放生了移动,当重新建立平衡时,体系中的H +量并无明显变化。

从而保持体系的pH 值相对稳定。

但从这一点也可以看出,缓冲体系的缓冲能力是有限的。

当外加酸(或碱)的量相当大时,会使共轭酸碱对的某一方消耗尽而失却缓冲能力。

缓冲溶液的酸碱度可按以下公式计算:对弱酸和其盐体系:盐酸c c K a =+][H 或盐酸c c K lg p pH -=对弱碱和其盐体系:盐碱c c K b =-][OH 或盐碱c c K b lg p pOH -=溶度积表示式如下:A m B n A n+ + n B m-=sp K n m m n ][B ]A [-+n m m n ][B ]A [-+>sp K 有沉淀析出n m m n ][B ]A [-+=sp K 平衡n m m n ][B ]A [-+<sp K 沉淀溶解负离子的应用近几年,负离子的应用取得了突飞猛进的发展,各种负离子产品层出不穷。

不知不觉间,负离子已经应用到我们生活的各方各面,为我们的健康体魄、清洁环境以及美好未来默默做着贡献。

负离子灯负离子灯是现代科技与节能照明技术相结合的产物,兼具照明与生成负离子两个功能。

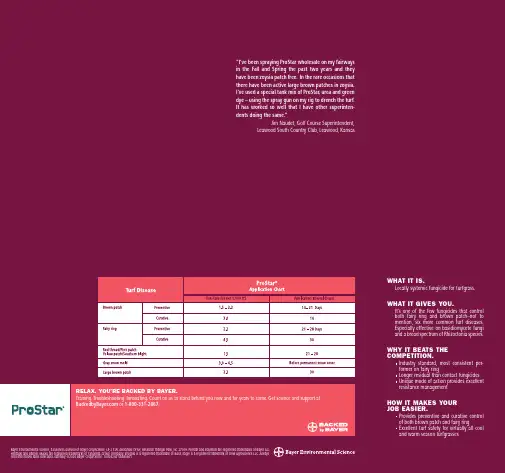

Bayer Environmental Science,a business division of Bayer CropScience,LP ,2 T.W.Alexander Drive,Research Triangle Park,NC 27709.ProStar and Bayleton are registered trademarks of Bayer AG.Heritage and Banner MAXX are registered trademarks of Syngenta Group Company.Insignia is a registered trademark of BASF .Eagle is a registered trademark of Dow AgroScience LLC.Always read and follow label directions carefully ©2007 Bayer CropScience 10003202 STAR0601RELAX. YOU’RE BACKED BY BAYER.Training.Troubleshooting.Innovating.Count on us to stand behind you now and for years to come.Get science and support at or 1-800-331-2867.WHAT IT IS.Locally systemic fungicide for turfgrass.WHAT IT GIVES YOU.It’s one of the few fungicides that control both fairy ring and brown patch–not to mention,six more common turf diseases.Especially effective on basidiomycete fungi and a broad spectrum of Rhizoctonia species.WHY IT BEATS THE COMPETITION.Industry standard,most consistent per-former on fairy ringLonger residual than contact fungicides Unique mode of action provides excellent resistance managementHOW IT MAKES YOUR JOB EASIER.Provides preventive and curative control of both brown patch and fairy ringExcellent turf safety for virtually all cool and warm season turfgrasses“I've been spraying ProStar wholesale on my fairways in the Fal l and Spring the past two years and they have been zoysia patch free.In the rare occasions that there have been active large brown patches in zoysia,I've used a special tank mix of ProStar,urea and green dye – using the spray gun on my rig to drench the turf.It has worked so wel l that I have other superinten-dents doing the same.”Jim Naudet,Golf Course Superintendent,Leawood South Country Club,Leawood,KansasTHE SCIENCE OF YOUR PROFESSION.Every ounce of ProStar is Backed by Bayer,and all the science and support you need to get the job done right.That’s what you should expect from an industry leader.Our staff is your staff.No one invests as much in product development as Bayer.Our scientists’ expertise in chemistry and formulation technology is unrivaled around the world.Our field sales and technical representatives are always ready to help you.You’ll find them,along with additional information,24 hours a day,7 days a week at .Product support year round.We’ll help you diagnose problems,troubleshoot issues,and get every product benefit you expect—and even some you don’t.We also offer interactive training throughout the year,to help grow your business and your plete satisfaction guarantee.Bayer guarantees your satisfac tion,after all,your suc c ess is our success.Any time,any question:1-800-331-2867/.THE SCIENCE OF PROSTAR FUNGICIDE.It’s preventive,it’s curative,and it’s locally systemic.ProStar ®doesn’t regulate turf growth and won’t interfere with PGR programs.ProStar fungicide is in control.Fairy ring Brown patchLarge brown patch (of zoysiagrass)Red thread Southern blight Yellow patch Pink patch Gray snow moldFrequently asked questions.>Q Is ProStar fungicide economical?>A Yes.Its long residual makes a big differenc e.Instead of spraying every 14 days,you get up to 21 days preventive protection against brown patch and up to 28 against other diseases such as fairy ring.>Q Does ProStar fungicide control localized dry spot?>AYes,it controls the fungi associated with localized dry spot.[PROSTAR ®FUNGICIDE REFERENCE GUIDE]®®。

欧洲药典8.0版3.1 用于包装容器生产的材料这一章描述的是用于药物包装容器生产的材料。

可能还用于部分或全部医疗手术器材的生产。

未包含在药典中的材料或聚合物的使用取决于主管当局的审批。

3.1.6聚丙烯用于注射液和眼用药的包装容器和包装塞定义聚丙烯是由丙烯单独聚合、或者由丙烯、乙烯(不超过25%)共同聚合而成,或者为聚丙烯、聚乙烯(不超过25%)的混合物,这些物质包含他们的同类高聚合物(C4-C10)或者羧酸或者酯类并且不超过25%。

可能含有添加剂。

成品聚合物中会添加一些特定的添加剂以使他们的化学、物理和机械性能更优,以适应预期用途。

所有这些添加剂均选自附件列表,并给出了每个产品中的最大允许含量。

产品中最多只能含有3种抗氧化剂,一种或更多润滑剂或者抗粘连剂,当材料必须提供遮光功能时,还要添加二氧化钛作为遮光剂。

—塑料添加剂07[128-37-0] 丁基羟基甲苯butylhydroxytoluene 抗氧剂BHT 限量:0.125%;—塑料添加剂09[6683-19-8] 四[β-(3,5-二叔丁基-4-羟基苯基)丙酸]季戊四醇酯[pentaerythritol tetrakys 3-(3,5-ditert-butyl-4-hydroxyphenyl )propionate] 抗氧剂1010限量:0.3%;—塑料添加剂13[27676-62-6] 1,3,5-三(3,5-二叔丁基-4-羟基苄基)-顺式-三嗪-2,4,6(1H,3H,5H)-三酮限量:0.3%;—塑料添加剂11[2082-79-3] 3-(3,5-二叔丁基-4-羟基苯基)丙酸正十八碳醇酯octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate 抗氧剂1076 限量:0.3%;—塑料添加剂08[32509-66-3] 3-(1,1-二甲基乙基)-β-[3-(1,1-二甲基乙基)-4-羟苯基]-4-羟基-β-甲基苯甲酸-1,2-亚乙基酯Ethylene bis[3,3-bis[3-(1,1-dimethylethyl)-4-hydroxyphenyl]butanoate] 限量:0.3%;—塑料添加剂15[2500-88-1] 二(十八烷基)二硫化物dioctadecyl disulfide限量:0.3%;—塑料添加剂10[1709-70-2] 2,2′,2″,6,6′,6″-己烷-叔丁基-4,4′,4″-[(2,4,6-三甲基-1,3,5-苯基)三亚甲基]三苯酚2,2′,2″,6,6′,6″-hexa-tert-butyl-4,4′,4″-[(2,4,6-trimethyl-1,3,5-benzenetriyl)trismet hylene] triphenol 抗氧剂330 限量:0.3%;—塑料添加剂14[3806-34-6] 2,2′-二(十八烷基氧)-5,5′-螺[1,3,2-二氧亚磷酸酯]2,2′-bis(octadecyloxy)-5,5′-spirobi[1,3,2-dioxaphosphinane] 限量:0.3%;—塑料添加剂16[123-28-4] 二(十二烷基)3,3′-硫代二丙酸盐didodecyl 3,3′-sulphanediyldipropanoate限量:0.3%;—塑料添加剂17[693-36-7] 硫代二丙酸双十八酯dioctadecyl3,3′-thiodipropionate抗氧剂DSTOP 限量:0.3%;—塑料添加剂12[31570-04-4] 三(2,4-二叔丁基苯基) 亚磷酸酯tris(2,4-di-tert-butylphenyl) phosphate 抗氧剂168 限量:0.3%;以上抗氧化剂总含量不得超过0.3%。

有机硅耐高温涂料的英文文献Organic Silicone High Temperature Resistant CoatingIntroduction:In recent years, there has been a growing demand for high temperature resistant coatings due to the increasing use of materials and equipment in high temperature environments. Organic silicone high temperature resistant coatings have emerged as a viable solution to protect surfaces from heat, corrosion, and erosion. These coatings are widely used in industries such as aerospace, automotive, and power generation.Composition and Properties:Organic silicone high temperature resistant coatings are typically composed of a silicone polymer, a heat-resistant filler, and special additives. The silicone polymer provides excellent thermal stability and flexibility, while the heat-resistant filler enhances the coating's resistance to high temperatures. The special additives improve the coating's adhesion, weatherability, and resistance to chemicals and abrasion.One key advantage of organic silicone high temperature resistant coatings is their ability to withstand temperatures up to 1000°C (1832°F) without significant degradation. This makes them suitable for applications where conventional coatings would fail. Additionally, these coatings have good thermal insulationproperties, low thermal conductivity, and excellent electrical insulation, making them ideal for high temperature environments.Application Areas:1. Aerospace: Organic silicone high temperature resistant coatings are widely used in the aerospace industry to protect parts and components from extreme temperatures encountered during space missions and atmospheric re-entry. These coatings provide excellent thermal protection, preventing heat transfer to sensitive equipment and materials.2. Automotive: In the automotive industry, organic silicone high temperature resistant coatings are used to protect engine components, exhaust systems, and brake systems from high temperatures. These coatings minimize heat-related damage and increase the durability and performance of these parts, ultimately extending their lifespan.3. Power Generation: Power plants and energy facilities often require coatings that can withstand high temperatures. Organic silicone high temperature resistant coatings are used to protect boilers, furnaces, and heat exchangers from corrosion, oxidation, and thermal cycling. These coatings contribute to the overall efficiency and reliability of power generation systems.Advancements and Future Prospects:Researchers and manufacturers continue to develop new formulations and techniques to improve the performance and versatility of organic silicone high temperature resistant coatings. Some advancementsinclude the integration of self-healing properties, increased resistance to thermal shock, and better adhesion to various substrates.The future prospects for organic silicone high temperature resistant coatings are promising. With the increasing demand for advanced materials and technologies, the need for high temperature resistant coatings will continue to grow. It is expected that further improvements in durability, flexibility, and cost-effectiveness will drive the widespread adoption of these coatings in various industries.Conclusion:Organic silicone high temperature resistant coatings play a vital role in protecting surfaces from the detrimental effects of high temperatures. Their exceptional thermal stability, flexibility, and resistance to corrosion and abrasion make them an excellent choice for applications in aerospace, automotive, and power generation. With ongoing research and development, these coatings will become more advanced, opening up new possibilities for heat protection in high temperature environments.。

有机硅双组分快干胶英文专业用语Title: Organic Silicone Two-Component Quick-Drying Adhesive: A Comprehensive GuideIntroduction:Organic silicone two-component quick-drying adhesive is a versatile and high-performance adhesive widely used in various industrial applications. This article aims to provide a comprehensive guide on the properties, applications, advantages, and considerations of this adhesive.Properties:Organic silicone two-component quick-drying adhesive is known for its excellent adhesion to a wide range of substrates such as metals, plastics, glass, ceramics, and rubber. It offers high temperature resistance, flexibility, and durability, making it suitable for applications that require a strong and long-lasting bond. The adhesive cures rapidly at room temperature, reducing production time and allowing for fast assembly.Applications:This type of adhesive is commonly used in the automotive, electronics, construction, and aerospace industries. It is ideal forbonding components in electronic devices, sealing joints in automotive parts, and attaching decorative elements in architectural structures. The adhesive can withstand harsh environmental conditions, making it suitable for outdoor applications.Advantages:Organic silicone two-component quick-drying adhesive offers several advantages over traditional adhesives. It provides a strong and reliable bond, resists moisture, chemicals, and temperature fluctuations, and does not shrink or expand during curing. The adhesive is easy to apply and can be customized to meet specific requirements, such as color, viscosity, and curing time.Considerations:When using organic silicone two-component quick-drying adhesive, it is important to follow the manufacturer's instructions carefully to ensure proper application and curing. The adhesive should be stored in a cool, dry place away from direct sunlight and heat sources. It is recommended to conduct compatibility tests with substrates to ensure adhesion strength and compatibility.Conclusion:Organic silicone two-component quick-drying adhesive is a reliable and versatile adhesive that offers high performance in various industries. Its excellent properties, applications, advantages, and considerations make it a preferred choice for bonding and sealing applications. By understanding the characteristics and best practices of this adhesive, users can maximize its benefits and achieve optimal results in their projects.。

Organic Syntheses, Coll. Vol. 2, p.515 (1943); Vol. 12, p.60 (1932).PHENYLPROPIOLIC ACID[Propiolic acid, phenyl-]Submitted by T. W. AbbottChecked by Henry Gilman and G. F. Wright.1. ProcedureA solution of potassium hydroxide is prepared by dissolving 252.5 g. (4.5 moles) of potassium hydroxide(Note 1) in 1.2 l. of 95 per cent alcohol contained in a 3-l. round-bottomed flask provided with a reflux condenser and heated on a steam bath. To the alkaline solution, cooled to 40–50°, is added 336 g. (1 mole) of crude ethyl α,β-dibromo-β-phenylpropionate(p. 270). When the initial reaction has subsided, the contents of the flask are refluxed for five hours on the steam bath.The reaction mixture is cooled, and the salts which separate are filtered by suction. The filtrate is treated with concentrated hydrochloric acid until neutral to litmus (Note 2), and the salts which precipitate are separated by filtration. The filtrate is then distilled until the vapor reaches 95°. The residue and the precipitated salts, previously separated by filtration, are combined, dissolved in 800 cc. of water, and chilled by the addition of cracked ice to make a volume of 1.8 l. (Note 3). The cooled solution is immersed in an ice-water bath and stirred mechanically while a 20 per cent sulfuric acid solution is added until the solution is strongly acid to litmus. After stirring for twenty minutes the phenylpropiolic acid is filtered by suction and washed with four 30-cc. portions of a 2 per cent sulfuric acid solution.The acid thus obtained as a light brown, granular product is dissolved in 1 l. of 5 per cent sodium carbonate solution, treated with 20 g. of Norite, and heated on a steam bath for thirty minutes with occasional stirring. The mixture is then filtered and cooled externally, and about 200 g. of cracked ice is added. The solution is stirred mechanically while a 20 per cent solution of sulfuric acid is added slowly. The precipitated acid is filtered by suction, washed first with 50 cc. of a 2 per cent sulfuric acid solution and then with a little water, and air-dried. The yield of acid melting between 115° and 125° is 112–118 g. (77–81 per cent of the theoretical amount).One hundred grams of the crude acid can be purified by crystallization from 200–300 cc. of carbon tetrachloride, yielding 70 g. of phenylpropiolic acid melting at 135–136°.2. Notes1. The best yields are obtained when a 50 per cent excess of potassium hydroxide is used. The concentration of alkali has little or no effect on the yield.2. The alcohol is best distilled from neutral rather than from alkaline solution.3. In order to prevent decarboxylation, the temperature should be kept as low as possible. If this precaution is not observed, the yield is lowered and the product is less pure.3. DiscussionThe procedure described is essentially that of Perkin.1Phenylpropiolic acid can also be prepared from ether solutions of β-bromostyrene2 and β-chlorostyrene3 with sodium and carbon dioxide; from β-bromostyrene and butyllithium in ether;4 by the action of alcoholic alkali on α-bromocinnamic acid,2β-bromocinnamic acid,5 or ethyl α-bromocinnamate;6 and by the action of carbon dioxide on sodium phenylacetylide.2, 7The preparation of phenylpropiolic acid by the action of alkali on α,β-dibromocinnamic acid, a more direct synthesis than that involving the ester, has not been much used because of the difficulty of preparing the dibromo acid. It has been reported, however, that α,β-dibromocinnamic acid can be prepared easily and in a 95 per cent yield by the addition of bromine to cinnamic acid in boiling carbon tetrachloride, and that the crude product can be used for the preparation of phenylpropiolic acid.8 A simplified procedure for the preparation of small amounts of phenylpropiolic acid from α,β-dibromocinnamic acid is described in the same article.References and Notes1.Perkin, J. Chem. Soc. 45, 172 (1884); Liebermann and Sachse, Ber. 24, 4113 (1891).2.Glaser, Ann. 154, 140, 162 (1870).3.Erlenmeyer, Ber. 16, 152 (1883).4.Gilman, Langham, and Moore, J. Am. Chem. Soc. 62, 2328 (1940).5.Barisch, J. prakt. Chem. (2) 20, 180 (1879).6.Michael, Ber. 34, 3647 (1901).7. E. I. du Pont de Nemours and Company, U. S. pat. 2,194,363 [C. A. 34, 4745 (1940)].8.Reimer, J. Am. Chem. Soc. 64, 2510 (1942).AppendixChemical Abstracts Nomenclature (Collective Index Number);(Registry Number)alcohol (64-17-5)sulfuric acid (7664-93-9)hydrochloric acid (7647-01-0)ether (60-29-7)sodium carbonate (497-19-8)bromine (7726-95-6)carbon tetrachloride (56-23-5)carbon dioxide (124-38-9)Norite (7782-42-5)potassium hydroxide (1310-58-3)sodium(13966-32-0)cinnamic acid (621-82-9)β-bromostyrene (103-64-0)Phenylpropiolic acid,Propiolic acid, phenyl- (637-44-5)β-Chlorostyrene (622-25-3)α-bromocinnamic acidEthyl α,β-dibromo-β-phenylpropionate (5464-70-0)butyllithium (109-72-8)β-bromocinnamic acidethyl α-bromocinnamatesodium phenylacetylideα,β-dibromocinnamic acidCopyright © 1921-2005, Organic Syntheses, Inc. All Rights Reserved。

光学和光子学-光学材料和元件-0.78 μm~25 μm红外光谱用光学材料特性1 范围本文件规定了在0.78 μm~25 μm红外光谱范围内使用的光学材料的命名、特性以及表征该类材料特性所需参数,并提供了部分性能的测试方法。

本文件仅适用于制造无源光学元件所用材料。

本文件中的材料也可以透过其它光谱(如微波、可见光或紫外线)。

2 规范性引用文件下列文件中的内容通过文中的规范性引用而构成本文件必不可少的条款。

其中,注日期的引用文件,仅该日期对应的版本适用于本文件;不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

ISO 9385:1990, Glass and glass-ceramics — Knoop hardness testISO 10110-18, Optics and photonics — Preparation of drawings for optical elements and systems —Part 18: Stress birefringence, bubbles and inclusions, homogeneity, and striaeISO 10345-2:1992, Glass determination of stress-optical coefficient—part 2: bending testISO 12123:2018, Optics and photonics — Specification of raw optical glassISO 15368, Optics and photonics — Measurement of reflectance of plane surfaces and transmittance of plane parallel elementsISO 19740:2018, Optics and photonics —Optical materials and components —Test method for homogeneity of infrared optical materialsISO 19741:2018, Optics and photonics — Optical materials and components — Test method for striae in infrared optical materialsISO 19742:2018, Optics and photonics — Optical materials and components — Test method for bubbles and inclusions in infrared optical materialsISO 22007-4:2017, Plastics Determination of thermal conductivity and thermal diffusivity—Laser flash methodISO 80000-7, Quantities and units — Part 7:Light and radiationGB/T 1409-2006 测量电气绝缘材料在工频、音频、高频(包括米波波长在内)下电容率和介质损耗GB/T 7962.14-2010 无色光学玻璃测试方法第14部分:耐酸稳定性GB/T 7962.15 -1987 无色光学玻璃测试方法耐潮稳定性测试方法GB/T 7962.16 -2010 无色光学玻璃测试方法第16部分:线膨胀系数、转变温度和弛垂温度GB/T 7962.20 -2010 无色光学玻璃测试方法第20部分:密度GB/T 7962.6-2010无色光学玻璃测试方法第6部分:杨氏模量、剪切模量及泊松比GB/T 34184-2017红外光学玻璃红外折射率测试方法偏折角法GB/T 38494-2020 陶瓷器抗冲击试验方法3 术语和定义ISO 12123、ISO 80000-7及以下给出的术语和定义均适用于本标准。

2009年第6期(总第55期)Storage &Process辣椒红色素的超临界萃取姜爱丽,胡文忠,刘程惠,田密霞(大连民族学院生命科学学院生物技术与资源利用国家民委—教育部重点实验室,大连116600)摘要:为了制备高质量的辣椒红色素,用正交实验设计对有机溶剂浸提辣椒油树脂及超临界CO 2流体技术提纯辣椒红色素的工艺条件进行优化筛选。

结果表明,制备辣椒油树脂的最佳工艺条件为:丙酮作有机溶剂,辣椒粉末细度为40目,固液比为1∶6,浸提时间40min ;辣椒油树脂提纯辣椒红色素的超临界萃取条件为:萃取釜温度35℃,萃取压力30MPa ,时间2.0h 。

有机溶剂浸提和超临界萃取结合使用可有效地提高辣椒红色素的色价与质量。

关键词:辣椒油树脂;超临界CO 2萃取;辣椒红色素Extraction of Capsicum Red Pigmentwith Supercritical CO 2FluidJIANG Ai-li,HU Wen-zhong,LIU Cheng-hui,TIAN Mi-xia(College of Life Science,Dalian Nationalities University,Key Laboratory of Biotechnology &Bioresources Utilization,The StateEthnic Affairs Commission-Ministry of Education,Dalian 116600,China )Abstract:In order to produce high quality of capsicum red pigment,the experimental orthogonal designs were used to select the optimum conditions of organic solvent extraction capsicum oleoresin and supercritical CO 2ex -traction technique to purify capsicum red pigment.The result indicated that,the optimum parameters of organic solvent extraction pepper oil are acetone to organic solvent,chili powder fineness of 40meshes,solid-liquid ratio of 1∶6,the extraction time is 40min.Moreover,supercritical CO 2technique was extraction temperature 35℃,ex -traction pressure 30MPa and extraction time 2.0h.The combined using of organic solvent extraction and super -critical fluid extraction effectively raised the color price and quality of capsicum red pigment.Key words:capsicum oleoresin;supercritical CO 2extraction technique;capsicum red pigment中图分类号:TS202.3文献标识码:A 文章编号:1009-6221(2009)06-0050-04辣椒红色素作为一种天然食用色素,不仅稳定性好,着色力强,而且还具有营养、保健、天然、安全等特点,因此,联合国粮农组织(FAO )和世界卫生组织(WHO )将辣椒红色素列为A 类色素,在使用中不加以限量。

Potassium phosphate monobasic Cell Culture TestedProduct Number P 5655Store at Room TemperatureProduct DescriptionMolecular Formula: KH2PO4Molecular Weight: 136.1CAS Number: 7778-77-0Synonyms: monopotassium phosphate, potassium dihydrogen phosphateThis product is cell culture and insect cell culture tested. It is suitable for use in cell culture and insect cell culture applications.Potassium phosphate is a reagent with very high buffering capacity that is widely used in molecular biology, biochemistry, and chromatography. Potassium phosphate occurs in several forms: monobasic (KH2PO4), dibasic (K2HPO4), and tribasic (K3PO4). Most neutral potassium phosphate buffer solutions consist of mixtures of the monobasic and dibasic forms to varying degrees, depending on the desired pH. A table for preparation of 0.1 M potassium phosphate buffer at 25 °C using various proportions of potassium phosphate monobasic and potassium phosphate dibasic has been published.1,2 Some limitations of the usefulness of phosphate buffers include their precipitation of Ca2+ and Mg2+, their inhibition of restriction enzyme activity, and their interference in protocols related to DNA ligation and bacterial transformation.1 A study of the effect of freeze-thaw storage cycles on proteins in potassium phosphate and sodium phosphate buffer solutions has been reported.3The use of high concentrations of potassium phosphate in the immobilization of affinity ligands onto epoxide-activated stationary phases has been reviewed.4 A two-phase system of aqueous potassium phosphate and poly(ethylene glycol) for the isolation of E. coliβ-galactosidase and β-galactosidase fusion proteins has been published.5 The quantitation of nonionic surfactants in buffered solutions using strong cation and anion exchange HPLC guard columns and potassium phosphate solution has been investigated.6 Precautions and DisclaimerFor Laboratory Use Only. Not for drug, household or other uses.Preparation InstructionsThis product is soluble in water (100 mg/ml), yielding a clear, colorless solution.References1. Molecular Cloning: A Laboratory Manual, 3rd ed.,Sambrook, J. F., et al., Cold Spring HarborLaboratory Press (Cold Spring Harbor, NY: 2001), p. A1.5.2. Green, A. A., and Hughes, W. L., ProteinFractionation on the Basis of Solubility in Aqueous Solutions of Salts and Organic Solvents. Meth.Enzymol., 1, 67-90 (1955).3. Pikal-Cleland, K. A., et al., Protein denaturationduring freezing and thawing in phosphate buffersystems: monomeric and tetrameric beta-galactosidase. Arch. Biochem. Biophys., 384(2),398-406 (2000).4. Wheatley, J. B., and Schmidt, D. E. Jr., Salt-induced immobilization of affinity ligands ontoepoxide-activated supports. J. Chromatogr. A.,849(1), 1-12 (1999).5. Enfors, S. O., et al., Combined use of extractionand genetic engineering for protein purification: recovery of beta-galactosidase fused proteins.Bioseparation, 1(3-4), 305-310 (1990). 6. Pardue, K., and Williams, D., Quantitativedetermination of non-ionic surfactants in proteinsamples, using ion-exchange guard columns.Biotechniques, 14(4), 580-583 (1993).GCY/RXR 2/03Sigma brand products are sold through Sigma-Aldrich, Inc.Sigma-Aldrich, Inc. warrants that its products conform to the information contained in this and other Sigma-Aldrich publications. Purchaser must determine the suitability of the product(s) for their particular use. Additional terms and conditions may apply. Please see reverse side ofthe invoice or packing slip.。

有机材料处理词汇英文版Organic Material Treatment: Vocabulary English VersionOrganic materials are widely used in various industries, including agriculture, woodworking, food production, and pharmaceuticals. In order to process and treat organic materials, it’s important to have a good understanding of the relevant vocabulary in English. Whether you’re an engineer, a researcher, or a student, this guide will provide you with a comprehensive list of English-language terms that you can use when working with organic materials.Aeration: The process of supplying air to organic materials to promote microbial activity and decomposition.Anaerobic Digestion: A process that breaks down organic materials in the absence of oxygen, producing biogas and effluent.Biodegradation: The breakdown of organic materials into simpler compounds by microorganisms like fungi and bacteria.Composting: The controlled decomposition of organic materials with the help of microorganisms, creating anutrient-rich soil amendment.Drying: The process of removing moisture from organic materials to increase their shelf life, reduce the risk of mold growth, and improve processing efficiency.Extrusion: The process of forcing organic materials through a die to form long, continuous shapes. Commonly used in the production of food products, such as pasta.Fermentation: The breakdown of organic materials by microorganisms in the presence of oxygen, generating energy and cellular growth.Hydrolysis: The process of breaking down organic materials into simpler compounds by adding water.Liquefaction: The process of converting organic materials into a liquid state for easier handling and transportation.Pyrolysis: The decomposition of organic materials in the absence of oxygen, typically resulting in the production of biochar, bio-oil, and syngas.Sanitization: The process of eliminating harmful microorganisms from organic materials to prevent contamination and improve product safety.Solid Waste Management: The process of collecting, processing, and disposing of organic waste materials in an environmentally responsible manner.Thermal Processing: The use of heat to sterilize, dry, or otherwise treat organic materials. Commonly used in the food, pharmaceutical, and manufacturing industries.Vermicomposting: The process of composting organic materials with the help of earthworms, creating a nutrient-rich soil amendment.Wet Milling: The process of grinding organic materials with water to create a fine paste. Commonly used in the production of food products, such as cornstarch.Zymurgy: The science of fermentation, including the study of microorganisms, biochemical reactions, and the production of fermented products.ConclusionThis guide provides a comprehensive list of vocabulary related to organic material treatm ent in English. Whether you’re a researcher, an engineer, or a student, having a good understanding of these terms will help you communicate more effectively with colleagues and stakeholders. With this knowledge, you can better navigate the complex world of organic materials and contribute to the development of innovative solutions for a more sustainable future.。

矿产资源开发利用方案编写内容要求及审查大纲

矿产资源开发利用方案编写内容要求及《矿产资源开发利用方案》审查大纲一、概述

㈠矿区位置、隶属关系和企业性质。

如为改扩建矿山, 应说明矿山现状、

特点及存在的主要问题。

㈡编制依据

(1简述项目前期工作进展情况及与有关方面对项目的意向性协议情况。

(2 列出开发利用方案编制所依据的主要基础性资料的名称。

如经储量管理部门认定的矿区地质勘探报告、选矿试验报告、加工利用试验报告、工程地质初评资料、矿区水文资料和供水资料等。

对改、扩建矿山应有生产实际资料, 如矿山总平面现状图、矿床开拓系统图、采场现状图和主要采选设备清单等。

二、矿产品需求现状和预测

㈠该矿产在国内需求情况和市场供应情况

1、矿产品现状及加工利用趋向。

2、国内近、远期的需求量及主要销向预测。

㈡产品价格分析

1、国内矿产品价格现状。

2、矿产品价格稳定性及变化趋势。

三、矿产资源概况

㈠矿区总体概况

1、矿区总体规划情况。

2、矿区矿产资源概况。

3、该设计与矿区总体开发的关系。

㈡该设计项目的资源概况

1、矿床地质及构造特征。

2、矿床开采技术条件及水文地质条件。