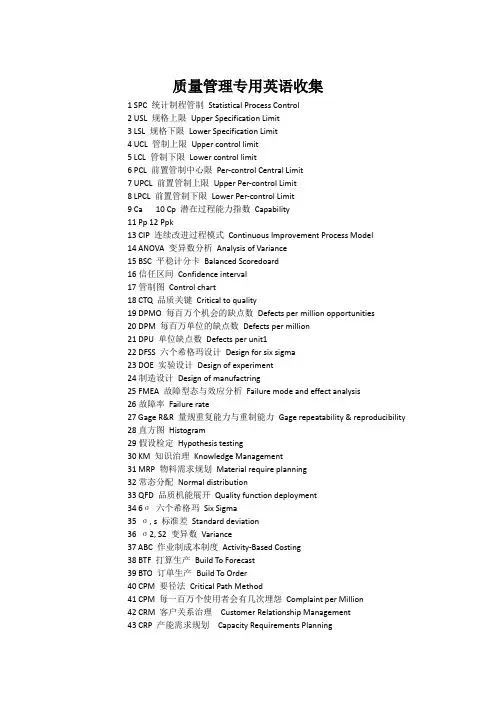

质量管理专用英语收集

- 格式:doc

- 大小:175.00 KB

- 文档页数:40

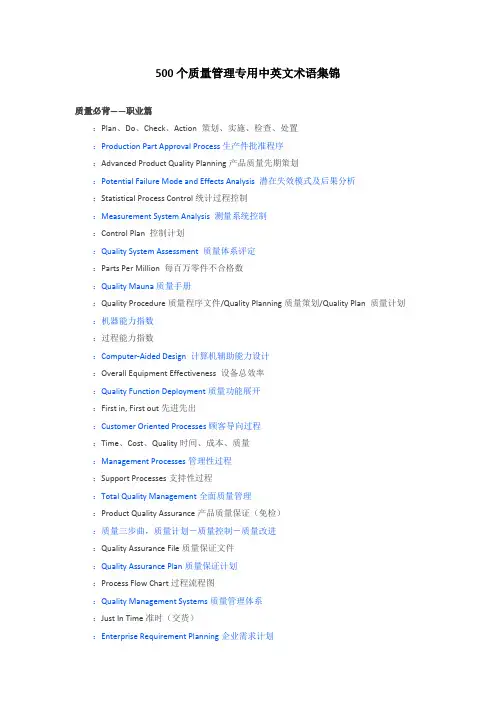

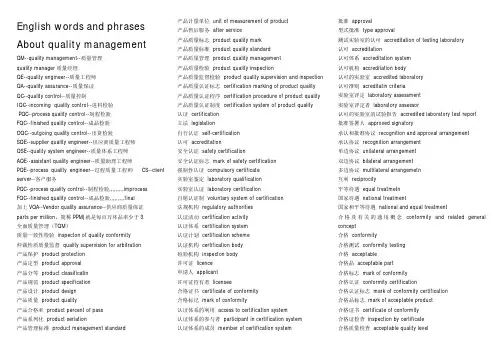

500个质量管理专用中英文术语集锦质量必背——职业篇:Plan、Do、Check、Action 策划、实施、检查、处置:Production Part Approval Process生产件批准程序:Advanced Product Quality Planning产品质量先期策划:Potential Failure Mode and Effects Analysis 潜在失效模式及后果分析:Statistical Process Control统计过程控制:Measurement System Analysis 测量系统控制:Control Plan 控制计划:Quality System Assessment 质量体系评定:Parts Per Million 每百万零件不合格数:Quality Mauna质量手册:Quality Procedure质量程序文件/Quality Planning质量策划/Quality Plan 质量计划:机器能力指数:过程能力指数:Computer-Aided Design 计算机辅助能力设计:Overall Equipment Effectiveness 设备总效率:Quality Function Deployment质量功能展开:First in, First out先进先出:Customer Oriented Processes顾客导向过程:Time、Cost、Quality时间、成本、质量:Management Processes管理性过程:Support Processes支持性过程:Total Quality Management全面质量管理:Product Quality Assurance产品质量保证(免检):质量三步曲,质量计划-质量控制-质量改进:Quality Assurance File质量保证文件:Quality Assurance Plan质量保证计划:Process Flow Chart过程流程图:Quality Management Systems质量管理体系:Just In Time准时(交货):Enterprise Requirement Planning企业需求计划:Quality Control 质量控制:Quality Audit 质量审核/Qality Assurance 质量保证:In Come Quality Control 进货质量控制:In Process Quality Control 过程质量控制:Final Quality Control 成品质量控制:Out Quality Control 出货质量控制:Man、Machine、Material、Method、Environment人、机、料、法、环:Why、What、Who、When、Where、How 为何/做什么/谁做/时间/地点/如何做:Seiri、Seiton、Seiso、Seiketsu、Shitsuke、Safety 整理、整顿、清扫、清洁、素养、安全值:Total Record Injury(三种)可记录工伤值:精明原则,Specific Measurable Achievable Result Oriented Timed(具体的描述、可以测量的、可以通过努力实现的、有结果导向性的、有时间性的)质量必背——企业篇:5S管理:作业制成本制度(Activity-Based Costing):实施作业制预算制度(Activity-Based Budgeting):作业制成本管理(Activity-Base Management):先进规划与排程系统(Advanced Planning and Scheduling):应用程序服务供货商(Application Service Provider):可承诺量(Available To Promise):认可的供货商清单(Approved Vendor List):物料清单(Bill Of Material):企业流程再造(Business Process Reengineering):平衡记分卡(Balanced ScoreCard):计划生产(Build To Forecast):订单生产(Build To Order):要径法(Critical Path Method):每一百万个使用者会有几次抱怨(Complaint per Million):客户关系管理(Customer Relationship Management):产能需求规划(Capacity Requirements Planning):客制化生产(Configuration To Order):限制驱导式排程法(Drum-Buffer-Rope):成熟度验证(Design Maturing Testing):设计验证(Design Verification Testing):运销资源计划(Distribution Resource Planning):决策支持系统(Decision Support System):设计变更/工程变更(Engineer Change):电子商务(Electronic Commerce):原件规格更改通知(Engineer Change Request Notice):电子数据交换(Electronic Data Interchange):主管决策系统(Executive Information System):电磁相容(Electric Magnetic Capability):基本经济订购量(Economic Order Quantity):企业资源规划(Enterprise Resource Planning):应用工程师(Field Application Engineer):预估(Forecast):弹性制造系统(Flexible Manufacture System):成品质量管理(Finish or Final Quality Control): 制程质量管理(In-Process Quality Control):进料质量管理(Incoming Quality Control):国际标准组织(International Organization for Standardization):首批样品认可(Initial Sample Approval Request):实时管理(Just In Time):知识管理(Knowledge Management):逐批订购法(Lot-for-Lot):最小总成本法(Least Total Cost):最小单位成本(Least Unit Cost):制造执行系统(Manufacturing Execution System):制令(Manufacture Order):主生产排程(Master Production Schedule):请修(购)单(Maintenance Repair Operation):物料需求规划(Material Requirement Planning):制造资源计划(Manufacturing Resource Planning):更改预估量的通知Notice for Changing Forecast:委托代工(Original Equipment Manufacture):委托设计与制造(Original Design & Manufacture):在线分析处理(On-Line Analytical Processing):在线交易处理(On-Line Transaction Processing):最佳生产技术(Optimized Production Technology):出货质量管理(Out-going Quality Control):PDCA管理循环(Plan-Do-Check-Action):产品数据管理系统(Product Data Management):计划评核术(Program Evaluation and Review Technique):订单(Purchase Order):预估在手量(Product on Hand):采购申请(Purchase Request):品质保证(Quality Assurance):质量管理(Quality Control):品管圈(Quality Control Circle):品质工程(Quality Engineering):粗略产能规划(Rough Cut Capacity Planning):退货验收(Returned Material Approval):再订购点(Re-Order Point):供应链管理(Supply Chain Management):现场控制(Shop Floor Control):策略信息系统(Strategic Information System):订单(Sales Order):特殊订单需求(Special Order Request):统计制程管制(Statistic Process Control):限制理论(Theory of Constraints):全面生产管理(Total Production Management):全面质量管理(Total Quality Control):全面品质管理(Total Quality Management):在制品(Work In Process)质量必背——部门篇QS: Quality system品质系统CS: Customer Service 客户服务QC: Quality control品质管理IQC: Incoming quality control 进料检验LQC: Line Quality Control 生产线品质控制IPQC: In process quality control 制程检验FQC: Final quality control 最终检验OQC: Outgoing quality control 出货检验QA: Quality assurance 品质保证SQA: Source(supplier) Quality Assurance 供应商品质保证(VQA) CQA:Customer Quality Assurance客户质量保证PQA rocess Quality Assurance 制程品质保证QE: Quality engineer 品质工程CE: component engineering零件工程EE: equipment engineering设备工程ME: manufacturing engineering制造工程TE: testing engineering测试工程PPE product Engineer 产品工程IE: Industrial engineer 工业工程ADM: Administration Department行政部RMA:客户退回维修CSDI:检修PC: producing control生管MC: mater control物管GAD: General Affairs Dept.总务部A/D: Accountant /Finance Dept.会计LAB: Laboratory实验室DOE:实验设计HR:人资PMC:企划RD:研发W/H:仓库SI:客验PD: Product Department生产部PA:采购(PUR: Purchasing Dept.)SMT: Surface mount technology 表面粘着技术MFG: Manufacturing 制造MIS: Management information system 资迅管理系统DCC: document control center 文件管制中心质量必背——场内作业QT: Quality target品质目标QP: Quality policy目标方针QI: Quality improvement品质改善CRITICAL DEFECT:严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(MI)MAX: Maximum最大值MIN: Minimum最小值DIA diameter直径DIM dimension尺寸LCL: Lower control limit管制下限UCL: Upper control limit管制上限EMI:电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO: Engineering change order工程改动要求(客户)ECR:工程变更需求单CPI: Continuous Process Improvement 连续工序改善Compatibility:兼容性Marking:标记DWG drawing图面Standardization:标准化Consensus:一致Code:代码ZD: Zero defect零缺点Tolerance:公差Subject matter:主要事项Auditor:审核员BOM: Bill of material物料清单Rework:重工ID:identification识别,鉴别,证明PILOT RUN: (试投产)FAI:首件检查FPIR:First Piece Inspection Report首件检查报告FAA:首件确认SPC:统计制程管制CP: capability index(准确度)CPK: capability index of process(制程能力)PMP:制程管理计划(生产管制计划)MPI:制程分析DAS effects Analysis System 缺陷分析系统PPB:十亿分之一Flux:助焊剂P/N:料号L/N:Lot Number批号Version:版本Quantity:数量Valid date:有效日期MIL-STD:Military-Standard军用标准ICT: In Circuit Test (线路测试)ATE:Automatic Test Equipment自动测试设备MO: Manufacture Order生产单T/U: Touch Up (锡面修补)I/N:手插件P/T:初测F/T: Function Test (功能测试-终测)AS 组立P/K:包装TQM: Total quality control全面品质管理MDA: Manufacturing defect analysis制程不良分析(ICT) RUN-IN:老化实验HI-pot:高压测试FMI:Frequency Modulation Inspect高频测试DPPM: Defect Part Per Million(不良率的一种表达方式:百万分之一) 1000PPM即为% Corrective Action: (CAR改善对策)ACC:允收REJ:拒收S/S:Sample size抽样检验样本大小SI-SIV:Special I-Special IV特殊抽样水平等级CON:Concession / Waive特采ISO:国际标准化组织ISA:Industry Standard Architecture工业标准体制结构OBA:开箱稽核FIFO:先进先出PDCA:管理循环Plan do check action计划,执行,检查,总结WIP:在制品(半成品)S/O: Sales Order (业务订单)P/O: Purchase Order (采购订单)P/R: Purchase Request (请购单)AQL: acceptable quality level允收品质水准LQL; Limiting quality level最低品质水准QVL: qualified vendor list合格供应商名册AVL :认可的供货商清单(Approved Vendor List)QCD: Quality cost delivery(品质,交期,成本)MPM: Manufacturing project management制造专案管理KPI: Key performance indicate重要绩效指标MVT: Manufacturing Verification Test制造验证试产Q/R/S:Quality/Reliability/Service质量/可靠度/服务STL: ship to line(料到上线)NTF: No trouble found误判CIP: capacity improvement plan(产能改善计划)MRB: material review board(物料审核小组)MRB: Material reject bill退货单JIT: just in time(即时管理)5S:seiri seiton seiso seiketsu shitsuke(整理,整顿,清扫,清洁,修养)SOP: standard operation process(标准作业程序)SIP: Specification inspection process制程检验规格TOP: Test Operation Process (测试作业流程)WI: working instruction(作业指导书)SMD: surface mounting device(表面粘着原件)FAR: failure analysis report故障分析报告CAR: Corrective action report改善报告BPR:企业流程再造(Business Process Reengineering)ISAR :首批样品认可(Initial Sample Approval Request)-JIT:实时管理(Just In Time)QCC :品管圈(Quality Control Circle)Engineering Department (工程部)TQEM: Total Quality Environment Management(全面品质环境管理)PD: Production Department (制造)LOG: Logistics (后勤支持)Shipping: (进出口)AOQ:Average Output Quality平均出货质量AOQL:Average Output Quality Level平均出货质量水平FMEA:failure model effectiveness analysis失效模式分析CRB: Change Review Board (工程变更会议)CSA:Customer Simulate Analysis客户模拟分析SQMS:Supplier Quality Management System供应商品质管理系统QIT: Quality Improvement Team 品质改善小组QIP:Quality Improvement Plan品质改善计划CIP:Continual Improvement Plan持续改善计划Material Quality Feedback Sheet (来料品质回馈单)SCAR: Supplier Corrective Action Report (供货商改善对策报告)8D Sheet: 8 Disciplines sheet ( 8D单)PDCA:PDCA (Plan-Do-Check-Action) (管理循环)MPQ: Material Packing Quantity (物料最小包装量)DSCN: Delivery Schedule Change Notice (交期变更通知)QAPS: Quality Assurance Process Sheet (品质工程表)DRP :运销资源计划(Distribution Resource Planning)DSS:决策支持系统(Decision Support System)EC :电子商务(Electronic Commerce)EDI :电子资料交换(Electronic Data Interchange)EIS :主管决策系统(Executive Information System)ERP:企业资源规划(Enterprise Resource Planning)FMS :弹性制造系统(Flexible Manufacture System)KM :知识管理(Knowledge Management)4L :逐批订购法(Lot-for-Lot)LTC :最小总成本法(Least Total Cost)LUC :最小单位成本(Least Unit Cost)MES :制造执行系统(Manufacturing Execution System)MPS :主生产排程(Master Production Schedule)MRP :物料需求规划(Material Requirement Planning)MRPⅡ:制造资源计划(Manufacturing Resource Planning)OEM :委托代工(Original Equipment Manufacture)ODM :委托设计与制造(Original Design & Manufacture) OLAP:线上分析处理(On-Line Analytical Processing)OLTP:线上交易处理(On-Line Transaction Processing)OPT :最佳生产技术(Optimized Production Technology)PDCA:PDCA管理循环(Plan-Do-Check-Action)PDM:产品数据管理系统(Product Data Management))RCCP:粗略产能规划(Rough Cut Capacity Planning)SCM :供应链管理(Supply Chain Management)SFC :现场控制(Shop Floor Control)TOC:限制理论(Theory of Constraints)TQC :全面品质管制(Total Quality Control)FYI/R: For your information/reference仅供参考ASAP:尽快S/T: Standard time标准时间TPM: total production maintenance:全面生产保养ESD Wrist strap:静电环IT: information technology信息技术,资讯科学CEO:Chief Executive Officer执行总裁COO:Chief Operating Officer首席业务总裁SWOT:Strength, Weakness, Opportunity, Threat优势﹐弱点﹐机会﹐威胁Competence:专业能力Communication:有效沟通Cooperation:统御融合Vibration Testing:振动测试IDP:Individual Development Plan个人发展计划MRP:Material Requirement Planning物料需求计划MAT'S:Material材料LRR:Lot Reject Rate批退率ATIN:Attention知会3C:Computer ,Communication , Consumer electronic消费性电子5W1H:When , Where , Who , What , Why , Ho5M: Man , Machine , Material , Method , Measurement人,机器,材料,方法,测量4MIE: Man, Material, Machine, Method, Environment人力,物力,财务,技术,时间(资源) 7M1I: Manpower , Machine , Material , Method, Market , Management , Money , Information人力,机器,材料,方法, 市场,管理,资金,资讯Accuracy 准确度Action 行动Activity 活动Analysis Covariance 协方差分析Analysis of Variance 方差分析Approved 承认Attribute 计数值Average 平均数Balance sheet 资产负债对照表Binomial 二项分配Brainstorming Techniques 脑力风暴法Cause and Effect Matrix 因果图(鱼骨图)CL: Center Line 中心线Check Sheets 检查表Complaint 投诉Conformity 合格(符合)Control 控制Control chart 控制(管制)图Correction 纠正Correlation Methods 相关分析法CPI: continuous Process Improvement 连续工序改善Cross Tabulation Tables 交叉表CS: Customer Service 客(户)服(务)中心DSA: Defects Analysis System 缺陷分析系统Data 数据Deion:品名DCC: Document Control Center 文控中心Decision 决策、判定Defects per unit 单位缺点数Deion 描述Device 装置Do 执行DOE: Design of Experiments 实验设计Element 元素Engineering technology 工程技Environmental 环境Equipment 设备Estimated accumulative frequency 计算估计累计数E Equipment Variation 设备变异External Failure 外部失效,外部缺陷FA: Failure Analysis 失效分析Fact control 事实管理Fatigue 疲劳FMEA: Failure Mode and Effect Analysis失效模式与效果分析FP First-Pass Yield (第一次通过)合格率FQA: Final Quality Assurance 最终品质保证FQC: Final Quality control 最终品质控制Gauge system 测量系统Grade 等级Histogram 直方图Improvement 改善Initial review 先期审查Inspection 检验Internal Failure 内部失效、内部缺陷IPQC: In Process Quality Control 制程品质控制IQC: Incoming Quality Control 来料品质控制IS International Organization for Standardization 国际标准化组织LCL: Lower Control limit 管制下限LQC: Line Quality Control 生产线品质控制LSL: Lower Size Limit 规格下限Machine 机械Manage 管理Materials 物料Measurement 测量Median 中位数MSA: Measurement System Analysis 测量系统分析Occurrence 发生率Operation Instruction 作业指导书Organization 组织Plato 柏拉图PPM arts per Million (百万分之)不良率Plan 计划Policy 方针Population 群体PQA: Process Quality Assurance 制程品质保证Practice 实务(践)Prevention 预防Probability 机率Probability density function 机率密度函数Procedure 流程Process 过程Process capability analysis 制程能力分析(图)Process control and Process capability制程管制与制程能力Product 产品Production 生产Projects 项目QA: Quality Assurance 品质保证QC: Quality Control 品质控制QE: Quality Engineering 品质工程QFD: Quality Function Design 品质机能展开(法)Quality 质量Quality manual 品质手册Quality policy 品质政策(质量方针)Random experiment 随机试验Random numbers 随机数R:Range 全距(极差)Reject 拒收Repair 返修Repeatusility 再现性Reproducibility 再生性Requirement 要求Responsibilities 职责Review 评审Reword 返工Rolled yield 直通率RPN: Risk Priority Number 风险系数Sample 抽样,样本Sample space 样本空间Sampling with replacement 放回抽样Sampling without replacement 不放回抽样Scatter diagram 散布图分析Scrap 报废Simple random sampling 简单随机取样Size 规格SL: Size Line 规格中心线Stratified random sampling 分层随机抽样SOP: Standard Operation Procedure 标准作业书SPC: Statistical Process Control 统计制程管制Specification 规范SQA: Source(Supplier) Quality Assurance 供货商品质保证Stage sampling 分段随机抽样Standard Deviation 标准差Sum of squares 平方和Taguchi-method 田口(试验)方法Theory 原理TQC: Total Quality Control 全面品质控制TQM: Total Quality Management 全面品质管理Traceability 追溯UCL: Upper Control Limit 管制(控制)上限USL: Upper Size Limit 规格上限Validation 确认Variable 计量值Verification 验证Version 版本VOC: Voice of Customer 客户需求VOE: Voice of Engineer 工程需求Inventory stock report:库存清单报告Sales order report:出货报告(来源:SQE供应商质量)。

(质量管理知识)质量管理专业英语词汇质量管理专业英语词汇Absolute deviation, 绝对离差Absolute number, 绝对数Absolute residuals, 绝对残差Acceleration array, 加速度立体阵Acceleration in an arbitrary direction, 任意方向上的加速度Acceleration normal, 法向加速度Acceleration space dimension, 加速度空间的维数Acceleration tangential, 切向加速度Acceleration vector, 加速度向量Acceptable hypothesis, 可接受假设Accumulation, 累积Accuracy, 准确度Actual frequency, 实际频数Adaptive estimator, 自适应估计量Addition, 相加Addition theorem, 加法定理Additivity, 可加性Adjusted rate, 调整率Adjusted value, 校正值Admissible error, 容许误差Aggregation, 聚集性Alternative hypothesis, 备择假设Among groups, 组间Amounts, 总量Analysis of correlation, 相关分析Analysis of covariance, 协方差分析Analysis of regression, 回归分析Analysis of time series, 时间序列分析Analysis of variance, 方差分析Angular transformation, 角转换ANOVA (analysis of variance), 方差分析ANOVA Models, 方差分析模型Arcing, 弧/弧旋Arcsine transformation, 反正弦变换Area under the curve, 曲线面积AREG , 评估从一个时间点到下一个时间点回归相关时的误差ARIMA, 季节和非季节性单变量模型的极大似然估计Arithmetic grid paper, 算术格纸Arithmetic mean, 算术平均数Arrhenius relation, 艾恩尼斯关系Assessing fit, 拟合的评估Associative laws, 结合律Asymmetric distribution, 非对称分布Asymptotic bias, 渐近偏倚Asymptotic efficiency, 渐近效率Asymptotic variance, 渐近方差Attributable risk, 归因危险度Attribute data, 属性资料Attribution, 属性Autocorrelation, 自相关Autocorrelation of residuals, 残差的自相关Average, 平均数Average confidence interval length, 平均置信区间长度Average growth rate, 平均增长率Bar chart, 条形图Bar graph, 条形图Base period, 基期Bayes' theorem , Bayes定理Bell-shaped curve, 钟形曲线Bernoulli distribution, 伯努力分布Best-trim estimator, 最好切尾估计量Bias, 偏性Binary logistic regression, 二元逻辑斯蒂回归Binomial distribution, 二项分布Bisquare, 双平方Bivariate Correlate, 二变量相关Bivariate normal distribution, 双变量正态分布Bivariate normal population, 双变量正态总体Biweight interval, 双权区间Biweight M-estimator, 双权M估计量Block, 区组/配伍组BMDP(Biomedical computer programs), BMDP统计软件包Boxplots, 箱线图/箱尾图Breakdown bound, 崩溃界/崩溃点Canonical correlation, 典型相关Caption, 纵标目Case-control study, 病例对照研究Categorical variable, 分类变量Catenary, 悬链线Cauchy distribution, 柯西分布Cause-and-effect relationship, 因果关系Cell, 单元Censoring, 终检Center of symmetry, 对称中心Centering and scaling, 中心化和定标Central tendency, 集中趋势Central value, 中心值CHAID -χ2 Automatic Interaction Detector, 卡方自动交互检测Chance, 机遇Chance error, 随机误差Chance variable, 随机变量Characteristic equation, 特征方程Characteristic root, 特征根Characteristic vector, 特征向量Chebshev criterion of fit, 拟合的切比雪夫准则Chernoff faces, 切尔诺夫脸谱图Chi-square test, 卡方检验/χ2检验Choleskey decomposition, 乔洛斯基分解Circle chart, 圆图Class interval, 组距Class mid-value, 组中值Class upper limit, 组上限Classified variable, 分类变量Cluster analysis, 聚类分析Cluster sampling, 整群抽样Code, 代码Coded data, 编码数据Coding, 编码Coefficient of contingency, 列联系数Coefficient of determination, 决定系数Coefficient of multiple correlation, 多重相关系数Coefficient of partial correlation, 偏相关系数Coefficient of production-moment correlation, 积差相关系数Coefficient of rank correlation, 等级相关系数Coefficient of regression, 回归系数Coefficient of skewness, 偏度系数Coefficient of variation, 变异系数Cohort study, 队列研究Column, 列Column effect, 列效应Column factor, 列因素Combination pool, 合并Combinative table, 组合表Common factor, 共性因子Common regression coefficient, 公共回归系数Common value, 共同值Common variance, 公共方差Common variation, 公共变异Communality variance, 共性方差Comparability, 可比性Comparison of bathes, 批比较Comparison value, 比较值Compartment model, 分部模型Compassion, 伸缩Complement of an event, 补事件Complete association, 完全正相关Complete dissociation, 完全不相关Complete statistics, 完备统计量Completely randomized design, 完全随机化设计Composite event, 联合事件Composite events, 复合事件Concavity, 凹性Conditional expectation, 条件期望Conditional likelihood, 条件似然Conditional probability, 条件概率Conditionally linear, 依条件线性Confidence interval, 置信区间Confidence limit, 置信限Confidence lower limit, 置信下限Confidence upper limit, 置信上限Confirmatory Factor Analysis , 验证性因子分析Confirmatory research, 证实性实验研究Confounding factor, 混杂因素Conjoint, 联合分析Consistency, 相合性Consistency check, 一致性检验Consistent asymptotically normal estimate, 相合渐近正态估计Consistent estimate, 相合估计Constrained nonlinear regression, 受约束非线性回归Constraint, 约束Contaminated distribution, 污染分布Contaminated Gausssian, 污染高斯分布Contaminated normal distribution, 污染正态分布Contamination, 污染Contamination model, 污染模型Contingency table, 列联表Contour, 边界线Contribution rate, 贡献率Control, 对照Controlled experiments, 对照实验Conventional depth, 常规深度Convolution, 卷积Corrected factor, 校正因子Corrected mean, 校正均值Correction coefficient, 校正系数Correctness, 正确性Correlation coefficient, 相关系数Correlation index, 相关指数Correspondence, 对应Counting, 计数Counts, 计数/频数Covariance, 协方差Covariant, 共变Cox Regression, Cox回归Criteria for fitting, 拟合准则Criteria of least squares, 最小二乘准则Critical ratio, 临界比Critical region, 拒绝域Critical value, 临界值Cross-over design, 交叉设计Cross-section analysis, 横断面分析Cross-section survey, 横断面调查Crosstabs , 交叉表Cross-tabulation table, 复合表Cube root, 立方根Cumulative distribution function, 分布函数Cumulative probability, 累计概率Curvature, 曲率/弯曲Curvature, 曲率Curve fit , 曲线拟和Curve fitting, 曲线拟合Curvilinear regression, 曲线回归Curvilinear relation, 曲线关系Cut-and-try method, 尝试法Cycle, 周期Cyclist, 周期性D test, D检验Data acquisition, 资料收集Data bank, 数据库Data capacity, 数据容量Data deficiencies, 数据缺乏Data handling, 数据处理Data manipulation, 数据处理Data processing, 数据处理Data reduction, 数据缩减Data set, 数据集Data sources, 数据来源Data transformation, 数据变换Data validity, 数据有效性Data-in, 数据输入Data-out, 数据输出Dead time, 停滞期Degree of freedom, 自由度Degree of precision, 精密度Degree of reliability, 可靠性程度Degression, 递减Density function, 密度函数Density of data points, 数据点的密度Dependent variable, 应变量/依变量/因变量Dependent variable, 因变量Depth, 深度Derivative matrix, 导数矩阵Derivative-free methods, 无导数方法Design, 设计Determinacy, 确定性Determinant, 行列式Determinant, 决定因素Deviation, 离差Deviation from average, 离均差Diagnostic plot, 诊断图Dichotomous variable, 二分变量Differential equation, 微分方程Direct standardization, 直接标准化法Discrete variable, 离散型变量DISCRIMINANT, 判断Discriminant analysis, 判别分析Discriminant coefficient, 判别系数Discriminant function, 判别值Dispersion, 散布/分散度Disproportional, 不成比例的Disproportionate sub-class numbers, 不成比例次级组含量Distribution free, 分布无关性/免分布Distribution shape, 分布形状Distribution-free method, 任意分布法Distributive laws, 分配律Disturbance, 随机扰动项Dose response curve, 剂量反应曲线Double blind method, 双盲法Double blind trial, 双盲试验Double exponential distribution, 双指数分布Double logarithmic, 双对数Downward rank, 降秩Dual-space plot, 对偶空间图DUD, 无导数方法Duncan's new multiple range method, 新复极差法/Duncan新法E-LEffect, 实验效应Eigenvalue, 特征值Eigenvector, 特征向量Ellipse, 椭圆Empirical distribution, 经验分布Empirical probability, 经验概率单位Enumeration data, 计数资料Equal sun-class number, 相等次级组含量Equally likely, 等可能Equivariance, 同变性Error, 误差/错误Error of estimate, 估计误差Error type I, 第一类错误Error type II, 第二类错误Estimand, 被估量Estimated error mean squares, 估计误差均方Estimated error sum of squares, 估计误差平方和Euclidean distance, 欧式距离Event, 事件Event, 事件Exceptional data point, 异常数据点Expectation plane, 期望平面Expectation surface, 期望曲面Expected values, 期望值Experiment, 实验Experimental sampling, 试验抽样Experimental unit, 试验单位Explanatory variable, 说明变量Exploratory data analysis, 探索性数据分析Explore Summarize, 探索-摘要Exponential curve, 指数曲线Exponential growth, 指数式增长EXSMOOTH, 指数平滑方法Extended fit, 扩充拟合Extra parameter, 附加参数Extrapolation, 外推法Extreme observation, 末端观测值Extremes, 极端值/极值F distribution, F分布F test, F检验Factor, 因素/因子Factor analysis, 因子分析Factor Analysis, 因子分析Factor score, 因子得分Factorial, 阶乘Factorial design, 析因试验设计False negative, 假阴性False negative error, 假阴性错误Family of distributions, 分布族Family of estimators, 估计量族Fanning, 扇面Fatality rate, 病死率Field investigation, 现场调查Field survey, 现场调查Finite population, 有限总体Finite-sample, 有限样本First derivative, 一阶导数First principal component, 第一主成分First quartile, 第一四分位数Fisher information, 费雪信息量Fitted value, 拟合值Fitting a curve, 曲线拟合Fixed base, 定基Fluctuation, 随机起伏Forecast, 预测Four fold table, 四格表Fourth, 四分点Fraction blow, 左侧比率Fractional error, 相对误差Frequency, 频率Frequency polygon, 频数多边图Frontier point, 界限点Function relationship, 泛函关系Gamma distribution, 伽玛分布Gauss increment, 高斯增量Gaussian distribution, 高斯分布/正态分布Gauss-Newton increment, 高斯-牛顿增量General census, 全面普查GENLOG (Generalized liner models), 广义线性模型Geometric mean, 几何平均数Gini's mean difference, 基尼均差GLM (General liner models), 通用线性模型Goodness of fit, 拟和优度/配合度Gradient of determinant, 行列式的梯度Graeco-Latin square, 希腊拉丁方Grand mean, 总均值Gross errors, 重大错误Gross-error sensitivity, 大错敏感度Group averages, 分组平均Grouped data, 分组资料Guessed mean, 假定平均数Half-life, 半衰期Hampel M-estimators, 汉佩尔M估计量Happenstance, 偶然事件Harmonic mean, 调和均数Hazard function, 风险均数Hazard rate, 风险率Heading, 标目Heavy-tailed distribution, 重尾分布Hessian array, 海森立体阵Heterogeneity, 不同质Heterogeneity of variance, 方差不齐Hierarchical classification, 组内分组Hierarchical clustering method, 系统聚类法High-leverage point, 高杠杆率点HILOGLINEAR, 多维列联表的层次对数线性模型Hinge, 折叶点Histogram, 直方图Historical cohort study, 历史性队列研究Holes, 空洞HOMALS, 多重响应分析Homogeneity of variance, 方差齐性Homogeneity test, 齐性检验Huber M-estimators, 休伯M估计量Hyperbola, 双曲线Hypothesis testing, 假设检验Hypothetical universe, 假设总体Impossible event, 不可能事件Independence, 独立性Independent variable, 自变量Index, 指标/指数Indirect standardization, 间接标准化法Individual, 个体Inference band, 推断带Infinite population, 无限总体Infinitely great, 无穷大Infinitely small, 无穷小Influence curve, 影响曲线Information capacity, 信息容量Initial condition, 初始条件Initial estimate, 初始估计值Initial level, 最初水平Interaction, 交互作用Interaction terms, 交互作用项Intercept, 截距Interpolation, 内插法Interquartile range, 四分位距Interval estimation, 区间估计Intervals of equal probability, 等概率区间Intrinsic curvature, 固有曲率Invariance, 不变性Inverse matrix, 逆矩阵Inverse probability, 逆概率Inverse sine transformation, 反正弦变换Iteration, 迭代Jacobian determinant, 雅可比行列式Joint distribution function, 分布函数Joint probability, 联合概率Joint probability distribution, 联合概率分布K means method, 逐步聚类法Kaplan-Meier, 评估事件的时间长度Kaplan-Merier chart, Kaplan-Merier图Kendall's rank correlation, Kendall等级相关Kinetic, 动力学Kolmogorov-Smirnove test, 柯尔莫哥洛夫-斯米尔诺夫检验Kruskal and Wallis test, Kruskal及Wallis检验/多样本的秩和检验/H检验Kurtosis, 峰度Lack of fit, 失拟Ladder of powers, 幂阶梯Lag, 滞后Large sample, 大样本Large sample test, 大样本检验Latin square, 拉丁方Latin square design, 拉丁方设计Leakage, 泄漏Least favorable configuration, 最不利构形Least favorable distribution, 最不利分布Least significant difference, 最小显著差法Least square method, 最小二乘法Least-absolute-residuals estimates, 最小绝对残差估计Least-absolute-residuals fit, 最小绝对残差拟合Least-absolute-residuals line, 最小绝对残差线Legend, 图例L-estimator, L估计量L-estimator of location, 位置L估计量L-estimator of scale, 尺度L估计量Level, 水平Life expectance, 预期期望寿命Life table, 寿命表Life table method, 生命表法Light-tailed distribution, 轻尾分布Likelihood function, 似然函数Likelihood ratio, 似然比line graph, 线图Linear correlation, 直线相关Linear equation, 线性方程Linear programming, 线性规划Linear regression, 直线回归Linear Regression, 线性回归Linear trend, 线性趋势Loading, 载荷Location and scale equivariance, 位置尺度同变性Location equivariance, 位置同变性Location invariance, 位置不变性Location scale family, 位置尺度族Log rank test, 时序检验Logarithmic curve, 对数曲线Logarithmic normal distribution, 对数正态分布Logarithmic scale, 对数尺度Logarithmic transformation, 对数变换Logic check, 逻辑检查Logistic distribution, 逻辑斯特分布Logit transformation, Logit转换LOGLINEAR, 多维列联表通用模型Lognormal distribution, 对数正态分布Lost function, 损失函数Low correlation, 低度相关Lower limit, 下限Lowest-attained variance, 最小可达方差LSD, 最小显著差法的简称Lurking variable, 潜在变量M-RMain effect, 主效应Major heading, 主辞标目Marginal density function, 边缘密度函数Marginal probability, 边缘概率Marginal probability distribution, 边缘概率分布Matched data, 配对资料Matched distribution, 匹配过分布Matching of distribution, 分布的匹配Matching of transformation, 变换的匹配Mathematical expectation, 数学期望Mathematical model, 数学模型Maximum L-estimator, 极大极小L 估计量Maximum likelihood method, 最大似然法Mean, 均数Mean squares between groups, 组间均方Mean squares within group, 组内均方Means (Compare means), 均值-均值比较Median, 中位数Median effective dose, 半数效量Median lethal dose, 半数致死量Median polish, 中位数平滑Median test, 中位数检验Minimal sufficient statistic, 最小充分统计量Minimum distance estimation, 最小距离估计Minimum effective dose, 最小有效量Minimum lethal dose, 最小致死量Minimum variance estimator, 最小方差估计量MINITAB, 统计软件包Minor heading, 宾词标目Missing data, 缺失值Model specification, 模型的确定Modeling Statistics , 模型统计Models for outliers, 离群值模型Modifying the model, 模型的修正Modulus of continuity, 连续性模Morbidity, 发病率Most favorable configuration, 最有利构形Multidimensional Scaling (ASCAL), 多维尺度/多维标度Multinomial Logistic Regression , 多项逻辑斯蒂回归Multiple comparison, 多重比较Multiple correlation , 复相关Multiple covariance, 多元协方差Multiple linear regression, 多元线性回归Multiple response , 多重选项Multiple solutions, 多解Multiplication theorem, 乘法定理Multiresponse, 多元响应Multi-stage sampling, 多阶段抽样Multivariate T distribution, 多元T分布Mutual exclusive, 互不相容Mutual independence, 互相独立Natural boundary, 自然边界Natural dead, 自然死亡Natural zero, 自然零Negative correlation, 负相关Negative linear correlation, 负线性相关Negatively skewed, 负偏Newman-Keuls method, q检验NK method, q检验No statistical significance, 无统计意义Nominal variable, 名义变量Nonconstancy of variability, 变异的非定常性Nonlinear regression, 非线性相关Nonparametric statistics, 非参数统计Nonparametric test, 非参数检验Nonparametric tests, 非参数检验Normal deviate, 正态离差Normal distribution, 正态分布Normal equation, 正规方程组Normal ranges, 正常范围Normal value, 正常值Nuisance parameter, 多余参数/讨厌参数Null hypothesis, 无效假设Numerical variable, 数值变量Objective function, 目标函数Observation unit, 观察单位Observed value, 观察值One sided test, 单侧检验One-way analysis of variance, 单因素方差分析Oneway ANOVA , 单因素方差分析Open sequential trial, 开放型序贯设计Optrim, 优切尾Optrim efficiency, 优切尾效率Order statistics, 顺序统计量Ordered categories, 有序分类Ordinal logistic regression , 序数逻辑斯蒂回归Ordinal variable, 有序变量Orthogonal basis, 正交基Orthogonal design, 正交试验设计Orthogonality conditions, 正交条件ORTHOPLAN, 正交设计Outlier cutoffs, 离群值截断点Outliers, 极端值OVERALS , 多组变量的非线性正规相关Overshoot, 迭代过度Paired design, 配对设计Paired sample, 配对样本Pairwise slopes, 成对斜率Parabola, 抛物线Parallel tests, 平行试验Parameter, 参数Parametric statistics, 参数统计Parametric test, 参数检验Partial correlation, 偏相关Partial regression, 偏回归Partial sorting, 偏排序Partials residuals, 偏残差Pattern, 模式Pearson curves, 皮尔逊曲线Peeling, 退层Percent bar graph, 百分条形图Percentage, 百分比Percentile, 百分位数Percentile curves, 百分位曲线Periodicity, 周期性Permutation, 排列P-estimator, P估计量Pie graph, 饼图Pitman estimator, 皮特曼估计量Pivot, 枢轴量Planar, 平坦Planar assumption, 平面的假设PLANCARDS, 生成试验的计划卡Point estimation, 点估计Poisson distribution, 泊松分布Polishing, 平滑Polled standard deviation, 合并标准差Polled variance, 合并方差Polygon, 多边图Polynomial, 多项式Polynomial curve, 多项式曲线Population, 总体Population attributable risk, 人群归因危险度Positive correlation, 正相关Positively skewed, 正偏Posterior distribution, 后验分布Power of a test, 检验效能Precision, 精密度Predicted value, 预测值Preliminary analysis, 预备性分析Principal component analysis, 主成分分析Prior distribution, 先验分布Prior probability, 先验概率Probabilistic model, 概率模型probability, 概率Probability density, 概率密度Product moment, 乘积矩/协方差Profile trace, 截面迹图Proportion, 比/构成比Proportion allocation in stratified random sampling, 按比例分层随机抽样Proportionate, 成比例Proportionate sub-class numbers, 成比例次级组含量Prospective study, 前瞻性调查Proximities, 亲近性Pseudo F test, 近似F检验Pseudo model, 近似模型Pseudosigma, 伪标准差Purposive sampling, 有目的抽样QR decomposition, QR分解Quadratic approximation, 二次近似Qualitative classification, 属性分类Qualitative method, 定性方法Quantile-quantile plot, 分位数-分位数图/Q-Q图Quantitative analysis, 定量分析Quartile, 四分位数Quick Cluster, 快速聚类Radix sort, 基数排序Random allocation, 随机化分组Random blocks design, 随机区组设计Random event, 随机事件Randomization, 随机化Range, 极差/全距Rank correlation, 等级相关Rank sum test, 秩和检验Rank test, 秩检验Ranked data, 等级资料Rate, 比率Ratio, 比例Raw data, 原始资料Raw residual, 原始残差Rayleigh's test, 雷氏检验Rayleigh's Z, 雷氏Z值Reciprocal, 倒数Reciprocal transformation, 倒数变换Recording, 记录Redescending estimators, 回降估计量Reducing dimensions, 降维Re-expression, 重新表达Reference set, 标准组Region of acceptance, 接受域Regression coefficient, 回归系数Regression sum of square, 回归平方和Rejection point, 拒绝点Relative dispersion, 相对离散度Relative number, 相对数Reliability, 可靠性Reparametrization, 重新设置参数Replication, 重复Report Summaries, 报告摘要Residual sum of square, 剩余平方和Resistance, 耐抗性Resistant line, 耐抗线Resistant technique, 耐抗技术R-estimator of location, 位置R估计量R-estimator of scale, 尺度R估计量Retrospective study, 回顾性调查Ridge trace, 岭迹Ridit analysis, Ridit分析Rotation, 旋转Rounding, 舍入Row, 行Row effects, 行效应Row factor, 行因素RXC table, RXC表S-ZSample, 样本Sample regression coefficient, 样本回归系数Sample size, 样本量Sample standard deviation, 样本标准差Sampling error, 抽样误差SAS(Statistical analysis system ), SAS统计软件包Scale, 尺度/量表Scatter diagram, 散点图Schematic plot, 示意图/简图Score test, 计分检验Screening, 筛检SEASON, 季节分析Second derivative, 二阶导数Second principal component, 第二主成分SEM (Structural equation modeling), 结构化方程模型Semi-logarithmic graph, 半对数图Semi-logarithmic paper, 半对数格纸Sensitivity curve, 敏感度曲线Sequential analysis, 贯序分析Sequential data set, 顺序数据集Sequential design, 贯序设计Sequential method, 贯序法Sequential test, 贯序检验法Serial tests, 系列试验Short-cut method, 简捷法Sigmoid curve, S形曲线Sign function, 正负号函数Sign test, 符号检验Signed rank, 符号秩Significance test, 显著性检验Significant figure, 有效数字Simple cluster sampling, 简单整群抽样Simple correlation, 简单相关Simple random sampling, 简单随机抽样Simple regression, 简单回归simple table, 简单表Sine estimator, 正弦估计量Single-valued estimate, 单值估计Singular matrix, 奇异矩阵Skewed distribution, 偏斜分布Skewness, 偏度Slash distribution, 斜线分布Slope, 斜率Smirnov test, 斯米尔诺夫检验Source of variation, 变异来源Spearman rank correlation, 斯皮尔曼等级相关Specific factor, 特殊因子Specific factor variance, 特殊因子方差Spectra , 频谱Spherical distribution, 球型正态分布Spread, 展布SPSS(Statistical package for the social science), SPSS统计软件包Spurious correlation, 假性相关Square root transformation, 平方根变换Stabilizing variance, 稳定方差Standard deviation, 标准差Standard error, 标准误Standard error of difference, 差别的标准误Standard error of estimate, 标准估计误差Standard error of rate, 率的标准误Standard normal distribution, 标准正态分布Standardization, 标准化Starting value, 起始值Statistic, 统计量Statistical control, 统计控制Statistical graph, 统计图Statistical inference, 统计推断Statistical table, 统计表Steepest descent, 最速下降法Stem and leaf display, 茎叶图Step factor, 步长因子Stepwise regression, 逐步回归Storage, 存Strata, 层(复数)Stratified sampling, 分层抽样Stratified sampling, 分层抽样Strength, 强度Stringency, 严密性Structural relationship, 结构关系Studentized residual, 学生化残差/t化残差Sub-class numbers, 次级组含量Subdividing, 分割Sufficient statistic, 充分统计量Sum of products, 积和Sum of squares, 离差平方和Sum of squares about regression, 回归平方和Sum of squares between groups, 组间平方和Sum of squares of partial regression, 偏回归平方和Sure event, 必然事件Survey, 调查Survival, 生存分析Survival rate, 生存率Suspended root gram, 悬吊根图Symmetry, 对称Systematic error, 系统误差Systematic sampling, 系统抽样Tags, 标签Tail area, 尾部面积Tail length, 尾长Tail weight, 尾重Tangent line, 切线Target distribution, 目标分布Taylor series, 泰勒级数Tendency of dispersion, 离散趋势Testing of hypotheses, 假设检验Theoretical frequency, 理论频数Time series, 时间序列Tolerance interval, 容忍区间Tolerance lower limit, 容忍下限Tolerance upper limit, 容忍上限Torsion, 扰率Total sum of square, 总平方和Total variation, 总变异Transformation, 转换Treatment, 处理Trend, 趋势Trend of percentage, 百分比趋势Trial, 试验Trial and error method, 试错法Tuning constant, 细调常数Two sided test, 双向检验Two-stage least squares, 二阶最小平方Two-stage sampling, 二阶段抽样Two-tailed test, 双侧检验Two-way analysis of variance, 双因素方差分析Two-way table, 双向表Type I error, 一类错误/α错误Type II error, 二类错误/β错误UMVU, 方差一致最小无偏估计简称Unbiased estimate, 无偏估计Unconstrained nonlinear regression , 无约束非线性回归Unequal subclass number, 不等次级组含量Ungrouped data, 不分组资料Uniform coordinate, 均匀坐标Uniform distribution, 均匀分布Uniformly minimum variance unbiased estimate, 方差一致最小无偏估计Unit, 单元Unordered categories, 无序分类Upper limit, 上限Upward rank, 升秩Vague concept, 模糊概念Validity, 有效性VARCOMP (Variance component estimation), 方差元素估计Variability, 变异性Variable, 变量Variance, 方差Variation, 变异Varimax orthogonal rotation, 方差最大正交旋转Volume of distribution, 容积W test, W检验Weibull distribution, 威布尔分布Weight, 权数Weighted Chi-square test, 加权卡方检验/Cochran检验Weighted linear regression method, 加权直线回归Weighted mean, 加权平均数Weighted mean square, 加权平均方差Weighted sum of square, 加权平方和Weighting coefficient, 权重系数Weighting method, 加权法W-estimation, W估计量W-estimation of location, 位置W估计量Width, 宽度Wilcoxon paired test, 威斯康星配对法/配对符号秩和检验Wild point, 野点/狂点Wild value, 野值/狂值Winsorized mean, 缩尾均值Withdraw, 失访Youden's index, 尤登指数Z test, Z检验Zero correlation, 零相关Z-transformation, Z变换。

一组质量管理体系术语(中英双语English Chinesereceipt (入厂接受,验收,进货handling 搬运packaging 包装storage 保存protection 保护comparison 比较identification 标识replacement of identification mark 标识标志更换maintenance of identification 标识的保持records of identification control 标识控制记录tender 标书normative document 标准文件supplemental 补充nonconforming product 不合格品control of nonconforming product 不合格品控制control procedure of nonconforming products 不合格品控制程序tendency of nonconformance 不合格倾向purchasing 采购verification of purchased product 采购的产品验证purchasing process 采购过程purchasing control procedure 采购控制程序purchasing information 采购信息reference standard 参照标准reference instructions 参照细则stockhouse 仓库measurement,analysis and improvement 测量,分析和改进measurement result 测量结果control procedure of monitoring and measuring devices 测量设备控制程序planning 策划preservation of product 产品保护control procedure for maintenance, replacement and records of product identification 产品标识的保持, 更换及记录控制程序procedure for product identification and traceability 产品标识和可追溯性程序conformity of product 产品的符合性monitoring and measurement of product 产品的监督和测量product plan 产品方案control procedure for product preservation 产品防护控制程序method of product release 产品放行方法conformity of product,product conformity 产品符合性product realization 产品实现planning of product realization 产品实现策划product characteristics 产品特性input to product requirements 产品要求的输入product status 产品状态final acceptance of product 产品最后验收procedure 程序program documents 程叙文件continual improvement 持续改进procedure for continual improvement of quality management system 持续改进质量体系程序adequacy 充分性storage location 存放地点agency personnel 代理人员submission of tenders 递交标书adjustment 调整,调节statutory and regulatory requirements 法律法规要求rework,vt 返工repair, vt 返修subcontractor 分承包方annex 附录improvement 改进improvement actions 改进措施on —the-job training 岗位技能培训responsibility of individual department and post 各部门,各岗位职责change identification 更改标记change order number 更改单编号process sheets 工艺单process specification 工艺规程procedure(process card 工艺规程(工艺卡process characteristics 工艺特性Job Description Format 工种描述单work environment 工作环境impartiality 公正性functional requirements 功能要求supplier 供方supplier evaluation procedure 供方评价程序supplier provided special processes 供方提供的特殊过程verification at supplier's premises 供方现场验证supply chain 供应链criteria for supplier selection, evaluation and re-evaluation 供应商选择、评估和再评估准则communication 沟通customer 顾客customer property 顾客财产control procedure for customer property 顾客财产控制程序customer feedback 顾客反馈Customer Service Contact Form 顾客服务联系表customer cummunications 顾客沟通customer satisfaction 顾客满意statistical analysis of customer satisfaction 顾客满意度统计分析customer complaint 顾客投诉identificaion of customer requirements 顾客要求的识别management review 管理评审records from management review 管理评审记录management review control procedure 管理评审控制程序management representative 管理者代表management responsibility 管理职责specified limits of acceptability 规定的可接受界限specified use 规定的用途process 过程complexity of processes 过程的复杂性monitoring and measurement of processes 过程的监视和测量operation of process 过程的运行status of processes 过程的状态process approach 过程方法process controls 过程控制process control documents 过程控制文件process performance 过程业绩appropriateness 合适性changes to contractor 合同的更改contract review control procedure 合同评审控制程序internet sales 互联网销售environmental conditions 环境条件monogram pragram requirements 会标纲要要求type of activities 活动类型infrastructure 基础建设infrastructure 基础设施fundamentals and vocabulary 基础与词汇control of records 记录控制technical specificaion 技术规范process trace sheet 加工跟踪单monitoring and measurement 监视和测量monitoring and measuring device 监视和测量装置control of monitoring and measuring devices 监视和测量装置控制check method 检查方法frequency of checks 检查频次calibration status 检定状态inspection and test control procedure 检验和试验控制程序identification procedure for inspection and test status 检验和试验状态标识程序inspection witness point 检验见证点inspection hold point 检验住手点buildings 建造物delivery 交付post —delivery activities 交付后的活动delivery activities 交付活动interface 接口acceptance of contract or orders 接受合同或者定单type of medium 介质类型experience 经验correction action 纠正措施Corrective action response time 纠正措施答复时间,纠正措施响应时间management procedure for corrective actions 纠正措施管理程序corrective action response times 纠正措施响应时间development activity 开辟活动traceability mark 可追溯性标志objectivity 客观性Customer Service Log 客户服务记录簿control feature 控制特性,控制细节control features 控制细则periodic assessment of stock 库存定期评估justification 理由routine 例程,惯例,常规质量职能分配表论证范围internal communication 内部沟通internal audit 内部审核internal audit procedure 内部审核程序internally controlled standard 内控标准internal audit 内审results of internal and external audits 内外部审核结果competence 能力training 培训training needs 培训需要evaluate 评价records of the results of the review 评审结果的记录review output 评审输出review input 评审输入Purchase Requisition 请购单authority 权限validation 确认concession 让步human resources 人力资源job training of personnel 人员岗位培训qualification of personnel 人员资格equipment control procedure 设备控制程序device type 设备类型order of design changes 设计更改通知单design and development control procedure 设计和开辟控制程序design and development 设计开辟design and development planning 设计开辟策划control of design and development changes 设计开辟更改控制design and development review 设计开辟评审design and development validation 设计开辟确认design and development outputs 设计开辟输出design and development inputs 设计开辟输入design and development verification 设计开辟验证design validation 设计确认design documentation 设计文件编制design acceptance criteria 设计验收准则design verification 设计验证audit program 审核大纲conduct of audits 审核行为audit criteria 审核准则production process control 生产过程控制production process control procedure 生产过程控制程序production and service provision 生产和服务提供control of production and service provision 生产和服务提供的控制validation of processes for production and service provision 生产和服务提供过程的确认production order 生产令identification and traceability 识别和可追溯性identification and traceability maintenance and replacement 识别和可追溯性维护与替换invalidate 使失效market survey 市场调研suitability 适宜性scope 合用范围controlled condition 受控状态terms and definitions 术语与定义analysis of data 数据分析sequence 顺序transfer of ownership 所有权转移system document 体系文件statistical technique 统计方法outsource(vt a process 外包过程external source 外部来源documents of external origin 外来文件outsource,vt 外协unique identification 惟一的标识maintenance 维护Document Change Control 文件更改控制Request For Document Change (RDC 文件更改需求单control of documents 文件控制documentation requirements 文件要求enquiry 问询,询价field nonconformity analysis 现场不符合分析relevance 相关性interaction 相互作用detail design 详细设计,详图设计,零件设计,施工设计sales department 销售部sales contract 销售合同checklist 校验表,一览表,检查一览表calibration 校准submission of action plans 行动计划的递交documented procedures 形成文件的程序documented statement 形成文件的声明performance requirements 性能要求licensee responsibilities 许可证持有者责任acceptance criteria 验收准则verification arrangement 验证安排verification results 验证结果customer focus 以客户为关注点, 以客户为焦点awareness 意识introduction 引言,概述,介绍normative references 引用标准application 应用visit to user 用户访问review of requirements related to the product 有关产品的要求评审competent 有能力的effectiveness 有效性determination of requirements related to the product 与产品有关的要求的确定customer —related processes 与顾客有关的过程preventive action 预防措施management procedure for preventive actions 预防措施管理程序planned results 预期的结果intended use 预期的用途procedure for competence,knowledge and training of personnel 员工能力,知识和培训程序personnel training procedure 员工培训程序supporting services 支持性服务functions 职能部门responsibility 职责assignment of responsibility 职责分工workmanship 创造工艺manufacturing acceptance criteria 创造验收准则quality policy 质量方针quality programs 质量纲领quality management system 质量管理体系quality management system planning 质量管理体系策划performance of the quality management system 质量管理体系业绩quality plan 质量计划quality records 质量记录quality objectives 质量目标quality audit 质量审核quality manual 质量手册quality problem handling form 质量问题处理单quality requirements 质量要求allocation table of quality responsibilities 质量职能分配表availability of resources 资源的可获得性resource management 资源管理allocation of resources 资源配置provision of resources 资源提供general requirements 总要求,普通要求constituent part 组成部件organization 组织continual improvement of the organization 组织的持续改进size of organization 组织的规模Organizational Diagram 组织机构图final acceptance 最终验收work instructions 作业指导书。

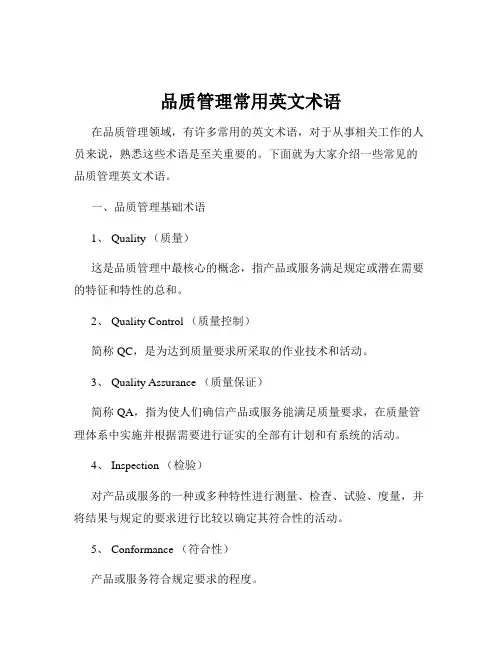

品质管理常用英文术语在品质管理领域,有许多常用的英文术语,对于从事相关工作的人员来说,熟悉这些术语是至关重要的。

下面就为大家介绍一些常见的品质管理英文术语。

一、基础术语1、 Quality 质量这是品质管理中最基本的概念,指产品或服务满足规定或潜在需要的特征和特性的总和。

2、 Quality Control (QC) 质量控制通过一系列的检验、测试和监控活动,确保产品或服务符合规定的质量标准。

3、 Quality Assurance (QA) 质量保证是为了提供足够的信任表明实体能够满足质量要求,而在质量管理体系中实施并根据需要进行证实的全部有计划和有系统的活动。

4、 Inspection 检验对产品或服务的一个或多个特性进行测量、检查、试验或度量,并将结果与规定要求进行比较以确定每项特性合格情况的活动。

5、 Test 测试通过特定的方法和设备,对产品或服务的性能、功能等方面进行检测和评估。

二、缺陷相关术语1、 Defect 缺陷产品或服务中存在的不符合规定要求的情况。

2、 Nonconformity 不合格未满足规定的要求。

3、 Minor Defect 轻微缺陷对产品或服务的功能和使用影响较小的缺陷。

4、 Major Defect 重大缺陷对产品或服务的功能和使用有较大影响的缺陷。

5、 Critical Defect 致命缺陷可能导致人身伤害、严重安全隐患或完全丧失产品或服务功能的缺陷。

三、统计分析术语1、 Statistical Process Control (SPC) 统计过程控制使用统计技术来监控和控制过程,以确保过程处于稳定状态并能够满足质量要求。

2、 Control Chart 控制图用于监控过程稳定性和识别过程变异的图表。

3、 Mean 均值一组数据的算术平均值。

4、 Median 中位数将一组数据按大小顺序排列后,位于中间位置的数值。

5、 Mode 众数一组数据中出现次数最多的数值。

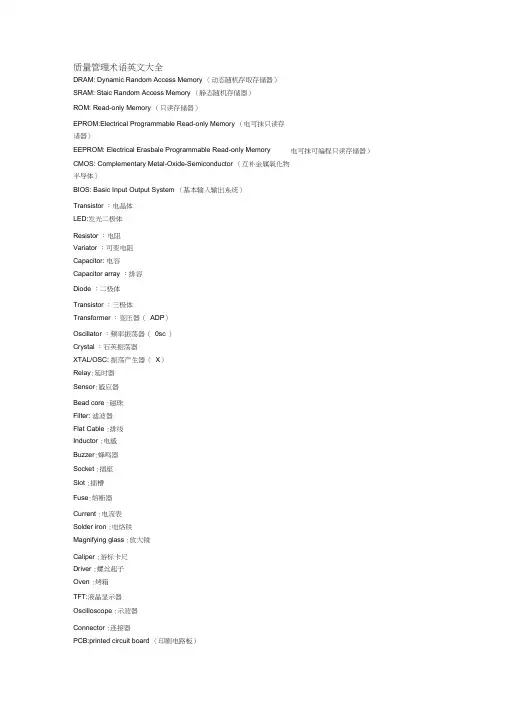

质量管理术语英文大全DRAM: Dynamic Random Access Memory (动态随机存取存储器)SRAM: Staic Random Access Memory (静态随机存储器)ROM: Read-only Memory (只读存储器)EPROM:Electrical Programmable Read-only Memory (电可抹只读存诸器)EEPROM: Electrical Erasbale Programmable Read-only Memory电可抹可编程只读存储器)CMOS: Complementary Metal-Oxide-Semiconductor (互补金属氧化物半导体)BIOS: Basic Input Output System (基本输入输出系统)Transistor :电晶体LED:发光二极体Resistor :电阻Variator :可变电阻Capacitor: 电容Capacitor array :排容Diode :二极体Transistor :三极体Transformer :变压器(ADP)Oscillator :频率振荡器(0sc )Crystal :石英振荡器XTAL/OSC: 振荡产生器(X)Relay:延时器Sensor:感应器Bead core :磁珠Filter: 滤波器Flat Cable :排线Inductor :电感Buzzer:蜂鸣器Socket :插座Slot :插槽Fuse:熔断器Current :电流表Solder iron :电烙铁Magnifying glass :放大镜Caliper :游标卡尺Driver :螺丝起子Oven :烤箱TFT:液晶显示器Oscilloscope :示波器Connector :连接器PCB:printed circuit board (印刷电路板)PCBA: printed circuit board assembly (电路板成品)PP:并行接口HDD: 硬盘FDD: 软盘PSU:power supply unit (电源供应器)SPEC:规格Attach: 附件Case: 机箱,盖子Cover :上盖Base :下盖Bazel :面板(panel)Bracket :支架,铁片Lable :贴纸Guide :手册Manual :手册,指南Card :网卡Switch :交换机Hub :集线器Router :路由器Sample :样品Gap :间隙Sponge :海绵Pallet :栈板Foam :保利龙Fiber :光纤Disk:磁盘片PROG:程序Barcode :条码System :系统System Barcode :系统条码M/B:mother board :主板CD-ROM: 光驱FAN:风扇Cable :线材Audio :音效K/B:Keyboard (键盘)Mouse :鼠标Riser card :转接卡Card reader :读卡器Screw :螺丝Thermal pad :散热垫Heat sink :散热片Rubber:橡胶垫Rubber foot :脚垫Bag :袋子Washer :垫圈Sleeve :袖套Config :机构Label hi-pot :高压标签Firmware label :烧录标签Metal cover :金属盖子Plastic cover :塑胶盖子Tape for packing :包装带Bar code :条码Tray:托盘Collecto :集线夹Holder :固定器,L 铁Connecter :连接器IDE: 集成电路设备,智能磁盘设备SCSI:小型计算机系统接口Gasket :导电泡棉AGP:加速图形接口PC I :周边组件扩展接口LAN: 局域网USB:通用串形总线架构Slim :小型化COM:串型通讯端口LPT :打印口,并行口Power cord :电源线I/O: 输入,输出Speaker:扬声器EPE:泡棉Carton :纸箱Button :按键,按钮Foot stand :脚架部门名称的专有名词QS:Quality system 品质系统CS:Coutomer Sevice 客户服务QC:Quality control 品质管理IQC:Incoming quality control 进料检验LQC:Line Quality Control 生产线品质控制IPQC:In process quality control 制程检验FQC:Final quality control 最终检验OQC:Outgoing quality control 出货检验QA:Quality assurance 品质保证SQA:Source(supplier) Quality Assurance 供应商品质保证(VQA) CQA:Customer Quality Assurance 客户质量保证PQA rocess Quality Assurance 制程品质保证QE:Quality engineer 品质工程CE:component engineering 零件工程EE:equipment engineering 设备工程ME:manufacturing engineering 制造工程TE:testing engineering 测试工程PPE roduct Engineer 产品工程IE:Industrial engineer 工业工程ADM: Administration Department 行政部RMA:客户退回维修CSDI: 检修PC:producing control 生管MC:mater control 物管GAD: General Affairs Dept 总务部A/D: Accountant /Finance Dept 会计LAB: Laboratory 实验室DOE: 实验设计HR: 人资PMC:企划RD: 研发W/H: 仓库SI: 客验PD: Product Department 生产部PA:采购(PUR: Purchaing Dept)SMT:Surface mount technology 表面粘着技术MFG:Manufacturing 制造MIS:Management information system 资迅管理系统DCC:document control center 文件管制中心厂内作业中的专有名词QT:Quality target 品质目标QP:Quality policy 目标方针QI:Quality improvement 品质改善CRITICAL DEFECT:严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(Ml)MAX:Maximum 最大值MIN:Minimum 最小值DIA iameter 直径DIM imension 尺寸LCL:Lower control limit 管制下限UCL:Upper control limit 管制上限EMI: 电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO:Engineering change order 工程改动要求(客户)ECR:工程变更需求单CPI:Continuous Process Improvement 连续工序改善Compatibility :兼容性Marking :标记DWG rawing 图面Standardization :标准化Consensus :一致Code :代码ZD:Zero defect 零缺点Tolerance :公差Subject matter :主要事项Auditor :审核员BOM:Bill of material 物料清单Rework :重工ID: identification 识别,鉴别,证明PILOT RUN: (试投产)FAI:首件检查FPIR: First Piece Inspection Report 首件检查报告FAA:首件确认SPC:统计制程管制CP: capability index (准确度)CPK: capability index of process(制程能力)PMP:制程管理计划(生产管制计划)MPI: 制程分析DAS efects Analysis System 缺陷分析系统PPB:十亿分之一Flux :助焊剂P/N: 料号L/N: Lot Number 批号Version :版本Quantity :数量Valid date :有效日期MIL-STD: Military-Standard 军用标准ICT: In Circuit Test (线路测试)ATE: Automatic Test Equipment 自动测试设备MO: Manafacture Order 生产单T/U: Touch Up (锡面修补)I/N: 手插件P/T: 初测F/T: Function Test (功能测试-终测)AS 组立P/K: 包装TQM:Total quality control 全面品质管理MDA:manufacturing defect analysis 制程不良分析(ICT)RUN-IN: 老化实验HI-pot :高压测试FMI :Frequency Modulation Inspect 高频测试DPPM: Defect Part Per Million (不良率的一种表达方式:百万分之一) 1000PPM 即为0.1% Corrective Action: (CAR 改善对策)ACC :允收REJ:拒收S/S : Sample size 抽样检验样本大小SI-SIV : Special I-Special IV 特殊抽样水平等级CON: Concession / Waive 特采ISO: 国际标准化组织ISA: Industry Standard Architecture 工业标准体制结构OBA: 开箱稽核FIFO: 先进先出PDCA:管理循环Plan do check action 计划,执行,检查,总结WIP: 在制品(半成品)S/O: Sales Order (业务订单)P/O: Purchase Order (采购订单) P/R: Purchase Request (请购单) AQL:acceptable quality level 允收品质水准LQL;Limiting quality level 最低品质水准QVL:qualified vendor list 合格供应商名册AVL :认可的供货商清单(Approved Vendor List) QCD: Quality cost delivery (品质,交期,成本)MPM:Manufacturing project management 制造专案管理KPI:Key performance indicate 重要绩效指标MVT:Manufacturing Verification Test 制造验证试产Q/R/S: Quality/Reliability/Service 质量/可靠度/服务STL:ship to line (料到上线)NTF:No trouble found 误判CIP:capacity improvement plan (产能改善计划)MRB:material review board (物料审核小组)MRB:Material reject bill 退货单JIT:just in time (即时管理)5S:seiri seiton seiso seiketsu shitsuke (整理,整顿,清扫,清洁,修养)SOP:standard operation process (标准作业程序)SIP:Specification inspection process 制程检验规格TOP: Test Operation Process (测试作业流程)WI: working instruction (作业指导书)SMD:surface mounting device (表面粘着原件)FAR:failure aualysis report 故障分析报告CAR:Corrective action report 改善报告BPR:企业流程再造(Business Process Reengineering)ISAR :首批样品认可(Initial Sample Approval Request)-JIT :实时管理(Just In Time)QCC :品管圈(Quality Control Circle)Engineering Department ( 工程部)TQEM: Total Quality Environment Management( 全面品质环境管理)PD: Production Department ( 制造)LOG: Logistics ( 后勤支持)Shipping: ( 进出口)AOQ:Average Output Quality 平均出货质量AOQL:Average Output Quality Level 平均出货质量水平FMEA:failure model effectiveness analysis 失效模式分析CRB: Change Review Board ( 工程变更会议)CSA:Customer Simulate Analysis 客户模拟分析SQMS:Supplier Quality Management System 供应商品质管理系统QIT: Quality Improvement Team 品质改善小组QIP:Quality Improvement Plan 品质改善计划CIP:Continual Improvement Plan 持续改善计划M.Q.F.S: Material Quality Feedback Sheet ( 来料品质回馈单) SCAR: Supplier Corrective Action Report ( 供货商改善对策报告) 8D Sheet: 8 Disciplines sheet ( 8D 单)PDCA:PDCA (Plan-Do-Check-Action) ( 管理循环)MPQ: Material Packing Quantity ( 物料最小包装量) DSCN: Delivery Schedule Change Notice ( 交期变更通知) QAPS: Quality Assurance Process Sheet ( 品质工程表) DRP :运销资源计划(Distribution Resource Planning)DSS:决策支持系统(Decision Support System)EC :电子商务(Electronic Commerce)EDI :电子资料交换(Electronic Data Interchange)EIS :主管决策系统(Excutive Information System)ERP :企业资源规划(Enterprise Resource Planning)FMS :弹性制造系统(Flexible Manufacture System)KM :知识管理(Knowledge Management)4L :逐批订购法(Lot-for-Lot)LTC :最小总成本法(Least Total Cost)LUC :最小单位成本(Least Unit Cost)MES :制造执行系统(Manufacturing Execution System)MPS :主生产排程(Master Production Schedule)MRP :物料需求规划(Material RequirementPlanning)MRP H :制造资源计划(Manufacturing Resource Planning)OEM :委托代工(Original Equipment Manufacture)ODM :委托设计与制造(Original Design & Manufacture)OLAP:线上分析处理(On-Line Analytical Processing)OLTP:线上交易处理(On-Line Transaction Processing)OPT :最佳生产技术(Optimized Production Technology)PDCA:PDCA 管理循环(Plan-Do-Check-Action)PDM:产品数据管理系统(Product Data Management))RCCP:粗略产能规划(Rough Cut Capacity Planning)SCM :供应链管理(Supply Chain Management)SFC :现场控制(Shop Floor Control)TOC :限制理论仃heory of Constraints)TQC :全面品质管制(Total Quality Control)FYI/R:for your information/reference 仅供参考ASAP:尽快S/T:Standard time 标准时间TPM:total production maintenance :全面生产保养ESD Wrist strap :静电环IT:information technology 信息技术,资讯科学CEO:Chief Executive Officer 执行总裁COO:Chief Operaring Officer 首席业务总裁SWOT:Strength,Weakness,Opportunity,Threat优势,弱点,机会,威胁Competence :专业能力Communication :有效沟通Cooperation :统御融合Vibration Testing :振动测试IDP:Individual Development Plan 个人发展计划MRP:Material Requirement Planning 物料需求计划MAT'S:Material 材料LRR:Lot Rejeet Rate 批退率ATIN:Attention 知会3C:Computer ,Communication , Consumer electronic消费性电子5W1H:When , Where , Who , What , Why , Ho5M: Man , Machine , Material , Method , Measurement人,机器,材料,方法,测量4MIE: Man,Material,Machine,Method,Environment人力,物力,财务,技术,时间(资源)7M1I: Manpower , Machine , Material , Method, Market , Management , Money , Information 人力,机器,材料,方法, 市场,管理,资金,资讯1 Accuracy 准确度2 Action 行动3 Activity 活动4 Analysis Covariance 协方差分析5 Analysis of Variance 方差分析6 Approved 承认7 Attribute 计数值8 Average 平均数9 Balance sheet 资产负债对照表10 Binomial 二项分配11 Brainstorming Techniques 脑力风暴法12 Cause and Effect Matrix 因果图(鱼骨图)13 CL:Center Line 中心线14 Check Sheets 检查表15 Complaint 投诉16 Conformity 合格(符合)17 Control 控制18 Control chart 控制(管制)图19 Correction 纠正20 Correlation Methods 相关分析法21 CPI: continuouse Process Improvement 连续工序改善22 Cross Tabulation Tables 交叉表23 CS: Customer Sevice 客(户)服(务)中心24 DSA: Defects Analysis System 缺陷分析系统25 Data 数据Description: 品名26 DCC: Document Control Center 文控中心27 Decision 决策、判定28 Defects per unit 单位缺点数29 Description 描述30 Device 装置31 Do 执行32 DOE: Design of Experiments 实验设计33 Element 元素34 Engineering recbnology 工程技35 Environmental 环境36 Equipment 设备37 Estimated accumulative frequency 计算估计累计数38 E Equipment Variation 设备变异39 External Failure 外部失效,外部缺陷40 FA: Failure Analysis 失效分析41 Fact control 事实管理42 Fatigue 疲劳43 FMEA: Failure Mode and Effect Analysis 失效模式与效果分析44 FP First-Pass Yield (第一次通过)合格率45 FQA: Final Quality Assurance 最终品质保证46 FQC: Final Quality control 最终品质控制47 Gauge system 测量系统48 Grade 等级49 Histogram 直方图50 Improvement 改善51 Initial review 先期审查52 Inspection 检验53 Internal Failure 内部失效、内部缺陷54 IPQC: In Process Quality Control 制程品质控制55 IQC: Incomming Quality Control 来料品质控制56 IS International Organization for Standardization 国际标准化组织57 LCL: Lower Control limit 管制下限58 LQC: Line Quality Control 生产线品质控制59 LSL: Lower Size Limit 规格下限60 Machine 机械61 Manage 管理62 Materials 物料63 Measurement 测量64 Median 中位数65 MSA: Measurement System Analysis 测量系统分析66 Occurrence 发生率67 Operation Instruction 作业指导书68 Organization 组织69 Parto 柏拉图70 PPM arts per Million (百万分之)不良率71 Plan 计划72 Policy 方针73 Population 群体74 PQA: Process Quality Assurance 制程品质保证75 Practice 实务(践)76 Prevention 预防77 Probability 机率78 Probability density function 机率密度函数79 Procedure 流程80 Process 过程81 Process capability analysis 制程能力分析(图)82 Process control and Process capability 制程管制与制程能力83 Product 产品84 Production 生产85 Projects 项目86 QA: Quality Assurance 品质保证87 QC: Quality Control 品质控制88 QE: Quality Engineering 品质工程89 QFD: Quality Function Desgin 品质机能展开(法)90 Quality 质量91 Quality manual 品质手册92 Quality policy 品质政策(质量方针)93 Random experiment 随机试验94 Random numbers 随机数95 R:Range 全距(极差)96 Reject 拒收97 Repair 返修98 Repeatusility 再现性99 Reproducibility 再生性100 Requirement 要求101 Responsibilities 职责102 Review 评审103 Reword 返工104 Rolled yield 直通率105 RPN: Risk Priority Number 风险系数106 Sample 抽样,样本107 Sample space 样本空间108 Sampling with replacement 放回抽样109 Sampling without replacement 不放回抽样110 Scatter diagram 散布图分析111 Scrap 报废112 Simple random sampling 简单随机取样113 Size 规格114 SL: Size Line 规格中心线115 Stratified random sampling 分层随机抽样116 SOP: Standard Operation Procedure 标准作业书117 SPC: Statistical Process Control 统计制程管制118 Specification 规范119 SQA: Source(Supplier) Quality Assurance 供货商品质保证120 Stage sampling 分段随机抽样121 Standard Deviation 标准差122 Sum of squares 平方和123 Taguchi-method 田口(试验)方法124 Theory 原理125 TQC: Total Quality Control 全面品质控制126 TQM: Total Quality Management 全面品质管理127 Traceablity 追溯128 Training 培训129 UCL: Upper Control Limit 管制(控制)上限130 USL: Upper Size Limit 规格上限131 Validation 确认132 Variable 计量值133 Verification 验证134 Version 版本135 VOC: Voice of Customer 客户需求136 VOE: Voice of Engineer 工程需求137 Inventory stock report: 庫存清单报告138 Sales order report: 出货报告质量人员名称类final quality control 终点质量管理人员质量保证类FAI first article inspection新品首件检查 FAA first article assurance首件确认 CP capability index 能力指数CPK capability process index 模具制程能力参数SSQA standardized supplier quality audit 合格供货商质量评估FMEA failure model effectiveness analysis失效模式分析 FQC 运作类AQL Acceptable Quality Level运作类允收质量水平 S/S Sample size 抽样检验样本大小 ACC Accept允收 REJ Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Minor 轻微的Q/R/S Quality/Reliability/Service质量/可靠度 /服务 P/N Part Number 料号L/N Lot Number 批号AOD Accept On Deviation特采UAI Use As It 特采FPIR First Piece Inspection Report 首件检查报告PPM Percent Per Million 百万分之一 制程统计品管专类SPC Statistical Process Control统计制程管制 SQC Statistical Quality Control 统计质量管理GRR Gauge Reproductiveness & Repeatability量具之再制性及重测性判断量可靠与否 DIM Dimension 尺寸DIA Diameter 直径N Number 样品数QCquality control 品质管理人员FQC IPQCOQCin process quality control 制程中的质量管理人员 最终出货质量管理人员 output quality control IQCincoming quality control 进料质量管理人员 TQCtotal quality control POCpassage quality control 全面质量管理 段检人员 QAquality assurance 质量保证人员 OQAoutput quality assurance 出货质量保证人员 QEquality engineering 质量工程人员其它质量术语类QIT Quality Improvement Team 质量改善小组ZD Zero Defect 零缺点QI Quality Improvement 质量改善QP Quality Policy 目标方针TQM Total Quality Management 全面质量管理RMA Return Material Audit 退料认可7QCTools 7 Quality Control Tools 品管七大手法通用之件类Standard Operation Procedure 制造作业规范 Inspection Specification 成品检验规范 BOM Bill Of Material 物料清单PS Package Specification包装规范SPEC Specification 规格DWG Drawing 图面 系统文件类ES Engineering Standard 工程标准CGOO China General PCE 龙华厂文件IWS International Workman Standard工艺标准 ISO International Standard Organization国际标准化组织 GS General Specification 一般规格 部类PMC Production & Material Control生产和物料控制PCC Product control center 生产管制中心PPC Production Plan Control 生产计划控制MC Material Control 物料控制DC Document Center 资料中心QE Quality Engineering 质量工程 (部 ) QA Quality Assurance 质量保证 (处 )QC Quality Control 质量管理 (课 )PD Product Department 生产部LAB Laboratory 实验室IE Industrial Engineering 工业工程R&D Research & Design设计开发部 生产类PCs Pieces 个(根 ,块等)PRS Pairs 双(对等 )CTN Carton 卡通箱PAL Pallet/skid 栈板PO Purchasing Order 采购订单 ECN ECO Engineering Change Notice Engineering Change Order PCN Process Change Notice 工程变更通知 (供货商 )工程改动要求 (客户 ) 工序改动通知PMP SIP Product Management Plan Standard Inspection Procedure生产管制计划制程检验标准程序 SOP ISMO Manufacture Order 生产单D/C Date Code 生产日期码ID/C Identification Code (供货商)识别码SWR Special Work Request 特殊工作需求L/N Lot Number 批号P/N Part Number 料号OEM Original Equipment Manufacture 原设备制造PC Personal Computer 个人计算机CPU Central Processing Unit 中央处理器A.S.A.P As Soon As Possible 尽可能快的E-MAIL Electrical-Mail 电子邮件N/A Not Applicable 不适用QTY Quantity 数量I/O input/output 输入/ 输出NG Not Good 不行,不合格C=0 Critical=0 极严重不允许APP Approve 核准,认可,承认CHK Check 确认ASS'Y Assembly 装配,组装T/P True Position 真位度5WIH When, Where, Who, What, Why, How to6M Man, Machine, Material, Method, Measurement, Message4MTH Man, Material, Money, Method, Time, How 人力,物力,财务,技术,时间(资源)SQA Strategy Quality Assurance 策略质量保证DQA Design Quality Assurance 设计质量保证MQA Manufacture Quality Assurance 制造质量保证SSQA Sales and service Quality Assurance 销售及服务质量保证LRR Lot Reject Rate 批退率SPS Switching power supply 电源箱DT Desk Top 卧式(机箱)MT Mini-Tower 立式(机箱)DVD Digital Video DiskVCD Video Compact DiskLCD Liquid Crystal DisplayCAD Computer Aided DesignCAM Computer Aided ManufacturingCAE Computer Aided EngineeringPCB Printed Circuit Board 印刷电路板CAR Correction Action Report 改善报告NG Not Good 不良WDR Weekly Delivery Requirement 周出货要求PPM Percent Per Million 百万分之一TPM Total Production Maintenance 全面生产保养MRP Material Requirement Planning 物料需计划OS Operation System 操作系统TBA To Be Assured 待定, 定缺D/C Drawing Change 图纸更改P/P Plans & Procedure 计划程序EMI Electrical-Music Industry 电子音乐工业Electrical Magnetic Interference 电子干扰RFI Read Frequency Input 读频输入MMC Maximum Material Condition MMS Maximum Material Size LMC Least Material Condition LMS Least Material Size LED lighting-emitting diode 发光二极管QBR Quarter Business Record CIP Continuous improvement process FGI Forecasted Goal Inventory CNC Computerized numeral controller B2C Business to customer B2B Business to business AVL Approved vendor list POP Procedure of packaging EOL End of lifeVDCS Vender defect correcting sheet PDCS Process defect correcting sheet GRN Goods receiving note A/R Accounting receivable A/P Accounting payable 专业词汇通用类president 董事长operator 作业员position 职务general manager 总经理special assistant 特助deputy manager |'depjuti| =vice manager 副理deputy supervisor =vice supervisor 副课长group leader 组长line leader 线长supervisor 课长responsible department 负责单位Human Resources Department人力资源部Head count 人头数production department 生产部门planning department 企划部QC Section 品管课stamping factory 冲压厂painting factory 烤漆厂molding factory 成型厂administration/general affairs dept./ 总务部production unit 生产单位meeting minutes 会议记录distribution department 分发单位subject 主题conclusion 结论decision items 决议事项pre-fixed finishing date 预定完成日Color management 颜色管理Visual management 目视管理production capacity 生产力first count 初盘first check 初盘复棹second count 复盘second check 复盘复核quantity of physical inventory second count 复盘点数量physical inventory 盘点数量physical count quantity 账面数量difference quantity 差异量spare parts physical inventory list 备品盘点清单cause analysis 原因分析waste materials 废料description 品名specification 规格model 机种work order 工令revision 版次remark 备注registration 登记registration card 登记卡to control 管制application form for purchase 请购单consume, consumption 消耗to notify 通知to fill in 填写to collect, to gather 收集statistics 统计cosmetic inspection standard 夕卜观检验规范computer case 计算机外壳(组件) personal computer enclosure 计算机机箱产品front plate 前板rear plate 后板chassis |' / 基座bezel panel 面板Hood 上盖base pan 基座bezel 面板riser card 扩充卡flat cable 排线TOP driver cage 上磁架bottom driver cage 下磁架resin film 树脂膜raw materials 原料materials 物料steel plate 钢板roll/coil material 卷料spare parts =buffer 备品plastic parts 塑料件sheet metal parts/stamping parts 冲件material check list 物料检查表finished product 成品semi-finished product 半成品good product/accepted goods/ accepted parts/good parts defective product/non-good parts 不良品disposed goods 处理品warehouse/hub 仓库packing material 包材basket蝴蝶竺plastic basket 胶筐flow chart流程窗体production tempo 生产进度现状lots of production 生产批量manufacture procedure 制程to revise, modify 修订to switch over to, switch —to, switching over 切换engineering bottleneck, project difficulty 工程瓶颈glove(s) 手套glove(s) with exposed fingers 割手套Band-Aid 创可贴Industrial alcohol 工业酒精broom 扫把mop 拖把vacuum cleaner 吸尘器rag 抹布garbage container 灰箕garbage can 垃圾箱garbage bag 垃圾袋liaison 联络单rags 抹布lamp holder 灯架to mop the floor 拖地to clean a table 擦桌子air pipe 气管delivery deadline 交货期dieworker 模工production, to produce 生产equipment 设备良品resistance 电阻beacon 警示灯coolant 冷却液crusher 破碎机club car 高尔夫球车plate 电镀power button 电源按键reset button 重置键forklift 叉车Workshop traveler 天车trailer =long vehicle 拖板车Hydraulic trolley 手压车hydraulic hand jack 油压板车casing = containerization 装箱velocity 速度patent 专利coordinate 坐标supply and demand 供求career card 履历卡barricade 隔板carton box 纸箱to pull and stretch 拉深work cell/work shop 工作间sub-line 支线bottleneck 瓶颈模具工程类plain die 简易模pierce die 冲孔模forming die 成型模progressive die 连续模stage die 工程模compound die 复合模shearing die 剪边模riveting die 铆合模feature die 公母模male die 公模female die 母模cavity 型控母模core 模心公模die change 换模to fix a die 装模to repair a die 修模punch set 上模座punch pad 上垫板punch holder 上夹板stripper pad 脱料背板up stripper 上脱料板upper plate 上模板lower plate 下模板die pad 下垫板die holder 下夹板die set 下模座bottom block 下垫脚bottom plate 下托板(底板) upper supporting blank 上承板upper padding plate blank 上垫板top plate 上托板(顶板)top block 上垫脚stripping plate 内外打(脱料板) outer stripper 外脱料板inner stripper 内脱料板lower stripper 下脱料板punch 冲头insert 入块(嵌入件) deburring punch 压毛边冲子groove punch 压线冲子stampedpunch 字模冲子round punch 圆冲子special shape punch 异形冲子bending block 折刀roller 滚轴baffle plate 挡块located block 定位块supporting block for location 定位支承块air cushion plate 气垫板air-cushion eject-rod 气垫顶杆trimming punch 切边冲子stiffening rib punch = stinger 加强筋冲子ribbon punch 压筋冲子reel-stretch punch 卷圆压平冲子guide plate 定位板sliding block 滑块sliding dowel block 滑块固定块die locker 锁模器pressure plate =plate pinch 压板thickness gauge 厚薄规cutting die, blanking die 冲裁模die block 模块folded block 折弯块sliding block 滑块location pin 定位销lifting pin 顶料销die plate, front board 模板padding block 垫块stepping bar 垫条panel board 镶块to load a die 装上模具to unload a die 御模具active plate 活动板lower sliding plate 下滑块板upper holder block 上压块upper mid plate 上中间板spring box 弹簧箱spring-box eject-rod 弹簧箱顶杆spring-box eject-plate 弹簧箱顶板bushing block 衬套cover plate 盖板guide pad 导料块pilot 导正筒trim 剪外边pierce 剪内边pocket for the punch head 挂钩槽slug hole 废料孔radius 半径shim/wedge/heel/pad/spacer/gasket 楔子torch-flame cut 火焰切割set screw 止付螺丝form block 折刀round pierce punch =die button 圆冲子shape punch =die insert 异形子stock located block 定位块metal plate 钣金miller 铣床grinder 磨床tolerance 公差score =groove 压线sliding block 滑块lathe 车active plate 活动板baffle plate 挡块cover plate 盖板groove punch 压线冲子air-cushion eject-rod 气垫顶杆spring-box eject-plate 弹簧箱顶板capability 能力parameter 参数factor 系数driller 钻床set up die 架模height of die setting up 架模高度analog-mode device 类模器inner guiding post 内导柱inner hexagon screw 内六角螺钉dowel pin 固定销coil spring 弹簧lifter pin 顶料销eq-height sleeves =spool 等高套筒pin 销lifter guide pin 浮升导料销guide pin 导正销wire spring 圆线弹簧outer guiding post 外导柱stop screw 止付螺丝located pin 定位销outer bush 外导套press specification 冲床规格die height 闭模高度flow mark 流痕welding mark 溶合痕post screw insert 螺纹套筒埋值self tapping screw 自攻螺丝stripper plate 脱料板piston 活塞handle mold 手持式模具flash mold 溢流式模具positive mold 挤压式模具split mold 分割式模具die lifter 举模器top stop 上死点bottom stop 下死点one stroke 一行程to continue, cont. 连动to grip(material) 吸料location lump, locating piece, location block reset 复位to file burr 锉毛刺embedded lump |in'bed| mp| 镶块|l stamping-missing 漏冲to tight a bolt 拧紧螺栓to loosen a bolt 拧松螺栓punched hole 冲孔to cut edge =side cut =side scrap切边to bending 折弯to pull, to stretch 拉伸engraving, to engrave 刻印stamping 油印to stake 铆合designing, to design 设计design modification 设计修改成gauge(or jig) 治具pedal 踩踏板stopper 阻挡器flow board 流水板torque 扭矩spline =the multiple keys 花键quenching 淬火tempering 回火annealing 退火carbonization 碳化alloy 合金tungsten high speed steel 钨高速的moly high speed steel 钼高速的forming 成型(抽凸,冲凸) draw hole 抽孔bending 折弯emboss 凸点dome 凸圆semi-shearing 半剪stamp mark 冲记号deburr or coin 压毛边punch riveting 冲压铆合side stretch 侧冲压平reel stretch 卷圆压平groove 压线stamp letter 冲字(料号) tick-mark nearside 正面压印tick-mark farside 反面压印冲压类定位块punch, press 冲punching machine 冲床hydraulic machine 油压机jack 升降机decoiler 整平机manufacture management 制造管理stamping, press 冲压feeder 送料机rack, shelf, stack 料架taker 取料机to reverse material 翻料to load material 上料to unload material 卸料to return material/stock to 退料scraped |'skr? pid| 报废scrape ..v. 刮;削robot 机械手production line 流水线packaging tool 打包机packaging 打包成型类well type 蓄料井insulated runner 绝缘浇道方式hot runner 热浇道runner plat 浇道模块valve gate 阀门浇口band heater 环带状的电热器spindle 阀针spear head 刨尖头slag well 冷料井cold slag 冷料渣air vent 排气道welding line 熔合痕eject pin 顶出针knock pin 顶出销return pin 回位销反顶针sleeve 套筒stripper plate 脱料板insert core 放置入子runner stripper plate 浇道脱料板guide pin 导销eject rod (bar)(成型机)顶业捧subzero 深冷处理three plate 三极式模具runner system 浇道系统stress crack 应力电裂orientation 定向sprue gate 射料浇口,直浇口nozzle 射嘴sprue lock pin 料头钩销(拉料杆) slag well 冷料井side gate 侧浇口edge gate 侧缘浇口tab gate 搭接浇口film gate 薄膜浇口flash gate 闸门浇口slit gate 缝隙浇口fan gate 扇形浇口dish gate 因盘形浇口diaphragm gate 隔膜浇口ring gate 环形浇口submarine gate 潜入式浇口tunnel gate 隧道式浇口pin gate 针点浇口runner less 无浇道sprue less 无射料管方式long nozzle 延长喷嘴方式spur 浇口; 溶waste 废料board 广告牌sliding rack 滑料架to impose lines 压线to compress, compressing 压缩character die 字模to feed, feeding 送料material change, stock change 材料变更feature change 特性变更prepare for , make preparations for 准备rotating speed, revolution 转速abnormal handling 异常处理组装类Assembly line 组装线Layout 布置图Conveyer 流水线运输带Rivet machine 拉钉机Rivet gun 拉钉枪Screw driver 起子Electric screw driver 电动起子Hydraulic machine 液压机Pneumatic screw driver 气动起子automation 自动化to stake, staking, riveting 铆合add lubricant oil 加润滑油argon welding 氩焊cylinder 油缸robot 机械手conveying belt 输送带transmission rack 输送架to draw holes 抽孔bolt 螺栓nut 螺母screw 螺丝identification tag 标示单screwdriver plug 起子插座automatic screwdriver 电动启子to move, to carry, to handle 搬运be put in storage 入库packing 包装staker = riveting machine 铆合机fit together 组装在一起fasten 锁紧(螺丝)fixture 夹具(治具)pallet/skid 栈板barcode 条形码barcode scanner 条形码扫描仪fuse together 熔合fuse machine/heat stake 热熔机processing, to process 加工delivery, to deliver 交货to return delivery to. to send delivery back to return of goods easily damaged parts 易损件standard parts 标准件to lubricate 润滑spring 弹簧spare tools location/buffer 手工备品仓spare molds location 模具备品仓tox machine 自铆机烤漆类phosphate 皮膜化成viscosity 涂料粘度alkalidipping 脱脂main manifold 主集流脉organic solvent 有机溶剂demagnetization 去磁; 消磁high-speed transmission 高速传递heat dissipation 热传rack 上料volatile 挥发性degrease 脱脂rinse 水洗alkaline etch 龄咬desmot 剥黑膜 D.I. rinse 纯水次Chromate 铬酸处理Anodize 阳性处理退货seal 封孔scraped products 报放品disposed products 处理品dismantle the die 折模auxiliary function 辅助功能heater band 加热片thermocouple 热电偶derusting machine 除锈机degate 打浇口dryer 烘干机induction 感应induction light 感应光response =reaction=interaction 感应ram 连杆edge finder 巡边器concave 凸convex 凹cold slug 冷块blush 导色gouge 沟槽; 凿槽satin texture 段面咬花witness line 证示线grit 沙砾granule =pellet =grain 细粒sand blasting 喷沙grit maker 抽粒机cushion 缓冲fillet 镶; 嵌边roller pin formality 滚针形式cam driver 铡楔shank 摸柄crank shaft 曲柄轴品质类qualified products, up-to-grade products 良品defective products, not up-to-grade products 不良品defective product box 不良品箱poor processing 制程不良poor incoming part 来件不良exposed metal/bare metal 金属裸露excessive defect 过多的缺陷critical defect 极严重缺陷major defect 主要缺陷minor defect 次要缺陷not up to standard 不合规格cosmetic defect 外观不良lack of painting 烤漆不到位slipped screw head/slippery slipped thread 滑丝missing part 漏件wrong part 错件oxidation 氧化defective threading 抽芽不良poor staking 铆合不良deficient purchase 来料不良deficient manufacturing procedure 制程不良cosmetic inspection 外观检查inner parts inspection 内部检查blister 气泡angular offset 角度偏差dent 压痕scratch 刮伤deformation 变形filings 铁削defective label 不良标签abrasion 磨损Breaking. (be)broken,(be)cracked 断裂short 射料不足nick 缺口speck 瑕疪shine 亮班splay 银纹gas mark 焦痕delaminating 起鳞speckle 斑点mildewed =moldy = mouldy 发霉deformation 变形burr( 金属)flash( 塑件) 毛边poor staking 铆合不良excessive gap 间隙过大grease/oil stains 油污inclusion 杂质shrinking/shrinkage 缩水mixed color 杂色fold of packaging belt 打包带折皱painting make-up 补漆discoloration 羿色water spots 水渍impurity 杂质Mismatch 错位failure, trouble 故障deformation 变形rust 生锈peel 脱漆Shrink 缩水Contamination 脏污water spots 水渍Gap 间隙label error 标签错误Missing label 漏贴rejection criteria 拒收标准Suspected rejects 可疑庇。

品质管理英文术语大全1. IntroductionIn the field of quality management, it is important to have a good understanding of the various terminology used. This document provides a comprehensive list of quality management terms in English.2. Quality Management Terms2.1 Quality•Quality: The degree to which a product or service meets the requirements and expectations of customers.•Quality Assurance: The process of systematically ensuring that a product or service meets specified requirements.•Quality Control: The process of checking that a product or service meets specified requirements.2.2 Quality Management Systems•ISO 9001: The international standard for quality management systems.•Quality Policy: A formal statement by an organization of its overall intentions and direction pertning to quality management.•Quality Objectives: The specific goals and targets set by an organization with respect to quality management.•Process Approach: Managing activities and resources as processes to achieve desired outcomes.2.3 Quality Planning•Quality Planning: The systematic process of identifying the quality-related activities that need to be performed to ensure that objectives are achieved.•Quality Metrics: The measurements used to evaluate the performance of processes, products, and services.•Risk Management: The process of identifying, assessing, and prioritizing risks to minimize or eliminate their impact on project objectives.2.4 Quality Assurance•Quality Audit: An independent examination to determine whether quality activities and related results comply with planned arrangements.•Supplier Quality Assurance: The process of assessing and ensuring the quality of products or services provided by suppliers.•Quality Management Review: An evaluation of the effectiveness and suitability of the quality management system.2.5 Quality Control•Statistical Process Control: The use of statistical techniques to monitor and control processes to ensure their stability and predictability.•Inspection: The process of examining a product or service to determine its conformity to specified requirements.•Defect: A nonconformance of a product or service with specified requirements.2.6 Continuous Improvement•Plan-Do-Check-Act (PDCA): A four-step iterative process for achieving continuous improvement.•Kzen: A Japanese term meaning continuous improvement.•Six Sigma: A data-driven approach forimproving the quality of processes by reducing variation and defects.3. ConclusionThis document has provided a comprehensive list of quality management terms in English. It is important for professionals in the field of quality management to have a good understanding of these terms in order to effectively communicate and implement quality management practices.。