The Vacuum Theta-Angle is Zero in Non-Abelian Gauge Theories

- 格式:pdf

- 大小:85.58 KB

- 文档页数:9

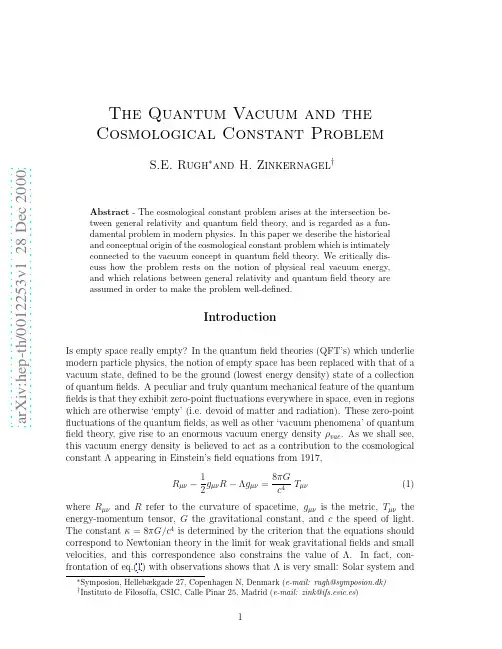

The Principle of Non-Gravitating Vacuum Energy and some of its consequencesE.I.Guendelman∗and A.B.Kaganovich†Physics Department,Ben Gurion University of the Negev,Beer Sheva84105,IsraelAbstractFor Einstein’s General Relativity(GR)or the alternatives suggested up to date,the vacuum energy gravitates.We present a model where a new measureis introduced for integration of the total action in the D-dimensional space-time.This measure is built from D scalarfieldsϕa.As a consequence of sucha choice of the measure,the matter lagrangian L m can be changed by addinga constant while no gravitational effects,like a cosmological term,are induced.Such Non-Gravitating Vacuum Energy(NGVE)theory has an infinite dimen-sional symmetry group which contains volume-preserving diffeomorphisms inthe internal space of scalarfieldsϕa.Other symmetries contained in this sym-metry group,suggest a deep connection of this theory with theories of extended ∗GUENDEL@BGUmail.BGU.AC.IL†ALEXK@BGUmail.BGU.AC.IL1objects.In general the theory is different from GR although for certain choices of L m,which are related to the existence of an additional symmetry,solutions of GR are solutions of the model.This is achieved in four dimensions if L m is due to fundamental bosonic and fermionic strings.Other types of matter where this feature of the theory is realized,are for example:scalars without potential or subjected to nonlinear constraints,massless fermions and point particles.The point particle plays a special role,since it is a good phenomeno-logical description of matter at large distances.de Sitter space is realized in an unconventional way,where the de Sitter metric holds,but such de Sitter space is supported by the existence of a variable scalarfield which in practice destroys the maximal symmetry.The only space-time where maximal symmetry is not broken,in a dynamical sense,is Minkowski space.The theory has non trivial dynamics in1+1dimensions,unlike GR.21IntroductionAs it is known,in the general theory of relativity energy is a source of gravity,whichis described by the metric tensor gµν.This makes an important difference to ideas developed forflat space physics where the origin with respect to which we measure energy does not matter,that is the energy is defined up to an additive constant.For general relativity in contrast,all the energy has a gravitational effect,therefore the origin with respect to which we define the energy is important.In quantum mechanics,there is the so called zero-point energy associated to the zero-pointfluctuations.In the case of quantumfields,such zero-pointfluctuations turn out to have an associated energy density which is infinite.In fact there is a zeropoint vacuum energy-momentum tensor of the form T vacµν=Aηµνinflat space(ηµνis the Minkowski metric),or T vacµν=Agµν+(terms∝R)in curved space.Here A is infinite.Notice that the appearance of an energy-momentum tensor proportional to gµνin Einstein’s equations is equivalent[1]to what Einstein called the‘’cosmological con-stant“or‘’Λ-term“.It was introduced by Einstein[2]in the formRµν−12gµνR−Λgµν=κ2Tµν(1)SuchΛ-term does not violate any known symmetry.Therefore,normally we would not consider excluding it,if we were to apply the arguments usually made in quantum field theory.However,we get into trouble if we note that the natural scale of such a term,obtained on dimensional grounds,is of the order of magnitude of the Planck3density.The problem is more severe once we realize that the zero point vacuumenergy appears as an infinite quantity.Indeed,in order to get agreement with observations,different sources of energy density have to compensate with each other almost exactly to high accuracy,thus creating an acute‘’fine tuning problem“.In order to explain this so called‘’cosmological constant problem“,a variety of ideas have been developed,see for example reviews[3].Among these attempts,pos-sible changes in gravity theory were studied[3],where the result was that the cosmo-logical constant appeared as an integration constant,for example,in‘’nondynamical √−g“models.The reason why such a constant should be picked zero is unclear however.In this paper we will also suggest a modification of gravity theory by imposing the principle that the vacuum energy density,to be identified with the constant part of the lagrangian density,should not contribute to the equation of motion.The realization of this idea in the model considered here,apart from leading to a geometrically interesting new theory,also leads to the possibility of new gravitational effects.2The Model2.1A new measure and generally coordinate invariant action All approaches to the cosmological constant problem have been made under the as-sumption that the invariant measure to be used for integrating the total lagrangian4density in the action is √−gd D x.In the present paper,this particular assumptionwill be modified,and the result will be that,by an appropriate generally coordinate invariant choice of the measure,the theory will not be sensitive to a change in the lagrangian density by the addition of a constant,in contrast to the Einstein-Hilbert action,where such a change generates a cosmological term.Let the measure of integration in a D dimensional space-time be chosen asΦd D x, whereΦis a yet unspecified scalar density of weight1.In order to achieve the result that the vacuum energy does not gravitate,we will start from the demand that the addition of a constant in the lagrangian density does not affect the dynamics of thetheory.This means thatLΦd D x and(L+constant)Φd D x must reproduce thesame equations of motion.This is of course achieved ifΦis a total derivative.The simplest choice for a scalar density of weight1,which is as well a total derivative,may be realized by using D scalarfieldsϕa(x)and then definingΦ≡εa1a2...a D εα1α2...αD(∂α1ϕa1)(∂α2ϕa2)...(∂αDϕaD)(2)Hereεα1α2...αD=1ifα1=0,α2=1...αD=D−1and±1according to whether(α1,α2,...,αD)is an even or an odd permutation of(0,1,...,D−1).Likewise forεa1a2...a D(a i=1,2,...,D)Therefore the total action we will consider isS=(−1κR+L m)Φd D x(3)whereκ=16πG,R is the scalar curvature and we will take L m not to depend on any of the scalarsϕa(x).Notice that if we consider parity or time reversal trans-formations,then S→−S,which does not affect the classical equations of motion.5Quantum mechanically(considering for example the path integral approach),such transformation will transform total amplitudes into their complex conjugates,there-fore leaving probabilities unchanged.Notice thatΦis the jacobian of the mappingϕa=ϕa(xα),a=1,2,...,D.If this mapping is non singular(Φ=0)then(at least locally)there is the inverse mapping xα=xα(ϕa),α=0,1...,D−1.SinceΦd D x=D!dϕ1∧dϕ2∧...∧dϕD we can think Φd D x as integrating in the internal space variablesϕa.Besides,ifΦ=0then there is a coordinate frame where the coordinates are the scalarfields themselves.ThefieldΦis invariant under the volume preserving diffeomorphisms in internal space:ϕ a=ϕ a(ϕb)whereεa1a2...a D ∂ϕ b1∂ϕa1∂ϕ b2∂ϕa2...∂ϕ bD∂ϕaD=εb1b2...b D(4)2.2Equations of motionThe equations of motion obtained by variation of the action(3)with respect to the scalarfieldsϕb areAµb ∂µ(−1κR+L m)=0(5)whereAµb ≡εa1a2...aD−1bεα1α2...αD−1µ(∂α1ϕa1)(∂α2ϕa2)...(∂αD−1ϕaD−1)(6)It follows from(2)that Aµb∂µϕb =D−1δbb Φand taking the determinant of bothsides,we get det(Aµb )=D−DD!ΦD−1.Therefore ifΦ=0,which we will assume in what6follows,the only solution for(5)is−1κR+L m=constant≡M(7)Variation of S g≡−1κRΦd D x with respect to gµνleads to the result[4]δS g=−1κΦ[Rµν+(gµν−∇µ∇ν)]δgµνd D x(8)In order to perform the correct integration by parts we have to make use the scalarfieldχ≡Φ√−g,which is invariant under continuous general coordinate transforma-tions,instead of the scalar densityΦ.Then integrating by parts and ignoring a totalderivative term which has the form∂α(√−gPα),where Pαis a vectorfield,we getδS g δgµν=−1κ√−g[χRµν+gµνχ−χ,µ;ν](9)In a similar way varying the matter part of the action(3)with respect to gµνand making use the scalarfieldχwe can express a result in terms of the standard matterenergy-momentum tensor Tµν≡2√−g∂(√−gL m)∂gµν.Then after some algebraic manipula-tions we get instead of Einstein’s equationsGµν=κ2[Tµν−12gµν(Tαα+(D−2)L m)]+1χD−32gµνχ+χ,µ;ν(10)where Gµν≡Rµν−12Rgµν.By contracting(10)and using(7),we getχ−κD−1[M+12(Tαα+(D−2)L m)]χ=0(11)By using eq.(11)we can now exclude Tαα+(D−2)L m from eq.(10):Gµν=κ2[Tµν+Mgµν]+1χ[χ,µ;ν−gµνχ](12) 7Notice that eqs.(5)and(10)are invariant under the addition to L m a constant piece,since the combination Tµν−12gµν[Tαα+(D−2)L m]is invariant.However byfixing the constant part of the difference L m−M in the solution(7)of eq.(5),we break this invariance.To give a definite physical meaning to the integration constant M, we conventionally take the constant part of L m equal to zero.It is very important to note that the terms depending on the matterfields in eq.(12)as well as in eq.(10)do not containχ-field,in contrast to the usual scalar-tensor theories,like Brans-Dicke theory.As a result of this feature of the NGVE-theory,the gravitational constant does not suffer space-time variations.However,the matter energy-momentum tensor Tµνis not conserved.Actually,taking the covariantdivergence of both sides of eq.(12)and using the identityχα;ν;α=(χ),ν+χαRαν, eqs.(12)and(11),we get the equation of matter non conservationTµν;µ=−2∂L m∂gµνgµα∂αlnχ(13)2.3Volume preserving symmetries and associated conservedquantitiesFrom the volume preserving symmetriesϕ a=ϕ a(ϕb)defined by eq.(4)which for the infinitesimal case impliesϕ a =ϕa+λεaa1...a D∂F a1a2...a D−1(ϕb)∂ϕaD(14)(λ 1),we obtain,through Noether’s theorem the following conserved quantitiesjµV =Aµa(−1κR+L m)εaa1...a D∂F a1a2...a D−1(ϕb)∂ϕaD(15)82.4Symmetry transformations with the total lagrangian den-sity as a parameter and associated conserved quantities Let us consider the following infinitesimal shift of thefieldsϕa by an arbitrary in-finitesimal function of the total lagrangian density L≡−1R+L m,that isϕ a=ϕa+ g a(L), 1(16) In this case the action is transformed according toδS= DAµaL∂µg a(L)d D x=∂µΩµd D x(17)whereΩµ≡DAµa f a(L)and f a(L)being defined from g a(L)through the equationL dg adL =d f adL.To obtain the last expression in the equation(17)it is necessary to notethat∂µAµa≡0.By means of the Noether’s theorem,this symmetry leads to the conserved currentjµL=Aµa(Lg a−f a)≡Aµa LL0g a(L )dL (18)For certain matter models,the symmetry structure is even richer(see discussion of the‘’Einstein symmetry“in the next section).The complete understanding of the group structure and the consequences of these symmetries is not known to us at present,but we will expect to report on this in future publications.93Einstein symmetry and Einstein sector of solu-tions3.1Einstein conditionWe are interested now in studying the question whether there is an Einstein sector of solutions,that is are there solutions that satisfy Einstein’s equations?First of all we see that eqs.(12)coincide with Einstein’s equations with cosmological constantκM only if theχ-field is a constant.From eq.(11)we conclude that this is possible only if an essential restriction on the matter model is imposed:2M+Tαα+(D−2)L m≡2[M+gµν∂L mµν−L m]=0.However we have not found any reasonable matter model where this condition is satisfied for M=0(recall that the constant part of L m is taken to be zero).In the case M=0this condition becomesgµν∂L m∂gµν−L m=0(19)which means that L m is an homogeneous function of gµνof degree one,in any dimen-sion.If condition(19)is satisfied then the equations of motion allow solutions of GR to be solutions of the model,that isχ=constant and Gµν=κTµν.3.2Einstein symmetryIt is interesting to observe that when condition(19)is satisfied,a new symmetry of the action(3)appears.We will call this symmetry‘’Einstein symmetry“(because(19) leads to the existence of an Einstein sector of solutions).Such symmetry consists of10the scalingsgµν→λgµν(20)ϕa→λ−1Dϕa(21) To see that this is indeed a symmetry,note that from definition of scalar curvature it follows that R→λR when the transformation(20)is performed.Since condition (19)means that L m is a homogeneous function of gµνof degree1,we see that under the transformation(20)the matter lagrangian L m→λL m.From this we conclude that(20)-(21)is indeed a symmetry of the action(3)when(19)is satisfied.3.3ExamplesThe situation described in the two previous subsections can be realized for special kinds of bosonic matter models:1.Scalarfields without potentials,includingfields subjected to non linear con-straints,like theσmodel.The general coordinate invariant action for these cases hasthe form S m=L mΦd D x where L m=1σ,µσ,νgµν.2.Matter consisting of fundamental bosonic strings.The condition(19)can be verified by representing the string action in the D-dimensional form where gµνplays the role of a background metric.For example,bosonic strings,according to our formulation,where the measure of integration in a D dimensional space-time is chosen to beΦd D x,will be governed by an action of the form:S m=L stringΦd D x,L string=−TdσdτδD(x−X(σ,τ))√−gdet(gµνXµ,a Xν,b)(22)11whereL string√−gd D x would be the action of a string embedded in a D-dimensionalspace-time in the standard theory;a,b label coordinates in the string world sheet and T is the string tension.Notice that under a scaling(20)(which means that gµν→λ−1gµν),L string→λD−2L string,therefore concluding that L string is a homogeneous function of gµνof degree one,that is eq.(19)is satisfied,if D=4.3.It is possible to formulate the point particle model of matter in a way such that eq.(19)is satisfied.This is because for the free falling point particle a vari-ety of actions are possible(and are equivalent in the context of general relativity).The usual actions are taken to be S=−mF(y)ds,where y=gαβdXαdXβands is determined to be an affine parameter except if F=√y,which is the case ofreparametrization invariance.In our model we must take S m=−mL partΦd4x withL part=−mdsδ4(x−X(s))√−gF(y(X(s)))whereL part√−gd4x would be the action of apoint particle in4dimensions in the usual theory.For the choice F=y,condition(19)is satisfied.Unlike the case of general relativity,different choices of F lead to unequivalent theories.Notice that in the case of point particles(taking F=y),a geodesic equation(andtherefore the equivalence principle)is satisfied in terms of the metric g effαβ≡χgαβevenifχis not constant.It is interesting also that in the4-dimensional case g effαβis invariant under the Einstein symmetry described by eqs.(20)and(21).Furthermore,since for point particles the theory allows an Einstein sector,we seem to have a formulation where at macroscopic distances there will be no difference with the standard GR,but where a substantial difference could appear in micro-physics.The theory could be12useful in suggesting new effects that may be absent in GR and that could constitute non trivial tests of the NGVE-theory and of GR.Deviations from GR may have also interesting cosmological consequences for the early Universe[5]In all the above cases1,2and3,solutions where thefieldχ≡Φ√is constant,−gexist if M=0and then solutions of the eq.(12)coincide with those of the Einstein theory with zero cosmological constant.Theories of fermions(including fermionic string theories)appear also can serve as candidate matter models where there will be an Einstein-Cartan sector of solutions,as will be studied elsewhere.4The Cosmological Constant Problem4.1The de Sitter solution in the context of the NGVE-theory If we allow non constantχ,we expect to obtain effects not present in Einstein gravity and cosmology.For example,as we will see,in the NGVE-theory de Sitter space is realized in an unconventional way,where the de Sitter metric holds,but such de Sitter space is supported by the existence of a variable scalarfieldχwhich in practice destroys the maximal symmetry.Effects of a non constantχcan be studiedfirst in the case where there is no matter(L m=Tµν=0).If we require maximal symmetry of the space-time metric in such a case,thefieldχmust satisfy the conditionχ,µ;ν=cχgµνwhere c is a constant. Geometry allows[6]suchχonly for the value of c=−Rand it is then possible12to have maximally symmetric metric with any value of R=−κM.For example a13de Sitter solution of eqs.(11)and(12)(taking D=4)is ds2=dt2−a2d x2,where a=a0exp(λt),χ=χ0exp(λt)andλ2=κM/12.Let us consider the point particle model(considered at the end of section3) which satisfies the Einstein condition.In this case the physics of the de Sitter space is described by geodesics with respect to the effective metric g eff.Notice that such aαβ=dτ2−τ6d x2,whereτ=τ0exp(λt) metric corresponds to a power law inflation:ds2effwe notice that there are not andλ2=κM/12.By examining the physical metric g effαβthe10Killing vectors of the de Sitter space.We see that although the metric gµνis maximally symmetric,the physical geometry is not maximally symmetric.4.2Particle creation,possible instability of the de Sitterspace and the Parker conditionSome years ago,Parker[7]suggested a possible mechanism,based on particle pro-duction in the early universe,for selecting a zero cosmological constant.The basic assumption Parker made was that of the existence of an underlying theory where the cosmological constant can be dynamically adjusted by a process based on some-thing like the familiar‘’Lenz’s law“,which requires that the equilibrium condition be achieved after the cosmological constant relaxes to a certain value.The idea is based on the fact that for a4-dimensional homogeneous,isotropic cosmological background,there is not real particle creation for massless conformally coupled scalarfields(MCCSF)satisfyingφ+Rφ=0(23)614If there are massless minimally coupled scalarfields(MMCSF)or gravitons,in general particle creation takes place.However,when considering particle creation effect in a given background metric with zero scalar curvature,the MCCSF and MMCSF theories behave in the same way[7].Also for such a background R=0,one expects no graviton production[7].The existence of radiation with Tµµ=0does not affect these conclusions[7].4.3Realization of the Parker cosmological condition in theEinstein sector of the NGVE-theoryIn the context of the NGVE-theory,we have that states with R=0exist among many other possible states,provided the integration constant M is chosen zero and the matter lagrangian on shell equals zero(see eq.(7)).The last condition is satisfied, for example,for the case of massless fermions and for electromagnetic radiation with Tµ=L em=E2−B2=0.Such a state may be realized apparently for the universe (em)µfilled by ultrarelativistic matter.As Parker[7]points out,a de Sitter space,although not satisfying the condition R=0,has a chance however of being stable due to its maximal symmetry.This seems in accordance with the calculations of Candelas and Raine[8].In our case however even this possibility seems to be excluded.Indeed,for the de Sitter space in the NGVE-theory we haveχ=χ(t)=constant which means explicit breaking of maximal symmetry since for a maximally symmetric space a scalarfield must obey[9] the condition∂µχ=0.Therefore we expect that in the NGVE-theory the de Sitter15space suffers from the above mentioned instability towards particle production.Only flat space-time allows the possibility of maximal symmetry since in this caseχmay be constant,which is clear from eq.(11).It is interesting to observe that the Parker condition in the framework of the NGVE-theory,when applied to the above mentioned case of an early universe dom-inated by ultrarelativistic matter(massless fermions and electromagnetic radiation with Tµ=L em=E2−B2=0)is a particular realization of the Einstein (em)µcondition(19).Notice that once the Einstein condition is satisfied,the direct cou-pling of theχ-field with matter disappears(see eq.(11)).When this decoupling does not exist,like for example is apparent from eq.(13),for the small matter perturba-tions around a de Sitter space,we expect a tendency for any homogeneousχstate to loose energy to inhomogeneous degrees of freedom(from the point of view of ther-modynamics a transfer of energy from homogeneous degree of freedom of theχ-field into inhomogeneous degrees of freedom is more preferable than the reverse since the inhomogeneous modes are more numerous).An effective way to describe this would be the introduction of a friction term in the equation of motion forχ.We expect this would lead to the decay of the de Sitter space towards a Friedmann epoch with M=0andχ=constant.The nonequilibrium dynamics explaining the details of how the relaxation of the cosmological constant is achieved,or in our case how the constant M is changed to zero,is a subject for future studies.165DiscussionThere are many directions in which research concerning the NGVE-theory could be expanded.A subject of particular interest consists of the study of the NGVE-theory in1+1dimensions.In this case,the model gives equations that coincide with those of Jackiw and Teitelboim[10]when the constant of integrationκM in the NGVE-theory is identified with the constant scalar curvature which is imposed on the vacuum solutions of that model[10]and where ourfieldχplays the same role,in the equations, as the lagrange multiplierfield in the Jackiw-Teitelboim model[10].Another model that resembles the NGVE-theory studied here is the non dynami-cal √−g theory(NDSQR)(for reviews,see articles of Weinberg and Ng[3]).For theNDSQR-theory,also any de Sitter space is a solution of the theory and the constant curvature of the vacuum solutions also appears as an integration constant.The differ-ences between the NDSQR-theory and the NGVE-theory are however very obvious. To mention just some:(a)The NDSQR-theory does not exist as a non trivial theory in1+1dimensions,while the NGVE-theory does.(b)The4-D de Sitter solutions do not posses the maximal symmetry for the NGVE theory case(due to the fact that the scalarfieldχis not constant)while maximal symmetry is respected in the NDSQR-theory whereflat space and de Sitter space have the same symmetry.(c)In the NGVE-theory,the matter energy-momentum tensor is not covariantly conserved, while in the NDSQR-theory it is.(d)In addition,the NDSQR-theory is for all prac-tical purposes indistinguishable from GR,while the NGVE-theory is really a new physical theory,which could contain an Einstein sector of solutions,but in addition17there is the potential offinding out new gravitational effects.We should also point out that a more thorough study of the infinite dimensional symmetry found here should be made.In particular the restrictions on the possible induced terms in the quantum effective action seem to be strong if the symmetries(14) and(16)remain unbroken after quantum corrections are also taken into account.In particular,symmetry under the transformations(16)seems to prevent the appearance of terms of the form f(χ)Φ(except of f(χ)∝1)in the effective action which although is invariant under volume preserving transformations(14),breaks symmetry(16). The case f(χ)∝1is not forbidden by symmetry(16)and appearance of such a termwould mean inducing a‘’real“cosmological term,i.e.a term of the form √−gΛin theeffective action.However,appearance of such a term seems to be ruled out becauseof having opposite parity properties to that of the action given in(3).Of course,in the absence of a consistently quantized theory,such arguments are only preliminary. Nevertheless it is interesting to note that if all these symmetry arguments are indeed applicable,this would imply that the scalarfieldsϕa can appear in the effective action only in the integration measure,that is they preserve their geometrical role.The physical meaning of the symmetry(16)is puzzling.To get a feeling of the meaning of this symmetry,it is interesting to notice that such transformation becomesnon trivial if L≡−1κR+L m is not a constant,in contrast to what we have studied so far in this paper.For the derivation of eq.(7),which implies L=constant,we have assumed thatΦ=0.AllowingΦ=0in some regions of space-time should be equivalent to allowing for‘’defects“which could be string-like or take the shape18of other extended objects.In such event,the symmetry(16)would become non trivial precisely at the location of such defects,a situation that reminds us of the reparametrization invariance of theories of extended objects.In this context,it becomes then natural to explore the possibility that all the matter could arise as regions of space-time whereΦ=0,i.e.as defects described above.This could be a way to realize an idea of Einstein and Infeld[11]that matter should arise as singular points from a pure gravitational theory.In their words[11]:‘’All attempts to represent matter by an energy-momentum tensor are unsatisfactory and we wish to free our theory from any particular choice of such a tensor.Therefore we shall deal here only with gravitational equations in empty space,and matter will be represented by singularities of the gravitationalfield“.In GR,however,such mechanism could lead only to singularities of the metric,i.e.black holes(if the cosmic censorship hypothesis[12]is correct).Although black holes are interesting objects, they are of course not satisfactory candidates for the description of the matter we see around.Defects that appear in the NGVE-theory are singularities of the measure which are not necessarily singularities of the metric.Furthermore the existence of the symmetry(16)suggests to us a close connection between these singularities and reparametrization invariance of extended objects as mentioned above.Finally,the crucial question concerning the large distance behavior of the model should be analyzed in detail.In particular,the study of general conditions under which the theory contains an Einstein sector of solutions or a set of solutions which deviate very little from those of the Einstein theory must be studied.In this respect,19let us recall that we have already reviewed a number of cases where the Einstein condition and Einstein symmetry hold.In these cases the theory is guaranteed to contain an Einstein sector of solutions.However,it would be interesting to study situations where the answer is not so clear.We have here in mind cases where neither the Einstein condition or the Einstein symmetry are exactly satisfied,but that they could appear only in the long distance behaviour of the theory,without being satisfied by the underlying microscopic theory. This possibility is suggested by the fact that the point particle limit allows a formu-lation consistent with the Einstein symmetry.In the point particle limit however, the underlying microscopic(field theoretic)structure is‘’integrated out“and in this way disappears.This of course suggests that the integration of microscopic degrees of freedom could,under very general circumstances,lead to a macroscopic theory satis-fying the Einstein symmetry.The answer to this last question will of course demand further research.6AcknowledgementsWe would like to thank H.Aratyn,J.Bekenstein,K.Bronnikov,A.Feinstein,J.Friedman, A.Guth,A.Heckler,J.Ib´a˜n ez,C.Kiefer,R.Mann,V.Mostepanenko,L.Parker,D.Pav´o n, J.Perez-Mercader,Y.Peleg and H.Terazawa for interesting conversations.20。

高一英语天文术语单选题30题1. The ______ is the largest planet in our solar system.A. EarthB. MarsC. JupiterD. Venus答案:C。

解析:在太阳系中,木星(Jupiter)是最大的行星。

地球(Earth)、火星(Mars)和金星(Venus)都比木星小,所以A、B、D选项错误。

2. Which of the following is a satellite of the Earth?A. The SunB. The MoonC. MarsD. Jupiter答案:B。

解析:月球 The Moon)是地球的卫星。

太阳 The Sun)是恒星,火星(Mars)和木星(Jupiter)是行星,它们都不是地球的卫星,所以A、C、D选项错误。

3. The ______ is closest to the Sun.A. MercuryB. VenusC. EarthD. Mars答案:A。

解析:水星(Mercury)是离太阳最近的行星。

金星(Venus)、地球 Earth)和火星 Mars)距离太阳都比水星远,所以B、C、D 选项错误。

4. Which planet is known as the "Red Planet"?A. EarthB. MarsC. JupiterD. Saturn答案:B。

解析:火星 Mars)被称为“红色星球”,因为它的表面呈现出红色。

地球(Earth)不是“红色星球”,木星(Jupiter)和土星 Saturn)也不是,所以A、C、D选项错误。

5. A ______ is a huge ball of gas that gives off light and heat.A. planetB. satelliteC. starD. comet答案:C。

解析:恒星(star)是巨大的气态球体,能发出光和热。

Features / BenefitsOverviewThe MPS150 is an easy to use, yet highly-precise manual probe platform for wafers and substrates up to 150 mm. It supports a wide variety of applications and accessories. The modular and flexible design allows to configure and individualize the system to match application requirements. With the System Integration for Measurement Accuracy (SIGMA™) kit, MPS150 can be seamlessly integrated with third-party instrumentation, ensuring the shortest signal bining the MPS150 probe system with our measurement expertise, FormFactor provides pre-configured application-focused probing solutions for a variety of applications, and an integrated measurement solution for accurate S-parameter measurements, which include everything you need to achieve accurate measurement results in the shortest time, with maximum confidence.Note: For physical dimensions and facility requirements, refer to the MPS150 Facility Planning Guide.Mechanical PerformanceChuck StageTravel155 mm x 155 mm (6 in. x 6 in.)Resolution 5 µmPlanarity over 150 mm (6 inch)< 10 µmLoad stroke, Y axis90 mmZ height adjustment range10 mmZ contact / separation / load stroke0-3 mm adjustableTheta travel (standard)360°Theta travel (fine)± 8°Theta resolution7.5 x 10-3 gradientManual Microscope Stage (On Bridge)Travel range50 mm x 50 mm (2 in. x 2 in.) / 150 mm x 100 mm (6 in. x 4 in)Resolution≤ 5 µm (0.2 mils)Scope lift Manual, tilt-back or linear pneumaticProgrammable Microscope Stage*Travel range50 mm x 50 mm (2 in. x 2 in.)Resolution0.25 µm (0.01 mils)Scope lift Programmable 130 mm* Electronics box for manual systems (P/N 157-137) requiredPlaten SystemPlatenPlaten space (typical)Universal platen: space for up to four DPP2xx/DPP3xx/DPP4xx/RPP210 or up to twelve DPP105 positionersUniversal platen with optional probe card adapter: space for up to eight DPP2xx/DPP3xx/DPP4xx/RPP210or up to sixteen DPP105 positionersMMW platen: space for up to four RPP305 or two LAP positionersZ-Height adjustment range Maximum 40 mm (depending on configuration)Minimum platen-to-chuck height16 mm (universal platen)Separation lift200 µmSeparation repeatability< 1 µmVertical rigidity / force 5 µm / 10 N (0.2 mils / 2.2 lb.)Accessory mounting options Universal platen: magnetic, vacuumRF-platen: bolt-down, magneticWafer ChuckStandard Wafer ChuckDiameter150 mmMaterial Stainless steelDUT sizes supported Shards or wafers 25 mm (1 in.) through 150 mm (6 in.)Vacuum ring diameter Universal: 4 mm, 7 mm, 22 mm, 42 mm, 66 mm, 88 mm, 110 mm, 132 mmStandard: 22 mm, 42 mm, 66 mm, 88 mm, 110 mm, 132 mmVacuum ring actuation Universal: all connected in meander, center hole 1.5 mm diameterStandard: mechanically selected, center hole 1.0 mm diameterChuck surface Planar with centric-engraved vacuum groovesSurface planarity≤ ± 3 µmRigidity< 15 µm / 10 N @ edgeRF Wafer ChuckDiameter150 mm with two additional AUX chucksMaterial Stainless steel with HF/OPTO surface (flat with 0.7 mm holes)DUT sizes supported Main: single DUTs down to 3 mm x 5 mm size or wafers 25 mm (1 inch) through 150 mm (6 inch)AUX: up to 18 mm x 26 mm (1 in. x 0.7 inch) eachVacuum hole sections (diameter)22 mm, 42 mm, 66 mm, 88 mm, 110 mm, 132 mm (four holes in center with 2.5 mm x 4.3 mm distance) Vacuum hole actuation Mechanically selectedChuck surface Planar with 0.7 mm diameter holes in centric sectionsSurface planarity≤ ± 3 µmRigidity< 15 µm / 10 N @ edgeTriax Wafer ChuckDiameter150 mm with three additional AUX chucks (two with vacuum fixation)Material Stainless steelDUT sizes supported Main: wafers 50 mm through 150 mmAUX: up to 18 mm x 26 mm (1 inch x 0.7 inch) eachVacuum hole sections (diameter)50 mm, 100 mm, 150 mm (2 inch, 4 inch, 6 inch)Vacuum hole actuation3x vacuum switch unitChuck surface Planar with 0.4 mm diameter holes in centric sectionsSurface planarity≤ ±5 µmNon-Thermal ChucksNote: Results measured with non-thermal chuck at standard probing height (10,000 µm) with chuck in a dry environment. Moisture in the chuck may degrade performance.MPS-CHUCK150-COAXOperation voltage Standard: in accordance with EC 61010, certificates for higher voltages available upon requestIsolation*> 2 GΩCapacitance100 pF* Factory test with multimeter with maximum 2 GΩ range.Non-Thermal Chucks (continued)MPS-CHUCK150-RFOperation voltage Standard: in accordance with EC 61010, certificates for higher voltages available upon request Isolation (Signal-Shield)> 200 GΩCapacitance (Signal-Shield)80 pFMPS-CHUCK150-TRIAX1In Purged Shield Enclosure Open2Humidity2< 30%50%Leakage (1 sigma)< 50 fA< 200 fALeakage (average)NA NALeakage (P-P)< 100 fA< 1000 fAResistance (F-G)> 1 TΩ> 1 TΩResistance (G-S)> 1 TΩ> 1 TΩResistance (F-S)> 1 TΩ> 1 TΩResidual capacitance @ 3 pA Tx< 20 pF< 20 pFCapacitance @ 300 pA (F-G)< 400 pF< 400 pFCapacitance @ 300 pA (G-S)< 400 pF< 400 pFTRIAXIAL PROBE ARMS1Standard Triaxal Arm (PN 100525)Advanced Triax Option (PN 157-450 and DCP)In Purged Shield Enclosure In Purged Shield EnclosureHumidity3< 30%< 30%Leakage (1 sigma)< 5 fA< 2 fAResistance (F-G)> 20 TΩ> 50 TΩResistance (G-S)> 4 TΩNAResidual capacitance @ 3 pA Tx< 1 pF< 0.3 fFCapacitance @ 300 pA (F-G)< 300 pF< 150 pFCapacitance @ 300 pA (G-S)< 400 pF< 200 pFCOAXIAL PROBE ARMS1Coaxial Probe Arm (PN 100561)Open / Ambient2, 4Resistance (Signal-Shield)> 20 TΩCapacitance (Signal-Shield)< 200 pF1. T est conditions: B1500 with SMU B1517, triax test cables and adapter ground unit (104-337). Resistor test setup: 10 V HR Mode PCL Factor 15.Capacitor test setup: 3 pA / 300 pA HR Mode PCL Factor 4. Leakage test setup: 10 V HR Mode PCL Factor 40.2. Depending on DC-/AC-noise environment.3. Environment data (not specification data).4. Depending on humidity.Thermal Chuck PerformanceNote: For details on facility requirements, refer to the Facility Planning Guide for your thermal system.MPS-TC150-CTX-300C1Triax @ 30°C Triax @ 200°C Triax @ 300°C Breakdown voltage2a Force-to-guard≥ 500 V≥ 500 V≥ 500 VGuard-to-shield≥ 500 V≥ 500 V≥ 500 VForce-to-shield≥ 500 V≥ 500 V≥ 500 V Resistance3a Force-to-guard≥ 1 x 1012≥ 1 x 1011≥ 5 x 109Guard-to-shield≥ 1 x 1011≥ 1 x 1010≥ 1 x 109Force-to-shield≥ 5 x 1012≥ 2 x 1011≥ 5 x 109 Chuck leakage4≤ 100 fA≤ 10 pA≤ 300 pA Residual capacitance≤ 50 pFSettling time6 @ 10 V 50 fA500 ms (typical)MPS-TC150-CTX-300C (using coax-triax adapter)1, 5Coax @ 30°C Coax @ 200°C Coax @ 300°C Breakdown voltage2a≥ 500 V≥ 500 V≥ 500 V Resistance3a Signal-to-shield≥ 1 x 1012≥ 1 x 1011≥ 5 x 109 Chuck leakage4≤ 600 fA≤ 15 pA≤ 1 nA Residual capacitance≤ 600 pFMPS-TC150-RF-300C1, 5Coax @ 30°C Coax @ 200°C Coax @ 300°C Breakdown voltage2a≥ 500 V≥ 500 V≥ 500 V Resistance3a Signal-to-shield≥ 1 x 1012≥ 1 x 1011≥ 5 x 109 Chuck leakage4≤ 600 fA≤ 15 pA≤ 1 nA Residual capacitance≤ 600 pFMPS-TC150-200C1Triax @ 30°C Triax @ 200°CBreakdown voltage2b Force-to-guard≥ 500 V≥ 500 VGuard-to-shield≥ 500 V≥ 500 VForce-to-shield≥ 500 V≥ 500 VResistance3b Force-to-guard≥ 5 x 1012≥ 5 x 1011Guard-to-shield≥ 2 x 1012≥ 8 x 1010Force-to-shield≥ 7 x 1012≥ 5 x 1011Chuck leakage4≤ 35 fA≤ 40 fAResidual capacitance6≤ 20 pFSettling time7 @ 10 V 50 fA500 ms (typical)Thermal Chuck Performance (continued)MPS-TC150-200C (using coax-triax adapter)1, 5Coax @ 30°C Coax @ 200°CBreakdown voltage2b≥ 500 V≥ 500 VResistance3b Signal-to-shield≥ 5 x 1012≥ 5 x 1011Chuck leakage4≤ 600 fA≤ 7.5 pAResidual capacitance6≤ 600 pF1. P erformance values determined using EMV shielded chamber. Actual value depend on electromagnatic surrounding and shielding situation of the probestation.2a. For fully-baked chuck: 90°C for 60 minutes + 200°C for 240 minutes + 300°C for 480 minutes.2b. For fully-baked chuck: 90°C for 60 minutes + 200°C for 800 minutes3a. For fully-baked chuck: 90°C for 60 minutes + 200°C for 240 minutes + 300°C for 480 minutes; controller on; 21-23C° environment with ≤ 50% humidity.3b. For fully-baked chuck: 90°C for 60 minutes + 200°C for 800 minutes; 21-23C° environment with ≤ 50% humidity.4. O verall leakage current is comprised of two separate components: 1) offset, and 2) noise. Offset is the DC value of current due to instrument voltageoffset driving through isolation resistance. Noise is low frequency ripple superimposed on top of offset and is due to disturbances in the probe station environment.*****************************************************************************************************************(1σ).5. Chuck: Guard-Shield shorted, B1500: triax, guard open.6. Depends on test environment7. Settling time is measured with B1500 with SMUB1517 - ST@10V CMI program or equivalentTransition TimeHeating Cooling30°C to 100°C°100°C to 200°C200°C to 300°C300°C to 200°C200°C to 100°C100°C to 30°C MPS-TC150-CTX-300C145 sec155 sec300 sec145 sec245 sec1525 secMPS-TC150-RF-300C180 sec300 sec540 sec165 sec310 sec1650 secMPS-TC150-200C155 sec260 sec na na120 sec425 secMPS-TC150-CTX-300C and MPS-TC150-RF-300C SpecificationsTemperature range+ 30°C to 300°CTemperature accuracy± 0.1°C (with calibrated controller)Temperature resolution0.1°CTemperature uniformity≤ 0.5°C @ 30°C, ≤ 3.0°C @ 300°CChuck flatness≤ 30 μm (0.12 mils) @ +30°C to 300°CAudible noise< 58 dB(A) (normal operation); < 79 dB(A) (max. cooling mode)MPS-TC150-200CTemperature range+ 30°C to 200°CTemperature accuracy± 0.5°CTemperature resolution0.1°CTemperature uniformity≤ ±1°C (30°C - 200°C)Chuck flatness≤ 30 μm (0.12 mils) @ +30°C to 200°CAudible noise< 54 dB(A) (normal operation); < 68 dB(A) (max. cooling mode)Ordering InformationPre-Configured Application-Focused PackagesEPS150 COAX / COAX PLUS EPS150TRIAX EPS150RFEPS150MMW EPS150FA EPS150TESLAIntegrated Measurement SolutionRFgeniusPart Number DescriptionEPS150COAX150 mm manual probing solution for DC parametric testEPS150COAXPLUS150 mm manual probing solution for DC parametric test (including platen lift)EPS150TRIAX150 mm manual probing solution for low-noise measurementsEPS150RF150 mm manual probing solution for RF applicationsEPS150MMW150 mm manual probing solution for mmW, THz and load pull applicationsEPS150FA150 mm manual probing solution for failure analysisRFgenius-xx*RFgenius education kit, turn-key solution for measurements up to 4.5/6.5/9/14/20/26.5 GHz 181-669FormFactor certified laptop for RFgenius-xx (optional)*** Enter the frequency range for a VNA of your choice. Example: RFgenius-4 for 4.5 GHz. RFgenius-26 for 26.5 GHz.** M inimum requirement for a laptop to be supplied by a user: Windows 7 or 10 (64 bit), Intel i5 6th Gen or newer, 4 GB memory or more (16 GB recommended),2 GB disk space or more, 1024 x 768 resolution, USB 3.o port.Corporate Headquarters 7005 Southfront Road Livermore, CA 94551Phone: © Copyright 2018 FormFactor, Inc. All rights reserved. FormFactor and the FormFactor logo are trademarks of FormFactor, Inc. All other trademarks are the property of their respective owners.All information is subject to change without notice.MPS150-DS-0518Regulatory ComplianceCertificationCE, cNRTLus, CBWarrantyWarranty* Fifteen months from date of delivery or twelve months from date of installation Service contracts Single and multi-year programs available to suit your needs*See FormFactor’s T erms and Conditions of Sale for more details.。

五年级英语宇宙探索发现单选题50题1. The ____ is the only planet known to have life.A. MarsB. MoonC. EarthD. Sun答案解析:C。

本题考查对星球相关词汇的认识。

选项A“Mars”是火星,目前没有发现有生命存在。

选项B“Moon”是月球,它是地球的卫星,不是行星,也没有生命。

选项C“Earth”地球,是我们所知道的唯一有生命的行星,符合题意。

选项D“Sun”是太阳,它是恒星,不是行星,更没有生命。

2. Which planet is called the "Red Planet"?A. VenusB. MarsC. JupiterD. Saturn答案解析:B。

这题考查特定星球的别名相关词汇。

选项A“Venus”是金星,它没有“Red Planet”这个别名。

选项B“Mars”火星,因其表面呈现红色,被称为“Red Planet”,正确。

选项C“Jupiter”是木星,与“Red Planet”无关。

选项D“Saturn”是土星,也不是“Red Planet”。

3. The Moon is a ____ of the Earth.A. starB. planetC. satelliteD. comet答案解析:C。

本题考查月球与地球关系相关的词汇。

选项A“star”是恒星,月球不是恒星。

选项B“planet”是行星,月球不是行星。

选项C“satellite”卫星,月球是地球的卫星,正确。

选项D“comet”是彗星,与月球的性质完全不同。

4. Which planet has a big red spot?A. MarsB. JupiterC. NeptuneD. Uranus答案解析:B。

这里考查对星球特征相关词汇的掌握。

选项A“Mars”火星没有大的红斑。

选项B“Jupiter”木星有一个很大的红斑,正确。

五年级英语天文现象单选题50题1. There are eight planets in the solar system. Which one is the biggest?A. EarthB. JupiterC. MarsD. Venus答案:B。

本题考查太阳系中行星的大小知识。

地球(Earth)不是最大的行星;火星(Mars)比木星小;金星(Venus)也比木星小。

木星 Jupiter)是太阳系中最大的行星。

2. The sun is a star. What gives the sun its energy?A. WaterB. CoalC. Nuclear fusionD. Wind答案:C。

本题涉及太阳能量来源的知识。

水(Water)、煤炭(Coal)和风(Wind)都不是太阳的能量来源。

太阳的能量来自核聚变(Nuclear fusion)。

3. Which planet is known as the "Red Planet"?A. MercuryB. SaturnC. MarsD. Uranus答案:C。

本题考查对行星特征的了解。

水星(Mercury)不是红色的;土星(Saturn)有环,但不是红色的;天王星(Uranus)也不是红色的。

火星 Mars)表面呈现红色,被称为“红色星球”。

4. How many moons does Saturn have?A. 53B. 62C. 82D. 100答案:C。

本题考查土星卫星数量的常识。

土星有82 颗卫星,A 选项53 颗、B 选项62 颗、D 选项100 颗均不符合实际情况。

5. Which is the closest planet to the sun?A. MercuryB. VenusC. EarthD. Mars答案:A。

本题考查太阳系行星与太阳的距离。

金星 Venus)、地球 Earth)、火星 Mars)距离太阳都比水星远,水星 Mercury)是距离太阳最近的行星。

Symbol complete(符号大全)Symbol Daquan 2010-07-22 12:29Formulas and notations in mathematical physics: Alpha alpha: Alfa AlphaBeta beta beta: BetaGamma gamma gamma: GammaDelta DelteEpsilon epsilon: episilon EpsilonSome of the zeta Jieta: ZetaEpsilon ETA: yita EtaTheta theta theta: ThetaI l: erota IotaKappa kappa Kapa: KappaA: Lamuda Lambda.Mu Mu: Bartholomew MuUpsilon V: Ao NuE: Roxy Xi.April: Mike Omicron / European roundPi Pi: send PiP P: soft RhoSigma: Sigma SigmaT: t TauR V: Yu Puxilong UpsilonPhi Phi: Fai PhiX x: ChiOnly psi pusai: PsiOmega Omega: Omega OmegaSymbol complete:(1) the number of symbols: such as: I, 2 + I, a, x, natural logarithm base e, PI pi.Such as: (2) operational symbol plus (+) and minus (-) sign, (* or *), division (or / /), the union of two sets (U), (a), Reagan (intersection), log (log, LG, LN), (:), differential ratio (d), integral (formula).(3) the relationship between symbols: such as "=" is equal to "value" or "," is the approximate symbol, not equal to is not equal, ">" is greater than the symbol, "<" is less than the symbol, "said variable trend," ~ "is similar to" Te "is congruent symbol. No," "parallel" is "an" symbol is the vertical symbol, "/" is "and" the proportion of symbols, symbols belong to.(4) a combination of symbols: such as parentheses (brackets) "," [] "braces" {} "line"-"(5) the nature of symbols such as a "+", "-" sign, the absolute value of the symbol """(6) ellipsis: (a) such as triangle, sine (SIN), X function (f (x)), limit (LIM), because (dreams), so (H0), sum (sigma), product (II), from each N element R from all the different elements the number of combinations (C), power (aM), factorial (!) Etc..Symbolic meaningH-infinity infinityPI.The absolute value of the |x| functionU set withA set intersectionIs greater than or equal toIs less than or equal toIt is less than or equal to the congruenceLn (x) the logarithm based on eLG (x) with 10 as the base of the logarithmFloor (x) on the integral functionCeil (x) under the integral functionX mod y for remainderDecimal part X - floor (x)Formula F (x) x integralFormula [a:b]f (x) integral to B a x.P equals 1, or 0[1 = k = n]f (k) of the N sum, can be extended to many Such as: Sigma [n, is, prime][n < 10]f (n)Sigma Sigma [1 = I = J = n]n^2Lim f (x) (x->) limitF (z) f on M's order derivative function of ZC (n:m) combination number, n take MP (n:m) permutationsM|n m divisible nM m and n n t coprimeA A a belongs to the set AThe number of elements in the #A collection AJunior physics formula:Physical quantity (unit) formula; deformation of remark formulaSpeed V (m/S) v= S: distance /t: timeGravity G (N) G=mg M: mass g:9.8N/kg or 10N/kgThe density of =m/V m (kg/m3) P: quality: Volume VThe resultant force is the same as F (N): F and =F1+F2In the opposite direction: when F is the opposite of =F1 - F2,F1>F2Buoyancy F float(N) F, floating =G matter - G, depending on the G: the gravity of the object in the liquidBuoyancy F float(N) F floating =G matter, this formula applies onlyObject floating or suspendedBuoyancy F float(N) F =G =m g= P floating row row row row row: G gV liquid liquid gravityPlatoon M: the quality of the liquidP: liquid liquid densityPlatoon V: the volume of the liquid(that is, the volume immersed in a liquid)Lever balance conditions F1L1=, F2L2, F1: power L1: power armF2: resistance L2: resistance armFixed pulley F=GS=h F: the pull of the free end of the ropeG: gravity of objectsS: the distance at which the end of the rope movesH: the distance that an object risesMoving pulley F= (G object +G wheel)S=2, h, G objects: the gravity of objectsG wheel: the gravity of the moving pulleyPulley block F= (G, +G wheel)S=n H N: the number of segments of the rope by moving the pulley Mechanical work W(J) W=Fs F: forceS: the distance traveled in the direction of forceUseful work, W, yesTotal W total W =G HW total =Fs applies pulley block verticallyMechanical efficiency = x 100%Power P(W) P=W: work!T: timePressure P(Pa) P=F: stressS: force areaLiquid pressure P(Pa) P= P GH P: liquid densityH: depth (from liquid level to desired point)Vertical distanceHeat Q(J) Q=cm T C: the specific heat capacity of material quality: MT: temperature change valueFuel combustionHeat Q (J) Q=mq M: qualityQ: calorific valueCommon Physics Formulas and important knowledge pointsI. physical formulaUnit) deformation of formula remark formulaSeries circuitCurrent I (A) I=I1=I2=...... Current is equal everywhere Series circuitVoltage U (V) U=U1+U2+...... Series circuitPartial pressure actionSeries circuitResistor R (omega) R=R1+R2+......Parallel circuitCurrent I (A) I=I1+I2+...... The current trunk is equal to theSum of branch currents (shunt)Parallel circuitVoltage U (V) U=U1=U2=......Parallel circuitResistor R (omega) = + +......Ohm's law I=Current and voltage in a circuitProportional to, inversely proportional to the resistance Current definition I=Q: the amount of charge (Coulomb)T: time (S)Electrical work W(J) W=UIt=Pt U: voltage I: currentT: time P: electric powerElectrical power P=UI=I2R=U2/R U: voltage I: currentR: resistanceElectromagnetic wave velocity and waveLong, the relationship between the frequencies of C= lambda V C:Unit formula of physical quantityName, symbol, name, symbolThe quality is m kg kg m=pvThe temperature is t degrees Celsius, C degrees CelsiusSpeed v m / sec, m/s v=s/tDensity p kg / M 3 kg/m3 p=m/vForce (gravity) F Newton (cow) N G=mgThe pressure is P Pascal (PA) Pa P=F/SWork W Joule (focus) J W=FsPower P watt (W) w P=W/tCurrent I ampere (an) A I=U/RVoltage U volts (volts) V U=IRResistance R ohm (OU) R=U/IElectrical work W Joule (focus) J W=UItElectrical power P watts (Watts) w P=W/t=UIHeat Q Joule (coke) J Q=cm (T-T degrees)Specific heat C Jiao / (kg degree C) J/ (kg degrees C)In the vacuum, the speed of light is 3 * 108 meters per secondG 9.8 Newton / kg15 degrees C air speed of 340 meters per secondCompilation of Physics Formulas for junior high school [mechanical part]1, speed: V=S/t2, gravity: G=mg3, density: P =m/V4, pressure: p=F/S5, liquid pressure: p= P GH6, buoyancy:(1) F float = F - F (pressure difference)(2) F floating = G - F (apparent gravity);(3) F floating = G (floating, suspended)(4), the Archimedes principle: F floating =G = P liquid gV 7, leverage balance conditions: F1 L1 = F2 L28, ideal slope: F/G = h/L9. Ideal pulley: F=G/n10, actual pulley: F = (G + G moving) / N (vertical direction) 11, work: W = FS = Gh (raise the object)12, power: P = W/t = FV13, work principle: W hand = W machine14, the actual total machinery: W = W is W extra15, mechanical efficiency: ETA = W /W total16 pulley block efficiency:(1) nF, ETA = G/ (vertical direction)(2), ETA = G/ (G + G) (vertical direction without friction)(3), ETA = f / nF (horizontal)[heat part]1, heat absorption: Q absorption = Cm (T - t0) = Cm, delta T2 heat release: Q = Cm (t0 - t) = Cm = t3, calorific value: q = Q/m4, the efficiency of furnace and heat engine: ETA = Q the effective use of /Q fuel5, heat balance equation: Q = Q suction6, thermodynamic temperature: T = T273K[electrical part]1, current strength: I = Q, electricity /t2, resistance: R= P L/S3 Ohm's Law: I = U/R4 Joule's law:(1) Q = I2Rt universal formula)(2) Q = UIt = Pt = UQ electric = U2t/R (pure resistance formula) 5 、 series circuit:(1) I = I1 = I2(2), U = U1U2(3), R = R1R2(4) U1/U2 = R1/R2 (partial pressure formula)(5) P1/P2 = R1/R26 、 parallel circuit:(1), I = I1I2(2) U = U1 = U2(3), 1/R = 1/R11/R2 [R = R1R2/ (R1R2)](4) I1/I2 = R2/R1 (shunt formula)(5) P1/P2 = R2/R17 fixed resistance:(1) I1/I2 = U1/U2(2) P1/P2 = I12/I22(3) P1/P2 = U12/U228 electric work:(1) W = UIt = Pt = UQ (universal formula)(2) W = I2Rt = U2t/R (pure resistance formula)9 electric power:(1) P = W/t = UI (universal formula)(2) P = I2R = U2/R (pure resistance formula) [common physical quantity]1, speed of light: C = 3 * 108m/s (in vacuum)2, sound speed: V = 340m/s (15 DEG C)3, the human ear distinguish echo: more than 0.1s 4, gravity acceleration: g = 9.8N/kg = 10N/kg5, the standard atmospheric pressure value:760 mm mercury column = 1.01 * 105Pa6, the density of water: P = 1 * 103kg/m37. Freezing point of water: 0 DEG C8. Boiling point of water: 100 DEG C9. The specific heat of water:C = 4.2 * 103J/ (kg DEG C)10, yuan charge: e = 1.6 * 10-19C11, a dry battery voltage: 1.5V12, a section of lead-acid battery voltage: 2V13, for human safety voltage: less than 36V (less than 36V)14 、 voltage of power circuit: 380V15 、 home circuit voltage: 220V16, unit conversion:(1) 1m/s = 3.6km/h(2) 1g/cm3 = 103kg/m3(3) and 1kW = H = 3.6 * 106J;Compilation of Physics Formulas for junior high school [mechanical part]1, speed: V=S/t2, gravity: G=mg3, density: P =m/V4, pressure: p=F/S5, liquid pressure: p= P GH6, buoyancy:(1) F float = F - F (pressure difference)(2) F floating = G - F (apparent gravity);(3) F floating = G (floating, suspended)(4), the Archimedes principle: F floating =G = P liquid gV 7, leverage balance conditions: F1 L1 = F2 L28, ideal slope: F/G = h/L9. Ideal pulley: F=G/n10, actual pulley: F = (G + G moving) / N (vertical direction) 11, work: W = FS = Gh (raise the object)12, power: P = W/t = FV13, work principle: W hand = W machine14, the actual total machinery: W = W is W extra15, mechanical efficiency: ETA = W /W total16 pulley block efficiency:(1) nF, ETA = G/ (vertical direction)(2), ETA = G/ (G + G) (vertical direction without friction)(3), ETA = f / nF (horizontal)[heat part]1, heat absorption: Q absorption = Cm (T - t0) = Cm, delta T2 heat release: Q = Cm (t0 - t) = Cm = t3, calorific value: q = Q/m4, the efficiency of furnace and heat engine: ETA = Q the effective use of /Q fuel5, heat balance equation: Q = Q suction6, thermodynamic temperature: T = T273K[electrical part]1, current strength: I = Q, electricity /t2, resistance: R= P L/S3 Ohm's Law: I = U/R4 Joule's law:(1) Q = I2Rt universal formula)(2) Q = UIt = Pt = UQ electric = U2t/R (pure resistance formula) 5 、 series circuit:(1) I = I1 = I2(2), U = U1U2(3), R = R1R2(4) U1/U2 = R1/R2 (partial pressure formula)(5) P1/P2 = R1/R26 、 parallel circuit:(1), I = I1I2(2) U = U1 = U2(3), 1/R = 1/R11/R2 [R = R1R2/ (R1R2)](4) I1/I2 = R2/R1 (shunt formula)(5) P1/P2 = R2/R17 fixed resistance:(1) I1/I2 = U1/U2(2) P1/P2 = I12/I22(3) P1/P2 = U12/U228 electric work:(1) W = UIt = Pt = UQ (universal formula)(2) W = I2Rt = U2t/R (pure resistance formula) 9 electric power:(1) P = W/t = UI (universal formula)(2) P = I2R = U2/R (pure resistance formula) [common physical quantity]1, speed of light: C = 3 * 108m/s (in vacuum)2, sound speed: V = 340m/s (15 DEG C)3, the human ear distinguish echo: more than 0.1s4, gravity acceleration: g = 9.8N/kg = 10N/kg5, the standard atmospheric pressure value:760 mm mercury column = 1.01 * 105Pa6, the density of water: P = 1 * 103kg/m37. Freezing point of water: 0 DEG C8. Boiling point of water: 100 DEG C9. The specific heat of water:C = 4.2 * 103J/ (kg DEG C)10, yuan charge: e = 1.6 * 10-19C11, a dry battery voltage: 1.5V12, a section of lead-acid battery voltage: 2V13, for human safety voltage: less than 36V (less than 36V)14 、 voltage of power circuit: 380V15 、 home circuit voltage: 220V16, unit conversion:(1) 1m/s = 3.6km/h(2) 1g/cm3 = 103KEncyclopedia of mathematical symbols:(1) the number of symbols: such as: I, 2+i, a, x, natural logarithm base e, pi.Such as: (2) operational symbol plus (+) and minus (-) sign, (* or *), division (or / /), the union of two sets (U), (a), the intersection of root (V), (log, LG, log LN), than (:). Differential (DX), integral (formula).(3) the relationship between symbols: such as "=" is equal, "is" is the approximate symbol, not equal to is not equal, ">" is greater than the symbol, "<" is less than the symbol, "said," variable trend, "~" is similar to "=" symbols are congruent. "The" "symbol is parallel," t "is the vertical symbol," / "is directly proportional to the symbols (not inversely proportional to the symbol, but can be used as a symbol with reciprocal" and "inversely) is a symbol of" C "or" C below a bar "is" contained "symbols.(4) a combination of symbols: such as parentheses "(in parentheses)" "" "," {} "horizontal braces"-"(5) the nature of symbols: such as a "+", "-" sign, the absolutevalue of the symbol """(6) ellipsis: (a) such as triangle, sine, cosine (SIN) (COS), X function (f (x)), limit (LIM), dreams because (a foot stand, stand (two) said so, foot standing, can stop) the sum (sigma), product (II), from each n elements of the R elements removed all the different number of combinations (C (R) (n) (A), power, Ac, Aq, x^n), factorial (!) Etc..(7) other symbols: alpha, beta, gamma and so forthThe origin of mathematical symbols:For example, the plus sign used to have several, and now the universal "+" number.The "+" is evolved from the Latin "et" (meaning of "harmony"). In sixteenth Century, Italy scientist Tartaglia in Italian "PLU" (and meaning) the first letter said, "Mu" grass have become the last "+"."-" is evolved from the Latin "minus" (minus) meaning. The abbreviation m, and then the omission of the letter, becomes "-".Some people say, liquor merchants "-" said how much the barrel of wine sold. Later, when the new wine is poured into the barrel, in the "-" with a vertical, meaning that the cancellation of the original lines, this became a "+".By fifteenth Century, the German mathematician Wei Demeiofficially confirmed: "+" is used as a plus, "-" used as a minus sign.Once a dozen times, now general two. One is "X", which was first proposed by British mathematician Okut in 1631, and was first invented by British mathematician, Hector ott. German mathematician Leibniz said: "X" number like the Latin alphabet "X" against, and in favor with "No.". He also said "are" put forward by. But this symbol is now applied to set theory.In eighteenth Century, American mathematician Oude Levin, the "X" as a symbol of multiplication. He thought that the "X" was "+" tilted to write, another sign of increasing."," first as a minus sign, long popular in continental europe. Until 1631 the British mathematician aucuy special "said in addition to or better than, other people" - "(except line) said in addition. Later, the Swiss mathematician Raha in his book "algebra", according to the people to create, will be officially "/" as a case.Square root Latin "Radix used" (root) and the two letters together and said that at the beginning of the seventeenth Century, the French mathematician in his "geometry", the first time the "tick" said reagan. "V" is from the Latin word line "R", "-" is the line.In sixteenth Century the French mathematician dimension leaves special "=" said the difference between the amount of two. But the British University of Oxford mathematics, Professor Leo Calder think any rhetoric, with two parallel and equal to theequivalent linear representation is the most appropriate, and equal to the symbol "=" from the beginning of 1540 to use.In 1591, Veda, a French mathematician, used the symbols in the diamond to be accepted gradually. Seventeenth Century German Leibniz made extensive use of "=", he is still used in geometry "~" similar, "=" said."Greater than" and less than "< <" is the 1631 British famous mathematician mathematician, "Rui Rui" created. As for the "more than", "less than", "and" the three symbols appear, is very very late. "{}" brackets and brackets "," is one of the founders of algebra Zhide created wei.Any number comes from the word "any" in English, because both lowercase and uppercase are prone to confusion, so capitalize the first letter of the word and turn it upside down, as shown.A mathematical symbol of a mathematical symbolSuch as: I, 2+i, a, x, natural logarithm base e, pi.Operational symbolAs a plus (+) and minus (-) sign, (* or *), division (or / /), the union of two sets (U), (a), the intersection of root (V), (log, LG, log LN), than (:), differential, integral (DX) (formula), (PHI) and curve integral.Relational symbolSuch as "=" is the sign "=" is the approximate symbol, not equal to is not equal, ">" is greater than the symbol, "<" is less than the symbol, "or" is greater than or equal to the symbol (can also be written as "less than", "less than") is less than or equal to the symbol (can also be written "using"),. "," said variable trend, "~" is similar to "=" symbols are congruent, "" parallel "is" an "symbol is the vertical symbol," / "is directly proportional to the symbols (not inversely proportional to the symbol, but can be used as a symbol with reciprocal inverse)" this is "symbol"? "Is" contained "symbols.Combination symbolAs in parentheses, "()) brackets [[]]","{}" horizontal braces"-"Property symbolAs a "+", "-" sign, the absolute value of the symbol "| |" sign ""Ellipsis(a) such as triangle, triangle (Rt delta), sine cosine (SIN), (COS), X function (f (x)), limit (LIM), angle (angle),Because of dreams, (a foot stand, stand)* so (two feet standing, can stop) the sum (sigma), product (II),from each n elements of the R elements removed all the different number of combinations (C (R) (n) (A), power, Ac, Aq, x^n), factorial (!) Etc..(7) other symbols: alpha, beta, gamma and so forthExpress existence",For any given"The meaning of mathematical symbols:Symbolic (Symbol) meaning (Meaning)= equal to is equal toIs not equal to is not equal to not equal< less than is less than> greater than is, greater, thanParallel is parallel to ||Greater than or is greater than or equal to is equal toLess than or is less than or equal to is equal toIt is less than or equal to the congruencePi Pi|x| absolute value absolute, value, of, XSimilar to is similar toIs equal to (especially = congruent for triangle) "is far greater than the number"Far less than number"U UnionA intersectionIncluded inThe circleDiameter of phiBeta betaH-infinity infinityLn (x) the logarithm based on eLG (x) with 10 as the base of the logarithmFloor (x) on the integral functionCeil (x) under the integral functionX mod y for remainderX - floor (x) decimal partFormula F (x) DX integralFormula [a:b]f (x) DX A to B integralThe use of mathematical symbols:P equals 1, or 0[1 = k = n]f (k) of the N sum, can be extended to many Such as: Sigma [n, is, prime][n < 10]f (n)Sigma Sigma [1 = I = J = n]n^2Lim f (x) (x->) limitF (z) f on M's order derivative function of ZC (n:m) combination number, n take MP (n:m) permutationsM|n m divisible nM m and n n t coprimeA A a belongs to the set AThe number of elements in the #A collection A。