100928.JYE.翻译OneSteel_Piping_Data_Chart__psa_

- 格式:pdf

- 大小:313.71 KB

- 文档页数:18

P86It is estimated that more than 50 per cent is liquid line in the petroleum and gas pipeline system ,the remainder gas .Pipeline size is governed by the amount of material to be transported through the line .lines may vary anywhere from a diameter of 3 or 4 inches for the liquid collection lines to 48 inches for the gas trunk lines .the oil lines tend toward the smaller sizes ,the gas toward the larger.据估计,在石油和天然气管道系统中,超过50%是液体,其余的气体。

管道的尺寸是通过线路输送的材料的输送量来控制的。

线路在任何地方都可能会发生用于液体收集线直径为3或4英寸变成48英寸的气体干线。

油线趋向于更小的尺寸,气体朝向较大尺寸。

P91Filtration is one of the most common applications of the flow of fluids through packed beds.as carried out industrially,it is exactly analogous to the filtrations carried out in a chemical laboratory using a filter paper in a funnel. The object is still the separation of a solid from the fluid in which it is carried. In every case , the separation is accomplished by forcing the fluid through a porous membrane. The solid particles are trapped within the pores of the membrane and build up a layer on the surface of this membrane. The fluid, which may be either gas or liquid, passes through the bed of solids and through the retaining membrane.过滤是流体通过填充层流动的最普遍的应用之一。

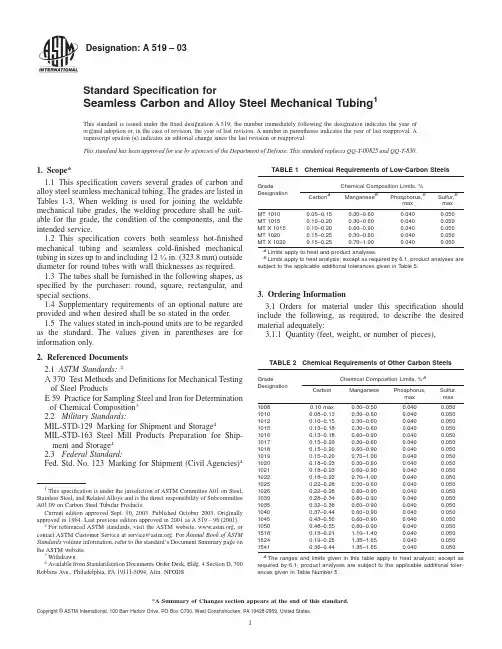

Designation:A519–03Standard Specification forSeamless Carbon and Alloy Steel Mechanical Tubing1This standard is issued under thefixed designation A519;the number immediately following the designation indicates the year oforiginal adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.Asuperscript epsilon(e)indicates an editorial change since the last revision or reapproval.This standard has been approved for use by agencies of the Department of Defense.This standard replaces QQ-T-00825and QQ-T-830.1.Scope*1.1This specification covers several grades of carbon andalloy steel seamless mechanical tubing.The grades are listed inTables1-3.When welding is used for joining the weldablemechanical tube grades,the welding procedure shall be suit-able for the grade,the condition of the components,and theintended service.1.2This specification covers both seamless hot-finishedmechanical tubing and seamless cold-finished mechanicaltubing in sizes up to and including123⁄4in.(323.8mm)outsidediameter for round tubes with wall thicknesses as required.1.3The tubes shall be furnished in the following shapes,asspecified by the purchaser:round,square,rectangular,andspecial sections.1.4Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order. 1.5The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information only.2.Referenced Documents2.1ASTM Standards:2A370Test Methods and Definitions for Mechanical Testing of Steel ProductsE59Practice for Sampling Steel and Iron for Determination of Chemical Composition32.2Military Standards:MIL-STD-129Marking for Shipment and Storage4MIL-STD-163Steel Mill Products Preparation for Ship-ment and Storage42.3Federal Standard:Fed.Std.No.123Marking for Shipment(Civil Agencies)43.Ordering Information3.1Orders for material under this specification should include the following,as required,to describe the desired material adequately:3.1.1Quantity(feet,weight,or number of pieces),1This specification is under the jurisdiction of ASTM Committee A01on Steel, Stainless Steel,and Related Alloys and is the direct responsibility of Subcommittee A01.09on Carbon Steel Tubular Products.Current edition approved Sept.10,2003.Published October2003.Originally approved st previous edition approved in2001as A519–96(2001).2For referenced ASTM standards,visit the ASTM website,,or contact ASTM Customer Service at service@.For Annual Book of ASTM Standards volume information,refer to the standard’s Document Summary page on the ASTM website.3Withdrawn.4Available from Standardization Documents Order Desk,Bldg.4Section D,700 Robbins Ave.,Philadelphia,PA19111-5094,Attn:NPODS.TABLE1Chemical Requirements of Low-Carbon SteelsGradeDesignationChemical Composition Limits,%Carbon A Manganese B Phosphorus,BmaxSulfur,Bmax MT10100.05–0.150.30–0.600.0400.050 MT10150.10–0.200.30–0.600.0400.050 MT X10150.10–0.200.60–0.900.0400.050 MT10200.15–0.250.30–0.600.0400.050 MT X10200.15–0.250.70–1.000.0400.050A Limits apply to heat and product analyses.B Limits apply to heat analysis;except as required by6.1,product analyses aresubject to the applicable additional tolerances given in Table5.TABLE2Chemical Requirements of Other Carbon SteelsGradeDesignationChemical Composition Limits,%ACarbon Manganese Phosphorus,maxSulfur,max 10080.10max0.30–0.500.0400.050 10100.08–0.130.30–0.600.0400.050 10120.10–0.150.30–0.600.0400.050 10150.13–0.180.30–0.600.0400.050 10160.13–0.180.60–0.900.0400.050 10170.15–0.200.30–0.600.0400.050 10180.15–0.200.60–0.900.0400.050 10190.15–0.200.70–1.000.0400.050 10200.18–0.230.30–0.600.0400.050 10210.18–0.230.60–0.900.0400.050 10220.18–0.230.70–1.000.0400.050 10250.22–0.280.30–0.600.0400.050 10260.22–0.280.60–0.900.0400.050 10300.28–0.340.60–0.900.0400.050 10350.32–0.380.60–0.900.0400.050 10400.37–0.440.60–0.900.0400.050 10450.43–0.500.60–0.900.0400.050 10500.48–0.550.60–0.900.0400.050 15180.15–0.21 1.10–1.400.0400.050 15240.19–0.25 1.35–1.650.0400.050 15410.36–0.44 1.35–1.650.0400.050A The ranges and limits given in this table apply to heat analysis;except asrequired by6.1,product analyses are subject to the applicable additional toler-ances given in Table Number5.1*A Summary of Changes section appears at the end of this standard. Copyright©ASTM International,100Barr Harbor Drive,PO Box C700,West Conshohocken,PA19428-2959,United States.3.1.2Name of material(seamless carbon or alloy steel mechanical tubing),3.1.3Form(round,square,rectangular or special shapes, Section1),3.1.4Dimensions(round,outside diameters and wall thick-ness,Section8;square and rectangular,outside dimensions and wall thickness,Section9;other,specify),3.1.5Length(specific or random,mill lengths,see8.5and 9.5),3.1.6Manufacture(hotfinished or coldfinished,4.5and4.6),3.1.7Grade(Section5),3.1.8Condition(sizing method and thermal treatment,Sec-tion12),3.1.9Surfacefinish(special pickling,shot blasting,or ground outside surface,if required),3.1.10Specification designation,3.1.11Individual supplementary requirements,if required, 3.1.12End use,if known,3.1.13Packaging,3.1.14Product analysis and chemical analysis,if required (Section6and Section7),3.1.15Specific requirements,or exceptions to this specifi-cation,3.1.16Special marking(Section15),and3.1.17Special packing(Section16).TABLE3Chemical Requirements for Alloy SteelsN OTE1—The ranges and limits in this table apply to steel not exceeding200in.2(1290cm2)in cross-sectional area.N OTE2—Small quantities of certain elements are present in alloy steels which are not specified or required.These elements are considered as incidental and may be present to the following maximum amounts:copper,0.35%;nickel,0.25%;chromium,0.20%;molybdenum,0.10%.N OTE3—The ranges and limits given in this table apply to heat analysis;except as required by6.1,product analyses are subject to the applicable additional tolerances given in Table Number5.Grade A,B Designa-tionChemical Composition Limits,%Carbon Manganese Phospho-rus,C maxSulfur,C,DmaxSilicon Nickel Chromium Molybde-num13300.28–0.33 1.60–1.900.0400.0400.15–0.35......... 13350.33–0.38 1.60–1.900.0400.0400.15–0.35......... 13400.38–0.43 1.60–1.900.0400.0400.15–0.35......... 13450.43–0.48 1.60–1.900.0400.0400.15–0.35......... 31400.38–0.430.70–0.900.0400.0400.15–0.35 1.10–1.400.55–0.75... E33100.08–0.130.45–0.600.0250.0250.15–0.35 3.25–3.75 1.40–1.75...4012 40230.09–0.140.20–0.250.75–1.000.70–0.900.0400.0400.0400.0400.15–0.350.15–0.35............0.15–0.250.20–0.3040240.20–0.250.70–0.900.0400.035−0.0500.15–0.35......0.20–0.30 40270.25–0.300.70–0.900.0400.0400.15–0.35......0.20–0.30 40280.25–0.300.70–0.900.0400.035−0.0500.15–0.35......0.20–0.30 40370.35–0.400.70–0.900.0400.0400.15–0.35......0.20–0.30 40420.40–0.450.70–0.900.0400.0400.15–0.35......0.20–0.30 40470.45–0.500.70–0.900.0400.0400.15–0.35......0.20–0.30 40630.60–0.670.75–1.000.0400.0400.15–0.35......0.20–0.30 41180.18–0.230.70–0.900.0400.0400.15–0.35...0.40–0.600.08–0.15 41300.28–0.330.40–0.600.0400.0400.15–0.35...0.80–1.100.15–0.25 41350.33–0.380.70–0.900.0400.0400.15–0.35...0.80–1.100.15–0.25 41370.35–0.400.70–0.900.0400.0400.15–0.35...0.80–1.100.15–0.25 41400.38–0.430.75–1.000.0400.0400.15–0.35...0.80–1.100.15–0.25 41420.40–0.450.75–1.000.0400.0400.15–0.35...0.80–1.100.15–0.25 41450.43–0.480.75–1.000.0400.0400.15–0.35...0.80–1.100.15–0.25 41470.45–0.500.75–1.000.0400.0400.15–0.35...0.80–1.100.15–0.25 41500.48–0.530.75–1.000.0400.0400.15–0.35...0.80–1.100.15–0.25 43200.17–0.220.45–0.650.0400.0400.15–0.35 1.65–2.000.40–0.600.20–0.30 43370.35–0.400.60–0.800.0400.0400.15–0.35 1.65–2.000.70–0.900.20–0.30 E43370.35–0.400.65–0.850.0250.0250.15–0.35 1.65–2.000.70–0.900.20–0.30 43400.38–0.430.60–0.800.0400.0400.15–0.35 1.65–2.000.70–0.900.20–0.30 E43400.38–0.430.65–0.850.0250.0250.15–0.35 1.65–2.000.70–0.900.20–0.30 44220.20–0.250.70–0.900.0400.0400.15–0.35......0.35–0.45 44270.24–0.290.70–0.900.0400.0400.15–0.35......0.35–0.45 45200.18–0.230.45–0.650.0400.0400.15–0.35......0.45–0.60 46150.13–0.180.45–0.650.0400.0400.15–0.35 1.65–2.00...0.20–0.30 46170.15–0.200.45–0.650.0400.0400.15–0.35 1.65–2.00...0.20–0.30 46200.17–0.220.45–0.650.0400.0400.15–0.35 1.65–2.00...0.20–0.30 46210.18–0.230.70–0.900.0400.0400.15–0.35 1.65–2.00...0.20–0.304718 47200.16–0.210.17–0.220.70–0.900.50–0.700.0400.0400.0400.0400.15–0.350.15–0.350.90–1.200.90–1.200.35–0.550.35–0.550.30–0.400.15–0.2548150.13–0.180.40–0.600.0400.0400.15–0.35 3.25–3.75...0.20–0.30 48170.15–0.200.40–0.600.0400.0400.15–0.35 3.25–3.75...0.20–0.30Grade A ,B Designa-tion Chemical Composition Limits,%Carbon Manganese Phospho-rus,C maxSulfur,C ,DmaxSilicon Nickel ChromiumMolybde-num 48200.18–0.230.50–0.700.0400.0400.15–0.35 3.25–3.75...0.20–0.30501550460.12–0.170.43–0.500.30–0.500.75–1.000.0400.0400.0400.0400.15–0.350.15–0.35......0.30–0.500.20–0.35......51150.13–0.180.70–0.900.0400.0400.15–0.35...0.70–0.90...51200.17–0.220.70–0.900.0400.0400.15–0.35...0.70–0.90...51300.28–0.330.70–0.900.0400.0400.15–0.35...0.80–1.10...51320.30–0.350.60–0.800.0400.0400.15–0.35...0.75–1.00...51350.33–0.380.60–0.800.0400.0400.15–0.35...0.80–1.05...51400.38–0.430.70–0.900.0400.0400.15–0.35...0.70–0.90...51450.43–0.480.70–0.900.0400.0400.15–0.35...0.70–0.90...51470.45–0.520.70–0.950.0400.0400.15–0.35...0.85–1.15...51500.48–0.530.70–0.900.0400.0400.15–0.35...0.70–0.90...51550.50–0.600.70–0.900.0400.0400.15–0.35...0.70–0.90...51600.55–0.650.75–1.000.0400.0400.15–0.35...0.70–0.90...52100E 0.93–1.050.25–0.450.0250.0150.15–0.35... 1.35–1.600.10max E501000.95–1.100.25–0.450.0250.0250.15–0.35...0.40–0.60...E511000.95–1.100.25–0.450.0250.0250.15–0.35...0.90–1.15...E521000.95–1.100.25–0.450.0250.0250.15–0.35...1.30–1.60...Vanadium61180.16–0.210.50–0.700.0400.0400.15–0.35...0.50–0.700.10–0.1561200.17–0.220.70–0.900.0400.0400.15–0.35...0.70–0.900.10min 61500.48–0.530.70–0.900.0400.0400.15–0.35...0.80–1.100.15min AluminumMolybdenum E71400.38–0.430.50–0.700.0250.0250.15–0.400.95–1.301.40–1.800.30–0.40Nickel81150.13–0.180.70–0.900.0400.0400.15–0.350.20–0.400.30–0.500.08–0.1586150.13–0.180.70–0.900.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586170.15–0.200.70–0.900.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586200.18–0.230.70–0.900.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586220.20–0.250.70–0.900.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586250.23–0.280.70–0.900.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586270.25–0.300.70–0.900.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586300.28–0.330.70–0.900.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586370.35–0.400.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586400.38–0.430.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586420.40–0.450.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586450.43–0.480.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586500.48–0.530.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586550.50–0.600.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2586600.55–0.650.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.15–0.2587200.18–0.230.70–0.900.0400.0400.15–0.350.40–0.700.40–0.600.20–0.3087350.33–0.380.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.20–0.3087400.38–0.430.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.20–0.3087420.40–0.450.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.20–0.3088220.20–0.250.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.30–0.4092550.50–0.600.70–0.950.0400.040 1.80–2.20.........92600.55–0.650.70–1.000.0400.040 1.80–2.20.........92620.55–0.650.75–1.000.0400.040 1.80–2.20...0.25–0.40...E93100.08–0.130.45–0.650.0250.0250.15–0.35 3.00–3.50 1.00–1.400.08–0.159********.38–0.430.48–0.530.70–0.900.70–0.900.0400.0400.0400.0400.15–0.350.15–0.350.85–1.150.85–1.150.70–0.900.70–0.900.20–0.300.20–0.3050B400.38–0.420.75–1.000.0400.0400.15–0.35...0.40–0.60...50B440.43–0.480.75–1.000.0400.0400.15–0.35...0.40–0.60...50B460.43–0.500.75–1.000.0400.0400.15–0.35...0.20–0.35...50B500.48–0.530.74–1.000.0400.0400.15–0.35...0.40–0.60...Grade A,B Designa-tionChemical Composition Limits,%Carbon Manganese Phospho-rus,C maxSulfur,C,DmaxSilicon Nickel Chromium Molybde-num50B600.55–0.650.75–1.000.0400.0400.15–0.35...0.40–0.60...51B600.55–0.650.75–1.000.0400.0400.15–0.35...0.70–0.90...81B450.43–0.480.75–1.000.0400.0400.15–0.350.20–0.400.35–0.550.08–0.15 86B450.43–0.480.75–1.000.0400.0400.15–0.350.40–0.700.40–0.600.15–0.25 94B150.13–0.180.75–1.000.0400.0400.15–0.350.30–0.600.30–0.500.08–0.15 94B170.15–0.200.75–1.000.0400.0400.15–0.350.30–0.600.30–0.500.08–0.15 94B300.28–0.330.75–1.000.0400.0400.15–0.350.30–0.600.30–0.500.08–0.15 94B400.38–0.430.75–1.000.0400.0400.15–0.350.30–0.600.30–0.500.08–0.15A Grades shown in this table with prefix letter E generally are manufactured by the basic-electric-furnace process.All others are normally manufactured by the basic-open-hearth process but may be manufactured by the basic-electric-furnace process with adjustments in phosphorus and sulfur.B Grades shown in this table with the letter B,such as50B40,can be expected to have0.0005%minimum boron control.C The phosphorus sulfur limitations for each process are as follows:Basic electric furnace0.025max%Acid electric furnace0.050max%Basic open hearth0.040max%Acid open hearth0.050max%D Minimum and maximum sulfur content indicates resulfurized steels.E The purchaser may specify the following maximum amounts:copper,0.30%;aluminum,0.050%;and oxygen,0.0015%.4.Materials and Manufacture4.1The steel may be made by any process.4.2If a specific type of melting is required by the purchaser,it shall be as stated on the purchase order.4.3The primary melting may incorporate separate degas-sing or refining,and may be followed by secondary melting,such as electroslag or vacuum-arc remelting.If secondarymelting is employed,the heat shall be defined as all of theingots remelted from a single primary heat.4.4Steel may be cast in ingots or may be strand cast.Whensteel of different grades is sequentially strand cast,identifica-tion of the resultant transition material is required.Theproducer shall remove the transition material by an establishedprocedure that positively separates the grades.4.5Tubes shall be made by a seamless process and shall beeither hotfinished or coldfinished,as specified.4.6Seamless tubing is a tubular product made without a welded seam.It is manufactured usually by hot working steel and,if necessary,by subsequently coldfinishing the hot-worked tubular product to produce the desired shape,dimen-sions and properties.5.Chemical Composition5.1The steel shall conform to the requirements as to chemical composition prescribed in Table1(Low Carbon MT Grades),Table2(Higher Carbon Steels),Table3(Alloy Standard Steels)and Table4(Resulfurized or Rephosphorized, or Both,Carbon Steels).5.2Grade MT1015or MTX1020will be supplied at the producer’s option,when no grade is specified.5.3When a carbon steel grade is ordered under this speci-fication,supplying an alloy grade that specifically requires the addition of any element other than those listed for the ordered grade in Table1and Table2is not permitted.5.4Analyses of steels other than those listed are available. To determine their availability,the purchaser should contact the producer.6.Heat Analysis6.1An analysis of each heat of steel shall be made by the steel manufacturer to determine the percentages of the ele-ments specified;if secondary melting processes are used,the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt.The heat analysis shall conform to the requirements specified,except that where the heat identity has not been maintained or where the analysis is not sufficiently complete to permit conformance to be determined,the chemical composition determined from a product analysis made by the tubular manufacturer shall conform to the requirements specified for heat analysis.When requested in the order or contract,a report of such analyses shall be furnished to the purchaser.7.Product Analysis7.1Except as required by6.1,a product analysis by the manufacturer shall be required only when requested in the order.7.1.1Heat Identity Maintained—One product analysis per heat on either billet or tube.TABLE4Chemical Requirements of Resulfurized orRephosphorized,or Both,Carbon Steels AGradeDesig-nationChemical Composition Limits,%Carbon Manganese Phosphorus Sulfur Lead 11180.14–0.20 1.30–1.600.040max0.08–0.1311L180.14–0.20 1.30–1.600.040max0.08–0.130.15–0.35 11320.27–0.34 1.35–1.650.040max0.08–0.1311370.32–0.39 1.35–1.650.040max0.08–0.1311410.37–0.45 1.35–1.650.040max0.08–0.1311440.40–0.48 1.35–1.650.040max0.24–0.3312130.13max0.70–1.100.07–0.120.24–0.3312L140.15max0.85–1.150.04–0.090.26–0.350.15–0.35 12150.09max0.75–1.050.04–0.090.26–0.35A The ranges and limits given in this table apply to heat analysis;except as required by6.1,product analyses aresubject to the applicable additional toler-ances given in Table Number5.7.1.2Heat Identity Not Maintained—A product analysis from one tube per2000ft(610m)or less for sizes over3in.(76.2mm),and one tube per5000ft(1520m)or less for sizes 3in.(76.2mm)and under.7.2Samples for chemical analysis,except for spectrochemi-cal analysis,shall be taken in accordance with Practice E59. The composition thus determined shall correspond to the requirements in the applicable section or Tables1-5of this specification and shall be reported to the purchaser or the purchaser’s representative.7.3If the original test for check analysis fails,retests of two additional billets or tubes shall be made.Both retests for the elements in question shall meet the requirements of the specification;otherwise all remaining material in the heat or lot shall be rejected or,at the option of the producer,each billet or tube may be individually tested for acceptance.Billets or tubes which do not meet the requirements of the specification shall be rejected.8.Permissible Variations in Dimensions of Round Tubing 8.1Hot-Finished Mechanical Tubing—Hot-finished me-chanical tubing is produced to outside diameter and wall thickness.Variations in outside diameter and wall thickness shall not exceed the tolerances shown in Table6and Table7. Table6and Table7cover these tolerances and apply to the specified size.8.2Cold-Worked Mechanical Tubing:8.2.1Variations in outside diameter,inside diameter and wall thickness shall not exceed the tolerances shown in Table 8and Table9.TABLE5Product Analysis Tolerances Over or Under SpecifiedRange or LimitN OTE1—Individual determinations may vary from the specified heat limits or ranges to the extent shown in this table except that any element in a heat may not vary both above and below a specified range.N OTE2—In all types of steel,because of the degree to which phospho-rus and sulfur segregate,product analysis for these elements is not technologically appropriate for rephosphorized or resulfurized steels unless misapplication is clearly indicated.Carbon Steel Seamless TubesElement Limit,or Maximum of SpecifiedRange,%Tolerance,Over the Maximum Limit or Under the Minimum Limit,%Under min Over maxCarbon to0.25,inclover0.25to0.55,inclover0.550.020.030.040.020.030.04Manganese to0.90,inclover0.90to1.65,incl 0.030.060.030.06Phosphorus basic steel to0.05,inclacid-bessemer steel to0.12,incl ......0.0080.010Sulfur to0.06,incl...0.008Silicon to0.35,inclover0.35to0.60,incl 0.020.050.020.05Copper...0.020.02Alloy Steel Seamless TubeElements Limit,or Maximum ofSpecified Element,%Tolerance Over Maximum Limit or Under Minimum Limit for Size Ranges Shown,% 100in.2(645cm2)or lessOver100to200in.2(645to1290cm2),inclCarbon to0.30,inclover0.30to0.75,inclover0.750.010.020.030.020.030.04Manganese to0.90,inclover0.90to2.10,incl 0.030.040.040.05Phosphorus over max,only0.0050.010 Sulfur to0.060,incl0.0050.010Silicon to0.35,inclover0.35to2.20,incl 0.020.050.020.06Nickel to1.00,incl0.030.03over1.00to2.00,incl0.050.05over2.00to5.30,incl0.070.07over5.30to10.00,incl0.100.10Chromium to0.90,inclover0.90to2.10,inclover2.10to3.99,incl 0.030.050.100.040.060.10Molybdenum to0.20,inclover0.20to0.40,inclover0.40to1.15,incl 0.010.020.030.010.030.04Vanadium to0.10,incl0.010.01over0.10to0.25,incl0.020.02over0.25to0.50,incl0.030.03min value specified,check0.010.01under min limitTungsten to1.00,inclover1.00to4.00,incl 0.040.080.050.09Aluminum up to0.10,incl0.03...over0.10to0.20,incl0.04...over0.20to0.30,incl0.05...over0.30to0.80,incl0.07...over0.80to1.80,incl0.10...TABLE6Outside Diameter Tolerances for Round Hot-FinishedTubing A,B,COutside Diameter Size Range,Outside Diameter Tolerance,in.(mm) in.(mm)Over UnderUp to2.999(76.17)0.020(0.51)0.020(0.51)3.000–4.499(76.20–114.27)0.025(0.64)0.025(0.64)4.500–5.999(114.30–152.37)0.031(0.79)0.031(0.79)6.000–7.499(152.40–190.47)0.037(0.94)0.037(0.94)7.500–8.999(190.50–228.57)0.045(1.14)0.045(1.14)9.000–10.750(228.60–273.05)0.050(1.27)0.050(1.27)A Diameter tolerances are not applicable to normalized and tempered or quenched and tempered conditions.B The common range of sizes of hotfinished tubes is11⁄2in.(38.1mm)to103⁄4 in.(273.0mm)outside diameter with wall thickness at least3%or more of outside diameter,but not less than0.095in.(2.41mm).C Larger sizes are available;consult manufacturer for sizes and tolerances. TABLE7Wall Thickness Tolerances for Round Hot-FinishedTubingWall ThicknessRange as Percentof OutsideDiameterWall Thickness Tolerance,A percent Overand Under NominalOutsideDiameter2.999in.(76.19mm)and smallerOutsideDiameter3.000in.(76.20mm)to5.999in.(152.37mm)Outside Diameter 6.000in. (152.40mm) to10.750in. (273.05mm)Under15 15and over 12.510.010.07.510.010.0A Wall thickness tolerances may not be applicable to walls0.199in.(5.05mm) and less;consult manufacturer for wall tolerances on such tube sizes.8.2.2Cold-worked mechanical tubing is normally produced to outside diameter and wall thickness.If the inside diameter is a more important dimension,then cold-worked tubing should be specified to inside diameter and wall thickness or outside diameter and inside diameter.8.3Rough-Turned Mechanical Tubing —Variation in outside diameter and wall thickness shall not exceed the tolerance in Table 10.Table 10covers tolerances as applied to outside diameter and wall thickness and applies to the specified size.8.4Ground Mechanical Tubing —Variation in outside diam-eter shall not exceed the tolerances in Table 11.This product is normally produced from a cold-worked tube.8.5Lengths —Mechanical tubing is commonly furnished in mill lengths,5ft (1.5m)and over.Definite cut lengths areTABLE 8Outside and Inside Diameter Tolerances for Round Cold-Worked Tubing A ,B ,COutside Diameter Size Range,in.DThermal Treatment after Final Cold Work Producing SizeWallThickness As Percent of Outside DiameterNone,or not exceeding1100°F Nominal Temperature Heated Above 1100°F NominalTemperature Without Accelerated Cooling Quenched and TemperedOD,in.DID,in.DOD,in.DID,in.DOD,in.DID,in.DOverUnder Over Under Over Under Over Under Over Under Over Under Up to 0.499all 0.0040.000——0.0050.002——0.0100.0100.0100.0100.500–1.699all 0.0050.0000.0000.0050.0070.0020.0020.0070.0150.0150.0150.0151.700–2.099all 0.0060.0000.0000.0060.0060.0050.0050.0060.0200.0200.0200.0202.100–2.499all 0.0070.0000.0000.0070.0080.0050.0050.0080.0230.0230.0230.0232.500–2.899all 0.0080.0000.0000.0080.0090.0050.0050.0090.0250.0250.0250.0252.900–3.299all 0.0090.0000.0000.0090.0110.0050.0050.0110.0280.0280.0280.0283.300–3.699all 0.0100.0000.0000.0100.0130.0050.0050.0130.0300.0300.0300.0303.700–4.099all 0.0110.0000.0000.0110.0130.0070.0100.0100.0330.0330.0330.0334.100–4.499all 0.0120.0000.0000.0120.0140.0070.0110.0110.0360.0360.0360.0364.500–4.899all 0.0130.0000.0000.0130.0160.0070.0120.0120.0380.0380.0380.0384.900–5.299all 0.0140.0000.0000.0140.0180.0070.0130.0130.0410.0410.0410.0415.300–5.549all0.0150.0000.0000.0150.0200.0070.0140.0140.0440.0440.0440.0445.550–5.559under 66to 71⁄2over 71⁄20.0100.0090.0180.0100.0090.0000.0100.0090.0090.0100.0090.0090.0180.0160.0170.0180.0160.0150.0180.0160.0160.0180.0160.0166.000–6.499under 66to 71⁄2over 71⁄20.0130.0100.0200.0130.0100.0000.0130.0100.0100.0130.0100.0100.0230.0180.0200.0230.0180.0150.0230.0180.0180.0230.0180.0186.500–6.999under 66to 71⁄2over 71⁄20.0150.0120.0230.0150.0120.0000.0150.0120.0120.0150.0120.0120.0270.0210.0260.0270.0210.0150.0270.0210.0210.0270.0210.0217.000–7.499under 66to 71⁄2over 71⁄20.0180.0130.0260.0180.0130.0000.0180.0130.0130.0180.0130.0130.0320.0230.0310.0320.0230.0150.0320.0230.0230.0320.0230.0237.500–7.999under 66to 71⁄2over 71⁄20.0200.0150.0290.0200.0150.0000.0200.0150.0150.0200.0150.0150.0350.0260.0360.0350.0260.0150.0350.0260.0260.0350.0260.0268.000–8.499under 66to 71⁄2over 71⁄20.0230.0160.0310.0230.0160.0000.0230.0160.0150.0230.0160.0160.0410.0280.0330.0410.0280.0220.0410.0280.0280.0410.0280.0288.500–8.999under 66to 71⁄2over 71⁄20.0250.0170.0340.0250.0170.0000.0250.0170.0150.0250.0170.0190.0440.0300.0380.0440.0300.0220.0440.0300.0300.0440.0300.0309.000–9.499under 66to 71⁄2over 71⁄20.0280.0190.0370.0280.0190.0000.0280.0190.0150.0280.0190.0220.0450.0330.0430.0450.0330.0220.0490.0330.0330.0490.0330.0339.500–9.999under 66to 71⁄2over 71⁄20.0300.0200.0400.0300.0200.0000.0300.0200.0150.0300.0200.0250.0450.0350.0480.0450.0350.0220.0530.0350.0350.0530.0350.03510.000–10.999under 66to 71⁄2over 71⁄20.0340.0220.0440.0340.0220.0000.0340.0220.0150.0340.0220.0290.0450.0390.0550.0450.0390.0220.0600.0390.0390.0600.0390.03911.000–12.000under 66to 71⁄2over 71⁄20.0350.0250.0450.0350.0250.0000.0350.0250.0150.0350.0250.0350.0500.0450.0600.0500.0450.0220.0650.0450.0450.0650.0450.045AMany tubes with inside diameter less than 50%of outside diameter or with wall thickness more than 25%of outside diameter,or with wall thickness over 11⁄4in.,or weighing more than 90lb/ft,are difficult to draw over a mandrel.Therefore,the inside diameter can vary over or under by an amount equal to 10%of the wall thickness.See also Footnote B .BFor those tubes with inside diameter less than 1⁄2in.(or less than 5⁄8in.when the wall thickness is more than 20%of the outside diameter),which are not commonly drawn over a mandrel,Footnote A is not applicable.Therefore,for those tubes,the inside diameter is governed by the outside diameter tolerance shown in this table and the wall thickness tolerances shown in Table Number 9.CTubing having a wallthickness less than 3%of the outside diameter cannot be straightened properly without a certain amount of distortion.Consequently such tubes,while having an average outside diameter and inside diameter within the tolerances shown in this table,require an ovality tolerance of 1⁄2%over and under nominal outside diameter,this being in addition to the tolerances indicated in this table.D1in.=25.4mm.。

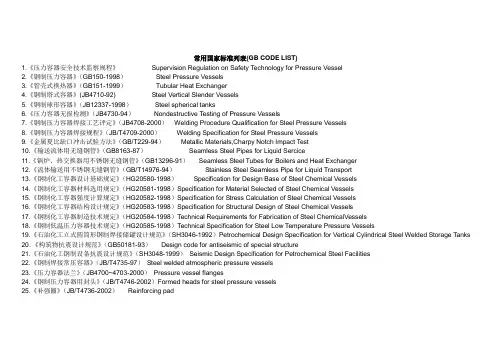

常用国家标准列表(GB CODE LIST)1.《压力容器安全技术监察规程》Supervision Regulation on Safety Technology for Pressure Vessel2.《钢制压力容器》(GB150-1998)Steel Pressure Vessels3.《管壳式换热器》(GB151-1999)Tubular Heat Exchanger4.《钢制塔式容器》(JB4710-92) Steel Vertical Slender Vessels5.《钢制球形容器》(JB12337-1998)Steel spherical tanks6.《压力容器无损检测》(JB4730-94)Nondestructive Testing of Pressure Vessels7.《钢制压力容器焊接工艺评定》(JB4708-2000)Welding Procedure Qualification for Steel Pressure Vessels8.《钢制压力容器焊接规程》(JB/T4709-2000)Welding Specification for Steel Pressure Vessels9.《金属夏比缺口冲击试验方法》(GB/T229-94)Metallic Materials,Charpy Notch Impact Test10.《输送流体用无缝钢管》(GB8163-87)Seamless Steel Pipes for Liquid Sercice11.《锅炉、热交换器用不锈钢无缝钢管》(GB13296-91)Seamless Steel Tubes for Boilers and Heat Exchanger12.《流体输送用不锈钢无缝钢管》(GB/T14976-94)Stainless Steel Seamless Pipe for Liquid Transport13.《钢制化工容器设计基础规定》(HG20580-1998)Specification for Design Base of Steel Chemical Vessels14.《钢制化工容器材料选用规定》(HG20581-1998)Specification for Material Selected of Steel Chemical Vessels15.《钢制化工容器强度计算规定》(HG20582-1998)Specification for Stress Calculation of Steel Chemical Vessels16.《钢制化工容器结构设计规定》(HG20583-1998)Specification for Structural Design of Steel Chemical Vessels17.《钢制化工容器制造技术规定》(HG20584-1998)Technical Requirements for Fabrication of Steel ChemicalVessels18.《钢制低温压力容器技术规定》(HG20585-1998)Technical Specification for Steel Low Temperature Pressure Vessels19.《石油化工立式圆筒形钢制焊接储罐设计规范》(SH3046-1992)Petrochemical Design Specification for Vertical Cylindrical Steel Welded Storage Tanks 20.《构筑物抗震设计规范》(GB50181-93)Design code for antiseismic of special structure21.《石油化工钢制设备抗震设计规范》(SH3048-1999)Seismic Design Specification for Petrochemical Steel Facilities22.《钢制焊接常压容器》(JB/T4735-97)Steel welded atmospheric pressure vessels23.《压力容器法兰》(JB4700~4703-2000)Pressure vessel flanges24.《钢制压力容器用封头》(JB/T4746-2002)Formed heads for steel pressure vessels25.《补强圈》(JB/T4736-2002)Reinforcing pad26.《容器支座》(JB/T4712~4725-92)Vessel support27.《输送流体用无缝钢管》(GB8163-87)Seamless Steel Pipes for Liquid Sercice28.《非金属软垫片》(JB/T4704-2000)Nonmetallic gaskets29.《缠绕垫片》(JB/T4705-2000)Spiral wound gaskets30.《金属包垫片》(JB/T4706-2000)Double-jacketed gaskets31.《等长双头螺柱》(JB/T4707-2000)Stud bolts32.《钢制管法兰、垫片、紧固件》(HG20592~20635-1997)Steel pipe flanges,gaskets, fastener33.《设备吊耳》(HG/T21574-1994)Lifting lugs34《立式圆筒形钢制焊接油罐施工及验收规范》(GBJ128-90)Vertical Cylindrical Steel Welded Storage Tank,Fabrication,Inspection and Testing Specification。

850900323436---------------------------------------------承插焊管件(一) Socket Welding FittingsGB/T 14383、SH 3410、HG/T 21634、ASME 、JIS B2316中心至承插孔底承插焊和螺纹活接头 Unions of Socket-Welding&ThreadedHG/T 21634、MSS SP-83公称通径Nominal PipeSize外径End DIA壁厚WallThickness螺母厚度Nut螺帽每英寸的螺纹扣数Threads Perinch球面凸缘厚度定位口高度公称装配长度Length AssemNominat结构尺寸LayingLength流通孔径Bore承插焊管件的接管外径、承插孔径及流通孔径尺寸表List of The Pipe Outside Diameter,Socket Diameter and Bore Diameter fo SW Fittings螺纹管件 Threaded Fittings GB/T 1426、ASME公称通径Nominal Pipe Size90°弯头、三通、四通90°Elbows、Tees、Crosses45°弯头45°Elbows所有管件All Fittings中心至端面Center to End中心至端面Center to End端部外径Outside Diameter ofBand最小壁厚Minimum Wall Thickness螺纹长度Length of Thread Min螺纹管件 Threaded Fittings GB/T 1426、ASME公称通径Nominal Pipe Size管箍、半管接头Couplings、Boss管帽Caps所有管件All Fittings 端面至端面End to End端面至端面End to End底部壁厚End Wall Thickness外径Outside Diameter 螺纹长度Length of Thread MinE F C min D65 80 100 21/2349210812160656864687592108140108127159螺纹管件 Threaded FittingsGB/T 1426、ASMEDN NPS A E、F E/2 6-81/8-1/4±±±10-203/8-3/4±±±25-501-2±±±65-10021/2-4±·The standards and codes of the fittings is conical threaded NPT angle 60°of GB/T 12716(ANSI/ASME if requiring other types o fthread,please indicate them in the purchased order.六角头双丝头 Hexagonal Nipples螺纹短节 Nipples公称通径Nominal Pipe Size管子外径Outside Diameter of Pipe螺纹长度Length of Thread Min长度End to End管子壁厚Wall Thickness of PipeDN NPS D L2 min L T6 8 1/81/475、100、150SCH80、SCH160。

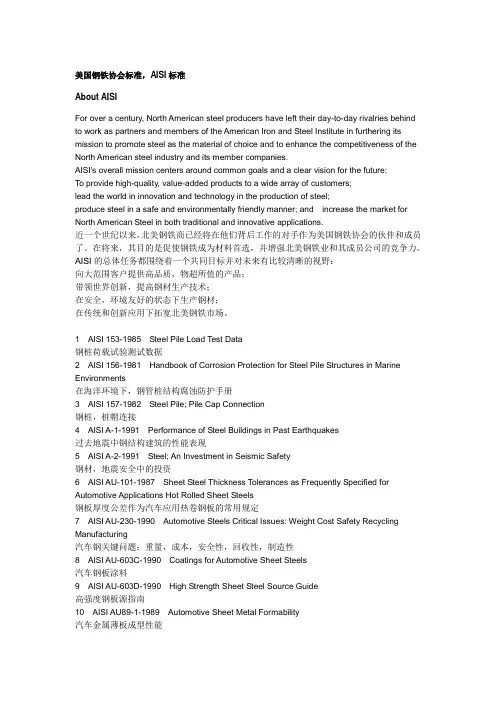

美国钢铁协会标准,AISI标准About AISIFor over a century, North American steel producers have left their day-to-day rivalries behind to work as partners and members of the American Iron and Steel Institute in furthering its mission to promote steel as the material of choice and to enhance the competitiveness of the North American steel industry and its member companies.AISI's overall mission centers around common goals and a clear vision for the future:To provide high-quality, value-added products to a wide array of customers;lead the world in innovation and technology in the production of steel;produce steel in a safe and environmentally friendly manner; and increase the market for North American Steel in both traditional and innovative applications.近一个世纪以来,北美钢铁商已经将在他们背后工作的对手作为美国钢铁协会的伙伴和成员了。

在将来,其目的是促使钢铁成为材料首选,并增强北美钢铁业和其成员公司的竞争力。

承插焊管件(一)Socket Welding FittingsGB/T 14383、SH 3410、HG/T 21634、ASME 、JIS B2316承插焊和螺纹活接头Unions of Socket-Welding&ThreadedHG/T 21634、MSS SP-83承插焊管件的接管外径、承插孔径及流通孔径尺寸表List of The Pipe Outside Diameter,Socket Diameter and Bore Diameter fo SW Fittings材料的化学成分和力学性是指标会因为某项条件的规定而有所改变,使用时请查阅原标准。

·The index of material chemical composition and mechanical properties shall change as to some defined condition,and please refer to the priginalmm管件坡口形式压力等级表(HG ~16-58,HGJ 514-87,SY 7510-87)mm注:表中HG为HG5010-87标准,HGJ为HGJ514-87,SY为SY7510-87标准。

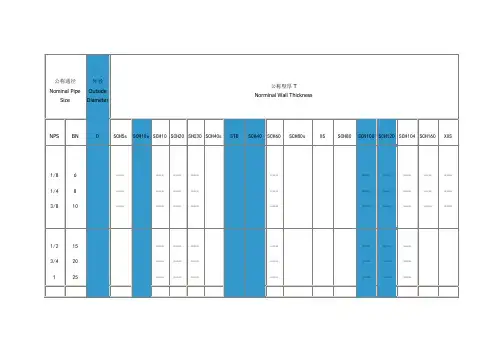

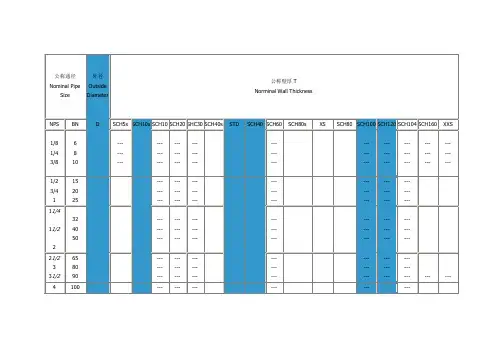

管件尺寸公差壁厚分级表ANSI &壁厚分级表GB 12459-90 GB/T 13401-92mm壁厚表 GB 12459、GB/T 13401公称通径外径公称壁厚 TA 系列B 系列 Sch 5s Sch 10s Sch 20s LGSch 20 Sch 30 STDSch 40 Sch 60 XsSch 80 Sch 100 Sch 120 Sch 140 Sch 160 15 20 25 18 25 32 ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ ┅ 32 40 5038 45 57┅ ┅ ┅┅ ┅┅ ┅ ┅┅ ┅ ┅┅ ┅ ┅┅ ┅ ┅┅ ┅ ┅┅ ┅ ┅┅ ┅ ┅65 80 90 (73) 7689┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅100 125 150 108133159┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅200 250 300 219273325┅┅┅┅┅┅┅┅┅350 400 450 500 377 426 478 529550 600 650 700 559610660711┅630┅720┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅750 800 850 900 762813864914┅820┅920┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅950 1000 1050 96510161067┅1020┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅1100 1150 1200 1118116812201120┅1220┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅┅注:1、sch5s、10s、20s用于不锈钢管件。

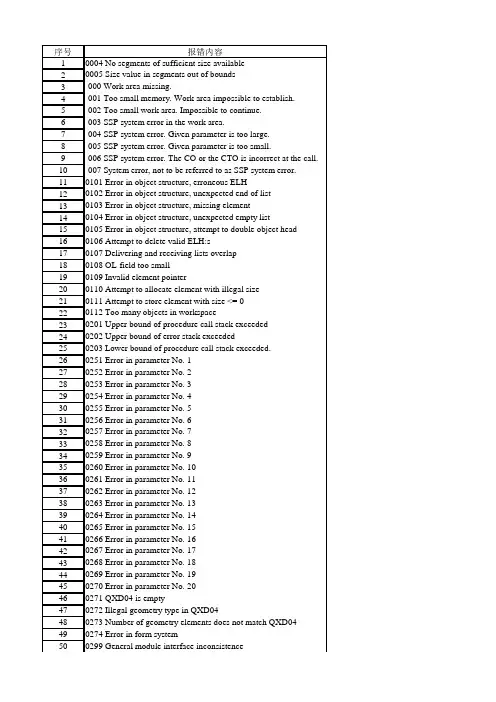

序号报错内容10004 No segments of sufficient size available20005 Size value in segments out of bounds3-000 Work area missing.4-001 Too small memory. Work area impossible to establish.5-002 Too small work area. Impossible to continue.6-003 SSP system error in the work area.7-004 SSP system error. Given parameter is too large.8-005 SSP system error. Given parameter is too small.9-006 SSP system error. The CO or the CTO is incorrect at the call. 10-007 System error, not to be referred to as SSP system error. 110101 Error in object structure, erroneous ELH120102 Error in object structure, unexpected end of list130103 Error in object structure, missing element140104 Error in object structure, unexpected empty list150105 Error in object structure, attempt to double object head 160106 Attempt to delete valid ELH:s170107 Delivering and receiving lists overlap180108 OL-field too small190109 Invalid element pointer200110 Attempt to allocate element with illegal size210111 Attempt to store element with size <= 0220112 Too many objects in workspace230201 Upper bound of procedure call stack exceeded240202 Upper bound of error stack exceeded250203 Lower bound of procedure call stack exceeded.260251 Error in parameter No. 1270252 Error in parameter No. 2280253 Error in parameter No. 3290254 Error in parameter No. 4300255 Error in parameter No. 5310256 Error in parameter No. 6320257 Error in parameter No. 7330258 Error in parameter No. 8340259 Error in parameter No. 9350260 Error in parameter No. 10360261 Error in parameter No. 11370262 Error in parameter No. 12380263 Error in parameter No. 13390264 Error in parameter No. 14400265 Error in parameter No. 15410266 Error in parameter No. 16420267 Error in parameter No. 17430268 Error in parameter No. 18440269 Error in parameter No. 19450270 Error in parameter No. 20460271 QXD04 is empty470272 Illegal geometry type in QXD04480273 Number of geometry elements does not match QXD04 490274 Error in form system500299 General module interface inconsistence510301 Overflow in object520302 New object name already in use530303 Object does not exist540304 Invalid object pointer550305 Open failure on input file560306 Invalid format on input file570307 Invalid object name (too long)580308 Write failure on file590321 Invalid logical data bank unit600322 Logical data bank unit already in use610323 Data bank table full620324 Lock entry found instead of object630325 Logical data bank unit not connected640326 Object already exists in working area650327 Object not found in the data bank660328 Object not locked670329 Data file has invalid format680330 Object currently locked by another user690331 Too many objects are already locked700332 Object has invalid format710333 Object already exists in data bank720334 No room in data bank730335 Unsupported object structure740336 Virtual data bank already conneced750337 Virtual data bank not connected760338 Databank may not be of type "sequential db directory" 770339Attempt to store a non-picture object in a sequential db directory780340 Open failure of directory file790341 Close failure of directory file800342 Record not found in the directory file810343 Record locked820344 Fatal error in directory file830345 Error creating directory file840346 Record already exists in directory file850347 No room on output device when updating directory file 860348 Data bank currently locked by another user.870349 Attempt to lock an object in a sequential db directory 880350 Open failure of data file890351 Close failure of data file900352 Record not found in the data file910353 Record locked920354 Fatal error in data file930355 Error creating data file940356 No room on output device when updating data file950357 Two revisions of the same object not allowed in workspace 960358 Allocation map has invalid format970360 Open failure of sequential data bank980361 Close failure of sequential data bank990362 End of file of sequential data bank1000364 Fatal error in sequential data bank1010365 Error creating sequential data bank1020366 No room on output device when updating sequential data bank 1030367 Error in object code1040368 Restored object size does not match the stored size. 1050369 Attribute type not recognized1060370 Access to object not allowed1070371 M2 can not read objects of version 41080372 Project not enabled to store objects of version 41090401 Too big contour, element maximum size exceeded1100402 Error in record (card) decoding1110403 Unknown record (card) type1120404 Wrong order of picture elements1130405 Unexpected end of file1140406 Erroneous input term, should be record type1150407 Unexpected new object, old one not completed1160408 Unexpected geometry element1170409 Erroneous term - violates input syntax1180410 Unexpected component element1190411 Unexpected subcomponent element1200412 Syntax error in input1210413 Data missing in input for component1220414 Data missing in input for subcomponent1230415 Data missing in input for text element1240416 Unexpected subpicture element1250417 Data missing in input for subpictures1260418 Set of rules is not initiated1270419 Number for placing rules is not found for specific parameter 1280501 Empty component1290502 Wrong level for subcomponent1300503 Empty subcomponent1310504 Unknown data type for geometry element1320505 Wrong level for geometry1330506 Empty picture object1340507 Unallowed scale factor1350508 The element is not a subpicture1360509 Unallowed level1370510 Unallowed number of subpicture levels1380511 Unallowed start level for identification1390512 Unallowed end level for identification1400513 Subordinate element missing1410514 Empty picture1420515 Transformation information missing1430516 The element is not a subcomponent1440517 Illegal font number1450518 Symbol font file does not exist1460524 Indicated segment does not exist1470525 Points on the contour not given in the direction of the contour 1480526 Indicate element does not exist1490527 Wrong type of element given1500529 Object not initialized1510530 Subordinate level not open1520531 Element on superior level not open1530532 Symbol does not exist 1540533 Size of element too big 1550534Mismatch between the opened subcomponent and the given 1560535 Text font file does not exist or out of range (8-99)1570536 Error in text font file (8-99)1580537 Error when loading text font file (8-99)1590538 Vector font file does not exist or out of range (1-99)1600539 Vector font does not exist 1610540 Vector font does exist but language not assigned 1620541 Internal symbol font error 1630701 Erroneous object head (ELH-error)1640702 Empty picture object 1650703 Attempt to identify an element not being a component 1660801 Error in activity code 1670802 First file does not exist 1680803 First message array too small 1690804 First index array too small 1700805 Second file does not exist 1710806 Second message array too small 1720807 Second index array too small 1730808 Message file not available 1740809 Impossible to open plotter file 1750810 Read error on first message file 1760811 Read error on second message file 1770812 Denoted message does not exist 1780901 Communication breakdown 1791001 CAT-object does not exist 1801002 Contour does not exist 1811003 Table row does not exist 1821004 Member does not exist 1831005 Segment part does not exist 1841006 Error in contour representation 1851007 Error in activity code specifying the contour to be treated 1861008Error in activity code specifying the part of the contour to be treated 1871009Error in activity code specifying the part of the table to be treated 188-100 Incorrect total name.1891010Error in activity code specifying the part of the table row to be treated 1901011Error in activity code specifying the table member to be treated 1911012Error in activity code specifying the part of the table member to be treated 1921013 Invalid segment number 1931014Error in activity code specifying the part of the segment to be treated 1941015 Error in specifying the attribute to be treated 1951016Error in location parameter defining the kind of attribute to be treated 1961017Error in location parameter defining the position of the wanted element 1971018 Invalid current CAT-object number1981019 Pointer in QCATPT of QWC030 to owner element not valid 199-101 Total name too long.2001020 The object is not a CAT-object 2011021 Error in attribute size 2021022 Erroneous segment type 2031023 Dimensions not equal in receiving and delivering contours 2041024Error in activity code specifying the part of a segment to be saved 2051025Error in activity code specifying the part of a contour to be saved 2061026 Given point is outside contour 2071027 Error in representation (must be 2 or 3)2081028Given representation does not correspond to the original representation in 2091029 Given data not sufficient to define the new coordinate system 210-102 Type too long.2111030Error in activity code specifying how to create a transformation matrix 2121031 Error in parameter defining the coordinate axis 2131032 Error in parameter defining the coordinate plane 2141033 Transformation matrix is not invertible 2151034 Error in activity code defining point or vector 2161035Error in activity code specifying storing of attribute data (common area of 2171036 Segment given from input is a zero segment 2181037 Beta given from input does not belong to (0,1)2191038 Tangent vector undefined 2201039 Equation root < 0221-103 Attribute name too long.2221040 Vector along line is the zero vector 2231041 Vector perpendicular to plane is the zero vector 2241042 The contour is not closed 2251043 Transformation not possible because the transformation matrix includes a 2261044 Points not given in the direction of the contour 2271045 Error in activity code controlling tangent calculations 2281046 Error in tangent code 2291047 Too many point attributes 2301048 Given activity code does not allow equal contours 2311049 The contour does not contain any segments 232-104 Incorrect pointer.2331050 The contour is closed 2341051 Impossible to insert contour 2351052Error in activity code (PTYPE)specifying the type of projection 2361053The centre of projection lies in the projection plane (central projection)2371054The projecting lines are parallel to the projection plane (parallel 2381055 Input object and resulting object must not be equal 2391056 Error in contour code 12401057 Error in object code 22411058 2-attribute at contour level not found 2421059 2-attribute at object level not found 243-105 The first of the given objects in the parameter list is missing.2441060 Space curve improperly stored2451061 Wrong geometry type for R2-contour2461062 Impossible tangent vectors2471063 Intersection point missing2481064 Too many intersection points2491065 Impossible to create fillet2501066 Argument array too small2511067 Array too small2521068 Unallowed value of scewness factor2531069 Undefined tangent vector254-106The second of the given objects in the parameter list is missing.2551070 Bad combination of data for a BC-segment (surface problem) 2561071 Coordinate outside given limits2571072 Impossible to create curve2581073 Intersection curve missing2591074 Given length longer than contour length2601075 Upper bound of attribute data structure exceeded261-107 Object missing.262-108 The given object is not a geometry object.263-109 The given object is not a table object.264-110 The given objects are of different kinds.265-111 Empty object at the call.266-112 Contour 0 empty at the call.267-113 The given contour number too large.268-114 The given contour 0 at the call closed.269-115 The last segment of the CO-0 at the call is not a line segment. 270-116The last segment of the CO-0at the call is parallel to the given line.271-117The end point of the CO-0at the call lies inside the given circle.272-118 The given segment does not exist.273-119 Incorrect orientation of the given segments.274-120 The given length is too large.275-121 The given point does not lie on the given segment.276-122 Incorrect end point selection (f = 0 and f = 1).277-123 One or several breakpoints outside KRANGE.278-124 Amplitude outside KRANGE.279-125The given amplitude is larger than half the distance between the end points280-126 Central angle greater than 360.281-127 Number of distinct points less than 2.282-128 Intersection point number not equal to + 1 or + 2. 283-129 The length of the interval is zero.284-130 Integer parameter outside the range.285-131 Incorrect location code.286-132 Too large attribute.287-133 Attribute of wrong format.288-134 Incorrect code number for part selection of contour. 289-135 Point on contour with given coordinate missing. 290-136 Incorrect boundary conditions.291-137 Incorrect intersection point designation.292-138 Incorrect storing of points in the CTO.293-139 Incorrect parameter data type.294-140 Table row missing.295-141 Improper storing of table. 296-142 The given radius is too large.297-143The second of the given objects in the parameter list existed at the call.298-144 Incorrect password.299-145 Incorrect number of parameters.300-146 Unallowed value of input parameters.301-147 Attribute number out of range.302-148 Table member missing.303-149 Input string is empty.304-150 Unallowed inclination angle.3052001 Unallowed record number in text input3062002 Wrong order among records in text input3072004 No object is current3082005 Current subpicture not panel3092006 Information about current measurement element missing 3102007 Erroneous table structure311-200 Attribute type out of bounds.312-201 Attribute head without attribute.313-202 Type out of bounds.314-203 I/O buffer too small.315-204 Row head without elements.316-205 Incomplete type 5 attribute.317-206 Impossible to unpack I/O buffer.31822000 Name of current deck is missing in modal storage. 31922001 Projection attribute is missing in picture object. 32022002 Transformation attribute is missing in picture object. 32122003 Erroneous item attribute.32222004 Name of deck is missing in picture object. 32322005 Name of room is missing in picture object. 32422006 No current room.32522007 Hole id out of range.32622008 Erroneous start element.32722009 Invalid identification number.32822010 Invalid data type.32922011 Error in conversion of a point from 2D to 3D. 33022012 Projection is not axis-parallel.33122013 Error transforming an arrangement.33222014 Copy an item failed.33322015 Unknown item type to recreate.33422016 Failed to identify a room.33522017 Erroneous type of item.33622018 Erroneous height axis.33722019 Pointer to the deck not found.33822020 Erroneous number of intersections.33922021 Copy geometry element failed.34022100 Erroneous type of item.34122300 Name of deck is missing in model object.34222301 Erroneous directrix.34322600 Error in form handling.34422601 Prohibited component type.34522602 Prohibited table.34622603 Erroneous table dimension.34722604 Prohibited table item.34822605 Incorrect data type of table value.34922606 Erroneous type of information.35022607 Erroneous description object.35122608 Error occured in the LIB$SET_LOGICAL function. 35223000 Invalid identification number.35323001 Error in form handling.35423002 Undefined symbolic name for test sequence directory. 35523003 File specification syntax error.3562501 Impossible to create default file.3572502 Mismatch between 01 and 04 objects in parts generation 3582503 Incorrect type of CAT-object3592504 Incorrect type of picture object3602505 Incorrect combination of objects3612506 Incorrect storing of 02-object3622507 Attribute describing detail missing or incorrect in 02-object 3632508 Incorrect type of subpicture in 03-element (ID missing) 3642509 Attribute 101 missing or incorrect in 01-object3652510 Attribute 101 missing or incorrect in 02-object3662511Attribute containing transformation matrix missing or incorrect in3672512 Undefined CAT-object3682513 Undefined picture object3692514 Illegal format on data file containing part names3702515 Parent plate missing in 03-object3712516 Subcomponent corresponding to attribute missing3722517 Contour attribute 101 missing3732518 Standard hook file has illegal format or does not exist 3742519 Component corresponding to attribute is missing3752520 Start order attributes do not correspond to the start attributes3762521Auxiliary function attribute found on segment level is missing on object3772522Gap attribute found on segment level is missing on object level3782523 Internal attribute arrays exceeded3792524 Inconsistency in plate structure3802525 Attribute not found3812526 Incorrect attribute3822527 Plate part contour missing or erroneous3832528 Verified path outside raw plate3842529 Impossible to create chamfer file3852530 Impossible to evaluate CVBA angle3863001 SLABEL too big. Impossible to put in index tables3873002 Information about SLABEL does not exist3883003 Invalid index to IDENT-table3893004 ID is not found in IDENT-table3903005 ID-table is full3913006Information about SLABEL exists,must be deleted before "put".3923007 No current scheme3933008 Editor not in system3943009 Any of the index table attributes missing395-300 One or more breakpoints outside KRANGE.3963010 Scheme name in attribute 199 "not =" current scheme name. 3973011 No picture object found3983012 Error opening scheme file for writing3993013 Error writing scheme file line4003014 Error converting scheme for writing4013015 Panel already occupied by scheme generation402-301 Amplitude outside KRANGE.403-302The amplitude is larger than half the distance between the starting point404-303 Intersection point missing.405-304 Intersection point before the given point missing. 406-305 Intersection point after the given point missing.407-306The last line segment of the CO-0at the call is not touched by the bending408-307 The given point lies on the contour 0 of the given description. 409-308 Incorrect boundary conditions.410-309 Part of CAT object missing.4113100 Failed to verify the shell curve object.4123101 Failed to verify the seam object.4133102 31024143103 The curve is outside the default box.4153104 Failed to verify the point object.4163105 Failed to verify the plane object.4173106 Failed to verify the cylinder object.4183107 Corrupt point object, the root attribute does not exist. 4193108 Corrupt seam object, the root attribute does not exist. 4203109 Corrupt curve object, the root attribute does not exist.421-310 Data file not open for reading.4223110 Corrupt cylinder object, the root attribute does not exist. 4233111 Corrupt plane object, the root attribute does not exist. 4243112 Corrupt object, a point attribute is missing.4253113 Corrupt object, a plane attribute is missing.4263114 Corrupt object, a curve attribute is missing.4273115 Corrupt object, a cylinder attribute is missing.4283116 Corrupt object, a surface attribute is missing.4293117 A referenced surface object was not found.4303118 A referenced curve object was not found.4313119 A referenced point object was not found.432-311 Data file not open for writing.4333120 A referenced plane object was not found.4343121 A referenced cylinder object was not found.4353122 Corrupt object, invalid definition data.4363123 Failed to intersect the surface with the plane.4373124 Failed to intersect the shell curve with the plane.4383125 Failed to convert a Lines Fairing curve to a space curve. 4393126 Failed to expand the point object.4403127 Failed to expand the plane object.4413128 Failed to expand the curve object.4423129 Failed to intersect the two curves.443-312 Data file already open for sequential processing.4443130 Could not define a parameter axis for proper space curve. 4453131 Failed to trim the curve with the default box.4463132 Corrupt object, invalid or missing root attribute.4473133 Failed to reduce object.4483134 Conversion failed: Could not find a parameter axis. 4493135 Failed to verify the shell profile object.4503136 Failed to verify the shell stiffener object.4513137 A referenced shell stiffener object was not found.4523138 Maximum number of points exceeded.4533139 Failed to verify the feature.454-313 Demanded unit missing.4553140 Failed to verify the hull curve object.4563141 Limit table object missing or incorrect.4573142 Mismatch in limit table.4583143 A referenced panel was not found.4593144 A referenced shell profile was not found.4603145 A referenced seam was not found.4613146The shell stiffener overlaps another stiffener in the shell profile.4623147 The point cannot be moved outside the curve.4633148 Failed to intersect the shell curves.464-314 Intersection point missing when n = 0.465-315 Impossible to write (e.g. secondary areas filled).466-316 Data file already closed.467-317 Spline calculations interrupted. Check input points.468-318Plane curve not single-valued with respect to the given coordinate.469-319 Record locked.4704001 PCDB - No component slot available4714002 PCDB - Component not found in the data bank4724003 PCDB - Component currently locked by another user 4734004 PCDB - Component already exists on the data bank 4744005 PCDB - Component has invalid format4754006 PCDB - Invalid current component number4764007PCDB-Component not current under given current component number4774008 PCDB - Invalid activity code4784009 PCDB - Object found instead of a component4794201 PCDB - Search object already exists4804202 PCDB - Search data not defined4814203 PCDB - Search data not defined at connection one4824301 PSDB - Failure creating lock entry4834302 PSDB - Named element already exists4844303 PSDB - Superior environment is not active4854304 PSDB - Already active in QWQ124864305 PSDB - Invalid data type4874306 PSDB - One or two project object missing4884307 PSDB - Invalid status encountered in QWQ124894308 PSDB - Object not locked when attempting to delete or update 4904309 PSDB - Attribute not found4914310 PSDB - Part not found4924311 PSDB - External part cannot be updated4934312 PSDB - Name missing in name table 4944313 PSDB - Impossible part4954314 PSDB - Erroneous data in attribute4964315 PSDB - Keyword not found in syntax definition4974316PSDB-Arguments do not match the application(is syntax definition4984317 PSDB - Error in deleting connection attribute4994318 PSDB - Error during deletion of a part5004319 PSDB - Error when restoring part5014320 PSDB - Failure deleting subview (interactive modelling) 5024321 PSDB - Transformation data for view missing5034322 PSDB - Failure copying subview (interactive modelling) 5044323 PSDB - Name attribute missing (interactive modelling) 5054324 PSDB - Interactive component choice menu not initiated 5064325 PSDB - Error in logical references5074326 PSDB - Branch element not found5084327 PSDB - Error in object pointer of part5094328 PSDB - Error when creating new branch5104329 PSDB - Referenced ppdb object not found5114330 PSDB - Pipe length not defined where it should be defined 5124331 PSDB - Unexpected element pointer5134332 PSDB - Branch not found5144333 PSDB - Failure open model subview5154334 PSDB - Impossible connection number5164335 PSDB - Invalid object name5174336 PSDB - Extra connection information attribute not found 5184337 PSDB - Conflicting co-ordinate data5194338 PSDB - Bad call of lock co-ordinate routines5204339 PSDB - Failure converting to equipment5214350 PSDB - Previously stored attribute is missing5224610 PPDB - Erroneous element pointer5234611 PPDB - Erroneous element type5244612 PPDB - Erroneous element size5254613 PPDB - Erroneous element structure5264620 PPDB - Error creating object name (names too long) 5274621 PPDB - Error splitting object name5284640 PPDB - Project not current5294641 PPDB - Position not current5304642 PPDB - Function not current5314643 PPDB - Pipe not current5324644 PPDB - Pipe sketch not current5334660 PPDB - Project already exists5344661 PPDB - Position already exists5354662 PPDB - Function already exists5364663 PPDB - Pipe already exists5374664 PPDB - Pipe sketch already exists5384670 PPDB - Project does not exist5394671 PPDB - Position does not exist5404672 PPDB - Function does not exist5414673 PPDB - Pipe does not exist5424674 PPDB - Pipe sketch does not exist5434680 PPDB - Subordinate element current5444681 PPDB - Object and reference element do not correspond 5454682 PPDB - Erroneous component limit5464683 PPDB - Element with spec. ID already exists5474684 PPDB - Element with spec. ID does not exist5484685 PPDB - Erroneous connection reference5494686 PPDB - Too many part elements in one material 5504690 PPDB - Referenced part not found in PSDB5514691 PPDB - Sketch limit not allowed5524692 PPDB - PSDB not current5534693 PPDB - Element not found in PSDB5544694 PPDB - Part not found in PSDB5554695 PPDB - PCM-attribute not found in PSDB5564801 PPDB - Erroneous font number5574802 PPDB - Contour attribute not found5584803 PPDB - Error in reading drawing form5594804 PPDB - Invalid format of bending machine attribute 5604901 PPDB - Pipe reference in common area QWP60 not found5614902PPDB-Maximum number of reference points in pipe sketch exceeded5624903 PPDB - More than three connections5635000 PCDB - Invalid component type5645001 PCDB - Invalid component group5655002 PCDB - Invalid component subgroup5665003 PCDB - Invalid pressure class5675004 PCDB - Failure reading component5685005 PCDB - Failure deleting component5695006 PCDB - Failure reading search object5705007 PCDB - Failure deleting search object5715008 PCDB - Failure storing component5725009 PCDB - Failure listing component573-500 Empty geometry object.5745010 PCDB - Failure storing search object5755011 PCDB - Nominal diameter could not be calculated5765012 PCDB - No search mask exists for given component type 5775013 PCDB - Search object not found5785014 PCDB - Failure creating MIS input579-501 Empty table object.580-502 The given points are collinear.581-503 Undefined axis.582-504 Incorrect storing of plane.583-505 Coordinates in wrong order.584-506 Incorrect storing of space curve.585-507 The space curve consists of more than one curve branch.586-508Space curve not single-valued with respect to the given coordinate.587-509 Undefined direction.588-510 No part of the curve inside the given interval.589-511 Incorrect storing of cylinder.590-512 Incorrect storing of surface or surface element.591-513 Intersection curve missing.592-514 Attribute 1 missing.。