methode

- 格式:pdf

- 大小:334.78 KB

- 文档页数:5

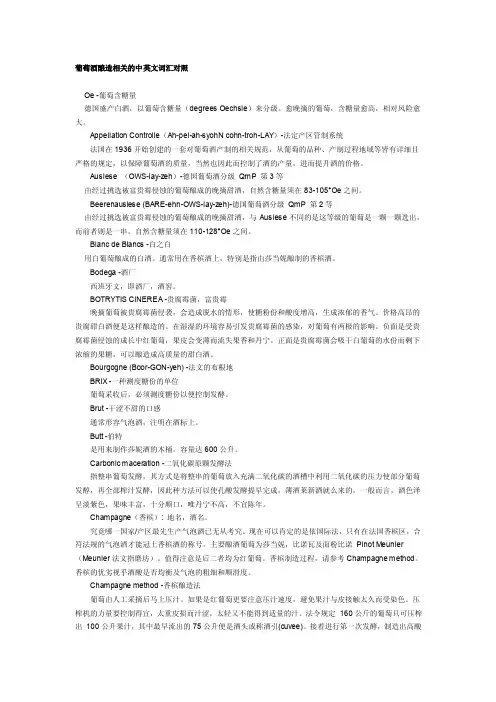

葡萄酒酿造相关的中英文词汇对照Oe -葡萄含糖量德国盛产白酒,以葡萄含糖量(degrees Oechsle)来分级。

愈晚摘的葡萄,含糖量愈高,相对风险愈大。

Appellation Controlle(Ah-pel-ah-syohN cohn-troh-LAY)-法定产区管制系统法国在1936开始创建的一套对葡萄酒产制的相关规范,从葡萄的品种、产制过程地域等皆有详细且严格的规定,以保障葡萄酒的质量,当然也因此而控制了酒的产量,进而提升酒的价格。

Auslese (OWS-lay-zeh)-德国葡萄酒分级QmP 第3等由经过挑选被富贵霉侵蚀的葡萄酿成的晚摘甜酒,自然含糖量须在83-105°Oe之间。

Beerenauslese (BARE-ehn-OWS-lay-zeh)-德国葡萄酒分级QmP 第2等由经过挑选被富贵霉侵蚀的葡萄酿成的晚摘甜酒,与Auslese不同的是这等级的葡萄是一颗一颗选出,而前者则是一串。

自然含糖量须在110-128°Oe之间。

Blanc de Blancs -白之白用白葡萄酿成的白酒。

通常用在香槟酒上,特别是指由莎当妮酿制的香槟酒。

Bodega -酒厂西班牙文,即酒厂,酒窖。

BOTRYTIS CINEREA -贵腐霉菌,富贵霉晚摘葡萄被贵腐霉菌侵袭,会造成脱水的情形,使糖粉份和酸度增高,生成浓郁的香气。

价格高昂的贵腐甜白酒便是这样酿造的。

在湿湿的环境容易引发贵腐霉菌的感染,对葡萄有两极的影响。

负面是受贵腐霉菌侵蚀的成长中红葡萄,果皮会变薄而流失果香和丹宁。

正面是贵腐霉菌会吸干白葡萄的水份而剩下浓缩的果糖,可以酿造成高质量的甜白酒。

Bourgogne (Boor-GON-yeh) -法文的布根地BRIX -一种测度糖份的单位葡萄采收后,必须测度糖份以便控制发酵。

Brut -干涩不甜的口感通常形容气泡酒,注明在酒标上。

Butt -伯特是用来制作莎妮酒的木桶。

容量达600公升。

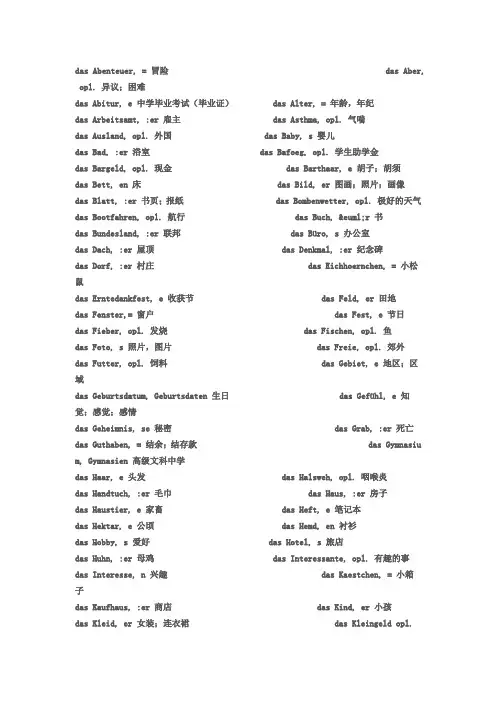

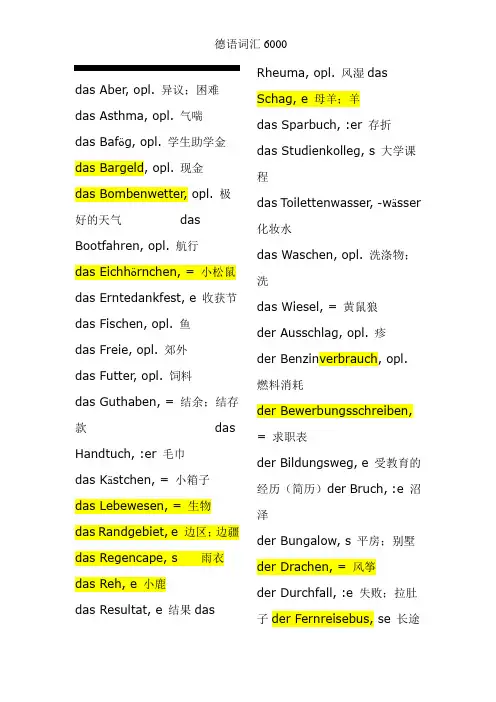

das Abenteuer, = 冒险 das Aber, opl. 异议;困难das Abitur, e 中学毕业考试(毕业证) das Alter, = 年龄,年纪das Arbeitsamt, :er 雇主 das Asthma, opl. 气喘das Ausland, opl. 外国 das Baby, s 婴儿das Bad, :er 浴室 das Bafoeg, opl. 学生助学金das Bargeld, opl. 现金 das Barthaar, e 胡子;胡须das Bett, en 床 das Bild, er 图画;照片;画像das Blatt, :er 书页;报纸 das Bombenwetter, opl. 极好的天气das Bootfahren, opl. 航行 das Buch, ër 书das Bundesland, :er 联邦das Büro, s 办公室das Dach, :er 屋顶 das Denkmal, :er 纪念碑das Dorf, :er 村庄 das Eichhoernchen, = 小松鼠das Erntedankfest, e 收获节 das Feld, er 田地das Fenster,= 窗户 das Fest, e 节日das Fieber, opl. 发烧 das Fischen, opl. 鱼das Foto, s 照片,图片 das Freie, opl. 郊外das Futter, opl. 饲料 das Gebiet, e 地区;区域das Geburtsdatum, Geburtsdaten 生日das Gefühl, e 知觉;感觉;感情das Geheimnis, se 秘密 das Grab, :er 死亡das Guthaben, = 结余;结存款 das Gymnasium, Gymnasien 高级文科中学das Haar, e 头发 das Halsweh, opl. 咽喉炎das Handtuch, :er 毛巾 das Haus, :er 房子das Haustier, e 家畜 das Heft, e 笔记本das Hektar, e 公顷 das Hemd, en 衬衫das Hobby, s 爱好 das Hotel, s 旅店das Huhn, :er 母鸡 das Interessante, opl. 有趣的事das Interesse, n 兴趣 das Kaestchen, = 小箱子das Kaufhaus, :er 商店 das Kind, er 小孩das Kleid, er 女装;连衣裙 das Kleingeld opl. 零钱das Kloster, = 寺庙 das Konto, s 银行帐户das Korn, :er 种子;颗粒 das Krankenhaus, :er 医院das Lamm, :er 小羊 das Land, :er 地;国家;郊外das Lebewesen, = 生物 das Liebespaar, e 情侣das Loch, :er 窟窿,破洞 das Mal, e 次,回das Medikament, e 药物 das Motiv, e 动机;创意das Motorrad, :er 摩托车 das Neue, opl. 新事物das Ohr, en 耳朵 das Organ, e 器官das Paar, e 一双,一对 das Papiergeld, opl. 纸币das Parfüm, e/s 香水 das Parlament, e 国会;会议das Pferd, e 马 das Problem, e 问题das Programm, e 程序;节目 das Randgebiet, e 边区;边疆das Regencape, s 雨衣 das Reh, e 小鹿das Reich, e 国家;领域;界 das Resultat, e 结果das Rheuma, opl. 风湿 das Richtige, opl. 正确das Schag, e 母羊;羊 das Schampon, s 香波das Schoene, opl. 美人 das Schreibenzug, opl. 文具das Silber opl. 银 das Sparbuch, :er 存折das Studentenwohnheim, e 学生宿舍 das Studienkolleg, s 大学课程das Studium, Studien 学期 das Talent, e 天才das Theaterspiel, en 戏剧 das Thema, Themen 题目;标题das Thermometer, = 温度计 das Tier, e 动物das Toilettenwasser, -waesser 化妆水 das Trinken, opl. 饮品das Verstaendnis, se 理解;领会 das Volksfest, e 民间节日das Waschen, opl. 洗涤物;洗 das Wasser, opl. 水das Werk, e 工作;活动 das Whonheim, e 住宅das Wiesel, = 黄鼠狼 das Wohl, opl. 幸福;健康das Zahlungsmittel, = 支付手段 das Zeichen, = 信号das Zelt, e 帐篷 das Zeugnis, se 证书;证明das Ziel, e 目标 das Zimmer, = 房间das Zuhause, opl. 家,家园 das, Diplom, e 毕业文凭der Abend, e 晚上 der Abschluss, :e 结束;终结der Absender, = 寄信人 der Affe, n 猴子der Anfang, :e 开始;初 der Anzug, :e 套服;制服der Appetit, opl. 胃口 der Arbeitsplatz, :e 工作岗位;职位der Arbeitstag, e 工作日 der aerger, opl. 不愉快的;der Arm, e 胳膊 der Arzt, aerzte 医生der Asuflug, :e 远足;郊游 der Atlantik 大西洋der Aufgang, :e 入口 der Augenblick, e 时刻,片刻der Ausschlag, opl. 疹 der Ausstieg, e 下车口;出口der Ausweis, e 证件;证明 der Balkon, e 阳台der Band, :e 册,本,磁带 der Bart, :e 胡须der Bauch, :e 肚子 der Bauer, n 农民der Bauernhof, :e 农舍 der Begriff, e 概念;观念;想法der Behoerdentag, e 政府工作日 der Benzinverbrauch, opl. 燃料消耗der Bescheid, e 告知;通知 der Besuch, e 访问;参观der Bewerbungsbrief, e 求职信 der Bewerbungsschreiben, = 求职表der Bildungsweg, e 受教育的经历(简历) der Biologe, n 生物学家der Bleistift, e 铅笔 der Blick, e 一瞥;一眼 [auf den ersten Blick.第一眼看上去]der Block, :e (象)块(一样的物品、事物) der Brauch, :e 风俗;习惯der Bruch, :e 沼泽 der Buchstabe, n 书写体der Bungalow, s 平房;别墅 der Damenschirm, e 女士衬衫der Daumen, n 拇指 der Dialog, e 对话der Dienst, e 工作;职务 der Drachen, = 风筝der Durchfall, :e 失败;拉肚子 der Einfluss, :e 影响;流入der Eingang, :e 入口 der Einkauf, :e 购买der Empfaenger, = 收件人;接收者 der Entwurf, :e 草图;设计图der Esel, = 驴 der Familienstand, opl. 婚姻状况der Fan, s 崇拜者;追随者 der Feind, e 敌人der Fernreisebus, se 长途汽车 der Fernsehtext, e 电视节目der Film, e 电影;胶片 der Fischer, = 渔夫der Fleck, en 地点;斑点 der Friseur, e 理发师der Frühling, e 春季 der Fuchs, :e 狐狸der Führerschein, e 驾驶执照 der Geburtsort, e 出生地der Geburtstag, e 生日 der Gefrierpunkt, e 冰点der Geier, = 秃鹰 der Gips, e 石膏der Glaube, n 信仰;认为 der Gliederschmerz, en 关节炎der Grund, :e 土地;基础 der Hals, :e 脖子der Halsschmerz, en 喉咙疼 der Hammer, : 糟糕的事der Hausbesuch, e 医生家访der Hausschlüssel, = 钥匙der Herbst, e 秋天 der Hof, :e 院子;宫廷der Hoerer, = 听众 der Hund, e 狗der Husten 咳嗽 der Hut, :e 帽子der Irrtum, :er 错误;失误 der Kassenzettel, = 收据;发票der Katalog, e 目录; der Kater, = 雄猫der Kollege, n 同事 der Komfort, opl. 舒适der Kommilitone, n 大学同学 der Komponist, en 作曲家der Kongress, e 代表会 der Koenig, e 国王der Konstrukteur, e 建造;构造 der Kontoauszug, :e 银行结单der Kopf, :e 头 der Kopfschmerz, en 头疼der Korb, :e 篮子;筐 der Korridor, e 走廊der Krankenschein, e 病假单 der Kredit, e 信用der Krieg, e 战争 der Kuchen, = 蛋糕der Küchenschrank, :e 橱柜 der Kugelschreiber, = 圆珠笔der Kuss, :e 吻 der Lebenslauf, :e 简历der Loewe, n 狮子 der Luftpostbrief, e 航空信der Magen, = 胃 der Manager, = 经理der Mantel, : 大衣,外衣 der Markt, :e 市场der Maulwurf, :e 鼹鼠 der Mond, e 月亮der Mund, :er 嘴 der Mut, opl. 勇气;大胆der Nachbar, n 邻居 der Nachfolger, = 继承者der Neffe, n 侄子 der Ort, e 场所;地区der Paedagoge, n 教师;教育家 der Papagei, en 鹦鹉der Papst, :e 罗马教皇 der Park, s 公园der Patient, en 病人 der Personalausweis, e 身份证der Platz, :e 位子;场所 der Preis, e 价格der Prospekt, e 前途;远景 der Prozess, Prozesse 过程der Pullover, = 毛外套 der Rabe, n 乌鸦der Rasierapparat, e 剃须刀 der Raucherhusten, opl. 吸烟引起的慢性咳嗽der Raum, :e 地区;体积 der Rhein 莱茵河der Rock, :e 裙子 der Roman, e 长篇小说der Rücke n, = 背部 der Sand, opl. 沙子der Schatz, :e 财宝 der Schirm, e 衬衫der Schlaf, opl. 睡眠 der Schlafanzug, :e 睡衣der Schluss, :e 锁;关闭;结局der Schlüssel, = 钥匙;关键der Schnee, opl. 雪 der Schneemann, :er 雪人der Schnupfen, opl. 抽涕;流鼻涕 der Schrank, :e 柜子der Schritt, e 步伐 der Schuh, e 鞋子der Schwanz, :e 尾巴 der Sommer, = 夏天der Sonnenaufgang, :e 日出 der Sonnenuntergang, :e 日落der Spatz, en 麻雀 der Spaziergang, :e 散步der Spielplatz, :e 游乐场 der Sprachkurs, e 语言课程der Sprecher, = 发言人 der Staat, en 国家der Stall, :e 棚;围栏 der Stamm, :e 干;茎;主干;骨干der Stand, :e 站立;位置 der Staub, opl. 灰尘der Stift, e 铅笔 der Stock, Stockwerke 棍;棒der Strand, :e 海滩;海岸 der Strauss, :e 花束der Stress, opl. 紧张;压力 der Strumpf, :e 袜子der Studentenausweis, e 学生证 der Studiosus, Studiosi 学生der Sturm, :e 狂风;暴风 der Tag, e 日,天,昼der Tagesablauf, :e 日程 der Tanz, :e 跳舞;舞蹈der Taxifahrer, = 出租车司机 der Tee, s 茶der Teller, = 服务员 der Tisch, e 桌子der Ton, :e 声音 der Trend, s 倾向;趋势der Umzug, :e 迁移;迁居 der Unbekannte, n 不熟悉的;不认识的der Unfall, :e 失事;事故 der Unterricht, e 课程der Verband, :e 绷带 der Verdienst, e 工资;收入der Verkauf, e 卖;出售 der Verlust, e 丢失der Versuch, e 尝试 der Vogel, : 鸟der Volleyball, :e 排球 der Vorgang, :e 事件经过der Vorrat, :e 储备 der Vorschlag, :e 提议;建议der Vorteil, e 利益 der Wald, :er 树林der Wein, e 葡萄酒 der Wille, opl. 愿望der Wind, e 风 der Winter, = 冬天der Witz, e 玩笑,笑话 der Wohnort, e 住所;居住地点der Wolf, :e 狼 der Wunsch, :e 愿望der Zahn, :e 牙齿 der Zank, opl. 争吵der Zettel, = 纸条;便条 der Zins, en 利息der Zucker, opl. 糖 der Zweig, e 树枝der/die Kranke, n 病人 der/die Tote, n 尸体die Abkürzung, en 缩写,简写 die Abteilung, en 部门die Adresse, n 通讯地址 die Aktivitaet, en 积极die Allee, n 林荫道 die Allergie, n 过敏die Ampel, n 交通灯 die Angst, :e 害怕;担心die Arbeit, en 工作 die Arbeitsstelle, n 工作场所die Aufgabe, n 任务;使命,职责die Aufnahmeprüfung, en 入学考试die Ausbildung, en 进修,深造 die Ausgabe, n 开支;分发die Ausnahme, n 例外情况 die Bahn, en 火车die Bank, :e 长椅 die Bank, en 银行die Bankleitzahl, en 银行编码 die Banknote, n 纸币,钞票die Basis, Basen 基础;基层 die Bedingung, en 条件;情况die Behoerde, n 行政机关 die Benutzung, en 使用die Berufserfahrung, en 工作经验 die Bescheinigung, en 证明;凭证die Bewerbung, en 求职 die Bibel, n 圣经die Biene, n 蜜蜂 die Bildung, opl. 教育die Birne, n梨 die Bitte, n 请求die Bluse, n 短上衣,短衫 die Box, en 箱子die Braut, :e 未婚妻;新娘 die Breite, n 宽度;纬度die Bronchitis, die Bronchitiden 支气管炎die Brühe, n 肉汁die Burg, en 城堡 die Creme, s 奶油die Dauer opl. 期间;持续的时间 die Diagnose, n 诊断die Doktorarbeit, en 博士论文 die Donau 多瑙河die Dorfstrasse, n 乡间小路 die Durchreise, n 周游die Dusche, n 淋浴装置 die Ecke, n 角落die Ehre, n 荣誉感 die Einnahme, n 服用die Einreise, opl. 入境 die Einzelheit, en 细节;详情die Elster, n 鹊 die Entscheidung, en 决定;判决die Erdbeere, n 草莓 die Erfahrung, en 经验;体会die Erfinung, en 发明;编造 die Erkaeltung, en 感冒die Erlaubnis, opl. 批准;准许 die Ernte, n 收割die Erntemaschine, n 收割机 die erste Hilfe, opl. 急救die Farbe, n 颜色,色彩 die Ferne, n 远处;远方;将来die Filiale, n 分店;分公司 die Flaeche, n 面积;平面die Fliege, n 苍蝇 die Folge, n 后果die Frage, n 问题 die Friseurin, nen 理发师die Frucht, :e 水果;果实die Frühe, opl. 早晨die Funktion, en 作用;功能 die Gans, :e 鹅die Geburtsstadt, :e 出生地 die Gefahr, en 危险;危机die Genesung, opl. 愈痊,复元 die Geologie, opl. 地质学die Germanistik, opl. 语法 die Geschichte, n 历史;历史学die Gesundheit, opl. 健康 die Gitarre, en 吉他die Grenze 边境 die Groesse, n 尺寸,号码die Gruppe, n 组;群;团体die Güte, opl. 善心;善心die Gymnastik, opl. 体* die Haelfte, n 一半die Haltestelle, n 车站 die Haut, opl. 皮肤die Heilmethode, n 治疗方 die Herkunft, :e 出身;来历die Hilfe, n 帮助;救助 die Hitze, opl. 热;加热;发怒die Hoffnung, en 希望;期望 die Hoeflichkeit, opl. 礼貌die Hoehe, n 高;高度 die Hose, n 裤子die Hosentasche, n 裤兜die Hütte, n 小屋;茅屋die Institution, en 国家机关 die Jacke, n 夹克die Jagdbeute, opl. 打猎 die Jahresernte, n 收割季节die Jahreszeit, en 季节 die Jeans, osg. 牛仔裤die Jugendherberge, n 青年旅馆 die Kaelte, opl. 寒冷die Kasse, n 收款台 die Katze, n 猫die Kombination, en 联合,联盟,团体 die Kondition, en 条件die Koenigin, nen 女王 die Kopie, n 副本;复印件die Kraft, :e 力气;力量 die Krankenversicherung, en 健康保险die Krankheit, en 疾病 die Kreide, n 粉笔die Kreuzung, en 十字路口;交叉 die Krise, n 危机die Küche, n 厨房 die Kuh, :e 母牛die Kur, en 治疗 die Kurzform, en 缩写形式die Kurzgeschichte, n 短篇小说 die Lampe, n 灯die Landwirtschaft, opl. 农业 die Leber, n 肝脏die Lehrstelle, n 培训 die Leine, n 绳子die Luft, :e 空气 die Lunge, n 肺die Mandel, n 扁桃腺die Mandelentzündung, en 扁桃腺炎die Marone, n 板栗 die Massage, n 按摩die Mathematik, opl. 数学 die Medizin, opl. 医药学die Menge, n 数量 die Milch, opl. 牛奶die Minderheit, en 少数 die Mitternacht, opl. 午夜die Mittlere Reife 中学毕业证die Mohrrübe, n 胡萝卜die Monatskarte, n 月票die Morgenfrühe, opl. 明早die Mühe, n 辛劳;费力die Münze, n 硬币die Musik, en 音乐die Mütze, n 帽子die Nachricht, en 新闻报导 die Nacht, :e 夜里die Nase, n 鼻子 die Natur, en 大自然;自然界die Nichte, n 侄女 die Niere, n 肾脏die Note, n 成绩;分 die Nummer, n 号码die Operation, en 外科手术 die Pastille, n 药丸die Pause, en 休息;暂停 die Person, en 人die Pflanze, n 植物 die Pflege, opl. 照看;看护die Philosophie, opl. 哲学 die Pille, n 药丸die Politik, opl. 政治 die Polizei, opl. 警察die Post, opl. 邮寄 die Postleitzahl, en 邮政编码die Praxis, Praxen 实践 die Produktion, en 生产制造die Prüfung, en 考试 die Qualitaet, opl. 质量die Redaktion, en 编辑 die Rede, n 谈话;谈论die Regel, n 规则 die Reihe, n 列,排die Reihenfolge, n 次序 die Reklamation, en 抱怨;投诉;退货die Rübe, n 萝卜 die Ruhe, opl. 安静;静止die Sachen, pl. 物,事物,东西 die Saison, s 时节;时令die Salbe, n 软膏 die Schlange, n 蛇die Schulden (pl.) 债务 die Schwester, n 姐妹die Seife, n 香皂 die Sicht, opl. 视力;视觉die Sinfonie, n 交响乐 die Sonate, n 奏鸣曲die Spitze, n 尖端;尖顶 die Stelle, n 空缺的职位die Stufe, n 级;阶段 die Tablette, n 药片die Tasche, n 衣袋;钱袋 die Tasse, n 盘子die Teilnahme, opl. 参加 die Temperatur, en 气温die Toilette, n 厕所;马桶 die Treppe, n 楼梯;阶梯die Überschrift, en 题目;标题 die Universitaet, en 大学die Unterschrift, en 签字;署名 die Verlobung, en 婚约die Vermaehlung, en 结婚 die Vermutung, en 推测;猜想die Verpflichtung, en 职责;义务 die Visite, n 访问;拜访die Vokabel, n 词汇 die Volkskrankheit, en 常见病die Volkswirtschaft, opl. 国民经济 die Vorbereitung, en 准备die Vorstellung, en 介绍;概念 die Vorwahl, en 预选die Waehrungsunion, opl. 金融 die Wand, :e 墙壁die Weide, n 草场;牧场 die Weite, n 宽阔;辽阔die Welt, en 世界 die Wiese, en 草地die Wohnung, en 住宅;住房 die Wolke, n 云die Wunde, n 创伤;伤口 die Wurzel, n 根die Zahl, en 数字 die Zeit, en 时间die Zeitung, en 报纸 die Zentralbank, en 中央银行Grad 度 ab-biegen 转向;转弯;ab-brechen A 折断,拆下 ab-haengen von D 取决于abhaengig adj. 不独立的;从属的 ab-heben* A 拿起,提取;取款ab-legen A 放下;摆脱 ab-schliessen A 锁住;缔结;订立ab-schneiden A 剪下;割下 ab-warten 等候;等待ab-waschen A 洗去,洗掉 achten 注意addieren A 加;加上 aehneln D 相象;相似akzeptieren A 承认;同意,接受 an-bauen 栽种;栽培ander- 另外的,其他的 an-fangen 开始an-geben A 说明,陈述,告知 an-melden A 申报an-nehmen A 接受,接到,赞成;假设 anschliessend adv. 紧接着,随后ansteckend adj. 传染的 anstrengend adj. 紧张的;费力的an-treten A 要求;权利 arbeitsfrei adj. 休息的arbeitslos adj. 失业的 arbeitsreich adj. 工作繁忙的arm adj. 贫穷的 aermlich adj. 贫穷的atmen 呼吸 attraktiv adj. 迷人的auf-geben A 交付;提交;布置;放弃 auf-hoeren mit D 停止auf-loesen A 解开,松开,解除 auf-nehmen 开始auf-passen 注意,当心 auf-steigen sein 登上auf-stellen A 竖立;安装;摆放 aus-drücken A 表达ausgezeichnet adj. 出色的;优秀的 aus-legen A 解释,分析aus-liegen 陈列;展览 aus-stellen 陈列;设置aus-waehlen A 选出;选定 baden 洗澡baldig adj. 迅速的;很快的 beantworten A 答复bebauen A 耕作;耕种 bedeuten A 具有……意义beissen A gebissen-biss 啃;咬 bekannt adj. bekannte, am bekanntest 著名的bekommen* A 来到 bestehen A 组成bestehen aus D 由…组成 bestellt adj. 订购bestimmen A 决定,判决;指定,任命; bestimmt adv. 确定的bezeichnen A 做记号 bieten A 显出,呈现billig 便宜的 bis zu D 到……止Bitte sehr! 不用客气! bitten A 请求blaettern 翻阅 blau 蓝色blind adj. 瞎的 bloed adj. 愚笨的boese adj. 不好的;祸事 brauchbar adj. 有用的brauchen 需要 braun 棕色brav adj. 勇敢的 buchstabieren A 拼读bunt adj. 彩色的 chronisch adj. 慢性的dick adj. 厚的;稠的 differieren 使不同drüben 那边 dumm adj. 笨dunkel adj. 暗的;黑的dünn adj. 薄的;细的durch A Praep. 通过;穿过 durch-führen A 进行durch-lesen A 通读; durchschnittlich adj. 平均的dürfen 可以 durstig 口渴的ebenso adv. 同样;仍然 ehemalig adj. 以前的ehrlich adj. 诚实的 eigen Dpron. 自己的eigentlich adv. 实际上,真的;竟然 eilig adj. 急迫的,紧急的einverstanden 同意;接受 einzeln Dpron. 单一的;个别的eisig adj. 冰冷的;冷淡的 empfehlen A 推荐;介绍emsig adj. 勤奋的endgültig adj. 最终的;确定了的endlich adv. 终于 eng adj. 狭窄的;紧的entlassen A 解雇 enttaeuscht sein 失望的entzündet adj. 发炎的 erklaeren A 解释ernten A 收割 erreichen A 够到;达到;到达errichten A 树立;建立 erst mal 第一次erteilen A 授予 fallen gefallen sein -fiel 下;下落;下沉falls =wenn falsch adj. 错的fantasieren 幻想 fest adj. 坚固的;固体的fest-legen A 限定;规定 fett adj. 肥的;胖的flink adj. 敏捷 folgen D gefolgt-sein 跟;跟随freiberuflich adj. 自由职业的 frei-lassen A 释放fremdsprachig adj. 外国语的 frieren* 感到冷froh adj. 快活的 froehlich adj. 快乐的fromm adj. 虔诚的fütten A 喂养gehen 给 gehen um A 关系到;涉及到es geht um etw. [Es geht um den Sieg. 这关系到胜利] gehoeren zu D 属于gelb 黄色 genauso (wie) adv. 同样的generell adj. 一般的;普通的 genug adj. adv. 足够的genügen 足够 gerecht adj. 公正的;合理的gestrig adj. 昨天的;以前的 gesund adj. 健壮的giftig adj. 有毒的 glauben D/A 想;认为;相信Grad 度 Gott sei Dank! 感谢上帝grün 绿色gründen A 成立;建立gründlich adj. 彻底的grüssen A 祝福,问候gucken 张望;瞧günstig adj. 有利的,有益的;良好的haltbar adj. 耐久的;坚固的 handeln 行为;处理haengen A 悬,挂 hastig adj. 匆忙的haeufig adj. 时常的;经常的 heilen 愈痊heiter adj. 晴朗的 heimlich adj. 秘密的heiss adj. 热的hellgrün 亮绿的heraus-lesen A 读出来 herzlich adv. 热烈的,衷心的hoch adj. 高的 hoeflich adj. 有礼貌的hübsch adj. 美丽的 hungrig adj. 饿的husten 咳嗽 indiskret adj. 轻率的intensiv adj. 紧张的;努力的 intensivieren A 加强;提高interessant adj. 有趣的 irreal adj. 不现实的jaehrlich adj. 每年的 jeder 每个kahl adj. 秃的;裸露的 kalt adj. 冷的kaufen A 买 Keine Ahnung! 不知道,没主意。

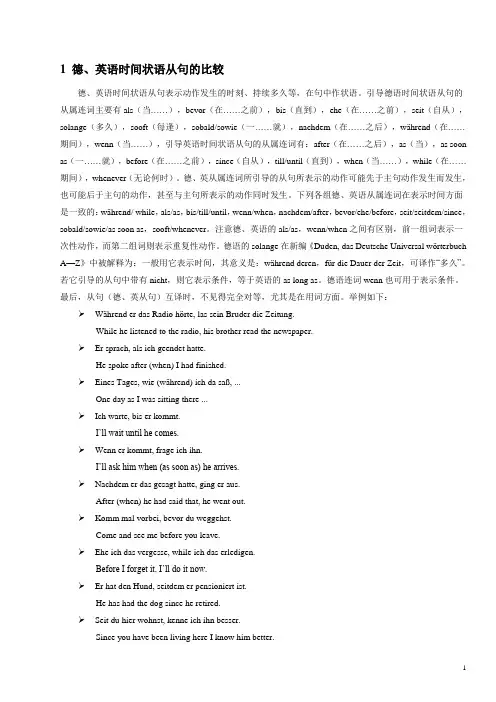

1 德、英语时间状语从句的比较德、英语时间状语从句表示动作发生的时刻、持续多久等,在句中作状语。

引导德语时间状语从句的从属连词主要有als(当……),bevor(在……之前),bis(直到),ehe(在……之前),seit(自从),solange(多久),sooft(每逢),sobald/sowie(一……就),nachdem(在……之后),während(在……期间),wenn(当……),引导英语时间状语从句的从属连词有:after(在……之后),as(当),as soon as(一……就),before(在……之前),since(自从),till/until(直到),when(当……),while(在……期间),whenever(无论何时)。

德、英从属连词所引导的从句所表示的动作可能先于主句动作发生而发生,也可能后于主句的动作,甚至与主句所表示的动作同时发生。

下列各组德、英语从属连词在表示时间方面是一致的:während/ while,als/as,bis/till/until,wenn/when,nachdem/after,bevor/ehe/before,seit/seitdem/since,sobald/sowie/as soon as,sooft/whenever。

注意德、英语的als/as,wenn/when之间有区别,前一组词表示一次性动作,而第二组词则表示重复性动作。

德语的solange在新编《Duden, das Deutsche Universal wörterbuch A—Z》中被解释为:一般用它表示时间,其意义是:während deren,für die Dauer der Zeit,可译作“多久”。

若它引导的从句中带有nicht,则它表示条件,等于英语的as long as。

德语连词wenn也可用于表示条件。

最后,从句(德、英从句)互译时,不见得完全对等,尤其是在用词方面。

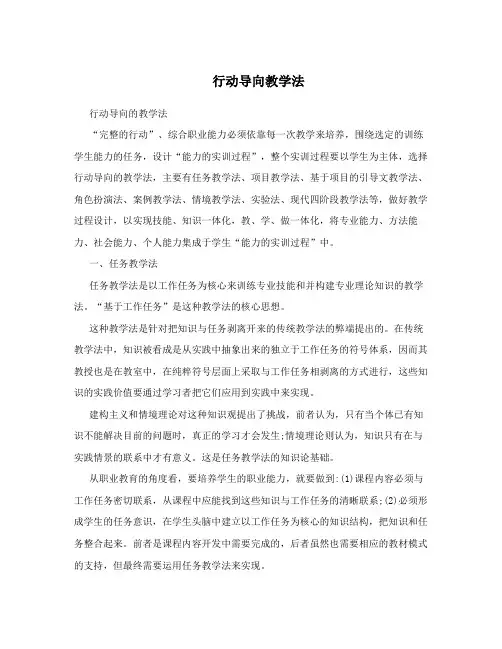

行动导向教学法行动导向的教学法“完整的行动”、综合职业能力必须依靠每一次教学来培养,围绕选定的训练学生能力的任务,设计“能力的实训过程”,整个实训过程要以学生为主体,选择行动导向的教学法,主要有任务教学法、项目教学法、基于项目的引导文教学法、角色扮演法、案例教学法、情境教学法、实验法、现代四阶段教学法等,做好教学过程设计,以实现技能、知识一体化,教、学、做一体化,将专业能力、方法能力、社会能力、个人能力集成于学生“能力的实训过程”中。

一、任务教学法任务教学法是以工作任务为核心来训练专业技能和并构建专业理论知识的教学法。

“基于工作任务”是这种教学法的核心思想。

这种教学法是针对把知识与任务剥离开来的传统教学法的弊端提出的。

在传统教学法中,知识被看成是从实践中抽象出来的独立于工作任务的符号体系,因而其教授也是在教室中,在纯粹符号层面上采取与工作任务相剥离的方式进行,这些知识的实践价值要通过学习者把它们应用到实践中来实现。

建构主义和情境理论对这种知识观提出了挑战,前者认为,只有当个体已有知识不能解决目前的问题时,真正的学习才会发生;情境理论则认为,知识只有在与实践情景的联系中才有意义。

这是任务教学法的知识论基础。

从职业教育的角度看,要培养学生的职业能力,就要做到:(1)课程内容必须与工作任务密切联系,从课程中应能找到这些知识与工作任务的清晰联系;(2)必须形成学生的任务意识,在学生头脑中建立以工作任务为核心的知识结构,把知识和任务整合起来。

前者是课程内容开发中需要完成的,后者虽然也需要相应的教材模式的支持,但最终需要运用任务教学法来实现。

任务教学法包括五个步骤:(1)提示工作任务,即教师首先给学生讲清楚要完成的工作任务的内容、条件和目标,并通过对工作任务的提示,激发学生的学习动机;(2)尝试完成工作任务,教师在简单演示后,即让学生尝试完成任务,教师适当指导,如果学生由于缺乏必要的知识准备而难以完成任务,那么就应当尽快转入第三个阶段;(3)提出问题,如果学生通过模仿教师能够基本完成任务,那么所提的问题就应当是针对如何理解操作过程的,如果学生无法完成任务,那么所提出的问题就应当是针对问题解决的;(4)查阅并理解和记住理论知识,引1导学生通过阅读教材或查阅其他资料,或通过教师讲解来让学生获得完成工作任务所需要的专业技能和专业知识,并理解和记住;(5)回归工作任务,把所获得的知识与任务联系起来,看看在掌握了这些专业知识后,能否把工作任务完成的更好。

das Aber, opl. 异议;困难das Asthma, opl. 气喘das Bafög, opl. 学生助学金das Bargeld, opl. 现金das Bombenwetter, opl. 极好的天气das Bootfahren, opl. 航行das Eichhörnchen, = 小松鼠das Erntedankfest, e 收获节das Fischen, opl. 鱼das Freie, opl. 郊外das Futter, opl. 饲料das Guthaben, = 结余;结存款das Handtuch, :er 毛巾das Kästchen, = 小箱子das Lebewesen, = 生物das Randgebiet, e 边区;边疆das Regencape, s 雨衣das Reh, e 小鹿das Resultat, e 结果das Rheuma, opl. 风湿das Schag, e 母羊;羊das Sparbuch, :er 存折das Studienkolleg, s 大学课程das T oilettenwasser, -wässer 化妆水das Waschen, opl. 洗涤物;洗das Wiesel, = 黄鼠狼der Ausschlag, opl. 疹der Benzinverbrauch, opl. 燃料消耗der Bewerbungsschreiben, = 求职表der Bildungsweg, e 受教育的经历(简历)der Bruch, :e 沼泽der Bungalow, s 平房;别墅der Drachen, = 风筝der Durchfall, :e 失败;拉肚子der Fernreisebus, se 长途汽车der Fernsehtext, e 电视节目der Gefrierpunkt, e 冰点der Geier, = 秃鹰der Gips, e 石膏der Gliederschmerz, en 关节炎der Hammer, : 糟糕的事der Kassenzettel, = 收据;发票der Komfort, opl. 舒适der Kommilitone, n 大学同学der Kontoauszug, :e 银行结单der Korridor, e 走廊der Krankenschein, e 病假单der Luftpostbrief, e 航空信der Maulwurf, :e 鼹鼠der Pädagoge, n 教师;教育家der Prospekt, e 前途;远景der Raucherhusten, opl.吸烟引起的慢性咳嗽der Spatz, en 麻雀der Studiosus, Studiosi 学生der Verdienst, e 工资;收入der Vorrat, :e 储备der Zank, opl. 争吵der Zins, en 利息die Allee, n 林荫道die Allergie, n 过敏die Bankleitzahl, en 银行编码die Banknote, n 纸币,钞票die Bescheinigung, en 证明;凭证die Braut, :e 未婚妻;新娘die Burg, en 城堡die Durchreise, n 周游die Einreise, opl. 入境die Einzelheit, en 细节;详情die Elster, n 鹊die Erfinung, en 发明;编造die Erntemaschine, n 收割机die Genesung, opl. 愈痊,复元die Heilmethode, n 治疗方die Jagdbeute, opl. 打猎die Jahresernte, n 收割季节die Jugendherberge, n 青年旅馆die Lehrstelle, n 培训die Mandel, n 扁桃腺die Mandelentzündung, en 扁桃腺炎die Marone, n 板栗die Massage, n 按摩die Mittlere Reife 中学毕业证die Mohrrübe, n 胡萝卜die Niere, n 肾脏die Pastille, n 药丸die Reklamation, en 抱怨;投诉;退货die Sonate, n 奏鸣曲die Verlobung, en 婚约die Vermählung, en 结婚die Visite, n 访问;拜访die Volkskrankheit, en 常见病die Währungsunion, opl. 金融die Wurzel, n 根ab-heben* A 拿起,提取;取款ab-legen A 放下;摆脱ab-schließen A 锁住;缔结;订立ab-warten 等候;等待ab-waschen A 洗去,洗掉an-nehmen A 接受,接到,赞成;假设ansteckend adj. 传染的an-treten A 要求;权利auf-nehmen 开始auf-stellen A 竖立;安装;摆放aus-legen A 解释,分析aus-liegen 陈列;展览aus-stellen 陈列;设置beißen A gebissen-biss 啃;咬bestellt adj. 订购bieten A 显出,呈现的differieren 使不同ebenso adv. 同样;仍然eisig adj. 冰冷的;冷淡的emsig adj. 勤奋的endgültig adj. 最终的;确定了的erteilen A 授予fantasieren 幻想fest-legen A 限定;规定flink adj. 敏捷freiberuflich adj. 自由职业的gestrig adj. 昨天的;以前的haltbar adj. 耐久的;坚固的hastig adj. 匆忙的heraus-lesen A 读出来indiskret adj. 轻率的klipp und klar 一清二楚konkretisieren A 使具体化Kopf stehen 混乱landen gelandetsein-landete 登陆;靠岸ländlich adj. 乡村的;粗俗的;淳朴的leicht fallen D/A 感到容易,不费力leiden gelitten—litt 忍受lila 淡紫色的;紫丁花色massieren A 按摩melken A 挤奶multiplizieren A 繁殖;再生;复制;增加reklamieren A 抱怨;投诉;退货reservieren A 保留roh adj. 生的schattig adj. 阴凉的;遮阴的scheu adj. 害羞的schläfrig adj. 困的schleichen um A 爬;滑行schleudern A 投,掷spüren A 感受到subtrahieren A 减tüchtig adj. 能干的;熟练的ab-arbeiten A 做工alkoholabhängig adj. 嗜酒的angeblich adj. 自称;所谓的an-ziehen A 穿戴;吸引;诱惑auf-brauchen A 用完;花完aufeinander 叠放(在另一个上面) liegen aufeinander.]auf-führen A 建造;提出aufregend adj. 激动;兴奋aus-brechen 挣脱ausgebucht sein 全部占用了;预售一空的[Die Reise ist ausgebucht] aus-statten A 布置;装饰aus-tricksen 用计谋阻止aus-zahlen A 支付;还债barmherzig adj. 富有同情心的beglaubigen A 公证bei-fügen A 附加bereit-halten A 准备好bzw. Beziehungsweise 确切的说da sein 来了diebisch adj. 偷窃成性的dirigieren A 指导;管理diskret adj. 谨慎的;缄默的dividieren A 除尽dringend adj. 迫切的,紧急的einheitlich adj. 一致的;同样的ein-nehmen A 占有;服用ein-reiben A 涂擦ein-schlagen in A 打入;钉入ein-sehen A 认识;看出ein-springen eingesprungen sein —sprang ein 帮忙;代替ein-zahlen A 缴纳erbrechen A 撬开;呕吐erfolglos adj. 无成效的ermüdet sein 疲倦的etwas zu Leide tun D 伤害etwas zu-schreiben D 添写fachspezifisch adj. 专业特征ffort 去掉;继续fressen A gefressen-fraß吞噬;消耗;腐蚀gastieren 巡回演出gebirgig adj. 多山的gemäßigt adj. 气候适度的eine gemeinsame Reise gräflich adj. 伯爵的;功勋的gurgeln 漱口herauf-klettern 爬上来heraus-geben A 递上来heraus-operieren A 切除(手术中)her-hören 注意听herum-liegen 位于⋯⋯周围herunter-fallen 到下面来herunter-holen A 取下来her-zeigen A 给⋯看hintereinander 连续的hinterher 随后;事后hundeelend adj. 不幸的;痛苦的;有病的hundertmal 百次的impfen 打预防针in Umlauf bringen/ sein 运行,循环inhalieren 吸入;吸气jucken 发痒kassieren A 没收;节销lutschen A 嘬;吸mit-telegrafieren A 打电话给⋯⋯mit-waschen A 冲洗nach-bilden 模仿nach-gucken 看透nach-schenken 再斟满nebenbei 完成nebeneinander 毗邻neigen 垂下niedlich adj. 雅观的;俊秀的nummerieren A 公开的philosophieren 哲学探讨plagen A 烦扰;折磨privatisieren A 使私有化regulieren A 整理;调节Reichen Es reicht. (足够了)递;够的着;接触的到;(物作主语)足够的。

浅析德语教学中的语法翻译法摘要:语法翻译法是建立在传统语法学基础上的、以语法为中心的视觉本位的教学法。

其特点是:在教学中注重利用语法规则,强调阅读,通过大量翻译和写作练习来检验学生是否掌握了语法规则。

语法翻译法在德语教学中主要应用于语法教学,虽带有明显的弱点,但许多方法在今天值得我们研究和借鉴。

关键词:语法翻译法外语教学德语学习演绎法1 语法翻译法导论语法翻泽法(德语crammatik-u bersetzunges-methode)是使用学生的母语来教授第二语言,外语,以系统地教授语法知识为教学基础的一种第二语言,外语教学法。

它在实践中的应用最早可以追溯到中世纪欧洲大学中的拉丁语和古希腊语教学,于19世纪作为系统的教学方法论登上历史舞台,并被广泛应用于重点高中的西欧民族语言的外语教学中。

它主张在第二语言教学过程中学生的母语与目的语并用,通过翻译和系统的语法知识的讲授学习第二语言。

语法翻译法是第一个系统的近现代外语教学法,从构词上来说,它分为“语法”和“翻译”两部分,这既是它的教学重点,也是它的教学目标。

课堂教学主要围绕着语法讲解和翻译练习。

只要掌握了语法,能够熟练掌握双语翻译,就算是掌握了这门语言。

语法翻译法是近现代语言教学法中生命力最强、使用域最宽的一种流派。

现在仍在相当广阔的范围中使用。

2 语法翻译法在中国德语教学中的应用由于汉语与德语的语法特点迥异,国内的德语学习者缺乏语言环境,所以在我国的德语语法教学中,至今仍沿用语法翻译法作为主要教学方法。

语法翻译法的教学主要分三个阶段2.1 导入阶段导入阶段的核心是语法教学,步骤如下:(1)先讲词法,后讲语法;(2)用演绎法教授语法规则,即先用母语给出语法概念,解释语法规则,后举外语例句,并翻译成学生的母语;与语法和练习有关的词汇会给出双语对照词汇表。

学生需要理解并背过语法规则。

同时还需注意的是,语法翻译法的课堂教学语言以母语为主。

2.2 练习阶段练习阶段主要是针对导入阶段的语法点辅以相关的练习,用母语和目的语互译的方法巩固所学的语法规则。

奢华香槟黑桃A香槟的文化法国香槟(Champagne),被称作葡萄酒之王,它代表高贵、典雅与奢华的浪漫情怀。

世界葡萄酒行业,有条约定俗成的规矩,香槟(Champagne)一词,仅限于法国巴黎东北一百五十公里的香槟省出产的汽酒,其他地方的汽酒不能用“(CHAMPAGNE)”词汇,仅这一点,彰显香槟酒的尊贵身份。

数百年来,欧洲曾有人试图以偷梁换柱的方式,窃取香槟酒的尊贵名份,将其他地方生产的香槟酒取名为“Methode Champenoise(香槟方法)”,但是法国人并不认同,葡萄酒业内同行也不买账。

后法律规定,其他地方以同样方法制成的汽酒,统称为“Methode Traditionelle(传统方法)”,以示与香槟的区别。

一个世纪以来,法国人为争取香槟“独一性”据理力争,与美国冒牌酒商就打了数百场官司,在全球捍卫了香槟的地位和尊严。

法国香槟的历史,可以追溯到公元三世纪前,那时以香槟省首府兰斯市为中心的葡萄园和酿酒作坊,就已初具规模。

据说早期香槟是无气泡形(现今仍有无泡香槟酒),一位名叫多姆·佩利贡的神职人员,利用主管修道院酒库“职务之便”对葡萄酒制作进行“改良”。

把不同葡萄制作的原酒调配在一起,但是所制出的葡萄酒起泡,他曾为此愁眉不展。

多姆还有一个贡献,把软木塞代替麻屑做香槟酒瓶塞,酒中的气泡可以保持更长时间。

多姆·佩利贡虽然不是第一个将香槟酒改良成汽酒和使用软木做瓶塞的人,但是他对法国香槟制作工艺所进行的“改造”,为现代香槟酒的发展奠定了良好基础,贡献举足轻重。

法国香槟业为了纪念多姆·佩利贡,为他竖起塑像,奉其为“香槟之父”。

香槟酒的四个产区香槟区是法国早期的葡萄酒法定产区,所以,只有在香槟区内生产酿制的酒才能叫香槟酒。

除此以外,全世界任何地方出品的同类型酒只能称之为起泡酒。

在香槟区内,共有四个产区生产香槟酒,它们分离是兰斯山脉,马恩河谷,白岸和巴尔河岸。

中国的香槟市场近些年,随着世界经济发展,法国香槟全球需求量猛增,欧美国家需求量与日俱增不说,香槟越来越受到亚洲国家和地区人们的欢迎,诸如印度、香港、新加坡等地,人们把香槟视为餐饮文化中的重要组成部分。

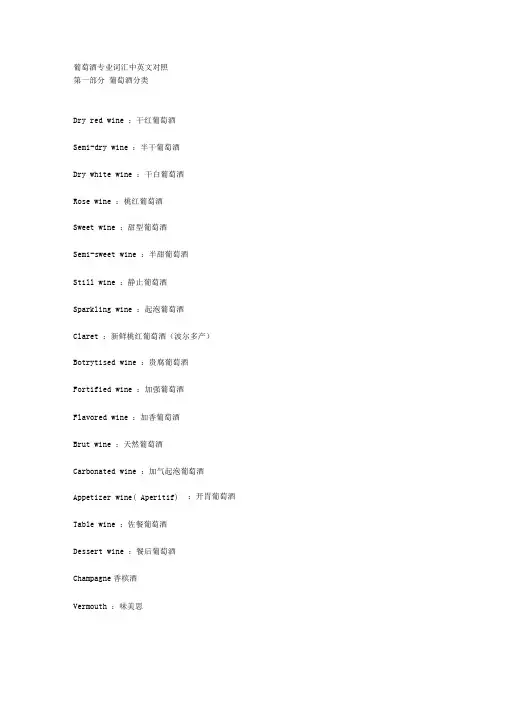

葡萄酒专业词汇中英文对照第一部分葡萄酒分类Dry red wine :干红葡萄酒Semi-dry wine :半干葡萄酒Dry white wine :干白葡萄酒Rose wine :桃红葡萄酒Sweet wine :甜型葡萄酒Semi-sweet wine :半甜葡萄酒Still wine :静止葡萄酒Sparkling wine :起泡葡萄酒Claret :新鲜桃红葡萄酒(波尔多产)Botrytised wine :贵腐葡萄酒Fortified wine :加强葡萄酒Flavored wine :加香葡萄酒Brut wine :天然葡萄酒Carbonated wine :加气起泡葡萄酒:开胃葡萄酒Appetizer wine( Aperitif)Table wine :佐餐葡萄酒Dessert wine :餐后葡萄酒Champagne香槟酒Vermouth :味美思Beaujolasis :宝祖利酒Mistelle :密甜尔Wine Cooler :清爽酒Cider :苹果酒Brandy :白兰地Fruit brandy :水果白兰地Pomace Brandy :果渣白兰地Grape brandy :葡萄白兰地Liquor ( Liqueur ):利口酒Gin :金酒(杜松子酒)Rum朗姆酒Cocktail :鸡尾酒Vodka:伏特加Whisky :威士忌Spirit :酒精,烈酒Cognac(France) :科尼亚克白兰地(法)Armagnac(France) :阿马尼亚克白兰地(法)Sherry(Spain) :雪莉酒(西班牙)Port(Portuguese) :波特酒(葡萄牙) BDX波尔多红酒第二部分酿酒微生物Yeast :酵母Wild yeast :野生酵母Yeast hulls :酵母菌皮Dry activity yeast :活性干酵母Bacteria :细菌Malolacticbacteria(MLB):乳酸菌Lactic acidbacteria(LAB):乳酸菌Acetic acid bacteria :醋酸菌Spoilage yeast :败坏酵母第三部分生理生化过程Transpiration :蒸腾作用Evaporation :蒸发Photosynthesis :光合作用Maillard Reaction :麦拉德反应Veraison :转色期Saturation :饱和Alcoholicfermentation(AF):酒精发酵Stuck (Sluggish)Fermentation:发酵停滞Primary Fermentation :前发酵,主发酵Secondary Fermentation ;二次发酵Heterofermentation :异型发酵Malolactic fermentation(MLF) :苹果酸- 乳酸发酵Malo-Alcohol Fermentation(MAF) :苹果酸-酒精发酵Methode Charantaise :夏朗德壶式蒸馏法Maceration Carbonique : CO2浸渍发酵Whole bunch fermentation : CO2浸渍发酵Beaujolasis method :宝祖利酿造法Unareobic fermentation :厌氧发酵法Thermovinification :热浸渍酿造法Charmat method :罐式香槟法Enzymatic browning :酶促褐变Acetification :酸败Ageing :陈酿Sur lies :带酒脚陈酿Esterify :酯化Saccharify :糖化Liquefy :溶解、液化Bottle aging :瓶内陈酿Amelioration :原料改良Chaptalization :加糖Distillation :蒸馏Fractional Distillation :分馏Rectification :精馏Clarification :澄清第四部分 葡萄酒酿酒辅料Betonite :膨润土(皂土) Kieselgur ,diatomite :硅藻土 Capsule :胶帽Tin Plat 、Foil :锡箔Pigment :颜料、色素Casein :酪蛋白Pectin :果胶酶Albume n :蛋白Blood powder :血粉第五部分 理化指标Total acid :总酸Titrable acid :滴定酸Residul sugar :残糖Carbon dioxide :二氧化碳 Sugar-free extract :干浸出物Silicagel:硅胶 Gelatin : 明胶 Isingla ss :鱼胶 Egg white:蛋清Volatile acid 挥发酸Sulfur dioxide 二氧化硫Total sulfur dioxide :总二氧化硫Free sulfur dioxide 游离二氧化硫Copp er (Cu):铜Iron (Fe):铁Potassium :钾( K)Calcium (Ca):钙Sodium ( Na):钠第六部分物质名词Methanol 甲醇High Alcohol :高级醇Polyalcohol :多元醇Ethyl acetate 乙酸乙酯Flavonol 黄酮醇Glycine :甘油Calcium Pectate 果胶酸钙Ochratoxin 棕曲霉毒素Butanol 丁醇Isobutanol 正丁醇Gastric:胃酸AcidPropanone:丙酮Acetic:乙酸AcidFormicAcidPhospholipid:磷脂sAmino氨基酸Acid :Fatty脂肪酸AcidCarbonic:碳酸AcidCarbohydrate :碳水化合物Fixed固定酸AcidTartaric:酒石酸AcidMalic苹果酸AcidCitric柠檬酸AcidLactic乳酸AcidSuccinic:琥珀酸AcidSorbic山梨酸acidAscorbic:抗坏血酸acidBenzyl苯甲酸acid :Gallic没食子酸acidFerulic:阿魏酸AcidPcoumaric acid :香豆酸Glucose, Dextrose ,Grape:葡萄糖SugarVanillin :香草醛 , 香兰素Fructose, Fruit Sugar :果糖 Cane Sugar, Short Sweetening :蔗糖 Polysaccharides :水解多糖 Starch :淀粉Amylase :淀粉酶Foam 泡沫Protein :蛋白质Mercaptan :硫醇Thiamine :硫胺( VB1)Ammonium Salt :铵盐Melanoidinen :类黑精Glycerol :甘油,丙三醇Copper citrate :柠檬酸铜 Copper sulphate :硫酸铜 Hydrogen sulphide :硫化氢 Oak (barrel ) :橡木(桶) Catechins :儿茶酚Low Flavour Threshold :香味阈值Vanillan :香子兰MaillardReaction :美拉德反应Volatile Phenols:挥发性酚Linalool :里那醇,沉香醇Geroniol :牻牛儿醇,香茅醇Pyranic acid :丙酮酸Furan Aldehydes :呋喃醛Eugenol :丁香酚Guaiacol :愈创木酚Carbohydrate Degradation Products :碳水化合物降解物Cellulose :纤维素Hemicellulose :半纤维素Hemicellulase :半纤维素酶Maltol :落叶松皮素Oak Lactone :橡木内酯Hydrolysable Tannins :水解单宁Ellagitannins :鞣花单宁Proanthocyanidin :原花色素Relative Astringency(RA) :相对涩性Lagic Acid :鞣花酸Polypetide Nitrogen :多肽氮Oxido-reduction Potential:氧化还原电位Condenced Phenols :聚合多酚Poly-phenols :多酚PVP ( P):聚乙烯(聚)吡咯烷酮Anthocyanin :花青素Alcohol, ethanol :乙醇Invert Sugar 转化糖Oxyge n:氧气Ester :酯类物质Nitrogen :氮气Aroma:果香Virus :病毒Bacteriophage :噬菌体Body:酒体Byproduct :副产物(KHT:酒石酸氢钾PotassiumBitartratePotassium Sorbate :山梨酸钾Diammonium Phosphate :磷酸氢二铵:偏重亚硫酸钾Potassium Meta-bisulfite (K2S2O5)Tannin :单宁Oak tannins :橡木丹宁Undesired ( Excessive ) Tannins :劣质单宁Desired tannins :优质单宁En zyme:酶Laccase :漆酶Polyphenol Oxidase(PPO) :多酚氧化酶Mannoprotein s:甘露糖蛋白Lees :酒泥Chateau :酒庄Bulk wine 、Raw wine :原酒Hygiene :卫生Activated carbon :活性碳Currant :茶蔗子属植物、无核小葡萄干Raspberry :木莓、山莓、覆盆子、悬钩子第七部分:设备Two-way Pump :双向泵 Screw Pump :螺杆泵Centrifuge :离心机Distillation :蒸馏Heat Exchanger :热交换器Crusher :破碎机Destemer :除梗机Presser :压榨机Atmosphere Presser :气囊压榨机3 -glucosidase:3 -葡(萄)糖苷酶 3 -glucanase : 3 -葡聚糖酶 Filtrate(filtration) :过滤Screw Presser :连续压榨机Filter :过滤机Bottling Line 灌装线Plate Filtration filter ):板框过滤(机)Vacuum Filtration filter ):真空过滤(机)Depth Filtration filter ):深层过滤(机)Cross Filtration filter ):错流过滤(机)Membrane Filtration filter ):膜过滤(机)Sterile Filtration filter ):除菌过滤(机)Pocket Filtration filter ):袋滤(机)Rotary Machine :转瓶机Pomace Draining :出渣Blending :调配Racking :分离(皮渣、酒脚)Decanting :倒灌(瓶)Remuage 吐渣Fining :下胶Deacidification :降酸Pump over :循环Skin Contact :浸皮(渍)Mix colors :调色Oxidative Ageing Method :氧化陈酿法Reducing Ageing Method :还原陈酿法Stabilization :稳定性Ullage :未盛满酒的罐(桶)Heads pace:顶空NTU浊度Receiving bin :接收槽Corkscrew :开瓶器Distilling Column :蒸馏塔Condenser :冷凝器Heat Exchanger :热交换器Cork :软木塞Cellar :酒窖Wine Showroo m:葡萄酒陈列室Optical Density (OD :光密度Metal Crown Lid :皇冠盖Blanket :隔氧层Pasteurisation :巴斯德杀菌法第八部分:原料、病虫害、农药Grape Nursery :葡萄苗圃Graft :嫁接苗Scion :接穗Seedling :自根苗Disease :病害Botrytis :灰霉病Downy Mildew :霜霉病Powdery Mildew :白粉病Fan Leaf :扇叶病毒病Anthracnose :炭疽病Mild Powder :灰腐病Black Rotten :黑腐病Noble rot :贵腐病Pearls :皮尔斯病Phylloxera :根瘤蚜Nematode:线虫Bird Damage :鸟害Pest :昆虫Lime Sulphur :石硫合剂Nursery :营养钵Herbicide :除草剂Pesticide :杀虫剂Fungicide :真菌剂Bordeaux mixture :波尔多液Microclimate :微气候Variety :品种Cluster :果穗Rachis :穗轴Scion :接穗Rootstock :砧木Grafting :嫁接第九部分: 学科名词Enology :葡萄酒酿造学Pom ology:果树学Vinification :葡萄酒酿造法Wine-making :葡萄酒酿造Ampelography :葡萄品种学Viniculture :葡萄栽培学Wine Chemistry 葡萄酒化学Enologist,Winemaker :酿酒师Vintage :年份Inoculation ( inoculum ):接种(物)):杂物MOG( material other than grapes Terpene :萜烯Terpenol :萜烯醇第十部分葡萄酒等级法国: :法定产区葡萄酒 :优良产区葡萄酒 :地区餐酒 :日常餐酒 德国:1. Tafelwein :日常餐酒;2. Landwein :地区餐酒;3. Qualitaetswein bestimmter Anbaugebiete4. Qualitaetswein mit Praedikat1. Kabinett :珍藏2. Spatlese :晚收3. Auslese :精选4. Beerenauslese :简称BA 颗粒精选5. Trockenbeerenauslese :简称TBA 用深度贵腐的葡萄酿成,葡萄大概要失去 95%的水 分,酿成的酒也最甜。

交换两个变量的值,不使用第三个变量的方法及实现:附录中有C/C++代码:通常我们的做法是(尤其是在学习阶段):定义一个新的变量,借助它完成交换。

代码如下:int a,b;a=10; b=15;int t;t=a; a=b; b=t;这种算法易于理解,特别适合帮助初学者了解计算机程序的特点,是赋值语句的经典应用。

在实际软件开发当中,此算法简单明了,不会产生歧义,便于程序员之间的交流,一般情况下碰到交换变量值的问题,都应采用此算法(以下称为标准算法)。

上面的算法最大的缺点就是需要借助一个临时变量。

那么不借助临时变量可以实现交换吗?答案是肯定的!这里我们可以用以下几种算法来实现:1)算术运算;2)指针地址操作;3)位运算;4)栈实现。

1)算术运算int a,b;a=10;b=12;a=b-a; //a=2;b=12b=b-a; //a=2;b=10a=b+a; //a=12;b=10它的原理是:把a、b看做数轴上的点,围绕两点间的距离来进行计算。

具体过程:第一句“a=b-a”求出ab两点的距离,并且将其保存在a中;第二句“b=b-a”求出a到原点的距离(b到原点的距离与ab两点距离之差),并且将其保存在b中;第三句“a=b+a”求出b到原点的距离(a到原点距离与ab两点距离之和),并且将其保存在a中。

完成交换。

此算法与标准算法相比,多了三个计算的过程,但是没有借助临时变量。

(以下称为算术算法)除了使用加、减法外,还可以使用乘、除法实现,实现代码如下://if a=10;b=12;a=a*b; //a=120;b=12b=a/b; //a=120;b=10a=a/b; //a=12;b=10缺点:是只能用于数字类型,字符串之类的就不可以了。

a+b有可能溢出(超出int的范围),溢出是相对的,+了溢出了,-回来不就好了,所以溢出不溢出没关系,就是不安全。

2)指针地址操作因为对地址的操作实际上进行的是整数运算,比如:两个地址相减得到一个整数,表示两个变量在内存中的储存位置隔了多少个字节;地址和一个整数相加即“a+10”表示以a为基地址的在a后10个a类数据单元的地址。

金状元试卷网考研真题二外德语————————————————————————————————作者:————————————————————————————————日期:2科目代码:216 请在答题纸(本)上做题,在此试卷或草稿纸上做题无效!山东科技大学2007年招收硕士学位研究生入学考试德语(英语专业)试卷Teil 1 Grammatik und WortschatzA.Wählen Sie die richtige Lösung. (15%, je 1 P)1. Peter ist nicht hier, er ist .A) mit seiner Tante B) bei seiner TanteC) zu seiner Tante D) an seiner Tante2. Die Mutter liebt ihr einzig Jungen.A)–e, -en B) –en, -en C) –em, -en D) –en, -em3. sie verheiratet ist, ist sie von ihrem Mann sehr abhängig.A)Bis B) Als C) Seitdem D) Nachdem4. Je Fortschritt man macht, desto Lust hat man zu lernen.A) schneller, mehr B) schnelleren, mehrC) schneller, mehre D) schnellere, mehre5. Ich bin schon einer Woche hier.A) vor B) in C) seit D) auf6. Der Euro kommt, er kommt nicht auf einen Schlag.A) oder B) denn C) aber D) trotzdem7. Das Herz vieler Deutschen hängt am Auto, aber auch am Wald.A) genauso B) nicht C) gleich D) nur8. Eine Krankenschwester kümmert sich um .A)der Verletzte B) den VerletzteC) dem Verletzten D) den Verletzten9. das Buch lesen möchte, gebe ich es.A) Wer, dem B) Wer, den C) Wem, den D) Wen, den10. Welche Pluralform ist falsch? In unserer Reisegruppe gibt es .A) Studenten B) Angestellte C) Ärzte D) Kaufmänner11. Bleiben Sie nicht zu lange bei einer Aufgabe, Sie nicht lösen können.A) das B) wenn C) dieses D) die12. 48 bin ich zu alt, einen neuen Beruf zu lernen.A) In B) Mit C) Bei D) Von13. Die Frau ist froh, wenn sie im Urlaub einmal keine Hausarbeit machen .A) darf B) soll C) muss D) will14. Musik haben Sie besonders gern, klassische oder moderne?A) Welche B) Was C) Was für D) Was für eine15. Viele Leute sitzen vor dem Bildschirm als gehen ins Kino.A) gern B) gerner C) lieber D) am liebstenB.Wählen Sie die richtige Lösung. (10%, je 1 P)SiemensDie Siemens AG ist weltbekannt durch ihre Elektrotechnik und 16 zu den fünf größten Privatunternehmen der Erde. Ihre Vertriebs- und Fertiungsorganisation erstreckt sich über den ganzen Globus 17 hat sich in 125 Ländern 18 etabliert. Der Konzern stellt über 250 000 verschiedene Produkte her. Siemens hat heute deshalb einen so großen Umfang, 19 er über eine große Menge der Wissenschaftler und Techniker verfügt. In München-Neuperlach beispielsweise gibt es eine neue Forschungsstadt von Siemens, mit der 20 von 350 000 Quadratmetern. Diese Stadt ist das größte und modernste Technologie-Zentrum, die …Denkfabrik“, in der 7 000 Wissenschaftler an der Zukunftsentwicklung arbeiten. Gerade innovationsträchtige Gedankengut beflügelt die Firmen Siemens. 21 drei Jahren forscht man in Siemen s die …künstliche Intelligenz“. Das ist ein großartiges Projekt, an 22 Endpunkt ein Computer stehen soll, der gespeicherte Informationen wiedergibt und 23 hinaus eigenständige Entscheidungen 24 . Solche Computer werden den Menschen bei der Suche 25 Lösungen von Problemen mit verlässlichen Tatschlägen zur Seite stehen und in …natürlicher“ Sprache auf den Benutzer einreden.16.A) gehört B) ist C) wird D) angehört17.A) aber B) und C) oder D) sondern18.A) kaum B) fest C) noch D) nur19.A) warum B) weil C) damit D) indem20.A) Boden B) Stadt C) Firma D) Fläche21.A) Vor B) In C) Für D) Seit22.A) dem B) den C) dessen D) diesem4 / 1023.A) darüber B) dafür C) damit D) darauf24.A) gibt B) macht C) trifft D) stößt25)A) nach B) von C) für D) zuC. Ergänzen Sie Präpositionen und Artikel. (10%, je 1 P)a. Jedes Jahr kommen im Frühling Sandstürme, 26 27 man Maßnamen treffen muss.b. Wir bitten Sie 28 29 schnelle Antwort.c. Er denkt oft 30 31 Freunde in Berlin.d. Nach zwei Semestern haben sich Li Ping und Huang Hua 32 33 Leben in Deutschland gewöhnt.e. Heute kommt der Brief, 34 35 ich schon lange gewartet habe.Teil 2 Lesenverstehen (30%, je 2 P)Text 1Reisen mit SportDer Büromensch macht mobil. Für eine kleine, aber wachsende Zahl von Erholungssuchenden muss Urlaub inzwischen mehr sein als der Wechsel vom Schreibtisch auf den Liegestuhl. Ob sie beim Radfahren um Kondition ringen, mit Fitnessgymnastik gegen Pfunde und Falten kämpfen oder bei einer der anderen …-ing“-Sportarten Freiheit und Abenteuer suchen –Reisen mit Sport- oder Gesundheitsangeboten finden stetig mehr Fans. Etwa 25 bis 30 Prozent der Leute wollten im Urlaub etwas machen, was mit Sport zu tun hat. Mit der Zeit wird diese Zahl noch zunehmen.Experten erklären sich den Bewegungsdrang mit einem neuen Körperbewusstsein. Ein Grund sei die Veränderung der Arbeitswelt hin zu vielen …sitzenden Berufen“. Die gewandelten Vorlieben signalisierten aber auch eine Bereitschaft, mehr Verantwortung für sich zu übernehmen.Anhänger der Trendsportarten wollten sich gerne beweisen, auch riskante Manöver voll im Griff zu haben. …Sie wollen Herr der Situation sein.“ Gefragt ist das kontrollierte Risiko. Statt selbst zu erkunden, lassen sich auch jüngere Leute ihre Erlebnisse gerne organisieren. Einerseits wollten sie rundum betreut sein, andererseits auch etwas sehr Abenteuerliches erleben. Die meisten Sporturlauber bringen sich mit Traditionellem ins Schwitzen. Am5 / 10beliebtesten sind die Radtouren. Ebenso viele buchen Golf-Reisen. Dagegen nehmen immer weniger Leute einen Tennisschläger in die Hand.Für die miesten Aktivurlauber zählt aber mehr als die Bewegung. Am wichtigsten sei, dass man Leute trifft, die gleiche Ansichten und Interessen wie man selber haben, und mit denen man sich über sein Spezialgebiet unterhalten kann. (…dpa“, Juni 1999 Online Materialien Inter Nationes)36. Es gibt immer mehr Leute, .A)die ihren Schreibtisch im Büro durch einen Liegestuhl ersetzen wollenB)die mit dem Rad in Urlaub fahrenC)die im Urlaub Sport treiben wollenD)die im Urlaub Gesundheitsmedizin kaufen möchten37. Ein Grund für den Bewegungsdrang besteht darin, .A)dass man mehr über den Körper wissen möchteB)dass man bei der Arbeit zuviel gesessen hatC)dass man dadurch die Arbeitswelt verändern möchteD)dass man wenig arbeiten möchte38. Man ist bereit, .A)mehr sitzende Berufe zu machenB)das Hobby zu ändernC)das Risiko zu kontrollierenD)mehr Verantwortung für sich zu übernehmen39. Die jüngeren Leute wollen .A)sich über alles selbst informierenB)die Situation mit ihren eigenen Händen kontrollierenC)das kontrollierte Risiko erlebenD)ihre Erlebnisse selbst organisieren40. Das wichtigste für die meisten Sporturlauber ist, .A)dass man sich bewegt, statt nur zu sitzenB)dass man an die frische Luft kommtC)dass man dadurch gesund bleiben kannD)dass man mit den Leuten zusammen sein kann, die gleiche Interessen wie man selber habenText 26 / 10Ein Leben ohne Auto? Was würde das bedeuten?Ohne Auto gäbe es unsere Wirtschaft nicht. Als Transportmittel ist das Auto einschließlich des Lastwagens überhaupt nicht zu ersetzen. Vom Automobil, seiner Produktion und Zubehörindustrie leben heute viele Millionen Bundesbürger. Jeder siebte ist in der Autoindustrie, der Reifen- und Mineralölindustrie oder bei den Zulieferern in der chemischen und der Elektroindustrie beschäftigt.Das Auto ist aber nicht nur Wirtschaftsfaktor, es macht das Leben bequemer und angenehmer. Man kann damit frei von Fahrplänen reisen. Die Mehrzahl der Bundesbürger könnte ohne Auto keine Urlaubsreise machen. Es gibt kein Verkehrsmittel, mit dem die Familie billiger reist. Und das wird auch morgen noch so sein.Für viele Menschen ist das Auto nicht nur ein Transportfahrzeug sein. Das Auto ist immer noch, und daran wird sich wenig ändern, nach außen hin ein Zeichen für das, was man erreicht hat, was man sich leisten kann.41. Was ist richtig?A) Ohne Auto ist unser Leben heute unvorstellbar.B) Ohne Auto könnten wir genauso gut leben.C) Das Auto ist nur für die Wirtschaft wichtig.42. Was ist richtig?A)70% der Arbeitnehmer haben auf diese oder jene Weise mit der Autoindustrie zu tun.B)Etwa 14% der Arbeitnehmer haben auf diese oder jene Weise mit der Autoindustrie zu tun.C)7% der Arbeitnehmer haben auf diese oder jene Weise mit der Autoindustrie zu tun.43. Was ist richtig?A)Das Leben ist bequemer und angenehmer, wenn man nach den Fahrplänen reist.B)Das Leben ist bequemer und angenehmer, wenn man unabhängig von den Fahrplänen reist.C)Nach den Fahrplänen reisen macht unser Leben bequemer und angenehmer.44. Was ist richtig?A)Die Familie kann morgen mit dem Auto billiger reisen als heute.B)Das Auto ist das billigste Verkehrsmittel für die Familie, die Urlaubsreise macht.C)Die Mehrzahl der Bundesbürger möchten ohne Auto ihre Urlaubsreise machen.45. Was ist richtig?A)Ein gutes Auto zeigt, dass sein Besitzer reich und erfolgreich ist.B)Das Auto ist heute für viele Menschen kein Transportfahrzeug mehr, weil es technischverbessert werden muss.7 / 10C)Nur wenige Leute können sich ein Auto leisten.Text 3Immer wichtiger im Job: FremdsprachenFremdsprachen sind heute Pflicht, wenn man in gehobene Positionen vordringen möchte. Durch Computer und Internet wied die ganze Berufswelt internationaler. Wer ohne Dolmetscher mit Kunden verhandeln kann, verbessert seine Karrierechancen. Ratsam: Mit dem Lernen nicht warten, bis der Druck auf dem Arbeitsmarkt dazu zwingt. Lieber gleich losgehen – solange das Hauptmotiv noch Spaß an der persönlichen Weiterentwicklung ist.Eine Sprache lernen – das ist auch im Erwachsenenalter ganz einfach, wenn man den richtigen Weg einschlägt. Der ist von Mann zu Mann und von Frau zu Frau verschieden und hängt von Faktoren wie Zeit, Lerntyp und Lernziel ab.Hier ein Überblick über die erfolgversprechendsten Methoden plus Erklärung, welche für wen geeignet ist.Volkshochschulkurse. Methode: Gruppenunterricht. Voraussetzung: Geduld und die Möglichkeit zur regelmäßigen Teilnahme. Zielgruppe: Berufstätige, die sich aus eigenem Antrieb weiterbilden wollen.Intensivkurse. Methode: Superintensiver Einzelunterricht, geblockt (zum Beispiel drei Wochen), bis zehn Stunden täglich. Voraussetzung: Grundkenntnisse der Sprache, Belastbarkeit. Zielgruppe: Arbeitnehmer, die kurzfristig ins Ausland versetzt werden. Erreichbares Ziel: perfekte Geschäftssprache, Fachausdrücke, in der Lage, sich flüssig zu unterhalten. Sprachreisen. Methode: vormittags Unterricht, nachmittags Anwendung im Alltag. Über das Kennen lernen von Land und Kultur sollen …Sprachwurzeln“ fest im Gehirm verankert werden. Voraussetzung: Kontaktfreude, Abenteuerlust. Zielgruppe: Leute, für die Lernen Freizeitspaßist. Ziel: Auch ohne Vorkenntnisse nach kurzer Zeit problemloses …Talken“.CD-ROM-Programme. Methode: Lernen ohne Lehrer, am eigenen Computer. Voraussetzung: viel Selbstdisziplin. Zielgruppe: Leute, die ihren Lehrplan (zum Beispiel wegen häufig wechselnder Arbeitszeiten) flexibel gestalten müssen.46. Wenn man in hohen Positionen arbeiten möchte, .A)muss man einen Dolmetscher haben.B)muss man Fremdsprachen können.C)braucht man nicht unbedingt Fremdsprachen zu beherrschen.D)muss man einen Computer haben.47. Eine Fremdsprache zu lernen ist .A)für einen Erwachsenen einfacher als für ein Kind.B)einfach, wenn man richtige Methode hat.C)für einen Erwachsenen schwer, auch wenn er den richtigen Weg einschlägt.8 / 10D)für einen Erwachsenen nicht nötig.48. Wer beim Sprachenlernen auch Land und Leute kennen lernen möchte, wählt .A)Volkshochschulkurse.B)Intensivkurse.C)Sprachreisen.D)CD-ROM-Programme.49. Wer in einem kurzen Zeitraum konzentriert und hart lernen kann, wählt .A)Volkshochschulkurse.B)Intensivkurse.C)Sprachreisen.D)CD-ROM-Programme.50. Wer sich auf Kontakte mit den anderen freut und in der Freizeit gern etwas lernt, wählt .A)Volkshochschulkurse.B)Intensivkurse.C)Sprachreisen.D)CD-ROM-Programme.Teil 3Verbinden Sie bitte die Sätze mit …deshalb“, …dass“, …ob“, …obwohl“, und …weil“! (10%, je 2 P)51. Er spricht kein Deutsch. Er will in Deutschland studieren.52. Sie ist wirklich satt. Sie isst die leckere Nachspeise nicht.53. Inge hat ein Kind bekommen. Sie kann ein Jahr zu Hause bleiben.54. Mein Bruder macht nächste Woche eine Dienstreise nach Shanghai. Meine Mutter hat es geschrieben.55. Will sie mit uns zusammen einen Spaziergang machen? Ich weiß es auch nicht.Teil 4Übersetzung aus dem Deutschen ins Chinesische. (10%, je 2 P)56. Die Aufgabe, die Sicherheit des Verkehrs zu verbessern, ist viel schwieriger, als wir vorher gedacht haben.57. Der Autofahrer hat sich gar nicht so schlimm verletzt, wie man es sich vorgestellt hat.58. Deutsch ist für 100 Millionen Menschen Muttersprache und damit die am häufigsten gesprochene in Europa.59. Um studieren zu können, muss man vorher entweder im Heimatland oder in Deutschland die deutsche Sprache lernen.60. Was machen die Deutschen eigentlich in ihrer Freizeit? Das hängt ganz von den Interessen9 / 10der einzelnen Menschen ab.Teil 5 Schriftlicher Ausdruck (15%)Thema: Mein VaterAnforderungen: Schreiben Sie einen Aufsatz mit 80 – 90 Wörtern. Der Aufsatz beinhaltet:1) allgemeine Angaben über Ihren Vater2) seine Tätigkeiten und seinen Charakter3) seine Besonderheiten nach Ihrer Meinung.10 / 10。

1/das Verb, -enabfahren 出发holen 取,拿abholen 接schreibenabschreiben 抄写ab/kürzen 缩写an/fangen (+mit)buchstabierenzeigenerzählen +A/von (+D)叙述,讲述verstehen +A 理解einverstanden 同意wiederholen +A重复,复习suchen 寻找versuchen 试图finden 找到;觉得besuchen 拜访probieren +A 尝试stimmen 对,确实klingelnmeinen 认为,觉得auf/stehen 起床los/gehen 开始,动身aus/gehen 外出,出门weg/gehen 离开bauen + A 建造bilden + A 造成,构成kennen + Abrauchen + A 需要könnenstecken 插进enden + mitein/kaufenverkaufen 卖wünschen + A (+ D)schenken + A + Dmalen (+A)zeichnen (铅笔)画,素描bekommen + Alieben + A Schach spielenbeachten +A 注意rufen +A 喊,叫schreien 喊,叫an/rufen (+A) 打电话zurück/rufen 回电话handeln 讨价还价bezahlen (+A)kostenrauchen (+A)zusammen/stellen +A编制,制定stellen +A +Dir放置bestellen + Aaus/sehen +Adj 显出empfehlen +A (+D)bringen +A (+D/Dir)mit/bringen +A +D带来,赠送zurück/bringen 送还,送schwimmenzurück/kommen回来,归来vor/lesen 朗读öffnen +A 打开schließen +A合上abschließen 锁上(on)auf/machen 打开(out)aus/machen 关掉zu/hören 倾听,专心听auf/hören(+mit) 停止chattensurfenjoggenkochentrainierentanzentreiben 从事于jobben 打工tunfeiernRad fahren 骑自行车schmecken (+D) 有滋味passen +D/+zuhelfen +Dgefallen +Ddanken +D +fürfehlen +Dgratulieren +Dantworten +Dgewinnen 获得,赢得singenfunktionieren(+Adj)telefonierenbleiben +Sit 停留,待begrüßen +Ageben +A +Ddürfenan/kommen +auf Akk重要的是trinken +auf Akk为...干杯erklären +A 解释,讲解mailen 发邮件an/wenden 应用verwenden 使用benutzen 使用sparen +A +für/auf Akk)节约,节省reden 谈论,说drauflos/reden 张口就说überlegen 考虑,思考fliegen +Dirmit/nehmen +A随身携带spazieren gehenverbinden 连接hängenwarten等schieben 推Besuch habenRecht habenschauen 看,瞧aus/schauen 看上去nach/schauen 查看um/räumen 重新布置auf/räumen 整理,收拾waschen 洗Wäsche waschen Sauber machen打扫卫生um/ziehen 搬家ein/ziehen 搬进aus/ziehen 搬出mieten 租freuen 使高兴legen 放置,平放2/ 形容词(对人/事/物)副词aktivallealleinalsamerikanischanderanderhalb(at)an+Dat/akksehrganzschlechtlangsamnatürlichrichtigwichtiginternationalmodernlautleisedeutlichspäter 以后weiter 继续,进一步的schnelldummam Telefon在电话旁,打电话时nach Nanjing kommen来南京leider 遗憾komischbeide 两个dabei 此外,与此同时sonst 此外darüber 关于这些,对比danach 此后dafürdamit 以此lieb 可爱的,亲爱的spätweg 离开langlangekurz 短interessantbekannt 熟悉的täglichbesserleichtschwerintelligentunintelligentfreundlichunfreundlichvielleichtprima 极好的genau 准确的gleich 立即,马上müde 疲倦的,累的ein paar 几个,一些billigziemlichwenigobenuntenvornzurzeit 现在jetzt 现在frisch 新鲜的krankin 时髦,走俏gesundungesundsatt 饱的sauer 酸的süß甜的besonders 特别,非常warmam bestennormalfreigleischfallsausgezeichnetsofort 立即,马上rotweißschwarz 黑的eigentlichlangweilichlieberhoffentlichanstrengend疲劳的,费力的nett 友好的schrecklichhübschschick 时髦的uninteressanttypischherzlichnützlich有用的glücklich 开心的traurig (+über Akk)悲伤的zuerstnun 现在,这时gerade 刚好,恰好schlimm 糟糕的,坏的womit 用什么wohin 去哪里effecktivaufmerksam聚精会神的,注意的aktivwert 有价值的,值得的voll 满的wertvoll有价值的,宝贵的gemeinsam 共同的selbst 自己,本人selbtständig 独立的außer + Dat 除..以外einfach 干脆,简直ander …另外的hinten 后面damit 以此dafürjetzt 现在letzt 上一次,最近kalt 冷的berühmtnicht nur ... sondern 不仅...而且fast 几乎niemand 无人,没有人für immer 永远praktisch 实际的tolerant 宽容的meist 大多数的seit +Dat 从...以来als 作为vor allem 首先,特别是zeimal 两次wöchentlichverbotenwahrscheinlich可能的die Möglichkeit, -en 可能性sauber 干净的(over)über + Dat/Akk到...去unter + Dat/Akkin + Dat/Akk(on)auf + Dat/Akkneben + Dat/Akkhinter + Dat/Akk到...后面去zwischen + Dat/Akkendlichfertig 完成的,准备好的wunderbar美妙的,极好的wunderschön 极美的halt 且慢ungefähr 大约,差不多jeder/jede/jedesfit 精力充沛的zufrieden(+mit) 满意的anfangs 开始zum Schluss 最后3/ 时间die Zeit, -endie Uhrzeitdie Tageszeit, -endie Freizeitdie Hochzeit, -en 婚礼der Termin, -das Alter, -der Tag, -eder Morgan, -morgansder Abend, -eabendsder Punkt, -edas Jahr, -edie Jahrszeit, -en 季节heuteder Vormittag, -evormittagsder Nachmittag, -eder Mittag, -emittags 中午die Nacht, -enachts 夜里der Moment, -eoftimmermeistensmanchmalseltennie 从不halbeineinhalb一又二分之一anderthalb 一个半die Minute, -n 分钟die Stunde, -ndie Pünktlichkeitdie Möglichkeit, -en可能性das Viertel, -die Dreiviertelstunde, -n der Anfänger, -der Anfang, ..eanfangsder Beginn der Unterrichtsbeginn das Ende , -nder Schlussdie Woche, -ndas Wochenende, -n der Wochentag, -eder Montag, -eder Dienstag, -eder Mittwoch, -eder Donnerstag, -eder Freitag, -eder Sonnabend, -eder Samstag, -eder Sonntag, -eder Monat, -eder Januar, -eder Februar, -eder März, -eder April, -eder Mai, -eder Juni, -sder Juli, -sder August, -eder September, -eder Oktober, -eder November, -eder Dezember, -edie Jahreszeit, -en 季节der Frühling, -eder Sommer, -eder Herbst, -eder Winter, -e4/ 交际der Abschied, -e 道别die Verzeihungdie Entschuldigungtschüssdas Gespräch, -edie Sprach, -n 语言die Begrüßung, -enVielen Dank!Gute Nacht!die Freiheit, -en 自由der Besuch, -eder Freund, -edie Freundin, -nendie Feier, -ndie Abschiedfeier, -ndie Liebeder Minidialoge, -edas Wohl 幸福,健康Zum Wohl!干杯!祝您健康!Prost!干杯!der Groß, ..er 问候Na klar. 那当然!das Sprechen 说das Sprichwort, ..erdie Geste, -n 手势der Kontakt, -e 联系der Gast, ..eFreut mich. 我很高兴。

化妆品品牌大全按品牌英文名称字母A-Z跳转查看ABCDEFGHIJKLMNOPQRSTUVWXYZA爱琪美Academie 阿迪达斯Adidas 伊索Aesop 唯美度Aesthetic艾哈佛Ahava 爱格纳Aigner 澳尔滨Albion 爱特纳Alterna爱茉莉Amore 安利Amway 安洁雅Andrea 安娜苏Anna sui雅呵雅Aqua 水之密语Aquair 水之印Aqualabel 雅男仕Aramis安利雅姿Artistry 花王护发Asience 安尚秀ASIXO 爱泊丽Asplir雅典娜Athena 欧珀莱Aupres 雅漾Avene 雅芳AvonB自然香调Bare Escentuals 倍丽颜Barrier Moist 美谛高丝Beaute de kose 牛尔BeautyDiy盼丽风姿Benefiance 贝玲妃benefit 碧生源Besunyoung 贝德玛Bioderma碧柔Biore 碧欧泉Biotherm 必列斯Bliss 波比布朗Bobbi brown博凯Boorkaee 自然风Boots 贝佳斯Borghese 夜巴黎BOURJOIS白兰氏Brand's 巴宝莉BURBERRY 小蜜蜂Burts Bees 宝格丽BvlgariC家美乐Camenae 凯伊黛Carita 卡姿兰Carslan 仙丽施Cellex-c香奈儿Chanel 婵真Charmzone 自然堂Chcedo 清妃Chinfie花皙蔻Chloe by natureland 克莉丝汀.伯顿Christian breton 娇韵诗Clarins CDPCle De Peau可伶可俐Clean&clear 倩碧Clinique 可贝尔COBOR 色彩地带Colourzone康美柯Comecoo 封面女郎Covergirl 美肤之匙CPBD大宝Dabao 丹姿danz 迪梵Darphin 臻水DDF蝶妆Debon 思妍丽Decleor 皮肤专家Dermablend 德美乐嘉Dermalogica蝶翠诗Dhc 迪奥Dior 迪士尼Disney 李医生Doctor li白大夫Doctorbai 多多Dodo DOUX MEDoux me 多芬Dove蒂珂DQ 勃兰特博士Dr. Brandt 丹尼斯博士Dr. Denese 赛贝格医师Dr. Sebagh德国世家Dr.Hauschka DSMDSME伊兰纤姿Elancyl 艾丽美Elemis 忆念美Elene 伊利莎白.雅顿Elizabeth Arden伊丽莎白.泰勒ElizabethTaylor 雅诗兰黛Estee lauder 爱丽Etude 优色林Eucerin依云EvianF芳凯尔Fancl 宠爱之名For Beloved One 芙丽芳丝Freeplus 冰凝24/7 Freeze 24/7清新Fresh 美容汇Fusion BeautyG倩美Galenic 卡尼尔Garnier 积姬仙奴Gatineau 阿玛尼GIORGIO ARMANI纪梵希Givenchy GK 化妆品GK Cosmetics 大印象Great Impression 古琦Gucci娇兰Guerlain 维健美GuinotH水芝澳H2o 夏士莲Hazeline 海飞丝Head&shoulders 德国小甘菊Herbacin康宝莱Herbalife 佰草集Herborist 本草堂herborn 赫莲娜HrI伊奈美Illume 悦诗风吟Innisfree 相宜本草INOHERB 茵芙纱Ipsa三宅一生ISSEY MIYAKE 一朵ItoJ乔伊纽约Joey New York 强生Johnson 果漾美颜juice beauty 求姿JuJu Cosmetics军献Junxian 茱莉蔻Jurlique 祖芬娜JuvenaK佳丽宝Kanebo 高田贤三Kenzo 卡诗Kerastase 契尔氏Kiehls纪娜丽诗Kinerase 高丝艾文莉Kose avenir 高丝绮丝碧Kose esprique 高丝葛伦黛娜Kose grandaine高丝纯肌粹Kose junkisui 高丝兰皙欧Kose recipeo 高丝清肌晶Kose seikisho 高丝雪肌精Kose sekkiseiL莱佳奴La cannelle 海蓝之谜La mer 蓓莉La prairie 兰蔻Lancome蓝顿Landun 兰芝Laneige 理肤泉Laroche posay 罗拉玛斯亚Laura Mercier靓妃Liangfei 里美Limi 欧舒丹Loccitane 巴黎欧莱雅Loreal力士LuxM魅可Mac 美即Magic 浮生若梦Make Up For Ever 梦妆Mamonde玛丽黛佳MARIE DALGAR 丸美Marubi 玫琳凯Mary kay 膜法世家1908 MaskFamily蜜丝佛陀Max Factor 美宝莲Maybelline 美素maysu 曼秀雷敦Mentholatum珍碧嘉Methode Jeanne Piaubert 谜尚Missha 慕拉MuradNNARSNARS 娜露可naruko 娜图比索Natura Bisse 自然美Naturalbeauty纽斯葆Nature-power 露得清Neutrogena 尼克Nickel 莲娜莉姿Nina ricci妮维雅Nivea 如新Nu skin 欧树NUXEO欧蕙O hui 玉兰油Olay 娥佩兰Opera 品木宣言Origins幽兰OrlaneP潘婷Pantene 柏氏pats Paul & JoePaul & Joe 柏姿PayotPBAPBA 百雀羚Pehchaolin 培礼雅Perlier 裴礼康MD Perricone MD彼得罗夫Peter Thomas Roth 飞利浦Philips 自然哲理Philosophy 旁氏Ponds普拉达Prada 汇美舍Pretty Valley 培法芝Prevage 珀莱雅PROY A泊美Pure&MildQ千艺彩妆QIANYI MAKE-UPR利维肤Re Vive 露华浓Revlon RMKRmk 若缇娜RutinaS贞水Sadamizu 珊娜Sana 赛维Sav 施华蔻schwarzkopf诗碧Shibi 资生堂Shiseido 吾诺SHISEIDO Uno 植村秀Shu uemura曲美Sibutramine 诗芬Sifone 希思黎Sisley 美之匙Sk-ii皮肤药用品Skin Ceuticals 斯美凯Skin Medica 思亲肤Skinfood 出色潮流Smashbox索菲娜Sofina 诗丹丽Stendhal 葆丽美Suisse programme 雪花秀SULWHASOO雪肌丽SwisslineT东洋之花Tayoi 刮胡学问The Art Of Shaving 美体小铺The body shop 菲丝小铺The face shop西藏红花Tibetan saffron 丁家宜TjoyU法国幽蒂薇ULRIC DE V ARENS 最美Ultima 法国玛朵Umi Miwaku 由你Up2u依泉Uriage 优白Uv whiteV法而曼Valmont 薇婷Veet 范思哲Versace 薇姿Vichy薇欧薇V ov 沙宣Vs sassoon 维亭VtW屈臣氏Watsons 唯美Weimei 威娜Wella 白娣颜WhitiaX赛尼可xenicalY圣罗兰Ysl 羽西Yue saiZ施比格狄Z. Bigatti 哲·碧卡狄Z.Bigatti 姬芮Za 瑟雅Zirh瑟雅国际Zirh International精彩推荐如何打造完美的美甲靓甲如何选择美甲培训学校揭秘女明星之美白的秘密肌肤保养不去美容院肌·[彩妆前沿] 彩妆小技巧急救肌肤重现美好容·[秀发护理] 短发DIY轻松变马尾(图片) ·[美容食谱] 美容视界:一周减肥养颜食谱·[品香水] 香奈儿香水N°19 香奈儿19号香水·[流行发型] 2013年最风行发型设计·[科技护肤] 隆胸最新技术:当下最先进的隆胸article right center1 300*250article right center2 300*250化妆品排行榜2012护肤品排行榜第17位2012护肤品排行榜第20位·[化妆品排行榜] 全球十大奢侈化妆品·[化妆品排行榜] 娇韵诗的化妆品怎么样·[化妆品排行榜] 国内知名化妆品品牌有哪些·[化妆品排行榜] 2012化妆品排行榜第5位·[化妆品排行榜] 2012化妆品排行榜第4位·[化妆品排行榜] 2012化妆品排行榜第3位·[化妆品排行榜] 2012化妆品排行榜第2位·[化妆品排行榜] 2012化妆品排行榜第1位·[化妆品排行榜] 2012化妆品排行榜第6位·[化妆品排行榜] 2012化妆品排行榜第7位article right center1 300*250友情链接:。

德语中阳性阴性中性词汇的辨别方法1) 凡是以Ge-开头的,并且表示“一类事物总称”的名词,100%是中性的例如:das Geb?ude 建筑物;das Gericht 菜肴、法院;das Getr?nk 饮料;das Gemüse 蔬菜;das Geb?ck 烘烤饼干;das Gep?ck 行李;das Gespr?ch 谈话、对话。

2) 凡是以-um结尾的名词,100%都是中性的,毫无悬念的,比如:das Studium 大学课程;das Stipendium 奖学金;das Museum 博物馆;das Kriteritum 标准;das Zentrum 中心;das Datum 日期、数据;das Wachstum 增长;das Visum 签证。

3) 凡是以-schaft结尾的名词,100%阴性,毫无悬念,类似于英语中的后缀-ship,表示“一种抽象的关系”,例如:die Wissenschaft 科学;die Wirtschaft 经济;die Nachbarschaft 邻里关系;die Freundschaft 友谊;die Bereitschaft 意愿;die Gewerkschaft 工会4) 凡是后缀是keit或者heit的名词,100%是阴性的,比如:die Gesundheit 健康,die Freiheit 自由,die M?glichkeit 可能性,die Flüssigkeit 液体,die Besonderheit 特别,die Einheit 统一,die ?hnlichkeit 相似性,die Unterschiedlichkeit 不同,区别。

5) 98% 以字母-e结尾的名词是阴性的,这条实在太有帮助了,解决很多的词性问题,比如:die Schule学校;die Tasche包、口袋;die Marmelade果酱;die Erdbeere草莓;die Tasse咖啡杯;die Folge顺序、后果;die Frage问题;die Reise旅游;die Panne故障;die Lunge肺另外有一小部分以-e结尾的名词是阳性的,并且都是弱变化,比如der Kunde顾客;der Affe猴子;der L?we狮子;der Kollege男同事;但是der K?se不是弱变化;还有少数是中性的,比如:das Ende结束;das Wochenende周末!die Geschichte历史,的确它是阴性的,因为我讲了是以-e结尾的;der Gebrauch用法,这个词来源于动词gebrauchen(使用)的词干, 动词词干构成名词往往是阳性的;derGesch?ftsmann商人,这是一个复合词,复合名词的词性取决于最后的一个单词,Mann是阳性的,所以是它也是阳性的1) 带如下拉丁或希腊语系的词尾/后缀的名词为阳性弱变化名词,其重音在后缀上:der Adjuntant (en en) 副官der Protestant (en en) 抗议者der Aristokrat (en en) 贵族der Autokrat (en en) 独裁者der Philosoph (en en) 哲学家der Theosoph (en en) 通神学der Philolog(e) (en en) 语言学家der Theolog(e) (en en) 神学家der Poet (en en) 诗人der Komet (en en) 彗星der Pianist (en en) 钢琴家der Prokurist (en en) 代理人der Bandit (en en) 土匪der Jesuit (en en) 耶酥会会士der Geograph (en en) 地理学家der Telegraph (en en) 电报der Enthusiast (en en) 热心人der Phantast (en en) 空想家der Kamerad (en en) 同志der Advokat (en en) 律师der Kandidat (en en) 候选人der Magistrat (en en) 高级官员还有带外来语后缀al, ar, ent, eur, ier, or, us 的词,也为阳性:der General (s e ) 将军der Ingenieur (s e ) 工程师der Student (en en) 学生der Kasus (- - ) (语法:格)2) 动词去掉词尾en,加er,形成阳性名词,指做动作的人,复数不再改变词尾:besuchen - der Besucher lehren - der Lehrer3) 阳性名词前加erz,表示大,为主或首要的意思,复数和原词相同:der Bischof der Erzbischof die Erzbischoefe4) 大多数表示阳性生物的名词,都为阳性:der Arbeiter 工人der Loewe 雄师der Vater 父亲der Hahn 公鸡5) 四季,月份,周日,都为阳性:der Fruehling 春天der Mai 五月der Montag 周一der Sonntag 周日6) 表示方向的词,都为阳性:der Osten 东方der Westen 西方7) 表示风霜雨雪的词,都为阳性:der Regen 雨der Wind 风der Schnee 雪der Reif 霜8) 大多数以en结尾(但不包括动名词或以chen结尾的词),为阳性:der Hafen 港口der Laden 商店9) 各种汽车名词,都为阳性:der VW(Volkswagen) 大众汽车der LKW(Lastkraftwagen) 载重汽车10) 大多数带er, el, ling, s, ich, ig 词尾的名词,为阳性:der Lehrer der Schluessel der Lehrling der Teppich der Koks der Honig1) 在形容词或名词后加tum变成中性名词,复数形式为:tuemerheilig - das Heiligtum - die Heiligtuemerder Koenig - das Koenigtum - die Koenigtuemeralt - das Altertum - die Altertuemer2) 词尾为ium 或um 的词是中性,复数形式为一般:ien 或en,但有例外*: das Studium die Studien das Museum die Museen*das Praktikum die Praktika还有带后缀chen, lein, sal, tel, icht, ett, in 的名词都为中性:das Haeuschen das Buechleindas Dickicht 灌木丛das Schicksaldas Drittel Das Ballett 芭蕾das Benzin3) 表示幼小生物的名词,多为中性:das Kind das Lamm 羊羔4) 几乎所以金属及化学名词,都为中性:das Gold das Jod 碘das Uran 铀等等例外:der Stahl die Bronze等5) 名词化了的动词,形容词或分词等,都为中性:das Leben das Gruen 绿色IV - 形成不同词性的前缀和后缀1) 形容词或动词后加nis形成的词为阴性或中性,复数形式为:nissewild die Wildnis die Wildnissekennen die Kenntnis die Kenntnissebilden das Bildnis die Bildnisse2) 名词前加ge形成集体性或联合性名词,复数形式按其不同词尾来定:das Wasser das Gewaesser die Gewaesserdas Spiel der Gespiele die Gespielen3) 动词前加ge形成表示动作的名词,复数形式按其不同词尾来定:reden das Gerede die Geredebauen das Gebaeude die Gebaeudebeten das Gebet die Gebete4) 名词前加un形成相反意思的名词,复数形式与原来的词相同:der Dank der Undank die Undank5) 名词前加ur形成的名词,表示原始,本源或古老的意思,复数形式与原来的词相同:das Volk das Urvolk die Urvoelker6) 带后缀ett, ier, il及ment的名词多为中性,少数为阳性,复数在后缀上加e: das Skelett die Skelettedas Papier die Papieredas Experiment die Experimentedas Reptil die Reptile1) 表示人的名词后加in则成为阴性名词,其复数形式是:innender Protestant 变成阴性:die Protestantin 成复数:die Protestantinnen2) 动词后加rei变来的名词为阴性,复数为:reienbacken die Baeckerei die Baeckereien3) 形容词或名词后加heit形成的词为阴性,复数形式为:heitenfrei die Freiheit die Freiheiten schoen die Schoenheit die Schoenheiten der Mensch die Menschheit die Menschheiten4) 在词尾为ig, bar或sam的形容词后加keit形成的词为阴性,复数形式为:keiten dankbar die Dankbarkeit die Dankbarkeitenlangsam die Langsamkeit die Langsamkeitentraurig die Traurigkeit die Traurigkeiten5) 动词去掉词尾en后加ung形成的词为阴性,复数形式为:ungenwarnen die Warnung die Warnungen meinen die Meinung die Meinungen verbinden die Verbindung die Verbindungen6) 名词后后加schaft形成的词为阴性,复数形式为:schaftender Feind die Feindschaft die Feindschaftendas Wissen die Wissenschaft die Wissenschaftendas Land die Landschaft die Landschaften7) 从外来语转化而来词尾为e的词是阴性,复数形式为:endie Adresse die Adressen die Methode die Methoden8) 词尾为sion或tion的词是阴性,复数形式为:sionen 或tionendie Division die Divisionen die Portion die Portionen9) 词尾为taet的词是阴性,复数形式为:taetendie Qualitaet die Qualitaeten10) 词尾为ur的词是阴性,复数形式为:urendie Natur die Naturen11) 词尾为enz或anz的词是阴性,复数形式为:enzen 或anzendie Residenz die Residenzen die Eleganz die Eleganzen12) 词尾为ie的词是阴性,复数形式为:iendie Industrie die Industrien还有带外来语后缀a, age, ik, ive 的名词为阴性die Aera 纪元die Garage 车库die Fabrik 工厂die Defensiv 防御13) 大多数表示阴性生物的名词为阴性:die Frau die Kuh die Stute14)大多数表示花草,树木,水果等名词为阴性:(苹果阳性)die Rose die Lilie die Birne15) 名词化的数词都为阴性:die Fuenf die Zehn die Tausend16) 以国家或城市命名的船只都为阴性:die Bremen die Hessen17) 后缀为t的名词都为阴性:die Fahrt。

德语基础词汇一das Abenteuer, = 冒险das Aber, opl. 异议;困难das Abitur, e 中学毕业考试(毕业证)das Alter, = 年龄,年纪das Arbeitsamt, :er 雇主das Asthma, opl. 气喘das Ausland, opl. 外国das Baby, s 婴儿das Bad, :er 浴室das Bafoeg, opl. 学生助学金das Bargeld, opl. 现金das Barthaar, e 胡子;胡须das Bett, en 床das Bild, er 图画;照片;画像das Blatt, :er 书页;报纸das Bombenwetter, opl. 极好的天气das Bootfahren, opl. 航行das Buch, ër 书das Bundesland, :er 联邦das Büro, s 办公室das Dach, :er 屋顶das Denkmal, :er 纪念碑das Dorf, :er 村庄das Eichhoernchen, = 小松鼠das Erntedankfest, e 收获节das Feld, er 田地das Fenster,= 窗户das Fest, e 节日das Fieber, opl. 发烧das Fischen, opl. 鱼das Foto, s 照片,图片das Freie, opl. 郊外das Futter, opl. 饲料das Gebiet, e 地区;区域das Geburtsdatum, Geburtsdaten 生日das Gefühl, e 知觉;感觉;感情das Geheimnis, se 秘密das Grab, :er 死亡德语词汇二das Guthaben, = 结余;结存款das Gymnasium, Gymnasien 高级文科中学das Haar, e 头发das Halsweh, opl. 咽喉炎das Handtuch, :er 毛巾das Haus, :er 房子das Haustier, e 家畜das Heft, e 笔记本das Hektar, e 公顷das Hemd, en 衬衫das Hobby, s 爱好das Hotel, s 旅店das Huhn, :er 母鸡das Interessante, opl. 有趣的事das Interesse, n 兴趣das Kaestchen, = 小箱子das Kaufhaus, :er 商店das Kind, er 小孩das Kleid, er 女装;连衣裙das Kleingeld opl. 零钱das Kloster, = 寺庙das Konto, s 银行帐户das Korn, :er 种子;颗粒das Krankenhaus, :er 医院das Lamm, :er 小羊das Land, :er 地;国家;郊外das Lebewesen, = 生物das Liebespaar, e 情侣das Loch, :er 窟窿,破洞das Mal, e 次,回das Medikament, e 药物das Motiv, e 动机;创意das Motorrad, :er 摩托车das Neue, opl. 新事物das Ohr, en 耳朵das Organ, e 器官das Paar, e 一双,一对das Papiergeld, opl. 纸币das Parfüm, e/s 香水das Parlament, e 国会;会议das Pferd, e 马das Problem, e 问题das Programm, e 程序;节目das Randgebiet, e 边区;边疆das Regencape, s 雨衣das Reh, e 小鹿德语词汇三das Reich, e 国家;领域;界das Resultat, e 结果das Rheuma, opl. 风湿das Richtige, opl. 正确das Schag, e 母羊;羊das Schampon, s 香波das Schoene, opl. 美人das Schreibenzug, opl. 文具das Silber opl. 银das Sparbuch, :er 存折das Studentenwohnheim, e 学生宿舍das Studienkolleg, s 大学课程das Studium, Studien 学期das Talent, e 天才das Theaterspiel, en戏剧das Thema, Themen 题目;标题das Thermometer, = 温度计das Tier, e 动物das Toilettenwasser, -waesser 化妆水das Trinken, opl. 饮品das Verstaendnis, se 理解;领会das Volksfest, e民间节日das Waschen, opl. 洗涤物;洗das Wasser, opl. 水das Werk, e工作;活动das Whonheim, e 住宅das Wiesel, =黄鼠狼das Wohl, opl.幸福;健康das Zahlungsmittel, = 支付手段das Zeichen, = 信号das Zelt, e 帐篷das Zeugnis, se 证书;证明das Ziel, e 目标das Zimmer, = 房间das Zuhause, opl. 家,家园das, Diplom, e 毕业文凭der Abend, e 晚上der Abschluss, :e 结束;终结der Absender, = 寄信人der Affe, n 猴子der Anfang, :e 开始;初der Anzug, :e 套服;制服der Appetit, opl. 胃口der Arbeitsplatz, :e 工作岗位;职位德语词汇四der Empfaenger, = 收件人;接收者der Entwurf, :e 草图;设计图der Esel,= 驴der Familienstand, opl. 婚姻状况der Fan, s 崇拜者;追随者der Feind, e 敌人der Fernreisebus, se 长途汽车der Fernsehtext, e 电视节目der Film, e 电影;胶片der Fischer, = 渔夫der Fleck, en 地点;斑点der Friseur, e 理发师der Frühling, e 春季der Fuchs, :e 狐狸der Führerschein, e 驾驶执照der Geburtsort, e 出生地der Geburtstag, e 生日der Gefrierpunkt, e 冰点der Geier, = 秃鹰der Gips, e 石膏der Glaube, n 信仰;认为der Gliederschmerz, en 关节炎der Grund, :e 土地;基础der Hals, :e 脖子der Halsschmerz, en 喉咙疼der Hammer, : 糟糕的事der Hausbesuch, e 医生家访der Hausschlüssel, = 钥匙der Herbst, e 秋天der Hof, :e 院子;宫廷der Hoerer, = 听众der Hund, e 狗der Husten 咳嗽der Hut, :e 帽子der Irrtum, :er 错误;失误der Kassenzettel, = 收据;发票der Katalog, e 目录;der Kater, = 雄猫der Kollege, n 同事der Komfort, opl. 舒适der Kommilitone, n 大学同学der Komponist, en 作曲家德语词汇五der Kongress, e 代表会der Koenig, e 国王der Konstrukteur, e 建造;构造der Kontoauszug, :e 银行结单der Kopf, :e 头der Kopfschmerz, en 头疼der Korb, :e 篮子;筐der Korridor, e 走廊der Krankenschein, e 病假单der Kredit, e 信用der Krieg, e 战争der Kuchen, = 蛋糕der Küchenschrank, :e 橱柜der Kugelschreiber, = 圆珠笔der Kuss, :e 吻der Lebenslauf, :e 简历der Loewe, n 狮子der Luftpostbrief, e 航空信der Magen, = 胃der Manager, = 经理der Mantel, : 大衣,外衣der Markt, :e 市场der Maulwurf, :e 鼹鼠der Mond, e 月亮der Mund, :er 嘴der Mut, opl. 勇气;大胆der Nachbar, n 邻居der Nachfolger, = 继承者der Neffe, n 侄子der Ort, e 场所;地区der Paedagoge, n 教师;教育家der Papagei, en 鹦鹉der Papst, :e 罗马教皇der Park, s 公园der Patient, en 病人der Personalausweis, e 身份证der Platz, :e 位子;场所der Preis, e 价格der Prospekt, e 前途;远景der Prozess, Prozesse 过程der Pullover, = 毛外套der Rabe, n 乌鸦der Rasierapparat, e 剃须刀der Raucherhusten, opl. 吸烟引起的慢性咳嗽der Raum, :e 地区;体积der Rhein 莱茵河德语词汇六der Rock, :e 裙子der Roman, e 长篇小说der Rücken, = 背部der Sand, opl. 沙子der Schatz, :e 财宝der Schirm, e 衬衫der Schlaf, opl. 睡眠der Schlafanzug, :e 睡衣der Schluss, :e 锁;关闭;结局der Schlüssel, = 钥匙;关键der Schnee, opl. 雪der Schneemann, :er 雪人der Schnupfen, opl. 抽涕;流鼻涕der Schrank, :e 柜子der Schritt, e 步伐der Schuh, e 鞋子der Schwanz, :e 尾巴der Sommer, = 夏天der Sonnenaufgang, :e 日出der Sonnenuntergang, :e 日落der Spatz, en 麻雀der Spaziergang, :e 散步der Spielplatz, :e 游乐场der Sprachkurs, e 语言课程der Sprecher, = 发言人der Staat, en 国家der Stall, :e 棚;围栏der Stamm, :e 干;茎;主干;骨干der Stand, :e 站立;位置der Staub, opl. 灰尘der Stift, e 铅笔der Stock, Stockwerke 棍;棒der Strand, :e 海滩;海岸der Strauss, :e 花束der Stress, opl. 紧张;压力der Strumpf, :e 袜子der Studentenausweis, e 学生证der Studiosus, Studiosi 学生der Sturm, :e 狂风;暴风der Tag, e 日,天,昼der Tagesablauf, :e 日程der Tanz, :e 跳舞;舞蹈der Taxifahrer, = 出租车司机der Tee, s 茶der Teller, = 服务员der Tisch, e 桌子德语词汇七der Ton, :e 声音der Trend, s 倾向;趋势der Umzug, :e迁移;迁居der Unbekannte, n 不熟悉的;不认识的der Unfall, :e 失事;事故der Unterricht, e 课程der Verband, :e绷带der Verdienst, e 工资;收入der Verkauf, e 卖;出售der Verlust, e丢失der Versuch, e尝试der Vogel, : 鸟der Volleyball, :e 排球der Vorgang, :e 事件经过der Vorrat, :e 储备der Vorschlag, :e 提议;建议der Vorteil, e 利益der Wald, :er 树林der Wein, e 葡萄酒der Wille, opl. 愿望der Wind, e 风der Winter, = 冬天der Witz, e 玩笑,笑话der Wohnort, e 住所;居住地点der Wolf, :e狼der Wunsch, :e 愿望der Zahn, :e 牙齿der Zank, opl.争吵der Zettel, = 纸条;便条der Zins, en 利息der Zucker, opl. 糖der Zweig, e 树枝der/die Kranke, n 病人der/die Tote, n尸体die Abkürzung, en 缩写,简写die Abteilung, en 部门die Adresse, n 通讯地址die Aktivitaet, en 积极die Allee, n 林荫道die Allergie, n 过敏德语词汇八die Ampel, n 交通灯die Angst, :e 害怕;担心die Arbeit, en 工作die Arbeitsstelle, n 工作场所die Aufgabe, n 任务;使命,职责die Aufnahmeprüfung, en 入学考试die Ausbildung, en 进修,深造die Ausgabe, n 开支;分发die Ausnahme, n 例外情况die Bahn, en 火车die Bank, :e 长椅die Bank, en 银行die Bankleitzahl, en 银行编码die Banknote, n 纸币,钞票die Basis, Basen 基础;基层die Bedingung, en 条件;情况die Behoerde, n 行政机关die Benutzung, en 使用die Berufserfahrung, en 工作经验die Bescheinigung, en 证明;凭证die Bewerbung, en 求职die Bibel, n 圣经die Biene, n 蜜蜂die Bildung, opl. 教育die Birne, n梨die Bitte, n 请求die Bluse, n 短上衣,短衫die Box, en 箱子die Braut, :e 未婚妻;新娘die Breite, n 宽度;纬度die Bronchitis, die Bronchitiden 支气管炎die Brühe, n 肉汁die Burg, en 城堡die Creme, s 奶油die Dauer opl. 期间;持续的时间die Diagnose, n 诊断die Doktorarbeit, en 博士论文die Donau 多瑙河die Dorfstrasse, n 乡间小路die Durchreise, n 周游die Dusche, n 淋浴装置die Ecke, n 角落die Ehre, n 荣誉感die Einnahme, n 服用德语词汇九die Einreise, opl. 入境die Einzelheit, en 细节;详情die Elster, n 鹊die Entscheidung, en 决定;判决die Erdbeere, n 草莓die Erfahrung, en 经验;体会die Erfinung, en 发明;编造die Erkaeltung, en 感冒die Erlaubnis, opl. 批准;准许die Ernte, n 收割die Erntemaschine, n 收割机die erste Hilfe, opl. 急救die Farbe, n 颜色,色彩die Ferne, n 远处;远方;将来die Filiale, n 分店;分公司die Flaeche, n 面积;平面die Fliege, n 苍蝇die Folge, n 后果die Frage, n 问题die Friseurin, nen 理发师die Frucht, :e 水果;果实die Frühe, opl. 早晨die Funktion, en 作用;功能die Gans, :e 鹅die Geburtsstadt, :e 出生地die Gefahr, en 危险;危机die Genesung, opl. 愈痊,复元die Geologie, opl. 地质学die Germanistik, opl. 语法die Geschichte, n 历史;历史学die Gesundheit, opl. 健康die Gitarre, en 吉他die Grenze 边境die Groesse, n 尺寸,号码die Gruppe, n 组;群;团体die Güte, opl. 善心;善心die Gymnastik, opl. 体* die Haelfte, n 一半die Haltestelle, n 车站die Haut, opl. 皮肤die Heilmethode, n 治疗方die Herkunft, :e 出身;来历die Hilfe, n 帮助;救助die Hitze, opl. 热;加热;发怒德语词汇十die Hoffnung, en 希望;期望die Hoeflichkeit, opl. 礼貌die Hoehe, n 高;高度die Hose, n 裤子die Hosentasche, n 裤兜die Hütte, n 小屋;茅屋die Institution, en 国家机关die Jacke, n 夹克die Jagdbeute, opl. 打猎die Jahresernte, n 收割季节die Jahreszeit, en 季节die Jeans, osg. 牛仔裤die Jugendherberge, n 青年旅馆die Kaelte, opl. 寒冷die Kasse, n 收款台die Katze, n 猫die Kombination, en 联合,联盟,团体die Kondition, en 条件die Koenigin, nen 女王die Kopie, n 副本;复印件die Kraft, :e 力气;力量die Krankenversicherung, en 健康保险die Krankheit, en 疾病die Kreide, n 粉笔die Kreuzung, en 十字路口;交叉die Krise, n 危机die Küche, n 厨房die Kuh, :e 母牛die Kur, en 治疗die Kurzform, en 缩写形式die Kurzgeschichte, n 短篇小说die Lampe, n 灯die Landwirtschaft, opl. 农业die Leber, n 肝脏die Lehrstelle, n 培训die Leine, n 绳子die Luft, :e 空气die Lunge, n 肺die Mandel, n 扁桃腺die Mandelentzündung, en 扁桃腺炎die Marone, n 板栗die Massage, n 按摩die Mathematik, opl. 数学die Medizin, opl. 医药学die Menge, n 数量die Milch, opl. 牛奶die Minderheit, en 少数die Mitternacht, opl. 午夜die Mittlere Reife 中学毕业证die Mohrrübe, n 胡萝卜德语词汇十一die Monatskarte, n 月票die Morgenfrühe, opl. 明早die Mühe, n 辛劳;费力die Münze, n 硬币die Musik, en 音乐die Mütze, n 帽子die Nachricht, en 新闻报导die Nacht, :e 夜里die Nase, n 鼻子die Natur, en 大自然;自然界die Nichte, n 侄女die Niere, n 肾脏die Note, n 成绩;分die Nummer, n 号码die Operation, en 外科手术die Pastille, n 药丸die Pause, en 休息;暂停die Person, en 人die Pflanze, n 植物die Pflege, opl. 照看;看护die Philosophie, opl. 哲学die Pille, n 药丸die Politik, opl. 政治die Polizei, opl. 警察die Post, opl. 邮寄die Postleitzahl, en 邮政编码die Praxis, Praxen 实践die Produktion, en 生产制造die Prüfung, en 考试die Qualitaet, opl. 质量die Redaktion, en 编辑die Rede, n 谈话;谈论die Regel, n 规则die Reihe, n 列,排die Reihenfolge, n 次序die Reklamation, en 抱怨;投诉;退货die Rübe, n 萝卜die Ruhe, opl. 安静;静止德语词汇十二die Sachen, pl. 物,事物,东西die Saison, s 时节;时令die Salbe, n 软膏die Schlange, n 蛇die Schulden (pl.) 债务die Schwester, n 姐妹die Seife, n 香皂die Sicht, opl. 视力;视觉die Sinfonie, n 交响乐die Sonate, n 奏鸣曲die Spitze, n 尖端;尖顶die Stelle, n 空缺的职位die Stufe, n 级;阶段die Tablette, n 药片die Tasche, n 衣袋;钱袋die Tasse, n 盘子die Teilnahme, opl. 参加die Temperatur, en 气温die Toilette, n 厕所;马桶die Treppe, n 楼梯;阶梯die Überschrift, en 题目;标题die Universitaet, en 大学die Unterschrift, en 签字;署名die Verlobung, en婚约die Vermaehlung, en结婚die Vermutung, en推测;猜想die Verpflichtung, en 职责;义务die Visite, n 访问;拜访die Vokabel, n 词汇die Volkskrankheit, en 常见病die Volkswirtschaft, opl. 国民经济die Vorbereitung, en 准备die Vorstellung, en 介绍;概念die Vorwahl, en 预选die Waehrungsunion, opl. 金融die Wand, :e 墙壁die Weide, n草场;牧场die Weite, n 宽阔;辽阔die Welt, en 世界die Wiese, en 草地die Wohnung, en 住宅;住房die Wolke, n 云die Wunde, n创伤;伤口die Wurzel, n 根die Zahl, en 数字die Zeit, en 时间die Zeitung, en 报纸die Zentralbank, en 中央银行德语词汇十三Grad 度ab-biegen 转向;转弯;ab-brechen A 折断,拆下ab-haengen von D 取决于abhaengig adj. 不独立的;从属的ab-heben* A 拿起,提取;取款ab-legen A 放下;摆脱ab-schliessen A 锁住;缔结;订立ab-schneiden A 剪下;割下ab-warten 等候;等待ab-waschen A 洗去,洗掉achten 注意addieren A 加;加上aehneln D 相象;相似akzeptieren A 承认;同意,接受an-bauen 栽种;栽培ander- 另外的,其他的an-fangen 开始an-geben A 说明,陈述,告知an-melden A 申报an-nehmen A 接受,接到,赞成;假设anschliessend adv. 紧接着,随后ansteckend adj. 传染的anstrengend adj. 紧张的;费力的an-treten A 要求;权利arbeitsfrei adj. 休息的arbeitslos adj. 失业的arbeitsreich adj. 工作繁忙的arm adj. 贫穷的aermlich adj. 贫穷的atmen 呼吸attraktiv adj. 迷人的auf-geben A 交付;提交;布置;放弃auf-hoeren mit D 停止auf-loesen A 解开,松开,解除auf-nehmen 开始auf-passen 注意,当心auf-steigen sein 登上德语词汇十四auf-stellen A 竖立;安装;摆放aus-drücken A 表达ausgezeichnet adj. 出色的;优秀的aus-legen A 解释,分析aus-liegen 陈列;展览aus-stellen 陈列;设置aus-waehlen A 选出;选定baden 洗澡baldig adj. 迅速的;很快的beantworten A 答复bebauen A 耕作;耕种bedeuten A 具有……意义beissen A gebissen-biss 啃;咬bekannt adj. bekannte, am bekanntest 著名的bekommen* A 来到bestehen A 组成bestehen aus D 由…组成bestellt adj. 订购bestimmen A 决定,判决;指定,任命;bestimmt adv. 确定的bezeichnen A 做记号bieten A 显出,呈现billig 便宜的bis zu D 到……止Bitte sehr! 不用客气!bitten A 请求blaettern 翻阅blau 蓝色blind adj. 瞎的bloed adj. 愚笨的boese adj. 不好的;祸事brauchbar adj. 有用的brauchen 需要braun 棕色brav adj. 勇敢的buchstabieren A 拼读bunt adj. 彩色的chronisch adj. 慢性的dick adj. 厚的;稠的differieren 使不同drüben 那边dumm adj. 笨dunkel adj. 暗的;黑的dünn adj. 薄的;细的durch A Praep. 通过;穿过durch-führen A 进行德语词汇十五durch-lesen A 通读;durchschnittlich adj. 平均的dürfen 可以durstig 口渴的ebenso adv. 同样;仍然ehemalig adj. 以前的ehrlich adj. 诚实的eigen Dpron. 自己的eigentlich adv. 实际上,真的;竟然eilig adj. 急迫的,紧急的einverstanden 同意;接受einzeln Dpron. 单一的;个别的eisig adj. 冰冷的;冷淡的empfehlen A 推荐;介绍emsig adj. 勤奋的endgültig adj. 最终的;确定了的endlich adv. 终于eng adj. 狭窄的;紧的entlassen A 解雇enttaeuscht sein 失望的entzündet adj. 发炎的erklaeren A 解释ernten A 收割erreichen A 够到;达到;到达errichten A 树立;建立erst mal 第一次erteilen A 授予fallen gefallen sein -fiel 下;下落;下沉falls =wenn falsch adj. 错的fantasieren 幻想fest adj. 坚固的;固体的fest-legen A 限定;规定fett adj. 肥的;胖的flink adj. 敏捷folgen D gefolgt-sein 跟;跟随freiberuflich adj. 自由职业的frei-lassen A 释放fremdsprachig adj. 外国语的frieren* 感到冷froh adj. 快活的froehlich adj. 快乐的德语词汇十六fromm adj. 虔诚的fütten A 喂养gehen 给gehen um A 关系到;涉及到es geht um etw. [Es geht um den Sieg. 这关系到胜利] gehoeren zu D 属于gelb 黄色genauso (wie) adv. 同样的generell adj. 一般的;普通的genug adj. adv. 足够的genügen 足够gerecht adj. 公正的;合理的gestrig adj. 昨天的;以前的gesund adj. 健壮的giftig adj. 有毒的glauben D/A 想;认为;相信Grad 度Gott sei Dank! 感谢上帝grün 绿色gründen A 成立;建立gründlich adj. 彻底的grüssen A 祝福,问候gucken 张望;瞧günstig adj. 有利的,有益的;良好的haltbar adj. 耐久的;坚固的handeln 行为;处理haengen A 悬,挂hastig adj. 匆忙的haeufig adj. 时常的;经常的heilen 愈痊heiter adj. 晴朗的heimlich adj. 秘密的heiss adj. 热的hellgrün 亮绿的heraus-lesen A 读出来herzlich adv. 热烈的,衷心的hoch adj. 高的hoeflich adj. 有礼貌的hübsch adj. 美丽的hungrig adj. 饿的husten 咳嗽indiskret adj. 轻率的intensiv adj. 紧张的;努力的intensivieren A 加强;提高德语词汇十七interessant adj. 有趣的irreal adj. 不现实的jaehrlich adj. 每年的jeder 每个kahl adj. 秃的;裸露的kalt adj. 冷的kaufen A 买Keine Ahnung! 不知道,没主意。