Additive manufacturing of wet-spun polymeric scaffolds forbone tissue engineering

- 格式:pdf

- 大小:961.85 KB

- 文档页数:13

聚己内酯药物控释材料的研究进展鲁手涛;徐海荣;刘黎明;曹文瑞;张海军【摘要】综述了聚ε-己内酯(PCL)药物控释材料的研究进展,以及PCL微球、PCL 纳米微粒、PCL纤维、PCL薄膜、PCL胶束、PCL水凝胶的制备方法及应用.PCL 在药物控释领域研究中,可通过与其他聚合物共混或共聚来改善亲水性和控释行为.PCL共聚物也可应用到靶向给药系统中,靶向给药系统不仅能够将药物输送至病灶部位,还能实现定向释放.随着新材料的不断研发,构建新型智能药物控释系统的前景将更加广阔.【期刊名称】《合成树脂及塑料》【年(卷),期】2018(035)004【总页数】5页(P94-98)【关键词】可降解高分子;药物控释;药物载体;聚ε-己内酯;靶向给药【作者】鲁手涛;徐海荣;刘黎明;曹文瑞;张海军【作者单位】生物医用材料改性技术国家地方联合工程实验室,山东省德州市251100;生物医用材料改性技术国家地方联合工程实验室,山东省德州市251100;生物医用材料改性技术国家地方联合工程实验室,山东省德州市251100;生物医用材料改性技术国家地方联合工程实验室,山东省德州市251100;生物医用材料改性技术国家地方联合工程实验室,山东省德州市251100;同济大学介入血管研究所,上海市200072【正文语种】中文【中图分类】TQ323.8药物控释是一种新兴的交叉学科,它可以控制药物在人体内的释放、吸收过程,使药物按照预定的剂量,以一定的模式在体内释放或使药物在指定部位释放。

与传统给药模式相比,控释系统不仅能够减少给药次数,维持血药浓度,提高药物浓度稳定性,还降低了药物的不良反应,提高了药物治疗的有效性[1-2]。

药物载体是控释技术的支撑点,不同性质的载体具有不同的药物释放参数。

可降解高分子药物控释载体具有良好的生物相容性和较高的载药量,而且人体的代谢可以清除它们的降解产物,使可降解高分子成为首选的药物控释载体之一。

可降解高分子载体(如微米和纳米微粒、纤维等),可用于药物运输和靶向药物输送系统[3-5]。

DOI: 10.29026/oea.2018.170004Additive manufacturing frontier: 3D printing electronicsBingheng Lu1, Hongbo Lan2,3* and Hongzhong Liu13D printing is disrupting the design and manufacture of electronic products. 3D printing electronics offers great potential to build complex object with multiple functionalities. Particularly, it has shown the unique ability to make embedded elec-tronics, 3D structural electronics, conformal electronics, stretchable electronics, etc. 3D printing electronics has been considered as the next frontier in additive manufacturing and printed electronics. Over the past five years, a large num-ber of studies and efforts regarding 3D printing electronics have been carried out by both academia and industries. In this paper, a comprehensive review of recent advances and significant achievements in 3D printing electronics is provided. Furthermore, the prospects, challenges and trends of 3D printing electronics are discussed. Finally, some promising so-lutions for producing electronics with 3D printing are presented.Keywords: 3D printed electronics; embedded electronics; 3D structural electronics; additive manufacturingLu B H, Lan H B, Liu H Z. Additive manufacturing frontier: 3D printing electronics. Opto-Electronic Advances1, 170004 (2018).Introduction3D printing (also known as additive manufacturing, AM) is a breakthrough technology that has been developing for more than 30 years, but has attracted more and more attentions in recent years. The American Society for Testing and Materials (ASTM) International defines AM as “A process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies”. The seven major additive manufacturing processes as classified per ISO (ASTM F42) are: material jetting, binder jetting, material extrusion, vat polymerization, powder bed fu-sion, direct energy deposition, sheet lamination. With the development of 3D printing (3DP) from rapid prototyp-ing to the end-of-use product manufacturing process, manufacturing constraints have been greatly relieved and the design freedom has been significantly expanded, in-cluding shape complexity, material complexity, hierar-chical complexity, and functional complexity1. In partic-ular, 3D printing has the unique capability to control the point-line-area in geometry and material of each layer for an object at full scale length ranging from micro to mac-ro-scale. The emerging multi-scale and multi-material 3D printing technique possesses great potential to im-plement the simultaneous and full control of fabricated object which involves the external geometry, internal architecture, functional surface, material composition and ratio as well as gradient distribution, feature size ranging from nano, micro, to macro-scale, embedded components and electro-circuit, etc. Therefore, it is able to construct the heterogeneous and hierarchical struc-tured object with tailored properties and multiple func-tionalities which cannot be achieved through the existing technologies. Such technology has been considered as a revolutionary technology and next-generation manufac-turing tool which can really fulfill the “creating material” and “creating life”, especially subvert traditional product design and manufacturing scheme. 3D printing paves the pathway and will result in great breakthrough in various applications for example functional tissue and organ, functionally graded material/structure, lattice materi-al/structure, metamaterial, smart material, functionally embedded electronic component, bio-inspired material/1State Key Laboratory for Manufacturing System Engineering, Xi’an Jiao Tong University, Xi’an 710049, China; 2Qingdao Engineering Research Center for 3D Printing, Qingdao University of Technology, Qingdao 266033, China; 3Nanomanufacturing and Nano-Optoelectronics Lab, Qingdao University of Technology, Qingdao 266033, China* Correspondence: H B Lan, E-mail: hblan99@Received 31 December 2017; accepted 21 January 2018; accepted article preview online 9 February 2018structure, multi-functionality product, soft robot, etc. Furthermore, it may promote the tremendous progress in many subjects involving material, bio-medical, elec-tronics, mechanics, bionics, aerospace, etc 2–8.In last few years, 3D printing has been utilized to fab-ricate electronics and structural electronics. More specif-ically, electronic/electrical components can be deposited and embedded in a 3D structure to form a mul-ti-functionality product by interrupting the 3D printing process. 3D printing promotes the integrated assemblage and embedded other components as results of layer-by- layer or point-by-point characteristics. Functional ele-ments such as sensors, circuits, and embedded compo-nents are now being integrated into 3D-printed products or structures, paving the way for exciting new markets, applications and opportunities. Furthermore, 3D print-ing can be harnessed to print electronics on stretchable and flexible bio-compatible “skins” with integrated cir-cuitry that can conform to irregularly-shaped mounting surfaces. Therefore, 3D printing electronics can offer great potential and unique capabilities to build complex object with multiple functionalities. Particularly, it has shown the unique ability to produce the embedded elec-tronics, 3D structural electronics, conformal electronics, stretchable electronics, OLED, etc 9–16. 3D printing appli-cations have been significantly expanded. 3D printing electronics has been considered as the next frontier in AM. Harrop J , the director of technology research firm IDTechEx, thinks the most promising use of multi mate-rial 3D printing will come in the electronics space. A large number of studies and efforts regarding 3D print-ing electronics have been carried out by both academia and industries. Great progresses in 3D printing electron-ics have been achieved in recent years. This paper mainly presents a comprehensive review of recent progresses in 3D printing electronics. Furthermore, the challenges and prospects of 3D printing electronics are discussed. This paper may provide a reference and direction for the fur-ther explorations and studies of 3D printing electronics.Recent progresses in 3D printing electronicEmbedded electronicsMany researchers have been conducted to add electronic functionality into the 3D printed structures by embed-ding electronic/electrical components and fully encapsu-lating interconnect conductive tracks. The ability of starting or stopping the build at any given layer enables the embedding of electronic components for manufac-turing conformal embedded 3D electronic systems. Tak-ing advantage of the layer-based additive manufacturing method and access to individual layers during fabrication, a single object with multiple materials and embedded components can be built now.Embedded electronics can greatly reduce the mass and assembly complexity due to the elimination of cabled interconnects and redundant electronics packaging. The ability to embed complex functioning components and electronics into 3D printed structures is very crucial for the small-satellite users who are looking to exploit 3DP in a limited space. NASA/GRC (National Aeronautics and Space Administration/Glenn Research Center) and America Makes have performed AM techniques to de-velop the embedded electronics used in the structures of spacecraft. A manufacturing platform, the multi 3D system which integrates two FDM (fused deposition modeling) systems, a CNC (computer numerical control) router for micromachining and a precision dispenser for depositing conductive inks (as shown in Fig. 1), has been developed to produce 3D, multi-material, multifunctional devices (3D-printed CubeSat module) for addressing the re-quirements of aerospace applications. The system can embed wires and components on a multi-material sub-strate to provide mechanical, electronic, thermal and electromagnetic functionality, and making conformal structures with integrated electronics. Figure 2 illustrates the process flow of the multi 3D system and fabricated parts using the platform. A CubeSat Trailblazer inte-grated a 3D-printed structure and the embeddedFig. 1 | (a ,b ) Photograph of the multi 3D system. (c ) Schematic of a fabrication example. Figure reproduced from: (a ) ref. 9, Springer International Publishing AG; (b ) ref. 14, Elsevier Ltd; (c ) ref. 9, Springer International Publishing AG.FDM1FDM2Pneumatic slideBuild platform aStrengthFlame retardancebcelectronics has been successfully launched in 20139,14,17–20. Figure 3 demonstrated the fabrication procedure of a fully encapsulated capacitive sensor. This study provides a proof of concept for advanced fully encapsulated 3D printable devices. It also verified the utility of fully em-bedded bulk conductors interconnect 21.A shoe insole with embedded pressure and tempera-ture sensing circuitry, with wireless communications chip for data transmission was fabricated by mul-ti-material 3D printing, shown in Fig. 4. Using a hybrid 3D printing process, multi-layer tactile sensors including insulating layers and sensing elements have been built. This process enables building a sensor body layer by lay-er, prints sensing elements onto the surface of the body, and builds additional layers. With the combination of ink jet, aerosol jet and extrusion print heads, the depositedmaterial can ranges from one to tens of thousands cps with a wide range of solvents. The case demonstrated the feasibility of fabricating an electronically functional ob-ject through 3D printing 22.Figure 5 shows a 3D “smart cap” with an embedded inductor–a wireless passive sensor, which has beenFig. 2 | (a ) Process flow of the multi 3D system. (b ) Fabricated parts. Figure adapted from ref. 9, Springer International Publishing AG.Build substrate with FDMabMachine channels and cavities for circuitryDispense conductive inkPlace electronic components Join traces and electronic componentsCure conductive inksabdFig. 3 | Fabrication procedure of fully encapsulated capacitive sensor with 3D printing . (a ) Polycarbonate (PC) substrate with recesses designed for all electronic components. (b ) Components arranged in in the PC substrate. (c) Electrical components with corresponding embedded wiring. (d ) Completed capacitive sensor with fully embedded wiring, diodes, LEDs, resistors, and a microcontroller. Figure reproduced from ref. 21, IEEE.cFig. 4 | (a ) Printed wireless pressure and temperature sensor within a shoe's insole. (b ) Pressure and temperature data obtained through wireless communication from the printed insole 22. Figure reproduced from ref. 22, Society for Imaging Science and Technology.Pressure 1 Pressure 2Temperature1200011000100009000T e m p e r a t u r e (d i g i t a l v a l u e )17000 16000 15000 1400013000 12000P r e s s u r e (d i g i t a l v a l u e )0 100200300400 500 600 Time (s)abdemonstrated to monitor the quality of liquid food wire-lessly. The 3D structures including both supporting and sacrificial structures are constructed with a resolution of 30 μm using the FDM technology equipped with a multi-ple-nozzle system. After removing the sacrificial materi-als, silver particles suspensions are injected subsequently and solidified as the metallic elements/interconnects. This may be the first demonstration of a comprehensive manufacture process for printing 3D additive polymer with liquid metal paste filling for the use of potential ap-plications 12.A commercial 3Dn-300 multi-material printer from nScrypt Inc. has been utilized to fabricate a fully embed-ded low-profile antenna. The 3D printer includes dual deposition heads allowing two different kinds of materi-als to be dispensed. The thermoplastic stock is dispensed from one head through a filament extrusion process to print the dielectric components. While the other head prints the ink/paste is printed from the other head with feature sizes of as small as 20 μm to build the conductive elements 23.A hybrid 3D printing process integrating stereolitho-graphy (SL) and direct print (DP) was adopted to pro-duce functional, monolithic 3D structures with embed-ded electronics. The hybrid SL/DP system (as shown in Fig. 6) consists of a 3D Systems SL 250/50 machine and an nScrypt micro-dispensing pump integrated within the SL machine through orthogonally-aligned linear transla-tion stages. The substrate/mechanical structure was fab-ricated by SL while interconnections were made by DP conductive inks. A process was developed to fabricate a 3D electronic device using the hybrid SL/DP machine with the requirement of multiple starts and stops of the SL process, removing the uncured resin from the SL sub-strate, inserting active and passive electronic components, and DP and laser curing of the conductive traces. By curing the conductive traces in situ, the construction of monolithic 3D structural electronic devices can be per-formed without removal of the device from the machine during fabrication. Functional 2D and 3D 555 timer cir-cuits have been fabricated by the hybrid 3D printing sys-tem combined with the proposed process 24. J ang et al. also presented a 3D circuit device fabrication by the hy-brid process of SL and DW technologies. A custom-made SL system was adopted instead of a commercial SL ma-chine 25.Fig. 5 | Fabrication process of 3D “smart cap” with an embedded inductor–a wireless passive sensor . (a ) 3D fabrication process with embedded and electrically conductive structures. (b ) 3D microelectronics components, including parallel-plate capacitors, solenoid-type inductors, and meandering-shape resistors. (c ) A 3D LC tank, which is formed by combining a solenoid-type inductor and a parallel-plate capacitor. (d ) A wireless passive sensor demonstration of a “smart cap”, containing the 3D-printed LC-resonant circuit. (e ) A smart cap with a half-gallon milk package, and the cross-sectional schematic diagram. (f) Sensing principle with the equivalent circuit diagram. Figure reproduced from ref. 12, Macmillan Publishers Limited.aDual 3D printing nozzlesInjection holeLiquid metalInjectionG-S-G padsCapacitorsInductorsResistorsLC tankViaSpiral inductorTop electrodeBottom electrode z yx bcd ReaderSmart capFrequency responseM a g n i t u d e o f S 11f res f res fEnergy RF coilInformationLiquid food qualityR CLfSpiral inductorSmart capViaTop electrodeBottom electrode BottleLiquid foode3D structural electronicsA hybrid technology combined with direct-write/cure (DWC) and projection microstereolithography (PμSL) has been utilized to make 3D structural electronics. A PμSL process was applied to build the 3D structures, and the conductive tracks was produced by the combination of DWC with CNT/polymer nanocomposites, which may capacitate a new generation of inexpensive 3D structural electronics in the field of consumer, defense, and medicalelectronics. The technology of hybrid manufacturing combined with AM technologies will offer capabilities of fully 3D, high-resolution, multimaterial and large-area fabrication as well as requiring only ambient processing conditions (no clean room, vacuum or high temperature environment required). Figure 7 demonstrated the hy-brid 3D printing process and the fabricated 3D structural electronics 10.Disadvantages in the manufacturing process of printedFig. 6 | (a ) Schematic of the hybrid SL/DP system. (b –d ) Fabricated 3D 555 timer circuits packaged within SL substrates. Figure reproduced from: (b –d ) ref. 24, Emerald Publishing Limited. SLA-250Z -axisnScrypt headnScrypt controller PLC controllerY -axisX -axisOptical tableDP computerScanning mirrorSL computer355 nm DPSSlaserLaser beamSL partPlatform SL resin SL vataLEDs bMicrochip Resistor Vertical interconnects Power supplyEmbedded capacitor cdThermistorFig. 7 | The hybrid 3D printing process and fabricated 3D structural electronics . (a ) Bottom insulating structure. (b ) “U” shape wire. (c ) Top insulating layer. (d ) Wires on top surface. (e ) P μSL of the bottom insulating structure. (f ) DWC of the “U” shape wire. (g ) P μSL of the topinsulating structure. (h ) DWC of wires on the top surface. (i ) Fabricated 3D structural electronics with embedded wires. Figure reproduced from ref. 10, Springer International Publishing AG.Projector lens Projected beamDispensing head Conductive material Photocurable materialPhotocurable materialConductive materialf be a cdg hicircuit board include complexity, time consuming, high-er cost, and limited product formation as the printed circuit board must be included. In order to get over these disadvantages, Jiang et al. reported a hybrid process us-ing stereolithography and direct writing (DW) to fabri-cate 3D circuit devices. The insulated structures of circuit boards having high precision were fabricated using SL. Furthermore, the circuits were made on the several layers using DW 25. Lopes et al. also presented a similar manu-facturing system using SL and DW technologies for the fabrication of 3D structural electronics 24.The integration of SL in combination with both microdispensing (nozzle deposition) and pick-and-place technology (component insertion) can produce dielectric substrates of intricately-detailed, complex shape where miniature cavities are used for the integration of press-fit electronic components. Printed conductive traces serve as electrical connections deposited by an integrated mi-cro-dispensing system within the SL system and this combination of fabrication technologies stands to revo-lutionize the integration of electronics within mechanical structures as ‘‘3D structural electronics’’. Wicker and MacDonald demonstrated the development of multiple material and multiple technology SL systems capable of manufacturing multiple material structures with me-chanical, electrical, and biochemical functionality. Some functional objects including multi-material tissue engi-neered implants, multi-material micro-scale parts, 3D structural electronics, have been successfully fabricated.Contamination issues associated with using multiple viscous materials in a single build, throughput, and lim-ited materials as well as conductive inks with low-temperature curing capabilities remain still a chal-lenging. Figure 8 shows some examples of printed 3D structural electronics 18,24.Stretchable electronicsWith the development of electronics, progresses in man-ufacturing techniques have promoted the development in the aspects of smaller, faster, more efficient. So far, the main focus has been on rigid electronics. However, re-cent interest in devices such as wearable electronics and soft robotics has led to an whole new set of electronic devices–stretchable electronics. These new devices re-quire new manufacturing solutions to integrate hetero-geneous soft functional materials. 3D printing can be harnessed to print electronics on stretchable and flexible bio-compatible “skins” with integrated circuitry that can conform to irregularly-shaped mounting surfaces.Muth et al. reported a method of embedded 3D print-ing (e-3DP) for the fabrication of strain sensors, as shown in Fig. 9. In this method, a viscoelastic ink is ex-truded into an elastomeric reservoir via a deposition nozzle. The ink is used as a resistive sensing element, while the reservoir form the matrix material. A capping (filler fluid) layer is used to fill the void space formed in the process of the nozzle translating through the reser-voir. Finally, a monolithic part was formed by theFig. 8 | Examples of printed 3D structural electronics . (a ) A gaming die which includes a microcontroller and accelerometer. (b , c ) A magnetometer system with microprocessor and orthogonal Hall Effect sensors. Figure reproduced from ref. 18, Taylor & Francis.5 mma5 mm5 mmb cFig. 9 | Schematic illustration of the embedded 3D printing (e-3DP) process and printed stretchable electronics . (a ) Schematicillustration of the e-3DP process. (b ) Photograph of a glove with embedded strain sensors produced by e-3DP. (c ) Photograph of a three-layer strain and pressure sensor in the stretched state. Figure reproduced from ref. 11, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.Printing directionabcFiller fluidco-cure of both the reservoir and filler fluid, which cov-ered and keep the embedded conductive ink fluid. The e-3DP can create soft sensors in a highly programmable and seamless manner. In order to enable e-3DP, a multi-component materials system composed of an ink, reser-voir, and filler fluid was developed. The above method that for building highly stretchable sensors by e-3DP opens new approaches for manufacturing soft functional devices for wearable electronics, human/machine inter-faces, soft robotics, and so on 11.The ability of printing integrated circuits on the flexi-ble substrate enables the electronic devices with con-formity, lightweight structure and shock-resistant con-struction, which are challenging to be achieved by using rigid substrates such as semiconductor wafers and glass plates. Bijadi et al. have successfully tested the feasibility of a syringe extrusion-based 3D printing process to print stretchable embedded electronics through the use of SS-26S conductive silicone on flexible non-conductive silicone substrates. Instead of merely using the conduc-tive silicone traces as flexible interconnects, this method used the conductive material for creating complete cir-cuitry with SMT components and embedded microcon-trollers 26. Vatani et al. presented a hybrid manufacturing process including direct print/cure (DPC) and projec-tion-based stereolithography for stretchable tactile sen-sors. The fabrication process of the tactile sensor (shown in Fig. 10) includes building the sensor body, printing sensing elements on the body surface, and building some additional layers to cover the cured sensing elements 27. The developed 3D printable stretchable sensing material is a photocurable and stretchable liquid resin filled with multi-walled carbon nanotubes (MWNTs).Other electronic/electrical products and related technologies3D printing possesses the ability of creating complex and conformal electronics integrated within a manufactured product. The Aerosol J et printing from Optomec has been demonstrated the ability of building the functional antennae on the conformal 3D printing substrates. The whole printing process accurately controls the location, geometry and thickness of the deposit and produces a smooth mirror-like surface finish to insure optimumFig. 10 | Fabricated stretchable tactile sensor using integrated PSL and DP processes . (a ) An example (partial sphere) of 3D structure built in the PSL system. (b ) Printed sensing elements using the DP process on the insulating layers built in the PSL system. (c ) Final sensor with two sensing layers. (d ) Deformed sensor. Figure reproduced from ref. 27, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.abcdFig. 11 | 3D printed electronics using Aerosol Jet printing from Optomec . (a ) 3D MID demonstrator. (b ) 3D MID with integrated sensor. (c ) Printed conformal electronics (curve). (d ) Printed conformal electronics (dome). (e ) Printed conformal electronics (dome). (f) Sub-mm lengthscale, custom made 3D metal-dielectric. Figure reproduced from (a –c ) ref. 28, Neotech; (d –f ) ref. 29, Optomec.d e a b cfantenna performance. Some kinds of mobile device an-tennas, such as the LTE, NFC, GPS, Wifi, WLAN, and BT, have been printed through the Aerosol J et process. And the performance of such antennas tested by a cell phone component supplier is in the same level with other production methods. For now, the Aerosol Jet technolo-gy has been using for the mass production of printed 3D conformal electronics in the application of antenna and sensor. As can been seen that a hybridized DW/AM pro-cess presents great potential for creating antennas with 3-dimensional structure. Figure 11 demonstrated 3D printed electronics using Aerosol Jet printing process 28–29. Aerosol J et printing process has the ability to print conformal interconnects on 3D surfaces eliminating the need for wire bonding – for example printing electrical connections on 3D stacked die or for LED chip fabrica-tion. Runge showed Leg prosthesis part produced from PLA (Polylactic Acid) via FDM showing complexnon-planar surfaces, with surface-integrated strain gauge sensors produced by Aerosol J et TM printing and con-ductive paths deposited via micro-dispensing, both using the modular manufacturing platform. The structural elements of this leg prosthesis shaft were produced via the FDM process from PLA, a thermoplastic polymer. Its functionalization relies on a surface-integrated strain gauge realized via Aerosol J et printing. The conductive paths that lead across the part as well as the contact pads at their end were deposited through micro-dispensing. The material of the resistive sensor is a silver based ink, while interconnects and contact pads are made from sil-ver particle-filled epoxy, as shown in Fig. 12 31.The first multi-material 3D electronics printer in the world, named as Voxel8, provides an all-in-one, desktop solution for designing and prototyping next generation 3D electronic devices. Therefore, it has been regarded as a disruptive manufacture platform with the capabilities of printing embedded electronics. It enables prototyping of 3D electronic devices by the method of co-printing both thermoplastics and a highly conductive silver ink, which can be printed and cured at ambient temperature without the need for thermal annealing. Figure 13 demonstrates Voxel8 and some printed products 32.Prospect, challenges and future trends3D printing is disrupting the design and manufacture of electronic products. Functionalities of the devic-es/products fabricated by 3D printing can be significantly expanded by incorporating electronic components, such as sensors and circuits, in predetermined cavities within fabricated structures. 3D printed objects include not only traditional mechanical characteristics, but also embedded optical and electrical functions, such as sensor; all com-plex structures are difficult to produce with existingFig. 13 | Voxel8 and some printed products . (a , b ) Photograph of Voxel8 3D printer. (c ) Printed unmanned aerial vehicle. (d ) Printed antenna (dome). (e ) Printed wearable device. Figure reproduced from ref. 32, Voxel8.bac d eFig. 12 | Leg prosthesis part produced by FDM and Aerosol Jet printing . Figure reproduced from ref. 31, University of Applied Science Bremerhaven.manufacturing methods. Many emerging and innovative products, such as embedded electronics, 3D structural electronics, conformal electronics, stretchable electronics, etc., have been fabricated using the technologies. 3D printing electronics has been considered as the next fron-tier in AM. Optomec has developed a high volume printing solution for the production of 3D antenna and 3D sensors that are tightly integrated with an underlying product ranging from smartphones to industrial com-ponents. It can be utilized for high volume printing of conformal sensors and antennas directly onto preformed 3D structures. Complex electronics can be 3D printed at micron resolution which will enable cheaper smartphones and medical gadgets. Aerosol J et 3D mi-cro-structure printing is capable of ultra-high resolutions with lateral features sizes of 10 μm and aspect ratios of more than 100:1 33–37.The conductivity is still one of the major difficulties in both 3D printed electronics and general 2D printed elec-tronics because of the poor conductivity of ink caused by the low curing temperature due to the limitation of sub-strate material such as cardboard, polymers. More and more challenges in the fields of material types and pro-cessing challenges in the process of printing from 2D electronics to 3D integrated objects. Therefore, the com-patible material sets should be explored and created to provide the adequate functionality and manufacturability for the product invention by designers. Besides, the ad-hesion between the materials is also a big issue, because the conductive materials would be stripped from the substrate with a poor adhesion. This is especially im-portant case for traces that are embedded within a print and not on the surface because repair is impossible after a circuit is embedded.In order to make electronics with 3D printing, new processes should be developed to possess the ability of depositing broader types of materials. To date, there are several solutions which have the ability to fabricate mul-tifunctional 3D structures or products with embedded functional systems. Compared to other methods, the hybrid process combining FDM and direct print/writing shows higher applied potential, more flexibility. Material jetting systems seem currently to be the most successful multi-material 3D printing process among AM technol-ogies. To date, fabrication of true 3D multiple material polymeric components using material jetting processes has been demonstrated. Currently, material jetting of polymers appears to be the nearest approximation to this vision that is currently available: The combination of high resolution, controlled material deposition with the possibility of photo polymerization, which allows imme-diate solidification of the material after printing and thus facilitates deposition of materials with different func-tional or structural roles directly besides each other, pro-vides the foundation for effectively printing a structural electronics system directly. Multi-material and mul-ti-scale 3D printing will be the most promising solutions. More and more 3D printed functional electronics and products with electronics will be fabricated. 3D printing electronic technology provides a powerful tool for inno-vative product development, and extends 3D printing multiple functionalities. Significant advances in 3D printing electronics have been accomplished in the re-cent years. However, there is still a long way to go for 3D printed functional electronics and products as well as their industrial-level applications. Further potentials of 3D printing electronics need still to be explored and in-vestigated.References1. Gibson I, Rosen D W, Stucker B. Additive manufacturing tech-nologies (Springer, New York, 2010).2. Derby B. Printing and prototyping of tissues and scaffolds. Sci-ence338, 921–926 (2012).3. Lewis J A, Ahn B Y. Device fabrication: Three-dimensionalprinted electronics. Nature518, 42–43 (2015).4. Kong Y L, Tamargo I A, Kim H, Johnson B N, Gupta M K et al.3D printed quantum dot light-emitting diodes. Nano Lett14, 7017–7023 (2014).5. Lan H. Active mixing nozzle for multimaterial and multiscalethree-dimensional printing. J Micro Nano-Manuf5, 040904 (2017).6. Zheng X, Smith W, Jackson J, Moran B, Cui H et al. Multiscalemetallic metamaterials. Nature Mater15, 1100–1106 (2016).7. Vaezi M, Seitz H, Yang S. A review on 3D micro-additive manu-facturing technologies. Int J Adv Manuf Technol67, 1721–1754 (2013).8. Tian X Y, Yin L X, Li D C. Current situation and trend of fabrica-tion technologies for three-dimensional metamaterials. Opto- Electron Eng44, 69–76 (2017).9. Espalin D, Muse D W, MacDonald E, Wicker R B. 3D Printingmultifunctionality: structures with electronics. Int J Adv Manuf Technol72, 963–978 (2014).10. Lu Y, Vatani M, Choi J W. Direct-write/cure conductive polymernanocomposites for 3D structural electronics. J Mech Sci Technol27, 2929–2934 (2013).11. Muth J T, Vogt D M, Truby R L, Mengüç Y, Kolesky D B et al.Embedded 3D printing of strain sensors within highly stretcha-ble elastomers. Adv Mater26, 6307–6312 (2014).12. Wu S Y, Yang C, Hsu W, Lin L. 3D-printed microelectronics forintegrated circuitry and passive wireless sensors. Microsys Nanoeng1: 15013 (2015).13. Sun K, Wei T S, Ahn B Y, Seo J Y, Dillon S J et al. 3D Printing ofinterdigitated Li-Ion microbattery architectures. Adv Mater25, 4539–4543 (2013).14. Lehmhus D, Aumund-Kopp C, Petzoldt F, Godlinskic D,Haberkorn A et al. Customized smartness: a survey on links between additive manufacturing and sensor integration.Procedia Tech26: 284–301 (2016).15. Ladd C, So J H, Muth J, Dickey M D. 3D printing of free stand-ing liquid metal microstructures. Adv Mater25, 5081–5085。

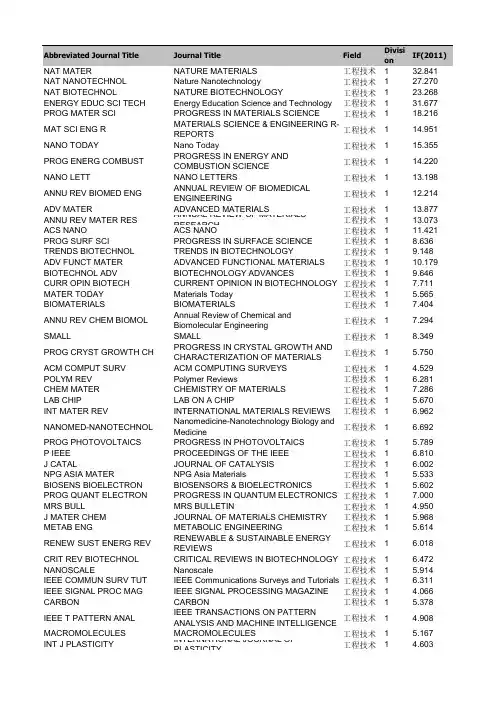

NAT NANOTECHNOL Nature Nanotechnology工程技术127.270 NAT BIOTECHNOL NATURE BIOTECHNOLOGY工程技术123.268 ENERGY EDUC SCI TECH Energy Education Science and Technology工程技术131.677 PROG MATER SCI PROGRESS IN MATERIALS SCIENCE工程技术118.216 MAT SCI ENG R MATERIALS SCIENCE & ENGINEERING R-RE工程技术114.951 NANO TODAY Nano Today工程技术115.355 PROG ENERG COMBUST PROGRESS IN ENERGY AND COMBUSTION工程技术114.220 NANO LETT NANO LETTERS工程技术113.198 ANNU REV BIOMED ENG ANNUAL REVIEW OF BIOMEDICAL ENGINEE工程技术112.214 ADV MATER ADVANCED MATERIALS工程技术113.877 ANNU REV MATER RES ANNUAL REVIEW OF MATERIALS RESEARC工程技术113.073 ACS NANO ACS NANO工程技术111.421 PROG SURF SCI PROGRESS IN SURFACE SCIENCE工程技术18.636 TRENDS BIOTECHNOL TRENDS IN BIOTECHNOLOGY工程技术19.148 ADV FUNCT MATER ADVANCED FUNCTIONAL MATERIALS工程技术110.179 BIOTECHNOL ADV BIOTECHNOLOGY ADVANCES工程技术19.646 CURR OPIN BIOTECH CURRENT OPINION IN BIOTECHNOLOGY工程技术17.711 MATER TODAY Materials Today工程技术1 5.565 BIOMATERIALS BIOMATERIALS工程技术17.404 ANNU REV CHEM BIOMOL Annual Review of Chemical and Biomolecular E工程技术17.294 SMALL SMALL工程技术18.349 PROG CRYST GROWTH CH PROGRESS IN CRYSTAL GROWTH AND CHA工程技术1 5.750 ACM COMPUT SURV ACM COMPUTING SURVEYS工程技术1 4.529 POLYM REV Polymer Reviews工程技术1 6.281 CHEM MATER CHEMISTRY OF MATERIALS工程技术17.286 LAB CHIP LAB ON A CHIP工程技术1 5.670 INT MATER REV INTERNATIONAL MATERIALS REVIEWS工程技术1 6.962 NANOMED-NANOTECHNOL Nanomedicine-Nanotechnology Biology and Me工程技术1 6.692 PROG PHOTOVOLTAICS PROGRESS IN PHOTOVOLTAICS工程技术1 5.789 P IEEE PROCEEDINGS OF THE IEEE工程技术1 6.810 J CATAL JOURNAL OF CATALYSIS工程技术1 6.002 NPG ASIA MATER NPG Asia Materials工程技术1 5.533 BIOSENS BIOELECTRON BIOSENSORS & BIOELECTRONICS工程技术1 5.602 PROG QUANT ELECTRON PROGRESS IN QUANTUM ELECTRONICS工程技术17.000 MRS BULL MRS BULLETIN工程技术1 4.950 J MATER CHEM JOURNAL OF MATERIALS CHEMISTRY工程技术1 5.968 METAB ENG METABOLIC ENGINEERING工程技术1 5.614 RENEW SUST ENERG REV RENEWABLE & SUSTAINABLE ENERGY REV工程技术1 6.018 CRIT REV BIOTECHNOL CRITICAL REVIEWS IN BIOTECHNOLOGY工程技术1 6.472 NANOSCALE Nanoscale工程技术1 5.914 IEEE COMMUN SURV TUT IEEE Communications Surveys and Tutorials工程技术1 6.311 IEEE SIGNAL PROC MAG IEEE SIGNAL PROCESSING MAGAZINE工程技术1 4.066 CARBON CARBON工程技术1 5.378 IEEE T PATTERN ANAL IEEE TRANSACTIONS ON PATTERN ANALYS工程技术1 4.908 MACROMOLECULES MACROMOLECULES工程技术1 5.167 INT J PLASTICITY INTERNATIONAL JOURNAL OF PLASTICITY工程技术1 4.603 BIOTECHNOL BIOFUELS Biotechnology for Biofuels工程技术1 6.088 MIS QUART MIS QUARTERLY工程技术1 4.447 SIAM J IMAGING SCI SIAM Journal on Imaging Sciences工程技术1 4.656 SOFT MATTER Soft Matter工程技术1 4.390 ACTA BIOMATER Acta Biomaterialia工程技术1 4.865 BIORESOURCE TECHNOL BIORESOURCE TECHNOLOGY工程技术1 4.980 ADV APPL MECH ADVANCES IN APPLIED MECHANICS工程技术1 5.000 ELECTROCHEM COMMUN ELECTROCHEMISTRY COMMUNICATIONS工程技术1 4.859MOL NUTR FOOD RES MOLECULAR NUTRITION & FOOD RESEARC工程技术1 4.301 IEEE T IND ELECTRON IEEE TRANSACTIONS ON INDUSTRIAL ELEC工程技术1 5.160 MACROMOL RAPID COMM MACROMOLECULAR RAPID COMMUNICATIO工程技术1 4.596 SOL ENERG MAT SOL C SOLAR ENERGY MATERIALS AND SOLAR CE工程技术1 4.542 J POWER SOURCES JOURNAL OF POWER SOURCES工程技术1 4.951 CRIT REV FOOD SCI CRITICAL REVIEWS IN FOOD SCIENCE AND工程技术1 4.789 CURR OPIN SOLID ST M CURRENT OPINION IN SOLID STATE & MATE工程技术1 4.233 INT J COMPUT VISION INTERNATIONAL JOURNAL OF COMPUTER 工程技术1 3.741 IEEE T EVOLUT COMPUT IEEE TRANSACTIONS ON EVOLUTIONARY C工程技术1 3.341 INT J HYDROGEN ENERG INTERNATIONAL JOURNAL OF HYDROGEN 工程技术1 4.054 J HAZARD MATER JOURNAL OF HAZARDOUS MATERIALS工程技术1 4.173 MED IMAGE ANAL MEDICAL IMAGE ANALYSIS工程技术1 4.424 HUM-COMPUT INTERACT HUMAN-COMPUTER INTERACTION工程技术1 1.476 MICROB CELL FACT Microbial Cell Factories工程技术1 3.552 INT J NEURAL SYST International Journal of Neural Systems工程技术1 4.284 TRENDS FOOD SCI TECH TRENDS IN FOOD SCIENCE & TECHNOLOGY工程技术1 3.672 IEEE J SEL AREA COMM IEEE JOURNAL ON SELECTED AREAS IN CO工程技术1 3.413 ORG ELECTRON ORGANIC ELECTRONICS工程技术1 4.047 ACTA MATER ACTA MATERIALIA工程技术1 3.755 APPL ENERG APPLIED ENERGY工程技术1 5.106 ACS APPL MATER INTER ACS Applied Materials & Interfaces工程技术1 4.525 BIOTECHNOL BIOENG BIOTECHNOLOGY AND BIOENGINEERING工程技术1 3.946 IEEE T POWER ELECTR IEEE TRANSACTIONS ON POWER ELECTRO工程技术1 4.650 BIOMASS BIOENERG BIOMASS & BIOENERGY工程技术1 3.646 ELECTROCHIM ACTA ELECTROCHIMICA ACTA工程技术1 3.832 ANNU REV FOOD SCI T Annual Review of Food Science and Technolog工程技术1 3.600 NANOTECHNOLOGY NANOTECHNOLOGY工程技术1 3.979 ACM T GRAPHIC ACM TRANSACTIONS ON GRAPHICS工程技术1 3.489 J MEMBRANE SCI JOURNAL OF MEMBRANE SCIENCE工程技术1 3.850 SENSOR ACTUAT B-CHEM SENSORS AND ACTUATORS B-CHEMICAL工程技术1 3.898 APPL SPECTROSC REV APPLIED SPECTROSCOPY REVIEWS工程技术2 3.385 IEEE J SEL TOP QUANT IEEE JOURNAL OF SELECTED TOPICS IN QU工程技术2 3.780 IEEE T FUZZY SYST IEEE TRANSACTIONS ON FUZZY SYSTEMS工程技术2 4.260 FOOD CHEM FOOD CHEMISTRY工程技术2 3.655 PLASMONICS Plasmonics 工程技术2 2.989 J NEURAL ENG Journal of Neural Engineering工程技术2 3.837 MICROFLUID NANOFLUID Microfluidics and Nanofluidics工程技术2 3.371 ENERGY ENERGY工程技术2 3.487 FUEL FUEL工程技术2 3.248 INT J NONLIN SCI NUM INTERNATIONAL JOURNAL OF NONLINEAR 工程技术2 1.484 FOOD MICROBIOL FOOD MICROBIOLOGY工程技术2 3.283 BIOMED MICRODEVICES BIOMEDICAL MICRODEVICES工程技术2 3.032 APPL MICROBIOL BIOT APPLIED MICROBIOLOGY AND BIOTECHNO工程技术2 3.425 CURR PROTEOMICS Current Proteomics工程技术2 3.179 BIOMECH MODEL MECHAN Biomechanics and Modeling in Mechanobiology工程技术2 3.192 IEEE J SOLID-ST CIRC IEEE JOURNAL OF SOLID-STATE CIRCUITS工程技术2 3.226 INT J FOOD MICROBIOL INTERNATIONAL JOURNAL OF FOOD MICRO工程技术2 3.327 INT J NANOMED International Journal of Nanomedicine 工程技术2 3.130 CHEM ENG J CHEMICAL ENGINEERING JOURNAL工程技术2 3.461 SCI TECHNOL ADV MAT SCIENCE AND TECHNOLOGY OF ADVANCED工程技术2 3.513 FOOD HYDROCOLLOID FOOD HYDROCOLLOIDS工程技术2 3.473 CORROS SCI CORROSION SCIENCE工程技术2 3.734 MICROSC MICROANAL MICROSCOPY AND MICROANALYSIS工程技术2 3.007 J MECH BEHAV BIOMED Journal of the Mechanical Behavior of Biomedic工程技术2 2.814 COMBUST FLAME COMBUSTION AND FLAME工程技术2 3.585 INT J ROBOT RES INTERNATIONAL JOURNAL OF ROBOTICS R工程技术2 3.107 ENVIRON MODELL SOFTW ENVIRONMENTAL MODELLING & SOFTWAR工程技术2 3.114IEEE COMMUN MAG IEEE COMMUNICATIONS MAGAZINE工程技术2 3.785 FUEL CELLS Fuel Cells工程技术2 3.149 J NANOPART RES JOURNAL OF NANOPARTICLE RESEARCH工程技术2 3.287 MAR BIOTECHNOL MARINE BIOTECHNOLOGY工程技术2 3.430 J STAT SOFTW Journal of Statistical Software工程技术2 4.010 INFORM SCIENCES INFORMATION SCIENCES工程技术2 2.833 DENT MATER DENTAL MATERIALS工程技术2 3.135 COMPOS SCI TECHNOL COMPOSITES SCIENCE AND TECHNOLOGY工程技术2 3.144 J BIOTECHNOL JOURNAL OF BIOTECHNOLOGY工程技术2 3.045 IEEE COMPUT INTELL M IEEE Computational Intelligence Magazine工程技术2 3.368 J CIV ENG MANAG Journal of Civil Engineering and Management工程技术2 2.171 IEEE T IMAGE PROCESS IEEE TRANSACTIONS ON IMAGE PROCESSI工程技术2 3.042 IEEE T SYST MAN CY B IEEE TRANSACTIONS ON SYSTEMS MAN AN工程技术2 3.080 INT J ELECTROCHEM SC International Journal of Electrochemical Science工程技术2 3.729 P COMBUST INST PROCEEDINGS OF THE COMBUSTION INST工程技术2 3.633 DYES PIGMENTS DYES AND PIGMENTS工程技术2 3.126 IEEE IND ELECTRON M IEEE Industrial Electronics Magazine工程技术2 5.000 SEP PURIF TECHNOL SEPARATION AND PURIFICATION TECHNOL工程技术2 2.921 CELLULOSE CELLULOSE工程技术2 3.600 GOLD BULL GOLD BULLETIN工程技术2 3.517 COMPUT-AIDED CIV INF COMPUTER-AIDED CIVIL AND INFRASTRUC工程技术2 3.382 J BIOMED MATER RES A JOURNAL OF BIOMEDICAL MATERIALS RES工程技术2 2.625 J SUPERCRIT FLUID JOURNAL OF SUPERCRITICAL FLUIDS工程技术2 2.860 IEEE T NEURAL NETWOR IEEE TRANSACTIONS ON NEURAL NETWOR工程技术2 2.952 SCRIPTA MATER SCRIPTA MATERIALIA工程技术2 2.699 IBM J RES DEV IBM JOURNAL OF RESEARCH AND DEVELO工程技术20.723 J ACM JOURNAL OF THE ACM工程技术2 2.353 J BIOACT COMPAT POL JOURNAL OF BIOACTIVE AND COMPATIBLE工程技术2 2.953 J MACH LEARN RES JOURNAL OF MACHINE LEARNING RESEAR工程技术2 2.561 VLDB J VLDB JOURNAL工程技术2 1.564 NANOSCALE RES LETT Nanoscale Research Letters工程技术2 2.726 IEEE ELECTR DEVICE L IEEE ELECTRON DEVICE LETTERS工程技术2 2.849 IEEE T INFORM THEORY IEEE TRANSACTIONS ON INFORMATION TH工程技术2 3.009 FUEL PROCESS TECHNOL FUEL PROCESSING TECHNOLOGY工程技术2 2.945 INNOV FOOD SCI EMERG Innovative Food Science & Emerging Technolo工程技术2 3.030 J NEUROENG REHABIL Journal of NeuroEngineering and Rehabilitation工程技术2 3.264 PROG AEROSP SCI PROGRESS IN AEROSPACE SCIENCES工程技术2 3.000 BIOFABRICATION Biofabrication工程技术2 3.480 IEEE T SOFTWARE ENG IEEE TRANSACTIONS ON SOFTWARE ENGI工程技术2 1.980 FOOD RES INT FOOD RESEARCH INTERNATIONAL工程技术2 3.150 SCI ADV MATER Science of Advanced Materials工程技术2 3.308 ADV BIOCHEM ENG BIOT ADVANCES IN BIOCHEMICAL ENGINEERING工程技术2 1.644 BMC BIOTECHNOL BMC BIOTECHNOLOGY工程技术2 2.349 FOOD CONTROL FOOD CONTROL工程技术2 2.656 ANNU REV INFORM SCI ANNUAL REVIEW OF INFORMATION SCIENC工程技术2 2.955 IEEE INTELL SYST IEEE INTELLIGENT SYSTEMS工程技术2 2.154 J FIELD ROBOT Journal of Field Robotics工程技术2 2.244 ARTIF INTELL ARTIFICIAL INTELLIGENCE工程技术2 2.252 IEEE T INTELL TRANSP IEEE TRANSACTIONS ON INTELLIGENT TRA工程技术2 3.452 RENEW ENERG RENEWABLE ENERGY工程技术2 2.978 IEEE-ASME T MECH IEEE-ASME TRANSACTIONS ON MECHATRO工程技术2 2.865 BIOTECHNIQUES BIOTECHNIQUES工程技术2 2.669 MABS-AUSTIN mAbs工程技术2 3.174 COMPR REV FOOD SCI F COMPREHENSIVE REVIEWS IN FOOD SCIEN工程技术2 3.724 FOOD CHEM TOXICOL FOOD AND CHEMICAL TOXICOLOGY工程技术2 2.999 IEEE T ROBOT IEEE Transactions on Robotics工程技术2 2.536 AUTOMATICA AUTOMATICA工程技术2 2.829IEEE INTERNET COMPUT IEEE INTERNET COMPUTING工程技术2 2.000 INTEGR COMPUT-AID E INTEGRATED COMPUTER-AIDED ENGINEER工程技术2 3.451 IEEE T GEOSCI REMOTE IEEE TRANSACTIONS ON GEOSCIENCE AND工程技术2 2.895 BIOCHEM ENG J BIOCHEMICAL ENGINEERING JOURNAL工程技术2 2.645 PATTERN RECOGN PATTERN RECOGNITION工程技术2 2.292 IEEE MICRO IEEE MICRO工程技术2 1.783 EARTHQ SPECTRA EARTHQUAKE SPECTRA工程技术20.894 J WEB SEMANT Journal of Web Semantics工程技术2 1.302 IEEE T SIGNAL PROCES IEEE TRANSACTIONS ON SIGNAL PROCESS工程技术2 2.628 REACT FUNCT POLYM REACTIVE & FUNCTIONAL POLYMERS工程技术2 2.479 ENERG FUEL ENERGY & FUELS工程技术2 2.721 COMPOS PART A-APPL S COMPOSITES PART A-APPLIED SCIENCE AN工程技术2 2.695 IEEE T ENERGY CONVER IEEE TRANSACTIONS ON ENERGY CONVER工程技术2 2.272 ISPRS J PHOTOGRAMM ISPRS JOURNAL OF PHOTOGRAMMETRY A工程技术2 2.885 IEEE POWER ENERGY M IEEE Power & Energy Magazine工程技术2 2.408 CEMENT CONCRETE RES CEMENT AND CONCRETE RESEARCH工程技术2 2.781 IEEE T MOBILE COMPUT IEEE TRANSACTIONS ON MOBILE COMPUTI工程技术2 2.283 COMPUT EDUC COMPUTERS & EDUCATION工程技术2 2.621 ENTERP INF SYST-UK Enterprise Information Systems工程技术2 3.684 J INF TECHNOL JOURNAL OF INFORMATION TECHNOLOGY工程技术2 2.321 J ELECTROCHEM SOC JOURNAL OF THE ELECTROCHEMICAL SOC工程技术2 2.590 J LIGHTWAVE TECHNOL JOURNAL OF LIGHTWAVE TECHNOLOGY工程技术2 2.784 J CEREAL SCI JOURNAL OF CEREAL SCIENCE工程技术2 2.073 TRANSPORT RES B-METH TRANSPORTATION RESEARCH PART B-MET工程技术2 2.856 J CHEM THERMODYN JOURNAL OF CHEMICAL THERMODYNAMIC工程技术2 2.422 ARCH COMPUT METHOD E ARCHIVES OF COMPUTATIONAL METHODS工程技术2 2.767 ANN BIOMED ENG ANNALS OF BIOMEDICAL ENGINEERING工程技术2 2.368 APPL SOFT COMPUT APPLIED SOFT COMPUTING工程技术2 2.612 INFORM MANAGE-AMSTER INFORMATION & MANAGEMENT工程技术2 2.214 J INSTRUM Journal of Instrumentation工程技术2 1.869 MAT SCI ENG C-MATER Materials Science & Engineering C-Materials fo工程技术2 2.686 IEEE CONTR SYST MAG IEEE CONTROL SYSTEMS MAGAZINE工程技术2 2.491 COMPUT INTELL-US COMPUTATIONAL INTELLIGENCE工程技术20.971 EXPERT SYST APPL EXPERT SYSTEMS WITH APPLICATIONS工程技术2 2.203 IEEE T ELECTRON DEV IEEE TRANSACTIONS ON ELECTRON DEVIC工程技术2 2.318 J EUR CERAM SOC JOURNAL OF THE EUROPEAN CERAMIC SO工程技术2 2.353 IEEE PHOTONICS J IEEE Photonics Journal工程技术2 2.320 INT DAIRY J INTERNATIONAL DAIRY JOURNAL工程技术2 2.401 PLANT FOOD HUM NUTR PLANT FOODS FOR HUMAN NUTRITION工程技术2 2.505 IEEE T POWER SYST IEEE TRANSACTIONS ON POWER SYSTEMS工程技术2 2.678 LWT-FOOD SCI TECHNOL LEBENSMITTEL-WISSENSCHAFT UND-TECH工程技术2 2.545 J IND MICROBIOL BIOT JOURNAL OF INDUSTRIAL MICROBIOLOGY 工程技术2 2.735 CHEM ENG SCI CHEMICAL ENGINEERING SCIENCE工程技术2 2.431 IEEE T AUTON MENT DE IEEE Transactions on Autonomous Mental Deve工程技术2 2.310 BIOTECHNOL PROGR BIOTECHNOLOGY PROGRESS工程技术2 2.340 J FOOD ENG JOURNAL OF FOOD ENGINEERING工程技术2 2.414 AUST J GRAPE WINE R AUSTRALIAN JOURNAL OF GRAPE AND WIN工程技术2 2.467 MEAT SCI MEAT SCIENCE工程技术2 2.275 IEEE PERVAS COMPUT IEEE PERVASIVE COMPUTING工程技术2 1.554 USER MODEL USER-ADAP USER MODELING AND USER-ADAPTED INTE工程技术2 1.400 EVOL COMPUT EVOLUTIONARY COMPUTATION 工程技术2 1.061 FOOD QUAL PREFER FOOD QUALITY AND PREFERENCE工程技术2 1.824 IEEE WIREL COMMUN IEEE WIRELESS COMMUNICATIONS工程技术2 2.575 IEEE J-STSP IEEE Journal of Selected Topics in Signal Proce工程技术2 2.880 SOL ENERGY SOLAR ENERGY工程技术2 2.475 IEEE T WIREL COMMUN IEEE TRANSACTIONS ON WIRELESS COMM工程技术2 2.586 COMMUN ACM COMMUNICATIONS OF THE ACM工程技术2 1.919BIOINTERPHASES Biointerphases 工程技术2 2.208 IEEE T AUTOMAT CONTR IEEE TRANSACTIONS ON AUTOMATIC CONT工程技术2 2.110 MATER CHEM PHYS MATERIALS CHEMISTRY AND PHYSICS工程技术2 2.234 ULTRAMICROSCOPY ULTRAMICROSCOPY工程技术2 2.471 J MATER SCI-MATER M JOURNAL OF MATERIALS SCIENCE-MATERI工程技术2 2.316 BIOMED MATER Biomedical Materials工程技术2 2.158 FUTURE GENER COMP SY FUTURE GENERATION COMPUTER SYSTEM工程技术2 1.978 J STRATEGIC INF SYST JOURNAL OF STRATEGIC INFORMATION SY工程技术2 1.457 J ALLOY COMPD JOURNAL OF ALLOYS AND COMPOUNDS工程技术2 2.289 PHOTONIC NANOSTRUCT Photonics and Nanostructures-Fundamentals an工程技术2 1.681 J BIOMED MATER RES B JOURNAL OF BIOMEDICAL MATERIALS RES工程技术2 2.147 COMPUT METHOD APPL M COMPUTER METHODS IN APPLIED MECHAN工程技术2 2.651 INT J COAL GEOL INTERNATIONAL JOURNAL OF COAL GEOLO工程技术2 2.542 J AM SOC INF SCI TEC JOURNAL OF THE AMERICAN SOCIETY FOR工程技术2 2.081 IEEE T VIS COMPUT GR IEEE TRANSACTIONS ON VISUALIZATION A工程技术2 2.215 DESALINATION DESALINATION工程技术2 2.590 J FOOD COMPOS ANAL JOURNAL OF FOOD COMPOSITION AND AN工程技术2 2.079 DECIS SUPPORT SYST DECISION SUPPORT SYSTEMS工程技术2 1.687 KNOWL INF SYST KNOWLEDGE AND INFORMATION SYSTEMS工程技术2 2.225 ARTIF LIFE ARTIFICIAL LIFE工程技术2 2.282 J AM CERAM SOC JOURNAL OF THE AMERICAN CERAMIC SOC工程技术2 2.272 J MICROMECH MICROENG JOURNAL OF MICROMECHANICS AND MICR工程技术2 2.105 IEEE ACM T NETWORK IEEE-ACM TRANSACTIONS ON NETWORKIN工程技术2 2.033 MATER LETT MATERIALS LETTERS工程技术2 2.307 NEURAL COMPUT NEURAL COMPUTATION工程技术2 1.884 INT J SEMANT WEB INF International Journal on Semantic Web and Info工程技术2 2.308 BUILD ENVIRON BUILDING AND ENVIRONMENT工程技术2 2.400 IEEE J QUANTUM ELECT IEEE JOURNAL OF QUANTUM ELECTRONIC工程技术2 1.879 IEEE NETWORK IEEE NETWORK工程技术2 2.239 COMPOS STRUCT COMPOSITE STRUCTURES工程技术2 2.240 IEEE ROBOT AUTOM MAG IEEE ROBOTICS & AUTOMATION MAGAZINE工程技术2 1.985 CHEMOMETR INTELL LAB CHEMOMETRICS AND INTELLIGENT LABOR工程技术2 1.920 INT J HEAT MASS TRAN INTERNATIONAL JOURNAL OF HEAT AND M工程技术2 2.407 FLUID PHASE EQUILIBR FLUID PHASE EQUILIBRIA工程技术2 2.139 IEEE T SYST MAN CY A IEEE TRANSACTIONS ON SYSTEMS MAN AN工程技术2 2.123 AICHE J AICHE JOURNAL工程技术2 2.261 J BIOMATER APPL JOURNAL OF BIOMATERIALS APPLICATION工程技术2 2.082 ENERG CONVERS MANAGE ENERGY CONVERSION AND MANAGEMENT工程技术2 2.216 IEEE T IND INFORM IEEE Transactions on Industrial Informatics工程技术2 2.990 IEEE T BIO-MED ENG IEEE TRANSACTIONS ON BIOMEDICAL ENG工程技术2 2.278 J CRYPTOL JOURNAL OF CRYPTOLOGY工程技术2 1.250 INTERMETALLICS INTERMETALLICS工程技术2 1.649 COMPUT CHEM ENG COMPUTERS & CHEMICAL ENGINEERING工程技术2 2.320 IEEE T CIRC SYST VID IEEE TRANSACTIONS ON CIRCUITS AND SY工程技术2 1.649 J SOLID STATE ELECTR JOURNAL OF SOLID STATE ELECTROCHEM工程技术2 2.131 J MANAGE INFORM SYST JOURNAL OF MANAGEMENT INFORMATION工程技术2 1.423 J MICROELECTROMECH S JOURNAL OF MICROELECTROMECHANICAL工程技术2 2.098 IEEE T SYST MAN CY C IEEE TRANSACTIONS ON SYSTEMS MAN AN工程技术2 2.009 J ASSOC INF SYST Journal of the Association for Information Syste工程技术2 1.667 MATER RES BULL MATERIALS RESEARCH BULLETIN工程技术2 2.105 FOOD ADDIT CONTAM A FOOD ADDITIVES AND CONTAMINANTS工程技术2 1.765 J ENG EDUC JOURNAL OF ENGINEERING EDUCATION工程技术2 1.569 BALT J ROAD BRIDGE E Baltic Journal of Road and Bridge Engineering工程技术2 1.610 INT J ELEC POWER INTERNATIONAL JOURNAL OF ELECTRICAL工程技术2 2.247 IND ENG CHEM RES INDUSTRIAL & ENGINEERING CHEMISTRY R工程技术2 2.237 EUR PHYS J E EUROPEAN PHYSICAL JOURNAL E工程技术2 1.944 INT J MACH TOOL MANU INTERNATIONAL JOURNAL OF MACHINE TO工程技术2 2.169J BIOMAT SCI-POLYM E JOURNAL OF BIOMATERIALS SCIENCE-POL工程技术2 1.691 NEURAL NETWORKS NEURAL NETWORKS工程技术2 2.182 J CHEM TECHNOL BIOT JOURNAL OF CHEMICAL TECHNOLOGY AND工程技术2 2.168 ACM T SENSOR NETWORK ACM Transactions on Sensor Networks 工程技术2 1.808 HYDROMETALLURGY HYDROMETALLURGY工程技术2 2.027 ENERG BUILDINGS ENERGY AND BUILDINGS工程技术2 2.386 MAT SCI ENG A-STRUCT MATERIALS SCIENCE AND ENGINEERING A工程技术2 2.003 IEEE PHOTONIC TECH L IEEE PHOTONICS TECHNOLOGY LETTERS工程技术2 2.191 IEEE ENG MED BIOL IEEE ENGINEERING IN MEDICINE AND BIOL工程技术2 2.057 INT J ADHES ADHES INTERNATIONAL JOURNAL OF ADHESION A工程技术2 2.170 INT J NUMER METH ENG INTERNATIONAL JOURNAL FOR NUMERICA工程技术2 2.009 FUNCT MATER LETT Functional Materials Letters工程技术20.724 IEEE T MICROW THEORY IEEE TRANSACTIONS ON MICROWAVE THE工程技术2 1.853 SMART MATER STRUCT SMART MATERIALS & STRUCTURES工程技术2 2.089 STRUCT SAF STRUCTURAL SAFETY工程技术2 1.867 INT J ENERG RES INTERNATIONAL JOURNAL OF ENERGY RES工程技术2 2.122 COMPUT LINGUIST COMPUTATIONAL LINGUISTICS工程技术20.721 J DISP TECHNOL Journal of Display Technology 工程技术2 2.280 BIODEGRADATION BIODEGRADATION工程技术2 2.017 IEEE T ANTENN PROPAG IEEE TRANSACTIONS ON ANTENNAS AND P工程技术2 2.151 MECH MATER MECHANICS OF MATERIALS工程技术2 1.769 J IND ENG CHEM JOURNAL OF INDUSTRIAL AND ENGINEERIN工程技术2 1.977 IEEE T NANOTECHNOL IEEE TRANSACTIONS ON NANOTECHNOLO工程技术2 2.292 ELECTROCHEM SOLID ST ELECTROCHEMICAL AND SOLID STATE LET工程技术2 1.995 APPL THERM ENG APPLIED THERMAL ENGINEERING工程技术2 2.064 SURF COAT TECH SURFACE & COATINGS TECHNOLOGY工程技术2 1.867 IEEE T KNOWL DATA EN IEEE TRANSACTIONS ON KNOWLEDGE AND工程技术2 1.657 CEMENT CONCRETE COMP CEMENT & CONCRETE COMPOSITES工程技术3 2.421 COAST ENG COASTAL ENGINEERING工程技术3 1.757 IET NANOBIOTECHNOL IET Nanobiotechnology工程技术3 1.833 DATA MIN KNOWL DISC DATA MINING AND KNOWLEDGE DISCOVER工程技术3 1.545 INT J APPROX REASON INTERNATIONAL JOURNAL OF APPROXIMAT工程技术3 1.948 POWDER TECHNOL POWDER TECHNOLOGY工程技术3 2.080 BIOPROC BIOSYST ENG BIOPROCESS AND BIOSYSTEMS ENGINEER工程技术3 1.809 STRUCT HEALTH MONIT STRUCTURAL HEALTH MONITORING-AN INT工程技术3 1.500 TRANSPORT RES A-POL TRANSPORTATION RESEARCH PART A-POL工程技术3 2.354 MECH SYST SIGNAL PR MECHANICAL SYSTEMS AND SIGNAL PROC工程技术3 1.824 MACROMOL MATER ENG MACROMOLECULAR MATERIALS AND ENGI工程技术3 1.986 J FUNCT FOODS Journal of Functional Foods工程技术3 2.446 J FOOD PROTECT JOURNAL OF FOOD PROTECTION工程技术3 1.937 COMPUT OPER RES COMPUTERS & OPERATIONS RESEARCH工程技术3 1.720 SYNTHETIC MET SYNTHETIC METALS工程技术3 1.829 ACM T WEB ACM Transactions on the Web 工程技术30.871 J PROCESS CONTR JOURNAL OF PROCESS CONTROL工程技术3 1.696 INT J THERM SCI INTERNATIONAL JOURNAL OF THERMAL SC工程技术3 2.142 ADSORPTION ADSORPTION-JOURNAL OF THE INTERNATI工程技术3 2.000 DIAM RELAT MATER DIAMOND AND RELATED MATERIALS工程技术3 1.913 TRANSPORT RES E-LOG TRANSPORTATION RESEARCH PART E-LOG工程技术3 1.648 THIN SOLID FILMS THIN SOLID FILMS工程技术3 1.890 COMPUT VIS IMAGE UND COMPUTER VISION AND IMAGE UNDERSTA工程技术3 1.340 IEEE T MULTIMEDIA IEEE TRANSACTIONS ON MULTIMEDIA工程技术3 1.935 ARTIF ORGANS ARTIFICIAL ORGANS工程技术3 2.000 APPL SURF SCI APPLIED SURFACE SCIENCE工程技术3 2.103 PROG ORG COAT PROGRESS IN ORGANIC COATINGS工程技术3 1.977 IEEE T INF FOREN SEC IEEE Transactions on Information Forensics an工程技术3 1.340 COMPUTER COMPUTER工程技术3 1.470 ACM T MATH SOFTWARE ACM TRANSACTIONS ON MATHEMATICAL S工程技术3 1.922J CHEM ENG DATA JOURNAL OF CHEMICAL AND ENGINEERING工程技术3 1.693 IEEE T BIOMED CIRC S IEEE Transactions on Biomedical Circuits and S工程技术3 2.032 ACM T COMPUT SYST ACM TRANSACTIONS ON COMPUTER SYST工程技术3 1.188 ENERG J ENERGY JOURNAL工程技术3 2.198 IEEE ACM T COMPUT BI IEEE-ACM Transactions on Computational Biolo工程技术3 1.543 FOOD SECUR Food Security工程技术3 1.970 PLASMA CHEM PLASMA P PLASMA CHEMISTRY AND PLASMA PROCES工程技术3 1.602 OPT MATER OPTICAL MATERIALS工程技术3 2.023 CHEM VAPOR DEPOS CHEMICAL VAPOR DEPOSITION工程技术3 1.796 SENSOR ACTUAT A-PHYS SENSORS AND ACTUATORS A-PHYSICAL工程技术3 1.802 MATER DESIGN MATERIALS & DESIGN工程技术3 2.200 IEEE MICROW WIREL CO IEEE MICROWAVE AND WIRELESS COMPON工程技术3 1.717 IEEE T BROADCAST IEEE TRANSACTIONS ON BROADCASTING工程技术3 1.703 CHEM ENG PROCESS CHEMICAL ENGINEERING AND PROCESSIN工程技术3 1.924 INT J CIRC THEOR APP INTERNATIONAL JOURNAL OF CIRCUIT THE工程技术3 1.625 TRANSPORT RES C-EMER TRANSPORTATION RESEARCH PART C-EME工程技术3 1.957 J FRANKLIN I JOURNAL OF THE FRANKLIN INSTITUTE-EN工程技术3 2.724 J MATER SCI JOURNAL OF MATERIALS SCIENCE工程技术3 2.015 SENSORS-BASEL SENSORS工程技术3 1.739 IET RENEW POWER GEN IET Renewable Power Generation工程技术3 1.742 POLYM ADVAN TECHNOL POLYMERS FOR ADVANCED TECHNOLOGIE工程技术3 2.007 KNOWL-BASED SYST KNOWLEDGE-BASED SYSTEMS工程技术3 2.422 INFORM FUSION Information Fusion工程技术3 1.467 POLYM TEST POLYMER TESTING工程技术3 1.608 WEAR WEAR工程技术3 1.872 J NUCL MATER JOURNAL OF NUCLEAR MATERIALS工程技术3 2.052 EMPIR SOFTW ENG EMPIRICAL SOFTWARE ENGINEERING工程技术3 1.854 APPL OPTICS APPLIED OPTICS工程技术3 1.748 AAPG BULL AAPG BULLETIN工程技术3 1.831 APPL BIOCHEM BIOTECH APPLIED BIOCHEMISTRY AND BIOTECHNOL工程技术3 1.943 FOOD NUTR BULL FOOD AND NUTRITION BULLETIN工程技术3 1.922 INT J HEAT FLUID FL INTERNATIONAL JOURNAL OF HEAT AND FL工程技术3 1.927 SIAM J COMPUT SIAM JOURNAL ON COMPUTING工程技术3 1.288 MACH LEARN MACHINE LEARNING工程技术3 1.587 COMPOS PART B-ENG COMPOSITES PART B-ENGINEERING工程技术3 1.731 FOOD BIOPHYS Food Biophysics工程技术3 2.187 MED ENG PHYS MEDICAL ENGINEERING & PHYSICS工程技术3 1.623 GPS SOLUT GPS SOLUTIONS工程技术3 1.667 INT J DAMAGE MECH INTERNATIONAL JOURNAL OF DAMAGE ME工程技术3 1.928 BIOINSPIR BIOMIM Bioinspiration & Biomimetics工程技术3 1.952 J AM OIL CHEM SOC JOURNAL OF THE AMERICAN OIL CHEMISTS工程技术3 1.773 MACROMOL RES MACROMOLECULAR RESEARCH工程技术3 1.153 EXP FLUIDS EXPERIMENTS IN FLUIDS工程技术3 1.735 INT J HUM-COMPUT ST INTERNATIONAL JOURNAL OF HUMAN-COM工程技术3 1.171 CURR NANOSCI Current Nanoscience工程技术3 1.776 J MICROSC-OXFORD JOURNAL OF MICROSCOPY-OXFORD工程技术3 1.631 ANNU REV CONTROL ANNUAL REVIEWS IN CONTROL工程技术3 1.319 BIOTECHNOL LETT BIOTECHNOLOGY LETTERS工程技术3 1.683 IEEE T INF TECHNOL B IEEE TRANSACTIONS ON INFORMATION TE工程技术3 1.676 METROLOGIA METROLOGIA工程技术3 1.750 IEEE SOFTWARE IEEE SOFTWARE工程技术3 1.508 IEEE T CONTR SYST T IEEE TRANSACTIONS ON CONTROL SYSTE工程技术3 1.766 EUR J LIPID SCI TECH EUROPEAN JOURNAL OF LIPID SCIENCE AN工程技术3 1.733 MACROMOL REACT ENG Macromolecular Reaction Engineering 工程技术3 1.848 COMPUT STRUCT COMPUTERS & STRUCTURES工程技术3 1.874 MATERIALS Materials工程技术3 1.677 DIG J NANOMATER BIOS Digest Journal of Nanomaterials and Biostructur工程技术3 1.200MODEL SIMUL MATER SC MODELLING AND SIMULATION IN MATERIAL工程技术3 2.298 J DATABASE MANAGE JOURNAL OF DATABASE MANAGEMENT工程技术30.875 AD HOC NETW Ad Hoc Networks工程技术3 2.110 CIRP ANN-MANUF TECHN CIRP ANNALS-MANUFACTURING TECHNOLO工程技术3 1.708 J THERM SPRAY TECHN JOURNAL OF THERMAL SPRAY TECHNOLOG工程技术3 1.812 IEEE T DEVICE MAT RE IEEE TRANSACTIONS ON DEVICE AND MAT工程技术3 1.543 ACM T SOFTW ENG METH ACM TRANSACTIONS ON SOFTWARE ENGIN工程技术3 1.269 J FOOD SCI JOURNAL OF FOOD SCIENCE工程技术3 1.658 APPL PHYS A-MATER APPLIED PHYSICS A-MATERIALS SCIENCE &工程技术3 1.630 IEEE T CIRCUITS-I IEEE TRANSACTIONS ON CIRCUITS AND SY工程技术3 1.970 J MICROENCAPSUL JOURNAL OF MICROENCAPSULATION工程技术3 1.553 APPL SPECTROSC APPLIED SPECTROSCOPY工程技术3 1.663 IEEE T ULTRASON FERR IEEE TRANSACTIONS ON ULTRASONICS FE工程技术3 1.694 INT J ROBUST NONLIN INTERNATIONAL JOURNAL OF ROBUST AND工程技术3 1.554 INT J FATIGUE INTERNATIONAL JOURNAL OF FATIGUE工程技术3 1.546 BIOL CYBERN BIOLOGICAL CYBERNETICS工程技术3 1.586 IEEE T AUDIO SPEECH IEEE Transactions on Audio Speech and Langu工程技术3 1.498 J APPL ELECTROCHEM JOURNAL OF APPLIED ELECTROCHEMISTR工程技术3 1.745 IEEE COMPUT GRAPH IEEE COMPUTER GRAPHICS AND APPLICAT工程技术3 1.411 J AUTOM REASONING JOURNAL OF AUTOMATED REASONING工程技术30.714 CERAM INT CERAMICS INTERNATIONAL工程技术3 1.751 LETT APPL MICROBIOL LETTERS IN APPLIED MICROBIOLOGY工程技术3 1.622 IEEE T VEH TECHNOL IEEE TRANSACTIONS ON VEHICULAR TECH工程技术3 1.921 J TAIWAN INST CHEM E Journal of the Taiwan Institute of Chemical Eng工程技术3 2.110 DATA KNOWL ENG DATA & KNOWLEDGE ENGINEERING工程技术3 1.422 INT J REFRACT MET H INTERNATIONAL JOURNAL OF REFRACTOR工程技术3 1.693 IEEE T COMP INTEL AI IEEE Transactions on Computational Intelligenc工程技术3 1.617 MACROMOL THEOR SIMUL MACROMOLECULAR THEORY AND SIMULAT工程技术3 1.709 CONTROL ENG PRACT CONTROL ENGINEERING PRACTICE工程技术3 1.481 NANOSC MICROSC THERM Nanoscale and Microscale Thermophysical Eng工程技术3 1.032 METALL MATER TRANS A METALLURGICAL AND MATERIALS TRANSA工程技术3 1.545 AUTON AGENT MULTI-AG AUTONOMOUS AGENTS AND MULTI-AGENT工程技术3 1.213 WIND ENERGY WIND ENERGY工程技术3 1.768 TRIBOL LETT TRIBOLOGY LETTERS工程技术3 1.582 J ARTIF INTELL RES JOURNAL OF ARTIFICIAL INTELLIGENCE RE工程技术3 1.143 TRIBOL INT TRIBOLOGY INTERNATIONAL工程技术3 1.553 MICRON MICRON工程技术3 1.527 DRY TECHNOL DRYING TECHNOLOGY工程技术3 2.084 COMPUT GRAPH FORUM COMPUTER GRAPHICS FORUM工程技术3 1.636 INT J REFRIG INTERNATIONAL JOURNAL OF REFRIGERAT工程技术3 1.817 NUMER HEAT TR A-APPL NUMERICAL HEAT TRANSFER PART A-APPL工程技术3 2.492 IEEE MICROW MAG IEEE MICROWAVE MAGAZINE工程技术3 2.111 IMAGE VISION COMPUT IMAGE AND VISION COMPUTING工程技术3 1.723 J MATER PROCESS TECH JOURNAL OF MATERIALS PROCESSING TEC工程技术3 1.783 AUTON ROBOT AUTONOMOUS ROBOTS工程技术3 1.500 INFORM SYST INFORMATION SYSTEMS工程技术3 1.198 MATER SCI ENG B-ADV Materials Science and Engineering B-Advanced工程技术3 1.518 WOOD SCI TECHNOL WOOD SCIENCE AND TECHNOLOGY工程技术3 1.727 J INTEL MAT SYST STR JOURNAL OF INTELLIGENT MATERIAL SYST工程技术3 1.953 MOB INF SYST Mobile Information Systems 工程技术3 2.432 J NANOPHOTONICS Journal of Nanophotonics工程技术3 1.570 SOFT COMPUT SOFT COMPUTING工程技术3 1.880 CHEM ENG RES DES CHEMICAL ENGINEERING RESEARCH & DES工程技术3 1.968 IEEE T PARALL DISTR IEEE TRANSACTIONS ON PARALLEL AND DI工程技术3 1.402 ELECTRON MATER LETT Electronic Materials Letters工程技术3 1.819 SOFT MATER SOFT MATERIALS工程技术3 1.154 IEEE T NANOBIOSCI IEEE TRANSACTIONS ON NANOBIOSCIENCE工程技术3 1.280J OPT COMMUN NETW Journal of Optical Communications and Networ工程技术3 1.872 ADV ENG MATER ADVANCED ENGINEERING MATERIALS工程技术3 1.185 INT COMMUN HEAT MASS INTERNATIONAL COMMUNICATIONS IN HEA工程技术3 1.892 OPT LASER ENG OPTICS AND LASERS IN ENGINEERING工程技术3 1.838 COMPUT IND COMPUTERS IN INDUSTRY工程技术3 1.529 ENG LIFE SCI ENGINEERING IN LIFE SCIENCES工程技术3 1.925 CONSTR BUILD MATER CONSTRUCTION AND BUILDING MATERIALS工程技术3 1.834 CMC-COMPUT MATER CON CMC-Computers Materials & Continua工程技术30.972 NONLINEAR DYNAM NONLINEAR DYNAMICS工程技术3 1.247 IEEE T DEPEND SECURE IEEE Transactions on Dependable and Secure C工程技术3 1.140 COMPUT IND ENG COMPUTERS & INDUSTRIAL ENGINEERING工程技术3 1.589 MICROELECTRON ENG MICROELECTRONIC ENGINEERING工程技术3 1.557 ADV ENG INFORM ADVANCED ENGINEERING INFORMATICS工程技术3 1.489 EARTHQ ENG STRUCT D EARTHQUAKE ENGINEERING & STRUCTURA工程技术3 1.778 INT J PHOTOENERGY INTERNATIONAL JOURNAL OF PHOTOENER工程技术3 1.769 B EARTHQ ENG Bulletin of Earthquake Engineering工程技术3 1.559 INFORM SOFTWARE TECH INFORMATION AND SOFTWARE TECHNOLO工程技术3 1.250 COMPUT ELECTRON AGR COMPUTERS AND ELECTRONICS IN AGRICU工程技术3 1.846 SCI TECHNOL WELD JOI SCIENCE AND TECHNOLOGY OF WELDING 工程技术3 1.735 IND MANAGE DATA SYST INDUSTRIAL MANAGEMENT & DATA SYSTEM工程技术3 1.472 INFORM PROCESS MANAG INFORMATION PROCESSING & MANAGEME工程技术3 1.119 IEEE SENS J IEEE SENSORS JOURNAL工程技术3 1.520 IEEE T NUCL SCI IEEE TRANSACTIONS ON NUCLEAR SCIENC工程技术3 1.447 ARTIF INTELL MED ARTIFICIAL INTELLIGENCE IN MEDICINE工程技术3 1.345 COMP MATER SCI COMPUTATIONAL MATERIALS SCIENCE工程技术3 1.574 IEEE T COMMUN IEEE TRANSACTIONS ON COMMUNICATION工程技术3 1.677 J SOL-GEL SCI TECHN JOURNAL OF SOL-GEL SCIENCE AND TECH工程技术3 1.632 FLAVOUR FRAG J FLAVOUR AND FRAGRANCE JOURNAL工程技术3 1.424 IEEE T COMPUT IEEE TRANSACTIONS ON COMPUTERS工程技术3 1.103 STRUCT MULTIDISCIP O STRUCTURAL AND MULTIDISCIPLINARY OP工程技术3 1.488 INT J IMPACT ENG INTERNATIONAL JOURNAL OF IMPACT ENG工程技术3 1.701 EUR FOOD RES TECHNOL EUROPEAN FOOD RESEARCH AND TECHNO工程技术3 1.566 J MATER RES JOURNAL OF MATERIALS RESEARCH工程技术3 1.434 TRANSPORT SCI TRANSPORTATION SCIENCE工程技术3 1.507 MATER CHARACT MATERIALS CHARACTERIZATION工程技术3 1.572 ENERGIES Energies工程技术3 1.865 REV SCI INSTRUM REVIEW OF SCIENTIFIC INSTRUMENTS工程技术3 1.367 IEEE T HAPTICS IEEE Transactions on Haptics工程技术3 1.490 EUR J INFORM SYST EUROPEAN JOURNAL OF INFORMATION SY工程技术3 1.500 NEUROCOMPUTING NEUROCOMPUTING工程技术3 1.580 ENG APPL ARTIF INTEL ENGINEERING APPLICATIONS OF ARTIFICIA工程技术3 1.665 ELECTRON COMMER R A Electronic Commerce Research and Application工程技术3 1.472 INFORMATICA-LITHUAN INFORMATICA工程技术3 1.627 COMPUT AIDED DESIGN COMPUTER-AIDED DESIGN工程技术3 1.234 SYST CONTROL LETT SYSTEMS & CONTROL LETTERS工程技术3 1.222 J POLYM ENVIRON JOURNAL OF POLYMERS AND THE ENVIRO工程技术3 1.349 J POLYM SCI POL PHYS JOURNAL OF POLYMER SCIENCE PART B-P工程技术3 1.531 COMPUT MATH APPL COMPUTERS & MATHEMATICS WITH APPLI工程技术3 1.747 J INF SCI JOURNAL OF INFORMATION SCIENCE工程技术3 1.299 TRANSPORTATION TRANSPORTATION工程技术3 1.023 J SENS STUD JOURNAL OF SENSORY STUDIES工程技术3 1.597 IEEE T SERV COMPUT IEEE Transactions on Services Computing工程技术3 1.468 IEEE GEOSCI REMOTE S IEEE Geoscience and Remote Sensing Letters工程技术3 1.560 J NANOSCI NANOTECHNO JOURNAL OF NANOSCIENCE AND NANOTEC工程技术3 1.563 INT J WEB GRID SERV International Journal of Web and Grid Services工程技术3 1.919 ENG ANAL BOUND ELEM ENGINEERING ANALYSIS WITH BOUNDARY工程技术3 1.451 J SOUND VIB JOURNAL OF SOUND AND VIBRATION工程技术3 1.588。

温敏水凝胶的英语The English Composition on Thermo-Sensitive HydrogelsThermo-sensitive hydrogels have gained significant attention in the field of biomedicine due to their unique properties and potential applications. These intelligent materials possess the ability to undergo reversible phase transitions in response to changes in temperature, making them particularly useful in various biomedical applications.Hydrogels are a class of hydrophilic polymeric networks that can absorb and retain large amounts of water or biological fluids within their three-dimensional structure. Thermo-sensitive hydrogels, specifically, exhibit a temperature-dependent phase transition, which means they can undergo a sol-gel transition as the temperature changes. This property is often referred to as the lower critical solution temperature (LCST) or upper critical solution temperature (UCST), depending on the specific polymer system.One of the most well-known thermo-sensitive hydrogels is poly(N-isopropylacrylamide) (PNIPAAm), wh ich has an LCST around 32°C, close to the human body temperature. Below the LCST, PNIPAAmhydrogels are in a swollen, hydrophilic state, allowing for the incorporation and release of various therapeutic agents. However, as the temperature increases above the LCST, the polymer chains undergo a conformational change, leading to the collapse of the hydrogel structure and the expulsion of water. This temperature-induced phase transition makes PNIPAAm-based hydrogels particularly useful for controlled drug delivery applications.The mechanism behind the temperature-responsive behavior of thermo-sensitive hydrogels, such as PNIPAAm, is related to the delicate balance between hydrophobic and hydrophilic interactions within the polymer network. At temperatures below the LCST, the polymer chains are hydrated, and the hydrogen bonding between water molecules and the polymer's amide groups dominates, leading to a swollen, hydrophilic state. As the temperature increases above the LCST, the hydrogen bonding between water and the polymer becomes weaker, and the hydrophobic interactions between the isopropyl groups of the polymer become more prominent. This results in the collapse of the polymer chains, causing the expulsion of water and the formation of a more compact, hydrophobic structure.The unique temperature-responsive behavior of thermo-sensitive hydrogels has led to their widespread application in various biomedical fields. One of the primary applications is in controlleddrug delivery systems. Thermo-sensitive hydrogels can be used as carriers for therapeutic agents, such as small-molecule drugs, proteins, or even cells. These hydrogels can be designed to release the encapsulated drugs in a controlled manner by responding to the temperature changes in the body. For example, a PNIPAAm-based hydrogel loaded with a drug can be administered in a liquid state at room temperature and then undergo a phase transition to a gel state upon reaching body temperature, effectively trapping the drug within the hydrogel matrix. As the temperature increases further, the hydrogel can undergo a volume phase transition, leading to the release of the drug in a controlled manner.Another important application of thermo-sensitive hydrogels is in tissue engineering and regenerative medicine. These hydrogels can be used as scaffolds for cell growth and tissue regeneration. The temperature-responsive nature of the hydrogels allows for easy administration and in situ gelation, which can facilitate the encapsulation of cells or the delivery of growth factors directly to the site of injury or disease. The hydrogel scaffold can then provide a suitable microenvironment for cell proliferation, differentiation, and tissue formation.Thermo-sensitive hydrogels have also found applications in wound healing and burn treatment. The ability of these hydrogels to undergo a sol-gel transition in response to temperature changes canbe exploited to create wound dressings that can be easily applied in a liquid form and then transition to a gel state upon contact with the body. This can help maintain a moist environment, promote wound healing, and prevent infection.Furthermore, thermo-sensitive hydrogels have been investigated for use in various diagnostic and sensing applications. For instance, they can be designed to incorporate responsive elements, such as enzyme-substrate pairs or antibody-antigen interactions, which can trigger a detectable change in the hydrogel's physical properties in response to the presence of specific analytes or biomarkers.The development of thermo-sensitive hydrogels has also led to advancements in the field of injectable biomaterials. These hydrogels can be designed to be injected in a liquid form and then undergo in situ gelation at the target site, allowing for minimally invasive procedures and the delivery of therapeutic agents or cells directly to the site of interest.Despite the numerous promising applications of thermo-sensitive hydrogels, there are still several challenges that need to be addressed. One of the key challenges is the optimization of the LCST or UCST to match the specific requirements of the target application. Researchers are exploring ways to fine-tune the polymer composition and structure to achieve the desired temperature-responsive behavior. Additionally, the long-term biocompatibility and biodegradability of these hydrogels need to be thoroughly investigated to ensure their safe and effective use in biomedical applications.In conclusion, thermo-sensitive hydrogels have emerged as a versatile class of biomaterials with tremendous potential in the field of biomedical engineering. Their temperature-responsive behavior, coupled with their ability to encapsulate and deliver therapeutic agents, make them a promising platform for a wide range of applications, from controlled drug delivery to tissue engineering and regenerative medicine. As research in this field continues to advance, we can expect to see even more innovative and impactful applications of thermo-sensitive hydrogels in the years to come.。

Vol. 35 No. 1功 能 高 分 子 学 报2022 年 2 月Journal of Functional Polymers93文章编号: 1008-9357(2022)01-0093-08DOI: 10.14133/ki.1008-9357.20210322002温度响应型酰腙可逆共价键水凝胶的制备及性能何 元1, 罗媛媛2, 刘 通1, 张银山1, 郭赞如1, 章家立1(1. 华东交通大学材料科学与工程学院,高分子材料与工程系,南昌 330013;2. 重庆市计量质量检测研究院,重庆 401120)摘 要: 首先,通过可逆加成-断裂转移(RAFT)聚合制备了丙烯酰胺(AM)、双丙酮丙烯酰胺(DAAM)和N-异丙基丙烯酰胺(NIPAM)的共聚物(PAM-co-PDAAM-co-PNIPAM);然后,使PAM-co-PDAAM-co-PNIPAM与己二酸二酰肼(ADH)反应后,得到了具有温度和pH双重响应性的水凝胶。

通过核磁共振氢谱(1H-NMR)和凝胶渗透色谱(GPC)、流变仪、扫描电镜(SEM)以及傅里叶变换红外光谱(FT-IR)对共聚物和水凝胶的结构和组成,以及水凝胶的温度和pH双重响应行为进行了研究。

研究表明,该水凝胶具有温度调控的自愈合性,对药物阿霉素(Dox)表现出pH和温度双重响应的可控释放行为。

关键词: 智能水凝胶;酰腙可逆共价键;自愈合;温度响应中图分类号: O633 文献标志码: APreparation and Properties of Temperature-Responsive HydrogelsBased on Acylhydrazone Reversible Covalent BondsAll Rights Reserved.HE Yuan1, LUO Yuanyuan2, LIU Tong1, ZHANG Yinshan1, GUO Zanru1, ZHANG Jiali1(1. Department of Polymer Materials and Engineering, School of Materials Science and Engineering, East China JiaotongUniversity, Nanchang 330013, China; 2. Chongqing Academy of Metrology andQuality Inspection, Chongqing 401120, China)Abstract: A series of PAM-co-PDAAM-co-PNIPAM copolymers were synthesized by reversible addition fracture transfer(RAFT) polymerization from acrylamide (AM), diacetone acrylamide (DAAM) and N-isopropylacrylamide (NIPAM). Theirstructure and composition were characterized by Nuclear Magnetic Resonance (NMR) and Gel Permeation Chromatography(GPC). Hydrogel with pH and temperature dual-response formed by the acyl hydrazone dynamic bonds between ketocarbonylin polymer and hydrazide in adipic dihydrazide (ADH). The dual-responsive behavior of hydrogels to temperature and pHwas researched by rheological measurement, Scanning Electron Microscope (SEM) and Fourier Transform Infrared (FT-IR)spectroscopy. At the same time, the hydrogel demonstrated temperature controlled self-healing properties. Besides, thehydrogels showed pH-and temperature-responsive controlled release behaviors for doxorubicin(Dox).Key words: smart gel; acylhydrazone dynamic covalent bond; self-healing; temperature response收稿日期: 2021-03-22基金项目: 国家自然科学基金(21802041,51563009,21865009);江西省杰出青年基金(20202ACBL214001)作者简介: 何 元(1994—),男,硕士,主要研究方向为功能高分子材料。

Additivemanufacturingofwet-spunpolymericscaffoldsforbonetissueengineering

DarioPuppi&CarlosMota&MatteoGazzarri&

DinuccioDinucci&AntonioGloria&

MairamMyrzabekova&LuigiAmbrosio&

FedericaChiellini

Publishedonline:6July2012#SpringerScience+BusinessMedia,LLC2012

AbstractAnAdditiveManufacturingtechniqueforthefabricationofthree-dimensionalpolymericscaffolds,basedonwet-spinningofpoly(ε-caprolactone)(PCL)orPCL/hydroxyapatite(HA)solutions,wasdeveloped.Thepro-cessingconditionstofabricatescaffoldswithalayer-by-layerapproachwereoptimizedbystudyingtheirinfluenceonfibresmorphologyandalignment.Twodifferentscaffoldarchitecturesweredesignedandfabricatedbytuninginter-fibredistanceandfibresstaggering.Thedevelopedscaf-foldsshowedgoodreproducibilityoftheinternalarchitec-turecharacterizedbyhighlyporous,alignedfibreswithanaveragediameterintherange200–250μm.MechanicalcharacterizationshowedthatthearchitectureandHAload-inginfluencedthescaffoldcompressivemodulusandstrength.CellcultureexperimentsemployingMC3T3-E1preosteoblastcelllineshowedgoodcelladhesion,prolifer-ation,alkalinephosphataseactivityandbonemineralizationonthedevelopedscaffolds.

KeywordsTissueengineering.Scaffolds.Wet-spinning.Additivemanufacturing.Polycaprolactone

1IntroductionBonetissueengineeringisoneofthemostpromisingapproachestobeusedasalternativetotheconventionalautogenicorallogenicsurgicaltechniquesforbonetissuerepair(Maroltetal.2010).Scaffold-basedtissueengineer-ingstrategiesinvolvetheuseofabiodegradable,porousscaffoldthatservesasstructuraltemplatetofillthetissuelesionandtosupportcell-cellinteractionsandextracellularmatrix(ECM)formation(Puppietal.2010).Underoptimalconditions,cellsharvestedfromdonortissues,includingadultorstemcells,areexpandedincultureandassociatedwithascaffoldofsyntheticand/ornaturalorigin.Thescaf-fold/cellsconstructisthenimplantedinthetargetedsitewherethedefectcanberegeneratedasconsequenceofagoodinteractionwiththehosttissue.Macroandmicro-structuralpropertiesofthescaffoldaffectnotonlycellssurvival,signalling,growth,propaga-tionandreorganization,butplayalsoamajorroleinmod-ellingcellshapeandgeneexpressions,bothrelatedtocellgrowthandpreservationofnativephenotypes(Leongetal.2003;KarageorgiouandKaplan2005).Sincethefirstpio-neeringexperimentscarriedoutbyLangerandVacantimorethan20yearsago(Vacantietal.1988;LangerandVacanti1993),severalstudieshavereporteddifferentmaterialspro-cessingtechniquesforthefabricationofpolymericscaffoldswithamacro-andmicro-architecturesuitablefortissueengineeringapplications.Theseinclude,amongothers,sol-ventcastingcombinedwithparticulateleaching,freezedry-ing,gasfoaming,meltmoulding,fibrebonding,phaseseparation,electrospinningandrapidprototypingtechni-ques(Puppietal.2010).

D.Puppi:C.Mota:M.Gazzarri:D.Dinucci:M.Myrzabekova:F.ChielliniLaboratoryofBioactivePolymericMaterialsforBiomedicalandEnvironmentalApplications(BIOlab),DepartmentofChemistryandIndustrialChemistry,UniversityofPisa,viaVecchiaLivornese1291,SanPieroaGrado(Pi),56010Pisa,Italy

A.Gloria:L.Ambrosio

InstituteofCompositeandBiomedicalMaterials,NationalResearchCouncil,Naples,Italy

F.Chiellini(*)viaVecchiaLivornese1291,56010SanPieroaGrado(Pi),Pisa,Italye-mail:federica@dcci.unipi.it

BiomedMicrodevices(2012)14:1115–1127DOI10.1007/s10544-012-9677-0Wet-spinningisanonsolvent-inducedphaseinversiontechniqueallowingfortheproductionofacontinuousmicrometricpolymerfibrethroughanimmersionprecip-itationprocess:apolymericsolutionisinjecteddirectlyintoacoagulationbathcontainingapoorsolventforthepolymer,andthesolutionfilamentsolidifiesbecauseofpolymerdesolvationcausedbysolvent–non-solventexchange(Puppietal.2011b).Amongothertechniquesformanufacturingpolymericfibresemployedinbiomedicalapplications,wet-spinninghasbeenmostlyusedtoprocessnaturalpolymers,suchaschitinandchitosan(Tuzlakogluetal.2008),whichcannotbeformedbyotherspinningtechni-ques.Agrowingbodyofliteraturehasrecentlyproposedwet-spunmicrofibresforTEapplications,includingchitosanfibres(Tuzlakogluetal.2004),braidedpoly(L-lacticacid)(PLLA)/chitosanfibres(Zhangetal.2007),starch-basednon-wovenfibrousmeshes(Pashkulevaetal.2010;Tuzlakogluetal.2010;Leonoretal.2011),poly(ε-caprolac-tone)(PCL)fibres(WilliamsonandCoombes2004),starpoly(ε-caprolactone)(*PCL)non-wovenfibrousmeshes(Puppietal.2011a;Puppietal.2011b).Inparticular,assembliesofwet-spunfibres,obtainedbyeitherphysicalbondingofprefabricatedfibresorbyasingle-stepmethodinvolvingthecontinuous,randomly-orienteddepositionofthesolid-ifyingfibreinthecoagulationbath,havebeenshowntopossessathree-dimensional(3D)structurewithhighandinterconnectedporositysuitablefortissueengineeringpur-poses(Tuzlakogluetal.2004;Pashkulevaetal.2010;Tuzlakogluetal.2010;Leonoretal.2011;Puppietal.2011a;Puppietal.2011b).However,thesefabricationmethodsdon’tallowanaccuratecontroloverscaffoldexter-nalshapeandinternalmorphology(Puppietal.2011a;Puppietal.2011b).Additivemanufacturing(AM),whichcanbedefinedas“theprocessofjoiningmaterialstomakeobjectsfrom3Dmodeldata,usuallylayeruponlayer”(ASTM2010),hasbeenextensivelyappliedforthefabricationof3Dscaffoldsbyemployingdifferenttechniques,suchasstereolitography,selectivelasersintering,3Dprintingandfuseddepositionmodelling(FDM)(WoodruffandHutmacher2010).Thankstotheirabilitytoproduceporouspolymericmatriceswithreproducibleandcustomizedmicrostructureandmacro-shape,suchtechniquesrepresentasignificantbreakthroughinscaffoldsmanufacturing.Inparticular,overthepastdec-adeandsincethefirstworkreportedbyHutmacheronscaffoldsfabricatedbyFDM(Hutmacher2000),anumberofstudieshavebeenpublishedonmeltextrusion-basedAMtechniquesforapplicationintissueengineering(Wangetal.2004;Woodfieldetal.2004;Domingosetal.2009;Motaetal.2011).Thesetechniquesinvolvethefabricationoflayersofparallelstrandswithdifferentorientationoneontopoftheother,bydepositingwithapredefinedpatternanextrudedfilamentofapolymermelt.PCLisasemicristallinepolymerthathasbeenwidelyinvestigatedinbonetissueregenerationapplicationsbecauseofitsbiocompatibilityandslowdegradation(Williamsetal.2005;Kohetal.2006;Raietal.2007;WoodruffandHutmacher2010).However,theimplantationofPCLsubstitutesintobonedefectstypicallycanpresentvariousdrawbacks,suchaslackofintegrationwiththesurroundingtissuebecauseofaninflammatoryreaction,encapsulationintofibroustissueandmechanicalstrengthreductionassociatedwithmaterialdegradation(Tayloretal.1994;Kokuboetal.2003;SchillerandEpple2003).Theincorporationofhydroxyapatite(HA),asyntheticcalciumphosphateceramicthatmimicsthenaturalapatitecomposi-tionofbonesandteeth,intobiodegradablepolyestershasbeeninvestigatedasaneffectivemeansofimprovingtheosteoconductivityandmechanicalpropertiesofboneimplantsandcreatingapHbufferagainsttheacidicdegra-dationproductsofthepolymericmatrices(Uraletal.2000;Kikuchietal.2004;Kimetal.2004;Kohetal.2006;Wutticharoenmongkoletal.2007).AimofthepresentworkwasthedevelopmentofanAMtechniqueallowingenhancedcontrolledoverinternalandexternalarchitectureofmicrofibrouspolymericscaffoldsfabricatedbywet-spinning.Byexploitingacomputer-assistedwet-spinningsystem,theprocessingconditionsforthefabricationof3Dscaffolds,withdifferentarchitecturesandmadeofeitherPCLorPCL/HAcomposite,wereopti-mized.Thedevelopedscaffoldswerecharacterizedfortheirmorphologyandelementalcompositionbymeansofscan-ningelectronmicroscopy(SEM),underbackscatteredelec-tronimagingandmicroanalysis,andmicro-computedtomography(Micro-CT),aswellasfortheirmechanicalcompressionpropertiesusingauniaxialtestingmachine.InvitrocellcultureexperimentsemployingMC3T3murinepreosteoblastcellswerecarriedoutinordertoevaluatethescaffoldscytocompatibility.Cellresponse,intermsofvia-bility,proliferation,morphology,differentiationandbonemineralization,wasinvestigatedbytetrazoliumsalts(WST-1cellproliferationreagent),confocallaserscanningmicroscopy(CLSM),alkalinephosphatesactivity(ALP)andalizarinredstaining(ARS)respectively.2Materialsandmethods2.1Additivemanufacturingofwet-spunscaffolds2.1.1MaterialsPoly(ε-caprolactone)(PCL,CAPA6800,Mw080000g·mol−1)