Water-stable lithium anode with LAGP sheet prepared by tape casting method for lithium-air batteries

- 格式:pdf

- 大小:489.25 KB

- 文档页数:5

张倩如,吴启赐,薛钰,等. 杏鲍菇废弃菌渣中D-氨基葡萄糖盐酸盐的制备工艺及生物学活性分析[J]. 食品工业科技,2023,44(17):263−271. doi: 10.13386/j.issn1002-0306.2022110139ZHANG Qianru, WU Qici, XUE Yu, et al. Preparation and Biological Activity of D-Glucosamine Hydrochloride from the Waste Residues of Pleurotus eryngii [J]. Science and Technology of Food Industry, 2023, 44(17): 263−271. (in Chinese with English abstract).doi: 10.13386/j.issn1002-0306.2022110139· 工艺技术 ·杏鲍菇废弃菌渣中D-氨基葡萄糖盐酸盐的制备工艺及生物学活性分析张倩如1,吴启赐1, *,薛 钰1,林志超1,黄家福1,吕昊坤1,彭 伟1,潘裕添1,林进妹2,*(1.闽南师范大学菌物产业福建省高校工程研究中心,福建漳州 363000;2.闽南师范大学化学化工与环境学院,福建漳州 363000)摘 要:本文以杏鲍菇废弃菌渣为原料,探究了D-氨基葡萄糖盐酸盐(D-glucosamine hydrochloride ,GAH )的制备工艺、液相-质谱(HPLC-MS )、红外光谱、理化指标及其对斑马鱼胚胎发育的影响。

采用单因素和响应面优化试验,获得盐酸水解制备GAH 的最佳条件:盐酸浓度31%,水解时间4 h ,水解温度82 ℃,液固比5 mL/g ,此时GAH 得率可达23.61%。

液相-质谱、红外光谱和理化指标分析显示,GAH 纯化样品纯度是标准品的101.9%,质谱和红外光谱图与标准品一致,各项指标均符合甚至优于美国药典43-国家处方集38(USP43-NF38)的质量标准,砷含量仅0.21 μg/g 。

密度泛函理论研究叶绿素a水合物的结构、结合能和电离能谷靖;王一波【摘要】用M06-2X/6-311G(d,P)密度泛函理论对叶绿素a及其两种水合物的结构进行优化,然后用M06-2X/6-311++G(2d,2p)方法计算结合能和电离能。

优化结果表明水合分子会使叶绿素a分子结构发生改变。

结合能计算结果表明叶绿素a的二水合物比一水合物更为稳定。

电离能计算结果表明随着叶绿素a水合分子数的增加,电离能逐渐减小,叶绿素a的水合有利于光合作用的发生。

%The structures of chlorophyll-a and its two hydrates were optimized at the level of density functional theory M06-2X/6-311G (d, p), and the binding energies and ionization energies were calculated using M06-2X/ 6-311 ++ G (2d, 2p) method. The optimized results show that the water can change the structure of chlorophyll- a. The results of binding energies suggest that the chlorophyll-a dihydrate is more stable than monohydrate. The i- onization energy results indicate that the ionization energies decrease gradually with the increase of the number of water, and photosynthesis is more likely to occur with the existence of water.【期刊名称】《贵州科学》【年(卷),期】2012(030)004【总页数】5页(P9-12,28)【关键词】叶绿素a;水合;结构;结合能;电离能【作者】谷靖;王一波【作者单位】贵州省高性能计算化学重点实验室贵州大学,贵阳550025;贵州省高性能计算化学重点实验室贵州大学,贵阳550025【正文语种】中文【中图分类】Q176在高等植物的光合作用中,叶绿素a既作为能量传递过程中的接受体和传递体,又作为电子传递链上的供体和受体,显得十分重要(Yang,2011)。

Electrochimica Acta 105 (2013) 378–383Contents lists available at SciVerse ScienceDirectElectrochimicaActaj o u r n a l h o m e p a g e :w w w.e l s e v i e r.c o m /l o c a t e /e l e c t a c taChitosan,a new and environmental benign electrode binder for use with graphite anode in lithium-ion batteriesLili Chai a ,Qunting Qu a ,Longfei Zhang a ,Ming Shen b ,Li Zhang a ,∗,Honghe Zheng a ,∗a School of Energy,Soochow University,Suzhou,Jiangsu 215006,China bHuasheng Chemical Corporation,Zhangjiagang,Jiangsu 215635,Chinaa r t i c l ei n f oArticle history:Received 22March 2013Received in revised form 30April 2013Accepted 6May 2013Available online 14 May 2013Keywords:Lithium-ion batteries Graphite anode Electrode binder Chitosana b s t r a c tChitosan was applied as the electrode binder material for a spherical graphite anode in lithium-ion pared to using poly (vinylidene fluoride)(PVDF)binder,the graphite anode using chitosan exhibited enhanced electrochemical performances in terms of the first Columbic efficiency,rate capabil-ity and cycling behavior.With similar specific capacity,the first Columbic efficiency of the chitosan-based anode is 95.4%compared to 89.3%of the PVDF-based anode.After 200charge–discharge cycles at 0.5C ,the capacity retention of the chitosan-based electrode showed to be significantly higher than that of the PVDF-based electrode.Electrochemical impedance spectroscopy (EIS)and scanning electron microscopy (SEM)measurements were carried out to investigate the formation and evolution of the solid electrolyte interphase (SEI)formed on the graphite electrodes.The results show that a thin,homogenous and stable SEI layer is formed on the graphite electrode surface with chitosan binder compared with that using the conventional PVDF binder© 2013 Elsevier Ltd. All rights reserved.1.IntroductionElectrode binder plays a very important role in fabricating high-performance electrodes as it holds active materials and conductive additives into a cohesive laminate and provides the adhesion between the laminate and the current collector.In the past two decades,poly (vinylidene fluoride)(PVDF)was the most widely used binder material for Li-ion battery electrodes.This is attributed to its good electrochemical stability,binding capability and ability to absorb electrolyte [1–5].However,PVDF polymer is costly and it requires the use of environmentally unfriendly N-methyl pyr-rolidone (NMP)solvent in the processing.Besides,this polymer is very sensitive to the environmental humidity.It undergoes a severe degradation of viscosity after absorbing water.As a fluorinated polymer,PVDF also shows a certain reactivity against lithium metal and lithiated graphite (Li x C 6),producing resistive LiFand C CF species on the electrode surface,especially at elevated tempera-tures [6,7].For these reasons,the development of greener,cheaper and more electrochemical stable electrode binder is considered as a goal of strategic importance for battery technologies.In recent years,many groups have been studying new electrode binder materials for the realization of greener battery processing and∗Corresponding authors.E-mail addresses:hhzheng@ (L.Zhang),zhangli81@ (H.Zheng).high performance Li-ion batteries.Among different binder systems,water-soluble binders are not only much cheaper than PVDF,but also allow electrode processing in aqueous slurries.These polymers can be easily disposed at the end of the life of the battery.Gelatin [8–11],sodium carboxy-methyl cellulose (CMC-Na)and styrene-butadiene rubber (SBR)[12–18],poly(acrylic acid)(PAA)[19–23],poly(methacrylic acid)(PMA)[24],poly(vinyl alcohol)(PVA)[25],alginate [26,27],poly(acrylamide-co-diallyldime-thylammonium chloride (AMAC)[28],poly (acrylonitrile-methyl methacrylate)(AMMA)[29],and polyimide (PI)[30],all have been reported as promising new binder systems replacing PVDF and some of them have been successfully used in commercial lithium ion batter-ies.In this paper,chitosan,as a water-soluble polymer,was adopted as a new electrode binder for a graphite anode.Chitosan is a polysaccharide composed mainly of -(1,4)-linked 2-deoxy-2-amino-d -glucopyranose units.The molecular structure of it is provided in Fig.1.This polymer is one of the most plentiful nat-ural biopolymers produced from poly (N-acetyl-d -glucosamine)(chitin)[31].Chitosan is widely used in many fields including molecular separation,food packaging film,artificial skin,bone substitutes,water treatment and so on [32–34].In Li-ion battery field,chitosan has also been attempted as the template for active material synthesis [35],and carbon coating precursor [36].How-ever,to the best of our knowledge,this polymer has never been adopted as an available binder material for Li-ion batteries up to today.0013-4686/$–see front matter © 2013 Elsevier Ltd. All rights reserved./10.1016/j.electacta.2013.05.009L.Chai et al./Electrochimica Acta105 (2013) 378–383379Fig.1.The molecular structure of chitosan polymer.As the matter of fact,chitosan-based aqueous slurry possesses good viscosity,which can be considered as an effective electrode binder.Herein,acid solution-based chitosan slurry was applied as the binder for a commercial spherical graphite material.Elec-trochemical performances of the chitosan-based and PVDF-based graphite anodes were compared in terms of reversible capacity,first Coulombic efficiency,rate capabilities and long-term cycling behavior.Electrochemical impedance spectroscopy(EIS)and scan-ning electron microscopy(SEM)measurements were performed to investigate the effect of binder on the formation and evolution of the solid electrolyte interphase(SEI)layer on the graphite elec-trode.Mechanisms for the higher electrochemical performance of the graphite anode with chitosan binder were discussed2.ExperimentalSpherical graphite powders(Shenzhen Beterui new energy Materials Group Co,Ltd Code No AGP-8,China)were applied as the electrode active material.Acetylene black(AB)with an average particle size of40nm was acquired from Denka Singapore Private Ltd PVDF(KF1100)binder was obtained from Kureha,Japan and chitosan(Code No C0831)was purchased from TCl Shanghai.All the materials were used as received in this study.PVDF was dissolved into NMP solvent(aladdin,anhydrous, 99.9%)with a concentration of15wt%while chitosan was dis-persed into0.5%acetic acid solution with a concentration of3wt% at room temperature.Even though the concentration of the PVDF-based solution is much higher,viscosity of the aqueous solution containing3wt%chitosan seems to be slightly higher than that of the15wt%PVDF solution.Both solutions were equilibrated for at least2h at room temperature with magnetic stirring.For the preparation of the electrodes,slurry consisting of94wt%graphite powders and6wt%chitosan was thoroughly mixed for12h and casted onto15m-thick copper foil(99.99%purity).As a refer-ence,the electrode using PVDF binder was prepared by casting the slurry containing88.8wt%graphite,3.2wt%super P and8wt% PVDF.The recipes were obtained in our lab as described in the lit-erature[37]for making high electrochemical performance MCMB anode.Both the two electrode laminates were controlled to have the same active material loading of∼1.8mg cm−2by varyingthedoctor blade height.The obtained electrodes were dried at120◦Cin a vacuum oven for16h and pressed to enhance the mechanicalcontact between the electrode laminate and current collector. Fig.2.SEM images of as-prepared graphite electrodes with chitosan(a and b)and PVDF binder(c and d).380L.Chai et al./Electrochimica Acta010020030 0400.00.51.01.52.02.53.0221Specific capacity (mAh.g -1)V o l t a g e v s . L i /L i + (V )1-W ater-based e lectrode 2-PVDF-based e lectrode1Fig.3.The first charge–discharge profiles of the graphite anode using (a)chitosanand (b)PVDF binder.The half cells (2032stainless-steel coin cell)were assembled in an Ar-filled glove box (OMNI-LAB,VAC).The electrolyte was 1M LiPF 6in ethylene carbonate/diethylene carbonate (EC/DEC,1:1by weight)with 10%fluoroethylene carbonate (FEC)as the addi-tive (Novolyte Technologies).The separator employed was Celgard 2400and lithium metal foil (99.9%purity)was utilized as the counter electrode.All the cells were tested on a Maccor S4000(Maccor Instruments,USA)at 303K in a Thermotron Environmen-tal Chamber.Three formation cycles at C/20charge and discharge were applied between 0.005V and 2V vs Li.Rate test of the graphite electrodes consisted of full discharges at rates of C/10,C/5,C/2,1C ,2C ,5C ,and 10C ,respectively.Long-term cycling of the cells was carried out with 0.5C charge and 0.5C discharge for 200cycles.Electrochemical impedance spectroscopy (EIS)was measured by applying an alternating voltage of 5mV over the frequency ranging from 10−2to 105Hz.All impedance measurements were carried out at the discharge state of 60%DOD (depth of discharge)at different cycling stages.Morphologies of the graphite electrodes using different binders before and after electrochemical tests were observed by scanning electron microscopy (SEM)using a Hitachi S-4700operated at 1kV and 5kV accelerating voltage.3.Results and discussionSEM images of the as-prepared graphite electrodes with chi-tosan and PVDF binders are presented in Fig.2at different magnifications.As there is no conductive carbon additive,only smooth and “clean”graphite particles are observed for the elec-trode with chitosan binder (as seen in Fig.2a,b).The graphite particle size is around 10m in the image.By contrast,as shown in Fig.2c,d,lots of nano-scale conductive carbon particles are seen well distributed in between the graphite particles.It has been reported that PVDF binder tends to shrink and cover the graphite powders,which blocks the migration of Li ion during electrochem-ical processes [38].Addition of conductive carbon additive within the PVDF-based electrode not only contributes to an improvement of the electronic conductivity of the laminate,but also helps to increase the electrode porosity.Fig.3shows the charge–discharge profiles of the graphite anodes using different binders in 1M LiPF 6/(EC:DEC)electrolyte containing 10%FEC.FEC is used as the electrolyte additive as it significantly improves electrochemical performances of graphite anode in the electrolyte and is now widely used in Li-ion battery R&D.For the two kinds of electrodes,the cell voltage drops rapidly from open circuit voltage down to 0.2V,corresponding to theof is at is at ofL.Chai et al./Electrochimica Acta 105 (2013) 378–38338180859095100105%/n o i t n e t e r y t i c a p a c e l b i s r e v e R Cycle nu mberFig.5.Rate capability of the graphite electrodes using (a)chitosan and (b)PVDFbinder.electrode using PVDF binder.The higher rate capability of chitosan-bonded graphite electrode seems not very identical with the highpolarization of the electrode in the first charge and this will be discussed next.Fig.6displays the cycling performance of the graphite anodes with chitosan and PVDF binders.As shown in this figure,chitosan-based graphite anode shows better cycling performance than the PVDF-based electrode.Upon deep galvanostatic cycling for 200cycles,the capacity retention of the chitosan-based electrode is no less than 91%while the capacity retention of the PVDF-based electrode is no more than 75%at the same cycling condition.The improved cycling capability of the electrode by using Chitosan binder illustrates better electrochemical stability of the electrode during electrochemical cycles.In order to explain the higher rate performance and cycling capability of the graphite anode using chitosan binder,elec-trochemical impedance spectroscopy (EIS)measurements of the graphite anode using different binders at different cycling stages were performed at 60%DOD and the results are displayed in Fig.7.All the sets consist of two semicircles [39].The high-frequency semicircle is believed to be related to the resistance of passivating SEI film (R SEI )or active material particle-to-particle interfacial con-tact resistance.The intermediate-frequency semicircle is attributed to the charge–transfer resistance (R ct ).For the chitosan-based20406080100%/n o i t n e t e r y t i c a p a c e l b i s r e v e R Cycle numberFig.6.Cycling performance of the graphite electrodes using chitosan (a)and PVDF (b)binder at 0.5C charge and 0.5C discharge.51015202530-Z '' / O h mZ' / Ohm10203040-Z '' / O h mZ' / OhmFig.7.Nyquist plots of graphite electrodes using chitosan (a)and PVDF (b)binder at different cycling stages at 60%DOD.electrode,higher impedance after formation cycles are observed compared to that of electrode using PVDF binder.The high resistance is most likely to be related to the graphite particle-to-particle interfacial contact resistance as there is no conductive carbon within the electrode matrix.The high impedance explains the higher polarization of the electrode in the first charge as shown in Fig.4.However,after the rate test,it is clear to see that impedance of chitosan-based electrode exhibits a remarkable decrease and the impedance seems to be even lower than that of PVDF-based electrode at this stage.The decrease of electrode impedance with electrochemical cycle implies an activation process for chitosan-bonded electrode.Along with the repeating lithiation/delithiation processes,more ion transport and charge–transfer sites may be created at the electrode/electrolyte interface,which leads to the electrode impedance decreases.Actually,this phenomenon always occurs for graphite anode with water soluble binders [28].The lower impedance for the chitosan-based electrode explains the high rate performance at this stage.After 200cycles,impedance of the chitosan-based anode is well maintained and even shows a continuous decrease of R ct .By comparison,a slight increase of R ct for the PVDF-based electrode is observed.Again,this result confirms that the surface condition of electrode using chitosan binder is relatively stable with electrochemical cycles.For the PVDF-based anode,the increase of electrode impedance indicates continuous growth of the surface components during the long-term cycling test.According to these analyses,chitosan presents obvious advantages in fabricating high-performance anode compared with conventional PVDF binder.382L.Chai et al./Electrochimica Acta 105 (2013) 378–383Fig.8.SEM images of graphite electrodes after formation and rate capability test,chitosan binder (a),(b);PVDF binder (c),(d).To clearly see the surface condition of the graphite anode with different binders after electrochemical cycles,scanning elec-tron microscopy (SEM)measurements were carried out.Fig.8presents the SEM microscope images of graphite anode with dif-ferent binders after formation cycles and after the rate capability test.After the formation cycles,many alien particles and fragments are seen dispersed on the graphite surface of the PVDF-based anode (Fig.8c)while few alien particles can be detected on the graphite surface with chitosan binder (Fig.8a).This agrees with the lower irreversible capacity loss of the electrode in the first cycle.After the rate capability tests,the graphite surface of the PVDF-based elec-trode became even more rough and thicker,with a lot of agglom-erate granules and fragments staying on the electrode surface (see Fig.8d).This evidence also supports our conclusion that the elec-trode with chitosan binder has better electrochemical stability.4.ConclusionChitosan was applied as an effective binder for graphite anode in Li-ion pared to the electrode using conventional PVDF binder,the first Columbic efficiency,rate capability and cycling behavior are considerably improved EIS studies showed that the electrode resistance of the chitosan-based electrode under-goes a distinct decrease after the initial several cycles and the electrode impedance is well maintained after long-term cycling tests.Meanwhile a continuous growth of electrode resistance with electrochemical cycles is observed for the electrode with PVDF binder.This is consistent with the continuous growth of the surface species with increasing electrochemical cycles.At last,it should be noted that many key physical parameters involved in making chitosan-based electrode are not optimized in this study.Given the chitosan content and electrode processing technologies are optimized,the results may be even more optimistic.AcknowledgementsThe authors are greatly indebted to the funding of Natural Sci-ence Foundation of China (NSFC,contract no 21073129,51272168,21203132,and 21203133).References[1]J.Chong,S.D.Xun,H.H.Zheng,X.Y.Song,G.Liu,P.Ridgway,J.Q.Wang,V.S.Battaglia,A comparative study of polyacrylic acid and poly(vinylidene difluo-ride)binders for spherical natural graphite/LiFePO 4electrodes and cells,Journal of Power Sources 196(2011)7707–7714.[2]A.Fedorkova,R.Orinakova,A.Orinak,I.Talian,A.Heile,H.D.Wiemhofer,D.Kaniansky,H.F.Arlinghaus,PPy doped PEG conducting polymer films synthe-sized on LiFePO 4particles,Journal of Power Sources 195(2010)3907–3912.[3]G.Liu,H.Zheng,A.S.Simens,A.M.Minor,X.Song,V.S.Battaglia,Optimizationof acetylene black conductive additive and PVDF composition for high-power rechargeable lithium-ion cells,Journal of the Electrochemical Society 154(2007)A1129–A1134.[4]N.S.Choi,Y.G.Lee,J.K.Park,Effect of cathode binder on electrochemical prop-erties of lithium rechargeable polymer batteries,Journal of Power Sources 112(2002)61–66.[5]D.W.Choi,D.H.Wang,V.V.Viswanathan,I.T.Bae,W.Wang,Z.M.Nie,J.G.Zhang,G.L.Graff,J.Liu,Z.G.Yang,T.Duong,Li-ion batteries from LiFePO 4cathode and anatase/graphene composite anode for stationary energy storage,Electro-chemistry Communications 12(2010)378–381.[6]A.Du Pasquier,F.Disma,T.Bowmer,A.S.Gozdz,G.Amatucci,J.M.Tarascon,Dif-ferential scanning calorimetry study of the reactivity of carbon anodes in plastic Li-ion batteries,Journal of the Electrochemical Society 145(1988)472–477.[7]H.Maleki,G.Deng,I.Kerzhner-Haller,A.Anani,J.N.Howard,Thermal stabilitystudies of binder materials in anodes for lithium-ion batteries,Journal of the Electrochemical Society 147(2000)4470–4475.[8]M.Gaberscek,M.Bele,J.Drofenik,R.Dominko,S.Pejovnik,Improved carbonanode properties:pretreatment of particles in polyelectrolyte solution,Journal of Power Sources 97-8(2001)67–69.[9]J.Drofenik,M.Gaberscek,R.Dominko,M.Bele,S.Pejovnik,Carbon anodes pre-pared from graphite particles pretreated in a gelatine solution,Journal of Power Sources 94(2001)97–101.[10]M.Bele,M.Gaberscek,R.Dominko,J.Drofenik,K.Zupan,P.Komac,K.Kocevar,I.Musevic,S.Pejovnik,Gelatin-pretreated carbon particles for potential use in lithium ion batteries,Carbon 40(2002)1117–1122.L.Chai et al./Electrochimica Acta105 (2013) 378–383383[11]R.Dominko,M.Gaberscek,J.Drofenik,M.Bele,S.Pejovnik,A novel coatingtechnology for preparation of cathodes in Li-ion batteries,Electrochemical and Solid-State Letters4(2001)A187–A190.[12]J.S.Wang,E.Sherman,M.Verbrugge,P.Liu,Composite electrodes of disor-dered carbon and graphite for improved battery state estimation with minimal performance penalty,Journal of Power Sources196(2011)9648–9653. [13]M.Holzapfel,H.Buqa,W.Scheifele,P.Novak,F.M.Petrat,A new type ofnano-sized silicon/carbon composite electrode for reversible lithium insertion, Chemical Communications12(2005)1566–1568.[14]M.Yoshio,T.Tsumura,N.Dimov,Silicon/graphite composites as an anodematerial for lithium ion batteries,Journal of Power Sources163(2006) 215–218.[15]J.H.Lee,U.Paik,V.A.Hac kley,Y.M.Choi,Effect of carboxymethyl celluloseon aqueous processing of natural graphite negative electrodes and their elec-trochemical performance for lithium batteries,Journal of the Electrochemical Society152(2005)A1763–A1769.[16]J.H.Lee,U.Paik,V.A.Hackley,Y.M.Choi,Effect of poly(acrylic acid)on adhesionstrength and electrochemical performance of natural graphite negative elec-trode for lithium-ion batteries,Journal of Power Sources161(2006)612–616.[17]N.Dimov,Y.Xia,M.Yoshio,Practical silicon-based composite anodes forlithium-ion batteries:fundamental and technological features,Journal of Power Sources171(2007)886–893.[18]S.L.Chou,J.Z.Wang,H.K.Liu,S.X.Dou,Rapid synthesis of Li4Ti5O12micro-spheres as anode materials and its binder effect for lithium-ion battery,Journal of Physical Chemistry C115(2011)16220–16227.[19]Z.A.Zhang,W.Z.Bao,H.Lu,M.Jia,K.Y.Xie,i,J.Li,Water-solublepolyacrylic acid as a binder for sulfur cathode in lithium-sulfur battery,ECS Electrochemistry Letters1(2)(2012)A34–A37.[20]A.Magasinski,B.Zdyrko,I.Kovalenko,B.Hertzberg,R.Burtovyy,C.F.Huebner,T.F.Fuller,I.Luzinov,G.Yushin,Toward efficient binders for Li-ion battery Si-based anodes:polyacrylic acid,ACS Applied Materials&Interfaces11(2010) 3004–3010.[21]S.Komaba,K.Shimomura,N.Yabuuchi,T.Ozeki,H.Yui,K.Konno,Study onpolymer binders for high-capacity SiO negative electrode of Li-ion batteries, Journal of Physical Chemistry C115(2011)13487–13495.[22]Z.P.Cai,Y.Liang,W.S.Li,L.D.Xing,Y.H.Liao,Preparation and performances ofLiFePO4cathode in aqueous solvent with polyacrylic acid as a binder,Journal of Power Sources189(2009)547–551.[23]Z.A.Zhang,T.Zeng,C.M.Qu,H.Lu,M.Jia,i,J.Li,Cycle performanceimprovement of LiFePO4cathode with polyacrylic acid as binder,Electrochi-mica Acta80(80)(2012)440–444.[24]S.Komaba,N.Yabuuchi,T.Ozeki,K.Okushi,H.Yui,K.Konno,Y.Katayama,T.Miura,Functional binders for reversible lithium intercalation into graphitein propylene carbonate and ionic liquid media,Journal of Power Sources195 (2010)6069–6074.[25]H.K.Park,B.S.Kong,E.S.Oh,Effect of high adhesive polyvinyl alcohol binderon the anodes of lithium ion batteries,Electrochemistry Communications13 (2011)1051–1053.[26]I.Kovalenko,B.Zdyrko,A.Magasinski,B.Hertzberg,icev,R.Burtovyy,I.Luzinov,G.Yushin,A major constituent of brown algae for use in high-capacity Li-ion batteries,Science333(2011)75–79.[27]J.X.Li,Y.Zhao,N.Wang,Y.H.Ding,L.H.Guan,Enhanced performance of a MnO2-graphene sheet cathode for lithium ion batteries using sodium alginate as a binder,Journal of Materials Chemistry22(2012)13002–13004.[28]S.S.Zhang,K.Xu,T.R.Jow,Evaluation on a water-based binder for the graphiteanode of Li-ion batteries,Journal of Power Sources138(2004)226–231. [29]S.S.Zhang,T.R.Jow,Study of poly(acrylonitrile-methyl methacrylate)as binderfor graphite anode and LiMn2O4cathode of Li-ion batteries,Journal of Power Sources109(2)(2002)422–426.[30]N.Ohta,T.Sogabe,K.Kuroda,A novel binder for the graphite anode of recharge-able lithium ion batteries for the improvement of reversible capacity,Carbon 39(9)(2001)1434–1436.[31]S.F.Wang,L.Shen,W.D.Zhang,Y.J.Tong,Preparation and mechanical prop-erties of chitosan/carbon nanotubes composites,Biomacromolecules6(2005) 3067–3072.[32]R.C.J.R.Chen,Discrimination between solid and liquid velocities in slurryflowusing laser-doppler velocimeter,Kadambi Powder Technology85(2)(1995) 127–134.[33]M.N.V.R.Kumar,A review of chitin and chitosan applications,Reactive andFunctional Polymers46(1)(2000)1–27.[34]K.Kurita,Controlled functionalization of the polysaccharide chitin,Progress inPolymer Science26(9)(2001)1921–1971.[35]C.Y.Hu,J.Guo,J.Wen,Hierarchical nanostructure CuO with peach kernel-likemorphology as anode material for lithium-ion batteries,Ionics19(2)(2013) 253–258.[36]K.S.Hong,S.M.Yu,M.G.Ha,Bulletin of the Korean Chemical Society30(8)(2009)1719–1723.[37]H.Zheng,L.Chai,X.V.Song,Electrochemical cycling behavior of LiFePO4cath-ode charged with different upper voltage limits,Battaglia Electrochim Acta62(15)(2012)256–262.[38]M.Yoo,C.W.Frank,S.Mori,Interaction of poly(vinylidenefluoride)withgraphite particles.1.Surface morphology of a compositefilm and its relation to processing parameters,Chemistry of Materials15(2003)850–861.[39]Y.Zhu,C.Wang,Strain accommodation and potential hysteresis of LiFePO4cathodes during lithium ion insertion/extraction,Journal of Power Sources196(3)(2011)1442–1448.。

锂离子电池陶瓷复合全固态电解质的制备和性能研究李承斌;岳红云;王秋娴;李静娴;杨书廷【摘要】Poly(ethylene oxide) (PEO) as a kind of promising candidates of polymer electrolyte is widely applied in all solid lithium ion batteries. In this study, a novel ceramic composite solid electrolyte (CLASP) was prepared by dip-coating PEO-LAGP-SN-LiTFSI (PEO-SPE) into Al2O3 nonwoven membrane. And all solid batteries were assembled with CLASP. CLASP showed excellent thermostability even at 170℃ for 2 h. When the ratio of PEO: LAGP: SN: LiT-FSI was 3: 1: 1: 1, the conductivities of CLASP reached 3.66×10-5 S/cm at 25℃ and 2.52×10-4 S/cmat 100℃, re-spectively. The electrochemical window of CLASP was 5.5 V, which had great potential to apply in battery with high voltage cathode material. The cycling performance of all solid batteries with CLASP was greatly improved at 55℃ as well. This new ceramic composite, solid polymer electrolyte, with all these outstanding performance is a promising candidate of all solid electrolytes.%以负载Al2O3的无纺布为支撑膜,浸涂PEO-LAGP-SN-LiTFSI的乙腈共混液干燥后制得新型复合固态电解质膜(CLASP).该膜的热稳定性好,即使在170℃的高温下依然不发生形变.当浸涂共混液中PEO:LAGP:SN:LiTFSI为3:1:1:1,固含量为10wt%时,室温电导率可以达到3.66×10-5 S/cm,100℃时电导率可达2.52×10-4 S/cm.CLASP膜的电化学窗口宽,以该膜代替液态电解质装配的全固态LiFePO4/CLASP/Li电池,在55℃循环时表现出良好的循环稳定性,高的库伦效率,有望成为电化学性能优越的全固态电解质.【期刊名称】《无机材料学报》【年(卷),期】2017(032)008【总页数】5页(P801-805)【关键词】全固态;复合电解质;磷酸锗铝锂;耐热【作者】李承斌;岳红云;王秋娴;李静娴;杨书廷【作者单位】河南师范大学物理与材料科学学院,新乡453007;河南工学院电气工程系,新乡453003;河南师范大学化学化工学院, 动力电源及关键材料国家地方联合工程实验室, 新乡453007;河南师范大学化学化工学院, 动力电源及关键材料国家地方联合工程实验室, 新乡453007;河南师范大学化学化工学院, 动力电源及关键材料国家地方联合工程实验室, 新乡453007;河南师范大学物理与材料科学学院,新乡453007;河南师范大学化学化工学院, 动力电源及关键材料国家地方联合工程实验室, 新乡453007【正文语种】中文【中图分类】Q152自从1991年索尼开发出商用锂离子电池以来, 锂离子电池以其具有高的能量密度, 无记忆效应, 环境友好等特点被广泛应用于手机和笔记本等数码产品中[1-3]。

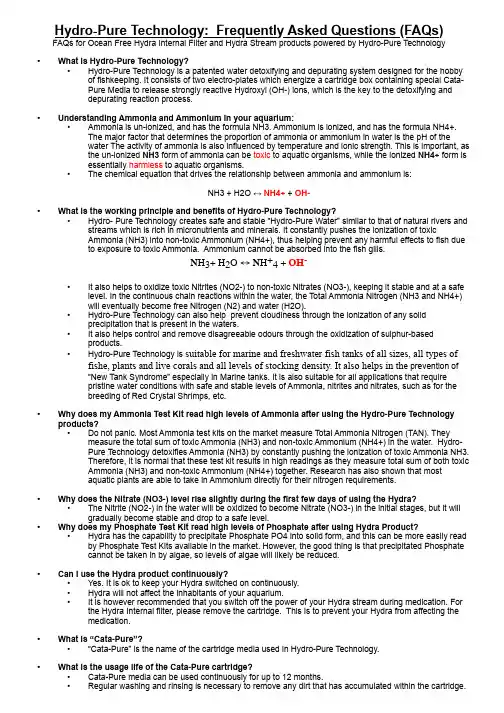

Hydro-Pure Technology: Frequently Asked Questions (FAQs)FAQs for Ocean Free Hydra Internal Filter and Hydra Stream products powered by Hydro-Pure Technology •What is Hydro-Pure Technology?•Hydro-Pure Technology is a patented water detoxifying and depurating system designed for the hobby of fishkeeping. It consists of two electro-plates which energize a cartridge box containing special Cata-Pure Media to release strongly reactive Hydroxyl (OH-) ions, which is the key to the detoxifying anddepurating reaction process.•Understanding Ammonia and Ammonium in your aquarium:•Ammonia is un-ionized, and has the formula NH3. Ammonium is ionized, and has the formula NH4+.The major factor that determines the proportion of ammonia or ammonium in water is the pH of thewater The activity of ammonia is also influenced by temperature and ionic strength. This is important, asthe un-ionized NH3 form of ammonia can be toxic to aquatic organisms, while the ionized NH4+ form isessentially harmless to aquatic organisms.•The chemical equation that drives the relationship between ammonia and ammonium is:NH3 + H2O ↔NH4+ + OH-•What is the working principle and benefits of Hydro-Pure Technology?•Hydro- Pure Technology creates safe and stable “Hydro-Pure Water” similar to that of natural rivers and streams which is rich in micronutrients and minerals. It constantly pushes the ionization of toxicAmmonia (NH3) into non-toxic Ammonium (NH4+), thus helping prevent any harmful effects to fish dueto exposure to toxic Ammonia. Ammonium cannot be absorbed into the fish gills.NH3+ H2O ↔ NH+4 + OH-•It also helps to oxidize toxic Nitrites (NO2-) to non-toxic Nitrates (NO3-), keeping it stable and at a safe level. In the continuous chain reactions within the water, the Total Ammonia Nitrogen (NH3 and NH4+)will eventually become free Nitrogen (N2) and water (H2O).•Hydro-Pure Technology can also help prevent cloudiness through the ionization of any solid precipitation that is present in the waters.•It also helps control and remove disagreeable odours through the oxidization of sulphur-based products.•Hydro-Pure Technology is suitable for marine and freshwater fish tanks of all sizes, all types of fishe, plants and live corals and all levels of stocking density. It also helps in the prevention of“New Tank Syndrome” especially in Marine tanks. It is also suitable for all applications that requirepristine water conditions with safe and stable levels of Ammonia, nitrites and nitrates, such as for thebreeding of Red Crystal Shrimps, etc.•Why does my Ammonia Test Kit read high levels of Ammonia after using the Hydro-Pure Technology products?•Do not panic. Most Ammonia test kits on the market measure Total Ammonia Nitrogen (TAN). They measure the total sum of toxic Ammonia (NH3) and non-toxic Ammonium (NH4+) in the water. Hydro-Pure Technology detoxifies Ammonia (NH3) by constantly pushing the ionization of toxic Ammonia NH3.Therefore, it is normal that these test kit results in high readings as they measure total sum of both toxicAmmonia (NH3) and non-toxic Ammonium (NH4+) together. Research has also shown that mostaquatic plants are able to take in Ammonium directly for their nitrogen requirements.•Why does the Nitrate (NO3-) level rise slightly during the first few days of using the Hydra?•The Nitrite (NO2-) in the water will be oxidized to become Nitrate (NO3-) in the initial stages, but it will gradually become stable and drop to a safe level.•Why does my Phosphate Test Kit read high levels of Phosphate after using Hydra Product?•Hydra has the capability to precipitate Phosphate PO4 into solid form, and this can be more easily read by Phosphate Test Kits available in the market. However, the good thing is that precipitated Phosphatecannot be taken in by algae, so levels of algae will likely be reduced.•Can I use the Hydra product continuously?•Yes. It is ok to keep your Hydra switched on continuously.•Hydra will not affect the inhabitants of your aquarium.•It is however recommended that you switch off the power of your Hydra stream during medication. For the Hydra Internal filter, please remove the cartridge. This is to prevent your Hydra from affecting themedication.•What is “Cata-Pure”?•“Cata-Pure” is the name of the cartridge media used in Hydro-Pure Technology.•What is the usage life of the Cata-Pure cartridge?•Cata-Pure media can be used continuously for up to 12 months.•Regular washing and rinsing is necessary to remove any dirt that has accumulated within the cartridge.•Replace the cartridges every 12 months for maximum performance.•Is Cata-Pure made of Activated Carbon?•Cata-Pure is a carbon-based media that has been specially formulated with additives to work with Hydro-Pure Technology.•Replacing Cata-Pure with activated Carbon will not work, and may even cause damage to the unit.•Do I have to clean the Cata-Pure Cartridge?•Yes. Regular maintenance is necessary to ensure that the Cata-Pure Cartridge does not get clogged with dirt.•Clean the Cata-Pure whenever you are cleaning the filtration.•How do I clean the Hydra and Cata-Pure Cartridge?•Remove the Cata-Pure cartridge out of the Hydra unit.•Rinse and shake the cartridge in water to release dirt.•Clean the cartridge exterior.•Clean the Electro-Plate surface.•Re-insert the cartridge into the Hydra Unit.•Are the electro-plates replaceable?•The electro-plates are made of titanium and do not need to be replaced throughout the entire operating life of the product. Regular cleaning is however recommended for optimum performance.•Why does one of the electro-plate’s surfaces turn brownish?•It is normal for one of the electro-plate’s surfaces to change colour in this way due to the deposits created by the chemical reaction.•Please clean the electro-plate’s surface during maintenance.•What is a Hydra Internal Filter?• A Hydra Internal Filter is basically a normal internal filter with Hydro-Pure Technology capability built in. •Which Hydra Internal Filter should I use?•Select your Hydra Internal Filter based on the flow rate and tank size you require for your aquarium.Please refer to the guidelines below.•How do I use a Hydra Internal Filter?•Your Hydra Internal filter needs to be fully submerged into the aquarium water.•It can be placed inside the main Aquarium Tank.•It can also be placed inside a Filtration system, such as a Sump Tank’s compartment, preferably after the mechanical filtration compartment.•What is a Hydra Stream?•Hydra Stream is an in-line canister adapter with Hydro-Pure Technology capability built in.•It is used as an enhancement to the main filtration system.•It needs to be connected into the back of a filtration system driven by a pump.•Which Hydra Stream should I use?•Select the size of your Hydra Stream size based on the volume of water to treat. Please refer to the guidelines below.•How do I use a Hydra Stream?•The Hydra Stream is an adapter unit. It is not a complete filter system.•Your Hydra Stream should be connected to a filtration flow system, preferably at the back end after the mechanical or bio-filtration phase, such as at the outlet of a canister filter.•Your Hydra Stream can also be attached with a pump and submerged into a sump tank compartment.•Is Hydra Stream waterproof?•Yes, the Hydra Stream unit is completely waterproof and may be fully submerged.•Does the Hydra Stream have a fix inlet and outlet direction?•The Hydra Stream is designed as a pass-through adapter. Any flow direction is fine.•Can I use a bigger Hydra on a small volume of water?•Yes you may do so. A bigger hydra will be more efficient and will not cause any over-reaction.•Can I use a smaller Hydra on a bigger volume of water?•Yes you may do so, but the efficiency will be reduced on a larger volume of water.•Can it be used in marine tank?•Yes.•Can it be used in freshwater tank?•Yes.•Can it be used in Planted Tank Setup?•Yes. A well balanced nitrogen cycled planted tank may develop algae in the first few days of using Hydra due to the rapid depletion of nutrients. It is advisable to partially change about 10% of the waterto prevent algae growth. The Hydra will stabilize the water quality thereafter.•Will the Hydra kill or react with beneficial bacterial?•Hydro-Pure technology will oxidize bacteria, but all good bacteria needs to adhere to a surface, those floating around free would be very low in number, so Hydro Pure technology will not affect the bio-filtration system.•Hydroxyl (OH) ions produced from the Hydra do not react with or kill live bacteria.•How often do I need to clean my Hydra Internal filter/ Hydra Stream?• A reduction in the flow rate indicates a clogged system. Please clean and maintain the Hydra Internal filter and Hydra Stream on a regular basis.•Does Hydro-Pure Technology affect the pH of the water?•There is no significant effect on pH of the water.•Will Hydra affect any fish medications?•During medication, please switch off the power of the Hydra Stream. For the Hydra Internal filter, please remove the cartridge. This is to prevent Hydra from affecting the medication.•Will Hydra’s reaction affect black water solution?•No.•Will Hydra’s reaction affect vitamins?•No.•Will Hydra’s reaction affect any water conditioner?•No.•Will Hydra’s reaction affect Nature Earth?•No.•Does it mean that it is not necessary to change the aquarium water at all after using the Hydro-Pure Technology products?•Hydro-Pure Technology helps to maintain stable, high-quality water, therefore it will greatly reduce the frequency of water changes. The user will however still need to check the water quality regularly anddetermine if a partial or total water change is necessary.•Does Hydro-Pure Technology help to remove/ prevent algae in the aquarium?•Algae develop due to many factors such as high nitrates, high oxygen and lighting exposure…etc.Different types of Algae need different conditions to grow. Hydro-Pure Technology helps to keep Nitritesand Nitrates at safe and low level, so it should help in algae problems to a certain extent, depending onthe aquarium conditions.•With Hydro-Pure Technology, does it mean that it is not necessary to use bio-media to cultivate beneficial bacteria?•In any aquarium setup, the more filtration media you have, the better it is. It all depends on the aquarium setup and bio-load. Depending on the extent of Hydro-Pure Technology usage, a reducedamount of Bio media will be adequate for the tank system.•Can I modify the hydra’s electro-plates and Cata-Pure cartridges?•No. Do not attempt to modify or use the Hydra in any other way. Serious injury may occur if you do so.•We will not be liable for any damage or injury inflicted due to illegal modifications and improper usage of Hydra Technology.•Will I get an electric shock if I touch the Hydra’s Electro-Plates?•The Electro-Plates are powered by low level DC voltage which is safe and will not cause any electric shock.•However, it is advisable that you switch off the Hydra’s Power whenever you are doing maintenance to it.。

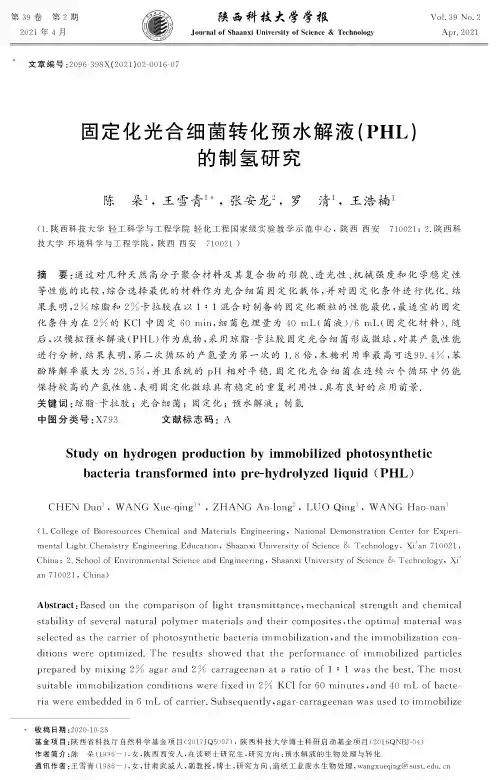

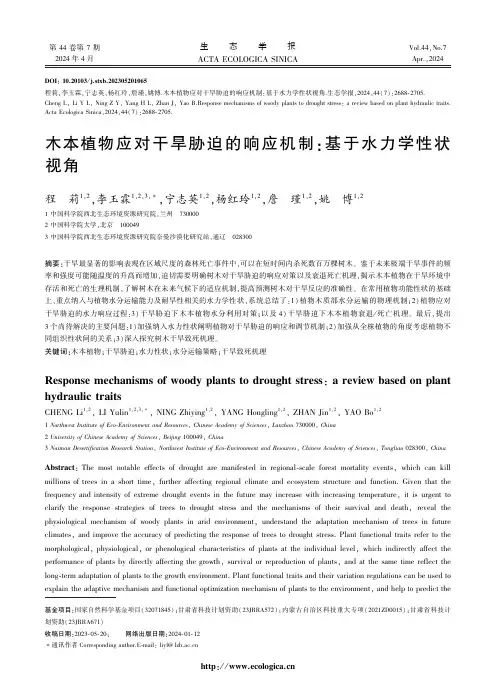

陕西科技大学学报Vol. 39 No. 2Apr 2021第39卷第2期2021年4月Journal of Shaanxi University of Science & Technology文章编号:2096-398X (2021 )02-0016-07固定化光合细菌转化预水解液(PHL )的制氢研究陈 朵】,王雪青1*,张安龙2,罗 清】,王浩楠*收稿日期:2020-10-28基金项目:陕西省科技厅自然科学基金项目(2017JQ5097);陕西科技大学博士科研启动基金项目(2016QNBJ-04)作者简介:陈 朵(1996 — )女,陕西西安人,在读硕士研究生,研究方向:预水解液的生物处理与转化通讯作者:王雪青(1986 —),女,甘肃武威人,副教授,博士,研究方向:造纸工业废水生物处理,wangxueqing@sust. edu. cn(1.陕西科技大学轻工科学与工程学院轻化工程国家级实验教学示范中心,陕西西安710021; 2.陕西科技大学环境科学与工程学院,陕西西安710021 )摘要:通过对几种天然高分子聚合材料及其复合物的形貌、透光性、机械强度和化学稳定性等性能的比较,综合选择最优的材料作为光合细菌固定化载体,并对固定化条件进行优化.结 果表明,2%琼脂和2%卡拉胶在以1 : 1混合时制备的固定化颗粒的性能最优,最适宜的固定化条件为在2%的KCl 中固定60 min,细菌包埋量为40 mL (菌液)/6 mL (固定化材料).随 后,以模拟预水解液(PHL )作为底物,采用琼脂-卡拉胶固定光合细菌形成微球,对其产氢性能进行分析.结果表明,第二次循环的产氢量为第一次的1. 8倍,木糖利用率最高可达99. 4%,苯酚降解率最大为28. 5%,并且系统的pH 相对平稳.固定化光合细菌在连续六个循环中仍能 保持较高的产氢性能,表明固定化微球具有稳定的重复利用性,具有良好的应用前景.关键词:琼脂-卡拉胶;光合细菌;固定化;预水解液;制氢中图分类号:X793文献标志码:AStudy on hydrogen production by immobilized photosynthetic bacteria transformed into pre-hydrolyzed liquid (PHL)CHEN Duo 1 , WANG Xue-qing 1* , ZHANG An-ong 2 , LUO Qing 1 , WANG Hao-nan 1(1. College of Bioresources Chemical and Materials Engineering , National Demonstration Center for Experi mental Light Chemistry Engineering Education , Shaanxi University of Science & Technology , Xi'an 710021 , China ; 2. School of Environmental Science and Engineering , Shaanxi University of Science & Technology, Xi' an710021,China )Abstract : Based on the comparison of light transmittance, mechanical strength and chemicalstabilityofseveralnaturalpolymermaterialsandtheircomposites ,theoptimalmaterialwasselectedasthecarrierofphotosyntheticbacteriaimmobilization ,andtheimmobilizationcon- ditions wereoptimized.Theresultsshowedthattheperformanceofimmobilizedparticlespreparedby mixing2% agarand2% carrageenanataratioof1:1 wasthebest.The most suitableimmobilizationconditionswerefixedin2% KClfor60 minutes ,and40 mLofbacte-riawereembeddedin6mLofcarrier.Subsequently ,agar-carrageenanwasusedtoimmobilize第2期陈朵等:固定化光合细菌转化预水解液(PHL)的制氢研究•17•photosynthetic bacteria to form microspheres and the hydrogen production performance was analyzed in a simulated pre-hydrolyzed solution(PHL).The results showed that the hydrogen production of the second cycle was1.8times that of the first cycle,the utilization rate of xylose and the degradation rate of phenol were up to99.4%and28.5%,respectively,and the pH of the system was relatively stable.The immobilized photosynthetic bacteria can still maintain high hydrogen production performance in six cycles,indicating that the immobilized microspheres have stable reusability and have good application prospects.Key words:agar-carrageenan;photosynthetic bacteria;immobilizition;pre-hydrolysate;hydrogenproduction0引言溶解浆厂是木质纤维素的主要利用者之一⑴,基于生物质精炼的原则在硫酸盐法制浆前需对其进行预水解处理,以抽出原料中的半纤维素[2],因此就如何充分对预水解液中的半纤维素高值化利用已成为当前生物质精炼的热点目前,对半纤维素的利用主要集中在发酵制取乙醇、乙酸、糠醛和木糖醇等物质[12].但是,普遍存在底物转化效率低的问题,主要原因是预处理过程产生的糖类或木素在高温和酸性条件下转化为乙酸、糠醛及酚类等物质[5'6],这些抑制剂对微生物的生长存在严重的抑制作用.利用光合细菌处理预水解液目前尚未见报道,由于光合细菌具有灵活的代谢方式和较高的底物适应性和耐受性[7],其可以利用预水解液中木糖和乙酸等主要碳源,在废水去污的同时实现了有机物的能源转化.Jiaqi Chen等8对光合细菌处理废水的应用范围、生物降解途径以及生物反应器模型进行了综述,提出以光合细菌为基础的技术是满足废水处理可持续发展的潜在替代方法.本课题组⑹前期对光合细菌转化秸秆解聚液的制氢特性进行了研究,发现光合细菌利用水解液具有很好的产氢潜力,最大产氢量为3944.2mL/L,且反应迟滞时间相对较短.Walailak Pattanamanee等[0]选用葡萄糖、木糖和醋酸为主要成分进行混合碳源光发酵产氢的研究,发现在使用水解产物进行光发酵制氢时,气体产量高度依赖于混合碳基质的组成.以上研究结果均表明预水解液作为光合细菌产氢底物的有效可行性.在预水解液作为底物时,为了克服预水解液中抑制剂的问题,需进行发酵前脱毒处理,常用的方法如离子交换[2,1]或灰碱处理⑶等,但是既增加了成本也造成了可利用糖分的损失[12].固定化微生物技术以其为微生物提供更多的保护、简单的细胞活化和良好的操作稳定性[3]等优势引起研究者的广泛关注.但是在选择固定化材料时,需满足无毒、简单易得和物化性能稳定等条件[14].以下三种材料海藻酸钠、琼脂和卡拉胶均为来源于大自然的生物大分子,对微生物无毒性.海藻酸钠是从褐藻或马尾藻中提取碘和甘露醇之后的副产物,当遇到Ca2+时会形成水凝胶,其网络互传结构使其具有良好的成球性和稳定性[15];琼脂是从海藻中提取的多糖体[16],因其较高的稳定性和良好的生物亲和性被视为固定化的理想载体;卡拉胶是从藻类提取出的一种天然凝固剂,具有很好的透明度和稳定性[17].用这三种材料对光合细菌进行固定化,成本较低且操作易行.本文以光合细菌HY01为目标菌株,通过几种天然高分子聚合材料及其复合物的透光性、化学稳定性等性能的比较,遴选出最佳的光合细菌固定化包埋载体,并对其固定化条件进行优化.之后对固定化的光合细菌在模拟预水解液中进行产氢特性分析,分析固定化细菌的产氢性能、对碳源的利用能力、对毒性物质的耐受性以及其循环特性.固定化光和细菌转化预水解液制氢不仅实现了光发酵一步法转化制氢,而且为预水解液的高值化利用提供了新的途径.1实验部分1.1实验菌株和培养条件1.1.1实验菌株实验使用的光发酵产氢菌株球形红细菌Rhodobacter sphaeroides HY01为实验室保藏菌种.1.1.2培养条件(1)MPYE生长培养基(/L):CaCl1g, MgCl1.6g,酵母提取物3g,鱼粉蛋白胨3g.(2)MedA产氢培养基(/L):D木糖6g,L-谷氨・18・陕西科技大学学报第39卷酸1.25g,10%NaCl10mL,氮川三乙酸10g,CaCl23.33g,MgSO4・7H2O29.5g,(NH4)6Mo7O24・4H2O93mg,FeSO4・7H2O99mg,微量元素溶液20mL,溶液灭菌后用微孔滤膜加入维生素溶液10mL,磷酸盐缓冲溶液20mL.(3)模拟预水解液的组成(/L):木糖、乙酸和苯酚碳的摩尔质量分别为162.5mmok25mmol 和125mmol.1.2实验菌株和培养条件1. 2.1光合细菌的活化与富集在一80C低温储存箱中取出冻存液,通过双层平板划线法,用纯木质接种棒蘸取冻存液进行平板划线,在恒温培养箱中培养72h,挑取平板上的单菌落接种至25mL的MPYE生长培养液中,将离心管置于30C,200rpm恒温摇床中富集培养,培养至对数生长期取出,调节菌液吸光度OD600=0.8士0.02,离心收集菌体备用.1. 2.2固定化载体的制备与选择分别配备海藻酸钠、琼脂、卡拉胶凝胶,用注射器缓慢吸取凝胶,避免产生气泡,悬空滴加到交联剂中形成小球即为载体的制备•固定好的小球用磷酸盐缓冲溶液冲洗三遍•对固定化载体进行透光性、机械强度和重复性等性能评判,综合选择最佳的固定化载体.1. 2.3固定化光合细菌微球的优化和产氢设置琼脂-卡拉胶不同的体积比例:2:4、2.5:3.5、3:335: 2.5、4:2;不同的交联剂浓度: 1%、2%、3%、4%;不同的细菌接种量:10mL、20 mL、30mL、40mL、50mL;不同的固定化时间:30 min、60min、90min、120min,来探究光合细菌固定化时的最佳条件.1.3分析方法采用比浊法对培养液中的生物量进行测定(OD600);固定化颗粒的透光性参考张念一等[8]的方法,采用拉压力测试仪测定固定化载体的机械强度;DNS法[9]测定培养液中还原糖的含量;4-氨基安替比邻比色法来测定苯酚的含量[0].所有实验均设置三个平行样.2结果与讨论2.1光合细菌固定化载体SEM形貌特征分别采用海藻酸钠、琼脂粉、卡拉胶、海藻酸钠-琼脂和琼脂-卡拉胶制作固定化小球,其SEM 形貌如图1所示.(a)海藻酸钠载体(f)海藻酸钠固定的HY01(b)琼脂载体(g)琼脂固定的HY01(d)海-琼复合载体(i)海-琼固定的HY01(e)琼-卡复合载体(j)琼-卡固定的HY01不同材料及其固定化HY01的SEM图图1图1(a)〜(e)表示没有负载细菌时固定化载体.可以看出,海藻酸钠(如图1(a)所示)的形貌为较为细小的丝网状结构,但是形态结构不太规则;琼脂(如图1(b)所示)的结构为较为规则的层状结构,并且表面光滑,但光滑的表面会减少细菌的附着点;卡拉胶(如图1(c)所示)具有网状结构的形貌,网孔大小从100毺m到400毺m不等;海藻酸钠-琼脂复合固定化载体(如图1(d)所示)和单一琼脂的表面结构相比,加入海藻酸钠后,琼脂表面变得粗糙但仍保持其原有的结构;从图1(e)可以明显地看出,琼脂-卡拉胶固定化载体同时具备琼脂的层状规则孔隙和卡拉胶的网状结构,卡拉胶的添加,缩小琼脂层状大孔结构的同时,也为细菌的固定化提供了更大的比表面积•图1(f)〜(j)表示固定化载体上的光合细菌分布情况•五种不同固定化载体的细菌分布具有很明第2期陈朵等:固定化光合细菌转化预水解液(PHL)的制氢研究・19・显的差异,琼脂凝胶上的光合细菌(如图1(g)所示)数量明显少于其他几种固定化载体,原因是琼脂的结构特点造成了细菌有较为严重的泄露;光合细菌在海藻酸钠中(如图1(f)所示)虽然可以稳定的生长增殖,但是其自身对pH的敏感性[1]导致在循环利用时便会出现颗粒变软甚至破碎的现象,这将对固定化实验带来很不利的影响;海藻酸钠-琼脂固定的光合细菌(如图1⑴所示)出现明显的分布不均现象;琼脂和卡拉胶固定化载体(如图1 (j)所示)使得光合细菌均匀的固定于载体当中,是固定化载体的良好选择.2.2光合细菌固定化包埋载体的选择对于光合细菌来说,理想的固定化载体应该是具有无毒性、良好的透光性、较高的机械强度以及优良的可循环利用性等优点[2].以木糖为唯一碳源时,固定化光和细菌的产氢结果如图2所示.实验结果可知,海藻酸钠和卡拉胶作为固定化载体时产氢量相近,但是随着时间的延长,小球的形态会变得疏松甚至破碎,说明可循环性较差.琼脂作为固定化载体时表现出良好的产氢性能,但游离的细菌对产氢量贡献较大.还观察到琼脂和卡拉胶混合后固定化细菌的产氢量和重复稳定性明显优于二者单独固定时性能.复合材料作为载体时通过键的断裂和结合或物理作用使得新的材料具有更好的机械性能和循环稳定性[3]・图3为不同载体固定化小球的机械强度测试琼脂凝胶具有足够大的机械强度,可达6.8N;卡拉胶在单独作为固定化载体时机械强度较低,当琼脂和卡拉胶复合之后的机械强度界于二者单独使用时之间•图4表示固定化小球的透光性测试,良好的透光性有助于光合细菌增加传质效率,卡拉胶的透光性明显大于其他载体材料,同时还发现,琼脂和卡拉胶复合之后的透光性比琼脂提高了 2.8倍.由于各类废水的化学条件都比较复杂,对不同材料固定化小球的化学稳定性进行测试如表1所示,当固定化小球在酸性和盐性环境中停留4h之后,海藻酸钠小球会变得易碎且结构松散;琼脂-卡拉胶复合的化学稳定性比较稳定.综合比较而言,卡拉胶具有良好的透光性,并且化学稳定性适中;琼脂作为固定化载体时化学稳定性较好,且在循环使用中表现出稳定的产氢性能;鉴于二者的优点,将琼脂和卡拉胶复合作为固定化材料时,不仅解决了琼脂透光性较差的缺陷同时,还减少细菌的泄露,而且复合材料固定化光合细菌体现出了较强的产氢性能和稳疋的循环利用性.ooooooOooooooO5555332211'uoppnpojdu①mojpah1st2nd3rd4th2图SA Agar Car Agar+SA Agar+CarThe carrier for immobilization不同材料化固定HY01的产氢结果图87654321Agar Car SA+Agar Car+Agar[]Mechanical Strength3图不同固定化材料的机械强度The carrier for immobilizationSA Agar Car SA+Agar Car+AgarThe carrier for immobilization图4不同固定化材料的透光率表1固定化材料的化学稳定性比较载体HCl NaOH NaCl Na2HPO4SA-0----Agar0+0+Car--++++ SA+Agar0--0Car+Agar-++++注:“一一”表示颗粒结构松散,易碎;“一”表示颗粒略变软,弹性下降;“0”表示颗粒未发生明显变化;“+”表示颗粒变硬,强度增加.2.3光合细菌固定化条件的优化以琼脂-卡拉胶为固定化载体,对其最佳的固定化条件进行优化,结果如图5所示.实验操作为:・20・陕西科技大学学报第39卷将离心收集好的菌体加入到浓度分别为2%的琼脂-卡拉胶的混合凝胶中(共6mL),采用涡旋仪震荡混合均匀,用注射器缓慢吸取5mL,避免产生气泡,滴加小球到KCl交联剂中固定化,固定化之后的微球用磷酸盐缓冲溶液冲洗三遍,产氢反应在50mL注射器中进行.选择细菌接种量、固定化时间、交联剂浓度和琼脂-卡拉胶的配比进行实验,最终确定最佳的固定化条件•2. 3.1接种量对固定化产氢的影响取OD660为0.8士0.02的菌液离心后与琼脂-卡拉胶凝胶混合均匀,制作小球进行产氢.如图5 (a)所示,当接种量过低时,光合细菌生长缓慢,导致产氢量较低;而当接种量为50mL时,细菌在培养基中对营养物质进行竞争•因此,选用40mL的细菌接种量进行实验.2. 3.2固定化时间对固定化产氢的影响固定化时间对固定化载体的强度和细菌活力都会产生影响,固定化时间太短可能会导致载体强度不够、容易破碎、细菌容易泄露;固定化时间过长使凝胶结构太致密,不利于细菌对底物的利用[4]・从图5(b)可以看出,固定化时间对产氢量的影响不是很大,但是随着固定化时间的延长,产氢量出现先上升后下降的趋势,且在固定化时间为60 min的时产氢量最高•因此选取60min为后续实验的固定化时间•2.3.3交联剂浓度对固定化产氢的影响毷型卡拉胶由于结构单元富含硫酸酯键一O—SO厂,因此可与交联剂KCl中的K+共价结合形成结构稳定的凝胶,K+浓度对固定化载体的强度和细菌的活性会产生较大的影响[4].如图5(c)所示,当KCl 浓度较低时,产氢量较低,因为制备的固定化载体结构不稳定,容易破裂•当交联剂浓度过高时,产氢量出现快速下降,是因为固定化载体的结构比较致密,传质性能变差;另外过高的K+浓度可能会导致细菌的细胞膜内外出现浓度差,会对细菌造成伤害.因此最终选择交联剂浓度为2%.2. 3.4琼脂-卡拉胶配比对固定化产氢的影响图5(d)为琼脂和卡拉胶在不同配比下固定化光合细菌的产氢量对比,当卡拉胶比例过高时(2:4)产氢量明显降低.过多的卡拉胶对琼脂形成了包覆作用,再加以KCl的交联作用使得载体表面形成了坚硬的包覆膜,严重影响了细菌的生长和底物的传质性能•当琼脂配比过高时(4:2),在产氢的体系中有较高的细菌浓度,说明细菌有明显的泄露•因此选择3:3的配比进行后续实验•O004旦'uoppnpojduebnOHPAH0053300(00520020015010000o10203040Bacterial load/mL(a)细菌接种量50OOOOOOOOOOOOOOOO55554332211目'uoppnpojdu①UOHPAH壬壬(b)固定化时间o*_―――306090120Time/min旦'UOHunpoJduebnOJPAH(d)琼脂-卡拉胶配比图5光合细菌固定化产氢条件的优化2.4木糖和苯酚混合物作为碳源时固定化细菌的产氢性能第 2 期陈 朵等:固定化光合细菌转化预水解液(PHL)的制氢研究・21・在硫酸盐预水解液中存在少量的酚类物质(约1〜2 g/L)[4],通常用苯酚作为模型化合物来替代酚类物质•前期实验得知游离光合细菌对苯酚的耐 受阈值为500 mg/L,因此选用500 mg/L 的苯酚 与木糖作为双碳源进行产氢性能的探究•如图6所示,初期光合细菌对底物的利用受到传质效率等因 素的限制,基质不能达到固定化小球内部[5],导致产氢量较低,苯酚和木糖的利用效果不明显•然而,在2〜4次循环产氢时,产氢量有明显的提升,第二次的累积产氢量可达到3 463. 2 mL/L,木糖利用 率(95. 7%)和苯酚降解率(24. 3%)也达到最大值.可见固定化的光合细菌对产氢基质有很好的适应性 和利用性,并且重复使用6次后产氢量为2 230. 8mL/L,具有很好的稳定性.相比于游离态细菌产氢(pH = 5. 9),固定化之后的细菌的对系统的pH 有更大的适应范围(pH = 4. 88),此结论与孙丽慧 等[5]的实验发现相一致•OOP 53态在光合细菌加入之后变得粗糙•图7(d)是在模 拟PHL 中产氢反应两个循环周期后的固定化微球的断面图图像,可以看出长时间的培养产氢使细 胞显著生长,从而占据了整个微球的内表面,这表 明细菌在微球内具有很高的生物附着量.(d)(a)琼脂-卡拉胶微球的形貌图(b)琼脂-卡拉胶微球的断面结构(c)琼脂-卡拉胶微球负载细菌后断面结构(d)循环2次后断面图(e)细菌的分布图图7 固定化细菌微球的SEM 图旦、u.24unpoJdue b£)OJPAHOOF 300OOF 250OOF 200150looOOF5B2. 6 模拟PHL 为碳源时的产氢性能图8(a)〜(e)分别表示固定化光合细菌在PHL 中的累计产氢量、末端pH 值、溶液中的游离细菌浓度、苯酚和木糖利用率的对比图•(a)以木糖-苯酚为碳源时固定化细菌的产氢量和pH 值L I 30L I52L I20L I1584*1 84*284*3 84*484*5 84*6Cycle(b)木糖和苯酚混合碳源时底物的利用率图6 木糖-苯酚为碳源时固定化细菌的产氢性能-★- Phenol —0—Xylose乞、oU O R e p e ^e p O S O I A X908070602. 5 固定化光合细菌利用PHL 产氢SEM 图以固定的琼脂-卡拉胶微球为研究对象,对其进行电镜扫描如图7所示.从图7(a)〜(c)可以观察到,琼脂-卡拉胶微球直径约4 mm ;未固定光合细菌的琼脂-卡拉胶凝胶珠表面光滑,这些交联形(a)产氢量(b)产氢结束培养液的pH 值(c)游离细菌浓度(d)苯酚利用率(e)木糖利用率图8 以模拟PHL 为碳源时固定化细菌的产氢性能L一、①l e A O U I①.io u ① qd・22・陕西科技大学学报第39卷首先,与游离态光合细菌利用PHL产氢相比,初始固定化的细菌不如游离态时的产氢量大(6420.6mL/L),但在重复第二次实验时,产氢量要大于游离状态,并且第三次和第四次重复时仍然表现出较为稳定的产氢性能(如图8(a)所示);其次,发酵产氢末端的pH值维持在6.3—6.4(如图 8(b)所示),产氢量的增加与产氢过程中培养液的pH值较为稳定有很大的关系.在PHL产氢系统中,除了木糖作为主要碳源之外,还存在一定的小分子酸,乙酸的转化利用会提高系统的pH,两种碳源的协同作用让产氢系统更稳定,产氢周期更长,产氢量更大;值得一提的是系统中苯酚的去除率最大可达到2&5%,木糖利用率相对比较稳定,基本上都在95%以上(如图8(d)和8(e)所示);最后,对产氢结束的细菌浓度进行测量,可以看出在整个循环过程中细菌泄露量较少(如图8(c)所示),说明所制备的固定化载体具有很好的循环使用性能,具有很好的应用前景.3结论本文通过比较不同天然高分子聚合物固定化材料海藻酸钠、琼脂、卡拉胶等作为载体来固定光合细菌,从细菌的生长适应性、透光性、机械强度和稳定性等方面确定了最佳的固定化材料为琼脂-卡拉胶,而后通过条件优化得出最佳固定化条件.并研究了木糖和500mg/L苯酚作为底物时的产氢性能,重复六个周期都具有比较稳定的产氢性能,且固定化细菌和游离态细菌相比对苯酚的耐受性有明显提升.最后,对固定化光合细菌在模拟PHL中的产氢性能进行研究,得知木糖利用率可达99.4%,苯酚降解率为2&5%,并且预水解液中的复合碳源对系统的pH具有自平衡作用是产氢性能提高的另一个原因.固定化光合细菌转化预水解液制氢不仅实现了光发酵一步法制氢,而且为预水解液的高值化利用提供了一定的理论基础.参考文献[1]YangS,WenY,Zhang H,etal.Enhancingthefockreac-tivityofdissolvingpulpbythecombinedprerefiningandpolydimethyldia l ylammoniumchloride-assistedce l ulasetreatment[J].BioresourceTechnology,2018,260(6):135-140.[2]ShenJ,KaurI,Baktash M M,etal.Acombinedprocessofactivatedcarbonadsorption,ionexchangeresintreatmentand membraneconcentrationforrecoveryofdissolvedor-ganicsin pre-hydrolysisliquorofthekraft-based dissol-vingpulpproductionprocess[J].BioresourceTechnology,2012,127(19):59-65.[3]Zheng Y,ZhaoJ,Xu F,etal.Pretreatmentoflignoce l u-losicbiomassforenhancedbiogasproduction[J].Progress inEnergyandCombustionScience,2014,42(2):35-53. [4]ChenJ,DongJ,YangG,etal.A processforpurifyingxy-losugarsofpre-hydrolysisliquorfrom kraft-baseddissol-ving pulp production process[J].Biotechnol Biofuels, 2018,11(1):337-349.[5]KaurI,NiY.Aprocesstoproducefurfuralandaceticacidfrom pre-hydrolysisliquorofkraftbaseddissolvingpulp process[J].SeparationandPurificationTechnology,2015, 146(6):121-126.[6]Du t aS,DeS,Alam MI,etal.Directconversionofce l u-lose and lignocellulosic biomass into chemicals and biofuel with metalchloride catalysts[J].Journalof Catalysis, 2012,288(3):8-15.[7]ZhangJ,YuanJ,Zhang W X,etal.Anaerobicdetoxifica-tionphotofermentationbyrhodospiri l umrubrumforcon-verting soy sauceresidueintofeed with moderate pre-treatment[J].World Journal of Microbiology&Biotech-nology,017,3(10):184-195.[8]ChenJ,WeiJ,MaC,etal.Photosyntheticbacteria-basedtech-nologyisapotentialalternativetomeetsustainabletreatment requirement[J].EnvironmentInternational,2020,137(4): 105417-105436.[]张安龙,王晔,王雪青,等.光合细菌利用秸秆解聚液制氢的优化研究:J].陕西科技大学学报,2018,36(1):17-22.[10]Pa t anamanee W,ChistiY,Choorit W.PhotofermentivehydrogenproductionbyrhodobactersphaeroidesS10u-sing mixedorganiccarbon:E f ectsof mixturecomposi-tion[J].AppliedEnergy,2015,157(16):245-254.[11]Baktash M M,Ahsan L,Ni Y.Production offurfuralfrom an industrial pre-hydrolysis liquor[J].SeparationandPurification Technology,2015,149(11):407-412. [12]Sivagurunathana P,Kumarb G,Mudhooc A,etal.Fer-mentativehydrogenproductionusinglignoce l ulosebio-mass[J].Renewableand Sustainable Energy Reviews,2017,77(7):28-42.[13]MaZ,LiC,Su H.Darkbio-hydrogenfermentationbyanimmobilized mixed culture of baci l uscereusand bre-vumdimonas naejangsanensis[J].Renewable Energy,2016,105(24):458-464.[14]BouabidiZB,ElNaas M H,ZhangZ.Immobilizationofmicrobialce l sforthebiotreatmentofwastewater:Are-view[J].EnvironmentalChemistryLe t ers,2018,17(1):241-257.[15]孙丽慧,沈爱萍,何宝龙.海藻酸钠-聚乙烯醇-活性炭共固定化重组大肠杆菌细胞[].中国食品学报,2015,15(2):21-27.[16]Pansook S,Incharoensakdi A,Phunpruch S.Enhanceddark fermentative H2production by agar-immobilizedcyanobacterium aphanothece halophytica[J].Journal of AppliedPhycology,2019,31(5):2869-2879.(下转第49页)第2期张乐乐等:魔芋多糖膳食纤维特性及其对糖代谢作用研究•49•[6]S.Ou,K.Kwok,Y.Li,et al.In vitro study of possible roleof dietary fiber in lowering postprandial serum glucose [J].Journal of Agricultural and Food Chemistry,2001,49(2):1026-1029.[]李恒.中国磨芋属的分类问题[].植物分类与资源学报,998,20(2):167-170.[]尉芹,马希汉•魔芋开发利用研究综述[]•西北林学院学报,1998,13(3):62-67.[]魏恩慧,吴继红,刘冰,等.魔芋葡甘聚糖的性质及在食品中的应用[].食品工业,016,7(5):239-241.[0]李宁,江骥,胡蓓.复合膳食纤维对健康受试者血糖及血脂的影响[].中国临床营养杂志,007,5(6):351-354.[1]向明,张晓煜,五三兰,等.魔芋葡甘聚糖对链脲霉素致大鼠糖尿病的防治作用[]•中国医院药学杂志,005,5(3):223-225.[12]V.Vuksan,J.L.Sievenpiper,Z.Xu,t al.Konjac-mannanand american ginsing:Emerging alternative therapies for type2diabetes mellitus[J].Journal of the American College of Nutrition,2001,20(S5):370-380.[3]R. D.Devaraj,C.K.Reddy,B.Xu.Health-promotingeffects of konjac glucomannan and its practical applica-tons:Acriticalreview[J].InternatonalJournalofBio-logicalMacromolecules,2019,126:273-281.[4]刘红.魔芋葡甘聚糖对肥胖及糖尿病小鼠的治疗作用:J].营养学报,002,4(4):437438.[5]杨大伟,王禹琦,午丽君,等.会同魔芋的干燥特性及其品质研究JJ]•农产品加工,018(9):4-69[6]邓利玲,徐小青,杨延迅,等.珠芽魔芋精粉的理化性质[]•食品科学,013,4(17):120-125.[7]张雯.基于胶原蛋白/细菌纤维素多孔微球的制备及药物吸附释放行为研究[D].西安:陕西科技大学,019[8]GB/T24401-2009,-淀粉酶制剂[S].[9]李瑞,杜双奎,李志西,等.细菌纤维素水悬浮液的流变特性[J].农业工程学报,014,30(11):285-292.[0] B.Koroskenyi,S.P.McCarthy.Synthesis of acetylatedkonjac glucomannan and effect of degree of acetylation on water absorbency]J].Biomacromolecules,2001,2(3):824-826.【责任编辑:蒋亚儒】(上接第22页)[17]Ke Q,Zhang Y,Wu X,et al.Sustainable biodegradationof phenol by immobilized Bacillus sp.SAS19with porous carbonaceous gels as carriers[J].Journal of Environmen-talManagement,2018,222(10):185-189.[8]张念一,黄秀晶,张青松.化学/离子交联水凝胶的透光度溶胀行为和力学性能[]•高分子材料科学与工程,014, 30(4):64-69.[9]王俊丽,聂国兴,李素贞.DNS法测定还原糖含量时最适波长的确定[].河南农业科学,010,(3):115118. [0]刘丁睿.苯酚含量分析方法的对比[].石化技术,2012,19(3):8-11.[1]Zhang H,Chen G,Zhang Q,t al.Photosynthetic hydrogen production by alginate immobilized bacterial consortium JJ].Bioresource Technology,2017,236(6):44-48. [2]Chuaphasuk C,Prapagdee B.Effects of biochar-immobilized bacteria on phytoremediation of cadmium-pollutedsoil[J].Environ Sfi Pollut Res Int,2019,26(23):23679- 23688.[3]徐梦洁,张秀梅,胡银春.双交联聚乙烯醇/海藻酸钠水凝胶的制备与表征:J].高分子材料科学与工程,2020,36(4):55-60.[24]Gonzalez Bautista E,Santana Morales J C t Rios FranquezF J,et al.Phenolic compounds inhibit cellulase and xyla-nase activities of cellulomonas flavigena PR-22during saccharification of sugarcane bagasse[J].Fuel,2017,196(2):32-35.[5]Singh B,Kumar P,Yadav A,et al.Degradation of fermentation inhibitors from lignocellulosic hydrolysate liquor using immobilized bacterium]〕].Chemical Engineering Journal,019,61(24):1152-1160.【责任编辑:陈佳】。

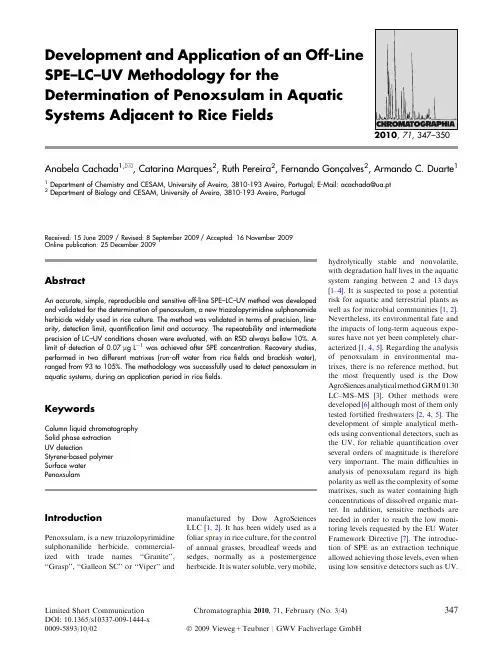

Development and Application of an Off-LineSPE–LC–UV Methodology for theDetermination of Penoxsulam in AquaticSystems Adjacent to Rice FieldsAnabela Cachada1,&,Catarina Marques2,Ruth Pereira2,Fernando Gonc¸alves2,Armando C.Duarte1 1Department of Chemistry and CESAM,University of Aveiro,3810-193Aveiro,Portugal;E-Mail:**************2Department of Biology and CESAM,University of Aveiro,3810-193Aveiro,PortugalReceived:15June2009/Revised:8September2009/Accepted:16November2009Online publication:25December2009AbstractAn accurate,simple,reproducible and sensitive off-line SPE–LC–UV method was developedand validated for the determination of penoxsulam,a new triazolopyrimidine sulphonamideherbicide widely used in rice culture.The method was validated in terms of precision,line-arity,detection limit,quantification limit and accuracy.The repeatability and intermediateprecision of LC–UV conditions chosen were evaluated,with an RSD always bellow10%.Alimit of detection of0.07l g L-1was achieved after SPE concentration.Recovery studies,performed in two different matrixes(run-off water from ricefields and brackish water),ranged from93to105%.The methodology was successfully used to detect penoxsulam inaquatic systems,during an application period in ricefields.KeywordsColumn liquid chromatographySolid phase extractionUV detectionStyrene-based polymerSurface waterPenoxsulamIntroductionPenoxsulam,is a new triazolopyrimidine sulphonanilide herbicide,commercial-ized with trade names‘‘Granite’’,‘‘Grasp’’,‘‘Galleon SC’’or‘‘Viper’’and manufactured by Dow AgroSciencesLLC[1,2].It has been widely used as afoliar spray in rice culture,for the controlof annual grasses,broadleaf weeds andsedges,normally as a postemergenceherbicide.It is water soluble,very mobile,hydrolytically stable and nonvolatile,with degradation half lives in the aquaticsystem ranging between2and13days[1–4].It is suspected to pose a potentialrisk for aquatic and terrestrial plants aswell as for microbial communities[1,2].Nevertheless,its environmental fate andthe impacts of long-term aqueous expo-sures have not yet been completely char-acterized[1,4,5].Regarding the analysisof penoxsulam in environmental ma-trixes,there is no reference method,butthe most frequently used is the DowAgroSiences analytical method GRM01.30LC–MS–MS[3].Other methods weredeveloped[6]although most of them onlytested fortified freshwaters[2,4,5].Thedevelopment of simple analytical meth-ods using conventional detectors,such asthe UV,for reliable quantification overseveral orders of magnitude is thereforevery important.The main difficulties inanalysis of penoxsulam regard its highpolarity as well as the complexity of somematrixes,such as water containing highconcentrations of dissolved organic mat-ter.In addition,sensitive methods areneeded in order to reach the low moni-toring levels requested by the EU WaterFramework Directive[7].The introduc-tion of SPE as an extraction techniqueallowed achieving those levels,even whenusing low sensitive detectors such asUV.2010,71,347–350This work describes a method based on off-line SPE–LC–UV to determine penoxsulam in agricultural drainage and brackish water.Parameters such as cali-bration linearity,limits of detection and quantification,precision and accuracy, were investigated.Finally,the concen-tration of penoxsulam infield samples was monitored.ExperimentalChemicalsAcetonitrile(ACN)(LC grade)waspurchased from Labscan and acetic acid(100%)from Merck.Only ultra purewater freshly produced by a MilliporeMilli-Q system was used in all analyticalexperiments.Mobile phases werefilteredunder vacuum through a0.2l m poly-amide membranefilter(Whatman)anddegasified in an ultrasonic bath.Penoxsulam(2-(2,2-difluoroethoxy)-N-(5,8-dimethoxy[1,2,4]triazolo[1,5-c]pyrimi-din-2yl)-6-(trifluoromethyl)bezenesulfona-mide)was kindly provided by DowAgroSciences LLC(analytical grade,ref.TSN104882).A stock standard solution(100mg L-1)was prepared in ACN andstored at-18°C.Calibration standardswere prepared by dilution of the stocksolution with the mobile phase,in con-centrations of0.10,0.25,0.50,0.75and1.0mg L-1.The sorbent used was astyrene-based polymer,Sepra SDB-L(95l m,255A,bulk sorbent),purchasedfrom Phenomenex.InstrumentationThe analytical instrumentation includedan LC Jasco model with a Rheodyne7125injector and a loop size of50l Lcoupled to a fast scanning UV detector(UV Chrom-A-Scope,BarSpec)operat-ing between190and370nm.Acquisi-tion was performed at205nm andstarted at5min until12min.The ana-lytical column used was a Supelcosil LC-8(15094.6m,5l m,120A),with aguard column of the same material.Chromatographic ConditionsThe temperature of the analytical col-umn was set to30°C.The mobile phaseselected consisted of water acidified with0.01%of acetic acid and40%of ACN ataflow rate of1mL min-1.In order toclean-up the column between samples,an elution gradient was used:100%ofmobile phase from0to12min,100%ACN at15min(during2min)andagain100%of mobile phase at18min.Each standard was injected twice andcalibration curves were constructedevery day.Quantification was performedby external calibration by measuring thepeak areas.The LOD was calculatedbased upon an S/N ratio of3:1,whereasthe LOQ was calculated based upon anS/N ratio of10:1.In order to assure thecorrect identification of the compoundthree techniques were used:co-chroma-tography(samples spiked with increas-ing amounts of standard and injected tothe LC system),peak spectrum(by usinga fast scanning UV detector)and reten-tion time comparison to those of thestandards.Water Samples ExtractionProcedureSamples werefiltered through a0.45l mnylon membrane(from Whatman)andextracted by SPE.Cartridges containing500mg of Sepra SDB-L sorbent werepreviously rinsed with4mL of methanoland conditioned with4mL of water.1Lof sample was then passed though thecartridge,via a vacuum manifold at10mL min-1.After loading the sampleinto the SPE cartridge,it was washed with4mL of methanol:water(5:95)and driedunder vacuum for30min.The herbicidewas eluted with5mL of ACN containing0.1%of acetic acid.The eluate was evap-orated to dryness by means of a rotaryevaporator(40°C),dissolved in3mL ofACN,transferred to a vial and thenevaporated again to dryness under a gen-tle stream of nitrogen.The residue wasthen redissolved in250l L of mobilephase and injected into the LC instrument.Results and DiscussionChoice of AnalyticalConditions for LC–UVSeveral mobile phases(water acidifiedwith formic acid or acetic acid,withdifferent proportions of ACN)and dif-ferent solvents for sample dissolution(ACN,50%ACN and mobile phase) were tested,using a standard of0.5mg L-1.The selection of mobile phase and samples dissolution was based on optimal peak shape.Figure1a shows the chromatogram of a standard using the selected conditions.The choice of the optimum wavelength for acquisi-tion(205nm),was based on the peak spectrum(Fig.1c).The precision of the method was examined by carrying out a repeatabilityand an intermediate precision study at three levels of concentration(0.25,0.75 and1.0mg L-1),with three consecutive injections during the same day and on three different days.Results presented in Table1show that the method is repeat-able for the same day and in day-to-day injections but,as observed in other works [8],RSD increases in the latter.Calibration curve was obtained by injecting each standard(n=5)three times.Good linearity was observed over the range tested(Table1),and the determination coefficient(r2)was always higher than0.9958(p<0.05).Table1 also shows other calibration parameters such as calibration equation,standard deviation of residuals(Sy/x),LOD (0.06mg L-1)and LOQ(0.20mg L-1). Water Samples ExtractionThe choice of extraction procedure(sor-bent used,pH,elution solvents)was based on previous studies performed with polar pesticides[4,8–12].In order to study the effect of SPE on the analysis of penoxsu-lam,a calibration curve was constructed by analysingfive calibration levels of fortified MQ water.Therefore,1L of spiked MQ water,with concentrations ranging from0.025to0.25l g L-1was extracted,and concentrated to250l L. The calibration curve obtained after pre-concentration using the selected method (Y=(39,421±2,051)X,r2=0.996) does not differ(t test,p=0.255)from the one presented in Table1,meaning that the SPE procedure is not affecting the determination of penoxsulam.The LOD and LOQ in water samples before pre-concentration was evaluated as0.02and 0.07l g L-1,respectively.Hence,this method can be considered very sensitive[3,6].Figures of Merit of theAnalytical ProcedureThe method was further evaluated for itsaccuracy and precision by analyzingspiked samples collected in a canalreceiving drainage water from ricefieldsand in a nearby estuary.Spikes wereprepared at three levels(0.1,0.5,2l gL-1),allowed to equilibrate for2h[12]and extracted.The method was accurateand precise,with the mean recovery(n=3)of penoxsulam obtained for theagricultural drainage water ranging from98(for0.5and2l g L-1)to105%(for0.1l g L-1).The RSD was below10%for all three levels:2%for0.1l g L-1;8%for0.5l g L-1;and5%for2l g L-1.The recoveries for brackish water rangedfrom93(for0.5and2l g L-1)to101%(for0.1l g L-1),and the RSDs were3,5and4%respectively.No interference was observed whenanalyzing control blanks and controlfield samples in both types of samples(Fig.1b shows the chromatograms foragricultural drainage water).The slopingbaseline observed infield samples(Fig.1b)is most likely due to the pres-ence of humic acids in a high level as aresult of the concentration factor ob-tained.Besides,as shown in Fig.1c,theUV spectrum at the specific retentiontime of penoxsulam did not show anyinterference.The increase of absorbanceat higher wavelengths may be due to thepresence of compounds with higheraromaticity and complexity such ashumic like substances.Application of the AnalyticalProcedures and LimitationsIn order to verify the applicability of theanalytical procedure in real environ-mental samples,agricultural drainagewater samples were collected during theapplication period of penoxsulam.Sam-ples were collected from one location,before(day0)and over7days after thebeginning of applications.A relative highrange of concentrations was observed:from non-detectable levels(before appli-cation)to2.3l g L-1(6th day).It waspossible to verify the existence of twopulses of application,on day1(0.36l g L-1)and day6,and a quickdecrease of concentrations observed inthe following days(0.10l g L-1on day4and0.8l g L-1on day7).ConclusionsThis method allows the quantification oflow concentrations(LOQ=0.07l gL-1)of penoxsulam in agricultural run-offwater and brackish water.Themethod described is precise(RSD rang-ing from2to8%)and accurate(recov-eries between93and105%).Thedifficulty of attribution of the chro-matographic peak to penoxsulam can bepartially overcome by comparing the UVspectra of samples with the UV spectraof pure penoxsulam.SPE–LC–UV is asimple,cheap and robust method whichallows achieving low monitoring levelsby pre-concentration of samples.Thismethod can therefore be used as analternative for monitoring purposes andfor studies of penoxsulam behaviour inthe aquatic environment.Table1.Results of the repeatability study in terms of retention time(RT),area,and calibration parametersRT(min)Intra-dayprecison a(RSD%)Day-to-dayprecision a(RSD%)Calibrationcurver2Sy/x LOD(mg L-1)LOQ(mg L-1) RT Area RT Area8.630.85 1.4 5.18.3Y=(40,919±2,245)X0.99581,1280.060.20a Data given for0.25mg L-1AcknowledgmentsThis work was supported by FCT (Fundac a o para a Cie ncia e Tecnologia), through a PhD grant attributed to A. Cachada(SFRH/BD/38418/2007),and by CESAM.The authors would like to thank Dow AgroSciences LLC for kindly providing the penoxsulam ana-lytical standard.ReferencesEPA(United States EnvironmentalProtection Agency)(2004)Pesticide factsheet:penoxsulam.Office of Prevention,Pesticides and Toxic Substances(7501C),Washington,USA2.Jabusch TW,Tjeerdema RS(2005)JAgric Food Chem53:7179–7183.doi:10.1021/jf050767g3.Roberts DW,Knuteson JA,Jackson R(2003)In:Pesticide in air,plant,soil,&water system.Proceedings of the XIISymposium pesticides chemistry.Piacen-za,Italy,pp.349–3574.Jabusch TW,Tjeerdema RS(2006)JAgric Food Chem54:5962–59675.Koschnick TJ,Netherland MD,HallerWTJ(2007)J Aquat Plant Manag45:47–516.Rubio DR,Kamp LM,Heilman M,Williams L,Rubio FM(2008)J AgricFood Chem56:7606–7612.doi:10.1021/jf80102737.EC(European Commission)(2000)Directive2000/60/EC of the EuropeanParliament and of the Council of23October2000establishing a frameworkfor community action in thefield of waterpolicy.OJ L327,pp1–728.Rodrıguez-Delgado MA,Herna ndez-Borges J(2007)J Sep Sci30:8–14.doi:10.1002/jssc.2006002719.Thorstensen CW,Lode O,ChristiansenAL(2000)J Agric Food Chem48:5829–583.doi:0.1021/jf000012410.Quintana J,Marti I,Ventura FJ(2001)J Chromatogr A938:3–1311.Tran ATK,Hyne RV,Doble P(2007)Chemosphere67:944–995.doi:10.1016/j.chemosphere.2006.11.002gana A,Bacaloni A,De Leva I,FaberiA,Fago G,Marino A(2002)Anal ChimActa462:187–198。