【机械类文献翻译】机床夹具的分类与构成

- 格式:pdf

- 大小:162.21 KB

- 文档页数:8

机械制造工艺学之夹具夹具是机械加工过程中必备的工具,是加工设备的重要组成部分,常用于钻、铣、刨、磨、镗、齿轮加工等工序中,能够确保工件在加工过程中保持准确的位置,并能够消除加工过程中所产生的振动和变形。

因此,夹具在机械制造工艺学中具有非常重要的地位。

一、夹具的基本概念和分类夹具是具有夹持和定位功能的装置,用于保持工件在加工过程中的准确位置和姿态。

夹具的基本概念涵盖了工件夹紧方式、夹紧形式、夹具定位方式、夹具调整方式等各方面。

夹具可以分为以下几类:1. 机械夹具:包括钳子、卡盘等,主要依靠机械原理来夹紧工件。

2. 气动夹具:主要使用气动原理来夹紧工件,具有夹紧快、力量大、使用方便等优点。

3. 液压夹具:主要依靠液压原理来夹紧工件,具有夹紧力量大、调整精度高等优点。

4. 电气夹具:包括电磁铁等,主要使用电气原理来夹紧工件,具有夹紧力量强、使用灵活等优点。

二、夹具的设计和制造夹具的设计和制造是机械制造工艺学中重要的内容之一,其设计和制造的过程需要遵循以下原则:1. 合理选用夹紧方式和夹紧形式,根据工件形状和大小选用合适的夹具。

2. 夹具在加工过程中需要有足够的强度和刚度,能够保证工件在加工过程中的精度和稳定性。

3. 夹具需要具有良好的适应性和可调节性,能够适应不同形状、大小的工件,并能够进行精确的调整。

4. 夹具的制造需要进行精密加工和调试,确保夹具的质量和精度达到要求。

三、夹具在机械制造工艺中的应用夹具在机械制造工艺中应用广泛,主要有以下几个方面:1. 夹具在工件的定位和夹紧中起着重要的作用,能够确保工件在加工过程中保持准确的位置和姿态,并且能够消除加工过程中所产生的振动和变形。

2. 夹具能够提高加工效率和加工精度,减少人为操作的误差和浪费,提高了机械加工的自动化程度和制造效益。

3. 夹具的使用能够有效地提高加工品质和减少加工成本。

夹具提高了加工精度和自动化程度,能够减少零件的修整和重工,从而降低了加工成本。

机床夹具的基本组成机床夹具是机械加工中不可或缺的工具,它通常由夹具底座、夹具卡盘、夹具底座定位孔、定位销、弹簧等组成。

下面我们来详细了解一下机床夹具的基本组成。

一、夹具底座夹具底座是机床夹具的主要部分之一,通常由底座本体、底座面、底座定位孔等组成。

底座本体通常采用铸铁或钢铸造,具有较高的刚度和稳定性。

底座面则是夹紧工件的部分,它通常采用平面或V 型面结构,以便更好地与工件接触。

底座定位孔的作用是为了定位夹具卡盘。

二、夹具卡盘夹具卡盘是机床夹具的主要功能部件,它通常由卡盘本体、卡盘爪、卡盘螺栓等组成。

卡盘本体采用铸造或锻造工艺,具有较高的刚度和稳定性。

卡盘爪则是夹紧工件的部分,它常用的类型有三爪卡盘、四爪卡盘、滚珠卡盘等。

卡盘螺栓用于将卡盘爪固定在卡盘本体上。

三、夹具底座定位孔夹具底座定位孔的作用是为夹具卡盘提供定位支撑,使夹具卡盘能够准确地定位在夹具底座上。

定位孔一般为直径为10-20mm的孔洞,需要与卡盘螺栓相匹配。

四、定位销定位销是机床夹具的重要组成部分,它通常用于工件的定位和夹紧。

定位销的材料多为优质合金钢,具有较高的硬度和耐磨性。

定位销的类型有圆柱销、方柱销、球锥销等。

五、弹簧弹簧是机床夹具的辅助部件,它通常用于夹具卡盘的夹紧和释放。

弹簧的材料多为优质弹簧钢,具有较高的弹性和耐腐蚀性。

弹簧的类型有压缩弹簧、拉伸弹簧等。

以上就是机床夹具的基本组成,它们共同作用,形成了机床夹具的完整结构。

不同类型的机床夹具在具体应用中会有所不同,但其基本组成结构是类似的。

机床夹具的结构设计和制造工艺的优化,对提高机械加工的精度和效率具有重要意义。

机床夹具的作用和种类(南京航空航天大学机电学院,江苏南京210016)摘要:机床夹具可分为通用夹具、专用夹具、可调夹具、组合夹具和自动线夹具等。

机床夹具可以保证加工精度,提高生产率,降低成本等。

关键词:机床;夹具;作用;分类Machine function and ClassificationShi Chuanfei(Nanjing University of Aeronautics and Astronautics Institute of electricity and mechanics,Jiangsu Nanjing210016)Abstract:Machine fixture can be divided into common fixture , special fixture , adjustablefixture , modular fixture and automatic line fixture , etc. Machine fixture can ensure accuracy, improve productivity and reduce costs.Key words:machine ;fixture ;function;classification引言:夹具是一种装夹工件的工艺装备,它广泛地应用于机械制造过程的切削加工、热处理、装配、焊接和检测等工艺过程中。

1 机床夹具在机械加工中的作用对工件进行机械加工时, 为了保证加工要求, 首先要使工件相对于刀具及机床有正确的位置, 并使这个位置在加工过程中不因外力的影响而变动。

为此, 在进行机械加工前, 先要将工件装夹好。

工件的装夹方法有两种:一种是工件直接装夹在机床的工作台或卡盘上;另一种是工件装夹在夹具上。

采用第一种方法装夹工件时, 一般要先按图样要求在工件表面划线, 划出加工表面的尺寸和位置, 装夹时用划针或百分表找正后再夹紧。

机床夹具按照其用途和工作方式的不同,可以分为以下几类:

机械夹具:利用机械原理,通过螺纹、齿轮等机械传动方式实现夹紧工件的夹具。

液压夹具:利用液压原理,通过液压缸、油泵等液压元件实现夹紧工件的夹具。

气动夹具:利用气压原理,通过气缸、气源等气动元件实现夹紧工件的夹具。

电磁夹具:利用电磁原理,通过电磁铁等电磁元件实现夹紧工件的夹具。

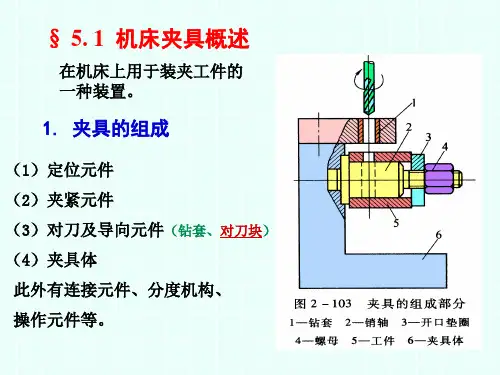

机床夹具通常由以下几个部分组成:

夹紧机构:夹紧工件的核心部分,包括夹紧块、夹紧钳、夹紧齿轮等。

固定机构:将夹具固定在机床上的部分,包括底座、连接板、固定螺钉等。

调节机构:用于调节夹具的位置、形状和尺寸的部分,包括调节螺钉、调节杆等。

传动机构:用于传递夹紧力和夹紧力矩的部分,包括螺旋副、齿轮副、链传动等。

辅助机构:用于辅助夹具的使用和维护的部分,包括润滑系统、冷却系统、防护罩等。

机床夹具机械手夹具机床夹具和机械手夹具是机器人工业中必不可少的两大组成部分。

机械手夹具可以用来抓取物体,而机床夹具是用来固定并加工工件。

在现代工业中,这两种夹具都发挥着重要的作用。

下面,我们将对它们进行一些详细的介绍。

机床夹具机床夹具是指用来固定工件,以便在机床上进行加工的夹具。

它通常放置在机器的工作台上,以保证工件稳定、而且安全地加工。

在机床夹具的设计中,通常要考虑到工件的大小、形状和材质等因素,以确保夹具具有足够的强度和刚性。

此外,夹紧力和精度也是至关重要的,因为精度决定了加工的质量和效率。

机床夹具通常分为三类:手动、液压和自动。

手动夹具适用于小型工件和试样;液压夹具适用于大尺寸工件和工艺复杂的零件;而自动夹具适用于大批量生产中。

机械手夹具机械手夹具一般用于机器人的抓取物体。

它通常需要进行高精度的操作,并且需要具有较高的响应速度和灵活性。

因此,在设计机械手夹具时,需要考虑到许多因素。

首先,需要考虑到夹具的应用场景。

如果夹具用于掌握物体,那么夹具必须设计成具有高精度、高刚性和高承载能力的形状。

如果夹具用于成像、测量或测试,那么夹具必须具备高精密度、刚性和反应速度。

此外,为了满足不同的操作需求,机械手夹具还需要具备多种夹紧方式,如夹钳、气动夹头、磁力夹头等。

机械手夹具通常分为三类:机械手手指夹具、气动手指夹具和电动手指夹具。

机械手手指夹具适用于较小的工件。

它可以精确地操作,并可以安装多个机械手手指夹具以适应不同类型的工件。

气动手指夹具通常由多个气缸组成,主要用于大型工件的操作。

电动手指夹具通常由电机和齿轮系统组成,可以在紧急情况下进行快速夹紧和松开。

总结因此,我们可以看到,机床夹具和机械手夹具在现代工业中发挥着越来越重要的作用。

这些夹具的设计需要同时考虑到多种因素,如工件的大小、形状和材质,夹具的精度和稳定性等等。

在未来,随着工业自动化和智能化的发展,这些夹具的功能和性能也会不断得到提升,以满足更加复杂和高效的生产需求。

夹具是一种用于夹持、固定工件以进行加工或测量的工具。

夹具的分类方法主要包括以下几种:一、按用途分类:1. 定位夹具:主要用于定位工件,确保工件在加工过程中位置准确。

2. 夹紧夹具:用于夹紧工件,防止工件在加工过程中移动或变形。

3. 支撑夹具:用于支撑工件,使工件在加工过程中保持稳定。

4. 复合夹具:具有多种功能的夹具,可以实现定位、夹紧、支撑等多种功能。

二、按加工方式分类:1. 铣床夹具:用于在铣床上夹持工件进行铣削加工。

2. 钻床夹具:用于在钻床上夹持工件进行钻孔加工。

3. 刨床夹具:用于在刨床上夹持工件进行切削加工。

4. 磨床夹具:用于在磨床上夹持工件进行磨削加工。

5. 组合机床夹具:用于在组合机床上夹持工件进行多种加工操作。

三、按工件形状分类:1. 平面夹具:用于夹持平面工件进行加工。

2. 圆形夹具:用于夹持圆形工件进行加工。

3. 异形夹具:用于夹持异形工件进行加工。

4. 钣金夹具:用于夹持薄板金属工件进行加工。

四、按结构特点分类:1. 机械夹具:通过螺杆、卡箍等机械结构夹持工件。

2. 液压夹具:利用液压系统实现对工件的夹持。

3. 气动夹具:利用气压驱动实现对工件的夹持。

4. 真空吸附夹具:利用负压吸附实现对工件的固定。

在实际应用中,夹具的名称也是根据其具体分类和功能特点而定。

铣床上用于夹持平面工件的夹具可以称为平面铣床夹具;用于夹持圆形工件的夹具可以称为回转夹具;用于夹持异形工件的夹具可以称为异形夹具等。

夹具的分类方法主要包括按用途、加工方式、工件形状和结构特点进行分类。

根据不同的分类方法,可以为不同的加工需求选择合适的夹具,并根据其名称来准确描述其功能特点和适用范围。

夹具是在工件加工和生产中不可或缺的重要工具,其分类方法和对应名称的深入了解,对于提高生产效率、保障加工质量具有重要意义。

一、按用途分类:1. 定位夹具:主要用于确定工件的位置,确保加工过程中工件的位置准确,可以保证工件的加工精度,避免加工后工件出现偏差。

毕业设计英文翻译翻译题目::机床夹具的分类与构成翻译题目学生姓名::学生姓名所在班级::所在班级Machine classification and pose fixture1fixture in the role of machiningWorkpiece clamping fixture is a kind of process equipment,it is widely used in mechanical machining of the manufacturing process,heat treatment,assembly, welding and testing processes.In the use of metal-cutting machine tools collectively referred to as the jig fixture.n a modern production machine is an indispensable fixture of the process equipment,machining of the workpiece,the processing requirements in order to ensure.First of all to the workpiece and the machine tool relative to a correct position,and this location during processing does not change the impact of external forces.To this end,during the pre-machining,workpiece clamping must be good.There are two ways to clamp workpiece:one is directly clamping the workpiece in the machine table or on the chuck;The other is the workpiece in the fixture on the fixture.The first method used when the workpiece clamping,the general design requirements have to press lines in the surface to draw the size and location,clamping,or when the needle is zoned dial indicator to find is after the clamping.This method need special equipment,but low efficiency,are generally used for one-piece and small batch rge quantities,mostly with the workpiece clamping fixture.With the merits of the workpiece clamping fixtures are as follows: (l)Guarantee the stability of the machining accuracy of workpiece.Workpieces with clamping fixture,the workpiece relative to the location of tool and machine tool to ensure the accuracy of the fixture from the technical level of workers,so that a number of workpiece machining accuracy of the line.(2)To improve labor productivity.Workpiece clamping fixture can facilitate the user easily、rapidly,and the workpiece does not need to find is crossed,can significantly reduce the supplementary working hours,to improve labor productivity; workpiece in the fixture after the fixture to improve the rigidity of the workpiece,thus cutting the amount of increase,to improve labor productivity;can use more pieces of multi-workpiece clamping fixture,and the use of efficient clamping bodies,to further improve labor productivity.(3)To expand the use of machine tools.Machine tools in general use a dedicated machine tool fixture can expand the scope of the process and give full play to the potential of machine tools to achieve a multi-machine use.For example,the use of a dedicated fixture can be easily Lathe processing small box to the workpiece.Even in the lathe out of oil,a reduction of expensive dedicated machines,reducing the cost,which is particularly important for small and medium-sized factories.(4)To improve the operator's working conditions.As the pneumatic,hydraulic, electro-magnetic power source,such as the application in the fixture,on the one hand to reduce the labor intensity of workers;the other hand,it guarantees the reliability of the workpiece clamping,and to achieve the interlocking machine,to avoid accidents, ensure the operator safety and machine tool equipment(5)To reduce costs.In mass production after the use of fixture,from stem to increase labor productivity,lower level technical workers,as well as lower scrap and other reasons,obviously to reduce the production costs.Fixture manufacturing cost-sharing in a group of workpieces,each workpiece to increase the cost is very minimal,far less than as a result of increased labor productivity and reduce costs.The greater volume of workpiece,fixture made to use has become more significant economic benefits.2Fixture Category2.1General characteristics of the fixture by CategoryAccording to the production in different types of fixtures in the common characteristics of machine tool fixture fixture can be divided into general,special fixtures,adjustable clamp,and automatic line of modular fixture fixture,such as:(l) General Fixture.Universal fixture refers to the structure,size has been standardized, and has a certain universal fixture.This type of fixture adaptable,can be used to setup the scope of a certain shape and size of various parts.(2)A dedicated fixture.This type of fixture is designed for a particular part of the processing procedures and the design and manufacture.Relatively stable in the product,the production of larger quantities, used a variety of special fixtures,access to higher productivity and machining accuracy.(3)Adjustable fixture.Adjustable fixture for general fixture and special fixture and the defects developed a new kind of fixture.Of different types and sizes of the workpiece,simply adjust or replace the fixture at the original location of the individual components and will be used to clamp components.(4)Modular Fixture. Modular fixture is a modular fixture.Standard components of the module with high precision and resistance to abrasion,can be assembled into a variety of fixtures. Removable fixture used to clean the assembly after the new fixture left.(5) Automatic line fixture.Automatic line clamp generally divided into two categories: fixed-type fixture,which is similar to a dedicated fixture;other accompanying a fixture for the use of the workpiece in the fixture,together with the movement,andautomatic workpiece along the line from a move to the next position position for processing.2.2Classification by the use of machine tools ClassificationBy the use of machine tools can be divided into lathe jig fixtures,milling fixtures, drilling fixtures,hang-bed fixture,jig gear machine,CNC machine tool fixture, automatic machine tool fixtures,accompanied by automatic line,and other fixtures, such as machine tools.This is a special fixture design of the classification method used.Dedicated fixture design,the machine group,the type and the main parameters have been determined.Their difference is the cutting forming machine tool movements,so the connection fixture with the machine in different ways.Machining accuracy of their different requirements.2.3Clamping fixture according to the power sourceClamping fixture according to the power source can be divided into manual fixture, pneumatic fixtures,hydraulic fixtures,gas fixtures by force,electromagnetic fixture, vacuum fixtures,fixture,such as centrifugal force.3the composition of fixtureAlthough the structure of machine tool fixture range,but their components can be summarized as the following sections.(1)Positioning components.Typically,when the shape of the workpiece datum position established,the position will be the basic components of the structure identified(2)Clamping device.Positioning of the workpiece in the fixture,the need to clamp the workpiece before processing to ensure that the workpiece during processing is not due to external force and undermine its position.(3)The specific folder.Fixture and the skeleton matrix,all the components through the fixture it will constitute a whole.(4)Of the knife or the guide.Tool used to determine position relative to the correct position of components.Of the knife device common in milling fixture. Used to adjust the cutter knife block position before machining.(5)To connect components.Connected components in the machine tool fixture is todetermine the correct position on the component,therefore,can double as a specific folder to connect the fixture on the transition plate,the positioning of milling machine fixture on key components are connected.(6)Other devices or components.According to the processing needs,somedegree fixture device were used by mode device,the whole device,and the balance of the top block and so on.These components or devices specially designed need.机床夹具的分类与构成1机床夹具在机械加工中的作用夹具是一种装夹工件的工艺装备,它广泛地应用于机械制造过程的切削加工、热处理、装配、焊接和检测等工艺过程中。