Control design of nonlinear mechanical systems with friction

- 格式:pdf

- 大小:269.80 KB

- 文档页数:6

• Getting Started• Introducing SimMechanics Software• Product OverviewProduct DefinitionMechanical Simulation and Physical Modeling• Related ProductsRequired ProductsOther Related Products• Running a Demo ModelWhat the Demo RepresentsViewing a Mechanical Drawing of the ConveyorWhat the Demo IllustratesOpening the ModelRunning the ModelModifying the ModelVisualizing and Animating the Model• What You Can Do with SimMechanics SoftwareAbout SimMechanics SoftwareModeling Mechanical SystemsBodies, Coordinate Systems, Joints, and Constraints Sensors, Actuators, Friction, and Force ElementsSimulating and Analyzing Mechanical MotionVisualizing and Animating ModelsFor More Information• Learning MoreUsing the MATLAB Help System for Documentation and Demos Finding Special SimMechanics Help• Modeling, Simulating, and Visualizing Simple Machines• Introducing the SimMechanics Block LibrariesAbout the SimMechanics Block LibraryAccessing the LibrariesUsing the Libraries• Essential Steps to Building and Running a Mechanical Model About Machine Modeling and SimulationEssential Steps to Build a ModelEssential Steps to Configure and Run a Model• Modeling and Simulating a Simple MachineModeling the Simple PendulumOpening the SimMechanics Block LibraryThe World Coordinate System and GravityConfiguring the GroundConfiguring the BodyConfiguring the JointAdding a Sensor and Starting the Simulation• Visualizing a Simple MachineVisualizing and Animating the Simple PendulumStarting VisualizationSelecting a Body GeometryDisplaying the PendulumModeling and Visualizing More Complex Machines• Modeling and Simulating a Closed-Loop Machine Modeling the Four Bar MechanismViewing a Mechanical Drawing of the Four Bar Mechanism Counting the Degrees of FreedomConfiguring the Mechanical EnvironmentSetting Up the Block DiagramConfiguring the Ground and JointsConfiguring the BodiesSensing Motion and Running the ModelFor More About the Four Bar Mechanism• Representing Motion• Kinematics and Machine Motion StateAbout KinematicsDegrees of FreedomThe State of MotionHome, Initial, and Assembled ConfigurationsFor More Information• Representations of Body MotionAbout Body MotionMachine Geometry and MotionReference Frames and Coordinate SystemsRelating Coordinate Systems in Relative Motion Observing Body Motion in Different Coordinate Systems Representing Body Translations and Rotations• Representations of Body OrientationAbout Body Orientation RepresentationsAxis-Angle RepresentationQuaternion RepresentationRotation Matrix RepresentationEuler Angle RepresentationConverting Rotation RepresentationsConverting the Angular Velocity• Orienting a Body and Its Coordinate SystemsAbout the Body Orientation ExamplesSetting Up the Test BodyRotating the Body and Its CG CS Relative to World Rotating the Body Relative to Its Center of Gravity Creating and Rotating Body Coordinate SystemsReferences• User's Guide• Reference• Blocks• FunctionsExamples• Release NotesGetting StartedIf you have limited Simulink® and/or mechanical simulation experience, you will especiallyUser's GuideThese chapters compose the SimMechanics™ User's Guide. They introduce you to SimMechanics software, help you to build simple models, and explain the general steps to modeling and simulating mechanical systems. They also present SimMechanics tools and methods for analyzing mechanical motion.Modeling Mechanical Systems How to represent machines with block diagramsRunning Mechanical Models How to set up and run your simulation, generate and use code,and troubleshoot simulation errorsAnalyzing Motion Advanced methods for analyzing motionMotion, Control, and Real-Time Simulation Advanced controls and code generation applications, based on the Stewart platformStewart Platform as SimMechanics Plant in Simulink Control ModelModeling Mechanical SystemsSimMechanics software gives you a complete set of block libraries for modeling machine parts and connecting them into a Simulink® block diagram.●Representing Machines with Models●Modeling Grounds and Bodies●Modeling Degrees of Freedom●Constraining and Driving Degrees of Freedom●Cutting Machine Diagram Loops●Applying Motions and Forces●Sensing Motions and Forces●Adding Internal Forces●Combining One- and Three-Dimensional Mechanical Elements●Validating Mechanical ModelsConsult Representing Motion to review body kinematics. If you need more information on rigid body mechanics, consult the physics and engineering literature, beginning with the Bibliography. Classic engineering mechanics texts include Goodman and Warner [2], [3] and Meriam [8]. The books of Goldstein [1] and José and Saletan [5] are more theoretically oriented.Running Mechanical ModelsSimMechanics software gives you multiple ways to simulate and analyze machine motion in the Simulink environment. Running a mechanical simulation is similar to running a simulation of any other type of Simulink model. It entails setting various simulation options, starting the simulation, interpreting results, and dealing with simulation errors. See the Simulink documentation for a general discussion of these topics. This chapter focuses on aspects of simulation specific to SimMechanics models.●Configuring SimMechanics Models in Simulink●Configuring Methods of Solution●Starting Visualization and Simulation●How SimMechanics Software Works●Troubleshooting Simulation Errors●Improving Performance●Generating Code●Limitations●ReferenceAnalyzing MotionSimMechanics analysis modes allow you to study machine motion beyond the simple forward dynamics integration of forces. This chapter explains how to specify machine motion, then deduce the necessary forces and torques, with the Inverse Dynamics and Kinematic analysis modes. You can also specify a machine steady state and analyze perturbations about any machine trajectory by trimming and linearizing your model, respectively.●Mechanical Dynamics●Finding Forces from Motions●Trimming Mechanical Models●Linearizing Mechanical ModelsThe Motion, Control, and Real-Time Simulation chapter covers more sophisticated motion analysis and control design techniques applied to more complex systems.Motion, Control, and Real-Time SimulationSimMechanics software and Simulink form a powerful basis for advanced controls applications:trimming and linearizing motion, analyzing and designing controllers, generating code from the plant and controller models, and simulating controller and plant on dedicated hardware. This chapter is a connected set of case studies illustrating these methods. As its example system, the studies use the Stewart platform, a moderately complex, six degree-of-freedom positioning system.●About the Stewart Platform Case Studies●About the Stewart Platform●Modeling the Stewart Platform●Trimming and Linearizing Through Inverse Dynamics●About Controllers and Plants●Analyzing Controllers●Designing and Improving Controllers●Generating and Simulating with Code●Simulating with Hardware in the Loop●ReferencesBefore attempting these intricate case studies, you should understand the simpler motion analysis concepts, methods, and results of Analyzing Motion.Translating a CAD Stewart Platform in the Importing Mechanical Models chapter presents a related example, converting a Stewart platform computer-aided design assembly into a SimMechanics model.Introducing Visualization and AnimationYou can visualize your model's bodies using the SimMechanics visualization window. This overview explains the essentials of starting visualization and choosing body colors and geometries.●About SimMechanics Visualization●About Body Color and Geometry●Hierarchy of Body, Machine, and Model Visualization SettingsGetting Started with the Visualization WindowThe SimMechanics visualization window allows you to control how you view your model's bodies in both static display and dynamic simulation-based animation. It also allows you to record animations.●Introducing the SimMechanics Visualization Window●Controlling Body and Body Component Display●Adjusting the Camera View●Communicating with the Model from the Visualization Window●Controlling Simulation from the Visualization Window●Controlling Animation●Recording Animation●SimMechanics Visualization Menus and Their ControlsCustomizing Visualization and AnimationYou can customize the colors and geometries of visualized bodies in the SimMechanics visualization window. Choice of colors is intrinsic to visualization. Specifying a custom body geometry requires an external graphics file for each customized body.As an alternative to the visualization window, you can also visualize your mechanical system with virtual reality.●About Custom SimMechanics Visualization●Customizing Visualized Body Colors●Customizing Visualized Body Geometries●Visualizing with a Virtual Reality Client●ReferenceImporting Mechanical ModelsUsing SimMechanics software with computer-aided design (CAD) extends your mechanical modeling and simulation capabilities, allowing you to create SimMechanics models from CAD assemblies. This chapter covers what you need to get started with CAD translation. It assumes some familiarity with SimMechanics modeling, as explained in the SimMechanics Getting Started Guide and SimMechanics User's Guide.●Introducing Mechanical Import●Generating New Models from Physical Modeling XML●Working with Generated Models●Updating Generated Models Using Physical Modeling XML●Controlling Model Update at the Block Level●Troubleshooting Imported and Updated ModelsComputer-Aided Design TranslationThese case studies illustrate how to translate mechanical systems defined externally, as computer-aided design (CAD) assemblies, into mechanical models.●About the CAD Translation Case Studies●Translating a CAD Part into a Body●Translating CAD Constraints into Joints●Updating and Retranslating a CAD Pendulum●Translating a CAD Robot Arm●Translating a CAD Stewart Platform。

Technical Bulletin n°106How to contact IMAGINE:North America imagine-us@Europe imagine@Asia imagine-japan@Visit for further contact information and details on other countries.Copyright © IMAGINE S.A. 1995-2002AMESim® and AMESet® are the registered trademark of IMAGINE SA.All other product names are trademarks or registered trademarks of their respective companiesLatest update: May 31st, 2001 –AMESim in the Automobile Industry: Some Case Studies 3/19 AMESim in the Automobile Industry: Some Case StudiesIn this document we present so me examples of how AMESim is used in the Automobile Industry. For confidentiality reasons, we present figures and a brief description, which illustrate the applicability of AMESim. –AMESim in the Automobile Industry: Some Case Studies4/19 –1. Electronic fuel injectionThis case study deals with the modeling of a diesel injection system known as common rail type. The objective was to build a detailed parameterized model that would allow the reproduction of measurement results.The major features of the modeling procedure were: Ä to take into account the distortion of the needle and theinjector when they are submitted to high pressures (1400 bar) Ä to allow the study of the cavitation on the injection system.The model developed was able to reproduce the experimental measurements with precision within a few percents for the following: Ä needle motionAMESim in the Automobile Industry: Some Case Studies 5/19 Ä pressuresÄ instantaneous flowÄ injected volume…The different components of the system (pump, pressure regulator, injectors and rail) can be modeled using AMESim Hydraulic Component Design library (see Technical Bulletin: “AMESim and Common Rail”). –AMESim in the Automobile Industry: Some Case Studies 6/19 –2. Mechanical Fuel InjectionMechanical injection systems represent for the engineer one of the most advanced applications in the 'Fluid Power Control' field. These systems ensure, by means ofvery rapiddynamics (several milliseconds), the injection of a quantity of fuel with incredible precision. This action is repeated millions of times during the life of the injector.The control of these systems has been achieved only by a fine understanding of the physicalphenomena having significant influence. At the functional level, we can cite the following aspects : Ä influence of fluid characteristics Ä flow rate in the control orifices taking into account evolutions of flow conditions (laminar-turbulent, cavitation influence) Ä pipe transient (see Technical Bulletin : “AMESim and Mechanical Injection”)Certainly, engineers designing these injection systems did not wait for the availability of current numeric simulation tools to develop them. However, it is unden iable that nowadays simulation takes a significant partAMESim in the Automobile Industry: Some Case Studies 7/19 in the design process. This is represented by different aspects:Ä by ensuring a finer analysis of experimental situationsÄ by a capitalization of acquired knowledgeÄ by an enriched framework of acquired experience to aid in the conception of new systems (case of the common rail). –AMESim in the Automobile Industry: Some Case Studies 8/19 –3. Automatic gearboxThis case study deals withthe development of models for the design of ahydraulic circuit and itscontrol system in an automatic gearbox.These models are made using the AMESimHydraulic Component Design library to construct specialist valves that are to be found on automatic gearboxes. It was validated by using experimental measurements of a benchmark. The parameters crucial in the stability of the valves and the circuit as a whole could be tuned by simulation. The design times for a gearbox are substantially reduced by using this model.The analysis of these hydraulic circuits requires the closest reproduction of phenomena and has led to the development of mechanical components such as multidisk clutches and brakes as well as band brakes and epicycloïdal gear trainsAMESim in the Automobile Industry: Some Case Studies 9/19 present in automatic gearboxes. Due to that, IMAGINE has built the AMESim Powertrain library for automatic and manual transmissions (see Technical Bulletin: “AMESim and Powertain”). –AMESim in the Automobile Industry: Some Case Studies 10/19 –4. Braking systemThe braking circuit analyzed is classic and consists of a pneumatic vacuum booster, a master cylinder converting the booster energy into hydraulic energy and lines allowing to reach the calipers.1.The model of the vacuum booster, including the rubberpart, used AMESim Mechanical, Hydraulic and Pneumatic libraries. The master cylinder and the calipers have been createdwith Hydraulic Component Design .The complete model allows to predict: Ä the assistance of the booster Ä the effect of the restrictions on the output of the front and rear chambers of the master cylinder Ä the pressure on the calipers, and consequently the braking torque applied on each wheel (see Technical Bulletin : “AMESim and Braking”)AMESim in the Automobile Industry: Some Case Studies 11/19 –5. Power steering systemAn early application of AMESiminvolved fault rectification of a power steering system. Bad vibrations occurred when the vehicle was stopped and the steering wheel turned. A detailed model of the hydraulic system shown above, based upon the physical sizes and characteristics of the components was built and validated by comparison with benchmarks.A sensitivity analysis of various parameters was carried out, and tuning proposals were submitted to the manufacturer to suppress the vibrations.For various working states, the model was linearized, and the following analyses were performed with linear analysis tools: Ä eigenvalue analysis and modal shape Ä root locus Ä transfert functions (see Technical Bulletin : “AMESim and Power steering”)AMESim in the Automobile Industry: Some Case Studies 12/19 –6. Variable Valve ActuationDifferent types of valve lift controls exist which are more or less complex. The third generation systems, which are in the process of development, allow total valve lift control: zero lift, partial or total. This concept allows to control, for each cylinder at each engine revolution, the exact quantity of air necessary for the correct combustion of the injected fuel. The prospects for the use of this technology are a 15% torque increase with a 10% reduction in consumption in the NEDC cycle.The creation of a numerical model of an electro-hydraulic system (EHV) should allow not only to help the designer in the choice of geometric values which will allow the system to respond to the specifications, but will also allow him/her to make it evolve easily.The method has allowed the development of a VVA system mounted on a 5-cylinder engine, 4 valves per cylinder. On each of the ten inlet valves, an EHV is mounted, the outlet valves do not have them since the benefit would be too insignificant.AMESim in the Automobile Industry: Some Case Studies 13/19 The coupling between the simulation and the experimental tests has limited the number of physical prototypes, which is a substantial benefit in terms of time and cost (see Technical Bulletin : “AMESim and Variable Valve Actuation”). –AMESim in the Automobile Industry: Some Case Studies 14/19 –7. LubricationThe main interest in the modeling of such networks is to size the pump thereby ensuring sufficient pressure levels in the system and consequently to estimate the lubricant flow rates in the different branches. These flow rates are directly dependent on the rotary speed and the characteristic of the pump, the dimension of the oil canals and on the characteristicsof some specific components suchas bearings.Flow resistance has a great influence on the design of lubricating circuits in which pressures are relatively low but flow rates are high. This is the motivation for creating the AMESim Hydraulic Resistance library. This library comprises a set of components such as T-junctions, bends, sudden expansions and contractions based on the Idel'cik formulae and experimental data, from which it is easy to model large hydraulic networks.When an engine is started, the lubrication circuit is empty. In order to reduce friction the lubricant has to reach each working part as soon as possible. In order to evaluate the time needed to fill in the whole circuit and to evaluate the order in which the different branches composing the network will be filled, Imagine has developed the AMESim Filling . This basic element library enables the user toAMESim in the Automobile Industry: Some Case Studies 15/19 calculate pressures, mass flow rates, type of flowing fluid and volumetric liquid fraction for the system (see Technical Bulletin: “AMESim and Lubrication”). –AMESim in the Automobile Industry: Some Case Studies 16/19 –8. Cooling SystemThe main purpose of engine cooling is to avoid metallurgical damage due to h igh temperatures in the engine cylinders. Therefore, the engine cooling system has to provide during cold start or low ambient temperature conditions a controlledincrease in coolant, oil and engine material temperatures. In addition, under uphill and full-load conditions, it must provide sufficient cooling of the oil and the engine metal masses.The AMESim Cooling System packageallowsto calculate the coolant flow rate distribution in the different branches and to check the thermal efficiency of the sy stem. The Cooling System library is composed of specific components from which complete engine cooling systems can be built. All these components are connected together using models of the Thermal-Hydraulic library. This library comprises a set of basic components such as resistance components (orifices, bends, T-junctions..), pipes/hoses components (adiabatic or with heat exchange), pump components...A cooling system model allows to predict the distribution of flow rates of coolant and its temperature in every branch of the circuit, the levels of pressures, the operating of the thermostat and consequently the regulation of the engine outlet coolant temperature, and cavitation. The technological elements approach allowsAMESim in the Automobile Industry: Some Case Studies 17/19 easy and fast modification of each module structure: effect of different circuit architectures, influence of immersion heater, influence of the air-conditioning system (see Technical Bulletin : “AMESim and Cooling system”). –AMESim in the Automobile Industry: Some Case Studies 18/19 –9. Vehicle thermal managementIn the framework of recent and future pollutant rejection standards, car manufacturers are brought to optimize the pollution treating functions by reducing engine emissions and fuel consumption and by increasing the performances of exhaust gas post-treating systems. In addition, it is essential to enhance or at least maintain the dynamic performances of vehicles without reducing cabin comfort in order to satisfy the ever-increasing demands of customers.From these considerations, it seems that the whole thermal management of the engine is concerned. It is essential to control the steady state and transient thermal behavior of the engine andthe exhaust line. Therefore, the sub-functions involved are cooling, lubrication, thermal exchanges in the engine block, exhaust thermal behavior, exhaust gas chemical treatment.A complete model has been created using models of AMESim Thermal, Thermal-Hydraulic and Cooling System libraries. This model allows to simulate the engine warm-up and to study the effect of technological changes on the engine: e ngine block material, architecture of the fluid circuits (cooling, lubrication and exhaust). This model can also be used to determine the influence of topological modifications of theAMESim in the Automobile Industry: Some Case Studies 19/19 cooling circuit: architecture of the cooling circuit, adding of extra heaters… (See Technical Bulletin: “AMESim and Vehicle Thermal Management”). –。

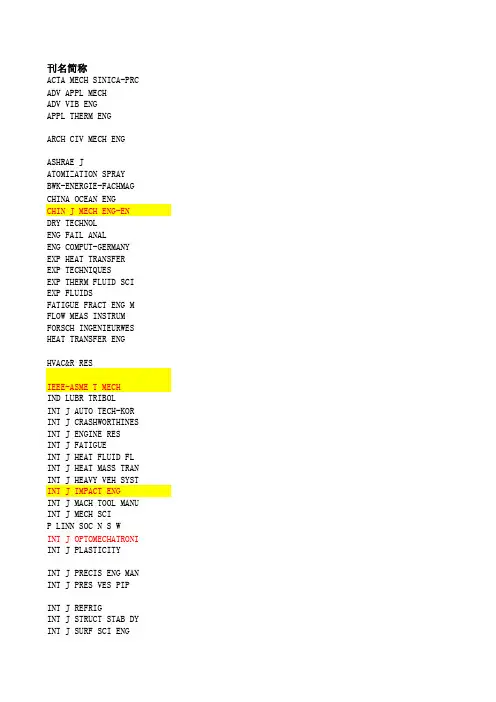

刊名简称ACTA MECH SINICA-PRC ADV APPL MECHADV VIB ENGAPPL THERM ENG ARCH CIV MECH ENG ASHRAE J ATOMIZATION SPRAY BWK-ENERGIE-FACHMAG CHINA OCEAN ENG CHIN J MECH ENG-EN DRY TECHNOLENG FAIL ANALENG COMPUT-GERMANY EXP HEAT TRANSFER EXP TECHNIQUESEXP THERM FLUID SCI EXP FLUIDSFATIGUE FRACT ENG M FLOW MEAS INSTRUM FORSCH INGENIEURWES HEAT TRANSFER ENG HVAC&R RESIEEE-ASME T MECH IND LUBR TRIBOLINT J AUTO TECH-KOR INT J CRASHWORTHINES INT J ENGINE RESINT J FATIGUEINT J HEAT FLUID FL INT J HEAT MASS TRAN INT J HEAVY VEH SYST INT J IMPACT ENGINT J MACH TOOL MANU INT J MECH SCIP LINN SOC N S WINT J OPTOMECHATRONI INT J PLASTICITYINT J PRECIS ENG MAN INT J PRES VES PIP INT J REFRIGINT J STRUCT STAB DY INT J SURF SCI ENG INT J THERM SCIINT J VEHICLE DESISI BILIM TEK DERGJ ADV MECH DES SYST J COMPUT NONLIN DYN J ELECTRON PACKAGINGJ ENG GAS TURB POWER J ENG MATER-T ASME J ENG MECH-ASCEJ ENG THERMOPHYS-RUS J ENHANC HEAT TRANSF J FLUID STRUCTJ FLUID ENG-T ASME J FRICT WEAR+J HEAT TRANS-T ASME J HYDRAUL ENG-ASCE J JPN SOC TRIBOLOGIS J MANUF SCI E-T ASME J MECH DESIGNJ MECH SCI TECHNOL J MICROELECTROMECH S J OFFSHORE MECH ARCT J POROUS MEDIAJ PRESS VESS-T ASME J SANDW STRUCT MATER J SOL ENERG-T ASME J SOUND VIBJ STRAIN ANAL ENGJ BALK TRIBOL ASSOC J BRAZ SOC MECH SCI J THERM SCIJ THERMOPHYS HEAT TR J TRIBOL-T ASMEJ TURBOMACHJ VIB ACOUSTJ VIB CONTROLJ VIBROENGLAT AM J SOLIDS STRU LUBR SCIMACH SCI TECHNOL MEC INDMECH ENGMECH SYST SIGNAL PR MECH MACH THEORY MECHATRONICS NANOSC MICROSC THERM NONLINEAR DYNAM PROBABILIST ENG MECH P COMBUST INSTP I MECH ENG A-J POW P I MECH ENG B-J ENG P I MECH ENG C-J MEC P I MECH ENG D-J AUT P I MECH ENG E-J PRO P I MECH ENG F-J RAIP I MECH ENG G-J AER P I MECH ENG J-J ENG P I MECH ENG K-J MUL PROF ENGPROG ENERG COMBUST RAPID PROTOTYPING J SCI IRANSHOCK VIBSMART STRUCT SYST SOUND VIB STROJARSTVOSTROJ VESTN-J MECH E STRUCT ENG MECH STRUCT INFRASTRUCT E THEOR APPL FRACT MEC T FAMENAT CAN SOC MECH ENG TRIBOL LUBR TECHNOL TRIBOL INTTRIBOL LETTTRIBOL TVEHICLE SYST DYN WEARWIND ENERGY刊名全称ACTA MECHANICA SINICAADVANCES IN APPLIED MECHANICSAdvances in Vibration EngineeringAPPLIED THERMAL ENGINEERINGArchives of Civil and Mechanical EngineeringASHRAE JOURNALATOMIZATION AND SPRAYSBWKCHINA OCEAN ENGINEERINGChinese Journal of Mechanical EngineeringDRYING TECHNOLOGYENGINEERING FAILURE ANALYSISENGINEERING WITH COMPUTERSEXPERIMENTAL HEAT TRANSFEREXPERIMENTAL TECHNIQUESEXPERIMENTAL THERMAL AND FLUID SCIENCEEXPERIMENTS IN FLUIDSFATIGUE & FRACTURE OF ENGINEERING MATERIALS & STRUCTURESFLOW MEASUREMENT AND INSTRUMENTATIONFORSCHUNG IM INGENIEURWESEN-ENGINEERING RESEARCHHEAT TRANSFER ENGINEERINGHVAC&R RESEARCHIEEE-ASME TRANSACTIONS ON MECHATRONICSINDUSTRIAL LUBRICATION AND TRIBOLOGYINTERNATIONAL JOURNAL OF AUTOMOTIVE TECHNOLOGYINTERNATIONAL JOURNAL OF CRASHWORTHINESSInternational Journal of Engine ResearchINTERNATIONAL JOURNAL OF FATIGUEINTERNATIONAL JOURNAL OF HEAT AND FLUID FLOWINTERNATIONAL JOURNAL OF HEAT AND MASS TRANSFERInternational Journal of Heavy Vehicle SystemsINTERNATIONAL JOURNAL OF IMPACT ENGINEERINGINTERNATIONAL JOURNAL OF MACHINE TOOLS & MANUFACTUREINTERNATIONAL JOURNAL OF MECHANICAL SCIENCESINTERNATIONAL JOURNAL OF OFFSHORE AND POLAR ENGINEERINGInternational Journal of OptomechatronicsINTERNATIONAL JOURNAL OF PLASTICITYInternational Journal of Precision Engineering and Manufacturing INTERNATIONAL JOURNAL OF PRESSURE VESSELS AND PIPINGINTERNATIONAL JOURNAL OF REFRIGERATION-REVUE INTERNATIONALE DU FROID International Journal of Structural Stability and DynamicsInternational Journal of Surface Science and Engineering INTERNATIONAL JOURNAL OF THERMAL SCIENCESINTERNATIONAL JOURNAL OF VEHICLE DESIGNISI Bilimi ve Teknigi Dergisi-Journal of Thermal Science and Technology Journal of Advanced Mechanical Design Systems and ManufacturingJournal of Computational and Nonlinear DynamicsJOURNAL OF ELECTRONIC PACKAGINGJOURNAL OF ENGINEERING FOR GAS TURBINES AND POWER-TRANSACTIONS OF THE A JOURNAL OF ENGINEERING MATERIALS AND TECHNOLOGY-TRANSACTIONS OF THE ASM JOURNAL OF ENGINEERING MECHANICS-ASCEJournal of Engineering ThermophysicsJOURNAL OF ENHANCED HEAT TRANSFERJOURNAL OF FLUIDS AND STRUCTURESJOURNAL OF FLUIDS ENGINEERING-TRANSACTIONS OF THE ASMEJournal of Friction and WearJOURNAL OF HEAT TRANSFER-TRANSACTIONS OF THE ASMEJOURNAL OF HYDRAULIC ENGINEERING-ASCEJOURNAL OF JAPANESE SOCIETY OF TRIBOLOGISTSJOURNAL OF MANUFACTURING SCIENCE AND ENGINEERING-TRANSACTIONS OF THE AS JOURNAL OF MECHANICAL DESIGNJournal of Mechanical Science and TechnologyJOURNAL OF MICROELECTROMECHANICAL SYSTEMSJOURNAL OF OFFSHORE MECHANICS AND ARCTIC ENGINEERING-TRANSACTIONS OF TH JOURNAL OF POROUS MEDIAJOURNAL OF PRESSURE VESSEL TECHNOLOGY-TRANSACTIONS OF THE ASME JOURNAL OF SANDWICH STRUCTURES & MATERIALSJOURNAL OF SOLAR ENERGY ENGINEERING-TRANSACTIONS OF THE ASMEJOURNAL OF SOUND AND VIBRATIONJOURNAL OF STRAIN ANALYSIS FOR ENGINEERING DESIGNJournal of the Balkan Tribological AssociationJournal of the Brazilian Society of Mechanical Sciences and Engineering JOURNAL OF THE CHINESE SOCIETY OF MECHANICAL ENGINEERSJournal of Thermal ScienceJOURNAL OF THERMOPHYSICS AND HEAT TRANSFERJOURNAL OF TRIBOLOGY-TRANSACTIONS OF THE ASMEJOURNAL OF TURBOMACHINERY-TRANSACTIONS OF THE ASMEJOURNAL OF VIBRATION AND ACOUSTICS-TRANSACTIONS OF THE ASMEJOURNAL OF VIBRATION AND CONTROLJournal of VibroengineeringLatin American Journal of Solids and StructuresLubrication ScienceMACHINING SCIENCE AND TECHNOLOGYMecanique & IndustriesMECHANICAL ENGINEERINGMECHANICAL SYSTEMS AND SIGNAL PROCESSINGMECHANISM AND MACHINE THEORYMECHATRONICSNanoscale and Microscale Thermophysical EngineeringNONLINEAR DYNAMICSPROBABILISTIC ENGINEERING MECHANICSPROCEEDINGS OF THE COMBUSTION INSTITUTEPROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART A-JOURNAL O PROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART B-JOURNAL O PROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART C-JOURNAL O PROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART D-JOURNAL O PROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART E-JOURNAL O PROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART F-JOURNAL OPROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART G-JOURNAL O PROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART J-JOURNAL O PROCEEDINGS OF THE INSTITUTION OF MECHANICAL ENGINEERS PART K-JOURNAL O PROFESSIONAL ENGINEERINGPROGRESS IN ENERGY AND COMBUSTION SCIENCERAPID PROTOTYPING JOURNALScientia IranicaSHOCK AND VIBRATIONSmart Structures and SystemsSOUND AND VIBRATIONSTROJARSTVOSTROJNISKI VESTNIK-JOURNAL OF MECHANICAL ENGINEERINGSTRUCTURAL ENGINEERING AND MECHANICSStructure and Infrastructure EngineeringTHEORETICAL AND APPLIED FRACTURE MECHANICSTransactions of FAMENATRANSACTIONS OF THE CANADIAN SOCIETY FOR MECHANICAL ENGINEERING TRIBOLOGY & LUBRICATION TECHNOLOGYTRIBOLOGY INTERNATIONALTRIBOLOGY LETTERSTRIBOLOGY TRANSACTIONSVEHICLE SYSTEM DYNAMICSWEARWIND ENERGY刊名中文翻译ISSN大类名称力学学报0567-7718物理应用力学进展0065-2156工程技术先进震动工程0972-5768工程技术实用热力工程1359-4311工程技术1644-9665工程——土木、机械、美国供暖、制冷与空调工程师学会志0001-2491工程技术-化学、机械、雾化与喷射1044-5110工程技术燃料、热能与动力1618-193X工程技术中国海洋工程0890-5487工程技术机械工程学报英文版1000-9345工程干燥技术0737-3937工程技术工程事故分析1350-6307工程技术计算机在工程中的应用0177-0667工程技术实验传热0891-6152工程技术实验技术0732-8818工程技术实验热力和流体科学0894-1777工程技术流体力学实验0723-4864工程技术工程材料及结构的疲劳与断裂8756-758X工程技术流动测量和仪表设备0955-5986工程技术工程研究0015-7899工程技术传热工程0145-7632工程技术国际供暖、通风、空调、制冷研究杂志1078-9669工程技术IEEE-ASME机械电子学汇刊1083-4435工程技术工业润滑与摩擦学0036-8792工程技术国际汽车技术杂志1229-9138工程技术国际防撞性能杂志1358-8265工程技术国际发动机研究杂志1468-0874工程技术国际疲劳杂志0142-1123工程技术国际热与流体流杂志0142-727X工程技术国际传热与传质杂志0017-9310工程技术国际重型机动车系统杂志1744-232X工程技术国际冲击工程杂志0734-743X工程技术国际机床与制造杂志0890-6955工程技术国际机械科学杂志0020-7403工程技术国际近海和极地工程师杂志0370-047X环境科学国际机电光杂志1559-9612工程技术国际塑性力学杂志0749-6419工程技术国际精密工程与制造杂志1229-8557工程技术国际压力容器与管道杂志0308-0161工程技术国际制冷杂志0140-7007工程技术国际结构稳定性与动力学杂志0219-4554工程技术国际表面科学与工程杂志1749-785X工程技术国际热科学杂志1290-0729工程技术国际机动车设计杂志0143-3369工程技术d Technology 1300-3615工程技术先进机械设计系统和制造1881-3054工程技术计算和非线性动力学1555-1423工程技术电子封装杂志1043-7398工程技术燃气轮机与动力工程杂志0742-4795工程技术工程材料与工艺杂志0094-4289工程技术工程材料与工艺杂志0733-9399工程技术工程热物理学报1810-2328物理强化传热杂志1065-5131工程技术流体与结构杂志0889-9746工程技术流体工程学杂志0098-2202工程技术摩擦磨损1068-3666工程技术传热杂志;美国机械工程师学会汇刊0022-1481工程技术水力工程杂志0733-9429工程技术摩擦学0915-1168工程技术制造科学与工程杂志;美国机械工程师学会汇1087-1357工程技术机械设计杂志;美国机械工程师学会汇刊1050-0472工程技术韩国机械工程师学会国际杂志1738-494X工程技术微机电系统杂志1057-7157工程技术0892-7219工程技术海上机械与极地工程杂志;美国机械工程师学会多孔介质杂志1091-028X工程技术压力容器技术杂志;美国机械工程师学会汇刊0094-9930工程技术夹层结构与材料杂志1099-6362工程技术太阳能工程杂志;美国机械工程师学会汇刊0199-6231工程技术声音和振动杂志0022-460X工程技术工程设计应变分析杂志0309-3247工程技术巴尔干摩擦学协会1310-4772工程技术机械科学与工程1678-5878工程技术中国机械工程学会会刊0257-9731工程技术热科学杂志1003-2169工程技术热物理学与热传导杂志0887-8722工程技术摩擦学杂志;美国机械工程师学会汇刊0742-4787工程技术涡轮机械杂志;美国机械工程师学会汇刊0889-504X工程技术振动与声学杂志;美国机械工程师学会汇刊1048-9002工程技术振动与控制杂志1077-5463工程技术1392-8716工程技术固体和结构1679-7817工程技术润滑科学0954-0075工程技术机械加工科学与技术1091-0344工程技术机械公司与工业1296-2139工程技术机械工程0025-6501工程技术机械系统与信号处理0888-3270工程技术机构学与机械原理0094-114X工程技术机械电子学0957-4158工程技术纳米尺度和微尺度热物理学工程1556-7265工程技术非线性动力学0924-090X工程技术概率工程力学0266-8920工程技术电力系统1540-7489工程技术机械工程师学会会报;A辑:动力与能源杂志0957-6509工程技术机械工程师学会会报;B辑:工程制造杂志0954-4054工程技术机械工程师学会会报;C辑:机械工程学杂志0954-4062工程技术机械工程师学会会报;D辑:机动车辆工程杂志0954-4070工程技术机械工程师学会会报;E辑:加工机械工程杂志0954-4089工程技术0954-4097工程技术机械工程师学会会报;F辑:铁路与快速运输杂志机械工程师学会会报;G辑:航空航天工程杂志0954-4100工程技术机械工程师学会会报;H辑:工程医学杂志1350-6501工程技术机械工程师学会会报;J辑:工程摩擦学杂志1464-4193工程技术专业工程0953-6639工程技术能源与燃烧科学进展0360-1285工程技术快速样机成型杂志1355-2546工程技术1026-3098工程技术撞击与振动1070-9622物理撞击与振动1738-1584工程技术声音和振动1541-0161物理机械制造0562-1887工程技术机械工程杂志0039-2480工程技术结构工程与力学1225-4568工程技术结构和基础设施工程1573-2479工程技术理论与应用断裂力学0167-8442工程技术1333-1124工程技术加拿大机械工程学会汇刊0315-8977工程技术摩擦学及润滑技术1545-858X工程技术国际摩擦学0301-679X工程技术摩擦学通讯1023-8883工程技术摩擦学汇刊1040-2004工程技术车辆系统动力学0042-3114工程技术磨损0043-1648工程技术风能1095-4244工程技术主办机构及国家期/年大类分区中国科学院主管、中国力学学会和中国科学院力学研究所Bimonthly4 ELSEVIER ACADEMIC PRESS INC 美国 Annual1 KRISHTEL EMAGING SOLUTIONS PVT LTD 印度Quarterly4 PERGAMON-ELSEVIER SCIENCE LTD 英国Monthly 3 WROCLAW UNIV TECHNOLOGY 波兰Quarterly4(72/112)Monthly 4(51/116) AMER SOC HEATING REFRIGERATING AIR-CONDITIONING ENG, I美国Bimonthly 4 SPRINGER-V D I VERLAG GMBH;德国Monthly 4 CHINA OCEAN PRESS;中国Quarterly 4中国Bimonthly 4 TAYLOR & FRANCIS INC 美国Monthly 3 PERGAMON-ELSEVIER SCIENCE LTD 英国Bimonthly 4 SPRINGER;USA Quarterly 4 TAYLOR & FRANCIS INC;USA Quarterly 4 WILEY-BLACKWELL PUBLISHING, INC;USA Bimonthly 4 ELSEVIER SCIENCE INC;USA Bimonthly 3 SPRINGER, 233 SPRING ST;USA Monthly 3 WILEY-BLACKWELL PUBLISHING;USA Monthly 4 ELSEVIER SCI LTD;英国Quarterly 4 SPRINGER HEIDELBERG;德国Bimonthly 4 TAYLOR & FRANCIS INC;美国Monthly 4Bimonthly4 AMER SOC HEATING REFRIGERATING AIR-CONDITIONING ENG, IIEEE-INST ELECTRICAL ELECTRONICS ENGINEERS INC;USA Quarterly 2 EMERALD GROUP PUBLISHING LIMITED;英国Bimonthly4 KOREAN SOC AUTOMOTIVE ENGINEERS;SOUTH KOREA Bimonthly4 TAYLOR & FRANCIS LTD;英国Bimonthly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Bimonthly4 ELSEVIER SCI LTD;英国Monthly 3 ELSEVIER SCIENCE INC;美国Bimonthly3 PERGAMON-ELSEVIER SCIENCE LTD;英国Biweekly 2 INDERSCIENCE ENTERPRISES LTD;瑞士Quarterly 4 PERGAMON-ELSEVIER SCIENCE LTD;英国Monthly 3 ELSEVIER SCI LTD;英国Monthly 3 PERGAMON-ELSEVIER SCIENCE LTD;英国Monthly 3INT SOC OFFSHORE POLAR ENGINEERS;美国Quarterly4 TAYLOR & FRANCIS INC;美国Quarterly4 PERGAMON-ELSEVIER SCIENCE LTD;英国Monthly1 KOREAN SOC PRECISION ENG;韩国Quarterly3 ELSEVIER SCI LTD, THE BOULEVARD;英国Monthly 3 ELSEVIER SCI LTD;英国Bimonthly3 WORLD SCIENTIFIC PUBL CO PTE LTD;新加坡Quarterly4 INDERSCIENCE ENTERPRISES LTD;瑞士Bimonthly4Monthly 3 ELSEVIER FRANCE-EDITIONS SCIENTIFIQUES MEDICALES ELSEVINDERSCIENCE ENTERPRISES LTD;瑞士Bimonthly4 TURKISH SOC THERMAL SCIENCES TECHNOLOGY;土耳其Semiannual 4 JAPAN SOC MECHANICAL ENGINEERS;日本Bimonthly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 ASCE-AMER SOC CIVIL ENGINEERS;美国Monthly4 MAIK NAUKA/INTERPERIODICA/SPRINGER;美国Quarterly4 BEGELL HOUSE INC;美国Quarterly4 ACADEMIC PRESS LTD- ELSEVIER SCIENCE LTD;英国Bimonthly3 ASME-AMER SOC MECHANICAL ENG;美国Bimonthly4 ALLERTON PRESS INC;美国Bimonthly4 ASME-AMER SOC MECHANICAL ENG;美国Monthly3 ASCE-AMER SOC CIVIL ENGINEERS;美国Monthly3 JAPAN SOC TRIBOLOGISTS;日本Monthly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 ASME-AMER SOC MECHANICAL ENG;美国Monthly4 KOREAN SOC MECHANICAL ENGINEERS;韩国Monthly4 IEEE-INST ELECTRICAL ELECTRONICS ENGINEERS INC Bimonthly2 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 BEGELL HOUSE INC;美国Bimonthly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 SAGE PUBLICATIONS LTD;英国Quarterly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 ACADEMIC PRESS LTD- ELSEVIER SCIENCE LTD;英国Weekly 3 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Bimonthly4 SCIBULCOM LTD;保加利亚Quarterly4 ABCM BRAZILIAN SOC MECHANICAL SCIENCES & ENGINEERING;Q uarterly4Bimonthly CHINESE SOC MECHANICAL ENGINEERS;中国机械工程学会SCIENCE PRESS;中国Quarterly4 AMER INST AERONAUT ASTRONAUT;美国Quarterly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 ASME-AMER SOC MECHANICAL ENG;美国Quarterly4 SAGE PUBLICATIONS LTD;英国Monthly4 JOURNAL VIBROENGINEERING;立陶宛Quarterly4 LATIN AMER J SOLIDS STRUCTURES;巴西Quarterly4 JOHN WILEY & SONS LTD;英国Monthly4 TAYLOR & FRANCIS INC;美国Quarterly4 EDP SCIENCES S A;法国Bimonthly4 ASME-AMER SOC MECHANICAL ENG;美国Monthly4 ACADEMIC PRESS LTD- ELSEVIER SCIENCE LTD;英国Bimonthly2 PERGAMON-ELSEVIER SCIENCE LTD;英国Bimonthly3 PERGAMON-ELSEVIER SCIENCE LTD;英国Bimonthly3 TAYLOR & FRANCIS INC;美国Quarterly3 SPRINGER;荷兰Monthly3 ELSEVIER SCI LTD;英国Quarterly3 ELSEVIER SCIENCE INC;美国Annual 2 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Bimonthly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Monthly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Monthly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Monthly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Quarterly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Quarterly4PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Bimonthly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Bimonthly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Quarterly4 PROFESSIONAL ENGINEERING PUBLISHING LTD;英国Semimonthly4 PERGAMON-ELSEVIER SCIENCE LTD;英国Bimonthly1 EMERALD GROUP PUBLISHING LIMITED;英国Bimonthly4 SHARIF UNIV TECH;伊朗Bimonthly4 IOS PRESS;荷兰Bimonthly4 TECHNO-PRESS;韩国Quarterly3 ACOUSTICAL PUBL INC;美国Monthly4 UREDNISTVO CASOPISA STROJARTVO;克罗地亚Tri-annual 4Monthly4 ASSOC MECHANICAL ENGINEERS TECHNICIANS SLOVENIA;南斯拉TECHNO-PRESS;韩国Semimonthly 4 TAYLOR & FRANCIS LTD;英国Quarterly 4 ELSEVIER SCIENCE BV Bimonthly 4Semiannual 4 UNIV ZAGREB FAC MECHANICAL ENGINEERING & NAVAL ARCHITECSME TRANS., C/O P J ZSOMBOR-MURRAY,;加拿大Quarterly 4 SOC TRIBOLOGISTS & LUBRICATION ENGINEERS;美国Monthly4 ELSEVIER SCI LTD;英国Monthly3 SPRINGER/PLENUM PUBLISHERS;美国Monthly3 TAYLOR & FRANCIS INC;美国Quarterly 4 TAYLOR & FRANCIS LTD;英国Monthly4 ELSEVIER SCIENCE SA;瑞士Monthly3 JOHN WILEY & SONS LTD;英国Quarterly 3是否为TOP期刊SCI/SCIE/EI目前内容2011年影响因子N Engineering, Computing & Technology0.86Y5N0.328N 2.064N0.855N0.392N0.526N SCI/SCIE Engineering, Computing & Technology0.056N SCIE Engineering, Computing & Technology0.468N SCIE0.208N SCI/SCIE Engineering, Computing & Technology 2.084N SCIE Engineering, Computing & Technology 1.086N SCIE0.739N SCIE0.537N SCIE0.257N SCIE 1.414N SCI/SCIE 1.735N SCI/SCIE0.847N SCIE0.8N SCIE0.268N SCIE0.892N SCIE0.683N SCI/SCIE 2.865N SCIE0.35N SCIE0.606N SCIE0.789N SCIE0.969N SCI/SCIE 1.546N SCI/SCIE 1.927Y SCI/SCIE 2.407N SCIE0.2N SCI/SCIE 1.701N SCI/SCIE 2.169N SCI/SCIE 1.231 SCIEN SCIE0.556Y SCI/SCIE 4.603N SCI/SCIEN SCIE0.989N SCI/SCIE 1.817N SCIE0.45N SCIE0.414N SCIE 2.142N SCIE0.457N SCIE0.229N SCIE0.205N SCIE0.827N SCIE0.694N SCI/SCIE0.679 N SCI/SCIE0.954 N SCI/SCIE0.99 N SCIE0.259 N SCIE0.275 N SCI/SCIE 1.567 N SCI/SCIE0.747 N SCIE0.409 N SCI/SCIE 1.83 N SCI/SCIE 1.429 N SCIE0.009 N SCIE0.727 N SCIE 1.017 N SCIE0.448 N SCI/SCIE 2.098 N SCIE0.427 N SCI/SCIE0.516 N SCI/SCIE0.516 N SCIE0.561 N SCI/SCIE0.846 N SCI/SCIE 1.588 N SCI/SCIE 1.085 N SCIE0.158 N SCIE0.2 SCIEN SCIE0.31 N SCI/SCIE0.739 N SCI/SCIE 1.196 N SCIE0.542 N SCIE 1.022 N SCIE1N SCIE0.346 N SCIE0.4 N SCIE0.53 N SCIE0.804 N SCIE0.221 N SCIE0.209 N SCIE 1.824 N SCI/SCIE 1.366 N SCI/SCIE 1.255 N SCI/SCIE 1.032 N SCI/SCIE 1.247 N SCI/SCIE 1.245 N SCIE 3.633 N SCIE0.7 N SCI/SCIE0.725 N SCI/SCIE0.473 N SCI/SCIE0.636 N SCI/SCIE0.393 N SCIE0.436N SCIE0.488 N SCIE0.733 N SCIE0.566 N SCIE0.000 0 Y SCI/SCIE14.22 N SCIE 1.023 N SCIE0.348 N SCIE0.26N SCIE 1.231 N SCIEN SCIEN SCIE0.398 N SCIE0.863 N SCIE0.966 N SCIE0.99N SCIE0.103 N SCIE0.188 N SCIE0.114 N SCI/SCIE 1.553 N SCI/SCIE 1.582 N SCI/SCIE0.854 N SCIE0.722 N SCI/SCIE 1.872 N SCIE2010年影响因子2009年影响因子2008年影响因子5年平均影响因子0.7490.8650.9390.8653.000 5.500 5.000 6.3570.1250.0000.0001.826 1.922 1.3492.3890.3830.5150.0000.4040.1880.2520.3630.9280.7540.4940.5780.0310.0990.0690.0310.3020.2600.4300.4030.1940.0000.0001.662 1.048 1.3932.1510.7700.9450.441 1.0540.6250.704 1.155 1.0000.4500.4880.5350.7980.5050.5000.2680.4341.267 1.234 1.037 1.6011.599 1.817 1.8542.0100.8940.8350.9340.9180.8080.7210.819 1.1770.3480.3910.1700.3080.9370.8410.792 1.1120.658 1.2240.637 1.0342.577 2.331 1.614 2.8520.3970.1780.2310.3620.5110.5170.5150.6150.6070.5530.4120.8520.9470.9030.0001.806 1.602 1.556 1.8221.802 1.498 1.3352.2471.899 1.947 1.8942.9130.2130.2220.2090.4001.522 1.301 1.398 1.7451.919 1.956 1.5762.5641.266 1.288 1.077 1.4950.6820.3540.0000.6245.082 4.791 3.875 4.7381.060 1.2070.0001.518 1.2560.862 1.2931.439 1.537 1.4582.0890.6440.7210.5370.6220.4140.5000.0000.3511.667 1.770 1.6832.3900.3580.4800.3890.5170.1790.2080.0000.2620.2100.0000.2590.5710.5570.000 1.1710.5820.7810.8270.8390.4820.6350.7350.8420.6950.8150.938 1.1070.9560.9800.792 1.1440.2090.0000.0000.4000.3140.4380.5481.482 1.256 1.380 1.7450.4400.4520.6280.9070.2040.0000.0000.9420.959 1.421 2.2861.227 1.478 1.272 1.8620.0330.0480.0610.0210.5670.5990.740 1.1170.6170.869 1.532 1.4830.4120.3740.2580.4012.157 1.922 2.226 2.5120.2770.2890.4470.5070.7070.6840.6120.6470.2930.3510.4490.4760.7730.5910.6460.7900.6440.8260.662 1.1641.334 1.414 1.364 1.7320.8970.7480.6260.9920.1610.1030.0000.2560.1210.0000.2120.1650.0000.2390.8230.6870.6470.7500.4490.7020.722 1.2640.3450.391 1.2970.9400.3900.7080.7280.9780.8630.8960.656 1.205 0.3230.3570.0000.5790.1880.0000.5880.0000.0000.4590.4330.6840.9090.1030.0650.0000.2500.2860.2770.2801.7622.075 1.984 2.4711.210 1.407 1.437 1.5400.944 1.198 1.434 1.4961.903 1.900 1.000 1.0101.741 1.658 1.295 1.4381.252 1.221 1.105 1.2451.797 3.256 1.906 3.5330.7990.6550.6090.7930.6990.4120.2810.7900.4510.4160.3170.5600.4410.4020.3420.7020.5200.4320.4630.4880.3890.4340.4070.6540.4800.7730.3660.5790.7210.6300.4900.8220.3460.3700.2790.7430.0300.0450.0710.00310.36211.0248.00017.1330.7200.662 1.086 1.285 0.2540.1230.0000.2600.0950.4650.4161.316 1.064 1.137 1.2480.1590.1890.3210.2220.0480.0000.4660.5330.2350.3740.4290.4380.5000.8120.5920.847 1.1910.9761.0730.771 1.011 1.0870.1430.2080.0000.2810.1950.1330.2280.1100.0690.1450.0981.560 1.690 1.423 1.8691.574 1.664 1.385 1.732 0.6690.3440.5780.7580.7520.6590.724 1.0191.635 1.771 1.5092.2601.716 1.342 1.271备注。

机械专业英文词典Mechanical Engineering English DictionaryAdhesion: The tendency of dissimilar particles or surfaces to cling to one another. Adhesion is an important property in the field of mechanical engineering as it affects the performance and durability of various materials and components.Airfoil: A structure designed to produce lift when air flows around it. Airfoils are commonly used in aircraft wings, propeller blades, and turbine blades.Bearings: Mechanical components that support and guide moving parts. Bearings reduce friction and enable smooth rotation or linear motion in machines and equipment.Casting: A manufacturing process in which a liquid material is poured into a mold and allowed to solidify into a desired shape. Castings are commonly used to produce complex metal components.Damping: The process of reducing or controlling the oscillations, vibrations, or noise in mechanical systems.Damping is achieved through the use of various materials and devices such as dampers and isolators.Elasticity: The ability of a material to deform under stress and return to its original shape when the stress is removed. Elasticity is an important property in the design and analysis of mechanical components.Fatigue: The weakening and eventual failure of a material subjected to repeated or fluctuating loads over time. Fatigue is a common cause of failure in mechanical components and structures.Gears: Mechanical components with toothed surfaces that transmit motion and power between rotating shafts. Gears are widely used in machinery, vehicles, and various mechanical systems.Heat exchanger: A device used to transfer heat between two or more fluids at different temperatures. Heat exchangers are commonly found in refrigeration, air conditioning, and power generation systems.Ignition: The process of initiating combustion in an internal combustion engine. Ignition systems are used toignite the fuel-air mixture in spark-ignition engines and diesel engines.Joule: A unit of energy in the International System of Units (SI). One joule is equal to the work done by a force of one newton acting over a distance of one meter.Kinematics: The branch of mechanics that deals with the motion of objects without considering the forces that cause the motion. Kinematics is concerned with the position, velocity, and acceleration of objects.Lubrication: The process of reducing friction and wear between moving surfaces by introducing a lubricant such as oil or grease. Lubrication is essential for the proper functioning and longevity of mechanical systems.Machining: The process of shaping or finishing a workpiece by removing material using various cutting tools. Machining operations include milling, turning, drilling, and grinding.Newton's laws of motion: Three fundamental principles that describe the behavior of objects under the influenceof forces. Newton's laws of motion are widely used in the analysis and design of mechanical systems.Optimization: The process of finding the best solutionto a problem within given constraints. Optimization is an important aspect of mechanical engineering, especially in the design and operation of systems and components.Pressure: The force per unit area exerted by a fluid or gas. Pressure plays a crucial role in the design and analysis of fluid systems, hydraulic systems, and pneumatic systems.Quality control: The process of ensuring that products and processes meet the desired standards and requirements. Quality control is essential in mechanical engineering to ensure the reliability and performance of manufactured components.Resilience: The ability of a material to absorb energy without undergoing permanent deformation. Resilience is an important property in the design of impact-resistant materials and structures.Stress analysis: The process of evaluating the internal forces and stresses in a mechanical component or structure. Stress analysis is used to ensure the safety andreliability of engineering designs.Thermodynamics: The branch of physics that deals with the relationships between heat, work, and energy. Thermodynamics is essential for understanding and analyzing the behavior of various mechanical and thermal systems.Ultrasonic testing: A non-destructive testing technique that uses high-frequency sound waves to detect flaws or defects in materials. Ultrasonic testing is widely used in the inspection of welds, castings, and other critical components.Vibration: The oscillation of mechanical systems or components around a reference point. Vibration analysis is important for predicting and controlling the dynamic behavior of machines and structures.Welding: The process of joining two or more metal pieces by heating them to a high temperature and applying pressure or filler material. Welding is a common method for fabricating metal structures and components.中文翻译:粘附:不同颗粒或表面相互粘附的倾向。

机械英语试题及答案详解一、选择题(每题2分,共20分)1. The term "mechanical" is most closely associated with which of the following fields?A. MedicineB. LiteratureC. EngineeringD. Art答案:C解析:"Mechanical"一词与工程领域最为相关,因为它涉及到机械系统和机械设备的设计、建造和维护。

2. What is the function of a bearing in a mechanical system?A. To generate powerB. To transmit motionC. To support and reduce frictionD. To provide electrical insulation答案:C解析:轴承在机械系统中的主要功能是支撑旋转部件并减少摩擦,从而提高效率和延长设备寿命。

3. Which of the following is not a type of material commonly usedin mechanical engineering?A. SteelB. PlasticC. ConcreteD. Rubber答案:C解析:混凝土通常不用于机械工程中,因为它是一种建筑材料,而钢、塑料和橡胶是机械工程中常用的材料。

4. What does the acronym "CAD" stand for in the context of mechanical engineering?A. Computer-Aided DesignB. Computer-Aided DraftingC. Computer-Aided DevelopmentD. Computer-Aided Documentation答案:A解析:在机械工程领域,"CAD"代表"Computer-Aided Design",即计算机辅助设计。

Mechanical DesignJohn ErnstAbstract:A machine is a combination of mechanisms and other components which transforms transmits。

Examples are engines, turbines,vehicles,hoists,printing presses,washing machines,and movie cameras. Many of the principles and methods of design that apply to machines also apply to manufactured articles that are not true machines. The term "mechanical design” is used in a broader sense than "machine design" to include their design. The motion and structural aspects and the provisions for retention and enclosure are considerations in mechanical design. Applications occur in the field of mechanical engineering, and in other engineering fields as well, all of which require mechanical devices, such as switches,cams, valves,vessels, and mixers。

Keywords:Mechanical Design; Mechanisms Design Process;Application1。

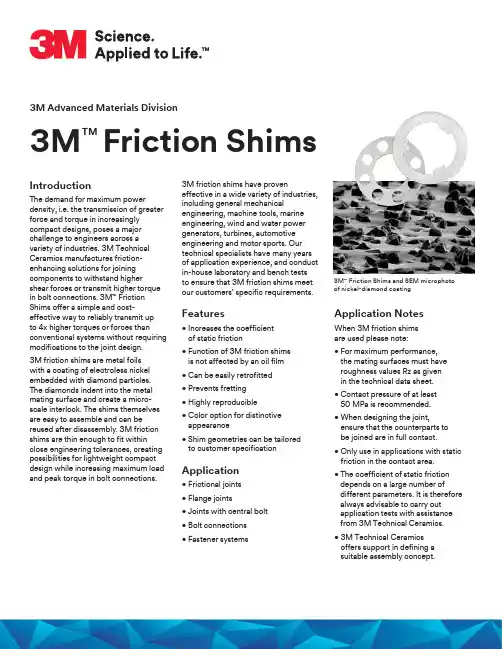

3M Advanced Materials DivisionIntroductionThe demand for maximum powerdensity, i.e. the transmission of greater force and torque in increasingly compact designs, poses a major challenge to engineers across a variety of industries. 3M Technical Ceramics manufactures friction-enhancing solutions for joining components to withstand highershear forces or transmit higher torque in bolt connections. 3M ™ Friction Shims offer a simple and cost-effective way to reliably transmit up to 4x higher torques or forces thanconventional systems without requiring modifications to the joint design.3M friction shims are metal foils with a coating of electroless nickel embedded with diamond particles. The diamonds indent into the metal mating surface and create a micro-scale interlock. The shims themselves are easy to assemble and can bereused after disassembly. 3M friction shims are thin enough to fit within close engineering tolerances, creating possibilities for lightweight compact design while increasing maximum load and peak torque in bolt connections.3M friction shims have proveneffective in a wide variety of industries, including general mechanicalengineering, machine tools, marine engineering, wind and water power generators, turbines, automotive engineering and motor sports. Our technical specialists have many years of application experience, and conduct in-house laboratory and bench tests to ensure that 3M friction shims meet our customers’ specific requirements.Features• I ncreases the coefficient of static friction• F unction of 3M friction shims is not affected by an oil film • Can be easily retrofitted • Prevents fretting • Highly reproducible • C olor option for distinctive appearance• S him geometries can be tailored to customer specificationApplication• Frictional joints • Flange joints• Joints with central bolt • Bolt connections • Fastener systemsApplication NotesWhen 3M friction shims are used please note:• F or maximum performance, the mating surfaces must have roughness values Rz as given in the technical data sheet.• C ontact pressure of at least 50 MPa is recommended.• W hen designing the joint,ensure that the counterparts to be joined are in full contact.• O nly use in applications with static friction in the contact area.• T he coefficient of static friction depends on a large number ofdifferent parameters. It is therefore always advisable to carry out application tests with assistance from 3M Technical Ceramics.• 3M Technical Ceramics offers support in defining a suitable assembly concept.3M ™Friction Shims3M ™ Friction Shims and SEM microphotoof nickel-diamond coatingHandling Instructions• S tore 3M™ Friction Shims onlyin original packaging.• D on’t handle 3M friction shimsas bulk unless a clip variant isused that has been specifically designed for bulk storage.• D on’t expose 3M friction shimsto temperatures above 400°C.• D ry storage recommended.• D on’t bend 3M friction shims.• N o mechanical treatmentof 3M friction shims.• B efore assembling 3M friction shims, make sure no dirt residue is present.• C heck correct quantityduring assembly.• A void relative movementof shims on surface.Matrix3M™ Friction Shim Diagram Typical Coefficient of Friction (Not for specification purposes)Figure 2. Results of a series of tests onthe coefficient of static friction with and without 3M™ Friction Shims. The shadedareas of the bar show the variation.Figure 1. Tribosystem with 3M friction shim. (This figure is intended as a guide. On request, we can provide you with a drawing frame for your specification.)0.10.20.30.40.50.60.70.8 0.03M is a trademark of 3M Company. Used under license by 3M subsidiaries and affiliates.Please recycle. Printed in USA © 3M 2018. All rights reserved. Issued: 7/18 14365HB 98-0050-0042-1 Rev. F3M Technical CeramicsZweigniederlassung der 3M Deutschland GmbH Max-Schaidhauf-Str. 25, 87437 Kempten, Germany Phone +49 (0)831 5618-0Web www.3M.de/Technical-CeramicsWarranty, Limited Remedy, and Disclaimer: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product in a particular application. User is solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and suitable for user’s method of application. User is solely responsible for evaluating third party intellectual property rights and for ensuring that user’s use of 3M product does not violate any third party intellectual property rights. Unless a different warranty is specifically stated in the applicable product literature or packaging insert, 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OF NON-INFRINGEMENT OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the purchase price.Limitation of Liability: Except where prohibited by law, 3M will not be liable for any loss or damages arising from the 3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract, negligence or strict liability.Technical Information: Technical information, recommendations, and other statements contained in this document or provided by 3M personnel are based on tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed. Such information is intended for persons with knowledge and technical skills sufficient to assess and apply their own informed judgment to the information. No license under any 3M or third party intellectual property rights is granted or implied with this information.3M Advanced Materials Division 3M CenterSt. Paul, MN 55144 USAP hone 1-800-367-8905Web /frictionshims。

![[37] 故障参数下齿轮系统非线性动力学行为](https://uimg.taocdn.com/8e79d86527284b73f242506c.webp)

故障参数下齿轮系统非线性动力学行为王彦刚, 郑海起, 杨通强, 关贞珍, 杨 杰(军械工程学院火炮工程系 石家庄,050003)摘要 为分析齿轮系统在故障条件下的非线性动力学变化机理,对不同故障参数下非线性齿轮系统的动力学行为进行了研究;建立了单齿冲击、单齿刚度、单齿磨损及全齿磨损的非线性动力学模型,采用齿轮混沌振子方法对其进行了分析;探讨了上述4种故障激励产生后齿轮系统吸引子的变化。

研究表明,利用齿轮混沌振子能够较好地区分故障信号的大小,为更好地进行故障诊断提供了理论支持,也为旋转机械的故障诊断提供了一种新方法。

关键词 齿轮 故障诊断 非线性 分岔中图分类号 T H113引 言齿轮作为一种最常用的传动机构,高速工作时,特别是在含微弱故障时,其动态性能的好坏对机械设备的工作可靠性影响很大。

近几年来,国内外学者对考虑齿侧间隙和轮齿啮合刚度变化等非线性因素的齿轮系统动力学问题进行了深入的研究,并应用于齿轮系统振动控制,取得了良好的效果。

但在以往的齿轮系统非线性动力学研究中,过多的研究是针对正常状态下的齿轮系统动力学特性[1-3],而忽视了含故障状态下齿轮系统动力学行为的研究。

Parey等人[4-5]在研究带有缺陷的齿轮系统动力学时,建立了含各种故障的齿轮动力学模型并进行了响应信号分析。

朱艳芬[6]研究了含故障齿轮系统的幅频特性,认为脉冲故障在低频时影响较大,上述研究中都没有涉及到齿轮系统的故障参数的动力学特性分析。

陈予恕[7]在研究机械故障诊断的非线性动力学时认为,对可建模系统,基于分岔理论的故障机理分析,可对某些疑难振动故障的机理、控制和预测提供指导。

本文在分析非线性齿轮系统连续匀加速状态下的分岔特性基础上,参考混沌控制中的微扰理论,分别研究了单齿冲击、单齿刚度、单齿磨损及全齿磨损4种故障激励类型产生后对齿轮系统动力学行为的影响。

1 含故障参数的齿轮系统非线性动力学模型 对于单级齿轮系统,考虑齿轮传动系统的齿侧间隙以及时变啮合刚度和内外部激励等因素的影响,其非线性齿轮系统无量纲动力学模型为[8-10] x¨(t)+2a x(t)+k(t)f(x(t))=F(t)F(t)=F m+F ah k2eh sin(k eh t+O h)(1)其中:a,k eh,F m,F ah,k(t)和f(x(t))分别为粘弹性阻尼、内部激励基频、平均载荷、内部激励幅值、啮合刚度和啮合力。

机械双字分词英文分词好的,以下为您生成 20 个关于机械相关的双字分词示例,包含英文分词、英语释义、短语、单词、用法和双语例句:---1. 机械加工- 英文分词:Mechanical Processing- 英语释义:The act or process of modifying or fabricating a material or component using machinery and tools.- 短语:mechanical processing technology(机械加工技术)- 单词:processing(加工;处理)- 用法:“Mechanical processing is widely used in the manufacturing industry.”(机械加工在制造业中被广泛应用。

)- 双语例句:The quality of the product depends on the accuracy of mechanical processing.(产品的质量取决于机械加工的精度。

)2. 机械设计- 英文分词:Mechanical Design- 英语释义:The process of creating or planning the structure, form, and functionality of a mechanical system or device.- 短语:mechanical design engineer(机械设计工程师)- 单词:design(设计;构思)- 用法:“The mechanical design of this machine needs to be improved.”(这台机器的机械设计需要改进。

)- 双语例句:He is specialized in mechanical design and has many innovative ideas.(他专攻机械设计,有很多创新的想法。

2021年5月第36卷第3期西安石油大学学报(自然科学版)JournalofXi′anShiyouUniversity(NaturalScienceEdition)May2021Vol.36No.3收稿日期:2020 04 13基金项目:国家自然科学基金资助项目(51804044)第一作者:彭冲(1995 ),男,硕士研究生,研究方向:油气田开发。

E mail:753712629@qq.com通讯作者:欧阳传湘(1964 ),男,教授,研究方向:油气藏开发及相关方向。

E mail:185867671@qq.comDOI:10.3969/j.issn.1673 064X.2021.03.013中图分类号:TE375文章编号:1673 064X(2021)03 0090 07文献标识码:A扩张式封隔器接触力学行为及坐封效果评价彭冲,欧阳传湘,谭钲扬,陈洲亮(长江大学石油工程学院,湖北武汉430100)摘要:以K344-114型扩张式封隔器为研究对象,基于橡胶材料的Mooney Rivlin本构模型,运用有限元分析方法按照封隔器坐封过程和坐封后两种工况,对封隔器的非线性接触力学行为进行了模拟研究,分析了坐封过程中施加载荷与轴向压缩距的关系以及坐封后的强度、接触应力和摩擦力校核。

分析结果表明:在封隔器坐封过程中,中胶筒首先与套管发生接触,当压差达到一定值时胶筒扩张到与套管接触,封隔器完成坐封;坐封后胶筒的应力集中于胶筒的肩部;胶筒与套管之间的摩擦力、接触应力均能满足分层注水工艺设计要求,能够有效封隔15MPa的层间压差。

关键词:扩张式封隔器;坐封;胶筒;接触应力;有限元EvaluationofContactMechanicalBehaviorandSettingEffectofExpandablePackerPENGChong,OUYANGChuanxiang,TANZhengyang,CHENZhouliang(CollegeofPetroleumEngineering,YangtzeUniversity,Wuhan,Hubei430100,China)Abstract:BasedonMooney Rivlinconstitutivemodelofrubbermaterial,thenonlinearcontactmechanicalbehaviorofK344 114ex pandablepackerwassimulatedbyusingfiniteelementmethod.Therelationshipbetweenappliedloadandaxialcompressiondistanceoftheexpandablepackerintheprocessofsettingisanalyzed,andthestrength,contactstressandfrictionaftersettingarechecked.There sultsshowthat:inthesettingprocessofpacker,themiddlerubbertubefirstcontactswiththecasing,whenthepressuredifferencerea chesacertainvalue,therubbercylinderexpandstocontactwiththecasing,andthepackercompletesthesetting;Aftersetting,thestressoftherubbercylinderisconcentratedontheshoulderoftherubbercylinder;thefrictionforceandcontactstressbetweentherub bercylinderandthecasingcanmeetthedesignrequirementsoflayeringwaterinjectionprocess,andtheinterlayerpressuredifferenceof15MPacanbeeffectivelysealed.Keywords:expandablepacker;setting;rubbercylinder;contactstress;finiteelement彭冲,欧阳传湘,谭钲扬,等.扩张式封隔器接触力学行为及坐封效果评价[J].西安石油大学学报(自然科学版),2021,36(3):90 96,104.PENGChong,OUYANGChuanxiang,TANZhengyang,etal.Evaluationofcontactmechanicalbehaviorandsettingeffectofexpandablepacker[J].JournalofXi'anShiyouUniversity(NaturalScienceEdition),2021,36(3):90 96,104.彭冲等:扩张式封隔器接触力学行为及坐封效果评价引 言封隔器广泛应用于油田现场施工作业,具有操作方便,成本相对低廉,并且能满足多种工艺要求的特点。

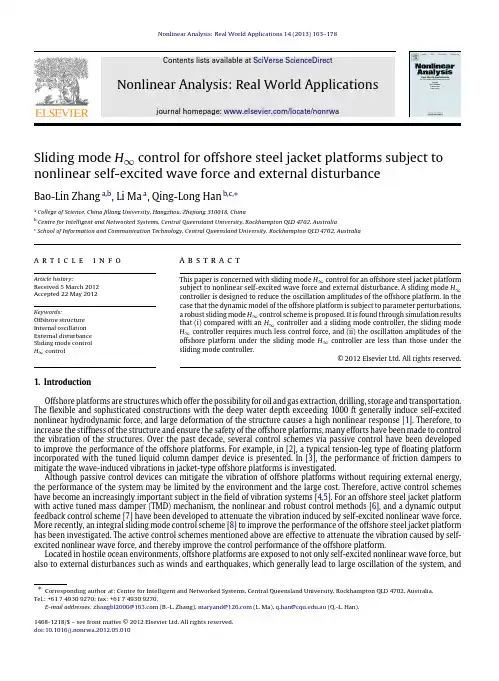

Control design of nonlinear mechanical systems with frictionTakashi Nakakuki and Katsutoshi Tamura1Abstract—This paper presents a solid analysis and control design of nonlinear mechanical systems with friction.Utilizing the Filippov solution concept,it is shown that the class of nonsmooth systems can not be asymptotically stabilized via any Lipschitz continuous static control law.Then,a sliding mode controller which makes the nonsmooth mechanical system asymptotically stable is derived.The validity of the controller design is verified by a simulation example for an electronic throttle control system.I.I NTRODUCTIONThere are several mechanical systems with nonsmooth-ness in applications.Nonsmooth nature in mechanical sys-tems is caused by several phenomena such as friction, backlash,hysteresis of dynamics,nonsmooth controller or switching structure of hybrid systems.While nonsmooth systems have many problems to be resolved,there are few theoretical tools to deal with them.In a mathematical sense,they are described by differential equations with nonsmooth right hand side.Also,in a practical sense, control performance degradation may appear such as limit cycle(chattering phenomenon),dead zone and so on.The systems with friction have important and interesting nature from the practical point of view.There are two kinds of friction such as static and dynamic friction.In either case, it is essentially that friction causes the nonsmoothness or discontinuity at zero-velocity.In nonsmooth analysis,the Filippov solution concept[1] and related Lyapunov stability theory[2],[3]are useful. In[2],the stability of a harmonic oscillator with Coulomb friction was shown by employing nonsmooth analysis.Pa-pers of the controller design for mechanical systems with friction include[3],[4],[5],[6].In[3],a sliding mode controller design of robot manipulators was presented,while the algorithm was a little complicated.[4]showed that for a Coulomb friction oscillator any continuous algorithm does not admit asymptotic stability.On the basis of this fact, [5]proposed a switched chattering controller for electrical servo-motors.Recently,[6]proposed a Lyapunov-based friction compensator for a hydraulic actuator.In this paper,we consider generic second order nonlinear mechanical systems with friction.It is proven that the class of nonsmooth systems does not admit asymptotic stability via any Lipschitz continuous static control law.Then,a sliding mode controller is proposed by employing rigorous nonsmooth analysis to make the system asymptotically stable.After illustrating our results by a simple example, 1Department of Mechanical Engineering,Graduate Division of Science and Technology,Sophia University,7-1,Kioicho,Chiyoda-ku,Tokyo, Japan,1028554;e-mail:t-nakaku@sophia.ac.jp a simulation for an electronic throttle control system is presented.II.P RELIMINARIESIn this section,we present some important definitions and theorems for nonsmooth analysis.Consider the vector autonomous differential equation˙x=f(x),x(t0)=x0(1) where f:R n→R n is defined almost everywhere and is measurable and essentially locally bounded in an open region D⊂R n.Under these conditions,the existence of Filippov solution is assured(see[1]).Definition2.1(Filippov solution):A vector function x(t)is called a solution of(1)on[t0,t1]if x(t)is absolutely continuous on[t0,t1],and for almost all t∈[t0,t1]˙x∈K[f](x)(2) whereK[f](x)=δ>0µN=0¯co f(B(x,δ)−N).(3)µN=0denotes the intersection over all sets N of Lebesgue measure zero,B(x,δ)={y∈R n| y−x <δ}and¯co denotes the convex closure.In the nonsmooth analysis,the behavior of the solution on nonsmooth surface is specifically important.Next two theorems by Filippov[1]are useful to investigate them. Theorem2.1(Lemma3in[1]):Let the regions G−and G+in the space R n be separated by a smooth surface S(x). Suppose that the vector function f(x)is bounded and its limiting values f−and f+exist when S(x)is approached from G−and G+.Let f−N and f+N be the projections of the vectors f−and f+on the normal to the surface S(x) directed from G−and G+.Let the vector function x(t)be absolutely continuous and for t1≤t≤t2let x(t)∈S(x), f−N≥0,f+N≤0,f−N−f+N>0.In order for x(t)to be a solution of equation(1),it is necessary and sufficient that for almost all t∈[t1,t2]˙x=αf++(1−α)f−,α=f−Nf−N−f+N.(4) Theorem2.2(Lemma8in[1]):If f+N≤0for t1<t< t2,x∈S0where S0is a part of the surface S(an open domain on S),then for t1≤t≤t2no solution can go out of S0into G+that does not atfirst go from S0into G−+S−S0.43rd IEEE Conference on Decision and ControlDecember 14-17, 2004Atlantis, Paradise Island, BahamasThA07.2Under the concept of Filippov solution,some related Lyapunov stability results have been proposed in[2]and [3].Theorem2.3(Chain rule[2]):Let x(t)be a Filippov solution of(1)on an interval containing t and V:R n→R be a Lipschitz and regular function(See[7]for definition). Then,V(x(t))is absolutely continuous,(d/dt)V(x(t)) exists almost everywhere andddtV(x(t))∈a.e.˙˜V(x)(5) where˙˜V(x)=ξ∈∂V(x(t))ξT K[f](x(t)).(6)Remark2.1:In Theorem2.3,we used Clarke’s general-ized gradient∂V(See[7]).Theorem2.4(Lyapunov’s theorem generalized,[3]):If1)V:R n→R,V(0)=0,and V(x)>0,∀x=0and2)x(t)and V(x(t))are absolutely continuous on[t0,∞) withddtV(x(t))<− <0 a.e.on{t|x(t)=0}(7) then x converges to0infinite time.III.A S TABILIZING C ONTROLLER D ESIGN Consider the nonsmooth mechanical system with friction˙x1=x2˙x2=g(x1,x2)−µ(x2,t)+h(x1,x2)u(8) where g:D→R and h:D→R are Lipschitz,with g(0,0)=0and h(x1,x2)=0for all x1,x2∈D,and D⊂R2is a domain containing the origin x=[x1,x2]T=0.We assume that both g and h are known.u∈R is the control input.The frictionµ(x2,t)which has the discontinuity at x2=0is illustrated in Fig.1,where narrow part represents the dynamic friction and the discontinuous part the static friction.Wefirst start with the following theorem.x2Fig.1.friction modelµ(x2,t):On x2=0the friction force can be represented as a fuction of t.The complex friction phenomena such as Stribeck effect may exist around x2=0.Theorem3.1:Consider system(8).Any Lipschitz con-tinuous static control lawξ(x1,x2)withξ(0,0)=0can not achieve the asymptotic stability of the origin.Proof:We will show that there exists a nontrivial equilibrium set including the origin.The closed loop system with u=ξ(x1,x2)is given by˙x1˙x2=x2−µ(x2,t)+φ(x1,x2)(9) whereφ(x1,x2)=g(x1,x2)+h(x1,x2)ξ(x1,x2),andφis Lipschitz.From(9)the switching surface is given by Ω={x∈D|S(x)=x2=0}.Let the regions G+and G−be defined byG+={x∈D|S(x)>0}G−={x∈D|S(x)<0}.(10) Since the normal vector N s for S(x)=0is N s=[0,1]T, at a point x∈Ωwe obtainf+N=−γf+φ(x1,0)f−N=γf+φ(x1,0).(11) Let the set S I beS I={x∈Ωf+N≤0,f−N≥0,f−N−f+N>0}.(12) Then,from(11)we have the following.φ(x1,0)≤γf→f+N≤0φ(x1,0)≥−γf→f−N≥0f−N−f+N=2γf>0,∀x∈Ω(13) which impliesS I=x1|φ(x1,0)|≤γf.(14) Sinceφis Lipschitz continuous andφ(0)=0,for given γf,there existsδ>0such that|x1|<δ⇒|φ(x1,0)|<γf.(15) Therefore,there exists a nonempty subset S I⊆S I such thatS I=x1|x1|<δ.(16) From Theorem2.1,any solution on S I is dominated by the differential equation˙x=αf++(1−α)f−(17) whereα=f−Nf−N+N=γf+φ(x1,x2)2γf.(18) Calculating the right hand side of(17),we obtain˙x=0on S I,which implies that S I is the nontrivial equilibrium set including the origin.Theorem3.1implies that a discontinuous control law should be applied in order to achieve the asymptotic sta-bility of the system.Theorem 3.2:Consider system (8).Assume that thereexists a positive constant ¯γf such that ¯γf >|µ(x 2,t )|for all x ∈D and t ∈R +.Then,the following control law asymptotically stabilizes the origin of system (8):u =1h (x 1,x 2){−g (x 1,x 2)+¯γf sgn (αx 1−x 2)+αx 2}(19)where α<0is a design parameter which is the slope of the switching surface in R 2.Proof:The closed loop system is given by ˙x 1˙x 2=f (x,t )=x 2−µ(x 2,t )+αx 2+¯γf sgn (αx 1−x 2).(20)First,we investigate the equilibrium point of the system.Let the set S 0beS 0={x ∈D |0∈K [f ](x,t )}.(21)On the x 1-axis,K [f ](x,t )is given byK [f ](x,t )=K 0−µ(0,t )+¯γf sgn (αx 1)(x,t )=⎧⎪⎪⎨⎪⎪⎩0−γfSGN (0)+¯γf SGN (αx 1) 0,if x 1=00−γf SGN (0)+¯γf SGN (0)0,if x 1=0(22)where SGN (·)is the set-valued sign function defined bySGN (x )=⎧⎨⎩{1},if x >0{−1},if x <0[−1,1],if x =0.(23)Thus,S 0={0}.Since it can be shown that x =0is the Filippov solution with ˙x =0,x =0is the equilibrium point.We now prove the asymptotic stability of (20).Sliding mode control consists of two modes,that is,sliding mode and reaching mode.·Stability of sliding modeThe switching surface of the controller is given byΩc ={x ∈D |S (x )=αx 1−x 2=0}.(24)We first show that Ωc is the sliding surface.At a point x ∈Ωc ,f +and f −are given byf += x 2−lim S (x )→0+µ(x 2,t )+αx 2+¯γff −= x 2−lim S (x )→0−µ(x 2,t )+αx 2−¯γf .(25)Since the normal vector N s for S (x )=0is N s =[α,−1]Tand ¯γf >|µ(x 2,t )|for all x ∈D and t ∈R +,we havef +N =limS (x )→0+µ(x 2,t )−¯γf <0f −N=limS (x )→0−µ(x 2,t )+¯γf >0(26)for all x ∈D and t ∈R +.Hence,from Theorem 2.2,weconclude that Ωc is actually the sliding surface.Further-more,from Theorem 2.1,it follows that the trajectory on Ωc is the Filippov solution,which is dominated by˙x =αf ++(1−α)f −(27)whereα=f −N f −N −f +N=µ(x 2,t )+¯γf 2¯γf .(28)Substituting (25)into (27),we obtain˙x 1=αx 1˙x 2=αx 2.(29)Since α<0,it follows that x →0as t →∞.·Behavior of reaching modeLet V (S (x ))be a positive definite,Lipschitz and regular function defined byV (S (x ))=|S (x )|=|αx 1−x 2|.(30)The generalized gradient of V is given by∂V (S (x ))= α−1SGN (S (x )).(31)Also,K [f ](x,t )is given byK [f ](x,t )=x 2−K [µ(x 2,t )]+αx 2+¯γf SGN (S (x )).(32)Thus,˙˜V (S (x ))= ξ∈∂V (S (x ))ξT K [f ](x,t )=⎧⎪⎨⎪⎩K [µ(x 2,t )]−¯γf ,if S (x )>0−K [µ(x 2,t )]−¯γf ,if S (x )<00,if S (x )=0.(33)Since ¯γf >|µ(x 2,t )|for all x ∈D and t ∈R +,for anyv ∈˙˜V(S (x )),there exists a positive constant =¯γf −sup x ∈Dt ∈R +|µ(x 2,t )|>0(34)such thatv ≤− <0,if S (x )=0.(35)Thus,from Theorem 2.3and 2.4,the trajectory starting from x (0)∈D reaches the switching surface Ωc in finite time.In the following example,we will examine two con-trollers associated with Theorem 3.1and 3.2.Example 3.1:Consider system (9)with µ(x 2,t )=sgn (x 2)˙x 1˙x 2 =x 2−sgn (x 2)+φ(x ).(36)-2-1.5-1-0.500.511.52x x 12Fig.2.trajectories via the controller associated with Theorem3.1-2-1.5-1-0.500.511.52x x 12Fig.3.trajectory via the controller associated with Theorem 3.2(1)Case when φ(x )=−a 0x 1−a 1x 2:This controller is associated with Theorem 3.1.The equi-librium set is given byS 0= q 0 ∀q ∈ −γf a 0,γf a 0 = −1a 0,1a 0 .(37)In Fig.2,the trajectories starting from some initial condi-tions are shown where a 0=a 1=1.Every trajectory iscaptured on S 0.(2)Case when φ(x )=αx 2+¯γf sgn (αx 1−x 2):This controller is associated with Theorem 3.2.The equi-librium point is given byS 0={0}.(38)In Fig.3,the trajectory starting from x (0)=(1,1)is shown where α=−1and ¯γf =2.The trajectory reaches S (x )=0in finite time,then it converges to the origin on the surface.IV.S IMULATIONIn this section,we will apply our controller to an elec-tronic throttle control (ETC)system.ETC system is an equipment of engine control systems,which adjusts the quantity of air flowing into the engine.Since the opening angle of valve plate is decided depending on the required quantity of air to achieve the desirable speed or torque in vehicle,the high performance control system of the valve plate is required.However ETC system has discontinuity and nonlinearity such as friction,spring and backlash.These facts motivate researchers to tackle the control problem,and some robust controllers including switching mechanism have been proposed [8],[9],[10].The ETC system is constructed by DC motor,some gears,valve plate and spring.Consider the model of ETC system as shown in Fig.4.Whole system is constructed by two systems.One is actuator system and another one is throttle system.actuator system:The relation between the input voltage v [V]and armature current i [A]is given byLdidt+Ri +K v ωm =v (39)where L [H]is the armature inductance,R [Ω]is the ar-mature resistance,K v [V ·sec /rad]is the back electromotive force constant and ωmt [rad /sec]is the angular velocity of motor.The relation between the armature current i and the torque generated by the motor is given byτmt =K i i(40)where K i [Nm /A]is torque constant.Since the rotating angle of motor θmt [rad]becomes the rotating angle of valve plate through the gear ratio K g ,we obtain the following relations.θ=K g θmt ω=K g ωmt τ=K g τmt(41)throttle system:The throttle’s dynamic equation is given byJ ¨θ=τapp −τf (˙θ,τapp )(42)Fig.4.Electronic Throttle Control Systemp o s i t i o n : θ, θ [d e g ]time : t [sec]m-10-8-6-4-20246810i n p u t v o l t a g e : v [v ]time : t [sec]Fig.5.position θ,θm and input voltage vwhere J [kg ·m 2]is the inertia of valve plate and τapp =τ−τS (θ).τS (θ)is nonlinear spring torque:τS (θ)=m (θ−θ0)+γs sgn(θ−θ0),(43)τf (˙θ,τapp )is static and dynamic frictional torque.In this simulation,we employ the bristle model [11]as the friction model.Now assume that we want to design the model following controller.The reference model is given by¨θm +λ1˙θm +λ0θm =λ0r.(44)where λ0,λ1are some constants and r is the referenceposition.Ignoring the armature inductance L and putting the error signal e =θm −θ,the error system is given by ˙x 1˙x 2 = x 2−λ0x 1−λ1x 2+β(θ,˙θ,r )+µ(t )−1Jτ(45)τ=K g K iR v −K v K i R˙θ(46)where [x 1x 2]=[e ˙e],β(θ,˙θ,r )=−λ0θ−λ1˙θ+λ0r +(1/J )τs ,and µ(t )=(1/J )τf .Setting τ=J (β(θ,˙θ,r)−u ),-0.050.050.10.150.2time : t [sec]p o s i t i o n e r r o r : e [d e g]0123v e l o c i t y e r r o r : e [d e g / s e c ]time : t [sec].Fig.6.position error e and velocity error ˙e we have˙x 1˙x 2 = x 2g (x 1,x 2)+µ(t )+h (x 1,x 2)u(47)where g (x 1,x 2)=−λ0x 1−λ1x 2and h (x 1,x 2)≡1.Then,the control law is given byu =−g (x 1,x 2)+¯γf sgn(αx 1−x 2)+αx 2v =RJ Kg K i(β(θ,˙θ,r )−u )+αx 2.(48)As shown in Fig.5and Fig.6,the controller realizes thegood performance,and the tracking error asymptotically converges to 0as t tends to infinity in spite of uncertain and complex friction phenomena.V.C ONCLUSIONWe have presented a stabilizing controller design for nonsmooth mechanical systems with friction.The approach to design the asymptotic stabilizing controller is based on the Filippov solution concept and related Lyapunov stability theory for nonsmooth systems.For the class of nonsmooth systems,it was shown that any Lipschitz continuous con-troller can not achieve the asymptotic stability because of the existence of the nontrivial equilibrium set.A slidingmode controller which makes the nonsmooth mechanical system asymptotically stable was derived.R EFERENCES[1] A.Filippov,“Differential equations with discontinuous right-handside,”American Mathematical Society Translations,vol.42,pp.199–231,1964.[2] D.Shevitz and B.Paden,“Lyapunov stability theory of nonsmoothsystems,”IEEE Transactions on Automatic Control,vol.39,pp.1910–1914,1994.[3] B.Paden and S.S.Sastry,“A calculus for computingfilippov’sdifferential inclusion with application to the variable structure control of robot manipulators,”IEEE Transactions on Circuits and Systems, vol.34,pp.73–82,1987.[4]J.Alvarez,I.Orlov,and L.Acho,“An invariance principle for dis-continuous dynamic systems with application to a coulomb friction oscillator,”Journal of Dynamic Systems,Measurement,and Control, vol.122,pp.687–690,2000.[5]Y.Orlov,L.Aguilar,and J.Cadiou,“Switched chattering controlvs.backlash/friction phenomena in electrical servo-motors,”Interna-tional Journal of Control,vol.76,pp.959–967,2003.[6]P.Sekhavat,Q.Wu,and N.Sepehri,“Lyapunov-based frictioncompensation for accurate positioning of a hydraulic actuator,”in Proceeding of the2004American Control Conference,Boston,June 30-July23,2004,pp.418–423.[7] F.Clarke,Optimization and Nonsmooth Analysis.New York:Addison-Wesley,1983.[8]M.Baric,I.Petrovic,and N.Peric,“Neural network based slidingmode control of electronic throttle,”in IFAC Symposium on Advances in Automotive Control,Italy,Apr19-23,2004.[9] C.Rossi,A.Tilli,and A.Tonielli,“Robust control of a throttle bodyfor drive by wire operation of automotive engines,”IEEE Transaction on Control Systems Technology,vol.8,pp.993–1002,2000. [10]M.Baotic,M.Vasak,M.Manfred,and N.Peric,“Hybrid systemtheory based optimal control of an electronic throttle,”in Proceedings of the American Control Conference,Denver,Colorado,2003,pp.5209–5214.[11] C.Canuadas de Wit,H.Olsson,K.J.Astrom,and P.Lischinsky,“Anew model for control of systems with friction,”IEEE Transactions on Automatic Control,vol.40,pp.419–425,1995.。