现代制造技术专业英语,阅读材料1-6,9(分段)

- 格式:doc

- 大小:34.41 KB

- 文档页数:6

Unit 1 Chemical Industry化学工业1.化学工业的起源尽管化学品的使用可以追溯到古代文明时代,我们所谓的现代化学工业的发展却是非常近代(才开始的)。

可以认为它起源于工业革命其间,大约在1800年,并发展成为为其它工业部门提供化学原料的产业。

比如制肥皂所用的碱,棉布生产所用的漂白粉,玻璃制造业所用的硅及Na2CO3. 我们会注意到所有这些都是无机物。

有机化学工业的开始是在十九世纪六十年代以William Henry Perkin 发现第一种合成染料—苯胺紫并加以开发利用为标志的。

20世纪初,德国花费大量资金用于实用化学方面的重点研究,到1914年,德国的化学工业在世界化学产品市场上占有75%的份额。

这要归因于新染料的发现以及硫酸的接触法生产和氨的哈伯生产工艺的发展。

而后者需要较大的技术突破使得化学反应第一次可以在非常高的压力条件下进行。

这方面所取得的成绩对德国很有帮助。

特别是由于1914年第一次世界大仗的爆发,对以氮为基础的化合物的需求飞速增长。

这种深刻的改变一直持续到战后(1918-1939)。

1940年以来,化学工业一直以引人注目的速度飞速发展。

尽管这种发展的速度近年来已大大减慢。

化学工业的发展由于1950年以来石油化学领域的研究和开发大部分在有机化学方面取得。

石油化工在60年代和70年代的迅猛发展主要是由于人们对于合成高聚物如聚乙烯、聚丙烯、尼龙、聚脂和环氧树脂的需求巨大增加。

今天的化学工业已经是制造业中有着许多分支的部门,并且在制造业中起着核心的作用。

它生产了数千种不同的化学产品,而人们通常只接触到终端产品或消费品。

这些产品被购买是因为他们具有某些性质适合(人们)的一些特别的用途,例如,用于盆的不粘涂层或一种杀虫剂。

这些化学产品归根到底是由于它们能产生的作用而被购买的。

2.化学工业的定义在本世纪初,要定义什么是化学工业是不太困难的,因为那时所生产的化学品是很有限的,而且是非常清楚的化学品,例如,烧碱,硫酸。

1. A white lie is better than a black lie,一个无关紧要的谎言总比一个善意的谎言要好。

2.To upset this cultural homicide, the Negro must rise up with an affirmation of his own Olympian manhood.为了挫败各种蓄意培植的低人一等的心态,黑人必须直起腰来宣布自己高贵的人格。

3.…with a spirit straining toward true self-esteem, the Negro must boldly throw off the manacles of self-abnegation…黑人必须以一种竭尽全力自尊自重的精神,大胆抛弃自我克制的枷锁。

4.What is needed is a realization that power without love is reckless and abusive, and love without power issentimental and anemic.必须懂得没有爱的权力是毫无节制、易被滥用的,而没有权力的爱则是多愁善感、脆弱无力的。

5.It is precisely this collision of immoral power with powerless morality which constitutes the major crisis of ourtimes.正是这种邪恶的权力和没有权势的道义的冲突构成了我们时代的主要危机。

6.Now, early in this century this proposal would have been greeted with ridicule and denunciation, as destructive ofinitiative and responsibility.在本世纪之初,这种建议会受到嘲笑和谴责,认为它对主动性和责任感起到负面作用。

Unit 91、As is found in all phases of polymer chemistry, there aremany exceptions to this categorization.译:正如在高分子化学的各个部分都可以看到的那样,对这种分类方法有很多例外情况。

2、When the molecular chains are ‘straightened out’orstretched by a process of extension, they do not have sufficient attraction for each other to maintain the oriented state and will retract once the force is released. 译:当通过一个拉伸过程将分子链拉直的时候,分子链彼此之间没有足够的相互吸引力来保持其定向状态,作用力一旦解除,将发生收缩。

3、Therefore, a potential fiber polymer will not become a fiberunless subjected to a ‘drawing’process, i.e., a process resulting in a high degree of intermolecular orientation. 译:因此,可以制成纤维的聚合物将不成其纤维,除非经受一个抽丝拉伸的过程,即一个可以形成分子间高度取向的过程。

4、It must be borne in mind that, with the advent ofZiegler-Natta mechanisms and new techniques to improve and extend crystallinity, and the closeness of packing of chains, many older data given should be critically considered in relation to the stereoregular andcrystalline structure.译:必须牢牢记住,随着Ziegler-Natta机理出现,以及随着提高结晶度和提高链的堆砌密度的新方法的出现,对许多过去已得到的关于空间结构和晶体结构旧的资料,应当批判的接受。

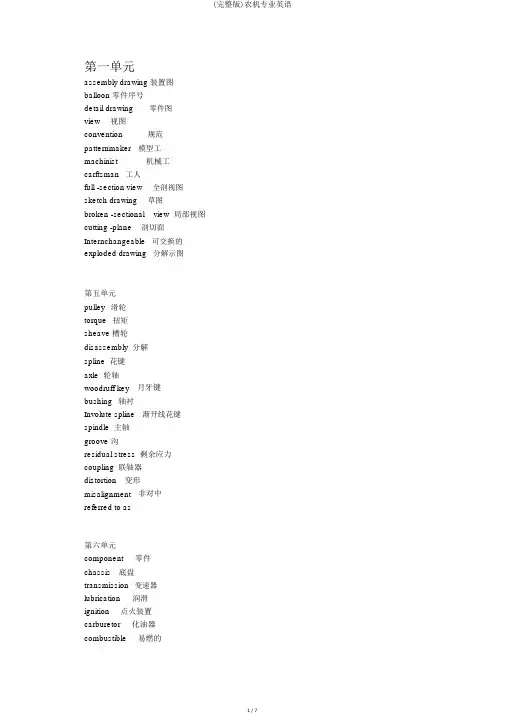

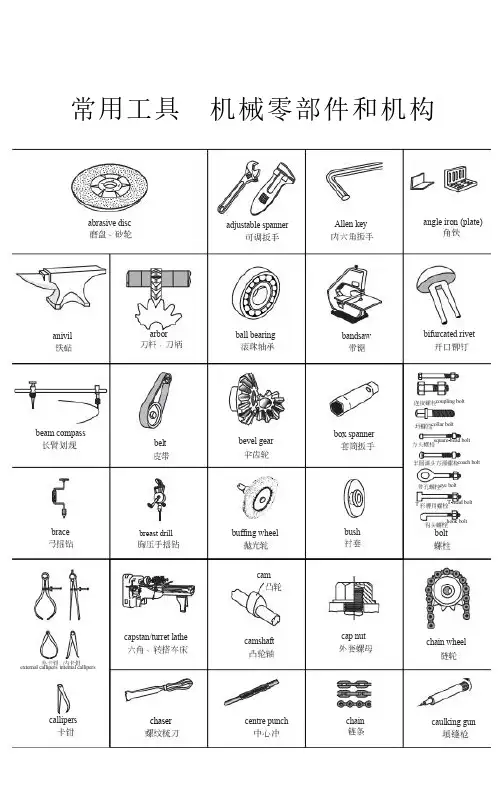

第一单元assembly drawing 装置图balloon 零件序号detail drawing零件图view视图convention规范patternmaker模型工machinist机械工carftsman工人full -section view全剖视图sketch drawing草图broken -sectional view 局部视图cutting -plane剖切面Internchangeable可交换的exploded drawing分解示图第五单元pulley滑轮torque扭矩sheave 槽轮disassembly 分解spline 花键axle 轮轴woodruff key 月牙键bushing 轴衬Involute spline 渐开线花键spindle 主轴groove 沟residual stress 剩余应力coupling 联轴器distortion 变形misalignment 非对中referred to as第六单元component零件chassis底盘transmission变速器lubrication润滑ignition点火装置carburetor化油器combustible易燃的hood 发动机罩capacity生产量suspension悬架differential差速器clutch离合器hydraulic液压的pedal 踏板spark-ignition engine点燃式发动机storage battery蓄电池charging circuit充电电路motor oil机油sheet metal金属板gnition coil点火线圈compression -ignition engine压燃式发动机第九单元small volume production小批量生产screw 丝杆servo motor 伺服电机saddle 滑板bedway 导轨shuttle 梭子conventional 一般的、惯例的horizontal 卧式的vertical 立式的spindle 轴第十五单元computer -integrated manufacturing 计算机集成制造automatic storage and retrieval systems 自动储存和检索系统database 数据库integrity完好性、完好第十六单元deploy 使用、配置mineral deposit矿床manipulator 机械手joint 接头、接合处gripper 钳子roll 转动articulated 相关节的、铰接的hydraulic actuator液压制动器link连杆。

Text 1 电脑黑客如何进入电脑这好像是一个直接的问题,但是内涵很复杂,答案绝不简单,如果随便地回答,那么黑客通过利用弱点进入目标电脑系统。

但是为了提供更多细节,我们还是从头说起。

“hacker”这个词在意义和解释上都很有争议。

有些人说hackers(开路人) 是好人,他们只是推动了知识的边界,并没造成什么伤害(至少不是故意的),而crackers (打砸者)是真正的坏蛋。

这种争论没有什么效果,如果是为了这种讨论的目的,术语“未授权的使用者”(UU)就足够用了。

这个术语包含了所有不同类型的人,从那些参与有组织犯罪行为的人到那些内部人士,他们突破了在系统中被授予的权限。

接下来我们探讨一下“进入”电脑意味着什么。

这可以指获得电脑系统储存的内容,获得系统的处理能力,或者捕获系统之间交流的信息。

每种攻击都需要不同的技巧,以不同的弱点为目标。

那么“未授权的使用者”利用的是什么?弱点存在于每个系统中,并且有两种弱点:已知的和未知的。

已知的弱点通常因为需要某些能力而存在。

比如,为了某个商业过程,你需要不同的人使用一个系统,你就有一个已知的弱点:使用者。

另一个已知弱点的例子是通过互联网交流的能力,为了具备这个能力,你要给未知和不被信任的实体开通一条路径。

未知的弱点是系统的拥有者或操作者所不了解的,可能是劣质工程的结果,或者是某些被需要的能力产生的非故意的结果。

按照定义,弱点可能被利用。

这些弱点可以是低级的密码保护,也可以是让电脑开着,让办公室的访客可以利用。

只要坐在接待员的桌前,用他的电脑获得需要的信息,就有超过一种技术被利用。

低级的密码(比如,用户名“Joe Smith”, 密码也是“Joe Smith”)也是接近电脑的丰富的来源:密码破译程序可以很容易在几分钟内确认字典中的单词、姓名,甚至常见短语。

通过用数字代替字母,使这些密码更复杂。

比如用0来代替字母O,并不会使任务更复杂。

当未获授权的使用者使用有效的用户名—密码组合,进入系统就是简单的登录了。

机械设计制造及其自动化专业英语翻译超级大全Mechanical Design, Manufacturing, and Automation机械 design:机械设计Manufacturing:制造Automation:自动化机械设计、制造和自动化是一个涵盖工程和技术各个方面的多学科领域。

它涉及到机械、工具和系统的设计、开发和生产,以促进工业过程。

机械设计是指创造和优化机械系统、零部件或产品的形态、结构和功能的过程。

这涉及到构思想法、进行分析和计算,并利用计算机辅助设计软件(CAD)创建详细设计。

机械设计还涉及选材、考虑制造方法,并确保最终产品符合行业标准和法规。

The manufacturing process involves transforming raw materials into finished products through various techniques and processes. This can include traditional methods such as casting, machining, and assembly, as well as more advanced techniqueslike additive manufacturing (3D printing). Manufacturing also involves quality control measures to ensure that products meet specifications and standards.制造过程涉及通过各种技术和工艺将原材料转化为成品。

这可能包括传统方法,如铸造、机械加工和组装,也包括更先进的技术,如增材制造(3D打印)。

制造还涉及质量控制措施,以确保产品符合规格和标准。

自动化在现代机械设计和制造中发挥着重要的作用。

它利用技术和控制系统在无人干预的情况下操作和控制机械和工序。

机械专业英语Assembly line组装线Layout布置图Conveyer流水线物料板Rivet table拉钉机Rivet gun拉钉枪Screw driver起子Electric screw driver电动起子Pneumatic screw driver气动起子worktable 工作桌OOBA开箱检查fit together组装在一起fasten锁紧(螺丝)fixture 夹具(治具)pallet栈板barcode条码barcode scanner条码扫描器fuse together熔合fuse machine热熔机repair修理operator作业员QC品管supervisor 课长ME制造工程师MT制造生技cosmetic inspect外观检查inner parts inspect内部检查thumb screw大头螺丝lbs. inch镑、英寸EMI gasket导电条front plate前板rear plate后板chassis 基座bezel panel面板power button电源按键reset button重置键Hi-pot test of SPS高源高压测试Voltage switch of SPS电源电压接拉键sheet metal parts 冲件plastic parts塑胶件SOP制造作业程序material check list物料检查表work cell工作间trolley台车carton纸箱sub-line支线left fork叉车personnel resource department 人力资源部production department生产部门planning department企划部QC Section品管科stamping factory冲压厂painting factory烤漆厂molding factory成型厂common equipment常用设备uncoiler and straightener整平机punching machine 冲床robot机械手hydraulic machine油压机lathe车床planer |'plein。

UNIT 1一、材料根深蒂固于我们生活的程度可能远远的超过了我们的想象,交通、装修、制衣、通信、娱乐(recreation)和食品生产,事实上(virtually),我们生活中的方方面面或多或少受到了材料的影响。

历史上,社会的发展和进步和生产材料的能力以及操纵材料来实现他们的需求密切(intimately)相关,事实上,早期的文明就是通过材料发展的能力来命名的(石器时代、青铜时代、铁器时代)。

二、早期的人类仅仅使用(access)了非常有限数量的材料,比如自然的石头、木头、粘土(clay)、兽皮等等。

随着时间的发展,通过使用技术来生产获得的材料比自然的材料具有更加优秀的性能。

这些性材料包括了陶瓷(pottery)以及各种各样的金属,而且他们还发现通过添加其他物质和改变加热温度可以改变材料的性能。

此时,材料的应用(utilization)完全就是一个选择的过程,也就是说,在一系列有限的材料中,根据材料的优点来选择最合适的材料,直到最近的时间内,科学家才理解了材料的基本结构以及它们的性能的关系。

在过去的100年间对这些知识的获得,使对材料性质的研究变得非常时髦起来。

因此,为了满足我们现代而且复杂的社会,成千上万具有不同性质的材料被研发出来,包括了金属、塑料、玻璃和纤维。

三、由于很多新的技术的发展,使我们获得了合适的材料并且使得我们的存在变得更为舒适。

对一种材料性质的理解的进步往往是技术的发展的先兆,例如:如果没有合适并且没有不昂贵的钢材,或者没有其他可以替代(substitute)的东西,汽车就不可能被生产,在现代、复杂的(sophisticated)电子设备依赖于半导体(semiconducting)材料四、有时,将材料科学与工程划分为材料科学和材料工程这两个副学科(subdiscipline)是非常有用的,严格的来说,材料科学是研究材料的性能以及结构的关系,与此相反,材料工程则是基于材料结构和性能的关系,来设计和生产具有预定性能的材料,基于预期的性能。

科技英语阅读理解目录Contents1.Mae Jemison ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,(2)2.Can a Computer Think?,,,,,,,,,,,,,,,,,,,,,,,,,,(4)3. BlackHoles,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,(6)cation May Protect against Effects of Shrinking Brain,,,,,,,,,(9)5.Radioactivity ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,(11)6. Uses of Ultrasound,,,,,,,,,,,,,,,,,,,,,,,,,,,(14)7.Challenges for a Webbed Society,,,,,,,,,,,,,,,,,,,,,(16)8.The World of Robots ,,,,,,,,,,,,,,,,,,,,,,,,,,(19)9.The Scientific Exploration of Space,,,,,,,,,,,,,,,,,,,(21) 10. Improving IndustrialEfficiency through Robotics,,,,,,,,,,,,(24)11. Heat Loss from the Human Body ,,,,,,,,,,,,,,,,,,,,,(26) 12. Energy and Public Safety ,,,,,,,,,,,,,,,,,,,,,,,(28)13.Earth Resources Technology Satellites ,,,,,,,,,,,,,,,,,(32)14.Can Stress Make You Sick? ,,,,,,,,,,,,,,,,,,,,,,,(35)15.Can It Really Happen? ,,,,,,,,,,,,,,,,,,,,,,,,,(37)16.An Ultrasonic Torch ,,,,,,,,,,,,,,,,,,,,,,,,,,(40) 17. Miracle of theBrain,,,,,,,,,,,,,,,,,,,,,,,,,,(42)18.All Over in a Flash ,,,,,,,,,,,,,,,,,,,,,,,,,,(45)19.Control Earthquakes,,,,,,,,,,,,,,,,,,,,,,,,,,(48) 20. Smoking and Cancer,,,,,,,,,,,,,,,,,,,,,,,,,,(51)21.How Well Do You See? ,,,,,,,,,,,,,,,,,,,,,,,,,,(54)22. A Killer Is Born ,,,,,,,,,,,,,,,,,,,,,,,,,,,(56)23.It May Be Easy To Live Longer--Just Stop Eating,,,,,,,,,,,,,(59)24.Study: T. Rex No Speedster ,,,,,,,,,,,,,,,,,,,,,,,(62)25.Modern Examination ,,,,,,,,,,,,,,,,,,,,,,,,,,(64)26.Ecology,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,(68)27.Appearances Can Be Important,,,,,,,,,,,,,,,,,,,,,,(70)28.Animal Senses ,,,,,,,,,,,,,,,,,,,,,,,,,,,,(74)29.Telecommunications Satellite Spins Out of Control,,,,,,,,,,,,(76)30.Building Better Ultralight Computers ,,,,,,,,,,,,,,,,,(78)31.NASA Oks Second Space Tourist ,,,,,,,,,,,,,,,,,,,,,(81)32.Drink to - and for - Your Health ,,,,,,,,,,,,,,,,,,,,(84)33.Three Things That Will Change Your Life,,,,,,,,,,,,,,,,,(86)34.Bye-bye Credit Cards & Hello Digital Money,,,,,,,,,,,,,,,(88)35.Gender Detector,,,,,,,,,,,,,,,,,,,,,,,,,,,,(90)1. Mae JemisonImagine you are lying on your back, strapped into a chair, with your knees bent in front ofyou. You feel your heart beating with excitement as you hear a voice on the earphone inside your helmet counting down slowly,” Three, two, one,” Then, beneath you, a deep rumble start as rocket fuel ignites in the huge engines. You① feel a lurch as the docking mechanisms let go, and your rocket begins to rise. This is the moment Mae Jemison has been waiting and working for since 1987. The firstAfrican-American female astronaut-in-training at the National Aeronautics and Space②Administration (NASA) , Jemison is scheduled to “fly” in September 1992. She is to serve as a specialist on Spacelab—J, a joint Japanese—American research project.Mae Jemison was thirty-three when she was selected for NASA’s astronaut training program. Astronaut candidates must have science degree. They must be fit and healthy with normal blood pressure and good eyesight. They must stand between five feet and six feet four inches tall. They must complete a one-year training program that includes water-survival lessons and weightless walks in a huge antigravity tank. On the 1991 mission, astronaut Jemison says that her “responsibility are to be familiar with the shuttle and how it operates, to do the experiments once you get③ into orbit, to help launch the payloads or satellites, and also to do extra-vehicular activities, or space walks.”How did Mae Jemison grow up to become such a special person? Science —especially astronomy—fascinated her from childhood.She also had a strong desire to help other people. Born in Alabama, but raised in Chicago,she studied chemical engineering and African—American culture and history at Stanford University. To help others, she decided to become a doctor. While still a medical student, she went to Cuba and Kenya on study trips, then worked in④a refugee camp in Thailand. She spent three years in West Africa as a doctor with the Peace Corps. When Dr. Jemison finally returned to the United States, she settled in California to practice medicine. And it was then that she decided to reach for the stars.Mae Jemison’s first application to NASA was not successful. Then, in 1986, the⑤Challenger space shuttle exploded, killing all aboard . NASA did not take in any new astronauts for about a year. When it finally reopened its application process, Mae Jemison was ready, and so was NASA. After being selected as a minority astronaut, Mae Jemison received a good deal of attention from newspaper and television. She explained to reporters that the space program and other fields in high technology offer promising careers for African-Americans and other minorities who study hard⑥ and make the most of their opportunities .1.The first paragraph is about ______.A.how excited Mae Jemison was when she became an astronautB. how Mae Jemisonbecame an astronautC.how the people usually feel when the rocket they take begins to riseD.what Mae Jemison did after she was able to fly a rocket2.Which of the following statements is true?A.Mae Jemison had a strong desire to become famous.B.Mae Jemison was brought up in Alabama.C.Mae Jemison studied astronomy at Stanford University.D.Mae Jemison studied medicine.3.When did the Challenger space shuttle explode? A. Before Mae Jemison became a doctor.B.Shortly after Mae Jemison graduated from Stanford University.C.About a year before Mae Jemison was selected as an astronaut.D.About a year after Mae Jemison became famous all over the world.4.Mae Jemison believed that _______.A.men and women were not equalB.women were better paid than men wereC.American blacks were unable to find satisfactory jobs no matter how hard they studiedD.American blacks were able to find satisfactory jobs if they studied hard and made gooduse of their chance5.What is the attitude of the writer towards Mae Jemison’s achievements?A.JealousB.UpsetC. NegativeD. PositiveNotes:①lurch v. : To roll or pitch suddenly or erratically. 突然倾斜,突然地或者无规则地倾斜或坠落。

. . 1. Cast iron 1.铸铁 Cast iron is a general term applied to a wide range of iron-carbon-silicon alloy combination with smaller percentages of several other elements. Cast iron has been used in various industrial fields. Fig.R1-1 shows the cylinder block made by cast iron. It is an iron containing so much carbon or its equivalent. It is not malleable. Quite obviously, cast iron has a wide range of properties, since small percentage variations of its elements may cause considerable change. Cast iron should not be thought of as a metal containing a single element, but rather, as one having in its composition at least six elements. All cast iron has still other elements, which should not be thought of as impurities, for they all have important effects on the physical properties. Pure iron, known as ferrite, is very soft and has few uses in industrial work. Regulating the elements other than ferrite in the cast iron controls all desirable properties, such as strength, hardness and machinability. 铸铁是一个总称,包括范围广泛的铁碳硅合金的结合小比例的其他几个要素。铸铁开始用于各种工业领域。图R1-1所示汽缸座用铸铁制造。这是铁含有了太多的碳或其他等效的物质。这是不可锻造的。很明显,铸铁具有广泛的性能,因为其元素的小百分比的变化可能会引起相当大的变化。铸铁不应被认为是一个金属包含一个单独的元素,而是,作为一个具有至少六个元素组成。所有铸铁含有铁,碳,硅,锰,磷,硫。合金铸铁还有其他元素,其他元素不应该被认为是杂质,因为他们所有的物理性质有重要的影响。纯的铁,称为铁素体,很软,几乎没有用于工业生产。其它元素在铸铁铁素体调节控制所有理想的性质,如强度,硬度和可锻造性。

The cast iron family includes gray, ductile (also called nodular), white, malleable and high-alloy irons. 铸铁系列包括灰口铸铁,球墨铸铁(也被称为nodular),白口铸铁,可锻铸铁和高合金铸铁。

Gray iron is itself a family of casting alloys, and is the most widely used, with an annual production several time the total for all other metals cast. 灰口铸铁本身所属的种类是铸造合金,是应用最广泛的,每年生产的总量是几倍于其他铸铁的。

A relatively new type of cast iron is ductile iron-also called nodular iron .As its name implies, ductile iron offers more ductility than gray iron, plus higher strength. 一种新型的球墨铸铁称为球墨铸铁。顾名思义,球墨铸铁具有比灰口铸铁更具延展性,加上高强度。

2.Heat Treatment of Steel . . 2.钢的热处理

Heat treatment is a method by which the heat treater can change the physical properties of metal .There are three main operations in the heat treatment of steel: hardening, tempering, and annealing. 热处理是热处理工作者用以改变金属物理性能的方法。钢热处理有三种法即淬火、回火和退火。

The hardening operation consists of heating the steel above its critical range and then quenching it, that is rapidly cooling in a suitable medium such as water, brine, oil, or some other liquid. Having been hardened, the metal must be given a tempering treat-ment which consists of reheating the hardened steel to a temperature below the critical range, thus producing the required physical properties. 淬火是将钢加热到临界点以上然后进行急冷。急冷是指在材料合适的介质如水、盐水、油或其他液体中快速冷却。金属在淬硬后必须进行回火处理。回火是将淬硬的钢重新加热到低于临界点的温度从而获得所需的物理性能。

The critical points or critical temperatures are the temperatures at which a certain change takes place in the physical condition of the steel. These points are very important because in order to properly harden a piece of steel, it must be heated to a temperature above the upper critical point. Having known the critical points for a certain steel, we can easily control the heat in the furnace. Gas, oil, and electric furnaces are the most commonly used for heat treating metals. 临界点或临界温度是指钢的物理性能发生某些变化的温度。这些临界点极为重要因为要使钢很好地硬化就必须把钢加热到上临界温度以上。我们知道某一钢种的临界点后就能较容易得控制炉温。煤气炉、油炉和电炉是金属热处理最普遍采用的炉子。

Annealing is the uniform heating of a metal above usual hardening temperatures, followed by very slow cooling. Annealing may be carried out either to soften a piece that is too hard to machine or to remachine a piece that has already been hardened. Annealing also relieves internal stresses produced by machining. 退火是将钢均匀地加热到通常的淬火温度以上然后极缓慢地冷却。若工件过硬无法机加工或是要重新机加工已经淬硬的零件这时可进行退火以使钢材软化。退火还可消除机加工时产生的内应力。

Low carbon steels do not become hard when subjected to such a heat treatment because of the small amount of carbon contained. If it is necessary to obtain a hard surface on a part made of such steel, surface hardening operation must be carried out. One of the methods of surface hardening is cyaniding, which is done by keeping the work in a molten bath of sodium cyanide from 5 to 30 minutes, depending on the size of the work and the depth of penetration required. Having been subjected to such a treatment, the work is then quenched in water of oil, and a very hard case 0.01 to 0.015 inch thick is formed. This process is also called case hardening. 低碳钢由于含碳量低,因此在经受这种热处理时材质不可能变硬。若欲在低碳钢制成的零件表面获得硬的表面层就须进行表面硬化处理。氰化是一种表面硬化方法。氰化时将工件