外文翻译-印染废水处理的研究

- 格式:doc

- 大小:72.00 KB

- 文档页数:15

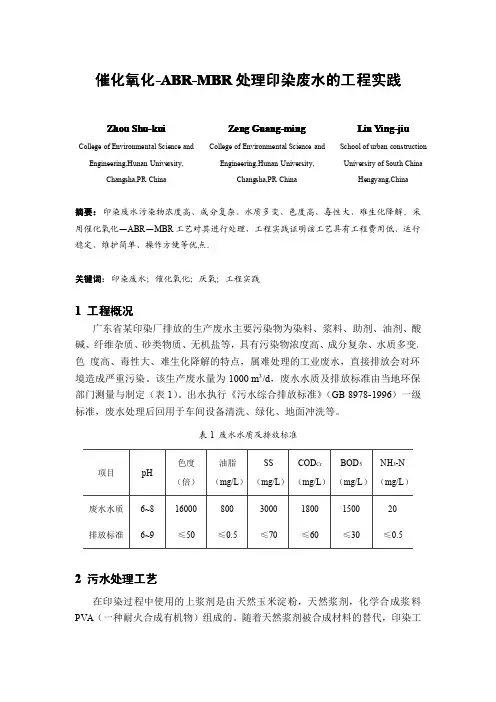

染料废水的处理现状与研究进展摘要我国是世界上的印染大国之一,印染工业较为发达,近年来,随着人们对环境问题越来越多的重视,怎样解决印染行业给人类带来的威胁也成为热门课题。

本文介绍了我国染料废水的特点、污染以及处理现状,在处理上包括膜法的应用、染料脱色、电化学方法的应用等,在总结国外研究的基础上对处理进行比较,加以归类,并通过工程实例分析它们在实际生产中应用。

关键词:染料废水,处理,综合运用,研究PROCESSING STATUS AND PROGRESS OF THE DYEWASTEWATERABSTRACTChina is one of the big countries of the world's printing and dyeing, printing and dyeing industry is more developed in recent years, with more and more attention to environmental issues, how to solve the printing and dyeing industry, the threat posed to humans has bee a hot topic. This article describes the characteristics of dye wastewater,pollution and to deal with the status quo, including the application of the membrane, dye bleaching, electrochemical methods application in handling, dealing with on the basis of summing up the research at home and abroad to pare, to be classified they are applied in actual production and engineering examples.KEY WORDS:Dye wastewater ,Process,Synthetically Applied,Research目录前言1第1章染料废水概述21.1 染料行业生产废水特点21.2 染料废水的污染危害4第2章染料废水的处理52.1 膜法在染料废水处理中的应用52.2染料废水的脱色62.3Fenton试剂在染料废水处理中的应用82.4 电化学法92.4.1 电化学氧化法的基本原理92.4.2 催化铁电解法102.5 厌氧—好氧工艺11第3章应用工程实例13第4章染料废水处理的研究进展17辞18参考文献19外文资料翻译21前言染料工业是化学工业中环境污染极其严重的产业之一。

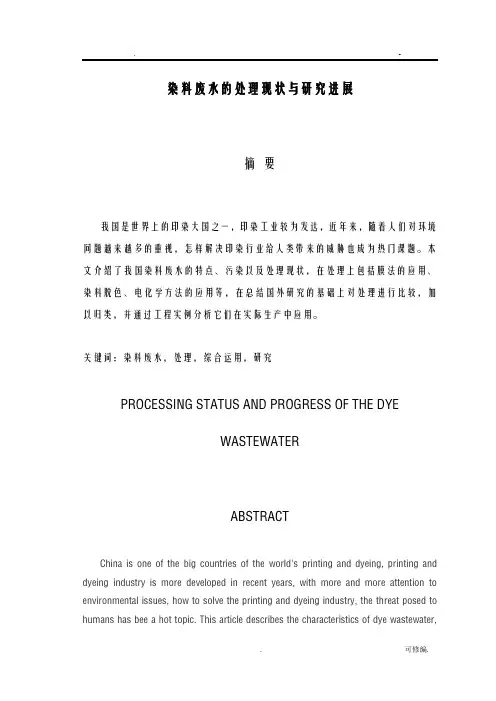

我国印染废水处理概况及研究进展王俊峰;赵英武;毛燕芳【摘要】The environmental protection status of dyeing and printing industry in China is summarized in this paper. The characteristics and source of printing and dyeing wastewater are analyzed ful y. Furthermore, the paper introduces tow main methods of printing and dyeing wastewater, physic-chemical treatment and biochemical treatment are emphasized. The cur-rent printing and dyeing wastewater processes are investigated comprehensively. According to the current situation, cleaner production, end-treatment and industry orientation are provided for reference.% 综述了我国印染行业的环保概况,分析了印染废水的来源与特点,介绍了印染废水的物化处理和生化处理方法,以及目前国内印染废水处理的工艺概况,提出了清洁生产、末端治理与行业导向等相关建议。

【期刊名称】《中国环保产业》【年(卷),期】2012(000)004【总页数】4页(P30-33)【关键词】印染废水;物化处理;生物降解【作者】王俊峰;赵英武;毛燕芳【作者单位】江西理工大学资源与环境工程学院,江西赣州 341000;上海颐瑾环保科技有限公司,上海 201824;上海同济科蓝环保设备工程有限公司,上海 200092【正文语种】中文【中图分类】X703随着我国经济的高速发展,纺织印染行业的排水量大幅度增长。

毕业论文(设计)文献综述题目:印染废水处理技术研究进展学院:环境科学与工程专业:环境工程班级:学号:学生姓名:指导教师:二○一六年三月印染废水处理技术研究进展摘要:印染废水处理一直是我国水处理领域的重要话题,经过多年的发展,处理技术已日趋成熟,很多新型印染废水处理技术也已经在国内外得到广泛使用,并且处理效果良好。

本文重点介绍印染废水处理的物理、化学、生物法的技术原理及相关工艺,为今后印染废水处理技术提供理论依据。

关键词:印染废水,物理处理,化学处理,生物处理Advances in printing and dyeing wastewater treatmenttechnologyAbstract:Printing and dyeing wastewater treatment has been an important topic in the field of water treatment. After many years of development, technology has become increasingly mature, many new printing and dyeing wastewater treatment technology has been widely used at home and abroad, and the treatment effect is good. This paper mainly introduces the technical principle and related treatment process of physical, chemical and biological method for the treatment of printing and dyeing wastewater, which provides a theoretical basis for the future treatment of printing and dyeing wastewater.Key words:Printing and dyeing wastewater, physical treatment, chemical treatment, biological treatment,treatment process.1引言纺织产业是我国的传统行业,一直以来也成为重要的经济支柱,经过多年的发展,我国已成为世界上最大的纺织品服装生产国。

多菌种生物强化SBR工艺处理印染废水沈旭丰1,孙先锋1,徐甜甜1,金鹏康2(1.西安工程大学环境与化学工程学院,陕西西安710048;2.西安建筑科技大学环境与市政工程学院,陕西西安7l∞55)摘要:印染废水是纺织工业污染的主要来源,其中的多种染料和化学助剂属于难降解有机物,采用常规生物方法难以迟标处理.向混凝沉淀SBR复合工艺系统中添加多茵种高效茵荆,生物强化处理COD约900 mg·L.1印染废水,取得了理想的效果。

废水中各项污染指标均达到排放标准,其中出水平均COD达到9l mg·L~,去除率为89.6%.证明多茵种生物强化SBR工艺处理纺织印染废水是可行的.关键词:生物强化;SBR;纺织废水;CODCLC 号码:X 79l印染废水是工业污染的主要来源。

据不完全统计,全国印刷废水每天的排放量约为(300-400)×104m3.总废水排放量不仅很大,而且其中含有的污染物很高,对环境污染严重。

这些废水如纤维产品,泥浆,洗涤剂,染料,化工助剂和涂饰剂使废水组成的不断变化和更难以治疗目前,生物治疗仍然是most-widely-used法在印染废水处理国内外。

在我国表面活性污泥工艺和接触oxidatioon是最典型的生物治疗。

其弊在于生物治疗无效的脱色。

然而,污水排放标准要求密度的有机物质泄漏是非常低,从而导致更高要求的生物方法。

S BR法应用较多,近年来国内外,具有一定的优势。

它起着重要的作用在处理各种来源的废水,特别是在处理难降解有机废水。

然而,,其应用在处理印染废水是很稀少的。

在本文中,根据应用的SBR工艺对印染纺织废水进行处理。

我们试图添加更多的高效菌株的细菌,即强化SBR工艺过程,处理印染废水,取得了良好的结果。

1.废水的水质和处理标准印染废水的实验中使用的主要来源于前处理,染色和后整理的工艺。

加工后,水质进行“纺织染整工业水污染物排放标准” GB 4287一1992主要标准。

应用技术Dyeing & Finishing Technology染整技术60纺织导报 China Textile Leader · 2018 No.3为印染废水。

当前发展印染行业需要解决的突出问题是有效解决废水处理问题。

本文简要介绍了印染废水处理技术,重点对当前染料废水处理新型技术和新工艺手段做了全面的阐述。

1 印染废水特点印染废水的特点有:污染物含量高,水质变化剧烈,处理难度高;浓度高,可生化性低;色度深,碱性和pH 值变化大,染料品种繁多而且酸碱度变化很大,给废水脱色处理带来技术上的困难;有机污染物中含有苯、氮、胺等基团组成的有毒物质等。

2 印染废水常规处理方法2.1 物理法2.1.1 混凝沉降法混凝沉降是较成熟、效果较稳定的常用废水处理方法之一。

通过投加混凝剂使细小的悬浮颗粒聚集成较大的颗粒,再利用沉降作用除去废水中的污染物。

混凝法印染废水处理研究进展文 | 陈晓燕 何秉宇 张 雯作者简介:陈晓燕,女,1993年生,硕士在读,主要从事环境科学研究工作。

通信作者:张 雯,博士,高级工程师, E-mail :358894195@ 。

作者单位:陈晓燕、何秉宇,新疆大学资源与环境科学学院、智慧城市与环境建模自治区高校重点实验室;陈晓燕、张 雯,新疆环境保护科学研究院。

基金项目:国家重点研发计划项目(2016YFC0400502);国家自然科学基金项目(21667030)。

作为全球纺织印染第一大国,我国极大推动着染料需求量的增加。

染料的生产和消耗会产生大量废水,相关废水已成为主要的水污染源之一,严重威胁了生态环境。

印染废水未经处理或超标排放,会导致自然生态的污染,因此国内外环保界持续关注着印染废水处理技术的研究进展。

据测算,每生产 1 t 染料,废水排放量约744 m 3,生产和使用中约有10% ~ 20%的染料被排放到水体中。

2014年我国工业废水排放量为205.3亿t ,纺织工业废水排放废水量21.6亿t ,占工业废水总量的10.5%,其中大部分Research Progress on the Treatment of Printing and Dyeing Wastewater摘要:印染废水中含有成分复杂而又种类繁多的染料,具有浓度高、色度深、不易降解等特点。

印染废水处理的英语英文回答:Textile Wastewater Treatment.Textile wastewater treatment is a critical environmental issue due to the significant amounts of hazardous chemicals and pollutants discharged into water bodies. These pollutants can harm aquatic life, contaminate drinking water sources, and pose risks to human health.Effective textile wastewater treatment involves amulti-step process that aims to remove or reduce pollutants to acceptable levels before discharging the treated water into the environment. The treatment process typically begins with a preliminary treatment stage, where large solids and suspended particles are removed using physical methods such as screening and sedimentation.The next step involves chemical treatment, wherecoagulants and flocculants are added to destabilize pollutants and promote their agglomeration into larger flocs. These flocs are then removed through sedimentation or flotation.Biological treatment is often employed as the next stage, where microorganisms break down organic pollutants into simpler, less harmful substances. Activated sludge, trickling filters, and anaerobic digestion are commonly used biological treatment technologies.Advanced treatment processes, such as membrane filtration, electrocoagulation, and ozonation, may be necessary to remove residual pollutants or meet stringent regulatory requirements.中文回答:印染废水处理。

1引言印染废水是工业废水的一种,不仅总量较大,而且含有复杂的成分,会对空气环境、土壤环境和水环境等造成严重影响。

近年来,随着我国印染行业的繁荣发展,印染废水处理问题也受到全社会的高度关注,在可持续发展理念下,应该提高印染废水的处理效果,使其符合国家和行业相关标准要求,以实现绿色化发展。

印染废水水质也会随着时间的推移而发生变化,这也为处理工作带来了较大的难度,应该注重对传统处理技术和工艺的不断改进,以满足实际生产要求。

在科学技术水平不断提升的趋势下,印染废水问题得到有效处理,但是依然受到多种影响因素的制约。

应该明确印染废水的特点及污染源,从而在技术应用中更具针对性和实效性,实现人与自然的和谐发展。

2印染废水的来源纤维材料、化学药剂和表面活性剂等,是导致印染废水污染的主要原因。

棉、丝、毛和化学纤维等在纺织工艺中的应用较多,尤其是其中杂质含量较高,例如,原毛杂质、油脂、含氮物质、色素,等等。

润滑剂和矿物油等应用于化学纤维当中,也会造成印染废水的污染问题[1]。

由于使用化学药剂而造成的印染废水,包括了分散染料、直接染料、还原染料和活性染料等多种类型。

表面活性剂能够为生产中的起泡处理、渗透处理和匀染处理等提供便捷,但是由于硫酸脂盐和磺酸盐等含量较大,也是一种常见的污染源类型。

3印染废水处理技术的应用措施3.1物理法3.1.1吸附法运用树脂和活性炭等对印染废水中的污染物进行吸附处理,这是吸附法的基本原则,其发展较为成熟。

如果印染废水的浓度不高,则可以采用活性炭进行吸附处理,但是无法满足循环利用的目的。

其吸附能力会受到孔径的影响,因此,在未来发展中主要以大孔径活性炭的研究为主,提高处理效率和质量。

应该注重对二次污染问题的处理,通常借助磁性铁氧化物实现固液分离,有助于实现循环利用,大大降低了印染废水处理的成本。

树脂也可以作为一种吸附剂使用,对于化学产品的回收能力较好,尤其是弱碱性离子交换树脂的应用较多。

3.1.2膜分离技术盐类物质和染料分子等可以通过特定的分离膜进行处理,在控制污染的同时,能够对盐和染料分子进行回收,满足其他生产工艺需求。

印染污水处理工艺流程英文描述:The treatment process for printing and dyeing wastewater typically involves several key steps. Initially, raw wastewater undergoes pretreatment to remove large particles, oils, and dyes. This pretreatment phase often includes both physical and chemical processes, such as sedimentation and coagulation.Subsequently, the pretreated wastewater enters the biological treatment stage, where microorganisms are utilized to degrade organic matter into inorganic substances. Common biological treatment methods include activated sludge processes and anaerobic treatments.After biological treatment, further purification steps may be applied, such as coagulation and sedimentation to remove residual suspended particles and colloids. Additionally, biological contact oxidation and filtration processes can enhance the removal of residual organic matter and fine particles.Finally, the treated water undergoes disinfection to eliminate any remaining pathogens before being discharged or reused. The entire process aims to ensure that the treated water meets the required discharge standards.中文描述:印染污水处理工艺流程通常包括几个关键步骤。

Fenton 试剂深度处理印染废水的研究摘要:Fenton试剂是由H2O2和Fe2+组成的氧化体系,它适用于某些难治理的或对生物有毒性的工业废水的处理,且由于具有反应迅速、温度和压力等反应条件缓和且无二次污染等优点,近30年来,其在工业废水处理中的应用越来越广泛。

本文主要研究Fenton 试剂对印染企业的废水的氧化作用,探究H2O2和Fe2+的加入量、温度、反应时间、PH对于氧化效果的影响,实验通过对实验条件下CODCR值的变化情况来研究该试剂对印染废水的处理效果。

分别以茜素红溶液和甲基红溶液分别作为水溶性染料和分散性染料的代表,其分别配置的模拟印染废水为水处理对象,通过单因素及正交实验,研究分析Fenton 氧化法处理后的废水色度和 CODCRCr的影响因素,确定最佳反应条件。

关键词: Fenton 试剂。

茜红素。

甲基红。

实验条件。

CODCr;色度去除率引言随着我国经济建设的不断深入,东部地区出现了许多服装布料生产厂家,产生了大量的印染废水,排入了长江以及周边的河流,给生态环境带来了严重的破坏,国家已经出台了相关的法律法规规定谁污染谁治理,所以企业对于印染废水的处理问题提上了日程。

Fenton试剂是一种可以高效净化印染废水的试剂,越来越得到大规模的应用。

Fenton试剂处理废水节约资金且高效,不会造成二次污染,对于实验条件的要求不苛刻,已经大规模的应用在印染废水的处理中了。

1.印染废水简况及Fenton试剂的优势印染厂是工业废水的主要排放大户,严重污染了我国的水体。

印染废水中主要含有污物、油脂以及一些表面活性剂、酸碱剂、染料、色素,成分相当复杂,净化难度非常大。

印染废水有机物成分复杂,对于人体和环境的伤害程度非常大,颜色深,PH范围广,是非常难以处理的一类废水。

而且纺织印染业不断开展新业务,使得印染废水的成分更加复杂,传统的一些废水处理技术早已不能满足要求,新型废水的CODCR(化学溶氧量)飙升至一个很高的水平,如何对该复杂的废水进行处理,是困惑各厂的技术难题。

印染废水处理研究论文本文旨在探讨印染废水处理研究论文的重要性以及在环境保护中的作用。

印染工业是一种传统的纺织工业,它通过在面料上应用颜色和图案来创造有吸引力的设计。

然而,在这个过程中,印染废水被排放到自然环境中,它包含各种污染物质和化学物质,如色素、重金属、钠盐和阴离子等。

这些污染物质会危害水资源、土壤和空气质量,从而对人类健康和环境造成潜在的威胁。

为了解决这一问题,许多研究人员致力于研究印染废水处理技术。

本文将介绍近年来发表的几篇印染废水处理研究论文,以探讨这项研究的现状和未来发展方向。

首先,2014年发表的“铁氧化物纳米材料用于染料废水的处理研究”(Research on the Treatment of Dye Wastewater with Iron Oxide Nanomaterials)是一篇重要的研究论文。

该研究使用铁氧化物纳米材料来处理多种染料废水,发现这种方法可以快速、高效地去除污染物质,并实现更低的水处理成本。

这项研究不仅为印染废水处理提供了新的解决方案,而且为其他废水处理领域带来了启示。

其次,2018年发表的“利用自组装技术处理染料废水的研究”(Research on Treatment of Dye Wastewater UsingSelf-Assembly Technology)是另一篇重要的研究论文。

该研究基于自组装技术,将复杂的染料废水自我净化,并减少了对环境的影响。

研究人员还发现,这种方法可以在相同的废水处理过程中产生更少的废物并提高能效。

这项研究为染料废水处理领域带来了新契机,其中自组装技术能够提供一种更加可持续的废水处理解决方案。

此外,2019年发表的“分子印染柔性水凝胶的制备及其对染料废水的处理效果研究”(Preparation of Molecular Dyeing Flexible Hydrogels and Their Treatment Performance for Dye Wastewater)是一项有潜力的研究,它将染料废水和柔性水凝胶有机地结合在一起。

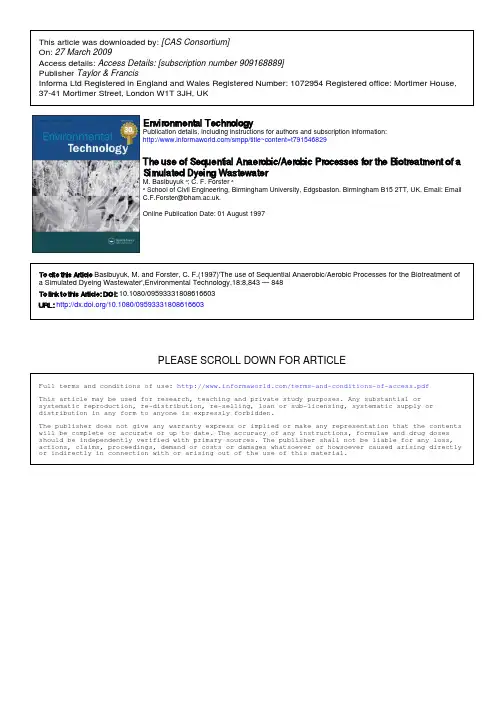

序贯式厌氧/好氧反应器系统在生物方法处理酸性印染废水中的应用摘要:处理的废水是一个羊毛加工厂在羊毛染色加工过程中产生的废水。

采用的废水处理工艺是序贯式厌氧/好氧反应工艺系统。

这一工艺包括UASB厌氧反应器和CSTR好氧反应器。

因为经过序贯式厌氧/好氧反应器系统处理的原水的碳含量、碳酸氢钠和色度均较低,葡萄糖,碱和偶氮染料被添加到原始的酸性印染废水中,以模拟印染工业废水。

在水力停留时间为17小时的条件下,UASB反应器对COD和色度的去除率分别为51-84%和81-96%。

在水力停留时间为3.3天的条件下,UASB/CSTR序贯式反应器系统对化学需氧量和色度的去除率分别为97-83%和87–80% 。

在厌氧阶段形成的的芳香胺类(TAA)将在好氧阶段得到有效去除。

1.简介纺织加工行业产生的废水中的不同的高化学需氧量和成分取决于使用的湿法工艺。

经Correria[1]等总结可知该纺织废水是由3—9/(Kg.dm3)的棉花退浆废水和高达334-835/(Kg.dm3)的洗毛废水组成的。

毛纺厂酸性印染废水中的主要污染物的种类可能是盐类(用于抵销纤维中的zeta电位的氯化钠和硫酸钠),酸类(用于控制pH值的醋酸和硫酸),碱类(用于调节pH值的氢氧化钠)和染料(用于使纤维着色) 。

残余染料以及辅助化学原料是造成印染废水中的颜色、溶解性固体和COD的主要原因。

酸性染料废水的特征取决于染料的类型、纤维和染色方法。

Horning[2]认为,使用不同印染工艺的毛纺厂酸性印染废水的平均色度负荷为3200 ADMI(美国印染工业研究院单位制),总有机碳为210mg/dm3,SS是9 mg/dm3。

PH值是4。

总之,印染废水具有较高的色度和高溶解性固体(DS)以及中等的生化需氧量[1]。

必须使用适当的技术来去除印染废水中的染料,因为它们对受纳水体会有不利影响。

迄今为止,纺织废水处理主要是利用好氧生物处理,主要包括常规的和扩展的活性污泥法[3]。

学号: 08438222 常州大学毕业论文外文翻译(2012届)外文题目Decolorization of Reactive Dye Solutions byElectrocoagulation Using Aluminum Electrodes译文题目铝电极电絮凝处理染料废水外文出处industrial. Engineering. Chemistry. Research. 2003, 42:3391-3396学生税勇学院环境与安全工程学院专业班级环工082 校内指导教师李英柳专业技术职务讲师校外指导老师无专业技术职务无二○一二年一月常州大学本科生毕业设计(论文)外文翻译铝电极电絮凝脱色活性染料O. T. Can, M. Bayramoglu, and M. Kobya*Engineering Faculty, Department of Environmental Engineering, Gebze Institute of Technology,41400 Gebze, Turkey.摘要:最近几年,电絮凝法去除化工废料中的污染物已经变成了一个引人注目的方法。

这篇文章讲述了用铝电极作为阳极电极在水介质中用电絮凝处理活性纺织染料中含有的雷马素RB133。

本文旨在研究废水电导率,初始pH值,电流密度,搅拌速率,染料浓度和处理时间对脱色效率和能源消耗的影响。

在早期操作过程中形成的铝羟基化合物可以有效地去除沉淀的染料分子;在接下来的过程中,Al(OH)3捕获到胶体沉淀,并且在浮选阶段中,使得固液分离更加容易。

在整个电絮凝操作阶段中,必须优化设计经济可行的的操作过程。

1 前言近年来,在纺织行业中,由染整工艺带来的染料流失和废水排放引起的污染已经变成了一个严重的环境问题。

染料在废水中进行生物和化学反应,消耗水体中的溶解氧并且因为他们的毒性危害水生生物。

因此,在向受纳水体排放纺织染料废水前进行处理是非常有必要的。

印染工业园区印染废水的处理工艺流程(中英文版)**English:**The印染工业园区, which is known for其complex印染processes, generates a significant amount of印染wastewater.This印染wastewater is known to be highly polluting due to the various dyes, chemicals, and residues present in it.Therefore, treating this印染wastewater is a crucial step in maintaining environmental standards.处理印染废水的第一步是初步筛选和预处理.This involves removing large solids, fibers, and debris from the印染wastewater.After this, the印染wastewater is settled in a sedimentation tank, where solid particles settle to the bottom and are removed.ext, the印染wastewater undergoes a biological treatment process.This is done in an activated sludge tank, where microorganisms break down the organic matter in the印染wastewater.The sludge that is produced is then separated from the treated water and disposed of properly.最后, the treated印染wastewater undergoes a final clarification process before being discharged.This ensures that the印染wastewater is clean and safe to be released back into the environment.**中文:**印染工业园区产生的印染废水含有多种染料、化学品和残留物,因此具有很高的污染性。

厌氧折流板反应器与生物接触氧化组合工艺处理印染废水的性能摘要:利用厌氧折流式反应器生物组合工艺进行了接触氧化对印染废水处理的研究。

结果表明,pH值和氧化还原电位数值不断在ABR 1-6逐渐下降,当水力停留时间为12 h,色度去除率为92%,流出水的颜色ABR可以满足专业排放标准(一级)中国纺织印染行业。

总的组合工艺COD去除率达到为86.6%,排放水中COD可满足专业排放标准(二级)中国纺织印染产业。

关键词:印染废水;缺氧折流板反应器;生物接触氧化;氧化还原电位1.引言大量的合成染料是全世界生产每一年印染和一部分排出废水。

有一些染料,浆,染色助剂,酸或碱,纤维和印染废水中的无机化合物。

此外,一些染料中含有硝基,胺基重金属,如铜,铬,锌砷等。

组件将发生变化,因为不同的染料范畴,染色过程中,染料浓度和设备规模。

因此,废水质量不稳定。

一般来说,印染废水呈碱性,流量大,浓度高,组成成分复杂,污染严重,难于降解。

因此,很难满足只使用简单的排放标准生物处理过程,而物理化学治疗过程中需要运行费用高。

目前,研究者们逐渐发现新的治疗方法,其中废水水解在缺氧条件下,通过有氧处理。

厌氧水解-好氧处理的印染废水是在传统工艺的一些优点。

对于缺氧水解,水力停留时间(HRT)短,废水中的难降解有机物可以转化为可降解的物质,即对废水降解性能的改善大。

同时,COD可去除一部分。

考虑到许多厌氧微生物的生长速度慢,关键反应器的设计必须与缺氧污泥量大从生物反应器厌氧微生物的损失不大。

所以剩余污泥好氧回流利用增加缺氧污泥量方法。

在同一时间,在整个处理过程中污泥将平衡。

厌氧折流板反应器(ABR)作为水解工艺本研究采用。

有几个小隔间ABR反应器中,相分离缺氧条件产生的废水在每节车厢电流。

该反应器的类型约为流动活塞。

除了这些,ABR反应器具有较好的抗冲击负荷和耐久性能。

它有一些其他特性,如容易启动和无短流,平流和返流。

因此,组合工艺,一种ABR作为水解-生物接触氧化为好氧工艺进行研究。

文献翻译:印染废水处理的研究摘要:本文分析了印染废水处理的所面临的问题,以及介绍了印染废水处理方法的研究进展与动向。

并指出不同印染废水处理方法的组合是印染废水处理的有效方法。

关键词:印染废水;处理方法印染废水是指棉、毛、化纤等纺织产品在染色、印花过程中所排放的废水,其成分复杂,主要含以芳烃和杂环化合物为母体的带有显色基团及极性基团的染料。

为使染色更加均匀,印染时还常加入一些助剂,从而使传统的生物处理工艺受到严重挑战翻。

纺织印染行业是工业废水排放大户。

因此开发经济有效的处理印染废水技术,成为当今环保工作者关注的课题。

印染废水具有水量大、有机污染物含量高、难降解物质多、色度高,以及组分复杂等特点,属难处理的工业废水。

印染废水中含有染料、浆料、助剂、油剂、酸碱,纤维杂质及无机盐等,其中染料中的硝基和胺基化合物,以及铜、铬、锌、砷等重金属元素,具有较大的生物毒性,严重污染环境。

1印染废水处理面临的问题1.1排放标准的日益严格随着社会经济的不断发展和人们环境意识的提高,各国加大了对印染污水的治理。

根据《纺织染整工业水污染物排放标准》,除Ⅲ类污水排放指标变化不大外,增加了Ⅰ类和Ⅱ类污水印染废BOD、COD、色度、悬浮物、氨氮、苯胺类、二氧化氯等指标的排放限定。

而印染废水水质一般平均为COD800-2000mg/L,色度200-800倍,pH值10-13,BOD/COD为0.25-0.4,因此印染废水的达标排放是印染行业急需要解决的问题。

1.2印染废水处理难度增加1.2.1印染废水组分复杂印染废水是指印染加工过程中各工序所排放的废水混合而成的混合废水。

主要包括:预处理阶段(如烧毛、退浆、煮练、漂白、丝光)排放的退浆、煮练、漂白、丝光废水;染色阶段排放的染色废水;印花阶段排放的印花废水和皂洗废水;整理阶段排放的整理废水。

印染废水水质随原材料、生产品种、生产工艺、管理水平的不同而有所差异,导致各个印染工序排放后汇总的废水组分非常复杂。

随着染料工业的飞速发展和后整理技术的进步,新型助剂、染料、整理剂等在印染行业中被大量使用,难降解有毒有机成分的含量也越来越多,有些甚至是致癌、致突变、致畸变的有机物,对环境尤其是水环境的威胁和危害越来越大。

总体而言,印染废水的特点是成分复杂、有机物含量高、色度深化学需氧量(COD)高,而生化需氧量(BOD5)相对较低,可生化性差,排放量大。

1.2.2印染废水处理方法的局限性80年代以前,印染废水的可生化性较高,CODcr浓度常在800mg/L以下,采用传统的生物与物化联合处理系统,出水即可达到排放标准。

近二十年来,印染废水水质发生了很大的变化。

传统的印染废水处理方法,如吸附、悬浮、过滤、混凝等具有设备简单,操作简便和工艺成熟的优点,但是这类处理方法通常是将有机物从液相转移到固相或气相,不仅没有完全消除有机污染物和消耗化学药剂,而且造成废物堆积和二次污染;生物法只能除去印染废水中的BOD,对于COD特别是有毒难降解有机物和色度的出去效果不明显。

单一的处理方法已不能满足当前印染废水发展的要求。

2印染废水处理研究进展与动向2.1传统方法和工艺的改进2.1.1吸附法活性炭又称活性炭黑。

黑色无定形粒状物或细微粉末。

活性炭在结构上由于微晶碳是不规则排列,在交叉连接之间有细孔,在活化时会产生碳组织缺陷,因此它是一种多孔碳,堆积密度低,比表面积大,不溶于任何溶剂。

对各种气体有选择性的吸附能力,对有机色素和含氮碱有高容量吸附能力。

活性炭具有一种强烈的“物理吸附”和“化学吸附”的作用,可将某些有机化合物吸附而达到去除效果,利用这个原理,我们就能很快而有效地去除水族箱水质中的有害物质、臭味以及色素等等,使水质获得直接而迅速的改善。

活性炭吸附是城市污水高级处理中最重要最有效的处理技术,得到广泛的应用。

活性炭作为一种优良吸附剂早已广泛应用于水处理中。

至今仍是有色印染废水的最好吸附剂。

不过,活性炭价格昂贵,加之再生困难,因此一般只应用于浓度较低的印染废水处理或深度处理。

吸附剂的最大问题在于难以实现现场再生。

目前,国内外已有采用活性炭吸附法,该法对去除水中溶解性有机物非常有效,但它不能去除水中的胶体和疏水性染料,并且它只对阳离子染料、直接染料、酸性染料、活性染料等水溶性染料具有较好的吸附性能。

活性炭并不是对所有类型的印染废水处理效果都是一致的。

活性炭对染料具有选择性,其脱色性能顺序依次为碱性染料、直接染料、酸性染料和硫化染料。

通常活性炭由动物性炭、木炭、沥青炭等以含炭为主的物质经高温炭化和活化而成。

活性炭微孔多、大中孔不足、亲水性强,限制了大分子及疏水性染料的内扩散,适用于分子量不超过400的水溶性染料分子脱色,对大分子或疏水性染料的脱色效果较差。

采用活性炭可以有效去除废水中的活性染料、碱性染料、偶氮染料。

在一定条件下,活性炭还可直接吸附某些重金属离子。

另外,活性炭吸附水溶性染料时吸附率高,但不能吸附悬浮固体及不溶性染料。

活性炭虽然吸附性能优良,但由于成本高,一般应用于浓度较低的染料废水处理或深度处理。

2.1.2混凝法印染废水絮凝脱色机制是以胶体化学的DLVO理论为基础的。

其投资费用低,设备占地少,处理量大,是一种被普遍采用的脱色技术。

包括无机混凝剂包括铁盐、铝盐、镁盐及无机絮剂,天然有机高分子絮凝剂,合成的有机高分子絮凝剂,传统混凝法对疏水性染料脱色效率很高。

缺点是需随着水质变化改变投料条件,对亲水性染料的脱色效果差,COD去除率低。

如何选择有效的混凝脱色工艺和高效的混凝剂,则是该技术的关键。

2.1.3化学氧化法化学氧化是目前研究较为成熟的方法。

借助氧化还原作用破坏染料的共轭体系或发色基团是印染脱色处理的有效方法。

除常规的氯氧化法外,国内外研究重点主要集中在臭氧化、超声波氧化、过氧化氢氧化、电解氧化和光氧化方面。

氧化剂一般采用Fenton试剂、臭氧、氯气、次氯酸钠等。

按氧化剂的不同,可将化学氧化分为:臭氧化法和芬顿试剂氧化法。

氧化法是一种优良的印染废水脱色方法,但如果氧化程度不足,染料分子的发色基团可能被破坏而脱色,但其中的COD仍未除尽;若将染料分子充分氧化,能量、药剂量消耗可能会过大,成本太高。

臭氧化法不产生污泥和二次污染,但是处理成本高,不适合大流量废水的处理,而且COD去除率低。

通常很少采用单一的臭氧法处理印染废水,而是将它与其它方法相结合,彼此互补达到最佳的废水处理效果。

所以氧化法一般用于氧化—絮凝或絮凝—氧化工艺。

2.1.4电化学法电化学法具有设备小、占地少、运行管理简单、CODcr去除率高和脱色好等优点,但是沉淀生成量及电极材料消耗量较大,运行费用较高。

传统的电化学法可分为电絮凝法、电气浮法、电氧化法以及微电解、电解内法等。

国外许多研究者从研制高电催化活性电极材料着手,对有机物电催化影响因素和氧化机理进行了较系统的理论研究和初步的应用研究,国内在这一领域的研究还刚刚起步。

2.1.5生物处理法生物处理法主要包括好氧法和厌氧法。

目前国内主要采用好氧法进行印染废水处理。

好氧法又分为活性污泥法和生物膜法。

活性污泥既能分解大量的有机物质,又能去除部分色度,还可以微调pH值,运转效率高且费用低,出水水质较好,适合处理有机物含量较高的印染废水;生物膜法对印染废水的脱色作用较活性污泥法高。

但是生物法存在着三个自身无法解决的问题:1.剩余污泥的处里费用较高;2.单一运用生物法己不能满足实际运用的需要;3.有时需要在其前端加一道提高废水可生化性的预处理,提高了投资及运行成本。

单一的好氧生物处理只能去除废水中的部分易降解的有机物,色度问题无法解决。

为了降低消耗及去除废水中较难降解的有机污染物,出现了厌氧-好氧新型处理工艺和生物强化技术。

厌氧-好氧法可先由厌氧过程中的产酸阶段,去除部分较易降解的有机污染物,将较难降解的大分子有机物分解为较简单的小分子有机物,再通过好氧生物处理过程进一步去除。

厌氧-好氧法处理难生化降解的印染废水具有除污染效率高、运行稳定和较强的耐冲击负荷能力等特点。

有研究报道,采用厌氧-好氧工艺处理印染废水,在进水CODcr为1085mg/L,BODS为315mg/L 的情况下,二者的去除率分别可达83.9和76.2,再经硫化床自然氧化和混凝沉淀处理,去除悬浮物,排水可达排放标准。

由于传统的生物方法对色度的去除往往不够理想,国内外许多学者致力于培育或改良高降解活性菌种用于印染废水处理,产生了生物强化技术。

其机理为向废水处理系统中投加自然界中的优势菌种或通过基因组合技术产生的高效菌种,增强生物量,强化生物量的反应,以去除某一种或某一类有害物质为目的。

目前,生物强化技术最普遍的应用方式是直接投加对目标污染物具有特效降解能力的微生物。

2.2高新技术的应用和实践2.2.1光化学氧化法光化学氧化法由于其反应条件温和(常温、常压)、氧化能力强和速度快等优点。

光化学氧化可分为光分解、光敏化氧化、光激发氧化和光催化氧化四种。

目前研究和应用较多的是光催化氧化法。

光催化氧化技术能有效地破坏许多结构稳定的生物难降解的有机污染物,具有节能高效、污染物降解彻底等优点,几乎所有的有机物在光催化作用下可以完全氧化为CO2、H2O等简单无机物。

但是光催化氧化方法对高浓度废水效果不太理想。

关于光催化氧化降解染料的研究主要集中在对光催化剂的研究上。

其中,TiO2化学性质稳定、难溶无毒、成本低,是理想的光催化剂。

传统的粉末型TiO2光催化剂由于存在分离困难和不适合流动体系等缺点,难以在实际中应用。

近年来,TiO2光催化剂的搀杂化、改性化成为研究的热点。

2.2.2膜分离技术膜分离技术处理印染废水是通过对废水中的污染物的分离、浓缩、回收而达到废水处理目的。

具有不产生二次污染、能耗低、可循环使用、废水可直接回用等特点。

膜分离技术虽然具有如此多的优点,但也存在着尚待解决的问题,如膜污染、膜通量、膜清洗、以及膜材质的抗酸碱、耐腐蚀性等问题,所以,现阶段运用单一的膜分离技术处理印染废水,回收纯净染料,还存在着技术经济等一系列问题。

现在膜处理技术主要有超滤膜,纳米滤膜和反渗透膜。

膜处理对印染废水中的无机盐和COD都有很好的去除作用。

2.2.3超声波技术利用超声波可降解水中的化学污染物,尤其是难降解的有机污染物。

它集高级氧化技术、焚烧、超临界水氧化等多种水处理技术的特点于一身,降解条件温和、降解速度快、适用范围广,可以单独或与其它水处理技术联合使用。

该方法的原理是废水经调节池加入选定的絮凝剂后进入气波振室,在额定的震荡频率的激烈震荡下,废水中的一部分有机物被开键成为小分子,在加速水分子的热运动下,絮凝剂迅速絮凝,废水中色度、COD、苯胺浓度等随之下降,起到降低废水中有机物浓度的作用。

目前超声技术在水处理上的研究已取得了较大的成果,但绝大部分的研究都还局限于实验室水平上。