HS-SPME)-and-simultaneous-distillationextraction-(SDE)

- 格式:pdf

- 大小:126.09 KB

- 文档页数:6

HS-SPME-GC-MS分析青皮挥发性成分青皮是柑橘类水果中具有独特风味和香气的部分,其挥发性成分对于其特殊的风味和香气起着至关重要的作用。

对青皮的挥发性成分进行分析具有重要意义。

HS-SPME-GC-MS是一种常用的分析方法,可以有效地提取和分析样品中的挥发性成分。

本文将针对HS-SPME-GC-MS分析青皮挥发性成分的方法和应用进行介绍和讨论。

HS-SPME-GC-MS分析方法是基于固相微萃取(SPME)技术和气相色谱-质谱联用(GC-MS)技术的结合。

其基本原理是将样品中的挥发性成分通过SPME纤维吸附和富集,然后在气相色谱-质谱联用仪上进行分离和鉴定。

这种方法具有操作简便、灵敏度高、分离效果好以及可以直接对固体、液体和气体样品进行分析等优点,因此在食品、环境、化学等领域得到了广泛的应用。

1. 样品准备首先需要收集新鲜的青皮样品,将其洗净并切成适当大小的块状。

然后可以选择使用直接曝露法或者溶剂萃取法来释放样品中的挥发性成分。

在直接曝露法中,样品可以直接暴露在室温下,通过自然挥发释放挥发性成分;而在溶剂萃取法中,则需要将样品置于适当的溶剂中进行萃取。

2. SPME提取将经过准备的样品放入SPME瓶中,再将SPME纤维插入瓶口,待一定时间后(通常为数小时)即可进行提取。

SPME提取的时间和温度可以根据具体样品和实验要求进行调整。

3. GC-MS分析经过SPME提取后的纤维可以直接插入气相色谱-质谱联用仪中进行分析。

在气相色谱中,挥发性成分将被分离,并通过质谱的检测和鉴定,确定所提取的成分。

通过HS-SPME-GC-MS分析青皮挥发性成分,可以得到有关青皮挥发性成分的详细信息,包括成分的种类、含量以及相互间的相对比例等。

这些信息对于揭示青皮的香气特征和品质特征具有重要的意义。

通过比较不同种类、不同产地、不同处理方式的青皮样品,可以发现它们在挥发性成分上的差异,从而为青皮的品种鉴定和质量控制提供依据。

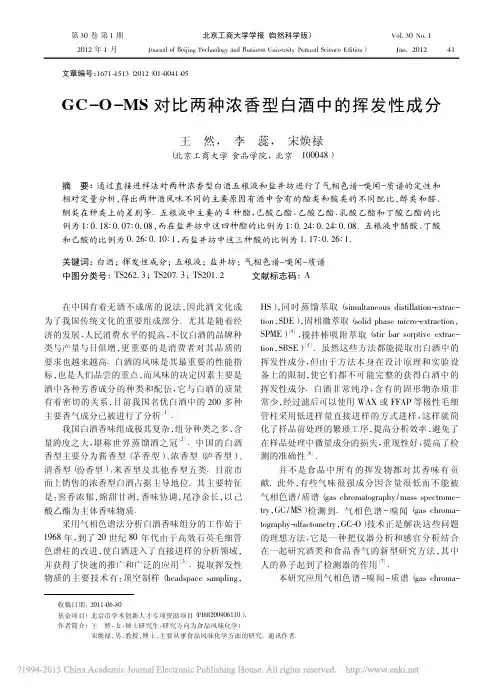

第30卷第1期2012年1月北京工商大学学报(自然科学版)Journal of Beijing Technology and Business University (Natural Science Edition )Vol.30No.1Jan.2012文章编号:1671-1513(2012)01-0041-05GC-O-MS 对比两种浓香型白酒中的挥发性成分王然,李蕊,宋焕禄(北京工商大学食品学院,北京100048)摘要:通过直接进样法对两种浓香型白酒五粮液和盐井坊进行了气相色谱-嗅闻-质谱的定性和相对定量分析,得出两种酒风味不同的主要原因有酒中含有的酯类和酸类的不同配比,醇类和醛、酮类在种类上的差别等.五粮液中主要的4种酯,己酸乙酯、乙酸乙酯、乳酸乙酯和丁酸乙酯的比例为1ʒ0.18ʒ0.07ʒ0.08,而在盐井坊中这四种酯的比例为1ʒ0.24ʒ0.24ʒ0.08.五粮液中醋酸、丁酸和己酸的比例为0.26ʒ0.10ʒ1,而盐井坊中这三种酸的比例为1.17ʒ0.26ʒ1.关键词:白酒;挥发性成分;五粮液;盐井坊;气相色谱-嗅闻-质谱中图分类号:TS262.3;TS207.3;TS201.2文献标志码:A收稿日期:2011-06-30基金项目:北京市学术创新人才专项资助项目(PHR200906110).作者简介:王然,女,硕士研究生,研究方向为食品风味化学;宋焕禄,男,教授,博士,主要从事食品风味化学方面的研究.通讯作者.在中国有着无酒不成席的说法,因此酒文化成为了我国传统文化的重要组成部分.尤其是随着经济的发展,人民消费水平的提高,不仅白酒的品牌种类与产量与日俱增,更重要的是消费者对其品质的要求也越来越高.白酒的风味是其最重要的性能指标,也是人们品尝的重点,而风味的决定因素主要是酒中各种芳香成分的种类和配伍,它与白酒的质量有着密切的关系,目前我国名优白酒中的200多种主要香气成分已被进行了分析[1].我国白酒香味组成极其复杂,组分种类之多、含量跨度之大,堪称世界蒸馏酒之冠[2].中国的白酒香型主要分为酱香型(茅香型)、浓香型(泸香型)、清香型(汾香型)、米香型及其他香型五类.目前市面上销售的浓香型白酒占据主导地位.其主要特征是:窖香浓郁,绵甜甘冽,香味协调,尾净余长,以己酸乙酯为主体香味物质.采用气相色谱法分析白酒香味组分的工作始于1968年,到了20世纪80年代由于高效石英毛细管色谱柱的改进,使白酒进入了直接进样的分析领域,并获得了快速的推广和广泛的应用[3].提取挥发性物质的主要技术有:顶空制样(headspace sampling ,HS ),同时蒸馏萃取(simultaneous distillation-extrac-tion ,SDE ),固相微萃取(solid phase micro-extraction ,SPME )[4],搅拌棒吸附萃取(stir bar sorptive extrac-tion ,SBSE )[5].虽然这些方法都能提取出白酒中的挥发性成分,但由于方法本身在设计原理和实验设备上的限制,使它们都不可能完整的获得白酒中的挥发性成分.白酒非常纯净,含有的固形物杂质非常少,经过滤后可以使用WAX 或FFAP 等极性毛细管柱采用低进样量直接进样的方式进样,这样就简化了样品前处理的繁琐工序,提高分析效率,避免了在样品处理中微量成分的损失,重现性好,提高了检测的准确性[6].并不是食品中所有的挥发物都对其香味有贡献.此外,有些气味很强成分因含量很低而不能被气相色谱/质谱(gas chromatography /mass spectrome-try ,GC /MS )检测到.气相色谱-嗅闻(gas chroma-tography-olfactometry ,GC-O )技术正是解决这些问题的理想方法,它是一种把仪器分析和感官分析结合在一起研究酒类和食品香气的新型研究方法,其中人的鼻子起到了检测器的作用[7].本研究应用气相色谱-嗅闻-质谱(gas chroma-14tography-olfactometry-mass spectrometry ,GC-O-MS )技术,采用低进样量直接进样方式,对五粮液和盐井坊这两种市售的浓香型白酒中的挥发性物质进行了比较,以期找出决定不同品牌浓香型白酒差异的主要挥发性成分.1材料与方法1.1材料与试剂五粮液(39%,V /V ),宜宾五粮液股份有限公司生产;盐井坊(45%,V /V ),四川省自贡市旭腾投资咨询有限责任公司生产.系列正构烷烃(C 7 C 22),色谱纯,美国Sigma -Aldrich 公司.图1五粮液与盐井坊的TIC 图Fig.1Total ions chromatogram of Wuliangye and Yanjingfang1.2仪器与设备7890A-7000B 型气质联机,美国Agilent 公司;Sniffer9000型嗅闻仪,瑞士Brechbuhler ;HP -INNO-WAX (30m ˑ0.25mm ˑ0.25μm )型色谱柱,美国Agilent 公司.1.3实验方法1.3.1色谱条件色谱条件为进样量1μL ;分流比20ʒ1;柱流量1.2mL /min ;升温程序为40ħ保持3min ,然后以5ħ/min 升到200ħ,保持0min ,再以10ħ/min 升到230保持3min.1.3.2质谱条件电子轰击(electron impact ,EI )离子源,电子能量70eV ,离子源温度230ħ,四级杆温度150ħ.溶剂延迟时间3min.质谱质量扫描范围40 550u.1.3.3化合物鉴定方法风味物质由质谱(mass spectrometry ,MS )、化合物保留指数(retention index ,RI )和化合物风味描述3种方法共同确定.化合物经质谱检测后,对照谱库NIST2.0进行人工检索,由定性结果与标准样品的质谱、RI 值和香气描述进行鉴定.RI 值是通过化合与相同条件下系列正构烷烃的保留时间(reten-24北京工商大学学报(自然科学版)2012年1月tion time,RT)计算得到,计算公式:RI=100N+100n(tRa -tRN)/(tR(N+n)-tRN)[8].如果没有标准品,则根据待测化合物的RI值及www.odour.org.uk报道的气味特征来进行风味物质的查询.2结果与分析GC-O-MS分别对两种浓香型白酒五粮液和盐井坊进行了定性和相对定量分析,图1为两种白酒的TIC图.分析结果如表1和表2.应用GC-O-MS检测到1μL五粮液和盐井坊这两种浓香型白酒中的挥发性物质分别有32种和24种.其中酯类是这两种白酒中的重要风味成分.虽然这两种酒含有的酯类在种类上区别不大,但是在含量和各种主要酯类的配比上差异显著,在五粮液中主要的4种酯,己酸乙酯、乙酸乙酯、乳酸乙酯表1五粮液分析结果Tab.1Analysis results of Wuliangye化合物RT RI风味含量/%鉴定方法酯类乙酸乙酯 5.047893水果0.65MS、odour、RI 丙酸乙酯 6.464962水果0.06MS、odour、RI 丁酸乙酯8.351039菠萝0.30MS、odour、RI 戊酸乙酯11.0141134水蜜桃0.15MS、odour、RI 己酸乙酯13.9551235水果 3.57MS、odour、RI 己酸戊酯16.3961320水果0.01MS、odour、RI 庚酸乙酯16.8251335花香0.07MS、odour、RI 乳酸乙酯17.1811348水果0.26MS、odour、RI 辛酸乙酯19.6071437水果0.03MS、odour、RI 2-羟基-4-甲基戊酸乙酯22.45715480.01MS、RI 酸类醋酸20.1571458醋味0.19MS、odour、RI 丁酸24.5541633汗臭0.07MS、odour、RI 戊酸27.1011742汗臭0.02MS、odour、RI 己酸29.4741850汗臭0.73MS、odour、RI 醇类乙醇 6.182949酒精92.52MS、odour、RI 2-丁醇7.9821026水果0.04MS、odour、RI 2-甲基-1-丙醇10.11111030.08MS、RI 3-甲基-2-丁醇10.8351128水果0.05MS、odour、RI 1-丁醇11.5041151甜香0.07MS、odour、RI 3-甲基-1-丁醇13.2351210香蕉0.37MS、odour、RI 1-戊醇14.4511252甜、花香0.01MS、odour、RI 1-己醇17.3281353水果0.07MS、odour、RI 醛、酮类乙醛 3.204704刺激性0.18MS、odour、RI 丙酮 4.058817溶剂0.09MS、odour、RI 戊醛 5.476916坚果0.01MS、odour、RI 3-甲基丁醛 5.564920巧克力0.05MS、odour、RI 2-戊酮 6.877981水果0.12MS、odour、RI 2,5-二甲基-3-己酮11.95811660.08MS、RI 3-羟基-2-丁酮15.6541293黄油0.03MS、odour、RI 糠醛20.5671473焦糊0.06MS、odour、RI 其它乙烯基乙醚 5.2439050.01MS、RI 1,1-二乙氧基-3-甲基丁烷9.35710760.04MS、RI 34第30卷第1期王然等:GC-O-MS对比两种浓香型白酒中的挥发性成分表2盐井坊分析结果Tab.2Analysis results of Yanjingfang化合物RT RI风味含量/%鉴定方法酯类乙酸乙酯 5.031893水果 1.04MS、odour、RI 丁酸乙酯8.3631039菠萝0.34MS、odour、RI 戊酸乙酯11.0301134水蜜桃0.04MS、odour、RI 己酸甲酯12.5891188水果微量MS、odour、RI 己酸乙酯13.9761235水果 4.30MS、odour、RI 庚酸乙酯16.8381335花香0.02MS、odour、RI 乳酸乙酯17.1861348水果 1.03MS、odour、RI 辛酸乙酯19.6101437水果0.02MS、odour、RI 2-羟基-4-甲基戊酸乙酯22.46115480.02MS、RI 酸类醋酸20.1531458醋味0.17MS、odour、RI 丁酸24.5551633汗臭0.04MS、odour、RI 己酸29.4761850汗臭0.15MS、odour、RI 醇类乙醇 6.255949酒精92.05MS、odour、RI 2-丁醇7.9971026水果0.05MS、odour、RI 2-甲基-1-丙醇10.10211030.06MS、RI 1-丁醇11.4831151甜香0.03MS、odour、RI 3-甲基-1-丁醇13.2271210香蕉0.36MS、odour、RI 1-己醇17.3281353坚果0.03MS、odour、RI 醛、酮类乙醛 3.206705刺激性0.07MS、odour、RI 3-甲基丁醛 5.572920巧克力0.02MS、odour、RI 三聚乙醛9.3601095辛辣0.04MS、odour、RI 3-羟基-2-丁酮15.6461293黄油0.02MS、odour、RI 糠醛20.5691473焦糊0.08MS、odour、RI 其它1,1-二乙氧基-3-甲基丁烷9.03610760.01MS、RI和丁酸乙酯的比例为1ʒ0.18ʒ0.07ʒ0.08,而在盐井坊中这四种酯的比例为1ʒ0.24ʒ0.24ʒ0.08.显然,盐井坊中乙酸乙酯和乳酸乙酯的含量相对较高,是这两种酒风味差别的重要原因.酸类是白酒香气的重要协调成分,适量的酸有助于酒体的放香舒适性,大多数酸的风味表现为醋味和汗臭味,而且风味强度很大.在五粮液中检测到了4种酸,即醋酸、丁酸、戊酸和己酸;而在盐井坊中只检测到了醋酸、丁酸和己酸.各种酸的配比对这两种白酒的香气起到了不同的协调作用,在五粮液中醋酸、丁酸和己酸的比例为0.26ʒ0.10ʒ1,而盐井坊中这三种酸的比例为1.17ʒ0.26ʒ1,盐井坊中醋酸和丁酸的比例较高,这使得这种酒闻起来没有五粮液那样柔和.醇类物质能赋予酒体以醇香和水果香等,是酒的重要风味成分,因此,在这两种白酒中的不同醇类物质也是其风味不同的重要原因.五粮液中检测到1-戊醇和1-己醇这两种具有甜香和水果香的物质,这两种物质对五粮液独特风味的形成也是必不可少的.另外,醛、酮等风味物质也是这两种白酒的重要风味物质,五粮液中的醛、酮类风味物质比盐井坊中的多了丙酮、戊醛、2-戊酮和2,5-二甲基-3-己酮,而盐井坊中发现了具有辛辣味的三聚乙醛,这种物质可能是形成盐井坊风味的独特物质.44北京工商大学学报(自然科学版)2012年1月3结论综上所述,形成五粮液和盐井坊这两种白酒风味差别的主要因素有酒中含有的酯类和酸类的不同配比,醇类和醛、酮类在种类上的差别等.在这两种酒中主要的四种酯,己酸乙酯、乙酸乙酯、乳酸乙酯和丁酸乙酯的比例具有明显区别,盐井坊中乙酸乙酯和乳酸乙酯的含量相对较高,是这两种酒风味差别的重要原因.醋酸、丁酸和己酸含量上的差别使得盐井坊闻起来没有五粮液那样柔和.另外,醇类、醛类和酮类物质也各具特点,它们对这两种酒风味的形成也具有重要的作用.参考文献:[1]孙兰萍.白酒中芳香成分的组成及其分离鉴定[J].化工装备技术,2002(1):12-14.[2]蔡心尧,尹建军,胡国栋.毛细管柱直接进样法测定白酒香味组分的研究[J].色谱,1997,15(5):367-371.[3]胡国栋.气相色谱法在白酒分析中的应用现状与回顾[J].食品与发酵工业,2003,29(10):65-69.[4]王蓓,曹雁平,许时婴.酶解奶油香精基料中特征风味组分分析研究[J].北京工商大学学报:自然科学版,2011,29(4):19-23.[5]宋焕禄.食品风味化学[M].北京:化学工业出版社,2008:1-123.[6]吴兆征,范志勇,左国营,等.GC-MS直接进样定性定量分析白酒的探讨[J].酿酒,2009,36(6):88-90.[7]夏玲君,宋焕禄.香味检测技术—GC/O的应用[J].食品与发酵工业,2006,32(1):83-87.[8]Dool H V D,Kratz P D.A generalization of the retention index system including linear temperature programmedgas-liquid partition chromatography[J].Journal of Chro-matography,1963,2:463-470.Comparison of Volatile Compounds from Two Kinds ofLuzhou-flavor Liquor by GC-O-MSWANG Ran,LI Rui,SONG Huan-lu(School of Food and Chemical Engineering,Beijing Technology and Business University,Beijing100048,China)Abstract:The volatile compounds of two kinds of luzhou-flavor liquor,Wuliangye and Yanjingfang,were analyzed qualitatively and quantitatively by gas chromatography-olfactometry-mass spectrometry(GC-O-MS).The main difference between the two kinds of wines were that esters and acids were in different proportions,and alcohols,aldehydes and ketones were different in types.In Wuliangye,there were four major esters,ethyl caproate,ethyl acetate,ethyl lactate and ethyl butyrate,the ratio of which was1ʒ0.18ʒ0.07ʒ0.08,however in Yanjingfang,the ratio of the four esters was1ʒ0.24ʒ0.24ʒ0.08.In Wu-liangye,the ratio of acetic acid,butyric acid and caproic acid was0.26ʒ0.10ʒ1,but the ratio was1.17ʒ0.26ʒ1in Yanjingfang.Key words:liquor;volatiles;wuliangye;yanjingfang;GC-O-MS(责任编辑:李宁)54第30卷第1期王然等:GC-O-MS对比两种浓香型白酒中的挥发性成分。

专题论述植物挥发性化学成分又称挥发油、精油,是植物体内的次生代谢物,由相对分子质量较小的简单化合物组成,具有芳香气味,在常温下可挥发。

植物精油多具有祛痰、止咳、平喘、驱风、健胃、解热、镇痛、抗菌消炎等作用。

精油还是天然香精、香料的重要组成部分,由于天然香料有着合成香料无法代替的、独特的香韵以及大多不存在毒副作用等原因,其生产和销售经久不衰。

在天然香料和食品添加剂的研制和生产中,提取和保留挥发油成分是保障其效用的重要步骤之一。

现将植物挥发油提取技术方法的研究进展作一综述,希望为植物挥发油的研究、开发、应用提供参考。

1传统的提取方法传统提取方法有:水蒸气蒸馏法[1-2]、溶剂提取法、压榨法、吸附法等方法。

水蒸气蒸馏(hydro distillation ,HD )是根据每种挥发性成分都有固定沸点且不同温度下具有相应蒸汽压的原理。

水蒸气蒸馏提取的方式有:水中蒸馏、水上蒸馏、直接蒸汽蒸馏、水扩散蒸汽蒸馏等。

其中,水扩散蒸气蒸馏是近年国外应用的一种新颖的蒸馏技术;水蒸气由锅顶进入,蒸气自上而下逐渐向料层渗透,同时将料层内的空气推出,其水散和传质出的精油无须全部气化即可进入锅底冷凝器。

蒸气为渗滤型,蒸馏均匀、一致、完全,而且水油冷凝液较快进入冷凝器,因此所得精油质量较好、得率较高、能耗较低、蒸馏时间短、设备简单。

水蒸气蒸馏适合于水中溶解度不大的挥发性成分的萃取。

此方法具有设备简单、易操作、成本低、产量大的优点,但若加热温度较高时,可能会使精油中热敏性成分发生热分解,易水解成分发生水解及原料焦化等。

HD 是目前应用较多的方法之一。

溶剂提取法是利用低沸点的弱极性有机溶剂如石油醚、乙醚等连续回流提取或冷浸提取,提取液经过蒸馏除去溶剂,即可得到粗挥发油。

此法得到的挥发油含有树脂、油脂、蜡、叶绿素等较多杂质,必须进一步精制提纯。

其方法是将挥发油粗品加适量的乙醇浸渍,放置冷冻(-20℃左右),过滤,滤液蒸馏除去乙醇;也可将挥发油粗品再进行水蒸气蒸馏。

一种特色鸭肉卤制品的风味与滋味分析朱冰洁;万杨红;夏萍萍【摘要】Sensory evaluation method was adopted to selecte the best evaluation feature duck meat halogen products.Headspace solid phase micro-extraction (HS-SPME), simultaneous distillation extraction (SDE) and gas chromatography-mass spectrometry (GC-MS) method were adoptedto conduct the experiment and analysis of volatile flavor.The materials playing a key role in flavor were primarily determined and it contained D-limonene, linalool, caproaldehyde, heptaldehyde, eugenol and so on.At last, according to conducting taste experiment and analysis by electronic tongue, the characteristic of sour taste, bitter taste, fresh flavor, aftertaste and astringent of selected samples were obtained, which might be the characteristic taste of feature duck meat halogen products.%实验采用感官评定的方法,选定评价最好的特色鸭肉卤制品.然后采用顶空固相微萃取(HS-SPME)和同时蒸馏萃取(SDE)与气质联用(GC-MS)的方法,对其进行挥发性风味的实验与分析,初步确定对风味起关键性作用的物质有D-柠檬烯、芳樟醇、已醛、庚醛、丁子香酚等.最后利用电子舌进行滋味的实验与分析,得出所选样品的酸味、苦味、鲜味、回味和涩味特点可能是特色鸭肉卤制品的特征滋味.【期刊名称】《肉类工业》【年(卷),期】2017(000)005【总页数】4页(P10-13)【关键词】顶空-固相微萃取(HS-SPME);同时蒸馏萃取(SDE);气质联用(GC-MS);电子舌;鸭肉;卤制品;风味;滋味【作者】朱冰洁;万杨红;夏萍萍【作者单位】武汉轻工大学食品科学与工程学院湖北武汉 430023;武汉轻工大学食品科学与工程学院湖北武汉 430023;武汉轻工大学食品科学与工程学院湖北武汉 430023【正文语种】中文酱卤禽肉制品是我国传统的特色肉制品,如南京盐水鸭、四川樟茶鸭、安徽符离鸡、河南道口烧鸡和近年来深受国内市场欢迎的武汉精武鸭脖等,这些产品工艺精湛、风味独特,深受消费者喜欢,但其生产多采用作坊式,模仿者无数,工艺五花八门,产品质量良莠不齐,给产业发展带来了隐患[1]。

农产品挥发性风味品质研究现状与展望摘要:随着经济社会的发展和物质生活水平的提高,人们的饮食观念已从“吃得饱”向“吃得好”转变,消费者比以往更加关注农产品品质。

在影响农产品品质的众多因素中,挥发性风味品质是农产品内在品质的重要评价指标之一,也是决定农产品可接受性和产品价值的首要条件。

因此,围绕农产品风味品质开展其物质基础、形成机理、鉴定评价新技术开发与应用等相关研究意义重大。

本文通过梳理近年来国内、外农产品风味品质的研究现状和发展趋势,重点介绍特征风味鉴定研究的新方法和新技术,概述基于分子感官组学的特征风味解析与鉴定,风味品质的生物调控技术研究,风味特征识别技术在农产品等级区分与真伪鉴别中的应用,智能嗅觉检测技术与风味评价,基质-风味及风味组分间相互作用机理等方面的最新研究进展,总结了我国现有风味研究存在的问题和不足,同时对新形势下农产品风味品质研究的发展趋势和研究重点进行了展望,以期为今后相关领域人员开展农产品风味品质研究与评价,推动优质特色风味农产品挖掘、培育、高值化开发利用和消费升级提供思路与参考。

关键词:农产品;风味品质;分子感官科学;生物技术;指纹图谱随着我国社会经济发展和消费结构升级,人们的饮食观念已从“吃得饱”向“吃得好”转变,消费者比以往更加关注农产品的品质问题。

农产品品质是指农产品的优质程度,不仅包括风味、外观和营养成分,还包括加工品质、卫生品质及商业品质。

在影响农产品品质的众多因素中,挥发性风味品质,作为农产品内在品质的重要评价指标之一,是直接决定农产品品质好坏和产品价值的首要条件,也是影响消费者购买行为的最重要评判指标[1]。

因此,开展农产品风味品质方面的研究与开发,不仅有助于农产品风味品质特色的精准定位、优质风味品质农产品的资源挖掘和品种培育,而且对特色风味农产品的生产指导和消费引导等方面也具有重要的借鉴和指导意义。

本文通过系统总结近年来国内外农产品风味品质研究的重要技术方法和各研究分支的最新进展,梳理了我国在农产品风味品质方面的研究现状及存在问题,展望了未来农产品风味品质研究的重要领域和发展方向。

顶空固相微萃取-气质联用分析荷叶香气成分付钦宝;蔡为荣;谢亮亮;潘汇;巫晓燕;曹雪【摘要】采用顶空固相微萃取和气相色谱-质谱联用技术(HS-SPME-GC-MS)对荷叶的挥发性成分进行分析,确定荷叶香气成分的组成.共鉴定了其中的51个成分,包含酸类化合物10种、烷烃类化合物8种、醛类化合物8种、烯类化合物4种、醇类化合物1种、酮类化合物6种、苯类化合物5种、萘类化合物3种、酯类化合物2种、其他3种,占其香气成分的92.26%.在荷叶的挥发性成分中,乙酸的含量最高,占总峰面积的18.90%,其次为DL-柠檬烯、己酸、苯乙醇、正壬醛、苯酚、丙酸、苯乙酸乙酯、醛、苯甲醛等.初步确定正壬醛、己醛和DL-柠檬烯是荷叶主要赋香成分;苯乙醇、苯乙酸乙酯和苯甲醛对荷叶的香味起了协调和增强作用.%Aroma components in lotus leaf sampleswere analyzed and determine by headspace solid phase micro extraction and gas chromatography-mass spectrometry (HS-SPME-GC-MS).51components that accounts for 92.26% of its aroma components were identified in total,which contains 10 acid,8 hydrocarbons,8 aldehydes,4 alkenes,1 alcohols,6 ketones,5 benzenes,3 napthalenes,2 esters,3 other compounds.Among the volatile components of lotus leaf,acetic acid content is the highest accounting for 18.90% peak area,followed by DL-limonene,hexanoic acid,benzyl alcohol,n-nonyl aldehyde,phenol,propionic acid,benzene ethyl acetate,formaldehydeand benzaldehyde.It is initially identified that nonylaldehyde,hexanal and DL-limonene are the main lotus scenting ingredients.Phenylethyl alcohol,ethyl phenylacetate and benzaldehyde have a synergistic effect on the aroma of lotus leaves.【期刊名称】《安徽工程大学学报》【年(卷),期】2017(032)001【总页数】5页(P24-28)【关键词】荷叶;固相微萃取;气相色谱-质谱联用;香气成分【作者】付钦宝;蔡为荣;谢亮亮;潘汇;巫晓燕;曹雪【作者单位】安徽工程大学生物与化学工程学院,安徽芜湖 241000;安徽工程大学生物与化学工程学院,安徽芜湖 241000;安徽工程大学生物与化学工程学院,安徽芜湖 241000;安徽工程大学生物与化学工程学院,安徽芜湖 241000;安徽工程大学生物与化学工程学院,安徽芜湖 241000;安徽工程大学生物与化学工程学院,安徽芜湖 241000【正文语种】中文【中图分类】TS207.3荷叶,又称莲花茎、莲茎.莲科莲属多年生草本挺水植物,生长在池塘或湖泊中,在我国长江流域以及华南、华北、东北等地区均大量分布.荷叶可作为复方中草药成分,1991年我国就已经把荷叶列为药食兼用的材料[1].传统的香气物质提取技术主要有液-液萃取(Liquid-Liquid Extraction)、顶空萃取(Headspace Extraction)、同时蒸馏萃取(Simultaneous Distillation Extraction,SDE)及超临界流体萃取(Supercritical Fluid Extraction,SCFE)等.这些方法各有优缺点,如液-液萃取香气成分时所需要的样品量大、耗时过长、成本也较高[2-4].固相微萃取法(Solid Phase Microextraction,SPME)是利用固相萃取吸附几何微区效应,通过萃取、解析两个过程,再结合气相色谱-质谱联用仪的一种快速采样分析技术.SPME操作简单、灵敏度高、重现性及线性好,完成整个过程一般只需十几分钟,所需样品量少且无需有机溶剂,成本低、环境污染小及其温和的操作条件使其迅速在环境、临床与法医分析及食品分析中得以应用[5].目前,国内外学者对荷叶精油的研究报道较多,但是采用SPME结合GC-MS分析荷叶天然香气成分的研究未见报道.尹慧晶[6]等用超临界CO2结合GC-MS分析萃取荷叶挥发性成分,共鉴定出26种成分;张赟彬[7]利用吹扫/捕集-热脱附气质联用法对荷叶挥发油成分进行分析,共检测出84种成分;傅水玉[8]等用水蒸汽蒸馏法得到的新鲜荷叶水-精油混合物经GC-MS法检出48种化合物.近年来,荷叶功能成分的研发已成天然药食研究热点之一,但对其天然香气的报道颇少,而民间早有用荷叶制茶或作为菜肴,其独特的田园清香备受消费者青睐.实验以8月份荷叶为研究对象,采用固相微萃取装置(SPME)萃取荷叶中的挥发性成分,利用气相色谱-质谱联用(GC-MS)进行检测,以香味物质的浓度与阈值之比,即香气值来确定荷叶的主要赋香成分[9-10].研究天然荷叶香气可为开发荷叶饮料、荷叶香料等产品提供理论基础.1.1 试验材料及处理荷叶,8月份采于安徽工程大学池塘(晒干打碎).1.2 主要仪器与设备HH-2数显恒温水浴锅,国华电器有限公司;FA1104电子天平,上海天平仪器厂;Trace MS气相色谱-质谱联用仪,美国Finnigan公司;手动SPME进样器,美国Supelco公司;7 μm PDMS(聚二甲基硅氧烷)非极性涂层、85 μm PA(聚丙烯酸酯)极性涂层、65 μm PDMS/DVB(聚二甲基硅氧烷/聚二乙烯基苯)双极性涂层,美国Supelco公司.1.3 样品预处理首先,对固相微萃取的萃取头进行老化处理,老化温度为250 ℃,老化时间为1h.其次,称取5 g干荷叶粉末放入50 mL顶空瓶中,置于恒温水浴锅中,60 ℃保温20 min,再将固相微萃取装置的萃取头插入到顶空瓶中,吸附20 min.最后,将萃取头插入到气相色谱-质谱联用仪的进样口,在250 ℃条件下解吸5 min,启动仪器收集数据.1.4 实验条件参考付蕾[11]等和孔维婷[12]等的测定条件,略作修改,最终确定色谱和质谱条件.色谱条件:色谱柱为DB-5柱(60 m×0.32 mm id;液膜厚度1.0 μm).升温程序为初始柱温40 ℃,保持4 min,以4 ℃/min升温至120 ℃,再以8 ℃/min升温至250 ℃,保持6 min;载气He,柱流速1 mL/min,不分流,恒压35 kPa,进样口温度250 ℃,接口温度250 ℃.质谱条件:电子轰击离子源,电子能量70 ev,离子源温度200 ℃,电离方式EI,扫描范围为33~450 u.定性方法:利用计算机的数据工作站NIST标准质谱图库和Wiley谱图库,对被分析样品组分的质谱进行检索,以匹配度大于80%作为鉴定依据,再结合相关参考资料对谱图进行人工解析,从而确定各个被分析组分的化学成分.通过采用面积归一化法对荷叶样品中的香气成分进行分析,即通过被检测出的各个组分的峰面积与待测样品总的峰面积做比较,从而得出各个检出组分的相对百分含量.2.1 固相微萃取头的选择不同固定相所构成的萃取头对香气成分的萃取吸附能力不同,萃取头的选择是荷叶香气成分分析的关键.以荷叶为研究对象,分别考察7 μm PDMS(非极性涂层)、85 μm PA(极性涂层)和65 μm PDMS/DVB(双极性涂层)3种萃取头对荷叶中的香气成分的吸附性能.不同SPME萃取头分析荷叶香气成分如表1所示.从表1可以看出,不同的纤维萃取头对荷叶香气成分的萃取效果影响较大.65 μm PDMS/DVB纤维头检出的香气成分种类最多,7 μm PDMS次之,85 μm PA纤维头检出的香气成分种类最少.这主要是因为不同萃取头涂层的极性不同,萃取头对所分析的化合物具有一定选择性.实验得出,复合涂层的萃取头更适合荷叶样品的分析,分离出的香气成分比较全面,因此,选择65 μm PDMS/DVB来作为实验萃取头.2.2 荷叶中香气成分分析采用固相微萃取仪分析干荷叶中香气成分时只需要很少样品即可得到较好的效果,其香气成分在DB-5柱上的总离子流图如图1所示.从图1可以看出,通过GC-MS 方法进行测定,经过计算机数据工作站NIST标准质谱图库、Wiley谱图库与检测出的样品质谱图进行对照,匹配度大于80%的共有51个化合物,按峰面积计算,其含量占干荷叶挥发性成分的92.26%,其组成及相对含量如表2所示.从表2可知,对荷叶香气贡献较大的依次是:酸类化合物10种,占29.39%;烷烃类化合物8种,占9.80%;醛类化合物8种,占8.83%;烯类化合物4种,占6.40%.检测结果与张赟彬[7]利用吹扫/捕集-热脱附气质联用法对荷叶挥发油成分的对比分析相一致.此外,醇类化合物1种,占3.23%;酮类化合物6种,占4.27%;苯类化合物5种,占2.76%;萘类化合物3种,占1.75%;酯类化合物2种,占3.05%;其他3种,占3.13%.说明酸类、烷类和醛类物质在荷叶香味中起重要作用.其中,酸类是荷叶主要的呈香物质,且乙酸为主要挥发性物质,占总峰面积的18.90%,其次为DL-柠檬烯、己酸、苯乙醇、正壬醛、苯酚、丙酸、苯乙酸乙酯、醛、苯甲醛等.荷叶的特征香味是由许多挥发性化合物混合形成的,单一的化合物不能构成荷叶的特征香味.每种化合物对香味所起的作用主要取决于它的阈值、香气值和含量.只有香气值大于1时,该挥发物才对荷叶香味起作用,在一定范围内该值越大,香味越浓.香气成分对香味的贡献程度不仅仅由其质量分数来决定的,阈值低的成分即使质量分数低,其对香味的贡献仍然有十分重要的影响;风味特征也受浓度变化影响,如β-甲基吲哚在浓度高时呈恶臭味,而在浓度较低时呈茉莉花香的气味[9].故常用香味物质的浓度与阈值之比即香气值来辅助确定主要的赋香成分.利用已有香气阈值的报道来计算香气物质的香气值,并据此确定特征香气成分[9-10].荷叶主要香气成分的比较如表3所示.由表3可知,荷叶的主要香气成分有4种,根据贡献大小依次为正壬醛、癸醛、己醛、DL-柠檬烯,其他苯乙醇、苯乙酸乙酯与苯甲醛、异戊酸、乙酸、己酸等对干荷叶的香味起了协调和增强作用.采用SPME技术处理样品,较真实地反映出荷叶天然香气的组成,是天然香气成分研究中一种极为有效的样品处理方法.实验结果表明,萃取头的不同对荷叶香气成分吸附效果明显不同,其中,65 μm PDMS/DVB对荷叶中的香气成分萃取效果最佳.通过HS-SPME-GC-MS检测方法共鉴定了荷叶样品中香气成分中的51个化合物,按照相对峰面积计算,检出化合物的总含量占荷叶总挥发性成分的92.26%,检测鉴定出的组分包括酸类、烷烃类、烯类、醛类、苯类、酮类、萘类、醇类、酯类及其他化合物,这些共同构造了荷叶特殊的香气.实验初步确定,荷叶的主要香气成分有4种,根据贡献大小依次为正壬醛、癸醛、己醛、DL-柠檬烯,其他苯乙醇、苯乙酸乙酯与苯甲醛、异戊酸、乙酸、己酸等对干荷叶的香味起了协调和增强作用.研究结果为荷叶致香机理、荷叶香气的开发提供技术依据和参考.【相关文献】[1] 叶林虎.荷叶代谢性药物相互作用及体内成分研究[D].北京:北京协和医学院,2014.[2] 于静,李景明,吴继红,等.顶空固相微萃取法(SPME)在红葡萄酒香气成分测定中的应用研究[J].中外葡萄与葡萄酒,2006(3):4-9.[3] 初众,王海茹,张彦军,等.HS-SPME-GC-MS技术分析香草兰果皮的挥发性成分[J].食品科学,2016,37(6):126-131.[4] 李明,曾茜,孙培冬,等.HS-SPME/GC-MS分析无锡绿茶香气成分[J].食品与机械,2015(3):32-36.[5] 刘晓慧,张丽霞,王日为,等.顶空固相微萃取-气相色谱-质谱联用法分析黄茶香气成分[J].食品科学,2010,31(16):239-243.[6] 尹慧晶,钱一帆,濮存海.均匀设计法优化荷叶超临界CO2萃取工艺及萃取物GC-MS分析[J].中药材,2007,30(4):464-466.[7] 张赟彬,缪存铅,崔俭杰.吹扫/捕集-热脱附气质联用法对荷叶挥发油成分的对比分析[J].化学学报,2009,67(20):2 368-2 374.[8] 傅水玉,黄爱今,刘虎威,等.荷叶香气成分的研究(I)-荷叶天然香气成分的分析[J].北京大学学报:自然科学版,1992,28(6):699-705.[9] 崔桂友.风味化学研究的困境和前景[J].食品科学,1995,16(10):24-28.[10] 李和,李佩文,于振华.食品香料化学——杂环香味化合物[M].北京:中国轻工业出版社,1992.[11] 付蕾,刘正生,孙鑫洋,等.4种纤维头对草莓香气成分的萃取效果[J].中国农业科学,2010,43(21):4 473-4 481.[12] 孔维婷,刘建军,司辉清.固相微萃取与气相色谱-质谱联用分析信阳毛尖香气成分[J].食品科学,2012,33(12):185-189.。

响应面分析法优化HS-SPME萃取黄豆酱挥发性成分工艺研究乔鑫;黄红霞;乔宇;康旭;李冬生【期刊名称】《食品科学》【年(卷),期】2010(031)022【摘要】为了优化黄豆酱挥发性风味成分检测的SPME萃取效率,采用Plackett-Burman设计法和响应面分析法对黄豆酱风味萃取条件进行优化.先用Plackett-Burman设计从8种萃取因素中筛选出对总峰面积有显著影响的因素,再用最陡爬坡试验及B0x-Behnken设计进一步优化.结果表明,萃取温度、萃取时间和基体中的无机盐添加量是影响总峰面积的显著因素,优化后的萃取条件为萃取温度56℃、萃取时间42min、基体中的无机盐添加量0.98g.在优化条件下,与初始最大总峰面积12880000相比,总峰面积提高到13107129.【总页数】6页(P69-74)【作者】乔鑫;黄红霞;乔宇;康旭;李冬生【作者单位】湖北工业大学生物工程学院,湖北,武汉,430068;湖北工业大学生物工程学院,湖北,武汉,430068;湖北省农业科学院农产品加工与核农技术研究所,湖北,武汉,430064;湖北工业大学生物工程学院,湖北,武汉,430068;湖北工业大学生物工程学院,湖北,武汉,430068;湖北省食品发酵工程技术研究中心,湖北,武汉,430068【正文语种】中文【中图分类】TS207.3【相关文献】1.响应面分析法优化湘西月见草籽油的超临界萃取工艺研究 [J], 欧阳辉;余佶;陈小原;张永康2.响应面法优化籼稻挥发性成分 SPME 萃取条件的研究 [J], 石嘉怿;张檬达;鞠兴荣3.响应面优化传统发酵豆酱风味物质萃取条件的研究 [J], 韩翠萍;汤慧娟;赵月;王宗莹;程建军;田波;李杨;谢凤英4.响应面法优化以SPME-GC-MS技术萃取人参花挥发性成分工艺的研究 [J], XIAO Yang;JIANG Tao;HAN Yan-yan;WANG Zhong-xi;WANG En-peng;CHEN Chang-bao5.顶空固相微萃取茶油挥发性成分的响应面优化 [J], 王静;唐旭晓;张应中;王明怀;徐煲铧;张盟雨因版权原因,仅展示原文概要,查看原文内容请购买。

国食品学报Journal of Chinese Institute of Food Science and Technology第20 第4寸2 0 2 0 4 月Vol. 20 No. 4Apr. 2 0 2 0酵子馒头与酵母馒头挥发性组分与香气特征分析王远辉 赵靖雯 吴宵云 常永锋 张兰兰(河南工业大学粮(食*学+ 郑-450001)摘要.用同时蒸3萃取(SDE )和顶空固相微萃取(HS-SPME )收集酵子馒头(JSB )与酵母馒头(YSB "的挥发性物质,并结合气-质谱联用(GC/MS )和气相嗅闻(GC-O )技术,对其挥发性物质和香气特征进行分析$结果显示,SDE 吸收液适合分3和浓缩$ HS-SPME 最佳条件为吸附温度55 !,吸附时间30 min ,解吸时间6min 。

GC/MS分析发现,两种馒头共有组分23种,主要组分是乙醇、3-甲基-1-丁醇、正己醇、(!)-2-壬烯醛、2-正戊基咲喃%蔡、苯甲醛、戊基苯、壬醛、香叶基丙酮,共有组分在JSB 中相对含量较高(>60%),在YSB 中含量较低(<50%), 其中JSB 中乙醇的相对含量最高(63%)$ JSB 中酸类、含苯环类、杂环类化合物的相对含量高于YSB ,表现出醇 香、果香和坚果香味。

而YSB 中烯胫类、醛类、酯类、酮类化合物高于JSB ,其香气不如JSB 浓郁$ JSB 与YSB 的挥发性物质种类和相对含量差异明显,导致两者表现出不同的香气特征$关键词 同时蒸3萃取;7空固相微萃取;气相保留指数;质谱;挥发性物质7章编号 1009-7848 (2020 )04-0281-10 doi : 10.16429/j.l009-7848.2020.04.035馒头是我国传统发酵面制品之一,在北方等 地作为主食。

馒头以小麦粉为主要原料,加入发酵 剂和水及其它辅料,经过和面、发酵、压面、成型、醒发、蒸制过程制作而成叫经过近千年的发展和 传承,不同地区的馒头制作工艺存在差别,添加的 辅料也各有特色,使用的发酵剂更是多种多样,形 成各种风味独特的、地域特色鲜明的馒头叫形成不同类型馒头风味的主要阶段是发酵过程,而我 国传统馒头制作工艺使用的是先辈们长期 ,祖辈传的传统发酵剂,例如老面、面 、面、 酵、头叫传统发酵剂制作的馒头在我国,百姓对此类馒头已形成深刻的风味记忆。

油炸对臭豆腐中挥发性风味物质的影响郑兵福;徐睿烜;蒋立文【摘要】以长沙臭豆腐为原料,采用顶空固相微萃取结合气相色谱质谱联用(HS-SPME-GC-MS)技术检测臭豆腐油炸前后的挥发性风味成分,研究油炸对臭豆腐的挥发性风味物质的影响.结果表明,油炸前的臭豆腐中共鉴定出37种挥发性物质,主要由醛类、醇类、烷类、含硫化合物和呋喃类组成;油炸后的臭豆腐中共鉴定出40种挥发性物质,除上述物质外,还含有苯类、酮类和酸酐类等物质,而醇类物质较少.与油炸前的臭豆腐相比,油炸后的臭豆腐中醇类、烯类、烷类的相对含量呈递减趋势,酮类、醛类、苯类、其他杂环类化合物的相对含量呈递增趋势.【期刊名称】《中国酿造》【年(卷),期】2019(038)003【总页数】4页(P14-17)【关键词】油炸;臭豆腐;风味物质;顶空固相微萃取结合气相色谱质谱联用【作者】郑兵福;徐睿烜;蒋立文【作者单位】湖南农业大学食品科学技术学院,湖南长沙410128;湖南志成食品技术服务有限公司,湖南长沙410008;湖南农业大学食品科学技术学院,湖南长沙410128;食品科学与生物技术湖南省重点实验室,湖南长沙410128;湖南农业大学食品科学技术学院,湖南长沙410128;食品科学与生物技术湖南省重点实验室,湖南长沙410128【正文语种】中文【中图分类】TS214长沙臭豆腐是一类典型的地方特色风味小吃,一般将豆腐经过发酵后具有特殊“臭”味的卤水经过浸泡、表面清洗、油炸再蘸调味汁食用。

臭豆腐特有的“闻起来臭吃起来香”风味与挥发性物质密切相关[1],油炸是南方臭豆腐特有的手段,既能赋予臭豆腐所具有的特殊香味物质,还能过滤浸泡卤水所带入的有害物质,但油炸对臭豆腐中的挥发性风味物质的具体影响暂不明确,本试验采用顶空固相微萃取结合气相色谱质谱联用(headspacesolid-phasemicroextraction-gas chromatography-mass spectrometer,HS-SPMEGC-MS)技术对臭豆腐油炸前后的挥发性风味物质进行了提取检测,研究油炸对臭豆腐的挥发性风味物质的影响。

同时蒸馏萃取和固相微萃取法提取国产干酪中风味物质Simultaneous distillation extractionand solid phase micro-extraction methods for analysis of aromacomponents in home-made cheese flavor衣宇佳1,2,田怀香3,郑小平4,汤坚1*YI Yu-jia1,2TIAN Huai-xiang3ZHENG Xiao-ping4TANG Jian1(1.食品科学与技术国家重点实验室,江南大学2.江南大学食品学院,江苏无锡214122;3.上海应用技术学院香料香精技术与工程学院,上海200235;4.光明乳业股份有限公司技术中心上海200072)(1.State Key Laboratory of Food Science and Technology,Jiangnan University2.School of Food Science and Technology,Jiangnan University,Wuxi,Jiangsu,214122;3.School of Perfume and Aroma Technology,Shanghai Institute of Technology,Shangha i200235;4.Technical Center of Bright Dairy&Food Co.,Ltd,Shanghai200072)摘要:对同时蒸馏萃取法(SDE)和固相微萃取法(SPME)提取的国产干酪样品中挥发性风味成分进行比较。

采用两种方法制备的样品经气-质联用分析后共检测到100种挥发性化合物,SDE法和SPME法分别鉴定出65种和62种风味组分。

前者对高沸点、低挥发性的物质以及长链羧酸、醛、酮、酯类检测效果良好;后者对低沸点的醇类、羧酸类以及含硫化合物有较好的检出。

中国医药报/2004年/06月/08日/SPM E在天然产物分析中的应用魏宁漪;段天璇;马长华固相微萃取(SPME)是一项新型的无溶剂化样品前处理技术。

SPM E是在一根纤细的熔融石英纤维表面涂布一层聚合物并将其作为萃取介质(萃取头),再将萃取头直接浸入样品溶液或采用顶空-固相微萃取方法(HS-SPM E)采样。

SPME在环境分析领域已经较为成熟,但在天然产物分析研究领域的应用正处于起步阶段。

中草药挥发性成分分析用SPME测定中药石菖蒲中挥发性成分,可鉴定出16种化合物。

运用H S-SPME-GC-MS (顶空-固相微萃取-气相色谱-质谱)方法可从新鲜的紫苏中鉴定出20多种挥发性成分。

使用HS-SPME-GC-M S方法分离栀子鲜花头香成分,鉴定54种化学成分。

可用SPM E测定肉桂中的香豆素、醋酸桂皮酯、石竹烯、2-甲氧桂皮醛等成分,以此来确定肉桂类植物的植物学起源及鉴别。

使用SPME-GC-MS技术分析了人工麝香的水溶液。

使用SPM E技术可从冷杉叶中提取挥发性成分,以及蛇麻草中的各种挥发性成分。

应用H S-SPME分析了针叶松叶中的蒎烯、樟烯、月桂烯等单萜类成分。

应用H S-SPME法可萃取脱氧麻黄碱及其主要代谢产物苯异丙胺,方法快速、灵敏、准确,可避免常用测定方法所遇到的干扰。

运用此法还可从中药丸剂中顶空萃取出17种萜类化合物。

天然香料分析用V-GC-M S分析白兰花的香气成分,分离了114个色谱峰并鉴定了其中的75个成分。

用HS-SPM E-GC-M S方法从新鲜的熏衣草中分离测定了香气成分。

从青霉菌和尼日尔黑霉菌的表面测定到了经过生物转化的柠檬醛、香叶醇和橙花醇。

此外,还可从食品中提取分析组分。

在天然产物分析中,仪器与信息技术的发展大大推动了分析学科的前进,但样品制备技术却远远落后于食品与电脑技术的发展,成为制约学科发展的瓶颈!之一。

SPM E技术出现后,由于其制备操作简单,快速实用等优点,而迅速发展。

㊀㊀㊀㊀㊀㊀㊀㊀㊀2024年2月第39卷第1期JOURNAL OF LIGHT INDUSTRY㊀Vol.39No.1Feb.2024㊀收稿日期:2023-08-08;修回日期:2023-10-08;出版日期:2024-02-15基金项目:湖北省重点研发计划项目(2020BBA045)作者简介:杨旖旎(1993 ),女,湖北省武汉市人,中国农业科学院油料作物研究所助理研究员,主要研究方向为食品风味化学㊂E-mail :361215820@通信作者:周琦(1985 ),女,湖北省武汉市人,中国农业科学院油料作物研究所特聘研究员,博士,主要研究方向为油脂风味化学及油料高值化利用㊂E-mail :zhouqi01@caas.cn杨旖旎,王林海,袁彬宏,等.基于SAFE 法分析市售小磨香油的关键风味成分[J].轻工学报,2024,39(1):30-37.YANG Y N,WANG L H,YUAN B H,et al.The analysis of key volatile flavor components of commercial sesame oil based on solvent-assisted flavor evaporation[J].Journal of Light Industry,2024,39(1):30-37.DOI:10.12187/2024.01.004基于SAFE 法分析市售小磨香油的关键风味成分杨旖旎,王林海,袁彬宏,岳杨,顾亚茹,韦小燕,周琦中国农业科学院油料作物研究所油料脂质化学与营养湖北省重点实验室/油料油脂加工技术国家地方联合工程实验室,湖北武汉430062摘要:以市售小磨香油为研究对象,采用溶剂辅助风味蒸发萃取(SAFE )法萃取其挥发性风味成分,利用三重四级杆气相色谱-质谱联用进行半定量分析,结合相对气味活度值(ROAV )进行关键风味成分贡献度分析㊂结果表明:从市售小磨香油中共鉴定出107种挥发性风味成分,其中35种挥发性风味成分(ROAV ȡ0.01)具有典型的风味特征贡献,包括4种硫化物㊁5种酚类㊁10种吡嗪类㊁4种呋喃类㊁3种醛类㊁4种噻唑类㊁2种吡咯类㊁2种噻吩类和1种吲哚,使小磨香油呈现卷心菜味㊁鱼腥味㊁硫磺味㊁烟熏味㊁爆米花味㊁油香和烤芝麻味㊂14种ROAV ȡ0.10的风味成分(乙酰基吡嗪㊁2-呋喃甲醇㊁2,3-二甲基-吡嗪㊁2,3,5-三甲基吡嗪㊁二甲基二硫醚㊁二甲基三硫醚㊁甲基糠基二硫醚㊁硫醇酸甲酯㊁4-乙烯基-2-甲氧基苯酚㊁2-甲氧基苯酚㊁己醛㊁2-乙基-6-甲基吡嗪㊁2-甲基-3-呋喃硫醇和3-乙基-2,5-二甲基-吡嗪)被确认为小磨香油的关键风味成分㊂综上,采用该方法确定小磨香油的关键风味成分,不仅可扩充小磨香油的风味数据库,还可为芝麻油风味品质评价及品质调控提供重要的物质基础㊂关键词:小磨香油;挥发性风味成分;溶剂辅助风味蒸发萃取法;三重四级杆气相色谱-质谱联用;相对气味活度值中图分类号:TS272.5㊀㊀文献标识码:A㊀㊀文章编号:2096-1553(2024)01-0030-080㊀引言芝麻油俗称小磨香油,是我国具有1600多年历史的传统风味型食用油,主要采用水代工艺制备,具体包括研磨㊁调温㊁均质㊁混合㊁搅拌等工序,这种复杂工艺可使小磨香油风味成分丰富,香气浓郁㊂小磨香油富含不饱和脂肪酸(>80%)㊁芝麻酚㊁木脂素等有益于人体健康的成分[1-2],且作为风味植物油的典型代表之一,深受消费者喜爱㊂已有学者对小磨香油的风味成分构成开展过研究,例如,尹文婷等[3]采用固相微萃取(SPME)技术从小磨香油中萃取了61种挥发性风味成分,其中吡嗪类占40%以㊃03㊃㊀杨旖旎,等:基于SAFE法分析市售小磨香油的关键风味成分上㊂李萍萍[4]采用SPME技术结合气相色谱-质谱(GC-MS)联用技术,从3种芝麻油中萃取了76种挥发性风味成分,其中从小磨香油中鉴定出42种挥发性风味成分,含量较多的是甲基吡嗪㊁2,5-二甲基吡嗪㊁2,3,5-三甲基吡嗪和3-乙基-2,5-二甲基吡嗪㊂目前鉴定芝麻油挥发性风味成分的方法主要集中于顶空-固相微萃取(Headspace-Solid Phase Mi-cro-extraction,HS-SPME)法㊁同时蒸馏-萃取(Simul-taneous Distillation Extraction,SDE)法㊁超临界CO2萃取(Supercritical Fluid Extraxtion-CO2,SFE-CO2)法等[5],但由于高温萃取或材料吸附的局限性,仍有较多风味成分未被真实捕捉到或已被改变原有状态㊂而溶剂辅助风味蒸发萃取(Solvent-assisted Flavor Evaporation,SAFE)法基于超低提取温度和高真空环境,可有效避免挥发性风味成分的流失,具有回收率高㊁香气成分真实等优点,已广泛应用于菜籽油[6]㊁特级初榨橄榄油[7]㊁生熟普洱茶[8]㊁白酒[9]等食品风味成分的萃取中,但鲜有利用该方法萃取小磨香油中挥发性风味成分的报道㊂同时,由于小磨香油风味成分构成复杂,传统GC-MS已无法满足其风味成分鉴定的需求㊂基于此,本文拟以市售小磨香油为研究对象,采用SAFE法结合定性定量能力更佳的三重四级杆气相色谱-质谱联用技术,辅以相对气味活度值(Rela-tive Odour Activity Value,ROAV)分析,以期明确市售小磨香油的关键挥发性风味成分,为从风味导向角度全面解析小磨香油风味构成和实现品质控制提供参考㊂1㊀材料与方法1.1㊀主要材料与试剂金龙鱼小磨香油(一级),市售;二氯甲烷㊁乙醇㊁无水Na2SO4,国药集团化学试剂有限公司;2-甲基-3-庚酮㊁C5 C30正构烷烃㊁二甲基二硫醚㊁二甲基三硫醚㊁2(5H)-呋喃酮㊁5-甲基-2-呋喃甲醇㊁5-甲基呋喃醛㊁2-戊基呋喃㊁2-甲基-3-呋喃硫醇㊁己醛㊁糠醛㊁苯甲醛㊁1-甲基-2-吡咯甲醛㊁2-吡咯甲醛㊁苯乙醛㊁壬醛㊁5-甲基-2-噻吩甲醛㊁3-羟基-2-丁酮㊁苯乙酮㊁2-甲基吡嗪㊁2,5-二甲基吡嗪㊁2,3-二甲基吡嗪㊁2-乙基-6-甲基吡嗪㊁2,3,5-三甲基吡嗪㊁5-甲基-2-乙烯基-吡嗪㊁2-甲基-5-异丙基吡嗪㊁3-乙基-2,5-二甲基吡嗪㊁2,3-二乙基-5-甲基吡嗪㊁2-甲基己酸㊁戊酸㊁2-噻吩甲醇㊁1-苯基乙醇㊁吲哚,纯度ȡ95.0%,美国Sigma公司㊂噻唑㊁2-甲基噻唑㊁吡咯㊁2-乙酰基吡咯㊁四氢噻吩-3-酮㊁甲苯㊁乙基苯㊁苯乙烯㊁烟酸甲酯㊁对甲酚㊁苯酚㊁麦芽酚㊁2,6-二甲氧基苯酚㊁丁香酚㊁2,4-二叔丁基苯酚㊁嘧啶,纯度ȡ95.0%,梯希爱上海化成工业发展有限公司㊂以上试剂均为色谱纯㊂1.2㊀主要仪器与设备SAFE装置,德国Glasblaserei公司;JA2003数字型电子天平㊁DZKW-S-4型水浴锅,北京国华电器有限公司;Edwards EXT75DX型真空泵,爱德华兹科技贸易有限公司;LD-D12SY型氮吹仪,山东莱恩德智能仪器有限公司;50cm Vigreux柱,郑州天择仪器设备有限公司;HP-5MS型毛细管柱(60mˑ0.25mmˑ0.25μm),美国J&W公司;8890-7000D 型三重四级杆气相色谱-质谱联用仪,美国Agilent 公司㊂1.3㊀实验方法1.3.1㊀小磨香油挥发性风味成分萃取㊀根据X.Jia 等[10]的方法,采用SAFE法萃取样品中的挥发性风味成分㊂称取50.0g样品,加入150mL二氯甲烷和100μL2-甲基-3-庚酮(0.816mg/mL)作为内标物,密封后于4ħ条件下水浴㊁超声波处理2h;利用真空泵使SAFE装置内压保持在10-6kPa,萃取样品中的挥发性风味成分;待萃取物升温至25ħ左右,加入无水Na2SO4进行干燥除水;利用Vigreux柱将萃取物浓缩至10mL后,继续采用氮吹仪(纯度ȡ99.999%)将萃取物浓缩至200μL;取1μL浓缩后的萃取物进行GC-MS分析㊂1.3.2㊀GC-MS分析㊀采用三重四级杆气相色谱-质谱联用仪,载气为He,气体流速为1.5mL/min;利用毛细管柱进行分离;进样器温度为250ħ,离子源温度为230ħ;柱温箱初始温度设定为40ħ,以4ħ/min的速率上升到200ħ,保持2min,再以8ħ/min的速率上升到280ħ;分流比为1ʒ10,进样量为1μL;溶剂延迟3min;质谱扫描范围为40~㊃13㊃㊀2024年2月第39卷第1期㊀400amu㊂每个化合物的线性保留指数(LRI)参照相同条件下C5 C30正构烷烃的保留时间计算㊂在毛细管柱的出口处连接嗅闻端口,ODP2和MS检测器之间的分流比为1ʒ1,嗅闻分析重复3次㊂根据NIST20数据库对挥发性风味成分色谱图进行检索和分析,并结合LRI进行定性分析㊂1.3.3㊀定量分析㊀采用内标法对小磨香油中的挥发性风味成分进行定量分析,内标物为2-甲基-3-庚酮(0.816mg/mL),根据内标物的质量浓度和各个待测挥发性风味成分的相对峰面积比值进行计算,具体公式如下:C i=VˑC sˑA i MˑA s式中,C i为待测挥发性风味成分的相对含量/(μg㊃kg-1);C s为已知内标物的质量浓度;V为内标物的体积/μL;A i为待测挥发性风味成分的相对峰面积;A s为已知内标物的相对峰面积;M为芝麻油的体积/μL㊂通常利用ROAV评估挥发性风味成分㊂一般认为当0.10ɤROAV<1.00时,该挥发性风味成分对整体香气特征有修饰作用;ROAVȡ1.00时,该挥发性风味成分对整体香气特征有显著影响;ROAV越高,该挥发性风味成分的香气特征贡献度越大[11]㊂评估样品中挥发性风味成分对主要香气特征的贡献度,可根据以下公式计算:ROAV=100ˑC AC MaxˑOT MaxOT a式中,C A和OT a分别为挥发性风味成分的含量和感官阈值/(μg㊃kg-1);C Max和OT Max分别为总体挥发性最强风味成分的含量和感官阈值/(μg㊃kg-1)㊂1.4㊀数据处理使用SPSS2021㊁Excel2019㊁SIMAC14.1进行数据处理和作图,所有实验均重复3次,数据结果取(平均值ʃ标准差)㊂2㊀结果与分析2.1㊀小磨香油挥发性风味成分定性定量分析小磨香油中挥发性风味成分及其含量见表1㊂由表1可知,小磨香油中共鉴定出107种挥发性风味成分,包括4种硫化物㊁10种呋喃类化合物㊁10种噻唑类化合物㊁6种吡咯类化合物㊁4种吡啶类化合物㊁5种噻吩类化合物㊁12种醛类化合物㊁4种酮类化合物㊁4种腈类化合物㊁23种吡嗪类化合物㊁4种苯环类化合物㊁3种酯类化合物㊁10种酚类化合物和8种其他类化合物,其中47种挥发性风味成分采用标准品鉴定㊂在已鉴定出的挥发性风味成分中,许多成分鲜有报道,例如甲基糠基二硫㊁4-甲基噻唑㊁2-乙酰基吡咯㊁3-甲基-2-乙酰基-吡嗪等㊂刘鑫等[12]和周易枚等[13]对比分析了市售芝麻油和水代法芝麻油的挥发性风味成分,发现水代法芝麻油在化合物种类上更丰富㊂王有菲[14]在对比不同产地㊁不同品种芝麻油挥发性风味成分时发现,吡嗪是芝麻油最主要的挥发性风味成分,其占比超过50%㊂赵宇航等[15]将微波生香技术应用于芝麻油预处理中,发现该技术能赋予芝麻油更浓郁的香气,其中呈香活性物质有91种㊂尹文婷等[3]从小磨香油中仅检测到61种挥发性风味成分㊂但本研究鉴定出的挥发性风味成分更多,且在重要呈香化合物吡嗪类中,2-异丙基吡嗪㊁2-乙基-3-甲基吡嗪㊁2-丙基吡嗪㊁2-甲基-5-异丙基吡嗪㊁异丙烯基吡嗪㊁(1-甲基乙烯基)-吡嗪㊁1-(5-甲基吡嗪基)-乙酮㊁3-甲基-2-乙酰基-吡嗪㊁2,3,5-三甲基-6-乙基吡嗪和2-甲基-3-甲硫基吡嗪这10种化合物在现有芝麻油相关文献中尚未见报道㊂从半定量角度可知,在鉴定出的107种挥发性风味成分中,含量大于10000.00μg/kg的是2种酚类和3种吡嗪类化合物,分别是2-甲氧基苯酚(23513.71μg/kg)㊁2,4-二叔丁基苯酚(19103.00μg/kg)㊁2-甲基吡嗪(19725.18μg/kg)㊁2,5-二甲基吡嗪(16425.24μg/kg)和3-乙基-2,5-二甲基-吡嗪(10308.50μg/kg)㊂苯酚类化合物可能来源于加工过程中芝麻中羟基衍生物的脱羧反应或木脂素的降解[5],使小磨香油具有烟熏味㊂吡嗪类化合物是小磨香油中含量最丰富的香气活性物质,共鉴定出23种,且总含量最高(88831.27μg/kg),占42.33%㊂吡嗪类化合物主要由热加工过程中的芝麻还原糖和氨基酸热降解反应生成,具有焙烤香㊁坚果味㊁爆米花味㊁甜香味等香气特征[16]㊂含量大㊃23㊃㊀杨旖旎,等:基于SAFE法分析市售小磨香油的关键风味成分㊃33㊃㊀㊀表1㊀小磨香油中挥发性风味成分及其含量㊀2024年2月第39卷第1期㊀表1(续)于1000.00μg/kg的吡嗪类化合物共有11种,分别是2-甲基吡嗪㊁2,5-二甲基吡嗪㊁2-乙基吡嗪㊁2,3-二甲基-吡嗪㊁2-乙基-6-甲基吡嗪㊁2,3,5-三甲基吡嗪㊁2-乙基-3-甲基吡嗪㊁乙酰基吡嗪㊁3-乙基-2,5-二甲基-吡嗪㊁1-(5-甲基吡嗪基)-乙酮和3-甲基-2-乙酰基-吡嗪㊂有研究[11,13]发现,3种工艺(不香型㊁淡香型㊁浓香型)预处理获取的6个芝麻品种炒籽芝麻油中,2-甲基吡嗪和2,5-二甲基吡嗪的含量均最高,这与本研究结果较一致㊂杂环类芳香化合物大多来自糖的非酶褐变和氨基酸的降解,以及热加工过程中发生的美拉德反应[17]㊂吡咯类化合物(6887.43μg/kg)和吡啶类化合物(1672.13μg/kg)赋予小磨香油焦香味㊁爆米花味和坚果味[13]㊂其中2-乙酰基吡咯(3545.16μg/kg)和吡咯(1486.42μg/kg)含量较高,2-乙酰基吡咯是芝麻油特征风味成分,在不同工艺提取的芝麻油中均存在[11]㊂噻吩类化合物(1436.16μg/kg)和噻唑类化合物(6460.27μg/kg)具有烤肉味和硫化物味[18],其中4-甲基噻唑(2156.73μg/kg)和2,4-二甲基-噻唑(1197.43μg/kg)含量较高㊂含氧的呋喃类化合物(15431.42μg/kg)赋予小磨香油甜香㊁焦糖味等气味,它们是焦糖化反应或脂质氧化反应的产物[19],其中2-呋喃甲醇(5314.25μg/kg)㊁5-甲基呋喃醛(4254.15μg/kg)㊁2-乙酰基呋喃(1800.05μg/kg)和2-甲基-3-呋喃硫醇(1131.66μg/kg)含量较高㊂腈类化合物和硫化物赋予小磨香油烤芝麻味㊁焦香味㊁坚果味㊁焦糊味和烟熏味,二者属于硫苷代谢产物[20]㊂其中二甲基三硫醚(3168.42μg/kg)㊁二甲基二硫醚(2510.25μg/kg)㊁甲基糠基二硫醚(1200.55μg/kg)和1,5-二甲基-2-吡咯甲腈(1862.67μg/kg)含量较高㊂小磨香油中醛类化合物(10952.31μg/kg)和酮类化合物(1728.43μg/kg)主要来源于脂质氧化或氨基酸Strecker降解产物[16]㊂芝麻中脂肪酸的氧化会导致醛类㊁酮类等羰基类化合物逐渐生成,而强反应活性的羰基类化合物发生缩合反应或与其他氨基化合物进一步反应会形成杂环类化合物[19]㊂2.2㊀小磨香油关键风味成分分析各挥发性风味成分的贡献大小不仅取决于其含量,还与其阈值有关㊂关键风味成分虽然只占风味成分的一小部分,但决定了小磨香油的整体香气轮廓㊂通过比较各挥发性风味成分对小磨香油香气特征的贡献度,可确定其中的关键风味成分㊂小磨香油挥发性风味成分的ROAV见表2㊂由表2可知,利用SAFE法结合三重四极杆气相色谱-质谱联用从小磨香油中共鉴定出35种ROAVȡ0.01的挥发性风味成分,更全面地获得了小磨香油的风味信息,也解释了小磨香油主要呈现卷心菜味㊁鱼腥味㊁硫磺味㊁烟熏味㊁爆米花味㊁油香和烤芝麻味风味特征的原因㊂在ROAVȡ1.00的4种关键风味成分中,包括2种硫化物,其中ROAV最高的是二甲基三硫醚(ROAV=100.00),但其阈值仅为0.03μg/kg,对小磨香油风味的贡献度最大㊂二甲基三硫醚普遍存在于菜籽油和白酒中,是公认的重要硫化物风味成分,呈现卷心菜味㊁鱼腥味[21]㊂其次是甲基糠基二硫醚(ROAV=28.42),具有烘烤味,对小磨香油风味贡献度较大[22]㊂小磨香油中的硫化物含量虽较少,但由于低阈值,其风味特征贡献度特别显著㊂酚类化合物可能来源于植物籽中木质素的降解,2-甲氧基苯酚(ROAV=1.71)也曾在葵花籽油中被鉴定出[23],㊃43㊃㊀杨旖旎,等:基于SAFE法分析市售小磨香油的关键风味成分㊀㊀㊀表2㊀小磨香油挥发性风味成分的ROAV Table2㊀ROAV of volatile flavour compoundsin sesame oil化合物名称阈值/(μg㊃kg-1)风味描述ROAV 二甲基三硫醚0.03卷心菜味㊁鱼腥味100.00甲基糠基二硫醚0.04烘烤味28.42 2-甲氧基苯酚13烟熏味 1.71硫醇酸甲酯0.10硫磺味 1.25 4-乙烯基-2-甲氧基苯酚5烟熏味0.61乙酰基吡嗪10爆米花味0.352-呋喃甲醇15蒜臭味0.34 2,3-二甲基-吡嗪8油香㊁烤芝麻味0.32 2,3,5-三甲基吡嗪22坚果味0.28二甲基二硫醚12卷心菜㊁洋葱味0.20己醛 4.50青草香0.19 2-乙基-6-甲基吡嗪40烤土豆味0.19 2-甲基-3-呋喃硫醇 5.70烤肉味㊁辛辣味0.19 3-乙基-2,5-二甲基-吡嗪79焙烤味㊁坚果味0.122-甲基吡嗪200咸味㊁坚果味0.09 2,4-二叔丁基苯酚200脂肪味0.09吲哚11樟脑味㊁臭味0.08 2-乙酰基噻唑10烘烤味㊁坚果味0.072-乙基吡嗪89油香㊁烤芝麻味0.07 1-甲基-2-吡咯甲醛20爆米花味㊁烘烤味0.05四氢噻吩-3-酮10蘑菇味0.04 6-甲基-2-乙烯基-吡嗪26榛子味0.03对甲酚10烟熏味0.02丁香酚6丁香味㊁蜂蜜味0.02苯甲醛60杏仁香0.02 2-乙酰基吡咯200坚果味0.02 5-甲基呋喃醛260焦糖味0.02 2-乙基-3-甲基吡嗪240焙烤香0.02噻唑38烘烤味㊁坚果味0.01 2-乙烯基吡嗪60酱香0.01 2,3-二甲基噻吩5焙烤味0.01 2,4-二甲基-噻唑100硫磺味0.014-甲基噻唑200硫磺味0.01二氢-4-甲基2(3H)-呋喃酮23烘烤味0.01苯乙醛22蜂蜜味㊁花香0.01㊀注:阈值和风味描述来自参考文献[10,14-15,19]和http:ʊ./flavornet.html.具有烟熏味㊂硫醇酸甲酯(ROAV=1.25)是首次在小磨香油中发现的一种关键风味成分,是硫磺味主要贡献化合物,目前尚未见其他相关报道㊂在0.10ɤROAVɤ1.00的10种关键风味成分中,包括1种酚类化合物(4-乙烯基-2-甲氧基苯酚)㊁5种吡嗪类化合物(乙酰基吡嗪㊁2,3-二甲基-吡嗪㊁2,3,5-三甲基吡嗪㊁2-乙基-6-甲基吡嗪和3-乙基-2,5-二甲基-吡嗪)㊁2种呋喃类化合物(2-呋喃甲醇和2-甲基-3-呋喃硫醇)㊁1种硫化物(二甲基二硫醚)和1种醛类化合物(己醛)㊂其中4-乙烯基-2-甲氧基苯酚(ROAV=0.61)为小磨香油贡献了烟熏味,也是微波芝麻油中的重要风味成分[24]㊂吡嗪类化合物是热加工植物油主要的挥发性风味成分,其风味阈值较低[15],主要为小磨香油贡献坚果味㊁烤芝麻味㊁油香和焙烤味㊂在许多烘焙加工的植物油中检测到了呋喃类物质,主要赋予烘焙产品水果味㊁豆腥味和青草味[23],而2-呋喃甲醇和2-甲基-3-呋喃硫醇主要贡献烤肉味和焦糖味[25],在热加工食品风味中起着重要作用㊂己醛(ROAV=0.19)是植物油中最常见的醛类化合物之一,具有青草香,主要由亚油酸氧化产生[26]㊂在0.01ɤROAVɤ0.10的21种对小磨香油整体香气特征具有修饰作用的挥发性风味成分中,5种吡嗪类化合物(2-甲基吡嗪㊁2-乙基吡嗪㊁6-甲基-2-乙烯基-吡嗪㊁2-乙基-3-甲基吡嗪和2-乙烯基吡嗪)主要为小磨香油贡献了坚果味㊁焙烤味和烤芝麻味[27];2-乙酰基噻唑㊁1-甲基-2-吡咯甲醛㊁四氢噻吩-3-酮㊁2-乙酰基吡咯㊁噻唑㊁2,3-二甲基噻吩㊁2,4-二甲基-噻唑和4-甲基噻唑均属于Strecker降解产物[28],主要为小磨香油贡献了烘烤味㊁坚果味㊁爆米花味和硫磺味,其中,四氢噻吩-3-酮(蘑菇味)由美拉德反应产生[29]㊂另外,还有2种呋喃类化合物(5-甲基呋喃醛(焦糖味)和二氢-4-甲基2(3H)-呋喃酮(烘烤味)),2种醛类化合物(苯甲醛(杏仁香)和苯乙醛(蜂蜜味㊁花香)),以及对甲酚(烟熏味),丁香酚(丁香味㊁蜂蜜味),吲哚(樟脑味㊁臭味)和2,4-二叔丁基苯酚(脂肪味)㊂3 结论本文采用SAFE法结合三重四极杆气相色谱-质谱联用从市售小磨香油中共鉴定出107种挥发性风味成分,通过半定量分析及相对气味活度值(ROAV)计算共发现35种关键风味成分(ROAVȡ㊃53㊃㊀2024年2月第39卷第1期㊀0.01)对小磨香油的风味特征贡献显著,其中重要的风味成分包括乙酰基吡嗪㊁2-呋喃甲醇㊁2,3-二甲基-吡嗪㊁2,3,5-三甲基吡嗪㊁二甲基二硫醚㊁二甲基三硫醚㊁甲基糠基二硫醚㊁硫醇酸甲酯㊁4-乙烯基-2-甲氧基苯酚㊁2-甲氧基苯酚㊁己醛㊁2-乙基-6-甲基吡嗪㊁2-甲基-3-呋喃硫醇和3-乙基-2,5-二甲基-吡嗪,使小磨香油呈现卷心菜味㊁鱼腥味㊁硫磺味㊁烟熏味㊁爆米花味㊁油香和烤芝麻味㊂本研究丰富了小磨香油风味轮廓的物质构成,后续拟着重开展不同加工工艺参数对小磨香油风味品质的影响研究,明晰加工过程中关键香气成分的形成机理,为风味导向芝麻油产品的开发提供理论基础㊂参考文献:[1]㊀WU L X,YU L,DING X X,et al.Magnetic solid-phaseextraction based on graphene oxide for the determinationof lignans in sesame oil[J].Food Chemistry,2017,217:320-325.[2]㊀刘配莲,李诚琨,董西余,等.一种风味接近小磨香油的芝麻油生产工艺研究[J].食品安全导刊,2022,192(33):164-166,192.[3]㊀尹文婷,马雪停,汪学德.不同工艺芝麻油的挥发性成分分析和感官评价[J].中国油脂,2019,44(12):8-13.[4]㊀李萍萍.芝麻油香气成分检测及其在香气形成机制与质量评价中的应用[D].北京:中国农业科学院,2010.[5]㊀马雪停,尹文婷,李诗佳,等.炒籽温度对芝麻油香气活性组分和感官品质的影响[J].中国油脂,2021,46(8):6-11.[6]㊀MATHEIS K,GRANVOGL M.Unraveling of the fishy off-flavor in steam-treated rapeseed oil using the sensomicsconcept[J].Journal of Agricultural and Food Chemistry,2019,67(5):1484-1494.[7]㊀ZHOU Q,LIU S M,LIU Y,et parative analysis ofvolatiles of15brands of extra-virgin olive oils using solid-phase micro-extraction and solvent-assisted flavor evapo-ration[J].Molecules,2019,24(8):1512.[8]㊀PANG X L,YU W S,CAO C D,et parison ofpotent odorants in raw and ripened Pu-Erh tea infusionsbased on odor activity value calculation and multivariateanalysis:Understanding the role of pile fermentation[J].Journal of Agricultural and Food Chemistry,2019,67(47):13139-13149.[9]㊀ZHU L,WANG X L,SONG X B,et al.Evolution of thekey odorants and aroma profiles in traditional Laowuzengbaijiu during its one-year ageing[J].Food Chemistry,2020,310:125898.[10]JIA X,DENG Q C,YANG Y N,et al.Unraveling of thearoma-active compounds in virgin camellia oil(Camelliaoleifera Abel)using gas chromatography-mass spectrome-try-olfactometry,aroma recombination,and omission stud-ies[J].Journal of Agricultural and Food Chemistry,2021,69(32):9043-9055.[11]唐晓丹,秦早,杨冉,等.不同香型芝麻油中挥发性风味成分的研究[J].中国油脂,2013,38(6):87-90. [12]刘鑫,李睿,徐漪沙,等.不同加工处理方式对芝麻油风味的影响研究[J].保鲜与加工,2020,20(6):148-156.[13]周易枚,吴达,蒋林惠,等.两种工艺芝麻油中挥发性风味物质的鉴别分析[J].中国油脂,2023,48(10):39-45.[14]王有菲.不同原料芝麻油挥发性风味成分的研究[J].粮食与食品工业,2017,24(2):24-27,31.[15]赵宇航,尹文婷,汪学德,等.微波预处理对芝麻油风味㊁营养和安全品质的影响[J].食品科学,2023,44(9):47-57.[16]袁彬宏,贾懿敏,杨旖旎,等.不同品种浓香亚麻籽油的呈香特征解析[J].食品安全质量检测学报,2023,14(8):90-100.[17]SRUTHI N U,PREMJIT Y,PANDISELVAM R,et al.Anoverview of conventional and emerging techniques ofroasting:Effect on food bioactive signatures[J].FoodChemistry,2021,348:129088.[18]吴浪,徐俐,谢婧,等.不同炒制温度对菜籽毛油挥发性风味物质的影响[J].中国油脂,2012,37(11):39-43.[19]YANG Y N,YUAN B H,YU P,et al.Flavor characteris-tics of peanut butter pretreated by radio frequency heat-ing,explosion puffing,microwave,and oven heating[J].Food Chemistry,2022,394:133487.[20]周琦,魏长庆,黄凤洪,等.基于全二维气相色谱-飞行时间质谱法鉴定冷榨菜籽油的挥发性风味成分[J].中国粮油学报,2018,33(12):127-133. [21]LIANG Q,XIONG W,ZHOU Q,et al.Glucosinolates orerucic acid,which one contributes more to volatile flavorof fragrant rapeseed oil?[J].Food Chemistry,2023,412:135594.[22]李涵,李佳颖,刘娜,等.基于GC-O-MS技术的植物肉风味特征及像真性分析[J].食品工业科技,2023,44(24):247-258.[23]师瑞.葵花籽预处理对葵花籽油的香气活性组分和感官品质的影响[D].郑州:河南工业大学,2022. [24]YIN W T,MA X T,LI S J,et parison of key aro-ma-active compounds between roasted and cold-pressedsesame oils[J].Food Research International,2021,150:110794.㊃63㊃㊀杨旖旎,等:基于SAFE法分析市售小磨香油的关键风味成分[25]鞠阳.微波处理对油料结构及油脂品质和风味的影响[D].郑州:河南工业大学,2015.[26]KIM J Y,KIM M J,LEE J.Role of moisture on the lipidoxidation determined by D2O in a linoleic acid model sys-tem[J].Food Chemistry,2014,146:134-140. [27]董迎章,李诚琨,刘配莲,等.生产工艺对压榨芝麻油风味的影响[J].中国油脂,2023,48(7):34-38. [28]尤秋爽,刘建平,何卫中,等.惠明茶香气品质的化学成分分析[J/OL].食品科学,2023,44(24):253-261.[29]王蓓,韩兆盛,杨智杰,等.6类常见食品中含硫化合物风味特征及形成机理研究进展[J].食品科学技术学报,2022,40(6):13-25.The analysis of key volatile flavor components of commercial sesame oilbased on solvent-assisted flavor evaporationYANG Yini,WANG Linhai,YUAN Binhong,YUE Yang,GU Yaru,WEI Xiaoyan,ZHOU Qi Hubei Key Laboratory of Lipid Chemistry and Nutrition,Oil Crops and Lipids Process/Technology National&Local JointEngineering Laboratory,Oil Crops Research Institute,Chinese Academy of Agricultural Sciences,Wuhan430062,China Abstract:The commercial sesame oil was selected as the research subject and its volatile flavor components was extracted through solvent-assisted flavor evaporation(SAFE).Then,the aroma substances of the sesame oil were semi-quantitatively analyzed based on triple quadrupole gas chromatography-mass spectrometry.Finally,the rela-tive odor activity values(ROAV)were combined to analyze the terms of volatile flavor contributions.The results showed that a total of107volatile flavor components were identified in sesame oil,of which35substances were seem as contributed flavor(ROAVȡ0.01),including4sulfides,5phenols,10pyrazines,4furans,3aldehydes, 4thiazoles,2pyrroles,2thiophenes,and1indole.They provided"cabbage""fishy""sulfur""smoky""pop-corn""oil"and"roasted sesame".In particular,compounds14flavor components with ROAVȡ0.10were deter-mined as key flavor components,such as acetyl pyrazine,2-furanmethanol,2,3-dimethyl-pyrazine,2,3,5-trimeth-ylpyrazine,dimethyl disulfide,dimethyl trisulphide,methyl furfuryl disulfide,methyl thiolacetate,4-vinyl-2-methoxyphenol,2-methoxyphenol,hexanal,2-ethyl-6-methyl-pyrazine,2-methyl-3-furanothiol and3-ethyl-2,ing this method to determine the key volatile flavor components of sesame oil,not only could expand the flavor database of sesame oil,but also could provide an important material basis for evaluating and regu-lating the flavor quality of sesame oil.Key words:sesame oil;volatile flavor component;solvent-assisted flavor evaporation;triple quadrupole gas chro-matography-mass spectrometry;relative odor activity value㊀[责任编辑:杨晓娟]㊃73㊃。

乙醚萃取法分析郫县豆瓣酱重要香气成分赵 聪,范文来*,徐 岩(教育部工业生物技术重点实验室,江南大学生物工程学院,江苏 无锡214122)摘 要:为明确郫县豆瓣酱的重要香气成分,应用不同提取方法萃取豆瓣酱香气物质,分析出乙醚为最优。

将乙醚萃取液分成酸-水溶性和中-碱性2 个组分,使用气相色谱-闻香法和气相色谱-质谱法,在郫县豆瓣酱中鉴定出46 种香气物质,其中醇类5 种、挥发性有机酸类13 种、醛酮类7 种、酚类11 种、芳香族类5 种、杂环类3 种以及吡嗪类2 种。

首次在郫县豆瓣酱中鉴定出3,4-二甲基-2,5-呋喃二酮、巴豆酸、2,6-二甲氧基苯酚、3-甲基-1,2-环戊二酮、 γ-丁内酯和3,4-二甲基苯甲醛6 个香气物质。

研究发现香气强度较大的物质有乙酸、3-甲基丁酸、3-甲基戊酸、2-苯乙醇、2,5-二甲基-4-羟基-3(2H )-呋喃酮、苯酚、1-辛烯-3-酮、3-甲硫基丙醛和丁子香酚,这些化合物是郫县豆瓣酱重要的香气物质。

关键词:郫县豆瓣酱;气相色谱-闻香法;气相色谱-质谱法;香气物质;2,6-二甲氧基苯酚;3,4-二甲基-2,5-呋喃二酮Analysis of Important Aroma Components in Pixian Bean Paste by Diethyl Ether ExtractionZHAO Cong, FAN Wenlai *, XU Yan(Key Laboratory of Industrial Biotechnology, Ministry of Education, School of Biotechnology, Jiangnan University, Wuxi214122, China)Abstract: In order to clarify the important aroma substances of Pixian bean paste, different extraction methods were applied to extract the aroma substances in Pixian bean paste, and ether was selected as the optimal extraction solvent. The ether extract was fractionated into an acid-water soluble component and a neutral-alkaline component for analysis by gas chromatography-olfactometry (GC-O) and gas chromatography-mass spectrometry (GC-MS). A total of 46 aroma substances were identified in Pixian bean paste, including 5 alcohols, 13 volatile organic acids, 7 aldehydes and ketones, 11 phenols, 5 aromatics, 3 heterocyclics, and 2 pyrazines. Six aroma compounds including 3,4-dimethyl-2,5-furandione, crotonicacid, 2,6-dimethoxyphenol, 3-methyl-1,2-cyclopentanedione, γ-butyrolactoneand 3,4-dimethylbenzaldehyde were first identified in Pixian bean paste. Acetic acid, 3-methylbutyric acid, 3-methylvaleric acid, 2-phenylethanol, 2,5-dimethyl-4-hydroxy-3(2H )-furanone (HDMF), phenol, 1-octen-3-one, 3-methylthiopropionaldehyde and eugenol were identified as important aroma substances of Pixian bean paste.Keywords: Pixian bean paste; gas chromatography-olfactometry; gas chromatography-mass spectrometry; aroma substances; 2,6-dimethoxyphenol; 3,4-dimethyl-2,5-furandione DOI:10.7506/spkx1002-6630-20200617-237中图分类号:TS261.2 文献标志码:A 文章编号:1002-6630(2021)12-0184-05引文格式:赵聪, 范文来, 徐岩. 乙醚萃取法分析郫县豆瓣酱重要香气成分[J]. 食品科学, 2021, 42(12): 184-188. DOI:10.7506/spkx1002-6630-20200617-237. ZHAO Cong, FAN Wenlai, XU Yan. Analysis of important aroma components in Pixian bean paste by diethyl ether extraction[J]. Food Science, 2021, 42(12): 184-188. (in Chinese with English abstract) DOI:10.7506/spkx1002-6630-20200617-237 收稿日期:2020-06-17基金项目:“十三五”国家重点研发计划重点专项(2016YFD0400503)第一作者简介:赵聪(1995—)(ORCID: 0000-0002-1498-9476),男,硕士,研究方向为酿酒科学与技术。

Analytical,Nutritional and Clinical MethodsChemical analysis of French beans (Phaseolus vulgaris L.)by headspace solid phase microextraction (HS-SPME)andsimultaneous distillation/extraction (SDE)A.Barra a ,N.Baldovinia,*,A.-M.Loiseau a ,L.Albino b ,C.Lesecq b ,L.Lizzani CuvelieraaUniversite´de Nice,Laboratoire Aro ˆmes,Synthe `ses et Interactions,Parc Valrose,06108Nice cedex 2,France bBonduelle S.A.,Service R&D,La Woestyne BP1,59173Renescure,France Received 23March 2005;received in revised form 10November 2005;accepted 29December 2005AbstractHeadspace Solid Phase Microextraction (HS-SPME)involving divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS)fibre and simultaneous distillation/extraction (SDE)techniques were applied to study the volatile and semi volatile compounds of thawed and cooked Phaseolus vulgaris L.A total of 104compounds were detected by GC and GC/MS.Thereof,76compounds were identified for the first time in this species.The major differences between HS-SPME and SDE were found in the content of identified alcohols (23.62%SDE versus 62.20%SPME),terpenoids (39.15%SDE versus 2.45%SPME),heterocyclic compounds (13.78%SDE versus 1.21%SPME),hydrocarbons (2.22%SDE versus 13.87%SPME)and esters (0.98%SDE versus 12.98%SPME).The SPME technique was found to be useful for rapid and routine quality controls of thawed French beans,while SDE is favourable to study the entire set of flavour volatiles in the corresponding cooked samples.Ó2006Elsevier Ltd.All rights reserved.Keywords:Phaseolus vulgaris L.;French beans;Aroma compounds;Headspace solid phase microextraction (HS-SPME);Simultaneous distillation/extraction (SDE)1.IntroductionThe flavour of fresh foods results from naturally occur-ring compounds and aroma chemicals produced by enzy-matic degradation during harvesting and processing (De Lumen,Stone,Kazeniac,&Forsythe,1978;Rowe,2005).The flavour of cooked foods is due to a complex sequence of enzymatic and chemical reactions depending of the tem-perature (Tressl &Rewicki,1999;Vernin &Parkanyi,1982).The French bean (Phaseolus vulgaris L.)is the most cul-tivated and one of the most consumed legume in France.The beans are marketed either fresh,frozen,dried or cooked.During thermal processing,such as cooking,thetypical ‘‘green odour’’changes significantly.Until today,only few investigations have been performed on the entire set of flavour volatiles of French beans.To evaluate the French beans volatile compounds,several techniques of extraction and analysis have been used.At first,Kermasha,Van de Voort,and Metche (1988)reported on the volatile carbonyl compounds produced by thermal or enzymatic treatment of the vegetable.Then,the high vacuum distilla-tion (Hinterholzer,Lemos,&Schieberle,1998)followed by gas chromatography-olfactometry and GC/MS permitted to characterise 28odour-active volatiles in raw and cooked beans and dynamic headspace sampling coupled with GC/MS analysis (Rodriguez-Bernaldo De Quironos,Lopez-Hernandez,Gonzalez-Castro,De la Cruz-Garcia,&Simal-Lozano,2000)allowed the identification of 27vola-tile compounds.Finally,the model system mouth-gas chro-matography-sniffing port analysis described by Van Ruth and Roozen (2000a,2000b),Van Ruth,Roozen,Holliman,0308-8146/$-see front matter Ó2006Elsevier Ltd.All rights reserved.doi:10.1016/j.foodchem.2005.12.027*Corresponding author.Tel.:+330492076133;fax:+330492076517/6125.E-mail address:baldovin@unice.fr (N.Baldovini)./locate/foodchemFood Chemistry 101(2007)1279–1284Food Chemistryand Posthumus(1996,1995a,1995b)permitted to identify the compounds that contribute to the mainflavours of dried or rehydrated French beans.We have applied the headspace solid phase micro extrac-tion(HS-SPME)and simultaneous distillation/extraction (SDE)to extract the aroma volatiles of French beans before analysis.Briefly,the HS-SPME is used for the extraction of volatile compounds by the use of a fused silicafibre coated with different stationary phases.This is a common tech-nique to evaluate theflavour compounds of various foods such as vegetables,fruits,juices,soft drinks or alcoholic beverages as recently reviewed from Kataoka,Lord,and Pawliszyn(2000).To the best of our knowledge,no studies have been published on the characterization of French beans aroma compounds with SPME.The SDE is a tech-nique based on the use of the Lickens–Nickerson apparatus (Likens&Nickerson,1964).Chaintreau(2001)have recently reviewed on this kind of extraction that simulates food cooking:it gives a concentrated extract that contains the volatile components of a fresh food and the compounds produced by the cooking process,particularly the Maillard reaction products(Tressl&Rewicki,1999;Vernin&Park-anyi,1982).This latter technique was widely applied to study aroma compounds in food research(Cai,Liu,&Su, 2001;Garcia-Esteban,Asorena,Astiasaran,Martin,& Ruiz,2004;Valeiro,Sanz,&Martinez-Castro,2001;Valette et al.,2003),but never concerning the French beans.In this report,HS-SPME and SDE techniques were used to study the volatile compounds of Phaseolus vulgaris L. The advantages and limitations of these techniques are considered.Thefinal objective of the present study is to identify and characterise new volatile compounds in the aroma of this vegetable.2.Materials and methods2.1.MaterialsCommercial samples of frozen French beans were pur-chased from a local supermarket and immediately kept at À18°C until analysis.2.2.HS-SPME GC and GC–MS analysisExtraction conditions such as SPMEfibre choice,time and temperature of extraction were optimised.A manual SPME device and SPMEfibres were obtained from Supe-lco Co(Bellefonte,PA).We used a divinylbenzene/carbo-xen/polydimethylsiloxane(DVB/CAR/PDMS)fibre(50/ 30l mfilm thickness).Before use thefibre was conditioned 1h at270°C as recommended by the manufacturer.Hun-dred grams of congealed French beans were grinded and 10g were placed in a40ml amber vial closed by a PTFE/silicone septum(Supelco).Before the extraction process,a time of30min at40°C was requested for thaw-ing and subsequent headspace equilibration.After1h of fibre exposure in the sample headspace,thefibre was ther-mally desorbed in a GC injection port(equipped with a 0.75mm i.d.inlet liner)for2min.The injector was set at 250°C and operated in a splitless mode for2min.GC and GC/MS analyses were carried out using an Agi-lent6890N gas chromatograph,equipped with a FID and coupled to a quadrupole Agilent5973Network mass selec-tive detector.The gas chromatograph was equipped with two fused silica capillary column HP-1(PDMS, 50m·0.2mm i.d.film thickness=0.33l m).The carrier gas was helium(head pressure for both columns=25psi); oven temperature was programmed from40°C(2min)to 200°C at2°C/min and then at15–250°C and held isother-mal for30min.The FID temperature was set at250°C and the temperatures of the ion source and the transfer line were170°C and280°C,respectively.Ionisation energy was set to70eV,ionisation mass range35–350amu.Before sampling,thefibre was reconditioned for15min in the GC injection port at250°C.A blank experiment was per-formed before analysis.2.3.SDE GC and GC–MS analysisExtraction conditions such as time of extraction, amount of vegetables,water and solvent have been opti-mised.SDE was realised with a Lickens–Nickerson appa-ratus.The French beans(300g)were suspended in1l of water.Dichloromethane(50mL)was used as the organic phase and was also added(20ml)tofill the apparatus sol-vent return loop.Solvent and sample mixture were boiled for2h.Dichloromethane was used as it was recognised as the most useful solvent for extraction of a wide class offlavour compounds(Chaintreau,2001).After cooling to ambient temperature for10min,the dichloromethane extract was collected and dried over anhydrous MgSO4. The extract was carefully concentrated to1ml at40°C with a rotary evaporator at atmospheric pressure and finally evaporated under gentle nitrogenflow to250l l. The concentrated extract was injected(0.2l l)directly into the GC apparatus.The GC and GC–MS conditions were the same as described for SPME except for the use of split mode(1:20)and solvent delay of5min for GC–MS.A blank experiment was performed before analysis.ponents identificationIdentification of Phaseolus vulgaris ponents was based on the comparison of their mass spectra with those stored in commercial MS databases,with literature data (Adams,1995;Garcia-Esteban et al.,2004),and with home-made mass spectra libraries built up from pure sub-stances.Identification was also confirmed by comparison of the GC retention indices(RI)on an apolar column(deter-mined from the retention times of a series of n-alkanes mix-ture)with GC data previously published(ESO2000,1999). The results were described in terms of percentage of areas of identified peaks and mean percentage values were calculated from5SPME and4SDE experiments.The results were1280 A.Barra et al./Food Chemistry101(2007)1279–1284A.Barra et al./Food Chemistry101(2007)1279–12841281 Table1Volatile compounds identified in thawed and cooked Phaseolus vulgaris ing HS-SPME and SDEKI a Compound Reliability b SDE RA c±SD d SPME RA±SD 472Ethanol e MS ND f0.61±0.14 515Carbon disulphide e MS;KI ND0.52±0.06 589Ethyl acetate e MS;KI ND 1.30±0.18 610But-2-enal MS0.20±0.02ND6253-Methylbutanal MS;KI0.36±0.05ND6352-Methylbutanal MS;KI0.25±0.07ND639Butanol e MS;KI0.07±0.02ND660Pent-3-en-1-ol MS;KI0.25±0.06ND665Pentane-2,3-dione MS;KI0.38±0.02ND665Valeraldehyde MS;KI0.07±0.010.17±0.02 6733-Hydroxybutan-2-one e MS0.69±0.11ND676Isopentenylmethylether e MS ND0.12±0.01 6842-Ethylfurane e MS;KI0.16±0.020.22±0.06 697n-Heptane MS;KI ND0.24±0.01 713Isoamyl alcohol e MS;KI ND0.82±0.12 714Pent-3-en-2-one e MS;KI0.16±0.02ND7153-Methylbut-3-en-1-ol e MS0.02±0.00ND716Pyridine e MS;KI10.38±1.49ND7183-Methylbutan-1-ol e MS 1.52±0.05ND725Pent-2-enal e MS;KI0.32±0.03ND7441-Pentanol e MS;KI 1.03±0.020.96±0.03 746Toluene e MS;KI0.48±0.03 2.33±0.24 7553-Methylbut-2-enal e MS;KI0.08±0.01ND7592-Methylheptane e MS ND0.31±0.02 7673-Methylheptane e MS ND0.38±0.02 770Hexanal MS;KI0.44±0.05 2.05±0.07 7831-Octene e MS;KI ND 1.58±0.14 7933-Methylhept-3-ene e MS ND 2.51±0.28 796n-Octane e MS;KI0.26±0.01 1.66±0.15 800(Z)-oct-2-ene e MS;KI ND 1.32±0.10 8033-Methylhept-2-ene e MS ND 2.22±0.21 803Furfural MS;KI 3.24±0.16ND807(E)-oct-2-ene e MS;KI ND 1.11±0.08 827(E)-hex-2-enal MS;KI0.53±0.03ND829Furfurol e MS0.03±0.00ND833(E)-hex-3-enol MS;KI0.06±0.00tr839(Z)-hex-3-enol MS;KI 5.59±0.697.76±0.42 852Isoamylacetate e MS;KI ND 1.22±0.1853Hexanol MS;KI 2.08±0.038.02±0.91 8663-Methylthiopropanal MS;KI0.05±0.00ND870Heptanal MS;KI0.07±0.000.07±0.02 921a-Pinene e MS;KI ND0.70±0.05 930Benzaldehyde MS;KI0.20±0.02ND934(E)-hept-2-enal e MS;KI0.31±0.01ND9573-Thiophencarboxaldehyde e MS0.26±0.01ND959Octan-3-one e MS;KI0.30±0.01 1.08±0.03 964Oct-1-en-3-ol MS;KI7.98±1.7230.51±0.92 9743-Octanol MS;KI0.82±0.09 4.37±0.07 9792-Pentylfurane e MS;KI0.83±0.070.78±0.01 982Hepta-2,4-dienal MS0.69±0.05ND986(Z)-hex-3-enylacetate e MS;KI0.70±0.068.23±0.77 990Hexyl acetate MS;KI ND 1.25±0.1 10083-Ethyl-4-methylpentanol e MS 2.93±0.348.69±0.44 10082-Ethylhexanol MS;KI ND0.03±0.00 10121,8-Cineole e MS;KI ND0.39±0.02 1022Limonene e MS;KI0.14±0.030.45±0.04 1024Methyl-2-ethyl-hexanoate e MS0.08±0.000.20±0.02 1033(E)-Oct-3-enal MS0.25±0.03ND1037(E)-b-ocimene e MS;KI0.21±0.03ND1045Oct-2-en-1-ol e MS;KI ND0.17±0.02 10491-Octanol MS;KI ND0.23±0.03 10523-Thienylmethanol e MS0.49±0.05ND10592-Thiophene e MS0.72±0.08ND(continued on next page)quite reproducible as shown by the standard deviations (Table1).3.Results and discussionIn our initial studies,we searched for the most useful technique to study the Phaseolus vulgaris L.aroma chemi-cals.HS-SPME was applied to cooked and thawed French beans.The preliminary HS-SPME assays on the cooked beans showed that most of the volatile compounds were lost during cooking,leading to a fall-offin detection. Indeed,the water cooking could induce the loss of volatile and/or hydrophilic compounds.Therefore,SDE was cho-sen to study the cooked French beans aroma compounds because it is a combined steam distillation and liquid–liquid extraction method(Chaintreau,2001).On the other hand,we optimised HS-SPME method to study the aroma chemicals of raw French beans as described in material and methods.A total of104compounds were identified in Phaseolus vulgaris ing the two techniques and76out of them have not been previously identified in this vegetable(Table 1).Using HS-SPME,50compounds were detected while75 compounds were detected in SDE extracts.The major fam-Table1(continued)KI a Compound Reliability b SDE RA c±SD d SPME RA±SD 1975(Z)-hex-3-enyl propionate e MS;KI ND0.38±0.06 1977Nonanal MS;KI ND0.47±0.03 1079a-terpinolene e MS;KI0.13±0.01ND10812-Phenylethanol e MS0.36±0.09ND1084Hexyl propanoate e MS;KI ND0.12±0.05 1085Linalool MS;KI15.30±1.920.75±0.02 1096Undecane e MS;KI ND0.07±0.01 1117Alloocimene e MS;KI tr ND11354-Ethylbenzaldehyde e MS;KI0.21±0.03ND1151Menthol e MS;KI tr0.16±0.04 1155Octadienoic acid e MS0.30±0.05ND11562-Isobutyl-3-methoxypyrazin MS;KI ND0.21±0.02 1163(Z)-hex-3-enyl butyrate e MS;KI ND0.17±0.02 1175a-terpineol e MS;KI 3.82±0.46ND1179Decanal MS;KI ND0.17±0.01 1189b-cyclocitral e MS;KI ND0.07±0.00 1185Benzothiazole e MS;KI0.25±0.03ND1193Dodecane e MS;KI0.14±0.020.10±0.01 1214Nerol e MS;KI 1.10±0.11ND1237Geraniol e MS;KI 3.37±0.52ND1247Nonanoic acid e MS;KI0.17±0.05ND1284Paravinylguaiacol e MS;KI0.91±0.08ND1290Deca-2,4-dienal e MS;KI0.24±0.03ND1300Tridecane e MS;KI ND0.04±0.00 1347Methyl cinnamate e MS,KI0.15±0.01ND1363(Z)-jasmone e MS,KI0.14±0.03ND1420Geranylacetone e MS,KI0.07±0.01ND1428Ethyl cinnamate e MS,KI0.05±0.01ND1439(E)-b-farnesene e MS,KI0.15±0.02ND1462b-Ionone MS,KI0.17±0.03ND1493a-Farnesene e MS;KI0.47±0.08ND1501b-Bisabolene e MS;KI0.15±0.02ND1532Dodecanoic acid e MS;KI0.31±0.07ND1541Nerolidol e MS;KI11.52±1.27ND1671a-Bisabolol e MS;KI0.84±0.09ND1698Farnesol e MS,KI 1.57±0.34ND1717Tetradecanoic acid e MS;KI 3.82±0.59ND1933Palmitoleic acid e MS;KI0.82±0.23ND2083Phytol e MS;KI0.83±0.15ND2287Tricosane e MS,KI0.23±0.01ND2498Alkane c25e MS;KI0.20±0.01ND Total identified93.4597.27Results are provided as percentage(area±standard deviation).a Kova´ts indices for a HP-1capillary positional values less than0.01%are noted as traces(tr).b Reliability of identification:MS,mass spectrum identified using libraries;KI,Kovats Index in agreement with literature.c RA:relative area.d SD:standard deviation(SDE:4replicates,SPME:5replicates).e Not previously identified in French beans.f ND:not detected.1282 A.Barra et al./Food Chemistry101(2007)1279–1284ilies of detected volatiles were alcohols(23.62%for SDE versus62.20%for SPME),terpenoids(39.15%for SDE ver-sus2.45%for SPME),heterocyclic compounds(13.78%for SDE versus1.21%for SPME),hydrocarbons(2.22%for SDE versus13.87%for SPME),esters(0.98%for SDE ver-sus12.98%for SPME),aldehydes(4.45%for SDE versus 2.84%for SPME),ketones(1.53%for SDE and1.08% for SPME)and sulphur compounds(1.49%for SDE versus 0.52%for SPME)as shown in Table1.SDE extracts showed higher proportions of terpenoids than the SPME extracts.On the other hand,the SPME extracts were richer in linear alcohols and esters.Thisfind-ing was in accordance to the results obtained from Ceva-Antunes,Bizzo,Alves,and Antunes(2003)that found some terpenoids as major components of SDE extract of Spondias mombin L.,while SPME extraction showed higher proportion of alcohols and esters.Compared to SDE,SPME is more efficient for the extraction of light esters.This result could be due to the evaporation step during the SDE process,that might lead to the loss of the most volatile components(Ceva-Antunes et al.,2003;Garcia-Esteban et al.,2004).Both SPME and SDE enabled the detection of most odour active compounds in French beans,such as C5,C6 and C8compounds derived from linoleic and linolenic acids(De Lumen et al.,1978),but their proportions depends strongly on the extraction technique.As shown in Table1,in comparison to SDE,SPME extracts were found richer in these compounds:(Z)-hex-3-enol:7.76% in HS-SPME versus 5.59%in SDE,1-hexanol:8.02% in HS-SPME versus 2.08%in SDE,oct-1-en-3-ol: 30.51%in HS-SPME and7.98%in SDE,3-octanol: 4.37%in HS-SPME and0.82%in SDE,(Z)-hex-1-ene-3-yl-acetate:8.23%in HS-SPME versus0.70%in SDE,3-ethyl-4-methyl-pentanol:8.69%HS-SPME versus 2.93%in SDE.Volatile aldehydes such as but-2-enal, 3-methyl-butanal,2-methyl-butanal,(E)-hex-2-enal,3-methyl-thio-propanal,benzaldehyde,hepta-2,4-dienal, (E)-oct-3-enal and4-ethylbenzaldehyde were detected using SDE but not with SPME.Aldehydes are known to derive from thermal Strecker oxidative degradation of amino acids and fatty acids(Tressl&Rewicki, 1999;Vernin&Parkanyi,1982),however SPME success-fully extracted hexanal naturally present in the French beans.The SDE process permitted also to identify het-erocyclic compounds such as pyridine,furfural and thi-ophenes derived from sugars and amino acids(Maillard reaction)(Tressl&Rewicki,1999;Vernin&Parkanyi, 1982).In conclusion,SDE enables the analysis of low volatil-ity and high molecular weigh compounds.The high tem-perature during distillation may led to formation of compounds not present originally,but important as keys odorant.For this reason,SDE can be useful to study the entire set offlavour volatiles in cooked French beans. On the other hand,HS-SPME allows the rapid extraction of highly volatile compounds without apparent hydrolysis and artefacts formation.Hence,this technique could be appropriate for the routine quality control analysis of Phaseolus vulgaris L.The present work contributes to a better knowledge of the volatile constituents of French beans:76volatile and semi volatile compounds were identified for thefirst time and interesting differences in the volatile profiles were observed between HS-SPME and SDE. AcknowledgementThe authors wish to thank the‘‘Re´gion Provence-Alpes-Cote d’Azur’’forfinancial support(grant2002_04847). ReferencesAdams,R.P.(1995).Identification of essential oil components by gas chromatography–mass spectroscopy.Carol Sream,IL:Allured Publ.Corp.ESO2000(1999).The complete database of essential oils.The Netherlands: Boelens Aroma Chemical Information Service(BACIS).Cai,J.,Liu, B.,&Su,Q.(2001).Comparison of simultaneous distillation extraction and solid-phase microextraction for the deter-mination of volatileflavour components.Journal of Chromatography A,930,1–7.Ceva-Antunes,P.M.N.,Bizzo,H.R.,Alves,S.M.,&Antunes,O.A.C.(2003).Analysis of volatile Compounds of Tapereba`(Spondias mombin L.)and Caja`(Spondias mombin L.)by simultaneous distillation and extraction(SDE)and solid phase microextraction(SPME).Journal of Agricultural and Food Chemistry,51,1387–1392.Chaintreau,A.(2001).Simultaneus distillation-extraction:from birth to maturity–Review.Flavour Fragragrance Journal,16,136–148.De Lumen,B.O.,Stone,E.J.,Kazeniac,S.J.,&Forsythe,R.H.(1978).Formation of volatile compounds in green beans from linoleic and linolenic acids.Journal of Food Science,43,698–708.Garcia-Esteban,M.,Asorena,D.,Astiasaran,I.,Martin,D.,&Ruiz,J.(2004).Comparison of simultaneous distillation extraction(SDE)and solid phase microextraction(SPME)for the analysis of volatile compounds in dry-cured ham.Journal of Science and Food Agricul-tural,84,1364–1370.Hinterholzer,A.,Lemos,T.,&Schieberle,P.(1998).Identification of key odorant in raw French beans and changes during cooking.Z Lebensm Unters Forsch A,207,219–222.Kataoka,H.,Lord,H.L.,&Pawliszyn,J.(2000).Application of solid phase microextraction in food analysis.Journal of Chromatography A, 880,35–62.Kermasha,S.,Van de Voort,F.R.,&Metche,M.(1988).Changes in carbonyl compounds in the French bean as a function of cooking and enzyme treatment.Journal of Agricultural and Food Chemistry,36, 133–137.Likens,T.S.,&Nickerson,G.B.(1964).Proceedings of American Society of Brewing Chemistry,5,13.Rodriguez-Bernaldo De Quironos,A.I.,Lopez-Hernandez,J.,Gonzalez-Castro,M.J.,De la Cruz-Garcia,C.,&Simal-Lozano,J.(2000).Comparison of volatile components in raw and cooked green beans by GC-MS using dynamic headspace sampling and microwave desorp-tion.European Food Research and Technology,210,226–230. Rowe,D.J.(2005).Chemistry and technology offlavours and fragrances.Oxford:Blackwell Publishing Ltd(pp.179–172).Tressl,R.,&Rewicki,D.(1999).Heat generatedflavours and precursors.In R.Teranishi,E.L.Wick,&I.Horstein(Eds.),Flavour Chemistry: 30years of progress(pp.305–325).New York:Kluwer Academic/ Plenum Publishers.Valeiro, E.,Sanz,J.,&Martinez-Castro,I.(2001).Direct thermal desorption in the analysis of cheese volatile by gas chromatography-A.Barra et al./Food Chemistry101(2007)1279–12841283mass spectrometry:comparison with simultaneous distillation extrac-tion and dynamic headspace.Journal of Chromatography Science,39, 222–228.Valette,L.,Fernandez,X.,Loiseau,A.M.,Lizzani-Cuvelier,L.,Levieil, R.,&Restier,L.(2003).Volatile constituents from Romanesco cauliflower.Food Chemistry,80,353–358.Van Ruth,S.M.,&Roozen,J.P.(2000a).Influence of mastication and saliva on aroma release in a model mouth system.Food Chemistry,71, 339–345.Van Ruth,S.M.,&Roozen,J.P.(2000b).Gas chromatography-sniffing port analysis of aroma compounds release under mouth conditions.Talanta,52,253–259.Van Ruth,S.M.,Roozen,J.P.,Cozijnsen,J.,&Posthumus,M.A.(1995b).Volatile compounds of rehydrated French beans,bell pepperand leeks.Part II.Gas chromatography/sniffing port analysis and sensory evaluation.Food Chemistry,54,1–7.Van Ruth,S.M.,Roozen,J.P.,Holliman,M.E.,&Posthumus,M.A.(1996).Instrumental and sensory analysis of theflavour of French beans(Phaseolus vulgaris)after different rehydration conditions.Z Lebensm Unters Forsch,203,7–13.Van Ruth,S.M.,Roozen,J.P.,&Posthumus,M. A.(1995a).Instrumental and sensory evaluation of theflavour of dried French beans(Phaseolus vulgaris)influenced by storage conditions.Journal of Science and Food Agricultural,69,393–401.Vernin,G.,&Parkanyi, C.(1982).Mechanisms of formation of heterocyclic compounds in maillard and pyrolysis reactions.In G.Vernin(Ed.),The chemistry of heterocyclicflavouring and aroma compounds(pp.151–161).Chichester:Ellis Howoord.1284 A.Barra et al./Food Chemistry101(2007)1279–1284。