Isolation and Analysis of Lignin

- 格式:pdf

- 大小:980.36 KB

- 文档页数:33

第18卷第4期2010年12月纤维素科学与技术Journal of Cellulose Science and TechnologyV ol. 18 No. 4Dec. 2010文章编号:1004-8405(2010)04-0013-06TiO2光催化氧化降解高沸醇木质素的研究陈婷1,陈云平1*,张英1,程贤甦2(1. 闽江学院化学与化学工程系,福建福州 350108;2. 福州大学材料科学与工程学院,福建福州 350002)摘要:高沸醇木质素是利用高沸醇溶剂(HBS)法制备纸浆过程中获得的木质素,具有较高的化学活性。

在TiO2光催化条件下,研究紫外光降解高沸醇木质素的结构变化,通过紫外分光光度法测定溶液吸光度来判断不同因素条件下高沸醇木质素降解的程度,包括TiO2加入量、光照强度、光照时间、氧化剂用量等。

对降解产物进行红外谱图和GC-MS分析,结果表明木质素本身具有复杂的结构形式,经过降解后可以得到香草醛、愈创木基衍生物等小分子物质。

关键词:高沸醇木质素;光催化;降解中国分类号:O636.2; O643 文献标识码:A木质素是自然界中含量仅次于纤维素的天然高分子物质,具有可再生、可降解、无毒等优点,可视为优良的绿色化学原料[1-2]。

木质素可用作水泥减水剂、水泥助磨剂、沥青乳化剂、钻井泥浆调节剂、稠油降粘剂、三次采油用表面活性剂、染料分散剂和吸附材料等[3-4]。

在当前石油资源日益枯竭和环境污染不断加剧的情况下,由于木质素富含芳香族官能团,未来有望成为芳香族化合物的主要来源之一[5]。

高沸醇木质素是利用高沸醇溶剂(HBS)法制备纸浆过程中获得的木质素[6-7]。

高沸醇溶剂法是纸浆制备的新工艺,具有无污染、节能等特点,是目前国内外对木质素研究的重要课题之一。

由于高沸醇溶剂法制浆所提取的木质素受到的结构破坏较小,基本上保持了木质素的大部分活性基团,如羧基、酚羟基和醇羟基等。

与从传统造纸废液中提取的碱木质素相比,高沸醇木质素具有灰分含量少、化学反应活性高等优点。

有机溶剂预处理溶剂修饰木质素英文回答:Organic Solvent Pretreatment for Solvent Modification of Lignin.Organic solvent pretreatment is a promising technique for the modification of lignin, with the aim of improving its solubility, reactivity, and functionality for various applications. Unlike traditional aqueous-based pretreatments, organic solvent pretreatments utilize non-polar or partially polar solvents to selectively dissolve lignin while preserving the cellulose and hemicellulose components of biomass.There are two main types of organic solvent pretreatments:1. Organosolv Pretreatment: This method involves the use of a mixture of organic solvents, such as ethanol,methanol, or acetone, with water to dissolve lignin. The solvent mixture is typically heated under pressure to enhance the extraction of lignin.2. Ionic Liquid Pretreatment: Ionic liquids are non-polar or partially polar salts that are liquid at room temperature. They have the ability to dissolve both polar and non-polar compounds, including lignin. Ionic liquid pretreatment involves the direct dissolution of biomass in the ionic liquid, followed by separation of the dissolved lignin.The choice of organic solvent or ionic liquid used in the pretreatment depends on several factors, including the type of biomass, the desired lignin properties, and the specific application. The pretreatment conditions, such as temperature, pressure, and reaction time, also play a crucial role in determining the efficiency and selectivity of the process.Organic solvent pretreatment can modify lignin in several ways:Removal of Impurities: Organic solvents caneffectively remove impurities from lignin, such as extractives, lipids, and proteins, which can interfere with lignin processing and applications.Fractionation: Organic solvent pretreatment can fractionate lignin into different molecular weight fractions. This allows for the selective isolation oflignin fractions with specific properties, which can be tailored for different applications.Functionalization: Organic solvents can react with lignin to introduce new functional groups, such as hydroxyl, carboxyl, and carbonyl groups. These functional groups can enhance the solubility, reactivity, and compatibility of lignin with other materials.Advantages of Organic Solvent Pretreatment:Improved lignin solubility and reactivity.Reduced formation of inhibitory compounds.Fractionation of lignin into different molecular weight fractions.Introduction of new functional groups.Applications of Modified Lignin:Biofuels and bioproducts.Carbon fiber precursors.Adhesives and coatings.Biocomposites.中文回答:有机溶剂预处理对溶剂改性木质素的影响。

第 2 期第 122-134 页材料工程Vol.52Feb. 2024Journal of Materials EngineeringNo.2pp.122-134第 52 卷2024 年 2 月木质素分离及主要物理和力学性能的研究进展Research progress in isolation ,main physical and mechanical properties of wood lignin周博鑫1,沈姿伶1,江京辉2,漆楚生1*,戴璐1*(1 北京林业大学 木质材料科学与应用教育部重点实验室,北京 100083;2 中国林业科学研究院 木材工业研究所,北京 100091)ZHOU Boxin 1,SHEN Ziling 1,JIANG Jinghui 2,QI Chusheng 1*,DAI Lu 1*(1 Key Laboratory of Wood Material Science and Application (Ministry of Education ),Beijing Forestry University ,Beijing 100083,China ;2 Wood Industry Research Institute ,ChineseAcademy of Forestry Science ,Beijing 100091,China )摘要:木质素是木材细胞壁的重要组成成分,其吸湿特性、热特性、力学特性等在木材的微宏观尺度相互影响,并对其高值化应用起决定性作用。

本文从分子结构、分离方法、吸湿特性、热特性、力学特性五个方面综述了木材木质素的研究进展。

木材木质素是高异质、不规则的三维网状高分子结构,相比原位木质素,不同分离方法的分离木质素有不同程度的解聚缩合,导致分离木质素分子结构、吸湿性、热特性、力学特性存在差异性。

木材木质素具有近似 S 型等温吸附曲线且存在吸湿滞后现象,平衡含水率在20%(质量分数)以下,可用 BET ,GAB 理论定性描述和定量分析单层水分子吸附量。

CHEMICAL INDUSTRY AND ENGINEERING PROGRESS 2016年第35卷第1期·294·化工进展木质纤维生物质精炼中木质素的分离及高值化利用平清伟,王春,潘梦丽,张健,石海强,牛梅红(大连工业大学,辽宁省制浆造纸重点实验室,辽宁大连 116034)摘要:木质纤维素作为最有前途的可再生资源,可替代现有的液体燃料。

因此,木质素作为木质纤维生物质细胞壁的主要成分之一,由其开发的高附加值产品将大大提高从可循环利用生物质生产能源的经济性。

本文回顾了自催化乙醇精炼技术的优势,相对于其他制浆技术不仅可以高效地从木质纤维生物质中分离出高活性的木质素,还可以获得高附加值的副产品(如糠醛、低聚糖、乙酰丙酸、甲酸、乙酸等)。

同时,抽提液可循环利用。

基于自催化乙醇精炼木质纤维生物质的特点,介绍了用自催化乙醇精炼所分离出的高活性木质素进行高值化利用的优势,以及用木质素生产高附加值产品的研究及利用,从而为木质纤维生物质中木质素在工业上大量开发利用提供了一条新的途径。

关键词:乙醇精炼;自催化;木质纤维生物质;乙醇木质素;高值化利用中图分类号:TS 79 文献标志码:A 文章编号:1000–6613(2016)01–0294–08DOI:10.16085/j.issn.1000-6613.2016.01.040Separation and high-value utilization of lignin from the lignocellulosebiomass refiningPING Qingwei,WANG Chun,P AN Mengli,ZHANG Jian,SHI Haiqiang,NIU Meihong (Dalian Polytechnic University,Key Laboratory of Pulp and Paper in Liaoning Province,Dalian 116034,Liaoning,China)Abstract:As the most promising renewable resource,lignocellulose may replace the existing liquid fuel. Lignin is one of the main components of lignocellulose biomass cell walls and therefore developing high value-added products from lignin will greatly improve the economic efficiency in recycling biomass to energy. This paper reviewed the advantages of the auto-catalytic ethanol refining technology. Compared with other pulping technology,it can not only separate highly active lignin from lignocellulose biomass feedstock,but also attain high-value co-products,for instance the furfural,oligosaccharide,levulinic acid,formic acid and acetic acid,etc. Simultaneously,the extracting liquor can be recycled. In the review,based on the characteristics of auto-catalytic ethanol refining lignocellulose biomass feedstocks,we introduced the advantages of high value application of highly active lignin separated from the lignocellulose biomass via autocatalytic ethanol refining. Furthermore,the utilizations of products prepared from the lignin were reported,which provides a new way in large scale development and utilization of lignocellulose biomass lignin in industries.Key words:ethanol refining; auto-catalytic; lignocellulose biomass; ethanol-lignin; high-value utilization纤维素、半纤维素、木质素构成了丰富的可再生植物纤维资源。

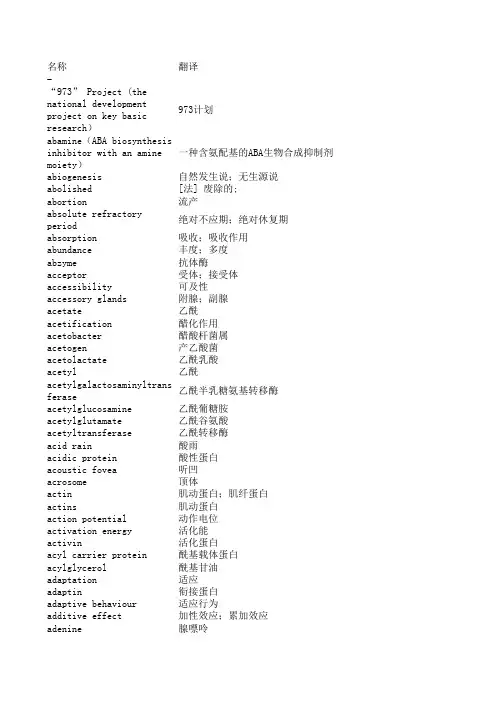

名称翻译-“973” Project (the nationa973计划abamine(ABA biosynthesis in一种含氨配基的ABA生物合成抑制剂abiogenesis自然发生说;无生源说abolished[法] 废除的;abortion流产absolute refractory period绝对不应期;绝对休复期absorption吸收;吸收作用abundance丰度;多度abzyme抗体酶acceptor受体;接受体accessibility可及性accessory glands附腺;副腺acetate乙酰acetification醋化作用acetobacter醋酸杆菌属acetogen产乙酸菌acetolactate乙酰乳酸acetyl乙酰acetylgalactosaminyltransfer乙酰半乳糖氨基转移酶acetylglucosamine乙酰葡糖胺acetylglutamate乙酰谷氨酸acetyltransferase乙酰转移酶acid rain酸雨acidic protein酸性蛋白acoustic fovea听凹acrosome顶体actin肌动蛋白;肌纤蛋白actins肌动蛋白action potential动作电位activation energy活化能activin活化蛋白acyl carrier protein酰基载体蛋白acylglycerol酰基甘油adaptation适应adaptin衔接蛋白adaptive behaviour适应行为additive effect加性效应;累加效应adenine腺嘌呤adenoviral腺病毒的 adj.adenovirus腺病毒adhesin粘附素adiantum铁线蕨adiponectin脂肪连接蛋白Adipophilin(ADFP)脂着素adipose脂肪adipsin抑渴蛋白adrenal肾上腺adrenal gland肾上腺adrenocortical肾上腺皮质adriamycin阿霉素adsorption吸附;吸附作用adventitious root不定根affinity chromatography亲和层析法agamous无性的agar琼脂;琼胶;洋菜胶agar medium琼脂培养基agar plate琼脂平面agaricales伞菌目age class龄级age distribution年龄分布age group年龄群age-dependent年龄-依赖性agenesis器官缺失畸形agglutination凝集aggregation聚集agmatine胍基丁胺agon辅基agonist拮抗因子air bubble气泡air embolism气栓air humidity大气湿度air space气室airlift bioreactor气升式生物反应器albumen(1)蛋白;蛋清,(2)清蛋白;白蛋白,(3)胚乳albumin清蛋白;白蛋白albuminous cell蛋白细胞alcohol醇alcoholic醇的alcoholic fermentation酒精发酵aldosterone醛甾酮,醛固酮alga藻;藻类algae藻类alignment联配aliquot等量样本;等分部份alkaline碱alkaline protein碱性蛋白质alkaline soil碱性土壤allantois尿囊allele frequency等位基因频率allelopathy异种克生[现象]allergen过敏素;致敏素;变应素allium葱属alloantigen同族抗原allometry异速生长allophycocyanin别藻蓝素allosteric modulator别构调节酶,别构效应物allotetraploid异源四倍体alloxan阿脲alluvial plain冲积平原alluvial soil冲积土aloe芦荟属alopecia秃发alpha helix a螺旋alpha-galactosidaseα-半乳糖苷酶altitudinal海拔alum矾,明矾aluminium oxide矾土alveolar肺泡alveolus腺泡Alzheimer disease阿尔茨海默病,老年性痴呆amaryllidaceae石蒜科amaurosis黑朦amelogenin成釉蛋白amensalism偏害共栖Amersham发玛西亚,安玛西亚Ames test埃姆斯试验amide酰胺; 胺amido black酰胺黑amino acid permease氨基酸透性酶aminoethyl氨乙基aminoglycan氨基聚糖aminolevulinate氨乙酰丙酸aminomethyl氨甲基aminopterin氨基蝶呤aminopurine氨基嘌呤aminotransferase转氨酶amitosis无丝分裂ammonium molybdate钼酸铵ammonium sulfate precipitati硫酸铵沉淀amniocentesis羊膜穿刺术amorphous无定形的amp腺苷一磷酸amphetamine安非他明;苯异丙胺amphibian两栖动物amphibians两栖amphioxus厦门文昌鱼amphipoda端足目amphiregulin双调蛋白amphisome自噬内涵体ampicillin氨芐青霉素;氨芐青霉素ampoule安瓿;针药管amur东北amylase淀粉酶[包括糖化酶和麦芽糖化酶] amylase inhibitor淀粉酶抑制剂amyotrophic肌萎缩性An Iterative Algorithm迭代算法an underestimate低估数据anaerobe厌氧生物;厌氧菌anal fin臀analogous protein类似蛋白质analytical balance分析天平analytical chemistry分析化学anatomist解剖学家anatomy(1)解剖,(2)解剖学anchor锚anchorin锚定蛋白androecium雄蕊群anemophily风媒anesthetic麻碎剂;麻碎的aneuploidy非整倍性angel天使蛋白angina咽峡炎angiogenin血管生成蛋白angiomyolipomas血管肌脂过多angiopoietin血管位蛋白angiospermae被子植物angiostatin血管稳定蛋白angle角度animal behavior动物行为animal husbandry畜牧;畜牧业animal kingdom动物界animal protein动物性蛋白质aniridia无铱症anisohydric behavior非等水行为ankyloglossia舌粘连annexin膜联蛋白annual plant一年生植物annulus环带ant plants蚁植物antagonist拮抗剂,拮抗物antenna触角anterior pituitary胸垂体前叶anterograde顺行性anther花药anther culture药培养antheridium雄器anthocyanidin花色素:;花青素anthocyanin花青苷,花色素苷anthranilate synthase邻氨基苯甲酸合成酶,邻氨基苯甲酸合酶anthrax炭疽热anthropogeny人类起源anthropoid类人猿antibody protein抗体蛋白质anticancer agent抗癌剂anticipation前发anticlinal wall垂周壁[见于植物]antigen presenting抗原呈递antigen presenting cell抗原呈递细胞,呈递抗原细胞antigenic heterogeneity抗原异质性antimicrobial agent抗微生物剂antimonate锑酸盐antioncogene,tumor suppresso抗癌基因,肿瘤抑制基因antiozonant防臭氧剂antiporter逆向运输antipyretic退热剂 ; 解热剂antiseptic防腐剂 ; 消毒剂 ; 抗菌剂antiserum抗血清antitoxin抗毒素antrum窦 ; 腔anura无尾目aortic arch大动脉弓apex顶点aphididae蚜属aphids蚜虫类apical bud顶芽apical cell顶端细胞,顶细胞apical initial顶端原始细胞Apicomplexanprotozoa顶复合器门的原生动物apicoplast质体样细胞器Apis蜜蜂属apnoea呼吸暂停aponeurosis腱膜apoplast非原质体apoptosis细胞凋亡apoptosome凋亡体; 凋亡复合体; 凋亡小体; 寡聚体apothecium子囊盘apparatus装置;器(官)apparent infection显性感染apparent viscosity表观粘度apple tree苹果树Applied Biosystems, ABI美国应用生物系统中国公司aquaculture(1) 水产养殖, (2) 溶液培养aquarius宝瓶座aquatic animals水生动物aquatic fungi水生真菌类aqueous水的,含水的araceae天南星科arachidic acid花生酸archaeology考古学Archaeopteryx始祖鸟属argininosuccinate精氨琥珀酸argon氩aridity(1) 干旱, (2) 干旱度Armadillo犰狳蛋白artemin, enovin, neublastin神经导向素arterial blood动脉血arterial pressure动脉压 ; 动脉血压arteriosclerosis动脉硬化 ; 动脉硬化症arthropoda节肢动物门artichoke朝鲜蓟articular cartilage关节软骨articular process关节突artifact人工产物artificial cell人工细胞artificial planting人工植树arylalkylamine芳烷基胺arylamine芳胺arylsulfatase芳硫酸酯酶ascocerida袋角石目ascus子囊asepsis无菌aseptically无菌地asparaginase天门冬酰胺酶asparagine天门冬氨aspartase天冬氨酸酶aspartate天冬氨酸;天冬氨酸盐、酯、根aspartic acid天冬氨酸Aspergillus曲霉属; 曲霉属assimilation同化 ; 同化作用associated virus伴随病毒asteraceae菊科astigmatism散光asymmetric PCR不对称PCR[引物用量不对称的PCR] ATCC ATCCatmospheric pollution大气污染atopy过敏症attenuation减毒作用auditory canal听道Aurelia海月水母属auricle(1) 心耳, (2) 叶耳aurora kinases极光激酶authentic真的,真实的,真正的Autoanalyzer[商]自动分析仪[Technicon公司商标] autoclave高压灭菌器; 消毒蒸锅autofluorescence自体荧光autogamy自体受精; 自核交配autograft自体组织移植片automaticity自动节律性autophagy自噬autoregulatory自调控Autosis自死亡autotic自死亡的avian鸟类的avifauna区系avirulent strain减毒株,无毒株axillary region腋区axons神经轴突Axygen爱思进azoospermia无精症azospirillum巴西固氮b cell epitope b细胞抗原决定基B cell lymphoma B细胞淋巴瘤Bacillus subtillis枯草芽胞杆菌backbone脊柱bacteria culture细菌培养bacterial motility细菌运动性bacterial virulence细菌毒力bacteriochlorophyll细菌叶绿素; 菌绿素bacteriocin细菌素bacteriophage噬菌体bacterioplankton异养浮游细菌bacteriostasis抑菌作用bacteroid类菌体balance of nature自然平衡balanced diet均衡膳食band centrifugation method层带离心法bar chart条线图 ; 棒形图 ; 条形图barbate具毛的barbiturate巴比妥酸盐barbituric acid巴比妥酸bark树皮baroreceptor reflex压力感受拼射Barr body巴氏体 ; 巴尔氏小体 ; 性染色质小体barren不孕baseplate基片basic ingredient基础成分basic number基数Basidiomycetes担子菌纲Basidiomycotina担子菌亚门basonuclin碱性核蛋白,碱核蛋白basophilic嗜碱的bast fiber韧皮纤维batch process分批工艺,分批法bathochromically红移bats蝙蝠Bdellovibrio bacteriovorus蛭弧菌beclin苄氯素bee venom蜂毒benign良性benzimidazoles苯甲亚胺醇benzyl alcohol苯甲醇bile胆bile duct胆管biliary duct胆管binding energy结合能binocular vision双眼视觉bioburden微生物量Bioceramics生物陶瓷biochip生物芯片biodegradable生物可降解的biodegradation生物降解 ; 生物降解作用Bio-energizer生物促生剂bioenergy生物能量biofeedback生物反馈biofilm生物薄膜,生物膜,生物被膜,微生物膜biogenesis生源说biogeographic region生物地理区biogeography生物地理bioinformatics生物信息学biolistic technology生物弹道技术biological glucoside生物甙Biological invasion生物入侵biological nitrogen fixation生物固氮酌biological products生物制品biological rhythm生物节律bioluminescence生物发光biomarker生物标志物Biomass Energy生物质能源biomimetic synthesis仿生合成biomimetics生体模仿学biomolecular生物大分子bionics仿生学biophysics生物物理学Bio-rad伯乐生物biosecurity生物安全biosensor生物传感器biostratigraphical生物地层的biotechnology生物技术 ; 生物科技biotelemetry生物遥测学biotic community生物群落群biotinylation生物素化biotransformation生物转化biotype(1) 生物型 ; 生物类型, (2)同型小种 ; biovar生物变型bird migration鸟迁移bird of prey猛禽类bird ringing鸟类环子birdsong鸟鸣birth出产bisexual flower两性花biting insect咬虫bitopic membrane proteins双顶膜蛋白bivalent(1) 二价的 , (2) 二价染色体blastospore芽生孢子bleaching agent漂白剂blight疫病blind spot盲点blinded study参加者不知情的研究blood circulation血循环blood flow血量blood group antigen血型抗原blood screening血液筛查blood type血型blunt end钝圆末端Bohr effect波尔效应boletus牛肝菌属bone骨,骨骼bone age骨龄bone ash骨灰bone lamella骨层板bone marrow transplantation骨髓移植bone meal骨粉bone tissue骨组织boron deficiency硼缺乏botulinum肉毒菌botulism肉毒中毒bound water结合水bract苞片brain cortex大脑皮质brainstem脑干branch point分支点[如见于RNA剪接]branchial鳃的BRAND普兰特breadths宽度breeding season繁殖期brefeldin布雷菲(尔)德菌素Brief Introduction简介broad leaved forest落叶林bromophenol blue溴酚蓝bromothymol blue溴百里酚蓝; 溴百里香酚蓝, 溴麝香草酚蓝bronchitis支气管炎bronchus支气管brown alga褐藻brownian motion布朗运动bryophyte苔藓植物 ; 苔藓类bryophytes苔藓Buchner funnel布氏漏斗buffer缓冲剂bulldog clamp动脉夹bullous大疱bupleurum柴胡属buster大体butterflies蝴蝶butyrylcholinesterase丁酰胆碱脂酶by product副产物C. elegans;Caenorhabditis e线虫,秀丽隐杆线虫cache缓冲cadherin钙粘着蛋白calciferol钙化醇calcification钙化 ; 钙化作用calcineurin钙调磷酸酶calcitonin降血钙蛋白calcium binding protein钙结合蛋白(质)calculating machine计算器calcyclin钙周期蛋白,钙(细胞)周期蛋白calibration curve校准曲线callose胼胝质,愈伤葡聚糖callosum胼胝质callus differentiation愈伤组织分化calmodulin钙调蛋白,钙调节蛋白,钙调素calnexin钙联结蛋白calpain钙蛋白酶camalexin一种植物保护素cambrian period寒武纪campaniform钟状的cancer cell癌细胞cane sugar甘蔗糖cannabinoid大麻成分capillary毛细管capping加帽,加帽反应;封闭反应;帽化,成帽反应capping protein加帽蛋白,戴帽蛋白caproyl己酸基capsid(病毒)衣壳,(病毒)壳体capsule(1) 荚膜, (2) 孢蒴, (3) 蒴果captivity笼养caragana锦鸡儿属carbamate氨基甲酸脂carbohydrate糖carbon balance碳平衡carbon dioxide fixation碳酸气固定carbonyl羰基carboxykinase羧激酶carboxylate羧酸cardiac glycoside强心苷cardiovascular心血管cardiovascular disease心血管疾病carex苔草属cargo笼carotenoid类胡萝卜素; 类叶红素carrying capacity(1) 携带力 ; 负载力 , (2) 容纳量cascade级联caspase胱冬酶caste阶级; 级castor bean蓖麻籽castration去势catabolite分解代谢物catalytic center催化中心catalytic constant催化常数,转换数[符号Kcat]catalytic mechanism催化机理catalytic subunit催化亚基catalyzer催化剂catenation链状排列catenin连环蛋白cathelicidin组织蛋白酶抑制素catheter导管cave洞穴caveolae(复)陷窝,小窝,小凹cavity腔cecropin蚕素cell adhesion molecule细胞粘着分子,细胞粘附分子cell biology细胞生物学cell fusion细胞融合 ; 细胞并合cell line细胞株cell membrance细胞膜cell membrane(细)胞膜cell migration细胞迁移cell nucleus细胞核cell polarity细胞极性cell protein细胞蛋白质cell respiration细胞呼吸cell strain细胞株cell theory,theory of cell细胞学说Cell-map proteomics细胞器蛋白质组学,细胞图谱蛋白质组学cellular respiration细胞呼吸 ; 细胞呼吸作用cellulase纤维素cellulose decomposing fungi纤维素分解真菌类cement gland黏腺center中心center of origin起源中心centrifugal separation离心分离(法)centrifuge离心机centrifuge tube离心管centriole中心粒centrum椎体cephalopod头足动物 ; 头足类cephalosporin头孢菌素cercaria摇尾幼虫; 尾蚴cereals谷粒cerebral cortex大脑皮质cerebrospinal fluid脑脊液降钙素基因相关肽CGRP,calcitonin gene related peptidechalaza(1)卵带; 卵黄系带, (2) 合点chalazal合点端chalone抑素,抑制素channel管道channel theory经络学说chaperone protein伴侣蛋白质,伴娘蛋白chara轮藻character字符characteristic性状charged particle带电粒子charophyte轮藻植物chemokine趋化因子chemotaxis趋化性chemotaxonomic分类学chenopodiaceae藜科植物Chest PA & LAT胸部正侧位chi square test检验chiasma frequency交叉频率chilling injury寒害chimeric嵌合的chimeric gene嵌合基因chimeric protein嵌合体蛋白质chiral手性的chitinase几丁酶chloral氯醛chloramphenicol氯霉素; 氯霉素chloramphenicol acetyltransf氯霉素乙酰转移酶Chlorella绿藻属; 绿球藻属chlorenchyma绿色组织chlorogenic acid绿原酸chlorophyllbody叶绿体chlorophyll-protein叶绿素蛋白chlorophyta绿藻chlorophyte绿色植物chlorpyrifos毒死蜱,氯吡硫磷cholecystokinin缩胆囊素; 胆囊收缩素cholera toxin霍乱毒素[分A、B亚基]cholesterol胆固醇cholesterol oxidase胆固醇氧化酶cholic acid胆酸choline esterase胆碱酯酶cholinesterase胆碱脂chondroitin软骨蛋白chondrosarcoma软骨瘤chorda tympani鼓索chorionic绒膜chromatin染色质chromatin condensation染色质凝聚chromatographic column层析柱chromophore生色团chromosomal aberration染色体畸变; 染色体异常chromosome mapping染色体作图,染色体定位chromosome polymorphism染色体多态性chromosome segregation染色体分离chronic慢性的chukar石鸡chymotrypsinogen胰凝乳蛋白 原cilium纤毛circadian生理节律circadian rhythm(近)昼夜节律circulation循环怜circulation of blood血循环circulatory system循环系统cisplatin[商]顺式铂氨,顺氯氨铂[一种抗癌药] citric acid柠檬酸cladistic分支系统学clasper交合突; 鳍脚class纲clavulanic acid棒酸clay粘土cleavage site切割位点climate气候climax community顶极群落clinical microbiology临床微生物学clinical trial临床实验clonal activation克隆活化clonal expansion克隆扩充clone克隆cloning无性繁殖系化closure闭合clot凝块clumped distribution丛生分布Cluster of Orthologous Group蛋白相邻类的聚簇CMP CMPcnidoblast刺细胞CNQX CNQXCNTF CNTFCoA CoAcoat protein外壳蛋白; 病毒蛋白外壳;病毒蛋白外壳;(病毒)外壳蛋白coating antigen包被抗原cocarboxylase辅羧酶coccus球菌cochlea耳蜗coding sequence编码序列codominant共显性种codon密码子codon bias密码子偏倚(性)coeliac artery腹腔动脉coenzyme辅cohesin黏连蛋白colchicine秋水仙碱colinearity共线性collagen胶原collagenase胶原酶collar襟collum颈colonization定居colony菌落color reaction呈色反应colouration着色coma昏迷commitment定型comparative morphology比较形态学Comparative proteomics analy比较蛋白质组学研究compartmentalization区域化compartmentation区域化compensation补偿compensation depth补偿深度compensation point补偿点competence感受态competent活性的,有能力的,(处于)感受态的competitive capacity竞争能力competitive inhibition竞争性抑制作用complement补体[补体系统包括C1-C9等多种成分]complementation互补(作用)complete response完全有效conazole唑类;一般是后缀中使用concatemer多联体,串联体,连环体;噬菌体]串联体concatenation连环酌concentration浓度concentration gradient浓度梯度concerted model齐变模式concretion结石condensation(1) 缩合, (2)凝聚; 凝结condiments刀conditional gene条件基因conductivity传导性conductivity detector电导率检测器cone(1) 视锥, (2) 球果 ; 球花configuration构形confluent culture铺满培养物,铺满培养congestion充血conglomerate聚块conidium分生孢子conifer针叶树; 松柏类植物conjugated bile acid结合胆汁酸conjugated protein缀合朊; 结合蛋白质;结合蛋白质;结合蛋白(质)conjugation接合connectomes连接组Connectomics连接组学consanguineous marriage血亲联婚consecutive连串的,相连续的conserved domain保存区段consortium聚生体[一种以上细菌聚集在一起,具有相对固定的依存关系] constipation便秘constriction狭窄construction构建,组建contamination污染Content of Heavy Metal重金属含量contig重叠群,毗连(序列)群[一组从基因组中克隆的毗连DNA序列] contiguity邻接continental shelf大陆架continuous passage culture连续传代培养(物)continuous variation连续变异contour line等高线contour map等高线图,等值线图control对照control gene第基因control plot对照小区conus芋螺convergence会聚[用于神经系统];趋同conzyme辅酶cooling jacket冷却套cooling tower冷却塔cooperative协同的cooperative behavior协同行为cooperative effect协同效应,合作效应coordination协调coordination bond配位键copepod桡足类copulation(1) 接合, (2) 交配cordycepin3'-脱氧腺苷;蛹虫草菌素cormorant鸬鹚Corn Straw玉米秸杆Corning康宁coronary heart disease冠心病correlation coefficient相关系数corrosion protection防腐cortex皮层corticoid类皮质激素cortin皮质激素cortisol皮质醇cortisone可的松cosmid黏粒cosmopolitan广布种costus lactone木香内酯cosurfactant助表面活性剂cotranslational integration共翻译整合cotranslational secretion共翻译分泌cotton棉花counter electrode对电极counterstaining对染(法),复染(法)[一种对比染色法] coupled偶联的coupled reaction偶联反应coupled transport偶联输送cover degree覆盖度cover glass盖玻片CpG island CpG岛cramp痉挛cre表达crecricetulus仓鼠cricket蟋蟀crickets蟋蟀CRO,contract research orgniz合同研究组织crops罪cross protection交叉保护cross section横切面crosstalk串华,通讯cruciferae十字花科植物crust地壳土壤crustacea甲壳动物cryogen冷冻剂,制冷剂cryopreservation深低温保藏[法]cryoprotectant冷冻保护剂cryptobiosis隐生cryptorchidism隐睾crystal structure晶体结构crystallization结晶(作用)cucumber黄瓜culm空心秆cultivar培养变种culture培养; 培养物culture collection培养物保藏culture tube培养(试)管cupule(1) 杯形托, (2) 胞芽杯, 93) 杯形器, (4) 壳斗current density电流密度cushion垫层cuticle角质膜cutis皮肤cuvette比色皿cyan氰cyanobacteria蓝细菌cyanobacterial蓝藻cyanobacterial toxins藻毒素cyanobacterium蓝细菌cybrid胞质杂种cycas苏铁属cycle循环cyclin细胞周期蛋白cyclophilin亲环蛋白,亲环素,环孢素A结合蛋白cymbidium兰属cystathionine胱硫醚cystoma囊瘤cytochemistry细胞化学cytochrome c oxidase细胞色素c氧化酶cytochrome oxidase细胞色素氧化酶cytokine细胞因子cytokine network细胞因子网络cytokinesis胞质分裂 ; 细胞质分裂cytokinin细胞分裂素; 细胞激动素cytological细胞学的cytomegalovirus巨细胞病毒cytometer血球计数器血球计cytometric[医] 细胞计数的;cytoneme胞管cytopathic effect(致)细胞病变(效应)cytopenia细胞减少(症)cytoplasmic membrane细胞质膜cytoplasmic tail胞质尾区[如指跨膜蛋白的胞内小区]cytosol细胞溶质cytotaxonomy细胞分类学cytotoxic T lymphocyte细胞毒性T淋巴细胞cytotrophoblast细胞滋养层dairy cow乳牛de novo n. 重新, 更始,【生物学】从头dead space无效空间decane癸烷decomposer分解者[可指具有分解动植物残体或其排泄物能力的微生物] defective缺损的,缺陷的defective virus缺损病毒,缺陷病毒defensin防卫素,防御素defined medium确定成分培养基,已知成分培养液deforestation滥伐 ; 滥伐林木deformation变形degenerate简并的degradation退化dehiscent fruit裂果dehydration脱水(作用)dehydrogenase脱氢dehydrogenation脱氢(作用)deiodinase脱碘酶deionized water去离子水delayed fluorescence迟延荧光delayed hypersensitivity迟发过敏性delayed recovery恢复延迟deletion mutagenesis缺失诱变delphinium翠雀属deme同类群 ; 混交群体demethylation脱甲基化denaturants变性剂dendron树突denitrification反硝化作用density gradient密度梯度dental齿骨dental caries龋齿dentine齿质deoxycytidine脱氧胞苷deoxysugar脱氧糖depletion排除depressed脱阻抑的deprived除去的,丧失的derivate衍生物dermatan皮层dermatitis皮炎dermatoglyphics肤纹desaturase去饱和酶desaturases去饱和酶descendants后代descent谱系description描述desertification沙漠化desmin结蛋白desmocollin桥粒(芯)胶(粘)蛋白desquamation脱鳞desulfurization脱硫(作用)detention滞留determination测定detritus碎屑; 腐质developmental genetics发生遗传学device仪器devonian period泥盆纪dextran葡聚糖,右旋糖酐dextran sulfate葡聚糖硫酸酯dextrin糊精dhamotil复方地芬诺酯片,芬诺酯和阿托品diabetes insipidus尿崩症diagnostic procedure诊断程序,诊断手续dianthus石竹属diapause(1) 滞育, (2) 休眠期diarrhea腹泻diastolic pressure舒张压; 心舒压dichotomy双歧分枝Dickkopf-1Wnt通路抑制因子dielectrophoresis介电(电)泳diester二酯differential centrifugation差速离心differential expression差异表达Differential-Display PCR, DD差别显示聚合酶链反应diffusion扩散dihybrid双基因杂种dihydrofolate二氢叶酸dihydrotestosterone二氢睾酮dihydroxyacetone二羟丙酮dihydroxyvitamin二羟维生素diluent稀释剂,稀释液dimethylarginine二甲基精氨酸dinitrophenol二硝基苯酚dinoflagellate腰鞭毛虫; 甲藻; 涡鞭藻dioecious雌雄异体的dioecism雌雄异体,雌雄异株dioxygenase双加氧酶diphtheria白候dipterocarpaceae龙脑香科discontinuous variation不连续变异dish平皿Dishevelled,Dsh或Dvl蓬乱蛋白disinfection消毒dislocation转换位置dispersal散布displacement位移disproportionation岐化(反应)disturbance of consciousness意识障碍disulfide bond二硫键disulfide linkage二硫键dna binding protein dna 结合蛋白质DNA ligase DNA 连接DNA typing DNA分型docking protein船坞蛋白,停靠蛋白,停泊蛋白dodecane十二烷dolphins海豚domain域,区域,结构域,功能域dominance显性;优势(度)dominant allele显性等位基因dominant gene显性基因dominant lethal显性致死dosimeter剂量计double chin二重颊double-reciprocal plot双倒数作图,Lineweaver_Burk作图dove鸠dragonflies蜻蜓drebrin脑发育蛋白drift漂变drosophila果蝇属drug abuse&dependence毒品滥用和依赖drug resistant strain抗药性菌株dry weight干重duality二重性duct管duplication复制dynamic balance动态平衡dynamin发动蛋白,缢断蛋白dynein动力蛋白dyslipidemia血脂异常dysregulation调节异常early gene早期基因eating habits饮食习惯ecdysis蜕皮ecdysone蜕皮素;蜕皮激素ecg心电图echinoderm棘皮类Echinodermata棘皮动物门echinoderms棘皮动物eclampsia子癫症ecological factor生态因素ecotone群落交错区;群落过渡带ecotope生态区ectoblast外胚层ectodomain胞外域ectoplasm外质effect of gene基因剂量效应elaioplast油质体elasticity弹性elastoma高弹性electric focusing电子聚焦electrofusion电融合electrolyte solution电解质溶液electromotive force电动势electron diffraction电子衍射electron microscope电(子显微)镜electron transfer电子传递,电子转移electrophoresis pattern电泳图谱electrophysiological propert电生理特性electrophysiology电生理学electroporated电穿孔electroporation电转化electrospinning电纺丝,静电纺丝electrotransformation电转化(法)element元素elevational海拔elfin矮人elicitins激发素elicitor诱导子elimination消去,消除;弃置elongated spermatids精子细胞elongation延伸eluant洗脱液eluate洗脱物,洗出液Eluted[医] 被洗脱的,被洗提的; embedding medium包埋剂embryo culture胚胎培养embryogenesis胚形成embryoid胚状体embryonal胚的emetine吐根碱[属异喹啉类生物碱] emotional reaction情写应emphysema肺气肿encephalon脑髓encephalopathy脑病变endangering濒危endemic特有种,特有的,地方性的,地方的endemic disease地方病endocrine内分泌endocuticle内表皮endocytosis胞吞endoderm内胚层endodermis内皮endogenous内源(性)的endogenous opioid peptide内源性阿片样肽endogenous protective system内生保护系统endomembrane system内膜系统endometrioid子宫内膜endopeptidase内 ; 键内切endoplasmic reticulum (ER)内质网endosymbiont内共生体endothecium药室内壁energetics能量学energy band能量带energy charge能荷energy conservation能量守恒energy crop能源作物energy transduction能量转移entomological昆虫entomophily虫媒entropy熵enucleation去核environmental conditions环境条件environmental pollution环境污染environmentalist环境问题专家enzymatically adv.enzymatically modified lecit酶改性磷脂enzyme kinetics酶动力学enzyme system酶系统eosinophilia嗜伊红粒细胞增多症eosinophils嗜伊红粒细胞ephedra麻黄属ephemeral短命ephrin蝶素epidemic流行病epidemic hemorrhagic fever流行性出血热epidemiology流行病学epidermis表皮epigenetics发育遗传学,表观遗传学epigenome表观基因组epinasty偏上性episome附加体,游离体episperm种皮epistatic gene上位基因epithelium上皮细胞epitope mapping表位作图,表位定位epitope tagging表位附加,表位追加[把附加的抗原表位融合到目的蛋白上] epoxide hydrolase环氧化物酶epoxygenase环氧化酶Eppendorf tube[商]Eppendorf离心管,微量离心管eppin细粒蛋白Equisetum木贼属equivalence等价equivalent当量ergosterol麦角固醇;麦角甾醇error correction错误校正erythroid网织红细胞erythroid differentiation fa红细胞分化因子erythropoiesis红血球生成;红血细胞生成;造红血球;造红血细胞ester酯estival夏季的estrogen雌激素estrous cycle动情周期estrus动情期ethnobotanical民族植物学ethological行为学的ethyl alcohol乙醇ethylenimine氮杂环丙烷etiolation黄化;黄化现象etoposide鬼臼亚乙苷eudicot双子叶植物;eukaryon真核eukaryotic真核生物的eutrophic lake富营养湖evolutionarily进化上exchange group可交换组[比较相似并常可互换的氨基酸残基]excimer受激子excitatory postsynaptic pote兴奋性突触后电位excreted排泄; 排出; 分泌; 排除( excrete的过去式和过去分词 ); Exendin-4唾液素4[暂名]exocyst泡外exocytosis胞吐酌exon shuffling外显子改组exonuclease核酸外切酶exosmosis外渗exosome外切体expiration呼explantation外植exponential growth指数生长expressed sequence tag序列表达标签Expression proteomics表达蛋白质组学expression vector表达载体external外的extine外壁extracellular胞外的;细胞外的extracellular fluid胞外液;细胞外液exudate渗出液eyebrow眉face shield面罩factor因子falciform镰刀状的Fallopian tube法类皮欧氏管;输卵管familial adenomatous polypos家族性多发性腺癌fang长牙fatal dose致死量fatty liver脂肪肝fatty substance脂肪物质favus白癣fecundity生育力;生殖力felling采伐female flower雌花ferment酶fermentation发酵fern蕨类ferns蕨类fertility受精能力fertilized已受精的fertilizer肥料ferulic acid阿魏酸fiber plant纤维植物fibrinogen纤维蛋白原fibrinolysis(血)纤(蛋白)溶(解)fibroblast成纤维细胞fibroblastic tumor纤维母细胞瘤fibronectin纤连蛋白fibrosis纤维化fibrous protein纤维状蛋白; 纤维状蛋白质; 纤维状朊;纤维状蛋白质;....field study实地考察;野外考察filamentous丝状的filter press压榨滤净器filtering过滤fin ray条finch雀fingerprint指纹,指纹结构[例如核酸或蛋白质的酶切消化物在双向电泳中显示的特征first leaf第一叶fish protein concentrate鱼粉; 浓缩鱼蛋的;浓缩鱼蛋的;鱼蛋白浓缩物flagellin鞭毛蛋白flanking sequence侧面序列flat bone扁平骨flats平原flavone黄酮flavonoid类黄酮flesh果肉flexion屈曲flexor muscle屈肌floor plate底板flora植物区系;植物相floral植物的floras区系florigen成花素flow瘤flow cell流动池flow cytometer流式细胞仪flower color gene花色基因flowering plant有花植物fluid mosaic model[膜的]流动镶嵌模型,流体镶嵌模型fluorescence microscopy荧光显微镜检术fluorescence recovery after 光脱色荧光恢复技术fluoroacetate氟乙酸;氟乙酸盐、酯、根fluorochrome荧光燃料flurbiprofen氟比洛芬foam cells泡沫细胞focal adhesion焦点粘连focal distance焦距focus聚焦foetus胎儿food protein食用蛋白forelimb前肢对称性formyl甲酸基formyltransferase甲酰转移酶fossa窝fractalkine曲动蛋白fraction分段fragmentation断裂frame rate帧率freeze冻结Freon[商]氟利昂frequency频度frequency index频率指数friction摩擦friction coefficient摩擦系数frizzled,Frz卷曲蛋白frontal analysis迎头(分析)法fru果糖fructofuranosidase呋喃果糖苷酶fructosamine果糖胺fructose果糖fucan岩藻多糖fucose岩藻糖fucosyltransferase岩藻糖转移酶fuel cell燃料电池fumarase延胡索酸酶fumarate延胡索酸fumaric acid反丁烯二酸Funaria葫芦藓属functional differentiation机能分化functional gene功能基团functional group官能团functional localization功能定位functional protein功能蛋白functional redundancy功能性丰余,功能丰余性functional response机能反应fundus眼底fungi真菌fungicide杀霉菌剂funiculus菌丝索furry毛皮fusion融合;并合G1 Phase G1期gadfly牛虻gain增益gait步态galactosyltransferase半乳糖基转移酶galea外叶gallbladder胆galliformes鸡形目galvanometer电疗gametogenesis配子发生ganglioside神经节苷脂garlic大蒜gastritis胃炎gastrointestinal cancer胃肠癌gastrulation原肠胚形成Gaucher disease戈谢病,高雪病gazelle羚GC content GC含量gel mobility shift assay凝胶迁移率变动分析,凝胶移位分析gelation凝胶作用gelsolin凝溶胶蛋白gena颊gene action基因作用gene analysis基因分析gene bank基因库; 基因文库;基因文库gene carrier基因携带者gene clone基因克隆gene cloning基因克隆化;基因无性繁殖gene cluster基因簇gene combination基因组合gene complex基因综合体gene content基因含量gene conversion基因转变gene copy基因复制; 基因拷贝;基因拷贝gene deletion基因缺失gene dosage基因剂量;基因量;基因数量; 基因剂量gene engineering遗传工程;基因工程gene flow基因怜;基因流; 基因流动;基因流动; &n....gene frequency基因频率;等位基因频率gene fusion基因融合gene information基因信息gene interaction基因互作; 基因相互作用;基因相互酌;基因相互作用gene location基因定位gene loci基因位点gene locus基因位点;基因座位gene map基因图;基因图谱gene mapping基因定位; 基因定位; 基因图;基因图; &....gene order基因序列gene pairs基因对gene pool基因储备;基因库; 基因文库gene recombination基因重组gene theory基因论;基因学说gene therapy基因疗法;基因治疗; 基因治疗general anesthesia全身麻醉genetic遗传的genetic distance遗传距离genetic engineering基因工程,遗传工程,遗传工程学genetic immunization基因免疫接种[采用基因疫苗进行接种]genetic screening遗传筛选genetic transformation遗传转化[例如一个品系的生物吸收另一品系生物的遗传物质,并获得后一genetic variance遗传方差genetics遗传学Genistein’,5,7三羟基异黄酮genome基因组,染色体组Genome Mismatch Scanning基因组错配扫描genomic imprinting基因组印记[配子发生过程中基因的选择性差异表达]genomics基因组学genophore基因线,基因带gentamicin艮他霉素gentianaceae龙胆科geranium老鹳草属geranylgeranyl香叶酰香叶酰germ cell胚细胞germ plasm种质, 生殖质germinal center发芽中心germination萌发;萌发作用germline生殖细胞系ghost菌蜕gibberellic acid赤霉酸;赤霉酸gibberellin赤霉素;赤霉素glacial period冰川时代glaciation冰河酌gland腺体glandular epithelium腺上皮glass beads玻璃念珠gley horizon潜育层glia胶质Global Proteomics整体蛋白质组学glomerulosclerosis肾小球硬化症glottis声门glucocorticoid糖皮质(激)素glucomannan葡甘露聚糖glucosamine葡糖胺,氨基葡糖glucose oxidase葡萄糖氧化酶glucosidase葡糖苷酶glucuronyl葡糖醛酸基glutaminase谷酰胺酶glutelin谷蛋白glycinebetaine甘氨酸甜菜碱glycoconjugates糖缀合物,糖复合物glycophorin血型糖蛋白glycoprotein糖蛋白glycosphingolipid鞘糖脂Glyoxal Oxidase乙二醛氧化酶glyoxylate cycle乙醛酸循环GM-CSF GM-CSFGMP GMPgneiss片麻岩GnRH GnRHgoblet cell杯形细胞gonads生殖腺grain protein content籽粒蛋白含量Gram stain革兰氏染液gramicidin A短杆菌肽Agramineae禾本科植物granulation tissue肉芽组织granuloma肉芽肿granulose细菌淀粉粒granzyme颗粒酶grape procyanidins葡多酚green plant绿色植物groundwater level地下水位grove林growth curve生长曲线growth promoter生长促进剂grus鹤GTP-Binding Proteins GTP结合蛋白质类guanosine鸟尿环核甙guild种群guinea pig豚鼠gull鸥gus gus酶habitat栖所haemagglutinin血球凝集素hail霰hail damage雹害hair follicle毛囊halophilic嗜盐菌halophilic bacteria嗜盐菌halosere盐生演替系列hamamelidaceae金缕梅科Hantaan virus汉坦病毒,汉滩病毒,汉他病毒harder哈德Hardy-Weinberg equilibrium哈迪-温伯格平衡hazard ratio风险比HBAg HBAgHBcAg乙型肝炎核心抗原HBeAg HBeAgHBsAg HBsAg。

Lignin Composition and Structure in Young versus Adult Eucalyptus globulus Plants1Jorge Rencoret,Ana Gutie´rrez,Lidia Nieto,J.Jime´nez-Barbero,Craig B.Faulds,Hoon Kim,John Ralph,A´ngel T.Martı´nez,and Jose´C.del Rı´o*Instituto de Recursos Naturales y Agrobiologı´a de Sevilla,Consejo Superior de Investigaciones Cientı´ficas, E–41080Seville,Spain(J.Rencoret,A.G.,J.C.d.R.);Centro de Investigaciones Biolo´gicas,Consejo Superior de Investigaciones Cientı´ficas,E–28040Madrid,Spain(L.N.,J.J.-B.,C.B.F.,A.T.M.);and Departments of Biochemistry and Biological Systems Engineering and Department of Energy Great Lakes Bioenergy Research Center,University of Wisconsin,Madison,Wisconsin53706(J.Rencoret,H.K.,J.Ralph)Lignin changes during plant growth were investigated in a selected Eucalyptus globulus clone.The lignin composition and structure were studied in situ by a new procedure enabling the acquisition of two-dimensional nuclear magnetic resonance (2D-NMR)spectra on wood gels formed in the NMR tube as well as by analytical pyrolysis-gas chromatography-mass spectrometry.In addition,milled-wood lignins were isolated and analyzed by2D-NMR,pyrolysis-gas chromatography-mass spectrometry,and thioacidolysis.The data indicated that p-hydroxyphenyl and guaiacyl units are deposited at the earlier stages,whereas the woods are enriched in syringyl(S)lignin during late lignification.Wood2D-NMR showed that b-O-4#and resinol linkages were predominant in the eucalypt lignin,whereas other substructures were present in much lower amounts. Interestingly,open b-1#structures could be detected in the isolated lignins.Phenylcoumarans and cinnamyl end groups were depleted with age,spirodienone abundance increased,and the main substructures(b-O-4#and resinols)were scarcely modified.Thioacidolysis revealed a higher predominance of S units in the ether-linked lignin than in the total lignin and,in agreement with NMR,also indicated that resinols are the most important nonether linkages.Dimer analysis showed that most of the resinol-type structures comprised two S units(syringaresinol),the crossed guaiacyl-S resinol appearing as a minor substructure and pinoresinol being totally absent.Changes in hemicelluloses were also shown by the2D-NMR spectra of the wood gels without polysaccharide isolation.These include decreases of methyl galacturonosyl,arabinosyl,and galactosyl (anomeric)signals,assigned to pectin and related neutral polysaccharides,and increases of xylosyl(which are approximately 50%acetylated)and4-O-methylglucuronosyl signals.Plant cell walls are composed mainly of three struc-tural polymers,the carbohydrates cellulose and the hemi-celluloses and the aromatic polymer lignin.The lignin polymer provides mechanical support to the plant.In addition,it waterproofs the cell wall,enabling trans-port of water and solutes through the vascular system, and plays a role in protecting plants against patho-gens.Lignin is a complex polymer synthesized mainly from three hydroxycinnamyl alcohols differing in their degree of methoxylation:p-coumaryl,coniferyl,and sinapyl alcohols(Higuchi,1997;Boerjan et al.,2003;Ralph et al.,2004a).Each of these monolignols gives rise to a different type of lignin unit called p-hydroxy-phenyl(H),guaiacyl(G),and syringyl(S)units,re-spectively,when incorporated into the polymer.The amount and composition of lignins vary among taxa, cell types,and individual cell wall layers and also with environmental conditions.Softwood lignin con-sists almost exclusively of G-type lignin,while hard-wood lignin also consists of S units(H units being minor components).After their synthesis,the lignin monomers are transported to the cell wall,where they are polymerized in a combinatorial fashion by free radical coupling mechanisms in a reaction mediated by peroxidases and/or laccases,generating a variety of structures and linkages within the polymer(Boerjan et al.,2003;Ralph et al.,2004a).Wood(secondary xylem)is produced seasonally at the periphery of the trunk by the vascular cambium(De´jardin et al.,2010). Lignin deposition is one of thefinal stages of xylem cell differentiation and mainly takes place during secondary thickening of the cell wall.Lignification starts in the middle lamella and cell corners and proceeds toward the lumen,filling up pores in the al-ready deposited polysaccharide network(Donaldson, 2001;Boerjan et al.,2003).The relative abundance of the different linkages formed depends on the relative1This study was supported by the Spanish project AGL2005–01748,the Consejo Superior de Investigaciones Cientı´ficas(project nos.200640I039and201040E075),the European Union projects BIORENEW(grant no.NMP2–CT–2006–026456),WALLESTER (grant no.PIEF–GA–2009–235938),and LIGNODECO(grant no. KBBE–244362),the Department of Energy Great Lakes Bioenergy Research Center(grant no.BER DE–FC02–07ER64494),and the Spanish Ministry of Education(postdoctoral fellowship to J. Rencoret).*Corresponding author;e-mail delrio@irnase.csic.es.The author responsible for distribution of materials integral to the findings presented in this article in accordance with the policy described in the Instructions for Authors()is: Jose´C.del Rı´o(delrio@irnase.csic.es)./cgi/doi/10.1104/pp.110.167254contribution of the particular monomers to the po-lymerization process as well as on steric hindrances and chemical interactions in the growing wall.There-fore,the differences in the timing of monolignol de-position and the changes in cell wall ultrastructure during growth would regulate lignin composition and structure during lignification.A main challenge in elucidating the structure of lignins is in obtaining high-yield isolation from wood in a chemically unaltered form(the same applies to hemicellulose polysaccharides).Several lignin isola-tion procedures have been developed,but it is well recognized that the different procedures,including the reference milled-wood lignin(MWL),yield only a part of the native lignin in wood and may not be represen-tative of the whole lignin.Indeed,it has also been demonstrated that MWL can undergo some structural modifications during isolation,especially during the milling process,and often contains some amount of “contaminating”compounds(such as lignin-linked carbohydrates;Fujimoto et al.,2005;Guerra et al.,2006; Hu et al.,2006;Balakshin et al.,2008).Because lignin is intimately interpenetrating the other major compo-nents(cellulose and hemicelluloses),it is obvious that its truly native form can only be studied by analytical methods applicable directly on the whole plant mate-rial.For this purpose,in this paper,the wood samples were analyzed in situ by two-dimensional(2D)-NMR spectroscopy and pyrolysis-gas chromatography-mass spectrometry(Py-GC-MS).The use of these techniques avoids isolation procedures that may lead to partial or modified polymer extraction.For in situ NMR analy-ses,a recent approach has been developed that con-sists of swellingfinely ground plant material in deuterated dimethyl sulfoxide(DMSO-d6;Kim et al., 2008;Rencoret et al.,2009)or DMSO-d6:pyridine-d5 (4:1;Kim and Ralph,2010)and forming a gel directly in the NMR tube,which is readily amenable to NMR analysis.Heteronuclear single quantum correlation (HSQC)NMR of these gels has been shown to be an efficient method for the rapid in situ analysis of lignin in plants without the need of prior isolation.The method requires only low amounts of sample and can be used for rapid characterization of the major struc-tural features of plant lignins(i.e.interunit linkages and H-G-S composition),also providing information on the hemicellulose polysaccharides.Py-GC-MS is another powerful tool for the in situ characterization of plant constituents,especially lignin(Ralph and Hatfield,1991;Rodrigues et al.,1999;del Rı´o et al., 2005;Rencoret et al.,2007).Wood lignin is pyrolyzed to produce a mixture of relatively simple phenols,which result from cleavage of ether and certain carbon-carbon linkages.These phenols retain their substitu-tion patterns from the lignin polymer,and it is thus possible to identify compounds from the H,G,and S lignin units.The aim of this paper is to elucidate the changes produced in the composition and structure of the lignin in eucalypt wood with maturation and includes analyses of young plants and adult trees.This knowl-edge is important not only for providing additional insight into the mechanisms of lignin deposition but also for the industrial processing of wood for pulp, chemical,or biofuel production,as the lignin compo-sition and structure greatly influence the delignifica-tion reactions(Gonza´lez-Vila et al.,1999;del Rı´o et al., 2005).For this purpose,samples of Eucalyptus globulus wood from the same clone(to avoid genetic variations within species)were collected at different stages of growth(1month,18months,and9years)and the composition and structure of their lignins were thor-oughly investigated.A combination of the above-mentioned2D-NMR and Py-GC-MS of whole wood samples was used for the in situ study of lignin changes.In order to obtain further insights into their structures and compare with the results from the in situ analyses,MWL was also isolated from the differ-ent woods and analyzed by NMR,pyrolysis,and thioacidolysis.As far as we know,this is thefirst report describing in situ structural analyses of wood lignin during tree growth using a combination of2D-NMR and other techniques.RESULTS AND DISCUSSIONAfter a general analysis of wood composition in E. globulus plants of different ages(young and adult trees from a clonal plantation),the changes in lignin(and hemicellulose)during growth were analyzed in situ by a combination of Py-GC-MS and2D-NMR of whole wood,and the results were compared(and comple-mented)with those obtained from lignins(MWL) isolated from the same samples.Wood Composition during Eucalypt GrowthThe contents of the main wood constituents(i.e.ace-tone extractives,water-soluble material,Klason lignin, acid-soluble lignin,crystalline cellulose,amorphous glucan,xylan,arabinan,galactan,mannan,rhamnan, fucan,total uronic acids,and ash)in the selected E. globulus clone at different stages of growth are sum-marized in Table I.The total lignin content(Klason lignin plus acid-soluble lignin)increased during growth(from16%in the1-month-old sample to25% in the9-year-old wood),whereas the content of other constituents(namely acetone extractives,water-soluble material,and ash)decreased with maturity.Interest-ingly,there is also a great variation in the composition of polysaccharides(from neutral sugar analysis)dur-ing maturation,with a depletion of Ara,Gal,and Man and a progressive enrichment of Xyl.The amount of crystalline cellulose has the highest content(37%)after 18months,while that of amorphous glucan was lower and showed a progressive increase during growth. Finally,the uronic acid content was the highest after 1month(7%)and showed only a moderate decrease during growth.Variations in the uronic acid natureRencoret et al.during growth are discussed after the NMR analyses below.Py-GC-MS of Whole Woods and Their Isolated Lignins Py-GC-MS,although not a fully quantitative tech-nique,has been successfully used to analyze the relative H-G-S composition of lignin in different hard-woods,including eucalypt wood(Rodrigues et al., 1999;Yokoi et al.,1999,2001;del Rı´o et al.,2005; Rencoret et al.,2007,2008).Pyrograms from the euca-lypt wood samples after different growth periods and their corresponding MWLs are shown in Figures1and 2,and the identities and relative molar abundances of the released lignin-derived compounds are listed in Table II.The pyrolysis of the different eucalypt woods re-leased both carbohydrate-and lignin-derived com-pounds.Among the latter,guaiacol-and syringol-type phenols,derived from the G and S lignin units,were identified,including guaiacol(compound2),4-vinyl-guaiacol(8),syringol(11),4-methylsyringol(14),4-vinyl-syringol(22),4-allylsyringol(25),trans-4-propenylsyringol (32),syringaldehyde(34),and trans-sinapaldehyde (49).In addition,significant amounts of compounds derived from H lignin units,such as phenol(1), methylphenols(3and4),and dimethylphenol(6), could be detected after pyrolysis of the youngest wood,although some of them can also derive from polysaccharides(Ralph and Hatfield,1991).The H-G-S composition of the lignin in the different woods, obtained from the molar areas of all the lignin-derived compounds,is shown in Table II.In all samples,the S-type phenols were released in higher abundances than the respective G-type phenols,with a S-G ratio ranging from1.4in the youngest wood to3.8in the oldest wood.The amount of H-type compounds from the youngest wood(9%)decreases during maturation(to only2%in the oldest wood).This indicates that H units are depositedfirst,followed by G and then S units,in agreement with previous microautoradiogra-phy and microspectroscopy studies in other plants (Terashima et al.,1986).An increase of lignin S-G ratio with plant maturity has also been reported after Py-GC-MS of nonwoodyfibers(Mazumder et al.,2005). This difference in timing of monolignol deposition would also be responsible for the within-tree variation of the S-G ratio observed in Eucalyptus camaldulensis wood(Ona et al.,1997;Yokoi et al.,1999).Pyrolysis of the MWLs isolated from the different E. globulus woods(Fig.2)released a similar distribution of lignin-derived compounds as from their respective woods,although the content of H units was lower (Table II).This is especially evident in the case of the MWL isolated from the1-month-old wood.However, we must note that MWL may reflect only the most accessible part of the native lignin in the plant,which may be depleted in highly condensed H lignin units. In any case,the same trend observed in the pyrolysis of woods,which indicates an increase of S lignin units and a decrease of H and G lignin units with maturity, was also observed in the pyrolysis products of MWL, supporting the in situ analysis and confirming a monolignol deposition order of H,G,and then S during E.globulus lignification.2D-NMR of Wood Gels and Their Isolated LigninsThe eucalypt wood samples from different growing periods were analyzed by2D-NMR(in the gel state)to overcome the drawbacks associated to polymer isola-tion,namely low yield and artifact formation,and the spectra were compared with those from the lignins (MWL)isolated from the same woods.The HSQC spectra of the different woods,and their MWLs,are shown in Figures3and4.Carbohydrate signals were predominant in the spectra of the whole wood.They included correlations in the range d C/d H 60to85/2.5to5.5,which partially overlapped with lignin signals,and the well-resolved anomeric corre-lations in the range d C/d H90to110/3.5to6.0.How-ever,lignin signals were also clearly observed in the HSQC spectra,including that of the youngest wood with the lowest lignin content.On the other hand,the spectra of the MWL presented mostly lignin signals that,in general terms,matched those observed in the HSQC spectra of the woods.Lignin and carbohydrate contours in the HSQC spectra were assigned by comparison with the litera-ture(A¨mma¨lahti et al.,1998;Ralph et al.,1999,2004b; Capanema et al.,2001,2004,2005;Balakshin et al.,2003, 2005;Liitia¨et al.,2003;Ha et al.,2005;Golovchenko et al.,2007;Ibarra et al.,2007a,2007b;del Rı´o et al., 2008,2009;Kim et al.,2008;Rencoret et al.,2008,2009; C¸etinkol et al.,2010;Kim and Ralph,2010;Ralph and Landucci,2010).The main lignin correlation assign-ments are listed in Table III,and the main lignin substructures found in the different eucalypt woods are depicted in Figure5.The assignments of the main carbohydrate signals are listed in Table IV.Table I.Abundances(%)of the main constituents of E.globuluswood at different growth stagesConstituents1Month18Months9YearsAcetone extractives8.60.50.6Water-soluble extracts 6.6 1.4 2.2Klason lignin13.017.519.8Acid-soluble lignin 2.7 5.2 4.7Cellulose(crystalline)25.036.729.9Glucan(amorphous)11.415.016.2Xylan12.214.017.1Arabinan 3.80.90.8Galactan 2.7 1.2 1.5Mannan0.90.40.4Rhamnan0.70.40.5Fucan0.30.10.1Uronic acids7.4 5.9 5.8Ash 4.60.70.4Lignin in Young and Adult Eucalypt PlantsSide Chain Region of the HSQC Spectra:Analysis of Interunit Linkages in LigninThe side chain region of the spectra gave useful information about the interunit linkages present in lignin.All the spectra showed prominent signals corresponding to b-O-4#ether units(substructure A). The C a-H a correlations in b-O-4#substructures were observed at d C/d H71to72/4.7to4.9ppm,while the C b-H b correlations were observed at d C/d H84/4.3and 86/4.1ppm for substructures linked to G and S units, respectively.The C g-H g correlations in b-O-4#sub-structures were observed at d C/d H59/3.4and3.7ppm, partially overlapped with other signals.In addition, strong signals for resinol(b-b#)substructures(B)were observed in all spectra,with their C a-H a,C b-H b,and the double C g-H g correlations at d C/d H85/4.7,54/3.1, and71/3.8and4.2,respectively.Phenylcoumaran (b-5#)substructures(C)were also found,although in lower amounts,the signals for their C a-H a and C b-H b correlations being observed at d C/d H87/5.5and54/ 3.5,respectively,and that of the C g-H g correlation overlapping with other signals around d C/d H63/3.7. Finally,small signals corresponding to spirodienone (b-1#/a-O-a’)substructures(D)could also be ob-served in the spectra,their C a-H a,C a#-H a#,C b-H b, and C b#-H b#correlations being at d C/d H82/5.1,87/4.4, 60/2.8,and79/4.1,respectively.Other small signals observed in the side chain region of the HSQC spectra corresponded to C b-H b correlations(at d C/d H84/5.2) of b-O-4#substructures bearing a C a carbonyl group (F)and the C g-H g correlation(at d C/d H62/4.1)as-signed to p-hydroxycinnamyl alcohol end groups(I). The HSQC spectra of the isolated MWL also reflected the same side chain signals observed in the spectra of the whole woods,although they were better resolved and some new signals were observed.These included small signals corresponding to C b-H b correlations(atdC/d H55/2.8)of conventional open b-1#substructures (E;Lundquist,1987)that were observed only in the MWL spectra.Some aliphatic(nonoxygenated)cross-signals appeared in the d C/d H10to40/0.5to2ppm region(not included in Fig.4),which were especially abundant in the1-month sample and couldincludecutin-like material(Deshmukh et al.,2005)or other polymethylenic structures.Aromatic Region of the HSQC Spectra:Analysis ofLignin UnitsThe main cross-signals in the aromatic region of the HSQC spectra corresponded to the aromatic rings of the different lignin units.Correlations from S,G,and H lignin units could be observed in the spectra of whole wood and their MWLs.The S lignin units showed a prominent signal for the C2,6-H2,6correlation at d C/d H 104/6.7,while the G units showed different correlations for C2-H2(d C/d H111/7.0),C5-H5(d C/d H115/6.7and 7.0),and C6-H6(d C/d H119/6.8).Signals corresponding to C2,6-H2,6correlations in C a-oxidized S lignin units(S#) were observed at d C/d H107/7.3and107/7.2.Signals of H lignin units at d C/d H115/6.7and128/7.2for C3,5-H3,5 and C2,6-H2,6respectively,were only detected in the HSQC spectra of the youngest wood sample(1month), in agreement with the higher presence of H units shown by Py-GC-MS.An extra and well-resolved sig-nal was also detected at d C/d H109/7.1in this sample (in both wood and MWL)that was tentatively assigned to a G-type structure.Olefinic cross-signals of fatty acid structures with one/two double bonds,similar to those from oleic acid(d C/d H130/5.3)and linoleic acid(d C/d H 128/5.3and130/5.3),were also identified(Fig.4).They probably originate from the cutin-like structures men-tioned in the previous section.The cross-signal of pyridine used to form the wood gels was also observed (d C/d H around124/7.3).Summary of Changes in Lignin Structure as Revealedby2D-NMRThe relative abundances of the H,G,and S lignin units,and those of the main interunit linkages(re-ferred to as per100aromatic units and as a percentage of the total side chains),calculated from the HSQC spectra of the whole woods and of their respective MWLs,are shown in Table V.The H-G-S composition and the S-G ratio(ranging from1.2in the youngest wood to3.3in the oldest one)are in closeagreementwith the data obtained by Py-GC-MS,indicating a decrease of H and G units and an increase of S lignin units during lignification.The content of H lignin in the isolated MWL was lower than in the respective wood samples,as already observed by Py-GC-MS.With respect to the different linkage types,all the lignins showed a predominance of b-O-4#units(A and F;69%–72%of total side chains)followed by b-b# resinol-type units(B;16%–19%)and lower amounts of b-5#phenylcoumaran-type(C;1%–5%)and b-1#spiro-Table II.Identification and relative molar abundance(%)of the lignin-derived compounds identified in the Py-GC-MS of E.globulus wood at the different growth stages and from their isolated MWLspounds1Month18Months9Years Wood MWL Wood MWL Wood MWL1Phenol 5.5 1.00.80.20.70.32Guaiacol8.78.4 4.0 3.6 3.5 3.83Methylphenol0.90.50.30.10.30.24Methylphenol 2.70.50.40.10.40.254-Methylguaiacol 2.97.3 1.7 3.5 2.2 3.06Dimethylphenol0.30.60.40.20.50.174-Ethylguaiacol 1.9 2.60.60.80.50.884-Vinylguaiacol9.710.0 4.5 3.9 4.9 3.39Eugenol0.90.50.60.60.60.610Propylguaiacol0.50.20.10.10.10.111Syringol11.813.414.110.711.413.112cis-Isoeugenol0.70.60.50.70.40.613trans-Isoeugenol 5.4 2.3 3.1 2.5 2.7 2.5144-Methylsyringol 3.99.07.99.09.68.515Vanillin0.9 2.60.7 2.40.8 1.916Propynylguaiacol0.40.40.5 1.00.40.417Propynylguaiacol0.40.50.6 1.10.40.518Homovanillin0.00.20.30.90.50.9194-Ethylsyringol 2.9 3.2 2.3 1.90.2 2.120Vanillic acid methyl ester0.00.30.00.30.00.321Acetoguaiacone0.6 1.60.8 1.30.6 1.3224-Vinylsyringol12.68.714.6 6.612.3 6.923Guaiacylacetone0.8 1.20.30.50.40.424Propylsyringol0.00.60.00.70.00.825Allylsyringol 2.40.4 3.4 1.6 3.5 1.726Propiovanillone0.10.40.10.30.10.327Guaiacylvinylketone0.00.40.0 1.10.0 1.028cis-Propenylsyringol 1.9 1.0 2.1 1.9 1.9 2.029Propynylsyringol0.50.6 1.8 1.7 2.4 1.130Propynylsyringol0.30.40.9 1.2 1.10.731Vanillic acid0.00.50.00.20.00.132trans-Propenylsyringol 6.4 3.011.2 6.511.47.133Dihydroconiferyl alcohol0.70.50.90.30.70.334Syringaldehyde 1.8 5.5 4.610.4 5.29.135Homosyringaldehyde0.00.00.7 2.3 3.2 3.136Syringic acid methyl ester0.10.30.20.60.20.537Acetosyringone 1.4 2.6 2.6 4.2 3.5 4.338trans-Coniferyl alcohol 3.00.00.80.50.30.839Coniferaldehyde0.5 1.30.8 1.6 1.1 1.440Syringylacetone 2.2 2.3 2.3 1.4 3.0 1.541Propiosyringone0.70.90.7 1.10.9 1.042Syringyl-3-oxo-propanal0.00.60.00.60.00.743Syringylvinylketone0.10.10.2 1.20.3 1.144Syringic acid0.00.70.00.70.00.545Dihydrosinapyl alcohol0.60.2 1.10.4 1.20.546cis-Sinapyl alcohol0.50.00.60.50.40.747cis-Sinapaldehyde0.00.10.10.10.10.148trans-Sinapyl alcohol 1.30.00.60.70.3 1.849trans-Sinapaldehyde0.7 2.0 4.8 6.0 5.7 5.7Total H9.4 2.6 1.90.7 1.90.8Total G38.542.021.227.520.424.3Total S52.155.476.971.877.674.9 Rencoret et al.dienone-type (D;1%–5%)units.The conventional open b -1#structures (E;Lundquist,1987),which were ob-served only in the MWL samples,ranged from 1%to 2%.Some interesting information could be obtained from the wood NMR data.First,it is clear that the changes in monolignol availability during growth influence not only the unit composition but also af-fect the abundances of some interunit linkages.For example,despite the relative percentage of the b -O -4#linkages remaining relatively constant with growth,their abundances per aromatic unit slightly increases (from 46to 50linkages per 100aromatic units),and the same happens with the b -b #resinol-type structures (which increase from 10to 12linkages per 100aro-matic units),probably as a consequence of the increase of S units.Interestingly,the ratio between theabun-Figure 3.HSQC NMR spectra (d C /d H 45–135/2.5-8.0ppm)of the E.globulus wood samples at different growth stages after forming a gel in DMSO-d 6:pyridine-d 5(4:1).See Table III for lignin signal assignment and Figure 5for the main lignin structures identified.The assignments of the carbohydrate signals are listed in Table IV.Figure 4.HSQC NMR spectra (d C /d H 45–135/2.5-8.0ppm)of the MWLs isolated from the E.globulus wood samples at different growth stages.See Table III for lignin signal assignment and Figure 5for the main lignin structures identified.Olefinic cross-signals of unsaturated fatty acid structures (U F )were also identified.Lignin in Young and Adult Eucalypt Plantsdances of b-O-4#and b-b#resinol-type structures seems to remain more or less constant along lignifica-tion.The spirodienone-b-1#ratio also increased during growth(from0.8to3.2).In contrast,the abundance of phenylcoumaran structures decreases with lignifica-tion,which is most probably related to the decrease in G lignin observed.On the other hand,a small but continuous oxidation of the C a of the lignin side chain (from one to four C a oxidized b-O-4#linkages per100 aromatic units)occurs during lignification,probably as a result of wood aging.Finally,the abundance of cinnamyl alcohol end groups decreases with lignifica-tion,as also observed by Py-GC-MS.Hemicellulose PolysaccharidesThe HSQC spectra also reveal differences in the carbohydrates present in eucalypt wood after the different growth periods,which are observed in two differentiated regions of the spectra:the aliphatic-oxygenated region and the region corresponding to the anomeric correlations(Fig.3).The aliphatic-oxy-genated region shows strong signals from carbohy-drates,including naturally acetylated hemicelluloses. Among them,signals from O-acetylated xylans(3-O-acetyl-b-D-xylopyranoside[X#3]and2-O-acetyl-b-D-xylopyranoside[X#2])and,at the earlier stages of growth,O-acetylated mannans(2-O-acetyl-b-D-man-nopyranoside[M#2])were observed.Other signals in this region correspond to C2-H2,C3-H3,C4-H4,and C5-H5correlations of xylans(b-D-xylopyranoside[X2,X3, X4,and X5]),which overlap with unassigned cross-signals of other pentose and hexose polysaccharide units(note that crystalline cellulose is practically“in-visible”in the HSQC spectra of the wood gels due to its reduced mobility),and the C4-H4correlation for 4-O-methyl-a-D-GlcUA(U4).However,the main differences are observed in the carbohydrate anomeric region of the spectra,which have been depicted in detail in Figure6.The main C1-H1correlation signals in this region,which are listed in Table IV,were assigned according to Kim and Ralph (2010),together with some additional references for pectin(Ha et al.,2005;Golovchenko et al.,2007, Hedenstro¨m et al.,2008).Cross-signals from arabinans (Ar1and Ar1(T)),mannans(M1),galactans(Ga1),xylans (X1,a X1(R),and b X1(R)),and glucans including non-crystalline cellulose(Gl1),as well as signals from O-acetylated mannans and xylans(M#1and X#1)and from the4-O-methyl-a-D-glucuronic(U1)and galact-uronic(UGA1)acids(the latter forming part of pectin as the methyl ester)are readily apparent and well resolved in this region of the spectra.A small signal ofa-Rha(R1)units was also observed,especially in the 18-month-old wood.Interestingly,the signals of arab-inans,mannans,and galactans,which are observed inTable III.Assignments of the lignin13C-1H correlation signals in the HSQC spectra of E.globuluswood at the different growth stages and their isolated MWLsLabels d C/d H AssignmentppmC b53.5/3.46C b-H b in phenylcoumaran substructures(C)B b53.5/3.06C b-H b in resinol substructures(B)E b55.0/2.75C b-H b in b-1#substructures(E)-OMe55.6/3.73C-H in methoxylsA g59.4/3.40and3.72C g H g in b-O-4#substructures(A)D b59.6/2.75C b-H b in spirodienone substructures(D)I g61.3/4.09C g-H g in cinnamyl(sinapyl/coniferyl)alcohol endgroups(I)C g62.5/3.72C g-H g in phenylcoumaran substructures(C)B g71.0/3.83and4.19C g-H g in resinol substructures(B)A a71.7/4.86C a-H a in b-O-4#substructures(A)D b#79.3/4.11C b#-H b#in spirodienone substructures(D)D a81.2/5.09C a H a in spirodienone substructures(D)A b(G)83.5/4.28C b-H b in b-O-4#linked to a G unit(A)F b83.8/5.23C b-H b in oxidized(C a=O)b-O-4#substructures(F)B a84.8/4.67C a-H a in resinol substructures(B)D a#84.8/4.75C a#H a#in spirodienone substructures(D)A b(S)85.8/4.11C b-H b in b-O-4#linked to a S unit(A)C a86.8/5.46C a-H a in phenylcoumaran substructures(C)S2,6103.8/6.69C2,6-H2,6in etherified syringyl units(S)S#2,6106.6/7.32and7.19C2,6-H2,6in oxidized(C a=O)phenolic syringyl units(S#)G2110.9/6.99C2-H2in guaiacyl units(G)D2#113.2/6.27C2#H2#in spirodienone substructures(D)H3,5114.9/6.74C3,5-H3,5in p-hydroxyphenyl units(H)G5/G6114.9/6.72and6.94;118.7/6.77C5-H5and C6-H6in guaiacyl units(G)D6#118.9/6.09C6#H6#in spirodienone substructures(D)H2,6128.0/7.23C2,6-H2,6in p-hydroxyphenyl units(H)Rencoret et al.。

核桃壳木质素的1H-NMR分析*郑志锋1,邹局春2,陈浪2,张宏健2*,凌敏2(1.东北林业大学,黑龙江哈尔滨 150040;2. 西南林学院,云南昆明 650224)摘要:在核桃壳磨木木质素(MWL)提取纯化的基础上,对纯化的核桃壳磨木木质素进行了C、H、O及OCH3含量的测定,并利用1H-NMR对核桃壳木质素基本化学结构进行研究。

结果表明:(1)核桃壳木质素的C、H、O含量分别为[C]=67.15%,[H]=5.73%,[O]=27.12%,甲氧基含量为18.19%;(2)核桃壳木质素C9经验式为C9H9.22O1.99(OCH3)1.05,其C9单元结构的相对分子量为181.61;(3)核桃壳木质素属GS型木质素,其中G型木质素占多数,为80.68%;(4)核桃壳木质素中酚羟基(OH ph)和脂肪族羟基(OH aliph)分别占总羟基数的32.21%和67.79%;(5)核桃壳木质素中存在较多的β-O-4、β-5和β-β结构。

关键词:核桃壳;木质素;元素分析;甲氧基;1H-NMR核桃壳是核桃取仁后的废弃物,目前大都被当作农户燃料,利用价值低,且污染环境。

随着全球资源的日益紧张,核桃壳这种林产废弃物的利用将会受到关注。

根据本课题组的前期研究表明[1],核桃壳最主要的成份为木质素。

因此,本研究在利用Björkman方法对核桃壳磨木木质素(MWL)进行提取和Lundguist方法对其进行提纯的基础上[2],对其进行C、H、O及OCH3含量的测定,并利用1H-NMR 对核桃壳木质素基本化学结构进行研究,为深入研究核桃壳木质素的特性提供支持,并为利用核桃壳全壳制备胶粘剂提供基础依据。

1 材料与方法1.1 材料漾濞泡核桃(Juglans Sigillata Dode)的核桃壳采自云南省漾濞县,粉碎至150目以下,烘箱干燥至绝干,密封贮存备用。

本实验采用的漾濞泡核桃壳木素含量(酸不溶木素)53.81%,纤维素(硝酸-乙醇法)含量22.06%,多戊聚糖含量19.90%。

xx微生物活性物质的研究进展专业:生物工程姓名:李振森学号:02海洋是生命的发源地,约占地球表面积的71%,其中生物种类20多万种,其多样性远远超过陆地生物的多样性。

由于海洋环境具有高盐度、高压、低营养、低温和无光照等条件,从而形成了海洋生物与陆地生物不同的生长方式和代谢系统。

近年来,随着人们对海洋生物研究的不断深入,发现了多种多样的生物及许多具有新颖、特异化学结构的生物活性物质。

海洋生物活性物质主要包括生物信息物质、生理活性物质、海洋生物毒素及生物功能材料等。

目前,从海洋生物中已相继发现300余种新型化合物,结构新颖并具有多样性:有枯类、聚醚类、当醇类、皂昔类、生物碱、多糖、小分子肤、核酸及蛋白质等,并具有丰富的生理及药理活性,包括抗菌、抗肿瘤、抗病毒、防治心血管疾病、延缓衰老及免疫调节等多种功能。

多年来,国内外一直致力于这方面的研究,试图从中开发结构明确,疗效肯定的新型生物活性物质,以用于攻克人类面临的重大疑难疾病,其中具有高生物活性和高选择性的海洋生物毒素备受重视,成为研究的热点。

近年来,海洋生物毒素是海洋生物活性物。

1、xx抗肿瘤活性物质1.1xx放线菌海洋有着极其丰富的放线菌资源,具有抗菌活性的海洋微生物中约有45%来源于放线菌。

就目前的报道,海洋放线菌产生的活性物质大部分来源于小单孢菌属和链霉菌属。

由于海洋放线菌所产生的代谢产物具有功能独特、结构新颖等特点而受到人们的广泛关注,例如抗真菌、抗疟等功能。

另一方面,陆生放线菌的不断开发,发现新的活性物质的可能性越发减少,迫使人们将目光转向海洋放线菌的开发。

1991年Fenical小组[1]首次发现一属全新的需盐生长的特殊海洋放线菌Salinispora,其广泛存在于热带和亚热带海泥中。

2003~2005年Fenical小组从[-]菌株Salinispora tropicaCNB-392中分离得到10个结构新颖的化合物24,其中化合物Salinosporamide A(1)[3]具有广阔的成药前景,对人结肠癌细胞的IC50为[5-6]0.035nmol /L,已作为癌症药物进入临床前研究。

巨龙竹木质素化学结构研究成聃睿;史正军;杨海艳;缪正调;刘蔚漪;郑志锋;辉朝茂;邓佳【摘要】为解析巨龙竹木质素化学结构特征,采用高效阴离子交换色谱、凝胶色谱、傅里叶变换红外光谱、核磁共振等现代仪器分析技术,对巨龙竹木质素样品进行检测.结果表明:弱酸性环境有利于打断巨龙竹木质素与半纤维素之间的化学联接而使木质素更易于分离,且对木质素中的主要联接键破坏较小;巨龙竹木质素含有紫丁香基(S)、愈创木基(G)以及对羟基苯基(H)3种基本结构单元,属于禾草类木质素;巨龙竹木质素基本单元间化学联接键以β-O-4'结构为主,并存在一定量的β-β'、β-5'、β-1'化学联接.【期刊名称】《世界竹藤通讯》【年(卷),期】2015(013)002【总页数】6页(P1-6)【关键词】巨龙竹;木质素;化学结构;结构表征;核磁共振【作者】成聃睿;史正军;杨海艳;缪正调;刘蔚漪;郑志锋;辉朝茂;邓佳【作者单位】西南林业大学云南省高校生物质化学炼制与合成重点实验室昆明650224;西南林业大学云南省高校生物质化学炼制与合成重点实验室昆明650224;西南林业大学云南省高校生物质化学炼制与合成重点实验室昆明650224;西南林业大学云南省高校生物质化学炼制与合成重点实验室昆明650224;教育部省部共建西南山地森林资源保育与利用重点实验室昆明650224;西南林业大学云南省高校生物质化学炼制与合成重点实验室昆明650224;教育部省部共建西南山地森林资源保育与利用重点实验室昆明650224;教育部省部共建西南山地森林资源保育与利用重点实验室昆明650224【正文语种】中文中国是世界竹类资源最丰富的国家,竹子种类和竹林面积居世界首位,具有发展竹产业的优越资源条件[1]。

巨龙竹(Dendrocalamus sinicus)属禾本科(Gramineae)竹亚科(Bambusoideae)牡竹属(Dendrocalamus)竹种,原产于云南南部西双版纳、德宏、普洱、保山等地区,1982年首次在云南西双版纳被发现并命名[2]。

第53卷第4期 辽 宁 化 工 Vol.53,No. 4 2024年4月 Liaoning Chemical Industry April,2024基金项目: 2023年“挑战杯”沈阳化工大学大学生课外学术科技作品竞赛(项目编号:K -03)。

收稿日期: 2023-03-03 作者简介: 李昶(2003-),男,辽宁省沈阳市人,研究方向:废弃物资源化利用。

造纸黑液治理现状及处理草浆黑液新思路李昶, 杨兴鑫, 阎慧鑫, 孙紫琳, 马娇*, 宋兴飞*(沈阳化工大学 化学工程学院,辽宁 沈阳 110142)摘 要: 介绍了中国造纸行业现状,总结了黑液处理技术的工艺及特点,针对草浆造纸黑液处理的可行性进行了分析。

最后,提出了采用循环流化床低温气化技术处理草浆造纸黑液的新思路,该方法能够解决低碳转化率的问题,有望成为处理草浆造纸黑液的最佳选择。

关 键 词:黑液;治理;循环流化床;低温气化中图分类号:X793 文献标识码: A 文章编号: 1004-0935(2024)04-0602-04我国是纸业生产和消费最大的国家,2021年全国纸浆生产总量8 177万t,废纸浆5 814万t,木浆1 809万t,非木浆554万t [1]。

制浆工艺主要包括原料制备、制浆、漂白和化学品回收,蒸煮过程中产生的废液在整个制浆工艺排放污染物中属于浓度最高、色度最深的废液,统称为黑液[2],占造纸行业废水总排放量的90.0%[3]。

黑液含有大量的木质素、半纤维素、色素、糖类、残碱及其他溶出物,具有色度大、味臭、碱度大和有机物含量高等特点,是一种很难治理的环境污染物[4]。

本文综述了造纸黑液的处理技术、工艺及其优缺点,特别是针对草浆黑液的特点,提出了资源化处理的新思路。

1 造纸黑液处理技术简介20纪70年代,汤姆林森发明并设计了黑液碱回收锅炉,生产的蒸汽和碱被回收并用于造纸流程,该设备成为制浆厂回收黑液中热能和化学品的主要设备。

木质素的分离提取最新研究进展摘要:综述现有使用酸、碱、超临界、两水相、离子液等手段分离提取木质素的方法,指出现有分离提取技术的发展方向与趋势.讨论了在微波加热条件下以乙二醇水溶液为溶剂,采用高沸醇溶剂法从胡萝卜中提取木质素的方法。

实验结果表明,该方法提取木质素,实现了高效、无污染的效果,具有“节能减排”的意义。

关键词:木质素;胡萝卜;分离提取;高沸醇溶剂法中图分类号:TQ936。

2;文献标识码:AProgress in Studying the Extraction of LigninAbstract:The isolation of lignin by different approaches such as acid,alkali,supercritical extraction,aqueous biphasic system and ionic liquid extraction are reviewed.Lignin was extracted from carrot root by microwave radiators with high boiling solvent(HBS)80%ethylene glycol aqueous solutions as solvent.To achieve efficient,non-polluting effect of the“energy saving emission reduction”of great significance.Keywords:Lignin;Carrot root;Extraction;HBS1 前言木质素是具有酚型结构的天然高分子物质,广泛存在于木本植物、草本植物、维管植物中,是自然界中在数量上仅次于纤维素的第二大天然高分子材料,是工业上唯一能从可再生资源中获取的芳香族化合物。

木质素在建材工业、石油工业、轻工业、农业中都有广泛的应用[1]。

CHEMICAL INDUSTRY AND ENGINEERING PROGRESS 2017年第36卷第8期·2910·化 工 进展五种甘蔗渣分离木质素热解特性及动力学崔兴凯1,赵雪冰1,2,刘德华1,2(1清华大学化学工程系,北京 100084;2东莞深圳清华大学研究院创新中心,广东 东莞 523808) 摘要:木质素是自然界中最丰富的芳香类化合物,也是制浆造纸和木质纤维素生物炼制过程的主要副产物。

热解是将木质素资源化、能源化利用的一个有效途径。

但由于分离方法不同,所得的木质素产品具有不同的热解特性。

本文通过有机酸处理、碱处理和氧化处理从甘蔗渣中分离得到5种木质素,即乙酸木质素(AAL )、Acetosolv 木质素(AsL )、Milox 木质素(ML )、过氧乙酸木质素(PAAL )和碱木质素(AL )。

采用差示扫描量热(DSC )和热重分析(TGA )对5种木质素的热解性质进行了研究。

发现5种木质素的热解过程均可分为水分脱除、玻璃化转变、热解和缓慢结焦4个阶段。

采用非等温的Coats-Redfern 积分法对热重数据进行动力学拟合。

结果表明,PAAL 在200~700℃范围内的热解为二级动力学反应,另外4种木质素则在250~700℃范围内为二级动力学反应。

5种木质素的热解表观活化能分别为AAL 33.33kJ/mol 、AsL 36.36kJ/mol 、ML 31.10kJ/mol 、PAAL 24.74kJ/mol 以及AL 36.93 kJ/mol 。

关键词:甘蔗渣;分离木质素;热解;动力学;分子量中图分类号:O636.2;TQ351 文献标志码:A 文章编号:1000–6613(2017)08–2910–06 DOI :10.16085/j.issn.1000-6613.2017-0002Pyrolysis characteristics and kinetics of five isolated lignins fromsugarcane bagasseCUI Xingkai 1,ZHAO Xuebing 1,2,LIU Dehua 1,2(1Department of Chemical Engineering ,Tsinghua University ,Beijing 100084,China ; 2 Tsinghua Innovation Centerin Dongguan ,Dongguan 523808,Guangdong ,China )Abstract :Lignin is the most abundant natural aromatic polymer on earth. It is also a major byproduct of pulp and papermaking industry and lignocellulose biorefinery. Pyrolysis is one of the most promising ways to utilize lignin for production of fuels and chemicals. However ,the pyrolysis characteristics of lignin products are greatly dependent on the isolation methods. In present work ,five lignin products were isolated from sugarcane bagasse by organic acid ,alkaline ,and oxidative pretreatments ,respectively ,namely acetic acid lignin (AAL ),acetosolve lignin (AsL ),milox lignin (ML ),peracetic acid lignin (PAAL )and alkaline lignin (AL ). The pyrolysis of these isolated lignins was investigated using differential scanning calorimetry (DSC )and thermogravimetric analysis (TGA ). As indicated by TGA ,all of the lignin products showed four stages of weight losses ,namely water removal ,glass transition ,pyrolysis to small molecules and slow coking. The pyrolysis kinetics was analyzed by Coats-Redfern method. The results indicated that the pyrolysis process could be described as a second-order reaction in temperature range of 200—700℃ for PAAL ,and 200―700℃ for the other four lignins. The activation energies were determined as 33.33kJ/mol ,36.36kJ/mol ,31.10kJ/mol ,维素基生物源。

Study of lignin structures andapplicationsLignin是一种天然高分子杂质,其属于木质素类。

它是一种复杂的有机聚合物,由不同种类的芳香化合物组成,例如苯丙烷,甲苯和甲基间苯二酚等。

Lignin分布在植物细胞的细胞壁中,它是三种天然高分子化合物中的第二种,其它两种是纤维素和半纤维素。

研究表明,不同植物的Lignin结构不同,主要受到植物的生长环境、类型和生长阶段等因素的影响。

一般来说,Lignin结构可分为三种类型:Guaiacyl(G)型、Syringyl(S)型和p-羟基苯丙二酚(H)型。

G和S型Lignin分别由G和S二聚体形成,而H-Lignin与G-Lignin的差异在于其含有一个或多个p-O-1结合的羟基苯丙醛单元。

由于Lignin的复杂性和多样性,研究者们一直在努力寻找新的应用领域。

目前,Lignin已经被广泛应用于多个方面,包括生物燃料、化学、医药和纸浆工业等领域。

Lignin的生物燃料应用Lignin可以成为生物质能源的重要来源。

在生物燃料领域,Lignin通常作为生物质(包括木质材料和农作物残留物)的副产物,它的使用有几个优点。

首先,Lignin的加热值很高,其加热能力比煤高90%,可以为能源制造商节约大量燃料费用。

其次,Lignin是可再生资源,与煤、天然气等不可再生资源相比具有更低的成本和环境影响。

Lignin的化学应用Lignin还可以用于制造一系列有机化学产品,包括生物塑料、表面活性剂和酸解剂等。

Lignin的这些特性使其能够成为多次循环使用的材料。

此外,使用Lignin制造这些化学品还具有多种优点。

例如,Lignin是一种天然的产物,可以减少化学污染和能源损失,其化学属性同时也可以改善可持续生产的节能效果。

Lignin的医药应用Lignin也被发现有一些医学应用。

例如,Lignin结合药物可以延长药物在人体内的存活时间,从而减少药物的数量和使用时间。

核桃壳木质素的1H-NMR分析*郑志锋1,邹局春2,陈浪2,张宏健2*,凌敏2(1.东北林业大学,黑龙江哈尔滨 150040;2. 西南林学院,云南昆明 650224)摘要:在核桃壳磨木木质素(MWL)提取纯化的基础上,对纯化的核桃壳磨木木质素进行了C、H、O及OCH3含量的测定,并利用1H-NMR对核桃壳木质素基本化学结构进行研究。

结果表明:(1)核桃壳木质素的C、H、O含量分别为[C]=67.15%,[H]=5.73%,[O]=27.12%,甲氧基含量为18.19%;(2)核桃壳木质素C9经验式为C9H9.22O1.99(OCH3)1.05,其C9单元结构的相对分子量为181.61;(3)核桃壳木质素属GS型木质素,其中G型木质素占多数,为80.68%;(4)核桃壳木质素中酚羟基(OH ph)和脂肪族羟基(OH aliph)分别占总羟基数的32.21%和67.79%;(5)核桃壳木质素中存在较多的β-O-4、β-5和β-β结构。

关键词:核桃壳;木质素;元素分析;甲氧基;1H-NMR核桃壳是核桃取仁后的废弃物,目前大都被当作农户燃料,利用价值低,且污染环境。

随着全球资源的日益紧张,核桃壳这种林产废弃物的利用将会受到关注。

根据本课题组的前期研究表明[1],核桃壳最主要的成份为木质素。

因此,本研究在利用Björkman方法对核桃壳磨木木质素(MWL)进行提取和Lundguist方法对其进行提纯的基础上[2],对其进行C、H、O及OCH3含量的测定,并利用1H-NMR 对核桃壳木质素基本化学结构进行研究,为深入研究核桃壳木质素的特性提供支持,并为利用核桃壳全壳制备胶粘剂提供基础依据。

1 材料与方法1.1 材料漾濞泡核桃(Juglans Sigillata Dode)的核桃壳采自云南省漾濞县,粉碎至150目以下,烘箱干燥至绝干,密封贮存备用。

本实验采用的漾濞泡核桃壳木素含量(酸不溶木素)53.81%,纤维素(硝酸-乙醇法)含量22.06%,多戊聚糖含量19.90%。