Effect of Organic and Bio- Fertilizer Application on Rice - Soybean- Rice Cropping System

- 格式:pdf

- 大小:910.23 KB

- 文档页数:17

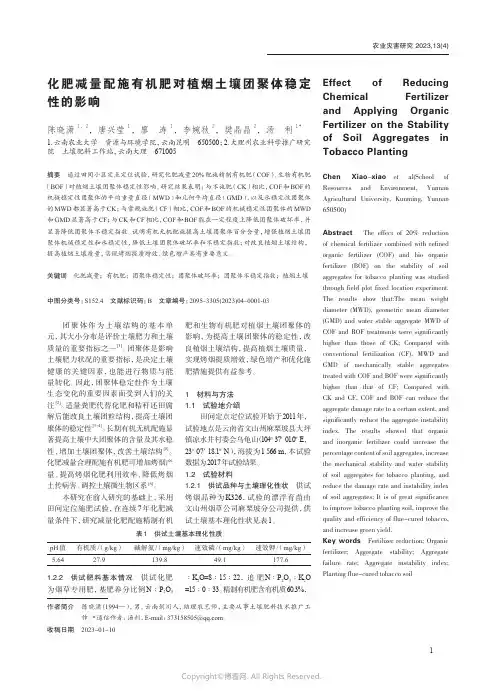

农业灾害研究 2023,13(4)化肥减量配施有机肥对植烟土壤团聚体稳定性的影响陈晓潇1,2,唐兴莹1,廖 涛1,李婉秋2,樊晶晶2,汤 利1*1.云南农业大学资源与环境学院,云南昆明 650500;2.大理州农业科学推广研究院土壤肥料工作站,云南大理 671005摘要 通过田间小区定点定位试验,研究化肥减量20%配施精制有机肥(COF)、生物有机肥(BOF)对植烟土壤团聚体稳定性影响。

研究结果表明:与不施肥(CK)相比,COF和BOF的机械稳定性团聚体的平均重量直径(MWD)和几何平均直径(GMD),以及水稳定性团聚体的MWD都显著高于CK;与常规施肥(CF)相比,COF和BOF的机械稳定性团聚体的MWD和GMD显著高于CF;与CK和CF相比,COF和BOF能在一定程度上降低团聚体破坏率,并显著降低团聚体不稳定指数。

说明有机无机配施提高土壤团聚体百分含量,增强植烟土壤团聚体机械稳定性和水稳定性,降低土壤团聚体破坏率和不稳定指数;对改良植烟土壤结构,提高植烟土壤质量,实现烤烟提质增效、绿色增产具有重要意义。

关键词 化肥减量;有机肥;团聚体稳定性;团聚体破坏率;团聚体不稳定指数;植烟土壤中图分类号:S152.4 文献标识码:B 文章编号:2095–3305(2023)04–0001-03团聚体作为土壤结构的基本单元,其大小分布是评价土壤肥力和土壤质量的重要指标之一[1]。

团聚体是影响土壤肥力状况的重要指标,是决定土壤健康的关键因素,也能进行物质与能量转化。

因此,团聚体稳定性作为土壤生态变化的重要因素而受到人们的关注[2]。

适量粪肥代替化肥和秸秆还田腐解后能改良土壤团粒结构,提高土壤团聚体的稳定性[3-4]。

长期有机无机配施显著提高土壤中大团聚体的含量及其水稳性,增加土壤团聚体,改善土壤结构[5]。

化肥减量合理配施有机肥可增加烤烟产量、提高烤烟化肥利用效率、降低烤烟土传病害、调控土壤微生物区系[6]。

英语作文实验报告Experiment Report。

Title: The Effects of Different Fertilizers on Plant Growth。

Objective:The objective of this experiment is to determine the effects of different types of fertilizers on the growth of plants. We will be testing three different types of fertilizers: organic fertilizer, synthetic fertilizer, and a control group with no fertilizer. We will measure the height, number of leaves, and overall health of the plants to determine which type of fertilizer is most effective in promoting plant growth.Materials:12 small pots。

Potting soil。

12 bean seeds。

Organic fertilizer。

Synthetic fertilizer。

Watering can。

Measuring tape。

Notebook and pen。

Procedure:1. Fill each pot with potting soil and plant one bean seed in each pot.2. Label four pots as organic fertilizer, four pots as synthetic fertilizer, and four pots as the control group.3. Apply the appropriate fertilizer to each group according to the instructions on the packaging.4. Water the plants as needed and ensure they receive adequate sunlight.5. Measure the height of the plants, count the numberof leaves, and assess the overall health of the plantsevery three days for a period of three weeks.6. Record the data in a notebook and compare theresults at the end of the experiment.Results:After three weeks of observation, the plants in the organic fertilizer group showed the most significant growth. They were the tallest, had the most leaves, and appeared to be the healthiest overall. The plants in the synthetic fertilizer group also showed some growth, but not as muchas the organic fertilizer group. The control group, whichreceived no fertilizer, showed the least amount of growth and appeared to be less healthy compared to the other groups.Conclusion:Based on the results of this experiment, it can be concluded that organic fertilizer is the most effective in promoting plant growth. The plants that received organic fertilizer grew taller, had more leaves, and appeared to be healthier overall compared to the other groups. Synthetic fertilizer also had a positive effect on plant growth, but not as much as organic fertilizer. The control group, which received no fertilizer, showed the least amount of growth and appeared to be less healthy. Therefore, it is important to use organic fertilizer to promote the growth of plants.Discussion:One possible explanation for the effectiveness of organic fertilizer is that it provides a more balanced and natural source of nutrients for the plants. Syntheticfertilizers, on the other hand, may contain higher levels of certain nutrients that can be harmful to the plants if not used properly. It is also important to consider the long-term effects of using synthetic fertilizers on the environment, as they can contribute to soil and water pollution. This experiment highlights the importance of using organic fertilizers to promote plant growth in a sustainable and environmentally friendly way.In conclusion, this experiment has shown that organic fertilizer is the most effective in promoting plant growth. The results of this experiment can be used to guide gardeners and farmers in choosing the most suitablefertilizer for their plants, while also promoting sustainable and environmentally friendly practices. Further research can be conducted to explore the specific nutrients and mechanisms that make organic fertilizer more effective, as well as its long-term effects on plant growth and the environment.。

一、教育经历1982.9-1986.6,湖南农业大学学习,获学士学位。

1990.9-1991.6,武汉大学学习分析化学研究生课程。

2003.9-2003.12,爱尔兰国立大学Cork College高级访问学者二、工作经历1986.7-2002.7,湖南农业大学,助教、讲师、副教授;2002.8-2004.2,湖南农业大学,教授;2004.2-今,南京农业大学,教授。

三、获奖情况1.经济作物抑病型土壤微生物区系调控技术创建与应用,2019年,农业农村部2018-2019年度神农中华农业科技奖,一等奖,第四完成人(2019-KJ013-1-R04)2.利用秸秆和废弃动物蛋白制造木霉固体菌种及木霉全元生物有机肥,2018年,教育部技术发明奖,一等奖(2018-148),第二完成人3.一种木霉直接发酵作物秸秆制备木霉固体菌种的方法及制备的产品,2018年,国家知识产权局中国专利奖,优秀奖,第二完成人4.病死畜禽动物零污染无害化处理和高附加值资源化利用工艺,2017年,国家知识产权局中国专利奖,优秀奖,第二完成人5.有机肥与土壤微生物创新团队,2015年,农业部中华农业科技奖优秀创新团队奖(等同于科研成果一等奖),第六完成人(TD2015-R-024-06)6.有机肥作用机制和产业化关键技术研究与推广,2015年,国务院,国家科技进步奖,二等奖,第十完成人(2015-J-25101-2-08-R10)7.克服土壤连作生物障碍的微生物有机肥及其新工艺,2011年,中华人民共和国国务院国家技术发明奖,二等奖,第四完成人(2011-F-251-2-01-R04)8.一种能防除连作作物枯萎病的拮抗菌及其微生物有机肥料,2010年,国家知识产权局中国专利奖,金奖,第三完成人9.有机肥作用机制和产业化关键技术研究与推广,2013年,教育部科技进步奖,一等奖(2013-198),第十完成人10.克服土壤连作障碍的微生物有机肥产品研制与产业化开发,2010 年,江苏省人民政府,江苏省科学技术奖,一等奖,第四完成人(2010-1-17-R4)11.一种能防除连作作物枯萎病的拮抗菌及其微生物肥料,2009 年,江苏省知识产权局和江苏省财政厅,江苏省专利奖,金奖,第三完成人四、教学情况连续多年主讲农业资源与环境本科专业的专业课程《植物营养学》理论和资源环境分析系列实验Ⅱ,为丰富植物营养学实习课程的内容,多次参与选点,制定更新实习计划。

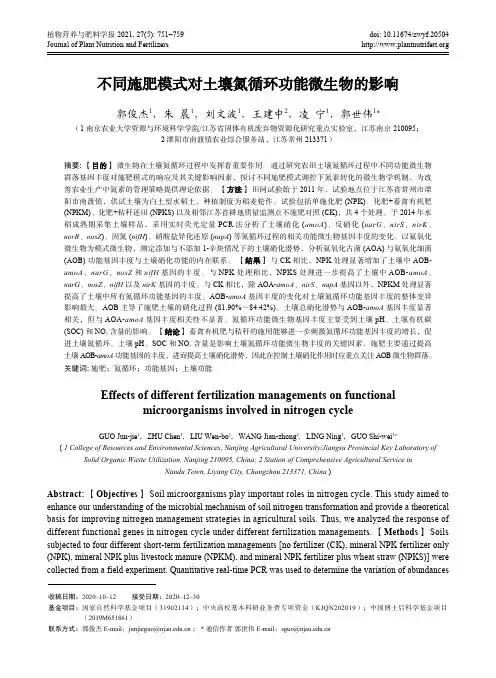

不同施肥模式对土壤氮循环功能微生物的影响郭俊杰1,朱 晨1,刘文波1,王建中2,凌 宁1,郭世伟1*(1 南京农业大学资源与环境科学学院/江苏省固体有机废弃物资源化研究重点实验室,江苏南京 210095;2 溧阳市南渡镇农业综合服务站,江苏常州 213371)摘要: 【目的】 微生物在土壤氮循环过程中发挥着重要作用。

通过研究农田土壤氮循环过程中不同功能微生物群落基因丰度对施肥模式的响应及其关键影响因素,探讨不同施肥模式调控下氮素转化的微生物学机制,为改善农业生产中氮素的管理策略提供理论依据。

【方法】 田间试验始于2011年,试验地点位于江苏省常州市溧阳市南渡镇,供试土壤为白土型水稻土,种植制度为稻麦轮作。

试验包括单施化肥 (NPK)、化肥+畜禽有机肥(NPKM)、化肥+秸秆还田 (NPKS) 以及相邻江苏省耕地质量监测点不施肥对照 (CK),共 4个处理。

于2014年水稻成熟期采集土壤样品,采用实时荧光定量PCR 法分析了土壤硝化 (amoA )、反硝化 (narG 、nirS 、nirK 、norB 、nosZ )、固氮 (nifH )、硝酸盐异化还原 (napA ) 等氮循环过程的相关功能微生物基因丰度的变化。

以氨氧化微生物为模式微生物,测定添加与不添加1-辛炔情况下的土壤硝化潜势,分析氨氧化古菌 (AOA) 与氨氧化细菌(AOB) 功能基因丰度与土壤硝化功能的内在联系。

【结果】 与CK 相比,NPK 处理显著增加了土壤中AOB-amoA 、narG 、nosZ 和nifH 基因的丰度。

与NPK 处理相比,NPKS 处理进一步提高了土壤中AOB-amoA 、narG 、nosZ 、nifH 以及nirK 基因的丰度。

与CK 相比,除AOA-amoA 、nirS 、napA 基因以外,NPKM 处理显著提高了土壤中所有氮循环功能基因的丰度。

AOB-amoA 基因丰度的变化对土壤氮循环功能基因丰度的整体变异影响最大。

文章编号:1673-887X(2023)04-0005-05生物有机肥对黍子生长产量及营养品质的影响王磊1,郑竹胜2,王旭1,刘俊峰1,王崇铭1,刘悦琦1,席甜3(1.繁峙县综合检验检测中心,山西繁峙034300;2.繁峙县农业农村局,山西繁峙034300;3.忻州市综合检验检测中心,山西忻州034000)摘要为提高黍子产量和品质,推动当地黍子产业高质量发展,指导黍子生产合理施肥,本试验通过复合肥、微肥的不同配比模拟不同的种植环境,研究了生物有机肥使用量对黍子产量、生长指标、营养品质及经济收益的影响。

结果表明:施用生物有机肥对黍子产量、株高、茎基粗、密度,以及黍米还原糖、蛋白质和脂肪含量有显著影响,对黍子穗质量、穗长、百粒质量和黍米直链淀粉无显著影响。

综合比较分析各指标得出,考虑增产和较高的经济效益时生物有机肥的最佳施用量为300kg/hm2;考虑抗倒伏性和黍米营养品质时,建议施生物有机肥450kg/hm2。

关键词黍子;生物有机肥;产量;生长指标;营养品质中图分类号S516文献标志码A doi:10.3969/j.issn.1673-887X.2023.04.001Effects of Bio-organic Fertilizers on the Growth,Yield and Nutritional Quality of Millet Wang Lei1,Zheng Zhusheng2,Wang Xu1,Liu Junfeng1,Wang Chongming1,Liu Yueqi1,Xi Tian3(1.Fanshi Comprehensive Testing Center,Fanshi034300,Shanxi,China;2.Fanshi Agricultural and Rural Bureau,Fanshi034300,Shanxi,China;3.Xinzhou Comprehensive Testing Center,Xinzhou034000,Shanxi,China)Abstract:In order to improve the yield and quality of millet,promote the high-quality development of the local millet industry,and guide the production of millet with reasonable fertilization.In this experiment,the effects of bio-organic fertilizer on the yield, growth index,nutritional quality and economic benefits of millet were studied by simulating different ratios of compound fertilizer, bio-organic fertilizer and micro-fertilizer.The results showed that the application of bio-organic fertilizer had significant effects on millet yield,plant height,stem base diameter,bulk density,as well as reducing sugar,protein and fat content of millet.There was no significant effect on the ear weight,ear length,100-grain weight of millet and amylose of prehensive comparison and analysis of various indicators showed that the optimal application rate of bio-organic fertilizer was300kg/hm2when considering yield increase and higher economic benefits;when considering lodging resistance and millet nutritional quality,it was recommended to apply bio-organic fertilizer450kg/hm2.Key words:millet,bio-organic fertilizer,yield,growth index,nutritional quality黍子是一年生禾本科作物,耐干旱[1],籽粒脱壳即成黍米,因呈金黄色,又称黄米。

科学实验-英语作文Last week, I conducted a science experiment in my school laboratory.I was given the task to test the effect of different types of fertilizers on the growth of plants.In the first part of the experiment, I used three different types of fertilizers organic, inorganic, and a combination of both. I planted the same type of seeds in each pot and watered them with the same amount of water every day. After a week, I observed that the plants that were fertilized with the organic fertilizer grew taller and had more leaves compared to the other two types of fertilizers.In the second part of the experiment, I decided to test the effect of different amounts of water on plant growth. I planted the same type of seeds in three different pots and watered them with different amounts of water one pot received more water, the other less, and the third received just the right amount. After a week, I observed that the plant that received just the right amount of water grew taller and had more leaves compared to the other two pots.In the third part of the experiment, I wanted to test the effect of music on plant growth. I played classical music to one pot of plants and no music to the other pot. After a week, I observed that the plants thatwere exposed to classical music grew taller and had more leaves compared to the plants that were not exposed to any music.In conclusion, I learned that organic fertilizers, the right amount of water, and classical music can have a positive effect on plant growth. This experiment has opened my eyes to the importance of taking care of plants and how different factors can affect their growth.。

麦类作物学报 2024,44(4):504-512J o u r n a l o fT r i t i c e a eC r o ps d o i :10.7606/j.i s s n .1009-1041.2024.04.11网络出版时间:2023-11-08网络出版地址:h t t ps ://l i n k .c n k i .n e t /u r l i d /61.1359.s .20231107.0925.012猪粪和羊粪对盐碱障碍粮田冬小麦生理特征和产量的影响收稿日期:2023-03-27 修回日期:2023-05-08基金项目:河北省农林科学院基本科研业务费项目(2021130202);国家重点研发计划项目(2021Y F D 1901002)第一作者E -m a i l :z t y 230308@163.c o m (张天英)通讯作者E -m a i l :g u o l i s o i l @163.c o m (郭丽);d o n gw e i x i n @163.c o m (董伟欣)张天英1,2,李义红1,3,黄朋娟1,2,张月辰2,董伟欣4,郭丽1,3(1.河北省农林科学院农业资源环境研究所,河北石家庄050051;2.河北农业大学农学院,河北保定071001;3.河北省肥料技术创新中心,河北石家庄050051;4.河北开放大学,河北石家庄050080)摘 要:为探明不同有机肥施用条件下河北低平原咸水补灌区盐碱障碍粮田冬小麦的耐盐抗氧化特征,设置常规施肥(C K )㊁推荐施肥(R C )以及在R C 基础上猪粪和羊粪各3个施用量(低量:9t ㊃h m -2;中量:18t㊃h m -2;高量:27t ㊃h m -2)处理,分析了不同处理下盐碱田冬小麦生长㊁碳氮代谢㊁抗氧化特性及产量的差异㊂结果表明,高量猪粪和羊粪处理下小麦孕穗期单株分蘖数较R C 处理分别提高了18.42%和23.68%;高㊁中量猪粪和羊粪处理下干物质积累量在孕穗期㊁开花期和收获期较C K 和R C 处理均显著提高,其中在收获期高量猪粪处理的增幅分别为24.54%和24.60%,高量羊粪处理的增幅分别为29.94%和29.99%;高量猪粪和羊粪处理较C K 和R C 处理均显著提高了冬小麦花后旗叶可溶性蛋白㊁可溶性糖㊁游离氨基酸含量及S O D ㊁P O D 活性,降低超氧阴离子自由基积累量,其中羊粪较猪粪显著提高了可溶性糖含量㊂高㊁中量有机肥处理提高了穗数和千粒重,增产效果显著,其中高㊁中量猪粪处理较C K 分别增产15.09%和8.95%,高㊁中量羊粪分别增产22.06%和9.34%,但两种有机肥处理间产量无显著差异㊂综合来看,针对河北低平原咸水补灌区轻度盐碱土壤,建议在生产实践中施用高量(27t ㊃h m -2)猪粪或羊粪,以改善冬小麦耐盐生理特征,进而促进产量提高,且总体上羊粪增产效果优于猪粪㊂关键词:有机肥;盐碱障碍粮田;冬小麦;生理特性;产量中图分类号:S 512.1;S 311 文献标识码:A 文章编号:1009-1041(2024)04-0504-09E f f e c t o fP i g a n dS h e e p M a n u r e o nP h y s i o l o g i c a l C h a r a c t e r i s t i c s a n d Y i e l do fW i n t e rW h e a t P l a n t s i nS a l i n i t y Fi e l d s Z H A N GT i a n y i n g 1,2,L IY i h o n g 1,3,H U A N GP e n g ju a n 1,2,Z H A N GY u e c h e n 2,D O N G W e i x i n 4,G U OL i 1,3(1.I n s t i t u t e o fA g r i c u l t u r a lR e s o u r c e s a n dE n v i r o n m e n t ,H e b e iA c a d e m y o fA g r i c u l t u r e a n dF o r e s t r y S c i e n c e ,S h i j i a z h u a n g ,H e b e i 050051,C h i n a ;2.C o l l e g e o fA g r i c u l t u r a l ,H e b e iA g r i c u l t u r a lU n i v e r s i t y ,B a o d i n g ,H e b e i 071001,C h i n a ;3.H e b e i F e r t i l i z e rT e c h n o l o g yI n n o v a t i o nC e n t e r ,S h i j i a z h u a n g ,H e b e i 050051,C h i n a ;4.H e b e i o p e nU n i v e r s i t y ,S h i j i a z h u a n g,H e b e i 050080,C h i n a )A b s t r a c t :T o i n v e s t i g a t e t h e e f f e c t o f o r g a n i c f e r t i l i z e r t y p e a n d d o s a ge o n t h e s a l t t o l e r a n c e a n d a n t i o x -i d a n t c h a r a c t e r i s t i c s o fw i n t e rw h e a t i n s a l i n i t yf i e l d s i n t h e l o w p l a i nb r a c k i s hw a t e r r e c h a r ge a r e aof H e b e i ,i n t h i s s t u d y ,t h r e e d o s ag e s e a ch o f pi g m a n u r e a n d s h e e p m a n u r e (l o w :9t ㊃h m -2;m e d i u m :18t ㊃h m -2;h i g h :27t ㊃h m -2)a n dc o n t r o l a n dr e c o mm e n d e df e r t i l i z e ra p p l i c a t i o n sw e r es e tu p,w i t ha t o t a l o f e i g h t t r e a t m e n t s .T h e e f f e c t s o n g r o w t h ,c a r b o n a n dn i t r o g e nm e t a b o l i s m ,a n t i o x i d a n t c h a r a c t e r i s t i c s a n d y i e l do fw i n t e rw h e a tw e r e i n v e s t i ga t e d .T h er e s u l t ss h o w e dt h a t t h en u mb e ro f t i l l e r s p e r p l a n tw i t hh i g h p i g m a n u r e a n ds h e e p m a n u r ew a s i nc r e a s e db y 18.42%a n d23.68%,r e -s p e c t i v e l y ,c o m p a r e dw i t h t h e r e c o mm e nde df e r t i l i z e r ;d r y m a t t e r a c c u m u l a t i o n a t t h e b o o t i n g,f l o w -e r i n g a n d h a r v e s t s t a g e sw a s s i g n i f i c a n t l y i n c r e a s e d b y h i g h a n dm e d i u m p i g m a n u r e a n d s h e e p ma n u r e t r e a t m e n t s ,c o m p a r e dw i t h t h e c o n t r o l a n dr e c o mm e n d e d f e r t i l i z e r a p pl i c a t i o n ,w i t ha n i n c r e a s e r a t eo f24.54%a n d24.60%f o r t h e h i g h p i g m a n u r e a n d h i g h s h e e p m a n u r e,r e s p e c t i v e l y,a n d a n i n c r e a s e r a t e o f29.94%a n d29.99%a t t h e h a r v e s t s t a g e f o r t h e h i g h s h e e p m a n u r e.T h e s o l u b l e p r o t e i n,s o l-u b l e s u g a r a n df r e ea m i n oa c i dc o n t e n t s,a n dS O Da n dP O Da c t i v i t i e so f p o s t-f l o w e r i n g f l a g l e a fo f w i n t e rw h e a t u n d e r t h eh i g h p i g m a n u r ea n ds h e e p m a n u r e t r e a t m e n t sw e r es i g n i f i c a n t l y i n c r e a s e d, a n d t h e a c c u m u l a t i o no f s u p e r o x i d e a n i o n r a d i c a l sw a s r e d u c e d c o m p a r e dw i t h t h e c o n t r o l a n d r e c o m-m e n d e d f e r t i l i z e r s,w i t hs h e e p m a n u r es i g n i f i c a n t l y i n c r e a s i n g t h es o l u b l es u g a rc o n t e n tc o m p a r e d w i t h p i g m a n u r e.H i g ha n d m e d i u m o r g a n i c f e r t i l i z e r s i n c r e a s e dt h en u m b e ro f s p i k e s p e ru n i ta n d t h o u s a n d-g r a i nw e i g h t,a n dt h e y i e l d i n c r e a s ew a ss i g n i f i c a n t,w i t ha n i n c r e a s er a t eo f15.09%a n d 8.95%f o r p i g m a n u r e t r e a t m e n t,a n d22.06%a n d9.34%f o r s h e e p m a n u r e,r e s p e c t i v e l y,c o m p a r e d w i t h t h e c o n t r o l,b u t t h e r ew a s n o s i g n i f i c a n t d i f f e r e n c e b e t w e e n t h e t w o o r g a n i c f e r t i l i z e r s.I n c o n c l u-s i o n,f o rm i l d l y s a l i n e s o i l s i n t h e l o w p l a i nb r a c k i s hw a t e r r e c h a r g e a r e a o fH e b e i,i t i s r e c o mm e n d e d t h a t h i g h a m o u n t s(27t㊃h m-2)o f p i g m a n u r e o r s h e e p m a n u r e c a nb e a p p l i e d i nw h e a t p r o d u c t i o n t o p r o m o t e t h e p h y s i o l o g i c a l c h a r a c t e r i s t i c s o f s a l t t o l e r a n c e a n d y i e l d,b u t o v e r a l l t h e e f f e c t o f s h e e p m a-n u r e o n i n c r e a s e d y i e l d i s b e t t e r t h a n p i g m a n u r e.K e y w o r d s:O r g a n i c f e r t i l i z e r;S a l i n e-a l k a l i f i e l d;W i n t e rw h e a t;P h y s i o l o g i c a l c h a r a c t e r i s t i c s;Y i e l d盐碱地是中国广泛分布的重要土地资源,总面积3.67ˑ107h m2,其中1.23ˑ107h m2具有农业应用价值[1]㊂目前,河北省盐碱耕地总面积为7.8ˑ105h m2,占总耕地面积的10.4%,适宜开发而未开发的盐碱地有7.83ˑ104h m2,主要分布在东部低平原的部分地区[2],也是河北省中低产田的主要组成部分[3]㊂由于河北低平原区淡水资源匮乏,而浅层微咸水资源丰富,矿化度在2~ 5g㊃L-1的微咸水有5.4ˑ109m3,年可利用量约22亿m3,且有易开采㊁补给快的特点,所以采用微咸水灌溉已成为解决该地区农业生产发展的重要手段之一[4-5]㊂但微咸水灌溉会引起盐分在土壤中的累积,导致土壤的次生盐碱化㊂由于盐碱土地的盐度高㊁养分匮乏,土壤易板结㊁肥力较低,会阻碍作物的正常生长㊂因此,如何有效改良河北省低平原咸水补灌区的盐碱地,使其变为可靠的耕地资源,不仅对于河北省中低产田改造,而且对于有效利用咸水资源满足农业生产需要㊁缓解华北平原淡水资源紧张具有长远意义㊂中国的规模化养殖业发展迅速,每年约有1.18亿头畜禽出栏量,同时也产生大量畜禽粪污废弃物,全国畜禽粪污年产生量约几十亿吨[6]㊂畜禽粪也是良好的有机肥源,含有丰富的有机质和氮㊁磷㊁钾等营养元素,施用后能够显著增加土壤有效养分,改善土壤物理性状和生物学特性[7-8],促进作物生长和增产[9-10]㊂施用畜禽粪对于盐碱地改良有很好的效果㊂研究表明,长期施用牛粪后松嫩平原盐渍化土壤p H值㊁碱化度㊁电导率和钠吸附比显著降低,土壤孔隙度和土壤有机质增加[11];山东滨州滨海盐碱土施用牛粪后棉花开花期叶绿素含量㊁光合特性㊁土壤有机质含量和土壤生物丰度均提高[12];施用生物炭和畜禽粪肥可显著提高盐碱地玉米叶面积指数㊁植株生物量和籽粒产量,并增强与渗透相关的叶片生物活性[13]㊂这些研究结果充分说明畜禽粪对盐碱地土壤理化性状以及植物生长具有改善效果,可对其进行肥料化利用,发挥其对盐碱地改良以及农业可持续发展的促进作用[14]㊂上述研究虽验证了有机肥对盐碱土壤的改良效果,但关于有机肥对河北省低平原咸水补灌区轻度盐碱土壤上冬小麦耐盐能力的提升效果还未见系统报道㊂本研究选择河北低平原咸水补灌区轻度盐碱土壤为对象,以养分含量较为丰富的猪粪和羊粪有机肥为试验材料,开展不同有机肥施用量对该地区盐碱地冬小麦植株耐盐抗氧化特性㊁碳氮代谢及产量的影响,以期为河北省盐碱障碍粮田改良以及中国的畜禽粪便资源化利用提供技术参考和理论依据㊂1材料与方法1.1试验地概况试验地位于河北省衡水市武强县东孙庄乡农业示范区(38ʎ12'57ᵡN,115ʎ88'27ᵡE)㊂该地属于北温带大陆性季风气候区,四季分明,光照充足,无霜期为185d,年平均降水量在485mm左右㊂试验开始前土壤p H值为8.3,E C值为396μs㊃㊃505㊃第4期张天英等:猪粪和羊粪对盐碱障碍粮田冬小麦生理特征和产量的影响c m-1,硝态氮含量15.6m g㊃k g-1,速效磷含量19.2m g㊃k g-1,速效钾含量169.3m g㊃k g-1㊂1.2试验设计本试验于2021年11月4日冬小麦生长季开始,采用完全随机设计,小区面积为55.8m2(6m ˑ9.3m),小区外设有保护行㊂试验设置常规施肥(C K)㊁推荐施肥(R C)以及在推荐施肥的基础上施用高量猪粪(H P)㊁中量猪粪(M P)㊁低量猪粪(L P)㊁高量羊粪(H S)㊁中量羊粪(M S)和低量羊粪(L S)8个处理,每个处理3次重复㊂常规施肥为当地农民习惯施肥量(N:300k g㊃h m-2; P2O5:120k g㊃h m-2;K2O:60k g㊃h m-2),推荐施肥为优化后的施肥量(N:195k g㊃h m-2; P2O5:120k g㊃h m-2;K2O:60k g㊃h m-2),有机肥的低㊁中㊁高施用量分别为9㊁18和27t㊃h m-2㊂所使用的氮肥为尿素(N46%),磷肥为磷酸二铵(P2O561%),钾肥为氯化钾(K2O62%);有机肥来自当地农场(发酵腐熟),猪粪有机肥的有机质㊁全氮㊁全磷和全钾含量分别为32.1%㊁1.04%㊁0.81%㊁1.54%,羊粪有机肥的有机质㊁全氮㊁全磷和全钾含量分别为42%㊁1.19%㊁0.42%和1.60%㊂试验地为冬小麦-夏玉米复种轮作田,供试小麦品种为衡4399,有机肥与50%氮肥及全部磷钾肥底施,剩余50%氮肥在拔节期追施,其他田间管理措施在所有处理中一致㊂1.3样品采集与项目测定方法于拔节期(3月28日)㊁孕穗期(4月18日)㊁开花期(5月6日)㊁收获期(6月15日)在田间选择长势均匀的区域,取1m双行小麦植株样品,带回进行株数㊁分蘖数㊁株高㊁地上部干物质重的测定;于灌浆前期(5月10日)㊁灌浆中期(5月23日)㊁灌浆后期(6月1日)到田间随机采集小麦旗叶10~15片,擦净后用锡纸包裹,迅速放入液氮中保存,带回贮存于冰箱,后期统一进行小麦叶片相关生理指标测定㊂可溶性糖㊁可溶性蛋白和游离氨基酸含量分别采用蒽酮法㊁考马斯亮蓝G-250蛋白染色法和茚三酮显色法测定,超氧化物歧化酶(S O D)和过氧化物酶(P O D)活性及超氧阴离子自由基(O2-㊃)含量分别采用氮蓝四唑(N B T)法㊁愈创木酚法和羟胺氧化反应法测定㊂收获期在各小区长势均匀一致的区域随机取30个麦穗,用于穗粒数的调查;统计取1m双行穗数,折合成单位面积穗数;收获1m2的小麦植株测定单位面积籽粒产量㊂1.4数据处理采用E x c e l软件对数据进行整理分析和绘图表,采用D P S软件进行统计分析,采用最小显著极差法L S D进行差异显著性检验(α=0.05)㊂2结果与分析2.1不同施肥处理对盐碱障碍粮田冬小麦植株形态特征的影响两种有机肥处理下小麦拔节期和孕穗期的单株分蘖数均表现为高量>中量>低量,且高量与低量处理间差异显著(表1)㊂H P处理单株分蘖数在孕穗期显著高于R C处理,H S处理在两时期均显著高于R C处理,M S处理在孕穗期显著高于R C处理,C K与R C处理间在两个时期均无显著差异,猪粪和羊粪相同施用量处理间也均无显著差异㊂孕穗期㊁开花期小麦株高均以H P处理最高,但不同处理间差异均不显著㊂小麦的株数在两时期均无明显差异,说明各处理下小麦出苗及播种均匀㊂两种有机肥处理下小麦干物质积累量在拔节㊁孕穗㊁开花㊁收获期均表现为高量>中量>低量,且高量与低量处理间差异显著(表1)㊂H P处理在各时期均显著高于C K和R C处理,增幅13.40%~41.71%;M P处理在孕穗㊁开花和成熟期显著高于C K和R C处理,增幅6.14%~ 22.85%;L P处理与C K和R C处理间差异均不显著㊂高㊁中量羊粪处理在四个时期内与C K和R C处理间差异均显著,H S和M S处理增幅分别为17.09%~78.22%和15.80%~53.19%,L S 处理在开花期和收获期显著高于R C处理㊂在冬小麦全生育期内羊粪处理平均干物质积累量较猪粪处理提高6.77%㊂综上可见,在盐碱障碍粮田增施猪粪和羊粪对冬小麦分蘖和干物质积累具有促进效应,总体看增施高量有机肥效果明显,尤其是羊粪对小麦干物质积量的提升效果优于猪粪㊂2.2不同施肥处理对盐碱障碍粮田冬小麦生理特性的影响2.2.1不同施肥处理下冬小麦旗叶可溶性蛋白、可溶性糖及游离氨基酸含量猪粪和羊粪对盐碱障碍粮田冬小麦旗叶可溶性蛋白㊁可溶性糖及游离氨基酸含量的影响总体㊃605㊃麦类作物学报第44卷表1 猪粪和羊粪对盐碱障碍粮田冬小麦植株形态特征的影响T a b l e 1 E f f e c t o f p i g a n d s h e e p m a n u r e o n t h em o r p h o l o g i c a l c h a r a c t e r i s t i c s o fw i n t e rw h e a t p l a n t s i n s a l i n i t yf i e l d s 处理T r e a t m e n t单株分蘖数N u m b e r o f t i l l e r s p e r p l a n t 拔节期J o i n t i n g s t a g e 孕穗期B o o t i n g s t a g e 株高P l a n t h e i g h t /c m 孕穗期B o o t i n g s t a g e 开花期F l o w e r i n g s t a g e 株数P l a n t n u m b e r/(ˑ104㊃h m -2)拔节期J o i n t i n g s t a g e 孕穗期B o o t i n g s t a ge 干物质质量D r y m a t t e r /(k g㊃h m -2)拔节期J o i n t i n g s t a g e 孕穗期B o o t i n g s t a g e 开花期F l o w e r i n g s t a g e 收获期M a t u r i t y s t a ge C K2.0a b c 2.7b c 40.5a 65.4a 622.2a 696.3a 340d 4080e 12968e 15287c d R C1.9b c2.5c 41.8a 65.9a 603.7a 629.6a 320d4020e12913e15280dH P 2.3a b 3.0a b 43.2a 66.7a 685.2a 659.3a 453b c 5402b c 14705a b 19039a M P 1.8c 2.6b c 40.6a 64.5a 633.3a 696.3a 404b c d4938c d 13764c d 18325a bL P1.6c2.5c42.2a 64.2a 714.8a 766.7a 342d 4129e 13401d e 16147c d H S 2.4a3.1a 42.1a 65.3a 714.8a 733.3a 570a6500a15184a 19863a M S2.1a b c3.0a b 41.4a 64.5a 659.3a 681.5a 490a b 5845b15016a19100aL S1.9b c2.6c40.9a64.1a663.0a688.9a395c d4527d e 14187b c 16893b c同列数据后不同小写字母表示不同处理间差异显著(P <0.05)㊂下表同㊂D i f f e r e n t s m a l l l e t t e r s f o l l o w i n g d a t a i n s a m e c o l u m n i n d i c a t e s i g n i f i c a n t d i f f e r e n c e a m o n gt r e a t m e n t s a t 0.05l e v e l .T h e s a m e i n t a b l e 2.表现为高量处理下含量最高,低量处理则一直处于较低水平(图1~图3)㊂高量有机肥处理下可溶性蛋白含量在灌浆前期㊁灌浆中期和灌浆后期显著高于不施有机肥处理(C K ㊁R C ),其中H P 和H S 处理的增幅分别为27.78%~44.37%和33.80%~50.10%,中㊁低量猪粪和羊粪处理与C K ㊁R C 处理间均无显著差异㊂可溶性糖含量在上述三个时期均表现为H P ㊁H S ㊁M S 处理显著高于C K ㊁R C 处理(图2),增幅分别为13.28%~25.28%㊁22.69%~49.44%和16.67%~28.14%,M P ㊁L P 与C K ㊁R C 处理间差异均不显著,L S 处理仅在灌浆前期显著高于C K ㊁R C 处理㊂游离氨基酸含量(图3)在三个时期均表现为H P ㊁H S 处理显著高于C K ㊁R C 处理,增幅分别为25.00%~66.66%和27.58%~64.64%,而中㊁低量猪粪和羊粪处理与C K ㊁R C 处理间均无显著性差异㊂两种有机肥比较发现,上述三个时期内羊粪处理下可溶性糖平均含量较猪粪处理提高了8.76%,可溶性蛋白和游离氨基酸则无明显差异㊂以上结果表明,增施两种有机肥均可提高盐碱障碍粮田冬小麦旗叶可溶性蛋白㊁可溶性糖及游离氨基酸含量,以增施27t ㊃h m -2有机肥的调控效应最佳,且羊粪对可溶性糖含量的提升效果优于猪粪,有助于增强植株的碳氮代谢能力㊂相同时期图柱上不同字母表示不同处理间差异显著(P <0.05)㊂下图同㊂D i f f e r e n t s m a l l l e t t e r s a b o v e c o l u m n s o f s a m e s t a g e i n d i c a t e s i g n i f i c a n t d i f f e r e n c e a m o n g t r e a t m e n t s a t 0.05l e v e l .T h e s a m e i n f i g-u r e s 2-6.图1 猪粪和羊粪对冬小麦花后旗叶可溶性蛋白的影响F i g .1 E f f e c t o f p i g a n d s h e e p m a n u r e o n s o l u b l e p r o t e i n i n p o s t -f l o w e r i n g f l a gl e a f o fw i n t e rw h e a t ㊃705㊃第4期张天英等:猪粪和羊粪对盐碱障碍粮田冬小麦生理特征和产量的影响图2 猪粪和羊粪对冬小麦花后旗叶可溶性糖的影响F i g .2 E f f e c t o f p i g a n d s h e e p m a n u r e o n s o l u b l e s u g a r s i n p o s t -f l o w e r i n g f l a gl e a f o fw i n t e rw h e at 图3 猪粪和羊粪对冬小麦花后旗叶游离氨基酸的影响F i g .3 E f f e c t o f p i g a n d s h e e p m a n u r e o n f r e e a m i n o a c i d s i n p o s t -f l o w e r i n g f l a gl e a f o fw i n t e rw h e a t 2.2.2 不同施肥处理下冬小麦旗叶抗氧化酶活性和膜脂过氧化程度不同猪粪和羊粪处理下小麦花后旗叶抗氧化酶活性整体上表现为高量>中量>低量,且高量与低量处理间差异均显著㊂高量有机肥处理下S O D 活性在灌浆前期㊁灌浆中期㊁灌浆后期与C K ㊁R C 处理均差异显著,H P 处理增幅为13.83%~37.60%,H S 处理增幅为15.99%~40.05%;灌浆后期中量处理较C K ㊁R C 处理显著提升,M P增幅分别为24.15%和20.88%,M S 处理增幅分别为22.89%和19.65%,低量处理则无显著提升效果(图4)㊂H P ㊁H S ㊁M S 处理下P O D 活性在三个时期与C K ㊁R C 处理差异显著,三个处理的增幅分别为32.17%~53.17%㊁40.76%~80.57%和27.51%~56.37%;M P 处理仅在灌浆前期与C K 差异显著,L P 处理的提升效果不显著,L S 处理在灌浆后期与R C 处理差异显著(图5)㊂在三个时期羊粪处理下小麦旗叶P O D 活性的平均值较猪粪处理提高12.55%,S O D 活性差异较小㊂上述结果表明,增施两种有机肥可提高盐碱障碍粮田冬小麦旗叶S O D 和P O D 活性,有助于增强冬小麦植株抗氧化和抵御盐胁迫能力㊂猪粪和羊粪不同用量对盐碱障碍粮田冬小麦旗叶O 2-㊃含量的影响总体表现为低量有机肥处理较高,高量处理下累积量较低(图6)㊂与C K ㊁R C 处理相比,H P 处理在灌浆前期和灌浆中期显著下降,降幅为29.82%~41.65%;M P 处理仅在灌浆后期较C K 显著降低;H S 处理在三个时期均显著低于C K ㊁R C 处理,降幅为29.06%~42.76%;M S 处理在灌浆前期和灌浆中期显著高于R C 处理;猪㊁羊粪低量处理与C K ㊁R C 均无显著性差异㊂在等量有机肥处理间,猪粪和羊粪对O 2-㊃含量无显著影响㊂综上,增施两种有机肥均可抑制盐碱障碍粮田冬小麦旗叶中O 2-㊃的积累,其中增施高量(27t ㊃h m -2)有机肥效果最好,这有助于小麦植物抵御盐胁迫的侵害㊂㊃805㊃麦 类 作 物 学 报 第44卷图4猪粪和羊粪对冬小麦花后旗叶S O D 活性的影响F i g .4 E f f e c t o f p i g a n d s h e e p m a n u r e o n t h e S O Da c t i v i t y o f p o s t -f l o w e r i n g f l a gl e a f o fw i n t e rw h e at 图5 猪粪和羊粪对冬小麦花后旗叶P O D 活性的影响F i g .5 E f f e c t o f p i g a n d s h e e p m a n u r e o n t h eP O Da c t i v i t y o f p o s t -f l o w e r i n g f l a gl e a f o fw i n t e rw h e at 图6 猪粪和羊粪对冬小麦花后旗叶O 2-㊃含量的影响F i g .6 E f f e c t o f p i g a n d s h e e p m a n u r e o n t h e O 2-㊃c o n t e n t o f p o s t -f l o w e r i n g f l a gl e a f o fw i n t e rw h e a t 2.3 不同施肥处理对盐碱障碍粮田冬小麦产量及产量构成因素的影响由表2可知,高㊁中量有机肥处理与C K ㊁R C 处理相比显著提高了冬小麦产量,其中H P 处理分别增产15.09%㊁17.82%,M P 处理分别增产8.95%㊁11.54%,H S 处理分别增产22.06%㊁24.95%,M S 处理分别增产9.34%㊁11.94%㊂低量有机肥处理的增产效果均不显著㊂猪粪和羊㊃905㊃第4期张天英等:猪粪和羊粪对盐碱障碍粮田冬小麦生理特征和产量的影响粪等量处理间产量无显著性差异㊂从产量构成因素来看,H P ㊁M P ㊁H S 处理的冬小麦穗数与C K ㊁R C 处理均差异显著,其余处理之间差异较小;不同施肥处理间穗粒数无显著差异;千粒重表现为高㊁中量有机肥处理显著高于C K ㊁R C 处理,低量有机肥处理与C K ㊁R C 处理差异不显著,同种有机肥不同用量处理间差异均显著,而猪粪和羊粪等量处理间无显著差异㊂上述结果表明,增施两种有机肥主要是通过增加盐碱障碍粮田冬小麦穗数和千粒重来提高籽粒产量㊂表2 猪粪和羊粪对盐碱障碍粮田冬小麦产量及产量构成因素的影响T a b l e 2 E f f e c t o f p i g a n d s h e e p m a n u r e o n y i e l da n d y i e l d c o m p o n e n t s o fw i n t e rw h e a t i n s a l i n i t y fi e l d s 处理T r e a t m e n t穗数S pi k e s /(ˑ104㊃h m -2)穗粒数G r a i n s p e r s pi k e 千粒重1000-g r a i nw e i g h t /g产量Y i e l d /(k g㊃h m -2)C K 540c d 36.0a 39.1c 6413d R C519d 35.8a 39.2c6265dH P 665a631a42.6a 7381a b M P 631a b 37.4a 41.2b 6988b cL P526d 34.3a 38.8c6571c d H S 652a b 34.6a 42.6a 7828aM S 604b c 34.4a 40.9b 7013b c L S552c d34.7a 38.7c 6356d3 讨论灌浆期是小麦产量形成的关键时期,花后旗叶也是小麦进行光合作用和产生碳水化合物的主要场所[15]㊂可溶性蛋白和可溶性糖是植物进行碳氮代谢的主要物质,也可以保护植物细胞膜和代谢相关物质[16];游离氨基酸来源于氮素的同化及蛋白质等含氮化合物的分解,一定游离氨基酸的积累对平衡液泡渗透势具有重要作用[17]㊂本研究中,与常规施肥和推荐施肥相比,高量猪粪㊁羊粪处理下盐碱地冬小麦旗叶可溶性蛋白㊁游离氨基酸含量在花后各时期(灌浆前期㊁灌浆中期和灌浆后期)均显著增加,中㊁低量处理下无显著提升;高量猪粪和中㊁高量羊粪也显著提升了花后各时期叶片可溶性糖含量,猪粪和羊粪等量处理间冬小麦旗叶可溶性蛋白和游离氨基酸含量无显著差异,高量羊粪在灌浆前期和灌浆后期对可溶性糖含量的提升效果优于高量猪粪㊂这与海藻酸有机肥对盐碱地小麦花后旗叶[18],牛粪有机肥在盐碱地糜子灌浆后期叶片[19]以及干旱胁迫下蚯蚓粪对亚麻籽植株[20]上的研究结果相似㊂这说明盐碱地中施入高量猪粪和羊粪,与常规施肥和推荐施肥相比,能够使小麦叶片在开花后仍然保持较高的活力,在一定程度上延缓植株衰老;推荐施肥处理与常规施肥并无显著差异,说明氮肥减量情况下也能够满足冬小麦生长的需求㊂也有研究发现,施用有机肥降低了盐碱地芸豆叶片中的游离脯氨酸和可溶性糖含量[21],可能由于不同类型有机肥对减轻盐胁迫的负面效应存在差异或与植株监测生育时期的不同有关㊂盐胁迫下,植物会发生膜脂过氧化作用,积累超氧阴离子自由基等有害物质,破坏细胞膜结构,同时会损害植物体内的抗氧化酶系统,打破活性氧产生与消除之间的平衡,对植物造成氧化胁迫㊂S O D 和P O D 是广泛存在于植物体内的抗氧化酶,能够清除活性氧自由基,有效地保护细胞免受毒害损伤[22]㊂研究表明,牛粪或牛粪与无机肥配施能够显著提高小麦生育后期旗叶S O D ㊁P O D ㊁C A T 活性,降低了MD A 含量[23];碱化土壤上玉米秸秆还田配施秸秆腐熟剂,能提高玉米根系S O D 和P O D 活性,降低根系M D A 含量[24];施用蚯蚓粪可提高干旱胁迫下植物S O D ㊁C A T 活性,降低了过氧化氢㊁M D A 含量[20]㊂本试验结果与上述研究结果基本一致,盐碱地施用高量猪粪和羊粪显著提升了小麦各时期S O D 活性,降低了超氧阴离子自由基含量,高量猪粪和高㊁中量羊粪对P O D 活性提升效果显著,低量有机肥处理对S O D 活性㊁P O D 活性和O 2-㊃含量的影响均不明显,不同有机肥等量处理间无显著差异㊂这说明盐碱地中施入高量猪粪和羊粪有机肥通过提高小麦旗叶S O D ㊁P O D 活性,增强清除超氧阴离子自由基的能力,进而保护了细胞膜系统的结构㊂小麦产量是其构成因素共同作用的结果,盐胁迫显著影响小麦产量及其构成[25]㊂研究表明,㊃015㊃麦 类 作 物 学 报 第44卷盐碱地中施加7.5t㊃h m-2猪粪有机肥可显著提高小麦产量,施用量达到10t㊃h m-2却使产量降低[26];45t㊃h m-2羊粪有机肥显著提高卤阳湖盐碱地的玉米产量[27];盐渍化耕地施用8.5t㊃h m-2的羊粪对棉花的增产效果不显著,施用8.1 t㊃h m-2鸡粪显著增加棉花产量[28]㊂在本试验中,除了低量(9t㊃h m-2)有机肥外,中㊁高量(18㊁27t㊃h m-2)猪粪和羊粪有机肥较常规施肥和推荐施肥均显著提高了小麦的产量,猪粪增产8.95%~17.82%,羊粪增产9.34%~24.95%;从小麦产量构成因素来看,高㊁中量猪粪和高量羊粪处理的穗数㊁千粒重显著高于常规施肥和推荐施肥处理,而穗粒数无显著差异,说明在本试验条件下,高量有机肥施入主要通过调节盐碱地小麦的单位面积穗数和千粒重而提高产量㊂这与张济世等[29]的研究结果相似,但与其他一些研究结果存在差异㊂如,谢娜娟等[30]发现,腐熟牛粪和鸡粪对盐渍土冬小麦的增产效应主要通过提高穗粒数及千粒重来实现;张乃丹等[31]认为,有机肥通过影响滨海盐碱地小麦的穗数㊁穗粒数和千粒重来提高产量㊂产生研究结果不尽一致的原因可能与试验中所使用的有机肥养分含量㊁用量㊁小麦品种遗传特性及试验土壤基础地力有关㊂从本试验设置的两种有机肥的各3个施用量来看,小麦产量基本随着有机肥用量的增加而增加,且没有出现减产的情况,说明猪粪和羊粪的最高用量(27t㊃h m-2)没有超过该盐碱地小麦对土壤养分吸收利用的最大需求㊂但试验设置的3个有机肥用量具有一定局限性,只能在此范围内为农户提供指导,且本研究只侧重于作物生理,关于施用有机肥后盐碱地土壤理化性状㊁盐分等指标的变化需进一步研究㊂4结论增施27t㊃h m-2猪粪和羊粪有机肥较推荐施肥显著提高了孕穗期小麦单株分蘖数,较常规施肥和推荐施肥相比,显著提升了小麦干物质积累量㊁旗叶碳氮代谢物质含量㊁抗氧化酶活性,降低了膜脂过氧化程度,其中除羊粪较猪粪显著提高了可溶性糖含量外,其他指标在两种有机肥间均无显著差异㊂有机肥施用量27和18t㊃h m-2较常规施肥和推荐施肥显著提高小麦产量,猪粪增产了8.95%~17.82%,羊粪增产了9.34%~ 24.95%,可见羊粪对产量的提升幅度高于猪粪,但等量处理间无显著差异;增施27t㊃h m-2猪粪和羊粪通过提高单位面积穗数和千粒重来增加小麦产量㊂参考文献:[1]杨劲松.中国盐渍土研究的发展历程与展望[J].土壤学报, 2008,45(5):837.Y A N GJS.D e v e l o p m e n t a n d p r o s p e c t o f t h e r e s e a r c ho n s a l t-a f f e c t e d s o i l s i nC h i n a[J].A c t aP e d o l o g i c aS i n i c a,2008,45(5):837.[2]冯伟,刘忠宽,刘振宇,等.河北省盐碱地分布成因及改良利用技术研究[J].河北农业科学,2015,19(1):56.F E NG W,L I UZK,L I UZY,e t a l.S t u d y o n t h e d i s t r i b u t i o n, c a u s e sa n di m p r o v e m e n tt e c h n o l o g y o fs a l i n e-a l k a l i l a n di nH e b e i P r o v i n c e[J].J o u r n a l o f H e b e iA g r i c u l t u r a l S c i e n c e s, 2015,19(1):56.[3]罗建美,靳根会,罗仲朋,等.河北平原中低产区小麦与玉米生产现状及增产潜力分析[J].中国生态农业学报,2016,24(8): 1123.L U O J M,J I N G H,L U O Z P,e ta l.P r o d u c t i o ns t a t ea n d y i e l d p o t e n t i a l o fw h e a t a n dm a i z e i n l o w-m e d i u m y i e l d f a r m-l a n d s i n H e b e iP l a i n[J].C h i n e s eJ o u r n a lo f E c o-A g r i c u l-t u r e,2016,24(8):1123.[4]郭丽,郑春莲,曹彩云,等.长期咸水灌溉对小麦光合特性与土壤盐分的影响[J].农业机械学报,2017,48(1):183.G U OL,Z H E N G C L,C A O C Y,e ta l.E f f e c t so f l o n g-t e r m s a l i n e w a t e ri r r i g a t i o n o n p h o t o s y n t h e t i c c h a r a c t e r i s t i c s o f w i n t e rw h e a ta n ds o i ls a l tc o n t e n t[J].T r a n s a c t i o n so f t h e C h i n e s eS o c i e t yf o r A g r i c u l t u r a l M a c h i n e r y,2017,48(1): 183.[5]李法虎,闫红,庞昌乐,等.华北地区微咸水应用对土壤水力传导性能的影响[J].农业工程学报,2013,29(2):73.L IFH,Y A N H,P A N GCL,e t a l.S o i l h y d r a u l i c c o n d u c t i v i t y a f f e c t e db y s l i g h t s a l i n ew a t e r i r r i g a t i o n i nN o r t hC h i n a[J]. T r a n s a c t i o n s o f t h eC h i n e s eS o c i e t y o f A g r i c u l t u r a lE n g i-n e e r i n g,2013,29(2):73.[6]杜为研,唐杉,汪洪.我国有机肥资源及产业发展现状[J].中国土壤与肥料,2020(3):210.D U W Y,T A N GS,WA N G H.T h e s t a t u s o f o r g a n i c f e r t i l i z e r i n d u s t r y a n d o r g a n i c f e r t i l i z e r r e s o u r c e s i nC h i n a[J].S o i l a n dF e r t i l i z e rS c i e n c e s i nC h i n a,2020(3):210.[7]宁川川,王建武,蔡昆争.有机肥对土壤肥力和土壤环境质量的影响研究进展[J].生态环境学报,2016,25(1):175.N I N GCC,WA N GJW,C A IKZ.T h eE f f e c t s o f o r g a n i c f e r-t i l i z e r s o n s o i l f e r t i l i t y a n d s o i l e n v i r o n m e n t a l q u a l i t y:a r e v i e w [J].E c o l o g y a n dE n v i r o n m e n t a l S c i e n c e s,2016,25(1):175.[8]杨小东,曾希柏,文炯,等.猪粪施用量对红壤旱地理化性质及酶活性的影响[J].土壤学报,2020,57(3):739.Y A N G XD,Z E N G X B,W E NJ,e ta l.E f f e c t so f a p p l i c a t i o n o f p i g m a n u r eo n p h y s i c o c h e m i c a l p r o p e r t i e sa n de n z y m ea c-t i v i t i e s o f r e d s o i l u p l a n d[J].A c t aP e d o l o g i c aS i n i c a,2020, 57(3):739.[9]尹嘉德,侯慧芝,张绪成,等.全膜覆土下施有机肥对春小麦旗叶碳氮比㊁光合特性和产量的影响[J].应用生态学报,2020, 31(11):3749.Y I NJD,HO U H Z,Z H A N G X C,e ta l.E f f e c t so fo r g a n i c f e r t i l i z e ra p p l i c a t i o n o nf l a g l e a f C/N r a t i o,p h o t o s y n t h e t i c c h a r a c t e r i s t i c s a n d y i e l do f s p r i n g w h e a tw i t h f u l l p l a s t i c f i l m m u l c h i n g[J].C h i n e s eJ o u r n a l o f A p p l i e dE c o l o g y,2020,31 (11):3749.[10]候丽丽,王伟,崔新菊,等.化肥减量配施有机肥对小麦生长㊁光合和产量的影响[J].麦类作物学报,2021,41(4):475.㊃115㊃第4期张天英等:猪粪和羊粪对盐碱障碍粮田冬小麦生理特征和产量的影响H O U LL,WA N G W,C U IXJ,e t a l.E f f e c t o f c h e m i c a l f e r-t i l i z e r r e d u c t i o nc o m b i n e d w i t ho r g a n i c f e r t i l i z e ra p p l i c a t i o n o n g r o w t h,p h o t o s y n t h e s i sa n d y i e l do fw h e a t[J].J o u r n a l o f T r i t i c e a eC r o p s,2021,41(4):475.[11]汪勇,孟庆峰.长期施用牛粪对松嫩平原盐渍化土壤脱盐碱化效果的影响(英文)[J].华北农学报,2022,37(2):142. WA N G Y,M E N G Q F.D e s a l i n i z a t i o ne f f e c t so f l o n g-t e r m c a t t l e a p p l i c a t i o ni ns a l i n e-s o d i cs o i l so nt h eS o n g n e nP l a i n [J].A c t aA g r i c u l t u r a eB o r e a l i-S i n i c a,2022,37(2):142.[12]WU YP,L IYF,Z H A N G Y,e t a l.R e s p o n s e so f s a l i n e s o i l p r o p e r t i e sa n dc o t t o n g r o w t ht o d i f f e r e n to r g a n i ca m e n d-m e n t s[J].P e d o s p h e r e,2018,28(3):521.[13]L A S HA R IM S,Y E Y X,J IH S,e ta l.B i o c h a r–m a n u r ec o m p o s t i n c o n j u n c t i o nw i t h p y r o l i g n e o u s s o l u t i o na l l e v i a t ed s a l t s t re s s a n d i m p r o v e d l e a fb i o a c t i v i t y o fm a i z e i nas a l i n e s o i lf r o mc e n t r a l C h i n a:a2-y e a r f i e l de x p e r i m e n t[J].J o u r-n a l o f t h eS c i e n c eo f F o o d&Ag r i c u l t u r e,2015,95(6): 1321.[14]侯胜鹏.中国主要有机养分资源利用潜力研究[D].北京:中国农业科学院,2017.H O USP.T h e u t i l i z a t i o n p o t e n t i a l o f t h em a i n o r g a n i c n u t r i-e n t r e s o u r c e s i nC h i n a[D].B e i j i n g:C h i n e s eA c a d e m y o fA g-r i c u l t u r a l S c i e n c e s,2017.[15]朱玉鹏,孟祥浩,盖伟玲,等.盐胁迫对冬小麦花后抗氧化酶㊁渗透调节物质的影响[J].中国农学通报,2017,33(19):1. Z HU YP,M E N GX H,G A IW L,e t a l.E f f e c t s o f s a l t s t r e s s o na n t i o x i d a n te n z y m e sa n do s m o t i ca d j u s t m e n ts u b s t a n c e s o fw i n t e rw h e a t[J].C h i n e s eA g r i c u l t u r a lS c i e n c eB u l l e t i n, 2017,33(19):1.[16]黄勇,郭猛,张红瑞,等.盐胁迫对石竹种子萌发和幼苗生长的影响[J].草业学报,2020,29(12):105.HU A N G Y,G U O M,Z H A N G H R,e ta l.E f f e c t so fs a l t s t r e s so ns e e d g e r m i n a t i o na n ds e e d l i n gg r o w t ho f c a r n a t i o n [J].A c t aP r a t a c u l t u r a eS i n i c a,2020,29(12):105. [17]S A L A R F A,S HA H R AM T.A n t i o x i d a n te n z y m ea n do s-m o t i c a d j u s t m e n tc h a n g e s i nb e a ns e e d l i n g sa sa f f e c t e db y b i o c h a r u n d e rs a l ts t r e s s[J].E c o t o x i c o l o g y a n d E n v i r o n-m e n t a l S a f e t y,2017,137:64.[18]李夕梅,韩伟,郭卫卫,等.有机肥与过磷酸钙混施对盐碱地冬小麦生长发育的影响[J].沈阳农业大学学报,2018,49 (3):331.L IX M,HA N W,G U O W W,e t a l.E f f e c t s o fm i x e d o r g a n i c f e r t i l i z e r a n d c a l c i u ms u p e r p h o s p h a t e o n g r o w t h a n d d e v e l o p-m e n t o fw i n t e r w h e a t i ns a l i n e-a l k a l is o i l[J].J o u r n a lo f S h e n y a n g A g r i c u l t u r a lU n i v e r s i t y,2018,49(3):331. [19]张盼盼,高立城,李晓敏,等.磷石膏和有机肥对盐碱地糜子产量和叶片生理特性的影响[J].中国农学通报,2018,34 (15):26.Z HA N GPP,G A OLC,L IX M,e t a l.P h o s p h o g y p s u ma n d o r g a n i c f e r t i l i z e r:e f f e c t s o n y i e l da n d l e a f p h y s i o l o g i c a l c h a r-a c t e r i s t i c s o f b r o o m c o r n m i l l e t i ns a l i n e-a l k a l i s o i l[J].C h i-n e s eA g r i c u l t u r a l S c i e n c eB u l l e t i n,2018,34(15):26.[20]F A L L A H M,H A D IH,AM I R N I A R,e t a l.E c o-f r i e n d l y s o i la m e n d m e n t s i m p r o v e g r o w t h,a n t i o x i d a n t a c t i v i t i e s,a n dr o o tc o l o n i z a t i o ni nl i n g r a i n(L i n u m u s i t a t i s s i m u m L.)u nde rd r o u g h t c o n d i t i o n s[J].P L o SO n e,2021,16(12):e0261225.[21]R A D Y M M,S E M I D A W M,H E M I D A K A,e ta l.T h ee f f e c t o f c o m p o s t o n g r o w t h a n d y i e l d o f P h a s e o l u s v u l g a r i s p l a n t s g r o w nu n d e r s a l i n e s o i l[J].I n t e r n a t i o n a l J o u r n a l o f R e c y c l i n g o f O r g a n i cW a s t e i nA g r i c u l t u r e,2016,5:311.[22]徐松华.逆境条件下植物体内活性氧代谢研究进展[J].安徽农学通报,2021,27(21):29.X U S H.R e s e a r c ha d v a n c e so fr e a c t i v eo x y g e ns p e c i e si n p l a n t s u n d e re n v i r o n m e n t a l s t r e s s[J].A n h u iA g r i c u l t u r a l S c i e n c eB u l l e t i n,2021,27(21):29.[23]赵隽,董树亭,刘鹏,等.有机无机肥长期定位配施对冬小麦群体光合特性及籽粒产量的影响[J].应用生态学报,2015, 26(8):2362.Z HA OJ,D O N G S T,L I U P,e ta l.E f f e c t so fl o n g-t e r m m i x e d a p p l i c a t i o n o f o r g a n i c a n d i n o r g a n i c f e r t i l i z e r s o n c a n o-p y a p p a r e n t p h o t o s y n t h e s i sa n d y i e l do fw i n t e rw h e a t[J].C h i n e s eJ o u r n a l o f A p p l i e dE c o l o g y,2015,26(8):2362.[24]萨如拉,杨恒山,邰继承,等.不同改良措施对碱化土壤特性及玉米生长的影响[J].玉米科学,2021,29(6):97.S A RL,Y A N G HS,T A I JC,e t a l.E f f e c t s o f d i f f e r e n t i m-p r o v e m e n t m e a s u r e s o n a l k a l i n e s o i l c h a r a c t e r i s t i c s a n d m a i z e g r o w t h[J].J o u r n a l o f M a i z e S c i e n c e s,2021,29(6):97.[25]陶荣荣,陆钰,于琪,等.盐逆境对不同耐盐性小麦花后生理特性及产量的影响[J].中国生态农业学报(中英文),2023, 31(3):428.T A O RR,L U Y,Y U Q,e t a l.E f f e c t s o f s a l t s t r e s s o n p h y s-i o l o g i c a lc h a r a c t e r i s t i c sa n d y i e l d o fd i f f e r e n ts a l t-t o l e r a n t w h e a tv a r i e t i e s[J].C h i n e s eJ o u r n a lo f E c o-A g r i c u l t u r e, 2023,31(3):428.[26]王世斌,高佩玲,赵亚东,等.生物炭㊁有机肥连续施用对盐碱土壤改良效果研究[J].干旱地区农业研究,2021,39(3): 154.WA N GSB,G A OPL,Z H A O YD,e t a l.E f f e c t s o f c o n t i n u-o u s a p p l i c a t i o no f b i o c h a r a n do r g a n i c f e r t i l i z e r s o n s a l i n e-a l-k a l i s o i l i m p r o v e m e n t[J].A g r i c u l t u r a lR e s e a r c h i n t h eA r-i dA r e a s,2021,39(3):154.[27]徐国凤,同延安.不同改良措施对卤阳湖盐碱地土壤性质及玉米产量的影响[J].干旱地区农业研究,2019,37(3):232. X U G F,T O N G Y A.E f f e c t so fs o i l p r o p e r t i e sa n d m a i z e y i e l d i nd i f f e r e n t i m p r o v e m e n tm e a s u r e so f s a l i n e-a l k a l i s o i l i nL u y a n g L a k e[J].A g r i c u l t u r a lR e s e a r c h i n t h eA r i dA r e-a s,2019,37(3):232.[28]罗佳,陈波浪,向光荣,等.有机肥对盐渍化耕地棉花干物质积累㊁养分吸收及产量的影响[J].中国土壤与肥料,2017 (2):107.L U OJ,C H E N B L,X I A N G G R,e ta l.E f f e c t so fo r g a n i c m a n u r e o nd r y m a t t e r a c c u m u l a t i o n,n u t r i e n t a b s o r p t i o na n d c o t t o n p r o d u c t i o no n s a l t-a f f e c t e d l a n d[J].S o i l a n dF e r t i l-i z e rS c i e n c e s i nC h i n a,2017(2):107.[29]张济世,于波涛,张金凤,等.不同改良剂对滨海盐渍土土壤理化性质和小麦生长的影响[J].植物营养与肥料学报, 2017,23(3):704.Z HA N GJ S,Y UBT,Z H A N GJ F,e t a l.E f f e c t s o f d i f f e r e n t a m e n d m e n t so ns o i l p h y s i c a la n dc h e m i c a l p r o p e r t i e sa n d w h e a t g r o w t h i na c o a s t a l s a l i n es o i l[J].J o u r n a l o f P l a n t N u t r i t i o na n dF e r t i l i z e r,2017,23(3):704. [30]谢娟娜,房琴,路杨,等.增施有机肥提升作物耐盐能力研究[J].中国农学通报,2018,34(3):42.X I EJN,F A N G Q,L U Y,e t a l.I n c r e a s i n g o r g a n i c f e r t i l i z e r s o n i m p r o v i n g s a l t r e s i s t a n c e o f c r o p[J].C h i n e s eA g r i c u l t u r-a l S c i e n c eB u l l e t i n,2018,34(3):42.[31]张乃丹,宋付朋,张喜琦,等.速缓效氮肥配施有机肥对滨海盐渍土供氮能力及小麦产量的影响[J].水土保持学报, 2020,34(6):337.Z HA N G N D,S O N GFP,Z HA N G X Q,e t a l.E f f e c t so f a-v a i l a b l e a n ds l o w-r e l e a s e dn i t r o g e nf e r t i l i z e rc o m b i n e d w i t h o r g a n i c f e r t i l i z e r o ns o i l n i t r o g e ns u p p l y c a p a c i t y a n dw h e a t y i e l d i nc o a s t a l s a l i n es o i l[J].J o u r n a lo f S o i la n d W a t e r C o n s e r v a t i o n,2020,34(6):337.㊃215㊃麦类作物学报第44卷。

微生物肥料术语〔NY/T 1113-2006〕1范围本标准规定了微生物肥料产品类型、菌种、培养基、灭菌、生产和质量检验等方面的主要术语。

本标准适用于微生物肥料生产、质检、应用、科研和教学等领域。

2产品类型微生物肥料microbial fertilizer; biofertilizer含有特定微生物活体的制品,应用于农业生产,通过其中所含微生物的生命活动,增加植物养分的供给量或促进植物生长,提高产量,改善农产品品质及农业生态环境。

注:目前,微生物肥料包括微生物接种剂〔〕、复合微生物肥料〔〕和生物有机肥〔〕。

微生物接种剂microbial inoculant[微生物]菌剂一种或一种以上的目的微生物经工业化生产增殖后直接使用,或经浓缩〔〕或经载体〔〕吸附〔〕而制成的活菌制品。

单一菌剂single species inoculant由一种微生物菌种制成的微生物接种剂〔〕。

复合菌剂multiple species inoculant由两种或两种以上且互不拮抗的微生物菌种制成的微生物接种剂〔〕。

细菌菌剂bacterial inoculant以细菌为生产菌种制成的微生物接种剂〔〕。

放线菌菌剂actinomycetic inoculant以放线菌为生产菌种制成的微生物接种剂〔〕。

真菌菌剂fungal inoculant以真菌为生产菌种制成的微生物接种剂〔〕。

固氮菌菌剂azotobacteria inoculant以自生固氮菌和/或联合固氮菌为生产菌种制成的微生物接种剂〔〕。

根瘤菌菌剂rhizobia inoculant以根瘤菌〔〕为生产菌种制成的微生物接种剂〔〕。

硅酸盐细菌菌剂silicate bacteria inoculant以硅酸盐细菌〔〕为生产菌种制成的微生物接种剂〔〕。

溶磷微生物菌剂inoculant of phosphate-solubilizing microorganism以溶磷微生物〔〕为生产菌种制成的微生物接种剂〔〕。

糖厂滤泥发酵制成生物有机肥谭宏伟【摘要】[目的]掌握采用糖厂滤泥经功能菌发酵制成生物有机肥的特点和规律,为促进广西蔗区糖料蔗产业可持续生产提供技术支持,同时为政府制定农业种植环境保护相关政策提供决策参考.[方法]在广西重要蔗糖生产区(来宾市兴宾区和崇左市大新县)开展以糖厂滤泥为原料、发酵生产生物有机肥的田间试验,研究糖厂滤泥发酵生产生物有机肥的特征及肥效.[结果]采用功能菌发酵糖厂滤泥生产生物有机肥的腐熟速度快,受环境因素影响较小,发酵效果稳定,发酵温度最高达77.2℃,且70.0~77.2℃的维持时间长达12 d;发酵后的有机质含量和有机酸转化率优势明显,分别较传统(自然)发酵提高30.2%和12.3%(绝对值).功能菌发酵生物有机肥对水稻、黄瓜和甘蔗有明显的增产作用,对应的平均产量分别为5971.5、76705.5和118780.5 kg/ha,较施等量传统(自然)发酵生物有机肥处理分别增产7.83%、41.19%和6.91%.施用功能菌发酵生物有机肥的土壤理化性状指标均高于施用传统(自然)发酵生物有机肥处理,其中土壤有机质、速效氮、速效磷和速效钾的含量分别为15.75 g/kg、67 mg/kg、14 mg/kg和69 mg/kg,而氮、磷和钾利用率分别为39.3%、12.8%和52.8%.[结论]采用功能菌发酵糖厂滤泥生产生物有机肥较传统(自然)发酵糖厂滤泥生产生物有机肥更具优势,具体表现为腐熟速度快、发酵温度高且保持时间长、发酵后有机质含量和有机酸转化率优势明显,同时具有增产、提高土壤肥力和肥料利用率的作用,生产上可大面积推广应用.%[Objective]The present study investigated characteristics and regulation of bio-organic fertilizer made by fermentation of filter mud from sugar refinery, in orderto provide technical support for sustainable development of sugar-cane industry in Guangxi sugarcane planting area and offer reference forgovernment to formulate agricultural planting and environmental protection policies. [Method]Field trial was conducted in important sugarcane planting area in Guangxi (Xingbin district in Laibin city, Daxin county in Chongzuo city) . Filter mud from sugar refinery was taken as raw materials and fermented into bio-organic fertilizer. Characteristics and fertilizer efficiency of the bio-organic fertilizer were studied.[Result]Bio-organic fertilizer fermented via functional bacteria rotted rapidly, hardly affected by environmental factors. Fermentation effects were stable, fermentation temperature could reach 77.2 ℃, and the temperature maintaining at 70.0-77.2 ℃ for 12 days. Organic matter content and organic acid conversion rate after fermented were 30.2% and 12.3%(abso-lute value) higher than those in traditional(natural) mode. Bio-organic fertilizer fermented via functional bacteria could im-prove yield of rice, cucumber and sugarcane greatly. Average yield of rice was 5971.5 kg/ha, an increase of 7.83% com-pared with the rice applied with bio-organic fertilizer fermented in traditional(natural) mode; average yield of cucumber was 76705.5 kg/ha, an increase of 41.18%, average yield of sugarcane was 118780.5 kg/ha, an increase of 6.91%.After application of bio-organic fertilizer fermented via functional bacteria, physical and chemical properties of soil were superior than those applied with bio-organic fertilizer fermented in traditional(natural) mode. In the soil, organic matter content was 15.75 g/kg, available nitrogen content 67 mg/kg, available phosphorus content 14 mg/kg, available potassium content 69 mg/kg. Utilization efficiency of nitrogen, phosphorus and potassium were 39.3% ,12.8% and 52.8% , respectively.[Conclusion]Bio-organic fertilizer fermented via functional bacteria using filter mud from sugar refinery is better thanfer-mentation in traditional(natural) mode. The advantages include rapid rotting speed, high fermentation temperature and long duration, superior organic matter content and organic acid conversion rate after fermentation. Meanwhile, it can increase the yield, soil fertility and fertilizer utilization efficiency. Therefore, it can be promoted for large scale application.【期刊名称】《南方农业学报》【年(卷),期】2017(048)003【总页数】5页(P428-432)【关键词】糖厂滤泥;发酵;生物有机肥;肥效;特征【作者】谭宏伟【作者单位】广西农业科学院甘蔗研究所, 南宁 530007【正文语种】中文【中图分类】S141.5【研究意义】广西是我国最大的糖业基地,蔗糖产量约占全国的70%(李杨瑞等,2014;覃泽林等,2015;谭芳等,2016)。

Chemical or Organic Farming? (Reading)Teaching aims:1.Develop students reading skills by skimming for main ideas and scanning for details。

2.Have students learn and talk about disadvantages of chemical farming and advantages of organic farming。

3.Master some key words and phrases: chemical, organic, build up,lead to,keep…free from,focus on,production,cause damage to.Important and different teaching points:1.Enable students to learn to use strategies such as skimming,scanning, and so on to dotheir reading。

2.To understand the main ideas by grasping some important information.Teaching aids:A multimedia project,colour chalks, text, workbook。

Teaching procedure:Step Ⅰ. Lead in1。

Self introduction: Good morning,students,my name is Li Ou,you can call me Mrs. Li or Teacher Li。

Hope we can have a good time in this class. Today, we are going to learn more about unit 2 – working the land。

新型生物有机肥在黄瓜连作障碍上的效果试验作者:张娜王永欢来源:《农业科技与装备》2020年第03期摘要:设施蔬菜土壤连作障碍是设施农业发展的一大难题。

选用微生物菌剂配合相关基质研制一种新型生物有机肥,并在黄瓜上施用。

结果表明:使用该产品后,黄瓜生育性状明显改观,患病植株大量减少,同时黄瓜产量显著增加。

·关键词:黄瓜;连作障碍;生物有机肥;效果中图分类号:S156 文献标识码:A 文章编号:1674-1161(2020)03-0005-02近年来,人口数量逐年上升,人们对粮食、蔬菜、水果等的需求量也随之增加。

但生態环境日渐恶化,水土资源严重流失,因此,提高土壤利用率与农村土地经营集约化已成为现代农业发展的大趋势。

设施蔬菜的发展不仅解决了我国蔬菜供应问题,也为农业产业结构调整和农民致富提供了重要途径。

但是,随着设施栽培的推广,作物种类单一、种植地域化、农业复种指数较高等问题导致的连作障碍成为一大难题,影响农业可持续发展。

目前,多采用轮作、化学防治、土壤消毒等措施来缓解设施土壤连作障碍。

本课题研制一种新型生物有机肥产品,以降低土传病害,改善黄瓜生育性状,提高黄瓜产量。

1 材料与方法1.1 试验材料供试肥料为自主研制的新型黄瓜连作障碍生物有机肥。

配比为:1~3质量份菌剂、25~35质量份的草炭土、33~43质量份的腐熟畜禽粪便、25~35质量份的腐殖酸、1~5质量份的香菇菇柄脚和1~3质量份的烟草梗。

菌剂的活性成分为地衣芽孢杆菌(Bacilluslicheniformis)ACCC No.02975,菌剂的质量份满足地衣芽孢杆菌含量为 2.0×107~2.4×108 cfu/g。

1.2 试验方法1.2.1 试验设计选择有连作障碍的棚区作为试验地。

试验设4个处理,不设重复,小区面积100 m2,随机排列,每个小区400株苗。

具体施肥方案如下:处理1(CK),常规施肥;处理2,常规施肥+连作障碍生物有机肥产品150 kg/667 m2;处理3,常规施肥+等量常规生物有机肥(以鸡粪为主要原料);处理4,常规施肥+等量常规有机肥+农用微生物菌剂(与处理2同菌)。

有机化肥和无机化肥有什么区别英语作文全文共3篇示例,供读者参考篇1The Difference Between Organic and Inorganic FertilizersFertilizers play a crucial role in agriculture by providing essential nutrients to plants to promote growth and increase crop yields. There are two main types of fertilizers commonly used in farming: organic and inorganic. While both types have their benefits and drawbacks, they differ in several key ways.Organic fertilizers are derived from natural sources such as plant and animal matter. Examples of organic fertilizers include compost, manure, and bone meal. These fertilizers contain a variety of nutrients and micronutrients that are released slowly over time as they decompose. Organic fertilizers also improve the soil structure and increase its ability to retain water and nutrients, leading to healthier plants and improved soil health.On the other hand, inorganic fertilizers are synthetic compounds that are manufactured using chemical processes. Examples of inorganic fertilizers include ammonium nitrate, potassium sulfate, and superphosphate. These fertilizers aremore concentrated and provide nutrients to plants more quickly than organic fertilizers. However, they can also leach into the soil and pollute water sources if not used properly. Inorganic fertilizers can also lead to a build-up of salts in the soil, which can harm plants and reduce the fertility of the soil over time.One of the main differences between organic and inorganic fertilizers is their impact on the environment. Organic fertilizers are made from natural materials and are considered to be more environmentally friendly because they do not contain synthetic chemicals that can harm the soil and water. In contrast, inorganic fertilizers can contribute to soil and water pollution if not used responsibly. They can also have a negative impact on soil organisms and beneficial bacteria that play a vital role in maintaining soil health.Another difference between organic and inorganic fertilizers is their cost. Organic fertilizers are often more expensive than inorganic fertilizers because they require more time and effort to produce. However, organic fertilizers provide long-term benefits to the soil and plants, making them a more sustainable option in the long run. In contrast, inorganic fertilizers are cheaper and easier to use, but they may lead to soil degradation and nutrient depletion over time.In terms of nutrient content, organic fertilizers are typically lower in nitrogen, phosphorus, and potassium compared to inorganic fertilizers. This means that organic fertilizers may need to be applied in larger quantities to meet the nutrient requirements of plants. However, organic fertilizers contain a wider range of micronutrients and organic matter that can improve soil fertility and plant health in the long term.Overall, both organic and inorganic fertilizers have their advantages and disadvantages. Organic fertilizers are more environmentally friendly and improve soil health, but they can be more expensive and require more time to see results. Inorganic fertilizers are cheaper and provide nutrients to plants more quickly, but they can harm the environment and lead to soil degradation over time. Farmers should carefully consider the benefits and drawbacks of each type of fertilizer and choose the one that best suits their needs and goals for sustainable agriculture.篇2Organic fertilizers and inorganic fertilizers are two types of fertilizers commonly used in agriculture. While both types serve the purpose of providing essential nutrients to plants, there are several key differences between the two.Organic fertilizers are made from natural sources such as compost, manure, bone meal, and fish emulsion. These materials are broken down by microorganisms in the soil, releasing nutrients slowly over time. Organic fertilizers are rich in organic matter, which helps improve soil structure, aeration, and water retention. They also stimulate the growth of beneficial microorganisms in the soil, which can help suppress plant diseases.On the other hand, inorganic fertilizers are synthetic chemicals that are manufactured in a laboratory. These fertilizers are typically water-soluble and provide nutrients to plants immediately after application. Inorganic fertilizers are often high in nitrogen, phosphorus, and potassium, which are essential nutrients for plant growth. However, their quick-release nature can lead to nutrient runoff and leaching, which can harm the environment.One of the main differences between organic and inorganic fertilizers is their nutrient availability. Organic fertilizers release nutrients slowly over time, providing a steady supply of nutrients to plants. In contrast, inorganic fertilizers provide nutrients immediately but can also wash away quickly, leading to nutrient depletion in the soil.Another key difference between the two types of fertilizers is their impact on soil health. Organic fertilizers help improve soil structure and microbial activity, leading to healthier, more resilient soils. In contrast, inorganic fertilizers can degrade soil quality over time, leading to soil compaction, erosion, and reduced microbial diversity.Organic fertilizers are also more environmentally friendly than inorganic fertilizers. Organic fertilizers are derived from natural sources and do not contain harmful chemicals that can leach into waterways and harm aquatic ecosystems. In contrast, inorganic fertilizers can contribute to water pollution and soil degradation if not used properly.In conclusion, both organic and inorganic fertilizers have their advantages and disadvantages. Organic fertilizers are beneficial for improving soil health and sustainability, while inorganic fertilizers provide a quick source of nutrients to plants. It is important for farmers to consider the long-term impact of their fertilizer choices on soil health and the environment and to use fertilizers responsibly to ensure sustainable agriculture practices.篇3Organic Fertilizer vs. Inorganic FertilizerFertilizers play a crucial role in enhancing crop growth and increasing yields. There are mainly two types of fertilizers- organic and inorganic. Each type of fertilizer has its own set of advantages and disadvantages.Organic fertilizer is derived from natural sources such as animal manure, compost, and plant materials. It contains organic matter and beneficial microorganisms that improve soil structure and fertility. Organic fertilizers are known for their slow-release nutrients, which provide a steady supply of essential elements to plants over time. They also help to improve soil health by promoting microbial activity and increasing organic matter content.In contrast, inorganic fertilizer is made from synthetic chemicals and minerals. It is commonly used in conventional agriculture due to its high nutrient content and fast-acting nature. Inorganic fertilizers provide plants with readily available nutrients, which can be immediately taken up by the roots. However, the downside of inorganic fertilizers is that they can lead to soil degradation and nutrient imbalances if overused. They can also decrease the soil's ability to retain water andnutrients, leading to environmental pollution and reduced crop resilience.One of the key differences between organic and inorganic fertilizers is their impact on the environment. Organic fertilizers are considered to be more environmentally-friendly as they do not contain harmful chemicals or contribute to soil and water pollution. They also help to reduce greenhouse gas emissions and promote sustainable farming practices. On the other hand, inorganic fertilizers can have negative effects on soil quality, biodiversity, and human health if not used responsibly.Another difference between organic and inorganic fertilizers is their cost and availability. Organic fertilizers are often more expensive and less readily available than inorganic fertilizers, as they require more time and resources to produce. However, organic fertilizers can be produced on-site using kitchen scraps, yard waste, and other organic materials, making them acost-effective and sustainable option for many farmers.In conclusion, both organic and inorganic fertilizers have their own advantages and disadvantages. It is important for farmers to consider factors such as soil health, environmental impact, cost, and availability when choosing the right fertilizer for their crops. By understanding the differences betweenorganic and inorganic fertilizers, farmers can make informed decisions that promote sustainable agriculture and ensure long-term soil fertility.。

吴瑕,周浩楠,刘德阳,等.有机肥与生物炭对小白菜光合作用及硝酸盐积累的影响[J].沈阳农业大学学报,2023,54(4):403-412.收稿日期:2023-04-10基金项目:黑龙江省自然科学基金联合引导项目(LH2021C066);大学生创新创业项目(202110223016);黑龙江八一农垦大学博士科研启动资助计划项目(XDB201819)第一作者:吴瑕(1978-),女,博士后,副教授,从事设施园艺生理生态与蔬菜安全生产研究,E-mail :wuxiaxia_2005@有机肥与生物炭对小白菜光合作用及硝酸盐积累的影响吴瑕a,b ,周浩楠a ,刘德阳a ,胡艺琛a ,王鹏c [黑龙江八一农垦大学a.园艺园林学院,b.农业农村部农产品加工质量监督检验检测中心(大庆)博士后工作站,c.农学院,黑龙江大庆163319]摘要:为探究提高小白菜生长及品质的适宜的施肥方式,通过小白菜盆栽试验,设置常规化肥(对照,CK )、有机肥替代化肥50%(O)和常规化肥添加3%生物炭(C)处理,研究不同施肥处理对小白菜光合作用、生长指标、硝酸还原酶活性及硝酸盐含量的影响。

结果表明:有机肥和生物炭处理显著提高小白菜的干、鲜重,有机肥处理提高小白菜干重达到55%以上,生物炭处理提高小白菜干重达到30%以上。

其中播种后28d 小白菜气孔导度和光合速率显著提升,42d 时蒸腾速率显著提升,不同施肥处理一定程度上提高小白菜净光合速率。

56d 时,50%有机肥替代化肥和3%生物炭处理小白菜的硝酸盐含量显著低于对照,两处理小白菜的硝酸还原酶活性均显著高于对照。

生长56d 时,施用50%有机肥和3%生物炭处理小白菜根际土壤中有机质含量、碱解氮含量、速效磷含量、速效钾含量、土壤EC 值和pH 值均显著高于施用常规化肥的对照,两处理小白菜的株高,干、鲜重和根长均显著高于对照。

小白菜干物质积累与胞间二氧化碳和硝酸还原酶呈显著正相关,与土壤速效养分呈显著负相关。

用英语做实验报告AbstractThis experiment aimed to investigate the effects of different fertilizers on plant growth. Five types of fertilizers, including organic fertilizer, chemical fertilizer, nitrogen fertilizer, phosphorus fertilizer, and potassium fertilizer, were tested on three groups of plants. The plants were observed and measured for growth over a period of four weeks. The results showed that organic and chemical fertilizers produced the highest growth rates, while plants treated with nitrogen, phosphorus, and potassium fertilizers exhibited varying degrees of growth. These findings suggest that the choice of fertilizer can significantly influence plant growth.IntroductionFertilizers are substances that are applied to plants to improve their growth and yield. They provide essential nutrients that may be lacking in the soil, such as nitrogen, phosphorus, and potassium. Different types of fertilizers contain different ratios of these nutrients, which can affect plant growth differently. Understanding the effects of different fertilizers on plant growth is important for optimizing agricultural practices and maximizing crop productivity.MethodsMaterials- Five types of fertilizers: organic, chemical, nitrogen, phosphorus, and potassium fertilizers- Thirty identical potted plants (species: Arabidopsis thaliana)- Measuring tape or ruler- Watering can- Stopwatch or timerExperimental Design1. Divide the thirty plants into three groups of ten plants each.2. Group 1: Control group - receive no fertilizer3. Group 2: Organic and chemical fertilizers4. Group 3: Nitrogen, phosphorus, and potassium fertilizers5. Apply the respective fertilizers to the plants according to their assigned group.6. Water all plants regularly to maintain consistent moisture levels.7. Measure the height of each plant using a measuring tape or ruler every seven days.8. Record the data and observe any visible changes in plant health, color, or size.Data AnalysisCalculate the average height of plants in each group at each week. Plot the average plant height against the number of weeks for visual analysis. Perform statistical analysis, such as t-tests, to compare the growth ratesof different groups and determine the significance of the differences observed.ResultsThe average plant heights for each group at each week are presented in Table 1 and depicted graphically in Figure 1.Week Control Organic & Chemical Nitrogen, Phosphorus & Potassium1 5.2 cm 6.5 cm 5.8 cm2 6.1 cm 8.3 cm 6.9 cm3 7.3 cm 10.1 cm 7.6 cm4 9.2 cm 12.4 cm 8.9 cmFrom the results, it is evident that plants treated with organic and chemical fertilizers exhibited higher growth rates compared to the control group. The increases in height for these groups were consistently higher each week. In contrast, the group treated with nitrogen, phosphorus, and potassium fertilizers showed a slight increase in growth compared to the control group but lower growth compared to the organic and chemical fertilizer groups.DiscussionThe results of this experiment demonstrate the importance of fertilizer choice in influencing plant growth. The organic and chemical fertilizersprovided a more balanced combination of nutrients, resulting in significant growth. This may be attributed to the presence of essential macronutrients and micronutrients in both types of fertilizers. The controlled release of nutrients from organic fertilizers and the fast-acting nature of chemical fertilizers can lead to better nutrient absorption and utilization by plants.On the other hand, the moderate growth observed in plants treated with nitrogen, phosphorus, and potassium fertilizers suggests that the plants may have experienced nutrient imbalances. Different plant species have varying nutrient requirements, and a mismatch between the supplied nutrients and the plant's needs can limit growth. Additionally, excessive amounts of certain nutrients, such as nitrogen, can lead to adverse effects on plant health and even environmental pollution.Further research could explore the optimal ratios of nutrients for specific plant species and growth stages. Additionally, investigating thelong-term effects of different fertilizers on soil quality and biodiversity would provide valuable insights for sustainable agricultural practices. ConclusionThis experiment demonstrated that organic and chemical fertilizers resulted in the highest growth rates in plants, while nitrogen, phosphorus, and potassium fertilizers showed varying degrees of growth. The findings highlight the importance of considering fertilizer choice tooptimize plant growth and maximize agricultural productivity. Further research is needed to explore optimal nutrient ratios for different crops and evaluate the long-term effects of fertilizers on soil health and biodiversity.References[Insert relevant references here]。