印度GMP 中英文对照

- 格式:pdf

- 大小:318.31 KB

- 文档页数:44

GMP规范中英文对照Chapter 1: General Provisions第一章总则Article 1: This Regulation is enacted in accordance with the "Drug Administration Law of The People's Republic of China".第一条根据《中华人民共和国药品管理法》规定,制定本规范。

Article 2: This Regulation is promulgated as the basic guideline for manufacturing and quality control of pharmaceutical products. This Regulation shall be applicable to all the manufacturing processes of drug preparations and to the key manufacturing processes of raw materials which may cause variation in the quality of finished products.第二条本规范是药品生产和质量管理的基本准则。

适用于药品制剂生产的全过程、原料药生产中影响成品质量的关键工序。

Chapter 2: Organization and PersonnelArticle 3: A pharmaceutical enterprise shall establish production and quality control departments. The responsibilities of departments at all levels and personnel shall be clarified, and each department shall be staffed by an appropriate number of management and technical personnel with expert knowledge, manufacturing experience and organization ability. 第三条药品生产企业应建立生产和质量管理机构。

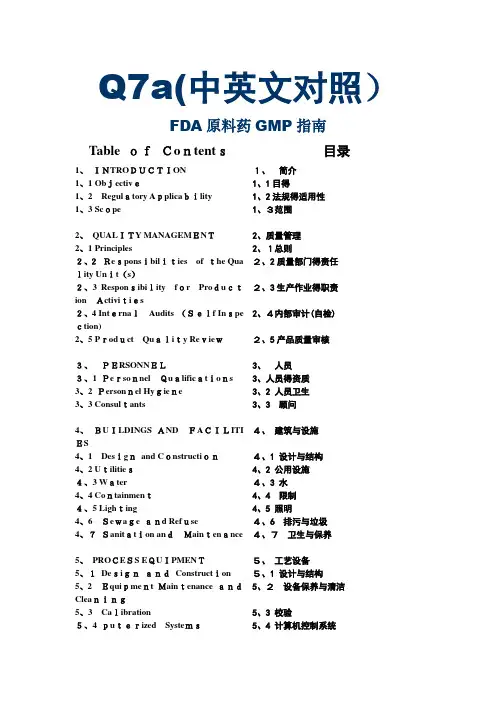

Q7a(中英文对照)FDA原料药GMP指南Table ofContents目录1、INTRODUCTION 1、简介1、1 Objective1、1目得1、2Regulatory Applicability 1、2法规得适用性1、3 Scope 1、3范围2、QUALITY MANAGEMENT2、质量管理2、1 Principles 2、1总则2、2质量部门得责任2、2Responsibilities of the Quality Unit(s)2、3生产作业得职责2、3 Responsibility for ProductionActivities2、4内部审计(自检)2、4 InternalAudits (Self Inspection)2、5 Product Quality Review2、5产品质量审核3、PERSONNEL3、人员3、1 PersonnelQualifications 3、人员得资质3、2 Personnel Hygiene 3、2 人员卫生3、3 Consultants 3、3 顾问4、建筑与设施4、BUILDINGS ANDFACILITIES4、1Designand Construction4、1 设计与结构4、2 Utilities4、2 公用设施4、3 Water4、3 水4、4 Containment4、4 限制4、5 Lighting 4、5 照明4、6Sewage and Refuse 4、6 排污与垃圾4、7Sanitation andMaintenance 4、7卫生与保养5、PROCESS EQUIPMENT5、工艺设备5、1DesignandConstruction 5、1 设计与结构5、2Equipment Maintenance and5、2设备保养与清洁Cleaning5、3Calibration 5、3 校验5、4 puterized Systems5、4 计算机控制系统6、DOCUMENTATION AND RECORDS6、文件与记录6、1 Documentation System andSpecifications6、1 文件系统与质量标准6、2EquipmentcleaningandUseRecord6、2 设备得清洁与使用记录6、3 Recordsof Raw Materials,Intermediates,APILabeling andPackaging Materials 6、3 原料、中间体、原料药得标签与包装材料得记录6、4Master Production Instructions (Master Production and ControlRecords)6、4 生产工艺规程(主生产与控制记录)6、5 BatchProduction Records(Batch Production andControlRecords)6、5 批生产记录(批生产与控制记录)6、6Laboratory ControlRecords 6、6 实验室控制记录6、7 Batch Production RecordReview6、7批生产记录审核7、MATERIALSMANAGEMENT7、物料管理7、1GeneralControls 7、1 控制通则7、2Receiptand Quarantine 7、2接收与待验7、3Sampling andTesting of IningProduction Materials7、3 进厂物料得取样与测试7、4 Storage 7、4储存7、5Re-evaluation 7、5复验8、PRODUCTION ANDIN—PROCESS CONTROLS8、生产与过程控制8、1ProductionOperations 8、1 生产操作8、2 Time Limits 8、2 时限8、3 In-process Sampling and Controls8、3 工序取样与控制8、4 BlendingBatches ofIntermediatesor APIs8、4 中间体或原料药得混批8、5 Contamination Control 8、5 污染控制9、PACKAGING AND IDENTIFICATION LABELING OF APIs AND INTERMEDIATES9、原料药与中间体得包装与贴签9、1General 9、1 总则9、2Packaging Materials 9、2 包装材料9、3Label Issuance andControl 9、3标签发放与控制9、4Packaging and LabelingOp9、4包装与贴签操作erations10、储存与分发10、STORAGE AND DISTRIBUTION10、1 Warehousing Procedures 10、1 入库程序10、2DistributionProcedures 10、2 分发程序11、LABORATORY CONTROLS 11、实验室控制11、1 General Controls 11、1控制通则11、2中间体与原料药得测试11、2 Testing ofIntermediatesandAPIs11、3 Validation of Analytical11、3 分析方法得验证Procedures11、4CertificatesofAnalysis11、4 分析报告单11、5 原料药得稳定性监测11、5 Stability Monitoringof APIs11、6 Expiryand RetestDating11、6 有效期与复验期11、7Reserve/Retention Samples 11、7 留样12、VALIDATION 12、验证12、1 Validation Policy 12、1 验证方针12、2 Validation Documentation12、2 验证文件12、3Qualification 12、3 确认12、4 工艺验证得方法12、4Approachesto ProcessValidation12、5 Process Validation Program12、5 工艺验证得程序12、6PeriodicReviewof12、6验证系统得定期审核Validated Systems12、7 CleaningValidation 12、7 清洗验证12、8 分析方法得验证12、8 Validation of Analytical Methods13、CHANGECONTROL 13、变更得控制14、REJECTIONANDRE-USEO14、拒收与物料得再利用FMATERIALS14、1 Rejection 14、1 拒收14、2Reprocessing14、2 返工14、3Reworking 14、3 重新加工14、4Recovery of Materialsand14、4 物料与溶剂得回收Solvents14、5Returns14、5 退货15、PLAINTS AND RECALLS 15、投诉与召回16、CONTRACTMANUFACTURERS (INCLUDING LABORATORIES)16、协议生产商(包括实验室)17、AGENTS,BROKERS, TRADERS,DISTRIBUTORS,REPACKERS,AND RELABELLERS17、代理商、经纪人、贸易商、经销商、重新包装者与重新贴签者17、1Applicability 17、1适用性17、2Traceabilityof DistributedAPIs and Intermediates17、2已分发得原料药与中间体得可追溯性17、3QualityManagement 17、3质量管理17、4Repackaging, Relabeling,and Holding of APIsandInterm ediates17、4原料药与中间体得重新包装、重新贴签与待检17、5Stability 17、5稳定性17、6 TransferofInformation 17、6 信息得传达17、7Handling ofplaints andRecalls17、7投诉与召回得处理17、8Handlingof Returns 17、8 退货得处理18、Specific Guidance for APIs Manufactured byCell Culture/Fermentation18、用细胞繁殖/发酵生产得原料药得特殊指南18、1 General 18、1总则18、2Cell Bank Maintenanceand Record Keeping18、2细胞库得维护与记录得保存18、3 CellCulture/Fermentation18、3细胞繁殖/发酵18、4 Harvesting, IsolationandPurification18、4收取、分离与精制18、5Viral Removal/Inactivation steps18、5 病毒得去除/灭活步骤19、APIsfor Use in Clinical Trials19、用于临床研究得原料药19、1General 19、1 总则19、2 Quality 19、2 质量19、3Equipment and Facilities 19、3设备与设施19、4 ControlofRaw Materials 19、4原料得控制19、5Production 19、5 生产19、6Validation 19、6 验证19、7 Changes19、7变更19、8 Laboratory Controls 19、8实验室控制19、9 Documentation 19、9 文件20、Glossary 20、术语Q7a GMP Guidance forAPIs Q7a原料药得GMP指南1、INTRODUCTION1、简介1、1 Objective1、1目得Thisdocument isintendedto provide guidance regarding good manufacturingpractice (GMP) for the manufacturing of active pharmaceuticalingredients (APIs)underan app ropriate systemfor managing qualit y、Itis also intended tohelp ensure that APIsmeet the qualityand puritycharacteristicstha ttheypurport,or arerepresented,to possess、本文件旨在为在合适得质量管理体系下制造活性药用成分(以下称原料药)提供有关优良药品生产管理规范(GMP)提供指南。

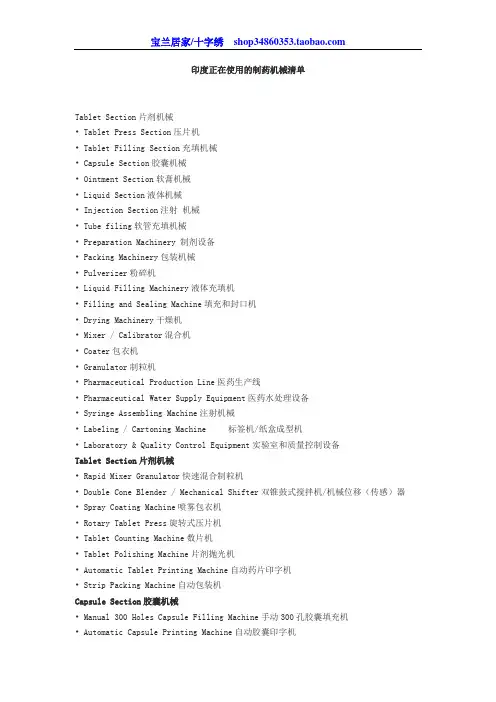

印度正在使用的制药机械清单Tablet Section片剂机械• Tablet Press Section压片机• Tablet Filling Section充填机械• Capsule Section胶囊机械• Ointment Section软膏机械• Liquid Section液体机械• Injection Section注射机械• Tube filing软管充填机械• Preparation Machinery 制剂设备• Packing Machinery包装机械• Pulverizer粉碎机• Liquid Filling Machinery液体充填机• Filling and Sealing Machine填充和封口机• Drying Machinery干燥机• Mixer / Calibrator混合机• Coater包衣机• Granulator制粒机• Pharmaceutical Production Line医药生产线• Pharmaceutical Water Supply Equipment医药水处理设备• Syringe Assembling Machine注射机械• Labeling / Cartoning Machine 标签机/纸盒成型机• Laboratory & Quality Control Equipment实验室和质量控制设备Tablet Section片剂机械• Rapid Mixer Granulator快速混合制粒机• Double Cone Blender / Mechanical Shifter双锥鼓式搅拌机/机械位移(传感)器• Spray Coating Machine喷雾包衣机• Rotary Tablet Press旋转式压片机• Tablet Counting Machine数片机• Tablet Polishing Machine片剂抛光机• Automatic Tablet Printing Machine自动药片印字机• Strip Packing Machine自动包装机Capsule Section胶囊机械• Manual 300 Holes Capsule Filling Machine手动300孔胶囊填充机• Automatic Capsule Printing Machine自动胶囊印字机• Automatic 300 Holes Capsule Loading Machine自动300孔胶囊上料机• Capsule Inspection cum Polishing Machine胶囊检查与抛光机• Blister Packaging Machine泡罩包装机• Capsule Counting and Packing Machine胶囊数粒包装机Ointment / Tube Filling Machine药膏/管充填机(灌装机)• Automatic Cream / Paste / Ointment Manufacturing Plant自动霜膏、软膏、药膏制造设备• Planetary Mixer行星搅拌机• Manual Tube filling / Manual Tube Crimping Machine手动软管充填机/手动软管翻边机• Tube Filling and Sealing Machine软管充填和封口机• Lami / Plastic Tube Filling and Sealing Machine Lami/塑料管灌封机• High Speed Automatic Double Head / Triple Head Container Filling Machine高速自动双头/三头灌装机• Automatic Bottle / Container Capping Machine自动瓶/容器压盖机Liquid Section液体机械• Manufacturing Vessels / Homogenizer / Stirrer均化器/搅拌器• High Speed Automatic Bottle Filling & Cap Sealing Machine高速自动装瓶压盖封口机• Twin Head Volumetric Filling Machine双头容积式灌装机• Filter Press / Colloid Mill压滤机/胶体磨• Rotary Bottle Washing Machine旋转式洗瓶机• Automatic Labeling / Gumming / Stikering Machine自动贴标/上胶/贴膜机Laboratory & Quality Control Equipment & Tablet Section实验室和质量控制设备和片剂设备• Leak Test Apparatus泄漏测试仪• Six Stage Dissolution Rate Test Apparatus六步溶出度试验仪• Microprocessor Based Tablet Disintegration Machine微处理操控的片剂崩解仪• Microprocessor control Programmable counter微处理控制的可编程计数器• Friabilator磨损度试验器• Tablet Hardness Tester (Automatic)片剂硬度测试仪(自动)• Tablet Friability Tester片剂磨损度测试仪• Melting Point Apparatus融点仪• Precision Melting Point cum – Boiling point apparatus精密融点和沸点仪• Automatic Tablet Counting Machine自动数片机• Disintegration Tester崩解测试仪• Tablet Dissolution Tester片剂溶出度测试仪• Room Dehumidifier / Inspection Tables除湿机/检验桌Injectables Section注射设备• Dry heat Sterilizer - GMP干热消毒器• Rubber Bung Washing Machine胶塞清洗机• Membrane Filter system膜过滤系统• Vertical Autoclave立式蒸压釜• Distilled Water Still蒸馏水蒸馏釜• Pressure Vessel压力容器• Filling Vessel灌装容器• Turn Table回转台• Ampoule Labeling Machine安瓿瓶贴标机• Automatic Vial 1/2/4 filling machine全自动小瓶1/2/4灌装机• Automatic Vial Capping Machine全自动小瓶压盖机• Volumetric Vial Washing Machine 小瓶清洗机Pharmaceutical Filling Machines填充机• Ampoule Filling Machine安瓶填充机• Capsule Filling Machine胶囊充填机• Liquid Filling Machine液体灌装机• Ointment Filling Machine药膏灌装机• Powder Filling Machine粉末充填机• Syringe Filling Machine注射式灌装机• Tube Filling Machine软管充填机• Vial Filling Machine小瓶灌装机• Volumetric Filling Machine容积式灌装机Pharmaceutical Processing Machines医药加工设备• Bottle Capping Machine瓶子封盖机• Capsule Counters胶囊数粒机• Compactors压实机• Electronic Counters电子计数器• Filter Press压滤机• Fluid Bed Dryer流化床干燥机• Freeze Drying Machine冻干机• Isostatic Press等静压机• Ointment Making Machine制膏机• Peristaltic Pump· Ph Meter 蠕动泵 Ph计• Pharmaceutical Separator分离器• Rotary Tablet Press旋转式压片机• Tablet Counters数片机• Tablet Deduster药片除尘器• Tablet Dust Extractor药片除尘器• Tablet Punching Machine冲片机• Vacuum Pump真空泵• Vibro ShifterPharmaceutical Mixer制药工业用混合器• Colloid Mill胶体磨• Cone Blender圆锥型混合机• Drum Mixer鼓式混合机• Homogenizer均化器• Magnetic Stirring Vessel磁力搅拌器• Mass Mixer• Ointment Mixer药膏混合机• Ribbon Blender带式搅拌机Sterilizers消毒器• CIP System CIP系统• SIP System SIP系统• Sterilizing Tunnel灭菌隧道• Sterile Garment Cabinet无菌衣柜• Steam Sterilizer蒸汽消毒器• Dry Heat Sterilizer干热消毒器• ETO SterilizerETO消毒器• Multi Column Distillation Plant多柱式蒸馏装置Pharmaceutical Packaging Machines医药包装机械• Blister Packaging Machine泡罩包装机• Bottle Labeling Machine瓶子贴标机• Box Strapping Machine打包机• Capsule Printing Machine胶囊印字机• Carton Sealing Machine封箱机• Cartoners纸板包装机• Conveyor Belt· Hand Pallet Truck输送带手动液压托盘车• L SealerL型封切机• Label Coding Machine、标签编码器• Overwrapping Machine热封机• Paper Folding Machine折纸机• Shrink Wrapping Machine收缩包装机• Vial Labeling Machine小瓶贴标机Pharmaceutical Inspection Machines制药工业用检验设备• Bottle Inspection Machine验瓶机• Capsule Inspection Machine胶囊检验机• Tablet Inspection Machine药片检验机• Vial Inspection Machine小瓶检验机• Ropp Cap Sealing Machine Ropp(卷装式防盗)封口机Pharmaceutical Granulators制药工业用造粒机• Centrifuge离心机• Comminuting Machine粉碎机• Pelletizer制粒机• Rapid Mixer Granulator快速搅拌造粒机• Spheroidizer球化剂Spray Granulator喷雾造粒机• Pharmaceutical Vessels制药工业用容器Pharmaceutical Coating Machines制药工业用包衣机• Polishing Machine抛光机• Coating Pan包衣盘• Spray Coating Machine喷雾包衣机• Sugar Coating Machine糖衣机Pharmaceutical Sealing Machines制药工业用封口机• Ampoule Sealing Machine安瓿封口机• Bottle Sealing Machine封瓶机• Tube Sealing Machine封管机• Vial Cap Sealing Machine小瓶封盖机Water Processing Equipments水处理设备• Cartridge Filters筒式过滤器• Demineralization Plant脱盐设备• ETP plantETP装置• Submersible Pump潜水泵• UF Water Plant超滤装置• Water Softener Plant软化水装置Other Pharma Equipments其它制药设备• Air Curtain空气帘• Dehumidifier抽湿机• HVAC暖通和空调系统• Laminar Airflow System层流气流系统• Nitrogen Plant制氮装置• Boiler锅炉• Cold Storage冷藏库• Liquid Manufacturing Vessel液体制造容器• Liquid Storage Tank储液槽• Pressure Vessel压力容器• Reactors反应器• Storage Vessel存储容器• Sugar Syrup Manufacturing Tank糖浆制造槽(罐)• WFI Vessel注射用水容器Pharmaceutical Washing Machines制药工业用清洗机• Ampoule Washing Machine安瓿清洗机• Bottle Washing Machine洗瓶机• Bung Washing Machine塞子清洗机• Vial Washing Machine小瓶清洗机Pharma Accessories制药工业用附件• Diaphragm Valve隔膜阀• S.S. Clamp/Triclover Clamp System不锈钢管夹/三管夹。

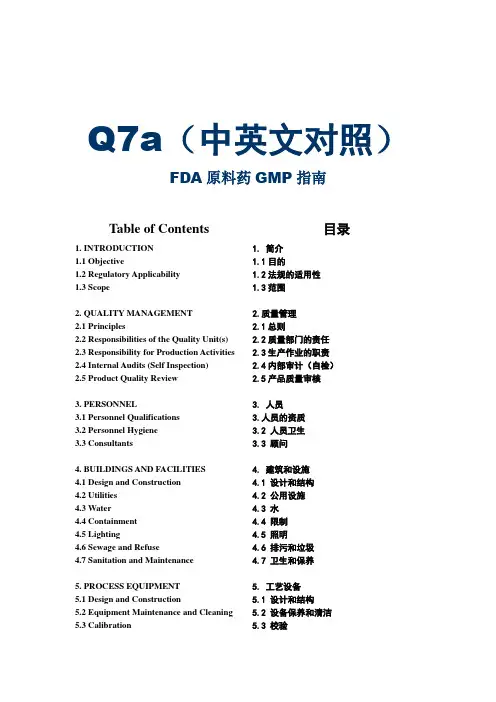

Q7a(中英文对照)FDA原料药GMP指南Table of Contents 目录1. INTRODUCTION 1. 简介1.1 Objective 1.1目的1.2 Regulatory Applicability 1.2法规的适用性1.3 Scope 1.3范围2. QUALITY MANAGEMENT 2.质量管理2.1 Principles 2.1总则2.2 Responsibilities of the Quality Unit(s) 2.2质量部门的责任2.3 Responsibility for Production Activities 2.3生产作业的职责2.4 Internal Audits (Self Inspection) 2.4内部审计(自检)2.5 Product Quality Review 2.5产品质量审核3. PERSONNEL 3. 人员3.1 Personnel Qualifications 3.人员的资质3.2 Personnel Hygiene 3.2 人员卫生3.3 Consultants 3.3 顾问4. BUILDINGS AND FACILITIES 4. 建筑和设施4.1 Design and Construction 4.1 设计和结构4.2 Utilities 4.2 公用设施4.3 Water 4.3 水4.4 Containment 4.4 限制4.5 Lighting 4.5 照明4.6 Sewage and Refuse 4.6 排污和垃圾4.7 Sanitation and Maintenance 4.7 卫生和保养5. PROCESS EQUIPMENT 5. 工艺设备5.1 Design and Construction 5.1 设计和结构5.2 Equipment Maintenance and Cleaning 5.2 设备保养和清洁5.3 Calibration 5.3 校验5.4 Computerized Systems 5.4 计算机控制系统6. DOCUMENTATION AND RECORDS 6. 文件和记录6.1 Documentation System andSpecifications6.1 文件系统和质量标准6.2 Equipment cleaning and Use Record 6.2 设备的清洁和使用记录6.3 Records of Raw Materials, Intermediates, API Labeling and Packaging Materials 6.3 原料、中间体、原料药的标签和包装材料的记录6.4 Master Production Instructions (MasterProduction and Control Records)6.4 生产工艺规程(主生产和控制记录)6.5 Batch Production Records (BatchProduction and Control Records)6.5 批生产记录(批生产和控制记录)6.6 Laboratory Control Records 6.6 实验室控制记录6.7 Batch Production Record Review 6.7批生产记录审核7. MATERIALS MANAGEMENT 7. 物料管理7.1 General Controls 7.1 控制通则7.2 Receipt and Quarantine 7.2接收和待验7.3 Sampling and Testing of IncomingProduction Materials7.3 进厂物料的取样与测试7.4 Storage 7.4储存7.5 Re-evaluation 7.5复验8. PRODUCTION AND IN-PROCESSCONTROLS8. 生产和过程控制8.1 Production Operations 8.1 生产操作8.2 Time Limits 8.2 时限8.3 In-process Sampling and Controls 8.3 工序取样和控制8.4 Blending Batches of Intermediates orAPIs8.4 中间体或原料药的混批8.5 Contamination Control 8.5 污染控制9. PACKAGING AND IDENTIFICATIONLABELING OF APIs ANDINTERMEDIATES9. 原料药和中间体的包装和贴签9.1 General 9.1 总则9.2 Packaging Materials 9.2 包装材料9.3 Label Issuance and Control 9.3 标签发放与控制9.4 Packaging and Labeling Operations 9.4 包装和贴签操作10. STORAGE AND DISTRIBUTION 10.储存和分发10.1 Warehousing Procedures 10.1 入库程序10.2 Distribution Procedures 10.2 分发程序11. LABORATORY CONTROLS 11.实验室控制11.1 General Controls 11.1 控制通则11.2 Testing of Intermediates and APIs 11.2 中间体和原料药的测试11.3 Validation of Analytical Procedures 11.3 分析方法的验证11.4 Certificates of Analysis 11.4 分析报告单11.5 Stability Monitoring of APIs 11.5 原料药的稳定性监测11.6 Expiry and Retest Dating 11.6 有效期和复验期11.7 Reserve/Retention Samples 11.7 留样12. V ALIDATION 12.验证12.1 Validation Policy 12.1 验证方针12.2 Validation Documentation 12.2 验证文件12.3 Qualification 12.3 确认12.4 Approaches to Process Validation 12.4 工艺验证的方法12.5 Process Validation Program 12.5 工艺验证的程序12.6 Periodic Review of Validated Systems 12.6验证系统的定期审核12.7 Cleaning Validation 12.7 清洗验证12.8 Validation of Analytical Methods 12.8 分析方法的验证13. CHANGE CONTROL 13.变更的控制14. REJECTION AND RE-USE OFMATERIALS14.拒收和物料的再利用14.1 Rejection 14.1 拒收14.2 Reprocessing 14.2 返工14.3 Reworking 14.3 重新加工14.4 Recovery of Materials and Solvents 14.4 物料与溶剂的回收14.5 Returns 14.5 退货15. COMPLAINTS AND RECALLS 15.投诉与召回16. CONTRACT MANUFACTURERS(INCLUDING LABORATORIES)16.协议生产商(包括实验室)17. AGENTS, BROKERS, TRADERS, DISTRIBUTORS, REPACKERS, AND RELABELLERS 17.代理商、经纪人、贸易商、经销商、重新包装者和重新贴签者17.1 Applicability 17.1适用性17.2 Traceability of Distributed APIs andIntermediates17.2已分发的原料药和中间体的可追溯性17.3 Quality Management 17.3质量管理17.4 Repackaging, Relabeling, and Holding of APIs and Intermediates 17.4原料药和中间体的重新包装、重新贴签和待检17.5 Stability 17.5稳定性17.6 Transfer of Information 17.6 信息的传达17.7 Handling of Complaints and Recalls 17.7 投诉和召回的处理17.8 Handling of Returns 17.8 退货的处理18. Specific Guidance for APIs Manufactured by Cell Culture/Fermentation 18. 用细胞繁殖/发酵生产的原料药的特殊指南18.1 General 18.1 总则18.2 Cell Bank Maintenance and RecordKeeping18.2细胞库的维护和记录的保存18.3 Cell Culture/Fermentation 18.3细胞繁殖/发酵18.4 Harvesting, Isolation and Purification 18.4收取、分离和精制18.5 Viral Removal/Inactivation steps 18.5 病毒的去除/灭活步骤19.APIs for Use in Clinical Trials 19.用于临床研究的原料药19.1 General 19.1 总则19.2 Quality 19.2 质量19.3 Equipment and Facilities 19.3 设备和设施19.4 Control of Raw Materials 19.4 原料的控制19.5 Production 19.5 生产19.6 Validation 19.6 验证19.7 Changes 19.7 变更19.8 Laboratory Controls 19.8 实验室控制19.9 Documentation 19.9 文件20. Glossary 20. 术语Q7a GMP Guidance for APIs Q7a原料药的GMP指南1. INTRODUCTION 1. 简介1.1 Objective 1.1目的This document is intended to provide guidance regarding good manufacturing practice (GMP) for the manufacturing of active pharmaceutical ingredients (APIs) under an appropriate system for managing quality. It is also intended to help ensure that APIs meet the quality and purity characteristics that they purport, or are represented, to possess. 本文件旨在为在合适的质量管理体系下制造活性药用成分(以下称原料药)提供有关优良药品生产管理规范(GMP)提供指南。

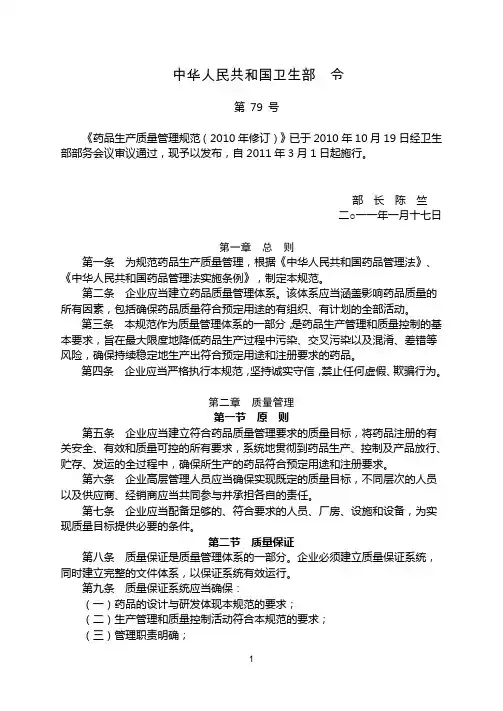

中华人民共和国卫生部令第 79 号《药品生产质量管理规范(2010年修订)》已于2010年10月19日经卫生部部务会议审议通过,现予以发布,自2011年3月1日起施行。

部长陈竺二○一一年一月十七日第一章总则第一条为规范药品生产质量管理,根据《中华人民共和国药品管理法》、《中华人民共和国药品管理法实施条例》,制定本规范。

第二条企业应当建立药品质量管理体系。

该体系应当涵盖影响药品质量的所有因素,包括确保药品质量符合预定用途的有组织、有计划的全部活动。

第三条本规范作为质量管理体系的一部分,是药品生产管理和质量控制的基本要求,旨在最大限度地降低药品生产过程中污染、交叉污染以及混淆、差错等风险,确保持续稳定地生产出符合预定用途和注册要求的药品。

第四条企业应当严格执行本规范,坚持诚实守信,禁止任何虚假、欺骗行为。

第二章质量管理第一节原则第五条企业应当建立符合药品质量管理要求的质量目标,将药品注册的有关安全、有效和质量可控的所有要求,系统地贯彻到药品生产、控制及产品放行、贮存、发运的全过程中,确保所生产的药品符合预定用途和注册要求。

第六条企业高层管理人员应当确保实现既定的质量目标,不同层次的人员以及供应商、经销商应当共同参与并承担各自的责任。

第七条企业应当配备足够的、符合要求的人员、厂房、设施和设备,为实现质量目标提供必要的条件。

第二节质量保证第八条质量保证是质量管理体系的一部分。

企业必须建立质量保证系统,同时建立完整的文件体系,以保证系统有效运行。

第九条质量保证系统应当确保:(一)药品的设计与研发体现本规范的要求;(二)生产管理和质量控制活动符合本规范的要求;(三)管理职责明确;(四)采购和使用的原辅料和包装材料正确无误;(五)中间产品得到有效控制;(六)确认、验证的实施;(七)严格按照规程进行生产、检查、检验和复核;(八)每批产品经质量受权人批准后方可放行;(九)在贮存、发运和随后的各种操作过程中有保证药品质量的适当措施;(十)按照自检操作规程,定期检查评估质量保证系统的有效性和适用性。

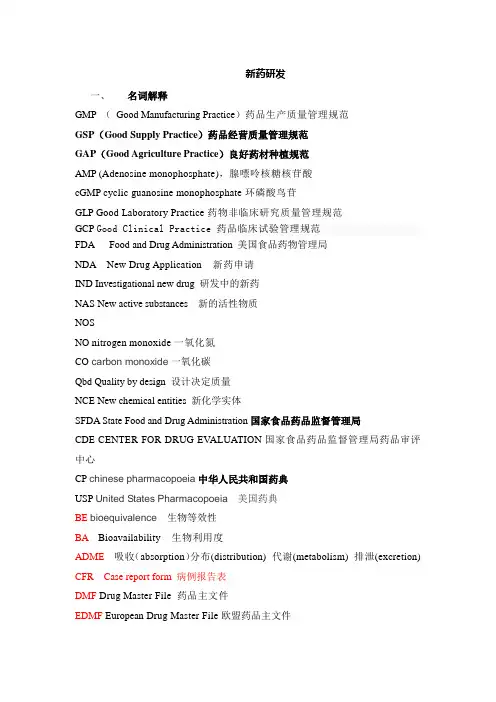

新药研发一、名词解释GMP (Good Manufacturing Practice)药品生产质量管理规范GSP(Good Supply Practice)药品经营质量管理规范GAP(Good Agriculture Practice)良好药材种植规范AMP (Adenosine monophosphate),腺嘌呤核糖核苷酸cGMP cyclic guanosine monophosphate环磷酸鸟苷GLP Good Laboratory Practice药物非临床研究质量管理规范GCP Good Clinical Practice 药品临床试验管理规范FDA Food and Drug Administration 美国食品药物管理局NDA New Drug Application 新药申请IND Investigational new drug 研发中的新药NAS New active substances 新的活性物质NOSNO nitrogen monoxide一氧化氮CO carbon monoxide一氧化碳Qbd Quality by design 设计决定质量NCE New chemical entities 新化学实体SFDA State Food and Drug Administration国家食品药品监督管理局CDE CENTER FOR DRUG EVALUATION国家食品药品监督管理局药品审评中心CP chinese pharmacopoeia中华人民共和国药典USP United States Pharmacopoeia 美国药典BE bioequivalence 生物等效性BA Bioavailability 生物利用度ADME 吸收(absorption)分布(distribution) 代谢(metabolism) 排泄(excretion) CFR Case report form 病例报告表DMF Drug Master File 药品主文件EDMF European Drug Master File欧盟药品主文件CTD Common Technical Document国际注册用常规技术文件COS(Certificate of Suitability)欧洲药典适应性认证CEP(Certificate of Suitability of Ph Eur)欧洲药典适用性认证Pharmacodynamics(药效学)pharmacokinetics(药动学)adverse reaction(不良反应HTS (High-throughput screening) 高通量筛选药物靶点是指药物在体内的作用结合位点,包括基因位点、受体、酶、离子通道、核酸等生物大分子。

制药行业常用英语词汇中英文对照严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复1、药品生产质量管理规范GMP: Good ManufacturingPractice 2、国家食品与药品监督管理局State Food andDrug Administration3、总则 GeneralProvisions4、《中华人民共和国药品管理法》the DrugAdministration Law of the People's Republic of China 5、制剂 Preparation 6、原料药/原液Drug Substance7、成品 Drug Product8、工艺 process9、机构与人员organization and personnel 10、专业知识professional knowledge严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复11、生产经验production experience 12、组织能力organizational skill 13、技术人员technical staff 14、实施implementation 15、药品生产pharmaceutical manufacturing 16、质量管理quality management 17、质量检验quality inspection 18、专业技术培训professional and technicaltraining 19、基础理论知识basic theoreticalknowledge21、高生物活性 highly potent22、高毒性 high toxicity23、污染 contamination 24、考核评估 assessment 25、厂房与设施 buildings and facilities 26、生产环境 production environment 27、空气洁净级别clean air level 28、昆虫insect29、洁净室(区)clean room(area)30、光滑smooth严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复41、设备 equipment42、物料 material43、中间产品 intermediate product 44、待验品 quarantined material 45、交叉污染cross-contamination 46、管道pipeline, ductwork 47、风口tuber48、公用设施, 公用工程 utilities of publicservice 49、照明 lighting50、照度 illumination31、无裂缝 no cracks 32、无颗粒物脱落 no particle shedding 33、耐受 endure34、消毒 disinfection35、无菌 sterile36、交界处 junction, joint37、弧形 arc38、灰尘积聚 dues accumulation 39、储存区store area 40、生产规模 production scale严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复61、低漏 地漏 floor drainer62、青霉素 penicillin 63、分装室separating room, fillingroom 64、相对负压relative negativepressure 65、废气waste gas,exhausted air 66、 β- 内酰胺结构类药品 β -Lactasestructure drug, drugs of β- Lactic group67、避孕药品 contraceptives68、激素类 hormone 69、抗肿瘤类anti-tumor, oncology70、放射性药品 Radiopharmaceuticals51、应急 紧急情况 emergency52、净化 purification, clean53、微生物, 微生物学, 微生物的 micro-organism, microbiology,microbiologic 54、监测monitoring 55、记录record56、天棚 天花板ceiling, roof57、密封 seal58、静压差Static DifferentialPressure59、温度 temperature 60、相对湿度RH: Relative Humidity严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复81、预防制品 prevention products82、灌装 filling 83、中药Chinesetraditional medicines84、前处理 pretreatment85、提取 extraction86、浓缩 concentration 87、动物脏器viscera of animal,organ of animal 88、蒸、炒、炙、煅steaming, frying,sunburn, testing 89、炮制 concocted90、通风 ventilation71、包装packing, package 72、循环使用recycling 73、微粒particles 74、辐射radiation, irradiation75、细菌 bacteria76、病毒 virus77、细胞 cell78、脱毒前后pre and post detoxification 79、活疫苗与灭活疫苗active vaccine/inactivatedvaccine 80、人血液制品blood products严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复91、除烟smoke removal 92、除尘dust removal 93、降温设施temperature-reducingestablishment, cooling 94、筛选screening, sift95、切片 slicing 96、粉碎grinding97、压缩空气 compressed air98、惰性气体 noble gas99、取样 Sampling 100、称量室weighing room, dispensingroom 101、中药标本Chinese herbal sample,exemplar ofTCM 102、检定 鉴定 verification, identification103、同位素 Isotope104、设备 equipment 105、选型model/type selection106、耐腐蚀anticorrosion 107、吸附adsorption, absorption 108、润滑剂, 润滑lubricant, lubricate 109、冷却剂 coolant 110、流向 flow direction严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复111、纯化水PW: Purified Water 112、注射用水WFI: Water for Injection 113、滋生 breeding114、储罐 tank115、死角 neglected portion 116、盲管blind pipe 117、纤维fiber118、疏水性hydrophobicity 119、仪表instrumentation 120、量具measuring tool121、衡器 weighing instrument 122、精密度 precision 123、维修、保养 maintenance 124、不合格 disqualified reject 125、物料 material126、购买 purchasing127、发放 releasing128、产地 origin129、入库 loading130、固体 solid严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复141、卫生, 清洁/消毒 sanitation142、车间, 辅房 workshop143、间隔时间 time interval144、清洁剂 detergent145、消毒剂 disinfectant146、废弃物 wastes147、更衣室 changing room148、工作服, work clothes149、颗粒性物质, 颗粒剂 granules150、耐药菌株drug-resistant strain131、液体 liquid132、挥发性 volatile133、净药材 net medicine, netTCM 134、麻醉药品 narcotics135、精神药品 psychotropic drug 136、易燃combustible 137、易爆explosive 138、验收acceptance139、使用说明书instruction 140、标签label严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复161、报废 reject162、 品名 product name163、处方 preion, formula 164、技术参数technicalparameter 165、容器container 166、半成品semi-finished product,intermediate167、申请 application168、稳定性 stability169、起草 draft170、生产管理production management,manufacturing control.151、传染病infectiousdisease 152、皮肤病dermatitis153、验证 verification, validation 154、确认 qualification 155、安装 installation 156、运行running operation 157、性能performance 158、原辅料raw material and incipient 159、文件 document160、投诉 complaint严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复181、产品销售与收回product sales andrecovery /recall 182、投诉与不良反应报告 complaints and adversereaction 183、自检self-inspection 184、附 则schedule appendix 185、平衡balance186、饮用水drinking water, potablewater187、蒸馏法 distillation188、离子交换法 ion exchange 189、反渗透法RO: Reverse Osmosis 190、附加剂添加剂additives171、事故 accident172、混淆 mix-up173、喷雾 spray174、合格证 certificate175、清场 clearance176、质量管理 quality management 177、内控internal control,on-line test 178、滴定液 tartan179、培养基 medium 180、有效期validity, expiry date,shelf life严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复191、滞留stranded resort 192、批batch, lot193、组分, 组成component194、无纤维脱落的过滤器 non-fiber-releasingfilter195、活性成份 Active Ingredient196、非活性成份 Inactive ingredient 197、中间产品in-process product,intermediate product 198、批号batch number 199、药用物料medicated feed 200、药用预混合料medicated premix201、质量控制部门Quality control department 202、理论产量 Theoretical yield203、实际产量 Actual yield204、比率 Percentage, rate205、验收标准可接受标准 Acceptance criteria206、代表性样品 Representative sample207、微粒状的 particulate 208、污染物contaminant 209、石棉asbestos 210、诊断diagnosis严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复221、密封件, 封盖 closure222、效价 Titer223、纯度 purity224、规格 strength225、监督 supervise, monitor226、实验室 laboratory 227、无菌操作aseptic operation,sterile operation 228、层流laminar flow 229、湍流turbulent air flow 230、空气过滤air filtration211、缓解 mitigation212、化学变化 chemical change 213、组分ingredient, component 214、制备fabricate preparation 215、复合 compound216、混合 blend217、加工 processing218、浓度 concentration219、单位剂量 unit dose220、药品包装容器drug product containers严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复241、有机废料organic waste 242、杀鼠剂rodenticides 243、杀昆虫剂insecticides 244、杀真菌剂fungicides 245、熏蒸剂fumigating reagents 246、去垢剂cleaning agents 247、消毒剂sanitizing agents 248、滂沱剂lubricant249、自动化设备、机械化设备和电子设备 automatic, mechanical,or electronic equipment 250、微型胶卷 microfilm231、空气加热 air heating 232、预过滤器 profiler 233、排气系统 exhaust system 234、管件 plumbing 235、虹吸倒流 back-siphon age 236、污水 sewage 237、废料 refuse 238、盥洗设备 toilet facilities 239、空气干燥器 air drier 240、垃圾 trash严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复261、片剂 tablet262、胶囊 capsule263、颗粒剂 granule264、溶解时间 溶出时间 dissolution time 265、澄清度clarity266、隔离系统quarantinesystem, isolation system 267、返工 reprocessing268、发放 issuance, release 269、非处方药OTC:over-the-counter 270、处方药preed medicine251、注射剂 injection252、灭菌设备 sterilization equipment 253、无菌取样技术aseptic sampling techniques 254、显微镜 microscope255、热源, 内毒素 pyrogen, endotoxin256、偏差 deviation257、变更 change control258、进料 charge-in259、项目代码 item code260、鉴别 identify严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复271、皮肤科药、牙粉、胰岛素、喉片 dermatological, dentifrice,insulin, or throat lozenge product 272、保险包装tamper-resistant package273、明胶硬胶囊 hard gelatin capsule274、顺势治疗 homeopathic275、入库 warehousing276、变质 deteriorate277、准确性 accuracy278、灵敏性 sensitivity 279、特异性specificity 280、重复性reproducibility, repeatability281、变应原提取物allergenic extracts 282、眼膏ophthalmic ointment 283、粗糙或磨蚀物质harsh or abrasivesubstances 284、控释制剂controlled-releasedosage form 285、实验动物laboratory animals 286、供应商Supplier 287、光谱spectrum288、测量单位units of measure 289、换算系数conversion factors 290、试剂reagent严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复301、批检验记录BAR: Batch AnalysisRecord 302、工艺规程PP: Process Procedure 303、健康,安全,环保EHS: Environment,Health and Safe 304、美国联邦法规CFR: Code of FederalRegulation 305、美国药典USP: The United StatesPharmacopeia 306、欧洲药典EP: European pharmacopeia 307、英国药典BP: British pharmacopeia 308、药物主文件DMF: Drug Master File 309、验证主计划VMP: Validation MasterPlan 310、验证方案VP: Validation Protocol291、安慰剂 placebo292、明确地 explicitly293、取代 supersede294、溶液 solution 295、批准approval 296、 (美国)食品药品监督管理局 FDA: Food and DrugAdministration 297、标准操作程序SOP: Standard OperatingProcedure 298、质量保证QA: Quality Assurance 299、质量控制QC:Quality Control 300、批生产记录BPR: Batch ProductionRecord 严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复311、验证报告VR: Validation Report 312、安装确认IQ: Installation Qualification 313、运行确认OQ: Operation Qualification 314、性能确认PQ: Performance Qualification 315、超出标准(限度)OOS: Out of Specification 316、冻干产品freeze-dry product,lyophilizated product 317、现场主文件SMF: Site Master File严禁复制复制严禁复制严禁复制严禁复制严禁复制严禁复。

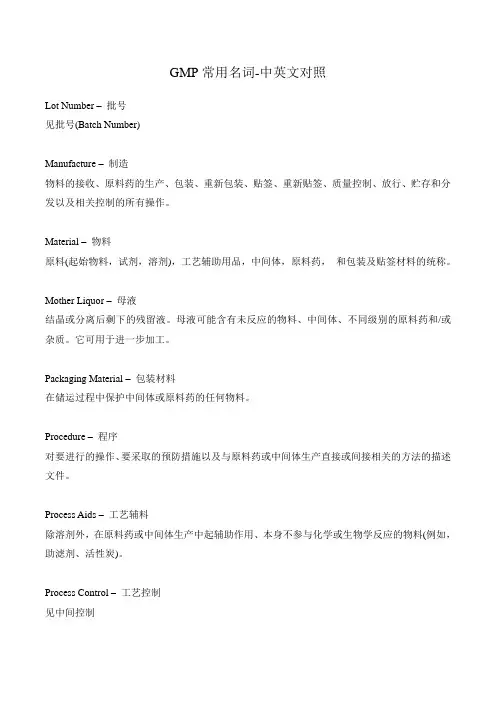

GMP常用名词-中英文对照Lot Number –批号见批号(Batch Number)Manufacture –制造物料的接收、原料药的生产、包装、重新包装、贴签、重新贴签、质量控制、放行、贮存和分发以及相关控制的所有操作。

Material –物料原料(起始物料,试剂,溶剂),工艺辅助用品,中间体,原料药,和包装及贴签材料的统称。

Mother Liquor –母液结晶或分离后剩下的残留液。

母液可能含有未反应的物料、中间体、不同级别的原料药和/或杂质。

它可用于进一步加工。

Packaging Material –包装材料在储运过程中保护中间体或原料药的任何物料。

Procedure –程序对要进行的操作、要采取的预防措施以及与原料药或中间体生产直接或间接相关的方法的描述文件。

Process Aids –工艺辅料除溶剂外,在原料药或中间体生产中起辅助作用、本身不参与化学或生物学反应的物料(例如,助滤剂、活性炭)。

Process Control –工艺控制见中间控制在原料药制备过程中,从接收原料,到工艺加工和原料药包装所涉及的所有操作。

Qualification –确认证明设备或辅助系统,安装正确、工作正常、确实产生预期的结果,并以文件佐证的行为。

确认是验证的一部分,但单独的确认步骤不构成工艺验证。

Quality Assurance (QA) –质量保证以确保所有原料药达到其应用所要求的质量,并维持质量体系为目的的全部组织安排的总和。

Quality Control –质量控制是否符合质量规格的检查或测试。

Quality Unit(s) –质量部门独立于生产部门的履行质量保证和质量控制职责的组织机构。

按照组织机构的大小和结构,可以是单独的QA 和QC部门,或个人,或小组。

Quarantine –待验在实物上或以其它有效方式将物料隔离,等待对其随后的批准或拒收做出决定的状态。

Raw Material –原料用来表示中间体或原料药的生产中要用的起始物料、试剂和溶剂的通用专业名词。

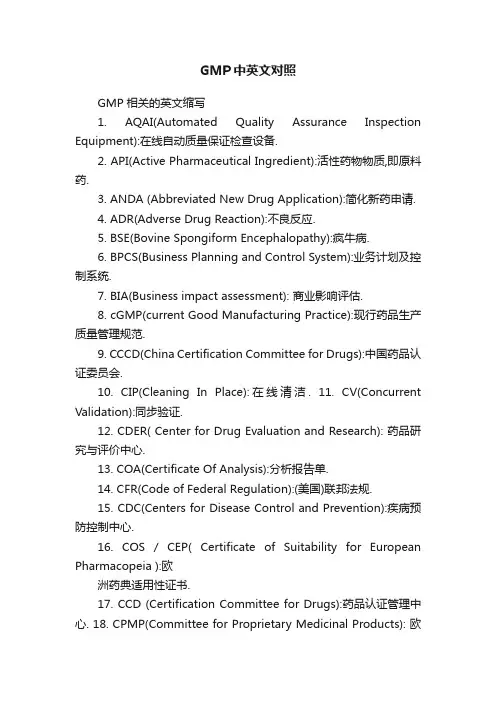

GMP中英文对照GMP相关的英文缩写1. AQAI(Automated Quality Assurance Inspection Equipment):在线自动质量保证检查设备.2. API(Active Pharmaceutical Ingredient):活性药物物质,即原料药.3. ANDA (Abbreviated New Drug Application):简化新药申请.4. ADR(Adverse Drug Reaction):不良反应.5. BSE(Bovine Spongiform Encephalopathy):疯牛病.6. BPCS(Business Planning and Control System):业务计划及控制系统.7. BIA(Business impact assessment): 商业影响评估.8. cGMP(current Good Manufacturing Practice):现行药品生产质量管理规范.9. CCCD(China Certification Committee for Drugs):中国药品认证委员会.10. CIP(Cleaning In Place):在线清洁. 11. CV(Concurrent Validation):同步验证.12. CDER( Center for Drug Evaluation and Research): 药品研究与评价中心.13. COA(Certificate Of Analysis):分析报告单.14. CFR(Code of Federal Regulation):(美国)联邦法规.15. CDC(Centers for Disease Control and Prevention):疾病预防控制中心.16. COS / CEP( Certificate of Suitability for European Pharmacopeia ):欧洲药典适用性证书.17. CCD (Certification Committee for Drugs):药品认证管理中心. 18. CPMP(Committee for Proprietary Medicinal Products): 欧洲专利药品委员会.19. CTD(Common Technical Document):通用技术文件.20. CDC( Centers for Disease Control and Prevention): 疾病预防控制中心.21. GMP(Good Manufacturing Practice):药品生产质量管理规范. 22. ICH(International Conference on Harmonization of Technical Requ irements for Registration of Pharmaceuticals for Human Use):人用药品注册技术要求国际协调会. 23. EU(European Union):欧洲联盟.24. EFPIA(European Federation of Pharmaceutical Industries Associations ):欧洲制药工业协会联合会.25. MHW(Ministry of Health and Welfare,Japan):日本厚生省.26. JPMA(Japan Pharmaceutical Manufacturers Association):日本制药工业协会.27. FDA(US Food and Drug Adminiistration):美国食品与药品管理局.28. PRMA(Pharmaceutical Research and Manufacturers of America):美国药物研究和生产联合会.29. WHO(World Health Organization):世界卫生组织.30. IFPMA(International Federation of Pharmaceutical Manufacturers As sociations):国际制药工业协会联合会.31. TQC(Total Quality Control),TQM(Total Quality Management): 全面质量管理.32. PDCA(Plan,Do,Check,Action):计划,执行,检查,处理.33. QA(Quality Assurance):质量保证.34. QC (Quality Control):质量控制.35. QS(Quality System):质量体系.36. QM(Quality Management): 质量管理.37. SOP(Standard Operating Procedure): 标准操作规程.38. SMP(Standard Management Procedure):标准管理程序.39. SOR(Standard Operating Record): 标准操作记录.40. GEP(Good Engineering Practice):工程设计规范.41. HVAC(Heating Ventilation and Air Conditioning):空调净化系统.42. DQ(Design Qualification):设计确认.43. IQ(Installation Qualification):安装确认.44. OQ(Operational Qualification):运行确认.45. PQ(Performance Qualification):性能确认.46. OOS(Out-Of-Specification):检验不合格;超标.47. PFDS(Process Flow Diagrams):工艺流程图.48. MRA(cMutual Reognition Agreements): 现场检查多边认同协议.49. DMF( Drug Master File):药物主文件.50. EDMF(European Drug Master File)欧盟药物主文件.51. EDQM(European Directorate for Quality Medicines): 欧洲药品质量管理局.52. ORA(Office of Regulatory Affairs):药政事务办公室.53. GGPs( Good Guidance Practices): 优良指南规范.54. MOA(Method Of Analysis):分析方法.55. VMP(Validation Master Plan):验证主计划.56. VP(Validation Protocol):验证方案.57. MSDS(Material Safety Data Sheet):物料安全技术说明书.58. NDA (New Drug Application):新药申请.59. OTC(Over-the-counter):非处方.60. INN(International Nonproprietary Name):国际非专有名称.61. USP(the united state pharmacopeia): 美国药典.62. NF(National Formulary):(美国)国家药品集.63. GAP(Good Agricultural Practice):中药材种植管理规范.64. GCP(Good Clinical Practice):药物临床试验质量管理规范.65. GLP(Good Laboratory Practice):药物实验室管理规范.66. GSP(Good Supply Practice):药品经营质量管理规范.67. GUP(Good Use Practice):药品使用质量管理规范.68. SM(Starting Material):起始物料.69. PMF(Plant Master File); SMF(Site Master File):工厂主文件.70. EDL(List of Essential Drugs ) : 基本药物目录.71. PI(Package Insert):说明书.72. PCT( Patent Cooperation Treaty): 专利合作条约.73. PPAC(Patent Protection Association of China):中国专利保护协会.74. PIC( Person In Charge) :负责人.75. PDS(Pharmaceutical Development Services): 整体新药研发机构.76. SPC(Summary of Product Characteristics):产品特性摘要.。

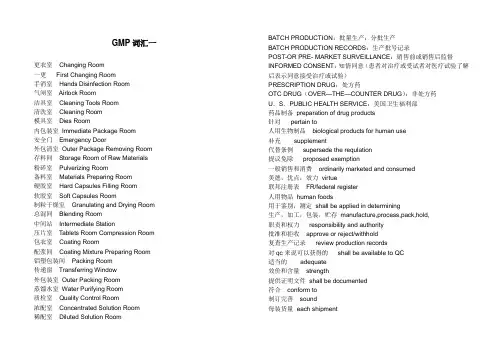

GMP词汇一更衣室 Changing Room一更 First Changing Room手消室 Hands Disinfection Room气闸室 Airlock Room洁具室 Cleaning Tools Room清洗室 Cleaning Room模具室 Dies Room内包装室Immediate Package Room安全门 Emergency Door外包清室Outer Package Removing Room 存料间 Storage Room of Raw Materials 粉碎室 Pulverizing Room备料室 Materials Preparing Room硬胶室 Hard Capsules Filling Room软胶室 Soft Capsules Room制粒干燥室 Granulating and Drying Room 总混间 Blending Room中间站 Intermediate Station压片室 Tablets Room Compression Room 包衣室 Coating Room配浆间 Coating Mixture Preparing Room 铝塑包装间 Packing Room传递窗 Transferring Window外包装室Outer Packing Room蒸馏水室Water Purifying Room质检室 Quality Control Room浓配室 Concentrated Solution Room稀配室 Diluted Solution Room BATCH PRODUCTION:批量生产;分批生产BATCH PRODUCTION RECORDS:生产批号记录POST-OR PRE- MARKET SURVEILLANCE:销售前或销售后监督INFORMED CONSENT:知情同意(患者对治疗或受试者对医疗试验了解后表示同意接受治疗或试验)PRESCRIPTION DRUG:处方药OTC DRUG(OVER—THE—COUNTER DRUG):非处方药U.S.PUBLIC HEALTH SERVICE:美国卫生福利部药品制备preparation of drug products针对 pertain to人用生物制品 biological products for human use补充 supplement代替条例supersede the requlation提议免除proposed exemption一般销售和消费 ordinarily marketed and consumed美德,优点,效力 virtue联邦注册表 FR/federal register人用物品 human foods用于鉴别,测定 shall be applied in determining生产,加工,包装,贮存 manufacture,process,pack,hold,职责和权力responsibility and authority批准和拒收 approve or reject/withhold复查生产记录review production records对qc来说可以获得的shall be available to QC适当的 adequate效价和含量 strength提供证明文件 shall be documented符合 conform to制订完善 sound每装货量 each shipment变质的is subject to deteriorationaccommodation (车,船,飞机等的)预定铺位批号 batch有害微生物 objectionable microorganism联合批号 the number of units准确性,灵敏性,特异性,重复性accuracy, sensitivity, specificity, and reproducibility特征,属性attribute配伍reconstitution设计 project顺势治疗药品 homeopathic drug products可配伍性compatibility标明 purporting to应成文并遵循shall be in writing and shall be followed.可检出水平 detectable levels通过参考文献具体化 incorporated by reference副作用 adeverse/side effect类型 type混放 mixups签收 receipt处理 disposition正压下过滤 be filtered under positive pressure层流或非层流laminar or nonlaminar;无菌环境aseptic conditions照明 lighting通风、空气过滤、空气加热与冷却 Ventilation, air filtration, air heating and cooling.空气输送系统 Air-handling systems附近建筑物immediate premises专用毛巾 single-service towels 进料 Charge-in标示量或规定量labeled or established amount实际产量 Actual yields理论产量 theoretical yields生产周期 the production of a batch of a drug product药品的一致性和完整性uniformity and integrity of drug products崩解时间 Disintegration time溶液的澄明度、溶解完全性及pH值 Clarity, completeness, or pH of solutions稳定性评估 variability estimates装卸 handlingNIH(NATIONAL INSTITUTE OF HEALTH):(美国)全国卫生研究所CLINICAL TRIAL:临床试验ANIMAL TRIAL:动物试验ACCELERATED APPROVAL:加速批准FDA(FOOD AND DRUG ADMINISTRATION):(美国)食品药品管理局IND(INVESTIGATIONAL NEW DRUG):临床研究申请(指申报阶段,相对于NDA而言);研究中的新药(指新药开发阶段,相对于新药而言,即临床前研究结束)NDA(NEW DRUG APPLICATION):新药申请ANDA(ABBREVIATED NEW DRUG APPLICATION):简化新药申请EP诉(EXPORT APPLICATION ):出口药申请(申请出口不被批准在美国销售的药品)TREATMENT IND:研究中的新药用于治疗ABBREVIATED(NEW)DRUG:简化申请的新药DMF(DRUG MASTER FILE):药物主文件(持有者为谨慎起见而准备的保密资料,可以包括一个或多个人用药物在制备、加工、包装和贮存过程中所及的设备、生产过程或物品。

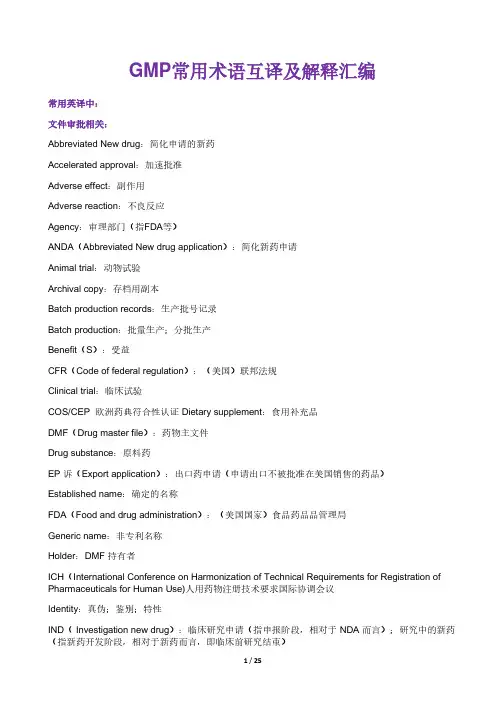

GMP常用术语互译及解释汇编常用英译中:文件审批相关:Abbreviated New drug:简化申请的新药Accelerated approval:加速批准Adverse effect:副作用Adverse reaction:不良反应Agency:审理部门(指FDA等)ANDA(Abbreviated New drug application):简化新药申请Animal trial:动物试验Archival copy:存档用副本Batch production records:生产批号记录Batch production:批量生产;分批生产Benefit(S):受益CFR(Code of federal regulation):(美国)联邦法规Clinical trial:临床试验COS/CEP 欧洲药典符合性认证 Dietary supplement:食用补充品DMF(Drug master file):药物主文件Drug substance:原料药EP 诉(Export application):出口药申请(申请出口不被批准在美国销售的药品)Established name:确定的名称FDA(Food and drug administration):(美国国家)食品药品品管理局Generic name:非专利名称Holder:DMF 持有者ICH(International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use)人用药物注册技术要求国际协调会议Identity:真伪;鉴别;特性IND( Investigation new drug):临床研究申请(指申报阶段,相对于 NDA 而言);研究中的新药(指新药开发阶段,相对于新药而言,即临床前研究结束)Informed consent:知情同意(患者对治疗或受试者对医疗试验了解后表示同意接INN(international nonproprietary name):国际非专有名称Investigator:研究人员;调研人员Labeled amount:标示量Narrative summary 记叙体概要NDA(New drug application):新药申请NF(National formulary):(美国)国家药品集NIH(NATIONAL INSTITUTE OF HEALTH):(美国)全国卫生研究所Official compendium:法定药典(主要指 USP、NF)OFFICIAL=Pharmacopeia=COMPENDIAL:药典的;法定的;官方的OTC drug(over—the—counter drug):非处方药Panel:专家小组Post-or Pre- market surveillance:销售前或销售后监督Preparing and Submitting:起草和申报Prescription drug:处方药Proprietary name:专有名称;Regulatory methodology:质量管理方法(FDA 用于考核原料药或药物产品是Regulatory methods validation:管理用分析方法的验证(FDA对NDA提供的方法进行验证)Regulatory specification:质量管理规格标准(NDA提供)Review copy:审查用副本Risk(S):受害 Sponsor:主办者(指负责并着手临床研究者)Standard drug:标准药物Strength:规格;规格含量(每一剂量单位所含有效成分的量)Submission:申报;递交Treatment IND:研究中的新药用于治疗U.S.Public Health Service:美国卫生福利部USP(The united states Pharmacopeia):美国药典(现已和NF合并一起出版)密资料,可以包括一个或多个人用药物在制备、加工、包装和贮存过程中所及的设备、生产过程或物品。

中英名词对照不动的水Stagnant water可接近性Accessibility外加研究法Spiking study抗原决定基Epitope依从性Compliance注射用水Water for injection物理性封闭Physically occluded空白物法Placebo method青霉素类Penicillins非反应性材质Non-reactive material洗涤剂Cleaning agent纯净水Purified water清洁剂Detergent细胞毒剂Cytotoxic最低定量浓度Limit of quantitation最低检测浓度Limit of detection最差状况Worst-case scenario媒介质Medium就地清洁Clean-in place减低的清洁参数Reduced cleaning parameter测试到清洁为止Test until clean无效应No effect荷尔蒙Hormone间隔时间Time frame对数性的移除Log removal滞留Carry over盘尼西林Penicillin头孢子菌素类Cephalosporins薄层层析法Thin layer chromatography篮状试验法Bracketing杂质组合Impurity profile类固醇Steroid警报点Alarm point英中名词对照Accessibility可接近性Alarm point警报点Bracketing篮状试验法Carry over滞留Cephalosporins头孢子菌素类Clean-in place就地清洁Cleaning agent洗涤剂Compliance依从性Cytotoxic细胞毒剂Detergent清洁剂Epitope抗原决定基Hormone荷尔蒙Impurity profile杂质组合Limit of detection最低检测浓度Limit of quantitation最低定量浓度Log removal对数性的移除Medium媒介质No effect无效应Non-reactive material非反应性材质Penicillin盘尼西林Penicillins青霉素类Physically occluded物理性封闭Placebo method空白物法Purified water纯净水Reduced cleaning parameter减低的清洁参数Spiking study外加研究法Stagnant water不动的水Steroid类固醇Test until clean测试到清洁为止Thin layer chromatography薄层层析法Time frame间隔时间Water for injection注射用水Worst-case scenario最差状况EWG:专家工作组MRA:现场检查多边协同协议企业常用缩写5S : 5S管理ABC : 作业制成本制度 (Activity-Based Costing)ABB : 实施作业制预算制度 (Activity-Based Budgeting)ABM : 作业制成本管理 (Activity-Base Management)APS : 先进规画与排程系统 (Advanced Planning and Scheduling) ASP : 应用程式服务供应商(Application Service Provider)ATP : 可承诺量 (Available To Promise)AVL : 认可的供应商清单(Approved Vendor List)BOM : 物料清单 (Bill Of Material)BPR : 企业流程再造 (Business Process Reengineering)BSC : 平衡记分卡 (Balanced ScoreCard)BTF : 计划生产 (Build To Forecast)BTO : 订单生产 (Build To Order)CPM : 要径法 (Critical Path Method)CPM : 每一百万个使用者会有几次抱怨(Complaint per Million)CRM : 客户关系管理 (Customer Relationship Management)CRP : 产能需求规划 (Capacity Requirements Planning)CTO : 客制化生产 (Configuration To Order)DBR : 限制驱导式排程法 (Drum-Buffer-Rope)DMT : 成熟度验证(Design Maturing Testing)DVT : 设计验证(Design Verification Testing)DRP : 运销资源计划 (Distribution Resource Planning)DSS : 决策支援系统 (Decision Support System)EC : 设计变更/工程变更 (Engineer Change)EC : 电子商务 (Electronic Commerce)ECRN : 原件规格更改通知(Engineer Change Request Notice)EDI : 电子资料交换 (Electronic Data Interchange)EIS : 主管决策系统 (Executive Information System)EMC : 电磁相容(Electric Magnetic Capability)EOQ : 基本经济订购量 (Economic Order Quantity)ERP : 企业资源规划 (Enterprise Resource Planning)FAE : 应用工程师(Field Application Engineer)FCST : 预估(Forecast)FMS : 弹性制造系统 (Flexible Manufacture System)FQC : 成品品质管制 (Finish or Final Quality Control)IPQC : 制程品质管制 (In-Process Quality Control)IQC : 进料品质管制 (Incoming Quality Control)ISO : 国际标准组织 (International Organization for Standardization) ISAR : 首批样品认可(Initial Sample Approval Request)JIT : 即时管理 (Just In Time)KM : 知识管理 (Knowledge Management)L4L : 逐批订购法 (Lot-for-Lot)LTC : 最小总成本法 (Least Total Cost)LUC : 最小单位成本 (Least Unit Cost)MES : 制造执行系统 (Manufacturing Execution System)MO : 制令(Manufacture Order)MPS : 主生产排程 (Master Production Schedule)MRO : 请修(购)单(Maintenance Repair Operation)MRP : 物料需求规划 (Material Requirement Planning)MRPII : 制造资源计划 (Manufacturing Resource Planning)NFCF : 更改预估量的通知Notice for Changing ForecastOEM : 委托代工 (Original Equipment Manufacture)ODM : 委托设计与制造 (Original Design & Manufacture)OLAP : 线上分析处理 (On-Line Analytical Processing)OLTP : 线上交易处理 (On-Line Transaction Processing)OPT : 最佳生产技术 (Optimized Production Technology)OQC : 出货品质管制 (Out-going Quality Control)PDCA : PDCA管理循环 (Plan-Do-Check-Action)PDM : 产品资料管理系统 (Product Data Management)PERT : 计画评核术 (Program Evaluation and Review Technique)PO : 订单(Purchase Order)POH : 预估在手量 (Product on Hand)PR : 采购申请Purchase RequestQA : 品质保证(Quality Assurance)QC : 品质管制(Quality Control)QCC : 品管圈 (Quality Control Circle)QE : 品质工程(Quality Engineering)RCCP : 粗略产能规划 (Rough Cut Capacity Planning)RMA : 退货验收Returned Material ApprovalROP : 再订购点 (Re-Order Point)SCM : 供应链管理 (Supply Chain Management)SFC : 现场控制 (Shop Floor Control)SIS : 策略资讯系统 (Strategic Information System)SO : 订单(Sales Order)SOR : 特殊订单需求(Special Order Request)SPC : 统计制程管制 (Statistic Process Control)TOC : 限制理论 (Theory of Constraints)TPM : 全面生产管理Total Production ManagementTQC : 全面品质管制 (Total Quality Control)TQM : 全面品质管理 (Total Quality Management)WIP : 在制品 (Work In Process)品管中英文名词对照表Accuracy准确度Active主动Action评价.处理Activity活动Add加Addition rule加法运算规则Analysis Covariance协方差分析Analysis of Variance方差分析Appraisal Variation评价变差Approved承认ASQC美国质量学会Attribute计数值Audit审核Automatic databaserecovery数据库错误自动回复Average平均数balance平衡Balance sheet资产负债对照表Binomial二项分配Body机构Brainstorming Techniques脑力风暴法 Business Systems Planning企业系统规划Cable电缆Capability能力Cause and Effect matrix因果图.鱼骨图Center line中心线check检查Check Sheets检查表Chi-square Distribution 卡方分布Clutch spring离合器弹簧Coining压印加工Common cause共同原因Complaint 投诉Compound factor调合因素Concept新概念Condenser聚光镜Conformity合格Connection 关联Consumer’s risk消费者之风险Control控制Control characteristic管制特性Control chart管制图Control plan管制计划Correction纠正Correlation Methods相关分析法Cost down降低成本CPI: continuouse Process Improvement连续工序改善Creep渐变Cross Tabulation Tables交叉表CS: customer Sevice客户中心Cushion缓冲Customer顾客DSA: Defects Analysis System缺陷分析系统Data数据Data Collection数据收集Data concentrator资料集中缓存器DCC: Document Control Center文控中心Decision决策.判定Defects per unit单位缺点数Description描述Detection难检度Device装置Digital数字Do执行DOE: Design of Experiments实验设计Element元素Else否则Engineering recbnology工程技术Entropy函数Environmental环境Equipment设备Estimated accumulative frequency计算估计累计数EV: Equipment Variation设备变异Event事件External Failure外部失效,外部缺陷FA: Failure Analysis坏品分析Fact control事实管理Fatique疲劳FMEA: Failure Mode and Effect analysis失效模式与效果分析FPY合格率FQA: Final Quality Assurance最终品质保证FQC: Final Quality control最终品质控制Full-steer完全转向f unction职能Gauge system量测系统Grade等级Gum-roll橡皮滚筒Health meter体重计Heat press冲压粘着Histogram直方图Hi-tech高科技hypergeometric超几何分配hysteresis磁滞现象Improvement改善Inductance电感Information信息Initial review先期审查Inspection检验Internal Failure内部失效,内部缺陷IPQC: In Process Quality Control制程品质控制IQC: Incomming Quality Control来料品质控制ISO: International Organization for Standardization国际标准组织Law of large number大数法则Link连接LCL: Lower Control limit管制下限LQC: Line Quality Control生产线品质控制LSL: Lower Size Limit规格下限Machine机械Manage管理Materials物料Measurement量测Median中位数Miss feed漏送Module,sub-system,sub-unit单位Momentum原动力Monte garlo method原子核分裂热运动法MSA: Measurement System Analysis量测系统分析Multiplication rule乘法运算规则NIST美国标准技术院Normal常态分布Occurrence发生率On.off system 开,关系统Operation Instruction作业指导书Organization组织Parameter参数Parto 柏拉图Parts零件Parts per million不良率Passive消极的,被动的Plan计划Pulse脉冲Policy方针Population群体Power力量,能源PQA: Process Quality Assurance制程品质保证Practice实务Precision精密度preemptive先占式多任务Pressure压缩Prevention预防Probability机率Probability density function机率密度函数Procedure流程Process过程Process capability analysis制程能力分析图Process control and process capability制程管制与制程能力Producer’s risk生产者之风险Product产品Production生产Program方案Projects项目QA: Quality Assurance品质保证QC: Quality Control品质控制QE: Quality Engineering品质工程QFD: Quality Function Desgin品质机能展开Quality质量Quality manual品质手册Quality policy品质政策Random experiment随机试验Random numbers随机数Range全距Record记录Reflow回流Reject拒收Repair返修Repeatusility再现性Reproducibility再生性Requirement要求Residual误差Response响应Responsibilities职责Review评审Reword返工Robustness稳健性Rolled yield直通率RPN: Risk Priority Number风险系数sample抽样,样本Sample space样本空间Sampling with replacement放回抽样Sampling without peplacement不放回抽样Scatter diagram散布图分析Scrap报废Screw螺旋Severity严重度Shot-peening微粒冲击平面法Simple random sampling 简单随机取样Size规格SL: Size Line规格中心线Slip滑动Stratified random sampling 分层随机抽样SOP: Standard Operation Procedure标准作业书SPC: Statistical Process Control统计制程管制Special cause特殊原因Specification规SQA:Source(Supplier) Quality Assurance供货商品质保证Stage sampling分段随机抽样Standard Deviation标准差Sum of squares统计表supplier平方和System供方systematic sampling系统,体系Statistical tables系统抽样Taguchi-method田口方法Technical committees技术委员会Test piece测试片Theory原理Time stamp时间戳印Time-lag延迟Title 标题Torque 转矩Total求和TQC: Total Quality Control全面品质控制TQM: Total Quality Management全面品质管理Traceablity追溯Training培训Transaction processing and logging交易处理Trouble困扰Up and down上和下UCL: Upper Control Limit管制上限USL: Upper Size Limit规格上限Validation确认Variable计量值Variance变异和Vector向量Verification验证Version版本VOC: voice of Customer客户需求VOE: Voice of Engineer工程需求。

原料药GMP指南(中英文对照)Q7a(中英文对照)FDA原料药GMP指南Table ofContents目录1、INTRODUCTION 1、简介1、1 Objective1、1目得1、2Regulatory Applicability 1、2法规得适用性1、3 Scope 1、3范围2、QUALITY MANAGEMENT2、质量管理2、1 Principles 2、1总则2、2质量部门得责任2、2Responsibilities of the Quality Unit(s)2、3生产作业得职责2、3 Responsibility for ProductionActivities2、4内部审计(自检)2、4 InternalAudits (Self Inspection)2、5 Product Quality Review2、5产品质量审核3、PERSONNEL3、人员3、1 PersonnelQualifications 3、人员得资质3、2 Personnel Hygiene 3、2 人员卫生3、3 Consultants 3、3 顾问4、建筑与设施4、BUILDINGS ANDFACILITIES4、1Designand Construction4、1 设计与结构4、2 Utilities4、2 公用设施4、3 Water4、3 水4、4 Containment4、4 限制4、5 Lighting 4、5 照明4、6Sewage and Refuse 4、6 排污与垃圾4、7Sanitation andMaintenance 4、7卫生与保养5、PROCESS EQUIPMENT5、工艺设备5、1DesignandConstruction 5、1 设计与结构5、2Equipment Maintenance and5、2设备保养与清洁Cleaning5、3Calibration 5、3 校验5、4 puterized Systems5、4 计算机控制系统6、DOCUMENTATION AND RECORDS6、文件与记录6、1 Documentation System andSpecifications6、1 文件系统与质量标准6、2EquipmentcleaningandUseRecord6、2 设备得清洁与使用记录6、3 Recordsof Raw Materials,Intermediates,APILabeling andPackaging Materials 6、3 原料、中间体、原料药得标签与包装材料得记录6、4Master Production Instructions (Master Production and ControlRecords)6、4 生产工艺规程(主生产与控制记录)6、5 BatchProduction Records(Batch Production andControlRecords)6、5 批生产记录(批生产与控制记录)6、6Laboratory ControlRecords 6、6 实验室控制记录6、7 Batch Production RecordReview6、7批生产记录审核7、MATERIALSMANAGEMENT7、物料管理7、1GeneralControls 7、1 控制通则7、2Receiptand Quarantine 7、2接收与待验7、3Sampling andTesting of IningProduction Materials7、3 进厂物料得取样与测试7、4 Storage 7、4储存7、5Re-evaluation 7、5复验8、PRODUCTION ANDIN—PROCESS CONTROLS8、生产与过程控制8、1ProductionOperations 8、1 生产操作8、2 Time Limits 8、2 时限8、3 In-process Sampling and Controls8、3 工序取样与控制8、4 BlendingBatches ofIntermediatesor APIs8、4 中间体或原料药得混批8、5 Contamination Control 8、5 污染控制9、PACKAGING AND IDENTIFICATION LABELING OF APIs AND INTERMEDIATES9、原料药与中间体得包装与贴签9、1General 9、1 总则9、2Packaging Materials 9、2 包装材料9、3Label Issuance andControl 9、3标签发放与控制9、4Packaging and LabelingOp9、4包装与贴签操作erations10、储存与分发10、STORAGE AND DISTRIBUTION10、1 Warehousing Procedures 10、1 入库程序10、2DistributionProcedures 10、2 分发程序11、LABORATORY CONTROLS 11、实验室控制11、1 General Controls 11、1控制通则11、2中间体与原料药得测试11、2 T esting ofIntermediatesandAPIs11、3 Validation of Analytical11、3 分析方法得验证Procedures11、4CertificatesofAnalysis11、4 分析报告单11、5 原料药得稳定性监测11、5 Stability Monitoringof APIs11、6 Expiryand RetestDating11、6 有效期与复验期11、7Reserve/Retention Samples 11、7 留样12、VALIDATION 12、验证12、1 Validation Policy 12、1 验证方针12、2 Validation Documentation12、2 验证文件12、3Qualification 12、3 确认12、4 工艺验证得方法12、4Approachesto ProcessValidation12、5 Process Validation Program12、5 工艺验证得程序12、6PeriodicReviewof12、6验证系统得定期审核Validated Systems12、7 CleaningValidation 12、7 清洗验证12、8 分析方法得验证12、8 Validation of Analytical Methods13、CHANGECONTROL 13、变更得控制14、REJECTIONANDRE-USEO14、拒收与物料得再利用FMATERIALS14、1 Rejection 14、1 拒收14、2Reprocessing14、2 返工14、3Reworking 14、3 重新加工14、4Recovery of Materialsand14、4 物料与溶剂得回收Solvents14、5Returns14、5 退货15、PLAINTS AND RECALLS 15、投诉与召回16、CONTRACTMANUFACTURERS (INCLUDING LABORATORIES)16、协议生产商(包括实验室)17、AGENTS,BROKERS, TRADERS,DISTRIBUTOR S,REPACKERS,AND RELABELLERS17、代理商、经纪人、贸易商、经销商、重新包装者与重新贴签者17、1Applicability 17、1适用性17、2Traceabilityof DistributedAPIs and Intermediates17、2已分发得原料药与中间体得可追溯性17、3QualityManagement 17、3质量管理17、4Repackaging, Relabeling,and Holding of APIsandInterm ediates17、4原料药与中间体得重新包装、重新贴签与待检17、5Stability 17、5稳定性17、6 TransferofInformation 17、6 信息得传达17、7Handling ofplaints andRecalls17、7投诉与召回得处理17、8Handlingof Returns 17、8 退货得处理18、Specific Guidance for APIs Manufactured byCell Culture/Fermentation18、用细胞繁殖/发酵生产得原料药得特殊指南18、1 General 18、1总则18、2Cell Bank Maintenanceand Record Keeping18、2细胞库得维护与记录得保存18、3 CellCulture/Fermentation18、3细胞繁殖/发酵18、4 Harvesting, IsolationandPurification18、4收取、分离与精制18、5Viral Removal/Inactivation steps18、5 病毒得去除/灭活步骤19、APIsfor Use in Clinical Trials19、用于临床研究得原料药19、1General 19、1 总则19、2 Quality 19、2 质量19、3Equipment and Facilities 19、3设备与设施19、4 ControlofRaw Materials 19、4原料得控制19、5Production 19、5 生产19、6Validation 19、6 验证19、7 Changes19、7变更19、8 Laboratory Controls 19、8实验室控制19、9 Documentation 19、9 文件20、Glossary 20、术语Q7a GMP Guidance forAPIs Q7a原料药得GMP指南1、INTRODUCTION1、简介1、1 Objective1、1目得Thisdocument isintendedto provide guidance re garding good manufacturingpractice (GMP) for the manufacturing of active pharmaceuticalingredients (APIs)underan app ropriate systemfor managing qualit y、Itis also intended tohelp ensure that APIsmeet the qualityand puritycharacteristicstha ttheypu rport,or arerepresented,to possess、本文件旨在为在合适得质量管理体系下制造活性药用成分(以下称原料药)提供有关优良药品生产管理规范(GMP)提供指南。

ICH(International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use)人用药物注册技术要求国际协调会。

Q10:药品质量管理体系(PQS),基于QMS(质量管理体系)而来,最合适的指南应该是ICH的Q10。

Q9:质量风险管理。

Q8:药物开发。

自动化生产规范GAMP5(Good Automated Manufacturing Practice)由ISPE(International Society For Pharmaceutical Engineering国际制药工程协会。

创立于1980年,是致力于培训制药领域专家并提升制药行业水准的世界最大的非盈利性组织之一)的GAMP论坛(GAMP Forum)组织编写发布的关于制药企业计算机化系统的综合性指南。

纠正和预防措施CAPA(Corrective Action & Preventive Action)超出标准的可疑结果OOS(out of specification)质量管理 QM(Quality Management)质量保证 QA(Quality Assurance)质量控制 QC(Quality Control)生产管理 PM(Production Maanagement)工程设备管理 EM (Enginccr Equipment Managemant)销售管理 MS (Maragement Of Sales)行政人员管理AP (Administration and Personael Managemeht)工艺验证 PV (Process Validation)设备验证 EV (Equipment Validation)工艺规程 PP (Process Procedure)质量标准 QS (Quality Management)物料管理 MM (Materid Management)原料管理 RM (Raw Material Management)辅料管理 EM (Excipient Management)质量标准 QS (Quality Standard)增补和修订A.A.A Addition and Amendments空调器AC Air Conditioner药物不良反应ADR Adverse Drug Reaction食品与药品官员协会(美国)AFDO Association of Food and Drug Officials 接受ACC Accept合格质量标准AQL Acceptable Quality Level简化的新药申请ADNA Abbreviated New Drug Application物料清单BOM Bill of Material原料药BPC Bulk pharmaceutical Chemiclls生物制品评价与研究中心CBER Center for Biologics Evaluation Research 菌落形成单位CFU Colony Forming Unet药品管理档案DMF Drug Master File药物评价与研究中心CDER Cemter for Drug Evaluation amd Research企业识别(形象)CI Corporate Identity (Image)在线清洗CIP Cleaning in Place消费者安全调查员CSI Consumer Safety Insepctor在线清洗程序CLP Cleaning Line Procedure缺陷作用水平DAL Defect Action Level管制药品管理DEA Drug Enforcement Adminestration文件系统DS Documentation Systim食品与药品管理局(美国)FDA Food and Drug Administration关贸总协会GATT General Agreemernt on Tariffs and Trade药品生质量管理规范GMP Good Manufacturing Practice药品临床实验管理规范GCP Good Clinical Practice实验室管理规范GLP Good Laboratory Practice药品商业质量规范GSP Good Supply Practice药品零业质量管理规范GRP Good RaTAIL Practice药材生产管理规范GAP Good Agriculture Practice验证管理规范GVP Good Validation Prctice药品使用规范GUP Good Use Practice国际标准化组织ISO Intematonal Organization for Standardization 谅解备忘录MOU Memorandum of Understanding生产记录用表格PF Porduction File非处方药品OTC Over the Counter (Drug)产品许可申请PLA Product License Application质量管理程序QMP Quality Management Procedure国家药品监督管理局SDA State Drug Administration标准管理程序SMP Standard Managmert Procedure标准操作程序SOP Standard Operating Procedure全面质量管理TQC Tatal Quality Control美国药典USA Uneted States Pharmacopeia生产管理中的术语系统: system起始原料:starting material物料:material物料平衡:reconcilination批: batch or lot批号:batch number (lot number)批档案:batch records文件: doocument标准操作规程:standard operating processsing工艺规程:master for processing纯化水: puritied water工艺用水:water for processing蒸馏水:distilled water去离子水:deionized water注射用水:water for injection无菌:sterile灭菌:sterlization(sterilise)无菌制剂:sterile product ?(preparation,dosage from) 非无菌制剂:non-sterile product状态标志:status mark (labet)中间产品:intermediate product制造:manufacture带包装品:bulk product成品:finished product活性药物组分:active pharmaceutical ingredient理论产量:theoretical yield质量管理中的术语待验:quarantine控制点:control point质量保证:quality assurance质量控制:quality control质量管理:quality management质量体系:quality system质量监督:quality surveillance规格标准:specification生产过程中控制:in-process control返工:reprocessing退货:retured product拒收:rejected交叉污染:cross contamination放行:released质量要求:quality requirement质量管理体系:quality management system可追溯性:traceability合格(符合):conformity不合格:nonconformity预防措施:preventive action质量手册:quality manual计量确认:metrological confirmation验证术语:验证:validation空调净化系统:HVAC( heating ventilation and air conditioning) 起泡点实验:bubbling point挑战性试验:challenge test最差状况:worst case不合格限:edge-of-failure严整方案:validation protocol在线清洗:CIP(cleaning in place)在线灭菌:SIP(sterilization in place)预确认:pre qualification安装确认:IQ(instalation qualification)运行确认:OQ(operational qualitification)性能确认:PQ(performance qualificantion产品验证:PV(product validation)工艺验证:process validation前验证:prospective validation同步验证:concurrent validation回顾性验证:retrospective认证:certification其他术语:管理体系:management system组织结构:organizational structure指南:guideline销售许可证:marketing authorization计算机系统:computerized system生物反应器:biogenerator生物试剂:biological agents细胞库系统:cell bank system主细胞库:master cell bank工作细胞库:working cell bank细胞培养:cell culture种子库:seed lot主种子库:master seed lot工作种子库:working seed lot外源生物体:exotic organism放射性药品:radio pharmaceutical原植物(植物药)crude plant(vegetable drug)药用植物:medicinal plant草药品:herbal pharmaceuticalOn the Road推荐阅读:•CAPA(Corrective Action & Preventive Action)纠正2010-08-09 19:25:00•oos和偏差2010-07-09 15:27:01•车间标识中英对照2010-08-16 15:37:56•GMP文件管理常用的英文缩写2009-06-08 11:23:40。

Q7a(中英文对照)FDA原料药GMP指南Table of Contents 目录1. INTRODUCTION 1. 简介1.1 Objective 1.1目的1.2 Regulatory Applicability 1.2法规的适用性1.3 Scope 1.3范围2. QUALITY MANAGEMENT 2.质量管理2.1 Principles 2.1总则2.2 Responsibilities of the Quality Unit(s) 2.2质量部门的责任2.3 Responsibility for Production Activities 2.3生产作业的职责2.4 Internal Audits (Self Inspection) 2.4内部审计(自检)2.5 Product Quality Review 2.5产品质量审核3. PERSONNEL 3. 人员3.1 Personnel Qualifications 3.人员的资质3.2 Personnel Hygiene 3.2 人员卫生3.3 Consultants 3.3 顾问4. BUILDINGS AND FACILITIES 4. 建筑和设施4.1 Design and Construction 4.1 设计和结构4.2 Utilities 4.2 公用设施4.3 Water 4.3 水4.4 Containment 4.4 限制4.5 Lighting 4.5 照明4.6 Sewage and Refuse 4.6 排污和垃圾4.7 Sanitation and Maintenance 4.7 卫生和保养5. PROCESS EQUIPMENT 5. 工艺设备5.1 Design and Construction 5.1 设计和结构5.2 Equipment Maintenance and Cleaning 5.2 设备保养和清洁5.3 Calibration 5.3 校验5.4 Computerized Systems 5.4 计算机控制系统6. DOCUMENTATION AND RECORDS 6. 文件和记录6.1 Documentation System andSpecifications6.1 文件系统和质量标准6.2 Equipment cleaning and Use Record 6.2 设备的清洁和使用记录6.3 Records of Raw Materials, Intermediates, API Labeling and Packaging Materials 6.3 原料、中间体、原料药的标签和包装材料的记录6.4 Master Production Instructions (MasterProduction and Control Records)6.4 生产工艺规程(主生产和控制记录)6.5 Batch Production Records (BatchProduction and Control Records)6.5 批生产记录(批生产和控制记录)6.6 Laboratory Control Records 6.6 实验室控制记录6.7 Batch Production Record Review 6.7批生产记录审核7. MATERIALS MANAGEMENT 7. 物料管理7.1 General Controls 7.1 控制通则7.2 Receipt and Quarantine 7.2接收和待验7.3 Sampling and Testing of IncomingProduction Materials7.3 进厂物料的取样与测试7.4 Storage 7.4储存7.5 Re-evaluation 7.5复验8. PRODUCTION AND IN-PROCESSCONTROLS8. 生产和过程控制8.1 Production Operations 8.1 生产操作8.2 Time Limits 8.2 时限8.3 In-process Sampling and Controls 8.3 工序取样和控制8.4 Blending Batches of Intermediates orAPIs8.4 中间体或原料药的混批8.5 Contamination Control 8.5 污染控制9. PACKAGING AND IDENTIFICATIONLABELING OF APIs ANDINTERMEDIATES9. 原料药和中间体的包装和贴签9.1 General 9.1 总则9.2 Packaging Materials 9.2 包装材料9.3 Label Issuance and Control 9.3 标签发放与控制9.4 Packaging and Labeling Operations 9.4 包装和贴签操作10. STORAGE AND DISTRIBUTION 10.储存和分发10.1 Warehousing Procedures 10.1 入库程序10.2 Distribution Procedures 10.2 分发程序11. LABORATORY CONTROLS 11.实验室控制11.1 General Controls 11.1 控制通则11.2 Testing of Intermediates and APIs 11.2 中间体和原料药的测试11.3 Validation of Analytical Procedures 11.3 分析方法的验证11.4 Certificates of Analysis 11.4 分析报告单11.5 Stability Monitoring of APIs 11.5 原料药的稳定性监测11.6 Expiry and Retest Dating 11.6 有效期和复验期11.7 Reserve/Retention Samples 11.7 留样12. V ALIDATION 12.验证12.1 Validation Policy 12.1 验证方针12.2 Validation Documentation 12.2 验证文件12.3 Qualification 12.3 确认12.4 Approaches to Process Validation 12.4 工艺验证的方法12.5 Process Validation Program 12.5 工艺验证的程序12.6 Periodic Review of Validated Systems 12.6验证系统的定期审核12.7 Cleaning Validation 12.7 清洗验证12.8 Validation of Analytical Methods 12.8 分析方法的验证13. CHANGE CONTROL 13.变更的控制14. REJECTION AND RE-USE OFMATERIALS14.拒收和物料的再利用14.1 Rejection 14.1 拒收14.2 Reprocessing 14.2 返工14.3 Reworking 14.3 重新加工14.4 Recovery of Materials and Solvents 14.4 物料与溶剂的回收14.5 Returns 14.5 退货15. COMPLAINTS AND RECALLS 15.投诉与召回16. CONTRACT MANUFACTURERS(INCLUDING LABORATORIES)16.协议生产商(包括实验室)17. AGENTS, BROKERS, TRADERS, DISTRIBUTORS, REPACKERS, AND RELABELLERS 17.代理商、经纪人、贸易商、经销商、重新包装者和重新贴签者17.1 Applicability 17.1适用性17.2 Traceability of Distributed APIs andIntermediates17.2已分发的原料药和中间体的可追溯性17.3 Quality Management 17.3质量管理17.4 Repackaging, Relabeling, and Holding of APIs and Intermediates 17.4原料药和中间体的重新包装、重新贴签和待检17.5 Stability 17.5稳定性17.6 Transfer of Information 17.6 信息的传达17.7 Handling of Complaints and Recalls 17.7 投诉和召回的处理17.8 Handling of Returns 17.8 退货的处理18. Specific Guidance for APIs Manufactured by Cell Culture/Fermentation 18. 用细胞繁殖/发酵生产的原料药的特殊指南18.1 General 18.1 总则18.2 Cell Bank Maintenance and RecordKeeping18.2细胞库的维护和记录的保存18.3 Cell Culture/Fermentation 18.3细胞繁殖/发酵18.4 Harvesting, Isolation and Purification 18.4收取、分离和精制18.5 Viral Removal/Inactivation steps 18.5 病毒的去除/灭活步骤19.APIs for Use in Clinical Trials 19.用于临床研究的原料药19.1 General 19.1 总则19.2 Quality 19.2 质量19.3 Equipment and Facilities 19.3 设备和设施19.4 Control of Raw Materials 19.4 原料的控制19.5 Production 19.5 生产19.6 Validation 19.6 验证19.7 Changes 19.7 变更19.8 Laboratory Controls 19.8 实验室控制19.9 Documentation 19.9 文件20. Glossary 20. 术语Q7a GMP Guidance for APIs Q7a原料药的GMP指南1. INTRODUCTION 1. 简介1.1 Objective 1.1目的This document is intended to provide guidance regarding good manufacturing practice (GMP) for the manufacturing of active pharmaceutical ingredients (APIs) under an appropriate system for managing quality. It is also intended to help ensure that APIs meet the quality and purity characteristics that they purport, or are represented, to possess. 本文件旨在为在合适的质量管理体系下制造活性药用成分(以下称原料药)提供有关优良药品生产管理规范(GMP)提供指南。

目录A.总则 (1)211.1 范围 (1)211.3定义 (1)B组织与人员 (2)211.22质量控制部门的指责 (2)211.25人员资格 (3)211.28人员职责 (4)211.34顾问 (4)C.厂房和设施 (5)211.42设计与建造特征 (5)211.44照明 (7)211.46通风、空气过滤、空气加热与冷却 (7)211.48管件 (8)211.50 污水和废料 (8)211.52 洗涤和洗设备 (8)211.56环境卫生 (9)211.58 保养 (10)D. 设备 (10)211.63 设备的设计、尺寸及位置 (10)211.65 设备制造 (10)211.67 设备清洁与保养 (11)211.68 自动化设备、机械化设备和电子设备 (12)211.72 过滤器 (13)E. 成分、药品容器和密封件的控制 (13)211.80 总要求 (13)211.82 未检验的成份、药品容器和密封件的接收与贮存 (14)211.84 成分、药品容器和封口物品的试验、批准或拒收 (14)211.86 获准的成份、药品容器和密封件的使用 (17)211.87 获准的成份、药品容器&密封件的复检 (17)211.89 拒收的成份、药品容器&封口物品 (17)211.94 药品密容器和密封件 (18)F. 生产和加工控制 (18)211.100 成文的规程,偏差 (18)211.101 成份的进料 (19)211.103 产量计算 (20)211.105 设备鉴别 (20)211.111 生产时间限制 (21)211.113 微生物污染的控制 (21)211.115返工 (21)G、包装和标签控制 (22)211.122材料的检查和使用标准 (22)211.125标签的发放 (23)211.130包装和标签操作 (24)211.132人用非处方药(OTC)保险包装的要求 (25)211.134药品检查 (29)211.137有效期 (29)H.贮存和销售 (30)211.150 销售程序 (30)I 实验室控制 (31)211.160 总要求 (31)211.165 销售要求的检验与发放 (32)211.166 稳定性试验 (34)211.167 特别检验要求 (35)211.170 样品保存 (36)211.173 实验动物 (38)211.176 青霉素污染 (38)J.记录和报告 (39)211.180 总要求 (39)211.182 设备清洁和使用记录 (41)211.184 成份、药品容器、密封件及标签的记录 (41)211.186 主要生产和控制的记录 (42)211.188 批生产和控制记录 (44)211.192 产品记录复查 (45)211.194 实验室记录 (45)211.196 销售记录 (47)211.198 投诉档案 (48)K.退回的药品和回收处理 (50)211.204 退回的药品 (50)211.208药品的回收处理 (51)Subpart A-General Provisions§ 211.1 Scope a) The regulations in this part contain the minimum current good manufacturing practicefor preparation of drug products foradministration to humans or animals. b) The current good manufacturing practice regulations in this chapter, as they pertain to drug products, and in parts 600 through 680 ofthis chapter, as they pertain to biological products for human use, shall be considered to supplement, not supersede , the regulations in this part unless the regulations explicitly provide otherwise. In the event it is impossible to comply with applicable regulations both in this part and in other parts of this chapter or in parts 600 through 680 of this chapter, the regulation specifically applicable to the drug product in question shall supersede the regulation in this part. c) Pending consideration of a proposed exemption , published in the Federal Register of September 29, 1978, the requirements in this part shall not be enforced for OTC drugproducts if the products and all their ingredients are ordinarily marketed and consumed as human foods, and which products may also fall within the legal definition of drugs by virtue of their intendeduse. Therefore, until further notice, regulations under part 110 of this chapter, and where applicable, parts 113 to 129 of this chapter, shall be applied in determining whether these OTC drug products that are also foods are manufactured, processed, packed, or held under current good manufacturing practice. § 211.3 Definitions. The definitions set forth in §210.3 of this chapter apply in this part. A .总则211.1 范围(a ) 本部分的条例包含人用或兽用药品制备的现行最低限度的药品生产管理规范(GMP )。

GMP常用名词-中英文对照GMP常用名词-中英文对照Lot Number –批号见批号(Batch Number)Manufacture –制造物料的接收、原料药的生产、包装、重新包装、贴签、重新贴签、质量控制、放行、贮存和分发以及相关控制的所有操作。

Material –物料原料(起始物料,试剂,溶剂),工艺辅助用品,中间体,原料药,和包装及贴签材料的统称。

Mother Liquor –母液结晶或分离后剩下的残留液。

母液可能含有未反应的物料、中间体、不同级别的原料药和/或杂质。

它可用于进一步加工。

Packaging Material –包装材料在储运过程中保护中间体或原料药的任何物料。

Procedure –程序对要进行的操作、要采取的预防措施以及与原料药或中间体生产直接或间接相关的方法的描述文件。

Process Aids –工艺辅料除溶剂外,在原料药或中间体生产中起辅助作用、本身不参与化学或生物学反应的物料(例如,助滤剂、活性炭)。

Process Control –工艺控制见中间控制在原料药制备过程中,从接收原料,到工艺加工和原料药包装所涉及的所有操作。

Qualification –确认证明设备或辅助系统,安装正确、工作正常、确实产生预期的结果,并以文件佐证的行为。

确认是验证的一部分,但单独的确认步骤不构成工艺验证。

Quality Assurance (QA) –质量保证以确保所有原料药达到其应用所要求的质量,并维持质量体系为目的的全部组织安排的总和。

Quality Control –质量控制是否符合质量规格的检查或测试。

Quality Unit(s) –质量部门独立于生产部门的履行质量保证和质量控制职责的组织机构。

按照组织机构的大小和结构,可以是单独的QA 和QC部门,或个人,或小组。

Quarantine –待验在实物上或以其它有效方式将物料隔离,等待对其随后的批准或拒收做出决定的状态。

Raw Material –原料用来表示中间体或原料药的生产中要用的起始物料、试剂和溶剂的通用专业名词。