FDA 制剂生产厂检查指南

- 格式:doc

- 大小:195.50 KB

- 文档页数:35

FDA检查员指导手册:原料药生产检查(药品质量保证)第I部分――背景至八十年代后期以来,美国食品与药品管理局以强化了其对原料药(API)生产企业的检查内容。

从部分方面来说,这归咎于对原料药质量在制剂的质量、效力、和安全方面所起的重要作用认识的提高。

例如,在配制成固体口服制剂,混悬剂和局部用药时原料药的化学特性会对制剂的溶出度/生物利用度产生不利影响。

另外,原料中的少量没有鉴别出的杂质或其特性未知的杂质会给病人造成的严重不良反应。

FDA长期以来一直认为,收载在制剂药品生产质量管理规范规定(21 CFR 210 and211)中的CGMP概念对原料药生产工艺同样有效。

这些概念包括,与其他一起,产品质量是生产出来的,雇佣能够胜任和经过培训的员工,建立适宜的书面程序和管理规定,建立一套在线测试和产品测试系统,工艺验证,和保证原料药在预期的使用期内质量稳定。

FDA在1991年出版的化学原料药检查指南,在1994年经过少量的编辑变化,包含有原料药生产的GMP/验证概念应用和范围方面的基本指南,并包含了FDA对杂质和杂质专论方面的要求。

在对国内和国外原料药进行检查时均必须使用该指南,以促进检查的一致性和均一性。

目前,FDA希望生产企业在API生产的全过程实施CGMP,即从起始原料的使用开始,到对原料药质量和纯度产生影响的关键工艺步骤的验证。

该方法认为所需的控制方法完全依赖于实际的生产工艺且随着合成步骤从早期的中间阶段向最终分离和纯化步骤的延伸控制水平也在不断加强。

该方法允许依据工艺本身(即,化学合成工艺和发酵工艺)及特殊工艺步骤的风险性和关键性采取适宜水平的控制方法。

该“控制所有步骤,验证关键工艺步骤”方法包含在FDA的《原料药制造,加工和储存指南》草案内,其在1996年9月20日公布供公众讨论。

后者可以从CDER的网站下载:/cder/api.htm.。

第II部分实施目的:该符合性程序的主要目的是为对国内和国外各类原料药生产企业的检查提供一份综合性的CGMP检查指南。

FDA行业指南-药品现场检查中被认为是延迟、否认、限制或拒绝的情形一、介绍2012年7月9日,《美国食品和药物管理局安全及创新法案》(FDASIA)被签署成为法律。

FDASIA章节707添加了501(j)到《食品、药品和化妆品法令》(FD&C Act),认为“任何从事生产、加工、包装或持有的生产企业、库房造成现场检查的延迟、否认、限制或拒绝的情况均被认为该产品为假劣药品”。

该指南的目的是对“延迟、否认、限制或拒绝”的情形进行定义。

二、定义1、延迟A、检查计划安排的延迟FDA将会根据当地的情况对检查计划进行适当的调整,例如天气、安保、节假日、其他非工作日、企业的生产计划等。

以下延迟的情况将会被认为产品是假劣药品,包括但不仅限于:●企业不同意建议的检查日期,但没有合理的解释。

●在检查安排后,企业要求延迟检查日期,但没有合理的解释。

●企业不能回答为什么FDA联系不上企业指定的联系人。

下面给出了将不会被认为是假劣药品的潜在合理解释的一个例子,但不仅限于:●企业没有正在生产,例如每个月只生产一次,企业要求检查日期另定,以便FDA检查时生产正在进行中。

B、检查期间的延迟以下检查期间的延迟情况将会被认为产品是假劣药品,包括但不仅限于:●企业不允许FDA检查官进入某个区域直至一段时间过去之后,即使这个区域是正在进行操作的并且是FDA有权检查的区域,对于这种行为没有合理的解释。

●企业长时间把FDA检查官单独撂在会议室,没有相应的文件或责任人供审查和询问,从而干扰检查官完成其相应的检查。

下面给出了将不会被认为是假劣药品的潜在合理解释的一个例子,但不仅限于:●企业不允许FDA检查官进入无菌工艺区域,直至检查官能满足企业的无菌更衣程序要求。

C、记录提供延迟以下记录提供延迟的情况将会被认为产品是假劣药品,包括但不仅限于:●在检查期间,FDA检查官要求在合理的时间内提供其有权查看的文件和记录,但是企业不能按时提供,且没有合理的解释。

FDA对制药企业文件的现场检查

一、文件的永久性

记录原始文件必须用黑色的墨水圆珠笔(有些公司也允许用蓝色的墨水圆珠笔)以确保文字的永久性。

当采用热敏性纸记录原始数据时,必须要另拷贝一份并与原始记录并行贴在一起,缩写签名和日期。

此外,原始文件绝对不允许用铅笔记录,也不允许用涂改液涂改文件。

二、文件的易读性

写了错字或不正确的信息,应将错误部分用单线划掉,然后补上正确的信息,缩写签名和日期。

特别不要涂改标准样品和分析样品的重量,因为实验的最终结果与标样和分析样品的重量直接相关,涂改这类数据具有很大的可疑性。

如果记录的数据确实有误,最好的改正的措施是将其数据划掉,注明记录的数据有误,样品将会重新称量。

三、文件的及时性

这一要求重点强调任何原始数据,生产过程中的具体操作指标,实验的程序,测试中标样和分析样品的信息,以及仪器型号和操作步骤都必须及时记录。

当原始记录(包括样品名称、来源、批号、有效日期、缓冲液的pH,有机溶剂的种类,来源和数量,稀释样品溶剂的制备步骤,所用仪器的型号及编号,液相柱子的种类,编号和尺度,标样和分析样品制备的步骤等)没有被及时记录下来时,原则上不可以补记。

四、文件的完整性

所有文件必须牢固附在正式的记录本上。

所有没有记录的空间必须用一单线划掉

引用的参考文献或操作步骤必须详细记录下来

五、文件的时间顺序性

文件记录的日期应与文件页码数相符合

还有就是不允许在正式文件上注明追溯日期或事后日期。

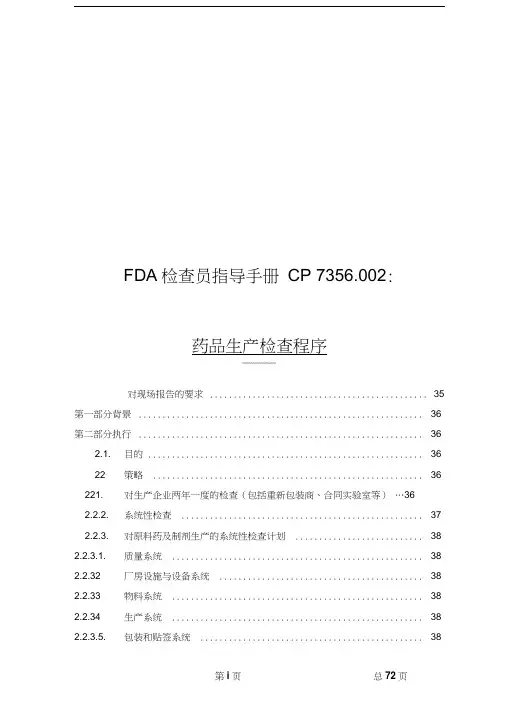

FDA检查员指导手册CP 7356.002:药品生产检查程序对现场报告的要求 (35)第一部分背景 (36)第二部分执行 (36)2.1. 目的 (36)22 策略 (36)221. 对生产企业两年一度的检查(包括重新包装商、合同实验室等) (36)2.2.2. 系统性检查 (37)2.2.3. 对原料药及制剂生产的系统性检查计划 (38)2.2.3.1. 质量系统 (38)2.2.32 厂房设施与设备系统 (38)2.2.33 物料系统 (38)2.2.34 生产系统 (38)2.2.3.5. 包装和贴签系统 (38)2.2.3.6. 实验室控制系统 (39)2.3. 程序管理指导 (39)2.3.1. 定义 (39)2.3.1.1. 监督性检查 (39)2.3.1.2. 达标检查 (40)2.3.1.3. 受控状态 (40)2.3.1.4. 药品工艺 (40)2.3.1.5. 药品生产检查 (41)第三部分检查 (41)3.1. 检查活动 (41)3.1.1. 总则 (41)3.1.2. 检查方法 (42)3.1.2.1. 全面性检查的选择 (43)3.1.2.2. 简略性检查的选择 (43)3.1.2.3. 综合性检查范围 (43)3.1.3. 系统性检查范围 (43)3.131. 质量系统 (44)3.1.32厂房设施与设备系统 (44)3.1.3.3. 物料系统 (45)3.1.3.4. 生产系统 (46)3.1.3.5. 包装和贴签系统 (47)3.1.3.6. 实验室控制系统 (48)3.1.4. 取样 (49)3.1.5. 检查组组成 (49)3.1.6. 报告 (49)第四部分分析 (50)第五部分法律性/行政性策略 (50)5.1. 质量系统 (51)5.2. 厂房设施和设备 (51)5.3. 物料系统 (51)5.4. 生产系统 (52)5.5. 包装和贴签系统 (52)5.6. 实验室控制系统 (52)对现场报告的要求作为法律行动的一部分,所有针对因在执行cGMP方面有缺陷而采取的检查,均要向药品评价和研究中心的达标办公室呈交一份现场检查报告(EIR) 。

(一 FDA 是如何对原料药厂进行检查的一、前言本文作者从 1981年起开始涉及原料药的 FDA 申请事务, 从 1992年一直专门从事这项专业工作至今。

其间先后参与或主持了近 20个原料药产品的 FDA 申请工作,制作归档了十几个 DMF 文件, 与十多位美国代理商或美国终端用户的 GMP 符合及 FDA 申请顾问一起工作, 九次参加 FDA 官员对我国一些制药企业进行的GMP 符合性现场检查, 其中 8个品种通过了 FDA 的现场检查, 从而积累了一些有益的经验。

作者现任北京康利华公司咨询服务有限公司终身董事和监事, 仍专门从事FDA 的申请工作。

本文就 FDA 对原料药管制的有关文件的学习了解, 结合作者 20年来的实际经验,对 FDA 官员对原料药厂如何进行现场检查作了简要的叙述, 希望能给我国广大原料药企业提供有益的参考。

1.定义1. 1原料药通过化学合成、微生物发酵、天然物提取分离、酶工程、 DNA 重组等技术和手段得到的具有药物活性、符合一定质量标准的物质。

原料药通常只供生产制剂之用, 不可直接用于临床。

欧美对原料药的称呼有以下几种:Bulk Pharmaceutical Chemical简称 BPC 。

现常用: Active Pharmaceutical Ingredient简称 API ,或 Drug Substance。

生产原料药的起始物料在生产过程中都要经历明显的化学变化, 然后经分离纯化制成具有药物活性、且符合一定质量标准的原料药。

原料药又分为无菌 (Sterile和非无菌 (Non— sterile 两种级别。

前者常用于生产非消化道给药的制剂药, 后者常用于生产口服制剂或外用制剂, 或再经过无菌处理生产非消化道制剂药。

1. 2制剂药将原料药与辅料一起进一步加工, 制成的适合临床应用的各种形式, 所得到的产品为制剂药。

欧美常把制剂药称作:Finished Pharmaceutical, Finished Product, Dosage Form, Finished Dosage Form或Drug product。

GUIDE(1) TO INSPECTIONSOF FOREIGN PHARMACEUTICAL MANUFACTURERS BACKGROUND背景There has been a significant increase in the number of foreign inspections of pharmaceutical manufacturing plants in the past few years. This trend is attributable mainly to the increase in the number of pre-approval inspections although the increase has been noted in other areas such as routine GMP inspections and compliance follow-up activities. Considering the resource-intensive nature of the foreign inspection program, it has become clear that effective and efficient inspectional coverage is crucial to the successful management of the program and that can be achieved only through maintenance of consistency and uniformity of inspection and enforcement activities.在最近几年医药制造厂外检查数量显著增加。

这一趋势主要是由增加的前置审批检查的次数虽然增加了在其他领域如日常GMP检查和合规性的后续活动记录。

美国FDA生产过程(工艺)验证总则指南1 9 8 7年I.目的 3II.范围 3III.序言 3Ⅳ. 总概念 4V.现行药品生产质量管理规范(CGMP)法规 6Ⅵ.医疗器械的生产质量管理规范法规7Ⅶ.验证预备阶段所需考虑的事情7Ⅷ.生产过程验证的内容8Ⅸ.产品检验的可接受性11I.目的本指南概述了人用和兽用药品和医疗器械的生产过程(工艺)验证的总则,其验证的基本原理是得到fdA认可的。

II.范围本指南是根据21CFR10-90颁布的,适用于药品和医疗器械的生产。

本指南阐述了一般适用范围的原则和方法,这些原则和方法在法律上未做规定要求,但是得到了fdA认可。

本指南可以作为依据,并保证可以得到FDA的批准,但也可以按照其他方法进行验证。

在使用不同方法进行验证时,可事前与(但也可以不与)fdA讨论所要进行的验证工作,以避免在以后被FDA认为不合格而浪费了财力和精力。

总而言之,本指南列述的有关药品和医疗器械的生产过程验证原则和方法,是得到FdA认可的。

但不是在所有情况下都必须使用本指南所列述的原则和方法以符合法律。

本指南是要经常进行修订的。

对此有兴趣的人士可对本文件及随后的任一版本提出意见。

书面意见应向FDA的Dockets Maragement Branch(HFA—305)上报。

地址为:Room 462,5600FishersLane,Rockville,Maryland20847。

在星期—至星期五,上午9:00到下午4:00可在该办公处查阅所收到的意见,III.序言生产过程验证是药品生产管理规范法规21CFR210•211和医疗器械生产管理规范法规21CFR820的规定要求,所以适用于药品和医疗器械的生产。

有些生产厂商曾向FDA要求提供具体的指导:关寸FDA要求生产商做些什么工作,以保证生产过程验证符合规定的要求。

本指南讨沦了生产过程验证的原理和概念,FDA认为这些原理和概念是符合验证方案要求的。

GUIDE TO INSPECTIONS ORAL SOLUTIONS AND SUSPENSIONSNote: This document is reference material for investigators and other FDApersonnel. The document does not bind FDA, and does no confer any rights,privileges, benefits, or immunities for or on any person(s).I. INTRODUCTIONThe manufacture and control of oral solutions and oral suspensions haspresented some problems to the industry. While bioequivalency concerns areminimal (except for the antiseptic products such as phenytoin suspension),there are other issues which have led to recalls. These includemicrobiological, potency and stability problems. Additionally, because thepopulation using these oral dosage forms includes newborns, pediatrics andgeriatrics who may not be able to take oral solid dosage forms and may becompromised, defective dosage forms can pose a greater risk because of thepopulation being dosed. Thus, this guide will review some of the significantpotential problem areas and provide direction to the investigator whengiving inspectional coverage.II. FACILITIESThe design of the facilities are largely dependent upon the type of productsmanufactured and the potential for cross-contamination and microbiologicalcontamination. For example, the facilities used for the manufacture of OTCoral products might not require the isolation that a steroid or sulfaproduct would require.Review the products manufactured and the procedures used by the firm for theisolation of processes to minimize contamination. Observe the addition ofdrug substance and powdered excipients to manufacturing vessels to determineif operations generate dust. Observe the systems and the efficiency of thedust removal system.The firm's HVAC (Heating Ventilation and Air Conditioning) system may alsowarrant coverage particularly where potent or highly sensitizing drugs areprocessed. Some manufacturers recirculate air without adequate filtration.Where air is recirculated, review the firm's data which demonstrates theefficiency of air filtration such should include surface and/or airsampling.III. EQUIPMENTEquipment should be of sanitary design. This includes sanitary pumps,valves, flow meters and other equipment which can be easily sanitized. Ballvalves, packing in pumps and pockets in flow meters have been identified assources of contamination.In order to facilitate cleaning and sanitization, manufacturing and filling lines should be identified and detailed in drawings and SOPs. In some cases, long delivery lines between manufacturing areas and filling areas have been a source of contamination. Also, SOPs, particularly with regard to timelimitations between batches and for cleaning have been found deficient inmany manufacturers. Review cleaning SOPs, including drawings and validation data with regard to cleaning and sanitization.Equipment used for batching and mixing of oral solutions and suspensions is relatively basic. Generally, these products are formulated on a weight basis with the batching tank on load cells so that a final Q.S. can be made byweight. Volumetric means, such as using a dip stick or line on a tank, have been found to be inaccurate.In most cases, manufacturers will assay samples of the bulk solution orsuspension prior to filling. A much greater variability has been found with batches that have been manufactured volumetrically rather than by weight.For example, one manufacturer had to adjust approximately 8% of the batches manufactured after the final Q.S. because of failure to comply with potency specifications. Unfortunately, the manufacturer relied solely on the bulkassay. After readjustment of the potency based on the assay, batchesoccasionally were found out of specification because of analytical errors.The design of the batching tank with regard to the location of the bottomdischarge valve has also presented problems. Ideally, the bottom discharge valve is flush with the bottom of the tank. In some cases valves, including undesirable ball valves, have been found to be several inches to a footbelow the bottom of the tank. In others, drug or preservative was notcompletely dissolved and was lying in the "dead leg" below the tank withinitial samples being found to be subpotent. For the manufacture ofsuspensions, valves should be flush. Review and observe the batchingequipment and transfer lines.With regard to transfer lines, they are generally hard piped and easilycleaned and sanitized. In some cases manufacturers have used flexible hoses to transfer product. It is not unusual to see flexible hoses lying on thefloor, thus significantly increasing the potential for contamination. Such contamination can occur by operators picking up or handling hoses, andpossibly even placing them in transfer or batching tanks after they had been lying on the floor. It is also a good practice to store hoses in a way that allows them to drain rather than be coiled which may allow moisture tocollect and be a potential source of microbial contamination. Observemanufacturing areas and operator practices, particularly when flexible hose connection are employed.Another common problem occurs when a manifold or common connections areused, especially in water supply, premix or raw material supply tanks. Such common connections have been shown to be a source of contamination.IV. RAW MATERIALSThe physical characteristics, particularly the particle size of the drugsubstance, are very important for suspensions. As with topical products in which the drug is suspended, particles are usually very fine to micronized(less than 25 microns). For syrups, elixir or solution dosage forms in which there is nothing suspended, particle size and physical characteristics ofraw materials are not that important. However, they can affect the rate of dissolution of such raw materials in the manufacturing process. Rawmaterials of a finer particle size may dissolve faster than those of alarger particle size when the product is compounded.Examples of a few of the oral suspensions in which a specific and welldefined particle size specification for the drug substance is importantinclude phenytoin suspension, carbamazepine suspension, trimethoprim andsulfamethoxazole suspension, and hydrocortisone suspension. Review thephysical specifications for any drug substance which is suspended in thedosage form.V. COMPOUNDINGIn addition to a determination of the final volume (Q.S.) as previouslydiscussed, there are microbiological concerns. For oral suspensions, there is the additional concern with uniformity, particularly because of thepotential for segregation during manufacture and storage of the bulksuspension, during transfer to the filling line and during filling. Review the firm's data that support storage times and transfer operations. Thereshould be established procedures and time limits for such operations toaddress the potential for segregation or settling as well as otherunexpected effects that may be caused by extended holding or stirring.For oral solutions and suspensions, the amount and control of temperature is important from a microbiological as well as a potency aspect. For thoseproducts in which temperature is identified as a critical part of theoperation, the firm's documentation of temperature, such as by controlcharts, should be reviewed.There are some manufacturers that rely on heat during compounding to control the microbiological levels in product. For such products, the addition ofpurified water to final Q.S., the batch, and the temperatures duringprocessing should be reviewed.In addition to drug substances, some additives, such as the parabens aredifficult to dissolve and require heat. The control and assurance of their dissolution during the compounding stage should be reviewed. From a potency aspect, the storage of product at high temperatures may increase the level of degradants. Storage limitations (time and temperature) should bejustified by the firm and evaluated during your inspection.There are also some oral liquids which are sensitive to oxygen and have been known to undergo degradation. This is particularly true of the phenothiazine class of drugs, such as perphenazine and chlorpromazine. The manufacture of such products might require the removal of oxygen such as by nitrogenpurging. Additionally, such products might also require storage in sealedtanks, rather than those with loose lids. Manufacturing directions for these products should be reviewed.VI. MICROBIOLOGICALQUALITYThere are some oral liquids in which microbiological contamination canpresent significant health hazards. For example, some oral liquids, such as nystatin suspension are used in infants and immuno-compromised patients, and microbiological contamination with organisms, such as Gram-negativeorganisms, is objectionable. There are other oral liquid preparations such as antacids in which Pseudomonas sp. contamination is also objectionable.For other oral liquids such as cough preparations, the contamination withPseudomonas sp. might not present the same health hazard. Obviously, thecontamination of any preparation with Gram-negative organisms is notdesirable.In addition to the specific contaminant being objectionable, suchcontamination would be indicative of a deficient process as well as aninadequate preservative system. The presence of a specific Pseudomonas sp. may also indicate that other plant or raw material contaminants couldsurvive the process. For example, the fact that a Pseudomonas putidacontaminant is present could also indicate that Pseudomonas aeruginosa, asimilar source organism, could also be present.Both the topical and microbiological inspection guides discuss the methods and limitations of microbiological testing. Similar microbiological testing concepts discussed apply to the testing of oral liquids for microbiological contamination. Review the microbiological testing of raw materials,including purified water, as well as the microbiological testing of finished products. Since FDA laboratories typically utilize more sensitive testmethods than industry, consider sampling any oral liquids in whichmanufacturers have found microbiological counts, no matter how low. Submit samples for testing for objectionable microorganisms.VII. ORAL SUSPENSIONSUNIFORMITYThose liquid products in which the drug is suspended (and not in solution) present manufacturer and control problems.Those liquid products in which the drug is suspended (and not in solution) present manufacture and control problems. Depending upon the viscosity, many suspensions require continuous or periodic agitation during the fillingprocess. If delivery lines are used between the bulk storage tank and thefilling equipment, some segregation may occur, particularly if the product is not viscous. Review the firm's procedures for filling and diagrams forline set-up prior to the filling equipment.Good manufacturing practice would warrant testing bottles from thebeginning, middle and end to assure that segregation has not occurred. Such samples should not be composited.In-process testing for suspensions might also include an assay of a sample from the bulk tank. More important, however, may be testing for viscosity.VIII. PRODUCTSPECIFICATIONSImportant specifications for the manufacture of all solutions include assay and microbial limits. Additional important specifications for suspensionsinclude particle size of the suspended drug, viscosity, pH, and in somecases dissolution. Viscosity can be important from a processing aspect tominimize segregation. Additionally, viscosity has also been shown to beassociated with bioequivalency. pH may also have some meaning regardingeffectiveness of preservative systems and may even have an effect on theamount of drug in solution. With regard to dissolution, there are at least three products which have dissolution specifications. These products include phenytoin suspension, carbamazepine suspension, and sulfamethoxazole andtrimethoprim suspension. Particle size is also important and at this point it would seem that any suspension should have some type of particle sizespecification. As with other dosage forms, the underlying data to supportspecifications should be reviewed.IX. PROCESS VALIDATIONAs with other products, the amount of data needed to support themanufacturing process will vary from product to product. Development (data) should have identified critical phases of the operation, including thepredetermined specifications, that should be monitored during processvalidation.For example, for solutions the key aspects that should be addressed during validation include assurance that the drug substance and preservatives are dissolved. Parameters, such as heat and time should be measured. Also,in-process assay of the bulk solution during and/or after compoundingaccording to predetermined limits are also an important aspects of process validation. For solutions that are sensitive to oxygen and/or light,dissolved oxygen levels would also be an important test. Again, thedevelopment data and the protocol should provide limits. Review firm'sdevelopment data and/or documentation for their justification of theprocess.As discussed, the manufacture of suspensions presents additional problems, particularly in the area of uniformity. Again, development data should have addressed the key compounding and filling steps that assure uniformity. The protocol should provide for the key in-process and finished product tests, along with their specifications. For oral solutions, bioequivalency studies<<< Continued to next message >>><<< This message is part 2 of a previous message >>>may not always be needed. However, oral suspensions, with the possibleexception of some of the antacids, OTC products, usually require abioequivalency or clinical study to demonstrate effectiveness. As with oral solid dosage forms, comparison to the biobatch is an important part ofvalidation of the process.Review the firm's protocol and process validation report and, ifappropriate, compare data for full scale batches to biobatch, data andmanufacturing processes.X. STABILITYOne area that has presented a number of problems includes the assurance of stability of oral liquid products throughout their expiry period. Forexample, there have been a number of recalls of the vitamins with fluoride oral liquid products because of vitamin degradation. Drugs in thephenothiazine class, such as perphenazine, chlorpromazine and promethazine have also shown evidence of instability. Good practice for this class ofdrug products would include quantitation of both the active and primarydegradant. Dosage form manufacturers should know and have specifications for the primary degradant. Review the firm's data and validation data formethods used to quantitate both the active drug and degradant.Because interactions of products with closure systems are possible, liquids and suspensions undergoing stability studies should be stored on their side or inverted in order to determine whether contact of the drug product with the closure system affects product integrity.Moisture loss which can cause the remaining contents to become superpotent and microbiological contamination are other problems associated withinadequate closure systems.XI. PACKAGINGProblems in the packaging of oral liquids have included potency (fill) ofunit dose products, accurate calibration of measuring devices such asdroppers that are often provided. The USP does not provide for doseuniformity testing for oral solutions. Thus, for unit dose solutionproducts, they should deliver the label claim within the limits described in the USP. Review the firm's data to assure uniformity of fill and testprocedures to assure that unit dose samples are being tested.Another problem in the packaging of Oral Liquids is the lack of cleanliness of containers prior to filling. Fibers and even insects have been identified as debris in containers, and particularly plastic containers used for these products. Many manufacturers receive containers shrink-wrapped in plastic to minimize contamination from fiberboard cartons. Many manufacturers utilize compressed air to clean containers. Vapors, such as oil vapors, from thecompressed air have occasionally been found to present problems. Review the firm's systems for the cleaning of containers.There are no references from this document.。

FDA迎查指南一、概述FDA检查工厂的背景:近年来,美国连续发生多起的污染事件,美国每年有4800万人感染食源性疾病,每6个人就有一人因食品危害受到感染,超过10万人住院,其中3000人死亡。

2011年1月4日,美国总统奥巴马签署了《FDA食品安全现代法案》,这是美国对《联邦食品药品化妆品安全法》的重大修订,根据现行法律,美国FDA有权对境外食品生产的厂家实施检查,以此提高供给美国的食品质量安全。

二、检查要点1、检查接受的重要性美国FDA在对被检查企业,接到通知后,必须24小时回复同意接受检查,否则将会列入FDA黑名单,该企业将不能对美国进行食品出口。

2、记录的检查FDA官员对工厂进行检查时,要求检查食品生产过程中的所有环节原料的种植、管理、收获、运输,环节控制,生产加工的质量控制措施,以及产品包装发货运输,同时需要提供原料的检验报告,半成品检验报告,成品检验报告以及辅助材料的检验报告,以此证明该批次产品质量每个环节都得到有效的控制。

要求记录必须严格一致,不得有造假现象(尤其是笔迹不得一样),尤其是公司有电子版的记录一定与纸质的记录一致。

3、检查依据FDA来厂检查时会拿着公司出口美国的通关单,根据通关单提供的信息,要求公司提供相关记录,所以要求所有出口到美国的产品,必须记录齐全,及时提供给FDA检查的官员。

4、沟通的重要性企业需要至少有一位精通外语并且熟悉公司质量控制体系的人,对FDA官员的检查给予合理的解释,如果解释的能让FDA官员所接受,对于检查的深度将会大大地减少,反之,FDA 官员将会对某一个问题刨根问底,直至查处问题。

5、产品标识的关注FDA来厂检查时,会重点关注产品的标识,所有标识必须严格与该产品的特性保持一致。

如果标识与产品不相符合,将严重影响检查结果。

6、制定计划的实施情况检查他们将会根据公司书面的监控计划,查验相关的检验记录,如果公司制定了计划,就必须有相关的记录来满足和支持计划的要求,否则将视为不符合项。

FDA检查员指导手册CP 7356.002:药品生产检查程序目录对现场报告的要求……………………………………………………3 5第一部分背景……………………………………………………………………36第二部分执行…………………………………………………………………362.1.目的……………………………………………………………………362.2.策略……………………………………………………………………362.2.1.对生产企业两年一度的检查(包括重新包装商、合同实验室等)…362.2.2.系统性检查……………………………………………………………372.2.3.对原料药及制剂生产的系统性检查计划……………………………382.2.3.1.质量系统………………………………………………………………382.2.3.2.厂房设施与设备系统…………………………………………………382.2.3.3.物料系统………………………………………………………………382.2.3.4.生产系统………………………………………………………………382.2.3.5.包装和贴签系统………………………………………………………382.2.3.6.实验室控制系统………………………………………………………392.3.程序管理指3导…………………………………………………………92.3.1.定义……………………………………………………………………392.3.1.1.监督性检查……………………………………………………………392.3.1.2.达标检查………………………………………………………………42.3.1.3.受控状态………………………………………………………………42.3.1.4.药品工艺………………………………………………………………42.3.1.5.药品生产检查…………………………………………………………41第三部分检查……………………………………………………………………413.1.检查活动………………………………………………………………413.1.1.总则……………………………………………………………………413.1.2.检查方法………………………………………………………………423.1.2.1.全面性检查的选择……………………………………………………433.1.2.2. 简略性检查的选择……………………………………………………433.1.2.3.综合性检查围………………………………………………………433.1.3.系统性检查围………………………………………………………433.1.3.1.质量系统………………………………………44………………………3.1.3.2. 厂房设施与设备系统…………………………………………………443.1.3.3.物料系统………………………………………………………………453.1.3.4.生产系统………………………………………………………………463.1.3.5.包装和贴签系统………………………………………………………473.1.3.6.实验室控制系统………………………………………………………483.1.4.取样……………………………………………………………………493.1.5.检查组组成……………………………………………………………493.1.6.报告……………………………………………………………………49第四部分分析……………………………………………………………………5第五部分法律性/行政性策略…………………………………………………55.1.质量系统………………………………………………………………515.2.厂房设施和设备………………………………………………………515.3.物料系统………………………………………………………………515.4.生产系统………………………………………………………………525.5.包装和贴签系统………………………………………………………525.6.实验室控制系统………………………………………………………52对现场报告的要求作为法律行动的一部分,所有针对因在执行cGMP方面有缺陷而采取的检查,均要向药品评价和研究中心的达标办公室呈交一份现场检查报告(EIR)。

美国FDA关注的问题1.原料2.工厂的每日卫生检查3.HACCP计划4.HACCP计划中列明的所有记录5.对出口美国的途径、方式、进口商的情况也很关心6.此外,FDA官员对培训、加工过程中的温度时间的控制等也表现出了相当的关注。

FDA HACCP官方验证的内容和方法1.进行初次访谈(具备一定资格的官方验证人员要事先了解有关情况,必要时进行初次访谈。

第一次初访应表明你的身份,要确定在检查期间所涉及的产品,时间尽可能短。

)了解有关信息,主要包括:(1)企业生产加工的食品品种;(2)当天正在加工的产品情况;(3) HACCP小组成员及培训情况;(4)被验证企业制定和实施食品HACCP体系、SSOP的情况;企业最近一次验证或体系审核情况,特别是存在的问题和整改措施。

2.官方验证人员进行自己的危害分析官方验证人员在对食品生产加工企业HACCP计划验证前本人首先应进行危害分析,通过比较,对企业危害分析的完整性和准确性做出判断自己的危害分析最好在检查工厂期间进行,检验检疫机构的官方验证人员要通过观察和交谈,尽可能多的收集有关加工过程和工厂控制方面的材料。

官方验证人员开展危害分析的前提条件:本人要有食品生产加工及检验的知识和工作经验;深入生产实际,熟悉整个加工过程,能主动向企业管理人员和操作人员了解情况。

•绘制或核查工厂提供的生产工艺流程图,并对每一个工序的描述进行核查;•观察生产加工过程;•可以向企业管理和操作人员了解有关的一些内容;•对生产加工过程每一工序存在的生物、化学、物理危害的可能性进行分析;•了解企业对生产加工中可能发生的危害是否采取了预防控制措施以控制危害的发生;•官方验证人员进行危害分析时,要特别注意企业在安全卫生方面存在的问题。

•对生产加工过程中观察和了解到的信息资料做出评价并将有关信息记录于危害分析工作单中。

•对在生产加工过程中观察了了解过程中确认的危害及控制产生质疑时,应该查阅有关法规、技术资料或向有关专家咨询。

美国FDA非肠道用冻干制剂检查指南引言冻干是指药品冷冻后在真空状态下不经液态,直接从固态升华至气态,由此去除水分的作业过程。

该过程包括三个彼此独立又相互依赖的步骤:冷冻、一级干燥(升华)以及二级干燥(解吸附)。

冻干工艺的优点在于:液体加工方便,简化了无菌作业过程;提高了干粉的稳定性;无需过热处理就能去除产品中的水分;增强了冻干产品的稳定性及复水(溶解)性。

冻干工艺的缺点在于:加工处理过程所需时间长;复水时需用无菌稀释液;设备复杂且生产成本高。

冻干工艺一般包括以下步骤:(1)将药品和赋形剂溶解于适当的溶剂中,通常使用注射用水。

(2)将药液通过一个0.22μm的微孔除菌过滤器,以此灭菌。

(3)灌装到各个已灭菌的容器中,并在无菌条件下半压塞。

(4)在无菌条件下将半压塞的容器转移至冻干腔室内。

(5)冷冻该溶液:把半压塞的容器置于冻干腔室的冷冻搁板上或在另一腔室内作预冷冻。

(6)将腔室抽真空并将冷冻搁板升温,以便在冷冻状态下通过蒸发除去水分。

(7)全压塞密封:通常由安装在冻干机内的液压式或螺杆式压塞装置来完成。

现在有许多新的非肠道药品,如抗感染药物、生物制剂、体外诊断用药等等都采用冻干工艺来加工。

调查及研究业已发现与冻干工艺及其控制相关的冻干剂在疗效、无菌性和稳定性方面存在问题。

为此,本检查指南对冻干产品有关的生产工艺和缺陷进行了讨论,以便为调研人员提供这方面的信息和指导。

人们已认识到冻干药品的生产和控制是一项很复杂的工艺技术。

冻干作业的重要内容包括药液的制备;西林瓶灌装及其验证;冻干机的灭菌和设计;冻干工艺的放大生产(批量放大)及其验证;最终产品的检验等等。

冻干剂成品生产和控制相关的问题是本文的重点内容。

药品种类和配方药品需经冻干是因为其溶液状态下的不稳定性。

有许多抗生素,如某些半合成的青霉素、头孢菌素和红霉素、强力霉素、氯霉素的盐类都是由冻干工艺制造的。

可以预计在生产过程中这类产品的带菌量很低,因为它们是抗生素。

Dosage Form Drug Manufacturers cGMPs (10/93)FDA 制剂生产厂检查指南GUIDE TO INSPECTIONS OF DOSAGE FORM DRUG MANUFACTURER'S- CGMPR'SNote: This document is reference material for investigators and other FDA personnel. The document does not bind FDA, and does no confer any rights, privileges, benefits, or immunities for or on any person(s).注:此指南是FDA检查官和其工作人员的参考资料。

此文件不约束FDA,也不赋予任何人任何权利,特权,利益或豁免权。

I. 简介This document is intended to be a general guide to inspections of drug manufacturers to determine their compliance with the drug CGMPR's. This guide should be used with instructions in the IOM, other drug inspection guides, and compliance programs.A list of the inspection guides is referenced in Chapter 10 of the IOM. Some of these guides are:该文件旨在为检查药品生产厂家提供一个总体性的指导,以决定他们是否符合药物生产的cGMP法规。

该指南应该与IOM(Investigations Operations Manual,即检查操作手册),其他的药品检查指南,及法规符合性程序中的指导一起使用。

fda 对食品工厂的检查流程下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!美国食品药品监督管理局(FDA)对食品工厂检查流程:1. 计划和准备。

FDA 制剂厂检查指南对制剂企业的检查-CGMP备注:这个文件是对检查者和其他的FDA 官员的参照。

这份文件并不限制FDA,并不猎取任何利益,义务,权利,或豁免某人1简介这个文件介绍到一个大约的药厂检查指导他们是否符合药物的CGMP。

这个指导应当被用来作IOM 的介绍,其他的药物检查指导,和复核工程。

这个检查的指导相对于IOM 的第十章,一些指导是:A 原料药视察指导B 高纯水系统视察的指导C QC 试验室视察的指导D 微生物QC 试验室的指导E 冻干注射剂视察的指导F清洁验证视察的指导G 制药过程中的计算机系统的视察的指导H 一般工艺过程验证的指导2CGMP处方和非处方全部的药物的生产过程要对应于CGMP 否则就被认为在FDC 实施中掺假。

501(a)(2)(B)依据处方药物的记录肯定要比照于704(a)(1)(B)章。

假设药物是OTC 药物被NDA 或ANDA 掩盖,FDA 可以回忆,复制,验证在505(k)(2)章下的FDC。

然而,假设产品是在FDA 没注册过的OTC 药物。

并没有法定的严格要求在视察过程中给视察者看的的记录要按704 章FDC 的要求。

而且,全部的处方药和OTC 药的生产必需符合CGMP 的要求,包括那些记录。

视察者应当回忆这些记录作为打算是否符合CGMP 要求的一局部。

在很少的场合,可以拒绝回忆OTC 的记录由于并没有法定要求这样做。

当工厂在没有法定义务去供给回忆这些记录时,没有减轻需要符合在501(a)(2)(B)CGMP的要求,包括对主体文件的要求。

假设一个工厂拒绝回忆OTC 的记录,视察者应当被其他的视察方法打算特别符合CGMP 的要求。

视察者观看和查找对于处方药和非处方药并不依据FDA-483 确定的检查表中做的行为。

组织和人员工厂肯定要有QC 把握文件描述CFR 的责任和权威。

QC 文件肯定要在说明它的相对于生产文件的独立性,在书面说明它的责任权属。

说明操作者的官员的名字,头衔和内在的责任,其他的主要的职员在IOM 中列出。

GUIDE TO INSPECTIONS OF TOPICAL DRUG PRODUCTS局部外用药物检查指南Note: This document is reference material for investigators and other FDA personnel. The document does not bind(进退两难) FDA, and does no confer(赠予) any rights,privileges (特权), benefits(权益), or immunities(豁免) for or on any person(s).注:该指南是FDA 检查官和其他工作人员的参考材料。

该指南不是约束FDA,但也不赋予任何人特权,利益或豁免的权利。

I. PURPOSE(目的)The purpose of this guide is to provide field investigators, who arefamiliar with the provisions(食品) of the Current Good Manufacturing Practice (CGMP) regulations for pharmaceuticals, with guidance on inspecting selected facets(方面) of topical(局部的) drug product production. The subjects covered in the guide are generally applicable to all forms of topical drug products, including those that are intended to be sterile(无菌的). However, this guide does not address(介绍) every problem area that the investigator may encounter(碰见), nor every policy that pertains to(附属)topical drug products.该指南的目的是向熟悉食品CGMP规程的检察官提供药品CGMP的指导,提供局部外用药物检查方面的指南。

FDA检查员指导手册原料药生产检查(药品质量保证)FDA检查员指导手册7356.002F原料药生产检查(药品质量保证)第一部分背景总则法案的501(a)(2)(B)条款要求所有药品的生产都必须遵守现行GMP的要求,而原料药也不例外。

对于原料药和制剂这两者的要求,法案并没有区别对待,而任何原料药或制剂方面的GMP缺陷都构成了对法案的偏离。

对于原料药或药物成分来说,FDA并没有为此而专门发布cGMP法规文件(就像我们现在有的制剂cGMP法规一样)。

因此,本文提到的“cGMP”指的是法案要求,而并非美国联邦法规(CFR)第21部分210和211条款中关于制剂的要求。

其实,FDA早就意识到cGMP对制剂的要求(美国联邦法规第21部分210、211条款)在理念上对于原料药生产来说同样适用且有效。

这些理念包括使用合适的设备;聘用经过培训且通过资质确认的人员;建立充分合理的书面程序和控制,确保生产工艺和控制的有效性,从而保证产品质量;建立一套中间体和最终药品检测方法的体系,确保药品在规定的使用期限内保持质量的稳定性。

2001年,FDA在人用药物注册技术要求国际协调会议(ICH)上与其他政府监管部门共同努力,采用了针对API行业cGMP的国际性指南,也就是ICH Q7A,活性药物成分的药品质量管理的指南。

ICH Q7A正体现了FDA对于原料药现行GMP体系的要求。

因此,遵循该指南要求的API及其相关生产和检验设施是符合法定cGMP要求的。

然而,1只要是能符合法案501(a)(2)(B)的要求,并能确保API符合其纯度、均一性和质量特性的方法都可以采用。

在本程序中所使用的术语“活性药物成分”(原料药)的含义与ICH Q7A中的定义一致。

在ICH Q7A中活性药物成分被定义为“旨在用于药品生产的任何物质或混合物,当用于药品生产时,这些物质即成为药品中的活性成分。

这种物质被用来提供药学活性或在诊断、治疗、止痛、缓解、处理或疾病预防中起着直接作用或用于影响机体结构和功能。

Dosage Form Drug Manufacturers cGMPs (10/93)FDA 制剂生产厂检查指南GUIDE TO INSPECTIONS OF DOSAGE FORM DRUG MANUFACTURER'S- CGMPR'SNote: This document is reference material for investigators and other FDA personnel. The document does not bind FDA, and does no confer any rights, privileges, benefits, or immunities for or on any person(s).注:此指南是FDA检查官和其工作人员的参考资料。

此文件不约束FDA,也不赋予任何人任何权利,特权,利益或豁免权。

I. 简介This document is intended to be a general guide to inspections of drug manufacturers to determine their compliance with the drug CGMPR's. This guide should be used with instructions in the IOM, other drug inspection guides, and compliance programs.A list of the inspection guides is referenced in Chapter 10 of the IOM. Some of these guides are:该文件旨在为检查药品生产厂家提供一个总体性的指导,以决定他们是否符合药物生产的cGMP法规。

该指南应该与IOM(Investigations Operations Manual,即检查操作手册),其他的药品检查指南,及法规符合性程序中的指导一起使用。

在IOM的第十章中提供了一个检查指南清单,其中有:o Guide to Inspections of Bulk Pharmaceutical Chemicals.o原料药检查指南o Guide to Inspections of High Purity Water Systems.o高纯水系统检查指南o Guide to Inspections of Pharmaceutical Quality Control Laboratories.o 药品QC实验室检查指南o Guide to Inspections of Microbiological Pharmaceutical Quality Control Laboratories.o微生物药品QC实验室检查指南o Guide to Inspections of Lyophilization of Parenterals.o冻干注射剂检查指南o Guide to Inspections of Validation of Cleaning Processes.o清洁验证检查指南o Guide to Inspections of Computerized Systems in Drug Processing.o制药过程中的计算机化系统检查指南o Guideline on General Principles of Process Validation.o工艺验证总体原则指南II. CURRENT GOOD MANUFACTURING PRACTICE REGULATIONSII. CGMPPrescription vs. Non-prescription处方药和非处方药All drugs must be manufactured in accordance with the current good manufacturing practice regulations otherwise they are considered to be adulterated within the meaning of the FD&C act, Section 501(a)(2)(B). Records relating to prescription drugs must be readily available for review in accordance with Sec. 704(a)(1)(B) of the FD&C Act. If the product is an OTC drug which is covered by an NDA or ANDA, FDA may review, copy and verify the records under Sec. 505(k)(2) of the FD&C Act. However, if the product is an OTC drug for which there is no application filed with FDA, the firm is not legally required to show these records to the investigator during an inspection being conducted under Section 704 of the FD&C Act. Nonetheless, all manufacturers of prescription and OTC drugs must comply with the drug CGMPR requirements, including those involving records. The investigator should review these records as part of the inspection in determining the firm's compliance with the CGMP regulations. On rare occasions, a firm may refuse to allow review of OTC records stating they are not legally required to. While the firm may be under no legal obligation to permit review of such records, this does not relieve the firm of its statutory requirement to comply with the good manufacturing practices under section 501(a)(2)(B) of the Food Drug and Cosmetic Act, including the requirements for maintaining records.所有药物的生产过程都必须遵循cGMP原则,否则依据FD&C 法令, 501(a)(2)(B)将认定其为掺假行为。

必须提供处方药的记录以便按照FD&C 法令第704(a)(1)(B)进行审核。

如果药物是NDA或ANDA范围内的OTC药物,FDA可以根据505(k)(2)进行记录的审核,复制和确认。

然而,如果该OTC药物并没有在FDA注册申请,在依据Section 704 of the FD&C 法规进行检查时将不会从法律上要求工厂必须提供给检查官这些记录。

尽管如此,所有的处方药和OTC 生产商必须符合cGMP的要求,包括涉及的记录。

检察官应当把对记录的审核作为决定生产商是否符合cGMP要求的一部分。

偶尔会有公司可能拒绝提供OTC的记录,因为并没有法定要求他们这样做。

工厂虽没有法律义务去提供这些记录以供审核,但是这并不减轻工厂仍需符合501(a)(2)(B)cGMP的法定要求,其中包括对记录保持的要求。

If a firm refuses review of OTC records, the investigator should determine by other inspectional means the extent of the firm's compliance with CGMPR's. Inspectional observations and findings that CGMPR's are not being followed are to be cited on a List of Inspectional Observations, FDA-483, for both prescription and non-prescription drugs.如果一个工厂拒绝审核OTC的记录,检查官应当根据其他检查手段决定该公司对cGMP的符合程度。

要把在检查处方药和非处方药时观察到的、发现的不遵循cGMP的地方援引到检查发现列表(即FDA-483)中。

Organization and Personnel [21 CFR 211 Subpart B]组织和人员The firm must have a quality control department that has the responsibility and authority as described in the referenced CFR. The quality control department must maintain its independence from the production department, and its responsibilities must be in writing. Obtain the name, title and individual responsibilities of corporate officers and other key employees as indicated in the IOM.工厂必须有质量控制部门,其职责和权限应与CFR描述的一致。

QC部门必须与生产部门保持独立,其职责必须有书面规定。

要获取IOM中公司官员和其他关键人员的姓名,头衔和个人职责。