How to Tilt and Decenter a Sequential Optical Component

- 格式:pdf

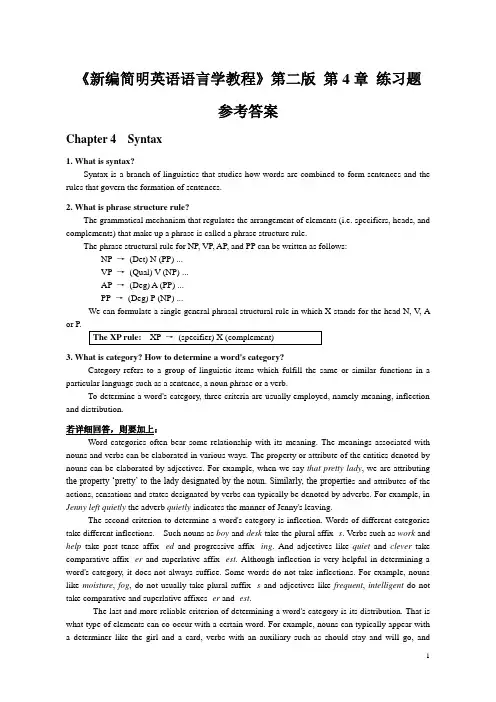

- 大小:177.67 KB

- 文档页数:10

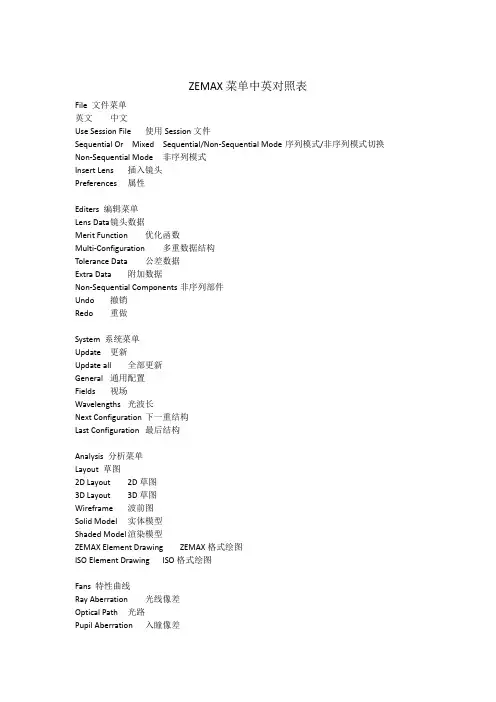

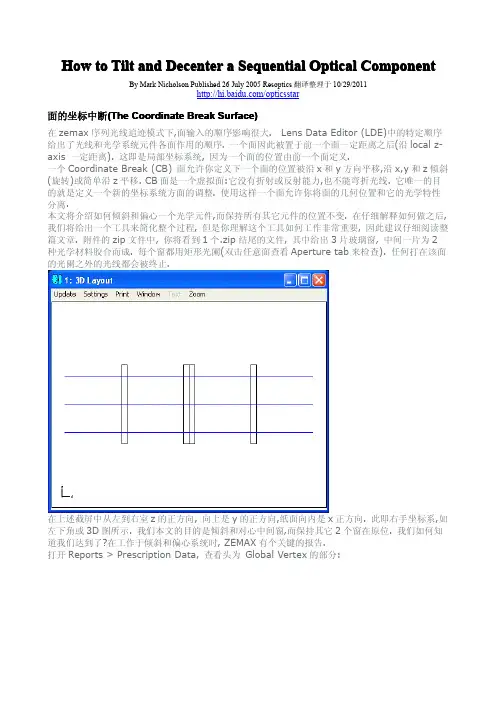

ZEMAX菜单中英对照表File 文件菜单英文中文Use Session File使用Session文件Sequential Or Mixed Sequential/Non-Sequential Mode序列模式/非序列模式切换Non-Sequential Mode非序列模式Insert Lens插入镜头Preferences属性Editers 编辑菜单Lens Data镜头数据Merit Function优化函数Multi-Configuration多重数据结构Tolerance Data公差数据Extra Data附加数据Non-Sequential Components非序列部件Undo撤销Redo重做System 系统菜单Update更新Update all全部更新General通用配置Fields视场Wavelengths光波长Next Configuration下一重结构Last Configuration最后结构Analysis 分析菜单Layout 草图2D Layout2D草图3D Layout3D草图Wireframe波前图Solid Model实体模型Shaded Model渲染模型ZEMAX Element Drawing ZEMAX格式绘图ISO Element Drawing ISO格式绘图Fans 特性曲线Ray Aberration光线像差Optical Path光路Pupil Aberration入瞳像差Spot Diagrams 点列图Standard标准Through Focus离焦Full Field全视场Matrix矩阵Configuration Matrix配置矩阵MTF (Modulation Transfer Function) 传递函数FFT MTF快速傅立叶变换FFT Through Focus MTF FFT离焦MTFFFT Surface MTF FFT曲面MTFFFT MTF vs. Field FFT MTF与市场FFT MTF Map FFT MTF图表Huygens MTF惠更斯MTFHuygens Through Focus MTF惠更斯离焦MTF Huygens Surface MTF Huygens曲面MTF Geometric MTF几何MTFGeometric Through Focu MTF几何离焦MTF Geometric MTF vs. Field几何MTF与视场Geometric MTF Map几何MTF图表PSF (Point Spread Function) 点扩散函数FFT PSF快速傅立叶变换FFT PSF Cross Section FFT横截面PSFFFT Line/Edge Spread FFT线性/边缘响应Huygens PSF惠更斯PSFHuygens PSF Cross Section惠更斯横截面PSFWavefront 波前Wavefront Map波前图表Interferogram干涉图Foueault Analysis佛科特分析Surface 曲面Surface Sag曲面失高Surface Phase曲面相位RMS 均方根RMS vs. Field RMS与视场RMS vs. Wavelength RMS与波长RMS vs. Focus RMS与焦点Encircled Enegry 能量分布Diffraction衍射Geometric几何Geometric Line/Edge Spread几何线性/边缘响应Extended Source扩展源Illumination 照度Relative Illumination相对照度Vignetting Plot渐晕PlotIllumination XY Scan照度XY ScanIllumination 2D Surface2D 曲面照度Image Analysis 像分析Geometric Image Analysis几何像分析Geometric Bitmap Image Analysis几何Bitmap格式像分析Diffraction Image Analysis衍射像分析Extended Diffraction Image Analysis扩展衍射像分析IMA/BIM File Viewer IMB/BIM格式文件浏览Biocular Analysis 双目分析Field of View观察视场Dipvergence/Convergence双目垂直角差/集中、收敛Miscellaneous 杂项Field Curv/Dist视场场曲/失真Grid Distortion方格失真Footprint Diagram光线痕迹图Longitudinal Aberration纵向像差Lateral Color横向色差Y-Ybar Drawing Y-Ybar图Chromatic Focal Shift焦点色位移System Summary Graphic系统概要图Aberration Coefficients 像差失真系数Seidel Coefficients赛德尔系数Zernike Fringe Coefficients泽尼克边缘系数Zernike Standard Coefficients泽尼克标准系数Zernike Annular Coefficients泽尼克环绕系数Calculations 计算Ray Trace光线追迹Fiber Coupling Efficiency光纤耦合效率YNI Contributions YNI贡献Sag Table面型凹陷表(失高表)Cardinal Points主要参数Glass and Gradient Index 玻璃和梯度折射率Dispersion Diagram散射图表Glass Map玻璃图表Internal Transmission vs. Wavelength内部透过率与波长Grin Profile表面轮廓(剖面)Gradium Profile梯度折射表面轮廓Universal Plot 通用图表New Universal Plot新通用图表Polarization 偏振Polarization Ray Trace偏振光追迹Polarization Pupil Map偏振瞳图表Transmission透过率Phase Aberration相位像差Transmission Fan透过率分布Coatings 镀膜Reflection vs. Angle映像与角度Transmission vs. Angle透过率与角度Absorption vs. Angle吸收与角度Diattenuation vs. Angle衰减与角度Phase vs. Angle相位角与角度Retardance vs. Angle光延迟与角度Reflection vs. Wavelength映像与波长Transmission vs. wavelength透过率与波长Absorption vs. Wavelength吸收与波长Diattenuation vs. Wavelength衰减与波长Phase vs. Wavelength相位角与波长Retardance vs. Wavelength光延迟与波长Physical Optics 物理光学Paraxial Gaussian Beam近轴高斯光束Skew Gaussian Beam倾斜高斯光束Physical Optics Propagation物理光学传播Beam File Viewer光速预览Tools 工具菜单Optimization 优化Optimization优化Global Search全局搜索Hammer Optimization锤形优化Merit Function Listing优化函数列表Remove All Variables移除所有变量Glass Substitution Template玻璃置换模板Tolerancing 公差Tolerancing公差Tolerance Listing公差列表Tolerance Summary公差概要Test Plates 样板Test Plate Fitting套样板Test Plate Lists样板列表Catalogs 目录Glass Catalogs玻璃目录Glass Compare玻璃部件Lens Catalogs镜头目录Coatings 镀膜Edit Coating File编辑镀膜文件Reload Coating File重新载入镀膜文件Add Coating to All Surfaces给所有表面添加膜层参数Coating Listing镀膜列表Scattering 散射ABg Scatter Data Catalogs ABg散射数据目录Scatter Function Viewer散射功能视窗Apertures 光圈Convert Semi-Diameters to Circular Apertures变换口径半径为环形口径Convert Semi-Diameters to Floating Apertures变换口径半径为浮动口径Remove All Apertures移除所有光圈Replace Vignetting With Apertures重新放置渐晕光圈Fold Mirrors 折叠反射镜Add Fold Mirror添加折叠反射镜Delete Fold Mirror删除折叠反射镜Export Data 导出数据Export IGES/STEP/SAT/STL Solid导出IGES/STEP/SAT/STL实体Export IGES Line Work导出IGES Line WorkExport 2D DXF File导出2D DXF文件Miscellaneous 杂项Reverse Elements反向排列零件Tilt/Decenter Elements倾斜/侦测器元素Scale Lens镜头缩放Make Focal生成焦距Quick Focus快速聚焦Ghost Focus Generator幻像发生器Performance Test性能测试Lock All Windows锁定所有窗口Unlock All Windows所有窗口解除锁定Slider滑块Convert to NSC Croup转到NSC组Replicate Object复制项目Create Polygon Object生成多边形项目Reports 报告菜单Surface Data曲面数据System Data系统数据Prescription规则数据Report Graphic 4图解报告4Report Graphic 6图解报告6Macros 宏指令菜单Edit/Run ZPL Macros编辑/运行ZPL宏Refresh Macro List浏览宏列表Extensions 外部扩展菜单Extensions外部扩展指令Refresh Extensions List浏览外部扩展列表Help 帮助菜单About关于Help帮助Tutorial指南Manual操作手册。

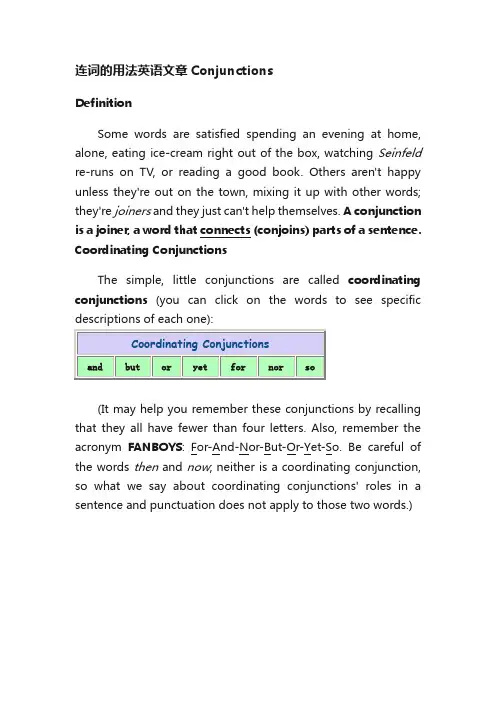

连词的用法英语文章ConjunctionsDefinitionSome words are satisfied spending an evening at home, alone, eating ice-cream right out of the box, watching Seinfeld re-runs on TV, or reading a good book. Others aren't happy unless they're out on the town, mixing it up with other words; they're joiners and they just can't help themselves. A conjunction is a joiner, a word that connects (conjoins) parts of a sentence. Coordinating ConjunctionsThe simple, little conjunctions are called coordinating conjunctions(you can click on the words to see specific descriptions of each one):(It may help you remember these conjunctions by recalling that they all have fewer than four letters. Also, remember the acronym FANBOYS: For-And-Nor-But-Or-Yet-So. Be careful of the words then and now; neither is a coordinating conjunction, so what we say about coordinating conjunctions' roles in a sentence and punctuation does not apply to those two words.)When a coordinating conjunctiontwo independent clauses, it is often (butalways) accompanied by a comma:•Ulysses wants to play for UConn, but he hasWhen the two independentconnected by a coordinating conjunctioncomma:•Ulysses has a great jump shot but hequick on his feet.The comma is always correct when usedseparate two independent clauses connected by a coordinating conjunction. See Punctuation Between Two Independent Clauses for further help.A comma is also correct when and is used to attach the last item of a serial list, although many writers (especially in newspapers) will omit that final comma:•Ulysses spent his summer studying basic math, writing, and reading comprehension.When a coordinating conjunction is used to connect all the elements in a series, a comma is not used:•Presbyterians and Methodists and Baptists are the prevalent Protestant congregations in Oklahoma.A comma is also used with but when expressing a contrast:•This is a useful rule, but difficult to remember.In most of their other roles as joiners (other than joining independent clauses, that is), coordinating conjunctions can join two sentence elements without the help of a comma.•Hemingway and Fitzgerald are among the Americanexpatriates of the between-the-wars era.•Hemingway was renowned for his clear style and his insights into American notions of male identity.•It is hard to say whether Hemingway or Fitzgerald is the more interesting cultural icon of his day.•Although Hemingway is sometimes disparaged for his unpleasant portrayal of women and for his glorification of machismo, we nonetheless find some sympathetic, even heroic, female figures in his novels and short stories.Beginning a Sentence with And or ButA frequently asked question about conjunctions is whetherand or but can be used at the beginning of a sentence.This is what R.W. Burchfield has to say about this use ofand:There is a persistentbelief that it isimproper to begin asentence with And,but this prohibitionhas been cheerfullyignored by standardauthors from Anglo-Saxon times onwards.An initial And is auseful aid to writersas the narrativecontinues.from The New Fowler's Modern English Usageedited by R.W. Burchfield. Clarendon Press: Oxford, England. 1996.Used with the permission of Oxford University Press.The same is true with the conjunction but. A sentencebeginning with and or but will tend to draw attention toitself and its transitional function. Writers shouldexamine such sentences with two questions in mind: (1)would the sentence and paragraph function just as wellAmong the coordinating conjunctions, the most common, of course, are and, but, and or. It might be helpful to explore the uses of these three little words. The examples below by no means exhaust the possible meanings of these conjunctions.ANDa.To suggest that one idea is chronologically sequential to another: "Tashonda sent in her applications and waited by the phone for a response."b.To suggest that one idea is the result of another: "Willie heard the weather report and promptly boarded up his house."c.To suggest that one idea is in contrast to another (frequently replaced by but in this usage): "Juanita is brilliant and Shalimar has a pleasant personality.d.To suggest an element of surprise (sometimes replaced by yet in this usage): "Hartford is a rich city and suffers from many symptoms of urban blight."e.To suggest that one clause is dependent upon another, conditionally (usually the first clause is an imperative): "Use your credit cards frequently and you'll soon find yourself deep in debt."f.T o suggest a kind of "comment" on the first clause: "Charlie became addicted to gambling — and that surprised no one who knew him."BUTa.To suggest a contrast that is unexpected in light of the first clause: "Joey lost a fortune in the stock market, but he still seemsable to live quite comfortably."b.To suggest in an affirmative sense what the first part of the sentence implied in a negative way (sometimes replaced by on the contrary): "The club never invested foolishly, but used the services of a sage investment counselor."c.To connect two ideas with the meaning of "with the exception of" (and then the second word takes over as subject): "Everybody but Goldenbreath is trying out for the team."ORa.To suggest that only one possibility can be realized, excluding one or the other: "You can study hard for this exam or you can fail."b.To suggest the inclusive combination of alternatives: "We can broil chicken on the grill tonight, or we can just eat leftovers.c.To suggest a refinement of the first clause: "Smith College is the premier all-women's college in the country, or so it seems to most Smith College alumnae."d.To suggest a restatement or "correction" of the first part of the sentence: "There are no rattlesnakes in this canyon, or so our guide tells us."e.To suggest a negative condition: "The New Hampshire state motto is the rather grim "Live free or die."f.T o suggest a negative alternative without the use of an imperative (see use of and above): "They must approve his political style or they wouldn't keep electing him mayor."Authority used for this section on the uses of and, but, and or: A University Grammar of English by Randolph Quirk and Sidney Greenbaum. Longman Group: Essex, England. 1993. Used with permission. Examples our own.The Others . . .The conjunction NOR is not extinct, but it is not used nearly as often as the other conjunctions, so it might feel a bit odd when nor does come up in conversation or writing. Its most common use is as the little brother in the correlative pair, neither-nor (see below):•He is neither sane nor brilliant.•That is neither what I said nor what I meant.>It can be used with other negative expressions:•That is not what I meant to say, nor should you interpret my statement as an admission of guilt.It is possible to use nor without a preceding negative element, but it is unusual and, to an extent, rather stuffy:•George's handshake is as good as any written contract, nor has he ever proven untrustworthy.The word YET functions sometimes as an adverb and has several meanings: in addition ("yet another cause of trouble" or "a simple yet noble woman"), even ("yet more expensive"), still ("he is yet a novice"), eventually ("they may yet win"), and so soon as now ("he's not here yet"). It also functions as a coordinating conjunction meaning something like "nevertheless" or "but." The word yet seems to carry an element of distinctiveness that but can seldom register.•John plays basketball well, yet his favorite sport is badminton.•The visitors complained loudly about the heat, yet they continued to play golf every day.In sentences such as the second one, above, the pronoun subject of the second clause ("they," in this case) is often left out. When that happens, the comma preceding the conjunction might also disappear: "The visitors complained loudly yetcontinued to play golf every day."Yet is sometimes combined with other conjunctions, but or and. It would not be unusual to see and yet in sentences like the ones above. This usage is acceptable.The word FOR is most often used as a preposition, of course, but it does serve, on rare occasions, as a coordinating conjunction. Some people regard the conjunction for as rather highfalutin and literary, and it does tend to add a bit of weightiness to the text. Beginning a sentence with the conjunction "for" is probably not a good idea, except when you're singing "For he's a jolly good fellow. "For" has serious sequential implications and in its use the order of thoughts is more important than it is, say, with because or since. Its function is to introduce the reason for the preceding clause:•John thought he had a good chance to get the job, for his father was on the company's board of trustees.•Most of the visitors were happy just sitting around in the shade, for it had been a long, dusty journey on the train.Be careful of the conjunction SO. Sometimes it can connect two independent clauses along with a comma, but sometimes it can't. For instance, in this sentence,•Soto is not the only Olympic athlete in his family, so are his brother, sister, and his Uncle Chet.where the word so means "as well" or "in addition," most careful writers would use a semicolon between the two independent clauses. In the following sentence, where so is acting like a minor-league "therefore," the conjunction and the comma are adequate to the task:•Soto has always been nervous in large gatherings, so it is no surprise that he avoids crowds of his adoring fans.Sometimes, at the beginning of a sentence, so will act as a kind of summing up device or transition, and when it does, it is often set off from the rest of the sentence with a comma:•So, the sheriff peremptorily removed the child from the custody of his parents.The Case of Then and ThanIn some parts of the United States, we are told, then andthan not only look alike, they sound alike. Like a teacherwith twins in her classroom, you need to be able todistinguish between these two words; otherwise, they'llbecome mischievous. They are often used and they shouldbe used for the right purposes.Than is used to make comparisons. In the sentence "Piggywould rather be rescued then stay on the island," we haveemployed the wrong word because a comparison is being madebetween Piggy's two choices; we need than instead. In the sentence, "Other than Pincher Martin, Golding did notwrite another popular novel," the adverbial construction"other than" helps us make an implied comparison; thisusage is perfectly acceptable in the United States butcareful writers in the UK try to avoid it (Burchfield). Generally, the only question about than arises when wehave to decide whether the word is being used as a conjunction or as a preposition. If it's a preposition(and Merriam-Webster's dictionary provides for thisusage), then the word that follows it should be in theobject form.•He's taller and somewhat more handsome than me.•Just because you look like him doesn't mean you canplay better than him.Most careful writers, however, will insist that than beused as a conjunction; it's as if part of the clauseintroduced by than has been left out:•He's taller and somewhat more handsome than I [amhandsome].•You can play better than he [can play].In formal, academic text, you should probably use than asa conjunction and follow it with the subject form of apronoun (where a pronoun is appropriate).Then is a conjunction, but it is not one of the little conjunctions listed at the top of this page. We can usethe FANBOYS conjunctions to connect two independentclauses; usually, they will be accompanied (preceded) bya comma. Too many students think that then works the sameway: "Caesar invaded Gaul, then he turned his attentionto England." You can tell the difference between then anda coordinating conjunction by trying to move the wordaround in the sentence. We can write "he then turned hisattention to England"; "he turned his attention, then, to England"; he turned his attention to England then." Theword can move around within the clause. Try that with a conjunction, and you will quickly see that the conjunctioncannot move around. "Caesar invaded Gaul, and then heturned his attention to England." The word and is stuckexactly there and cannot move like then, which is morelike an adverbial conjunction (or conjunctive adverb —see below) than a coordinating conjunction. Our originalsentence in this paragraph — "Caesar invaded Gaul, thenhe turned his attention to England" — is a comma splice,a faulty sentence construction in which a comma tries tohold together two independent clauses all by itself: thecomma needs a coordinating conjunction to help out, andthe word then simply doesn't work that way.Subordinating ConjunctionsA Subordinating Conjunction(sometimes called a dependent word or subordinator) comes at the beginning of a Subordinate (or Dependent) Clause and establishes the relationship between the dependent clause and the rest of the sentence. It also turns the clause into something that depends on the rest of the sentence for its meaning.•He took to the stage as though he had been preparing for this moment all his life.•Because he loved acting, he refused to give up his dream of being in the movies.•Unless we act now, all is lost.Notice that some of the subordinating conjunctions in the table below — after, before, since — are also prepositions, but as subordinators they are being used to introduce a clause and to subordinate the following clause to the independent element in the sentence.•It looks like as if it's going to snow this afternoon.•Johnson kept looking out the window like as though he had someone waiting for him.In formal, academic text, it's a good idea to reserve the use of like for situations in which similarities are being pointed out:•This community college is like a two-year liberal arts college.However, when you are listing things that have similarities, such as is probably more suitable:•The college has several highly regarded neighbors, like such as the Mark Twain House, St. FrancisHospital, the Connecticut Historical Society, andthe UConn Law School.•The problem is, that production in her department has dropped.•Remember, that we didn't have these problems before she started working here.As a general rule, if the sentence feels just as good without the that,if no ambiguity results from its omission, if the sentence is more efficient or elegant without it, then we can safely omit the that. Theodore Bernstein lists three conditions in which we should maintain the conjunction that:•When a time element intervenes between the verb and the clause: "The boss said yesterday that productionin this department was down fifty percent." (Noticethe position of "yesterday.")•When the verb of the clause is long delayed: "Our annual report revealed that some losses sustainedby this department in the third quarter of last yearwere worse than previously thought." (Notice thedistance between the subject "losses" and its verb,"were.")•When a second that can clear up who said or did what: "The CEO said that Isabel's department wasslacking off and that production droppedprecipitously in the fourth quarter." (Did the CEOsay that production dropped or was the drop a resultof what he said about Isabel's department? Thesecond that makes the sentence clear.)Authority for this section: Dos, Don'ts & Maybes of English Usage by Theodore Bernstein. Gramercy Books: New York. 1999. p. 217. Examples our own.clause.•Because e-mail now plays such a huge role in ourcommunications industry.When the "because clause" is properly subordinated toanother idea (regardless of the position of the clause inthe sentence), there is absolutely nothing wrong with it: •Because e-mail now plays such a huge role in ourcommunications industry, the postal service wouldvery much like to see it taxed in some manner. Correlative ConjunctionsSome conjunctions combine with other words to form what are called correlative conjunctions. They always travel in pairs, joining various sentence elements that should be treated as grammatically equal.•She led the team not only in statistics but also by virtue of her enthusiasm.•Polonius said, "Neither a borrower nor a lender be."•Whether you win this race or lose it doesn't matter as long as you do your best.Correlative conjunctions sometimes create problems in parallel form. Click HERE for help with those problems. Here is a brief list of common correlative conjunctions.Conjunctive AdverbsThe conjunctive adverbs such as however, moreover, nevertheless, consequently, as a result are used to create complex relationships between ideas. Refer to the section on Coherence: Transitions Between Ideas for an extensive list of conjunctive adverbs categorized according to their various uses and for some advice on their application within sentences (including punctuation issues).Guide to Grammar and Writing Principles of CompositionIndexThe Guide to Grammar and Writing is sponsored by the Capital Community College Foundation, a nonprofit 501 c-3 organization that supports scholarships, faculty development, and curriculum innovation. If you feel we have provided something of value and wish to show your appreciation, you can assist the College and its students with a tax-deductible contribution.For more about giving to Capital, write to CCC Foundation, 950 Main Street, Hartford, CT 06103. Phone (860) 906-5102 or email: *********************.edu. Contributions are tax-deductible to the extent allowed by law.。

《现代语言学》问答题1.What are the main features of human language that have been specified by C.Hockett to show that it is essentially different from animal communication system?ArbitrarinessIt means that there is no logical connection between meanings and sounds. A good example is the fact that different sounds are used to refer to the same object in different languages.ProductivityLanguage is productive or creative in that it makes possible the construction and interpretation of new signals by its users. This is why they can produce and understand an infinitely large number of sentences.DualityLanguage is a system, which consists of two sets of structures. At the lower level there is a structure of sounds, which are meaningless by themselves. But the sounds of language can be grouped and regrouped into a large number of units of meaning, which are found at the higher level of the system. Then the units at the higher level can be arranged and rearranged into an infinite number of sentences. DisplacementLanguage can be used to refer to contexts removed from the immediate situations of the speaker. This property provides speakers with an opportunity to talk about a wide range of things, free from barriers caused by separation in time or place.Cultural transmissionLanguage is culturally transmitted. It is passed on from one generation to the next through teaching and learning rather than by instinct. In contrast, animal call systems are genetically transmitted.2. How are the English consonants classified?1)by manner of articulation.a.stops(plosive爆破音): [p],[b],[t],[d],[k],[g]b.fricatives(磨擦音): [f],[v],[s],[z],[ θ],[ð], [∫], [ʒ], [h]c.affricates(破擦音): [ t∫], [dʒ]d.liquids(lateral边音,流音): [l], [r]e.nasals(鼻音): [m],[ n],[ŋ]f.glides (semivowels半元音): [w], [ j]2)by place of articulation :a.bilabial(双唇音): [p],[b],[m],[w]biodental(唇齿音): [f],[v]c.dental(舌齿音): [θ],[ ð]d.alveolar(齿龈音): [t],[d],[s],[z],[n],[l],[r]e.palatal(腭音): [∫], [ʒ],[ t∫], [dʒ], [j]f.velar(软腭音): [k], [g], [ŋ ]g.glottal(喉音,声门单): [h]3. What criteria are used to classify the English vowels? 英语的元音是如何分类的?1) According to the position of the tongue, vowels may be distinguished as front vowels such as [i:] [i] [e] [æ] [a], central vowels such as [ɜ:] [ə] [ʌ], and back vowels such as [u:] [ʊ] [ɔ:] [ɔ] [ɑ:]2) According to the openness of the mouth, we classify the vowels into four groups: close vowels such as [i:] [i] [u:] [ʊ], semi-close vowels such as [e] [ɜ:], semi-open vowels such as [ə] [ɔ:], and open vowels such as [æ] [a] [ʌ] [ɔ] and [ɑ:].3) According to the shape of the lips, vowels are divided into rounded vowels and unrounded vowels. In English all the front and central vowels are unrounded vowels, all the back vowels, with exception of [ɑ:], are rounded.4) According to the length of the vowels, the English vowels can also be classified into long vowels and short vowels. The long vowels include [i:] [ɜ:] [ɔ: ] [u:] [ɑ:],while the rest are short vowels.4. What are phonemic contrast, complementary distribution, and minimal pair?If two phonetically similar sounds can occur in the same environments and they distinguish meaning, they are in phonemic contrast. [p], [b]If two phonetically similar sounds are two allophones of the same phoneme and they occur in different environments, they are said to be in complementary distribution. [p], [ph].When two different forms are identical in every way except for one sound segment which occurs in the same place in the strings, the two words are said to form a minimal pair. For example, kill and bill.5. Explain with examples the sequential rule, the assimilation rule, and the deletion rule.Sequential rule refers to the rule that governs the combination of sounds in a particular language.For example, if a word begins with a [l] or a [r] , then the next sound must be a vowel. If three consonants should cluster together at the beginning of a word, the combination should obey the following three rules:the first phoneme must be /s/the second phoneme must be /p/ or /t/ or /k/the third phoneme must be /l/ or /r/ or /w/Assimilation rule assimilates one sound to another by “copying” a feature of a sequential phoneme, thus making the two phones similar.For example, the [i:] sound in words like bean, green, team, and scream. This is because in all these sound combinations the [i:] sound is followed by a nasal [n] or [m].Deletion rule tells us when a sound is to be deleted although it is orthographically represented.For example, in the pronunciation of the word sign or design, there is no [g] soundalthough it is represented in spelling by the letter g. But in their corresponding forms signature, designation, the [g] represented by the letter g is pronounced. The rule: delete a [g] when it occurs before a final nasal consonant.6. What are suprasegmental features? How do the major suprasegmental features of English function in conveying meaning?Suprasegmental features are phonological features above the sound segment level. The major suprasegmental features in English are word stress, sentence stress and intonation.1)The location of stress in English distinguishes meaning, such as `import and im`port. The similar alternation of stress also occurs between a compound noun and a phrase consisting of the same elements. A phonological feature of the English compounds is that the stress of the word always falls on the first element and the second element receives secondary stress, for example: `blackbird is a particular kind of bird, which is not necessarily black, but a black `bird is a bird that is black.2) Sentence stress refers to the relative force which is given to the words in a sentence. The more important words such as nouns, main verbs, adjectives, adverbs, and demonstrative pronouns, are pronounced with greater force and made more prominent. And the other categories of words (articles, personal pronouns, auxiliary verbs, prepositions, and conjunctions) are usually not stressed. But to give special emphasis to a certain notion, a word in sentence that is usually unstressed can be stressed to achieve different effect. Take the sentence “He is driving my car.” For example, to emphasize the fact that the car he is driving is not his, or yours, but mine, the speaker can stress the possessive pronoun my, which under normal circumstances is not stressed.3)English has four basic types of intonation: When spoken in different tones, the same sequence of words may have different meanings. Generally speaking, the falling tone indicates that what is said is a straight-forward, matter-of-fact statement, the rising tone often makes a question of what is said, and the fall-rise tone often indicates that there is an implied message in what is said.7. Discuss the types of morphemes with examples.Free morphemes: They are the independent units of meaning and can be used freely all by themselves, for example, “book-” in the word “bookish”.Bound morphemes: They are those that cannot be used independently but have to be combined with other morphemes, either free or bound, to form a word such as “-ish” in “bookish”.Bound morphemes can be subdivided into roots and affixes. A root is seen as part of a word; it can never stand by itself although it has a clear and definite meaning, such as “gene-” in the word “generate”. Affixes are of two types: inflectional and derivational. Inflectional morphemes manifest various grammatical relations or grammatical categories such as “-s” in the word “books” to indicate plurality of nouns. Derivational affixes are added to an existing form to create a word such as “mis-” in the word “misinform”. Derivational affixes can also be divided into prefixes andsuffixes. Prefixes occur at the beginn ing of a word such as “dis- ” in the word “dislike”, while suffixes occur at the end of a word such as “-less” in the word “friendless”.8. What is the relation between sense and reference?Sense and reference are two terms in the study of meaning. (1) Sense is concerned with the inherent meaning of the linguistic form. It is the collection of all the features of the linguistic form; it is abstract and de-contextualized. It is the aspect of meaning that dictionary compilers are interested in. Reference means what a linguistic form refers to in the real, physical world; it deals with the relationship between the linguistic element and the non-linguistic world of experience. (2) Obviously, linguistic forms having the same sense may have different references in different situations. On the other hand, there are less frequent occasions when linguistic forms with the same reference might differ in sense, e.g. “morning star” and “evening star”.9. What are the major lexical sense relations?1)Synonymya)Dialectal synonyms --- regional dialectse.g. British English: autumn/liftAmerican English: fall/elevatorb)Stylistic synonymse.g. old man, daddy, dad, father, male parentc)Synonyms that differ in their emotive or evaluative meaninge.g. collaborator & accompliced)collocational synonymse.g. accuse…of/ charge…with/ rebuke…fore)semantically different synonymse.g. amaze: confusion and bewildermentastound: difficulty in believing2)Polysemye.g. “table” has many meanings such as 1.a piece of furniture 2. a level area, a plateau and etc.3)HomonymyHomophones: identical in sound e.g. night/ knightHomographs: identical in spelling e.g. bow v./ bow n.4)Hyponymye.g. superordinate: furniturehyponyms: bed, table5)Antonymya)Gradable antonymse.g. old and young are immediately recognized as antomyms, between whichthere exist intermediate forms such as “mature”, “middle-aged”b)complementary antonymse.g. a person can be either alive or dead; there is no third possibilityc)Relational oppositese.g. husband and wife are a paior of relational opposites.10. Illustrate Searle’s classification of speech acts with examples.According to Searle, speech acts fall in five general categories. Specific acts that fall into each type share the same illocutionary point, but differ in their strength.1)Representatives/assertives: stating or describing, saying what the speaker believes to be trueTypical cases: stating, believing, swearinge.g. (I swear)I have never seen the man before.(I state)The earth is a globe.2)Directives: trying to get the hearer to do somethingTypical cases: Inviting, suggesting, requesting, advising, warning, threatening, orderinge.g. Open the window, please.You’d better go to the clinic.3)Commissives: committing the speaker himself to some future course of action Typical cases: Promising, undertaking, vowinge.g. I promise to come.4)Expressives: expressing feelings of attitude towards an existing stateTypical cases: apologizing, thanking, congratulatinge.g. I’m sorry for the mess I have made.It’s really kind of you to have thought of me.5)Declarations: bringing about immediate changes by saying somethingThe successful performance of an act of this type brings about the correspondence between what is said and reality.e.g. I now declare the meeting open.I fire you!11. Illustrate Grice's Cooperative Principle with examples.Grice's Cooperative Principle consists of four maxims: QUANTITY, QUALITY, RELATION, and MANNER.1)A: What are you reading?B: A book.A knowsB is reading a book, and is asking about the content of the book. Simply by saying "a book", B is not offering enough information. The implicature here is: I do not want to talk to you right now. In this case, the maxim of QUANTITY is violated.2)He is made of iron.Our common sense tells us no human being is made of iron. Obviously this is a false statement and has violated the maxim of QUALITY. The implicature here is: he is as strong as iron.3)A: Mrs. Smith was such a bore at the party last night.B: It's really chilly here. I want to go out to warm up.When A is talking about Mrs. Smith, B turns to talk about something totally irrelevant.Therefore the maxim of RELATION is violated. The implicature here is: It is impolite to say that.4)a. Miss Smith sang "Home sweet home".b. Miss Smith produced a series of sounds that corresponded closely with the song of "Home sweet home".The two sentences actually are basically talking about the same thing. But sentence b is stated in such a way that makes it more obscure for the audience and therefore violates the maxim of MANNER. The implicature here is: Miss Smith does not sing well and I do not like her singing.12. With examples, give some plausible explanations for linguistic change.The rapid development of science and technologye.g. fax, laser printer, hi-tech, CD-ROM, lapto p computer and etc.Social and political changes and political needse.g. mini-summit, jungle war, Euro and etc.more and more women have taken up activities formerly reserved for mene.g. chairman---chairpersonfireman---fire fighterpoliceman---police officerThe way children acquire a languagee.g. “It’s I.”---“It’s me”.Economy of memory(results in grammar simplification)e.g. By analogy to foe/foes, dog/dogs, speaker started saying cows as the plural of cow instead of kine.Theory of least efforte.g. Cheap is always used in the place of cheaplySimplification of grammar occurs, so does elaboration and complication.13. Is standard language better than non-standard language? Explain your answer.The standard language is a superposed, socially prestigious dialect of language. It is the language employed by the government and the judiciary system, used by the mass media, and taught in educational institutions, including school settings where the language is taught as a foreign or second language. Nonstandard, or vernacular, languages are language varieties other than the standard language. Standard language is not superior to nonstandard language at all. The designation of the standard language variety is motivated by historical and socio-political reasons and has nothing to do with any supposed linguistic superiority intrinsic to the grammatical components of that particular language variety. In view of language as an effective means of communication, no single dialect of a language, be it standard or nonstandard, is any more correct, any more logical, or any purer than any other dialect of the language. All dialects of a language are equally effective in expressing ideas.14. What is the relationship between pidgin and creole?A pidgin is a variety of language that is generally used by native speakers of otherlanguages as a medium of communication. A pidgin is used for some practical purposes, such as trading, by groups of people who do not know each other' s languages. It is not a native language of a particular region, but only a marginal language used by people whose cultures are sharply separated and whose business contact is very specialized .As a simplified language, a pidgin involves reductions in sounds, vocabulary and syntax. Although pidgins are simplified languages, they are rule-governed.A Creole language is originally a pidgin that has become established as a native language in some speech community. When a pidgin comes to be adopted by a population as its primary language, and children learn it as their first language, then the pidgin language is called a creole. A creole involves expansion in sounds, vocabulary and syntax. Creoles are fully developed languages.。

语言学辽宁慕课习题整理chapter1-7Chapter 1 Invitations to linguistics1introduction to linguistics选择题1、Which of the following statements is NOT true?A Language consists of the systems of sounds and grammar.B Language is instrumental.C Language is social and conventional.D Language is a system of symbols.2、The scope of linguistic study may be generally divided into ______________.A interlinguistic study and extralinguistic studyB sociolinguistics and psycholinguisticsC descriptive linguistics and prescriptive linguisticsD phonetics and phonology3、Saussure made the distinction between _______________.A Langue and paroleB theoretical linguistics and applied linguisticsC comparative linguistics and historical linguisticsD competence and performance4、Chomsky made the distinction between _______________.A diachronic linguistics and synchronic linguisticsB Langue and paroleC competence and performanceD comparative linguistics and historical linguistics5、As modern linguistics aims to describe and analyze the language people actually use, and not to lay down rules for “correct” linguistic behavior, it is said to be ___________.A prescriptiveB descriptiveC sociolinguisticD psycholinguistic判断题6、Language consists of the systems of sounds and grammar.7、The actual production and comprehension of the speech by speakers of a language is called performance.8、English is an intonation language.9、The fact that children can speak before they can read or write shows that language is arbitrary.10、According to Chomsky, a language user’s underlying knowledge about the system of rules is called his linguistic competence.答案:AAACB X√√X√2design features of language选择题1、Which of the following is NOT a frequently discussed design feature of language?A DualityB ConventionC DisplacementD Arbitrariness.2、“I can refer to Confucius even though he died 2000 years ago.” This shows that language has the design feature of __________.A dualityB creativityC arbitrarinessD displacement3、The design feature of __________ refers to the property ofhaving two levels of structures, such that units of the primary level are composed of elements of the secondary level.A arbitrarinessB creativityC displacementD duality4、One of the properties of language is that a language user can understand and produce sentences he/she has never heard before. This property of language is called ________.A productivityB dualityC displacementD arbitrariness5、In broad terms, linguists agree to define language as a system of ____vocal symbols used for human communication.A arbitraryB conventionalC motivatedD dual答案:BDDAA3origins of language选择题1、There are some well-known theories about the origin of language, the natural response theory, also called .A the sing-song theoryB the pooh-pooh theoryC the Ding-Dong theoryD the yo-he-ho theory2、Ding-Dong theory is put forward by German scholar .A M. MULLerB HallidayC SaussureD Malinowski3、holds that language develops from primitive ritual songs of praise.A the yo-he-ho theoryB The sing-song theoryC the pooh-pooh theoryD the Ding-Dong theory4、holds that language originated from people’s imitations of animal cries and other sounds heard in nature.A The bow-wow theoryB the pooh-pooh theoryC the yo-he-ho theoryD the Ding-Dong theory判断题5、The bow-wow theory is a theory on the origin of language.6、Now linguists have known the specific origin of language.7、The yo-he-ho theory explains that language originated from the cries uttered during strain of work.答案:CABA √X√4functions of language选择题1、When people use language to express attitudes, feelings and emotions, people are using the ____________function of language.A creativeB phaticC emotiveD metalingual2、The social functions of language do NOT include_______________.A interrogative functionB phatic functionC metacognitive functionD informative function3、Which of the following is NOT a metafunction of language proposed by Halliday?A IdeationalB ConventionalC InterpersonalD Textual4、The social functions of language do NOT include_______________.A interrogative functionB informative functionC metacognitive functionD phatic function5、The ______ function refers to the fact that language can be used for establishing a favorable atmosphere or maintaining social contact rather than for exchanging information or ideas.A phaticB evocativeC directiveD performative判断题6、“Language operates by rules” is a fu ndamental view about language.7、When people use language to indulge in itself for its ownsake, people are using the creative function of language.8、According to Halliday’s theory of metafunctions of language, interpersonal function enacts social relationship.9、According to Halliday, a theory of metafunctions of language, that is , language has ideational, interpersonal and textual function.10、When people use language to indulge in itself for its own sake, people are using the poetic function of language.答案:CCBCA √X√√√Chapter 1 主观题1、名词解释:Diachronic linguisticsDiachronic linguistics is the study of a language through the course of its history.2、名词解释:Synchronic linguisticsA synchronic description takes a fixed instant (usually, but not necessarily, the present) as its point of observation.3、名词解释:PsycholinguisticsPsycholinguistics is the study of psychological aspects of language; it usually studies the psychological states and mental activity associated with the use of language. Most problems in psycholinguistics are more concrete, involving the study of language acquisition especially in children and linguistic performance such as producing and comprehending utterances or sentences among adults.4、名词解释:DualityBy Duality is meant the property of having two levels of structures, such that units of the primary level are composed of elements of the secondary level and each of the two levels has its own principles of organization. The property of duality only exists in such a system, namely, with both elements and units.Besides, the language is hierarchical.5、名词解释:DisplacementDisplacement means that human languages enable their users to symbolize objects, events and concepts which are not present (in time and space) at the moment of communication. Displacement benefits human beings by giving them the power to handle generalizations and abstractions. In a word, the intellectual benefits of displacement to us is that it makes it possible for us to talk and think in abstract terms.6、Do you think that onomatopoeia indicates a non-arbitrary relationship between form and meaning? Why or why not?No matter whether you say “Yes” or “No”, you cannot deny that onomatopoeia needsarbitrariness. Before we feel a word is onomatopoeic we should first know which sound the word imitates. In order to imitate the noise of flying mosquitoes, there are many choices like “murmurous” and “murderous”. They both bear more or less resemblance to the genuine natural sound, but “murmurous” is fortunately chosen to mean the noise while “murderous” is chose n to mean something quite different. They are arbitrary as signifiers.(参考答案)No, I don't think so. There exists the arbitrary relationship between the sound of a morpheme and its meaning. Also, in English, totally different words are used to describe the sound. In fact, arbitrariness and onomatopoeic effect may work at the same time. For example, Widdowson cites a line from Keats' Ode to a Nightingale to illustrate. The murmurous haunt of flies on summer eves. To test this, just think of using the similar sounding word murderous to substitute murmurous, and no connectionwhatsover will be established between the sounds and the little noises of the flying flies. "It's only when you know the meaning that you infer that the form is appropriate." (我的答案)7、Illustrate the origins of language you have known.The sing-song theory: it holds that language develops from primitive ritual songs of praise.The Ding-Dong theory: the natural response theory postulates that language began with vocal expressions being assigned to objects found in the environment.The pooh-pooh theory: the theory traces language back to interjections which expresses the speakers’ emotions.The yo-he-ho theory: it explains that language originated form the cries uttered during strain of work.The bow-wow theory: it holds that language originated from people’s imitations of animal cries and other sounds heard in nature.Ta-Ta theory: it believes that body movement preceded language. language began as an unconscious vocal imitation of these movements.8、Language is generally defined as a system of arbitrary vocal symbols used for human communication. Explain it in detail.Language is a means of verbal communication. It is instrumental in that communicating by speaking or writing is a purposeful act. It is social and conventional in that language is a social semiotic and communication can only take place effectively if all the users share a broad understanding of human interaction including such associated factors as nonverbal cues, motivation, and socio-cultural roles.Chapter 2 Phonetics5phonetics选择题1、Pair ___________ doesn’t form a minimal pair.A cat and actB tip and dipC gap and capD pat and pad2、The study of the production of speech sounds is closely connected with ____________.A articulatory phoneticsB auditory phoneticsC acoustic phoneticsD arbitrary phonetics3、The study of the physical properties of speech sounds is closely connected with ____________.A acoustic phoneticsB articulatory phoneticsC auditory phoneticsD arbitrary phonetics4、The study of the perception of speech sounds is closely connected with .A acoustic phoneticsB articulatory phoneticsC auditory phoneticsD arbitrary phonetics5、Pair ________is not in complementary distribution.A spot and potB stop and topC light and gladD school and cool判断题1、A single phoneme always represents a single morpheme.2、When the vocal folds are apart, the air can pass through easily and the sound produced is said to be voiced.3、Cave and shave forms a minimal pair.4、Phonetics studies how speech sounds are produced, transmitted, and perceived.5、The tongue is divided into five parts: the tip, the blade, the front, the back and the root.主观题1、Please describe what is phoneme.The speech sound segments that can distinguish or contrast words in sound and meaning are phonemes. (A phoneme is the minimal or smallest distinctive linguistic unit in a language.)2、Please describe what is complementary distribution.The different allophones of the same phoneme never occur in the same phonetic context. When two or more allophones of one phoneme never occur in the same linguistic environment they are said to be in complementary distribution.答案:AAACC ××√√√6English Consonan t选择题1、The classification and description of English consonants are based on ___________________.A narrow and broad transcriptionB the shape of vocal tractC the place and manner of articulationD the position of the tongue2、According to the manner of articulation, [m] is a ___________.A nasalB plosiveC bilabialD lateral3、In terms of the place of articulation, the following sounds [t], [n], [z] share the feature of ____________.A alveolarB velarC palatalD bilabial4、Which of the following sounds is a bilabial?A [ t ]B [ b ]C [ g ]D [ d ]5、Which of the following sounds is an alveolar?A [ d ]B [ m ]C [ g ]D [ b ]判断题1、The difference between vowels and consonants lies in the obstruction of the airstream.2、According to the manner of articulation, [s] is a fricative.3、English consonants can be classified in terms of place of articulation and the part of the tongue that is raised the highest.4、According to the manner of articulation, some of the types into which the consonants can be classified are stops, fricatives, bilabial and alveolar.5、/d/ is a voiced alveolar stop.主观题Please describe what are consonants.Consonants are sounds produced by constricting or obstructing the vocal tract at some place to divert, impede or completely shut off the flow of the air in the oral cavity.答案:CAABA √√××√7English Vowels1、The classification and description of English vowels are based on ___________________.A the position of the tongueB the shape of the lipsC the shape of vocal tractD all of the above2、The difference between vowels and consonants lies in ___________________.A the intonation of the soundsB the obstruction of the airstreamC the place and manner of articulationD the aspiration of the sounds3、A ____ vowel is one that is produced with the front part of the tongue maintaining the highest position.A centralB frontC middleD back3、can be differentiated by a number of factors: the position of tongue in the mouth, the openness of the mouth, the shape of the lips, and the length of the vowels.A Consonant soundsB Voicing soundsC Vowel soundsD devoicing sounds主观题1、Please describe what are vowels.V owels are sounds produced without obstruction, so no turbulence or a total stopping of the a ir can be perceived.2、What are the criteria that a linguist uses in classifying vowels?1. V owels may be distinguished as front, central and back in terms of the position of the tongue in the mouth.2. According to how wide our mouth is opened, we classify the vowels into four groups: close vowels, semiclose vowels, semi-open vowels, and open vowels.3. According to the shape of the lips, vowels are divided into rounded vowels and unrounded vowels.4. The English vowels can also be classified into long vowels and short vowels according to the length of the sound.答案:DBBCChapter 3 Phonology8phonology选择题1、Of all the speech organs, the _______ is/are the most flexible.A lipsB tongueC mouthD vocal cords2、A(n) ___________ is a unit that is of distinctive value. It is an abstract unit, a collection of distinctive phonetic features.A soundB phoneC phonemeD allophone3、The different phones which can represent a phoneme in different phonetic environments are called the ____ of that phoneme.A phonesB soundsC allophonesD phonemes4、Since /p/ and /b/ are phonetically similar, occur in the same environments and they can distinguish meaning, they are said to be ___________.A in phonemic contrastB the allophonesC in complementary distributionD minimal pair5、The assimilation rule assimilates one sound to another by “copying”a feature of a sequential phoneme, thus making the two phones ____________.A sameB identicalC exactly alikeD similar判断题1、Phonetics is different from phonology in that the latter studies the combinations of the sounds to convey meaning in communication.2、Phonology is concerned with how the sounds can be classified into different categories.3、The rules governing the phonological patterning arelanguage specific.4、Distinctive features of sound segments can be found running over a sequence of two or more phonemic segments.5、When two different forms are identical in every way except for one sound segment which occurs in the same place in the strings, the two words are said to form a phonemic contrast.主观题What are the major differences between phonology and phonetics?1.They differ in their approach and focus.2.Phonetics is of a general nature; it is interested in all the speech sounds used in all human languages: how they are produced, how they differ from each other, what phonetic features they p ossess, how they can be classified.3.Phonology, on the other hand, is interested in the system of sounds of a particular languag e; it aims to discover how speech sounds in a language form patterns and how these sounds are use d to convey meaning in linguistic communication.答案:BCCA D √×√√×9coarticulation选择题1、When such simultaneous or overlapping articulation are involved, we call the process .A coarticulationB aspirationC nasalizationD epenthesis2、In producing a nasal the soft palate is lowered to allow airflow through the .A nasal tractB vocal foldsC vocal cordsD larynx3、The fact that the vowel in lamb has some quality of the following nasal is a phenomenon we call .A devoicingB velarizationC nasalizationD aspiration4、In coarticulation, if the sound becomes more like the following sound, as in lamb, it is known as .A perseverative coarticulationB aspirationC nasalizationD anticipatory coarticulation5、When we use a simple set of symbols in our transcription, it is called a .A aspirationB narrow transcriptionC nasalizationD broad transcription判断题1、In English, the distinction between aspirated [p?] and unaspirated [p] is not phonemic.2、In the word peak, /p/ is unaspirated, phonetically transcribed as [p]3、Aspiration is a distinctive feature in English.4、In phonetic terms, phonemic transcriptions represent the “narrow” transcription.5、Speech is a continuous process, so the vocal organs donot move from one sound segment to thenext in a series of separate steps.主观题名词解释:CoarticulationCoarticulation:Simultaneous or overlapping articulations, as when the nasal quality of a nasal sound affects the preceding or following sound so that the latter becomes nasalized. If the affected sound becomes more like the following sound, it is known as anticipatory coarticulation; if the sound shows the influence of the preceding sound, it is perseverative coarticulation.答案:AACDD √×××√10suprasegmentals选择题1、Which of the following is NOT a Suprasegmental feature?A toneB intonationC syllableD stress2、In a syllable, a vowel often serves as ____________.A onsetB sequenceC peak or nucleusD coda3、The word “digitalization” consists of _______ syllables, and _________ morphemes.A six/ threeB five/ threeC six/ fourD five /five4、The word “digitalization” consists of _______ syllables, and _________ morphemes.A six/ threeB six/ fourC five /fiveD five/ three5、Distinctive features can be found running over a sequence of two or more phonemic segments. The phonemic features that occur above the level of the segments are called _______.A immediate constituentsB phonetic componentsC suprasegmental featuresD semantic features主观题1、名词解释:suprasegmental featuresThe features that occur above the level of the segments and can distinguish meaning are called suprasegmental features, which include syllable structure, stress, tone and intonation.2、名词解释: intonationWhen pitch, stress and sound length are tied to the sentence rather than the word in isolation,they are collectively known as intonation.3、Illustrate with examples how suprasegmental features can affect meaning.1. The location of stress in English distinguishes meaning, such as `import and im`port. The similar alternation of stress also occurs between a compound noun and a phrase consisting of the same elements. A phonological feature of the English compounds, is that the stress of the word always falls on the firstelement and the second element receives secondary stress, for example: `blackbird is a particular kind of bird, which is not necessarily black, but a black `bird is a bird that is black.2. The more important words such as nouns, verbs adjectives, adverbs, etc. are pronounced with greater force and made more prominent. But to give special emphasis to a certain notion, a word in sentence that is usually unstressed can be stressed to achieve different effect. Take the sentence “He is driving my car.” for example. To emphasize the fact that the car he is driving is not his, or yours, but mine, the speaker can stress the possessive pronoun my, which under normal circumstances is not stressed.3. English has four basic types of intonation, known as the four tones: When spoken in different tones, the same sequence of words may have different meanings. Generally speaking, the falling tone indicates that what is said is a straight-forward, matter-of-fact statement, the rising tone often makes a question of what is said, and the fall-rise tone often indicates that there is an implied message in what is said.答案:CCCBCChapter 4 Morphology11morphology选择题1.Derivational affixes are bound morphemes added to existing form to construct new words. English derivational affixes are divided into ________and _______.A prefixes, infixesB suffixes and infixesC prefixes, suffixesD morphemes, allomorphs2.In the word “unavailability”, ______________ is the root.A unB availableC availD ability3.In today’s grammar we normally say that English does not have a “future tense”. This is because in English ________________.A the future can be expressed in many waysB the future is not expressed by morphological changeC the future is expressed by modal verbsD the future belongs to the category of “aspect”4.The morpheme “vision” in the word “television” is a(n)____________.A inflectional morphemeB bound formC free morphemeD bound morpheme5.Which of the following words is made up of bound morphemes only?A televisioB happinessC ecologyD teacher6.Morpheme is the minimal unit of meanin7.–ing is an “inflectional suffix”8.Stems in English can be classified into derivational morphemes and inflectional morphemes.9.The bound morpheme in “apples” is inflectional morpheme.10.Although is an open-class word.主观题11..名词解释:RootRoot: Root refers to the base form of a word that cannot be further analyzed without loss of identity. That is to say, it is that part of the word that is left when all the affixes are removed. And roots can be further classified into free root morpheme and bound root morpheme.12.名词解释:AllomorphAllomorph: A morpheme, like a phoneme, is a linguistic abstraction, which must be realized as certain phonetic forms or variants in different phonetic environments. Each of the phonetic for ms or variants is a morph. A single morpheme may be phonetically realized as two or more morph s. The different morphs that represent or which are derived from one morpheme is called the allom orphs of that morpheme答案:CCBCC √√×√×12word formation选择题1._________can best describe the following group of words: table--tables, influenza--flu.A Inflection and derivationB Derivation and blendingC Inflection and abbreviationD Compound and derivation2.Which of the following ways of word-formation does not change the grammatical class of the stem?A inflectionB compoundC derivationD coinage3._________can best describe the word formation rules of thefollowing group of words: to burgle (from burglar), Eurodollar (from European + dollar).A Back-formation and blendingB Inflection and derivationC Derivation and blendingD Compound and derivation4._________can best describe the following group of words: table—tables, day + break—daybreak.A Inflection and derivationB Derivation and blending.C Compound and derivation.D Inflection and compound5.__________can be best describe the following group of words: advertisement—ad, bicycle—bike.A abbreviationB compoundC derivationD coinage6.“Invention” is a form of compounding, in which two words are blended by joining the initial par t of the first word and the final part of the second word, or by joining the initial parts of the two w ords.7.Blending is a relatively complex form of compounding.8.Derivation does not change the grammatical class of the stem.9.Derivation can be further divided into two sub-types: the derivational type and the compositional type.10.Inflection shows a relationship between roots and affixes.主观题11.What is the distinction between inflectional affixes andderivational affixes?1.When an affix, usually a suffix in English, indicates the tense of a verb, the plurality of a counta ble noun, or the comparative/superlative degree of an adjective, it is termed as inflectional morphe me. For example, '-ed' in 'worked', '-ing' in 'studying', '-s' in 'books' or 'er' in 'shorter' and 'est' in 'lo ngest' are all inflectional morphemes. Usually, the inflectional morpheme will not change the part of speech of a word to which it is attached.2.But a derivational morpheme usually changes the part of speech of a word to which it is attached . When we attach '-al' to the word 'nation' to form 'national', the part of speech of the word 'nation', i.e. a noun, has been changed into an adjective. As we can see, the concept of derivational morphe me is related to a kind of word formation called derivation.答案:CAADA ×√×√×Chapter 5 Syntax13concept of grammar选择题1.A sentence is considered ____ when it does not conform to the grammatical knowledge in the mi nd of native speakers.A wrongB ungrammaticalC rightD grammatical2. A __________ in the embedded clause refers to the introductory word that introduces the embedded clause.A particleB prepositionC subordinatorD coordinator3. Phrase structure rules have ____ properties.A recursiveB grammaticalC socialD functional4. Phrase structure rules allow us to better understand _____________.A All of the above.B how words and phrases form sentences.C what constitutes the grammaticality of strings of wordsD how people produce and recognize possible sentences5. The syntactic rules of any language are ____ in number.A smallB largeC finiteD infinite判断题6.Descriptive grammar refers to grammarian’s attempt to legislate what speakers’ grammatical rules should be, rather than what they are.7.Grammatical sentences are formed following a set of syntactic rules.8.Universally found in the grammars of all human languages, syntactic rules that comprise the system of internalized linguistic knowledge of a language speaker are known as linguistic competence9.The syntactic rules of any language are finite in number, but there is no limit to the number of sentences native speakers of that language are able to produce and comprehend.10.In a complex sentence, the two clauses hold unequal status, one subordinating the other.答案:DBDDD XX√√√主观题1. What are the basic components of a sentence?Normally, a sentence consists of at least a subject and its predicate which contains a finite verb or a verb phrase.2. What are the major types of sentences? Illustrate them with examples.①Traditionally, there are three major types of sentences. They are simple sentence, coordinate (compound) sentence, and complex sentence. A simple sentence consists of a single clause which contains a subject and a predicate and stands alone as its own sentence.For example: John reads extensively.②A coordinate sentence conta ins two clauses joined by a linking word that is calledcoordinat ing conjunction, such as “and”, “but”, “or”.For example: John is reading a linguistic book, and Mary is preparing for her history exam.A complex sentence contains two, or more, clauses, one of which is incorporated into the other. The two clauses in a complex sentence do not have equal status, one is subordinate to the other.For example: Before John gave her a lecture, Mary showed no interest in linguistics.14Cultural Approach选择题1. A __________ in the embedded clause refers to the introductory word that introduces the embedded clause.。