Abstract Online 3D Collaboration System for Engineering Education

- 格式:pdf

- 大小:242.10 KB

- 文档页数:10

四面体插值算法在计算机油墨配色中的应用

赵震飞

【期刊名称】《包装工程》

【年(卷),期】2009()10

【摘要】把四面体插值法应用在油墨的计算机配色中,建立了一种新型的油墨配色系统,可实现油墨从CIELAB色彩空间到CMY(K)空间的转换。

该系统可节省油墨配色的时间、成本,提高配色的速度和效率,加快印前工艺的数据化流程。

【总页数】3页(P108-110)

【关键词】四面体插值;油墨配色;计算机

【作者】赵震飞

【作者单位】陕西科技大学,西安71021

【正文语种】中文

【中图分类】TS801.3

【相关文献】

1.计算机配色系统在油墨配色上的应用 [J], 李效周

2.插值分析在织物染色计算机配色中的应用研究 [J], 李敏;张秉森;武洋洋

3.计算机配色系统油墨数据库建立及应用研究 [J], 郭雷

4.颜色光谱分析在计算机油墨配色中的应用 [J], 赵晨飞

5.计算机配色系统油墨数据库建立及应用 [J], 邢洁芳;胡桂春

因版权原因,仅展示原文概要,查看原文内容请购买。

网络互助行业市场现状分析及未来三到五年发展趋势报告Title: Analysis of the Current Market Situation in the Online Assistance Industry and a Report on Future Development Trends in the Next Three to Five YearsAbstract:This article aims to analyze the current market situation in the online assistance industry and provide insights into the future development trends over the next three to five years. The online assistance industry has witnessed significant growth in recent years, driven by the increasing demand for convenient and efficient services. This article will examine the market size, key players, challenges, and opportunities in the industry. Additionally, it will explore the potential trends that are likely to shape the industry's future.Introduction:The online assistance industry has experienced rapid growth in recent years, driven by technological advancements and changing consumer behavior. With the increasing reliance ondigital platforms and the need for convenient services, the industry has gained traction across various sectors, including e-commerce, travel, finance, and healthcare. This article aims to provide an in-depth analysis of the current market situation and forecast the future development trends in the online assistance industry.Market Analysis:The online assistance industry has witnessed remarkable growth, with a significant increase in market size. According to market research, the global online assistance market was valued at USD XX billion in 2020 and is projected to reach USD XX billion by 2025, growing at a CAGR of XX during the forecast period. This growth can be attributed to several factors, including the proliferation of smartphones, increasing internet penetration, and the rising adoption of digital services.Key Players:The online assistance industry is highly competitive, with several key players dominating the market. Companies such as A, B, and C have established themselves as leaders in providingonline assistance services. These companies leverage their technological capabilities, extensive networks, and customer-centric approach to gain a competitive edge. However, the market also comprises numerous smaller players, offering specialized services or targeting niche markets.Challenges:Despite the rapid growth, the online assistance industry faces several challenges. One of the significant challenges is ensuring data security and privacy. As online assistance involves handling sensitive customer information, maintaining robust security measures is crucial to gain and retain customer trust. Additionally, the industry needs to address issues related to quality control, customer satisfaction, and regulatory compliance to sustain long-term growth.Opportunities:The online assistance industry presents several opportunities for growth. The increasing integration of artificial intelligence (AI) and machine learning (ML) technologies can enhance the efficiency and effectiveness of online assistance services. Furthermore, the emergence of newtechnologies, such as blockchain and virtual reality, can open up new possibilities for the industry. Additionally, expanding into untapped markets and offering personalized and customized services can help companies gain a competitive advantage.Future Development Trends:Looking ahead, several trends are likely to shape the future of the online assistance industry. Firstly, the industry is expected to witness increased collaboration between online assistance platforms and traditional businesses to provide a seamless customer experience. Secondly, the integration of voice assistants and smart devices will become more prevalent, enabling users to access online assistance services effortlessly. Lastly, personalized and on-demand services will gain prominence, as customers seek tailored solutions to their specific needs.Conclusion:The online assistance industry has experienced significant growth and is poised for further development in the coming years. As technology continues to advance and consumer expectations evolve, the industry needs to adapt and innovate to staycompetitive. By addressing challenges, leveraging opportunities, and embracing emerging trends, companies in the online assistance industry can position themselves for success in the future.标题:网络互助行业市场现状分析及未来三到五年发展趋势报告摘要:本文旨在分析网络互助行业的市场现状,并提供未来三到五年发展趋势的见解。

美国研究人员开发出3D打印纹理溯源的新方法

张宇

【期刊名称】《科技中国》

【年(卷),期】2018(0)11

【摘要】据布法罗大学官网2018年10月16日消息,3D打印枪支模型由于不含可追踪的枪支序列号,为潜在犯罪分子提供了便利,给社会带来了安全隐患。

美国纽约州立大学布法罗分校研究人员开发出一种方法,可根据3D打印物品的纹理精确地跟踪到其源3D打印机。

3D打印对象每层都会包含以亚毫米为单位的微小纹理,由于3D打印机的型号、所用材料、喷嘴尺寸和其他因素都会导致图案出现轻微缺陷,且是独特、无法避免且不可改变的,研究人员利用此纹理与数据库数据进行比对,能够精确追溯到源3D打印机。

该方法可帮助企业以及执法机构追踪3D打印物品起源,提高3D打印的安全性。

【总页数】1页(P101-101)

【关键词】3D打印;研究人员;纹理;开发;美国;州立大学;数据库数据;打印机;

【作者】张宇

【作者单位】不详

【正文语种】中文

【中图分类】TP334.84

【相关文献】

1.美国开发出快速检测牛奶中三聚氰胺新方法/英国试用激光和药物联合法治疗肿瘤/免疫系统缺陷易引发流感病毒抗药性/美国研究人员找到让癌细胞衰老死亡方法/每日吃40克熟芝麻可保肝护心 [J],

2.美国科学家研发出一种3D打印高强度铝合金的新方法 [J],

3.美国研究人员开发出石墨烯制备新方法 [J], W.MIT

4.美国西北大学研发出金属3D打印新方法 [J], 船信

5.美国研究人员开发出二氧化碳高效转化为乙烯的新方法 [J],

因版权原因,仅展示原文概要,查看原文内容请购买。

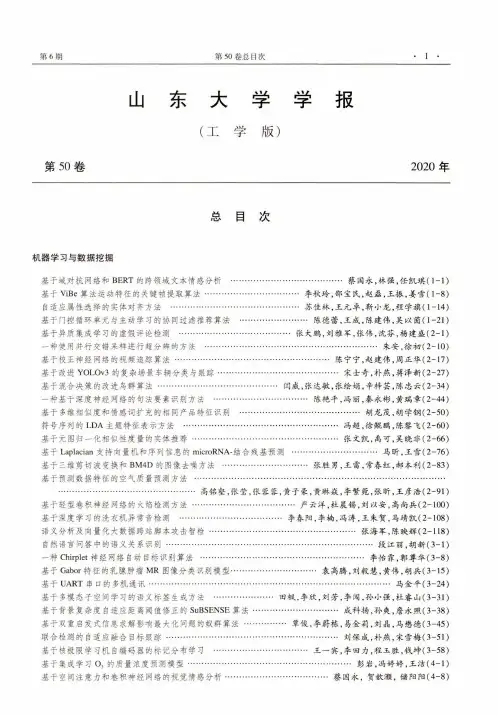

第6期第50卷总目次山东大学学报(工学版)第50卷2020 年总目次机器学习与数据挖掘基于域对抗网络和B E R T 的跨领域文本情感分析...............基于V i B e 算法运动特征的关键帧提取算法......................自适应属性选择的实体对齐方法.............................基于门控循环单元与主动学习的协同过滤推荐算法...........基于异质集成学习的虚假评论检测..........................一种使用并行交错采样进行超分辨的方法....................基于校正神经网络的视频追踪算法...........................基于改进Y O L O v 3的复杂场景车辆分类与跟踪..................基于混合决策的改进鸟群算法..............................一种基于深度神经网络的句法要素识别方法..................基于多维相似度和情感词扩充的相同产品特征识别...........符号序列的L D A 主题特征表示方法 .........................基于元图归一化相似性度量的实体推荐.......................基于Laplacian 支持向量机和序列信息的m i c r o R N A -结合残基预测 基于三维剪切波变换和B M 4D 的图像去噪方法................................蔡国永,林强,任凯琪(1-1)……李秋玲,邵宝民,赵磊,王振,姜雪(1-8)……苏佳林,王元卓,靳小龙,程学旗(1-14)......陈德蕾,王成,陈建伟,吴以茵(1-21)…张大鹏,刘雅军,张伟,沈芬,杨建盛(2-1)........................朱安,徐初(2-10)...........陈宁宁,赵建伟,周正华(2-17).............宋士奇,朴燕,蒋泽新(2-27)闫威,张达敏,张绘娟,辛梓芸,陈忠云(2-34)......陈艳平,冯丽,秦永彬,黄瑞章(2-44)...................胡龙茂,胡学钢(2-50).............冯超,徐鲲鹏,陈黎飞(2-60).............张文凯,禹可,吴晓非(2-66).....................马昕,王雪(2-76)......张胜男,王雷,常春红,郝本利(2-83)基于预测数据特征的空气质量预测方法...................................................................................................高铭壑,张莹,张蓉蓉,黄子豪,黄琳焱,李繁菀,张昕,王彦浩(2-91)基于轻型卷积神经网络的火焰检测方法..........................严云洋,杜晨锡,刘以安,高尚兵(2-100)基于深度学习的洗衣机异常音检测..........................李春阳,李楠,冯涛,王朱贺,马靖凯(2-108)语义分析及向量化大数据跨站脚本攻击智检.....................................张海军,陈映辉(2-118)自然语言问答中的语义关系识别.....................一种Chirplet 神经网络自动目标识别算法..............基于G a b o r 特征的乳腺肿瘤M R 图像分类识别模型......基于U A R T 串口的多机通讯.............................基于多模态子空间学习的语义标签生成方法.........基于背景复杂度自适应距离阈值修正的S u B S E N S E 算法基于双重启发式信息求解影响最大化问题的蚁群算法…联合检测的自适应融合目标跟踪.....................基于核极限学习机自编码器的标记分布学习.........基于集成学习〇,的质量浓度预测模型................基于空间注意力和卷积神经网络的视觉情感分析..............................段江丽,胡新(3-1)......................李怡霏,郭尊华(3-8).........袁高腾,刘毅慧,黄伟,胡兵(3-15).............................马金平(3-24)田楓,李欣,刘芳,李闯,孙小强,杜睿山(3-31)...............成科扬,孙爽,詹永照(3-38)•…覃俊,李蔚栋,易金莉,刘晶,马懋德(3-45)...............刘保成,朴燕,宋雪梅(3-51).......王一宾,李田力,程玉胜,钱坤(3-58)..................彭岩,冯婷婷,王洁(4-1)............蔡国永,贺歆灏,储阳阳(4-8)• 2 ■山东大学学报(工学版)第50卷一种基于多目标的容器云任务调度算法...............基于卷积神经网络的深度线段分类算法................基于类激活映射-注意力机制的图像描述方法...........基于Bi -LSTM 的脑电情绪识别.........................带特征指标约束描述的设计模式分类挖掘..............基于NRC 和多模态残差神经网络的肺部肿瘤良恶性分类中文对话理解中基于预训练的意图分类和槽填充联合模型融合残差块注意力机制和生成对抗网络的海马体分割••…........................谢晓兰,王琦(4-14)..............赵宁宁,唐雪嵩,赵鸣博(4-22).....廖南星,周世斌,张国鹏,程德强(4-28)..................刘帅,王磊,丁旭涛(4-35).....肖卓宇,何锫,陈果,徐运标,郭杰(6-48)■•…霍兵强,周涛,陆惠玲,董雅丽,刘珊(6-59)........................马常霞,张晨(6-68)张月芳,邓红霞,呼春香,钱冠宇,李海芳(6-76)控制科学与工程基于空间隐患分布与运动意图解析的危险评估方法........一类非仿射非线性大系统的结构在线扩展.................GPRS 监管的多协议异构现场总线控制系统................基于新型趋近律的参数未知分数阶Rucklidge 系统的滑模同步分数阶Brussel 系统混沌同步的三种控制方案...............一类非线性混沌系统的自适应滑模同步...................含对数项分数阶T 混沌系统的滑模同步...................赵越男,陈桂友,孙琛,卢宁,譽立伟(1 -28)............曹小洁,李小华,刘辉(1-35)……侯鹏飞,孙竹梅,王琦,白建云(1-49).........王春彦,邸金红,毛北行(4-40).........................程春蕊(4-46)..................程春蕊,毛北行(5-1)..................孟晓玲,毛北行(5-7)土木工程含层状节理岩体力学性质数值模拟研究.......................................徐子瑶,虞松,付强(3-66)水泥土搅拌桩沿海软基处理..............................................吕国仁,葛建东,肖海涛(3-73)高地应力下砂岩力学参数和波速变化规律试验研究..............................宫嘉辰,陈士海(3-82)饱和地基中单排孔近场隔振的现场试验与数值分析智慧公路关键技术发展综述...................双节理岩体T B M 滚刀破岩过程数值模拟......基于熵值法的水利施工企业绩效考核K P I 设计方法偏压大跨小净距公路隧道施工力学行为..........基于B P 神经网络算法的结构振动模态模糊控制••砂土介质中颗粒浆液扩散距离变化规律........预应力中空棒构件设计与力学特性..............隐伏溶洞对隧道围岩稳定性影响规律及处治技术硬岩隧道纯钢纤维混凝土管片应用..............喷扩锥台压灌桩最优构造.......................松散地层隧道进洞段管棚注浆加固效应分析……孙连勇,时刚,崔新壮,周明祥,王永军,纪方,闫小东(3-88)................................吴建清,宋修广(4-52)施雪松,管清正,王文扬,许振浩,林鹏,王孝特,刘洁(4-70).........................................程森(4-80)........................................王春国(4-85)...........................王志伟,葛楠,李春伟(5-13)........................冯啸,夏冲,王凤刚,张兵(5-20).............................林超,张程林,王勇(5-26).....................陈禹成,王朝阳,郭明,林鹏(5-33)..............徐振,李德明,王彬,詹谷益,张世杰(5-44)...........李连祥,邢宏侠,李金良,黄亨利,王雷(6-82)...................余俊,翁贤杰,樊文胜,张连震(6-92)机械与能动工程柔性Rushton 桨的振动特性.........................................................刘欣,杨锋茶(5-50)湿法脱硫塔一维传热传质性能模型理论与试验.....................陈保奎,孙奉仲,高明,史月涛(5-56)波浪能发电装置浮体形状参数对俘能性能影响............刘延俊,王伟,陈志,王冬海,王登帅,薛钢(6-1)深拖地震线列阵的动力学建模与位置预报...................朱向前,魏峥嵘,裴彦良,于凯本,宗乐(6-9)淹没深度对三自由度波能浮子获能的影响........................黄淑亭,翟晓宇,刘延俊,史宏达(6-17)尾缘襟翼振荡水翼的水动力特性.................................孙光,王勇,谢玉东,陈晨,张玉兵(6-23)深海带电插拔连接器力学特性分析…韩家桢,王勇,谢玉东,王启先,张新标,高文彬,李荣兰,张传军(6-30) 振荡翼改进运动模型的能量捕获性能分析............................乔凯,王启先,王勇,谢玉东(6-40)第6期第50卷总目次电气工程能源消费发展及预测方法综述..............................杨明,杜萍静,刘凤全,郝旭鹏,孛一凡(1-56)基于物理不可克隆函数的电网NB-IoT端到端安全加密方案............................................................................................刘冬兰,刘新,陈剑飞,王文婷,张昊,马雷,李冬(丨-63)中央空调紧急控制应对受端电网直流闭锁故障研究.................................................................................................刘萌,程定一,张文,张恒旭,李宽,张国辉,苏建军U-72)风电爬坡事件的非精确条件概率预测..........................王勃,汪步惟,杨明,赵元春,朱文立(丨-82)考虑同步调相机无功特性的多馈入直流同时换相失败风险评估方法............................................................................................麻常辉,王亮,谭邵卿,卢奕,马欢,赵康(3-98)考虑路灯充电桩接入的城市配电网电压控制方法............宋士瞻,陈浩宇,张健,王坤,郝庆水(3-104)基于分时电价的含光伏的智慧家庭能量调度方法…潘志远,刘超男,李宏伟,王婧,王威,刘静,郑鑫(3-111)基于弹性梯度下降算法的B P神经网络降雨径流预报模型..........金保明,卢光毅,王伟,杜伦阅(3-117)基于学习理论的含光储联合系统的输电网双层规划……孙东磊,赵龙,秦敬涛,韩学山,杨明,王明强(4-90) 考虑内部动态约束的MMC功率运行区间的确定及控制方法……张锋,杨桂兴,岳晨晶,郝全睿,李东(4 - 9 8)虾米腰弯管内置导流板优化...................................祁金胜,曹洪振,石岩,杜文静,王湛(5-64)基于B P神经网络的短期光伏集群功率区间预测........孙东磊,王艳,于一潇,韩学山,杨明,闰芳晴(5-70)偏心方圆节扩散管数值模拟.................................曹洪振,祁金胜,袁宝强,杜文静,王湛(5-77)烟气成分对湿式电除尘器电晕放电特性的影响.................王磊,张玉磊,李兆东,张金峰,王翔(5-83)含电极式电锅炉的地区电网电源侧综合效益分析......葛维春,李昭,赵东,李振宇,叶青,傅予,于娜(5-90)基于特征频带相电流提取的故障选相和选线方法........................张贺军,王鹏,徐凯,石访(5-99)电动汽车虚拟储能可用容量建模.......................................李蓓,赵松,谢志佳,牛萌(6-101)基于RTDS的配电网一二次融合仿真技术...............李志,余绍峰,苏毅方,王蔚,蒋宏图,张伟(6-112)芒刺参数对电晕放电及细颗粒物脱除特性的影响............................王磊,李明臻,王翔(6-118)含不凝气蒸汽在锯齿形表面的凝结传热特性............................闫吉庆,王效嘉,田茂诚(6-129)化学与环境济南城区大气PM2.5、PM,。

Page 1 3D Virtual Learning Environments(3D VLE ) Darren NonisWhat is a 3D VLE?A 3 dimensional (3D) virtual environment is created entirely from a computer database consisting of objects modeled by computer-aided design (CAD) software. These objects are programmed to behave in certain ways as the user interacts with them (Winn, Hunter, Hollander, Osberg, Rose & Char, 1997).A 3D virtual environment is special because the mixture of software and hardware gives the user an illusion of being immersed in a 3D space and the ability to interact with the 3D space (Byrne, 1996). To feel immersed, the user must get a sense that there are things all around. He/she must take these things literally as objects with position and properties. One good test of the illusion of immersion is the following: if one turns away from something in an environment, that thing should feel as if it is still there, just that it is out of his/her field of vision. In this case, we say that the object has a strong sense of presence. If the things in the environment have behaviour and react to the user’s motions, he/she will take those objects more seriously as actual things and the illusion of immersion will be enhanced. Input devices like the keyboard and mouse allow the user to interact with the elements in the 3D space. Thus, the contributing factors that characterize a 3D virtual environment are the 3-dimensional element, interaction and the illusion of immersion.Where a 3D virtual technology is used to create an immersive and interactive environment tofacilitate or aid learning, this is known as 3Dvirtual learning environment (3D VLE). Figure 1 is a screenshot of a 3D VLE called QuestAtlantis showing a scene of the user interface.Typically, 3D VLE is a learning and teaching program that makes use of a MUVE (multi-user virtual environment) or a single user virtual environment to immerse students in educational tasks. The task may be termed a quest, mission or challenge, depending very much on the scenario of the 3D VLE. Students move around the 3D space to virtual places and perform educational tasks. In the pursuance of these tasks, students are able to interact with digital artifacts and they can represent themselves through 'avatars'1 or virtual characters.In addition, the multi-user version of the 3D VLE is online and enables students to communicate with each other using real time chat or email.Simulation and 3D VLEComputer simulations are computer-generated versions of real-world objects (for example chemical molecules) or processes (for example, population growth or biological decay). They may be presented in 2-dimensional, text-driven formats, or, increasingly, 3-dimensional, multimedia formats. Computer simulations can take many different forms, ranging from computer renderings of 3-dimensional geometric shapes to highly interactive, computerized laboratory experiments. A 3D VLE, allows1A graphical icon that represents a real person in acyberspace system. When you enter the system, you can choose from a number of fanciful avatars. Sophisticated 3D avatars even change shape depending on what they are doing (e.g., walking, sitting, etc.).© Educational Technology DivisionMinistry of Education, Singapore 2005Page 2 students’ immersion, exploration and manipulation of computer-generated, 3-dimensional, multimedia environments in real time. Thus, simulations can easily exist within a 3D VLE. Just to draw a small distinction, a simulation may well be non-virtual and non-immersive. Examples of 3D VLEs, 3D VEs and interesting websites are cited in the Annex. Reasons for using 3D VLE in Teaching & Learning The main aim of the IT Masterplan 2 is to effectively harness technology to promote engaged learning. The 3D VLE has the potential to contribute positively to student engagement since the three-dimensional element reminds students of commercially available computer games. The immersive and interactive environment has the capability to ensure that students' engagement is positive and where the students' attention is willingly given and held (Chapman, Selvarajah & Webster, 1999). From the research literature, the following advantages have been associated with using 3D VLE for teaching and learning:digitalartefact 3D VirtualSpacepersonal homepage avatarreal-time chat space Figure 1. A screenshot from the 3D VLE, Quest Atlantis showing a scene of the user interface and elements of the interface.The novelty of the three-dimensional virtual reality environment (Byrne, 1992)• The sense of empowerment, control and interactivity (Byrne, 1996) & (Bricken, 1990) • The game-like experience, heightened levelsof motivation and extrinsic and intrinsic rewards (BECTA, 2001) & (Fromme, 2003) • The concretizing of objects to support visual learners (Yair, Mintz, & Litvak, 2001) • It supports a constructivist approach to learning. Students can learn by doing rather than, for example, reading. They can also test theories by developing alternative realities. This greatly facilitates the mastery of difficult concepts, for example the relation between distance, motion, and time or abstract science concepts (Yair, Mintz, & Litvak, 2001) • The allowance of greater self-awareness, support for interaction, and the enabling of real-time collaboration (Jonassen, 2000), (Schrage, 1990) & (Schwienhorst, 2002) • The ability to situate students in environments and contexts unavailable © Educational Technology Division Ministry of Education, Singapore 2005Page 3within the classroom (Yair, Mintz, & Litvak, 2001)• The ability to scaffold student learning (Jiang & Potter, 1994) & (Follows, 1999).EngagementThere is a myriad of definitions for the term engagement. What is apparent about the definitions of engagement is that they entail some kind of mindfulness (the trait of staying aware of or paying close attention to), cognitive effort and attention. Engagement is not an absolute term. In general, engaged students comply with minimal requirements of a given task and disengaged students go off-task (Bangert-Drowns & Pike, 2001). However, there are different levels of engagement that one can attain. The engagement can either be classified as high or low.Points to note before making use of 3D VLE in TeachingAlthough the idea of using a 3D VLE to motivate and engage students in learning is an attractive and worthwhile venture, the following must always be kept in mind.Scaffold LearningAnecdotal experiences indicate that problems may arise in 3D VLE without appropriate guidance and support for students (Ge, Yamashiro & Lee, 2000). The teacher needs to scaffold a lesson to ensure that his students are able to follow the lesson and learn. One must be aware of the two different levels of scaffolds. The first level takes place before the lesson begins and the next level of scaffolding is determined by the structure of the lesson in the 3D VLE itself. The first level takes place at the start of the lesson, that is, before even the students start using the computers. Pre-lessonbriefings, teacher demonstrations and guided worksheets are some examples of such scaffolds. Pre-lesson briefings help students to understand what to expect, what to accomplish and also allow students to clarify any doubt. The teacher should also conduct a demonstration in the 3D VLE so that the students do not lose their way or be distracted by irrelevant elements in the 3D space. A guided worksheet to direct students through the different tasks may be helpful and a map may be included if the 3D space is potentially complex or a flowchart sequencing the tasks may be required if the task online is potentially complex.Know your StudentsTeachers often develop comprehensive lesson plans with elaborate instructional objectives without really taking the student and his/her skill set into account. It is essential that the teacher first understand his/her students before embarking on the use of a particular 3D VLE. Some online tasks may require students to have specific IT skills, for example, they may need to ‘cut and paste’ information from websites or even access certain software outside the 3D VLE, like Microsoft Word or PowerPoint. Students who do not already have this IT skill may experience cognitive overload since they have to grapple with the task together with such IT related issues.Know the 3D VLEFrom experience, students appear upset, nervous, and lost when an unforeseen technical problem, such as being suddenly disconnected from the 3D VLE, occurs. Thus, the teacher should be able and prepared to troubleshoot when the need arises. For example, should the 3D VLE environment suspends during the lesson, the teacher should be able to re-start the system© Educational Technology Division Ministry of Education, Singapore 2005Page 4independently; this ensures that valuable curriculum time is maximized on uptime. Needless to say, the teacher should know how to use the 3D VLE chosen for the lesson. This will be useful since students often ask ‘how’ questions when exploring the 3D VLE. Inaddition, before the students use the 3D VLE,the teacher may be required to handle useradministration issues from the assignment of user identifications and passwords to the settingup of the different tasks in the 3D VLE forstudents to gain access.Are 3D VLE gender biased since they are oftenviewed as or considered games? It has beenconstantly reported in research that boys play more video games per week than girls. However, it was also found that girls were more likely than boys to list educational games as favorites, but that for both boys and girls, there was a decreasing preference for educational games from fourth through eighth grade (Buchman & Funk, 1996). This simply tells usthat the teacher needs to keep this issue in mindand be aware that using a 3D VLE in teachingmay not necessarily achieve heightened levels ofengagement.Engagement in 3D space versus Engagement with the ContentTeachers cannot always assume that students areengaged with the content even if they arelooking intently at the computer screens and notcausing any disruption during the lesson.A student can be engaged within the 3D VLE and roam aimlessly around the 3D space, for his/her own entertainment, thus, not engaging with the content at all. Indicators of suchdisengagement with content include thefollowing: Moving around in the 3D space and not engaging in the task;Unreasonable delay in submitting work required by the task; andHanding in shoddy and/or incomplete work.Once the teacher notices such indicators, intervention is necessary to get the student backon course and engaged with the content. The teacher needs to investigate the reason for the student not engaging with the content. The reasons may vary from willfully refusing to engage in the task to not being able to understand what the task requires of them. Conclusion There is a need to reiterate that one must not use technology for the sake of it. The use of technologies like the 3D VLE needs to fit into and add value to the lesson. Most 3D VLE is in line with inquiry based learning 2 and thisencourages self-directed and independent learning. Undoubtedly, 3D VLE has a part to play in education as it possesses the potential to motivate learning and engage students.2Inquiry based learning begins with questioning andmaking connections with students’ current knowledge. Thereafter, students plan and investigate the issue througha series of activities. They then record and report their findings and finally reflect on their findings. For more information on inquiry based learning, refer to/Blackboard/P2SST2/inqu.htm .© Educational Technology Division Ministry of Education, Singapore 2005AnnexQuest Atlantis (3D VLE)/River City (3D VLE)/muvees2003/index.htmMonja Kids/monjakids/Moon Base (3D VE)/Interesting Sites on 3D Worlds1 3D Portal/2 Active Worlds In Education/edu/index.asp3 Shop In 3D/aw2.html4 Virtual Worlds Learning Resources/virtual/home.htmReferencesBangert-Drowns, R. & Pike, R. (2001). A taxonomy of student engagement with educational software : an exploration of literate thinking with electronic text. Journal of Educational Computing Research, 24(3).BECTA (2001). What Aspect of Games Contribute to Education. Computer Games in Education Project.Retrieved on April, 10, 2005 from/technology/software/curriculum/computergames/index.htmPage 5 Ministry of Education, Singapore 2005Page 6Bricken, W. (1990). Learning in Virtual Reality (Technical Memorandum M-90-5). University ofWashington.Bryson, S. Survey on the Virtual Environment Technologies & Techniques. Retrieved April 4, 2005 from pgraf.ufu.br/alexandre/cg/vr.survey.pdfByrne, C.M. (1992). Summer students in virtual reality : a pilot study on educational applications of VRtechnology, paper presented at the annual meeting of American educational research association, San Francisco . (ERIC Document Reproduction Service No ED358853)Byrne, C.M. (1996). Water on Tap : The Use of Virtual Reality as an Educational Tool . Unpublisheddoctoral dissertation. University of Washington, Seattle, WA.Buchman, Debra D., & Funk, Jeanne B. (1996). Video and computer games in the '90s: Children's timecommitment & game preference. CHILDREN TODAY, 24(1), 12-15.Chapman, P. Selvarajah, S. & Webster, J. (1999). Engagement in Multimedia Training Systems.Proceedings of the 32nd Hawaii International Conference on System Sciences, 1-9.Follows, S. B. (1999). Virtual Learning Environments . T.H.E. Journal Online, November 1999.Retrieved March 5, 2005, from /magazine/vault/articleprintversion.cfm?aid=2374Fromme, D. (2003). Computer Games as a Part of Children's Culture. The International Journal ofComputer Game Research , Vol. 3(1), May 2003.Jiang, Z., & Potter, W. D. (1994). A computer microworld to introduce students to probability. Journal ofComputers in Mathematics and Science Teaching, 13(2)Ge X., Yamashiro K. A. & Lee J. (2000). Pre-class Planning to Scaffold Students for OnlineCollaborative Learning Activities. Educational Technology & Society 3(3) 2000. Retrieved April 12, 2005, from /periodical/vol_3_2000/b02.htmlJonassen D. H. (2000). Computers as Mindtools for Schools : Engaging Critical Thinking . Merrill,Prentice Hall, Second Edition.Schrage, M. (1990). Shared minds: The new technologies of collaboration . New York: Random House. Schwienhorst, K. (2002). Why virtual, why environments? Simulation and Gaming, 33 (2).Strangman, N. & Hall, T. (2003). Virtual reality & Computer Simulations. CAST Universal Design forLearning . Retrieved April 4, 2005 from /publications/ncac/ncac_vr.html#downloadWinn W., Hunter H., Hollander A., Osberg K., Rose H. & Char, P. (1997). The Effect of StudentConstruction of Virtual Environments on the Performance of High-and-Low Ability Students . A Paper presented at the Annual Meeting of the American Educational Research Association in Chicago. University of Washington.Yair, Y., Mintz, R., & Litvak, S. (2001). 3-D virtual reality in science education: An implication forastronomy teaching. Journal of Computers in Mathematics and Science Education 20, 3.© Educational Technology Division Ministry of Education, Singapore 2005。

第1篇Abstract:This case study investigates the effectiveness of project-based learning (PBL) in enhancing English language acquisition among secondary school students. The study focuses on a 10-week PBL project conducted in arural Chinese high school. Data were collected through observation, interviews, and students' reflective journals. The findings suggest that PBL not only improved students' English proficiency but also fostered critical thinking, collaboration, and self-directed learning skills.Introduction:The integration of project-based learning into language education has gained significant attention in recent years. PBL is an inquiry-driven approach that encourages students to learn by doing, solving real-world problems, and working collaboratively (Krajcik, Blumenfeld, & Marx, 2006). This case study aims to explore the impact of PBL on English language acquisition among secondary school students in a rural Chinese context.Methodology:The study was conducted in a rural high school in China, involving a total of 30 students in the 10th grade. The PBL project lasted for 10 weeks and was designed around the theme of "Cultural Exchange." The project involved the following stages:1. Introduction to the Project: Students were introduced to theproject's theme and goals, and they were divided into groups of four.2. Research and Planning: Each group was tasked with researching a specific culture, collecting information on cultural practices, traditions, and languages.3. Production: Students created a multimedia presentation, including videos, slideshows, and interactive activities, to showcase their findings.4. Presentation: Each group presented their project to the class, receiving feedback from their peers and the teacher.5. Reflection: Students reflected on their learning experience through written journal entries.Data were collected through the following methods:- Observation: The researcher observed students during the project, noting their engagement, collaboration, and problem-solving skills.- Interviews: Semi-structured interviews were conducted with the teacher and a few students to gather their perspectives on the PBL project.- Reflective Journals: Students kept reflective journals throughout the project, detailing their experiences, challenges, and learning outcomes.Results:The results of the study indicate that PBL had a positive impact on students' English language acquisition and development of other skills.1. English Proficiency: Students demonstrated significant improvement in their English proficiency, particularly in reading, writing, and speaking skills. This was evident in their research reports, presentations, and reflective journals.2. Critical Thinking: The PBL project encouraged students to think critically about the cultural differences and similarities between their own culture and the one they were studying. This helped them develop analytical skills and the ability to evaluate information.3. Collaboration: Students worked effectively in groups, sharing responsibilities and providing support to each other. This collaboration was evident in their joint research, production, and presentation of the project.4. Self-Directed Learning: The project empowered students to take ownership of their learning. They were motivated to explore new topics, seek additional resources, and develop their own ideas.5. Engagement and Motivation: The PBL project was well-received by the students, who reported feeling more engaged and motivated in their English classes. This was reflected in their increased participation in class discussions and activities.Discussion:The findings of this case study support the effectiveness of PBL in enhancing English language acquisition and fostering other important skills. PBL provides a more authentic and meaningful context for language learning, allowing students to apply their knowledge in real-world situations. Additionally, the collaborative nature of PBL encourages students to communicate and work together, which is essential for language development.Conclusion:This case study demonstrates the potential of project-based learning in improving English language acquisition and developing critical skills among secondary school students. The PBL project discussed in this study not only improved students' English proficiency but also fosteredcritical thinking, collaboration, and self-directed learning skills. Further research is needed to explore the long-term impact of PBL on students' language development and overall educational outcomes.References:- Krajcik, J. S., Blumenfeld, P. C., & Marx, R. W. (2006). Project-based learning: An evidence-based practice. In E. L. Baker & P. King (Eds.), International handbook of research on scientific literacy (pp. 9-30). Springer.第2篇Abstract:This case study explores the implementation of project-based learning (PBL) in an English language classroom to enhance student engagement and improve language proficiency. The study focuses on a semester-long English course for undergraduate students at a Chinese university. Thefindings reveal that PBL not only increased student motivation and participation but also improved their critical thinking and communication skills.Introduction:In recent years, there has been a growing interest in project-based learning (PBL) as an effective instructional approach in language education. PBL involves students in real-world tasks that require them to apply their knowledge and skills to solve complex problems. This approach has been shown to enhance student engagement, promote critical thinking, and improve language proficiency (Kang, 2014). This case study aims to investigate the impact of PBL on English language learning in a Chinese university setting.Methodology:The study was conducted over a semester at a Chinese university, involving an English course for undergraduate students. The course consisted of 15 weekly sessions, each lasting 90 minutes. The participants were 30 students, divided into six groups of five members each.The PBL approach was implemented in the following steps:1. Introduction to the Project: The teacher introduced the project topic and its relevance to real-life situations. Students were encouraged to brainstorm and share their ideas on the topic.2. Task Design: Each group was assigned a specific task related to the project topic. The tasks were designed to require students to use English in various contexts, such as writing, speaking, listening, and reading.3. Research and Collaboration: Students were expected to conduct research on the topic using both online and library resources. They were encouraged to collaborate and share information within their groups.4. Presentation and Reflection: At the end of the project, each group presented their findings to the class. The teacher facilitated areflective discussion to allow students to evaluate their learning process and the effectiveness of the PBL approach.Results:The implementation of PBL in the English language classroom had several positive outcomes:1. Increased Student Engagement: Students reported higher levels of engagement and motivation during the project-based learning activities. They were excited about the opportunity to work on real-world tasks and collaborate with their peers.2. Improved Language Proficiency: The tasks required students to use English in various contexts, which helped them improve their language proficiency. The teacher observed an increase in students' ability to express themselves clearly and coherently in English.3. Critical Thinking Skills: PBL encouraged students to think critically about the project topic. They were required to analyze information, evaluate different perspectives, and make informed decisions, which contributed to the development of their critical thinking skills.4. Communication Skills: The collaborative nature of PBL allowed students to practice their communication skills. They had to negotiate, persuade, and convince their peers, which helped them become more effective communicators.Discussion:The findings of this case study suggest that project-based learning can be an effective approach to enhance student engagement and improve language proficiency in English language classrooms. The active learning environment created by PBL promotes a deeper understanding of the subject matter and encourages students to take ownership of their learning process.However, there were also some challenges associated with the implementation of PBL. For instance, some students found it difficult to collaborate effectively within their groups, and others were concernedabout the time required to complete the tasks. The teacher had to address these issues by providing clear guidelines and support to the students.Conclusion:This case study provides evidence that project-based learning can be a valuable tool for English language teachers looking to enhance student engagement and improve language proficiency. By incorporating real-world tasks and encouraging collaboration, PBL can create a dynamic and interactive learning environment that promotes critical thinking and communication skills. Future research could explore the long-term impact of PBL on student learning and the effectiveness of different PBL strategies in diverse educational settings.References:Kang, S. (2014). Project-based learning in English language teaching: A case study of college English. Language Learning, 64(2), 529-558.第3篇Abstract:This case study explores the implementation of project-based learning (PBL) in an English language classroom. The study focuses on a 10-week module in an intermediate-level English course at a local university in China. The aim was to investigate how PBL could enhance student engagement, improve language proficiency, and foster critical thinking skills. This paper provides an overview of the project design, implementation, and outcomes, highlighting the challenges faced and the lessons learned.Introduction:In recent years, there has been a growing interest in project-based learning as an effective approach to teaching and learning in various educational settings. PBL involves students in active learning through the completion of projects that are real-world oriented, collaborative, and require critical thinking and problem-solving skills (Kirschner,Sweller, & Clark, 2006). This case study aims to explore the effectiveness of PBL in an English language classroom, specifically focusing on student engagement and language proficiency.Background:The study was conducted in a local university in China, where the majority of students are non-native English speakers. The participants were 30 students enrolled in an intermediate-level English course. The course aimed to improve students' overall language proficiency,including reading, writing, speaking, and listening skills.Methodology:The study employed a mixed-methods approach, combining quantitative and qualitative data collection. The data were collected through pre-and post-tests, project evaluations, student reflections, and interviews with the instructor.Project Design:The PBL module lasted for 10 weeks and was structured around a central theme: "Globalization and its Impact on Culture." The project required students to work in groups of four to research a specific aspect of globalization and its effect on culture. The project objectives were as follows:1. To research a specific aspect of globalization and its impact on culture.2. To present their findings in a creative and engaging format.3. To develop critical thinking and problem-solving skills.4. To enhance collaboration and communication skills.The project was divided into several stages:1. Introduction (Weeks 1-2): Students were introduced to the project theme and its objectives. They were provided with background information and resources to help them start their research.2. Research and Planning (Weeks 3-6): Students worked in groups to research their chosen aspect of globalization. They were required to use various sources, including academic articles, books, and online resources. They also had to plan their presentation and decide on the format.3. Presentation and Feedback (Weeks 7-8): Students presented their research findings to the class. They were evaluated on the content, organization, presentation skills, and engagement with the audience.4. Reflection and Evaluation (Weeks 9-10): Students reflected on their project experience and provided feedback on the project and their peers. They also received feedback from the instructor.Implementation:The instructor played a crucial role in facilitating the project-based learning process. They provided guidance and support throughout the project, ensuring that students were on track and able to meet the project objectives. The instructor also encouraged collaboration and communication among students, and facilitated peer feedback sessions.Outcomes:The outcomes of the PBL module were evaluated through various means:1. Pre-and Post-Tests: The students' language proficiency was assessed through pre-and post-tests. The results showed a significant improvement in reading, writing, and speaking skills.2. Project Evaluations: The students' project presentations were evaluated by both the instructor and their peers. The evaluations focused on the content, organization, presentation skills, and engagement with the audience.3. Student Reflections: Students were asked to reflect on their project experience and provide feedback on the project and their peers. The reflections indicated that the project was engaging and provided valuable learning opportunities.4. Interviews with the Instructor: The instructor's perspective on the project was also gathered through interviews. The instructor highlighted the positive impact of PBL on student engagement and language proficiency.Discussion:The results of this case study suggest that project-based learning can be an effective approach to teaching English in a higher education setting. The PBL module in this study demonstrated several benefits:1. Enhanced Student Engagement: The project-based learning approach engaged students in active learning, fostering a more dynamic and interactive classroom environment.2. Improved Language Proficiency: The project required students to use English in various contexts, leading to an improvement in their overall language proficiency.3. Fostering Critical Thinking Skills: The research and presentation stages of the project encouraged students to think critically and solve problems.4. Promoting Collaboration and Communication: The collaborative nature of the project helped students develop important teamwork and communication skills.Challenges and Lessons Learned:Despite the positive outcomes, the study also identified several challenges associated with implementing PBL in an English language classroom:1. Time Management: The project required students to manage their time effectively, which was challenging for some students.2. Group Dynamics: Ensuring that all group members contributed equally to the project was a challenge for the instructor.3. Assessment: Evaluating the project was time-consuming and required careful consideration of various factors.Conclusion:This case study provides evidence that project-based learning can be an effective approach to teaching English in higher education. The project-based learning module in this study demonstrated positive outcomes in terms of student engagement, language proficiency, and critical thinking skills. While challenges were encountered, the lessons learned from this experience can inform future PBL implementations in English language classrooms.References:Kirschner, P. A., Sweller, J., & Clark, R. E. (2006). Why minimal guidance during instruction does not work: An analysis of the failure of constructivist, discovery, problem-based, experiential, and inquiry-based teaching. Educational Psychologist, 41(2), 75-86.。

不完整多视图聚类综述

董瑶;付怡雪;董永峰;史进;陈晨

【期刊名称】《计算机应用》

【年(卷),期】2024(44)6

【摘要】多视图聚类是近年来图数据挖掘领域的研究热点。

由于数据采集技术的限制或人为因素等原因常导致视图或样本缺失问题。

降低多视图的不完整性对聚类效果的影响是多视图聚类目前面临的重大挑战。

因此,综合研究不完整多视图聚类(IMC)近年的发展具有重要的理论意义和实践价值。

首先,归纳分析不完整多视图数据缺失类型;其次,详细比较基于多核学习(MKL)、矩阵分解(MF)学习、深度学习和图学习这4类IMC方法,分析代表性方法的技术特点和区别;再次,从数据集类型、视图和类别数量、应用领域等角度总结22个公开不完整多视图数据集;继次,总结评价指标,并系统分析现有不完整多视图聚类方法在同构和异构数据集上的性能表现;最后,归纳分析不完整多视图聚类目前存在的问题、未来的发展方向和现有应用领域。

【总页数】10页(P1673-1682)

【作者】董瑶;付怡雪;董永峰;史进;陈晨

【作者单位】河北工业大学人工智能与数据科学学院;河北省大数据计算重点实验室(河北工业大学);河北省数据驱动工业智能工程研究中心(河北工业大学)

【正文语种】中文

【中图分类】TP391.4

【相关文献】

1.生成式不完整多视图数据聚类

2.基于多阶近邻融合的不完整多视图聚类算法

3.面向不完整多视图聚类的深度互信息最大化方法

4.基于自表示和投影映射的不完整多视图聚类

5.基于多阶近邻约束的深度不完整多视图聚类方法

因版权原因,仅展示原文概要,查看原文内容请购买。

DCWIndustry Observation产业观察161数字通信世界2024.041 研究背景研究之初,我们对西南地区多家动画制作企业的校企融合模式进行调查,结果显示,绝大多数合作模式表象是新型学徒制或现代学徒制,但本质还是企业将项目外包给高校,由高校教师和学生负责制作,而企业的参与度相对较低,主要在项目分配和验收阶段参与。

这种模式存在一些问题,包括项目与实际需求的脱节和学生职业技能的有限培养。

我们与成都云顶动画有限公司进行合作并通过一个实际的三维动画电影项目探寻更加适合的校企融合方式,包括共建项目团队、实习和导师制度、深度项目合作以及持续反馈机制,以提高合作效率和学生就业竞争力。

本研究将从三维动画设计与制作产教融合的理论分析、师生参与三维动画电影的创作过程实践教学以及产业发展等多个角度,深入探讨这一主题,并为产教融合在数字媒体设计领域的实践提供建议和展望。

2 产教融合的理论分析产教融合是指产业界和教育界之间建立紧密联系与合作,将教育培训与产业需求有机结合的一种教育模式。

它的目标是通过将教育和产业实践紧密结合,为学生提供更接近实际工作环境的培训和教育,培养出更符合产业发展需求的人才。

在三维动画电影的设计和创作过程中,产教融合可以体现在多个方面。

(1)前期策划阶段:这一阶段主要包括故事构思、剧本创作、角色设计、场景设计等。

在教学中,可以通过让学生参与这一阶段的工作,来训练他们的创新思维和艺术审美。

(2)中期制作阶段:这一阶段主要是根据设计稿,用三维软件进行模型的建造、材质制作、灯光构建、动作制作等。

此阶段应是学生主要参与的工作阶段,可以让学生了解和学习三维动画制作原理和方法,并通过实践操作,学习相关的技术和技巧,提高他们作者简介:姚缙轩(1990-),男,汉族,助教,本科,研究方向为高职数字媒体艺术教育。

基于原创三维动画电影制作探索产教融合方式姚缙轩(眉山职业技术学院,四川 眉山 620010)摘要:文章以一个三维动画电影项目为案例,深入探讨了产教融合在动画电影制作领域的实际应用,研究发现,通过采用一种创新的合作模式,企业在项目进程中扮演主导角色,学生和教师积极参与,可以实现教育与产业的有机结合。

第20卷第1期2021年2月Vol.20No.lFeb.2021浙江医学教育Zhejiang Medical Education•教学研究与管理・3D打印模型结合PBL教学法在骨盆骨肿瘤临床教学中的应用孙凌凌,李冰皓,潘伟波@(浙江大学医学院附属第二医院,浙江杭州310009)摘要:目的:以骨盆骨肿瘤临床教学为例,研究3D打印模型结合以问题为基础的教学方法(PBL)在住院医师规范化培训中的应用价值。

方法:选取2019年7-12月在我院参加住院医师规范化培训的住院医师50名,随机分为试验组(3D打印模型结合PBL教学法)和对照组(传统教学法)各25名,比较2组规培生考试成绩及教学调查问卷评分。

结果:试验组学生理论知识成绩(39.0± 4.1)高于对照组(34.0± 5.9)(P<0.05);试验组病例分析得分(40.2± 3.3)高于对照组(36.3± 4.7)(P<0.05);问卷评分显示试验组在激发自主学习兴趣、提高临床思维能力、增加知识的理解、增强实际工作能力及对教师的满意度均高于对照组(P V0.05)o结论:运用3D打印模型结合PBL的教学模式在骨科住院医师规范化培训骨盆骨肿瘤临床教学中取得了良好的效果,有利于提高教学质量和培养学生的临床思维能力。

关键词:PBL;3D打印模型;住院医师规范化培训;骨肿瘤中图分类号:G642.44文献标识码:B文章编号:1672-0024(2021)01-0024-03Application of3D Printing Model Combined with PBL Teaching Method forStandardized Training of Residents in Clinical Teaching of Pelvic Bone TumorSUN Lingling,LI Binghao,PAN Weibo@(The Second Affiliated Hospital,School of Medicine,Zhejiang University,Hangzhou310009,China)Abstract:[Objective]To study the application value of3D printing model combined with problem-based learning(PBL)in clinical teaching of pelvicbone tumor for residents of standardized training.[Method]From July2019to December2019,50 residents who participated in the standardized training in our hospital were randomly divided into two groups:the experimental group(3D printing model combined with PBL teaching method)and the control group(traditional teaching method).The test scores and teaching questionnaire scores of the two groups were compared.[Result]Compared with the control group's scores of theoretical knowledge(34.0± 5.9),the test group's scores(39.0± 4.1)were higher(P<0.05).The test group5s case analysis scores(40.2± 3.3)were also higher than that of the control group(36.3± 4.7)(P<0.05).The test group had higher scores than the control group in stimulating interest in autonomous learning,improving clinical thinking ability,increasing understanding of knowledge,enhancing practical work ability and teacher satisfaction,all with statistically significant differences.[Conclusion]3D printing model combined with PBL teaching method has achieved good results in the standardized training of pelvicbone tumor clinical teachingand is beneficial to improve the quality of teaching and cultivate clinical thinking for orthopedic residents.Key words:PBL;3D printing model;bone tumor;clinical teaching作者简介:孙凌凌(1982-),男,浙江余杭人,博士研究生,主治医师。

科学家开发出三维光学存储新技术

佚名

【期刊名称】《现代科学仪器》

【年(卷),期】2010(0)5

【摘要】法国昂热大学的卡拉曼利斯·伊利奥普洛斯和同事设计出了一种新的非线性光学(NLO)香豆素类聚合物。

他们解释道,在不同波长光的照射下,这种聚合物能可转化为二聚物(由两个相同的小分子组成的大分子,可能具有单一小分子没有的性质或功能)。

波长大于300纳米的光波会产生二聚物;而波长小于280纳米的光波则会将二聚物分离成两个独立的分子。

由于每类分子都带电,并且分子结构也不相同,因此,使用光学方法控制这个可逆转过程便可对数据进行写入、读出、删除、修改等操作。

【总页数】1页(P60-60)

【关键词】光学存储;新技术;科学家;三维;开发;非线性光学;大分子;二聚物

【正文语种】中文

【中图分类】O437

【相关文献】

1.三维光学存储新技术 [J],

2.法国开发出三维光学存储新技术 [J],

3.中国科学家研发出光学存储加解密技术 [J],

4.法开发出三维光学存储新技术以香豆素类聚合物为存储载体 [J],

5.法开发出三维光学存储新技术 [J],

因版权原因,仅展示原文概要,查看原文内容请购买。

专逊撷显MBD技术在白车身生产中的应用研究口赵钢口袁宜友口徐本晔口徐美应奇瑞汽车股份有限公司安徽芜湖241009摘要:对基于模型的定义(MBD)技术在汽车白车身生产中的应用进行了研究。

介绍了应用MBD技术的路径,分析了三维标注流程和要%,开发了自定义工具,并给出了应用实例。

基于MBD技术,可以通过三维数字化模型完整表达产晶定位基准、公差、尺寸等定义信息,实现产晶全三维可视化,确保产晶三维数据信息源唯一,不需要出具二维图纸,为汽车公司各部门间实现三维数据在线协同提供基础支撑。

关键词:白车身基于模型的定义生产应用中图分类号:TH162;U463.82文献标志码:A文章编号:1000-4998(2020)06-0011-04Abstract:The application of the MBD technoloay in tOe automobiie body—in—white production was studied.The path of applying MBD technoloay was introduced%the3D labeling proces s and main points were analyzed%usef—deSned toois were developed%and application examples were given.Based on W c MBD Wchnolocy,the3D digital modd con fully express the definition information such as product positioning referenco%toleranco%size,etc.,and realize full3D visualization of the product.It con be ensured that the products3D dia information sourco is unique,and it does not need to issue2D drawings,se that it con provige basic support for the online collaboration of3D data between various departwents of the automobile tompany.Keywords:Bodyinwhitr BMD Production Application1研究背景MBD技术是一种在三维数据上承载建模设计定义、工艺过程描述、属性项、管理项等信息的先进数字化定义技术,MBD技术的实施使三维模型取代二维图纸成为可能。

第1篇Abstract:The recent English教研活动旨在通过集体研讨、案例分析、专家讲座和教学观摩等多种形式,提升教师的专业素养和教学能力。

本次活动吸引了来自不同学校的英语教师参与,共同探讨如何更好地教授英语,激发学生的学习兴趣,并提高教学效果。

以下是对本次教研活动的详细摘要。

I. IntroductionThe English教研活动 was organized with the primary goal of fostering a collaborative environment where teachers could share their experiences, exchange innovative teaching strategies, and enhance their professional development. The event was held over a period of two days and featured a variety of activities designed to cater to different aspects of English language teaching.II. Key Activities1. Opening Remarks and Keynote SpeechThe event commenced with an opening address by the head of the English department, who emphasized the importance of continuous professional development in the field of English language teaching. The keynote speech, delivered by a renowned linguist, highlighted the latest trends in language education and the role of technology in shaping modern classroom practices.2. Workshops and Interactive SessionsA series of workshops were conducted to address specific areas of concern in English teaching. These included:- Fluency and Pronunciation Techniques: A workshop focused on practical methods to improve students' speaking skills and pronunciation.- Integrating Technology in the Classroom: Participants explored various digital tools and platforms that can be used to enhance learning experiences.- Assessment Strategies: An interactive session on effective assessment methods that provide meaningful feedback to both students and teachers.3. Case Studies and Group DiscussionsParticipants engaged in case studies that presented real-life scenarios faced by English teachers. These cases were discussed in small groups, allowing teachers to analyze the issues, propose solutions, and share their insights with the larger group.4. Expert Lecture SeriesRenowned educators and subject matter experts delivered a series of lectures on topics such as:- The Role of Language in Culture: Exploring how language reflects and shapes cultural identity.- Student-Centered Learning: Strategies for creating a classroom environment that promotes active learning and critical thinking.- Special Educational Needs in English Language Teaching: Addressing the challenges of teaching students with diverse learning styles and needs.5. Teaching Observations and Peer FeedbackTeachers observed each other's lessons and provided constructive feedback. This activity aimed to promote reflective practice and encourage continuous improvement in teaching methods.III. Outcomes and ImpactThe English教研活动 was met with overwhelming positive feedback from participants. Key outcomes and impacts of the event include:- Enhanced Professional Development: Teachers gained new insights into effective teaching strategies and left the event with a wealth of resources and ideas to implement in their classrooms.- Increased Collaboration: The event fostered a sense of community among teachers, encouraging them to collaborate and support each other intheir professional growth.- Improved Teaching Practices: Through the use of case studies, workshops, and peer observations, teachers were able to identify areas for improvement in their teaching methods and apply new techniques immediately.- Student Learning: The focus on student-centered learning and the integration of technology in the classroom are expected to lead to improved learning outcomes for students.IV. ConclusionThe English教研活动 served as a platform for teachers to come together, learn from each other, and collectively strive for excellence in English language teaching. By emphasizing the importance of professional development, collaboration, and reflective practice, the event has laid a solid foundation for ongoing improvement in the field. The insights and strategies shared during the event will undoubtedly contribute to the continued growth and success of English language teaching in our schools.V. Recommendations for Future ActivitiesBased on the success of this year's English教研活动, the following recommendations are made for future events:- Regular Follow-Up Workshops: Organize follow-up workshops to provide ongoing support and guidance to teachers as they implement new teaching strategies.- Networking Opportunities: Create a platform for ongoing communication and collaboration among teachers, such as a virtual community or regular meet-ups.- Focus on Specialized Areas: Tailor future events to address specific areas of need or emerging trends in English language teaching.- International Collaboration: Explore opportunities for international collaboration to bring diverse perspectives and experiences into the local English teaching community.In conclusion, the English教研活动 has proven to be a valuableinitiative that has benefited both teachers and students. With continued dedication to professional development and collaboration, the quality of English language teaching in our schools will undoubtedly continue to improve.第2篇Introduction:The English Department of [School Name] recently organized a comprehensive teaching and research activity aimed at enhancing the quality of English language instruction and promoting professional development among faculty members. The event featured workshops, guest lectures, and interactive sessions, providing a platform for teachers to share their experiences, discuss innovative teaching methods, and explore new approaches to language learning. The following is a detailed summary of the key highlights of the activity.I. Opening Remarks and Welcoming AddressThe activity commenced with an opening ceremony, where the Head of the English Department delivered a welcoming address. He emphasized the importance of continuous professional development and the role of research in shaping effective teaching practices. The address was followed by a brief introduction to the agenda and expectations for the participants.II. Workshop on Innovative Teaching MethodsThe first session of the activity was a workshop on innovative teaching methods. Led by a renowned English language expert, the workshop focused on the following key areas:1. Flipped Classroom Model: Participants were introduced to the flipped classroom approach, which involves assigning video lectures for studentsto watch at home and using class time for interactive activities and discussions. The workshop provided practical tips on how to implementthis model effectively.2. Technology Integration: The importance of incorporating technologyinto language teaching was highlighted. Participants were encouraged to explore various digital tools and resources, such as online dictionaries, grammar checkers, and interactive learning platforms, to enhance their teaching and engage students more effectively.3. Project-Based Learning: The workshop emphasized the benefits ofproject-based learning, which encourages students to workcollaboratively on real-world tasks. Participants were guided throughthe process of designing project-based activities that promote critical thinking and language skills development.III. Guest Lecture on Assessment and EvaluationA guest lecture on assessment and evaluation was delivered by a leading educator in the field of English language teaching. The lecture covered the following topics:1. The Importance of Formative and Summative Assessment: The speaker emphasized the need for a balanced approach to assessment, incorporating both formative and summative assessments to monitor student progress and provide constructive feedback.2. Assessment Tools and Techniques: Participants were introduced to various assessment tools, such as quizzes, essays, presentations, and portfolios, and were provided with guidelines on how to design effective assessment tasks.3. Feedback and Reporting: The lecture highlighted the importance of providing timely and constructive feedback to students, as well as the role of progress reports and parent-teacher conferences in promoting student achievement.IV. Interactive Session on Classroom ManagementThe third session of the activity was an interactive session on classroom management. A panel of experienced teachers shared their insights and strategies for creating a positive and conducive learning environment. Key points discussed included:1. Building Rapport: The importance of establishing a strong rapport with students was emphasized. Participants were encouraged to engage in activities that promote trust and respect, such as icebreakers and group discussions.2. Setting Clear Expectations: Clear rules and expectations help maintain order in the classroom. The panel discussed the importance of communicating these expectations to students and following through consistently.3. Addressing Behavioral Issues: Strategies for dealing with behavioral issues were shared, including positive reinforcement, consequences, and collaboration with parents and administrators.V. Research Presentation and DiscussionThe final session of the activity was a research presentation and discussion. A faculty member shared their research findings on the effectiveness of a particular teaching method, followed by an open discussion among participants. The research focused on the following aspects:1. Methodology: The study employed a mixed-methods approach, combining quantitative and qualitative data to investigate the impact of the teaching method on student achievement.2. Findings: The research revealed that the teaching methodsignificantly improved students' language proficiency and engagement in the classroom.3. Implications for Practice: The findings provided valuable insightsfor educators looking to implement similar strategies in their own teaching practices.Conclusion:The English teaching and research activity was a resounding success, providing a valuable opportunity for faculty members to enhance their teaching skills, exchange ideas, and explore innovative approaches to language learning. The workshops, guest lectures, and interactive sessions not only fostered professional growth but also reinforced the importance of research in shaping effective teaching practices. As a result, the English Department at [School Name] is committed to continuing this tradition of excellence in teaching and research, ultimately leading to improved student outcomes and a more dynamic and engaging learning environment.第3篇Abstract:The English Department of [Institution Name] recently hosted a comprehensive教研 activity aimed at enhancing the quality of English language teaching and fostering a collaborative learning environment among faculty members. This abstract provides an overview of the objectives, activities, outcomes, and reflections of the event, which was attended by over 30 teachers from various departments across the institution.Introduction:The primary objective of the教研活动 was to explore innovative teaching methods, share best practices, and discuss strategies for addressing the diverse needs of English language learners. The event aimed to promote professional development, encourage peer collaboration, and ultimately improve student engagement and academic performance in English language courses.Objectives:1. To identify and discuss current challenges in English language teaching.2. To explore innovative teaching strategies and resources.3. To foster a collaborative learning environment among faculty members.4. To develop a comprehensive plan for professional development within the English Department.Activities:The教研活动 was structured into three main segments:1. Workshops and Presentations:- A series of workshops were conducted by experts in the field of English language teaching, covering topics such as flipped classrooms, project-based learning, and the use of technology in language instruction.- Faculty members presented their own experiences and best practices, allowing for a sharing of insights and ideas.2. Group Discussions:- Participants were divided into small groups to discuss specific challenges they faced in their teaching, such as student motivation, assessment strategies, and curriculum development.- Each group generated practical solutions and shared their findings with the larger group.3. Interactive Sessions:- An interactive session was held to showcase various teaching resources and technologies available to the department, including educational apps, online platforms, and digital textbooks.- Participants had the opportunity to try out these resources and provide feedback on their effectiveness.Outcomes:1. Enhanced Teaching Practices:- Faculty members reported a renewed enthusiasm for teaching and a desire to incorporate new strategies into their classrooms.- Participants developed a deeper understanding of the latest pedagogical trends and techniques.2. Increased Collaboration:- The event fostered a strong sense of community among the faculty, with many teachers expressing a willingness to collaborate on future projects and initiatives.- A collaborative platform was established to facilitate ongoing communication and resource sharing.3. Improved Student Engagement:- The implementation of new teaching methods and resources has led to increased student engagement and improved academic performance in English language courses.- Students have shown greater enthusiasm for learning and have become more active participants in the classroom.Reflections:1. Value of Professional Development:- Participants emphasized the importance of ongoing professional development in maintaining the quality of English language teaching.- The event highlighted the need for regular opportunities forfaculty members to learn from each other and stay updated on the latest educational trends.2. Collaborative Learning Environment:- The success of the教研活动 underscored the value of acollaborative learning environment, where teachers can support and inspire each other.- Faculty members expressed a strong belief that collaboration is key to addressing the diverse needs of students and creating a more dynamic and engaging learning experience.3. Future Directions:- The English Department plans to continue hosting similar教研活动on a regular basis, with a focus on specific themes and topics of interest to faculty members.- The department also aims to establish partnerships with other institutions and organizations to further enhance the quality of English language teaching.Conclusion:The教研活动 at [Institution Name] served as a valuable opportunity for faculty members to enhance their teaching practices, foster collaboration, and improve the overall quality of English language instruction. The event’s success has been attributed to the commitment of the faculty, the engagement of participants, and the innovative approaches explored during the workshops and discussions. As the department continues to evolve and adapt to the changing needs of its students, the insights gained from this event will undoubtedlycontribute to the ongoing success of its English language programs.。

3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015S9949: A new PBR Material serving Mobile, Web, Real-timeEngines and RaytracingJan Meseth (3DS)Marc Ellens (X-Rite)Pierre Maheut (Allegorithmic)Jan Jordan (NVIDIA)3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Motivation3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Design MarketingEngineeringimage courtesy of Opel3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015PowerwallVRARDesign MarketingEngineeringimage courtesy of OpelMobile3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015VRARPowerwallDesign MarketingEngineeringimage courtesy of OpelMobile3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015GGX PBR◆Different proposals♦Disney PrincipledBRDF♦Unreal 4 PBR Material ♦…◆Widely adopted ◆Very performant◆Not all relevant effects covered3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Component Models◆Many proposals♦MDL (Material Definition Language)♦OSL (Open Shading Language)♦…◆Widely adopted ◆Very expressive◆Hard to implement efficiently3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015New Proposal: Enterprise PBRGreat expressiveness at great performanceGGX PBRComponent modelEnterprise PBRp e r f o r m a n c eexpressiveness3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Proposed Appearance Model3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Enterprise PBR◆Design Goals♦Expressiveness–model most common materials♦Performance –AR / VR / mobile ♦Easeof use –few intuitive parameters♦Fitness forGlobal Illumination◆Inspired by existing GGX models3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Enterprise PBR –Base Layer ◆Albedo *◆Metallic *◆Roughness *◆Anisotropy *◆Normal Map *◆Transparency◆Cutout Opacity *◆Sheen *◆Specular *◆Specular Tint *◆Not:Sheen Tint3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015◆Clearcoat *◆Clearcoat Roughness *◆Not:♦Clearcoat IOR ♦Tinting ♦Thin Filmno coating coating glossy coatingcoating glossy coating coating3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015◆Flake Color ◆Flake Density ◆Flake Roughness ◆Flake Size ◆Not:♦Differentiation Flip vs. Flop ♦Roughness of individual flakes replace roughness size densitycolor color color3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Enterprise PBR –Emission Layer ◆Emission color * (normalized or not)◆Emission value (in lm/m² or lm)◆Not:♦Goniometric profile spheres with 1 lm spheres with 1 lm/m²3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Enterprise PBR –Volume Layer ◆Thin Walled ◆IOR ◆Attenuation Color ◆Attenuation Distance ◆Subsurface Color *◆Not:♦Phase Functionthin thick IOR 2.5roughgreenish SSS3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Energy Preservation ◆Previous PBR models: energy conservation ◆Enterprise PBR: also energy preservation / multi-scattering ◆Solutions: ♦Lookup table ♦Approximation via closed formularoughness = 0roughness = 1; no preservation roughness = 1; preservation3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Implementation in 3DS engines3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Path tracer OpenGL 4.6WebGL3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Path tracer OpenGL 4.6WebGL3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Consistency in different Engines Path tracer (GI)OpenGL 4.6 (OGL)WebGL (Web)in collaboration with3DS .COM©DassaultSy stème s|C onfi denti alIn fo rma ti on|3/18/2019|r ef.:3DS_Docume nt_2015Consistency in different Engines (with baking)OGL Web in collaboration with3D S .C O M © D a s s a u l t S y s t èm e s | C o n f i d e n t i a l I n f o r m a t i o n | 3/18/2019| r e f.: 3D S _D o c u m e n t _2015Enterprise PBR –Github project◆Published on Github https:///DassaultSystemes-Technology/EnterprisePBRShadingModel ♦Specification ♦User Guide ♦Images ♦Format Example (based on glTF 2.0)◆Target: Evolve into widely used standard3DS .COM©DassaultSy stème s|C onfi denti alIn fo rma ti on|3/18/2019|r ef.:3DS_Docume nt_2015EcosystemCreating and Using Enterprise PBRWHO WE AREMETHODS TO GENERATE DIGITAL MATERIALSTOTAL APPEARANCE CAPTUREIS THE DIGITIZATION OF MATERIALSWITH TRUE, FULLAPPEARANCE MEASUREMENT .TEXTURESCANNER ARTISTIC PROCESSES FULLAPPEARANCE MEASUREMENTPLAUSIBLE COLOR DECLINING ACCURACY WITH INCREASING MATERIAL COMPLEXITYARBITRARY RESULTS DEPENDING ON ARTISTIC SKILLS OF OPERATOR TYPICALLY OPTIMISED FOR A SPECIFIC SCENE PHYSICALLY CORRECT AS BASED ON MEASUREMENTS HIGH ACCURACY EVEN FORCOMPLEXMATERIALSSCENE INDEPENDENTAccuracyCOMMUNICATETHE APPEARANCE EXCHANGE FILE FORMATTHE AxF FILE IS THE DIGITAL TWINOF A PHYSICAL MATERIAL SAMPLECOMPRISING, FULL APPEARANCEMEASUREMENT INFORMATION PLUSMETADATA.AxF MATERIAL FORMATS MEASURED MATERIALS SVBRDFWardGGXEP-GGX (Dassault Systems) CarPaint(BTF/BRDF Hybrid) Translucent PlasticEP-GGX in AxF 1.7DEFAULT SVBRDF MATERIAL MODEL EP-GGXAxF 1.7GGX AxF 1.5MeasuredIncreasing Roughness ConvertedCAPTURETHE TAC7 SCANNEREDIT AND MANAGETHE PANTORA DIGITAL MATERIAL HUB VISUALIZETHE VIRTUAL LIGHT BOOTHDEMOMDL and Enterprise PBRbridging worldsMarch 18, GTC San Jose 2019Jan Jordan Software Product Manager MDLThe NVIDIA Material Definition Language (MDL)•is technology developed by NVIDIA•to define physically-based materials•for physically-based rendering solutions.•Materials are defined by combining elementalbuilding Blocks (BSDF)More info:S9346Sharing Physically Based Materials betweenRenderers with MDL (https:////mdl3940Diffuse Transmission Spec. Refl.+Transm.Glossy (various)MDL Materials: combinations of (X)DF Diffuse Reflection Fresnel Layer Measured Curve Layer Custom Curve Layer BSDF building blocks (subset)Recursive layering and mixing of DF +Complex example4 anisotropic glossy highlights + translucencyMDL vs. Enterprise PBRWhen to use MDL-if your users often have exotic requirements for materials-if you want to give users choice about material interfaces and features-if flexibility in content creation is key When to use Ubershaders-if your users are ok with you choosing a material interface for them-if you need performance guarantees (VR, Games)-if most work is using a similar set of materialsBridging worlds: going there…Fixed Material ModelMDL MaterialComplex BSDF layering Complex proceduralsSimple BSDF structureOne texture per parameterImplementing Ubershaders in MDLFixed Material ModelMDL MaterialComplex BSDF layering Complex proceduralsSimple BSDF structureOne texture per parameterImplementationMDL is powerful enough to implement common physically based Ubershaders.Sharing of content is reduced to sharing of parameter values and textures.Bridging worlds: …and coming backFixed Material Model MDL MaterialComplex BSDF layering Complex procedurals Simple BSDF structure One texture per parameterDistillation to Fixed Material ModelFixed Material Model MDL MaterialComplex BSDF layering Complex proceduralsSimple BSDF structureOne texture per parameter DistillationDistillation to Fixed Material ModelFixed Material ModelMDL MaterialComplex BSDF layering Complex proceduralsSimple BSDF structure One texture per parameterDistillationtextex tex tex texMaterialdiffuse specular glossy kurtosis normalfctbsdfbsdffct fctfct fct fct fct fct fctbsdfbsdffctfctfct fct bsdf bsdfbsdfDistillation to Fixed Material ModelFixed Material ModelMDL MaterialComplex BSDF layering Complex proceduralsSimple BSDF structure One texture per parameterDistillationtextex tex tex texMaterialdiffuse specular glossy kurtosis normalfctbsdfbsdffct fctfct fct fct fct fct fctbsdfbsdffctfctfct fct bsdf bsdfbsdfApproximate render result: Some materials will look quite differentDistillation to Fixed Material ModelFixed Material ModelMDL MaterialComplex BSDF layering Complex proceduralsSimple BSDF structure One texture per parameterDistillationtex tex tex tex texMaterialdiffuse specular glossy kurtosis normalfct bsdfbsdffct fctfct fct fct fct fct fctbsdfbsdffctfctfct fct bsdf bsdfbsdfFast projection of material instances: Realtime editingApproximate render result: Some materials will look quite differentMDL DistillingReleased as part of Iray/MDL SDKMultiple distilling targets (diffuse only, diffuse_glossy, UE4)GLSL rendering sample using Distilling and bakingMDLUE4。

Suggestions for Improving Online Classes In the era of digital transformation, online classes have become an integral part of education, enabling students to learn from anywhere and anytime. However, as with any new mode of learning, online classes also present certain challenges and areas for improvement. This essay aims to explore suggestions for enhancing the quality and effectiveness of online classes.Firstly, it is crucial to enhance the interaction between teachers and students. Unlike traditional classrooms, online classes often lack the face-to-face interaction that fosters a sense of community and engagement. To address this, teachers can utilize interactive tools such as polls, chat features, and real-time question-and-answer sessions. These tools not only allow teachers to gauge students' understanding but also encourage active participation, leading to a more engaging learning experience.Secondly, online classes should incorporate more multimedia content. Visual and auditory aids, such as videos, animations, and audio clips, can significantlyenhance the learning process. These multimedia elements make abstract concepts easier to grasp and retain, thus improving comprehension and recall. Teachers can incorporate these elements into their lectures or assign them as supplementary materials for students to explore further.Thirdly, online classes should provide personalized learning paths. Every student learns differently, and online platforms have the potential to cater to individual learning styles and paces. By utilizing adaptive learning algorithms and personalized learning plans, online classes can ensure that students are challenged appropriately and progress at their own speed. This approach not only boosts student motivation but also ensures that they master the concepts effectively.Furthermore, it is essential to ensure the technical stability of online classes. Frequent technical issues, such as lags, glitches, or audio/video problems, can disrupt the learning process and frustrate both teachers and students. Therefore, it is vital to invest in reliable technology and infrastructure to ensure a smooth onlinelearning experience. Regular testing and maintenance of the platform can also help mitigate any potential technical issues.Lastly, online classes should promote collaboration and teamwork. Although online learning can be isolating, it also presents opportunities for students to work togetherin virtual environments. Teachers can encourage group projects, collaborative discussions, and peer reviews to foster a sense of community and cooperation among students. These collaborative activities not only enhance learning outcomes but also develop important skills such as communication, teamwork, and critical thinking.In conclusion, improving online classes requires a multifaceted approach that addresses interactivity, multimedia content, personalized learning, technical stability, and collaboration. By incorporating these suggestions, online classes can become more engaging, effective, and enjoyable for both teachers and students, paving the way for a more robust and inclusive educational experience in the digital age.**网课改进建议**在数字化转型的时代,网课已经成为教育不可或缺的一部分,使学生能够随时随地学习。

《Nature》采用3D形式出版尚玮姣【期刊名称】《图书情报工作动态》【年(卷),期】2009(000)001【摘要】《Nature》这周获得了新的进展,在它的第一个PDF文档中包含了一个立体交互式的图表。

在2009年1月1日出版的一期杂志中,一篇Alyssa Goodman和其同事们所写的论文中的图表使《Nature》的读者可以查看并转动分子云图。

【总页数】1页(P16)【作者】尚玮姣【作者单位】无【正文语种】中文【中图分类】G237.5【相关文献】1.A review on biocompatibility nature of hydrogels with 3D printing techniques, tissue engineering application and its future prospective [J], Jabran Saroia;Wang Yanen;Qinghua Wei;Kun Zhang;Tingli Lu;Bo Zhang2.国际顶级学术期刊出版机构作者服务体系建设经验与借鉴\r——以Springer Nature和Elsevier出版集团为例 [J], 刘杨3.Nature子刊《Nature:地球科学》正式出版 [J],4.谈应采用书面形式而未采用书面形式的合同 [J], 陈福胜[1];杨昌宇[2]5.Nature Inspired MXene-Decorated 3D Honeycomb-Fabric Architectures Toward Efficient Water Desalination and Salt Harvesting [J], Zhiwei Lei;Xuantong Sun;Shifeng Zhu;Kai Dong;Xuqing Liu;Lili Wang;Xiansheng Zhang;Lijun Qu;Xueji Zhang因版权原因,仅展示原文概要,查看原文内容请购买。

技术专题:C#

透明

【期刊名称】《程序员》

【年(卷),期】2002(000)004

【摘要】看到这一期《程序员》杂志的时候,你应该已经知道了Visual Studio.NET北京发布会的盛况。

无论你在哪个平台下开发,无论你是否喜欢微软,对于作为开发者的你来说,Visual Studio.NET都是一个不可不关心的新工具。

【总页数】1页(P54)

【作者】透明

【作者单位】无

【正文语种】中文

【中图分类】TP311

【相关文献】

1.技术专题精彩无限——科印网隆重推出系列技术专题 [J],

2.c++转向c#的疑惑:C# 中类间通信方法初探 [J], 朱伟

3.浅谈信息技术专题学习网站的设计与开发 [J], 杨净

4.传承创新再谱新篇——第十三届急、慢性创面治疗新技术专题系列研讨会暨浙江大学医学院附属第二医院广济学术周烧伤与创面修复论坛顺利召开 [J], 蒋妍妍;甘丽;杨立妍;孙永华

5.多语言计算前沿技术专题序言 [J], 黄河燕;颜永红;黄德根;余正涛;熊德意

因版权原因,仅展示原文概要,查看原文内容请购买。