PIC S VMP 验证主计划(中英文对照)

- 格式:pdf

- 大小:307.42 KB

- 文档页数:25

1 验证方针与目的1.1 验证方针➢GMP是保证生产出符合既定质量标准药品的唯一手段,而验证是证明和保证关键生产要素,包括设施、系统、仪器设备、生产工艺、分析方法、清洁规程以及消毒/灭菌规程符合既定要求的公认方法。

验证主计划是公司进行确认与验证的纲领性文件,指导公司在各项验证过程中,有组织,有计划,有步骤的进行,使各项验证必须依据计划起草、审批和实施,确保验证工作能够顺利进行和验证的有效性,为保证产品质量提供可靠的保障和依据。

➢鉴于验证工作的重要性,本公司将验证工作放在GMP管理体系的重要位置,并给予高度重视。

提出通过确认与验证确立控制生产过程的运行标准,通过对已验证状态进行监控,控制整个工艺过程,确保质量,并不断通过验证、建标、监控、再验证、再建标的循环动态控制为指导方针。

1.2 验证目的编制验证主计划是GMP(2010版)法规及附录《确认与验证》的要求。

➢GMP(2010版)法规要求:验证主计划中应当作出规定,确保厂房、设施、设备、检验仪器、生产工艺、操作规程和检验方法等能够保持持续稳定。

➢附录《确认与验证》的要求:⏹所有的确认与验证活动都应当事先计划。

确认与验证的关键要素都应在验证主计划或同类文件中详细说明。

⏹验证主计划应当至少包含以下信息:◆确认与验证的基本原则;◆确认与验证活动的组织机构及职责;◆待确认或验证项目的概述;◆确认或验证方案、报告的基本要求;◆总体计划和日程安排;◆在确认与验证偏差处理和变更控制的管理;◆保持持续验证状态的策略,包含必要的再确认和再验证;◆所引用的文件、文献。

⏹对于大型和复杂的项目,可制定单独的项目验证主计划。

文件编号:生效日期:第2 页共17页本验证主计划概括地描述了本公司应该进行的验证和确认活动的管理原则,包括验证方针、组织机构、范围领域、文件管理、计划安排、实施程序、简要方法和可接受标准等,以确保本公司的验证工作按照规定得到良好执行,满足新版GMP有关验证的要求。

验证主计划一、项目介绍1.1公司企业简介这里主要是对企业进行简单介绍,如:名称、地址、占地面积、生产车间数量、公用系统情况等。

描述企业的验证方针如:1)确定需要进⾏的确认或验证⼯作,以证明有关操作的关键要素能够得到有效控制。

2)确认和验证的范围和程度应根据⻛险评估的结果确认。

(采⽤最差状况⽅法来确定验证)。

3)确认与验证应当贯穿于产品⽣命周期的全过程。

4)⼚房、设施、设备或⼯艺的的重要变更可能会直接或间接影响到产品质量时,应进⾏确认和验证。

包括:①所有新的关键⽅法、规程、⼯艺及关键系统、设备在投⼊使⽤前应经验证。

②所有的变更当影响产品质量时,应经过验证。

③当质量回顾、偏差或其它事件表明验证状态发⽣漂移时应进⾏再验证。

④关键⼯艺参数和关键⼯艺步骤应进⾏验证。

⑤检验⽅法发⽣变化时应进⾏验证。

本验证总计划(VMP)描述了企业应该进行的验证和确认活动的验证组织机构、验证方针、验证内容及其计划安排。

以确保公司的各项验证活动有组织,有计划,有步骤的进行,满足GMP对于验证的要求。

概括地阐述验证目的、原则、方针、项目、计划、方法和可接受标准等。

四、组织机构及职责简单描述公司的验证的组织机构的组成,及各部门和关键人员职责如:人员职责质量负责人确保为相关部门的验证工作提供足够的资源,以达到VMP中规定的验证目标,并符合GMP要求。

带领验证委员会,按照本验证总计划与各项次级验证计划,领导和组织本公司的全部验证活动的发动和实施。

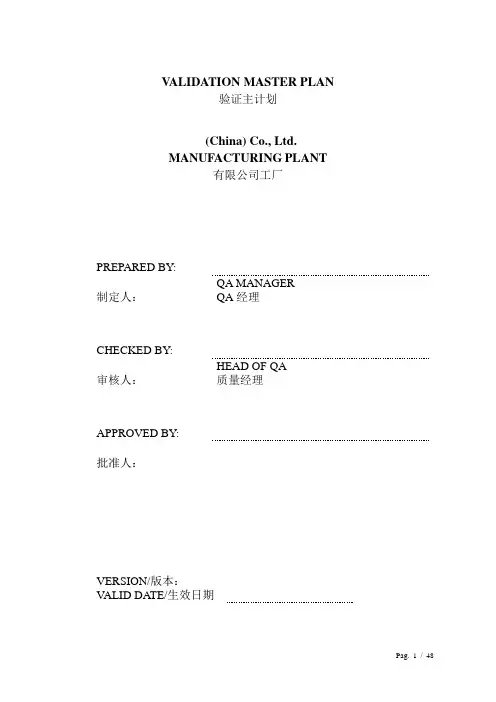

V ALIDATION MASTER PLAN验证主计划(China) Co., Ltd.MANUFACTURING PLANT有限公司工厂PREPARED BY:制定人:QA MANAGER QA经理CHECKED BY:审核人:HEAD OF QA 质量经理APPROVED BY:批准人:VERSION/版本:V ALID DATE/生效日期Content/目录1.INTRODUCTION 简介 ----------------------------------------------------------------------------------- 41.1. Validation policy 验证方针------------------------------------------------------------------------------------------ 41.2. Aim of the Validation Master Plan (VMP) 验证主计划(VMP)的目的--------------------------------- 42.LOCATION 位置 ------------------------------------------------------------------------------------------- 63.RESPONSIBILITIES 职责-------------------------------------------------------------------------------- 64.V ALIDATION: FLOW SHEETS AND DEFINITIONS 验证:流程和定义 ------------------- 104.1. General criteria 一般标准 ------------------------------------------------------------------------------------------104.2. Validation flow chart 验证流程图 -------------------------------------------------------------------------------- 114.3. Operative scheme 实施程序 ---------------------------------------------------------------------------------------125.ACCEPTANCE CRITERIA 接收标准: ------------------------------------------------------------- 165.1. General acceptance criteria for qualifications 确认的一般接收标准 --------------------------------------165.1.1. Design Qualification (DQ) 设计确认(DQ) ---------------------------------------------------------165.1.2. Installation Qualification (IQ) 安装确认(IQ) ------------------------------------------------------165.1.3. Operation Qualification (OQ) 运行确认(OQ)------------------------------------------------------175.1.4. Performance qualification (PQ) 性能资料(PQ)----------------------------------------------------185.2. Specific acceptance criteria for qualifications 确认的专属接收标准--------------------------------------185.3. General acceptance criteria for process validations 工艺验证和一般接收 -------------------------------185.4. General acceptance criteria for cleaning validations 清洁验证的一般接收标准------------------------245.4.1. Chemical check 化学检查 ---------------------------------------------------------------------------------245.4.2. Microbiological check 微生物检查 ----------------------------------------------------------------------256.QUALIFICATIONS AND V ALIDATIONS LISTS 确认和验证清单---------------------------- 266.1. List of GMP related building and building services qualifications including level of validation GMP相关的建筑物和厂房服务系统确认清单包括各层水平的验证 ------------------------------------------266.2. List of equipment qualifications including level of validation and critical items设备确认验证层次的重要项目之清单--------------------------------------------------------------------------276.2.1. MANUFACTURING EQUIPMENT 生产设备 -------------------------------------------------------276.3. List of Quality Control Equipment including the level of qualification 质量控制设备清单 ----------296.3.1. Quality Control equipment – Chemical Laboratory 质量控制设备-化学试验室 ---------------296.3.2. Quality Control equipment – IPC 质量控制设备-中间过程控制室-------------------------------306.3.3. Quality Control equipment – Microbiological Laboratory质量控制设备–微生物试验室 -------------------------------------------------------------------------306.4. Analytical method validation 分析方法验证 -------------------------------------------------------------------316.5. List of products with manufacturing steps 产品清单及生产步骤 ------------------------------------------326.6. List of products including level of process validation 拟进行验证的产品清单 -------------------------336.7. Maintenance of validation 验证维护 -----------------------------------------------------------------------------347.DOCUMENTATION 文件 ------------------------------------------------------------------------------ 357.1. Validation protocol 验证方案--------------------------------------------------------------------------------------357.2. Validation report 验证报告-----------------------------------------------------------------------------------------357.3. Deviations 偏差-------------------------------------------------------------------------------------------------------367.4. Document structure for DQ, IQ, OQ, PQ. DQ, IQ, OQ及PQ的文件结构 -------------------------------367.5. Documents numbering 文件编号 ---------------------------------------------------------------------------------387.6. Document filing of qualification and validation protocols and reports确认和验证方案及报告的归档 -----------------------------------------------------------------------------------388.STANDARD OPERATING PROCEDURES 标准运作程序-------------------------------------- 389.GLOSSARY 术语----------------------------------------------------------------------------------------- 3810.GUIDELINES ----------------------------------------------------------------------------------------- 44 ANNEX 1. ORGANIZATION CHART 附录1:组织机构图 ----------------------------------------- 45 ANNEX 2: LIST OF ROOMS IN GMP AREA 附录2:GMP房间清单 ---------------------------- 45 ANNEX 3: Annual validation plan 附录3:年度验证计划 -------------------------------------------- 481.INTRODUCTION简介1.1.Validation policy验证方针Validation is a part of our quality policy. We believe in it as a concept which provides both regulatory compliance and cost benefits. It is the responsibility of the Head of QA to assure that the compliance with this VMP is maintained. Plant Director to assure the resources necessary to achieve the compliance with this guideline shall be provided within the operating budgets of all organizational units.验证是我们质量方针的组成部份。

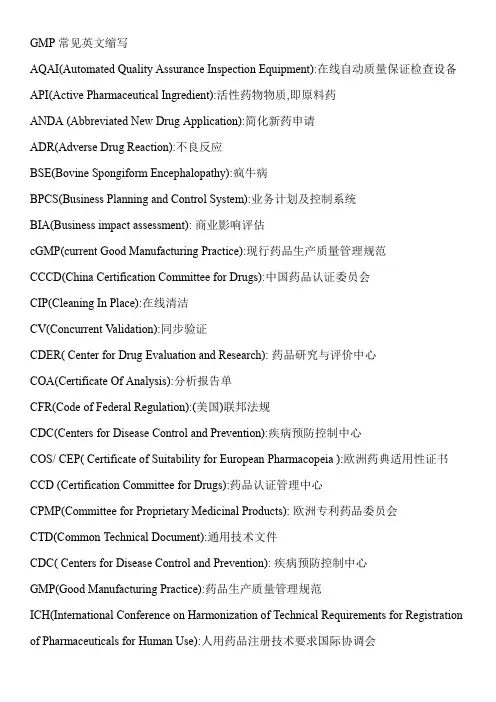

GMP常见英文缩写AQAI(Automated Quality Assurance Inspection Equipment):在线自动质量保证检查设备API(Active Pharmaceutical Ingredient):活性药物物质,即原料药ANDA(Abbreviated New Drug Application):简化新药申请ADR(Adverse Drug Reaction):不良反应BSE(Bovine Spongiform Encephalopathy):疯牛病BPCS(Business Planning and Control System):业务计划及控制系统BIA(Business impact assessment):商业影响评估cGMP(current Good Manufacturing Practice):现行药品生产质量管理规范CCCD(China Certification Committee for Drugs):中国药品认证委员会CIP(Cleaning In Place):在线清洁CV(Concurrent Validation):同步验证CDER(Center for Drug Evaluation and Research):药品研究与评价中心COA(Certificate Of Analysis):分析报告单CFR(Code of Federal Regulation):(美国)联邦法规CDC(Centers for Disease Control and Prevention):疾病预防控制中心COS/CEP(Certificate of Suitability for European Pharmacopeia):欧洲药典适用性证书CCD(Certification Committee for Drugs):药品认证管理中心CPMP(Committee for Proprietary Medicinal Products):欧洲专利药品委员会CTD(Common Technical Document):通用技术文件CDC(Centers for Disease Control and Prevention):疾病预防控制中心GMP(Good Manufacturing Practice):药品生产质量管理规范ICH(International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use):人用药品注册技术要求国际协调会EU(European Union):欧洲联盟EFPIA(European Federation of Pharmaceutical Industries Associations):欧洲制药工业协会联合会MHW(Ministry of Health and Welfare,Japan):日本厚生省JPMA(Japan Pharmaceutical Manufacturers Association):日本制药工业协会FDA(US Food and Drug Adminiistration):美国食品与药品管理局PRMA(Pharmaceutical Research and Manufacturers of America):美国药物研究和生产联合会WHO(World Health Organization):世界卫生组织IFPMA(International Federation of Pharmaceutical Manufacturers Associations):国际制药工业协会联合会TQC(Total Quality Control),TQM(Total Quality Management):全面质量管理PDCA(Plan,Do,Check,Action):计划,执行,检查,处理QA(Quality Assurance):质量保证QC(Quality Control):质量控制QS(Quality System):质量体系QM(Quality Management):质量管理SOP(Standard Operating Procedure):标准操作规程SMP(Standard Management Procedure):标准管理程序SOR(Standard Operating Record):标准操作记录GEP(Good Engineering Practice):工程设计规范HV AC(Heating Ventilation and Air Conditioning):空调净化系统DQ(Design Qualification):设计确认IQ(Installation Qualification):安装确认OQ(Operational Qualification):运行确认PQ(Performance Qualification):性能确认OOS(Out-Of-Specification):检验不合格;超标PFDS(Process Flow Diagrams):工艺流程图MRA(cMutual Reognition Agreements):现场检查多边认同协议DMF(Drug Master File):EDMF(European Drug Master File)欧盟药物主文件EDQM(European Directorate for Quality Medicines):欧洲药品质量管理局ORA(Office of Regulatory Affairs):药政事务办公室GGPs(Good Guidance Practices):优良指南规范MOA(Method Of Analysis):分析方法VMP(Validation Master Plan):验证主计划VP(Validation Protocol):验证方案MSDS(Material Safety Data Sheet):物料安全技术说明书NDA(New Drug Application):新药申请OTC(Over-the-counter):非处方INN(International Nonproprietary Name)国际非专有名称USP(the united state pharmacopeia):美国药典NF(National Formulary):(美国)国家药品集GAP(Good Agricultural Practice):中药材种植管理规范GCP(Good Clinical Practice):药物临床试验质量管理规范GLP(Good Laboratory Practice):药物实验室管理规范GSP(Good Supply Practice):药品经营质量管理规范GUP(Good Use Practice):药品使用质量管理规范SM(Starting Material):起始物料PMF(Plant Master File);SMF(Site Master File):工厂主文件EDL(List of Essential Drugs):基本药物目录PI(Package Insert):说明书PCT(Patent Cooperation Treaty):专利合作条约PPAC(Patent Protection Association of China):中国专利保护协会PIC(Person In Charge):负责人PDS(Pharmaceutical Development Services):整体新药研发机构SPC(Summary of Product Characteristics):产品特性摘要。

Note that this document is based in the PICS/S recommendations 注意本文件基于PICS/S建议。

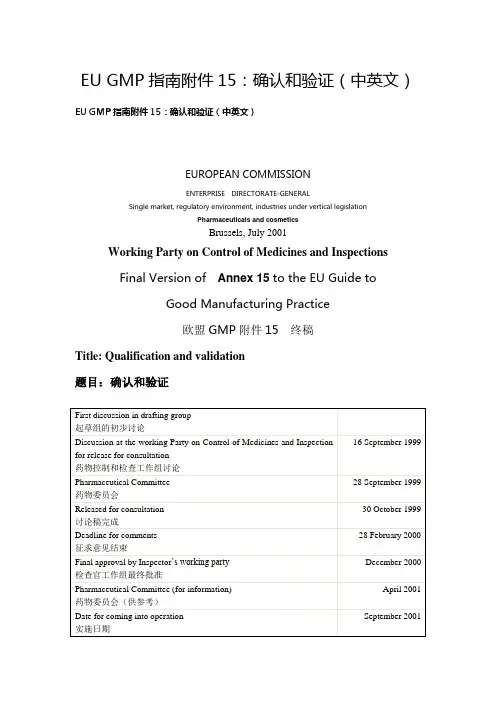

Table of Contents 目录Page页1. Qualification and Validation 确认和验证 32. Planning for Validation 验证计划 43. Documentation 文件 44. Qualification 确认 55. Processs Validation. 工艺验证 66. Cleaning Validation 清洁验证 77. Change Control 变更控制 88. Revalidation 再验证 99. Glossary 术语 10QUALIFICATION AND VALIDATION 确认和验证Principle 原则1. This Annex describes the principles of qualification and validation which are applicable to the manufacture of medicinal products. It is a requirement of GMP that manufacturers identify what validation work is needed to prove control of the critical aspects of their particular operations. Significant changes to the facilities, the equipment and the processes, which may affect the quality of the product, should be validated. A risk assessment approach should be used to determine the scope and extent of validation. 本附件描述了确认和验证的原则,应用于药品生产。

V ALIDATION MASTER PLAN验证主计划(China) Co., Ltd.MANUFACTURING PLANT有限公司工厂PREPARED BY:制定人:QA MANAGER QA经理CHECKED BY:审核人:HEAD OF QA 质量经理APPROVED BY:批准人:VERSION/版本:V ALID DATE/生效日期Content/目录1.INTRODUCTION 简介 ----------------------------------------------------------------------------------- 41.1. Validation policy 验证方针------------------------------------------------------------------------------------------ 41.2. Aim of the Validation Master Plan (VMP) 验证主计划(VMP)的目的--------------------------------- 42.LOCATION 位置 ------------------------------------------------------------------------------------------- 63.RESPONSIBILITIES 职责-------------------------------------------------------------------------------- 64.V ALIDATION: FLOW SHEETS AND DEFINITIONS 验证:流程和定义 ------------------- 104.1. General criteria 一般标准 ------------------------------------------------------------------------------------------104.2. Validation flow chart 验证流程图 -------------------------------------------------------------------------------- 114.3. Operative scheme 实施程序 ---------------------------------------------------------------------------------------125.ACCEPTANCE CRITERIA 接收标准: ------------------------------------------------------------- 165.1. General acceptance criteria for qualifications 确认的一般接收标准 --------------------------------------165.1.1. Design Qualification (DQ) 设计确认(DQ) ---------------------------------------------------------165.1.2. Installation Qualification (IQ) 安装确认(IQ) ------------------------------------------------------165.1.3. Operation Qualification (OQ) 运行确认(OQ)------------------------------------------------------175.1.4. Performance qualification (PQ) 性能资料(PQ)----------------------------------------------------185.2. Specific acceptance criteria for qualifications 确认的专属接收标准--------------------------------------185.3. General acceptance criteria for process validations 工艺验证和一般接收 -------------------------------185.4. General acceptance criteria for cleaning validations 清洁验证的一般接收标准------------------------245.4.1. Chemical check 化学检查 ---------------------------------------------------------------------------------245.4.2. Microbiological check 微生物检查 ----------------------------------------------------------------------256.QUALIFICATIONS AND V ALIDATIONS LISTS 确认和验证清单---------------------------- 266.1. List of GMP related building and building services qualifications including level of validation GMP相关的建筑物和厂房服务系统确认清单包括各层水平的验证 ------------------------------------------266.2. List of equipment qualifications including level of validation and critical items设备确认验证层次的重要项目之清单--------------------------------------------------------------------------276.2.1. MANUFACTURING EQUIPMENT 生产设备 -------------------------------------------------------276.3. List of Quality Control Equipment including the level of qualification 质量控制设备清单 ----------296.3.1. Quality Control equipment – Chemical Laboratory 质量控制设备-化学试验室 ---------------296.3.2. Quality Control equipment – IPC 质量控制设备-中间过程控制室-------------------------------306.3.3. Quality Control equipment – Microbiological Laboratory质量控制设备–微生物试验室 -------------------------------------------------------------------------306.4. Analytical method validation 分析方法验证 -------------------------------------------------------------------316.5. List of products with manufacturing steps 产品清单及生产步骤 ------------------------------------------326.6. List of products including level of process validation 拟进行验证的产品清单 -------------------------336.7. Maintenance of validation 验证维护 -----------------------------------------------------------------------------347.DOCUMENTATION 文件 ------------------------------------------------------------------------------ 357.1. Validation protocol 验证方案--------------------------------------------------------------------------------------357.2. Validation report 验证报告-----------------------------------------------------------------------------------------357.3. Deviations 偏差-------------------------------------------------------------------------------------------------------367.4. Document structure for DQ, IQ, OQ, PQ. DQ, IQ, OQ及PQ的文件结构 -------------------------------367.5. Documents numbering 文件编号 ---------------------------------------------------------------------------------387.6. Document filing of qualification and validation protocols and reports确认和验证方案及报告的归档 -----------------------------------------------------------------------------------388.STANDARD OPERATING PROCEDURES 标准运作程序-------------------------------------- 389.GLOSSARY 术语----------------------------------------------------------------------------------------- 3810.GUIDELINES ----------------------------------------------------------------------------------------- 44 ANNEX 1. ORGANIZATION CHART 附录1:组织机构图 ----------------------------------------- 45 ANNEX 2: LIST OF ROOMS IN GMP AREA 附录2:GMP房间清单 ---------------------------- 45 ANNEX 3: Annual validation plan 附录3:年度验证计划 -------------------------------------------- 481.INTRODUCTION简介1.1.Validation policy验证方针Validation is a part of our quality policy. We believe in it as a concept which provides both regulatory compliance and cost benefits. It is the responsibility of the Head of QA to assure that the compliance with this VMP is maintained. Plant Director to assure the resources necessary to achieve the compliance with this guideline shall be provided within the operating budgets of all organizational units.验证是我们质量方针的组成部份。

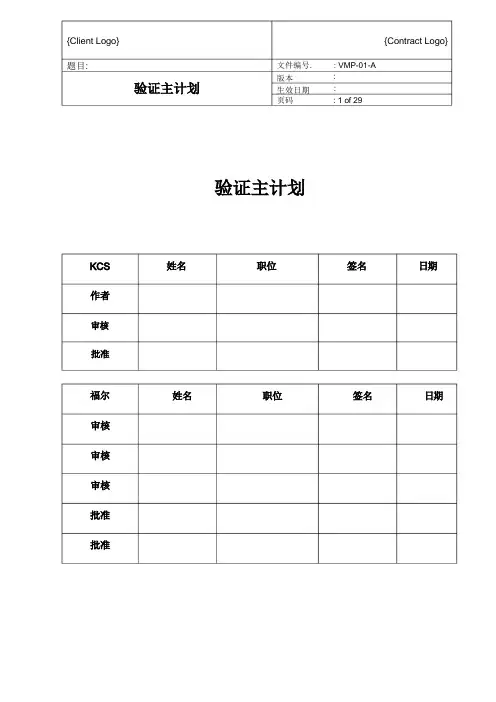

{Contract Logo}: VMP-01-A : :: 1 of 29{Client Logo}题目:文件编号.版本 生效日期 页码A 供审核及讨论徐文勤2022-03-11.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................5.1. 组织结构表 (6)5.2. 福尔验证经理 (6)5.3. 福尔质量保证部 (6)5.4. KCS 验证项目经理 (6)5.5. KCS 验证工程师主管 (6)5.6. KCS 验证工程师(公用设施) (6)5.7. KCS 验证工程师(工艺) (7)5.8. KCS 文档控制员 (7)5.9. 设备供应商验证团队 (7)........................................................................................................6.1. 总原则 (7)6.2. 验证序列 (7)6.3. 文件系统 (8)6.4. 再验证 (9)...................................................................................................................................................................................8.1. 用户需求(URS) (10)8.2. 验证主计划(VMP) (10)8.3. 设计确认(DQ) (10)8.4. FAT/SAT (11)8.5. 调试 (11)8.6. 安装确认(IQ) (11)8.7. 运行确认(OQ) (13)8.8. 性能确认(PQ) (15)8.9. 工艺验证(PV) (17)....................................................................................9.1 工程变更控制 (20)9.2 验证变更控制 (20)9.3 验证偏差管理 (20).......................................................................................................................................................................................................................................................................................................12.1 项目验证计划 (21)12.2 常规验证计划 (21)............................................................................................................................................................................................................附录一验证序列表 (22)附录二验证明细表 (22)附录三验证时间表 (22)附录四工厂布局图(最新版本) (22)附录五人流和物流图(最新版本) (22)附录六GMP 区域分级图(最新版本) (22)附录七工艺P & ID 图(最新版本) (22)本验证主计划为福尔生化狂苗改造项目验证活动的指导文件。

验证总计划确认或验证方案项目的概述英文版Validation Master Plan Overview: Confirmation or Verification Protocol ProjectsThe Validation Master Plan (VMP) serves as a comprehensive roadmap for ensuring the quality, safety, and effectiveness of processes, systems, and products within an organization. It outlines the key principles, strategies, and procedures required to validate various aspects of an organization's operations. In this article, we focus on the overview of confirmation or verification protocol projects that are a crucial part of the VMP.1. Purpose of Confirmation or Verification Protocol ProjectsConfirmation or verification protocol projects aim to provide a structured approach to validating specific processes, systems, or products. These projects ensure that the validation activities are conducted in a systematic and reproducible manner, leading to reliable and defensible validation outcomes.2. Key Elements of Confirmation or Verification Protocol ProjectsConfirmation or verification protocol projects typically involve the following key elements:Scope Definition: Clearly defining the scope of the validation project, including the processes, systems, or products to be validated.Protocol Development: Developing detailed validation protocols that outline the validation approach, methods, and criteria.Execution of Validation Activities: Carrying out the validation activities in accordance with the approved protocols, ensuring adherence to defined procedures and standards.Data Analysis and Interpretation: Collecting, analyzing, and interpreting validation data to assess compliance with predefined criteria.Reporting and Documentation: Preparing comprehensive validation reports that document the validation activities, findings, and conclusions.3. Importance of Confirmation or Verification Protocol ProjectsConfirmation or verification protocol projects are crucial to the overall validation process for several reasons:Consistency and Reproducibility: These projects ensure that validation activities are conducted in a consistent and reproducible manner, leading to reliable results.Risk Mitigation: By identifying and addressing potential issues early on, these projects help mitigate risks associated with product or process failures.Compliance with Regulations: These projects ensure compliance with applicable regulations and standards, protecting the organization from legal liabilities.4. ConclusionConfirmation or verification protocol projects play a pivotal role in the Validation Master Plan. They provide a structured and systematic approach to validating critical processes, systems, and products within an organization. By ensuring consistent, reproducible, and compliant validation activities, these projects contribute to the overall quality, safety, and effectiveness of the organization's operations.中文版验证总计划概述:确认或验证方案项目验证总计划(VMP)是确保组织内部流程、系统和产品质量、安全和有效性的综合路线图。

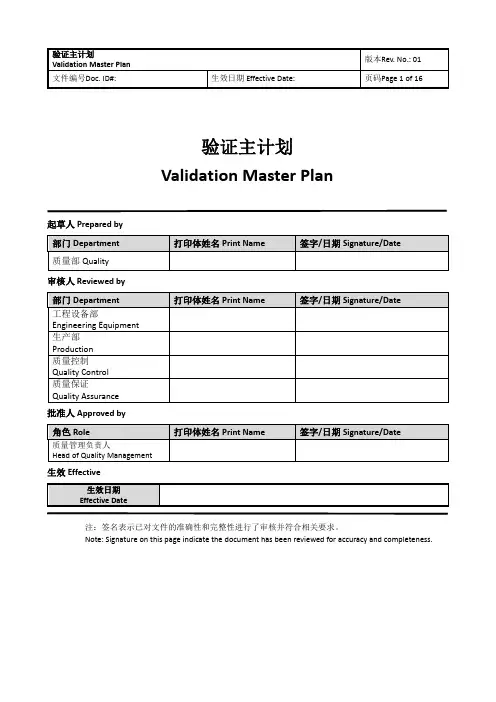

验证主计划Validation Master Plan起草人 Prepared by审核人 Reviewed by批准人Approved by生效Effective注:签名表示已对文件的准确性和完整性进行了审核并符合相关要求。

Note: Signature on this page indicate the document has been reviewed for accuracy and completeness.目录Contents1.项目介绍Project Introduction (3)2.目的Purpose (3)3.适用范围Scope (3)4.参考文献Reference Documents (4)5.验证职责 Validation Responsibilities (5)6.缩略语 Abbreviations (7)7.产品及工艺描述 Product and Process Description (8)8.设施、设备、仪器、系统描述 Facility\Equipment\ Instrument \System Description (8)9.验证原则 Validation Policy (9)10.验证策略Validation Strategy (9)11.验证文件 Validation Document (10)12.验证偏差管理和变更控制 Validation Deviation Management and Change Control (10)13.验证状态维护和系统退役 Validation Status Maintaining and System Retirement (10)14.验证矩阵和时间进度 Validation Matrix and Schedule (10)15.附件Attachments (10)16.修订历史Revision History (10)1. 项目介绍Project IntroductionXX有限公司位于XX,设计用于制造临床及商业用途的XX产品。

Verification department (department):验证科室(部门):Verify completion date:验证完成日期:Validity:有效期:Index 目录1.Purpose目的 (5)2.Scope范围 (5)3.Responsibility职责 (5)3.1 AAA responsibilities AAA的职责 (5)3.2 XXX responsibilities XXX的职责 (6)4.Regulation and Guidance 法规和指南 (8)5.Abbreviations缩略语 (9)6.Protocol Description方案说明 (11)7.Product And Process Description产品和工艺描述 (14)7.1 Product specification (14)7.2 Drug approval No. (14)7.3 Standard Followed: (14)7.4 Raw Materials and Adjuvants原辅料情况 (14)7.5 Process description: (16)7.6 Process Recipe工艺处方: (21)7.7 List of Production Plants生产车间一览 (26)7.8 List of Production Equipment 生产设备一览 (29)7.9 Process Flow Diagram 工艺流程图 (33)7.10 CPP Identification CPP确认 (34)7.11 Validation Plan验证计划 (49)8.Validation prerequisite验证先决条件 (51)8.1 Personal Identification人员确认 (51)8.2 Process Documentation Verification 生产文件确认 (51)8.3 Training Verification 培训确认 (52)8.4 System and Equipment Instruments Calibration Verification 系统和设备仪表校验确认.. 528.5 System and Equipment Instruments Calibration Verification 生产相关验证状态确认 (53)8.6 Test Instruments Calibration Verification 测试仪器和仪表校验确认 (53)8.7 Testing Method Validation Verification检验方法验证的确认 (54)8.8 Raw Material and Excipient Verification原辅料确认 (54)9.Sampling Plan and Evaluation Criteria取样计划及评估标准 (56)10.Sample Coding Method样品编码原则 (70)11.Process Validation Test Execution 工艺验证执行 (72)11.1 Liquid Preparation 液体配制 (72)11.2 Cell Resurrection and Passage细胞复苏及传代 (74)11.3 Harvest liquid test 收获液检测 (81)11.4 Clarification Filtration Efficacy Test 澄清过滤效果检测 (83)11.5 UF Concentration 1 Efficacy Test超滤浓缩1效果检测 (83)11.6 Ammonium sulfate precipitation efficacy test 硫酸铵沉淀效果检测 (84)11.7 Potassium bromide extraction efficacy test 溴化钾提取效果检测 (85)11.8 First density gradient centrifugation efficacy test 一次密度梯度离心效果检测 (86)11.9 Second density gradient centrifugation efficacy test 二次密度梯度离心效果检测 (87)11.10 UF Concentration 2 Efficacy Test 超滤浓缩2效果检测 (88)11.11 Chromatography purification product test 层析纯化产物检测 (90)12.Bulk Determination原液检验 (92)13.Process Validation Summarization工艺验证总结 (93)14.PV Report工艺验证报告 (94)14.1 Process Validation Report 工艺验证报告 (94)14.2 Process Validation Analysis and Evaluation 工艺验证分析与评价 (94)15.Requirements on Execution Records 执行记录要求 (95)16.Deviation Handling 偏差处理 (95)17.Change Handling 变更处理 (95)18.Test Form测试表 (96)表格1 缩略语 (9)表格2原辅料质量标准表 (11)表格3物料消耗表1 (21)表格4物料消耗表2 (21)表格5所用液体配料表 (22)表格6生产车间一览表 (26)表格7主要生产设备一览表 (29)表格8工艺风险分析表 (33)表格9工艺时间表 (49)表格10取样计划表 (56)表格11样品编码原则 (70)表格12配液取样检测信息表 (72)表格13复苏和传代取样表 (74)表格14复苏和传代样品编码 (80)表格15收获液标准 (81)表格16澄清过滤标准 (83)表格17超滤浓缩1标准 (83)表格18硫酸铵沉淀标准 (85)表格19溴化钾提取标准 (86)表格20一次密度梯度离心标准 (87)表格21二次密度梯度离心标准 (88)表格22超滤浓缩2标准 (89)表格23纯化产物标准 (90)表格24原液标准 (92)表格25测试表列表 (96)1. Purpose目的This purpose of this process validation is to provide documented evidence to show that the combination of the personnel, materials, equipment, methods, environmental conditions and the other related utilities XXX Co., LTD (XXX) can ensure the consistent production of products conforming to the enterprise internal standards and the national standards, and the processes are reliable and conforming to the GMP requirements. The process validation and the test results are to be documented based on this validation protocol.本工艺验证用于提供文件化的证据,证明XXX疫苗一室生产XXX原液的人员、材料、设备、方法、环境条件以及其它有关公用设施的组合可以始终如一的生产出符合企业内控标准及国家法定标准的产品,工艺稳定可靠,符合GMP要求,工艺验证的过程和检查的结果将按照该验证方案进行记录。

OPERATIONAL QUALIFICATION STERILE PROCESS VALIDATIONCLEANING VALIDATION (1/25)1. DOCUMENT HISTORYAdoption by PIC/S Committee 10 - 11 December 1998Entry into force of version PR 1/99-1 01 March 1999Entry into force of version PI 006-1 01 September 20012. INTRODUCTIONThe basic principles and application of qualification and validation are describedin Annex 15 to the PIC/S and EU Guide to GMP. This document comprises individual Recommendations on four topics relating to Equipment Qualification and Process Validation in pharmaceutical manufacture, as follows:Ø Validation Master PlanØ Installation and Operational QualificationØ Non-Sterile Process ValidationØ Cleaning ValidationThe four Recommendations comprising this document define general principles pertaining to each of the topics.2. 导言PIC/S和EU GMP指导原则的附录15中对确认(Qualification)和验证(Validation)的基本原则及应用进行了阐述。

药品生产验证总计划(VMP)PHARMACY MANUFACTURING UNIT VALIDATION MASTER PLAN (VPM).General NotesAims of Qualification and ValidationAny significant changes to, premises, equipment or processes, which may affect the quality of the final product, directly or indirectly, should be qualified and validated.The key elements of a qualification and validation program should be clearly defined and documented in a Validation Master Plan. The process should establish and provide documentary evidence that: premises, supporting utilities, equipment and processes have been designed in accordance with the requirements of GMP. This normally constitutes the Design Qualification or ‘DQ’ and includes confirmation that the premises, supportingutilities and equipment have been built and installed in compliance with their design specifications (this constitutes Installation Qualification or ‘IQ’) and that they operate in accordance with their design specifications (this constitutes Operational Qualification or OQ).A specific process will consistently produce a product meeting its predetermined specifications and quality attributes (this constitutes Process Validation or PV. The term Performance Qualification or PQ may be used also).PurposeThe VMP is intended to be a ‘live’ document that supports the design and construction of any production facility, its subsequent operation, maintenance and changes to the facilityfor its life span. The VMP should present an overview of the entire validation operation, its organisational structure, its content and planning. The core of the VMP is the list/inventory of items to be validated and the planning schedule.The VMP should provide your organisation with the basis for validation and quality system activities required for cGMP compliance. This will enable any sterile or non-sterile medicinal product that is produced, processed, stored or distributed, by the manufacturing unit, to be validated under the control of an appropriate quality system.The VMP should provide a cross-reference to other documents, such as SOP’s, validation protocols, validation reports, and design plans. A rationale for the inclusion or exclusion of validations, from the approach adopted should be included.VMP DocumentThe VMP template is attached for completion as appropriate the document should becross-referenced with design specifications, design plans and other relevant documentation. Appendices should contain all the relevant documentation referenced or stated in the VMP.Company LogoCompany NameVALIDATION MASTER PLAN Document Reference: Reference NumberRevision: Draft Number or Revision NumberDate of Issue: ____/____/____Page: 3 of ___Approved by: Name: Signature: Date: Production Team LeaderQuality Control OfficerSenior EngineerCompiled byTitle: Name: Signature: Date: Validation EngineerCONTENTS1.0 LIST OF ABBREVIATIONS (6)2.0 DOCUMENT REVISION HISTORY (8)3.0 VALIDATION STEERING COMMITTEE (9)3.1 M EMBERSHIP OF V ALIDATION S TEERING C OMMITTEE (9)3.2 R ESPONSIBILITIES (10)3.2.1 Pharmacy Production Team Leader (10)3.2.2 Pharmacy Senior Production Technician (10)3.2.3 Trust Senior Engineer (10)3.2.4 Pharmacy Quality Control Officer (10)3.2.5 Validation Engineer (10)4.0 INTRODUCTION (11)4.1 P URPOSES OF VMP (11)4.2 O VERVIEW OF P ROJECT (11)4.3 V ALIDATION P HILOSOPHY (11)5.0 REGULATORY STANDARDS AND GUIDELINES (12)6.0 DESCRIPTION OF PRODUCTS AND PROCESSES (13)6.1 I NTRODUCTION (13)6.2 P RODUCT G ROUPS (13)6.3 P ROCESSES (13)6.4 P RODUCT S TORAGE AND D ISTRIBUTION (13)7.0 PROJECT DESCRIPTION (14)7.1 S ITE L OCATION (14)7.2 F ACILITY D ESIGN AND L AYOUT. (14)7.3 P RODUCTION S UITES (14)7.3.1 Zone 1, Non-Sterile Manufacturing (14)7.3.2 Zone 2, Preparation of Cytotoxic Products and Parental Nutrition Products (14)8.0 EQUIPMENT AND SERVICES TO BE VALIDATED (16)8.1 I MPACT A SSESSMENT (16)8.2 R ISK A SSESSMENT (16)8.3 V ALIDATION M ATRIX (16)9.0 VALIDATION ACTIVITIES (17)9.1 V ALIDATION A CTIVITIES (17)9.1.1 User Requirement Specification (URS) (17)9.1.2 Technical Specification (17)9.1.3 Impact Assessment (17)9.1.4 Design Review/Qualification (17)9.1.5 Factory Acceptance Tests (17)9.1.6 Commissioning (18)9.1.7 Installation Qualification (18)9.1.8 Calibration (18)9.1.9 Operational Qualification (18)9.1.10 Standard Operating Procedures (19)9.1.11 Performance Qualification (19)9.1.12 Combined Qualifications (I/OQ & O/PQ) (20)9.1.13 Process Validation (PV) (20)9.1.14 Cleaning Validation (20)9.1.16 Product Storage and Distribution Validation (21)9.1.17 Relocated Equipment (21)9.1.18 Computer Validation Testing (22)9.1.19 Computer Operational Qualification ....................................................................... 错误!未定义书签。

PICS验证指南(VMP,DQ,IQ,OQ,PQ中文)1.文档历史2.导言PIC/S 和 EU GMP 指导原则的附录 15 中对确认(Qualification)和验证(Validation)的基本原则及应用进行了阐述。

本文件包含了药物生产过中与设备确认和工艺验证相关的如下这四个方面的建议,验证主计划、安装和运行确认、非无菌工艺验证、清洗验证。

本文件中的建议确定了上述这四个方面的基本原则。

2.1本文件的目的2.1.1 这些建议性文件的主题涉及的是那些审计人员和制药企业都认为需要对现行 PIC/S GMP 指导原则进行补充的领域。

2.1.2 本文件的目的在于给 GMP 审计人员提供一个指导文件,可用于培训和检查的准备工作。

2.2 范围2.2.1 每个建议文件中所确定的原则既适用于原料药也适用于制剂。

2.2.2 在公布时,本文件反映了当前的技术水平。

但并不能因此而成为技术革新和追求卓越的一种障碍。

2.2.3 本文件中的建议并不强制制药企业执行。

然而,制药企业应当要适当考虑这些建议。

2.2.4 需要注意的是本文件并未包括会影响 GMP 的计算机系统方面的附加要求。

2.3 确认和验证的目的在于建立和提供如下这些方面的书面证据:2.3.1 厂房,设施,设备和工艺是根据 GMP 要求进行设计的。

这通常就是设计确认(DQ,Design Qualification)。

2.3.2 厂房,设施和设备是根据设计要求进行建造和安装的。

这就是安装确认(IQ,Installation on Qualification)。

2.3.3 厂房,设施和设备的运行符合其设计要求。

这就是运行确认(OQ, Operational Qualify action)。

2.3.4 一特定工艺能够持续地生产出符合预期质量标准和质量属性的产品。

这就是工艺验证(PV, Process Validation)。

也被称为性能确认(PQ, Performance Qualification)。

制药工程常用英文缩写,缩略语1GMP Good Manufacturing Practices药品生产质量管理规范2GxP各种药品规范的统称3GCP Good Clinical Practice药物临床试验质量管理规范4GLP Good Laboratory Practice药物非临床试验(实验室)质量管理规范5GSPGDPGood Supplg practiceGood Distribute Practice(美)药品经营质量管理规范6GDP Good Dossier practice申报资料质量管理规范7GPP Good Pharmacy practice药房质量管理规范8GQP Good Quality Practice 药品质量管理规范9GRP Good Rearch Practice药品研究质量管理规范10GUPGPPGood Use PracticeGood Preparation Practice(欧美)药品使用质量管理规范11GVP Good Validation Practice验证管理规范12GAP Good Agricultural Practice中药材生产质量管理规范13GEP Good Engineering Practice工程管理规范14GWP Good Warehousing Practice药品仓储规范15GMPC Good Manufacture Practice of Cosmetic Products 化学品生产质量管理规范16cGMP Current Good Manufacturing Practice现行药品生产质量管理规范17EU-GMP European –Good Manufacturing Practice欧洲GMP18CFR Code of Federal Regulations美国联邦法规19ChP Chinese Pharmacopoeia中国药典20USP United States Pharmacopoeia美国药典21EP European Pharmacopoeia欧洲药典22JP Japanese Pharmacopoeia日本药典23BP British Pharmacopoeia英国药典24IP Indian Pharmacopoeia印度药典25EN European Norm欧洲规范,欧洲标准26ANSI American National Standards Institute美国国家标准学会27ASME American Society of Mechanical Engineers美国机械工程师学会28ASTM American Society for Testing and Materials美国材料实验学会29ISPE International Society for Pharmaceutical Engineering 国际制药工程学会30WHO World Health Organization世界卫生组织31ISO International Standards Organization国际标准组织32EEC European Economic Community欧洲共同体、欧共体33EU European Union欧盟34ES European Commission欧洲委员会35CFDA China Food and Drug Administration中国食品和药品监督管理局36FDA Food and Drug Administration(美国)食品和药品管理局37MHRA Medicines & Healthcare Products Regulatory Agency(英国)药品和健康产品管理局38EHX Environment Health Safety环境、职业健康、安全管理体系39BPE Bioprocessing Equipment生物处理设备403A美国卫生行业协会、美国卫生论证标识41NBST National Bureau of Standards and Technology美国国家标准研究院42EMA European Medicines Agency欧洲药监局43EMEA European Agency for the evaluationof medicinal欧洲药品评价局44EDQM European Directorate for the Quality of Medicines 欧洲药品理事会45EQDM European Directorate for the Quality of Medicines & Healthcare欧洲药品与健康理事会46EHEDG European Hygienic Equipment Design Group欧洲卫生设备设计组织47ICH International Conference on Harmonization of TechnicalRequirements for Registration of Pharmaceuticals for Human 人用药物注册技术要求国际协调会议48IEC International Electrotechnical Commission国际电工委员会通用及组织49NEMA National Electrical Manufacturers Association美国电器制造商协会50CEP Certificate of Suitability for European Pharmacopeia欧洲药典适用性证书51CE Conformite Europeenne 欧洲电气安全论证52PIC/S Pharmaceutical Inspection ConventionPharmaceutical Inspection Cooperation Scheme国际医药品稽查协约组织53HHS United States Department of Health and Human Services美国卫生及公共服务部、美国卫生部54PDA Parenteral Drug Association(美国)注射剂协会55EPA Environmental Protection Agency(美国国家)环境保护局56CDER Center for Drug Evaluation and Research药物评价与研究中心57MHWMHLWMinistry of Health and WelfareMinistry of Health, Labor and Welfare(日本)厚生省(日本)厚生劳动省5821 CFR Title 21―Food and Drugs美国联邦法规,第21篇,食品与药品59Part11Electronic Records; Electronic Signatures第11节,电子记录与电子签名60Part210Current Good Manufacturing Practice in Manufacturing,Processing,Packing,or Holding of Drugs;General第210节,药品生产、加工、包装、储存质量规范部分61Part211Current Good Manufacturing Practice for Finished 第211节,制剂药物生产质量规范部分62Part314Applications for FDA Approval to Market a New Drug第314节,新药上市申请部分63Part320Bioavailability and Bioequivalence Requirements 第320节,生物利用度和等效性要求1QMS Quality Management System质量管理体系2QRS Quality Regulation System质量控制体系3QA Quality Assurance质量保证4QC Quality Control质量控制5QM Quality Management质量管理6QI Quality Inspection质量检验7QP Quality Plan质量计划8QRM Quality Risk Management质量风险管理9URS User Requirement Specification用户需求10DQ Design Qualification设计确认11IQ Installation Qualification安装确认12OQ Operational Qualification操作确认13PQ Performance Qualification性能确认14VIT Vendor Internal Test供应商内部测试15FAT Factory Acceptance Test工厂验收测试16SAT Site Acceptance Test现场验收测试17SOP Standard of Operation标准操作规程18FDS Functional and Design Specifications功能设计说明、功能设计规范19FS Functional Specifications功能说明20DS Design Specifications设计说明21TS Technical Specification技术说明、技术规范22RTM(TM)Requirement Traceability Matrix需求追溯矩阵23ITR Inspection T est Reports检查测试报告24QOR Quality Observation Report质量检查报告25QR Quality Requirements质量要求26QR Quality Records质量记录27RA Risk Assessment风险评估28SIA System Impact Assessment系统影响性评估29CCA CriticalComponents Assessment部件关键性评估30PV Process Validation工艺验证31CV Cleaning Validation清洁验证32CSV Computer System Validation计算机验证33VMP Validation Master Plan 验证主计划质量、验证34VP Validation Plan 验证计划35VP Validation Protocol验证方案36VR Validation Report验证报告37PVP Project Validation Plan项目验证计划38PVR Project Validation Report项目验证报告39QbD Quality by Design质量源于设计40DMF Drug Master File药品主文件、药物管理档案41FMEA Failure Mode and Effects Analysis失效模式和效果分析42SST System Suitability Test系统适应性测试43CAL Calibration校验、校准44CAPA Corrective Action and Preventive Action纠正预防措施45RCA Root Cause Analysis根本原因分析46ERES Electronic Record and Electronic Signature电子记录与电子签名47AQL Acceptable Quality Level可接受质量水平48CQA Critical Quality Attribut关键质量属性49CPP Critical Process Pararneter关键工艺参数50CTD Common T echnical Document通用技术文件51IA Impact Assessment影响评估52PQR Procut Quality Review产品质量回顾53COA Certification of Analysis分析合格证书、检验报告54BPR Batch Production Records批生产记录55BR Batch Records批记录56CC Change Control变更控制57DR Deviation Records偏差记录58COM Commissioning试车59BAR Batch Analysis Record批检验记录60PP Process Procedure工艺规程61OOS Out of Specification超出标准(限度)62LAL Limulus Smoebocyte Lysate鲎试剂63AQL Acceptable Quality Level可接受质量水平64SMF Site Master File工厂主文件65PM Preventive Maintenance预防性维修66QP Qualified Person质量授权人67R&D Research and Development研发部门68NDA New Drug Application新药申请电气及自控1GAMP Good Automated Manufacturing Practices设备自动化生产管理规范2HMI Human Machine Interface人机界面3OIT Operator Interface Terminals操作员界面终端4OIP Operator Interface Panel操作员界面面板5PLC Programmable Logic Controller可编程序控制器6PCS Process Control System过程控制系统7DCS Distributed Control System集散控制系统8PCS Process Control System工艺控制系统9DDC Direct Digital Controller直接数字控制器10IPC Industrial Personal Computer工业控制计算机,工控机11PAC Programmable Automation Controller可编程自动化控制器12PCC programmable computer controller可编程计算机控制器13MCU Microcontroller Unit单片机14CPU Central Process Unit中央处理器15PC Personal Computer个人电脑16SCADA Supervisory Control And Data Acquisition监控及数据采集17SDS Software design specification软件设计说明18HDS Hardware Design Specification硬件设计说明19FL Functional Logic功能逻辑说明20I/O Input / Output输入/输出21AI Analog Input模拟量输入22AO Analog Output模拟量输出23DI Digital Input数字量输入24DO Digital Output数字量输出25RTD Resistance Temperature Detector热电阻26T/C Thermocouple热电偶27RTU Remote Terminal Unit远程终端单元28ARS Automation Requirement Specification自动化需求规范29VFD Variable Frequency Drive变频驱动30EMC Electromagnetic Compatibility电磁兼容31UPS Uninterrupted Power supply不间断电源32EPS Emergency Power supply应急电源33FL Functional Logic功能逻辑说明34ER and Electronic Signature电子记录35ES Electronic Signature电子签名36AT Audit Trail审计踪迹37NO Normally Open常开38NC Normally Close常关39FO Fault Open故障开40FC Fault Close故障关41AC Alternating Current交流42DC Direct Current直流43PID Proportional Integral Derivative比例积分微分44LED Light Emitting Diode发光二极管45LCD Liquid Crystal Display液晶显示器46LIMS Laboratory Information Management System实验室信息管理系统 47LECP Laboratory Equipment Calibration Program 实验室仪器校准程序48WMS Warehouse Management System仓库管理系统49MES Manufacturing Execution System制造执行系统50ERP Enterprise Resource Planning企业资源计划其它1N/A Not Applicable不适用2NLT Not Less Than不少于3NMT Not More Than不多于4NB Nominal Bore公称管径5PED Pressure Equipment Directive压力设备指令(欧洲) 6PW Purified Water纯化水7WFI Water for Injections注射用水8PS Pure Steam纯蒸汽发生器9PWG PW Generator Unit纯化水制备机组10WFIG WFI Generator注射用水制备机组11MEWD Multi-effect Water Distillator 多效蒸馏水机12PSG PS Generator纯蒸汽发生器13PAC Poly Alumina Chlorine聚合氯化铝14DW Demineralized Water脱盐水,去离子水15MF Micro-Filter微滤16UF Ultra-Filter 超滤17NF Nano-Filter纳滤18MMF Multi-Media Filter多介质过滤器19ACF Activated Carbon Filter活性炭过滤器20SF Softener软化器21DG Degasifier脱气塔22RO Reverse Osmosis 反渗透23EDI Electrodeionization电法去离子24MB Mixed Bed混床25MDG Membrane Degasifier膜脱气26COP Clean out Place离线清洗27CEB Chemical Enhanced Backwash化学增强反冲洗28CIP Clean In Place在线清洗29SIP Sterilization in Place在线灭菌30POU Point Of Use使用点31PH Potential of Hydrogen酸碱度32TOC Total Organic Carbon总有机碳33ORP Oxidation-Reduction Potential氧化还原电位34COD Chemical Oxygen Demand化学耗氧量35BOD Biological Oxygen Demand生物耗氧量36SDI Silt Density Index污染密度指数37TUB Turbidity浊度38TSS Suspended Solid总悬浮固体39DO Dissoved Cxygn溶解氧40TDS Total dissolved solids总溶解固体41TH Total Hardness总硬度42PAT Process Analytical & Measurement T echnology过程分析技术43IRS Installation Requirement Specification安装要求说明44OEM Original Equipment Manufacturer 原始设备制造商45GDS General Design Specification总体设计说明46DDS Detailed Design Specification详细设计说明47PCP Preparation of Construction Plan施工组织设计48WMS Work Method Statement施工方案49BOQ Bill of Quantities工程量清单50BOM Bill of Material材料清单51P&ID Process and Instrumentation Diagram工艺与仪表流程图52PFD Process Flow Diagram工艺流程示意图53ANDA Abbreviation New Drug Application仿制药或仿制新药申请54OPQ Operational Personnel Qualification操作人员资格鉴定55MBT Microbiologic Test微生物测定56ADR Adverse Drug Reaction药物副作用报告,药品不良报告57OMM Operating and Maintenance Manual操作和维护保养手册58HACCP Hazard Analysis and Critical Control Point危害分析及关键环节控制点59CCP Critical Control Point关键环节控制点60IPC In Process Control过程控制61IPC Intermediate Production Control中间生产控制62CIPC Critical In-Process Control关键中间控制点63MBR Master Batch Record主生产批记录64PPM Parts Per Million百万分之一65OC Organizational Charts组织结构图66FIT Filter Integrity Test过滤器完整性测试67WIT Water Intergrity Test水侵入测试68GA General Arrangement总平面图69RPM Rotations per minute转/分70PD Prescription Drug处方药71Rx Receptor x处方药72NPD Nonprescription Drug非处方药73OTC Over The Counter非处方药74API Active Pharmaceutical Ingredient原料药、活性药75BPC Bulk Pharmaceutical Chemical原料药(原简称)76DS Drug Substance原料药77DP Drug Product成品药78RO Restriction orifice限流孔板79SG Sight Glass视镜80LG Lamp Glass,Light Glass灯镜81RD Rupture Disk爆破片材料1MOC Material Of Construction建造材质2SS Stainless Steel不锈钢3CI Cast iron铸铁4NCI Nodular east iron球墨铸铁5CS Carbon Steel碳钢6 C.Stl Cast Steel铸钢7 F.Stl Freezing Steel锻钢8PA Polyamide聚酰胺9PB Polybutylene聚丁烯10PC Polycarbonate聚碳酸酯11PE Polyethylene聚乙烯12PEX Cross-linked PolyEthylene交联聚乙烯13HDPE High-density polyethylene plastics高密度聚乙烯14MDPE Medium-density polyethylene plastics中密度聚乙烯15PO Polyolefin聚烯烃16PP Polypropylens聚丙烯17FRPP Polypropylens玻纤增强聚丙烯18PPR Polypropyla无规共聚聚丙烯19PPS PolyPhenylene Sulfide聚苯硫醚20PS Polystrene聚苯乙烯21PU Polyurethane,或者缩写为PUR聚氨酯22POM PolyOxyMethylene or Polyacetal聚甲醛,聚氧化亚甲基23HIPS High impact polystyrene高抗冲聚苯乙烯26PFA Polyfluoroalkoxy四氟乙烯—全氟烷氧基乙烯基醚共聚物27PTFE Polytetrafluoroethylene聚四氟乙烯28PVDF Poly vinylidene fluofide聚偏二氟乙烯29PVC Polyvinyl chloride聚氯乙烯30UPVC Unplasticised Polyvinyl Chloride硬聚氯乙烯,增强聚氯乙烯31CPVC Chlorinated polyvinyl chloride,或者缩写为PVCC氯化聚氯乙烯32PA Nylon,Polyamide尼龙,聚酰胺33PES PolyEtherSulfone聚醚砜,聚酯34AAS Acrylonirile butadiene styrene丙烯腈-丙烯酸酌-苯乙烯35ABS Acrylonitrile-Butadiene-Styrene丙烯腈-丁二烯-苯乙烯共聚物36ACS Acrylonitrile Chlorinated polyethylene Styrene丙烯胯-氯化聚乙烯-苯乙烯37ASB Asbestos石棉38PMMA Polymethel methacrylate聚甲基丙烯酸甲酯39SR Styrene-rubber苯乙烯橡胶24EPDM Ethylene Propylene Diene Monomer三元乙丙橡胶25EPM Ethylene Propylene Methylene乙丙橡胶,乙烯/丙烯共聚物40SR Silicone rubber硅橡胶40HTV High Temperature Vulcanization高温硫化(硅橡胶)40RTV Room Temperature Vulcanization室温硫化(硅橡胶)40MQ Silicone rubber甲基硅橡胶40VMQ Silicone rubber甲基乙烯基硅橡胶40PVMQ Silicone rubber甲基乙烯基苯基硅橡胶41FPMFKMFluororubberFluorocarbon Rubber氟橡胶42NBR Vulcanized nitrile rubber丁腈橡胶43FRP Glass Fibre Reinforced Plastic玻璃钢,玻璃纤维增强塑料1HVAC Heating Ventilation and Conditioning供热通风空调2AC Air Conditioner空调3AHU Air Handling Unit空气处理单元4BMS Building Monitoring System建筑管理系统、楼宇检测系统5CFU Colony Forming Unit菌落形成单位6CNC Controlled Non-Classified控制但未分级7FFU Fan Filter Unit风机过滤单元8FMS Factory Monitoring System车间监控系统9HEPA High Efficiency Particulate Air高效空气过滤器10LAF Laminar Air Flow层流、单向流11UDF Unidirectional Flow单向流12RABS Restricted Access Barrier Systems限制通过隔离系统13DP Differential Pressure压差14SDP Static Differential Pressure静压差15RH Relative Humidity相对湿度16CHWs Chilled Water (Supply)冷冻水(供给)17CWr Cooling Water (Return)冷却水(回流)18HW Hot Water热水19FS Factory Steam工厂蒸汽20SC Steam Condensate蒸汽冷凝水21WD Waste Drain废水排放22PWW Process Wastewater工艺污水23CA Compressed Air压缩空气24PA Process Air工艺压缩空气25IA Instrument Air仪表压缩空气26RW Raw Water原水27SW Soft Water软水28MW Middle Water中水29DW Domestic Water生活用水30CW City Water市政供水、自来水31DK Drinking Wat 饮用水32LPG Liquefied Petroleum Gas液化石油气33LNG Liquefied Natural Gas液化天然气34CNG Compressed natural gas压缩天然气35VE Visual Examination外观检查36UT Ultrasonic inspection Test超声探伤37RT Radiographic inspection Test射线探伤38MT Magnetic particle inspection Test磁粉探伤39PT liquid Penterant inspection Test液体渗透探伤40AutoclaveSterilizer灭菌柜公用工程41FBD Fluid Bed Dryer流化床42BFS Blowing Filling and Sealing吹灌封43HPLC High Pressure Liquid Chromatograph高效液相色谱44TLC Thin Layer Chromatograph薄层色谱45GC Gas Chromatograph气相色谱46UV Ultra-Violet紫外线47IR InfraRed红外线48RFQ Request for Quotations报价征询书49NPT American standard taper pipe thread美国标准锥管螺纹50NPS American standard straight pipe thread美国标准直管螺纹51NF American national fine thread美国标准细牙螺纹52NC American national coarse thread美国标准粗牙螺纹53Union Union 活接头,由宁。

OPERATIONAL QUALIFICATION STERILE PROCESS VALIDATIONCLEANING VALIDATION (1/25)1. DOCUMENT HISTORYAdoption by PIC/S Committee 10 - 11 December 1998Entry into force of version PR 1/99-1 01 March 1999Entry into force of version PI 006-1 01 September 20012. INTRODUCTIONThe basic principles and application of qualification and validation are describedin Annex 15 to the PIC/S and EU Guide to GMP. This document comprises individual Recommendations on four topics relating to Equipment Qualification and Process Validation in pharmaceutical manufacture, as follows:Ø Validation Master PlanØ Installation and Operational QualificationØ Non-Sterile Process ValidationØ Cleaning ValidationThe four Recommendations comprising this document define general principles pertaining to each of the topics.2. 导言PIC/S和EU GMP指导原则的附录15中对确认(Qualification)和验证(Validation)的基本原则及应用进行了阐述。

本文件包含了药物生产过中与设备确认和工艺验证相关的如下这四个方面的建议:验证方案安装和运行确认非无菌工艺验证清洗验证本文件中的建议确定了上述这四个方面的基本原则。

2.1 Purpose of the document2.1.1 The topics of these Recommendation documents reflect some of the areas in pharmaceutical manufacture identified by both Inspectorates and the Pharmaceutical Industry as requiring guidance additional to that given in the current PIC/S GMP Guide.2.1.2 The purpose of this document is to provide guidance for GMP inspectors in reviewing the issues covered to use for training purposes and in preparation for inspections.2.1 本文件的目的2.1.1 这些建议性文件的主题涉及的是那些审计人员和制药企业都认为需要对现行PIC/S GMP指导原则进行补充的领域。

2.1.2 本文件的目的在于给GMP审计人员提供一个指导文件,可用于培训和审计的准备工作。

2.2 Scope of the document2.2.1 It is considered that the principles defined in the individual Recommendation documents can be applied equally in the manufacture of active pharmaceutical ingredients (APIs) and finished pharmaceuticals.2.2.2 At the time of issue, this document reflected the current state of the art. It is not intended to be a barrier to technical innovation or the pursuit of excellence.2.2.3 The advice in these Recommendations is not mandatory for industry. However,industry should consider these Recommendations as appropriate. 2.2.4 It should be noted that additional requirements not contained in these Recommendations pertain to computer systems impacting GMP.2.2 范围2.2.1 每个建议文件中所确定的原则既适用于原料药,也适用于制剂。

2.2.2 在公布时,本文件反映了当前的技术水平。

但并不能因此而成为技术革新和追求卓越的一种障碍。

2.2.3 本文件中的建议并不强制制药企业执行。

然而,制药企业应当要适当考虑这些建议。

2.2.4 需要注意的是本文件并未包括会影响GMP的计算机系统方面的补充要求。

2.3 Aims of Qualification and ValidationThe qualification and validation process should establish and provide documentary evidence that: 2.3.1 The premises, the supporting utilities, the equipment and the processes have been designed in accordance with the requirements of GMP. This normally constitutes Design Qualification or DQ.2.3.2 The premises, supporting utilities and the equipment have been built and installed in compliance with their design specifications. This constitutes Installation Qualification or IQ. 2.3.3 The premises, supporting utilities and the equipment operate in accordancewith their design specifications. This constitutesOPERATIONAL QUALIFICATION STERILE PROCESS VALIDATIONCLEANING VALIDATION (2/25)Operational Qualification or OQ.2.3.4 A specific process will consistently producea product meeting its predetermined specifications and quality attributes. This constitutes Process Validation or PV. The term Performance ualification or PQ may be used also.2.3 确认和验证的目的确认和验证的目的在于建立和提供如下这些方面的书面证据:2.3.1 厂房,设施,设备和工序是根据GMP要求进行设计的。

这通常就是设计确认(DQ, Design Qualification).2.3.2 厂房,设施,设备和工序是根据GMP要求进行建造或安装的。

这就是安装确认(IQ, Installation Qualification).2.3.3 厂房,设施,设备和工序是根据其设计标准进行操作的。

这就是操作确认(OQ, Operational Qualification).2.3.4 一特定工艺能够持续地生产出符合已定质量标准和质量属性的产品。

这就是工艺验证(PV, Process Validation)。

也被称为性能确认(PQ, Performacne Qualification)2.4 Terminology2.4.1 Terminology used in the four Recommendation documents which is not defined in the current glossary of the PIC/S Guide to GMP, is presented at the end of this document.2.4.2 It is worth commenting on the interchangeability of terms typically accepted internationally. The term ‘validation’ is often assumed to encompass the elements of equipment qualification, both Installation Qualification and Operational Qualification, in addition to validation of the process itself. However, for the purpose of these Recommendations, terms are not used interchangeably.2.4 术语2.4.1 本文件中所用到的术语,若现行PIC/S GMP 指导文件中没有对其进行解释,则在本文件的结尾处会有其解释。

2.4.2 有必要对术语的可替换性进行说明,特别是那些国际认可的术语。