Numerical studies on the inter-particle breakage of a confined particle assembly in rock crushing

- 格式:pdf

- 大小:1.27 MB

- 文档页数:20

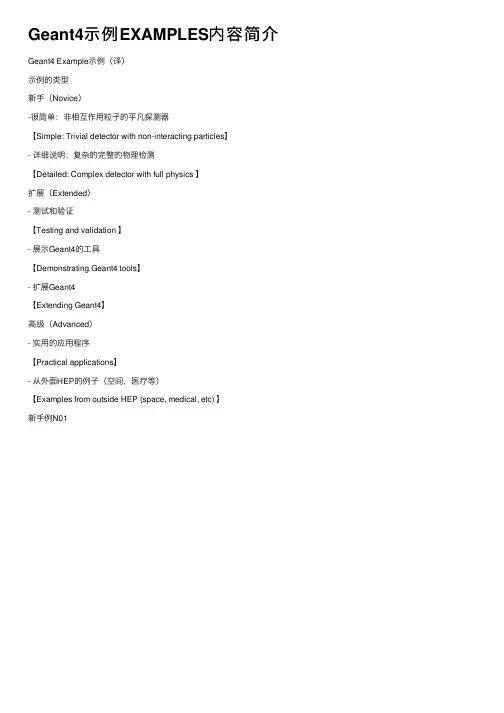

Geant4⽰例EXAMPLES内容简介Geant4 Example⽰例(译)⽰例的类型新⼿(Novice)-很简单:⾮相互作⽤粒⼦的平凡探测器【Simple: Trivial detector with non-interacting particles】- 详细说明:复杂的完整的物理检测【Detailed: Complex detector with full physics 】扩展(Extended)- 测试和验证【Testing and validation 】- 展⽰Geant4的⼯具【Demonstrating Geant4 tools】- 扩展Geant4【Extending Geant4】⾼级(Advanced)- 实⽤的应⽤程序【Practical applications】- 从外⾯HEP的例⼦(空间,医疗等)【Examples from outside HEP (space, medical, etc) 】新⼿例N01固定⼏何:氩⽓母卷,铝圆柱和铅铝块⽚与Al⽚块【Fixed geometry: Ar gas mother volume with Al cylinder and Pb block with Al slices】⼊射粒⼦是⼀个geantino;没有物理相互作⽤【Incident particle is a geantino;no physics interactions】⽆磁场,只有运输过程中启⽤【No magnetic field and only the transportation process is enabled】硬编码的批处理作业和冗长【Hard coded batch job and verbosity】新⼿⽰例N02铅靶,氙⽓室【Pb target, Xe gas chambers】所有的EM流程+衰变,γ和带电轻⼦和带电强⼦【All EM processes + decay,included for γ, charged leptons and charged hadrons】探测器响应【Detector response】轨迹和命中可能被存储【Trajectories and chamber hit collections maybe stored】可视化检测器和事件【Visualization of detector and event】命令接⼝介绍【Command interface introduced】运⾏时可以改变⽬标,室材料,⼊射粒⼦类型,动量等【Can change target, chamber materials, incident particle type, momentum, etc. at run time】Ps:⼊射三种粒⼦,先经过⼀个⼩铅块(标出)然后经过五个氙⽓室(黄⾊)。

主动配电网分布式电源渗透率研究刘 剑,李学斌(中国能源建设集团天津电力设计院,天津 300400)摘要:本文提出一种基于网络重构的提高主动配电网分布式电源渗透率的方法。

一种基于粒子群和启发式算法的混合优化方法被用来寻找具有更高渗透率的网络结构。

首先,利用二进制粒子群(BPSO)优化算法进行初始搜索,然后,对粒子群优化结果进行聚类分析,作为启发式算法的初始解进一步寻优。

一种新的网络拓扑分析方法与粒子群算法相结合用于提高粒子的搜索效率。

连续潮流方法被用来精确求解配电网最大输送能力,克服常规潮流计算分岔点附近不收敛的问题。

通过IEEE123算例仿真分析,测试结果验证了本文所提方法在大幅提高系统最大输送能力方面的有效性。

关键词:主动配电网;分布式电源;网络重构;二进制粒子群优化算法;连续潮流;启发式方法。

中图分类号:TM72 文献标志码:B 文章编号:1671-9913(2018)S2-0239-06Research on Distributed Power SupplyPermeability of Active D istribution NetworkLIU Jian, LI Xue-bin(China Energy Engineering Group Tianjin Electric Power Design Institute, Tianjin 300400, China)Abstract: This paper proposes a method based on network reconfiguration technology to improve the permeability of DG outs in an active distribution network. A hybrid optimization method based on particle swarm optimization (PSO) is used to seek the better network configuration with a higher permeability. Firstly, binary particle swarm optimization (BPSO) algorithm is employed for a preliminary search. Secondly, make the results obtained from PSO clustering analysis and are used as the initial solution of the heuristic algorithm. A new method of network topology analysis combined with PSO is used to improve the efficiency of particle search. The continuation power flow method is used to seek the maximum delivery capacity of distribution network accurately, overcoming the problem of nonconvergence near the bifurcation point for the conventional power flow solver. The IEEE 123-bus test network is used to verify the proposed methodology and the numerical studies demonstrate the effectiveness of the proposed methodology in greatly increasing available delivery capability.Key words: active distribution network; distributed generation; network reconfiguration; BPSO; continuation power flow; heuristic method.* 收稿日期:2018-04-11作者简介:刘剑(1984- ),男,江苏邳州人,硕士,工程师,从事智能配电网研究及设计工作。

PERSPECTIVESChinese Journal of Chemical Engineering, 18(6) 889—898 (2010)Advances in Studies on Turbulent Dispersed Multiphase Flows*ZHOU Lixing (周力行)**Department of Engineering Mechanics, Tsinghua University, Beijing 100084, ChinaAbstract Dispersed multiphase flows, including gas-particle (gas-solid), gas-spray, liquid-particle (liquid-solid), liquid-bubble, and bubble-liquid-particle flows, are widely encountered in power, chemical and metallurgical, aeronautical and astronautical, transportation, hydraulic and nuclear engineering. In this paper, advances and re-search needs in fundamental studies of dispersed multiphase flows, including the particle/droplet/bubble dynamics, particle-particle, droplet-droplet and bubble-bubble interactions, gas-particle and bubble-liquid turbulence interac-tions, particle-wall interaction, numerical simulation of dispersed multiphase flows, including Reynolds-averaged modeling (RANS modeling), large-eddy simulation (LES) and direct numerical simulation (DNS) are reviewed.The research results obtained by the present author are also included in this review.Keywords dispersed flows, multiphase flows, turbulent flows, fundamentals, numerical simulation1 INTRODUCTIONDispersed multiphase flows denote gas-particle (gas-solid), gas-spray, liquid-particle (liquid-solid), liquid-bubble, and bubble-liquid-particle flows, where the continuous phase is fluid (gas or liquid) and the dispersed phase is particles (including droplets and bubbles). Unlike these kinds of multiphase flows there are gas-liquid stratified flows, annular flows, plug flows and bullet flows. Dispersed multiphase flows are widely encountered in natural environment and biological bodies. Examples are dust in air, sedimen-tation in river, cosmic dust, cloud and fog, air-sand flows, and blood flows. There is a variety of dispersed multiphase flows in engineering, such as pneumatic and hydraulic conveying, dust/droplet separation and collection, spray/pulverized-coal combustion, fluid-ized beds, spray cooling/drying/coating, plasma chem-istry, bubble-particle-liquid flows in steel making fur-naces, gas-particle flows in solid rockets and gun bar-rels, gas-fiber flows in textile engineering, bubbling steam-water flows in boilers, nuclear reactors and pe-troleum pipes. In most engineering facilities due to large geometrical sizes, higher flow velocity and the existence of various barriers, sudden expansions or swirlers, the flows are complex turbulent flows.In order to understand the physical phenomena of dispersed multiphase flows, fundamental studies, nu-merical simulation and measurements were carried out for many years. Fundamental studies cover particle/ droplet/bubble dynamics, particle/droplet/bubble-fluid turbulence interactions, particle-particle, droplet-droplet and bubble-bubble collisions and particle/droplet/bubble- wall interactions.For numerical modeling, there are two ap-proaches: Eulerian-Eulerian (or two-fluid) modeling and Eulerian-Lagrangian modeling. In E-E modeling, besides the modeling of fluid flows the dispersed phase is regarded as a pseudo fluid. The continuous and dispersed phases coexist in the same space and interpenetrate with each other; both of them are de-scribed in Eulerian coordinates. On the other hand, in E-L modeling, only the fluid is regarded as a continu-ous phase and described in Eulerian coordinates, whereas particles are treated as a discrete system and are described in Lagrangian coordinates. The Lagran-gian approach is also called particle trajectory ap-proach, which is equivalent to a direct numerical simulation of the dispersed phase. In the 1950s to 1960s, the particle motion was simulated using the single-particle dynamics model [1], where the parti-cle/droplet trajectories in a known flow field (e.g. uniform velocity and temperature fields) were consid-ered and the effect of particles on the fluid flows is neglected (one-way coupling). Also, the particle fluc-tuation was not considered (diffusion frozen). This analytical method is too simple, far from the practical situation, and nowadays is no more used as a simula-tion method, but it is helpful for understanding the basic phenomena of particle motion, such as the “par-ticle relaxation time” and “particle terminal velocity”. Near the end of 60s years of the last century the con-cept of pseudo fluid of particles was proposed, where the velocity slip between fluid and particles is consid-ered as a result of particle diffusion drift, i.e., slip is a result of diffusion. It is called by the present author a “small-slip model”. The particles were treated in Eul-erian coordinates and the effect of particles on fluid motion was also neglected. Till the beginning of 70s of the last century, when the method of computational fluid dynamics for single-phase flows was used to simulate gas-particle flows, the single-fluid model or no-slip model was proposed, where particles are treated as a pseudo fluid in Eulerian coordinates, but no velocity slip and temperature slip between fluid and particles are taken into account, i.e., the particle velocity and temperature are considered to be equal toReceived 2010-11-02, accepted 2010-11-18.* Supported by the Key Projects of National Natural Science Foundation of China (50736006, 9587003-13), the State Key De-velopment Program for Basic Research of China (G1999-0222-08) and the National Pandeng Project of China (85-06-1-2).** To whom correspondence should be addressed. E-mail: zhoulx@Chin. J. Chem. Eng., Vol. 18, No. 6, December 2010 890the fluid velocity and temperature everywhere; the continuous and dispersed phases are in dynamic and thermodynamic equilibrium. Also, the particle fluc-tuation is assumed to be equal to the fluid fluctuation (diffusion equilibrium). Hence this model is called single-fluid model or no-slip model. It is another kind of simplified models, and in many cases it is far from the practical situation. Since the 80s years of the 20th century, the full particle trajectory models and two-fluid models were proposed.In the full particle trajectory model, the particles are treated as a discrete system and the particle motion is described in Lagrangian coordinates, with both ve-locity and temperature slip considered. Unlike the single- particle dynamics model, in the modern particle tra-jectory models, the mass, momentum and energy cou-pling between the fluid and particle phases are taken into account, i.e. it is a two-way coupling model. The particle trajectory models are divided into “determi-nistic trajectory models”, in which the particle diffu-sion (dispersion) due to fluctuation is not taken into account, and “stochastic trajectory models” account-ing for the particle fluctuation. For dense fluid- parti-cle flows, it is needed to introduce inter-particle colli-sion or particle-particle interaction models, so some-times it is called four-way coupling models.In modern Eulerian-Eulerian models or two-fluid models, particles are treated as a pseudo fluid; the par-ticle motion is described in Eulerian coordinates. Unlike the single-fluid model and the small-slip model, not only the velocity and temperature slips are taken into account, but also they are not related to particle diffusion. The particle diffusion is a result of particle fluctuation. The E-E models are also two-way cou-pling or four-way coupling models. For E-E models, it is necessary to develop particle turbulence models such as particle turbulent kinetic energy or particle Reynolds stress equation models.The above-stated simulation is based on Reynolds-averaged Navier-Stokes simulation, and it is now called RANS modeling. In recent years, due to the development of computer hardware and CFD software, more refined simulation, called large-eddy simulation (LES) and direct numerical simulation (DNS) for single-phase flows are introduced to the simulation of dispersed multiphase flows. DNS needs not any closure models, it can give the detailed struc-ture of all scales, but it needs huge computation re-quirement and cannot be directly used to solve engi-neering problems. It can be used to validate the LES or RANS modeling. Comparing to RANS modeling, LES can give the detailed instantaneous flow struc-tures and more accurate statistical results than those given by RANS modeling, but it needs much less computation requirement than DNS. So, LES is just under its fast development, and is by and by becoming a new generation of CFD tools.In the following sections a brief review of the advances in fundamental studies and numerical simu-lation of dispersed multiphase flows will be stated. 2 ADV ANCES IN FUNDAMENTAL STUDIES 2.1 Single particle/droplet/bubble dynamicsRecent studies on dispersed phase dynamics are concentrated on exerted forces and motion of particles with mass change, deformable droplets and bubbles and non-spherical (cylindrical or irregular shapes) particles. Deformation of droplets or bubbles during their motion leads to the change of exerted forces. Besides, the motion of bubbles with surfactants is dif-ferent from that of bubbles without surfactants. For the exerted forces on particles of irregular shapes, the results of some studies show the increase of Magnus force due to particle rotation, but other studies indicate that this effect is not remarkable. Sommerfeld and Kussin [2] reported their studies on the dispersion of non-spherical particles, and it was found that spherical glass beads are more homogeneously distributed across the channel than non-spherical quartz and non-spherical duroplast particles, as shown in Fig. 1.Figure 1 Particle number density profiles●glass beads 195 μm;◆Duroplast irregular 240 μm;★quartz particle 185 μmZhang and Lin [3] systematically studied the ori-entation, motion and exerted forces of cylindrical par-ticles. The forces acting on particles are studied using direct numerical simulation of turbulent flow passing a single particle by Lee and Balachandar [4] and using Lattice-Boltzmann simulation of motion of finite-size particles in turbulent flow by Sundaresan and Cate [5]. From the results of these studies the detailed flow field around a particle is obtained and by integration of the friction and pressure forces on the surface of a particle, various forces, including the drag force, lift force and added mass force are obtained. The results indicate that the relative importance of the added mass force depends on the ratio of particle/bubble material density to the fluid density. When this ratio is very small, the effect of added mass force can be neglected. The effect of small-scale turbulence on the particle drag force is also studied. Mechaelides [6] systemati-cally studied the exerted forces, heat and mass transfer of a particle/droplet/bubble. A comparison is made among the results of classical analytical solution, direct numerical simulation and Lattice-Boltzmann simulation.Chin. J. Chem. Eng., Vol. 18, No. 6, December 2010 891The effect of particle concentration on the particle drag force, and the effect of added mass force are also discussed. Based on numerical studies he suggested a drag force expression as()()()D s D s D s 24,,0,226c Re c Re c Re λλλλ−=++for 02λ≤≤, and s 51000Re <≤ (1) where Re s is the particle Reynolds number and λ is the ratio of particle material density to fluid density.In general, the exerted forces and motion of de-formable and irregular-shaped particles remain to be further studied in details.2.2 Particle-particle, droplet-droplet, bubble-bubble interactions and their collision with wallFor particle-particle interactions, hard-sphere and soft-sphere models were proposed [7]. A collision fre-quency model was proposed by Sommerfeld [8]. You et al . [9] measured the particle collision frequency using PIV and modified Sommerfeld’s formula. Zhang et al . [10] studied various forces for particle-particle elastic and plastic collisions, including van de Waals force, and proposed a particle clustering model. The bubble-bubble collisions and agglomerations are still complex, and were studied using volume of fluid (VOF) [11] and level-set methods [12]. For parti-cle-wall interaction, Zhang and Zhou [13] introduced the particle collision dynamics into the two-fluid models by using the integral over probability density distribution function (PDF), taking into account the friction, restitution and wall roughness. For example, the axial component of the particle normal Reynolds stresses at the wall is obtained as(){}()()()22b 112221122211112221121113213113123213(23)(1)33131232(12)3uu u u f e v v e f f u u f e u u f e v v ef e ef v v f e αααααα⎡⎤′′′′′=−−++⎣⎦⎡⎤′′′′′++−+⎣⎦⎡⎤′′′′′′−++++⎣⎦⎡⎤′++−−⎣⎦′+ (2)where f , e and α denote the friction coefficient, restitu-tion coefficient and wall roughness respectively, and the subscripts b and 1 denote the values at the wall and at the near-wall grid nodes respectively.2.3 Particle/bubble-fluid turbulence interactionsThis is an important aspect of fundamental stud-ies. For a long time period there was less understand-ing to particle/bubble fluctuations. Till 1986 it wasconsidered that the particle fluctuation is determined only by the local fluid fluctuation, the particle fluctua-tion, following the fluid fluctuation, is always weaker than the fluid fluctuation, and the larger the particle size, the weaker the particle fluctuation. This is the Hinze- Tchen model of particle fluctuation [14], given by21p T p T p r1T //(/)(1/)D D k k ννττ−===+ (3)where ν, D and k express the viscosity, diffusivity and turbulent kinetic energy respectively, and the subscripts p and T denote the values for particle and gas, r1T ,ττ are the particle relaxation time and gas fluctuation time respectively. However, in the 1980s to 1990s it was discovered by Zhou et al . [15] that for gas-particle jet and separating flows and in a certain range of par-ticle sizes the particle fluctuation is stronger than the fluid fluctuation, and the larger the particle size, the stronger the particle fluctuation. In contrast to previ-ous understandings, larger particles diffuse not slower but faster than smaller particles. A transport equation of particle turbulent kinetic energy was proposed by Zhou and Huang [15] as()()p p p p,p p p p pp p p j j jj N k N V k t x N k P N x x νεσ∂∂+∂∂∂⎛⎞∂=+−⎜⎟⎜⎟∂∂⎝⎠(4) Further studies indicate that the anisotropy of particle fluctuation is stronger than that of fluid. Hence, Zhou et al . subsequently proposed a unified second-order moment (USM )two-phase turbulence theory, or a theory of two-phase Reynolds stress equa-tions [16, 17] given by the following equations()()p,R,i j m i j mij ij ij ij ij ij ij v v V v v t x D P G G G ρρΠε∂∂+∂∂=+++−++ (5) ()()p p,p,p p,p,p,p,p,p,i j k i j kji ij ijN v v N V v v t x D P ε∂∂+∂∂=++ (6)It is seen that the particle turbulent kinetic energyor particle Reynolds stress depends on not only the local fluid turbulence, but also its own convection, shear production and diffusion. Hence, in some cases or in some regions of the flow field, the particle fluc-tuation may be stronger than the fluid fluctuation. This is a result of the inertia of particle fluctuation. Subse-qunt discrete-vortex and experimental studies show that small particles follow the fluid vortex motion, and medium-size particles locate at the periphery of fluid vortices, and their dispersion is stronger than that of small particles [18].Numerical simulation and experimental results validate that the k p -equation and USM model theory are more reasonable than the Hinze-Tchen theory. ForChin. J. Chem. Eng., Vol. 18, No. 6, December 2010 892bubble-liquid flows it was argued whether bubbles re-duce or induce liquid turbulence. The studies made by Zhou et al. show that under certain conditions the bub-ble fluctuation is stronger than the liquid fluctuation [19], and under different velocities and void fractions bubbles may enhance or reduce liquid turbulence [20].The interaction between inter-particle collisions and particle turbulence for dense gas-particle flows remains to be studied. Zhou et al. reports that particle- particle collision leads to redistribution of particle Rey-nolds stresses in different directions, i.e., reduction of particle fluctuation in a certain direction and enhance-ment of particle fluctuation in other directions [21].The effect of particles on fluid turbulence, i.e. the so-called turbulence modification or turbulence modu-lation is a hot point of international studies. In the 1990s, Crowe summarized the experimental results and pointed that small particles reduce fluid turbulence due to their dissipation of fluid turbulent kinetic en-ergy and larger particles enhance fluid turbulence due to their wake effect. Different investigators used laser Doppler velocimeter (LDV), phase Doppler particle anemometer (PDPA), and particle image velocimeter (PIV) to measure the turbulence modulation. Various semi-empirical expressions were proposed [22-24]. However, these semi-empirical models are insuffi-ciently used and validated in numerical simulation of turbulent gas-particle flows. In present RANS model-ing (Reynolds-Averaged Navier-Stokes modeling), LES (large-eddy simulation) and DNS (direct nu-merical simulation), the particles are treated as point sources, only models of particle reducing gas turbu-lence can be taken into account, and the particle wake effect is difficult to be taken into account. It was dis-covered in experiments that for a certain range of par-ticle sizes particles may reduce and enhance fluid tur-bulence in different locations of the same flow field. This particle size range may depend on different flow types. Based on LES of turbulent flows passing a sin-gle particle, Zeng et al. proposed a model of gas tur-bulence enhancement by the particle wake effect [25]. The additional source term due to particle wake effect in the gas Reynolds stress equation is proposed. It is shown that the production of particle turbulence due to the particle wake effect is proportional to the particle diameter and the square of relative velocity. By in-corporating this sub-model into the USM two-phase turbulence model for turbulent gas-particle flows, the effects of both reduction and enhancement of fluid turbulence by particles of different sizes in vertical and horizontal pipe flows can be properly predicted, and the modeling results are in good agreement with ex-perimental results. Hence the mechanism of the effect of solid particles on fluid turbulence is well clarified.Obviously, it still needs to further study: (1) the interaction between inter-particle collision and particle turbulence; (2) in what situations (flow types, particle Reynolds number and particle size) or in what regions of the flow field, particles reduce or enhance fluid turbulence; (3) the interaction between inter-particle collision and fluid turbulence modification. 3 ADV ANCES IN NUMERICAL SIMULATION 3.1 RANS modelingIn the framework of Eulerian-Lagrangian model-ing, the stochastic particle trajectory model is widely used in simulating practical gas-particle/droplet flows, in particular liquid spray and pulverized-coal combus-tion, because it can give the detailed particle behavior and particle mass and temperature history during reac-tions. It is a direct simulation of particle motion and needs not closure models. However, for the fluid phase, due to adopting turbulence models in RANS modeling, a model for the instantaneous velocity or fluctuation velocity should be developed. In the early stage of development Gosman and Ioannides proposed an isotropic Gaussian distribution for the random fluctuation velocity [26]. In the 1980s Cen and Fan proposed a Fourier stochastic series model of fluctua-tion frequency [27].Subsequently, Sommerfeld et al. introduced Langevin equation model [28], which is now being applied in many cases. Due to the large computation requirement of the particle trajectory model, Smith and Baxter [29] and Chen and Pereira [30] proposed the methods of most probable trajectories plus empirical PDF, in order to not use too many tra-jectories for obtaining the information of particle Eul-erian flow field. Starting from the 1990s, more atten-tion was paid to dispersed particle trajectory models for dense gas-particle flows, such as in pneumatic con-veying, dense-phase gas-solid cyclones, hydrocyc-lones, fluidized beds, etc. Tsuji et al. [31] at first con-ducted these studies, called DEM (discrete element method), using hard-sphere and soft-sphere models to simulate inter-particle collision. By using the soft-sphere model it is possible to predict the particle clusters and core-annulus flows, experimentally observed in circu-lating fluidized beds. These kinds of simulations in-clude discrete particle simulation (DPS) of dual-body collision and discrete-particle simulation Monte-Carlo (DSMC) of multiple-body random collisions. In recent years, Yu and co-workers [32-34] made tremendous strides in developing and using DEM models to suc-cessfully simulate complex gas-particle flows in prac-tical engineering equipments, as in pneumatic con-veying, gas-solid cyclones, circulating fluidized beds and iron-making blast furnaces. Nevertheless, the dis-crete particle simulation is a direct simulation of parti-cle motion, and computationally very expensive for predicting large-size engineering facilities.The existing problem for application of DEM models in engineering is that the simulation results have not yet been extensively validated by detailed measurement results.On the other hand, the Eulerian-Eulerian or two- fluid modeling has obtained remarkable development in recent years, in particular for predicting dense gas- particle flows, since its computation requirement is much less than that for discrete particle simulation. The key problem in two-fluid modeling is to develop the closure models for dispersed-phase (particles, droplets,Chin. J. Chem. Eng., Vol. 18, No. 6, December 2010893bubbles) turbulence and inter-particle collisions. As already mentioned above, different gas-particle two- phase turbulence models were developed, including k-ε-Ap model, based on Hinze-Tchen’s algebraic model (Ap model), k-ε-k p and USM models by Zhou et al., which obtained wide application and were de-veloped into a bubble-liquid-particle three-phase tur-bulence model at the beginning of this century [35]. On the other hand, many authors [36-41] developed two-fluid models based on PDF transport equations, including finite-difference and Monte-Carlo methods for solving PDF equations. For simulating inter-particle collisions in dense gas-particle flows, Gidaspow et al. proposed a kinetic theory [42], using particle pseudo- temperature equation to simulate particle collision energy, particle collisional pressure and viscosity. This model gives good results for bubbling fluidized beds. However, in cases of circulating fluidized beds, riser and downer flows, both particle turbulence and in-ter-particle collisions play important role in particle mixing. Zhou et al. [43] simulated dense gas-particle flows by using LES for gas flows and the kinetic the-ory for particle flows. It should be noted that the grid size is too large that the simulation looks like an un-steady RANS modeling using a very coarse turbulence model. Xiao et al. [44] improved the two-fluid model with the kinetic theory by introducing a three-region (dilute, dense and intermediate regions) drag-force law based on the minimum energy principle. Cheng et al. [45, 46] combined the k-ε-k p model with the kinetic theory model to propose a k-ε-k p-Θ model and a k-ε-k p-εp-Θ model, and found that these models are better than the k-ε-Θ model not accounting for the particle turbulence and the k-ε-k p model not account-ing for the inter-particle collision. Recently, Yu et al.[22] proposed a USM-Θ model and Zeng and Zhou [47] proposed a two-scale SOM (second-order moment) particle turbulence model. These models are better than the k-ε-k p-Θ and a k-ε-k p-εp-Θ models. The superiority of the USM-Θ model over other models is shown in Fig. 2Figure 2 Particle volume fraction●experiment; USM-Θ; k-ε-k p-Θ;○DSM (differ-ential Reynolds stress model)-Θ; × USMIn general, the E-E two-fluid models have the potential to well solve the engineering problems, but the closure models remain to be further studied. One of the important research needs is using DNS/LES plus dispersed particle models and measurement results to extensively validate the particle turbulence models or two-phase turbulence models in E-E modeling.3.2 Direct numerical simulation (DNS) and large- eddy simulation (LES)The direct numerical simulation (DNS) and large-eddy simulation (LES) of dispersed multiphase flows have been developed for more than 20 years. The point-particle DNS is directly to solve the N-S equation and point-particle motion equation on fine grids of Kolmogorov scales. It needs not any closure models but requires high-accuracy numerical methods, such as spectral methods and compact difference schemes, and also periodic boundary conditions. DNS of channel, mixing layer and jet gas-particle flows exhibit the instantaneous structures of turbulence, i.e., its production and development processes, the details of particle motion in turbulence eddies and particle dispersion, and also the effect of particles on gas tur-bulence. LES is using a white-noise filtration to di-rectly solve the instantaneous N-S equation and point-particle motion in resolved large scales, whereas for the unresolved small scales using a SGS (sub-grid scale) stress model. The frequently used SGS models are the Smagorinsky eddy-viscosity mode, Smagorin-sky-Lilly model, Germano dynamic eddy-viscosity model and SGS energy equation model.In recent DNS studies of dispersed multiphase flows the special attention is paid to FDNS (Fully re-solved DNS) or TDNS (True DNS). This is using the Lattice-Boltzmann or finite-difference methods to solve 3-D instantaneous N-S equation with finite-size particles and using VOF, front-tracking, level-set or immerse-boundary methods to treat the moving inter-face. It can give the particle wake structure and the effect of particle wake on gas turbulence, and the par-ticle drag, lift and added-mass forces. Bagchi and Balachandar simulated steady and unsteady turbulent flows passing a stagnant and a moving particle with Re P=10-300 using FDNS [48]. The results give the instantaneous vorticity isolines. The DNS database is used to obtain the drag, lift and other forces. DNS of flow passing a single particle with sizes of double Kolmogorov scales was reported in [49]. The gas vor-ticity isolines for cases with and without the particle were obtained. The result is that the turbulence is en-hanced near the particle, but generally is reduced. The velocity vectors of flows around two interacting cyl-inders are given by DNS in [50]. The instantaneous bubble position and fluid velocity isolines for fluid flows around several bubbles made by DNS [51] are shown in Figs. 3 and 4 respectively. From these results the bubble rising velocity, bubble drag and fluid sub-grid scale stress are obtained. The vorticity tubes be-hind 78 particles in isotropic homogeneous turbulent flows made by DNS [52] show an enhancement of fluid turbulence by particles.Chin. J. Chem. Eng., Vol. 18, No. 6, December 2010894Figure 3Instantaneous bubble positionsFigure 4 Instantaneous fluid velocity isolinesThe fluid flows around 45 bubbles of different sizes are reported in [53]. The instantaneous velocity vectors (Fig. 5) and bubble fluctuation velocities (Fig. 6) are obtained. It is seen that the fluctuation velocities (in terms of particle Reynolds number) of larger parti-cles are stronger than those of smaller particles.Figure 5Instantaneous velocity vectorsFigure 6 Fluctuation velocities of particlesThe point-particle DNS was studied from about 1994 [54]. The instantaneous gas velocity vectors and particle position in isotropic homogeneous turbulent flows given by point-particle DNS made in [55] are shown in Fig. 7, indicating that particles are located in the periphery of vortex structures.(a)(b)Figure 7 Instantaneous velocity vectors and particle positionThe point-particle DNS of a gas-particle jet [56] gives the instantaneous particle position for particles of (a) St =0.01, (b) St =1, and (c) St =50, as shown in Fig. 8. These results show the dispersion of particles of different sizes under the effect of gas turbulence, similar to the results obtained by other investigators using large-eddy simulation and discrete vortex simu-lation. However, the modeling results for particles have not been validated by experiments and the results show only the reduction of gas turbulence even for large particles with St =50, indicating the limitation of point-particle DNS.All LES of gas-particle and bubble-liquid flows are based on the point-particle approach. These studies are focused on particle dispersion under the effect of gas turbulence and the effect of particles on gas tur-bulence. Also, the LES statistical results are used to validate the two-phase turbulence models. The two-way coupled Eulerian-Lagrangian large-eddy simulation of bubble-liquid jets were made in [57] using a Sma-gorinsky-Lilly SGS stress model and the bubble tra-jectory model accounting for the drag force, buoyancy force and added-mass force. The results show the in-duced liquid turbulence by bubbles.The large-eddy simulation of backward-facing step gas-particle flows is made in [58], using the Smagorinsky。

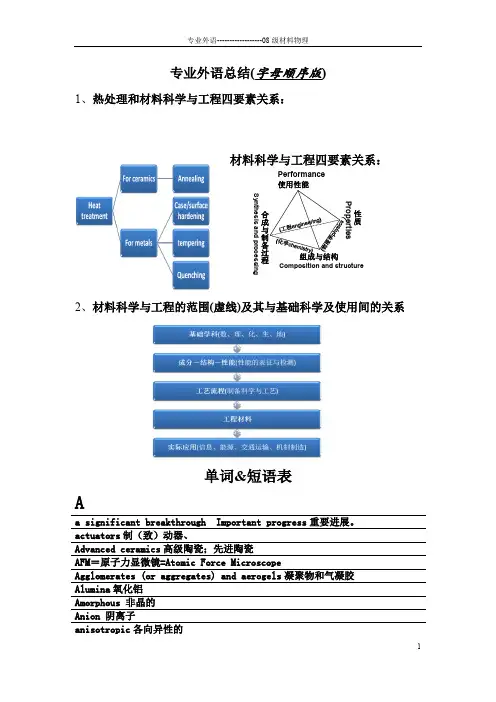

专业外语总结(字母顺序版)1、热处理和材料科学与工程四要素关系:材料科学与工程四要素关系:Performance 使用性能组成与结构合成与制备过程Synthesis and processingComposition and structure性质Properties2、材料科学与工程的范围(虚线)及其与基础科学及使用间的关系单词&短语表Aa significant breakthrough Important progress 重要进展。

actuators 制(致)动器、Advanced ceramics 高级陶瓷;先进陶瓷 AFM =原子力显微镜=Atomic Force MicroscopeAgglomerates (or aggregates) and aerogels 凝聚物和气凝胶 Alumina 氧化铝Amorphous 非晶的 Anion 阴离子anisotropic 各向异性的anode阳极axial projection轴投影BBCC=body-centered cubic体心立方Bioceramics生物陶瓷biodegradable adj. 生物所能分解的Biodegradable systems生物可降解系统biodegradable可生物降解的bio-inspired medical prostheses仿生医学人工器官。

biological tagging生物标记biomedical applications生物医学应用。

biomimetic adj. 仿生的biomolecular single-electron devices生物分子的单电子器件Biotechnology生物技术bivalent/divalent二价的。

bulk acoustic waves BAWs体声波Bulk material 体材料CCapacitor电容器carbon Nanotube碳纳米管Catalyst催化剂Cathode 阴极Cation 阳离子Cement水泥; 接合剂ceramic based composites陶瓷基复合材料Ceramic coating 陶瓷涂层Chemical Composition化学成分Chemical reagent化学试剂civil engineering土木工程Cold isostatic pressing(CIPing) 冷等静压compacting equipment压实设备。

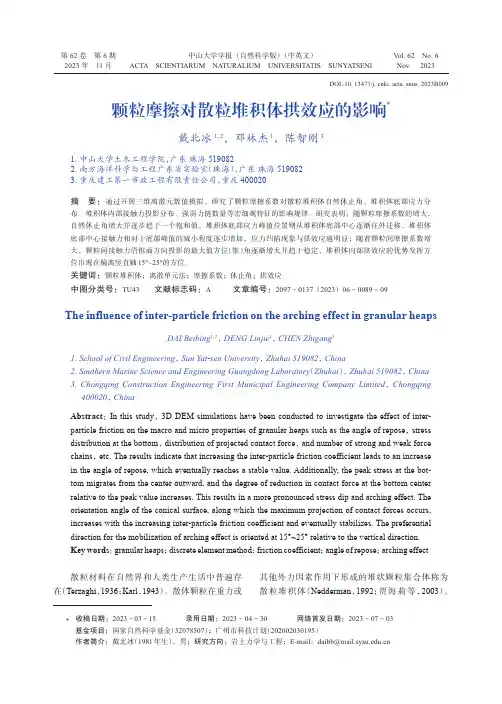

第 62 卷第 6 期2023 年11 月Vol.62 No.6Nov.2023中山大学学报(自然科学版)(中英文)ACTA SCIENTIARUM NATURALIUM UNIVERSITATIS SUNYATSENI颗粒摩擦对散粒堆积体拱效应的影响*戴北冰1,2,邓林杰1,陈智刚31. 中山大学土木工程学院,广东珠海 5190822. 南方海洋科学与工程广东省实验室(珠海),广东珠海 5190823. 重庆建工第一市政工程有限责任公司,重庆 400020摘要:通过开展三维离散元数值模拟,研究了颗粒摩擦系数对散粒堆积体自然休止角、堆积体底部应力分布、堆积体内部接触力投影分布、强弱力链数量等宏细观特征的影响规律。

研究表明:随颗粒摩擦系数的增大,自然休止角增大并逐步趋于一个饱和值,堆积体底部应力峰值位置则从堆积体底部中心逐渐往外迁移,堆积体底部中心接触力相对于底部峰值的减小程度逐步增加,应力凹陷现象与拱效应越明显;随着颗粒间摩擦系数增大,颗粒间接触力沿锥面方向投影的最大值方位(锥)角逐渐增大并趋于稳定,堆积体内部拱效应的优势发挥方位出现在偏离竖直轴15°~25°的方位。

关键词:颗粒堆积体;离散单元法;摩擦系数;休止角;拱效应中图分类号:TU43 文献标志码:A 文章编号:2097 - 0137(2023)06 - 0089 - 09The influence of inter-particle friction on the arching effect in granular heapsDAI Beibing1,2, DENG Linjie1, CHEN Zhigang31. School of Civil Engineering, Sun Yat-sen University, Zhuhai 519082, China2. Southern Marine Science and Engineering Guangdong Laboratory(Zhuhai), Zhuhai 519082, China3. Chongqing Construction Engineering First Municipal Engineering Company Limited,Chongqing400020, ChinaAbstract:In this study, 3D DEM simulations have been conducted to investigate the effect of inter-particle friction on the macro and micro properties of granular heaps such as the angle of repose, stress distribution at the bottom, distribution of projected contact force, and number of strong and weak force chains, etc. The results indicate that increasing the inter-particle friction coefficient leads to an increase in the angle of repose, which eventually reaches a stable value. Additionally, the peak stress at the bot‐tom migrates from the center outward, and the degree of reduction in contact force at the bottom center relative to the peak value increases. This results in a more pronounced stress dip and arching effect. The orientation angle of the conical surface, along which the maximum projection of contact forces occurs, increases with the increasing inter-particle friction coefficient and eventually stabilizes. The preferential direction for the mobilization of arching effect is oriented at 15°~25° relative to the vertical direction. Key words:granular heaps; discrete element method; friction coefficient; angle of repose; arching effect散粒材料在自然界和人类生产生活中普遍存在(Terzaghi,1936;Karl,1943)。

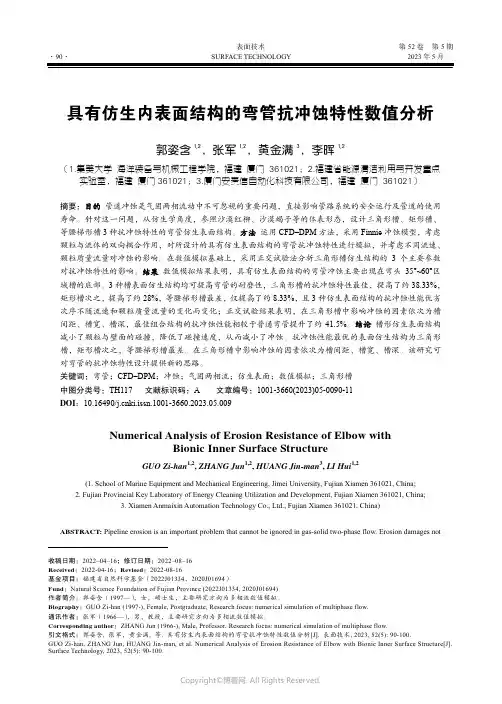

表面技术第52卷第5期具有仿生内表面结构的弯管抗冲蚀特性数值分析郭姿含1,2,张军1,2,黄金满3,李晖1,2(1.集美大学 海洋装备与机械工程学院,福建 厦门 361021;2.福建省能源清洁利用与开发重点实验室,福建 厦门361021;3.厦门安麦信自动化科技有限公司,福建 厦门 361021)摘要:目的管道冲蚀是气固两相流动中不可忽视的重要问题,直接影响管路系统的安全运行及管道的使用寿命。

针对这一问题,从仿生学角度,参照沙漠红柳、沙漠蝎子等的体表形态,设计三角形槽、矩形槽、等腰梯形槽3种抗冲蚀特性的弯管仿生表面结构。

方法运用CFD–DPM方法,采用Finnie冲蚀模型,考虑颗粒与流体的双向耦合作用,对所设计的具有仿生表面结构的弯管抗冲蚀特性进行模拟,并考虑不同流速、颗粒质量流量对冲蚀的影响。

在数值模拟基础上,采用正交试验法分析三角形槽仿生结构的3个主要参数对抗冲蚀特性的影响。

结果数值模拟结果表明,具有仿生表面结构的弯管冲蚀主要出现在弯头35°~60°区域槽的底部。

3种槽表面仿生结构均可提高弯管的耐磨性,三角形槽的抗冲蚀特性最佳,提高了约38.33%,矩形槽次之,提高了约28%,等腰梯形槽最差,仅提高了约8.33%,且3种仿生表面结构的抗冲蚀性能优劣次序不随流速和颗粒质量流量的变化而变化;正交试验结果表明,在三角形槽中影响冲蚀的因素依次为槽间距、槽宽、槽深,最佳组合结构的抗冲蚀性能相较于普通弯管提升了约41.5%。

结论槽形仿生表面结构减小了颗粒与壁面的碰撞,降低了碰撞速度,从而减小了冲蚀。

抗冲蚀性能最优的表面仿生结构为三角形槽,矩形槽次之,等腰梯形槽最差。

在三角形槽中影响冲蚀的因素依次为槽间距、槽宽、槽深。

该研究可对弯管的抗冲蚀特性设计提供新的思路。

关键词:弯管;CFD–DPM;冲蚀;气固两相流;仿生表面;数值模拟;三角形槽中图分类号:TH117 文献标识码:A 文章编号:1001-3660(2023)05-0090-11DOI:10.16490/ki.issn.1001-3660.2023.05.009Numerical Analysis of Erosion Resistance of Elbow withBionic Inner Surface StructureGUO Zi-han1,2, ZHANG Jun1,2, HUANG Jin-man3, LI Hui1,2(1. School of Marine Equipment and Mechanical Engineering, Jimei University, Fujian Xiamen 361021, China;2. Fujian Provincial Key Laboratory of Energy Cleaning Utilization and Development, Fujian Xiamen 361021, China;3. Xiamen Anmaixin Automation Technology Co., Ltd., Fujian Xiamen 361021, China)ABSTRACT: Pipeline erosion is an important problem that cannot be ignored in gas-solid two-phase flow. Erosion damages not收稿日期:2022–04–16;修订日期:2022–08–16Received:2022-04-16;Revised:2022-08-16基金项目:福建省自然科学基金(2022J01334,2020J01694)Fund:Natural Science Foundation of Fujian Province (2022J01334, 2020J01694)作者简介:郭姿含(1997—),女,硕士生,主要研究方向为多相流数值模拟。

有关量子力学的英语作文Quantum Mechanics: The Mysterious World of Particles。

Quantum mechanics is a branch of physics that studies the behavior of particles on a microscopic level. It is a theory that explains the nature of matter and energy at the smallest scale, where classical physics fails to provide an accurate description. The principles of quantum mechanics have revolutionized our understanding of the universe, and have led to the development of many technological advancements.One of the most fundamental principles of quantum mechanics is the wave-particle duality. This principlestates that particles can exhibit both wave-like andparticle-like behavior, depending on the experimental setup. For example, electrons can behave like particles when they are detected by a screen, but like waves when they pass through a double-slit experiment. This duality is not intuitive, and it challenges our classical understanding ofphysics.Another important principle of quantum mechanics is superposition. This principle states that particles can exist in multiple states at the same time until they are observed or measured. For example, an electron can exist in multiple energy states simultaneously until it is measured, and then it collapses into a single state. This concept is central to the idea of quantum computing, which promises to revolutionize computing technology by exploiting the power of superposition and entanglement.Entanglement is another fascinating concept of quantum mechanics. It refers to the phenomenon where two particles can become correlated in such a way that their states are dependent on each other, even when they are separated by vast distances. This concept has been demonstrated in experiments, and it has led to the development of quantum teleportation, which allows the transfer of quantum information between two entangled particles.The principles of quantum mechanics have led to manytechnological advancements, such as transistors, lasers, and MRI machines. Quantum mechanics has also led to the development of new materials, such as superconductors, which have zero resistance to electrical current. Furthermore, quantum mechanics has the potential to revolutionize cryptography, by enabling the creation of unbreakable codes using the principles of entanglement.In conclusion, quantum mechanics is a fascinating and mysterious world that challenges our classical understanding of physics. Its principles have revolutionized our understanding of the universe, and have led to the development of many technological advancements. As we continue to explore the world of quantum mechanics, we are sure to discover new and exciting phenomena that will change our understanding of the universe.。

Numerical Study of the Effect of Foundation Sizefor a Wide Range of SandsNobutaka Yamamoto1;Mark F.Randolph2;and Itai Einav3Abstract:This paper presents a numerical investigation of the effect of foundation size on the response of shallow circular foundations on siliceous and calcareous sands.The study is based on the predictive capabilities of the MIT-S1soil model for simulating both the compression and shear behaviors of natural sands over a wide range of densities,K0values and confining pressures.The paper highlights the variations in the deformation mechanisms for the siliceous and calcareous sands cases.The assessment of the bearing capacity factor, N␥,is examined,showing a dramatic decrease in the values with increasing foundation size for the case of footings on calcareous sands, eventually converging to a terminal N␥value.At this stage the sand resistance is insensitive to variations in initial density and foundation size because the sand tends to loose its initial characteristics due to grain crushing,leading the material rapidly toward ultimate conditions. In the silicious sand case,it is found that,eventually,for extremely large footing diameters,the deformation mechanism progresses toward a punching shear mechanism,rather than the classical rapture pattern accompanied by surface heave as employed in current bearing capacity equations.A dimensional transition between the failure mechanisms can clearly be defined,referred to as a“critical size”in the N␥–D relationship.DOI:10.1061/͑ASCE͒1090-0241͑2009͒135:1͑37͒CE Database subject headings:Sand;Calcareous soils;Silica;Shallow foundations;Size effect;Finite element method;Numerical analysis.IntroductionThe bearing capacity of foundations on granular materials has been studied extensively as one of the fundamental problems of geotechnical engineering.The most common method to estimate the bearing capacity is the classical Terzaghi equation that in-cludes three factors:the N c factor for cohesion,the N q for embed-ment depth,and the N␥for the self-weight component.These different factors are modified for the particular loading condition and material case in hand.The N␥factor is of primary importance for shallow foundations on sands but it is extremely sensitive to variations in the material properties.Early experimental studies of this factor in sand were mainly concerned with relatively small model foundations,tested in natural1g conditions.It was real-ized that N␥decreases with increasing footing width or diameter, and this is now widely recognized as the“foundation size effect”͑De Beer1963͒.De Beer reasoned that the foundation size ef-fect results from the fact that the strength criterion of sands should be nonlinear,with the friction angle decreasing with in-creasing stress level,rather than linear as in the conventional linear Mohr–Coulomb criterion.The nonlinear failure envelope arises from the stress dependency of dilation,which by itself arises from particle rearrangement and crushing͑Lee and Seed 1967;Bolton1986͒.There are several numerical approaches for assessing the in-fluence of N␥using nonassociated constitutive models͑i.e.,mod-els that incorporate a dilation angle that is not equal to the friction angle͒.Frydman and Burd͑1997͒and Erickson and Drescher ͑2002͒studied the effect of the dilation angle on N␥for strip and circular footings,respectively,using a nonassociated Mohr–Coulomb model.They found that the effect of dilation angle is negligible at low friction angles,but quite important for friction angles greater than35°,especially for the case of rough circular footings.However,these previous numerical studies are limited by the fact that the Mohr–Coulomb model cannot capture suffi-ciently well the stress and density state dependency of sand be-havior or the compressibility of sands.The intention of the work reported here was to perform a more comprehensive numerical study that accounts for many more be-havioral aspects of sand.For that purpose the MIT-S1constitutive model͑Pestana and Whittle1999͒was adopted as that model has sufficient complexity to simulate both compression and shear be-haviors of natural sands over a wide range of densities,K0values, and confining pressures using a single set of model parameters of a given sand type.In summary,this paper presents a numerical investigation of the foundation size effect in the case of shallow circular footings on siliceous and calcareous sands using the MIT-S1model.Fol-lowing a brief description on the MIT-S1model,the strength characteristics of siliceous and calcareous sands are discussed in the context of drained triaxial shear test results.The effects are1Engineer,Advanced Geomechanics,4Leura St.,Nedlands,WA, 6009,Australia;formerly,Ph.D.Student,Centre of Offshore Foundation Systems,Univ.of Western Australia,Crawley,WA6009,Australia. E-mail:nobutakay@.au2Professor,Centre for Offshore Foundation Systems,Univ.of Western Australia,35Stirling Highway,Crawley,WA6009,Australia.E-mail: randolph@.au3Senior Lecturer,School of Civil Engineering J05,Univ.of Sydney, Sydney,NSW2006,Australia.E-mail:I.Einav@.au Note.Discussion open until June1,2009.Separate discussions must be submitted for individual papers.The manuscript for this paper was submitted for review and possible publication on March15,2007;ap-proved on April30,2008.This paper is part of the Journal of Geotech-nical and Geoenvironmental Engineering,V ol.135,No.1,January1, 2009.©ASCE,ISSN1090-0241/2009/1-37–45/$25.00.then translated to explain the foundation problem for both typesof sand,followed by a discussion of the foundation size effect interms of the N␥factor.Modeling Sands Using the MIT-S1ModelFull details of the MIT-S1model can be found in Pestana andWhittle͑1999͒.According to Pestana et al.͑2002͒,the model iscapable of simulating many behavioral characteristics of sandbehavior,including nonlinearity of the compression curves andcritical state lines on e–ln pЈplots,the dilatancy behavior of sands,and the variation of peak friction angle as a functionof stress level and density.The model can capture a range ofdifferent characteristics of both compressible and incompressiblegranular materials through appropriate adjustment of the modelparameters.The MIT-S1model requires13input parameters to model thebehavior of freshly deposited sand͑which is the type of sand thispaper is concerned with͒.According to Pestana and Whittle ͑1999,2002͒these parameters can be determined from standard laboratory tests.This paper focuses on two different types of sands,Toyourasiliceous sand͑from Japan͒,and Goodwyn calcareous sand͑fromthe North West Shelf of Australia͒.The model parametersfor these sands were determined in Pestana et al.͑2002͒andYamamoto et al.͑2008͒.The model parameters for Dogs Bay calcareous sand and Goodwyn calcareous silt are also provided to enable a complete discussion on the foundation size effect.The physical properties of the sands and the silt are summarized in Table1,and the model input parameters are given in Table2.The particle size distributions for Toyoura siliceous sand͑Ishihara 1993͒,Dogs Bay calcareous sand͑Coop1990͒,Goodwyn calcar-eous sand͑Ismail2000͒,and Goodwyn calcareous silt͑Finnie 1993͒are shown in Fig.1.As may be seen,the Dogs Bay calcar-eous sand has larger particles than the Toyoura siliceous sand. Further,it is noted that the Goodwyn sand is relatively well graded with30%fines content.Compression BehaviorFig.2shows the MIT-S1predictions of the compression curves of both siliceous and calcareous sands.The initial densities and cur-vature of the compression curves vary significantly,but the model captures these variations well.Calcareous sands have higher ini-tial void ratios and greater reduction of volume than siliceous sands.The critical state lines of the sands are also significantly different,but again the model predicts them nicely.Shear BehaviorFig.3shows the MIT-S1predictions for drained isotropically consolidated shear tests on siliceous and calcareous sands with different initial densities but the same confining stress͑100kPa͒.Table1.Index Properties of SoilsPropertySiliceous CalcareousToyoura sand Goodwyn sand Dogs Bay sand a Goodwyn siltMineralogy Quartz,feldspar,magnetite Calcium carbonate͑94%͒Calcium carbonate͑98%͒Calcium carbonate͑94%͒Grain shape Subangular Skeletal grain Skeletal grain Skeletal grain Specific gravity,G s 2.65 2.72 2.75 2.77Mean particle size,D50͑mm͒0.16–0.200.1–0.20.20.03Coefficient of uniformity,C u 1.3–1.710–15 2.0645Maximum void ratio,e max0.98 2.32–1.97 2.21–1.83 2.40 Minimum void ratio,e min0.61–0.58 1.41–0.94 1.48–0.98 1.21a Properties of Dogs Bay sand were reassessed and different from the value provided by Pestana͑1994͒.Table2.MIT-S1Model Parameters for Various SoilsTest type Symbol Physical meaningSiliceous Calcareous b Toyoura sand a GW sand b DB sand b GW silt bCompression testc Compressibility at large stresses͑LCC regime͒0.3700.3500.3500.250 p refЈReference stress at unity void ratio for the H-LCC͑kPa͒5,5002,5004,0002,000First loading curve transition parameter0.2000.9000.4000.900 K0consolidation test K0NC K0in the LCC regime0.4900.4900.5100.4500ЈPoisson’s ratio0.2330.1500.2000.200Parameter for nonlinear Poisson’s ratio 1.00 2.00 1.00 2.00 Shear testcs Critical state friction angle͑°͒31.039.646.040.0mrЈPeak friction angle as a function of void ratio͑°͒28.560.080.072.0np Constant of peak friction angle 2.45 2.00 2.00 2.00m Geometry of bounding surface0.550.350.550.30Rate of evolution of anisotropy50.050.050.050.0Shear test with local measurement systems C b Small strain stiffness parameter750450750450s Small strain nonlinearity parameter 2.50 3.00 2.50 3.0a Pestana͑1994͒.b GW=Goodwyn;DB=Dogs Bay.In siliceous sand,denser samples exhibit a clear peak stress at relatively small strain levels,whereas no peak stress is found for looser samples.On the other hand,all calcareous samples show contractive behavior,although the experimental response from Finnie ͑1993͒for relative dense Goodwyn sand shows a slight peak at small strain levels.Sensitivity Study of the MIT-S1ParametersAs mentioned earlier,the MIT-S1model requires 13model pa-rameters to define the behavior of sand.Although the parameters should be specified precisely,the particular shallow footing prob-lem in this paper tends to be dominated by only a few parameters.Yamamoto ͑2006͒carefully investigated the effect of the different model parameters on the response of shallow circular footings on siliceous and calcareous sands.A summary of these sensitivityanalyses is given in Table 3.The compression parameters,p ref Јand ,and the shear parameter,m ,are the most significant,whereas the remaining parameters have less effect.It is found that the shear parameters ͑apart from m ͒have little effect on the results for calcareous sand,implying that the bearing response on calcar-eous sand is dominated more by the compression component than by shear.Hence,for the shallow footing problem the relatively large number of 13parameters was reduced to a more manageable study involving three significant parameters.Effects of Stress Level,Density,andCompressibility on the Strength Characteristics of SandsThe effects of stress level,density,and compressibility are of great importance for assessing the behavior of sands.The effects can be captured through a relationship between the peak friction angle,p Ј,the initial mean effective stress at failure,p 0Ј,and void ratio,e .Fig.4illustrates the relationship between p Ј,p 0Јand e for theP e r c e n t a g e f i n e rFig.1.Particle size distributions forsandsV o i d R a t i o ,eMean Effective Stress,p'(kPa)Fig.2.Consolidation curves and critical state lines for siliceous andcalcareous sands510152025300100200300400500Linee 00.950.900.800.700.60CID testsToyoura siliceous sand p'0=100kPaD e v i a t o r i c s t r e s s ,q (k P a )Shear strain,H s (%)(a)0100200300400500D e v i a t o r i c s t r e s s ,q (k P a )Shear strain,H s (%)(b)Fig. 3.Triaxial drained shear tests results for siliceous and calcareous sands:͑a ͒siliceous sand;͑b ͒calcareous sandToyoura siliceous and Goodwyn calcareous sands.The peak fric-tion angles at lower stress levels for Toyoura siliceous sand are initially only weakly dependent on the increase in pressure,but this dependency then strengthens to a rapid reduction with in-creasing confining pressure.At higher stress levels,the peak fric-tion angles eventually converge to the critical state values͑i.e.,pЈ=csЈ͒at“critical stresses,”as suggested by Vesic and Clough ͑1968͒.It is noticed that the critical stress decreases as the densitydecreases.The peak friction angles for calcareous sands also de-pend on the combined influence of e and p0Ј.However,they re-duce rapidly with increasing p0Ј,even at low stress level.The critical stresses for calcareous sands are significantly lower than for siliceous sands.Three triaxial compression test results using Goodwyn sand are plotted in Fig.4,one for e0=1.1͓from Finnie ͑1993͔͒and two others for e0=1.4͓from Sharma͑2004͔͒.The MIT-S1predictions underestimate the peak friction angles for these data,which is consistent with the slight peak in deviator stress observed in triaxial tests͑Fig.3͒.The variation of peak friction angle raises questions on the applicability of conventional bearing capacity theories,which are based on constant friction angle with depth͑normalized by foun-dation size͒.For example,an analysis of a10m diameter foun-dation with practical settlement limits of5–10%of foundation diameter͑or width͒may be based on initial stresses of40kPa ͑multiplying half of the diameter,5m,by a soil effective unit weight of8kN/m3͒.However,when the same settlement level is applied to a100m diameter foundation,the corresponding stress level is simply ten times͑400kPa͒that for the10m diameter footing.At that stress level,the peak friction angles are no longer constant with depth.The peak friction angles for calcareous sands are obviously not constant at40kPa,thus for this sand the con-ventional bearing capacity formulas do notfit even for a moderate foundation size.Responses of Shallow Foundations on SandsThe following describes numerical results for the response of10 and100m diameter footings on siliceous and calcareous sands. Initial void ratios at the ground surface,e0,and effective unit weights,␥Ј,are0.8͑dense͒and8kN/m3for the siliceous sand, and1.3͑medium dense͒and7kN/m3for the calcareous sand.To carry out the100m diameter analyses,the effective unit weight has been taken ten times higher,avoiding the need to modify the finite-element meshes.Thus the increase in the foundation size is simulated simply by increasing the initial stress gradient. Pressure–Displacement CurvesFig.5͑a͒shows N␥and␦/D relationships for100m diameter smooth and rough footings on siliceous sand,with the10m di-ameter results also plotted for comparison.The bearing response of the large scale rough footing shows no peak value but rather increases continuously with increasing penetration depth.This is because the compression component of the material dominates the bearing response as the foundation size increases.For the 100m diameter smooth footing case,however,an ultimate bear-ing capacity is still observed although it needs much larger verti-cal displacement than for the small footing.This appears to be because the deformation mechanism for siliceous sand progres-sively shifts toward punching shear with increasing size of foun-dation.It is worth noting that the effect of roughness for larger foundations is much smaller.The bearing responses on calcareous sand with different foun-dation sizes show similar trends but the100m diameter founda-tion shows a more linear response͓Fig.5͑b͔͒,and the mobilized N␥for the100m case is smaller.Deformation MechanismsAs described earlier,a transformation in the mechanisms from small to large foundations may be seen,in particular for rough footings on siliceous sand.Fig.6͑a͒shows that at a penetration of 10%of the diameter the amount of surface heave reduces signifi-cantly with increasing diameter.However,for the smooth footing analysis͓Fig.6͑b͔͒,a classical rupture failure pattern with surface heave is still evident for the100m diameter calculations although more obvious downward deformations are exhibited at shallower penetration.The incremental displacement vectors for10and100m diam-eter footings on calcareous sand show almost identical defor-Initial mean effective stress,p'(kPa)Fig.4.Peak friction angle and initial state relationships for siliceous and calcareous sandsmation patterns at all penetration levels ͓Fig.6͑c ͔͒.The soil be-neath the footings compress almost in a one-dimensional vertical manner.Effect of Foundation Size on Bearing Capacity Factor,N ␥The following explores the effect of foundation size on the mo-bilized bearing resistance factor,N ␥.This effect of foundation size has been explained previously as due to the stress dependency of granular materials ͑De Beer 1963;Hettler and Gudehus 1988;Kusakabe et al.1991͒,or more precisely on the stress dependency of the peak friction angles.The numerical investigation using the MIT-S1model provides further explanations of this effect andalso allows a possible deduction of the dimensional transition between dilative and contractive responses of the soil.Siliceous SandFig.7summarizes the bearing response from analyses with dif-ferent footing sizes of fully smooth shallow circular footings on siliceous sand,by plotting the N ␥–␦/D relationships for e 0=0.8͑loose ͒,and N ␥-␦/D for e 0=0.65͑dense ͒,where ␦denotes the footing downward displacement.The effect of the foundation size has been recognized experimentally with the mobilized N ␥de-creasing with increasing diameter ͑e.g.,De Beer 1963͒,but with experimental evidence only over a relatively small diameter range.The numerical predictions using the MIT-S1model suggest that the foundation size effect exists for larger foundations as well.Moreover,as expected,a transition from dilative to contractive deformations can be seen as the foundation size increases.The smaller footings tend to show dilative behavior with clear peak stress,whereas the larger foundations present contractive re-sponse and exhibit lower mobilized N ␥values.This is also re-flected from the results of drained triaxial tests with different initial void ratios as shown in Fig.3.Fig.8shows N ␥–D rela-tionships for loose and dense siliceous sands.Two N ␥values are shown,one corresponding to the peak bearing resistance ͑if one exists ͒and the other corresponding to ␦/D =10%͑shown only if N ␥keeps increasing for ␦/D greater than 10%͒.The two020406080100M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDisplacement/Diameter,G /D (%)(a)020406080100M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDisplacement/Diameter,G /D (%)(b)Fig.5.Shallow foundation responses for siliceous and calcareous sands:͑a ͒siliceous sand;͑b ͒calcareous sandFig.6.Incremental displacement vectors after a penetration of 10%of the diameter:͑a ͒siliceous sand,rough,D =10m ͑left ͒,100m ͑right ͒;͑b ͒siliceous sand,smooth,D =10m ͑left ͒,100m ͑right ͒;and ͑c ͒calcareous sand,smooth,D =10m ͑left ͒,100m ͑right ͒N ␥values merge at about 20m diameter for loose ͑e 0=0.8͒samples and 60m diameter for dense ͑e 0=0.65͒samples ͑indi-cated by arrows ͒and this will be defined as the transition diam-eter point from dilative to contractive response.This diameter may be referred to as a “critical size,”D cr ,which basically fol-lows the same concept behind the definition of the ‘critical stress’by Vesic and Clough ͑1968͒,as described before.Kimura et al.͑1985͒suggested that the N ␥value reduces with reduction in density.Fig.8shows the great variation with density over a wide range of foundation size.The factor diminishes rap-idly with increasing foundation diameter for small diameters,but the effect reduces at larger diameters ͑noting the logarithmic scale of the plot ͒.Fig.8also compares the numerical results with centrifuge model tests for circular footings ͑D =1.5–3m ͒on Toyoura sili-ceous sand performed by Okamura et al.͑1997͒.Unfortunately,the finite-element results could not be obtained for small diam-eters owing to numerical instability for the high dilation rates associated with shearing at low stress levels.However,both re-sults show the reduction of N ␥with increasing diameter.Calcareous SandFig.9shows bearing responses of fully smooth shallow circular footings on calcareous sand with K 0=1for two representative densities ͑e 0=1.3for dense or e 0=1.9for loose ͒,applied over a wide range of diameters ͑1–100m ͒.It is noticed that the effect of foundation size and density are very strong for smaller diameters.Fig.10plots N ␥–D relationships for calcareous sand.Additional analyses to those in Fig.9were undertaken with identical soil parameters apart from taking K 0=0.49,and those results are shown in Fig.10alongside those for K 0=1.The rate of decrease of N ␥with increasing foundation size becomes gradually lower for larger foundation sizes and for loose samples the N ␥values become nearly constant for diameters of more than 30m.Physi-cal model results from Finnie and Randolph ͑1994͒are also shown,and though these show some decrease in N ␥with increas-ing foundation size,the rate of decrease is not as dramatic as for the numerical results.It may also be seen that the numerical re-sults give higher N ␥values,for a given void ratio,than those reported by Finnie and Randolph,in spite of giving lower peak friction angles for triaxial tests ͑see Figs.3and 4earlier ͒.Again,this emphasizes the importance of the soil compressibility in the bearing response.In Fig.9,none of the analyses exhibits a clear ultimate state.The calculation for a 1m diameter foundation on dense calcare-ous sand was terminated at about 15.5%normalized displace-ment,at which stage the incremental displacement vectors were as shown in Fig.11.These indicate a significant component of surface heave adjacent to the footing,as in a classical rupture failure pattern.It may be concluded that the critical foundation size for the dense calcareous sand may be estimated as about 1m.020406080100M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDisplacement /Diameter,G /D (%)(a)020406080100M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDisplacement /Diameter,G /D (%)(b)Fig.7.Effect of foundation size for shallow circular footings on siliceous sand:͑a ͒dense;͑b ͒loose020406080100120140160180200M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDiameter,D (m)Fig.8.N ␥and D relationships for siliceous sandN ␥–D Relationship for Various SandsThe investigation of the effect of foundation size has also been conducted with respect to two other types of calcareous soils,namely Dogs Bay calcareous sand and Goodwyn calcareous silt.The MIT-S1model parameters for the sand and silt are tabulated in Table 1.Effective unit weights were set to 7kN /m 3for the Dogs Bay sand and 6kN /m 3for the Goodwyn silt.The N ␥values from the analyses for Dogs Bay sand are shown in Fig.12.The computed factor is high for small diameters,even in comparison with those for siliceous sand shown in Fig.8.This appears related to the higher values of mr Јand np ͑i.e.,higher friction angles ͒and higher p ref Ј͑i.e.,higher stiffness ͒.The com-puted results are still much lower than the experimental results from Klotz and Coop ͑2001͒,although these are taken from the end-bearing resistance of jacked piles,extrapolated back to thesurface.The values reduce strongly with increasing diameter,but still lie above the computed values for the overlapping diameter range of 2–3m.Thus,although the general trends are similar for the experimental and numerical results,it is difficult to demon-strate complete consistency.The calcareous silt analyses are based on extremely low p ref Јand values and lead to very low N ␥values even for small foundation sizes ͑see Fig.13͒.The N ␥values for loose samples ͑e 0=2.7͒,in particular,are essentially independent of the founda-tion size.Physical model results ͑Finnie and Randolph 1994͒lie between the numerical predictions of loose and dense states.The experimental data also revealed that the N ␥values for calcareous silt are insensitive to the foundation size.The N ␥–D curves for all the above-presented materials are compared in Fig.13.For small diameters,Dogs Bay sand has the highest bearing capacity,whereas the Goodwyn silt gives the low-est,although it should be noted that results for Toyoura sand are050100150M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDisplacement/Diameter,G /D (%)(a)050100150M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDisplacement/Diameter,G /D (%)(b)Fig.9.Effect of foundation size for shallow circular footings on calcareous sand:͑a ͒dense;͑b ͒loose020406080100M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDiameter,D (m)Fig.10.N ␥and D relationships for calcareous sandFig.11.Incremental displacement vectors for 1m diameter footing on dense calcareous sand ͑␦/D =15.5%͒not available at smaller diameters.The different trends of the calcareous materials are evident and result from changes in the compression parameters,p ref Јand ,which primarily control the bearing response for calcareous materials ͑see Table 3͒.It is also found that the N ␥values for different calcareous materials and densities reduce with increasing diameter and merge to a some-what uniform N ␥͑in the range 5–10͒,independent of the density,foundation size,and material type.On the other hand,the N ␥values for large foundations on siliceous sand are significantly larger than those for calcareous soils ͑Fig.14͒.LimitationsThe principal limitation of the analyses conducted is that the finite-element results for smaller diameter foundations on sili-ceous sand could not be obtained due to calculation instability.One possible reason is the highly dilative response of silica sand at low effective stress levels,in conjunction with extremely large deformations at the edge of footings during loading.Due to the rupture type of failure pattern,neighboring element immediately inside and outside the footing show downward and upward defor-mations,respectively,which led to termination of the solution due to the extremely high displacement gradient.The smaller the foundation size ͑so low effective stresses ͒,the more significant this issue became.By contrast,the failure mechanism for calcar-eous sands gave downward deformations just beyond the edge of the footings.0200400600800M o b i l i z e d B e a r i n g R e s i s t a n c e ,NJ =2q b /J 'DDiameter,D (m)Fig.12.N ␥and D relationships for Dogs Bay calcareous sand020406080100M ob i l i z e d B e a r i n g R e s i s t a nc e ,N J =2q b /J 'DDiameter,D (m)Fig.13.N ␥and D relationships for Goodwyn calcareous silt020406080100M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDiameter,D (m)(a)020406080100M o b i l i z e d B e a r i n g R e s i s t a n c e ,N J =2q b /J 'DDiameter,D (m)(b)Fig.14.N ␥and D relationships for different types of soils:͑a ͒dense;͑b ͒loose。