新 TL 52 231

- 格式:doc

- 大小:80.00 KB

- 文档页数:5

该文件为保密性文件。

我们保留一切更改权利。

未经大众公司康采恩集团标准部门的书面许可,不得转载、复印。

采购者只能通过相关的采购部门才能得到该标准。

© 大众汽车公司在使用标准之前要检查是否为最新版本来源:N O L I S 部门格式F E 41-12.00第二页TL 522 31:2002-123.2 生产制造采用注塑方法。

3.3 材料类型-TL522 31,无指标的类型为ABS/PC聚合材料,标准型,其耐热变形的温度最高为100°C。

-TL522 31, A型为ABS/PC聚合材料,其耐热变形的温度更高,能达到110°C。

-TL522 31, B型为ABS/PC聚合材料,其耐热变形的温度更高,能达到120°C。

3.4 特性符合VDA 260标准所有种类:ABS+PC聚合材料3.5 试验前的正常化处理每项试验所需的试样在检验之前至少要在DIN50 014-23/50-2标准规定的正常气候条件下放置48小时。

3.6 要求的适用性所要求的这些数值适用于每一项的单独测定检验。

3.7 材质请参见第5.1章节所有种类:聚碳酸酯-丁二烯-丙烯腈-苯乙烯-聚合材料。

3.8 颜色按照图纸要求来确定颜色。

第三页2002-12TL 522 31:请见表1表 1第四页TL 522 31:2002-125. 检验说明5.1 材质用红外光谱学的方法进行一致性检测。

5.2 布式硬度至少需要用三个尺寸为(20×20)mm的大试样进行测量(每个试样测量两次)。

如果试样是用一面有坑洼缺陷的成品件加工制成的,则需要用平面打磨机将凹凸不平的面磨平。

将这一平面作为放置面放置试样,然后在未做加工的另一面上进行测量,测量时间为10秒。

5.3 抗弯强度根据DIN EN ISO 178标准确定当加载力最大时弯曲应力是多大,试样长度为(50±1)毫米,宽度为: (6±0.2)毫米,厚度与产品厚度一致(最厚为4毫米),跨距为:40毫米,支撑架半径:1.0至1.2毫米;检验速度: (14±1)毫米/分钟。

Group StandardTL 523102009-04Class. No.: 55270Descriptors:microfiber, nonwoven microfiber fabric, Alcantara, upholstery cover, interior trimCheck standard for current issue prior to usage. The English translation is believed to be accurate. In case of discrepancies the German version shall govern. Numerical notation acc. to ISO practice.Page 1 of 12This electronically generated standard is authentic and valid without signature.Technical ResponsibilityStandardsI/GQ-325 Mr. Frank Tel.: +49-841-89-32164 I/EZ-11 Heinz J. WinklerTel.: +49-841-89-30965Confidential. All rights reserved. No part of this document may be transmitted or reproduced without the prior permission of a Standards department within the Volkswagen Group. Contract partners shall obtain the standard only through the B2B supplier platform .© VOLKSWAGEN AG vwnorm-2007-07Microfiber Decorative Material Material RequirementsPrevious issues1987-04; 1989-08; 1998-05; 2001-11; 2002-05; 2007-10ChangesThe following changes have been made as compared to Technical Supply Specification TL 52310: 2007-10:─ Section 2 revised─ Table 1: No. 9 changed ─ Table 1: No. 10 changed ─Section 7.1 revisedContentsPage1 Scope................................................................................................................................2 2 Basic specifications...........................................................................................................2 3 Marking .............................................................................................................................2 4 Aging.................................................................................................................................2 5 Designs.............................................................................................................................2 6 Properties..........................................................................................................................3 7 Special requirements.........................................................................................................9 7.1 Appearance.......................................................................................................................9 7.2 Bonding.............................................................................................................................9 7.3 Chemical treatment...........................................................................................................9 8 Notes on testing ................................................................................................................9 9 Referenced standards.. (11)Page 2TL 52310: 2009-041 ScopeThis standard applies to─Sides of seats─Centers of seats─Door trim panels, arm rests─Rear shelves, sun visors, pillar trims─Other trim panel parts2 Basic specificationsApproval of first supply and changes according to Volkswagen standard VW 01155.Emission behavior according to VW 50179 and VW 50180.Avoidance of hazardous substances according to VW 91101.A complete examination requires 2 m2.The required numerical values apply to each individual measurement.Design according to drawing; deviating requirements in drawings take precedence over this Technical Supply Specification.The material is not suitable for the following areas of application: steering wheel, gearshift knob, and dashboard.For seats, very light colors are not suitable due to the soiling behavior. A limit of L* (lightness) ≤ 70 in daylight (D65) applies. This limit value applies to Audi AG. Measurement is performed according to VW 50190.Application-specific parameters for processing components (e.g. elongation values for headliner manufacturing) must be agreed upon between the contracting parties.3 MarkingThe back of the roll stock must be visibly marked with the manufacturer's code or according to specification. The marking must not have any adverse effects on the face fabric. A batch marking must be agreed upon accordingly.4 AgingPrior to testing, the specimens must be conditioned for at least 24 h in ISO 554 23/50 standard climate (ordinary).5 DesignsThe designs are subdivided according to use cases:─Sides of seats─Center of seats─Door trim panels, armrests, head restraints─Rear shelf, headliner, sun visors, pillars─Other trim panel partsPage 3TL 52310: 2009-046 PropertiesFor requirements, see Tabelle 1 .(For footnotes, see Section 8 "Notes on testing".)Page 4TL 52310: 2009-04Tabelle 1 PropertiesNo.PropertiesUnitRequirementsSides of seatCenter of seatDoor trim panel,armrests, head restraintsRear shelf, headliner, pillars, sun visorsOther trim panel parts1 Thickness1.1 Microfiber fabric acc. to DIN EN ISO 5084Nominal value ± 12% 1.2 Total structure acc. to DIN EN ISO 5084 mmNominal value ± 15%2Weight per unit area 1)Specifications according to original sample, drawing or release2.1 Total structure Nominal value ± 12% 2.2 Face fabricNominal value ± 12% 2.3 Backing support fabric Nominal value ± 12% 2.4 Base knit fabricg/m 2According to requirement3 Tear strength of total structure 2) 3.1 Initial condition 3.1.1 Length ≥ 600 ≥ 450 ≥ 300 ≥ 200 ≥ 200 3.1.2 Width≥ 600≥ 450≥ 300 ≥ 200≥ 2003.2After aging in water for 2 h at (23 ± 2)°CN/50 mm width≥ 70 %Page 5TL 52310: 2009-04 No. Properties Unit RequirementsSides of seat Center of seat Door trimpanel,armrests, headrestraints Rear shelf,headliner,pillars,sun visorsOthertrim panelparts3.3 Tear strength after high-temperaturelight exposure3.3.1 Length, width in initial condition ≥ 70 %4 Separating force 3)Between the composite layers in length and width N≥ 10 N Rear shelf,pillar, headliner≥ 15 NBetween sunvisor decorativematerial andPVC film≥ 60 N≥ 10 NElongation of total structure5Test Specification PV 3909, suspendedloadN 125 505.1 Static5.1.1 Length and width Specification of requirement with tolerance according to structure 4) 5.2 Permanent5.2.1 Length and width % ≤ 3Page 6TL 52310: 2009-04No. Properties Unit RequirementsSides of seat Center of seat Door trimpanel,armrests, headrestraints Rear shelf,headliner,pillars,sun visorsOthertrim panelparts6 Wear characteristics 50 000 cycles 35 000 cycles 25 000 cycles 10 000 cycles 10 000 cyclesTest with Martindale method 5)DIN EN ISO 12947-1; 12 kPa load Number of revolutions depending on the intended usageEvaluation of wear and color change FastnessgradePilling, void or pitting are not permittedGrade ≥ 3, DIN EN 20105-A026.1Evaluation of standard rubbing cloth for staining after removal of loose microfibers (compressed air) FastnessgradeGrade ≥ (3 - 4), DIN EN 20105-A036.2 Test with Martindale methodDIN EN ISO 12947-1; 12 kPa load;10 000 revolutions after 2 cyclesPV 1303, evaluation of wear and colorchange FastnessgradeEvaluation based on maximum deviation sample 6)Void or pitting are not permittedGrade ≥ 3, DIN EN 20105-A027 Fastness to high-temperature light, high-temperature light agingPV 1303, 3 periodsGray-scale level DIN EN 20105-A02≥ 3No color change≥ (3 - 4)No color change≥ 3No color changeFastness to high-temperature light, high-temperature light agingPV 1303, 5 periodsGray-scale level DIN EN 20105-A02No color changePage 7TL 52310: 2009-04No.PropertiesUnitRequirementsSides of seatCenter of seatDoor trim panel,armrests, head restraintsRear shelf, headliner, pillars, sun visorsOther trim panel parts8 Color fastness DIN EN 20105-A03 8.1 To water≥ (4 - 5)8.2To abrasion, crockmeter test DIN EN ISO 105-X12 and DIN EN 20105-A03 7)8.2.1 Dry ≥ 4 8.2.2 Wet≥ (3 - 4) 8.2.3 Alkaline solution 8) ≥ (3 - 4) 8.2.4 Acid solution 8)Fastness grade≥ (3 - 4)9 Water vapor transmission acc. to DIN EN ISO 14268 9)mg/cm 2*h≥ 4Testing not required10 Seam strengthacc. to DIN EN ISO 13935-1 10) 10.1Longitudinal, transverseN/50 mm≥ 350for coverings with self-fasteningstraps ≥ 400≥ 25011 Tear propagation force DIN EN ISO 13937-2 11.1Longitudinal, transverseN≥ 25Page 8TL 52310: 2009-04No. Properties Unit RequirementsSides of seat Center of seat Door trimpanel,armrests, headrestraints Rear shelf,headliner,pillars,sun visorsOthertrim panelparts12 Soiling and cleaning behavior 11)12.1 Cleanability with aqueouswetting agent solution and organicsolvents The material must be cleanable with an aqueous wetting agent solutionand conventional organic solvents, e.g. petroleum ether, without forming rings.After evaporation of petroleum ether (special boiling point spirit II according toDIN 51631) on a wetted surface of the fabric (approx. 50 cm2), there mustnot be any ring formation on the surface.In cleaning tests using a white, petroleum ether-soaked cloth, unused material must not exhibit any color change. Staining of the cloth: grade 3 to 4.12.2 Soiling and cleaning behavior accordingto PV 3356Soiling behavior dE ≤ 20Cleaning behavior dE ≤ 10Not required13 Burning behavior According to TL 1010 According to TL 1010Test on finished part 14 Emission behavior For requirements, see VW 50180 and VW 50179Page 9TL 52310: 2009-04 7 Special requirements7.1 AppearanceThe fabric must be uniformly dyed and needle-punched and must have uniform density. It must not exhibit any surface defects or stripes.Color deviations acc. to DIN EN 20105-A02 gray-scale level:─Within one pallet ≥ grade (4 - 5)─Within one shipment ≥ grade 4Color deviations with respect to the original sample according to DIN EN 20105-A02 gray-scale level:─Between different shipments ≥ grade (3 - 4)The following applies to Audi AG: ≥ grade 4 with respect to original sample.Alcantara indicates the gray-scale value and the color on every batch.Color values:R = redG = greenB = blueY = yellow7.2 BondingFabric with a backing layer must be completely joined. The individual layers must be laminated in a stress-free manner. Partial hardening is not permissible.7.3 Chemical treatmentTextile finishes and impregnating agents are not permissible. Exceptions are possible in special cases if the "touch" of the covering material is not impaired.Every change in the finishing or fabrication method must be approved by means of a sample release.Organic or inorganic substances that impair the lightfastness or the burning behavior must not be added to the face fabric. These include additives containing phosphate, for example.8 Notes on testing1) Weight per unit areaTest according to DIN EN 29073-1 or DIN EN 12127. The weight per unit area is measured on at least five round specimens of 100 cm2 each, which are taken distributed over the total width of the roll.2) Tear strengthDetermination of the tear strength in the strip tensile test according to DIN EN ISO 13934-1 and DIN EN 29073-3 at a traverse speed of 100 mm/min and a free clamping length (gage length) of 100 mm.Page 10TL 52310: 2009-043) Separating forceTest according to DIN 53357. During the evaluation, not only the peak values but also the entire separating force scatter range must be recorded.4) Examples of elongation values of materials currently in use:Static elongation at 125 N:Alcantara Cover FR longitudinal (3 ± 2) % transverse (7 ± 2) %Dinamica (San Remo/Nardia) longitudinal (7 ± 3) % transverse (16 ± 3) %5) TextilesTest method for nonwovens according to DIN EN 29073-3; determination of maximum tensile strength and maximum elongation, color fastness (filter paper test).A specimen of approximately 25 cm2 is wetted with 2 cm3 of deionized water, placed between filter paper (Schleicher & Schüll, "Blauband 5893") and 2 glass plates, and loaded with a weight of 5 kg for 1 h. The filter paper is evaluated for staining based on the gray-scale level according to DIN EN 20105-A03.6) Martindale methodThe wear characteristics are evaluated based on the maximum deviation samples:Maximum deviation sample OK Maximum deviation sample not OK7) AbrasionColor fastness against abrasion (crockmeter test) is determined using ECE cotton fabric according to DIN EN ISO 105-X12. The woven fabric is evaluated for staining based on the gray-scale level according to DIN EN 20105-A03.8) Alkaline and acid solution according to description in DIN EN ISO 105-E049) Deviating test for Volkswagen AG:Test of air permeability acc. to DIN EN ISO 9237; 20 cm² test surface; 2 mbar pressure difference; requirement ≥ 30 (l/min*100 cm²)10) Deviating test for Volkswagen AG:Testing of seam strength acc. to PV 3946. The requirement given in the Table is identical.11) Behavior upon soiling and cleaningThe two soiling types specified in PV 3356 are used for testing. Bile soap or neutral soap is recommended for cleaning. The evaluation is performed according to colorimetric measurement. In so doing, the largest possible aperture must be used. Each specimen must be measured with 4 individual values. Attention must be paid that the position to be tested varies. After every measurement, the specimen must be turned by 90°.Page 11TL 52310: 2009-049 Referenced standards*PV 1303 Non-Metallic Materials; Exposure Test of Passenger Compartment ComponentsPV 3356 Textiles and Films; Soiling and Cleaning BehaviorPV 3909 Non-Metallic Planar Materials, Measurement of Static and Permanent ElongationPV 3946 Upholstery Material; Determination of the Strength, Resistance to Tearing and Shifting of SeamsTL 1010 Materials for Vehicle Interiors; Burning Behavior; Material Requirements VW 01155 Vehicle Supply Parts; Approval of First Supply and ChangesVW 50179 Emission Behavior of Components in the Passenger CompartmentVW 50180 Components in Passenger Compartment; Emission BehaviorVW 50190 Components of the Vehicle Interior Trim; Colorimetric EvaluationVW 91101 Environmental Standard for Vehicles; Vehicle Parts, Materials, Operating Fluids; Avoidance of Hazardous SubstancesDIN 53357 Testing of Plastics Sheets; Adhesion TestDIN EN 12127 Textiles – Fabrics – Determination of Mass Per Unit Area Using Small SamplesDIN EN 20105 -A02 Textiles - Tests for Colour Fastness - Part A02: Grey Scale for Assessing Change in ColourDIN EN 20105 -A03 Textiles - Tests for Colour Fastness - Part A03: Grey Scale for Assessing StainingDIN EN 29073-1 Textiles; Test Method for Nonwovens; Part 1: Determination of Mass Per Unit AreaDIN EN 29073-3 Textiles; Test Method for Nonwovens; Part 3: Determination of Tensile Strength and ElongationDIN EN ISO 105-E04 Textiles – Tests for Colour Fastness – Part E04: Colour Fastness to PerspirationDIN EN ISO 105-X12 Textiles – Tests for Colour Fastness – Part X12: Colour Fastness to RubbingDIN EN ISO 5084 Textiles - Determination of Thickness of Textiles and Textile ProductsDIN EN ISO 9237 Textiles – Determination of Permeability of Fabrics to AirDIN EN ISO 12947-1 Textiles – Determination of the Abrasion Resistance of Fabrics by the Martindale Method – Part 1: Martindale Abrasion Testing ApparatusDIN EN ISO 13934-1 Textiles – Tensile Properties of Fabrics – Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the StripMethodDIN EN ISO 13935-1 Textiles – Seam Tensile Properties of Fabrics and Made-up Textile Articles – Part 1: Determination of Maximum Force Using the StripMethod* In this Section, terminological inconsistencies may occur as the original titles are used.Page 12TL 52310: 2009-04DIN EN ISO 13937-2 Textiles – Tear Properties of Fabrics – Part 2: Determination of Tear Force of Trouser-Shaped Test Specimens (Single Tear Method)DIN EN ISO 14268 Leather – Physical and Mechanical Tests – Determination of Water Vapour PermeabilityISO 554 Standard Atmospheres for Conditioning and/or Testing; Specifications。

BZT52 seriesSingle Zener diodes in a SOD123 packageRev. 1 — 16 March 2017Product data sheet1Product profile1.1General descriptionGeneral-purpose Zener diodes in a SOD123 small Surface-Mounted Device (SMD)plastic package.1.2Features and benefits•Total power dissipation: ≤ 590 mW•Wide working voltage range: nominal 2.4 V to 75 V (E24 range)•Small plastic package suitable for surface-mounted design •Low differential resistance •AEC-Q101 qualified1.3Applications•General regulation functions1.4Quick reference data[1]Pulse test: t p ≤ 300 μs; δ ≤ 0.02.[2]Device mounted on an FR4 Printed-Circuit Board (PCB), single-sided copper, tin-plated and standard footprint.[3]Device mounted on an FR4 PCB, single-sided copper, tin-plated, mounting pad for cathode 1 cm 2.Single Zener diodes in a SOD123 package 2Pinning information[1]The marking bar indicates the cathode.3Ordering information[1]The series consists of 37 types with nominal working voltages from 2.4 V to 75 V.4MarkingSingle Zener diodes in a SOD123 package 5Limiting valuesTable 5. Limiting valuesIn accordance with the Absolute Maximum Rating System (IEC 60134).[1]t p = 100 μs; square wave; T j = 25 °C prior to surge.[2]Device mounted on an FR4 PCB, single-sided copper, tin-plated and standard footprint.[3]Device mounted on an FR4 PCB, single-sided copper, tin-plated, mounting pad for cathode 1 cm2.6Thermal characteristics[1]Device mounted on an FR4 Printed-Circuit Board (PCB),single-sided copper, tin-plated and standard footprint.[2]Device mounted on an FR4 PCB, single-sided copper, tin-plated, mounting pad for cathode 1 cm2.[3]Soldering point of cathode tab.7CharacteristicsTable 7. CharacteristicsT = 25 °C unless otherwise specified.[1]Pulse test: t p ≤ 300 μs; δ ≤ 0.02.Single Zener diodes in a SOD123 package Table 8. Characteristics per type; BZT52-C2V4 to BZT52-C24= 25 °C unless otherwise specified.T[1] f = 1 MHz; V R = 0 V.[2]t p = 100 μs; T amb = 25 °C.Single Zener diodes in a SOD123 packageTable 9. Characteristics per type; BZT52-C27 to BZT52-C51T= 25 °C unless otherwise specified.[1] f = 1 MHz; V R = 0 V.[2]t p = 100 μs; T amb = 25 °C.Table 10. Characteristics per type; BZT52-C56 to BZT52-C75T = 25 °C unless otherwise specified.[1] f = 1 MHz; V R = 0 V.[2]t p = 100 μs; T amb = 25 °C.Single Zener diodes in a SOD123 package8Test information8.1Quality informationThis product has been qualified in accordance with the Automotive Electronics Council(AEC) standard Q101 - Stress test qualification for discrete semiconductors, and issuitable for use in automotive applications.Single Zener diodes in a SOD123 package9Package outline10Packing informationTable 11. Packing methodsThe indicated -xxx are the last three digits of the 12NC ordering code.Single Zener diodes in a SOD123 package 11SolderingSingle Zener diodes in a SOD123 package 12Revision historySingle Zener diodes in a SOD123 package 13Legal information13.1 Data sheet status[1]Please consult the most recently issued document before initiating or completing a design.[2]The term 'short data sheet' is explained in section "Definitions".[3]The product status of device(s) described in this document may have changed since this document was published and may differ in case of multipledevices. The latest product status information is available on the Internet at URL .13.2 DefinitionsDraft — The document is a draft version only. The content is still under internal review and subject to formal approval, which may result in modifications or additions. Nexperia does not give any representations or warranties as to the accuracy or completeness of information included herein and shall have no liability for the consequences of use of such information.Short data sheet — A short data sheet is an extract from a full data sheet with the same product type number(s) and title. A short data sheet is intended for quick reference only and should not be relied upon to contain detailed and full information. For detailed and full information see the relevant full data sheet, which is available on request via the local Nexperia sales office. In case of any inconsistency or conflict with the short data sheet, the full data sheet shall prevail.Product specification — The information and data provided in a Product data sheet shall define the specification of the product as agreed between Nexperia and its customer, unless Nexperia and customer have explicitly agreed otherwise in writing. In no event however, shall an agreement be valid in which the Nexperia product is deemed to offer functions and qualities beyond those described in the Product data sheet.13.3 DisclaimersLimited warranty and liability — Information in this document is believed to be accurate and reliable. However, Nexperia does not give any representations or warranties, expressed or implied, as to the accuracyor completeness of such information and shall have no liability for the consequences of use of such information. Nexperia takes no responsibility for the content in this document if provided by an information source outside of Nexperia. In no event shall Nexperia be liable for any indirect, incidental, punitive, special or consequential damages (including - without limitation -lost profits, lost savings, business interruption, costs related to the removal or replacement of any products or rework charges) whether or not such damages are based on tort (including negligence), warranty, breach of contract or any other legal theory. Notwithstanding any damages that customer might incur for any reason whatsoever, Nexperia's aggregate and cumulative liability towards customer for the products described herein shall be limited in accordance with the Terms and conditions of commercial sale of Nexperia.Right to make changes — Nexperia reserves the right to make changesto information published in this document, including without limitation specifications and product descriptions, at any time and without notice. This document supersedes and replaces all information supplied prior to the publication hereof.Suitability for use — Nexperia products are not designed, authorized or warranted to be suitable for use in life support, life-critical or safety-critical systems or equipment, nor in applications where failure or malfunctionof an Nexperia product can reasonably be expected to result in personal injury, death or severe property or environmental damage. Nexperia and its suppliers accept no liability for inclusion and/or use of Nexperia products in such equipment or applications and therefore such inclusion and/or use is at the customer’s own risk.Applications — Applications that are described herein for any of these products are for illustrative purposes only. Nexperia makes no representation or warranty that such applications will be suitable for the specified use without further testing or modification. Customers are responsible for the design and operation of their applications and products using Nexperia products, and Nexperia accepts no liability for any assistance with applications or customer product design. It is customer’s sole responsibility to determine whether the Nexperia product is suitable and fit for the customer’s applications and products planned, as well as for the planned application and use of customer’s third party customer(s). Customers should provide appropriate design and operating safeguards to minimize the risks associated with their applications and products. Nexperia does not accept any liability related to any default, damage, costs or problem which is based on any weakness or default in the customer’s applications or products, or the application or use by customer’s third party customer(s). Customer is responsible for doing all necessary testing for the customer’s applications and products using Nexperia products in order to avoid a default of the applications and the products or of the application or use by customer’s third party customer(s). Nexperia does not accept any liability in this respect.Limiting values — Stress above one or more limiting values (as defined in the Absolute Maximum Ratings System of IEC 60134) will cause permanent damage to the device. Limiting values are stress ratings only and (proper) operation of the device at these or any other conditions above thosegiven in the Recommended operating conditions section (if present) or the Characteristics sections of this document is not warranted. Constant or repeated exposure to limiting values will permanently and irreversibly affect the quality and reliability of the device.Terms and conditions of commercial sale — Nexperia products aresold subject to the general terms and conditions of commercial sale, as published at /profile/terms, unless otherwise agreed in a valid written individual agreement. In case an individual agreement is concluded only the terms and conditions of the respective agreement shall apply. Nexperia hereby expressly objects to applying the customer’s general terms and conditions with regard to the purchase of Nexperia products by customer.No offer to sell or license — Nothing in this document may be interpreted or construed as an offer to sell products that is open for acceptance orthe grant, conveyance or implication of any license under any copyrights, patents or other industrial or intellectual property rights.Export control — This document as well as the item(s) described herein may be subject to export control regulations. Export might require a prior authorization from competent authorities.Single Zener diodes in a SOD123 packageNon-automotive qualified products — Unless this data sheet expressly states that this specific Nexperia product is automotive qualified, the product is not suitable for automotive use. It is neither qualified nor tested in accordance with automotive testing or application requirements. Nexperia accepts no liability for inclusion and/or use of non-automotive qualified products in automotive equipment or applications. In the event that customer uses the product for design-in and use in automotive applications to automotive specifications and standards, customer (a) shall use the product without Nexperia's warranty of the product for such automotive applications, use and specifications, and (b) whenever customer uses the product for automotive applications beyond Nexperia's specifications such use shall be solely at customer’s own risk, and (c) customer fully indemnifies Nexperia for any liability, damages or failed product claims resulting from customer design and use of the product for automotive applications beyond Nexperia's standard warranty and Nexperia's product specifications.Translations — A non-English (translated) version of a document is for reference only. The English version shall prevail in case of any discrepancy between the translated and English versions.13.4 TrademarksNotice: All referenced brands, product names, service names and trademarks are the property of their respective owners.Single Zener diodes in a SOD123 package TablesTab. 1.Quick reference data (1)Tab. 2.Pinning (2)Tab. 3.Ordering information (2)Tab. 4.Marking codes (2)Tab. 5.Limiting values (3)Tab. 6.Thermal characteristics (3)Tab. 7.Characteristics ...................................................3Tab. 8.Characteristics per type; BZT52-C2V4 toBZT52-C24 (4)Tab. 9.Characteristics per type; BZT52-C27 toBZT52-C51 (5)Tab. 10.Characteristics per type; BZT52-C56 toBZT52-C75 (5)Tab. 11.Packing methods (7)Tab. 12.Revision history (9)FiguresFig. 1.Non-repetitive peak reverse powerdissipation as a function of pulse duration;maximum values (6)Fig. 2.Forward current as a function of forwardvoltage; typical values .......................................6Fig. 3.Temperature coefficient as a function ofworking current; typical values (6)Fig. 4.Temperature coefficient as a function ofworking current; typical values (6)Fig. 5.Package outline SOD123 (7)Fig. 6.Reflow soldering footprint SOD123 (8)Single Zener diodes in a SOD123 packagePlease be aware that important notices concerning this document and the product(s)described herein, have been included in section 'Legal information'.Contents1Product profile ....................................................11.1General description ............................................11.2Features and benefits ........................................11.3Applications ........................................................11.4Quick reference data .........................................12Pinning information ............................................23Ordering information ..........................................24Marking .................................................................25Limiting values ....................................................36Thermal characteristics ......................................37Characteristics ....................................................38Test information ..................................................68.1Quality information .............................................69Package outline ...................................................710Packing information ............................................711Soldering ..............................................................812Revision history .. (913)Legal information (10)Mouser ElectronicsAuthorized DistributorClick to View Pricing, Inventory, Delivery & Lifecycle Information:N experia:BZT52-C10J BZT52-C12X BZT52-C15X BZT52-C16X BZT52-C18X BZT52-C5V6J BZT52-C6V2X BZT52-C7V5X BZT52-C8V2J BZT52-C33J BZT52-C39J BZT52-C3V3X BZT52-C3V9X BZT52-C4V7J BZT52-C5V1J BZT52-C11J BZT52-C22X BZT52-C24J BZT52-C7V5J BZT52-C2V7J BZT52-C30J BZT52-C39X BZT52-C36J BZT52-C6V8X BZT52-C15J BZT52-C51X BZT52-C10X BZT52-C56X BZT52-C13J BZT52-C51J BZT52-C20J BZT52-C2V7X BZT52-C27J BZT52-C4V3X BZT52-C56J BZT52-C62J BZT52-C33X BZT52-C12J BZT52-C3V3J BZT52-C3V9J BZT52-C68J BZT52-C75J BZT52-C43J BZT52-C3V6J BZT52-C24X BZT52-C3V6X BZT52-C62X BZT52-C9V1X BZT52-C47J BZT52-C30X BZT52-C11X BZT52-C68X BZT52-C36X BZT52-C47X BZT52-C27X BZT52-C2V4J BZT52-C5V1X BZT52-C13X BZT52-C22J BZT52-C9V1J BZT52-C4V3J BZT52-C6V8J BZT52-C18JBZT52-C16J BZT52-C3V0X BZT52-C75X BZT52-C43X BZT52-C2V4X BZT52-C4V7X BZT52-C20X BZT52-C8V2X BZT52-C3V0J BZT52-C6V2J BZT52-C5V6X。

网游公会名字网游公会名字500个1、丿完美丶公会灬2、网游之神顶集集团3、龙之谷-皇族公会4、Vip皇家丶贵族丿家族5、丿惜缘灬公会6、悲伤丶代言人7、God灬亓巛公会8、战无不胜9、丶巛全F最嗨o灬10、凶弚寔→传说11、再战帝王路ㄨ☆12、Storm风灬晨曦灬13、fr娇柔丶壹队14、萌幻学园15、沧州地狱战神16、花街MG公17、卩灬左手vs右手18、丄﹁个,街角19、王丶技术团队彡20、万盟山庄21、丿诸葛亮丶孔明22、≮蔑视丶圣光≯23、Man灬卟丶酷派丨24、丿Aini冰kiss吻丿25、丿纯丶氺氺26、噬魂联盟27、丿永灬恒丨国度28、卩灬左手vs右手29、奕剑末涯30、Np新势力网游公会31、丨飞车部落丨公会32、索马里海盗33、╲`M家族╰潮人34、一生丨灬LOVE公会35、丨情义丨灬神之队36、蓝色メ義薄雲天37、じ邪君战队38、LK丶明星俱乐部39、彡Air丨公会灬40、HaDea41、丿浪漫丨个性BabY42、Mua丨据点丶公会43、卩丶圣域丨神话44、丿伊波吕丶巛帝王45、の﹏謎。

46、丨聚义堂丨灬神话47、丿冥灬神界丶公会48、SGL丶工会49、霸下网游公会50、м▂_贵镞51、丿Van灬傀儡52、〆巫蒒战队ゾ53、丶蜀灬Mars战队丿54、生化主宰ヤ55、盛唐丶年56、妖艳丶舞者莫於狐57、ゞ卜喓铥丅唩58、Ghost丿灬战59、在老子面前装60、〓Good丶魔族61、纵横天下62、御苑阁公会63、い☆誅門の茵遡64、『蜀都∞聚贤阁』65、New丶会灬公会66、Ferrari丨灬腾飞67、丿无敌狂飙灬战队68、仇杀队69、一假装败给你70、丿Star炫Love绿茶71、ゞ掩埋我de爱情≈72、KiSs丶筱沫灬73、Vip皇家丶贵族丿家族74、名人堂灬75、黔堂丶家族彡76、(中国)感忆★人生77、丨飞车部落丨公会78、HC'黑潮公会79、枪林弹雨80、断断续续的暧昧81、丿丶渔美人灬钕子82、丨飞车部落丨公会83、氵至尊丨小帅84、〓※豪〓城〓世〓家※〓85、熊爸天下86、fr娇柔壹队87、乄MAR鬼镞﹎88、丨Ace丶Team丨89、血弑╮°新起公会90、永乐王朝91、傲视ん天下92、邪恶Devil公会Y93、Aos丶天网网游94、属于俄的角落95、皇城|公会96、巛Angel灬圣灵会97、Star丶Drifts公会98、?蹩愛渥〇?99、丿辉煌丶永续100、丶巛赞丶美B灬101、丶巛绝世骚神丿灬102、NE网游公会103、传说中的兄弟灬104、杀猪_小分队105、聚义堂丶神话彡106、丶巛赞丶美B灬107、丿TK丶灬丨莳绱108、丿龙氏丨灬殇爷109、Пzh昰童话110、『情谊┷咏恒』111、┏-哒不愛我112、彡Air丶家族灬113、卩s灬Lies巛团114、丶鬼式丿灬战队丶115、离弃v情侣家族116、丿oO飚风oO丨公会117、蒙推DANGAN公会118、Evp丨贵119、灬Ray糖果丶团彡120、蓝血族121、fr娇柔壹队122、彡Air丶家族灬123、邪恶Devil公会Y 124、丨Vampire丶永恒125、星球狂想战队126、艹丨当红世家丨丶127、z取其辱╮128、spyker丨灬夜丶眠129、Crazy丨狂飙zu丨130、丿战神灬诳磝131、艹糸祢丶视觉Show 132、丿乱世丶名流站队133、蓝色激浪134、〣Ai呦﹏★正式公会★135、逆天の煤油瓶136、狼族少年们咆哮吧137、丿惜缘灬家族138、万世浩劫YY139、卩丶圣域丨神话140、卩丶圣域丨神话141、℡鬼域り公会142、茗菛『贵族』UP√143、丿丶渔美人灬钕子144、巔峰メ戰天斗地145、战无不胜146、嗜血帝国147、紫禁丨灬城毒148、一大群丶基佬丶149、灬边境炫队灬150、巛柒彩丨战堂灬151、新視覺集团152、┽失心疯公会153、中国苏家154、丿oO飚风oO丨公会155、丨Ace丶Team丨156、河南车神灬157、传说中的兄弟灬158、忧筱醉159、fr娇柔丶壹队160、灬Cherish丨丶嗳161、仇家灬三千奈我何丶162、紫禁丨灬城毒爱163、God灬亓巛公会164、巅峰时代网游公会165、雄霸天下疯狂公会166、SunLife灬丿缘噬167、丶全网走红灬战队168、Charm丨灬梦之队169、蓝天之巅170、国理丬感视彡171、狼魂丶网游公会172、Hunter猎人公会173、辉煌之巅174、卩丶幻城灬帝国175、无所谓伱Sんī恏魜176、夜涩狼177、china简约公会178、死亡诗社》179、丿LovE丨红星灬180、NE鹏哥181、火焰丿之河彡182、e丿Shine丨NO丶183、巛手芯丨手褙灬族184、公会名字大全185、BOS网游公会186、丨Ace丶Team丨187、引领先锋188、丿LoVe丶丨公会灬189、丿杀手丨炫丶190、God灬亓巛191、巛神领域丶丨禁区192、vp丶★狼神193、fr娇柔壹队194、Storm风灬晨曦灬195、巛Viva丨摇摆全F 196、卩丶幻城灬帝国197、Beyond丨极限198、绚夜灬天使199、丨霸气灬靓兰宝贝200、丶Taizi丨灬皇族201、弹药の族→卅202、邪恶Devil公会Y 203、超级Hero°204、丿夯族灬狠爱祢205、Fe飞车一簇Pass 206、TL通辽公会TL 207、打手↘公司灬208、丨Ace丶Team丨209、吞天灬军团丶210、Vampire丶永恒彡211、丿约锭So灬幸福212、灬Ray糖果丶团彡213、Poppy灬残香丶214、Sdu清萍筑215、SM≮计划≯216、﹏Sωeet°家族217、丿Somnus丨灬公会218、王丶技术团队彡219、丿Star炫Love绿茶220、嗤古灬战队221、天神公会222、o埘绱o灬vIp荣耀223、‖Empの224、陰獸部落225、河南丶车神彡226、Charm丨灬梦之队227、圣灵玫瑰灬梦之队228、丿冥灬神界丶公会229、特命战队GoBusters 230、爱你是我つ231、国理丬感视彡232、CH丶执著彩虹233、丿Van灬傀儡234、Cc小峰灬斗魂235、韩国首尔公会236、Star丶Drifts公会237、丿oO飚风oO丨公会238、东北灬将军VS战团239、Spurt丶俱乐部240、浪欢狂派241、丿龙氏丨灬殇爷242、丿AnGel灬翼丶族243、棒棒堂NO公会244、神堂丨灬艹鸳鸯战245、鬼翼之领246、紫诏天胤247、丿冥灬神界丶家族248、BOS兵哥249、卩s灬Lies巛团250、e丿Shine丨NO丶251、蓝狼vvv站队252、津灬VIP丨龙之队253、°刁蛮≠魅ル254、笑赞丶红颜美255、先生,请让开256、x车神x帅哥x战队x 257、丿风云丨灬丶争霸258、打手↘公司灬259、河南丶车神彡260、丶巛赞丶美B灬261、丶浅浅活埋上只花262、非主流丨灬丶集团263、卩s丶惶会丨灬264、丿Somnus丨灬公会265、丶巛韩日明星灬艹266、巛流火灬客栈丿灬267、散人天下族268、一生一世vip时代269、半萌半媚半妖骚丶270、T丿黔堂丨丶公会271、ˇ初战的つ信仰272、Star丶Drifts公会273、TL通辽公会TL 274、雄霸天下疯狂公会275、丿Sakura灬皇家276、彡魅力丶红人馆277、专属o丶宁丨278、spyker丨灬夜丶眠279、巛Angel灬圣灵会280、卩s灬Lies巛团281、sY名称282、沪于天下283、棒棒堂NO丶家族284、蒙推DANGAN公会285、MJ丶YY天下公会286、酷潮轩ぃ公会287、神堂丨灬艹鸳鸯战288、罘过茹呲浅唱那情289、仙聚王者贵族290、丿Death丨丶战队291、TL通辽公会TL 292、丿完美丶公会灬293、丶丿年少灬轻狂刂294、紫禁之巅网游公会295、分开也不必须分手296、丿冥灬神界丶家族297、丿A名牌货灬战队298、丿Fo吓败灬神话灬299、丿杀手丨炫丶300、丿LoVe丶家族灬301、其实还爱ta明朗旳笑容302、丨Vampire丶永恒303、╄葃ㄖの触动304、Vision丶Team 305、Lies巛丶团ぃ306、战无不胜307、火焰丿之河彡308、丿LoVe丶丨公会灬309、╮Barbara310、彡kiss丿灬夜店311、灬Cherish丨丶嗳312、╰ゝ|倾城殿313、丿Sa灬羽化恋佳314、Metersbonwe 315、Mua丨据点丶公会316、丶Cecil丿琪琪317、御苑阁网络游戏公会318、灬颠覆丿想像灬丿319、Mua丨据点丶公会320、叛逆无罪灬家族321、战胜丶禁卫军322、传说中的.兄弟灬323、e丿Shine丨NO丶324、卩灬左手vs右手325、Beyond丨极限326、℡Mcゝ公会327、〓Good丶魔族328、卩丶圣域丶神话329、丶巛兄弟帮灬Team 330、灬边境炫队灬331、二选一为僾繁华332、一生丨灬LOVE公会333、圣灵玫瑰灬梦之队334、战魂领域网游公会335、spyker丨灬夜丶眠336、乖乖灬NB丨公会337、蓝天黑云338、-O縌の焰ヤ339、懓上迗使の错340、刺青ㄣ貉北ヽFamily 341、丿LoVe丶家族灬342、专属o丶宁丨亮343、东北丶战团灬344、蓝狮丶战队彡345、一生丨灬LOVE公会346、丿水阳灬乐升战队347、crazy戦魂348、皇族网络俱乐部349、丨Sky灬丨夜吻350、冷血剑魔岛351、毒家つ总创352、丿惜缘灬公会353、GangsTa丶多多354、真心换真情355、黔堂丶家族彡356、MY嗜血战团357、蓝狮丶战队彡358、盛唐丶年359、丿D调灬丶T eam 360、隱形超亼。

Klass-编号5020 0;02642 2005年2月英文翻译被认为是准确无误的,但发生差异,以德文版本为准。

(左边竖行翻译)使用前请检查当前问题使用的标准。

(右边竖行翻译)目录1.范围 (3)2.描述 (3)2.1代码结构 (3)2.2描述举例 (3)3.要求 (3)3.1一般要求 (3)3.2图纸说明 (4)3.3可焊性 (4)3.4影响润湿能力的制剂 (5)3.5摩擦性能 (5)3.6 锌涂层 (5)3.7螺钉、螺栓、螺母、螺纹部件和成型件 (5)3.8 商用表面保护类型 (5)3.9 无表面保护的部件 (6)3.9.1连接元件 (6)3.9.2 其他部件(如片材) (6)3.10表面保护类型和代码的分配 (6)4.参考标准2 (12)A.1 “不用于新设计”和“用于新设计”的比较 (13)更改与大众标准VW 137 50,1999-04相比,已作如下更改:-规定表面保护类型“磷酸盐化,钝化”(代码b101)。

-规定表面保护类型“磷酸盐化,银灰色(供内部应用)”(代码b111)。

-规定表面保护类型“磷酸盐化,黄釉,供内部应用(水基油漆)”(代码b112)。

-表面保护类型“磷酸锰化”(代码b130),限于可能的应用领域(不再允许用于连接元件的新设计,替代为b140)。

-增加无铬化处理的表面保护类型“电解镀锌”(代码c341,c641,c342,c642,c343,c643,c347,c647,c696和c697)。

-含铬表面保护类型“电解镀锌”(代码c350,c650,c351,c651,c355,c360,c660,c683,c385,c685),限于可能的应用领域(不再允许用于新设计,替代类型见表A.1)。

保密,版权所有。

未得到大众集团标准部门的同意,不得传播或复制本文件的任何一部分。

合同方仅能通过B2B供应商平台获得该标准。

-删除表面保护类型“光亮镀铬,含微细裂纹“(代码f320)(由Ofl-f350代替)。

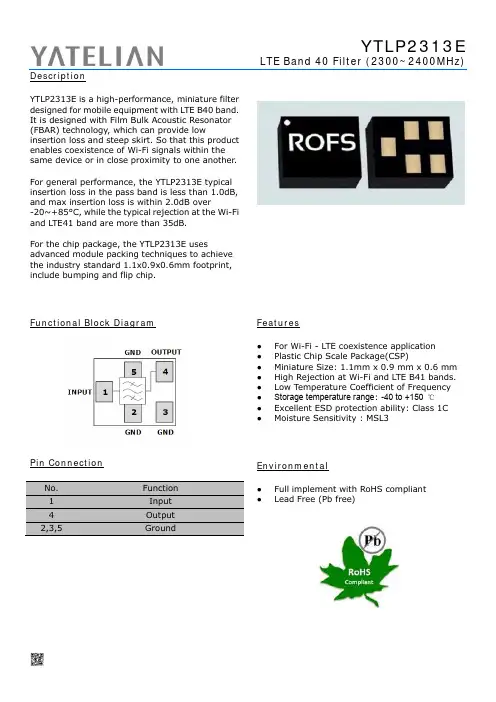

YTLP2313ELTE Band 40 Filter (2300~2400MHz) DescriptionYTLP2313E is a high-performance, miniature filterdesigned for mobile equipment with LTE B40 band.It is designed with Film Bulk Acoustic Resonator(FBAR) technology, which can provide lowinsertion loss and steep skirt. So that this productenables coexistence of Wi-Fi signals within thesame device or in close proximity to one another.For general performance, the YTLP2313E typicalinsertion loss in the pass band is less than 1.0dB,and max insertion loss is within 2.0dB over-20~+85°C, while the typical rejection at the Wi-Fiand LTE41 band are more than 35dB.For the chip package, the YTLP2313E usesadvanced module packing techniques to achievethe industry standard 1.1x0.9x0.6mm footprint,include bumping and flip chip.Functional Block DiagramPin ConnectionNo. Function1 Input4 Output2,3,5 Ground Features●For Wi-Fi - LTE coexistence application●Plastic Chip Scale Package(CSP)●Miniature Size: 1.1mm x 0.9 mm x 0.6 mm ●High Rejection at Wi-Fi and LTE B41 bands.●Low Temperature Coefficient of Frequency ●Storage temperature range: -40 to +150 ℃●Excellent ESD protection ability: Class 1C ●Moisture Sensitivity : MSL3Environmental●Full implement with RoHS compliant●Lead Free (Pb free)YTLP2313ELTE Band 40 Filter (2300~2400MHz) Electrical SpecificationsParameter(Operable Temperature:-20 to +85°C) Min Typ(1) Max(2) Unit Insertion Loss (2300 ~ 2400 MHz) \ 0.9 2.0 dBRipple (2300 ~ 2400 MHz) \ 0.4 1.0 dBVSWR Input (2300 ~ 2400 MHz) \ 1.2 1.5VSWR Output (2300 ~ 2400 MHz) \ 1.2 1.5Absolute Attenuation10 ~ 1574 MHz -23 -35 \ dB1574 ~ 1577 MHz -23 -25 \ dB1577 ~ 1680 MHz -22 -25 \ dB1845 ~ 1880 MHz -22 -24 \ dB2110 ~ 2170 MHz -26 -30 \ dB2421 ~ 2443 MHz (ch05,18MHz-BW) -25 -55 \ dB2421 ~ 2443 MHz (ch05,18MHz-BW,+25~+85°C) -40 -60 \ dB2426 ~ 2448 MHz (ch06,18MHz-BW) -55 -60 \ dB2431 ~ 2483 MHz (ch07-13,18MHz-BW) -40 -50 \ dB4600 ~ 4800 MHz -45 -48 \ dB6900 ~ 7200 MHz -31 -32 \ dBRF Input Power(3)(2300 ~ 2400 MHz) 30 dBm(1)Typ Data is the integrated value of the linear S-parameter over indicated band at +25°C.(2)Min/Max Data is being specified over -20 to +85°C.(3)Input power applied for a minimum of 5,000 hrs at 55°C in the specified frequency band.YTLP2313ELTE Band 40 Filter (2300~2400MHz)Typical Performance at Tc=25˚CFigure.1 Wideband Insertion LossFigure.2 Narrowband Insertion LossFigure.3 Input VSWR S11 Figure.4 Output VSWR S22Figure.5 Input Smith Chart S11Figure.6 Output Smith Chart S22V S W R1V S W R 20.51.02.05.0102020-2010-105.0-5.02.0-2.01.0-1.00.5-0.50.2-0.2freq (2.300GHz to 2.400GHz)S (1,1)0.51.02.05.0102020-2010-105.0-5.02.0-2.01.0-1.00.5-0.50.2-0.2freq (2.300GHz to 2.400GHz)S (2,2)Package Outline Drawing1.10±0.050.90±0.05PIN 1 Mark06Test CircuitPCB FootprintNotes:1. Dimension: mm2. Dimensions nominal unless otherwise noted3. Contact area are gold plated4. Pad(1) to (5) are same size5. XX is ROFS inside code Pin Connection: 1 Input 4 Output 2.3.5GroundNotes:1. Matching component values shown are ROFSevaluation board results, please adjust component values by the actual use environment. Notes:1. Black indicates metalized area.2. This footprint represents a recommendation only,some modification may be necessary to suit end user assembly materials and processes.3. For solder pad recommendation see mechanicalinformation.4. Dimensions shown are nominal in millimeters.Packing1.Tape Dimension2.Reel Dimension5000Pcs/ReelRecommended IR Reflow ProfileOrder InformationPart NumberQty Per ReelContainerYTLP2313E 5000 7 inchReel。

大众股份有限公司TL 528集团标准 2015-01发布分类编号:55121描述词:塑料部件,铬,铬电镀,金属处理,塑料镀铬塑料部件材料要求4种类别:A,B,C,D先期发布TL528:1965-01,1973-09,1979-01,1985-01,1986-06,1988-06,1993-06,2000-07,2006-04,2008-06更改与TL528:2008-06相比做出如下改动:-表1.“PA6”已删除(聚酰胺不允许作为基材)-表1. 类别“B”扩充-表1. 类别“D”批准限制废除-3.1“基材要求”:增加户外天气阻力要求-3.2.1“基材”和3.2.2外观和发白处应力”扩充-3.3.1“表面抛光”,3.3.3“电镀过程”,和3.3.4“电镀件技术要求”修正-表2完全修正-4新增”供应商生产监控要求”-5.1”电镀系统”修正-5.2”镀层厚度、微裂纹、微孔数、电位差测试点”更新-5.3修正”十字划格实验”,增加图1和图2-5.4增加”盐雾实验执行”TL 528:2015-01表1修正1.范围此技术支持说明针对各类规格的镀铬塑料部件,定义了对其表面抛光的要求(见表1)表1a)迄今塑料已在这些范围内通过了试验2.描述作为内部零件使用和镀铬处理的由ABS制成的零件成品的描述实例:ABS按TL527,镀铬按照TL528-A3.要求3.1基本要求首次供货和更改按大众标准VW01155对有害物质的避免按VW91101户外天气阻力按VW50185要求有10个零件成品完成实验(视尺寸而定)针对所有需实验的零件,供应商需附加提供以下的信息(附录A)TL 528:2015-013.2 浇铸零件3.2.1 基本材料基质生产商指定的材料,作为适用电镀的材料,按表一。

如有必要,偏离于此的塑料类型需在此基础试验之外附加进行一些试验以单独确认。

针对由两个零部件组成的产品,如旋钮,其中一个塑料部件(例如聚碳酸酯[PC])不能添加涂层。

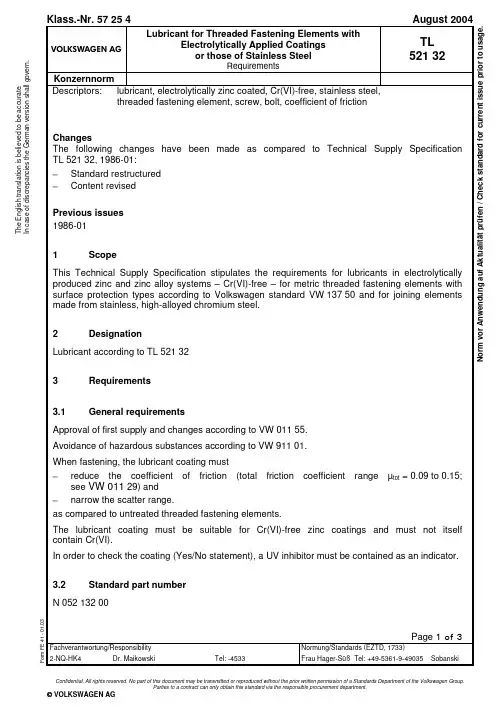

Confidential. All rights reserved. No part of this document may be transmitted or reproduced without the prior written permission of a Standards Department of the Volkswagen Group.Parties to a contract can only obtain this standard via the responsible procurement department.© VOLKSWAGEN AGT h e E n g l i s h t r a n s l a t i o n i s b e l i e v e d t o b e a c c u r a t e . I n c a s e o f d i s c r e p a n c i e s t h e G e r m a n v e r s i o n s h a l l g o v e r n .Page 2TL 521 32: 2004-083.3 TypeWater-dispersed synthetic polymers (PE suspension) that, after application and drying, produce a friction film/layer that is resistant to handling (commercial products include, for example, Microgleit DF 911/DF 921 produced by the Microgleit company, Gleitmo 605/625 from Fuchs Lubritec or Torque’N’Tension Control Fluid from the MacDermid company).Note: The properties of the products differ in part and must be tested for the relevant application with respect to the friction coefficients to be achieved. Special influences such as threading speeds, counter layers and operational temperatures of the joining elements in contact must be taken into consideration.Thus, for example, Microgleit DF 911, Gleitmo 605 and T’N’T Control Fluid are particularly suited for coating galvanized joining elements. Gleitmo 625 and Microgleit DF 921 are preferred for stainless steel joining elements; the coefficient-of-friction-reducing effect is particularly strong here. The coating medium must be silicone-free and must not contain any substances that would require it to be labeled as hazardous to health (X n) according to the Hazardous Substances Regulation.3.4 Requirements for the lubricant coating processIt must be ensured that no residues of chromic acid, chromic solutions or other acid residues can enter into the lubricant coating bath.A process-sure, even wetting of the surface with lubricant shall be guaranteed.Before the lubricant is applied, the parts to be coated should be dry and warmed slightly (approx. 40 °C to 50 °C; not above 75 °C). The temperature of the coating medium must not drop below 20 °C during the coating process (optimal: 25 °C to 35 °C; not above 75 °C).The coating medium is generally supplied as a concentrate. The mixing ratio of the coating medium concentrate and water must be selected such that the required friction coefficients are achieved and maintained. Empirical standard value: 1 part coating medium to 3 parts water(e.g., for Microgleit DF 911, Gleitmo 605 or Torque’N’Tension Control Fluid).The bath concentration shall be tested by determining the dry residue or using a refractometer, and documented.The bath must be checked (pH value) in accordance with the specifications of the coating medium manufacturer (frequency: minimum 1 x per shift/day, taking into consideration the specified limit values).Coated threaded parts should preferably be dried in a through-type system, but a centrifugal system is also possible. Drying must be performed at a speed suited to the parts spectrum and with the application of heat. The exact settings (speed, temperature, filling quantity) are to be determined by the coating operator in cooperation with the coating medium manufacturer, and documented. Here, the maximum permitted temperature for the coating system must be observed, e.g., max. 90 °C for Cr(VI)-free passivation treatments.In order to avoid the risk of condensation, the parts shall be packed in a dry state and only after reaching ambient (room) temperature.The efficacy of the lubricant coating with respect to the friction coefficients of the threaded fastening elements is to be checked in coordination with the accepting factory.Note: If elements that have already been coated with lubricant are coated once again, this can yield different friction coefficients than for the first coating.Page 3TL 521 32: 2004-084 Referenced standards*)VW 011 29 Limit Values for Coefficients of Friction; Mechanical Joining Elements with Metric ISO ThreadVW 011 55 Vehicle Supply Parts; Approval of First Supply and ChangesVW 137 50 Surface Protection of Metal Parts; Degrees of Protection, Codes, Requirements VW 911 01 Environmental Standard for Vehicles; Vehicle Parts, Materials, Operating Fluids;Avoidance of Hazardous Substances*)In this section, terminological inconsistencies may occur as the original titles are used.。

关键词:PC+ABS,ABS+PC,ABS,PC,共聚物,共聚混合物,仪表饰板,仪表板、盛物槽、饰板更改与TL 522 31: 2002-12相比,有以下更改:-对表1和试验说明进行了修订-取消按照DIN EN ISO 2039-1进行的布氏硬度试验较早的版本1981-08;1987-08;2002-121 适用范围本供货技术条件规定了由ABS和PC共聚混合物制成的成品件,如仪表饰板、仪表板、盛物槽等的材料要求。

2 标识法耐热变形温度达+1100C的类型的标识示例:PC+ABS-共聚混合物,按照TL 522 31-A3 要求3.1 基本要求首批供货和更改的批准按照VW 011 55。

排放特性按照VW 501 80。

大气曝晒试验按照VW 501 85。

比色测定按照VW 501 90。

有害物质的避免按照VW 911 01。

一次完整的试验要求使用6个成品件。

3.1.1 特性成品件的表面和内部不得有诸如渗化线、缩孔、裂纹以及其它类似的缺陷部位和制造缺陷。

在筋和加强件凸出部位上允许有缩孔,但它不得影响零件的功能和外观。

3.1.2 对人的亲和性所使用的材料不得损害人的身体健康。

在温度较高时所蒸发出的物质不得含有有毒成分。

3.2 制造工艺注射成形3.3 类型-TL 522 31 ABS+PC-共聚物混合物,标准类型,耐热变形温度达 +1000C-TL 522 31-A ABS+PC-共聚物混合物,耐热变形温度达+1100C-TL 522 31-B ABS+PC-共聚物混合物,耐热变形温度达+1200C3.4 按照VDA 260的标识-TL 522 31 >ABS+PC<-TL 522 31-A,TL 522 31-B > PC+ ABS <3.5 预处理每次试验前,应将试验所需使用的试样在按照DIN 50 014 – 23/50-2规定的标准气候下放置至少48小时。

3.6 测量结果的评定所要求的数值适用于每次单独的测量。

商用VPN路由器用户手册1910041065 REV1.0.0声明Copyright © 2022 普联技术有限公司版权所有,保留所有权利未经普联技术有限公司明确书面许可,任何单位或个人不得擅自仿制、复制、誊抄或转译本手册部分或全部内容,且不得以营利为目的进行任何方式(电子、影印、录制等)的传播。

为普联技术有限公司注册商标。

本手册提及的所有商标,由各自所有人拥有。

本手册所提到的产品规格和资讯仅供参考,如有内容更新,恕不另行通知。

除非有特殊约定,本手册仅作为使用指导,所作陈述均不构成任何形式的担保。

目录商用VPN路由器 (1)用户手册 (1)第1章用户手册简介 (1)1.1目标读者 (1)1.2产品简介 (2)第2章联网配置 (3)2.1快速联网配置 (3)2.1.1登录准备 (3)2.1.2登录步骤 (3)2.2Web远程管理 (6)2.3云管理 (8)2.4IPv6上网配置 (10)第3章基本配置 (16)3.1接口模式 (16)3.2WAN口设置 (16)3.2.1WAN口设置 (16)3.2.2流量均衡 (17)3.2.3ISP选路 (18)3.3LAN口配置 (19)3.4.1DHCP服务 (19)3.4.2DHCPv6服务 (20)3.5客户端列表 (21)3.5.1客户端列表 (21)3.5.2IPv6客户端列表 (22)3.6静态地址分配 (22)3.6.1静态地址分配 (22)3.6.2IPv6静态地址分配 (23)3.7SLAAC (24)第4章路由功能 (25)4.1设置策略路由 (26)4.1.1策略路由 (26)4.1.2策略路由配置实例 (27)4.2设置静态路径 (29)4.2.1静态路由 (29)4.2.2静态路由配置实例 (30)4.3NAT设置 (32)4.3.1NAT介绍 (32)4.3.2NAPT (33)4.3.4一对一NAT (35)4.3.5一对一NAT配置实例 (37)4.4ALG服务 (39)4.5虚拟服务器 (40)4.5.1虚拟服务器 (40)4.5.2虚拟服务器配置实例 (41)4.6NAT-DMZ (43)4.6.1NAT-DMZ (43)4.6.2NAT-DMZ配置实例 (44)4.7查看系统路由 (45)第5章终端管理 (46)5.1限制终端上网速度 (46)5.2限制终端上网时间 (47)5.3黑名单管理 (48)第6章AP管理 (49)6.1AP设置 (49)6.1.1AP设置 (49)6.1.2AP定时重启 (51)6.1.3AP指示灯开关 (51)6.2.1无线网络设置 (52)6.2.2SSID定时开关 (57)6.2.3访客网络设置 (58)6.3智能漫游 (59)6.3.1智能漫游 (59)6.3.2智能漫游配置实例 (61)6.4射频调优 (63)6.4.1射频调优 (63)6.4.2射频调优配置实例 (66)6.5客户端状态 (68)第7章易展管理 (69)7.1管理易展AP (70)7.1.1添加易展AP (70)7.2管理易展AP (72)7.3查看网络拓扑结构 (72)7.4查看客户端列表 (75)第8章行为管控 (76)8.1对象管理 (76)8.1.1地址组管理 (76)8.1.2时间管理 (76)8.2应用控制 (78)8.2.1应用控制 (78)8.2.2QQ白名单 (79)8.3网站访问控制 (80)8.3.1网站分组 (80)8.3.2网站访问 (80)8.3.3网站访问配置实例 (81)8.4网页安全 (85)8.4.1网页安全 (85)8.4.2网页安全配置实例 (86)8.5配置带宽控制功能 (87)8.5.1带宽控制介绍 (87)8.5.2例外管理 (89)8.5.3带宽控制配置实例 (90)8.6连接数限制 (93)8.6.1连接数限制 (93)8.6.2连接数限制配置实例 (94)8.7访问控制 (95)8.7.1访问控制 (95)8.8行为审计 (99)8.8.1行为审计模块记录到系统日志 (99)8.8.2行为日志发送到服务器 (100)8.8.3系统日志发送到服务器 (101)8.8.4开启安全审计功能 (102)第9章安全防护 (104)9.1ARP防护 (104)9.1.1IP-MAC绑定 (104)9.1.2ARP防护 (106)9.1.3ARP列表 (107)9.1.4ARP防护配置实例 (107)9.2MAC地址过滤 (111)9.2.1MAC地址过滤 (111)9.2.2MAC地址过滤配置实例 (112)9.3攻击防护 (113)第10章VPN (115)10.1IPSec (115)10.1.1IPSec安全策略 (115)10.1.2IPSec安全联盟 (121)10.2L2TP (128)10.2.1L2TP服务器 (129)10.2.2L2TP客户端 (130)10.2.3隧道信息列表 (132)10.2.4L2TP配置实例 (132)10.2.5L2TP代理配置实例 (139)10.3PPTP (143)10.3.1PPTP服务器 (143)10.3.2PPTP客户端 (145)10.3.3隧道信息列表 (147)10.3.4PPTP配置实例 (147)10.3.5PPTP代理配置实例 (154)10.4用户管理 (158)10.4.1用户管理 (158)10.4.2IP地址池 (160)第11章认证管理 (161)11.1认证设置 (161)11.1.1Web认证介绍 (161)11.1.2跳转页面 (163)11.1.4远程认证 (168)11.1.5免认证策略 (169)11.1.6全局参数 (171)11.2认证设置配置实例 (172)11.2.1一键上网配置实例 (172)11.2.2短信认证配置实例 (176)11.2.3Web认证配置实例—使用内置Web服务器和内置认证服务器 (180)11.2.4Web认证配置实例—使用内置Web服务器和外部认证服务器 (185)11.2.5Web认证配置实例—使用外置Web服务器和内置认证服务器 (191)11.2.6Web认证配置实例—使用外置Web服务器和外置认证服务器 (195)11.2.7免认证策略配置实例 (200)11.3用户管理 (204)11.3.1认证用户管理 (204)11.3.2用户配置备份 (205)11.4认证服务器 (206)11.4.1Radius服务器 (206)11.4.2认证服务器 (207)11.5认证状态 (208)第12章高级功能 (209)12.1PPPoE服务器 (209)12.1.1全局设置 (209)12.1.2IP地址池 (211)12.1.3账号管理 (211)12.1.4例外IP管理 (213)12.1.5账号信息列表 (214)12.1.6PPPoE服务器配置实例 (214)12.2动态DNS (218)12.2.1TP-LINK动态域名 (218)12.2.2花生壳动态域名 (219)12.2.3科迈动态域名 (219)12.2.43322动态域名 (220)12.2.5DDNS配置实例 (220)12.3UPnP (223)12.4IP流量统计 (225)12.5端口监控 (226)12.5.1端口监控介绍 (226)12.5.2端口监控配置实例 (227)12.6网络唤醒 (229)12.6.1网络唤醒介绍 (229)12.6.2网络唤醒功能配置实例 (230)12.7故障诊断 (231)12.7.1诊断工具 (231)12.7.2诊断工具配置实例 (233)12.7.3故障诊断 (235)第13章系统配置 (237)13.1云管理 (237)13.2设置用户名和密码 (237)13.3恢复出厂配置 (238)13.4备份与导入配置 (238)13.5重启路由器 (239)13.6自动清理 (240)13.7时间设置 (240)13.8升级系统 (242)13.8.1在线和本地升级 (242)13.8.2应用特征库升级 (243)13.9License管理 (243)13.10系统日志管理 (244)13.10.1系统日志管理 (244)13.10.2安全审计功能 (245)13.11系统管理设置 (245)第1章 用户手册简介本手册详细介绍登录商用VPN路由器配置各项功能的方法,以及使用管理软件的方法。

Confidential. All rights reserved. No part of this document may be transmitted or reproduced without prior permission of a Standards Department of the Volkswagen Group.Parties to a contract can only obtain this standard via the B2B supplier platform “”VOLKSWAGEN AG Q U E L L E : N O L I SPage 2TL 524 76: 2006-03D3.1.2 PackagingFinished part packaging shall not be air tight to allow air circulation. In case of delivery in large packaging units (cardboard boxes, pallets), they should be stacked or arranged so that air circulation is possible.3.2 Marking according to VDA 260>POM<3.3 ConditioningPrior to testing, the specimens required for the individual tests must be conditioned for at least 48 h in the DIN 50014 – 23/50-2 standard climate.3.4 Evaluation of the measuring resultsThe required numerical values apply to each individual measurement.3.5 MaterialSee Section 5.2.Polyoxymethylene (POM) homopolymer, or copolymer alternatively.3.6 ColorAccording to drawing and/or release.4 PropertiesSee Table 1.Table 1No. Property Requirement1 Density acc. to DIN EN ISO 1183-1, buoyancy(1,42 ± 0,02) g/cm3method2 Melting temperature acc. to DIN EN ISO 3146,+166 °C to +179 °Calternatively with DSCsee Section 5.33 Dimensional stability under heat acc. to Vicat and≥ 145 °CDIN EN ISO 306, method B50≥ 60 MPa4 Yield stress acc. to DIN EN ISO 527-2see Section 5.45 Elongation acc. to DIN EN ISO 527-2≥ 6,5%see Section 5.46 Impact resistance acc. to DIN EN ISO 179-1/1eUNo fracture (kJ/m2)see Section 5.57 Notched impact strength acc. to DIN EN ISO 179-≥ 4,5 kJ/m21/1eA.see Section 5.6Page 3TL 524 76: 2006-035 Notes on testingbehavior5.1 EmissionIf the test results do not comply with the requirements of VW 50180, the parts shall be tempered until the limit values are met. The temperature shall be selected such that no changes in form, color, and surface occur.5.2 MaterialThe identity test is performed using infrared spectroscopy.temperature5.3 MeltingIf the DSC method is chosen to identify the melting temperature, the following procedure shall be applied:Test equipment such as the DSC 821e from Mettler Toledo can be used. A plane parallel finished part section of a weight of approx. 5 mg to 10 mg serves as specimen.Testing parameters: The specimen is heated from +50 °C to +200 °C at a heating rate of 10 °C/min. Afterwards, it is cooled with 5° C/min to +50° C and reheated with 10° C/min to +200° C. The test is carried out in normal atmosphere.Page 4TL 524 76: 2006-03D5.4 Yield stress and elongationTensile test according to DIN EN ISO 527-2, 5A specimen, test rate 50 mm/min. In case the 5A specimen cannot be prepared, it is permissible to use S3A tensile specimens (standard test specimens) acc. to DIN 53504.strength5.5 ImpactTest equipment: pendulum impact tester 4J.If for reasons concerning equipment and/or specimen shape and size a test according to Table 1 No. 6 cannot be performed, the following procedure may be substituted:Impact resistance test (broadside impact) according to DIN EN ISO 179-1; deviating specimen length: (50 ± 1) mm, width: (6 ± 0,2) mm, thickness according to product thickness (up to max.4 mm); mounting flange interval (support separation): 40 mm, test equipment: pendulum impact tester 4J.Specimens taken from finished parts grained or painted on one side are placed on the mounting flange of the pendulum impact tester so that the grained or painted side faces the direction of impact.Note that this procedure requires prior agreement.5.6 Notched impact strengthTest equipment: pendulum impact tester 4J.If for reasons concerning equipment and/or specimen shape and size a test according to Table 1 No. 7 cannot be performed, the following procedure may be substituted:Impact resistance test (broadside impact) according to DIN EN ISO 179-1; deviating specimen length: (50 ± 1) mm, width: (6 ± 0,2) mm, thickness according to product thickness (up to max. 4 mm); mounting flange interval (support separation): 40 mm, test equipment: pendulum impact tester 4J.The specimens are given a 0.8 mm wide U-shaped notch on the broad side. The notch depth shall be 1/3 the specimen thickness. The edges adjoining the base of the notch shall have a curvature radius of < 0,1 mm.Finished parts with one-sided graining shall be notched on the grained side and subsequently placed on the pendulum impact tester’s mounting flanges in such a manner that the center of the notch is precisely within the impact plane. Care shall be taken that the notch is located on the side away from the direction of impact. Note that this procedure requires prior agreement.behavior5.7 Elevated-temperatureAging test at elevated temperature according to DIN 53497, method B, on at least one complete finished part; aging temperature (+90 ± 1) °C; aging period (22 + 2) h.behavior5.8 Low-temperatureA minimum of two complete finished parts are aged in air at (-30 ± 1) °C; aging period (22 + 2) h.5.9 Ball drop testBall drop test acc. to PV 3905, however, base plate (specimen support) made from 10 mm thick sheet steel without recess on at least three finished parts. Ball drop height (450 ± 5) mm.Page 5TL 524 76: 2006-03D 5.10 LightfastnessIf the number of exposure periods is not defined in the drawing, the following rule applies:─ 3 periods of exposure for components in areas with indirect sun radiation.─ 5 periods of exposure for components in areas with direct sun radiation (e.g. door upper trim).─10 periods of exposure for components in areas subject to the highest sun radiation (e.g. rear shelf).standards16 ReferencedTL 1010 Materials for Vehicle Interiors; Flammability, Material RequirementsPV 1303 Non-Metallic Materials;Exposure Test of Passenger Compartment ComponentsPV 3905 Organic Materials; Ball Drop TestVW 01155 Vehicle Supply Parts; Approval of First Supply and ChangesVW 50180 Components in Passenger Compartment; Emission BehaviorVW 50185 Vehicle Components; Resistance to Open Air WeatheringVW 50190 Components of the Vehicle Interior Trim; Colorimetric EvaluationVW 91101 Environmental Standard for Vehicles; Vehicle Parts, Materials, Operating Fluids; Avoidance of Hazardous SubstancesDIN 50014 Climates and Their Technical Application; Standard AtmospheresDIN 53497 Testing of Plastics; Hot Storage Test on Mouldings Made of Thermoplastic Moulding Materials without External Mechanical StressingDIN 53504 Testing of Rubber; Determination of Tensile Strength at Break, Tensile Stress at Yield, Elongation at Break and Stress Values in a Tensile TestDIN EN ISO 179-1 Plastics; Determination of Charpy Impact Properties, Part 1: Non-Instrumented Impact TestDIN EN ISO 306 Plastics – Thermoplastic Materials – Determination of Vicat Softening Temperature (VST)DIN EN ISO 527-2 Plastics - Determination of Tensile Properties – Part 2: Test Conditions for Moulding and Extrusion PlasticsDIN EN ISO 1183-1 Plastics – Methods for Determining the Density of Non-Cellular Plastics – Part 1: Immersion Method, Liquid Pyknometer Method and Titration Method DIN EN ISO 3146 Plastics, Determination of Melting Behaviour (Melting Temperature or Melting Range) of Semi-Crystalline Polymers by Capillary Tube andPolarizing-Microscope MethodsDIN EN 20105-A02 Textiles – Tests for Colour Fastness – Part A02: Grey Scale for Assessing Change in ColourVDA 260 Motor Vehicle Components; Marking of Materials1 In this section terminological inconsistencies may occur as the original titles are used.。