Effect of Sn addition on stress hysteresis and superelastic properties of a Ti-15Nb-3Mo alloy

- 格式:pdf

- 大小:1.46 MB

- 文档页数:19

附着强度英语Adhesive StrengthThe concept of adhesive strength is a fundamental aspect of material science and engineering, with far-reaching implications in various industries. Adhesives are materials that facilitate the bonding of two or more surfaces, creating a strong and durable connection. The strength of this bond, known as adhesive strength, is a critical factor in determining the overall performance and reliability of the joined components.Adhesive strength is influenced by a multitude of factors, including the chemical composition of the adhesive, the surface properties of the materials being bonded, the environmental conditions, and the applied stresses. Understanding and optimizing these factors is crucial for ensuring the integrity and longevity of adhesive-based assemblies.One of the primary determinants of adhesive strength is the chemical composition of the adhesive itself. Adhesives can be classified into various categories, such as epoxies, acrylics, silicones, and polyurethanes, each with its own unique properties andperformance characteristics. The choice of adhesive depends on the specific application, the materials being bonded, and the desired level of strength and durability.Epoxy adhesives, for instance, are known for their exceptional strength and resistance to environmental factors, making them a popular choice for applications in the aerospace, automotive, and construction industries. These adhesives form a strong covalent bond with the substrate, resulting in a high-strength connection that can withstand significant stresses and loads.Acrylic adhesives, on the other hand, offer a more versatile and flexible bonding solution. They are commonly used in the electronics and consumer goods industries, where the ability to bond a wide range of materials, including plastics and metals, is essential. Acrylic adhesives typically exhibit good impact resistance and can accommodate slight movements or deformations in the bonded components.Silicone adhesives, in contrast, are prized for their excellent resistance to high temperatures, weathering, and chemical exposure. They are often employed in applications where these environmental factors are a concern, such as in the automotive, aerospace, and construction industries. Silicone adhesives can form strong bonds with a variety of substrates, including glass, metal, and plastic.Polyurethane adhesives, meanwhile, are known for their superior flexibility and impact resistance. They are commonly used in the construction and transportation industries, where the ability to accommodate movement and vibration is crucial. Polyurethane adhesives can form strong bonds with a wide range of materials, including wood, concrete, and various plastics.The surface properties of the materials being bonded also play a significant role in determining the adhesive strength. The surface roughness, wettability, and chemical composition of the substrates can influence the adhesive's ability to form a strong and durable bond. Surface preparation techniques, such as cleaning, etching, or priming, can be employed to enhance the adhesion properties of the materials, thereby improving the overall adhesive strength.Environmental factors, such as temperature, humidity, and exposure to chemicals or UV radiation, can also have a significant impact on the adhesive strength. Adhesives may experience degradation or weakening over time due to these environmental stresses, leading to a reduction in the overall bond strength. Understanding and mitigating these environmental factors is essential for ensuring the long-term performance and reliability of adhesive-based assemblies.The applied stresses on the bonded assembly are another criticalfactor in determining the adhesive strength. Adhesives can experience various types of stresses, including tensile, shear, peel, and cleavage stresses, each of which can have a different effect on the bond strength. Designing the bonded assembly to minimize the impact of these stresses, through the use of appropriate joint geometries and load-bearing configurations, can help maximize the adhesive strength and ensure the overall integrity of the assembly.In addition to these fundamental factors, advances in adhesive technology have led to the development of specialized adhesives that can further enhance the adhesive strength. For example, structural adhesives, which are designed to withstand high loads and stresses, are commonly used in the aerospace and automotive industries. These adhesives can provide superior strength and durability, often outperforming traditional mechanical fasteners in certain applications.Another example of advanced adhesive technology is the use of nanoparticle-reinforced adhesives. These adhesives incorporate nanoscale reinforcements, such as carbon nanotubes or graphene, which can significantly improve the adhesive strength, toughness, and thermal stability of the bond. The incorporation of these nanomaterials can lead to enhanced interfacial interactions between the adhesive and the substrate, resulting in a stronger and more resilient bond.In conclusion, adhesive strength is a critical factor in the design and performance of a wide range of products and structures. Understanding the factors that influence adhesive strength, such as the chemical composition of the adhesive, the surface properties of the materials being bonded, environmental conditions, and applied stresses, is essential for ensuring the reliability and durability of adhesive-based assemblies. Advances in adhesive technology, including the development of specialized structural adhesives and nanoparticle-reinforced adhesives, have further expanded the capabilities and applications of adhesive bonding in various industries.。

刘容旭,李春雨,王语聪,等. 超高压辅助酶解法改性汉麻分离蛋白及其理化性质的研究[J]. 食品工业科技,2023,44(19):99−107.doi: 10.13386/j.issn1002-0306.2023010016LIU Rongxu, LI Chunyu, WANG Yucong, et al. Study on the Modification and Physicochemical Properties of Hemp Protein Isolate by Ultra-High Pressure Assisted Enzymatic Hydrolysis[J]. Science and Technology of Food Industry, 2023, 44(19): 99−107. (in Chinese with English abstract). doi: 10.13386/j.issn1002-0306.2023010016· 研究与探讨 ·超高压辅助酶解法改性汉麻分离蛋白及其理化性质的研究刘容旭1,李春雨2,王语聪2,谢智鑫2,谢宜桐2,李双鹏2,刘丹怡1, *,韩建春2,*(1.黑龙江省绿色食品科学研究院,黑龙江哈尔滨 150028;2.东北农业大学 食品学院,黑龙江哈尔滨 150030)摘 要:本研究以汉麻分离蛋白(Hemp Protein Isolate ,HPI )为原料,通过超高压辅助酶解反应对HPI 进行改性,以溶解度和水解度为判定指标筛选酶解改性反应最佳条件,并探究超高压辅助酶解反应对酶解产物溶解性、起泡性、乳化性、持水性、持油性的影响。

结果表明,HPI 酶解反应最适条件为:加酶量(复合蛋白酶)5000 U/g 、酶解改性pH8.0、酶解改性温度55 ℃、酶解改性时间50 min 。

以HPI 为对照,当压力为200 MPa 时,酶解产物的溶解度、起泡性、乳化性、持油性最高,压力为100 MPa 时,泡沫稳定性最好,酶解后的乳化稳定性存在不同程度的下降,压力为0.1 MPa 时其持水性达到最大值。

如何解决疲劳效应英语作文Title: Strategies to Combat Fatigue Effect。

Fatigue effect, the depletion of mental and physical energy over time, poses a significant challenge to individuals in various aspects of life, be it academic, professional, or personal. Addressing this issue requires a multifaceted approach encompassing lifestyle adjustments, cognitive strategies, and self-care practices. In this essay, we will delve into effective methods to tackle fatigue effect and enhance overall well-being.Firstly, establishing a balanced lifestyle is paramount in combating fatigue. Adequate sleep is fundamental for replenishing energy levels and sustaining cognitive function. Research suggests that adults should aim for 7-9 hours of sleep per night for optimal health. Additionally, maintaining a consistent sleep schedule, even on weekends, helps regulate the body's internal clock, promoting better sleep quality and reducing daytime fatigue.Moreover, incorporating regular physical activity into one's routine is beneficial for combating fatigue. Exercise stimulates the release of endorphins, neurotransmittersthat elevate mood and energy levels. Engaging in activities such as jogging, yoga, or swimming not only enhances physical fitness but also boosts mental clarity and alertness. Even short bouts of exercise throughout the day can mitigate feelings of fatigue and improve overall productivity.In conjunction with lifestyle modifications, adopting cognitive strategies can mitigate the impact of fatigue on cognitive function. Time management techniques, such as the Pomodoro Technique, involve breaking tasks into manageable intervals separated by short breaks. This method prevents burnout and enhances focus by capitalizing on the brain's natural rhythm of attention.Furthermore, implementing mindfulness practices can counteract the cognitive effects of fatigue. Mindfulness meditation, characterized by non-judgmental awareness ofthe present moment, promotes mental clarity and resilience to stress. Studies have shown that regular meditation reduces fatigue and enhances cognitive flexibility, enabling individuals to navigate challenges with greater ease.In addition to lifestyle and cognitive interventions, self-care practices play a crucial role in combatingfatigue effect. Nutrition plays a pivotal role in sustaining energy levels throughout the day. Consuming a balanced diet rich in whole grains, lean proteins, fruits, and vegetables provides essential nutrients that support optimal brain function and mitigate fatigue.Moreover, practicing self-compassion and setting realistic expectations are vital components of self-care. Perfectionism and excessive self-criticism can contribute to burnout and exacerbate feelings of fatigue. Cultivating self-compassion involves treating oneself with kindness and understanding, particularly during periods of heightened stress or fatigue.Furthermore, establishing boundaries and prioritizing self-care activities is essential for preventing burnout. Carving out time for leisure activities, social connections, and relaxation fosters resilience and replenishes depleted energy stores. Whether it's reading a book, spending time with loved ones, or engaging in hobbies, prioritizing activities that bring joy and fulfillment is essential for maintaining well-being.In conclusion, addressing fatigue effect necessitates a comprehensive approach encompassing lifestyle adjustments, cognitive strategies, and self-care practices. Byprioritizing sleep, exercise, mindfulness, nutrition, and self-compassion, individuals can mitigate the impact of fatigue and cultivate resilience in the face of challenges. Empowering oneself with effective coping mechanisms is keyto sustaining energy levels and optimizing overall well-being.。

第44卷第6期2021年6月V ol.44,No.6June2021核技术NUCLEAR TECHNIQUES熔盐堆低功率工况下反应性引入事故初始条件敏感性探讨焦小伟王凯王超群杨群何兆忠(中国科学院上海应用物理研究所上海201800)摘要熔盐堆低功率工况反应性引入事故中,不同的反应性引入速率将触发不同的停堆信号。

同时反应堆初始功率和反应性温度系数等初始条件影响事故的进程,引起事故后果的差异。

本文选取了7个反应性引入速率工况、25个初始功率水平和反应性温度系数的参数组合初始工况,分别讨论了这三个参数对事故后果的影响。

分析结果表明:熔盐堆低功率工况反应性引入事故的后果对反应性引入速率的变化较敏感,在其他初始条件一定的情况下,存在特定的反应性引入速率会导致最不利的事故后果;事故后果对反应堆初始功率和反应性温度系数的变化不敏感,由初始功率和反应性温度系数差异造成的事故后果差异较小。

关键词熔盐堆,低功率,反应性引入事故,敏感性中图分类号TL36DOI:10.11889/j.0253-3219.2021.hjs.44.060602Study on sensitivity of initial conditions of reactivity initiated accident under low powerconditions of molten salt reactorJIAO Xiaowei WANG Kai WANG Chaoqun YANG Qun HE Zhaozhong(Shanghai Institute of Applied Physics,Chinese Academy of Sciences,Shanghai201800,China)Abstract[Background]In the reactivity initiated accidents under low power operating conditions of molten salt reactor(MSR),different reactivity insertion rates will trigger different emergency shutdown signals.At the same time,the initial conditions such as the initial reactor power and the temperature coefficients of reactivity affect the accident process and cause differences in accident consequences.[Purpose]The study aims to conduct a sensitivity analysis of the impact of the reactivity insertion rate,the initial reactor power,and the reactivity temperature coefficient on transient consequences.[Methods]First of all,7reactivity insertion rate conditions were selected and simulated through RELAP5-TMSR.Then,25combinations of the initial reactor power and the temperature coefficients of reactivity were assumed as initial conditions.Finally,the effects of these three parameters on the consequences of the accident were discussed separately by using local sensitivity analysis method.[Results]The insertion rate that causes a concurrent trigger of the high outlet temperature and the high-power shutdown signal leads to the most unfavorable consequence.The difference between the peak temperatures of the fuel salt and structural materials and their respective initial values under the worst reactivity insertion rate condition is negatively correlated with initial power.However,the temperature difference of each parameter caused by different initial power does not中国科学院青年创新促进会项目(No.Y929022031)资助第一作者:焦小伟,男,1989年出生,2019年于中国科学院大学获博士学位,副研究员,主要从事反应堆事故分析通信作者:杨群,E-mail:收稿日期:2021-01-14,修回日期:2021-03-29Supported by the Project of Youth Innovation Promotion Association of Chinese Academy of Sciences(No.Y929022031)First author:JIAO Xiaowei,male,born in1989,graduated from University of Chinese Academy of Sciences with a doctoral degree in2019,associate professor,focusing on reactor safetyCorresponding author:YANG Qun,E-mail:Received date:2021-01-14,revised date:2021-03-29焦小伟等:熔盐堆低功率工况下反应性引入事故初始条件敏感性探讨exceed3℃.The difference between the peak temperatures decrease first and then increases with the increase of the temperature coefficients of reactivity,but the maximum difference does not exceed0.5℃.[Conclusions]Under low power operating conditions of MSR,the consequences of reactivity introduced events are highly sensitive to the reactivity insertion rate and low sensitivity to the initial power and temperature coefficients of reactivity.Key words Molten salt reactor,Low power,Reactive initiated accident,Sensitivity熔盐堆(Molten Salt Reactor,MSR)是第四代核能系统候选堆型之一。

The Effect of Temperature on ProteinConformationProteins are essential components of living organisms and are responsible for carrying out various cellular functions. They are composed of long chains of amino acids that are folded into intricate 3-dimensional structures. The specific shape of a protein, or its conformation, plays a critical role in its function. Temperature is one of the key factors that can influence protein conformation. In this article, we will explore the effect of temperature on protein conformation and how it impacts their function.Temperature-induced protein denaturationProtein denaturation is a process in which the protein loses its native conformation and unfolds into a linear or random coil structure. This process can be triggered by several factors, including pH, salts, mechanical stress, and temperature. Among these, temperature is the most commonly studied factor that can induce protein denaturation.When proteins are exposed to high temperatures, the thermal energy causes the bonds that hold the protein structure together to break. Hydrogen bonds, which are weaker than covalent bonds, are the first to be broken. As the temperature continues to rise, the more significant covalent bonds that hold the protein together begin to break, further destabilizing the structure. Ultimately, the protein loses its native conformation, and its function is impaired.The effect of temperature on protein stabilityThe stability of a protein refers to its ability to maintain its native conformation in the face of various environmental conditions, including temperature. The stability of a protein is influenced by several factors, including the amino acid sequence, solvent conditions, and the presence of ligands or cofactors. Temperature can disrupt the stability of a protein by altering its structure and causing it to denature.Proteins have a range of thermal stability that depends on their amino acid sequence and their specific structure. Generally, proteins that are stable at higher temperatures have a higher content of hydrophobic amino acids, which can help to stabilize the structure through hydrophobic interactions. In contrast, proteins that are stable at lower temperatures tend to have more polar amino acids and a lower content of hydrophobic amino acids.The temperature at which a protein denatures is known as its melting temperature or Tm. The Tm of a protein is influenced by its intrinsic stability as well as the specific conditions under which it is studied. For example, the pH, salt concentration, and presence of other molecules can all affect the Tm of a protein.The effect of temperature on protein functionThe specific conformation of a protein plays a critical role in its function. Therefore, changes in protein conformation due to temperature can have a significant impact on their function. The effect of temperature on protein function can vary depending on the specific protein and the conditions under which it is studied.Some proteins are more sensitive to changes in temperature than others. For example, enzymes, which catalyze chemical reactions in the cell, have a specific optimal temperature range at which they function best. Outside of this range, the reaction rate can slow down or even stop altogether due to changes in protein conformation.Other proteins, such as transporters and receptors, are also sensitive to changes in temperature. Changes in protein conformation due to temperature can affect the ability of these proteins to bind to their ligands and carry out their function.ConclusionIn conclusion, temperature has a significant impact on protein conformation. High temperatures can cause proteins to denature, while changes in temperature can alter their stability and affect their function. Understanding the effect of temperature on protein conformation and function is essential for designing experiments and developing new drugs and therapies that target specific proteins.。

压力交变试验英语Stress Alternating TestStress is an integral part of our daily lives, and it can have a significant impact on our physical and mental well-being. The ability to manage stress effectively is crucial for maintaining a healthy and balanced lifestyle. One method of assessing and understanding the effects of stress is through the use of a stress alternating test.The stress alternating test is a technique used to evaluate an individual's response to varying levels of stress. The test involves exposing the subject to a series of controlled stress-inducing situations, alternating between high and low-stress conditions. This approach allows researchers and clinicians to observe how the body and mind react to the fluctuations in stress levels.During the stress alternating test, the subject may be asked to perform a variety of tasks or engage in different scenarios that are designed to elicit specific stress responses. For example, the subject may be required to solve complex mathematical problems under time pressure, engage in public speaking, or participate in simulated high-stakes decision-making scenarios. The test may also involveexposing the subject to environmental stressors, such as loud noises, extreme temperatures, or challenging physical activities.As the subject navigates through these varying stress conditions, researchers closely monitor a range of physiological and psychological parameters. These may include heart rate, blood pressure, cortisol levels, skin conductance, and self-reported measures of anxiety, mood, and cognitive performance. By analyzing these data points, researchers can gain insights into how the individual's body and mind respond to the fluctuations in stress levels.One of the key benefits of the stress alternating test is its ability to provide a comprehensive understanding of an individual's stress resilience. By observing how the subject's physiological and psychological responses change in response to the alternating stress levels, researchers can identify patterns and identify potential areas of vulnerability or strength. This information can then be used to develop personalized stress management strategies and interventions.Moreover, the stress alternating test can also be valuable in the context of occupational health and safety. Many professions, such as emergency services, military, and high-stakes decision-making roles, often require individuals to navigate high-stress situations regularly.The stress alternating test can be used to assess the suitability and resilience of individuals for these demanding roles, ensuring that they are equipped to handle the challenges they may face.In addition to its practical applications, the stress alternating test also contributes to our scientific understanding of the human stress response. By studying the physiological and psychological reactions to varying stress levels, researchers can gain insights into the underlying mechanisms that govern the stress response. This knowledge can then be used to develop more effective strategies for stress management and prevention, ultimately improving overall health and well-being.In conclusion, the stress alternating test is a valuable tool for assessing and understanding the effects of stress on the human body and mind. By exposing individuals to controlled stress-inducing situations and monitoring their responses, researchers and clinicians can gain valuable insights that can be used to develop personalized stress management strategies and interventions. As we continue to navigate the challenges of modern life, the stress alternating test will likely play an increasingly important role in promoting health, well-being, and resilience.。

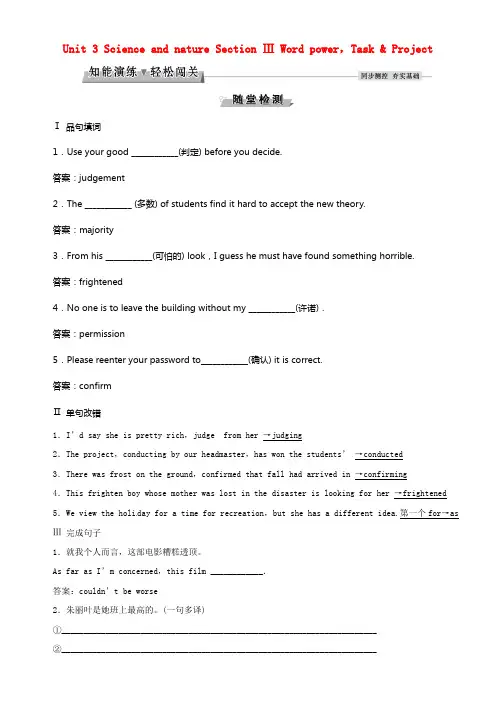

Unit 3 Science and nature Section Ⅲ Word power,Task & ProjectⅠ品句填词1.Use your good ____________(判定) before you decide.答案:judgement2.The ____________ (多数) of students find it hard to accept the new theory.答案:majority3.From his ____________(可怕的) look,I guess he must have found something horrible.答案:frightened4.No one is to leave the building without my ____________(许诺).答案:permission5.Please reenter your password to____________(确认) it is correct.答案:confirmⅡ单句改错1.I’d say she is pretty rich,judge from her →judging2.The project,conducting by our headmaster,has won the students’→conducted3.There was frost on the ground,confirmed that fall had arrived in →confirming4.This frighten boy whose mother was lost in the disaster is looking for her →frightened 5.We view the holi day for a time for recreation,but she has a different idea.第一个for→as Ⅲ完成句子1.就我个人而言,这部电影糟糕透顶。

鲶鱼效应可以有效促进竞争英语作文The Catfish Effect stimulates competition in various fields, propelling individuals to achieve greater accomplishments. This phenomenon describes the notion that if a small entity enters a larger competitive environment, it can motivate the established players to work harder and achieve better results. This effect can be observed in different domains such as sports, education, technology, and business.In sports, the Catfish Effect is often witnessed when a talented newcomer emerges and challenges the established athletes. The presence of this new talent motivates the existing players to train harder, improve their skills, and maintain their position at the top. The competition created by the Catfish Effect drives athletes to push beyond their limits, breaking records and achieving remarkable feats.Similarly, in the field of education, the Catfish Effect can enhance competition among students. When a new student with exceptional abilities joins a class, it inspires others to strive for excellence. The existing students realize the need to work harder, study more rigorously, and actively participate in academic activities to maintain their academic standing. This competitive environment fosters a culture of continuous improvement and enhances overall academic performances.The Catfish Effect is also evident in the realm of technology. When a small startup with an innovative idea enters an industry dominated by established companies, it often disrupts the market. The established companies recognize the potential of the new entrant and are motivated to innovate and develop better products or services in order to maintain their market share. This healthy competition drives technological advancements, benefiting consumers with improved offerings.Moreover, in the world of business, the Catfish Effect fuels healthy competition among companies. When a new player emerges with a unique value proposition or a disruptive business model, it compels existing companies to reassess their strategies and find ways to stay competitive. Established companies may invest in research and development, improve their products or services, or enhance customer experiences to successfully counter the competition andretain their market position.In conclusion, the Catfish Effect is a catalyst for competition in various domains. It motivates individuals and entities to step up their game, work harder, and strive for excellence. This effect has a positive impact on sports, education, technology, and business, fostering innovation and enhancing overall performances. The presence of new players creates an environment of healthy competition, pushing everyone to reach their full potential.。

琴弦不能太紧也不能太松英语作文The Delicate Balance of String Tension.In the realm of musical instruments, the strings that produce the enchanting melodies and harmonies are finely tuned to a specific tension. This tension plays a crucial role in determining the instrument's tone, intonation, and overall playability.The Effects of String Tension on Tone.String tension has a direct impact on the pitch of a musical note. When a string is tighter, it vibrates at a higher frequency, producing a higher sound. Conversely, a looser string vibrates at a lower frequency, resulting in a lower pitch. This principle is evident across all stringed instruments, from violins to guitars to pianos.Moreover, string tension affects the timbre, or tonal quality, of the sound produced. Tighter strings tend toproduce a brighter, more piercing tone, while looserstrings often yield a warmer, more mellow sound. This variation in timbre is due to the different overtone series generated by strings of different tensions.The Importance of Intonation.String tension also plays a vital role in intonation, the accuracy of pitch intervals. When the strings are tuned to the correct tension, they will produce notes that are perfectly in tune with each other. However, if the strings are too tight or too loose, the notes will be out of tune, making it difficult to produce harmonious intervals and melodies.Playability and String Tension.The tension of the strings also affects theinstrument's playability. Tighter strings require more force to press down and produce a clear sound, which can be physically demanding for musicians, especially in extended playing sessions. On the other hand, looser strings areeasier to play but may lack the responsiveness and articulation required for certain musical styles.Finding the Optimal Balance.The optimal string tension for a musical instrument depends on various factors, including the size and construction of the instrument, the type of music being played, and the musician's personal preferences. Finding the right balance requires experimentation and careful consideration.Generally, strings that are too tight can cause excessive stress on the instrument, leading to damage or premature wear. They can also result in a sharp, metallic sound that lacks warmth and depth. Conversely, strings that are too loose may produce a dull, lifeless tone and poor intonation.Conclusion.The tension of musical strings is a delicate balancethat must be carefully maintained to achieve the desired tone, intonation, and playability. Musicians must strive to find the optimal string tension for their instruments, taking into account the specific characteristics of the instrument, the musical genre, and their own individual needs. By mastering this aspect of their craft, they can unlock the full potential of their musical endeavors and create truly captivating performances.。

New1H-Pyrazole-Containing Polyamine Receptors Able ToComplex L-Glutamate in Water at Physiological pH ValuesCarlos Miranda,†Francisco Escartı´,‡Laurent Lamarque,†Marı´a J.R.Yunta,§Pilar Navarro,*,†Enrique Garcı´a-Espan˜a,*,‡and M.Luisa Jimeno†Contribution from the Instituto de Quı´mica Me´dica,Centro de Quı´mica Orga´nica Manuel Lora Tamayo,CSIC,C/Juan de la Cier V a3,28006Madrid,Spain,Departamento de Quı´mica Inorga´nica,Facultad de Quı´mica,Uni V ersidad de Valencia,c/Doctor Moliner50, 46100Burjassot(Valencia),Spain,and Departamento de Quı´mica Orga´nica,Facultad deQuı´mica,Uni V ersidad Complutense de Madrid,A V plutense s/n,28040Madrid,SpainReceived April16,2003;E-mail:enrique.garcia-es@uv.esAbstract:The interaction of the pyrazole-containing macrocyclic receptors3,6,9,12,13,16,19,22,25,26-decaazatricyclo-[22.2.1.111,14]-octacosa-1(27),11,14(28),24-tetraene1[L1],13,26-dibenzyl-3,6,9,12,13,16,-19,22,25,26-decaazatricyclo-[22.2.1.111,14]-octacosa-1(27),11,14(28),24-tetraene2[L2],3,9,12,13,16,22,-25,26-octaazatricyclo-[22.2.1.111,14]-octacosa-1(27),11,14(28),24-tetraene3[L3],6,19-dibenzyl-3,6,9,12,13,-16,19,22,25,26-decaazatricyclo-[22.2.1.111,14]-octacosa-1(27),11,14(28),24-tetraene4[L4],6,19-diphenethyl-3,6,9,12,13,16,19,22,25,26-decaazatricyclo-[22.2.1.111,14]-octacosa-1(27),11,14(28),24-tetraene5[L5],and 6,19-dioctyl-3,6,9,12,13,16,19,22,25,26-decaazatricyclo-[22.2.1.111,14]-octacosa-1(27),11,14(28),24-tetra-ene6[L6]with L-glutamate in aqueous solution has been studied by potentiometric techniques.The synthesis of receptors3-6[L3-L6]is described for the first time.The potentiometric results show that4[L4]containing benzyl groups in the central nitrogens of the polyamine side chains is the receptor displaying the larger interaction at pH7.4(K eff)2.04×104).The presence of phenethyl5[L5]or octyl groups6[L6]instead of benzyl groups4[L4]in the central nitrogens of the chains produces a drastic decrease in the stability[K eff )3.51×102(5),K eff)3.64×102(6)].The studies show the relevance of the central polyaminic nitrogen in the interaction with glutamate.1[L1]and2[L2]with secondary nitrogens in this position present significantly larger interactions than3[L3],which lacks an amino group in the center of the chains.The NMR and modeling studies suggest the important contribution of hydrogen bonding andπ-cation interaction to adduct formation.IntroductionThe search for the L-glutamate receptor field has been andcontinues to be in a state of almost explosive development.1 L-Glutamate(Glu)is thought to be the predominant excitatory transmitter in the central nervous system(CNS)acting at a rangeof excitatory amino acid receptors.It is well-known that it playsa vital role mediating a great part of the synaptic transmission.2However,there is an increasing amount of experimentalevidence that metabolic defects and glutamatergic abnormalitiescan exacerbate or induce glutamate-mediated excitotoxic damageand consequently neurological disorders.3,4Overactivation ofionotropic(NMDA,AMPA,and Kainate)receptors(iGluRs)by Glu yields an excessive Ca2+influx that produces irreversible loss of neurons of specific areas of the brain.5There is much evidence that these processes induce,at least in part,neuro-degenerative illnesses such as Parkinson,Alzheimer,Huntington, AIDS,dementia,and amyotrophic lateral sclerosis(ALS).6In particular,ALS is one of the neurodegenerative disorders for which there is more evidence that excitotoxicity due to an increase in Glu concentration may contribute to the pathology of the disease.7Memantine,a drug able to antagonize the pathological effects of sustained,but relatively small,increases in extracellular glutamate concentration,has been recently received for the treatment of Alzheimer disease.8However,there is not an effective treatment for ALS.Therefore,the preparation of adequately functionalized synthetic receptors for L-glutamate seems to be an important target in finding new routes for controlling abnormal excitatory processes.However,effective recognition in water of aminocarboxylic acids is not an easy task due to its zwitterionic character at physiological pH values and to the strong competition that it finds in its own solvent.9†Centro de Quı´mica Orga´nica Manuel Lora Tamayo.‡Universidad de Valencia.§Universidad Complutense de Madrid.(1)Jane,D.E.In Medicinal Chemistry into the Millenium;Campbell,M.M.,Blagbrough,I.S.,Eds.;Royal Society of Chemistry:Cambridge,2001;pp67-84.(2)(a)Standaert,D.G.;Young,A.B.In The Pharmacological Basis ofTherapeutics;Hardman,J.G.,Goodman Gilman,A.,Limbird,L.E.,Eds.;McGraw-Hill:New York,1996;Chapter22,p503.(b)Fletcher,E.J.;Loge,D.In An Introduction to Neurotransmission in Health and Disease;Riederer,P.,Kopp,N.,Pearson,J.,Eds.;Oxford University Press:New York,1990;Chapter7,p79.(3)Michaelis,E.K.Prog.Neurobiol.1998,54,369-415.(4)Olney,J.W.Science1969,164,719-721.(5)Green,J.G.;Greenamyre,J.T.Prog.Neurobiol.1996,48,613-63.(6)Bra¨un-Osborne,H.;Egebjerg,J.;Nielsen,E.O.;Madsen,U.;Krogsgaard-Larsen,P.J.Med.Chem.2000,43,2609-2645and references therein.(7)(a)Shaw,P.J.;Ince,P.G.J.Neurol.1997,244(Suppl2),S3-S14.(b)Plaitakis,A.;Fesdjian,C.O.;Shashidharan,S Drugs1996,5,437-456.(8)Frantz,A.;Smith,A.Nat.Re V.Drug Dico V ery2003,2,9.Published on Web12/30/200310.1021/ja035671m CCC:$27.50©2004American Chemical Society J.AM.CHEM.SOC.2004,126,823-8339823There are many types of receptors able to interact with carboxylic acids and amino acids in organic solvents,10-13yielding selective complexation in some instances.However,the number of reported receptors of glutamate in aqueous solution is very scarce.In this sense,one of the few reports concerns an optical sensor based on a Zn(II)complex of a 2,2′:6′,2′′-terpyridine derivative in which L -aspartate and L -glutamate were efficiently bound as axial ligands (K s )104-105M -1)in 50/50water/methanol mixtures.14Among the receptors employed for carboxylic acid recogni-tion,the polyamine macrocycles I -IV in Chart 1are of particular relevance to this work.In a seminal paper,Lehn et al.15showed that saturated polyamines I and II could exert chain-length discrimination between different R ,ω-dicarboxylic acids as a function of the number of methylene groups between the two triamine units of the receptor.Such compounds were also able to interact with a glutamic acid derivative which has the ammonium group protected with an acyl moiety.15,16Compounds III and IV reported by Gotor and Lehn interact in their protonated forms in aqueous solution with protected N -acetyl-L -glutamate and N -acetyl-D -glutamate,showing a higher stability for the interaction with the D -isomer.17In both reports,the interaction with protected N -acetyl-L -glutamate at physiological pH yields constants of ca.3logarithmic units.Recently,we have shown that 1H -pyrazole-containing mac-rocycles present desirable properties for the binding of dopam-ine.18These polyaza macrocycles,apart from having a highpositive charge at neutral pH values,can form hydrogen bonds not only through the ammonium or amine groups but also through the pyrazole nitrogens that can behave as hydrogen bond donors or acceptors.In fact,Elguero et al.19have recently shown the ability of the pyrazole rings to form hydrogen bonds with carboxylic and carboxylate functions.These features can be used to recognize the functionalities of glutamic acid,the carboxylic and/or carboxylate functions and the ammonium group.Apart from this,the introduction of aromatic donor groups appropriately arranged within the macrocyclic framework or appended to it through arms of adequate length may contribute to the recognition event through π-cation interactions with the ammonium group of L -glutamate.π-Cation interactions are a key feature in many enzymatic centers,a classical example being acetylcholine esterase.20The role of such an interaction in abiotic systems was very well illustrated several years ago in a seminal work carried out by Dougherty and Stauffer.21Since then,many other examples have been reported both in biotic and in abiotic systems.22Taking into account all of these considerations,here we report on the ability of receptors 1[L 1]-6[L 6](Chart 2)to interact with L -glutamic acid.These receptors display structures which differ from one another in only one feature,which helps to obtain clear-cut relations between structure and interaction(9)Rebek,J.,Jr.;Askew,B.;Nemeth,D.;Parris,K.J.Am.Chem.Soc.1987,109,2432-2434.(10)Seel,C.;de Mendoza,J.In Comprehensi V e Supramolecular Chemistry ;Vogtle,F.,Ed.;Elsevier Science:New York,1996;Vol.2,p 519.(11)(a)Sessler,J.L.;Sanson,P.I.;Andrievesky,A.;Kral,V.In SupramolecularChemistry of Anions ;Bianchi,A.,Bowman-James,K.,Garcı´a-Espan ˜a,E.,Eds.;John Wiley &Sons:New York,1997;Chapter 10,pp 369-375.(b)Sessler,J.L.;Andrievsky,A.;Kra ´l,V.;Lynch,V.J.Am.Chem.Soc.1997,119,9385-9392.(12)Fitzmaurice,R.J.;Kyne,G.M.;Douheret,D.;Kilburn,J.D.J.Chem.Soc.,Perkin Trans.12002,7,841-864and references therein.(13)Rossi,S.;Kyne,G.M.;Turner,D.L.;Wells,N.J.;Kilburn,J.D.Angew.Chem.,Int.Ed.2002,41,4233-4236.(14)Aı¨t-Haddou,H.;Wiskur,S.L.;Lynch,V.M.;Anslyn,E.V.J.Am.Chem.Soc.2001,123,11296-11297.(15)Hosseini,M.W.;Lehn,J.-M.J.Am.Chem.Soc.1982,104,3525-3527.(16)(a)Hosseini,M.W.;Lehn,J.-M.Hel V .Chim.Acta 1986,69,587-603.(b)Heyer,D.;Lehn,J.-M.Tetrahedron Lett.1986,27,5869-5872.(17)(a)Alfonso,I.;Dietrich,B.;Rebolledo,F.;Gotor,V.;Lehn,J.-M.Hel V .Chim.Acta 2001,84,280-295.(b)Alfonso,I.;Rebolledo,F.;Gotor,V.Chem.-Eur.J.2000,6,3331-3338.(18)Lamarque,L.;Navarro,P.;Miranda,C.;Ara ´n,V.J.;Ochoa,C.;Escartı´,F.;Garcı´a-Espan ˜a,E.;Latorre,J.;Luis,S.V.;Miravet,J.F.J.Am.Chem.Soc .2001,123,10560-10570.(19)Foces-Foces,C.;Echevarria,A.;Jagerovic,N.;Alkorta,I.;Elguero,J.;Langer,U.;Klein,O.;Minguet-Bonvehı´,H.-H.J.Am.Chem.Soc.2001,123,7898-7906.(20)Sussman,J.L.;Harel,M.;Frolow,F.;Oefner,C.;Goldman,A.;Toker,L.;Silman,I.Science 1991,253,872-879.(21)Dougherty,D.A.;Stauffer,D.A.Science 1990,250,1558-1560.(22)(a)Sutcliffe,M.J.;Smeeton,A.H.;Wo,Z.G.;Oswald,R.E.FaradayDiscuss.1998,111,259-272.(b)Kearney,P.C.;Mizoue,L.S.;Kumpf,R.A.;Forman,J.E.;McCurdy,A.;Dougherty,D.A.J.Am.Chem.Soc.1993,115,9907-9919.(c)Bra ¨uner-Osborne,H.;Egebjerg,J.;Nielsen,E.;Madsen,U.;Krogsgaard-Larsen,P.J.Med.Chem.2000,43,2609-2645.(d)Zacharias,N.;Dougherty,D.A.Trends Pharmacol.Sci.2002,23,281-287.(e)Hu,J.;Barbour,L.J.;Gokel,G.W.J.Am.Chem.Soc.2002,124,10940-10941.Chart 1.Some Receptors Employed for Dicarboxylic Acid and N -AcetylglutamateRecognitionChart 2.New 1H -Pyrazole-Containing Polyamine Receptors Able To Complex L -Glutamate inWaterA R T I C L E SMiranda et al.824J.AM.CHEM.SOC.9VOL.126,NO.3,2004strengths.1[L1]and2[L2]differ in the N-benzylation of the pyrazole moiety,and1[L1]and3[L3]differ in the presence in the center of the polyamine side chains of an amino group or of a methylene group.The receptors4[L4]and5[L5]present the central nitrogens of the chain N-functionalized with benzyl or phenethyl groups,and6[L6]has large hydrophobic octyl groups.Results and DiscussionSynthesis of3-6.Macrocycles3-6have been obtained following the procedure previously reported for the preparation of1and2.23The method includes a first dipodal(2+2) condensation of the1H-pyrazol-3,5-dicarbaldehyde7with the corresponding R,ω-diamine,followed by hydrogenation of the resulting Schiff base imine bonds.In the case of receptor3,the Schiff base formed by condensation with1,5-pentanediamine is a stable solid(8,mp208-210°C)which precipitated in68% yield from the reaction mixture.Further reduction with NaBH4 in absolute ethanol gave the expected tetraazamacrocycle3, which after crystallization from toluene was isolated as a pure compound(mp184-186°C).In the cases of receptors4-6, the precursor R,ω-diamines(11a-11c)(Scheme1B)were obtained,by using a procedure previously described for11a.24 This procedure is based on the previous protection of the primary amino groups of1,5-diamino-3-azapentane by treatment with phthalic anhydride,followed by alkylation of the secondary amino group of1,5-diphthalimido-3-azapentane9with benzyl, phenethyl,or octyl bromide.Finally,the phthalimido groups of the N-alkyl substituted intermediates10a-10c were removed by treatment with hydrazine to afford the desired amines11a-11c,which were obtained in moderate yield(54-63%).In contrast with the behavior previously observed in the synthesis of3,in the(2+2)dipodal condensations of7with 3-benzyl-,3-phenethyl-,and3-octyl-substituted3-aza-1,5-pentanediamine11a,11b,and11c,respectively,there was not precipitation of the expected Schiff bases(Scheme1A). Consequently,the reaction mixtures were directly reduced in situ with NaBH4to obtain the desired hexaamines4-6,which after being carefully purified by chromatography afforded purecolorless oils in51%,63%,and31%yield,respectively.The structures of all of these new cyclic polyamines have been established from the analytical and spectroscopic data(MS(ES+), 1H and13C NMR)of both the free ligands3-6and their corresponding hydrochloride salts[3‚4HCl,4‚6HCl,5‚6HCl, and6‚6HCl],which were obtained as stable solids following the same procedure previously reported18for1‚6HCl and2‚6HCl.As usually occurs for3,5-disubstituted1H-pyrazole deriva-tives,either the free ligands3-6or their hydrochlorides show very simple1H and13C NMR spectra,in which signals indicate that,because of the prototropic equilibrium of the pyrazole ring, all of these compounds present average4-fold symmetry on the NMR scale.The quaternary C3and C5carbons appear together,and the pairs of methylene carbons C6,C7,and C8are magnetically equivalent(see Experimental Section).In the13C NMR spectra registered in CDCl3solution, significant differences can be observed between ligand3,without an amino group in the center of the side chain,and the N-substituted ligands4-6.In3,the C3,5signal appears as a broad singlet.However,in4-6,it almost disappears within the baseline of the spectra,and the methylene carbon atoms C6and C8experience a significant broadening.Additionally,a remark-able line-broadening is also observed in the C1′carbon signals belonging to the phenethyl and octyl groups of L5and L6, respectively.All of these data suggest that as the N-substituents located in the middle of the side chains of4-6are larger,the dynamic exchange rate of the pyrazole prototropic equilibrium is gradually lower,probably due to a relation between proto-tropic and conformational equilibria.Acid-Base Behavior.To follow the complexation of L-glutamate(hereafter abbreviated as Glu2-)and its protonated forms(HGlu-,H2Glu,and H3Glu+)by the receptors L1-L6, the acid-base behavior of L-glutamate has to be revisited under the experimental conditions of this work,298K and0.15mol dm-3.The protonation constants obtained,included in the first column of Table1,agree with the literature25and show that the zwitterionic HGlu-species is the only species present in aqueous solution at physiological pH values(Scheme2and Figure S1of Supporting Information).Therefore,receptors for(23)Ara´n,V.J.;Kumar,M.;Molina,J.;Lamarque,L.;Navarro,P.;Garcı´a-Espan˜a,E.;Ramı´rez,J.A.;Luis,S.V.;Escuder,.Chem.1999, 64,6137-6146.(24)(a)Yuen Ng,C.;Motekaitis,R.J.;Martell,A.E.Inorg.Chem.1979,18,2982-2986.(b)Anelli,P.L.;Lunazzi,L.;Montanari,F.;Quici,.Chem.1984,49,4197-4203.Scheme1.Synthesis of the Pyrazole-Containing MacrocyclicReceptorsNew1H-Pyrazole-Containing Polyamine Receptors A R T I C L E SJ.AM.CHEM.SOC.9VOL.126,NO.3,2004825glutamate recognition able to address both the negative charges of the carboxylate groups and the positive charge of ammonium are highly relevant.The protonation constants of L 3-L 6are included in Table 1,together with those we have previously reported for receptors L 1and L 2.23A comparison of the constants of L 4-L 6with those of the nonfunctionalized receptor L 1shows a reduced basicity of the receptors L 4-L 6with tertiary nitrogens at the middle of the polyamine bridges.Such a reduction in basicity prevented the potentiometric detection of the last protonation for these ligands in aqueous solution.A similar reduction in basicity was previously reported for the macrocycle with the N -benzylated pyrazole spacers (L 2).23These diminished basicities are related to the lower probability of the tertiary nitrogens for stabilizing the positive charges through hydrogen bond formation either with adjacent nonprotonated amino groups of the molecule or with water molecules.Also,the increase in the hydrophobicity of these molecules will contribute to their lower basicity.The stepwise basicity constants are relatively high for the first four protonation steps,which is attributable to the fact that these protons can bind to the nitrogen atoms adjacent to the pyrazole groups leaving the central nitrogen free,the electrostatic repulsions between them being therefore of little significance.The remaining protonation steps will occur in the central nitrogen atom,which will produce an important increase in the electrostatic repulsion in the molecule and therefore a reduction in basicity.As stated above,the tertiary nitrogen atoms present in L 4-L 6will also contribute to this diminished basicity.To analyze the interaction with glutamic acid,it is important to know the protonation degree of the ligands at physiological pH values.In Table 2,we have calculated the percentages ofthe different protonated species existing in solution at pH 7.4for receptors L 1-L 6.As can be seen,except for the receptor with the pentamethylenic chains L 3in which the tetraprotonated species prevails,all of the other systems show that the di-and triprotonated species prevail,although to different extents.Interaction with Glutamate.The stepwise constants for the interaction of the receptors L 1-L 6with glutamate are shown in Table 3,and selected distribution diagrams are plotted in Figure 1A -C.All of the studied receptors interact with glutamate forming adduct species with protonation degrees (j )which vary between 8and 0depending on the system (see Table 3).The stepwise constants have been derived from the overall association constants (L +Glu 2-+j H +)H j LGlu (j -2)+,log j )provided by the fitting of the pH-metric titration curves.This takes into account the basicities of the receptors and glutamate (vide supra)and the pH range in which a given species prevails in solution.In this respect,except below pH ca.4and above pH 9,HGlu -can be chosen as the protonated form of glutamate involved in the formation of the different adducts.Below pH 4,the participation of H 2Glu in the equilibria has also to be considered (entries 9and 10in Table 3).For instance,the formation of the H 6LGlu 4+species can proceed through the equilibria HGlu -+H 5L 5+)H 6LGlu 4+(entry 8,Table 3),and H 2Glu +H 4L 4+)H 6LGlu 4(entry 9Table 3),with percentages of participation that depend on pH.One of the effects of the interaction is to render somewhat more basic the receptor,and somewhat more acidic glutamic acid,facilitating the attraction between op-positely charged partners.A first inspection of Table 3and of the diagrams A,B,and C in Figure 1shows that the interaction strengths differ markedly from one system to another depending on the structural features of the receptors involved.L 4is the receptor that presents the highest capacity for interacting with glutamate throughout all of the pH range explored.It must also be remarked that there are not clear-cut trends in the values of the stepwise constants as a function of the protonation degree of the receptors.This suggests that charge -charge attractions do not play the most(25)(a)Martell,E.;Smith,R.M.Critical Stability Constants ;Plenum:NewYork,1975.(b)Motekaitis,R.J.NIST Critically Selected Stability Constants of Metal Complexes Database ;NIST Standard Reference Database,version 4,1997.Table 1.Protonation Constants of Glutamic Acid and Receptors L 1-L 6Determined in NaCl 0.15mol dm -3at 298.1KreactionGluL 1aL 2aL 3bL 4L 5L 6L +H )L H c 9.574(2)d 9.74(2)8.90(3)9.56(1)9.25(3)9.49(4)9.34(5)L H +H )L H 2 4.165(3)8.86(2)8.27(2)8.939(7)8.38(3)8.11(5)8.13(5)L H 2+H )L H 3 2.18(2)7.96(2) 6.62(3)8.02(1) 6.89(5)7.17(6)7.46(7)L H 3+H )L H 4 6.83(2) 5.85(4)7.63(1) 6.32(5) 6.35(6) 5.97(8)L H 4+H )L H 5 4.57(3) 3.37(4) 2.72(8) 2.84(9) 3.23(9)L H 5+H )L H 6 3.18(3) 2.27(6)∑log K H n L41.135.334.233.634.034.1aTaken from ref 23.b These data were previously cited in a short communication (ref 26).c Charges omitted for clarity.d Values in parentheses are the standard deviations in the last significant figure.Scheme 2.L -Glutamate Acid -BaseBehaviorTable 2.Percentages of the Different Protonated Species at pH 7.4H 1L aH 2LH 3LH 4LL 11186417L 21077130L 3083458L 4083458L 51154323L 6842482aCharges omitted for clarity.A R T I C L E SMiranda et al.826J.AM.CHEM.SOC.9VOL.126,NO.3,2004outstanding role and that other forces contribute very importantly to these processes.26However,in systems such as these,which present overlapping equilibria,it is convenient to use conditional constants because they provide a clearer picture of the selectivity trends.27These constants are defined as the quotient between the overall amounts of complexed species and those of free receptor and substrate at a given pH[eq1].In Figure2are presented the logarithms of the effective constants versus pH for all of the studied systems.Receptors L1and L2with a nonfunctionalized secondary amino group in the side chains display opposite trend from all other receptors. While the stability of the L1and L2adducts tends to increase with pH,the other ligands show a decreasing interaction. Additionally,L1and L2present a close interaction over the entire pH range under study.The tetraaminic macrocycle L3is a better(26)Escartı´,F.;Miranda,C.;Lamarque,L.;Latorre,J.;Garcı´a-Espan˜a,E.;Kumar,M.;Ara´n,V.J.;Navarro,mun.2002,9,936-937.(27)(a)Bianchi,A.;Garcı´a-Espan˜a,c.1999,12,1725-1732.(b)Aguilar,J.A.;Celda,B.;Garcı´a-Espan˜a,E.;Luis,S.V.;Martı´nez,M.;Ramı´rez,J.A.;Soriano,C.;Tejero,B.J.Chem.Soc.,Perkin Trans.22000, 7,1323-1328.Table3.Stability Constants for the Interaction of L1-L6with the Different Protonated Forms of Glutamate(Glu) entry reaction a L1L2L3L4L5L6 1Glu+L)Glu L 3.30(2)b 4.11(1)2HGlu+L)HGlu L 3.65(2) 4.11(1) 3.68(2) 3.38(4) 3Glu+H L)HGlu L 3.89(2) 4.48(1) 3.96(2) 3.57(4) 4HGlu+H L)H2Glu L 3.49(2) 3.89(1) 2.37(4) 3.71(2)5HGlu+H2L)H3Glu L 3.44(2) 3.73(1) 2.34(3) 4.14(2) 2.46(4) 2.61(7) 6HGlu+H3L)H4Glu L 3.33(2) 3.56(2) 2.66(3) 4.65(2) 2.74(3) 2.55(7) 7HGlu+H4L)H5Glu L 3.02(2) 3.26(2) 2.58(3) 4.77(2) 2.87(3) 2.91(5) 8HGlu+H5L)H6Glu L 3.11(3) 3.54(2) 6.76(3) 4.96(3) 4.47(3) 9H2Glu+H4L)H6Glu L 2.54(3) 3.05(2) 3.88(2) 5.35(3) 3.66(4) 3.56(3) 10H2Glu+H5L)H7Glu L 2.61(6) 2.73(4) 5.51(3) 3.57(4) 3.22(8) 11H3Glu+H4L)H7Glu L 4.82(2) 4.12(9)a Charges omitted for clarity.b Values in parentheses are standard deviations in the last significantfigure.Figure1.Distribution diagrams for the systems(A)L1-glutamic acid, (B)L4-glutamic acid,and(C)L5-glutamicacid.Figure2.Representation of the variation of K cond(M-1)for the interaction of glutamic acid with(A)L1and L3,(B)L2,L4,L5,and L6.Initial concentrations of glutamate and receptors are10-3mol dm-3.Kcond)∑[(H i L)‚(H j Glu)]/{∑[H i L]∑[H j Glu]}(1)New1H-Pyrazole-Containing Polyamine Receptors A R T I C L E SJ.AM.CHEM.SOC.9VOL.126,NO.3,2004827receptor at acidic pH,but its interaction markedly decreases on raising the pH.These results strongly suggest the implication of the central nitrogens of the lateral polyamine chains in the stabilization of the adducts.Among the N-functionalized receptors,L4presents the largest interaction with glutamate.Interestingly enough,L5,which differs from L4only in having a phenethyl group instead of a benzyl one,presents much lower stability of its adducts.Since the basicity and thereby the protonation states that L4and L5 present with pH are very close,the reason for the larger stability of the L4adducts could reside on a better spatial disposition for formingπ-cation interactions with the ammonium group of the amino acid.In addition,as already pointed out,L4presents the highest affinity for glutamic acid in a wide pH range,being overcome only by L1and L2at pH values over9.This observation again supports the contribution ofπ-cation inter-actions in the system L4-glutamic because at these pH values the ammonium functionality will start to deprotonate(see Scheme2and Figure1B).Table4gathers the percentages of the species existing in equilibria at pH7.4together with the values of the conditional constant at this pH.In correspondence with Figure1A,1C and Figure S2(Supporting Information),it can be seen that for L1, L2,L5,and L6the prevailing species are[H2L‚HGlu]+and[H3L‚HGlu]2+(protonation degrees3and4,respectively),while for L3the main species are[H3L‚HGlu]+and[H4L‚HGlu]2+ (protonation degrees4and5,respectively).The most effective receptor at this pH would be L4which joins hydrogen bonding, charge-charge,andπ-cation contributions for the stabilization of the adducts.To check the selectivity of this receptor,we have also studied its interaction with L-aspartate,which is a competitor of L-glutamate in the biologic receptors.The conditional constant at pH7.4has a value of3.1logarithmic units for the system Asp-L4.Therefore,the selectivity of L4 for glutamate over aspartate(K cond(L4-glu)/K cond(L4-asp))will be of ca.15.It is interesting to remark that the affinity of L4 for zwiterionic L-glutamate at pH7.4is even larger than that displayed by receptors III and IV(Chart1)with the protected dianion N-acetyl-L-glutamate lacking the zwitterionic charac-teristics.Applying eq1and the stability constants reported in ref17,conditional constants at pH7.4of 3.24and 2.96 logarithmic units can be derived for the systems III-L-Glu and IV-L-Glu,respectively.Molecular Modeling Studies.Molecular mechanics-based methods involving docking studies have been used to study the binding orientations and affinities for the complexation of glutamate by L1-L6receptors.The quality of a computer simulation depends on two factors:accuracy of the force field that describes intra-and intermolecular interactions,and an adequate sampling of the conformational and configuration space of the system.28The additive AMBER force field is appropriate for describing the complexation processes of our compounds,as it is one of the best methods29in reproducing H-bonding and stacking stabiliza-tion energies.The experimental data show that at pH7.4,L1-L6exist in different protonation states.So,a theoretical study of the protonation of these ligands was done,including all of the species shown in5%or more abundance in the potentiometric measurements(Table4).In each case,the more favored positions of protons were calculated for mono-,di-,tri-,and tetraprotonated species.Molecular dynamics studies were performed to find the minimum energy conformations with simulated solvent effects.Molecular modeling studies were carried out using the AMBER30method implemented in the Hyperchem6.0pack-age,31modified by the inclusion of appropriate parameters. Where available,the parameters came from analogous ones used in the literature.32All others were developed following Koll-man33and Hopfinger34procedures.The equilibrium bond length and angle values came from experimental values of reasonable reference compounds.All of the compounds were constructed using standard geometry and standard bond lengths.To develop suitable parameters for NH‚‚‚N hydrogen bonding,ab initio calculations at the STO-3G level35were used to calculate atomic charges compatible with the AMBER force field charges,as they gave excellent results,and,at the same time,this method allows the study of aryl-amine interactions.In all cases,full geometry optimizations with the Polak-Ribiere algorithm were carried out,with no restraints.Ions are separated far away and well solvated in water due to the fact that water has a high dielectric constant and hydrogen bond network.Consequently,there is no need to use counteri-ons36in the modelization studies.In the absence of explicit solvent molecules,a distance-dependent dielectric factor quali-tatively simulates the presence of water,as it takes into account the fact that the intermolecular electrostatic interactions should vanish more rapidly with distance than in the gas phase.The same results can be obtained using a constant dielectric factor greater than1.We have chosen to use a distance-dependent dielectric constant( )4R ij)as this was the method used by Weiner et al.37to develop the AMBER force field.Table8 shows the theoretical differences in protonation energy(∆E p) of mono-,bi-,and triprotonated hexaamine ligands,for the (28)Urban,J.J.;Cronin,C.W.;Roberts,R.R.;Famini,G.R.J.Am.Chem.Soc.1997,119,12292-12299.(29)Hobza,P.;Kabelac,M.;Sponer,J.;Mejzlik,P.;Vondrasek,put.Chem.1997,18,1136-1150.(30)Cornell,W.D.;Cieplak,P.;Bayly,C.I.;Gould,I.R.;Merz,K.M.,Jr.;Ferguson,D.M.;Spelmeyer,D.C.;Fox,T.;Caldwell,J.W.;Kollman,P.A.J.Am.Chem.Soc.1995,117,5179-5197.(31)Hyperchem6.0(Hypercube Inc.).(32)(a)Fox,T.;Scanlan,T.S.;Kollman,P.A.J.Am.Chem.Soc.1997,119,11571-11577.(b)Grootenhuis,P.D.;Kollman,P.A.J.Am.Chem.Soc.1989,111,2152-2158.(c)Moyna,G.;Hernandez,G.;Williams,H.J.;Nachman,R.J.;Scott,put.Sci.1997,37,951-956.(d)Boden,C.D.J.;Patenden,put.-Aided Mol.Des.1999, 13,153-166.(33)/amber.(34)Hopfinger,A.J.;Pearlstein,put.Chem.1984,5,486-499.(35)Glennon,T.M.;Zheng,Y.-J.;Le Grand,S.M.;Shutzberg,B.A.;Merz,K.M.,put.Chem.1994,15,1019-1040.(36)Wang,J.;Kollman,P.A.J.Am.Chem.Soc.1998,120,11106-11114.Table4.Percentages of the Different Protonated Adducts[HGlu‚H j L](j-1)+,Overall Percentages of Complexation,andConditional Constants(K Cond)at pH7.4for the Interaction ofGlutamate(HGlu-)with Receptors L1-L6at Physiological pH[H n L‚HGlu]an)1n)2n)3n)4∑{[H n L‚HGlu]}K cond(M-1)L13272353 2.44×103L2947763 4.12×103L31101324 3.99×102L423737581 2.04×104L51010222 3.51×102L6121224 3.64×102a Charges omitted for clarity.A R T I C L E S Miranda et al. 828J.AM.CHEM.SOC.9VOL.126,NO.3,2004。

应力对电化学的滞后作用英语Electrochemical Lag Effects of Stress.Stress can have a significant impact on the electrochemical processes that occur in materials. These effects can be either positive or negative, depending on the specific material and the type of stress applied. In some cases, stress can lead to an increase in electrochemical activity, while in other cases it can lead to a decrease.One of the most common ways that stress affects electrochemical processes is by altering the microstructure of the material. When a material is subjected to stress,its atoms and molecules are forced to move and rearrange themselves. This can lead to changes in the material's grain size, crystal structure, and other microstructural features. These changes can, in turn, affect the material's electrochemical properties.For example, a study by the University of California, Berkeley found that stress can increase the corrosion rate of steel. The researchers found that when steel was subjected to tensile stress, its grain boundaries became more active and more susceptible to corrosion. This led to an increase in the overall corrosion rate of the steel.In other cases, stress can have the opposite effect and decrease electrochemical activity. A study by theUniversity of Tokyo found that stress can decrease the rate of hydrogen evolution from platinum. The researchers found that when platinum was subjected to compressive stress, its surface became less active and less likely to react with hydrogen ions. This led to a decrease in the rate of hydrogen evolution.The effects of stress on electrochemical processes can be complex and depend on a number of factors, including the type of material, the type of stress applied, and the environmental conditions. However, it is clear that stress can have a significant impact on the electrochemical properties of materials.Applications of Electrochemical Lag Effects of Stress.The electrochemical lag effects of stress can be usedin a variety of applications. One common application is in the field of corrosion control. By understanding how stress affects the corrosion rate of materials, engineers can design materials and structures that are more resistant to corrosion.Another application of the electrochemical lag effects of stress is in the field of energy storage. By understanding how stress affects the electrochemicalactivity of materials, scientists can develop new and more efficient energy storage devices.Conclusion.The electrochemical lag effects of stress are a complex and fascinating phenomenon. By understanding these effects, scientists and engineers can develop new materials and technologies that are more resistant to corrosion, moreefficient at energy storage, and more responsive to external stimuli.。