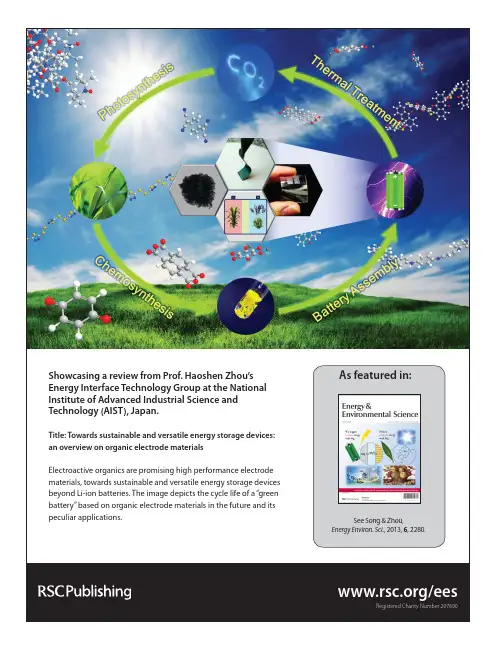

Hierarchically-Ordered Electroactive Silica-Polyaniline Nanohybrid

- 格式:pdf

- 大小:1.17 MB

- 文档页数:10

电气自动化专业英语abbreviate 缩写,缩写为abscissa axis 横坐标absolute encoder 绝对编码器ac squirrel cage induction motor 交流笼型感应电动机ac motor 交流环电动机academic 纯理论的accelerometer 加速度测量仪accommodate 适应accutrol 控制器acoustic wave 声波active 有源的active region 动态区域active filter 有源滤波器active component 有功分量active in respect to 相对….呈阻性active(passive) circuit elements 有(无)源电路元件actuate 激励,驱动actuator 执行机构actuator 执行器adjacent 临近的,接近的adjacent 相邻的,邻近的Adjustable-voltage inverter 电压型逆变器admittance 导纳advent 出现air gap 气隙aircraft 飞机air-gap flux 气隙磁通air-gap line 气隙磁化线air-gap flux distribution 气隙磁通分布algebraic 代数的algebraic 代数的algebraical 代数的algorithm 算法algorithmic 算法的align 调整,校准allowable temperature rise 允许温升alloy 合金allude 暗指,直接提到alnico 铝镍钴合金alphabet 字母表alternating current, AC 交流aluminum 铝ambient 环境的ambiguity 模棱两可Ammeter 安培计、电流表ammeter 电流表ampere-turns 安匝(数)amplidyne 微场扩流发电机amplification 扩大Amplitude Modulation AM调幅analog electronics 电力电子学analog-to-digital conversion, ADC 模数转换器analytical 解析的analytical 分析的,分解的angular 角的anode 阳极、正极antenna 天线aptly 适当地,适宜地arbitration 仲裁,公断arc welding 电弧焊armature 电枢armature coil 电枢线圈armature m.m.f wave 电枢磁势波armature 衔铁armature 电枢armature circuit 电枢电路arrangement 结构as a rule of thumb 根据经验asynchronous machine 异步电机attenuate 衰减audio 音频的automatic station 无人值守电站automatic oscillograph 自动示波器automatic Voltage regulator(AVR) 自动电压调整器automobile 汽车automobile starter motor 汽车启动机autonomic 自治的autonomous 匿名的autotransformer 自耦变压器auxiliary 辅助的auxiliary motor 辅助电动机auxiliary 辅助的backlash 啮合间隙,齿隙ballast 镇流器bandwidth 带宽bar code reader 条码阅读器base 基极bearing 轴承bellows 膜盒bilateral circuit 双向电路bimotored 双马达的binary 二进制binary-coded decimal BCDbiphase 双相的bipolar junction transistor(BJT 双极性晶体管bistable circuit 双稳电路blend 混合,调和,配料block diagram 方框图blow (保险丝)烧断bode plot 波特图bolt 螺栓boost 增压boost-buck 升压去磁boredom 讨厌,无趣braking 制动branch circuit 直路breakaway force 起步阻力breakdown 击穿breakdown torque 极限转矩bronze 青铜brush 电刷brute 僵化的buck 补偿bushing 套管bushing 高压套bypass 旁路by-product 副产品calibrate 校正calibration 校准,标定,刻度calibration 标定,标准化call for 需要cam 凸轮cantilever 悬臂capability 容量capacitance effect 电容效应capacitor 电容器capacitor 电容器capacity 容量capsule 封装carbon 碳carbon-filament lamp 碳丝灯泡carrier 载波Cartesian coordinates 笛卡儿坐标系cartridge 盒式保险丝cast-aluminum rotor 铸铝转子cathode 阴极cease 停止,终了centimeter 厘米centrifugal 离心的,离心力centrifugal force 离心力ceramic 陶瓷的chamber 室,腔chao 混乱checksum 检查和chopper circuit 斩波电路circuit components 电路元件circuit parameters 电路参数circuit diagram 电路图circuit branch 支路circuitry 电路,线路circumference 圆周circumnavigate 饶过clamp 夹住,夹紧clamp 夹,钳classic 古典的,经典的,传统的clearance 间隙client-server 客户-服务器client-server model 客户服务器模型clinker-cooler 熟料冷却器closed-loop 闭环■coast 跟踪惯性coaxial 共轴的,同轴的cogging 齿槽效应coil winding 线圈绕组coils 线圈、绕组coincide in phase with 与….同相coincidence 一致,相等collector 集电极]collector 集电极commutation 换向commutation condition 换向状况commutator 换向器commutator 换向器commutator-brush combination 换向器-电刷总线compatible 兼容的complement 补码complex impedance 复数阻抗complex number 复数compound 紧密、结合compound generator 复励发电机compounded 复励compound-wound 复励condominium (国际)共官conductance 电导conductor 导体conduit 导线,导线管cone pulley 塔轮,快慢轮configuration 组态connection 接线端constraint 强制,约束contact 触点contactor 接触器contiguous 邻近的conveyance 运输工具conveyor 传送机copper bar 铜导条copper end rings 铜端环core 铁心corona 电晕,放电corridor 通路corridor 通道,走廊corrosion 腐蚀cost-effective 花费大的counter emf 反电势counter electromotive force、CEMF 反电势counteract 抵抗,抵消,消除counterclockwise 逆时针counterpart 对应物coupling capacitor 结合电容creep 蠕动criteria 标准,判据crude 不精细的,粗略的crystal 晶体crystal 晶体的,水晶,晶体cubicle 立方体culminate 达到极值点culprit 犯罪者cumulative compound 积复励cumulatively compounded motor 积复励电动机Current source inverter 电流型逆变器cutoff 截止,关闭Cyclic Redundancy Check 循环冗余检查cylindrical 圆柱式的damper 减速器dashpot relay 油壶式继电器dashpot 阻尼器DC link 直流环节dc generator 直流发电机dc motor 直流电动机de machine 直流电机decouple 解耦,去除干扰deenergize 不给…通电deflection 挠度、挠曲demagnetization 退磁,去磁demodulation 解调demodulator 解调器demystify 阐明denominator 分母depict 描绘、描写depict 描述depress 压下derivative 导数derive 推倒deteriorate 使….恶化deterioration 损坏,磨损deterioration 变化,降低品质deviation 偏差dial 刻度盘dial 刻度盘,调节控制盘diameter 直径diaphragm 震动膜diaphragm 膜片,挡板diaphragm 膜片diaphragm 膜,隔板dictate 确定differential compound 差复励differential pressure transducer 差压变送器differential equation 微分方程differentiation 微分diode 二极管direct axis 直轴direct axis transient time constant 直轴瞬变时间常数direct-current 直流discrete 离散的displacement 位移displacement current 位移电流dissipate 散发dissipate 浪费distillation 蒸馏distributed system 分布式系统distribution 分配,配电doubly excited 双边励磁drill 钻床due 应得到的dungen 地牢dwelling 住房dynamic response 动态响应dynamic braking 能耗制动dynamic-state operation 动态运行dynamometer 测力计,功率计e.m.f=electromotive fore 电动势eddy 涡流eddy current braking 涡流制动eddy current 涡流effective values 有效值effects of saturation 饱和效应elapse 时间(流逝)elapse 过去,消逝elbow 弯头electric energy 电能electrical stressing 电气应力electrical device 电气设备electrode 电极电焊条electrodynamometer 电测力计electro-hydraulic 电动液压的electrolytic 电解的electromagnetic torque 电磁转矩electromagnetic interference 电磁干扰electromechanical 机电的electronic mail 电子邮件electro-pneumatic 电动气动的elusive 难以捉摸的emitter 发射极emitter 发射管放射器、发射极enclosure 外(机)壳enclosure 机壳enclosure 设备外壳encode 编码encoder 编码器end ring 端环energize 励磁energy converter 电能转换器entity 实体enumerate 列举envision 预见epoch angle 初相角equilibria 平衡equilibrium level 平均值equivalent T–circuit T型等值电路equivalent circuit 等效电路error signal 误差信号error detector 误差检测器error 误差,偏差escalation 升级,提高establishment 组织,部门etiquette 规则excitation system 励磁系统excited by 励磁exciting voltage 励磁电压expedite 加速expel 排出,放出expire 期满,终止exponential 指数external armature circuit 电枢外电路external characteristic 外特性extruded 型材的fabricate 制造faithful 正确的,可靠的fallout 余波,附带结果fasten 固定,连接feasible 可行的feedback system 反馈系统feedback loop 反馈回路feedback 反馈feedback component 反馈元件feedback signal 反馈信号feeder 馈电线,电源线,馈电板feedforward 前馈felt 毡ferromagnetic 铁磁的fidelity 保真度fidelity 重现精度,真实,正确field winding 磁场绕组、励磁绕组field coils 励磁线圈field current 励磁电流field effect transistor(FET) 场效应管field pole 磁极figure of merit 品质因数,优值filter 滤波器fin 飞边fixture 设备,装置]flicker 闪烁,摇曳flip-flop 触发器fluctuation 升降剥动,不规则的变化fluorescent 荧光的,有荧光性的flux density 磁通密度flux linkage 磁链flux per pole 每极磁通forced commutation 强迫换流forced-draft 强制通风forging 锻造form-wound 模绕forward transfer function 正向传递函数forward 转发fraction 分数frame 机座,机壳frequency 频率frequency- domain 频域Frequency Shift Keying(FSK) 移频键控friction 摩擦full load 满载full-duplex 全双工full-load torque 满载转矩furnace 炉fuse 保险丝、熔丝fuse 熔断器,保险丝fuse 熔断器gain 增益gamut 全体,整体gear 齿轮、传动装置general-purpose relay 通用继电器generating 发电generator 发电机generator 发电机generator voltage 发电机电压Geometrical position 几何位置geometry 几何结构glitch 同步glue 胶合,粘贴goggles 护目镜,潜水镜graphite 石墨grinder 磨床grossly 大概,大体上的ground-fault protector (GFP)ground-fault circuit interrupter(GFCI) 接地故障保护器,接地故障断路器gyroscope 陀螺仪half-duplex 半双工hand-wheel 手轮,驾驶盘,操纵盘hardwired 硬接线的harmonic 谐波的havoc 大破坏hazard 危险hazardous 危险的heat sink 散热器heating appliance 电热器hierarchy 阶梯,等级high-gain 高增益high-pass filter 高通滤波器high-performance 高性能的high-volume 大容量hitherto 迄今,至今hockey puck 冰球hoist 起重机horsepower 马力horsepower 马力horseshoe magnet 马蹄形磁铁host 主机humidity 湿度hydraulic 液压传动hydraulic 液力的hydraulic 液压的,液压传动装置hydropower station 水电站hysteresis 磁滞ideal source 理想电源ideological 思想的imaginary part 虚部immunity 抗扰性impedance 阻抗impulse 推动力in parallel with 并联in series with 串联in terms of 根据,在……方面in the vicinity of 在…附近,在…左右in(inch,inches) 英寸incident 入射的increment encoder 增量编码器indicating needle 仪表、指针indispensable 必需的,必不可少的induced current 感生电流induced-draft fan 吸风机induction generator 感应发电机induction coupling 感应耦合induction machine 感应式电机induction machine 感应电机induction motor 感应电动机induction motor 感应电动机induction-disc relay 感应圆盘式继电器inductive component 感性(无功)分量inertia 惯性inertial 惯性的,惯量的inference 干扰infinite voltage gain 无穷大电压增益infrastructure 基础,底层结构inherent 固有的inhibit 禁止initiate 引起,促进injection molding 注模inrush current 涌流instantaneous electric power 瞬时电功率instantaneous mechanical power 瞬时机械功率instruction set 指令集insulation 绝缘insulation 绝缘insulation 绝缘insulator string 绝缘子串intake 吸入integrate 求…的积分integrated circuit 集成电路integration 积分下限integration 积分interactive 交互式interconnection 相互连接interface 接口interface data unit 接口数据单元interfere with 有害于... internal resistance 内阻interoffice 局间的interrupter 断续(流、电、路)器intimately 密切地intimately 紧密地,直接的inventory 存货,清单inventory 存货inverse 倒数inverse time relay 反时限继电器inversion 反相,反转inverting amplifier 反向放大器iron-loss 铁损isolation 隔离、分离、绝缘、隔振isolation transformer 隔离变压器jerk 振动,冲击jog 啮合joint 关节,铰链keyway 键槽killer 迷人的kiln 炉kinematic 运动的,运动学的knob 旋钮、圆形把手knob 钮,圆形把手lable 为……标号lagging(trailing) edge 下降沿laminate 叠制,叠压laminated core 叠片铁芯lamination 叠片latch circuit 锁存电路latching relay 自锁继电器lathe 车床launcher 发生器,启动装置laundry 洗衣房leading edge 上升沿leakage 漏电流leakage reactance 漏磁电抗leakage flux 漏磁通leakage current 漏电流leakage 泄漏left-hand rule 左手定则lever 杆,杠杆lever 手柄,控制杆liable 有责任的light emitting diode 发光二极管light-dimmer 调光lightning shielding 避雷lightning arrester 避雷装置limit switch 限位开关limiter 限幅器line 线电压line trap 限波器linear zone 线性区line-to-neutral 线与中性点间的link 连杆live conductor 带电导体load characteristic 负载特性load-saturation curve 负载饱和曲线locked-rotor 锁定转子locked-rotor torque 锁定转子转矩longitudinal 经度了;纵向的long-shunt 长复励loss 损耗low-pass filter 低通滤波器lubricant 润滑剂、润滑油lubrication 润滑,注油magnetic torque 电磁转矩magnetic amplifier 磁放大器magnetic circuit 磁路magnetic field 磁场magnetic flux 磁通magnetization curve 磁化曲线magnetizing current 磁化电流,励磁电流magnetizing reacance 磁化电抗magneto 磁发电机magnitude 振幅maintenance 维护malfunction 故障manipulations 操作,控制,处理manipulator 机械手,操作器manual control 手动控制margin 余量,裕度mass 物质,块,堆mass-produce 大量生产mature 成熟的means 手段,工具measurand 被测量,被测量对象mechanical rectifier 机械式整流器mechanical stressing 机械应力mechanical rectifier 机械式换向器Megohmmeter 兆欧表merit 优点,长处,指标metallic 金属的meticulous 详细的micrometer 千分尺mid-frequency band 中频带milliammeter 毫安表milling machine 铣床mine minder 矿坑卷扬机mismatch 失配moderate 适度的,适中的modulation 调制modulator 调制器modulus 模moisture 潮湿、湿气moisture 潮气,湿度molecule 分子morally 道德上,道义上motoring 电动机驱动mount 安装multimeter 万用表multiple axis drive 多轴驱动multiplexer 多路转换器mutual flux 交互(主)磁通mutual-inductor 互感narrowband filter 带通滤波器neutral 中性的nevertheless 然而newsgroup 新闻组no load 空载no-load 空载nomenclature 术语nominally 标称nonetheless,none the less 仍然,依然nonvolatile 非挥发的nuisance 障碍,公害number of poles 极数numerator 分子numerical 数值的object-oriented 面向对象的obsolete 废弃的occupancy 占有,占用,居住octal-base 八脚的offset 偏心Ohmmeter 欧姆计、电阻表open-loop 开环operating condition 运行状态operation amplifier 运算放大器operational calculus 算符演算optical fiber 光纤orifice 孔,注孔orifice 侧流板,隔板orthogonal 垂直的,正交的Oscillation 振荡oscillation 振荡oscillatory 振动的,摆动的oscilloscope 示波器outgoing 外出了,离开的out-of-step 不同步的over-current relay 过电流继电器overhauling 检修overload 过载P.D=potential drop 电压降panel 操纵台,面板parity 校验pedal 踏板,踏蹬penetrate 透过,渗透per unit value 标么值percentage 百分数performance characteristic 工作特性peripheral 外设periphery 周围,圆周permanent magnet 永磁体permanent-magnet 永磁permissible 允许的perpendicular 垂直的,正交的perpendicular 垂直的,正交的Personnel 人员、职员pertinent 有关的per-unit value 标么值pharmaceutical 药剂,药品phase 相位(控制)phase displacement 相位差phase reversal 反相phase sequence 相序philosophy 基本原理photosensor 光电传感器pickup current 始动电流piezoelectric 压电的pilot light 信号灯piston 活塞pitch 齿轮pitfall 缺陷pivot 支点pivot 轴,支点,旋转中心pivot 轴,支点plant 装置,设备plate (电)镀plug fuse 插头式保险丝plugging 反向制动plunger 可动铁心,插棒式铁心pneumatic 气动的pneumatic 气动的pneumatic 气动的,气动力学的pointer 指针polarity 极性polarity 极性polarity 极性pole 极点Polyphase 多相(的)polyphase rectifier 多相整流器polyphase rectifier 多相整流器potential transformer 电压互感器potential distribution 电位分布potential transformer 电压互感器potentiometer 电位器power frequency 工频power amplifier 功率放大器power flow diagram 功率流程图prebias 预偏置predominant 主要的,突出的prefix 前缀,把…放在前面premise 上述各点,前言,根据primary cell 原生电池primary 最初的,基本的,初级线圈prime 上撇号prime mover 原动机prime motor 原动机primitive 操作,原型prismatic 棱型的private line 专用线路process of self–excitation 自励过程process 进程profile 轮廓,仿行profile 轮廓prolong 延长propagate 传导、传播propagation 传播,宣传proposition 命题pros and cons 优缺点protective gap 保护性间隙放电protocol 协议protocol data unit 协议数据单元protrude 使伸出,突出proximity 距离quadrant 象限quadruple 四合一quantization 量化r.m.s values=root mean square values 均方根值rack mounting 机架安装radial 径向的radial 径向的,辐射状的radiated 传播random 随机的random-wound 散绕rated 额定的rated torque 额定转矩rating 额定值,标称值,定额ratio 比,比率reaction 电感reactive power 无功功率reactive component 无功分量reactive in respect to 相对….呈感性real part 实部recast 重做receptacle 插座receptacle 插座,插孔rectifier 整流器redundant 多余的redundant 多余的,重复的reference Voltage 基准电压refinement 改进refinement 明确表达regeneration 再生,、后反馈放大regenerative braking 回馈制动regulator 调节器relay 继电器release current 释放电流reluctance 磁阻reluctance 磁阻remarks 附注,要点remote database 远程数据库remote login 远程登陆remote terminal 终端representation 代表,表示reprisal 报复residence 住宅resident program 驻留程序residential 住宅的,居住的resolver 解算器resonance 共鸣resonance 共振restriking 电弧再触发resynchronize 再同步retarding torque 制动转矩retrofit 改型reveal 展现reverse braking 反接制动revolute 旋转的,转动的revolutions per minute 转/分revolutions per second 转/秒revolving magnetic field 旋转磁场RF noise 射频干扰rheostat 变阻器,电阻箱rheostat 变阻器rig 设备right-hand rule 右手定则rigid 刚性的,坚固的riiple 纹动ripple 脉动.robustness 鲁棒性rolling 轧制rolling mill 轧钢机rotating commutator 旋转(整流子)换向器rotating magnetic field 旋转磁场rotor (stator) winding 转子(定子绕组) rotor 转子rotor core 转子铁芯rotor resistance 转子电阻router 路由器rugged 坚固的runout table 输出轨道salient 突出的salient poles 凸极salient-pole 凸极式sampling 采样sampling period 采样周期saturate 使…饱和saturation curve 饱和曲线saturation effect 饱和效应scale 刻度、量程scale 改变比例schematic (电路)原理图符号sealed-off 封的self excited 自励self–excitation process 自励过程self-bias resistor 自偏置电阻self-exciting 自励的self-inductor 自感self-latching 自锁semiconductor 半导体separately 单独励磁地separately excited 他励separately excited 他励的series 串励series excited 串励series-wound 串励service data unit 服务数据单元servo 伺服servomechanism 伺服机构,伺服系统shock 冲击short-circuiting ring 短路环short-shunt 短复励shunt 分流,分路,并联,旁路shunt 并励shunt 分路器shunt excited 并励shunt displacement current 旁路位移电流shunt field 并励磁场shunt-wound 并励signal amplifier 小信号放大器signal-to-noise ration、SNR 信噪比signify 表示silica 硅石、二氧化硅silicon 硅simulate 模拟,方针simultaneous 同时的Single Side Band(SSB) 单边带single-phase 单相的singly excited 单边励磁sinusoidal 正弦的sinusoidal time function 正弦时间函数sinusoidal–density wave 正弦磁密度slip 转差率slip rings 滑环slot 槽,开槽solenoid relay 螺管式继电器solenoid 线圈solenoids 螺线管solid state 固体solid-state relay 固态继电器solt 槽sophisticated 复杂的,完善的spare 备用的spark gap 火花放电隙spatial waveform 空间波形speed regulation 速度调节speed-torque characteristic 速度转矩特性speed-torque curve 转速力矩特性曲线sphere 球体spiral 螺旋形的spring 弹簧spring 弹簧square 平方squeeze 压榨,挤,挤榨squirrel 鼠笼式squirrel cage 鼠笼squirrel-cage 鼠笼式,笼型stabilization network 稳定网络stabilize 使稳定stabilizer 稳定器stabilizing transformer 稳定变压器stand-alone 独立的standby 后备的staor winding 定子绕组starting current 启动电流starting torque 启动转矩static allocation 静态分配stator 定子stator 定子stator 定子steady–state condition 瞬态暂态steady direct current 恒稳直流电steer 驾驶,操纵,引导stepper 步进电机storage battery 蓄电池strain gage 应变计量器strategy 策略stress 应力strip 条,带,(跨接)片strive for 争取structural 结构上的studmounted 拴接式subnet 子网subsequently 其后substantially 主要地,实质上地subtle 微妙的,巧妙的subtract 减去summation 求和,加法summer 加法器summing circuit 总和线路反馈系统中的比较环节switchyard 户外配电装置symmetry 对称synchronous 同步电动机synchronous generator 同步发电机synchronous condenser 同步进相(调相)机synchronous reactance 同步电抗synchronous machine 同步电机synchronous speed 同步转速synchronous speed 同步转速synchroscops 同步指示器synthesis 综合物tachogenerator 测速发电机tachometer 转速计tachometer 测速仪tap 抽头tap 抽头taxonomy 分类学,分类technical specifications 技术条件telemedicine 远程医疗terminal 端子terminal voltage 端电压terminology 术语,专门名词terminology 术语testbed 测试平台the dielectric 电介质theorem 定理therapy 治疗thermal 热的,热量的thermocouple 热电偶thermocouple 热电偶thermometer 温度计third harmonic voltage 三次谐波电压three-phase 三相threshold 门限,阈值threshold 门,界限,阈值throttle 节流阀,风门thumb 检查、查阅thyristor 晶闸管time constant 时间常数time delay 延时time invariant 时不变的time-phase 时间相位timing relay 延时继电器toggle (来回)切换toggle 搬扭,刀闸token 令牌topology 拓扑学toroid 环状物torque 转矩,扭矩trade-off 权衡,折衷trajectory 轨迹transducer 传感器transducer 变送器transformer 变压器transformer 变压器transformer 变压器transient 瞬态的transient response 瞬态响应transistor 电子晶体管transistor 晶体管transistor-to-transistor logic,TTL 晶体管-晶体管逻辑transit 运输translatory 平移的traveling-wave 行波triac 双向可控硅Triac 双向晶闸管trial and error 试错法,试凑法triangular symbol 三角符号trigger 引起,触发trigger 起动装置trigonometric transformations 瞬时值trip coil 跳闸线圈troubleshoot 排除故障truthtable 真值表tuner 调谐器turns 匝数turns ratio 变比、匝比two-way configuration 二线制undervoltage 欠电压unidirectional 单方向的,方向不变的unidirectional current 单方向性电流uninterruptible power supply 不间断电源uninverting amplifer 同相放大器validity 正确性vane 机器的叶,叶片vector equation 向(相)量方程velodyne 伺服积分器vendor 生产厂商ventilation 通风,流通空气vernier 游标尺vibration 振动vibration 震动vicinity 附近,邻近,接近videoconference 可视会议virtual reality 虚拟现实virtually 实际上,实质上virtue 优点viscous 粘稠的viscous friction 粘滞摩擦volatile 挥发的,易失的voltage control system 电压控制系统voltage across the terminals 端电压volt-ampere characteristics 伏安特性Voltmeter 电压表、伏特计voltmeter 电压表wafer 薄片Ward-Leonard system 发电机-电动机组系统watchdog timer 看门狗定时器water-tight 防水Watt-hour 瓦时、瓦特小时watt-hour meter 电度表Wattmeter 瓦特计、电表、功率wattmeter 电力表waveguide 波导、波导管wavy groove 起伏的沟槽wear 磨损,损耗weighted 加权的whilst=whilewide area network 广域网windage 通风wind-driven generator 风动发电机winding 绕组winding 绕组winding loss 绕组(铜)损耗worldwide shared 全球共享的wound-rotor 绕线式wrap 捆,缠,环绕wreak 发泄,报复wrench 扳手wye-connected 星形连接yield 产生,提供yoke 轭zener diode 齐纳二极管zero sequence current 零序电流。

专业英语电路基础characterize描绘…的特征,塑造人物,具有….的特征property 性质,财产equal in magnitude to 在数量(数量级)上等同于convert 转换converter 转换器time rate 时间变化率mathematically 从数学上来讲differen tiate v 区分,区别in honor of 为纪念某人name in honor of为纪念某人而以他命名electromotive force (e m f )电动势voltaic battery 伏打电池,化学电池an element 一个电器元件interpret 口译,解释,说明the potential at point a with respect to point b is点a关于点b的电势Potential difference/voltage 电势差/电压expend 花费,消耗instantaneous 瞬时的,促发的passive sign convention 关联参考方向the law of conservation of energy 能量守恒定律reference polarity 参考极性electron 电子electronic 电子的electric 电的,电动的time-varying 时变的constant-valued 常量的metal lic 金属的be due to 是因为,由于,归功于building block 模块Coulomb库伦,Ampere安培,joule焦耳,Volt伏特,Watt 瓦特,work 功变量u(t),i(t)是电路中最基本的概念。

他们描述了电路中的各种关系。

电荷量的概念是解释电现象的基本原理,电荷量也是电路中最基本的量。

电荷也是构成物质的原子的电器属性,量纲是库伦。

我们从初等物理可以得知所有物质是由基本组成部分原子组成,而原子又包括电子(electron),质子(proton)和中子(neutron)我们都知道电荷e是带负电的电子,在数量上等于1.60210*1019 C, 而质子携带同等电荷量的正电荷,相同数量的质子,电子使原子呈现电中性(neutrally charged)。

离子选择电极法英文简写Ion-Selective Electrode Method (ISEM): An Overview.The ion-selective electrode method (ISEM) is a widely used analytical technique for the determination of specific ions in solutions. It is based on the principle of electrochemical transduction, where the ion concentration is directly converted into an electrical signal. This method finds applications in various fields, including environmental monitoring, clinical diagnostics, and industrial process control.Principle of Ion-Selective Electrodes.Ion-selective electrodes are sensors that have a selective response to a particular ion in a solution. They consist of a sensing membrane that is sensitive to the ion of interest and an internal reference electrode. The sensing membrane is typically made of a material that exhibits a specific affinity for the target ion. When theion contacts the membrane, it interacts with it, resulting in a change in the membrane's electrical properties.This change in electrical properties is measured as a potential difference between the reference electrode and the solution. The potential difference, known as the ion-selective electrode potential, is directly related to the logarithm of the ion concentration according to the Nernst equation. By measuring this potential difference, the concentration of the target ion can be determined.Types of Ion-Selective Electrodes.There are several types of ion-selective electrodes available, depending on the ion being measured. Some common examples include:1. Potassium Ion-Selective Electrode (K+ ISE): Used for the determination of potassium ions in biological samples and environmental waters.2. Sodium Ion-Selective Electrode (Na+ ISE): Utilizedfor sodium ion monitoring in clinical and environmental samples.3. Chloride Ion-Selective Electrode (ClISE): Employed for chloride ion determination in water and biological fluids.These electrodes are designed to be highly selective for their respective ions, minimizing interference from other ions present in the sample.Advantages of Ion-Selective Electrode Method.The ion-selective electrode method offers several advantages over other analytical methods:Selectivity: Ion-selective electrodes are highly specific to their target ions, reducing interference from other ions.Sensitivity: The method can detect low concentrations of ions, making it suitable for trace analysis.Rapid Analysis: Ion-selective electrodes provide rapid results, often within a few minutes.Ease of Use: The method is relatively straightforward and does not require complex sample preparation.Portability: Some ion-selective electrodes are designed for field use, enabling on-site monitoring.Applications of Ion-Selective Electrode Method.The ion-selective electrode method finds applications in various fields:1. Environmental Monitoring: ISEM is used to monitor ions such as chloride, sodium, and potassium in water bodies, assessing water quality and pollution levels.2. Clinical Diagnostics: Ion-selective electrodes are employed in clinical laboratories for the determination of electrolytes like sodium, potassium, and chloride in bloodand urine samples.3. Industrial Process Control: The method is used in industries to monitor ion concentrations in process streams, ensuring product quality and process efficiency.4. Food and Beverage Analysis: ISEM is used to analyze ions in food and beverage samples, such as sodium and chloride content in processed foods.5. Agricultural Research: Ion-selective electrodes are employed to study ion exchange processes in soils and plants, helping understand nutrient uptake and plant growth.Limitations of Ion-Selective Electrode Method.Although the ion-selective electrode method has numerous advantages, it also has some limitations:Interference from Other Ions: Although ion-selective electrodes are designed to be highly selective,interference from other ions can still occur, especially athigh concentrations.Temperature Dependence: The electrode response can be affected by temperature, requiring temperature compensation for accurate measurements.Sensitivity to pH: Some ion-selective electrodes are sensitive to changes in pH, necessitating pH stabilization or adjustment.Limited Lifetime: The sensing membranes of ion-selective electrodes have a limited lifetime and may require periodic replacement.Conclusion.The ion-selective electrode method is a valuable tool for the determination of specific ions in various sample matrices. Its selectivity, sensitivity, and rapidity make it an ideal choice for a wide range of applications, including environmental monitoring, clinical diagnostics, and industrial process control. However, it is important toconsider the limitations of the method and take necessary precautions to ensure accurate and reliable results.。

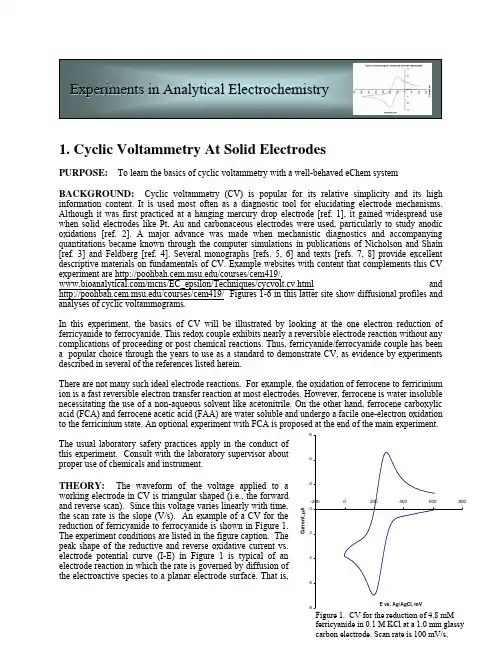

E x p e r i m e n t s i n A n a l y t i c a l E E l e c t r o c h e m i s t r y1. Cyclic Voltammetry At Solid ElectrodesPURPOSE:To learn the basics of cyclic voltammetry with a well-behaved eChem systemBACKGROUND: Cyclic voltammetry (CV) is popular for its relative simplicity and its highinformation content. It is used most often as a diagnostic tool for elucidating electrode mechanisms.Although it was first practiced at a hanging mercury drop electrode [ref. 1], it gained widespread usewhen solid electrodes like Pt, Au and carbonaceous electrodes were used, particularly to study anodicoxidations [ref. 2]. A major advance was made when mechanistic diagnostics and accompanyingquantitations became known through the computer simulations in publications of Nicholson and Shain[ref. 3] and Feldberg [ref. 4]. Several monographs [refs. 5, 6] and texts [refs. 7, 8] provide excellentdescriptive materials on fundamentals of CV. Example websites with content that complements this CVexperiment are /courses/cem419/,/mcns/EC_epsilon/Techniques/cycvolt.cv.html and /courses/cem419/ Figures 1-6 in this latter site show diffusional profiles andanalyses of cyclic voltammograms.In this experiment, the basics of CV will be illustrated by looking at the one electron reduction offerricyanide to ferrocyanide. This redox couple exhibits nearly a reversible electrode reaction without anycomplications of proceeding or post chemical reactions. Thus, ferricyanide/ferrocyanide couple has beena popular choice through the years to use as a standard to demonstrate CV, as evidence by experimentsdescribed in several of the references listed herein.There are not many such ideal electrode reactions. For example, the oxidation of ferrocene to ferriciniumion is a fast reversible electron transfer reaction at most electrodes. However, ferrocene is water insolublenecessitating the use of a non-aqueous solvent like acetonitrile. On the other hand, ferrocene carboxylicacid (FCA) and ferrocene acetic acid (FAA) are water soluble and undergo a facile one-electron oxidationto the ferricinium state. An optional experiment with FCA is prop osed at the end of the main experiment.he usual laboratory safety practices apply in the conduct of HEORY:Tthis experiment. Consult with the laboratory supervisor about proper use of chemicals and instrument.Tworking electrode in CV is triangular shaped (i.e., the forward and reverse scan). Since this voltage varies linearly with time, the scan rate is the slope (V/s). An example of a CV for the reduction of ferricyanide to ferrocyanide is shown in Figure 1. The experiment conditions are listed in the figure caption. The peak shape of the reductive and reverse oxidative current vs. electrode potential curve (I-E) in Figure 1 is typical of an electrode reaction in which the rate is governed by diffusion of the electroactive species to a planar electrode surface. That is,the rate of the electron transfer step is fast compared to the rate at which ferricyanide is transported (diffuses) from the bulk solution to the electrode surface due to a concentration gradient, as ferricyanide is reduced to ferrocyanide. In such a case the peak current, Ip, is governed by the Randle-Sevcik relationshipI p = k n3/2 A D1/2 C bυ½ (1)where the constant k = 2.72 x 105; n is the number of moles of electrons transferred per mole of electroactive species (e.g., ferricyanide); A is the area of the electrode in cm2; D is the diffusion coefficient in cm2/s; C b is the solution concentration in mole/L; and υ is the scan rate of the potential in volt/s.The I p is linearly proportional to the bulk concentration, C b, of the electroactive species, and the square root of the scan rate, υ 1/2. Thus, an important diagnostic is a plot of the Ip vs. υ 1/2. If the plot is linear, it is reasonably safe to say that the electrode reaction is controlled by diffusion, which is the mass transport rate of the electroactive species to the surface of the electrode across a concentration gradient. The thickness, δ, of the "diffusion" layer can be approximated by δ ~ [D t]1/2, where D is the diffusion coefficient and t is time in seconds. A quiet (i.e. unstirred solution) is required. The presence of supporting electrolyte, such as KNO3 in this example, is required to prevent charged electroactive species from migrating in the electric field gradient.Another important diagnostic for characterizing the electrode reaction is the value of the peak potential, E p. When the rate of electron transfer is fast, the E p value will be independent of the scan rate; indicating a reversible electrode reaction. Then the difference between the anodic peak potential, E pa, and the cathodic, E pc value will be equal to 57 mV/n. The thermodynamically reversible potential, E o, is found at E0.85. That is, 85% of the way-up the I-E wave to E p. This value should also be independent of the scan rate. There are a few issues to consider -To compare your E0.85 value with values listed in books, it must be corrected since youused an Ag/AgCl reference electrode rather than the Normal Hydrogen Electrode (NHE)that was used when the Standard Values of Electrode Potentials, E o, were defined fromthe Nernst expression.Also the measured electrode potential must be corrected if there is a significant solutionresistance (ohmic) between the working and reference electrode. The measured potentialthen contains an additional component, E (ohmic) =i R. It is best to minimize thepossibility of such i R by use of a high background electrolyte concentration (ions thatcarry the current in the solution) and/or by placing the tip of the reference electrode closeto (but not touching) the surface of the working electrode.The electrode reaction during the scan from +600 mV to 0.0 mV isFe III(CN)63- + e-Æ Fe II(CN)64-E o = 0.361 V vs. NHE at 25ºC (2)The electrode potential, E, is thermodynamically determined by the Nernst relationship(3)E = E o + (0.0591/n) log (a ox/a R)where a ox is the activity of the oxidized species, ferricyanide in the present case, and a R is the activity of the reduced species, ferrocyanide. Experimentally, the activity is affected by the presence of other ions. For practicality, we therefore define a “formal potential” that uses concentration in mole/L rather than activity, which we do not know. The Nernst becomesE = E o’ + (0.0591/n) log [C ox/C R] (4)The “formal” potential, E o’, depends on the nature of electrolytes in the solution as seen in this list of Formal Potentials for ferri/ferrocyanide in aqueous solutions at 25ºC vs. NHE:E o’ valuesFe(CN)6 3- + e- = Fe(CN)64-0.1 M HCl 0.56 V1.0 M HCl 0.71 VHClO40.72 V1.0MThe potential, E, at any point along the I-E wave should reflect the concentration of the ferricyanide and ferrocyanide at the electrode surface in the presence of whatever background electrolyte you are using.Irreversibility is when the rate of electron transfer is sufficiently slow so that the potential no longer reflects the equilibrium activity of the redox couple at the electrode surface. In such a case, the E p values will change as a function of the scan rate. The computer-controlled potentiostat has algorithms to evaluate the I p and E P values, calculate the area under the I-E curves (the integrated charge), and compute an estimated electron transfer rate constant. A unique feature of an electrochemical reaction is that a "reversible" electrode reaction at low scan rates can become "irreversible" at high scan rates. Why is this? [Click on “Concepts” on the home page for additional discussion of fundamentals.]EXPERIMENTEquipment•Obtain instructions on the use of a 3-electrode potentiostat from your laboratory instructor.•Electrochemical cell and electrodeso A 3 - 4 mm diameter (planar) glassy carbon or Pt working electrodeo Pt auxiliary electrodeo Ag/AgCl reference electrodeo Small volume electrochemical cello Polishing kit•Volumetric flasks with ground glass stoppers and pipettesChemical SolutionsA.100 ml of 1.0 M KNO3B.100 ml stock solution of 10 mM potassium ferricyanide [K3Fe(CN)6] in 0.1. M potassium nitrate[KNO3]C.An unknown concentration of potassium ferricyanide solution provided by instructor (optional).Procedure1.Polishing: Prepare the working glassy carbon electrode by first lightly polishing the electrodesurface with 1 μm or smaller particles of alumina (wet) on a flat polishing plate. Wash the electrode carefully with pure water to remove any alumina. If a sonicator is available, fill a small beaker with pure water, place the electrode (tip down) and sonicate for 1 minute. Remove, rinse with pure water and touch the edges of the tip with Kimwipe or clean tissue paper but do not touch the electrode surface.2.Prepare 1, 2, 5 and 8 mM ferricyanide in 0.1 M KNO3 in 50 ml volumetric flasks.3.To run background scan, insert the electrodes (GC, reference Ag/AgCl and Pt auxiliary) and fillthe cell with 0.1 M KNO3 until the ends of the electrodes are immersed. Add stirring bar and turn ON the magnetic stirrer to stir the solution so that there is homogeneity of concentration from the surface of the electrode to the bulk solution. After the stirrer is turned OFF, if any tiny gasbubbles should be adhering to the bottom of the electrodes, lightly tap the electrode to dislodge them. If a stirrer is not used, wait ~ 2 minutes before each scan to allow equilibration of the bulk concentration with that at the electrode surface.4.Run a CV scan from an initial potential (E i) of + 600 mV to 0.0 mV and then back to + 600 mV ata scan rate of 100 mV/s. Repeat the scan after stirring the solution for 10-15 seconds andallowing the solution to quiet. The two voltammograms should match each other within 2-3 %.If not, re-polish the GC electrode and rerun.5.Run duplicate CVs on each ferricyanide solution (1, 2, 8 and 10 mM) at the scan rate of 100mV/s.6.Run duplicate CVs on the 2 mM ferricyanide solution at scan rates of 20, 50, 200 and 500 mV/s.bel and save each CV with the “save function” if using a computerized potentiostat or print outa hardcopy of what you want to save.REPORT (Data Analysis and Discussion):Consult with your laboratory instructor about the content and format of your report for this experiment. The following are suggestions and considerations regarding the content.Note: With computerized potentiostats you may be able to use Math function to determine E p and I p values. Similarly, the I p values can often be corrected for the background charging current.1.Write a short summary of what you did in this experiment, noting any deviations or substitutionsin the procedure. Show example cyclic voltammograms.2.Plot I p vs. concentration of ferricyanide. It should be linear (background corrected?). Determinethe concentration of the unknown sample of ferricyanide from this calibration plot.3.Determine the E o’ value from the voltammograms. If the values vary with the scan rate, plot themversus the scan rate and extrapolate to obtain the E o’ at zero scan rate. Compare this value with the tabulated formal potential of ferri/ferrocyanide in 0.1 M HCl.4.Tabulate the difference between E pc and E pa values – are they close to the theoretical value for areversible electrode reaction? If not, can you account for the deviation?5.Plot I pa and I pc vs. ν1/2, and from the slope, determine the value of the diffusion coefficient (mustmeasure the electrode area). How does your value compare to the literature one of 0.62 x 10-5 cm2/s? Should there be a difference in the diffusion coefficient between ferricyanide and ferrocyanide? If so, why?6.The I pc/I pa = 1 for a diffusion controlled reversible electrode reaction. [Note: the baseline needs tobe extrapolated by drawing the best straight line so that the I pc and I pa can be corrected for the background solution] Do you get unity for this ratio from your CV experiments?7.There is a current decrease at ~ 100 mV past I pc or I pa due to the concentration of the speciesbeing electrolyzed going to zero at the electrode surface. This condition is similar to that found in chronoamperometry where the rate is diffusion controlled. Under such a condition, the current decreases as a function of 1/[t]1/2. Do a plot of I vs. t1/2, starting at ~ 60 mV past E p and see if you get a linear plot. Does the same condition apply also to the anodic wave?8.Calculate δ at I p of a CV at a scan rate of 100 mV/s, assuming t = 0 occurs at the start of the risingportion of the CV wave. This value of δ is only a rough approximation but will give you a "feel"for dimensions of the diffusion layer thickness.REFERENCES1.W. Kemula, Z. Kublik, Nature, 182 (1958) 793.2.R. N. Adams, Electrochemistry at Solid Electrodes, 1968, Published by Marcel Dekker, Inc.3.R. S. Nicholson, I. Shain, Theory of Stationary Electrode Polarography. Single Scan and CyclicMethods Applied to Reversible, Irreversible, and Kinetic Systems, Anal. Chem., 36 (1964) 706.4.S. W. Feldberg, A General Method for Simulation, Vol. 3 in Electroanalytical Chemistry Series,Marcel Dekker, N.Y., 1969.5. D. K. Gosser, Jr., Cyclic Voltammetry: Simulation and Analysis of Reaction Mechanisms, VCHPublishers, 1993.6.J. Bard, L. R. Faulkner, Electrochemical Methods: Fundamentals and Applications, 2nd Ed., JohnWiley and Sons, Inc., 2001,7. D. T. Sawyer, Wm. R. Heineman and J. M. Beebe, Chemistry Experiments for InstrumentalMethods, J. Wiley & Sons, 1984, Chapter 4.8.H. A. Strobel & Wm. R. Heineman, Chemical Instrumentation: A Systematic Approach, 3rd Ed.,John Wiley & Sons, 1989, Chapter 26.OPTIONAL EXPERIMENTS:1.Run CV of ferricyanide with a Pt working electrode in place of glassy carbon. Oxygen is reducedmore readily at Pt than GC so the scan should not go below 0.0 V. Which electrode gave results closest to what is expected for a reversible electrode reaction? How close to the theoretical value of I p did you get for the reduction of ferricyanide?2.Run CVs of ferrocene carboxylic acid (FCA, concentration at 3–5 mM) in pH 7 buffer containing0.1M KNO3. FCA is water soluble as the carboxylate ion. It undergoes a nearly ideal one-electron transfer reaction without any complications. The E p separation between the E pa and E pc should be close to the theoretical value. Do scan rate studies and tabulate E pa, E pc, (E pa + E pc)/2, and the I pa and I pc (corrected for baseline) in your report. Comment on FCA’s electron transfer reversibility compared to ferri/ferrocyanide.The F.W. of FCA is 230.04. It can be purchased in small quantities from Sigma Aldrich chemicals. Please read the manufacturers label about care in handling.An example CV for the oxidation of FCA at a GC electrode is shown in Figure 2.-4-3-2-1120200400600800E vs. Ag/AgCl, mV Curre nt,µAFigure 2. CV for the oxidation of 2 mM ferrocene carboxylic acid at pH 7. Scan rate is 100 mV/s。

Highly ordered monocrystalline silver nanowire arraysG. Sauer, G. Brehm, S. Schneider, K. Nielsch, R. B. Wehrspohn et al.Citation: J. Appl. Phys. 91, 3243 (2002); doi: 10.1063/1.1435830View online: /10.1063/1.1435830View Table of Contents: /resource/1/JAPIAU/v91/i5Published by the American Institute of Physics.Related ArticlesHighly ordered self-assembled nanoscale periodic faceting in GaAs(631) homoepitaxial growthAppl. Phys. Lett. 101, 073112 (2012)Diameter dependent optical emission properties of InAs nanowires grown on SiAppl. Phys. Lett. 101, 053103 (2012)Hole spectra and conductance for quantum wire systems under Rashba spin-orbit interactionJ. Appl. Phys. 110, 113705 (2011)Structural and optical properties of m-plane GaN/AlGaN quantum wires grown by metalorganic chemical vapor depositionAppl. Phys. Lett. 99, 113106 (2011)Vibronic coupling in quantum wires: Applications to polydiacetyleneJ. Chem. Phys. 135, 054906 (2011)Additional information on J. Appl. Phys.Journal Homepage: /Journal Information: /about/about_the_journalTop downloads: /features/most_downloadedInformation for Authors: /authorsHighly ordered monocrystalline silver nanowire arraysG.Sauer,G.Brehm,and S.SchneiderInstitute of Physical and Theoretical Chemistry,University Erlangen-Nuremberg,Egerlandstrasse3,D-91058Erlangen,GermanyK.Nielsch,R.B.Wehrspohn,a)J.Choi,H.Hofmeister,and U.Go¨seleMax-Planck-Institute of Microstructure Physics,Weinberg2,D-06120Halle,Germany͑Received18September2001;accepted for publication15November2001͒Highly ordered silver nanowire arrays have been obtained by pulsed electrodeposition in self-ordered porous alumina templates.Homogeneousfilling of all the pores of the alumina template is achieved.The interwire distance is about110nm corresponding to a density of silver nanowires of61ϫ109in.Ϫ2and the diameter can be varied between30and70nm.The silver wires are monocrystalline with some twin lamella defects and grow perpendicular to the͗110͘direction.The previously encountered difficulty to obtain100%filling of the alumina pores is discussed in the framework of electrostatic instabilities taking into account the different potential contributions during electrodeposition.To obtain homogeneouslyfilled pore membranes,a highly conductive metal containing electrolyte,a homogeneous aluminum oxide barrier layer,and pulsed electrodeposition are a prerequisite.©2002American Institute of Physics.͓DOI:10.1063/1.1435830͔I.INTRODUCTIONWe report on the preparation of ordered silver nanowire arrays obtained by pulsed electrodeposition in porous alu-mina.Nearly100%filling of the nanometer sized pores with silver has been obtained.The difficulty of achieving a homo-geneousfilling is based on instabilities occurring during growth of the highly conducting silver nanowires.In other publications concerningfilling of nanopores with silver the problem of the homogeneity of thefilling is not addressed and it can be deduced from the data that only a very low filling fraction has been achieved.1–3Furthermore,so far most people dealing with thefilling of porous materials used disordered alumina,track-etched polycarbonate-membranes, or other disordered pore arrays as templates,4–6which even in case of homogeneous porefilling would yield disordered wire arrays with a large dispersion in the pore diameter.Pos-sible applications for such ordered wire arrangement include photonic crystals7and surface enhanced Raman spectroscopy ͑SERS͒.8Other applications might be based on the sharp size distribution of the wire dimensions replicating the high order of the template.After dissolving the alumina matrix,these wires can be either used as conducting nanowires in nanode-vices or as templates for hollow cylinders similar to hollow spheres.9This article is organized as follows.Wefirst report on the porous alumina template preparation.Then we will present thefilling procedure and characterize the silver nano-wire arrays.Finally we discuss the instabilities occurring during silver nanowire growth in the framework of a linear stability analysis.II.TEMPLATE PREPARATIONHexagonally ordered porous alumina templates havebeen prepared via a two-step anodization process,which isreported in detail elsewhere.10–12Briefly,afirst long-durationoxidation of high purity aluminum and subsequent completedissolution of the formed porous alumina leads to patternedaluminum substrates.The surface keeps the regular hexago-nal texture,formed during thefirst oxidation process by self-assembly,which acts as a mask for the second anodization ͑Fig.1͒.After the second oxidation,an ordered nanopore array is obtained.The diameter and depth of the pores aswell as the distance between them and the degree of orderingdepends critically on the anodization parameters.Typical pa-rameters used in this work are0.3M oxalic acid,U oxϭ40V, and Tϭ2°C.To obtain homogeneous electrodeposition intothe pores in thefinal step it is highly necessary to previouslyreduce the alumina barrier thickness at the pore bottom.Thethinning is achieved by chemical etching and/or by currentlimited anodization steps.13First,isotropic chemical porewidening reduces the barrier thickness and increases the porediameter.Then,the sample is oxidized several times for10–15min using constant current conditions,reducing thecurrent after each step by a factor of2.The anodizationpotential decreases slowly with decreasing barrier thickness.The thinning is stopped when the anodization potentialreaches a value of6to7V,which is equivalent to a barrierlayer thickness of about10nm.Further thinning might causethe oxide structure to peel off of the aluminum substrateduring the deposition.Applying current limited anodizationsteps not only results in a thinning of the barrier oxide,butalso in a modification of the pore structure.The originallystraight pores branch out at the formation front because thepore density is inversely proportional to the square of theanodizing potential͑Fig.1͒.14,15The splitting up of the poresa͒Author to whom correspondence should be addressed;electronic mail:wehrspoh@mpi-halle.deJOURNAL OF APPLIED PHYSICS VOLUME91,NUMBER51MARCH200232430021-8979/2002/91(5)/3243/5/$19.00©2002American Institute of Physicsinto the barrier layer leads to the formation of several nucle-ation sites in each pore at the beginning of the electrodepo-sition.Since the potential drop at the deposition interface depends critically on the barrier thickness,it has to be highly uniform.This is achieved by our thinning process described above.III.ELECTRODEPOSITIONThe pores are filled with silver under constant current conditions adopting the concept of pulsed electrodeposition.To achieve homogeneous filling of the pores,the choice of a suitable electrolyte is crucial.In order to avoid corrosive attack of the alumina template,the p H of the electrolyte has to be adjusted between 4and 8.16Therefore it is hardly pos-sible to work with cyanide containing silver baths,which generally require a higher p H.To supply the deposition in-terface sufficiently fast with metal ions the concentration of electroactive silver species has to be as high as possible,otherwise hydrogen evolution can become dominant.Fur-thermore,pulsed electrodeposition through an insulating bar-rier layer requires high negative polarization (U pulse as high as Ϫ8V ͒.Consequently,the electrolyte must not contain other electroactive species like,e.g.,nitrate ions,which also might react in side reactions under these conditions.Finally,stability analysis shows ͑see below ͒that the conductivity in the electrolyte has to be quite high to obtain uniform depo-sition into the pores.Based on these considerations the choice of a suitable electrolyte is not trivial.As the presence of nitrate ions and other electroactive species is excluded silver sulfate ͑8.5g/l ͒was chosen as the silver ion source.Diammoniumhydrogencitrate ͑200g/l ͒was added to ensure a high conductivity and to adjust the p H value to around 4.5.Furthermore,diammoniumhydrogencitrate has the function of a repairing agent as it favors the formation of stable alu-mina during the positive polarization in the pulse sequence͑see below ͒.Finally,the electrolyte contained potassiumthio-cyanate ͑105g/l ͒,which was necessary to dissolve precipi-tated silver salt through complexation.The pulsed elec-trodeposition consists of modulated pulses in the millisecond range ͑Fig.2͒.During each pulse of negative current (t pulse ϭ6ms,I pulse ϭ15mA/cm 2),silver is deposited at the pore bottom.A relatively high current density is applied in order to increase the number of nucleation sites in each pore.12After the deposition pulse,another pulse with positive polar-ization (t pulse ϭ6ms,U pulse ϭ6V ͒was applied to discharge the capacitance of the barrier layer and to interrupt the elec-tric field at the deposition interface immediately.The posi-tive pulse also repairs discontinuities in the barrier oxide,an important mechanism especially at the beginning of the elec-trodeposition.The current for this second pulse is also lim-ited to I max ϭ15mA/cm 2.To avoid depletion of the silver ions at the deposition interface,the ion concentration has to recover before the next double pulse is applied.Introducing a delay time t off of typically 0.4–1s is sufficient to ensure the restoration of a high silver concentration at the pore bottom before the subsequent deposition pulse appears.This im-proves the homogeneity of the deposition and prevents ex-cessive hydrogen evolution.During the electrodeposition,the potential required to ensure the desired current density is measured for each pulse.Hence the electrodeposition can easily be followed via a potential versus pulse number plot ͑Fig.3͒.Generally,the plot can be divided into three regions.At the beginning of the filling process the electrons have to tunnel through the barrier oxide before they react with the silver ions and nucleation takes place at numerous sites in each pore.The surface available for electrodeposition is quite large.Further electrodeposition leads to a filling of the branched structure and thus the electrochemically active sur-face area decreases,accompanied by an increase in the depo-sition potential ͑first region ͒.When the depositedsilverFIG.1.Schematic diagram describing the fabrication of a highly ordered porous alumina matrix and the preparative steps necessary for the subse-quent filling of the structure.The Al substrate is prestructured by a long-time anodizing until the pores arrange in a hexagonal lattice.Then the aluminum oxide is selectively removed.Starting from a prestructured Al substrate,a highly ordered alumina pore structure is obtained in a second anodization step.Afterwards,the barrier layer is thinned and the pores are widened by isotropic chemical etching.For further thinning of the barrier layer two current-limited anodization steps are used and dendrite pore formation oc-curred at the barrier layer.Then,the pores are filled by pulsed electrodepo-sition withsilver.FIG.2.Current and potential transients during electrodeposition.First a current-limited negative pulse t pulse is applied to deposit Ag.Then a positive pulse is applied to discharge the capacitance of the alumina barrier layer.The cycle is repeated after t off in order to avoid depletion of metal ions near the deposition interface.reaches the beginning of the straight part of the pores the increase in the deposition potential slows down distinctly,but still proceeds ͑second region ͒.The decreasing silver con-centration in the pore channel can be made responsible for a gentle increase in the deposition potential in this region,but it cannot explain the significant rise of more than one volt.The filling of the pores continues until the deposition poten-tial drops or exhibits some noise ͑third region ͒,which is due to an increase of the electroactive surface arising from silver deposition on top of the porous alumina matrix.Although the significant increase in the deposition potential,especially in the second region,is not completely understood yet,the po-tential versus pulse number plot at least allows one to follow and control the filling process.Additionally the charge can be calculated from the measured data and thus allows one to estimate the degree of pore filling and to control the wire length.IV.CHARACTERIZATIONThe filled alumina templates were examined by scanning electron microscopy ͑SEM ͒to determine the degree of pore filling and the extension of the silver nanowires.By etching the filled porous structure from the top,nanowires ending somewhat below the membrane surface became observable for scanning electron microscopy ͑SEM ͒examination.Etch-ing of the samples was performed by Ar sputtering with an ion mill ͑Gatan Duo Mill 600͒and led to a funnel-shaped excavation in the surface.The depth of the hole was corre-lated with the etching time.Figure 4shows two top view micrographs and one side view micrograph of a highly or-dered alumina pore structure filled with silver.The pore di-ameter is approximately 35nm and the interpore distance is 110nm.The thickness of the porous layer is approximately 2m.Figure 4͑a ͒was taken before etching the sample.In some pores,the silver nanowires reached the pore opening and excessive electrodeposition yielded three-dimensional growth of silver particles on top of the matrix structure ͑bright spots ͒.In most of the remaining ͑not completely filled ͒pores,the top of the nanowires can be seen ͑different gray levels indicate different levels of residual pore depth ͒.Figure 4͑b ͒shows the same sample after etching the initially 2m thick porous structure by about 200nm.As can be seen clearly,almost every pore is filled with silver to this level indicating fluctuations in the height of the filling of less than 10%.The same information can be obtained from Fig.4͑c ͒.Simple cutting of an ͑unthinned ͒substrate with wire cutting pliers leads to a fracture of the rigid alumina layer.Most of the pores are filled with silver wires ͑bright sticks ͒to at least 90%in height.The lack of wires in some of the pores as well as the presence of twisted and ruptured wires can easily be explained by the mechanical stress evolving during the process of the cleavage of the alumina membrane.Crystallinity and surface configuration of the silver wires were further analyzed by high-resolution transmission elec-tron microscopy ͑HRTEM ͒.After dissolving the alumina ma-trix such wires have been placed on electron microscopy copper grids covered by a thin carbon film.Although ar-ranged randomly on the carbon film,the silver wires tendtoFIG.3.V oltage-pulse-number curve during the filling process of porous alumina with Ag.In regime I the dendride-like nucleation pores are filled with Ag.The potential increases due to a reduction of the deposition area.In regime II the silver wires grow and the potential increases slightly.In regime III the silver wires reach the top of the alumina template and the noise and slight potential drop are due to the uncontrolled increase in depositionarea.FIG.4.SEM micrographs of a silver-filled alumina membrane.͑a ͒Top view of an unthinned sample,͑b ͒top view of the same sample approximately 200nm underneath the initial surface,and ͑c ͒side view of a fracture.align parallel in groups because of capillary forces acting during evaporation of the solvent.Figure 5shows a HRTEM image of a segment of two adjacent wires touching each other along a nearly horizontal line.From selected area elec-tron diffraction these silver wires are found to be single crys-talline.Nevertheless,they contain a certain extent of lattice defects such as twin boundaries and stacking faults.While the wire in the lower part of Fig.5does not exhibit lattice defects in the frame of this image,the upper wire has three planar defects that may be recognized as narrow bands of stronger contrast running obliquely across the wire.Their structures are shown in more detail in the boxes beneath.From the course of the lattice plane fringes seen here,and reflected also by the diffractogram ͑Fourier transform ͒of the image given in the circular inset,the ͗110͘zone axis of the silver lattice is deduced to be perpendicular to the wire axis.The wires have generally a face-centered-cubic ͑fcc ͒lattice,which was also confirmed by x-ray diffraction analysis.They do not show indications of neither oxide coverage nor incor-poration.V.DISCUSSIONAs mentioned in the Introduction,most studies have not discussed the achieved degree of filling of the pores with either silver 1–3or other metals like Au,17Co,18–21Fe,22or Ni.23In the present work we demonstrated that under very specific conditions of pulsed electrodeposition,one can ob-tain a nearly 100%homogeneous filling of pore arrays also with silver.In a former publication we have shown that it is indeed possible to fill homogeneous nickel and cobalt into porous alumina.13Now we are presenting a model to explain the physical reasons underlying this process.The key ingredients of our model are a thin homogeneous barrier layer,pulsed elec-trodeposition,and a highly conducting electrolyte.Figure 6shows a schematic diagram of the equivalent electrical cir-cuit applicable during pulsed electrodeposition.Starting from the current source,there is a resistance in the aluminum sub-strate (R s ),then all the pores are in parallel consisting of a thin interfacial oxide layer (R i ),the deposited metal (m ),and the electrolyte (e ).Finally,there is a common resis-tance of the electrolyte in the electrochemical cell (R e ).For a stability analysis,we can neglect the potential drop in the aluminum substrate and the electrolyte since they are simple series resistances and do not contribute significantly to the instability.The first instability arises from the fact that the alumina barrier layer at the pore bottom is not uniform.If it would be uniform,then it would represent an overall series resistance like R e or R s .However,due to the electrochemi-cal process,there are always fluctuations in the barrier layer thickness.Therefore as already pointed out by Zagiel et al.,24the barrier layer thickness and therefore the overall potential drop iR i should be as small as possible compared to the potential drop across e and m .This is the reason for thin-ning the alumina barrier layer to typically 10nm.However,this still results in a significant contribution to the potential drop of ϳ6V in the barrier layer compared to a few tenths mV for the electrolyte solution ͑Table I ͒.Therefore and be-cause of the rectifying nature of the barrier layer,we have applied a self-limiting current process by using pulsed elec-trodeposition.During the 6ms negative pulses,all of the metal ions in the pore are deposited due to the high current.Thus once all the ions have been deposited in one specific pore,the current flow is reduced and other pores with a slightly thicker barrier layer take over the current.A uniform filling of the pore bottom is achieved and the impact of fluc-tuations of R i is reduced due to a time dependent electrolyte resistivity e ͑t ͒.During the positive pulse,the capacitanceofFIG.5.HRTEM image of a segment of two adjacent silver nanowires.The upper one exhibits three planar defects shown in more detail in the box below.The diffractogram ͑circular inset ͒reflects the lattice relation between the twin lamella ‘‘T’’and wirematrix.FIG.6.Schematic diagram of the electric circuit during pulsed electrodepo-sition.TABLE I.Resistivities ͑at 38°C ͒of some metals and electrolytes used in this work and similar work in literature.MaterialResistivity in ⍀cmnickel ͑bulk ͒ 6.3ϫ10Ϫ6silver ͑bulk ͒1.4ϫ10Ϫ6nickel Watts-bath electrolyte 14Metzger Co bath 77Xu Ni bath500silver containing electrolyte ͑this work ͒5.2the barrier layer is discharged.Moreover,as pointed out by Dobrev et al.,25the use of positive pulses leads to monocrys-talline nanowires.They speculate that during the positive pulse,a certain amount of current will lead to the preferential dissolution of the defect rich metal deposit of the previous negative pulse,thus promoting monocrystalline growth.Another electrostatic instability arises during the growth of the silver wires.Since the Ag nanowires are always more conductive than the electrolyte,smallfluctuations in the length of the wire will be enhanced and will lead to nonuni-form growth.Similar to the case of pore growth in highly resistive p-type silicon,this effect can be described by a linear stability model.Following Wehrspohn et al.,26,27we can define a instability coefficient␣␣ϭeϪmeϩqR iϩm q,͑1͒where q is thefluctuation wavenumber͑in cmϪ1).If␣is negative,the metal wire front grows uniformly,i.e.,thefill-ing is homogeneous.If␣is positive,the metal wire front will in general be unstable and an inhomogeneousfilling willoccur.The inverse1/␣represents the typical length for which one silver wire will start to grow faster in one porethan in the others.To obtain a homogeneousfilling becauseof negative␣,the resistivity of the electrolyte must be lower than that of the metal wire.Such a condition is unrealistic forany metal since the conductivity of pure metals͑ϳ⍀cm͒is a few orders of magnitude higher than that of concentratedelectrolytes(ϳ10⍀cm͒.The only possibility tofill a thinlayer of porous alumina rather homogeneously is therefore toincrease1/␣so that it is larger than the membrane thickness. This means the onset of the instability will not occur belowthis critical thickness and a homogeneousfilling is possible.SincemӶe,the critical thickness1/␣simplifies to1/␣ϭ1/qϩR i/e.For qϷ105cmϪ1,R iϷ36⍀cm2for a cur-rent density Iϭ15mA/cm2and a porosity of9%,eϷ10⍀cm,1/␣is limited by the term R i/e,i.e.,interface or barrier-layer limited.Thus the barrier layer thickness is pro-portional to the critical thickness1/␣and the conductivity of the electrolyte is inversely proportional to1/␣.This under-lines the importance of using highly conductive electrolytes like Watts-bath-type electrolytes in the case of Ni and Co nanowires.Indeed,the Xu group28and the Metzger group29 both obtain very good Nifilling degrees in alumina pore arrays applying these rules.Xu uses barrier layer thinning, pulsed electrodeposition,and high temperature deposition to increase the mobility of the ions in the organic electrolyte.28 Metzger uses pulsed electrodeposition,barrier layer thinning, and also highly conducting electrolytes.However,in both studies,the resistivities are much higher than for the Watts-bath type electrolyte used in our work.13Therefore instabili-ties have to be compensated in these groups by decreased pulse duration.However,a drawback of the latter strategy is that a thicker barrier layer has to be used to reduce the dis-charge time of the barrier layer capacitance.The thicker bar-rier layer leads to significantly higher overpotentials during deposition and to a worse crystallinity of the nanowires.29VI.CONCLUSIONSA highly efficient method of depositing silver into the nanochannels of ordered porous alumina is presented.Nearly 100%of the pores werefilled with silver and only small fluctuations in the growth rate in different pores were ob-served.The silver nanowires are monocrystalline with some twin-lamella defects.The growth direction is perpendicular to the͗110͘direction.The wire diameter can be varied from 30to70nm depending on how the alumina template is pre-pared.Based on a linear stability analysis,we have modeled the electrochemicalfilling behavior.To obtain homoge-neouslyfilled pore membranes,a homogeneous aluminum oxide barrier layer,pulsed electrodeposition,and a highly conductive electrolyte are a prerequisite. ACKNOWLEDGMENTSThe authors thank S.Hopfe for the SEM sample prepa-rations and Dr.H.-N.Lee for the x-ray measurements.1Q.Zhang,Y.Li,D.Xu,and Z.Gu,J.Mater.Sci.Lett.20,925͑2001͒. 2I.Mikuslkas et al.,Opt.Mater.17,343͑2001͒.3F.Mu¨ller,A.D.Mu¨ller,M.Kro¨ll,and G.Schmid,Appl.Surf.Sci.171, 125͑2001͒.4X.Jiang et al.,J.Mater.Chem.11,1775͑2001͒.5V.M.Cepak and C.R.Martin,J.Phys.Chem.B102,9985͑1998͒.6N.F.Jana et al.,mun.͑Cambridge͒7,617͑2001͒.7H.van der Lem and A.Moroz,J.Opt.2,395͑2000͒.8G.Sauer͑unpublished͒.9F.Caruso,R.A.Caruso,and H.Mo¨hwald,Chem.Mater.11,3309͑1999͒. 10H.Masuda and K.Fukuda,Science268,1466͑1995͒.11H.Masuda,K.Yada,and A.Osaka,Jpn.J.Appl.Phys.,Part237,L1340͑1998͒.12O.Jessensky,F.Mu¨ller,and U.Go¨sele,Appl.Phys.Lett.72,1173͑1998͒. 13K.Nielsch,F.Mu¨ller,A.-P.Li,and U.Go¨sele,Adv.Mater.12,582͑2000͒. 14F.Keller,M.S.Hunter,and D.L.Robinson,J.Electrochem.Soc.100,411͑1953͒.15A.-P.Li,F.Mu¨ller,A.Birner,K.Nielsch,and U.Go¨sele,J.Appl.Phys. 84,6023͑1998͒.16P.P.Mardilovich,yadinov,N.I.Mazurenko,and R.Paterson,J. Membr.Sci.98,143͑1995͒.17X.Y.Zhang et al.,J.Mater.Chem.11,1732͑2001͒.18H.Zeng,M.Zheng,R.Skomski,D.J.Sellmyer,Y.Liu,L.Menon,and S. Bandyopadhyay,J.Appl.Phys.87,4718͑2000͒.19A.Kazadi Mukenga Bantu et al.,J.Appl.Phys.89,3393͑2001͒.20T.Thurn-Albrecht,J.Schotter,G.A.Ka¨stle,N.Emley,T.Shibauchi,L. Krusin-Elbaum,K.Guarini,C.T.Black,M.T.Tuominen,and T.P.Rus-sell,Science290,2126͑2000͒.21H.Q.Cao,Z.Xu,H.Sang,D.Sheng,and C.Y.Tie,Adv.Mater.13,121͑2001͒.22Y.Peng,H.-L.Zhang,S.-L.Pan,and H.-L.Li,J.Appl.Phys.87,7405͑2000͒.23P.M.Paulus,F.Luis,M.Kro¨ll,G.Schmid,and L.J.de Jongh,J.Magn. Magn.Mater.224,180͑2001͒.24A.Zagiel,P.Natishan,and E.Gileadi,Electrochim.Acta35,1019͑1990͒. 25D.Dobrev,J.Vetter,N.Angert,and R.Neumann,Appl.Phys.A:Mater. Sci.Process.69,233͑1999͒.26R.B.Wehrspohn,J.-N.Chazalviel,and F.Ozanam,J.Electrochem.Soc. 145,2958͑1998͒.27R.B.Wehrspohn,F.Ozanam,and J.-N.Chazalviel,J.Electrochem.Soc. 146,3309͑1999͒.28A.J.Yin,J.Li,W.Jian,A.J.Bennett,and J.M.Xu,Appl.Phys.Lett.79, 1039͑2001͒.29M.Sun,G.Zangari,M.Shamsuzzoha,and R.M.Metzger,Appl.Phys. Lett.78,2964͑2001͒.。

W. Nernst, Ann. Phys. (Leipzig) 267 (1887) 760. 760 W. Nern t关于金属板中的磁性所唤醒的电动势,热量通过金属板流动目录关于金属板中的磁性所唤醒的电动势,热量通过金属板流动 (1)1.序言 (2)2.设备说明 (2)3.测量经横向效应的方法。

(4)4.横向效应的一般信息 (5)5.对各个金属的横向影响。

(7)6.测量结果概述。

(11)8. 纵向效应 (15)9.测量结果调查 (17)10.扭转纵向出力。

(19)11,其他一些尝试。

(19)12.附录: (20)1.序言教授v。

在户外,有时对霍尔现象进行实验性研究,我很荣幸能成为我倍受尊敬的老师的雇员,观察到了新的现象,我们称之为“ h hermomagnetis chen”当磁化的金属板在正确的方向和热梯度的方向上流过热电流时,会在金属化的金属板上产生占据的电动势1)因此,我们发现,在垂直于磁场力线的金属板上,一方面两个等温线,另一方面位于同一热流线上的两个点具有电势差,并且性质明显不同。

前者-“ Transsersaleffect”一大约与场的强度成比例,并与其方向相通;后者-“ longitudinaleffect”-来自场的方向。

场大小的平方独立且平衡,而场大小的平方基本上取决于板的尺寸和热量,后者与板的形状无关,并且仅取决于电极的温度。

我们当然检测到了铋,锑,镍,钴和铁中的横向变形,并且在某种意义上它是与铁一起发生的,那个通过在替代磁场的电流方向上旋转90°来使加热梯度的方向达到水平,以使板中的电势降均匀。

对于其他四种金属,他的方向则相反。

仅铋显示出纵向效应,并且它以各种铋形式发生,有时在某种意义上,有时在与河水流动方向相反的方向上发生。

两种效应均与电极线的性质无关,并且当前随着电场的激发而发生。

下面将描述我为进一步追求这个目的而在维尔茨堡大学物理实验室进行的研究, F. Kohlrauc教授给了我机会。