常用模具英语句子

- 格式:pdf

- 大小:156.35 KB

- 文档页数:10

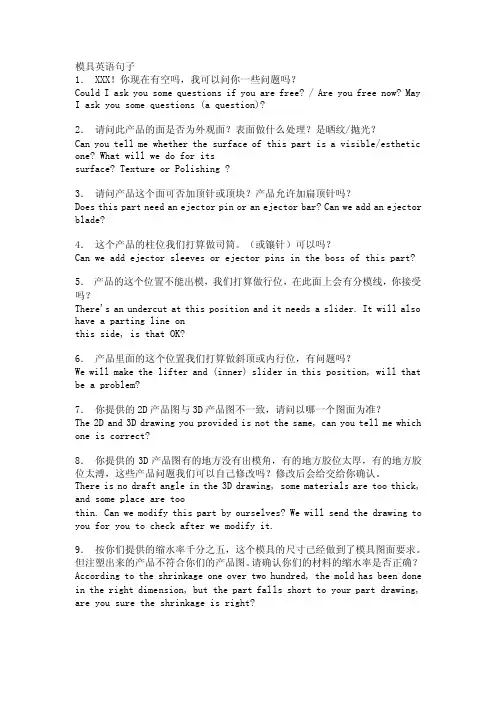

1.XXX!你现在有空吗,我可以问你一些问题吗?Could I ask you some questions if you are free? / Are you free now? May I ask you some questions (a question)?2.请问此产品的面是否为外观面?表面做什么处理?是晒纹/抛光?Can you tell me whether the surface of this part is a visible/esthetic one? What will we do for itssurface? Texture or Polishing ?3.请问产品这个面可否加顶针或顶块?产品允许加扁顶针吗?Does this part need an ejector pin or an ejector bar? Can we add an ejector blade?4.这个产品的柱位我们打算做司筒。

(或镶针)可以吗?Can we add ejector sleeves or ejector pins in the boss of this part?5.产品的这个位置不能出模,我们打算做行位,在此面上会有分模线,你接受吗??There's an undercut at this position and it needs a slider. It will also have a parting line onthis side, is that OK?6.产品里面的这个位置我们打算做斜顶或内行位,有问题吗?We will make the lifter and (inner) slider in this position, will that be a problem? 7.你提供的2D产品图与3D产品图不一致,请问以哪一个图面为准?The 2D and 3D drawing you provided is not the same, can you tell me which one is correct?8.你提供的3D产品图有的地方没有出模角,有的地方胶位太厚,有的地方胶位太溥,这些产品问题我们可以自己修改吗?修改后会给交给你确认。

项目模具英语一、引言模具(Mold),是制造工业中常用的一种工具,用于制造成型产品。

模具制造是一个复杂而精细的过程,需要涉及到多个环节和专业知识。

在国际交流与合作中,掌握模具英语是非常重要的,本文将介绍与模具相关的英语词汇、短语和常用句型,以帮助读者更好地理解和应对模具制造过程中的沟通需求。

二、模具英语词汇1. Mold:模具2. Die:模具3. Injection mold:注塑模具4. Casting mold:铸造模具5. Press mold:压铸模具6. Mold cavity:模具腔7. Core:芯子8. Ejector pin:顶针9. Runner system:流道系统10. Cooling system:冷却系统11. Mold release agent:脱模剂12. Mold design:模具设计13. Mold manufacturing:模具制造14. Mold maintenance:模具维护15. Mold repair:模具修复16. Mold trial:模具试模17. Mold flow analysis:模流分析18. Mold steel:模具钢19. Mold base:模具底板20. Mold cavity surface:模具腔面三、模具英语短语1. Mold making:模具制作2. Mold polishing:模具抛光3. Mold assembly:模具组装4. Mold testing:模具测试5. Mold modification:模具修改6. Mold maintenance and repair:模具维护和修复7. Mold design and development:模具设计与开发8. Mold manufacturing process:模具制造过程9. Mold flow simulation:模具流动模拟10. Mold release agent application:脱模剂的应用11. Mold temperature control:模具温度控制12. Mold surface treatment:模具表面处理13. Mold quality inspection:模具质量检验14. Mold life cycle:模具寿命周期15. Mold production efficiency:模具生产效率四、模具英语常用句型1. Could you please provide me with the mold design specification?(请提供模具设计规范好吗?)2. We need to modify the mold cavity to meet the product requirements.(我们需要修改模具腔以满足产品要求。

模具英语常用100 句如今的英语普及,各行各业都会用到英语,模具行业也不例外。

下面,小编为大家分享模具英语常用100 句,希望能帮助到大家!1. 4 point in HRC different to lifterscontacting or cavity steel. 斜顶和与其接触的内模或镶件在硬度上有4 度的差别(HRC)。

2. 4X size section , dimensioned toreflect the actual size. 水口及水口顶针的4 倍放大视图,按实际尺寸标注。

3. General ,safety and handling. 常规、安全和搬运要求。

4. Guided ejection recommended for mouldabove 100 tons clampcapacity, ejector pins of 1.5mm or smaller, or ejectorstroke longer than 50mm. 建设模具用于锁模力超过100 吨的注塑机,或有1.5mm 以下的顶针或顶出行程超过50mm 时,应装上顶针板导柱。

5. Guide pin cleared and vented?边钉插入模板有否顶着及加疏气空?6. Hot manifold wired to print and checked?热咀电线接位有否编号?7. Horn pin clearance hole?斜边与行位有否空间?8. Hydraulic actuated slide together withelectrical limit switch. 行位采用油压推动,配合安全电制。

9. Heaters fitted+0.002/-.000, leadstagged and connected toterminal. 热嘴装配,电线源头、尾有否安装稳固。

(+0.002/.000)。

模具加工业常用英语1. IntroductionIn the field of mold processing, having a good command of English vocabulary is essential for effective communication and collaboration with international clients and colleagues. This document ms to provide a comprehensive list of commonly used English terms and phrases in the mold processing industry. It will serve as a handy reference for professionals who encounter English-language materials and conversations in their dly work.2. Mold Processing Terminology2.1 Mold Types•Injection mold: A mold used for injection molding, where molten material is injected into a mold cavity to create a part.•Blow mold: A mold used for blow molding, where r pressure is used to shape molten material into a hollow object.•Compression mold: A mold used for compression molding, where materials are compressed into a specific shape using heat and pressure.•Extrusion mold: A mold used for extrusion molding, where materials are forced through a die to create continuous shapes.2.2 Mold Components•Cavity: The part of the mold that forms the external shape of the product.•Core: The part of the mold that forms the internal shape of the product.•Runner: The channel that allows molten material to flow into the mold cavity.•Sprue: The mn channel through which molten material enters the mold.•Ejector pin: A pin used to push the finished product out of the mold.•Cooling system: The system of channels and water lines used to cool the mold during production.2.3 Mold Processing Techniques•Milling: The process of removing material from a workpiece using a rotary cutter.•Turning: The process of shaping a workpiece on a lathe by rotating it agnst a cutting tool.•Grinding: The process of removing material from a workpiece using an abrasive wheel.•EDM (Electrical Discharge Machining): A process in which material is removed from a workpiece by a series of rapidly recurring electrical discharges.•CNC (Computer Numerical Control) machining: A process in which computer-controlled machines are used to perform various manufacturing tasks.3. Common Phrases and Expressions•Mold design: The process of creating a blueprint or drawing for a mold.•Mold production: The manufacturing process of producing molds.•Mold mntenance: The routine care and repr of molds to ensure their longevity.•Mold inspection: The process of examining a mold for defects or damage.•Mold testing: The process of using a mold to create sample parts for evaluation.•Mold repr: The process of fixing or restoring a damaged mold.•Mold polishing: The act of smoothing and shining the surface of a mold.•Mold cavity filling: The process of injecting molten material into the mold cavity.•Mold release agent: A substance applied to the mold surface to facilitate the release of the finished product.4. ConclusionThis document has provided a comprehensive list of commonly used English terms and phrases in the mold processing industry. By familiarizing yourself with these terms, you will be better equipped to communicate and collaborate effectively in an English-speakingprofessional environment. Remember to refer back to this document whenever you encounter English-language materials or conversations related to mold processing.。

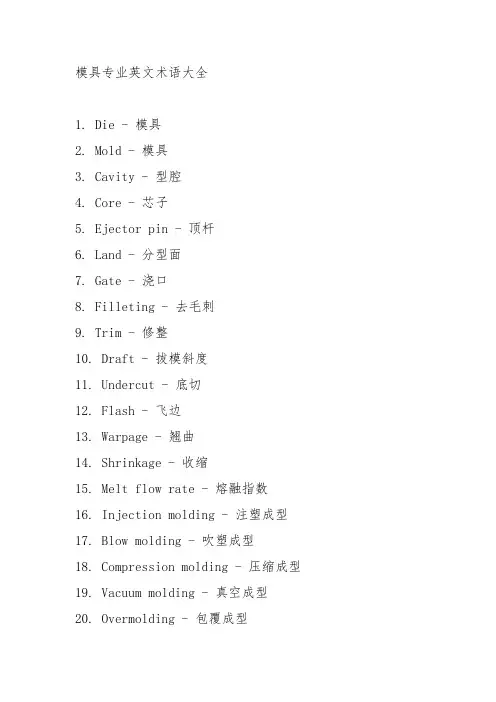

模具专业英文术语大全1. Die - 模具2. Mold - 模具3. Cavity - 型腔4. Core - 芯子5. Ejector pin - 顶杆6. Land - 分型面7. Gate - 浇口8. Filleting - 去毛刺9. Trim - 修整10. Draft - 拔模斜度11. Undercut - 底切12. Flash - 飞边13. Warpage - 翘曲14. Shrinkage - 收缩15. Melt flow rate - 熔融指数16. Injection molding - 注塑成型17. Blow molding - 吹塑成型18. Compression molding - 压缩成型19. Vacuum molding - 真空成型20. Overmolding - 包覆成型21. Co-injection molding - 双色注塑成型22. Gas assist injection molding - 气体辅助注塑成型23. Rotational molding - 旋转成型24. Injection compression molding - 注射压缩成型25. Injection blow molding - 注射吹塑成型26. Injection stretch blow molding - 注射拉伸吹塑成型27. Injection transfer molding - 注射传递成型28. Injection foam molding - 注射发泡成型29. Injection gas assisted rotational molding - 注射气体辅助旋转成型30. Injection compression blow molding - 注射压缩吹塑成型31. Injection stretch blow molding - 注射拉伸吹塑成型32. Injection transfer blow molding - 注射传递吹塑成型33. Injection foam blow molding - 注射发泡吹塑成型34. Injection gas assisted transfer molding - 注射气体辅助传递成型35. Injection compression foam molding - 注射压缩发泡成型36. Injection stretch foam molding - 注射拉伸发泡成型37. Injection transfer foam molding - 注射传递发泡成型38. Injection gas assisted foam blow molding - 注射气体辅助发泡吹塑成型39. Injection compression foam blow molding - 注射压缩发泡吹塑成型40. Injection stretch foam blow molding - 注射拉伸发泡吹塑成型41. Injection transfer foam blow molding - 注射传递发泡吹塑成型42. Injection gas assisted compression molding - 注射气体辅助压缩成型43. Injection gas assisted stretch blow molding - 注射气体辅助拉伸吹塑成型44. Injection gas assisted transfer blow molding - 注射气体辅助传递吹塑成型45. Injection gas assisted foam compression molding - 注射气体辅助发泡压缩成型46. Injection gas assisted foam stretch blow molding - 注射气体辅助发泡拉伸吹塑成型47. Injection gas assisted foam transfer blow molding - 注射气体辅助发泡传递吹塑成型48. Injection gas assisted compression foam molding - 注射气体辅助压缩发泡成型49. Injection gas assisted stretch foam blow molding - 注射气体辅助拉伸发泡吹塑成型50. Injection gas assisted transfer foam blow molding - 注射气体辅助传递发泡吹塑成型51. Mold temperature control system - 模具温度控制系统52. Coolant system - 冷却系统53. Ejector system - 顶出系统54. Feed system - 喂料系统55. Packaging machine - 包装机56. Automated guided vehicle (AGV) - 自动导引车(AGV)57. Robotic arm - 机械臂58. Computer numerical control (CNC) machine - 计算机数控(CNC)机床59. Plastics injection machine - 塑料注塑机60. Plastics extruder - 塑料挤出机61. Plastics blow molding machine - 塑料吹塑机62. Plastics injection compression molding machine -塑料注塑压缩成型机63. Plastics injection stretch blow molding machine - 塑料注塑拉伸吹塑成型机64. Plastics injection transfer molding machine - 塑料注塑传递成型机65. Plastics injection foam molding machine - 塑料注塑发泡成型机66. Plastics injection gas assisted rotational molding machine - 塑料注塑气体辅助旋转成型机67. Plastics injection compression foam molding machine - 塑料注塑压缩发泡成型机68. Plastics injection stretch foam molding machine - 塑料注塑拉伸发泡成型机69. Plastics injection transfer foam molding machine - 塑料注塑传递发泡成型机70. Plastics injection gas assisted foam blow molding machine - 塑料注塑气体辅助发泡吹塑成型机71. Plastics injection compression foam blow molding machine - 塑料注塑压缩发泡吹塑成型机72. Plastics injection stretch foam blow molding machine - 塑料注塑拉伸发泡吹塑成型机73. Plastics injection transfer foam blow moldingmachine - 塑料注塑传递发泡吹塑成型机74. Plastics injection molding machine with movable platen - 带活动模板的塑料注塑机75. Plastics injection molding machine with fixed platen - 带固定模板的塑料注塑机76. Plastics injection molding machine with hot runner system - 带热流道系统的塑料注塑机77. Plastics injection molding machine with cold runner system - 带冷流道系统的塑料注塑机78. Plastics injection molding machine with multi-cavity design - 带多腔设计的塑料注塑机79. Plastics injection molding machine with clamping force control - 带夹紧力控制的塑料注塑机80. Plastics injection molding machine with cycle time reduction - 带循环时间缩短的塑料注塑机81. Plastics injection molding machine with energy saving features - 带节能功能的塑料注塑机82. Plastics injection molding machine with high precision control - 带高精度控制的塑料注塑机83. Plastics injection molding machine with automatic tool changing system - 带自动换模系统的塑料注塑机84. Plastics injection molding machine with roboticautomation - 带机器人自动化的塑料注塑机85. Plastics injection molding machine with quality control system - 带质量管理系统的塑料注塑机86. Plastics injection molding machine with process monitoring system - 带工艺监控系统的塑料注塑机87. Plastics injection molding machine with maintenance reminder system - 带维护提醒系统的塑料注塑机88. Plastics injection molding machine with data logging and analysis - 带数据记录和分析的塑料注塑机89. Plastics injection molding machine with remote control and monitoring - 带远程控制和监控的塑料注塑机90. Plastics injection molding machine with safety features - 带安全功能的塑料注塑机91. Plastics injection molding machine with operator interface - 带操作员界面的塑料注塑机92. Plastics injection molding machine with easy cleaning system - 带易清洁系统的塑料注塑机93. Plastics injection molding machine with quick change tooling - 带快速换模装置的塑料注塑机94. Plastics injection molding machine with low noiseoperation - 带低噪音运行的塑料注塑机95. Plastics injection molding machine with high throughput capacity - 带高产量能力的塑料注塑机96. Plastics injection molding machine with energy recovery system - 带能量回收系统的塑料注塑机97. Plastics injection molding machine with environmental protection features - 带环保功能的塑料注塑机98. Plastics injection molding machine with advanced materials compatibility - 带先进材料兼容性的塑料注塑机99. Plastics injection molding machine with customizable options - 可定制选项的塑料注塑机100. Plastics injection molding machine with reliable performance and durability - 具有可靠性能和耐用性的塑料注塑机。

模具英语句子1. XXX!你现在有空吗,我可以问你一些问题吗?Could I ask you some questions if you are free? / Are you free now? May I ask you some questions (a question)?2.请问此产品的面是否为外观面?表面做什么处理?是晒纹/抛光?Can you tell me whether the surface of this part is a visible/esthetic one? What will we do for itssurface? Texture or Polishing ?3.请问产品这个面可否加顶针或顶块?产品允许加扁顶针吗?Does this part need an ejector pin or an ejector bar? Can we add an ejector blade?4.这个产品的柱位我们打算做司筒。

(或镶针)可以吗?Can we add ejector sleeves or ejector pins in the boss of this part?5.产品的这个位置不能出模,我们打算做行位,在此面上会有分模线,你接受吗?There's an undercut at this position and it needs a slider. It will also have a parting line onthis side, is that OK?6.产品里面的这个位置我们打算做斜顶或内行位,有问题吗?We will make the lifter and (inner) slider in this position, will that be a problem?7.你提供的2D产品图与3D产品图不一致,请问以哪一个图面为准?The 2D and 3D drawing you provided is not the same, can you tell me which one is correct?8.你提供的3D产品图有的地方没有出模角,有的地方胶位太厚,有的地方胶位太溥,这些产品问题我们可以自己修改吗?修改后会给交给你确认。

模具英语大全-51. Injection molding (注塑成型)Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. The molten material, usually a thermoplastic or thermosetting polymer, solidifies and takes the shape of the mold. Injection molding is widely used in various industries because it allows for the production of complex and precise parts with high efficiency.2. Ejector pins (顶针)Ejector pins are cylindrical pins used in injection molding to eject the finished parts from the mold. They are placed in the ejector plate and push the molded parts out of the mold cavity. Ejector pins can be made of various materials, such as hardened steel or bronze, and come indifferent shapes and sizes depending on the requirements of the molding process.3. Runner system (流道系统)The runner system in injection molding refers to the channels through which the molten material flows from the injection machine to the mold cavity. It includes the sprue, runners, and gates. The sprue is the mn channel that connects the injection machine nozzle to the mold cavity. The runners distribute the molten material to different cavities, and the gates control the flow of the material into the cavities. The design of the runner system can affect the filling pattern, cooling, and overall efficiency of the injection molding process.4. Venting (排气)Venting is an important aspect of injection molding that involves the removal of trapped r or gases from the mold cavity during the molding process. Insufficient venting can lead to defects in the parts, such asvoids, burns, or surface imperfections. Proper venting is necessary to ensure the success of the molding process and the quality of the finished parts. Venting can be achieved through the design of the mold, adding venting channels, or using venting devices.5. Cavity pressure (腔压)Cavity pressure refers to the internal pressure exerted on the mold cavity during the injection molding process. It is an important parameter that affects the quality and consistency of the molded parts. Monitoring and controlling the cavity pressure can help detect and prevent defects, such as short shots, flash, or warpage. Cavity pressure sensors are often used in injection molding machines to provide real-time feedback and ensure accurate and stable production.6. Overmolding (双色注塑)Overmolding is a molding process that involves molding one material over another to create a single, integrated part. It is often usedto add functional or aesthetic features to a base part. In the overmolding process, the base part is first molded, and then a second material is injected over it to create the final part. The second material can be of a different color, texture, or material properties. Overmolding is commonly used in the production of handles, grips, and soft-touch surfaces.7. Mold temperature control (模温控制)Mold temperature control is an important factor in the injection molding process as it affects the quality and properties of the molded parts. Proper temperature control is necessary to achieve uniform filling, cooling, and solidification of the molten material. It helps prevent defects, such as sink marks, warping, and dimensional variations. Mold temperature can be controlled using various methods, such as cooling channels, water or oil circulation, or electric heaters.8. Parting line (分型线)The parting line in injection molding refers to the line where the two halves of the mold meet and separate to release the molded part. It is also called the mold split line. The location of the parting line is an important consideration in mold design as it can affect the appearance and functionality of the part. Care must be taken to minimize the visibility of the parting line and ensure a smooth and consistent surface finish.9. Mold mntenance (模具维护)Mold mntenance is a critical aspect of the injection molding process to ensure the longevity and performance of the molds. Regular mntenance and cleaning are necessary to prevent damage, wear, or contamination that can affect the quality of the molded parts. Mold mntenance includes tasks such as cleaning, lubricating, inspecting, andrepring the molds. It also involves the proper storage and handling of the molds when not in use.10. Mold release agent (脱模剂)A mold release agent is a substance applied to the mold surface to prevent the adhesion of the molded part to the mold cavity. It helps facilitate the easy release of the part after solidification. Mold release agents can be in the form of a spray, liquid, or paste and are typically made of silicone, wax, or other lubricating materials. The selection of the appropriate mold release agent depends on factors such as the type of material being molded and the desired surface finish.以上是模具英语大全的第五部分,涵盖了注塑成型、顶针、流道系统、排气、腔压、双色注塑、模温控制、分型线、模具维护和脱模剂等方面的内容。

模具专业术语英文1. “Core Cavity(型芯型腔),嘿,就像房子的里里外外。

比如说做个塑料小盒子的模具,Core Cavity就决定了盒子的形状,是凹进去还是凸出来的部分,要是搞混了,哎呀,那做出来的盒子可就奇形怪状啦。

”2. “Gating System(浇口系统),这就好比是给模具‘输血’的通道呢。

想象一下你在浇花,那个浇花的水管就像是Gating System。

如果这个通道设计不好,就像水管堵住或者水流太大太小,那模具可就‘营养不良’或者‘撑坏’啦。

”3. “Ejection Mecha nism(顶出机构)。

哟,这可是模具里的‘小助手’呢。

就像从蛋糕模具里把蛋糕取出来得有个东西帮忙顶一下,在模具里,Ejection Mechanism就是干这个的。

要是没有它呀,那些成型的零件就只能卡在里面干着急喽。

”4. “Mold Base(模架),它可是模具的‘骨架’啊。

就像人没了骨架就瘫了一样,模具没了Mold Base那可就散架了。

比如说做个大的汽车零件模具,Mold Base要是不结实,整个模具能行吗?肯定不行呀。

”5. “Runner(流道),这就像小河流一样。

塑料或者金属材料就像河水在这个‘小河’里流动。

要是Runner设计得弯弯曲曲的,就像河流里到处是石头和弯角,那材料流动起来磕磕绊绊的,能做出好的模具产品吗?我看悬。

”6. “Draft Angle(脱模斜度),嘿,这个很重要呢。

这就像是给模具里的零件一个小斜坡,方便它们‘走出来’。

你想想,如果没有这个小斜坡,就像把东西硬塞进一个严丝合缝的盒子里,再想拿出来可就难喽。

”7. “Cooling Channel(冷却通道),它就像模具的‘空调’。

比如说你在夏天干活,没有空调热得受不了。

模具在工作的时候,如果没有Cooling Channel来降温,那热得可就乱套了,可能会影响模具的精度和寿命呢。

”8. “Parting Line(分型线),这就像是模具的‘分界线’。

模具英语句子1. XXX!你现在有空吗,我可以问你一些问题吗?Could I ask you some questions if you are free? / Are you free now? May I ask you some questions (a question)?2.请问此产品的面是否为外观面?表面做什么处理?是晒纹/抛光?Can you tell me whether the surface of this part is a visible/esthetic one? What will we do for itssurface? Texture or Polishing ?3.请问产品这个面可否加顶针或顶块?产品允许加扁顶针吗?Does this part need an ejector pin or an ejector bar? Can we add an ejector blade?4.这个产品的柱位我们打算做司筒。

(或镶针)可以吗?Can we add ejector sleeves or ejector pins in the boss of this part?5.产品的这个位置不能出模,我们打算做行位,在此面上会有分模线,你接受吗?There's an undercut at this position and it needs a slider. It will also have a parting line onthis side, is that OK?6.产品里面的这个位置我们打算做斜顶或内行位,有问题吗?We will make the lifter and (inner) slider in this position, will that be a problem?7.你提供的2D产品图与3D产品图不一致,请问以哪一个图面为准?The 2D and 3D drawing you provided is not the same, can you tell me which one is correct?8.你提供的3D产品图有的地方没有出模角,有的地方胶位太厚,有的地方胶位太溥,这些产品问题我们可以自己修改吗?修改后会给交给你确认。

常用朮語中英文對照short shot缺膠break斷裂flash披鋒gap too large after assembly裝配間隙大dimension NG尺寸NGfailed to assembked不能裝配no conduct due to broken wire銅絲線斷,不導電力度不良defective forcedistortion變形poor plating電鍍不良damage破損returned by production line生產線退貨wire come off端子松脫printing defect tapping defect打印不良,滑絲hurt批傷Crack爆裂bruise碰傷broken snap斷扣Rust生銹Reworked by supplier供應商返工Hurt on wire線披傷Holes有針孔Scratch划傷Foreign material異物Dust灰塵Cable come off線脫落Press hurt壓傷Which caused the abnormal voice from assembly造成裝配有異音Broken pins扞腳斷Lead wire導線Motor馬達It cannot rotate smoothly轉動不暢Loose gear齒輪松Lead wire導線Loose tube and bad insertion wire線頭熱熔膠管脫落Panel按健表板Key defect按健不良Fold皺折Structure different with sample結构與樣板不符Broken tab柱子斷Lead wire assy導線組Adaptor火牛Black specks黑點Hole blocked up塞孔Crack 破裂Mixed color料花Spec標准Actual實測Spring彈弓Non homogeneouse colour混色Hole larger孔徑大There are oil on the part surface部品表面有油Gear dent齒輪位碰傷Thickness NG厚度NGE-PIN too high頂針位高Higher gate水口位高Colour different異色Contamination 雜物Grease 油污Cosmetic defects熔膠不良Rusting 銹斑Resilience NG彈力NGSmudge 污跡Without chamfer未倒角Wire is broken線斷White plastie of terminal peal off白膠脫落Wire is broken線破損Broken snap扣位斷Loose connector線頭松脫焊線脫落The welded wire looseThe boss is shorter柱子低Oddment 碎屑Rand pick 選別游標卡尺/Vemier Caliper ( VC)電子卡尺/Digital Caliper( DC)三座標測量儀(三次元)/Coordinate Measuring Maching(CMM) 電子千分尺/Digital Micrometer( DM)游標千分尺/Vernier Micrometer(VM)針規/Pin Gauge( PG)投影儀/Projector( P)電子高度尺/Digital Height Gauge( DH)游標高度尺/ Vemier Height Gauge( VH)塞尺/Thickness Gauge( TG)直尺/Ruler( R)百分表/Dial Indicator( DI)涂層厚度計/Coating Thickness Gauge( CT)塊規/Block Gauge( BG)角度規(尺)/Goniometer/Bevel Protracter( G)直角尺/Right Angle Ruler/Spuare( AR)溫適度計表/Hygrothermograph( H)平台板/Flat/Plate( F)色差儀/Chromometer( C)鈕具表/Torfque Gauge( TE)推拉力計/Pull-Push Gauge( PP)數字鈕鉅儀/Digital Torfque Gauge( DT)電子稱/ Digital Scale( DS)法碼/Weights( WT)天平/Balance( BG)照度計/Light Meter( LM)萬用表/Multimeter(M)螺紋規/Thread Gauge( TD)表面粗糙度樣塊/Roughness Block( RB)功力表/Power Meter( PM)硬度計/Sclerometer( S)秒表/Stop Watch( SW)刀口尺/Knife Gauge( KG)放大鏡/Amlifer( A)水平儀/Level Balance ( LB)內徑千分尺/Internal Micrometer( IM)卷尺/Roll Meter( RM)耐壓測試儀器/Pressure Meter( PM)千分尺/Micrometer( M)內側千分尺/Insiele Micrometer( IM)深度千分尺/Depth Micrometer( DM)其他要求(1) presentation of electrodes (2)dimension report (3)placket texture approval 1。

项目模具英语一、背景介绍模具行业是制造业的重要组成部分,涉及到各个领域的生产和加工。

为了更好地与国际市场接轨,提高模具行业的竞争力,掌握一定的模具英语是必不可少的。

本文将为您介绍模具英语的基本知识和常用表达,以便在项目中与国际客户和合作伙伴进行有效的沟通。

二、模具英语基础知识1. Mold/mould:模具2. Injection molding:注塑3. Die casting:压铸4. CNC machining:数控加工5. Mold cavity:模腔6. Mold core:模芯7. Mold base:模座8. Ejector pins:顶针9. Cooling system:冷却系统10. Mold release agent:脱模剂三、模具英语常用表达1. Could you provide us with the mold specifications?(请提供模具规格。

)2. We need a quotation for the mold manufacturing.(我们需要模具制造的报价。

)3. How long does it take to manufacture the mold?(制造模具需要多长时间?)4. What are the payment terms for the mold?(模具的付款方式是什么?)5. We require a mold with high precision.(我们需要高精度的模具。

)6. The mold design needs to be approved by our engineers.(模具设计需要经过我们的工程师批准。

)7. Could you provide us with the mold testing report?(请提供模具测试报告。

)8. We need to make some modifications to the mold.(我们需要对模具进行一些修改。

各式模具分类用语中英文对照(补充) loose detail mold 活零件模具chill mold 冷硬用铸模loose mold 活动式模具clod hobbing 冷挤压制模louvering die 百叶窗冲切模composite dies 复合模具manifold die 分歧管模具counter punch 反凸模modular mold 组合式模具double stack mold 双层模具multi-cavity mold 多模穴模具electroformed mold 电铸成形模multi-gate mold 复式浇口模具expander die 扩径模offswt bending die 双折冷弯模具extrusion die 挤出模palletizing die 叠层模family mold 反套制品模具plaster mold 石膏模blank through dies 漏件式落料模porous mold 通气性模具duplicated cavity plate 复板模positive mold 全压式模具fantail die 扇尾形模具pressure die 压紧模fishtail die 鱼尾形模具profile die 轮廓模flash mold 溢料式模具progressive die 顺序模gypsum mold 石膏铸模protable mold 手提式模具hot-runner mold 热流道模具prototype mold 雏形试验模具ingot mold 钢锭模punching die 落料模lancing die 切口模raising(embossing) 压花起伏成形re-entrant mold 倒角式模具sectional die 拼合模runless injection mold 无流道冷料模具sectional die 对合模具segment mold 组合模semi-positive mold 半全压式模具shaper 定型模套single cavity mold 单腔模具solid forging die 整体锻模split forging die 拼合锻模split mold 双并式模具sprueless mold 无注道残料模具squeezing die 挤压模stretch form die 拉伸成形模sweeping mold 平刮铸模swing die 振动模具three plates mold 三片式模具trimming die 切边模unit mold 单元式模具universal mold 通用模具unscrewing mold 退扣式模具cassette 卡座color display 彩色显示器command 指令communication 通信compact 精简小型computer 电脑copy 复制cursor 游标curve modeling 曲面模拟database 资料库design 设计digitizing 数位化disk 磁碟dot 点eyelet 眼孔floppy 磁碟片format 格式化graphic 圆解hardware 硬体honeycomb 蜂巢interface 界面know how 秘诀laser printer 雷射印表机lay out 布置memory 记忆memory swap 交换记忆microprocessor 微处理器modeling 造型module 模组monitor 萤幕mouse 滑鼠need 需求network 网路new version 新版on line 上线中option 选择PC 个人电脑Plotter 绘图机Program 程式scanning 扫描simulation 模拟software 软体solid model 实体模型system 系统tape 磁带terminal 终端机texture 构造trim 修边word processor 文书处理器各种冲模加工关连用语barreling 滚光加工belling 压凸加工bending 弯曲加工blanking 下料加工bulging 撑压加工burring 冲缘加工cam die bending 凸轮弯曲加工coining 压印加工compressing 压缩加工compression bending 压弯曲加工crowning 凸面加工curl bending 卷边弯曲加工curling 卷曲加工cutting 切削加工dinking 切断蕊骨double shearing 叠板裁断drawing 引伸加工drawing with ironing 抽引光滑加工embossing 浮花压制加工extrusion 挤制加工filing 锉削加工fine blanking 精密下料加工finish blanking 光制下料加工finishing 精整加工flanging 凸缘加工folding 折边弯曲加工folding 摺叠加工forming 成形加工impact extrusion 冲击挤压加工indenting 压痕加工ironing 引缩加工knurling 滚花lock seaming 固定接合louvering 百叶窗板加工marking 刻印加工necking 颈缩加工notching 冲口加工parting 分断加工piercing 冲孔加工progressive bending 连续弯曲加工progressive blanking 连续下料加工progressive drawing 连续引伸加工progressive forming 连续成形加工reaming 铰孔加工restriking 二次精冲加工riveting 铆接加工roll bending 滚筒弯曲加工roll finishing 滚压加工rolling 压延加工roughing 粗加工scrapless machining 无废料加工seaming 折弯重叠加工shaving 缺口修整加工shearing 切断加工sizing 精压加工slitting 割缝加工stamping 锻压加工swaging 挤锻压加工trimming 整缘加工upsetting 锻粗加工wiring 抽线加工冲压机械及周边关连用语back shaft 支撑轴blank determination 胚料展开bottom slide press 下传动式压力机board drop hammer 板落锤brake 煞车buckle 剥砂面charging hopper 加料漏斗clearance 间隙closed-die forging 合模锻造clump 夹紧clutch 离合器clutch brake 离合器制动器clutch boss 离合器轮壳clutch lining 离合器覆盖coil car 带卷升降运输机coil cradle 卷材进料装置coil reel stand 钢材卷料架column 圆柱connection screw 连杆调节螺钉core compound 砂心黏结剂counter blow hammer 对击锻锤cradle 送料架crank 曲柄轴crankless 无曲柄式cross crank 横向曲轴cushion 缓冲depression 外缩凹孔dial feed 分度送料die approach 模口角度die assembly 合模die cushion 模具缓冲垫die height 冲压闭合高度die life 模具寿命die opening 母模逃孔die spotting press 调整冲模用压力机double crank press 双曲柄轴冲床edging 边锻伸embedded core 加装砂心feed length 送料长度feed level 送料高度filling core 埋入砂心filling in 填砂film play 液面花纹fine blanking press 精密下料冲床forging roll 辊锻机finishing slag 炼後熔渣fly wheel 飞轮fly wheel brake 飞轮制动器foot press 脚踏冲床formboard 进模口板frame 床身机架friction 摩擦friction brake 摩擦煞车gap shear 凹口剪床gear 齿轮gib 滑块引导部gripper 夹具gripper feed 夹持进料gripper feeder 夹紧传送装置hammer 槌机hand press 手动冲床hand rack pinion press 手动齿轮齿条式冲床hand screw press 手动螺旋式冲床hopper feed 料斗送料idle stage 空站inching 微调尺寸isothermal forging 恒温锻造key clutch 键槽离合器knockout 脱模装置knuckle mechanic 转向机构land 模具直线刀面部level 水平loader 供料器unloader 卸料机loop controller 闭回路控制器lower die 下模micro inching device 微寸动装置microinching equipment 微动装置motor 马达moving bolster 活动工作台notching press 冲缺口压力机opening 排料逃孔overload protection device 防超载装置pinch roll 导正滚轮pinion 小齿轮pitch 节距pressfit 压入progressive 连续送料pusher feed 推杆式送料pusher feeder 料片押片装置quick die change system 快速换模系统regrinding 再次研磨releasing 松释动作reversed blanking 反转下料robot 机器人roll forming machine 辊轧成形roll forming machine 辊轧成形机roll release 脱辊roller feed 辊式送料roller leveler 辊式矫直机rotary bender 卷弯成形机safety guard 安全保护装置scrap cutter 废料切刀scrap press 废料冲床seamless forging 无缝锻造separate 分离shave 崩砂shear angle 剪角sheet loader 薄板装料机shot 单行程工作shrinkage fit 闭合高度sieve mesh 筛孔sintering of sand 铸砂烧贴slide balancer 滑动平衡器slug hole 逃料孔spin forming machine 旋压成形机spotting 合模stack feeder 堆叠拨送料机stickness 黏模性straight side frame 冲床侧板stretcher leveler 拉伸矫直机strip feeder 料材送料装置stripping pressure 弹出压力stroke 冲程take out device 取料装置toggle press 肘杆式压力机transfer 传送transfer feed 连续自动送料装置two speed clutch 双速离合器uncoiler 闭卷送料机unloader 卸载机vibration feeder 振动送料机wiring press 嵌线卷边机线切割放电加工关连用语abnormal glow 不规则辉光放电arc discharge 电弧放电belt 皮带centreless 无心chrome bronze 铭铜clearance angle 後角corner shear drop 直角压陷deflection 挠曲度discharge energy 放电能量dressing 修整dwell 保压flange 凸缘gap 间隙graphite 石墨graphite contraction allowance 电极缩小余量graphite holder 电极夹座hair crack 发裂horn 电极臂jump 跳刀magnetic base 磁性座master graphite 标准电极pipe graphite 管状电极pulse 脉冲rib working 肋部加工roller electrode 滚轮式电极rotary surface 旋转面shank 柄部sharp edge 锐角部tough bronze 韧铜traverse 摇臂waviness 波形起伏work 工件working allowance 加工余量working dischard 加工废料锻铸造关连用语accretion 炉瘤acid converter 酸性转炉acid lining cupola 酸性熔铁炉acid open-hearth furnace 酸性平炉aerator 松砂机air set mold 常温自硬铸模airless blasting cleaning 离心喷光all core molding 集合式铸模all round die holder 通用模座assembly mark 铸造合模记号back pouring 补浇注backing sand 背砂base bullion 粗金属锭base permeability 原砂透气度belling 压凸billet 坏料bleed 漏铸blocker 预锻模膛blocking 粗胚锻件blow hole 铸件气孔board drop hammer 板落锤bottom pour mold 底浇bottom pouring 底注boxless mold 脱箱砂模break-off core 缩颈砂心brick molding 砌箱造模法buckle 剥砂面camber 错箱cast blade 铸造叶片casting flange 铸造凸缘casting on flat 水平铸造chamotte sand 烧磨砂charging hopper 加料漏斗cleaning of casting 铸件清理closed-die forging 合模锻造core compound 砂心黏结剂core template 砂心模板core vent 砂蕊排气孔corner gate 压边浇口counter blow hammer 对击锻造counter lock 止口镶嵌方式depression 外缩凹孔die approach 模口角度draw out 锻造拔长draw plate 起模板draw spike 起模长针dummying 预锻embedded core 加装砂心erosion 冲砂fettling 铸件清理filling core 埋入砂心filling in 填砂film play 液面花纹finishing slag 炼後熔渣flash gutter 锻模飞边槽flask molding 砂箱造模forging roll 辊锻机formboard 进模口板gutter 锻模飞边槽hammer man 锻工heading machine 顶镦机impacter 卧式锻造机inblock cast 整体铸造ingot 铸锭ingot blank 铸坯inlay casting 镶铸法investment casting 失模铸造isothermal forging 恒温锻造loose piece 木模活块molding pit 铸模地坑pouring process 浇注法recasting 重铸roll forging 轧锻rolled surface 轧制表面rough sand 粗砂roughing forge 粗锻sand crushing 塌箱seamless forging 无缝锻造separate 分离shave 崩砂shrinkage fit 收缩配合shut height 闭合高度sieve mesh 筛孔sintering of sand 铸砂烧贴slag 熔渣slag inclusion 夹渣stickness 黏模性strip layout 带状胚料排样法tap casting 顶注top gate 顶注浇口unworked casting 不加工铸件upender 翻转装置upending 顶锻uphill casting 底铸white cast iron 白口铸件模具加工方法barrel 滚筒(加工)bending 波纹加工broaching 拉刀切削centering 定中心cutting 切削cylindrical lathe cutting 外圆车削electric discharge machine 放电加工electrolytic grinding 电解研磨embossing 压花加工facing 面车削filing 锉刀修润hand finishing 手工修润hemming 卷边加工hobbing 滚齿加工joggling 摇动加工lapping 抛光/研磨修润laser beam machining 雷射加工lathe cutting 车床车削planning 刨削加工polishing 抛亮光reaming 铰孔修润rough machining 粗切削rounding 圆形加工sawing 锯削scaling 清除钢碇缺陷shaping 成形加工skiving 表面研磨slotting 切缝切削taper turning 锥度车削thread cutting 螺纹切削ultrasonic machining 超音波加工up cut milling 逆铣加工学理实验与试验用语air permeability test 透气性试验austenitic steel 沃斯田铁钢Brinell hardness 布耐内尔硬度Brinell hardness test 布氏硬度试验Charpy impact test 夏比冲击试验conical cup test 圆锥杯突试验cup flow test 杯模式流动度试验dart drop impact test 落锤冲击试验Elmendorf test 埃罗门多撕裂强度试验environmental stress cracking test境应力龟裂试验Ericessen test 埃留伸薄板拉伸试验falling ball impact test 落球冲击试验fatigue test 疲劳试验ferrite 纯铁体Gantt chart 甘特图heat cycle test 热循环试验histogram 柱状图hot bend test 热弯试验Izod impact test 埃左德冲击试验loop tenacity 环结强度martens heat distortion temperature test 马顿斯耐热试验Martensite 马氏体Mullen bursting strength tester密廉式破裂强度试验机Nol ring test 诺尔环试验normal distribution 常态分配ozone resistance test 抗臭氧试验Pareto diagram 柏拉图peeling test 剥离试验pinhole test 针孔试验机rattler test 磨耗试验Rockweel hardness test 洛氏硬度试验Rockweel hardness 洛氏威尔硬度Rolinx process 罗林克斯射出压缩成形法Rossi-peakes flow test 罗西皮克斯流动试验sampling inspection 抽样检查scratch hardness 抗刮硬度shore hardness 萧氏硬度spiral flow test 螺旋流动试验surface abrasion test 表面磨耗试验Taber Abraser 泰伯磨耗试验机tensile impact test 拉伸冲击试验tensile strength 抗拉强度tension test 张力试验thermal shock test 冷热剧变试验torsion test 扭曲试验Ubbelohde viscometer 乌别洛德黏度计Vicat indentation test 维卡针压陷试验Vickers hardness test 维氏硬度试验warpage test 翘曲试验weatherometer 人工老化试验机Weissenberg effect 威森伯格回转效应砂轮用语abrasive 砂轮Al2O3 氧化铝balance 平衡bond 结合borazon 氧化硼立方晶buffing wheel 抛光布轮diamond 钻石dresser 砂轮整修机dressing 修整endless grinding belt 循环式研磨带finishing allowance 加工余量grain 磨粒grinding disc 研磨盘mesh 网筛目parameter 参数resinoid grinding wheel 半树脂型砂轮slitting 切缝量vitrified 陶瓷的wheel 旋转机械设计及周边其他用语assembly drawing 装配图auto tool change cycle 自动换刀时间周期beam 横梁bending moment 弯矩bending stress 弯曲应力bottoming 底靠buckling 纵弯曲chamfering 去角斜切channel 凹槽chattering 颤动check point 查核点chip 切屑chip conveyor 排屑输送机coefficient of friction 摩擦系数compact 小型的cooling pipe 冷却管coupon 试样胚deflection 挠曲量distortion 扭曲变形draft taper 拔模锥度draw out 拉拔fit tolerance 配合公差flexible rigidity 弯曲刚性gas vent 气孔hatching 剖面线heater cooler 加热器冷却装置hook cavity 钩穴inching 寸动lug 凸缘maintenance 维修保固metallurgy 冶金学notch effect 切口效果out of roughness 真圆度performance 动作性能pit 坑plane strain 倒角应力plug mill 蕊棒轧管机repeated load 重覆载荷sand paper 砂纸shift 偏移shrink fit 热压配合shrinkage hole 缩孔sinking 凹陷sketch 草图spalling 剥落straightness 直度submarine 深陷式surface roughness 表面粗度tapping 攻螺丝thermocouple 热电耦torsion load 扭转载荷toughness 韧性tracing 描图under cut 凹割业务与贸易关连用语accept order 接受订货account 帐户after service 售后服务amendment 修正annual sales 年销售额at sight 见票即付balance 余额bank draft 汇票bargain goods 廉价品batch 批次bid 出价bid sales 投标买卖bill of landing 提单bills receivable 应收票据brand 品牌bulk cargo 散装货business transaction 商业交易buyer 买方carbon copy 打字副本cargo collection 揽货carton 纸箱cash in advance 预付现金catalogue 型录cheque 支票CLF 运费保险费在内价格claim 索赔clearance goods 清仓品commision 佣金commission 批发商complain 抱怨container 货柜correspondence bank 往来银行cost 成本cost and freight; C&F 含运费价格custom broker 报关行customer 客户D/A 承兑交单D/P 付款交单deferred payment 分期付款deferred shipment 分期装运delivery on spot 当场交货delivery time 交期delivery order 交货单discount 折扣discount on draft 贴现documentary draft 跟单汇票down payment 订金enclosure 附件endorsement 背书exhibition 展览会export 出口factory visit 工厂参观favourable price 合宜价格foreign exchange 外汇free on board 船上交货价idea price 希望价格import 进口Japanese Industrial 日本工业规格invoice 发票L/C 信用状margin 利润market 市价net weight 净重no payment 拒绝付款odd item 零头offer 报价open account 交互计算order 订单over looked 疏漏packing 包装pamphlet 小册子partial shipment 分批装船patent 专利paying price 合算价格payment method 付款方式port of destination 目地港port of trans-shipment 转口港price 价格price descending 减价price rising 涨价procurement 采办prompt delivery 即时交货purchase 购入purchasing agent 采购代理商quotation 报价单rebate 回扣reference 查询remittance 汇款repeat order 追加订货request letter 请求函rumor 风评second hand goods 二手货shipper 货主shipping 装船shipping mark 麦头shipment 出货sold out 卖完sole agent 总代理商special discount 特别折扣specification 规格sample order 指样订货standing 信用情形storage charge 仓租subcontract 外包subject to final confirmation 有待确认之报价supplier 供应商T/T 电汇tie-in sale 搭售trade fair 商展会trans-shipment 转运transferred 已转运wharf 码头A 3D coordinate measurement 三次元量床3D modeling 三次元模拟aberration 色差abnormal glow 不规则辉光放电abrasive 砂轮access 通路account 帐户accretion 炉瘤accurate die casting 精密压铸acid converter 酸性转炉acid lining cupola 酸性熔铁炉acid open-hearth activator 活化剂acetylene 乙炔adjustable spanner 活动扳手aerator 松砂机ageing 老化处理air hardening 气体硬化airless plasting cleaning 离心喷光air patenting 空气韧化air permeability test 透气性试验air set mold 常温自硬铸模air vent valve 通气阀all core molding 集合式铸模alloy tool steel 合金工具钢allround die holder 通用模型aluminium alloy 铝合金钢amendment 修正ampere 电流安培anchor pin 锚梢angle cutter 角铣刀angle welding 角焊angular pin 角梢breathing 排气caulking compound 填隙料cell 气孔cold slug 半凝式射出colorant 著色剂color matching 调色compound 混合料copolymer 共聚合体cull 残料废品cure 凝固化cryptometer 不透明度仪daylight 开隙dry cycle time 空料试车周期时间ductility 延性elastomer 弹性体extruded bead sealing 压出粒涂层法feed 供料filler 充填剂film blowing 薄膜吹制法floating platen 活动模板foaming agent 发泡剂gloss 光泽granule 颗粒料gunk 料斗hot mark 热斑hot stamping 烫印injection nozzle 射出喷嘴injection plunger 射出柱塞injection ram 射出冲柱isomer 同分异构物kneader 混合机leveling agent 匀涂剂lubricant 润滑剂matched die method 配合成形法mould clamping force 锁模力mould release agent 脱模剂nozzle 喷嘴oriented film 取向薄膜parison 吹气成形坏料pellet 粒料plasticizer 可塑剂plunger 压料柱塞porosity 孔隙率post cure 後固化premix 预混料purging 清除reciprocating screw 往复螺杆resilience 回弹性resin injection 树脂射出法rheology 流变学sheet 塑胶片shot 注射shot cycle 射出循环slip agent 光滑剂take out device 取料装置tie bar 拉杆toggle type mould clamping system 肘杆式锁模装置torpedo spreader 鱼雷形分流板transparency 透明性void content 空洞率塑胶原料acrylic 压克力casein 酪素cellulose acetate 醋酸纤维素CA cellulose acetate butyrate 醋酸丁酸纤维素CAB composite material 复合材料cresol resin 甲酚树CF dially phthalate 苯二甲酸二烯丙酯disperse reinforcement 分散性强化复合材料engineering plastics 工程塑胶epoxy resin 环氧树脂EPethyl cellulose 乙基纤维素ethylene vinylacetate copolymer乙烯-醋酸乙烯EV A ethylene-vinlacetate copolyme醋酸乙烯共聚物EV A expanded polystyrene 发泡聚苯乙烯EPS fiber reinforcement 纤维强化复合材料high density polyethylene 高密度聚乙烯HDPE high impact polystyrene 高冲击聚苯乙烯HIPS high impact polystyrene rigidity高冲击性聚苯乙烯low density polyethylene 低密度聚乙烯LDPE melamine resin 三聚氰胺酚醛树脂MF nitrocellulose 硝酸纤维素phenolic resin 酚醛树脂plastic 塑胶polyacrylic acid 聚丙烯酸PAP 耐龙PA 聚对苯二甲酸丁酯PBT 聚碳酸酯PC 聚乙二醇PFG 聚氧化乙烯PEO 聚乙醇对苯PETP 聚甲基丙烯酸甲酯PMMA 聚缩醛POM 聚硫化亚苯polyphenyleneoxide 聚苯醚PPO 聚丙烯PP 聚苯乙烯PSpolytetrafluoroethylene 聚四氟乙烯PTFE polytetrafluoroethylene 聚四氟乙烯polythene 聚乙烯PE polyurethane 聚氨基甲酸酯PU polyvinylacetate 聚醋酸乙烯PV AC polyvinylalcohol 聚乙烯醇PV A polyvinylbutyral 聚乙烯醇缩丁醛PVB polyvinylchloride 聚氯乙烯PVC polyvinylfuoride 聚氟乙烯PVF polyvinylidenechloride 聚偏二氯乙烯PVDC prepolymer 预聚物silicone resin 矽树脂thermoplastic 热塑性thermosetting 热固性thermosetting plastic 塑胶unsaturated polyester 不饱和聚酯树脂成形不良用语aberration 色差atomization 雾化bite 咬入blacking hole 涂料孔(铸疵)blacking scab 涂料疤blister 起泡blooming 起霜blow hole 破孔blushing 泛白body wrinkle 侧壁皱纹breaking-in 冒口带肉bubble 膜泡burn mark 糊斑burr 毛边camber 翘曲cell 气泡center buckle 表面中部波皱check 细裂痕checking 龟裂chipping 修整表面缺陷clamp-off 铸件凹痕collapse 塌陷color mottle 色斑corrosion 腐蚀crack 裂痕crazing 碎裂crazing 龟裂deformation 变形edge 切边碎片edge crack 裂边fading 退色filler speak 填充料斑fissure 裂纹flange wrinkle 凸缘起皱flaw 刮伤flow mark 流痕galling 毛边glazing 光滑gloss 光泽grease pits 污斑grinding defect 磨痕hair crack 发裂haze 雾度incrustation 水锈indentation 压痕internal porosity 内部气孔mismatch 偏模mottle 斑点necking 缩颈nick 割痕orange peel 橘皮状表面缺陷overflow 溢流peeling 剥离pit 坑pitting corrosion 点状腐蚀plate mark 模板印痕pock 麻点pock mark 痘斑resin streak 树脂流纹resin wear 树脂脱落riding 凹陷sagging 松垂saponification 皂化scar 疤痕scrap 废料scrap jam 废料阻塞scratch 刮伤/划痕scuffing 深冲表面划伤seam 裂痕shock line 模口挤痕short shot 充填不足shrinkage pool 凹孔sink mark 凹痕skin inclusion 表皮摺叠straightening 矫直streak 条状痕surface check 表面裂痕surface roughening 橘皮状表皮皱摺surging 波动sweat out 冒汗torsion 扭曲]warpage 翘曲waviness 波痕webbing 熔塌weld mark 焊痕whitening 白化wrinkle 皱纹。

种类中文名称英文名称中文名称英文名称模具种类连续模Progressive die 冲孔模Pierce die 机械手Transfer die 剪边模Trimming die 手动机械手Hand transfer die 下料模Blanking die 单工程模Single die 成形模Forming die 铸造结构模Cast die 折弯模Bending die 简易模Prototype die 围边模Flange die 铆合模Riveting die 拉伸模Draw die 复合模Compound die 快换模Changeable die工序类料带strip 料带图strip layout 工序process 冲导正孔pilot pierce 冲孔pierce 侧冲cam pierce 切边notch 切侧刃notch french 折弯bend 墩薄coin成形form 侧成形cam form 整形restrike 围边flange打凸米boss / dimple 打凸包emboss打字印stamp 打沙拉孔hourglass 面押coin burr 抽孔extrude hole 拍平flat 卷圆curl种类中文名称英文名称中文名称英文名称工序类旋转rotate 铆接rivet产品切边线trim line 铆螺母stake nut 切断cutoff 接刀口mismatch 料带带料处carrier tab 毛刺方向burr direction 压线groove 下料blanking模板类上托板top plate 下托板bottom plate 上垫脚upper parallel 下垫脚lower parallel 上模座upper die set 下模座lower die set 上垫板punch backup 下垫板lower backup 上夹板punch holder 下夹板die holder 上脱料板stripper 下模板die plate 冲头punch 凹模die零件类浮块lifter 浮料板lifter plate 成型公form punch 压料块pressure pad 切边冲头trim punch 刀口trim steel 沉头孔counter bore 冲孔入子button 顶针kick off / ejector 废料切断刀slug breaker 成型凹模forming die 整形公restrike punch 导尺rail 导尺顶杆lifter bolt 导料板rail plate 镶件/入子insert侧冲组件cam 滑块slide滑块上油槽oil groove 铲机driver码模槽mounting slot 储运块storage block 限位柱stop block 起吊孔handing hole 起吊环eyebolt 靠块heel脱料拉杆spool 模座导正块thrust heel种类中文名称英文名称中文名称英文名称零件类耐磨片wear plate 垫片shim压块keeper 初始管位first start pin键槽key slot 键key氮气弹簧nitrogen spring 螺旋弹簧coil spring聚氨酯弹簧urethane导柱guide post 导套guide bushing 插针pilot pin插针套pilot bushing 侧刃french传感器sensor 销dowel螺丝screw 拔牙jackscrew垫圈washer 盲销blind dowel压毛边冲头deburring punch 挡块stopping plate压线冲头groove punch 定位块location block字模冲头stamp punch 圆冲头round punch压筋冲头ribbon punch 气垫板air cushion plate 异形冲头special shape punch 气垫顶杆air-cushion eject-rod 切边冲头trimming punch 上压块pressure block加强筋冲头stiffening rib punch 弹簧箱spring box 定位板guide plate 弹簧箱顶杆spring-box eject-rod 压边圈binder 弹簧箱顶板spring-box eject-plate公差类公差tolerance 公差范围tolerance range 上公差upper tolerance 下公差lower tolerance 公差+/- 0.05 plus minus 0.05 形位公差图GD&T 平面度flatness 直线度Straightness 倾斜度angularity 垂直度perpendicularity 平行度parallelism 圆度roundness种类中文名称英文名称中文名称英文名称公圆柱度cylindricity 面轮廓度surface profile差类线轮廓度line profile 位置度true position 同轴度concentricity 对称度symmetry 圆跳动runout 全跳动total runout 尺寸dimension 角度值angle degree 尺寸全检报告dimensional layout 三次元尺寸报告CMM report冲床相关机械冲床mechanical press 油压机hydraulic press 吨位tonnage 行程stroke / travel 冲床上台面ram 冲床下台面bolster冲床台面布置图press layout 冲床上的快速对正QDC 冲床气垫air cushion 码仔stirrup 闭合高度shut height T型槽T-slot送料机feeder 送料高度feeding height工具卡尺caliper 千分尺micrometer 直尺ruler 高度尺height gage 丝攻screw tap 起子screwdriver 拨牙器jacker 扳手wrench风磨机hand grinder 油石oil stone加工类开料cutting material 钻drill (DR) 攻牙tap 铰ream铣mill 车lathe电脑锣NC mill 线切割wire cutting(W/C) 磨grind 刨planer电火花EDM 镭射laser cutting 倒角chamfer xx的精加工finish XX真空热处理vacuum heattreatment镀钛TD coating 退磁demagnetization 烧焊weld4.1.2 加工说明对照表:加工说明Machining Note注:有0.00的地方为数据填入处外导套OUTER GUIDE BUISHING 起吊杆HANDING PIN实数铣通MILL THRU 正反两面各铣TOP SIDE AND OPP SIDE MILLX:-¢0.00(氮气弹弓过孔,锣穿)单+0.00X:-¢0.00 (DR.THRU FOR GAS SPRING) S+0.00X:-¢0.00(氮气弹弓沉头,正面CNC单+0.00,锣深0.00.)X:-¢0.00 ( CNC C'BORE TOP SIDE FOR GAS SPRING, S+0.00, DP0.00)X:-¢0.00(氮气弹弓沉头,反面CNC单+0.00,锣深0.00.)X:-¢0.00 (CNC C'BORE OPP SIDE FOR GAS SPRING, S+0.00, DP0.00)X:-¢0.00(合销孔,铰)X:-¢0.00 (REAM FOR DOWEL)X:-¢0.00(合销孔,割)单+0.00X:-¢0.00 (W/C FOR DOWEL) S+0.00(正面沉头¢0.00*0.00深,内攻M0.00*1.5牙)(¢0.00*0.00 C'BORE DP0.00 TOP SIDE, TAP M0.00*1.5 THR)(反面沉头¢0.00*0.00深,内攻M0.00*1.5牙)(¢0.00*0.00 C'BORE DP.0.00 OPP. SIDE, TAP M0.00*1.5 THR)X:-¢0.00(合销孔,钻穿)X:-¢0.00 (DR.THRU FOR DOWEL)X:-¢0.00(一般孔,钻穿)X:-¢0.00 (DR.THRU HL)X:-¢0.00(穿丝孔,钻穿)X:-¢0.00 (DR.THRU FOR WEDM S.H.)X:-¢0.00(漏油孔,钻穿) 按向视图加工X:-¢0.00 (DR.THRU FOR DRAIN HL) ACCORDING VIEW DRAWING TO MACHINING X:-(漏油槽,反面CNC单+0.00,锣深0.00)X:- (CNC POCKET OPP.SIDE FOR DRAIN, S+0.00, DP0.00)X:-¢0.00(基准孔,铰)X:-¢0.00 (REAM FOR DATUM HL)X:-¢0.00钻穿(螺丝过孔)内攻M0.00牙X:-¢0.00 (DR.THRU FOR CLEARANCE HL, TAP M0.00 THR)(正面沉头¢0.00*0.00深)(¢0.00*0.00 C'BORE DP0.00 TOP SIDE)(反面沉头¢0.00*0.00深)(¢0.00*0.00 C'BORE DP0.00 OPP. SIDE)(侧面沉头¢0.00*0.00深)(¢0.00*0.00 C'BORE DP0.00 EDGE SIDE)X:-M0.00钻穿,反面攻深0.00,有效牙0.00X:-M0.00 DR.THRU, TAP DP0.00 OPP.SIDE, THR DP0.00)X:-M0.00钻穿,正面攻深0.00,有效牙0.00X:-M0.00 DR.THRU, TAP DP0.00 TOP SIDE, THR DP0.00)X:-M0.00钻穿,正反面攻深0.00,有效牙0.00X:-M0.00 DR.THRU, TAP DP0.00 TOP&OPP. SIDE, THR DP0.00)X:-M0.00盲孔,反面攻深0.00,有效牙0.00X:-M0.00 BLIND HL, TAP WORK DP0.00 OPP. SIDE)X:-M0.00盲孔,正面攻深0.00,有效牙0.00X:-M0.00 BLIND HL, TAP WORK DP0.00 TOP SIDE, THR DP0.00)X:-M0.00盲孔,正反面攻深0.00,有效牙0.00X:-M0.00 BLIND HL, TAP DP0.00 TOP&OPP. SIDE, THR DP0.00)X:-M0.00盲孔,侧面分中攻深0.00,组模自配X:-M0.00 BLIND HL, TAP DP0.00 ON EDGE FROM CENTER , DIE MAKER FIT) (侧面沉头¢0.00*0.00深)(¢0.00*0.00 C'BORE DP0.00 EDGE SIDE)X:-M0.00盲孔,侧面分中钻深0.00X:-M0.00 BLIND HL, DR. DP0.00 ON EDGE FROM CENTERX:-M0.00(拨牙螺丝孔,攻穿)X:-M0.00 TAP.THRU FOR JACK SCREWX:-¢0.00(塞打过孔,钻穿)X:-¢0.00 DR.THRU FOR SPOOLX:-¢0.00(弹弓过孔,钻穿)X:-¢0.00 DR.THRU FOR SPRINGX:-¢0.00(弹弓孔,反面沉深0.00)有效深0.00X:-¢0.00 (C'BORE FOR SPRING DP.0.00 OPP.SIDE, USED DP.0.00)X:-¢0.00(弹弓孔,正面沉深0.00)有效深0.00X:-¢0.00 (C'BORE FOR SPRING DP.0.00 TOP.SIDE, WORK DP.0.00)X:-(避空孔,锣穿)单+0.00X:- (POCKET THRU)S+0.00X:-(避空孔,正面CNC单+0.00,锣深0.00)X:- (POCKET, CNC MILL S+0.00 DP0.00 TOP SIDE)X:-(避空孔,反面CNC单+0.00,锣深0.00)X:- (POCKET, CNC MILL S+0.00 DP0.00 OPP SIDE)X:-¢0.00(避空孔,反面CNC单+0.00,锣深0.00)X:-¢0.00 (POCKET, CNC MILL S+0.00, DP0.00 OPP.SIDE)X:-¢0.00(避空孔,正面CNC单+0.00,锣深0.00)X:-¢0.00 (POCKET, CNC MILL S+0.00, DP0.00 EDGE SIDE)X:-¢0.00(两用销过孔,割)单+0.00X:-¢0.00 (LIFTER PIN, W/C S+0.00)X:-(导尺避空,CNC单+0.00锣穿)X:- (POCKET FOR RAIL, CNC MILL THRU, S+0.00)X:-(导尺避空,正面CNC单+0.00,锣深0.00)X:- (POCKET FOR RAIL, CNC MILL DP.0.00 TOP SIDE, S+0.00) X:-(导尺避空,反面CNC单+0.00,锣深0.00)X:- (POCKET FOR RAIL, CNC MILL DP.0.00 OPP. SIDE, S+0.00) X:-(浮块避空,正面CNC单+0.00,锣深0.00)X:- (POCKET FOR LIFTER, CNC MILL DP.0.00 TOP SIDE, S+0.00) X:-(浮块孔,割)单+0.00(反面避空单+0.00,锣深0.00)X:-(LIFTER HL, W/C)S+0.00(POCKET DP0.00 S+0.00 OPP.SIDE)X:-(浮块孔,锣)单+0.00(反面避空单+0.00,锣深0.00)X:-(LIFTER HL, MILL)S+0.00(POCKET DP0.00 S+0.00 OPP.SIDE)X:-¢0.00(顶针孔,钻穿)(反面沉头¢0.00*0.00深,内攻M0.00*1.5牙)X:-¢0.00 (EJECT PIN, DR.THRU.)(¢0.00 C'BORE DP0.00 OPP. SIDE, TAP M0.00*1.5 THR)X:-¢0.00(顶针孔,钻穿)(正面沉头¢0.00*0.00深,内攻M0.00*1.5牙)X:-¢0.00 (EJECT PIN, DR.THRU.)(¢0.00 C'BORE DP0.00 TOP SIDE, TAP M0.00*1.5 THR)X:-¢0.00(导柱(导套)孔,CNC锣)单+0.00X:-¢0.00 CNC MILL FOR GUIDE PIN(BUSHING) S+0.00X:-¢0.00(导柱(导套)孔,割)单+0.00X:-¢0.00 W/C FOR GUIDE PIN(BUSHING) S+0.00X:-M0.00*1.5(止付螺丝,正面攻深0.00)X:-M0.00*1.5(SET SCREW, TAP DP0.00 TOP SIDE)X:-M0.00*1.5(止付螺丝,反面攻深0.00)X:-M0.00*1.5(SET SCREW, TAP DP0.00 OPP SIDE)X:-(入子孔,CNC单+0.00,锣穿)X:-(INSERT HL, CNC MILL THRU S+0.00)(阴影部分正面沉头单+0.00,锣深0.00)(SHADE AREA, MILL DP0.00 S+0.00 TOP SIDE)(阴影部分反面沉头单+0.00,锣深0.00)(SHADE AREA, MILL DP0.00 S+0.00 OPP SIDE)X:-(入子孔,割)单+0.00X:-(INSERT HL, W/C S+0.00)(阴影部分扣位正面锣深0.00)(SHADE AREA FOR HEAD POCKET, MILL DP0.00 TOP SIDE)(阴影部分扣位反面锣深0.00)(SHADE AREA FOR HEAD POCKET, MILL DP0.00 OPP. SIDE)(正面沉头单+0.00,锣深0.00)(POCKET, MILL DP0.00 TOP SIDE)注: 此处的沉头不能用C'BORE, 只有圆形的沉头才用C'BORE.(反面沉头单+0.00,锣深0.00)(POCKET, MILL DP0.00 TOP SIDE)X:-(入子孔,CNC单+0.00,锣穿)X:- (INSERT HL, CNC MILL THRU. S+0.00)X:-(入子孔,正面CNC单+0.00,锣深0.00)X:- (INSERT HL, CNC MILL DP0.00 S+0.00 TOP SIDE)X:-(入子孔,反面CNC单+0.00,锣深0.00)X:- (INSERT HL, CNC MILL DP0.00 S+0.00 OPP. SIDE)X:-¢0.00(插针孔,铰)单+0.00X:-¢0.00(REAM S+0.00 FOR PILOT PIN)X:-¢0.00(插针孔,割)单+0.00(正面沉头¢0.00*0.00深)X:-¢0.00(W/C FOR PILOT PIN)(¢0.00 C'BORE DP0.00 TOP SIDE)X:-¢0.00(插针孔,钻穿)(正面沉头¢0.00*0.00深)X:-¢0.00(DR.THRU FOR PILOT PIN)(¢0.00 C'BORE DP0.00 TOP SIDE)X:-(冲头过孔,割)单+0.00(正面避空,CNC单+0.00,锣深0.00)(阴影部分扣位正面锣深0.00)X:-(W/C S+0.00 FOR PUNCH CLEARANCE HL)(POCKET, CNC DP 0.00 S+0.00 TOP SIDE)(POCKET SHADE FOR HEAD, DP0.00 TOP SIDE)X:-(冲头过孔,锣穿)单+0.00(正面避空,CNC单+0.00,锣深0.00)X:-(MILL THRU.FOR PUNCH CLEARANCE HL)(POCKET DP0.00 CNC S+ TOP SIDE)X:-(异形冲孔,直x斜x,割)单+0.00(双线部分,割)单+0.00X:-(W/C FOR SPECIAL HL, 0.00 LAND 0.00 TAPER, S+0.00) (W/C PER DOUBLE LINE S+0.00)X:-(冲孔,直x斜x,割)单+0.00X:-(W/C FOR PIERCE DIE HL, 0.00 LAND 0.00 TAPER S+0.00) X:-(冲孔,割)单+0.00X:-(W/C FOR PIERCE DIE HL S+0.00)X:-¢0.00(冲孔漏屎,钻穿)X:-¢0.00 (DR. THRU FOR CHUTE)X:-(异形冲孔漏屎,CNC单+0.00,锣穿)X:-¢0.00 (MILL. THRU FOR SPECIAL CHUTE S+0.00)X:-(产品落料斜度,实数斜30º锣)X:-(MILL 30 TAPER FOR PART RAMP NO CLEARANCE)X:-(漏屎斜度,直x斜45º锣)X:-(MILL FOR CHUTE 0.00 LAND 45 TAPER)反面沉深底面留0.00MILL UNTIL DP正面沉深底面留MILL UNTIL DP五金模具单词总结模具种类:连续模progressive die机械手transfer die手动机械手hand transfer die单工程模single die/line die复合模compound die铆接模riveting die铸造结构模cast die能快换的模changeover die泡沫模pattern互换性:公差tolerance上公差upper tolerance下公差lower tolerance公差范围tolerance range公差+/- 0.05 plus minus 0.05形位公差图GD&T平面度flatness直线度straightness倾斜度angularity垂直度perpendicularity / squareness平行度parallelism圆度roundness / circularity圆柱度cylindricity面轮廓度surface profile线轮廓度line profile位置度true position同轴度concentricity对称度symmetry圆跳动runout全跳动total runout尺寸dimension角度angle degree全尺寸报告dimensional layout工艺性:料带strip料带图strip layout工序process冲导正孔pilot pierce冲孔pierce侧冲cam pierce切边notch成形后的切边trim切侧刃french trim / fringe trim 厚料切边后的精修边shave折弯bend墩薄coin折弯处压筋gusset成形form侧成形cam form整形restrike / rehit围边flange压线/压长条状筋ribbon打凸米boss / dimple打凸包emboss打字印stamp打沙拉孔hourglass面押coin burr抽孔extrude hole拍平flat / spanking包边hem edge压角cone张角flare切舌lance半剪knockout卷圆curl/热恶劣旋转rotate铆接rivet铆螺母stake nut切断cutoff接刀口mismatch料带带料处carrier tabs毛刺方向burr direction产品切边线trim line模具零件:模具die / tool上托板upper mounting plate 上垫脚upper parallel上模座upper die set上垫板punch backup上夹板punch holder止挡板traveling stop脱料板stripper下模板die plate下垫板die backup plate下模座lower die set下垫脚lower parallel上托板base mounting plate浮块lifter浮料板lifter plate成型公form punch压料块pressure pad切边冲头trim punch刀口trim steel刀口直身位land直5斜1 5mm Land 1 taper 刀口上沉头的深度die life 沉头counter bore冲头倒斜shear高低冲stagger punch球锁冲头ball-lock punch球锁座ball-lock retainer冲孔入子button顶针kick off / ejector废料切断刀slug breaker成型凹模form die整形公restrike form punch 导尺rail /stock guidance导尺顶杆lifter bolt导料板rail plate镶件/入子insert侧冲组件cam滑块slide滑块上油槽oil groove铲机driver码模槽mounting slot储运块storage block限位柱stop block起吊孔handing hole起吊环eyebolt模柄shank靠块heel摆块rocker bender脱料板拉杆stripper bolt模座导正块thrust耐磨片wear sheet耐磨板wear plate垫片shim两用销lifter pin初始管位first start pin内限位standoff压块keeper导柱导套压块keeper/ boss 键槽key slot键key氮气弹簧gas spring / nitrogen spring 氮气弹簧安装法兰mounting flange 氮气弹簧系统nitrogen manifold螺旋弹簧coil spring聚氨酯弹簧urethane弹簧套spring cage导柱guide post导套guide bushing插针pilot pin插针套pilot bushing插针通孔pilot through hole侧刃french误检装置misfeeder传感器sensor误检杆trigger油嘴oil nipple销针dowel pin螺丝screw牙thread拔牙jackscrew内六角螺钉socket head screw垫圈washer螺塞screw plug盲销blind dowel行程,走位stroke / travel吨位tonnage机械冲床mechanical press油压机hydraulic press冲床下台面bolster冲床上台面ram冲床台面布置图press layout冲床码模槽press mounting slot冲床气垫air cushion码模钳stirrup闭合高度shut height送料高度feeding height送料机feederT型槽T-slot避位clearance /pocket掏空pocket挂台head扣位pocket of head通气孔air vent hole漏油孔drain hole漏料孔slug hole基准孔datum hole通孔through hole穿丝孔first wire holeT型槽T-slot拔牙jackscrew摆块rocker bender闭合高度shut height避位clearance /pocket侧冲组件cam侧刃french插针pilot pin插针套pilot bushing插针通孔pilot through hole铲机driver沉头counter bore成型凹模form die成型公form punch冲床码模槽press mounting slot冲床气垫air cushion冲床上台面ram冲床台面布置图press layout冲床下台面bolster冲孔入子button冲头倒斜shear初始管位first start pin储运块storage block穿丝孔first wire hole传感器sensor弹簧套spring cage氮气弹簧gas spring / nitrogen spring 氮气弹簧安装法兰mounting flange氮气弹簧系统nitrogen manifold刀口trim steel刀口上沉头的深度die life刀口直身位land导尺rail /stock guidance导尺顶杆lifter bolt导料板rail plate导套guide bushing导柱guide post导柱导套压块keeper/ boss垫片shim垫圈washer顶针kick off / ejector吨位tonnage废料切断刀slug breaker浮块lifter浮料板lifter plate高低冲stagger punch挂台head滑块slide滑块上油槽oil groove机械冲床mechanical press基准孔datum hole键key键槽key slot聚氨酯弹簧urethane靠块heel扣位pocket of head两用销lifter pin漏料孔slug hole漏油孔drain hole螺塞screw plug螺丝screw螺旋弹簧coil spring码模槽mounting slot码模钳stirrup盲销blind dowel模柄shank模具die / tool模座导正块thrust内六角螺钉socket head screw 内限位standoff耐磨板wear plate耐磨片wear sheet起吊环eyebolt起吊孔handing hole切边冲头trim punch球锁冲头ball-lock punch球锁座ball-lock retainer上垫板punch backup上垫脚upper parallel上夹板punch holder上模座upper die set下托板base mounting plate 上托板upper mounting plate 送料高度feeding height送料机feeder掏空pocket通孔through hole通气孔air vent hole脱料板stripper脱料板拉杆stripper bolt误检杆trigger误检装置misfeeder下垫板die backup plate下垫脚lower parallel下模板die plate下模座lower die set限位柱stop block镶件/入子insert销针dowel pin行程,走位stroke / travel压块keeper压料块pressure pad牙thread油压机hydraulic press油嘴oil nipple整形公restrike form punch 直5斜1 5mm Land 1 taper 止挡板traveling stop机加工:开料cutting material钻drill (DR)攻牙tap铰ream铣mill车lathe电脑锣NC mill线切割wire cutting (W/C)磨grind刨planer电火花EDM镭射laser cutting倒角chamfer精加工finish XX真空热处理vacuum heat treatment镀钛TD coating退磁demagnetization烧焊weldG :40-M6BLIND HL,TAP DP18.00 OPP SIDE,THR DP18.00) 盲孔,反面攻深**G10:4-M30BLIND HL,TAP DP18.00 EDGE SIDE)盲孔,侧攻深**(%%c34.00*14.00 C'BORE DP14.00 TOP SIDE) 正面沉头多少×多少深G2 :24-%%c8.00(REAM FOR DOWEL WORK DP16.00 OPP SIDE,DR%%c6.00 HL)G2 :24-%%c8.00(合销,背铰深16.00,有效深,内钻%%C6.00通孔)G4 :3-%%c10.00(基准孔,背铰深20.00)背面锣25.00*25.00方形沉头,深1.00%%P0.01 (REAM FOR DATUM HL DP20.00,MILL25.00*25.00 OPP SIDE DP1.00%%P0.01)M:2-%%c15.00(弹簧孔,锣深33.00) (C'BORE OR SPRING DP33.00 TOP SIDE,WORK DP33.00)X :3-%%c32.00(导套孔,锣穿,单+0.01)(MILL THRU FOR GUIDE BUSHING S+0.01)G :2-M10盲孔,侧攻深30.00(有效深)(BLIND HL,TAP WORK DP30.00 EDGE SIDE)(沉头5.20%%P0.05深)(SLOT DP5.20%%P0.05 TOP SIDE)L :2-%%c8.000(合销,割)单+0.005 (W/C FOR DOWEL)S+0.005盲孔,攻深20.00(有效深) (BLIND HL,TAP DP20.00 TOP SIDE,THR DP20.00)(插针孔,割,单+0.01) (W/C S+0.01 FOR PILOT PIN)(避位孔,背锣9.80(有效深) (POCKET,MILL DP9.80 OPP SIDE WORK)(冲头过孔,锣穿) (MILL THRU FOR PUNCH CLEARANCE HL)(导柱孔,锣穿,单+0.005) (MILL FOR GUIDE PIN) S+0.005避位槽,背锣深19.00) (POCKET,MILL DP15.40 OPP SIDE)(背,沉头%%c14.00,掏深留11.00) (%%c14.00 C'BORE UNTIL DP14.00 OPP SIDE)下模刀口,实数割,直5斜1.5 (内钻%%C5.0穿丝孔)W/C S+0.00 TRIM STEEL,5.0LAND 1.5TAPER,(DR THRU%%c3.00 WEDM S.H)(MILL FOR INSERT DP30.0%%P0.01 S+0.01)(入子槽,锣深30.00%%p0.01,单+0.01)(氮气槽,背锣深4.00%%P0.1,单+0.1) (GAS SPRING MILL DP4.00 OPP SIDE)S+0.1按向视图加工ACCORDING VIEW DRAWING TO MACHINING试模材料:热扎板HRS (hot-roll steel)冷扎板CRS (cold-roll steel)不锈钢板Stainless steel镀锌板galvanized steel镀铝锌板galvalume steel热扎酸洗板HRPO steel (hot-rolled pickled and oiled steel)工具:卡尺caliper千分尺micrometer拨牙器jacker扳手wrench丝攻screw tap起子screwdriver码模钳stirrup设备/工具:3D Programmable CMM三次元检测仪3D CMM Beam Drilling Machine摇臂钻Bench Drilling Machine钻铣床Caliper卡尺CNC EDM电火花机CNC Machine Center加工中心CNCCNC Milling Machine数控铣床CNCCNC Planer Type Milling Machine龙门刨铣床Hardness Tester硬度计Height Gauge高度仪High Wire Cutting快走丝Hole Puncher 打孔机Horizontal surface grinder小水磨/卧式平面磨床Horizontal surface large grinder大水磨Lathe车床Measurement Surface Plate测量平台Metal Saw Machine锯床Milling Machine铣床Oil Press油压机Pin Gauge标准针规Plastic Injection Machine注塑机Point to Point CMM三次元测量仪Precision surface grinder精密手摇磨Press冲床Projector profile投影机Shear Press剪板机Slow Wire Cutting慢走丝Vertical Milling Machine卧式强力铣床扳手wrench拨牙器jacker卡尺caliper码模钳stirrup起子screwdriver千分尺micrometer丝攻screw tapCARVE 雕刻pothook 挂钩SPECIAL HL 异形孔漏斗 filler角铁 ANGLE IRON展开 expanding微调开关 INCHING SWITCH合叶 HINGE优力胶 RUBBER球锁垫板 LOCK WASHER双线边刀口,不倒角TRIM STEEL NEAR THE DOUBLE LINE NO CHAMFER滑块座:SLIDE SET机械:(engine type) liquid cooled, in-line, 4cylinder, carb (发动机型号)水冷,直列,四缸,化油器式(engine) compression ratio (发动机)压缩比(engine) displacement (发动机)排量(engine) fuel (发动机)燃料13-mode 13工况3rd gear 三档齿轮3-way seat 三向座椅4WD control device 四轮驱动控制装置4WD indicator switch 四轮驱动指示灯开关4WD lamp electrical connection 四轮驱动指示灯接线4WD switch 四轮驱动开关5th synchromesh assy. 五档同步器总成6PK belt 6PK 多楔驱动皮带A / C compressor assembly 空调压缩机总成A / C control assembly 空调控制装置A/C & heater assy. 空调加热器总成A/C blower 空调鼓风机A/C clutch 空调压缩机离合器A/C compressor MTG bracket 空调压缩机安装支架A/C control assy. 空调控制器A/C housing assy. 空调箱总成A/C low pressure switch 空调低压开关A/C mode select switch 空调状态选择开关abdomen performance criterion 腹部性能指标Abdominal Peak Force 腹部力峰值ABS 防抱死制动系统acceleration fuel system 加速系统acceleration running noise level 加速行驶噪声accelerator interlocking type 加速踏板联锁式accounting foundation 财政基础Actual cycle work 实际循环功Actual torso angle 实际躯干角adapter 连接器additional features 附加装置additional rule 附加法规adjust screw 调整螺钉adjuster cable 调整拉线adjuster plug 调整盖adjuster screw assy. 调整螺栓总成adjuster washer 调整棘片adjuster, diff. bearing 差速器轴承调整螺母Adjustment system 调节装置Administration and Registration Division 管理科Agreement Concerning the Adoption of Uniform Technical Prescriptions for Wheeled Vehicles, Equipment and Parts Which Can Be Fitted and/or Be Used on Wheeled Vehicles and the Conditions for Reciprocal Recognition of Approvals Granted on the Basis of These Prescriptions关于对轮式车辆、安装和/或用于轮式车辆的装备和部件采用统一条件并相互认可基于上述条件批准的协定书Agreement Regulations 协定法规air cleaner 空气滤清器air cleaner assy. 空气滤清器总成air cleaner cartridge 空气滤清器滤芯Air compressor 空压机air condition compressor 空调压缩机air direct 空气走向air filter 空气滤清器air flow 空气流向Air flow meter 空气流量计air jet 空气量孔air metering hole 空气量孔air path 气道Air Pressure of Tire 轮胎气压Air type 空气型air valve 空气阀air-cooled 风冷Aisles 通道Alcohol 酒精all bearing 球轴承alternater bracket 发动机支架alternator 交流发电机alterntor assembly 交流发电机总成alumininum-rim 铝合金钢圈alumininum opposed model 铝制对开式AM/FM cassette stereo radio 调幅/调频立体声收放机ambulance 救护车Amended by 修正文amount of exhaust emission 排气排放量Amplitude resolution 幅度分辨率Analogue magnetic recorder 模拟式磁记录仪ANALYZER 分析仪anchor plate, brake caliper 制动钳安装支架Anchorage 座椅固定装置Angle of divergence 偏离角Angle of rotation 旋转角angles drift off vertical line 指针偏离垂直线的角度Angular diameter of the retro-reflecting device 回复反射装置的角直径annex 附件Announcement 公告anti, shutdown screw 防不灭车调整螺钉Antilock Brake System 防抱死制动系统appendix 附录Applicable motor vehicle 适用机动车Applicable scope 适用范围applicant 申请人application 申请application for notification 认可申请书approval 认可arm, valve rocket 摇臂armature 转子总成armature shaft 电枢轴Arm-rests 靠手Article 条Article 1 第1条Asphalt solution 沥青溶剂Attached document 附署文件attached sheet 附表Attached Table 附表attaching location of seat belt anchorage 座椅安全带固定装置的固定位置attachment 附属文件Attendants onboard 车上值班人员automatic chock cover setting 自动阻风门盖调到automotive electric system 汽车电系automotive engine system 引擎系统automatic transmission 自动变速器,自动排挡变速箱Auxiliary Brake 辅助制动器Auxiliary Direction Indicator Lamps 辅助转向信号灯auxiliary spring 副簧Auxiliary Stop Lamp 辅助驻车灯axle case 桥壳axle case assy. 桥壳总成axle ratio 桥速比axle tube 桥管axle weight 轴重back angle level 靠背角水平仪back angle quadrant 靠背角量角器back pan 靠板back spring 回位弹簧backing plate 制动底板Backing sheet 衬背板Back-Up Light 倒车灯backup washer 支撑挡圈bail wire 卡紧环balance tube 平衡管ball 钢球ball bearing 球轴承ball joint assy. , upper 上球销总成ball valve 球阀ball valve, inlet 进油口球阀bar 拉杆barrier 障碍壁battery 蓄电池battery terminal 蓄电池接线柱bearing cap 轴承盖bearing cover, input shaft 输入轴轴承盖bearing, connecting rod 连杆轴承bearing, input shaft 输入轴轴承Bed for babies 婴儿床bell 带束层bench seat 长条座椅berived cap 轴承盖bezel assy. 框板总成bezel, cluster 表框be pilot 小批量产品blead door 混合风门bleeder screw 放气螺钉blower assy. 鼓风机总成blower motor 鼓风发电机blower resistor 鼓风机电阻blower switch 鼓风机开关body 车身,阀体body & liftgate assembly 车身和举升门总成body assy. 车身总成body block 人体模块body of A/C & heater 空调加热器壳体bolt 主缸连接螺栓bolt, connecting rod 连杆螺栓Booster 助力器boot 护罩BOSCH starter motor assembly “波舍”起动机总成bottle assy. , coolant recover 冷却液回收罐总成bottom houseing, fuel pump 燃油泵下壳体bottom housing, fuel tank 燃油箱下壳体bracket 支架bracket assy. , spring seat 弹簧座支架bracket, steering damper mounting 转向减振器支架brake alarm lamp 制动报警灯brake alarm lamp switch 制动报警灯开关Brake booster 制动助力器brake caliper 制动钳brake caliper assy. 制动钳总成brake caliper piston 制动钳活塞brake combination valve 制动组合阀brake disc 制动盘Brake drum 制动鼓brake fluid 刹车油Brake hose 制动软管brake lining 刹车来令brake line, LF 左前制动油管brake line, RF 右前制动油管brake oil flow 制动液流向brake paddle 制动踏板brake pedal 制动踏板Brake pipe 制动管brake shoes 刹车蹄片brake shoe 制动衬块Brake System 制动系Brake Systems for Tractors and Trailers 牵引车及挂车的制动装置Brake tester 制动器试验台brake valve 制动阀brake warning lamp 制动报警灯brake warning switch 制动报警开关Braking efficiency 制动效能braking force control system 制动控制装置Braking wheel 制动轮branch office 分署breaker 断电器bridge 过桥broadcasting vehicle 广播车brush 碳刷总成Buckle 带扣bulkhead 隔板Bulldozer 推土机bumper 保险杠Bumper element 保险杠构件bus transfer 车辆转移台bushing 衬套bushing, upper control arm 上控制臂衬套Business Place 业务场所bypass valve 旁通阀Cabinet Decision 内阁决议cable guide 拉线导向块cable-operated control system 液压式离合器系统Calibration factor of a data channel 数据通道校正系数calibration gas 标定气体calibration method 标定方法caliper assy. , front brake 前制动钳总成Camber 外倾camber angle 前轮外倾角camshaft 凸轮轴camshaft oil gallery 凸轮轴油道cap 加机油口盖cap assy. , power steering fluid reservoir 动力转向液油罐盖cap assy. , radiator 散热器盖总成cap screws 螺钉cap, connecting rod 连杆盖Capacity 容量,规格Capacity of the fuel tank 燃油箱容量capillary tube 毛细管carbon brushes & brush holder 电刷支架总成Carbon monoxide measuring instrument 一氧化碳分析仪Carburetor 化油器carburetor assy. 化油器总成carburetor bowl 化油器浮子室carburetor bowl vent system 化油器浮子室通风系统carburetor overhaul scheme 化油器分解图carburetor working scheme 化油器工作示意图carcase 胎体case runout (Max.) 差速器壳圆跳动(最大)Caster 后倾Catalyst 催化器category 类别cement and aggregate 水泥和混凝料Centreplane of occupant 乘员中心面Certified 经认证的Cetane number 十六烷值chain 驱动链chain drive 驱动链Channel amplitude class 幅度级通道Channel Frequency Class 频率级通道chassis 底盘chassis dynamometer 底盘测功机chassis shuttle 底盘平移台chassis number 底盘号Check and Maintenance 检查和保养check assy. , front door 前门限位器总成check assy. , rear door 后门限位器总成check ball 回止球check bracket 限位器支架check nut 限位器螺母check valve 单向阀check valve hole 回止阀孔check valve retainer 单向阀保持架check valve spring 单向阀弹簧check weight 回止块Chigi Circular No. 地技第…号Chigi No. 地技第…号Child Restraints 儿童约束装置chime module 蜂鸣器Chishin Circular No. 地审第…号Chishin No. 地审第…号chock heater 阻风门加热器总成chock plate 阻风门chock unloaded 阻风门连动装置choke 阻风门choke device 阻风装置choke unload mode 阻风门卸载状态cigarette lighter 点烟器circuit breaker, wiper/washer 刮水器/洗涤器电器断路器Circular 通告circular notice 通告clamp 卡圈Clamp ring type 锁紧圈式Cleaning efficiency 清洗效率Cleaning period 清洗周期clearance 最小离地间隙Clearance Lamp 示廓灯clinder head 气缸盖clip 卡子cluster housing 组合仪表壳Clutch system 离合器clutch assembly 离合器总成clutch control device 离合器控制装置clutch disc,clutch 离合器片clutch housing 离合器壳clutch master cylinder 离合器主缸clutch working cylinder 离合器工作缸Coating 涂层Code No. 型号Code of Federal Regulations 美国联邦法规总览Coefficient of luminous intensity (CIL) 亮度系数coil spring 圈状弹簧cold air 冷空气cold cranking voltage(min.) 最小冷启动电压collapsible spacer 可压缩隔垫collector 拼装台colorimeter 色度计coloured-light unit 有色灯光组column assy. 转向管柱总成combination brake switch and proporting 组合阀combined lamp 复合灯combined pump 复合泵combined pump diaphragm 复合泵膜片combined pump diaphragm rod 复合泵膜片杆combined pump lifter link 复合泵举升拉杆combined pump move direct 复合泵运动方向Combustion Chamber 燃烧室commutator 换向器compensate opening 补偿孔completion inspection certificate 终了检验证书Completion of notification 完成认可compressor 压缩机compression (both) 气环槽(两个)compression ignition type 压燃式Compression ratio 压缩比concrete mixer truck 混凝土搅拌车condenser 冷凝器condenser assy. 冷凝器总成conduit pipe 导管cone , diff. side bearing 差速器轴承,内圈带滚子cone, pinion front bearing 主动齿轮前轴承内圈带滚子cone, pinion rear bearing 主动齿轮后轴承内圈带滚子Confirmor 确认者connecting rod 连接杆connecting link 连接杆connecting rod journal diameter 连杆轴径connecting rod journal width 连杆轴径宽度connecting rod throttle 连杆喷油孔connector 连接器connector of service valve 维修阀接口Constant speed 等速construction and device 结构和装置control & tube assy. , hyd clutch 离合器工作缸和油管总成Control System 操纵系control valve 控制阀阀门control valve model 控制阀型式control valve seat 控制阀阀座convex plate 凸台cooling fan 冷却风扇cooling system 冷却系统Cornering Lamp 转弯灯corrected 修正的cotter 开口销counter 5th gear 中间轴五档齿轮counter shaft 中间轴coupled condition 连接状态Coupling Device 牵引装置cover 端盖cover & plate assy. 离合器盖及压盘总成cover assy. , air cleaner 空气滤清器盖总成cover, gear 侧盖cover, heater air 空气加热罩cover, rear axle case 后桥壳盖crane vehicle 起重车crankcase 曲轴箱crankshaft 曲轴crankshaft gear 曲轴齿轮crankshaft & connecting 曲轴连杆机构crankshaft oil gallery 曲轴油道crankshaft sprocket 轴承链轮critical flow 临界流Cross sensitivity of a linear transducer 线性传感器的横向灵敏度Crush distance 压碎距离Crush rate 压碎速率Crush Strength 压碎强度Cumulative time 累计时间cup 皮碗cup, diff. side bearing 差速器轴承外圈cup, pinion front bearing 主动齿轮前轴承外圈cup, pinion rear bearing 主动齿轮后轴承外圈Cut-off 明暗截止线cycle 冲程cyclinder head cover 气门室罩Cylinder 气缸cylinder block 汽缸体cylinder body 缸体Cylinder bore 缸径cylinder head 汽缸盖cylinder head cover 气门室罩cylinder number 气缸数cylinder working order(clockwise) 气缸工作顺序(顺时针)damper 转向减振器dangerous article 危险物darkroom 暗室Data channel 数据通道Data Processing 数据处理Date of notification 认可日期Deceleration of the structure 地板减速度Definitions 定义Definitions 术语deflection 偏移defroster 除霜器dehydrator 储液器和干燥器。

模具专业英语词汇IntroductionThe field of mold manufacturing and design requires professionals to possess a solid understanding of specialized vocabulary in English. This is essential for effective communication within the industry. In this document, we will explore and expln key terminology related to mold manufacturing and design. The glossary below will assist you in expanding your knowledge and improving your English proficiency in the field of mold manufacturing.Glossary1. Mold Manufacturing Terminology(1) MoldA mold is a tool used in the manufacturing industry to shape materials such as plastic, metal, or glass by injecting, pouring, or pressing the material into the mold cavity.(2) CavitiesCavities are the hollow spaces within a mold where the material is injected or poured. The number of cavities in a mold can vary depending on the complexity and desired production volume of the part.(3) CoreA core is the part of a mold that creates the internal features of a molded part. It is usually placed inside the mold cavity and is used to form the desired shape of the part.(4) Runner SystemThe runner system is a network of channels within a mold that allows for the passage of molten material from the injection point to the cavities. It ensures a smooth flow of the material and ds in achieving uniform filling of the mold.(5) Ejector PinsEjector pins are used to push the finished molded part out of the mold once it has cooled and solidified. They are activated by a mechanism in the mold and assist in the removal of the part from the mold.(6) Cooling SystemThe cooling system is an essential part of the mold that helps in controlling the temperature of the mold and the material being injected. It ensures proper solidification of the material and minimizes the cycle time.(7) Mold Release AgentA mold release agent is a substance applied to the surface of a mold before injection to prevent the material from sticking to the mold. It allows for easy removal of the part after molding.2. Mold Design Terminology(1) Draft AngleA draft angle is the angle designed on the vertical surfaces of a molded part to facilitate its easy ejection from the mold. It helps in avoiding undercuts and ensures a smooth release of the part.(2) Parting LineThe parting line is the line where two or more mold sections meet. It is the boundary between the mold cavity and the core. Proper alignment and accuracy of the parting line are crucial for a well-designed mold.(3) GateThe gate is the point where the molten material enters the mold cavity. It controls the flow of material into the cavity and determines the filling pattern of the mold. Different types of gates, such as sprue gate, edge gate, and pin gate, can be used depending on the part design and requirements.(4) ShrinkageShrinkage refers to the reduction in dimensions of a molded part as it cools and solidifies. It is a natural phenomenon due to the curing and cooling process of the material. Proper consideration of shrinkage is important to achieve accurate dimensions in the final part.(5) Mold VentingMold venting refers to the process of allowing trapped r or gases to escape from the mold during injection. Adequate venting is essential toprevent r pockets or voids in the finished part, ensuring high-quality and defect-free molding.(6) Mold Surface FinishThe mold surface finish refers to the texture or smoothness of the surface of the molded part. It can be achieved through various techniques like polishing, etching, or coating. The surface finish is an important consideration for the appearance and functionality of the final part.(7) Mold ToolingMold tooling refers to the collection of tools and equipment required for the manufacturing and assembly of the mold. It includes items like mold bases, inserts, ejector pins, and other components used in the construction of the mold.ConclusionFamiliarity with specialized vocabulary in English is crucial for professionals in the field of mold manufacturing and design. The glossary provided in this document covers key terminology in mold manufacturing and design, allowing individuals to enhance their understanding and communication within the industry. Whether you are involved in mold manufacturing, mold design, or related fields, this resource will equip you with the necessary terminology to excel in your work.。

以下是30 个模具常用语的中英文对照:1.模具:mold2.模具设计:mold design3.模具制造:mold manufacturing4.模具加工:mold processing5.模具寿命:mold life6.模具维护:mold maintenance7.模具成本:mold cost8.模具材料:mold material9.模具结构:mold structure10.模具零件:mold part11.模具装配:mold assembly12.模具调试:mold debug13.模具成型:mold forming14.模具分型面:mold parting surface15.模具型腔:mold cavity16.模具型芯:mold core17.模具滑块:mold slider18.模具斜顶:mold lifter19.模具顶针:mold ejector pin20.模具冷却系统:mold cooling system21.模具浇注系统:mold gating system22.模具排气系统:mold venting system23.模具尺寸公差:mold dimensional tolerance24.模具表面粗糙度:mold surface roughness25.模具硬度:mold hardness26.模具钢:mold steel27.模具加工工艺:mold processing technology28.模具检测:mold inspection29.模具修改:mold modification30.模具报废:mold scrap。

模具常用英语!2008年09月12日 星期五 15:56模具英语句子1. XXX!你现在有空吗,我可以问你一些问题吗?Could I ask you some questions if you are free? / Are you free now? May I ask you some questions (a question)?2. 请问此产品的面是否为外观面?表面做什么处理?是晒纹/抛光?Can you tell me whether the surface of this part is a visible/esthetic one? What will we do for itssurface? Texture or Polishing ?3. 请问产品这个面可否加顶针或顶块?产品允许加扁顶针吗?Does this part need an ejector pin or an ejector bar? Can we add an ejector blade?4. 这个产品的柱位我们打算做司筒。

(或镶针)可以吗?Can we add ejector sleeves or ejector pins in the boss of this part?5. 产品的这个位置不能出模,我们打算做行位,在此面上会有分模线,你接受吗?There's an undercut at this position and it needs a slider. It will also have a parting line onthis side, is that OK?6. 产品里面的这个位置我们打算做斜顶或内行位,有问题吗?We will make the lifter and (inner) slider in this position, will that be a problem?7. 你提供的2D产品图与3D产品图不一致,请问以哪一个图面为准?The 2D and 3D drawing you provided is not the same, can you tell me which one is correct?8. 你提供的3D产品图有的地方没有出模角,有的地方胶位太厚,有的地方胶位太溥,这些产品问题我们可以自己修改吗?修改后会给交给你确认。

There is no draft angle in the 3D drawing, some materials are too thick, and some place are toothin. Can we modify this part by ourselves? We will send the drawing to you for you to check after we modify it.9. 按你们提供的缩水率千分之五,这个模具的尺寸已经做到了模具图面要求。

但注塑出来的产品不符合你们的产品图。

请确认你们的材料的缩水率是否正确?According to the shrinkage one over two hundred, the mold has been done in the right dimension, but the part falls short to your part drawing, are you sure the shrinkage is right?10. 产品的这个位置太小,导致模具钢料太溥,能够加宽这个位置吗?This position is too small and will make the steel material here too thin, can we widen it here?11. 斜顶与后面的柱位空间太小,斜顶在运动时会干涉到柱子,能移动这个柱子的位置吗?The angular lifter interferes with the boss during ejection. Please consider changing the position of the boss.12. 这个筋骨位胶厚太溥,而且高度偏高,注塑时很难填充这个筋位,可以增加这个筋骨位的厚度吗?The rib here is too thin and on the high side, so it will be difficult to fill here when we do theinjection, can you increase the thickness of this rib?13. 你是想将此筋骨位的高度加高/减低吗?加胶的位置我们将用铜公放电加深。

但减胶的位置有两种做 法,1、做镶件;2、烧焊;因为镶件的底部有运水,我们简单的做法是烧焊处理,你可以接受吗?Will you increase/decrease the material on this rib? We will use EDM if you add material, but there are two option if you choose to decrease: 1. Make inserts;2 Welding, because there is water in the bottom of the insert, is that OK?14. 这个样板的筋骨位底部烧焦,是因为排气不良,我们可以在筋骨位的中间增加一个镶件。

This sample has been burned in the bottom because the venting is not good, we can add an insert in the middle of the rib.15. 重做镶件大约需要5-6天时间,你能接受吗?It will take about 5 or 6 days to redo the insert, is that OK?16. 产品的这个面我们已经做了晒纹处理,如果需要加胶,这个面我们需要重新外发晒纹。

可能需要几天的时间。

所以我们直接以铜公放电的火花纹取代你要求的纹路,你可以接受吗?We have made the texture on this side, if we add material, it will take some days to remake thetexture by out-resourcing, so we suggest using the texture by EDM instead, is that OK?17. 模具是用公制/英制的配件?需要备用件吗?Is this mold dimension measured in inches or meters? Does it need spare parts? 18. 模具上铭牌上的刻字内容是由你们提供吗?你们什么时候可以这些刻字资料。

Will you provide the engraving content of the plate of this mold to us? Whenwill you send it?19. 可否提供此模具生产时,注塑机的型号及相关资料。

如:啤机大小、呵林柱尺寸、顶棍孔尺寸等Can you provide the type of injection machine and other related information of this mold to us?Such as the boss dimension, the hole's dimension of the ejector pin and the size of the injectionmachine and so on.20. 这个问题我需要同其它同事商议会再答复你。

I need to discuss this problem with the other colleagues and then I will reply back to you.21. 我们将尽力达成你的计划,如有异常,会及时通知你。

We will try our best to complete your plan, if there are any complications, we will notify youimmediately.22.这个产品的长度为330.12MM,宽度为78.96MM,高度为45MM.胶厚为2MM,重量为70.63g,试模注塑机型号为250吨,胶料颜色为黑色,产品外表面晒纹处理,内表面为抛光.需要日期章、环保章、材料章.前后模用2344氮硬,斜顶和行位座用738H,以上模具信息正确吗?请确认!The length of this part is 330.12MM, Width is 78.96MM, height is 45MM, thickness is 2MM, weight is 70.63g, the injection machine is 250T, the material is black, the outside of the part has texture, inner side needs polishing, and it also needs a date and recycle stamp ,the core & cavity is 2344 nitridng, the lifter and slider shelf is 738H. Please check the information above!23. 现在到了吃午钣的时间,我们下午再继续好吗?It is time to have lunch, let's discuss this project later this afternoon?24.和滑塊干涉的倒勾請加料填平至滑塊可以順利滑動(The undercut area interferes with the slide block and needs to be filled with material to help the slider move smoothly.)25. 加肉太多 (The thickness added is too thick.)26. 加肉面積太大 (The thickening area is too wide.)27.GATE位置移位 ( The gate position is moved.)28. 滑塊拆的位置 (The split line of slide block or the area of slide.)29. 此處有尖角,填充困難 (It is hard to fill this area due to the sharp feature.)30. 此處鋼材太薄,強度不足而且不容易冷卻(The strength of this area is too weak and it is hard to cool because the steel is too thin.)31. 圓柱特徵要有一半圓不可以拆在滑塊上,以免粘滑塊造成拉白,拉斷(We avoid designing the semicircle of the cylinder on the slide block because it will be pulledapart or cause drag marks.)32. 此處做斜銷在作動時會削到成品肉厚(The part will be damaged if we make the lifter in this area.)33. 這個面是裝配面,不能加料(This is a critical surface where we cannot add additional material.)34. 此處料位太厚,會有縮水,建議減料改善(Because of the shrinkage of the thickness, we suggest reducing some wall thickness to improve it.)35. 此面是不是外觀面,此處做滑塊的話會有夾線,是否可以接受(Please confirm whether it is a critical surface or not. Also, confirm whetherit is acceptable tohave a slide split line if we have a slide in this area. )36. 此處有倒勾,能否減料,使公母模靠破,不做滑塊和斜銷(Please confirm whether we can reduce material to the area where we have an undercut as indicated to have shut off on cavity side. No slide block and lifter will be made. )37. 請盡快確認這種拆模方式和結構,否則會影響模期(Please confirm the issues of Parting line, Gate position...Etc. as soon as possible; otherwise,the lead-time will be extended.)38. 此面是否有特殊要求,能否有頂針印(Please confirm whether it is a critical surface or not and if we can have E.J. pin marks on it.)39. P.L面開在此處,模具上會有尖角和刀口,對模具壽命有影響(There are sharp edges if we set the parting line here, It will reduce the tool life)40. 加大拔模角,以便脫模順利 We suggest enlarging the draft angle to help release the tool.)41. GATE做在此處的話有兩個缺點:1.蓋子打開時可以看到GATE的修剪部位; 2.兩個斜銷在同一側,頂出也不是很平衡.(There are two problems if the gate is to be designed in this area:a). It is easy to see the gate mark when you open the cap.b). The ejectors are unbalanced when two lifters are on the same side)42. GATE做在此處的話.蓋子打開後看不到GATE的修剪部位(The gate mark is not visible if the gate position is designed like this.)43. 如果GATE一定要做在你們指定的位置的話,那還不如做在這一側,這樣的話還可以減小這個位置的縮水(If you insist that the gate position has to be like the original design, then we would furtherrecommend to have it to the area indicated so it can avoid a shrink problem in 44. 在此處GATE做潛頂針的話,背後的外觀面會有沖料痕,而且成品又是黑色的,會最明顯(If the design of the gate has to be a sub. Gate, then the back surface of the part will haveserious flow marks due to the black color.)22. P.L開在此處不合理,模具加工困難,P.L應改為和圖示的一樣(This area is not suitable to have a Parting line because the tool will become more complicated;therefore we recommend to have the Parting line as indicated)45。