Fabrication of extended-release patient-tailored

- 格式:pdf

- 大小:1.71 MB

- 文档页数:7

HIGHLIGHTS OF PRESCRIBING INFORMATIONThese highlights do not include all the information needed to use DESVENLAFAXINE EXTENDED-RELEASE TABLETS safely and effectively. See full prescribing information for desvenlafaxine extended-tablets in a patient who is being treated with linezolid or intravenousmethylene blue (4).-----------------------WARNINGS AND PRECAUTIONS-----------------------release tablets.DESVENLAFAXINE extended-release tablets, for oral useInitial U.S. Approval: 2008WARNING: SUICIDAL THOUGHTS AND BEHAVIORSSee full prescribing information for complete boxed warning.•••Increased risk of suicidal thinking and behavior in children, adolescents and young adults taking antidepressants (5.1). Monitor for worsening and emergence of suicidal thoughts and behaviors (5.1).Desvenlafaxine extended-release tablets are not approved for use in pediatric patients (8.4).----------------------------INDICATIONS AND USAGE---------------------------Desvenlafaxine extended-release tablets, a serotonin and norepinephrine reuptake inhibitor (SNRI), are indicated for the treatment of major depressive disorder (MDD) (1).----------------------DOSAGE AND ADMINISTRATION----------------------•Recommended dose: 50 mg once daily with or without food (2.1). •There was no evidence that doses greater than 50 mg per day confer any additional benefit (2.1).•Discontinuation: Reduce dose gradually whenever possible (2.1). •Take tablets whole; do not divide, crush, chew, or dissolve (2.1). •Moderate renal impairment: Maximum dose is 50 mg per day (2.2). •Severe renal impairment and end-stage renal disease (ESRD): Maximum dose is 50 mg every other day (2.2).•Moderate to severe hepatic impairment: Maximum dose is 100 mg per day (2.2).---------------------DOSAGE FORMS AND STRENGTHS---------------------• Desvenlafaxine extended-release tablets are available as 50 mg and 100 mg (3).• Each tablet contains 75.45 mg or 150.9 mg of desvenlafaxine fumarate equivalent to 50 mg or 100 mg of desvenlafaxine (3).-------------------------------CONTRAINDICATIONS-----------------------------• Hypersensitivity to desvenlafaxine fumarate, venlafaxine hydrochloride or any excipients in the desvenlafaxine extended-release tabletformulation (4).• Serotonin syndrome and MAOIs: Do not use MAOIs intended to treat psychiatric disorders with desvenlafaxine extended-release tablets orwithin 7 days of stopping treatment with desvenlafaxine extended-release tablets. Do not use desvenlafaxine extended release tabletswithin 14 days of stopping an MAOI intended to treat psychiatricdisorders. In addition, do not start desvenlafaxine extended release FULL PRESCRIBING INFORMATION: CONTENTS*WARNING: SUICIDAL THOUGHTS AND BEHAVIORS1 INDICATIONS AND USAGE2 DOSAGE AND ADMINISTRATION2.1 General Instruction for Use2.2 Special Populations2.3 Maintenance/Continuation/Extended Treatment2.4 Discontinuing Desvenlafaxine Extended-Release Tablets2.5 Switching Patients From Other Antidepressants to DesvenlafaxineExtended-Release Tablets2.6 Switching Patients To or From a Monoamine Oxidase Inhibitor(MAOI) Intended to Treat Psychiatric Disorders3 DOSAGE FORMS AND STRENGTHS •Serotonin Syndrome: Serotonin syndrome has been reported with SSRIs and SNRIs, including with desvenlafaxine extended-release tablets, both when taken alone, but especially when co-administered with otherserotonergic agents (including triptans, tricyclic antidepressants,fentanyl, lithium, tramadol, tryptophan, buspirone, and St. John's Wort).If such symptoms occur, discontinue desvenlafaxine extended-releasetablets and initiate supportive treatment. If concomitant use ofdesvenlafaxine extended-release tablets with other serotonergic drugs is clinically warranted, patients should be made aware of a potentialincreased risk for serotonin syndrome, particularly during treatmentinitiation and dose increases (5.2).•Elevated Blood Pressure: Control hypertension before initiating treatment. Monitor blood pressure regularly during treatment (5.3). •Abnormal Bleeding: Desvenlafaxine extended-release tablets may increase risk of bleeding events. Caution patients about risk of bleeding associated with concomitant use of desvenlafaxine extended-releasetablets and NSAIDs, aspirin, or other drugs that affect coagulation (5.4). •Narrow-angle Glaucoma: Mydriasis has occurred with desvenlafaxine extended-release tablets. Monitor patients with raised intraocularpressure or those at risk of angle-closure glaucoma (5.5).•Activation of Mania/Hypomania: Use cautiously in patients with Bipolar Disorder. Caution patients about the risk of activation ofmania/hypomania (5.6).•Discontinuation Syndrome: Taper dose when possible and monitor for discontinuation symptoms (5.7). (5.7).•Seizure: Can occur. Use cautiously in patients with seizure disorder(5.8).•Hyponatremia: Can occur in association with SIADH (5.9). •Interstitial Lung Disease and Eosinophilic Pneumonia: Can occur(5.10).------------------------------ADVERSE REACTIONS------------------------------Most common adverse reactions (incidence ≥ 5% and twice the rate of placebo in the 50 or 100 mg dose groups) were: nausea, dizziness, insomnia, hyperhidrosis, constipation, somnolence, decreased appetite, anxiety, and specific male sexual function disorders (6.1).To report SUSPECTED ADVERSE REACTIONS, contact TEVA USA, PHARMACOVIGILANCE at 1-866-832-8537 ordrug.safety@; or FDA at 1-800-FDA-1088 or/medwatch.-----------------------USE IN SPECIFIC POPULATIONS-----------------------• Pregnancy: Based on animal data, may cause fetal harm. (8.1).• Nursing Mothers: Discontinue drug or nursing taking into consideration importance of drug to mother (8.3).• Geriatric Use: There is an increased incidence of orthostatic hypotension in desvenlafaxine extended-release tablet treated patients ≥ 65 years (6.1 and 8.5).See 17 for PATIENT COUNSELING INFORMATION and Medication Guide.Revised: 10/20134 CONTRAINDICATIONS5 WARNINGS AND PRECAUTIONS5.1 Suicidal Thoughts and Behaviors in Adolescents and Young Adults5.2 Serotonin Syndrome5.3 Elevated Blood Pressure5.4 Abnormal Bleeding5.5 Narrow-Angle Glaucoma5.6 Activation of Mania/Hypomania5.7 Discontinuation Syndrome5.8 Seizure5.9 Hyponatremia5.10 Interstitial Lung Disease and Eosinophilic Pneumonia6 ADVERSE REACTIONS6.1 Clinical Studies Experience6.2 Postmarketing Experience7 DRUG INTERACTIONS7.1 Monoamine Oxidase Inhibitors (MAOI)7.2 Serotonergic Drugs7.3 Drugs that Interfere with Hemostasis (e.g., NSAIDs, Aspirin, andWarfarin)7.4 Potential for Desvenlafaxine to Affect Other Drugs7.5 Other Drugs Containing Desvenlafaxine or Venlafaxine7.6 Ethanol8 USE IN SPECIFIC POPULATIONS8.1 Pregnancy8.3 Nursing Mothers8.4 Pediatric Use8.5 Geriatric Use8.6 Renal ImpairmentFULL PRESCRIBING INFORMATION8.7 Hepatic Impairment9 DRUG ABUSE AND DEPENDENCE9.1 Controlled Substance10 OVERDOSAGE10.1 Human Experience With Overdosage10.2 Management of Overdosage11 DESCRIPTION12 CLINICAL PHARMACOLOGY12.1 Mechanism of Action12.2 Pharmacodynamics12.3 Pharmacokinetics13 NONCLINICAL TOXICOLOGY13.1 Carcinogenesis, Mutagenesis, Impairment of Fertility14 CLINICAL STUDIES16 HOW SUPPLIED/STORAGE AND HANDLING17 PATIENT COUNSELING INFORMATION*Sections or subsections omitted from the full prescribing information are not listed.WARNING: SUICIDAL THOUGHTS AND BEHAVIORSAntidepressants increased the risk of suicidal thoughts and behavior in children,adolescents, and young adults in short-term studies. These studies did not show anincrease in the risk of suicidal thoughts and behavior with antidepressant use in patientsover age 24; there was a reduction in risk with antidepressant use in patients aged 65 andolder [see Warnings and Precautions (5.1)].In patients of all ages who are started on antidepressant therapy, monitor closely forworsening, and for emergence of suicidal thoughts and behaviors. Advise families andcaregivers of the need for close observation and communication with the prescriber [seeWarnings and Precautions (5.1)].Desvenlafaxine extended-release tablets are not approved for use in pediatric patients[see Use in Specific Populations (8.4)].1 INDICATIONS AND USAGEDesvenlafaxine extended-release tablets, a serotonin and norepinephrine reuptake inhibitor (SNRI), are indicated for the treatment of major depressive disorder (MDD) [see Clinical Studies (14) and Dosage and Administration (2.1)]. The efficacy of desvenlafaxine extended-release tablets has been established in four short-term (8-week, placebo-controlled studies) in adult outpatients who met DSM-IV criteria for major depressive disorder.2 DOSAGE AND ADMINISTRATION2.1 General Instruction for UseThe recommended dose for desvenlafaxine extended-release tablets is 50 mg once daily, with or without food.In clinical studies, doses of 50 mg to 400 mg per day were shown to be effective, although no additional benefit was demonstrated at doses greater than 50 mg per day and adverse reactions and discontinuations were more frequent at higher doses.When discontinuing therapy, gradual dose reduction is recommended whenever possible to minimize discontinuation symptoms [see Dosage and Administration (2.4) and Warnings and Precautions (5.7)].Desvenlafaxine extended-release tablets should be taken at approximately the same time each day. Tablets must be swallowed whole with fluid and not divided, crushed, chewed, or dissolved.2.2 Special PopulationsPatients with renal impairmentThe maximum recommended dose in patients with moderate renal impairment (24-hr creatinine clearance [CrCl] = 30 to 50 mL/min, Cockcroft-Gault [C-G]) is 50 mg per day. The maximum recommended dose in patients with severe renal impairment (24-hr CrCl less than 30 mL/min, C-G) or end-stage renal disease (ESRD) is 50 mg every other day. Supplemental doses should not be given to patients after dialysis [see Use in Specific Populations (8.6) and Clinical Pharmacology (12.3)].Patients with hepatic impairmentThe recommended dose in patients with moderate to severe hepatic impairment is 50 mg per day. Dose escalation above 100 mg per day is not recommended [see Clinical Pharmacology (12.3)].2.3 Maintenance/Continuation/Extended TreatmentIt is generally agreed that acute episodes of major depressive disorder require several months or longer of sustained pharmacologic therapy. Patients should be periodically reassessed to determine the need for continued treatment.2.4 Discontinuing Desvenlafaxine Extended-Release TabletsSymptoms associated with discontinuation of desvenlafaxine extended-release tablets, other SNRIs and SSRIs have been reported [see Warnings and Precautions (5.7)]. Patients should be monitored for these symptoms when discontinuing treatment. A gradual reduction in the dose rather than abrupt cessation is recommended whenever possible. If intolerable symptoms occur following a decrease in the dose or upon discontinuation of treatment, then resuming the previously prescribed dose may be considered. Subsequently, the physician may continue decreasing the dose, but at a more gradual rate.2.5 Switching Patients From Other Antidepressants to Desvenlafaxine Extended-Release Tablets Discontinuation symptoms have been reported when switching patients from other antidepressants, including venlafaxine, to desvenlafaxine extended-release tablets. Tapering of the initial antidepressant may be necessary to minimize discontinuation symptoms.2.6 Switching Patients To or From a Monoamine Oxidase Inhibitor (MAOI) Intended to Treat Psychiatric DisordersAt least 14 days should elapse between discontinuation of an MAOI intended to treat psychiatric disorders and initiation of therapy with desvenlafaxine extended-release tablets. Conversely, at least 7 days should be allowed after stopping desvenlafaxine extended-release tablets before starting an MAOI intended to treat psychiatric disorders [see Contraindications (4)].Use of Desvenlafaxine Extended-Release Tablets with other MAOIs such as Linezolid or Methylene BlueDo not start desvenlafaxine extended-release tablets in a patient who is being treated with linezolid or intravenous methylene blue because there is increased risk of serotonin syndrome. In a patient who requires more urgent treatment of a psychiatric condition, other interventions, including hospitalization, should be considered [see Contraindications (4)].In some cases, a patient already receiving desvenlafaxine extended-release tablet therapy may require urgent treatment with linezolid or intravenous methylene blue. If acceptable alternatives to linezolid or intravenous methylene blue treatment are not available and the potential benefits of linezolid or intravenous methylene blue treatment are judged to outweigh the risks of serotonin syndrome in a particular patient, desvenlafaxine extended-release tablets should be stopped promptly, and linezolid or intravenous methylene blue can be administered. The patient should be monitored for symptoms of serotonin syndrome for 7 days or until 24 hours after the last dose of linezolid or intravenous methylene blue, whichever comes first. Therapy with desvenlafaxine extended-release tablets may be resumed 24 hours after the last dose of linezolid or intravenous methylene blue [see Warnings and Precautions (5.2)].The risk of administering methylene blue by non-intravenous routes (such as oral tablets or by local injection) or in intravenous doses much lower than 1 mg/kg with desvenlafaxine extended-release tablets is unclear. The clinician should, nevertheless, be aware of the possibility of emergent symptoms of serotonin syndrome with such use [see Warnings and Precautions (5.2)].3 DOSAGE FORMS AND STRENGTHSDesvenlafaxine extended-release tablets are available as:50 mg, light-pink, film-coated round shaped tablets, debossed with "T" on one side of the tablet and with "N1" on the other side.100 mg, reddish-orange, film-coated round shaped tablet, debossed with "T" on one side of the tablet and with "N2" on the other side.4 CONTRAINDICATIONS• Hypersensitivity to desvenlafaxine fumarate, venlafaxine hydrochloride or to any excipients in the desvenlafaxine extended-release tablet formulation. Angioedema has been reported in patients treated with desvenlafaxine extended-release tablets [see Adverse Reactions (6.1)].• The use of MAOIs intended to treat psychiatric disorders with desvenlafaxine extended-release tablets or within 7 days of stopping treatment with desvenlafaxine extended-release tablets is contraindicated because of an increased risk of serotonin syndrome. The use of desvenlafaxine extended-release tablets within 14 days of stopping an MAOI intended to treat psychiatric disorders is also contraindicated [see Dosage and Administration (2.6) and Warnings and Precautions (5.2)].Starting desvenlafaxine extended-release tablets in a patient who is being treated with MAOIs such as linezolid or intravenous methylene blue is also contraindicated because of an increased risk of serotonin syndrome [see Dosage and Administration (2.6) and Warnings and Precautions (5.2)].5 WARNINGS AND PRECAUTIONS5.1 Suicidal Thoughts and Behaviors in Adolescents and Young AdultsPatients with major depressive disorder (MDD), both adult and pediatric, may experience worsening of their depression and/or the emergence of suicidal ideation and behavior (suicidality) or unusual changes in behavior, whether or not they are taking antidepressant medications, and this risk may persist until significant remission occurs. Suicide is a known risk of depression and certain other psychiatric disorders, and these disorders themselves are the strongest predictors of suicide. There has been a long-standing concern, however, that antidepressants may have a role in inducing worsening of depression and the emergence of suicidality in certain patients during the early phases of treatment. Pooled analyses of short-term placebo-controlled studies of antidepressant drugs (SSRIs and others) showed that these drugs increase the risk of suicidal thinking and behavior (suicidality) in children, adolescents, and young adults (ages 18 to 24) with major depressive disorder (MDD) and other psychiatric disorders. Short-term studies did not show an increase in the risk ofsuicidality with antidepressants compared to placebo in adults beyond age 24; there was a reduction with antidepressants compared to placebo in adults aged 65 and older.The pooled analyses of placebo-controlled studies in children and adolescents with MDD, obsessive compulsive disorder (OCD), or other psychiatric disorders included a total of 24 short-term studies of 9 antidepressant drugs in over 4,400 patients. The pooled analyses of placebo-controlled studies in adults with MDD or other psychiatric disorders included a total of 295 short-term studies (median duration of 2 months) of 11 antidepressant drugs in over 77,000 patients. There was considerable variation in risk of suicidality among drugs, but a tendency toward an increase in the younger patients for almost all drugs studied. There were differences in absolute risk of suicidality across the different indications, with the highest incidence in MDD. The risk differences (drug vs. placebo), however, were relatively stable within age strata and across indications. These risk differences (drug-placebo difference in the number of cases of suicidality per 1000 patients treated) are provided in Table 1.Table 1Drug-Placebo Difference in Number of Cases of Suicidality per 1,000Patients TreatedAge RangeIncreases Compared to Placebo< 18 14 additional cases18 to 24 5 additional casesDecreases Compared to Placebo25 to 64 1 fewer case≥ 65 6 fewer casesNo suicides occurred in any of the pediatric studies. There were suicides in the adult studies, but the number was not sufficient to reach any conclusion about drug effect on suicide.It is unknown whether the suicidality risk extends to longer-term use, i.e., beyond several months. However, there is substantial evidence from placebo-controlled maintenance studies in adults with depression that the use of antidepressants can delay the recurrence of depression.All patients being treated with antidepressants for any indication should be monitored appropriately and observed closely for clinical worsening, suicidality, and unusual changes in behavior, especially during the initial few months of a course of drug therapy, or at times of dose changes, either increases or decreases.The following symptoms, anxiety, agitation, panic attacks, insomnia, irritability, hostility, aggressiveness, impulsivity, akathisia (psychomotor restlessness), hypomania, and mania, have been reported in adult and pediatric patients being treated with antidepressants for major depressive disorder as well as for other indications, both psychiatric and nonpsychiatric. Although a causal link between the emergence of such symptoms and either the worsening of depression and/or the emergence of suicidal impulses has not been established, there is concern that such symptoms may represent precursors to emerging suicidality.Consideration should be given to changing the therapeutic regimen, including possibly discontinuing the medication, in patients whose depression is persistently worse, or who are experiencing emergent suicidality or symptoms that might be precursors to worsening depression or suicidality, especially if these symptoms are severe, abrupt in onset, or were not part of the patient’s presenting symptoms.If the decision has been made to discontinue treatment, medication should be tapered, as rapidly as is feasible, but with recognition that abrupt discontinuation can be associated with certain symptoms [see Dosage and Administration (2.4) and Warnings and Precautions (5.7) for a description of the risks of discontinuation of desvenlafaxine extended-release tablets].Families and caregivers of patients being treated with antidepressants for major depressive disorder or other indications, both psychiatric and nonpsychiatric, should be alerted about the need to monitor patients for the emergence of agitation, irritability, unusual changes in behavior, and the other symptoms described above, as well as the emergence of suicidality, and to report such symptoms immediately to healthcare providers. Such monitoring should include daily observation by families and caregivers.Prescriptions for desvenlafaxine extended-release tablets should be written for the smallest quantity of tablets consistent with good patient management, in order to reduce the risk of overdose.Screening patients for bipolar disorderA major depressive episode may be the initial presentation of bipolar disorder. It is generally believed (though not established in controlled studies) that treating such an episode with an antidepressant alone may increase the likelihood of precipitation of a mixed/manic episode in patients at risk for bipolar disorder. Whether any of the symptoms described above represent such a conversion is unknown. However, prior to initiating treatment with an antidepressant, patients with depressive symptoms should be adequately screened to determine if they are at risk for bipolar disorder; such screening should include a detailed psychiatric history, including a family history of suicide, bipolar disorder, and depression. It should be noted that desvenlafaxine extended-release tablets are not approved for use in treating bipolar depression.5.2 Serotonin SyndromeThe development of a potentially life-threatening serotonin syndrome has been reported with SNRIs and SSRIs, including desvenlafaxine extended-release tablets, alone but particularly with concomitant use of other serotonergic drugs (including triptans, tricyclic antidepressants, fentanyl, lithium, tramadol, tryptophan, buspirone, and St. John's Wort), and with drugs that impair metabolism of serotonin (in particular, MAOIs, both those intended to treat psychiatric disorders and also others, such as linezolid and intravenous methylene blue).Serotonin syndrome symptoms may include mental status changes (e.g., agitation, hallucinations, delirium, and coma), autonomic instability (e.g., tachycardia, labile blood pressure, dizziness, diaphoresis, flushing, hyperthermia), neuromuscular symptoms (e.g., tremor, rigidity, myoclonus, hyperreflexia, incoordination), seizures, and/or gastrointestinal symptoms (e.g., nausea, vomiting, diarrhea). Patients should be monitored for the emergence of serotonin syndrome.The concomitant use of desvenlafaxine extended-release tablets with MAOIs intended to treat psychiatric disorders is contraindicated. Desvenlafaxine extended-release tablets should also not be started in a patient who is being treated with MAOIs such as linezolid or intravenous methylene blue. All reports with methylene blue that provided information on the route of administration involved intravenous administration in the dose range of 1 mg/kg to 8 mg/kg. No reports involved the administration of methylene blue by other routes (such as oral tablets or local tissue injection) or at lower doses. There may be circumstances when it is necessary to initiate treatment with a MAOI such as linezolid or intravenous methylene blue in a patient taking desvenlafaxine extended-release tablets. Desvenlafaxine extended-release tablets should be discontinued before initiating treatment with the MAOI [see Contraindications (4) and Dosage and Administration (2.6)]. If concomitant use of desvenlafaxine extended-release tablets with other serotonergic drugs, including triptans, tricyclic antidepressants, fentanyl, lithium, tramadol, buspirone, tryptophan, and St. John's Wort is clinically warranted, patients should be made aware of a potential increased risk for serotonin syndrome, particularly during treatment initiation and dose increases.Treatment with desvenlafaxine extended-release tablets and any concomitant serotonergic agents should be discontinued immediately if the above events occur and supportive symptomatic treatment should be initiated.5.3 Elevated Blood PressurePatients receiving desvenlafaxine extended-release tablets should have regular monitoring of blood pressure since increases in blood pressure were observed in clinical studies [see Adverse Reactions (6.1)]. Pre-existing hypertensionshould be controlled before initiating treatment with desvenlafaxine extended-release tablets. Caution should be exercised in treating patients with pre-existing hypertension, cardiovascular, or cerebrovascular conditions that might be compromised by increases in blood pressure. Cases of elevated blood pressure requiring immediate treatment have been reported with desvenlafaxine extended-release tablets.Sustained blood pressure increases could have adverse consequences. For patients who experience a sustained increase in blood pressure while receiving desvenlafaxine extended-release tablets, either dose reduction or discontinuation should be considered [see Adverse Reactions (6.1)].5.4 Abnormal BleedingSSRIs and SNRIs, including desvenlafaxine extended-release tablets, may increase the risk of bleeding events. Concomitant use of aspirin, nonsteroidal anti-inflammatory drugs, warfarin, and other anticoagulants may add to this risk. Case reports and epidemiological studies (case-control and cohort design) have demonstrated an association between use of drugs that interfere with serotonin reuptake and the occurrence of gastrointestinal bleeding. Bleeding events related to SSRIs and SNRIs have ranged from ecchymosis, hematoma, epistaxis, and petechiae to life-threatening hemorrhages. Patients should be cautioned about the risk of bleeding associated with the concomitant use of desvenlafaxine extended-release tablets and NSAIDs, aspirin, or other drugs that affect coagulation or bleeding.5.5 Narrow-Angle GlaucomaMydriasis has been reported in association with desvenlafaxine extended-release tablets; therefore, patients with raised intraocular pressure or those at risk of acute narrow-angle glaucoma (angle-closure glaucoma) should be monitored.5.6 Activation of Mania/HypomaniaDuring all MDD 2 and phase 3 studies, mania was reported for approximately 0.02% of patients treated with desvenlafaxine extended-release tablets. Activation of mania/hypomania has also been reported in a small proportion of patients with major affective disorder who were treated with other marketed antidepressants. As with all antidepressants, desvenlafaxine extended-release tablets should be used cautiously in patients with a history or family history of mania or hypomania.5.7 Discontinuation SyndromeDiscontinuation symptoms have been systematically and prospectively evaluated in patients treated with desvenlafaxine extended-release tablets during clinical studies in Major Depressive Disorder. Abrupt discontinuation or dose reduction has been associated with the appearance of new symptoms that include dizziness, nausea, headache, irritability, insomnia, diarrhea, anxiety, fatigue, abnormal dreams, and hyperhidrosis. In general, discontinuation events occurred more frequently with longer duration of therapy.During marketing of SNRIs (Serotonin and Norepinephrine Reuptake Inhibitors), and SSRIs (Selective Serotonin Reuptake Inhibitors), there have been spontaneous reports of adverse events occurring upon discontinuation of these drugs, particularly when abrupt, including the following: dysphoric mood, irritability, agitation, dizziness, sensory disturbances (e.g., paresthesia, such as electric shock sensations), anxiety, confusion, headache, lethargy, emotional lability, insomnia, hypomania, tinnitus, and seizures. While these events are generally self-limiting, there have been reports of serious discontinuation symptoms.Patients should be monitored for these symptoms when discontinuing treatment with desvenlafaxine extended-release tablets. A gradual reduction in the dose rather than abrupt cessation is recommended whenever possible. If intolerable symptoms occur following a decrease in the dose or upon discontinuation of treatment, then resuming the previously prescribed dose may be considered. Subsequently, the physician may continue decreasing the dose, but at a more gradual rate [see Dosage and Administration (2.4) and Adverse Reactions (6.1)].。

Emergency stop switches, generally referred to as E-Stops, ensure the safety of persons and machinery and provide consistent, predictable, failsafe control response. A wide range of electrical machinery must have these specialized switch controls for emergency shutdown to meet workplace safety and established international and U.S. regulatory requirements. E-Stops – critical human machine interface (HMI) devices – differ from simple stop switches (that merely turn equipment off) in that they offer “foolproof” equipment shutdown. This is accomplished through advanced switch design that requires a twist, pull, or key to release electrical contacts to allow machinery restart.E-Stops are generally designed for failsafe operation so the stop command has priority over the sustaining function. This has led to innovative switch designs that prevent “blocking” (wanton or accidental obstruction of the actuator with foreign objects) and “teasing” (which could result in premature or unreliable action). Switch companies also are developing new solutions to problems that arise when contact block and actuator are improperly installed or separated because of vibration or other malfunction. Safe Emergency StoppingAccording to international standards, the emergency stop function must be initiated by a single human action using a manually actuated control device. The E-Stop function mustbe operational at all times and designed to stop the machine without creating additional hazards.Resetting the electrical system can only be done by first releasing the E-Stop that was originally activated. If E-Stops were activated at multiple locations, all must be released before machinery restart. It should be noted that resetting E-Stops does not in itself restart the machinery; it only permits restarting through normal procedures appropriate for the machinery involved. Ergonomic, electrical, mechanical, and color requirements for E-Stops are quite specific. The E-Stop control, commonly a distinctive pushbutton switch or “mushroom type” pushbutton (although wires, ropes, bars, handles, or foot pedals are sometimes employed), must use direct mechanical actionwith mechanical latching. When the E-Stop is activated (pushed), it permanently opens the electrical contacts through a latching mechanism. To close the electrical contacts and allow machinery restart, the E-Stop actuator must be manually unlatched with a twist or a key release. Some E-Stop actuators can simply be pulled to close the electrical contacts.This approach may be less desirable from a safety standpoint than a twist or key release, which requires a more deliberate action by an operator.Designers should be aware of international and U.S. standards and regulations that impact the design and use of E-Stops.Emergency Stop SwitchesJoseph Torzillo, VP Sales, HMI ComponentsLance A. Scott, President, EAO Switch CorporationPicture Picture(grayscale)E-Stops are critical to the human machine interface (HMI).Selecting the Right E-Stopfor Your ApplicationBecause of the confusing array ofE-Stops available, it is important to understand the design basics that contribute to high-quality, ergonomic switch design. EAO is a leader in HMI Components and Systems, including innovative, rugged, reliable, and affordable E-Stops that meet or exceed international and U.S. standards. One of the first steps is determiningwhere the E-Stop fits within your machine control system and whether your particular application requires Category 0 or Category 1 type emergency shutdown. The intended application often determines the placement, size, electrical specifications, mechanical characteristics, ergonomics, color/legends, and number of E-Stops required. So a thorough understanding of the machinery and associated control systems is key to making the right E-Stop choice.A second, and equally important step, is determining what international and U.S. standards, performance ratings, and codes apply for your application. Requirements vary by industry segment, so standards for E-Stops used on transportation vehicles may differ significantly from those used on process machinery or medical equipment and will be governed by different regulatory bodies specific to those segments. Regulatory bodies may also specify size, color, legend, contact terminals, etc.It is then useful to construct or consultan existing E-Stop series selector chart (often supplied by vendors). For example, EAO provides a chart that allows easy comparison of key design factors(see Figure 2). You can select panel opening size, type of actuator, type andnumber of contact blocks, connectors,colors, and maximum electrical rating tocome up with one or more appropriatemodels.Like many vendors, EAO provides specialenclosures, switch guards, palm guards,custom labeling, and other accessories tocomplete virtually any E-Stop application.Some accessories may be specified byindustry standards, such as the SEMIstandards for semiconductor fabricationequipment that mandate the use of palmguards. EAO and other vendors also offerservices to assist customers in the design,engineering, and production of HMISystems, integrating E-Stops.Designed for rough dutyRobust, heavy-duty construction is thehallmark of the original 22.5 mm switches.Many, like the EAO Series 04 E-Stops,have stackable contact blocks, optionalkey release actuators, and mountingoptions for 22.5 mm panel openings. ThisEAO series is rated at up to 10 A, 600VAC, has silver contacts with availablegold over silver or silver over palladiumcontacts, and silver-plated screw terminalswith available quick-connect terminals.Smaller mounting footprintModern applications often demanda slimmed down E-Stop with 16 mmmounting. Innovative products, like theEAO Series 61, are now available with anactuator shape that prevents blockagefrom foreign objects, a black indicatorring visible from long distances, andavailable key release actuators. This EAOseries is rated at 5 A, 250 VAC, and has achoice of silver or gold contacts, screw orsolder quick-connect terminals.An E-Stop must be initiated by a single human action using a manual control device.A 22.5 mm switch must be durable and rugged.T oday’s applications often require a slimmer footprint.12345Figure 1 – Parts of an E-StopShort behind-panel depthNewer electronic applications are requiring E-Stops with shorter behind-panel depth. EAO’s Series 84 E-Stop,for example, features a very short behind-panel depth (18 mm maximum), single “mono-block” construction, 22.5 mm mounting, and available LED illumination that is visible from the side as well as front of the actuator. This series is rated at 3 A, 120 VAC and 1.5 A, 240 VAC, has gold contacts, quick-connect/solder printed circuit board terminals, and ribbon cable terminals.ApplicationsVirtually all industry segments – from machinery, instrumentation, medical treatment and diagnostic, lifting/ moving, and transportation – mandateE-Stops for safe operation. Designers need to have a thorough knowledge ofE-Stop fundamentals, E-Stop switch characteristics and capabilities, and the international and U.S. standards and compliance requirements that apply to their application areas.E-Stops are required on all machinery independent of the type of energy used to control the function, except for ma-chines in which an E-Stop function would not lessen the risk. An E-Stop switch is intended to be one part of a compre-hensive safety system, so the equip-ment designer must also consider safetyfunctions, such as reversal or limitationof motion, deflection, shielding, braking,or disconnecting, that are not specificallyaddressed in this paper. Primary applica-tion areas where electrical machineryis safeguarded with E-Stop technologyinclude:MetalworkingWood productionTextile productionFood processingPrintingMedical laser & x-ray equipmentPackaging equipmentSemi-fab equipmentPumpingLifting/moving equipmentPlastics & rubber processingMaterials handlingElectronic production equipmentPaper & cardboard productionInspection/testing equipmentCompressorsLaundry/dry cleaning facilitiesTransportationConstruction/building materialsX-ray EquipmentCabinet x-ray systems used fordiagnostic and therapeutic medicalapplications, industrial non-destructiveinspection and thickness gauging,security inspection of baggage, andother imaging are closely regulated foroperational safety. E-Stops are coveredby standards and regulations of theFDA Department of Health and HumanServices. The key document is CFR Title21, Part 1020 – Performance Standardsfor Ionizing Radiation Emitting Products,section 40, which requires accessibleemergency stop switches and keyedlock-out switches to disable the system.Semiconductor ManufacturingSemiconductor chips used in electricaland electronic devices are fabricatedthrough a sequence of photographicand chemical processing steps. Theprocess includes lithography, steppers,etching, and deposition equipment. Thecomplex process is governed by specificoperational and safety guidelines setdown by SEMI, a trade organization ofsuppliers of equipment and materialsused in the fabrication of semiconductordevices. SEMI S2-93 makes a cleardistinction between emergency off (EMO)switches and E-Stops, requiring the latterto be clearly distinguishable from EMOsthrough the use of color (red), actuatorshape (extended not mushroom), andlabeling (“Emergency Stop”). It alsospecifies that E-Stops should stop allhazardous mechanical motion at theequipment interface, but not shut offMedical imaging E-Stops are closely regulated.In semiconductor manufacturing, there are strictguidelines set by the SEMI trade organization.E-Stops may require shorter behind-panel depth.associated equipment.Overhead and Gantry CranesThese large lifting and moving devices may have a gantry mounted cab which includes an E-Stop on the operator console. Smaller overhead cranes usually have a wired or wireless pendant control operated from ground level. The pendant includes an E-Stop. The chief regulating body for these massive devices is the Occupational Safety and Health Administration. OSHA 29 CFR 1910.179 (a)(59) defines “emergency stop switch” as a manually or automatically operated electric switch to cut off electric power independent of the regular operating controls. Another section, 9 CFR 1910.179(a)(61) defines “main switch”as a device controlling the entire power supply to the crane.U.S. Standards for E-Stops Occupational Safety and Health Administration (OSHA) – Standards –29 CFR (Code of Federal Regulations); OSHA 1910American National Standards Institute (ANSI) – B11, Electrical and Mechanical Equipment GuidelinesANSI/NFPA (National Fire Protection Association) – 79, Electrical Standardsfor Industrial MachineryUnderwriters Laboratories Inc. (UL) –Category NISD, Emergency Stop DeviceFood and Drug Administration,Department of Health and HumanServices, Subchapter J – RadiologicalHealth: CRF Title 21, Part 1020,Performance Standards for IonizingRadiation Emitting ProductsOther Complianceand Rating BodiesMost quality E-Stop switches, includingthose made by EAO, are RoHS andREACH compliant, meet cUL (CanadianUL) requirements, and TÜV (TechnischerÜberwachungsverein, a German safetymonitoring agency), SEV (a Swissdesignation) and CE (European Union)approvals.Depending on design and applicationrequirements, many E-Stops are listedas UL category NISD emergencystop devices. This rating covers twocategories of E-Stop function as definedin ANSI/NFPA 79, Electrical Standardsfor Industrial Machinery (ANSI is theAmerican National Standards Instituteand NFPA is the National Fire ProtectionAssociation):1. Stop Category 0 – Immediate removalof power to the machine or mechanicaldisconnection (de-clutching) of hazardouselements.2. Stop Category 1 – Controlled stopwith power available to stop the machinefollowed by removal of power when thestop is achieved.The emergency stop actuator providedin these devices must be a self-latchingtype. E-Stops with this rating have beenreviewed for their functionality in additionto fire and electric shock safety.ISO 13850 (formerly EN418)Max rating: 5 A/250 VACMax rating: 3 A/250 VACE-Stops can be mounted on a console or on awireless pendant.Figure 3 – International standards that apply to Emergency Stops vs. Stop SwitchesFuture of the TechnologyThe pace of change in E-Stop technology is steady, not revolutionary. By their nature, these devices must be recognizable, reliable, and rugged. They have a straightforward function: instantly shut down equipment witha simple push of a (usually) bright red actuator. For safety, reactivation of the switch requires twisting or pulling the actuator by hand or, for even more security, unlocking it with a key beforemachinery can be restarted. Established standards, function, and familiarity dictate a certain beneficial inertia in new E-Stop developments.Many advances are driven by norm changes for E-Stops, such as DIN EN ISO 13850: 2008 that now requires mechanical latching and manual resetting of E-Stops. Most researchand development is aimed at improving the safety and reliability of the switches themselves and expanding their roles as lockout devices in some worker safety applications.One area of current interest is making sure that the E-Stop itself will “failsafe” should the actuator and contact block be separated. The contact block has normally closed contacts that allow power to flow to the machinery. Pushingan E-Stop separates the spring-loadedcontacts, and mechanical latching keepsthem open, stopping the machinery. Butwhat happens if the actuator separatesfrom the contact block or the latchingmechanism fails?Separation of the contact block from theactuator renders an E-Stop ineffective.Current solutions include mono-blockor unibody switches with a one-pieceactuator/contact block, as well asswitches with failsafe contact blocks thatautomatically cause machinery shutdownif the actuator and contact block areseparated.Other advances are application-driven.EAO’s Series 84 E-Stops, for example,were developed for hand-held enclosureswith slim behind-panel depth for roboticsapplications. These versatile E-Stopsalso are used in pendant controls forlifting and moving machinery. Applicationrequirements have also created a widevariety of available optional features andaccessories for most E-Stop products –illumination, protective rings, enclosures,guards, legend plates, etc. – that addto the functionality and safety of E-Stopinstallations.E-Stops will continue to evolve to meetnew standards and new applications.For designers, the most importantconsiderations in making the right designdecisions are a thorough understandingof E-Stop function; a grounding in thestandards, codes, and compliancesinvolved; proper selection of devicesthat meet or exceed the applicationrequirements.Once you understand the E-Stop function and relevant standards, codes, and compliances you candetermine the appropriate device.Emergency Stop Switches J. T orzillo, L. ScottEAO Switch Corporation98 Washington StreetMilford CT 06460T: (203) 877 4577F: (203) 877 3694E-mail:*******************Member of the EAO Group。

Materials Science and Engineering B132(2006)143–146Sustained-release of caffeine from a polymeric tablet matrix:An in vitro and pharmacokinetic studyDonna Tan a,Bin Zhao a,Shabbir Moochhala a,∗,Yi-Yan Yang ba Defence Medical&Environmental Research Institute,DSO National Laboratories(Kent Ridge),27Medical Drive,#12-00,Singapore117597,Republic of Singaporeb Institute of Bioengineering and Nanotechnology,31Biopolis Way,#04-01,The Nanos,Singapore138669,Republic of SingaporeAbstractCaffeine is utilized as a stimulant to impart a desired level of alertness during certain working ually,a single dose of caffeine induces 2–3h of alertness coupled with side effects whereas a longer effect of8–12h is very useful for both daily life and military action.Thus,there is a need to deliver the stimulant continuously to an individual at one time to impart an increased level of alertness for the period stated after administration. This study aimed to design a polymeric microparticle system for sustained delivery of caffeine using a polymeric matrix.Poly(ethylene oxide)(PEO) was used as the erodible matrix material and the caffeine polymeric tablets were fabricated by compression using a Graseby Specac hydraulic press.In vitro release profiles as well as the pharmacokinetics studies data were obtained.Caffeine tablets fabricated using various polymers showed a high initial burst release type profile as compared to the caffeine-PEO-tablet.The PK studies showed sustained delivery of caffeine resulted in two expected phenomena:a reduction in the initial high rate of caffeine release(burst release)as well as a reduction in the change in caffeine concentration in the systemic circulation.A simple two-component system for sustained-release caffeine formulation therefore has been achieved.©2006Elsevier B.V.All rights reserved.Keywords:Pharmacokinetics;Sustained-release;Caffeine;Tablet1.IntroductionMilitary personnel involved in sustained and continuous oper-ations as well as civilian shift-workers will experience situations in which long-period of alertness is required.The use of caffeine could help alleviate cognitive performance degradation during extended wakefulness[1,2].Caffeine is a well-known and widely used stimulant for cen-tral nervous system from the group of xanthine derivatives and can be used to impart a desired level of increased alertness[2]. It is safe as a component of food at doses required to over-come sleep deprivation and has been included in diets in coffee and many soft drinks.However,a single dose of caffeine usually induces2–3h of alertness coupled with side effects.An extended duration of action of8–12h is very useful for both daily life and military action[1–3].As coffee might not be readily available to soldiers and shift-workers in such situations,therefore there is a need to develop a polymeric system to achieve a sustained-release of caffeine and prolong the stimulant action.∗Corresponding author.Tel.:+6564857201;fax:+6564857226.E-mail address:mshabbir@.sg(S.Moochhala).Tablets are among the simplest drug delivery systems and hence,the obvious choice for oral delivery of drugs.For this reason,a tablet system is being optimised for the oral sustained delivery of caffeine in the gastro-intestinal tract.Poly(ethylene)oxide(PEO)is the polymeric device used to sustain the delivery of caffeine.Its advantages as a polymer of choice are mainly because of its non-toxicity,high water-solubility,insensitivity to the pH of the biological medium[4–7], and it is safe for use in humans[5].This paper describes the fabrication method as well as in vitro and in vivo animal release profiles of the polymeric-caffeine-tablet.This study aimed to design a polymeric microparticle system for sustained delivery of caffeine using a polymeric matrix.2.Materials and methods2.1.MaterialsPolymers,poly(ethylene oxide)with M w of8×106and 4×106;poly(ethylene glycol)(PEG)with M w8×103; poly(vinyl alcohol)(PV A)M w 3.1–5×104(87–89%0921-5107/$–see front matter©2006Elsevier B.V.All rights reserved. doi:10.1016/j.mseb.2006.02.031144 D.Tan et al./Materials Science and Engineering B132(2006)143–146hydrolyzed);ethyl cellulose(EC)(ethyl48%,viscosity 46cP);were purchased from Aldrich(Milwaukee,USA). Poly(vinyl pyrrolidone)(PVP)M w4×104;poly(dl-lactide-co-glycolide)(PLGA50:50)M w4–7.5×104;were purchased from Sigma(St Louis,USA).Poly(dl-lactic acid)(PLA)M w 1.5–2.5×104was purchased from Polyscience(Warrington, USA).As the original PLGA was not afine power,it was micro-nised with a freeze mill(SPEX6800freeze/mill,Metuchen, USA)to facilitate tablet fabrication.Poly(ethylene oxide)with M w of8×106and4×106(Aldrich waukee,USA).2.2.Tablet fabricationThe polymer,used as the dissoluble matrix material,was mixed thoroughly with caffeine powder(Sigma,St.Louis,USA) by manually grinding in a stone mortar.The resultant powder mixture is then compressed with a laboratory hydraulic press (Graseby Specac)under a pressure of38MPa for1min using two tablet punches in10-or5-mm diameter,which have convex surfaces.The total mass of each10-mm diameter tablet was maintained at360mg with different loadings of caffeine while that of the5-mm diameter tablet was kept at35mg.2.3.In vitro release studyApparatus2of the USP dissolution test(VK7000,VanKel Technology Group,Weston Parkway,USA)was employed for in vitro drug release studies.Simulated intestinalfluid(SIF, without pancreatin),which is prepared using monobasic potas-sium phosphate and sodium hydroxide(Merck,Darmstadt,Ger-many),is used as a release medium.The dissolution tests are performed in1000mL of recep-tor medium with an agitation rate of110rpm.Samples of1mL, which are replaced by an equal volume of fresh receptor medium, are periodically taken.All samples arefiltered with0.2-m syringefilters(Whatman,Clifton,USA)before being analysed with high performance liquid chromatography(HPLC).2.4.In vivo animal experimentsPharmacological evaluation was carried out using20male Sprague–Dawley rats weighing between220and250g.Ani-mals were catheterised via the left iliac vein and were allowed a post surgical recovery period of at least24h.They were fasted overnight with free access to water prior to dosing.Subjects were administered a single dose of either the polymeric-tablet-formulation(n=11)or the control-tablets(n=9)orally.Blood samples for measurement of plasma Caffeine concentrations were obtained predose,1–8,10,12,24,30,36and48h fol-lowing oral dosing.Plasma were immediately separated from the blood samples and frozen at−70◦C until assayed.Before the samples can be analysed for caffeine quan-tities,caffeine has to be extracted.One hundred andfifty microlitres of an internal standard(I.S.,500g mL−1N-acetyl-p-aminophenol in water),and an additional3mL of dichloromethane–isopropanol(88:12,v/v)were added to 150L of plasma.It was vortex-mixed and shaken for45min.Table1HPLC Gradient used for detection of caffeineTime(min)Flowrate(mL/min)SolventA(%)Solvent B(%)Solvent C(%)0 1.00100005 1.00950522 1.00950524 1.00095535 1.00095545 1.000604050 1.000604051 1.001000056 1.0010000 Solvent A:0.05%acetic acid;solvent B:50mM ammonium acetate;solvent C: methanol.After centrifugation for10min at11×g,the organic phase was separated and evaporated to dryness under a gentle stream of nitrogen.The extract was reconstituted with200L of0.05% acetic acid–methanol solution(92:8,v/v).2.5.HPLC analysisThe reconstituted sample of caffeine was analysed for caf-feine quantity using a chromatographic HPLC system(Waters 2690Separation Module)consisting of a600E multi-solvent delivery system pump,Ultra WISP715auto-injector and a UV–Vis996photodiode array detector,all were obtained from Waters Asia Ltd.An injection volume of50L was used.The detector was operated at a wavelength of254nm.The caffeine metabolites were separated on a SymmetryShield TM Cartridge Column RP18(250mm×4.6mm i.d.;particle size,5m)from Waters Asia Ltd.at22◦C and aflow rate of1mL min−1.A mobile phase comprising0.05%acetic acid,50mM ammonium acetate and methanol was used.The mobile phase consisted of 0.05%acetic acid,50mM ammonium acetate and methanol according to the following gradient program as listed in Table1.3.Results and discussion3.1.In vitro release profiles for sustained-release ofcaffeineA polymeric matrix is used to impede the diffusion of caffeine into the external environment.The efficiency of this impedance is dependent upon a variety of parameters,including polymer type,molecular weight and concentration.In the same manner, caffeine release is also effected by erosion of the tablets,which frees the caffeine from the matrices.The effect of various poly-mers on caffeine release profile was studied.Fig.1shows that PEG,PVP,PV A and EC as well as PLGA exert only a slight retardance on caffeine release.As PEG and PVP used were of low molecular weight,they would be expected to dissolve very quickly in an aqueous phase, thus removing their effects from the system.PV A and EC’s dis-solution may have caused the disintegration of the tablet(resultsD.Tan et al./Materials Science and Engineering B 132(2006)143–146145Fig.1.Cumulative caffeine release profiles of tablets containing various poly-mers:( )PEG M w 1×104;(᭹)PVP M w 4×104;( )PV A M w 3.1–5×104;( )EC,viscosity of 46cP;( )PLGA 50:50M w 4–7.5×104.The dotted line represents the release profile of pure caffeine tablets for comparison.not shown).PLGA tablets showed no satisfactory retardance although the tablet structure was maintained.This may be due to the hydrophilicity of the PGA chain segment,which would not retard the penetration of the aqueous phase.Thus,caffeine would still be able to solubilise and diffuse with ease in the presence of PLGA.Figs.2and 3show the release profiles of PEO tablets of M w of 8×106and 4×106with various percentage caffeine loading.Caffeine at 8.3%,16.7%,33.3%,50%,80%and 90%loading were fabricated with PEO as the dissoluble matrix [8].The figures show the release of caffeine from both tablets is nearly linear in the first 20h suggesting an almost constant rate of caffeine release during this period.The tablets had similar release profiles,despite differing caffeine contents.The trend is similar for the two different molecular weight PEO tablets.The tablets retained their characteristic capabilities to retard caffeine release from their matrices despite the use of varying proportions of caffeine,up to caffeine content of 80%.It can also be observed that the release of caffeine from tablets of the higher molecular weight PEO tends to be more gradual (lower rate)compared to the release rate in PEO of lowermolec-Fig.2.Release profiles of PEO M w 4×106tablets with various percentage caffeine loading:( )8.3%;( )16.7%;( )33.3%;(+)50%;(−)80%;( )90%.Fig.3.Release profiles of PEO M w 8×106tablets with various percentage caffeine loading:( )8.3%;(×)16.7%;(᭹)33.3%;( )80%;( )90%.ular weight.This is probably due to the slower dissolution and erosion,and hence release of caffeine,of the higher molecular weight polymer.The sole exceptions to the release profiles of the tablets were those with 90%caffeine-loading.These tablets tended to release their caffeine load faster than the trends of the other tablets pre-dicted.This may be explained by the dominance of the diffusion gradient created by the high caffeine content,over the retardation effect of the reduced polymer content.Since the release rates of caffeine are not significantly altered by changes in loading (up to percentage loading of 80%),it is possible to choose the most suitable percentage loading amount based upon usage of the tablet and desired overall caffeine released.3.2.In vivo tablet release profiles and pharmacokinetics analysisIt was necessary to use 5-mm diameter tablets instead of the 10-mm diameter ones studied in vitro previously because the larger tablets were too difficult for the rats used in the in vivo assays to swallow.An ideal caffeine content suitable for sustained-release for use in the animal models was determined to be 32%caffeine-loading in the PEO tablet.Sustained delivery of caffeine was expected to result in two phenomena:a reduction in the initial high rate of caffeine release (burst release),as well as the reduction in the change in caffeine concentration in the systemic circulation.The PK analysis was performed with WinNonlin ®Version 3.2(Pharsight Corporation,CA,USA).From Fig.4,it may be observed that the highest systemic concentration of caffeine attained within the first hour is 5.0g mL −1for negative control I (8%,w/w caffeine sucrose tablets).In contrast,the 8%(w/w)caffeine poly(ethylene oxide)tablets attained a highest systemic caffeine concentration of only 0.93g mL −1within 6h.This indicates a 5.4-fold decrease in the burst release.The latency to the peak concentration is 1and 5h for negative control I and 8%(w/w)caffeine PEO tablets,respectively.This is a 5-fold delay in the latency to peak concentration for the PEO tablets.However,the half-life for the 8%(w/w)caffeine PEO tablets is 1.97h and that of the negative control is 1.87h.Thus,the half-146 D.Tan et al./Materials Science and Engineering B132(2006)143–146Table2Summary of pharmacokinetics(PK)parameters of the various caffeine-loaded tabletsPolymer/%caffeine loading(w/w)Peak concentration(g mL−1)T max(h)AUC(hg mL−1)Half-life(h) Negative control I Sucrose/8 5.00120.01 1.87 Negative control II Sucrose/3223.353146.73 6.72 Sustained-release PEO/80.935 5.834 1.97Sustained-release PEO/3212.23690.8534.37Fig.4.Mean(±S.E.M.)plasma concentration of caffeine following single oral dose of the following:( )32%(w/w)caffeine-loaded sucrose tablets;(᭹) 32%(w/w)caffeine-loaded PEO tablets;(♦)8%(w/w)caffeine-loaded sucrose tablets;( )8%(w/w)caffeine-loaded PEO tablets.life is not significantly increased.Both of these tablets failed to maintain the systemic caffeine concentrations at a constant and also to sustain the release of caffeine beyond12h.In order to demonstrate the ability to maintain the systemic caffeine concentration,it is necessary to increase the amount of caffeine in the PEO tablets.In vitro studies showed that the release profile of the caffeine-loaded PEO tablets was not affected by the quantity of caffeine used,so long as this quantity did not exceed80%(w/w).As such,32%(w/w)caffeine PEO tablets were used.The caffeine load was increased to four times of that previously used,with the intention of extending the half-life of caffeine.A second negative control was also used—32% (w/w)caffeine sucrose tablets.The highest systemic concentration for the32%(w/w)caf-feine PEO tablets achieved was12.23g mL−1.The latency to the peak concentration was achieved at6h after dosing.This is compared to the32%(w/w)caffeine sucrose tablets where the highest systemic concentration—23.35g mL−1was achieved at3h after dosing.A1.90-fold decrease for initial burst release and a2-fold delay in the latency to peak concentration were obtained with the32%(w/w)caffeine PEO tablets.The half-life for the32%(w/w)caffeine PEO tablets was4.37h and that for the32%(w/w)caffeine sucrose tablets was6.72h. Table2summarizes the pharmacokinetics(PK)parameters of the caffeine-loaded tablets.The32%(w/w)caffeine PEO tablets have shown to be able to maintain a systemic caffeine concentration with a2.3-fold increase in half-life,as compared to negative control I(8%,w/w caffeine sucrose tablets),yet avoiding the burst release of caf-feine that was exhibited in negative control II(32%,w/w caffeine sucrose tablets).4.ConclusionWe have achieved a sustained-release of caffeine from our 32%(w/w)caffeine polymeric PEO tablet core.The half-life of 32%(w/w)caffeine PEO was increased2.3-fold compared to negative control I.References[1]A.P.Smith,Hum.Psychopharmacol.20(2005)441–445.[2]T.M.McLellan,G.H.Kamimori,D.M.V oss,D.G.Bell,K.G.Cole,D.Johnson,Aviat.Space Environ.Med.76(2005)647–654.[3]E.De Valck,E.De Groot,R.Cluydts,Percept.Mot.Skills96(2003)67–78.[4]nger,mun.6(1980)1–48.[5]nger,N.Peppas,J.Marcomol.Sci.Rev.Macromol.Chem.Phys.C23(1983)61–126.[6]C.G.Pitt,A.Schindler,Biodegradation of polymers,in:S.D.Bruck(Ed.),Controlled Drug Delivery,vol.I,Basic Concepts,CRC Press,Boca Raton, Florida,1983,pp.53–80.[7]R.W.Baker,Controlled Release of Biologically Active Agent,John Wileyand Sons,New York,1987,pp.84–131.[8]N.Wu,L.S.Wang,D.Tan,S.M.Moochhala,Y.Y.Yang,J.ControlledRelease102(2005)569–581.。

固定式义齿工艺流程英文回答,The fixed denture process involves several steps to ensure the creation of a high-quality and custom-fitted dental prosthetic. The process begins with a comprehensive examination and assessment of the patient's oral health, including the condition of the teeth and gums. This initial step is crucial in determining the suitability of fixed dentures for the patient.Following the assessment, the next step involves taking impressions of the patient's teeth and gums. These impressions are used to create a precise mold of thepatient's mouth, which serves as the basis for the fabrication of the fixed dentures. The use of advanced technology, such as digital scanning and 3D imaging, has significantly improved the accuracy and efficiency of this step.Once the mold is obtained, the dental laboratory fabricates the fixed dentures according to the specificrequirements of the patient. This may involve the selection of appropriate materials, such as porcelain or ceramic, to achieve the desired aesthetic and functional results. The use of high-quality materials is essential in ensuring the durability and longevity of the fixed dentures.After the fabrication of the dentures, the next step is the try-in process, where the dentures are placed in the patient's mouth to assess the fit, comfort, and aesthetics. Any necessary adjustments are made at this stage to ensure that the fixed dentures provide a natural and comfortable bite. The dentist also evaluates the patient's bite and makes any final modifications to the dentures to achieve optimal function.Once the fixed dentures are deemed satisfactory, they are securely attached to the patient's existing teeth or dental implants. The dentist ensures that the dentures are properly positioned and secured to provide stability and support for the patient's bite. Proper care and maintenance instructions are provided to the patient to ensure the longevity of the fixed dentures.Overall, the fixed denture process requires careful planning, precise fabrication, and meticulous attention to detail to achieve optimal results for the patient. By following a systematic and comprehensive approach, dental professionals can provide patients with high-quality fixed dentures that restore function, aesthetics, and confidence.中文回答,固定式义齿工艺流程包括多个步骤,以确保制作出高质量且合身的牙科假体。

英文医疗:医疗术语的英文引言:"Health is not valued till sickness comes." - Thomas Fuller在现代医疗领域中,了解医学术语的英文翻译是非常重要的。

无论是医生、护士还是患者,都需要掌握这些术语以便有效地进行沟通和理解。

本文将介绍一些常见的医疗术语及其英文翻译,旨在帮助读者更好地了解医学领域。

一、常见医疗术语1. Diagnosis and Treatment(诊断与治疗)- Diagnosis(诊断): determination of the nature of a disease or condition through examination or assessment of the signs and symptoms.- Treatment(治疗): medical care given to a patient for an illness or injury.2. Symptoms and Signs(症状与体征)- Symptoms(症状): subjective evidence of a disease or condition experienced by the patient.- Signs(体征): objective evidence of a disease or condition observed by a healthcare professional.3. Medication and Prescription(药物与处方)- Medication(药物): substance used to diagnose, cure, treat, or prevent a disease or condition.- Prescription(处方): written order for medication or treatment from a healthcare professional to a pharmacy or patient.4. Surgery and Anesthesia(外科手术与麻醉)- Surgery(外科手术): medical specialty that uses operative manual and instrumental techniques on a patient to investigate or treat a pathological condition.- Anesthesia(麻醉): medical procedure used to induce a state of controlled unconsciousness, loss of sensation, or absence of reflexes for the performance of surgery or other medical procedures.5. Medical Imaging(医学影像学)- X-ray(X射线): form of electromagnetic radiation used in medical imaging to visualize the internal structures of the body.- MRI (Magnetic Resonance Imaging)(磁共振成像): medical imaging technique that uses a strong magnetic field and radio waves to generate images of the body's internal structures.- CT Scan (Computed Tomography)(计算机断层扫描): medical imaging technique that uses X-rays and computer processing to create detailed cross-sectional images of the body.6. Laboratory Tests(实验室检查)- Blood Test(血液检查): analysis of a sample of blood to measure various components, such as blood cell counts, glucose levels, and cholesterol levels.- Urine Test(尿液检查): analysis of a urine sample to detect the presence of substances or evaluate organ function.- Biopsy(活体组织检查): removal and examination of a sample of tissue from the body to diagnose or monitor a disease.7. Rehabilitation(康复)- Physical Therapy(物理疗法): use of physical methods, such as exercise and massage, to improve muscle strength, mobility, and function.- Occupational Therapy(职业疗法): therapeutic use of daily activities to enhance physical and cognitive skills for individuals with disabilities or injuries.二、总结通过本文的介绍,我们了解了一些常见的英文医疗术语及其对应的中文意思。

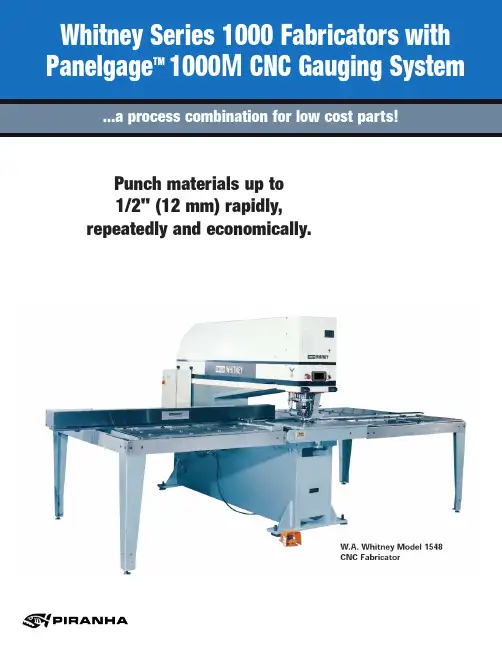

1000Punch materials up to1/2" (12 mm) rapidly, repeatedly and economically.Affordable. Versatile. Easy Operation. Ruggedly reliable for continuous heavy-duty punching.Totally simpleEliminate manual machine set-ups with Series 1000 Fabricators. Protect profit margins on proto-type and production runs.Hydraulic punching powerMaximum punching force is available throughout the entire stroke!With the longer effective stroke, Series 1000Fabricators rapidly and repeatedly punch through materials up to 1/2" (12 mm) thick, using fully controlled hydraulic power.Series 1000 Fabricator AdvantagesBoost Productivity — Fabricate four to ten times as many parts as conventional presses.Fast Set-Up — Eliminate lost time due to lengthy set-ups and tear-downs. Set up quickly, easily, in just minutes.Minimize Inventory — Profitable short runs let you cut inventory and space needs.Reduce Material Handling — Fabricate parts up to 72” (1825 mm) long without removing or repo-sitioning. Optional 120”/144” (3050 mm/3660 mm)axis for more capability. Handling time reduced by as much as 50 percent.“C” Frame Design with Rear Address Gauging —Fabricate material twice as wide as the y-axis.No Clamps — No clamps to interfere with work surface. Programmed control change positions are not required.Easy Operation — Operator simply positions mater-ial against the CNC-positioned gauge points, and uses a footswitch to initiate the punch cycle. Upon punch-stroke completion, the gauging advances automatically to the next programmed position.Hydraulic Punching with Positive Stripping — Full tonnage capacity and safety control throughentire punching stroke.Series 1000 Fabricators are designed and built to operate on heavy sheet and plate. Punch up to 5"(125 mm) diameter holes.Punch material up to 1/2" (12 mm) thick.SimpleCanned Cycle ProgrammingSix canned cyclessimplify programming. Enter the coordinates and pattern from the part drawing and the Panelgage 1000M control establishes the locationof each punch cycle.Bolt Hole Circle•X, Y of circle center Line at an Angle:• X, Y of starting hole •Angle•Hole spacing •Number of holes •X, Y of starting hole •Starting angle •Hole spacing •Length•X, Y of starting hole •Hole spacing •X length • Y lengthPanelgage 1000M CNC ControlOperator-friendly, machine-mounted control requires no special training for programmers. With only part dimensions, an operator uses a simple touchscreen to setup for a complete part.•Multiple part program storage in nonvolatile memory•Software provided for additional storage/backup —easily added to your PC•Full program review, edit and manual display •Conversation-type, plain English programming •English-metric operation •On-board diagnostics •Position display•Manual operation with “Go To” position•Electronic zeroing on standard and extended material stops •OffsetsStandard Tooling — Whitney 28XX punches and dies save up to 50 percent in tooling costs.Rapid Tool Change — Changes completed in 15 seconds for round or shaped holes up to 5" (125 mm) diameter.Accuracy — Gauge positioning accuracy is ±.005"with a repeat accuracy of ±.003".Overload Protection — Hydraulic punching system is protected from overload and automatically reset.IncreaseLow CostQuick-set stroke lengthSimply turning the cam on an adjustable limit switch assembly lets you work with the most efficient stroke length for every job.Adjustable limit switch assembly set for material up to 1/8" (3 mm) thick.Adjustable limit switch assembly set formaterial 10 ga. through 1/4". This position is also used for material 1/4" to 1/2" (6 mm to 12 mm) thick.•Reduce set-up times.•Convert quickly from thin-gauge to thick materials.•Use maximum machine hit rates without lengthy adjustments.Stripper plate versatilityStandard stripper plate with insert for material to 1/8" (3 mm).Standard stripper plate without insert for 10 ga. through 1/4" (3.5 mm through 6 mm)material.An optional stripper is available for material 1/4" to 1/2" thick.Pressure control switchFor reversing underpressure to countersink,extrude, coin, louvre and knockout.Standard EquipmentSeries 1000 CNC Fabricators meet application needs.Model Punching Force Throat Depth153050 tons30"(450 kN)(760 mm)154850 tons48"(450 kN)(1220 mm)Series 1000 Fabricatorsuse standard 28XX punches and dies with either flat face, 1/8" (3 mm)shear, or 7/16" max-shear.This economical tooling allows for rapid toolchanges, and is self-align-ing with shaped sizes keyed for orientation.Positive stripping allows the workpiece to strip free for instantaneous positioning without low-ering punching tonnage..001" TIR concentricityAll 28XX punches and dies are concentric to .001 TIR.On all punches, the punch tip is concentric with the punch shank. On all dies, the hole in the die is concentric with the outer diameter of the die. Shaped tooling is pinned for proper alignment. Custom pin location is available.Optional urethane stripper sleevesUrethane stripper sleeves are available for punching close-center holes in light gauge metal and for many other special applications. No marking or deformity of material occurs.Strippers are sup-plied with only a small hole. The first punch stroke produces a snug fit of the stripper to its punch.Economical. Accurate. Fast and easy tool changing.Tool changing is easy with economical 28XX style quick-change tooling.Tool and die standard sizesCountersinking in one strokeEliminate costly secondary opera-tions when coun-tersinking andextruding by using special tools and techniques. One stroke of a Series 1000 can produce partial, full or formed counter-sinks, pierce andextrude holes, countersink both sides of a hole,or pierce and form holes.The special tooling is designed for use on hydraulic presses equipped with pressure adjustment controls.The basic countersinks: partial (A), full (B), and formed (C). They vary widely in size and angle,but all can be produced in one press stroke.A full countersink (see photo above) is widely used in approximately 3/16" to 1/2" (5 mm to 12 mm) material. It requires a pre-punched hole larger than the pilot on the countersink punch.A standard die and a countersink punch with a pilot is used to extrude the metal back into the hole. No material-thickening or burr is produced.For complete information on standards and special-purpose toolssee the Whitney 28XX Punch & Die Catalog.An increase of two to three times punchingcapacity is available from Series 1000 Fabricators by using special tooling to increase the tonnage capabilities.For example, a 30 ton Series 1000 can punch up to a 2" (50 mm) diameter hole through4 ga. (5.7 mm) thick mild steel using a standard 2" (50 mm) punch with a 1/8" (3 mm) concave shear. Using a punch with 7/16" (11 mm) highcapacity concave shear the same machine can punch up to a 5" (127 mm) diameter hole in 5 ga. (5.3 mm) material.This means a 30 ton (275 kN) press can be tooled up to produce holes which normally require an 80 ton (730 kN) capacity mechanical press. A 50 ton (455 kN) press can be tooled up to produce holes which normally require a 100 ton (910 kN) capacity mechanical press.Sheared tooling increases press capacityComparison ChartStandard Round vs. High Capacity Round with Concave ShearOff-line Program Software•Do remote programming on your PC•Full color graphic representation •Editing•Copying•Convert Panelgage 2 and Panelgage 2E programs •Upload and Download •Generate Tool List•Save/Restore machine parameters•Create part program back-up files •English/metric conversionPunching shaped materialsSeries 1000 Fabricators can be supplied with special toolingaccessories to punch a wide range of shapes other than flat stock. Angles, channels and special extrusions can all beprocessed.Special attachments, designed by Whitney engineers, help the Series 1000 Fabricators meet virtually any punching requirement.Angle/channel iron punching assemblyPunch both angle and channel iron on the Series 1000 with the Angle Iron Attachment. Fabricate angle up to 3" x 3"(75 mm x 75 mm) and channel iron up to 3" x 12" x 20.7 lbs./ft.(75 mm x 305 mm x 9.4 kg/m). Consult Whitney for angle and channel iron over 3" (75 mm).The attachment is easily installed without modifications to the press. Package includes special strippers and punch adapter with point of operation guarding.Brush top tablesBrush top tables provide easy material movement and eliminate marks andscratches on polished, painted or anodized materials. The brushes maintain smoothworkpiece support during thefabrication process.Optional EquipmentTool BoxTool box organizes strippers, die adapters,punches and dies for easy use and offers convenient storage.Optional EquipmentOptional EquipmentCenter PunchThe center punch is used primarily for layout of drilled holes. This can also be used to layout shear,bend lines and optional equipment added later.Extended Gauge Point84510351L E D O M R O T A C I R B A F Punching Force50 Tons (445 kN)50 Tons (445 kN)Punching Capacity: A36 - 60,000 psi shear strength s s e n k c i h T l a i r e t a M r e t e m a i D e l o H Std. Tooling Max. Shear Std. Tooling Max. Shear Std. Tooling Max. Shear 1" (25 mm)5/16" (8 mm)5/16" (8 mm)1/2" (12 mm)1/2" (12 mm)1/2" (12 mm)1/2" (12 mm)2" (50 mm) 4 ga. (5.7 mm)1/4" (6 mm)5/16" (8 mm)3/8" (9 mm)5/16" (8 mm)3/8" (9 mm)3" (75 mm)8 ga. (4 mm)1/4" (6 mm) 4 ga. (5.7 mm)3/8" (9 mm) 4 ga. (5.7 mm)3/8" (9 mm)4" (100 mm)10 ga. (3.5 mm)7/32" (5.6 mm) 6 ga. (5 mm)5/16" (8 mm) 6 ga. (5 mm)5/16" (8 mm)5" (125 mm)11 ga. (3 mm)5 ga. (5.3 mm)8 ga. (4 mm)9/32" (7 mm)8 ga. (4 mm)9/32" (7 mm)Positioning Accuracy +.005" (.125 mm)+.005" (.125 mm)(CNC gauging)Throat Depth)m m 0221( "84)m m 067( "03Positioning Area Max.Standard "27 x "84"27 x "03(760 mm x 1825 mm)(1220 mm x 1825 mm)Optional30" x 120" or 144"48" x 120" or 144"(760 mm x 3050 mm(1220 mm x 3050 mm)m m 0663 r o )m m 0663 r o Punching Stroke Normal)m m 21( "2/1)m m 21( "2/1Adjustable — Minimum)m m 6( "8/3)m m 6( "8/3— Maximum )m m 05( "2)m m 05( "2Hydraulic Power Unit PH 02PH 02Machine Shipping Weight12,410 lbs. (5641 kg)17,120 lbs. (7782 kg)MODEL A BC DEF153033" (838 mm)154830" (762 mm) 48" (1219 mm)80" (2032 mm) 80" (2032 mm)33" (838 mm)16-1/2" (419 mm)16-1/2" (419 mm)95" (2413 mm) 111" (2819 mm)78" (1981 mm) 94" (2388 mm)*Number of optional support tables required varies with machine model and length of gauging system x-axis. Tables available with ball or brush transfer tops. NOTE: Because Whitney is continually improving its products, specifications are subject to change without notice.。