Preparation and characterization of activated carbon from sunflower seed oil

- 格式:pdf

- 大小:584.72 KB

- 文档页数:30

第52卷第2期表面技术2023年2月SURFACE TECHNOLOGY·297·石墨表面TaC涂层的熔盐法制备及表征董天下1,孟凡桂1,陈红梅2,3,张九阳4,高超4,王宗玉4(1.中南林业科技大学 材料科学与工程学院,长沙 410004;2.湖南人文科技学院 精细陶瓷与粉体材料湖南省重点实验室,湖南 娄底 417000;3.湖南涉外经济学院,长沙 410205;4.山东天岳先进科技股份有限公司,济南 250000)摘要:目的以K2TaF7和Ta粉为主要原料,在石墨材料表面制备TaC涂层。

方法反应物在1 200 ℃的熔盐体系中保温3 h,反应生成碳化物,经后续2 300 ℃真空保温1 h后,得到TaC涂层材料。

采用XRD和SEM对涂层的组成结构进行表征,采用拉开法对涂层的和石墨基体的结合强度进行测量,采用纳米压痕对涂层的硬度和弹性模量进表征,最后对TaC涂层的抗腐蚀性能进行模拟测试评估和实际的SiC 长晶测试。

结果熔盐法制备的TaC涂层连续地覆盖在石墨表面,保持了原始石墨的形貌,其物相组成为TaC,呈现出亮黄色,厚度为20~40 μm,涂层的晶粒无择优取向生长,呈现出无序堆积的状态。

TaC 涂层与石墨基体的结合强度为9.49 MPa,硬度和弹性模量分别为14.42 GPa和123.32 GPa。

TaC涂层样品于2 300 ℃的SiC腐蚀气氛环境下保温3 h,质量损失率仅为0.01 g/(m2·h),远低于同测试条件下无涂层石墨样品的质量损失率4.67 g/(m2·h)。

在2 300 ℃氩气气氛下保温3 h的SiC粉包埋TaC涂层的接触腐蚀试验中,SiC和TaC涂层的界面清晰,没有发生相互的扩散。

TaC涂层部件应用于2 000 ℃以上保温150 h以上的SiC单晶的生长制备后,涂层部件总体形貌保持完整,部件边缘棱角区域出现了脱落,但其他部位的TaC涂层仍和基体结合良好,涂层在长晶过程中的质量损失率约为0.41 g/(m2·h),表现出良好的抗腐蚀性能。

经硫脲改性后的酸化缓蚀剂的研究一、绪论1.1 研究背景1.2 研究目的1.3 研究意义二、硫脲改性的酸化缓蚀剂的制备及表征2.1 硫脲改性过程2.2 产品结构及表征方法2.3 影响因素分析三、改性酸化缓蚀剂的性能分析3.1 腐蚀抑制性能评价3.2 缓蚀机理分析3.3 耐热性、耐水性和流变性能测试四、改性酸化缓蚀剂的应用4.1 涂料添加剂4.2 水处理剂4.3 金属防锈剂五、总结与展望5.1 硫脲改性酸化缓蚀剂的优点5.2 未来研究方向5.3 结论注:该提纲仅供参考,具体内容可根据研究方向进行调整。

第一章绪论1.1 研究背景金属材料在各种工业生产过程中起着重要作用,但其易受到大气、水分和化学物质等外界环境的侵蚀和腐蚀,从而引起设备、构件或工具的性能下降、寿命缩短,甚至出现安全事故,造成严重经济损失。

因此,如何有效地抵抗金属腐蚀成为各项工业领域关注的热点问题。

酸化缓蚀剂是一种应用广泛的防腐材料,能够缓慢地向金属表面释放缓蚀物,从而形成一层保护膜,起到缓慢地延缓金属腐蚀的作用。

目前市场上供应的酸化缓蚀剂一般为无机硫酸盐类化合物,如硫酸铜、硫酸锌等。

然而,无机酸化缓蚀剂的缺点在于使用时需要较高的前处理温度、较大的剂量、而且容易出现环境污染问题。

此外,这些无机酸化缓蚀剂同时也表现出原料成本较高、稳定性较差等缺点。

因此,寻求一种新型酸化缓蚀剂,能够综合考虑到正确的缓蚀性能、良好的耐久性、环境友好性和低成本,十分必要。

1.2 研究目的本研究旨在开发一种新型的酸化缓蚀剂。

针对无机酸化缓蚀剂的不足,我们将以改性的硫脲为原料,制备一种新型的缓蚀剂,并对其进行全面的性能研究。

我们的目标是通过对改性酸化缓蚀剂的性能分析,探索其最佳用量、适用范围、缓蚀性能等,为工业生产的金属材料防腐提供可靠的技术支撑。

1.3 研究意义本研究的意义在于:1. 开发出一种效益更高的新型酸化缓蚀剂,可降低金属材料的腐蚀速率,延长金属材料使用寿命,有效提高工业生产效率和经济效益。

Preparation and Characterization of a High Molecular Weight UV-Stabilizer Based on a Derivative of2,4-Dihydroxybenzophenone and Its Application in Polymer MaterialsYi Zhao,Yi DanState Key Laboratory of Polymer Materials Engineering,Polymer Research Institute of Sichuan University,Sichuan University,Chengdu610065,ChinaReceived24October2005;accepted18January2006DOI10.1002/app.24286Published online in Wiley InterScience().ABSTRACT:In this study,a polymerizable UV-stabilizer, 2-hydroxy-4-(3-methacryloxy-2-hydroxylpropoxy)benzo-phenone(BPMA),was synthesized using2,4-dihydroxyben-zophenone(UV-0)and glycidyl methacrylate(GMA).It was copolymerized with methyl methacrylate(MMA)to prepare poly(MMA-co-BPMA)by emulsion polymerization.The composition and characteristics of poly(MMA-co-BPMA) were determined by using proton nuclear magnetic reso-nance(1H-NMR),gel permeation chromatography(GPC), and ultraviolet-visible absorption spectroscopy(UV–vis). Further,the obtained poly(MMA-co-BPMA)was used as a high molecular weight UV-stabilizer and was blended with PVC to prepare PVC/poly(MMA-co-BPMA)films.These films were presented under UV light,using PVCfilm as standard substance.Insoluble substance,GPC,and color difference were used to characterize UV degradation.The results show that poly(MMA-co-BPMA)is an effective high molecular weight UV-stabilizer.To detect the migration of poly(MMA-co-BPMA),water extraction and heat migration test were used to accelerate the movement of poly(MMA-co-BPMA).As a reference,these tests were also carried out on PVC/UV-0film.The results show that poly(MMA-co-BPMA)has very small migration,while nearly80%UV-0 migrated out from the plastic matrix after the experiments.©2006Wiley Periodicals,Inc.J Appl Polym Sci102:2203–2211,2006 Key words:2,4-dihydroxybenzophenone;polymerizable; UV-stabilizer;degradationINTRODUCTIONUltraviolet light stabilizers are used widely in plastics, cosmetics,andfilms.The main purpose of UV-stabi-lizer is to prevent polymers from photodegradation or photocrosslinking caused by ultraviolet light pre-sented in sunlight and artificial light source. Ultraviolet light stabilizers are divided into inor-ganic UV-stabilizers,organic UV-stabilizers,and other kinds.Inorganic UV-stabilizers,such as iron oxide, titanium oxide,chromic oxide,and carbon black,usu-ally cannot evenly distribute in the plastic substrate so much as incompatible with the polymer matrix.The final effects depend on the particle size and concen-tration.1These drawbacks limit the application of in-organic anic UV-stabilizers,gener-ally with small molecular weight,includefluorescent compounds,phenyl-ester of benzoic acid,hydroxyl-benzophenone,benzotriazoles,etc.In the addition of these stabilizers to plastic materials,problems such as migration,incompatibility,volatility,and solvent ex-traction will inevitably occur.It leads to a strong dim-inution of the materials’utilization.To resolve such problems,many approaches have been developed, such as preparing reactive UV-stabilizer,2–11introduc-ing compatible side chains,or chemically anchoring of the additive to the polymer backbone,12–15etc.Among these methods,preparing high molecular weight UV-stabilizer is a highlight because,for most of the poly-mer materials,blending is thefirst choice to enhance their UV-resistance.Meanwhile,different high molec-ular weight UV-stabilizers can be prepared by the copolymerization of a reactive UV-stabilizer with other monomers.In this point,it is very convenient to ameliorate the compatibility between UV-stabilizer and plastic matrix by preparing suitable high molec-ular weight UV-stabilizer.In this study,we prepared a polymerizable UV-stabilizer2-hydroxy-4-(3-methacryloxy-2-hydroxyl-propoxy)benzophenone(BPMA),and then,it was co-polymerized with methyl methacrylate(MMA)to get a high molecular weight UV-stabilizer poly(MMA-co-BPMA).In consideration of the efficiency of poly(MMA-co-BPMA)as a UV-stabilizer,we appliedCorrespondence to:Y.Dan(zhaoyi_910@). Contract grant sponsor:National Natural Science Foun-dation of China;contract grant numbers:20374036, 50533080.Contract grant sponsor:Program for Changjiang Scholars and Innovative Research Team in University of China. Journal of Applied Polymer Science,Vol.102,2203–2211(2006)©2006Wiley Periodicals,Inc.PVC as a polymer matrix because PVC is widely used in the world and is easily destroyed by UV light.We investigated the water extraction and heat migration of poly(MMA-co -BPMA).The results show that poly(MMA-co -BPMA)is an effective high molecular weight UV-stabilizer and it has a lower migration trend than low molecular weight UV-0.EXPERIMENTALMaterials2,4-Dihydroxybenzophenone (purity above 99.5%),provided by Jinchun Meibang Chemical (Wuhan,China),was used as received without further purifi-cation.Analytical reagent grade NaOH,tetrahydrofu-ran (THF),N ,N -dimethyl formamide (DMF),and cy-clohexanone were provided by Kelong Chemical Re-agent Factory of China (Chengdu,China).Glycidyl methacrylate was available commercially.Methyl methacrylate (MMA),which was provided by Shang-hai Waigang Chemical Factory (Shanghai,China),was distilled before application.Sodium dodecanesulfon-ate (SDS),azobisisobutyronitrile (AIBN),and potas-sium persulfate (KPS)were purchased from Wuhan Chemical Reagent Factory (Wuhan,China).PVC was supplied by Yibin Tianyuan Chemical Factory of China (Yibin,China).Water was deionized twice be-fore use.Synthesis of 2-hydroxy-4-(3-methacryloxy-2-hydroxylpropoxy)benzophenone2-Hydroxy-4-(3-methacryloxy-2-hydroxylpropoxy-)benzophenone (BPMA)was synthesized (Scheme 1)as described in an earlier literature.16A mixture of 2,4-dihydroxybenzophenone (UV-0;0.05mol)and so-dium hydroxide (0.155g)were added into a 150mL three-necked round-bottom flask with a stirrer,a re-fluxing condensation pipe,and a ventilation pipe.To exclude the oxygen gas,the reactor was deaired by vacuum pump and was aerated with nitrogen gas,and then,glycidyl methacrylate (GMA;0.055mol)was introduced into the reactor by syringe.The reaction temperature was 80°C,and the reaction time was 5h.At the end of the reaction,a yellow viscous liquid as coarse product was got.The pure BPMA was got bycolumn chromatography using thin layer chromatog-raphy as monitor,and it was confirmed by 1H-NMR,FTIR,and UV–vis spectroscopy.Preparation of poly(MMA-co -BPMA),PMMA,and PBPMAPoly(MMA-co -BPMA)was obtained through emulsion copolymerization of MMA with BPMA in different molar ratios respectively.The process for preparation of poly(MMA-co -BPMA)was shown as follows.First,BPMA (1.8mmol)was dissolved in MMA (70.8mmol).The mixture of MMA with BPMA,SDS (0.8g),and deionized water (40mL)were placed in a three-necked round-bottom flask equipped with a thermom-eter,a stirrer,and a refluxing condensation pipe to prepare MMA-BPMA emulsion.KPS (0.032g)was dissolved in deionized water and then added to the emulsion.The reaction was carried out at 80°C for 3h.After being coagulated with 5%CaCl 2aqueous solu-tion,poly(MMA-co -BPMA)was purified by deionized water with the assistant of centrifugal machine.The final product was dried under 70°C and pulverized to get poly(MMA-co -BPMA)powder.PMMA was pre-pared by the same method without BPMA in the feed,and PBPMA was prepared by solution polymerization in THF using AIBN as initiator at 70°C.Preparation of PVC/poly(MMA-co -BPMA)film,PVC/UV-0film and PVC filmPVC/poly(MMA-co -BPMA)film,PVC/UV-0film,and PVC film were prepared by the solution casting method.17A typical process is stated here.PVC and poly(MMA-co -BPMA)were blended together in dif-ferent molar ratios in 15mL THF.With the help of a magnetic stirrer,the mixture became homogeneous.Then,it was poured on a 15cm ϫ15cm glass plate to form a 0.5mm film.The solvent was allowed to evap-orate slowly at room temperature.After 24h,the film was removed from the plate and dried in a vacuum oven at room temperature.PVC/UV-0film and PVC film were prepared by the same method with different molar ratios of the UV-stabilizer.UV irradiation of PVC/poly(MMA-co -BPMA)film,PVC/UV-0film,and PVC filmThe PVC/poly(MMA-co -BPMA),PVC/UV-0and PVC films were marked before UV irradiation.Then,the films were settled vertically under an artificial anti-mony–mercury lamplight (500W)in a self-assemble UV irradiation cabinet.The distance between the poly-mer and the lamplight was 0.5m,and the main wave-length range of the antimony–mercury lamplight was between 270and 400nm.The irradiation testwasScheme 1Synthesis of BPMA by UV-0and GMA.2204ZHAO AND DANtaken at40°C with air circulating.Samples were re-moved at different intervals.MeasurementSpectral studyBefore measurement,poly(MMA-co-BPMA)was puri-fied by cyclohexanone/methanol system three times andfinally dried in vacuum oven at50°C.Then,both PMMA and poly(MMA-co-BPMA)were extracted with deionized water for7days in a Soxhlet extractor. High resolution1H-NMR spectrum was recorded on a Varian INOVA-400spectrometer of400MHz. Deuterated chloroform was used as solvent and tetra-methylsilane was used as internal standard.UV–vis absorption spectra of PMMA and poly(MMA-co-BPMA)were measured on a Shimadzu UV-720spec-trophotometer in the range of200–400nm,using DMF as solvent.GPC measurementPMMA,poly(MMA-co-BPMA),PVC/poly(MMA-co-BPMA)film,PVC/UV-0film,and PVCfilm were characterized by GPC measurement.Samples before irradiation were tested directly,while samples after irradiation were treated by removing the insoluble substance before the test.The molecular weight and its distribution were tested at35°C using Waters2410 GPC instrument.THF was used as solvent at aflow rate of1.0mL/min,and the instrument was calibrated with standard narrow-molecular weight distribution polystyrene samples.Determination of color difference of PVC/UV-stabilizer films and PVC filmPVC/poly(MMA-co-BPMA)films,PVC/UV-0films, and PVCfilm were irradiated under UV light after0, 48,96,144,192,240,288,and336h.Unirradiated PVC film was used as reference material.Color differences (⌬E)of all thefilms were tested by Color Reader CR-10 (Minolta,Japan).Insoluble substance measurementThe insoluble substance in PVC/poly(MMA-co-BPMA),PVC/UV-0,and PVCfilms were calculated bya same method.A typical process was as follows.First,0.1g PVC/poly(MMA-co-BPMA)film was dissolved in25mL cyclohexanone for24h.The weight of afilter paper was measured on an accurate Sartorius balance, and then,the solution was disposed by it.Thefilter paper with insoluble substance was dried at80°C in vacuum oven,and thefinal weight was also measured by Sartorius balance.The percent of insoluble sub-stance was calculated using eq.(1):Insoluble substance(%)ϭm1Ϫm00.1ϫ100%(1)m0is the weight(g)of thefilter paper,and m1is the weight(g)of thefilter paper with dried insoluble substance.Weight loss by water extractionThe PVC/poly(MMA-co-BPMA)films and PVC/UV-0films werefirst measured on an accurate Sarorius balance,and then,it was enclosed with afilter paper. Thefilms were extracted by water in a Soxhlet extrac-tor.Samples were taken out at different intervals.The films were dried in vacuum oven at80°C.The weight was recorded again.The weight loss of thefilms was calculated using eq.(2):Weight loss(%)ϭm0Ϫm1ϫ100%(2)m0is thefilm weight(g)before the test,and m1is the film weight(g)after water extraction.Migration test of the UV-stabilizerThe PVC/poly(MMA-co-BPMA)films and the PVC/ UV-0films were prepared using solution casting method.To detect the migration significantly,we in-creased the concentration of UV-stabilizer to10%in thesefilms.It was tested by using a modified method of ISO/R-183.The diameter of thefilm was50mm, and the thickness of thefilm was0.5mm.Before the test,the weight of thefilms was exactly measured on a Sartorius balance.The sequence of placement was (from bottom to up)glass plate,filter paper,PVC/UV-stabilizerfilm,filter paper,glass plate,and heavy sub-stance(5kg).The test was done at(70Ϯ2)°C for72h.The migration substance was absorbed by rubber orfilter paper.The weight loss was calculated as eq.(3):Weight loss(%)ϭm0Ϫm1ϫ100%(3)UV-STABILIZER BASED ON BPMA DERIVATIVE2205m 0is the film weight (g)before the test,and m 1is the film weight (g)after heat migration.RESULTS AND DISCUSSIONCopolymer composition and characterization The mole fraction in feed,mole fraction in copolymer,conversion and GPC data about PMMA and poly(MMA-co -BPMA)were summarized in Table I.The mole fraction in feed is calculated by starting materials,and the mole fraction in copolymer is de-termined by 1H-NMR spectrum.As BPMA increased in feed,the mole fraction of BPMA also increased in poly(MMA-co -BPMA),and a little higher concentra-tion was detected.This result shows that BPMA is easy to copolymerize with MMA,and they have a similar reactivity.It is ascribed to the structure of BPMA because a 3-methacryloxy-2-hydroxylpropoxy group existed at 4-position of BPMA.The methacry-loxy group is so far away from the benzophenone group that no steric hindrance in the copolymeriza-tion.Meanwhile,MMA and BPMA have methacrylate group with high reactivity,and they can easily react with each other to prepare random copolymer.Nowadays,emulsion polymerization is an effective method in preparing copolymer.Owing to its unique advantages,such as environment friendliness,high reaction rate,and relative simple engineering technol-ogy in industrialization,emulsion polymerization was applied in preparing poly(MMA-co -BPMA).The con-version of polymerization is very high as shown in Table I,and it confirms that BPMA and MMA can react with each other easily.This is a better result than solution polymerization,3,4which has a low conver-sion about 10%.The molecular weights of the copol-ymers are listed in Table I.The M w values of the random copolymers are about 6.03e5–1.64e6with polydispersity index (D )between1.1and 3.2,and the M w of PMMA is 1.47e6with polydispersity index of 1.36.The chemical structures of poly(MMA-co -BPMA)were characterized by 1H-NMR which is shown in Figure 1.Hydrogen atoms of poly(MMA-co -BPMA)are marked using 1,2,3,4,5,6,7,8,a,b,c,d.The peaks at ␦ϭ7.39–7.49ppm are due to aromatic pro-tons,and they belong to H 1,2,3,4,5,6,and the peaks at ␦ϭ6.46–6.57ppm are also ascribed to aromatic pro-tons H 7,8.From Figure 1,it is also realized that peaksTABLE IPreparation and Characterization of Poly(MMA-co-BPMA)and PMMASamples Mole fraction infeedMole fraction in copolymer a Conversion(%)GPCMMA BPMA MMA BPMA M n M w D PMMA1000100098.5 1.08e6 1.47e6 1.36P(MMA -co-BPMA)-199.540.4699.510.4994.5 1.85e5 6.03e5 3.27P(MMA -co-BPMA)-299.070.9398.78 1.2293.2 3.87e5 1.27e6 3.29P(MMA -co-BPMA)-398.24 1.7698.30 1.7096.5 1.46e6 1.62e6 1.10P(MMA -co-BPMA)-497.622.3897.302.7087.51.48e61.64e61.11aDetermined by 1H-NMRspectrum.Figure 1The 1H-NMR spectrum of poly(MMA-co -BPMA).2206ZHAO AND DANat about␦ϭ4.11–4.30ppm pertaining tofive protons of O CH2O CH O CH2O and peaks at about␦ϭ3.58 ppm are vested to O OCH3.Other peaks at␦ϭ0.84–1.44ppm and␦ϭ1.81–2.06ppm are ascribed to␣-CH3 and O CH2O,respectively.The1H-NMR spectrum also helps us in confirming that poly(MMA-co-BPMA)is a copolymer.The impor-tant signals and corresponding assignment of PMMA, PBPMA,and poly(MMA-co-BPMA)were listed in Ta-ble II.PMMA and poly(MMA-co-BPMA)have the same chemical shifts at␣-CH3,O CH2O,and O OCH3. But,when compared with the1H-NMR spectrum of PBPMA,poly(MMA-co-BPMA)has a higher chemical shift at aromatic proton and O CH2O CH O CH2O.The 1H-NMR spectrum data of aromatic proton in PBPMA are6.33,6.43,7.39,and7.49,while6.46,6.57,7.51,and 7.64in poly(MMA-co-BPMA).The chemical shift of O CH2O CH O CH2O in PBPMA is about4.04,while it is4.11–4.30in poly(MMA-co-BPMA).This is ascribed to the different structures of the main chains of PB-PMA and poly(MMA-co-BPMA).Benzophenone is an electron-donating group that makes the chemical shift of the neighboring benzophenone group and O CH2O CH O CH2O lower in PBPMA(Scheme2).But,in poly(MMA-co-BPMA),this effect is weakened by the-MMA-section.These data help us prove that the structure of poly(MMA-co-BPMA)is a copolymer. UV-absorbance of poly(MMA-co-bpma)In this study,the main purpose is to enhance the UV-resistance of poly(MMA-co-BPMA)by bringing the BPMA unit onto to the PMMA chain,and then, poly(MMA-co-BPMA)can be used as a high molecular weight UV-stabilizer.So,it is necessary to characterize the UV-absorbance of poly(MMA-co-BPMA).The UV–vis absorption spectra of poly(MMA-co-BPMA),PB-PMA,and PMMA were shown in Figure2.A peak at 264nm ascribed to the n3*transition of C A O group appears at the curve of PMMA,while the peak is shifted to261nm in poly(MMA-co-BPMA)because of the addition of BPMA onto the polymer chains.Other two peaks at284and324nm ascribed to the3* transition and n3*transition,respectively,appears at the curve of PBPMA,indicating that284and324nm are the character peaks of PBPMA.All of the three peaks at261,284,and324nm appear atpoly(MMA-Scheme2The main chain structures of PBPMA andpoly(MMA-co-BPMA).TABLE II1H-NMR Characteristics of Homopolymers and CopolymerCompound␣-CH3O CH2O O OCH3Ar O H Ar O OH O CH2O CH O CH2O PMMA0.83 1.00 1.80 1.88 3.58———1.20 1.42 1.922.05Poly(MMA-co-BPMA)0.84 1.01 1.81 1.89 3.59 6.46 6.57—a 4.11 4.301.25 1.44 1.962.067.517.64PBPMA0.99 1.25 2.00— 6.33 6.4312.62 4.041.402.547.397.49a The proton of Ar O OH cannot be detected because of its low concentration and lowsensitivity.Figure2The UV–vis absorption spectra of poly(MMA-co-BPMA),PBPMA and PMMA.A:PMMA;B,C,D,E:0.46,0.93,1.76,2.38%BPMA by mole in poly(MMA-co-BPMA);F:PBPMA)(PBPMA is0.01%in THF while others are0.1%inTHF by weight).UV-STABILIZER BASED ON BPMA DERIVATIVE2207co-BPMA).It indicates that when BPMA was copoly-merized with MMA in different molar ratios,the BPMA can retain its UV-absorbance,thereby the ob-tained copolymers have stronger UV-resistance at284 and324nm.This is very useful for protecting poly(MMA-co-BPMA)from UV degradation and is also helpful for using poly(MMA-co-BPMA)as a high molecular weight UV-stabilizer.Efficiency of poly(MMA-co-BPMA)on protecting polymer materialsPoly(MMA-co-BPMA)is a high molecular weight UV-stabilizer prepared by the copolymerization of MMA and BPMA.In this study,PVC is used as the polymer matrix to determine the efficiency of poly(MMA-co-BPMA)because PVC is widely used and is destroyed by UV light easily.PVC/poly(MMA-co-BPMA)blend-ingfilms were prepared by adding the poly(MMA-co-BPMA)to the PVC in different molar ratios,and these films were presented under artificial UV light.As a reference material,PVC/UV-0film and PVCfilm were also irradiated under UV light.Polymer materials are destroyed by UV-irradiation in two ways:pho-tocrosslinking and photodegradation.In this point,we use percent insoluble substance,molecular weight test,and color difference to determine the UV degra-dation of PVC.The insoluble substance of PVC/poly(MMA-co-BPMA),PVC/UV-0,and PVCfilms after UV-irradia-tion are listed in Table III.It clearly shows that PVC is easy to crosslink under UV irradiation.After144h UV irradiation,the PVCfilm has52.4%insoluble sub-stances.However,the insoluble substance of PVC/ poly(MMA-co-BPMA)film is only about7–10%,which is much less than that of PVCfilm.This result shows that the UV-resistance of PVC is enhanced remarkably by the incorporation of poly(MMA-co-BPMA).Fur-ther,the insoluble substance PVC/poly(MMA-co-BPMA)film is near to that of PVC/UV-0film,indicat-ing that poly(MMA-co-BPMA)is as good as UV-0in protecting PVC from photocrosslinking.The efficiency of a UV-stabilizer can not only be detected by insoluble substance,but can also be exam-ined by the molecular weight change.The GPC data of PVC/poly(MMA-co-BPMA)film,PVC/UV-0film, and PVCfilm are shown in Table IV.It can be seen that the molecular weight of PVC was changed from 7.03ϫ104to6.19ϫ104after326h UV irradiation.This result shows that PVC is destroyed easily by UV-irradiation.But,the PVC/poly(MMA-co-BPMA)film and PVC/UV-0film have less decrease in molecular weight.The molecular weight of PVC/poly(MMA-co-BPMA)film is changed from6.87ϫ104to7.11ϫ104, while that of PVC/UV-0film is changed from7.03ϫ104to6.97ϫ104.These results show that both poly(MMA-co-BPMA)and UV-0are effective UV-sta-bilizers and poly(MMA-co-BPMA)is more effective than UV-0because no molecular weight decrease wasTABLE IIIThe Insoluble Substance of PVC/Poly(MMA-co-BPMA),PVC/UV-0,and PVC FilmsSamples UV-stabilizer content(wt%)Insoluble substance after UV irradiation(%)0h48h96h144hPVC0033.447.752.4 PVC/UV-0–10.30 6.78.111.1 PVC/UV-0–20.60 5.47.410.8 PVC/UV-0–30.90 3.9 5.511.9 PVC/UV-0–4 1.20 4.2 5.18.7 PVC/PMB-10.30 6.57.39.0 PVC/PMB-20.60 6.37.88.8 PVC/PMB-30.90 5.08.310.3 PVC/PMB-4 1.20 4.0 6.87.7 PMB,poly(MMA-co-BPMA)TABLE IVThe Molecular Weight and Its Distribution Change after UV-IrradiationSamples UV-stabilizer content(wt%)Unirradiated Irradiated for326h M n(104)D M n(104)DPVC07.03 1.90 6.19 3.38 PVC/UV-00.37.03 1.90 6.97 2.23 PVC/PMB0.3 6.87 1.887.11 1.97 PMB,poly(MMA-co-BPMA)2208ZHAO AND DANdetected in PVC/poly(MMA-co -BPMA)film.Before the UV-irradiation,the polydispersity index (D )of PVC is 1.90,but after 326h of UV irradiation,the polydispersity index changes to 3.38.This result shows that the main chain of PVC was destroyed to form small molecular weight part and high molecular weight part by photodegradation and photocrosslink-ing,respectively,which leads to the polydispersity of PVC broader.However,D changes only from 1.88to 1.97in PVC/poly(MMA-co -BPMA)film.This result shows that the PVC has been protected effectively by poly(MMA-co -BPMA).It is better than UV-0because the change in D of PVC/poly(MMA-co -BPMA)is smaller than that of PVC/UV-0film (from 1.90to 2.23).In one word,poly(MMA-co -BPMA)is an effec-tive UV-stabilizer in protecting PVC from UV degra-dation.By the accumulation of the UV irradiation time,the color of PVC film changes from transparent to yellow and then changes from yellow to back.The color change of PVC/poly(MMA-co -BPMA)and PVC/UV-0films are also detected during the UV irradiation pro-cess.The yellow color is due to the formation of big conjunction carbon–carbon double bond,and the black color is ascribed to the oxidation of PVC.In this point,it is necessary to apply color difference to de-termine the UV degradation of PVC/poly(MMA-co -BPMA)films,PVC/UV-0films,and PVC film.Figures 3and 4show color difference of PVC/poly(MMA-co -BPMA)films and PVC/UV-0films.As a reference material,the color difference of PVC film was also examined in this measurement.Before the UV-irradi-ation,color difference of PVC/poly(MMA-co -BPMA)and PVC/UV-0films are enhanced as the increasing concentration of UV-stabilizer in the polymer materi-als because poly(MMA-co -BPMA)and UV-0are yel-low substances.After 50h UV irradiation,the PVC/poly(MMA-co -BPMA)films and PVC/UV-0films have less color difference than PVC because of the addition of UV-stabilizers.In Figure 3,color difference becomes distinctive after 100h,exhibiting that the PVC/poly(MMA-co -BPMA)films have less color dif-ference.It is also realized that PVC/poly(MMA-co -BPMA)films containing 0.6%,0.9%,and 1.2%BPMA in polymer matrix have the same color difference.This result demonstrates that only 0.6%BPMA contained in PVC/poly(MMA-co -BPMA)film can act as an effec-tive UV-stabilizer in protecting PVC from color change.All the measurement results show that poly(MMA-co -BPMA)plays as efficient UV-stabilizer in protecting PVC matrix from UV degradation.Its function is no less than the low molecular weight UV-0(Fig.4)in protecting PVC from UV degradation.Migration of high molecular weight UV-stabilizer poly(MMA-co -BPMA)Low molecular weight UV-stabilizer usually migrates from the polymer matrix by solvent,heat,or UVlight.Figure 4Color difference of PVC and PVC/UV-0blends afterUV-irradiation.Figure 5The weight loss of PVC/poly(MMA-co -BPMA)and PVC/UV-0films after water extraction test (1.2%UV-stabilizer inblending).Figure 3Color difference of PVC,PVC/poly(MMA-co -BPMA)blends,and PMMA/PVC blend after UV-irradia-tion.UV-STABILIZER BASED ON BPMA DERIVATIVE 2209It will weaken the UV-resistance of polymer materials.The main purpose of preparing high molecular weight UV-stabilizer is to resolve such problems.In this study,poly(MMA-co -BPMA)was used as a high mo-lecular weight UV-stabilizer,and UV-0was used as a small molecular weight stabilizer.Water extraction test and heat migration test were used to determine the migration of the UV-stabilizers.In Figure 5,it shows that the weight loss of PVC/poly(MMA-co -BPMA)film (0.05%)is less than that of the PVC/UV-0film (0.33%)after 20h water extraction.It indicates that poly(MMA-co -BPMA)keeps well in PVC film,while the small molecular weight UV-stabilizer UV-0has been extracted by water.This is consistent with the UV–vis spectra in Figures 6and 7.The UV absor-bance of PVC/poly(MMA-co -BPMA)film changes less than that of PVC/UV-0film,especially at 284and 324nm.All these results indicate that poly(MMA-co -BPMA)is effective in protecting UV-stabilizer from migration.The heat migration measurement was carried out to test the migration of UV-stabilizer under heat.After heat migration,the PVC/UV-stabilizer films will be lightened because the UV-stabilizer has mi-grated out of the PVC matrix.In this measurement,crystal powder UV-0was detected on the surface of PVC/UV-0films,but was not detected on the sur-face of PVC/poly(MMA-co -BPMA)film.The weight loss of PVC/poly(MMA-co -BPMA)film and PVC/UV-0film are shown in Figure 8.It reveals that the weight loss of PVC/poly(MMA-co -BPMA)(0.55%)is much less than that of PVC/UV-0(7.5%),indicat-ing that poly(MMA-co -BPMA)is a more effective UV-stabilizer in protecting UV-stabilizer from mi-gration than UV-0.CONCLUSIONSA high molecular weight UV-stabilizer poly(MMA-co -BPMA)can be prepared by copolymerization of MMA and BPMA.The migration problems can be resolved by increasing the molecular weight of the UV-stabilizer and the poly(MMA-co -BPMA)is effective in protecting PVC from UV degradation and photocrosslinking.References1.Ranby,B.;Rabek,J.F.Photodegradation,Photooxidation and Photostabilization of Polymer;Wiley:New York,1975;p 36ionis,J.P.;Brook,S.B.;Arthen,F.J.;Township,F.;County,S.U.S.Pat.3,049,503(1962).3.Fertig,J.;Goldberg,A.I.;Skoultchi,M.J Appl Polym Sci 1965,9,903.4.Osawa,Z.;Matsui,K.;Ogiwara,Y.J Macromol Sci Chem 1967,1,581.Figure 6The UV–vis spectra of PVC/poly(MMA-co -BPMA)film before and after extraction (0.1%in THF byweight).Figure 7The UV–vis spectra of PVC/UV-0film before and after extraction (0.1%in THF byweight).Figure 8The weight loss of PVC/poly(MMA-co -BPMA)and PVC/UV-0films after heat migration test (10%UV-stabilizer in blending).2210ZHAO AND DAN5.Patel,M.;Parmar,J.S.;Patel,M.R.;Patel,M.M.J Macromol SciChem1987,24,1085.6.Recca,A.;Libertini,E.;Finocchiaro,P.;Munro,H.S.;Clark,D.T.Macromolecules1988,21,2641.7.Patel,M.;Parmar,J.S.;Patel,M.R.;Patel,M.M.J Macromol SciChem1986,23,1363.8.Bottino,F.A.;Pasquale,G.D.;Pollicino,A.;Recca,A.;Clark,D.T.Macromolecules1990,23,2662.9.Parmar,R.J.;Saxena,S.;Parmar,J.S.Die Angew MakromolChem1998,259,1.10.Xiaoxuan,L.;Jianwen,Y.;Yonglie,C.Polym Adv Technol2002,13,247.11.Li,H.;Zheng,Y.;Wang,L.China Synth Resin Plast2004,21,56.12.Albertsson,A.C.;Fu,X.;Shanjun,L.;Vogl,O.Polym Prepr1984,25,64.13.Shanjun,L.;Qin,A.;Zhang,H.;Chen,J.;Vogl,O.Acta Polym1991,42,193.14.Pan,J.Q.;Lau,W.Y.;Zhang,Z.F.;Hu,X.Z.Polym Degrad Stab1996,53,153.15.Seliger,H.;Happ,E.;Cascaval,A.;Birsa,L.;et al.Eur Polym J1999,35,827.16.Fertig,J.;Goldberg,A.I.;Skoultchi,M.J Appl Polym Sci1966,10,663.17.Zhu Hongfa.Experimental Methods and Evaluation of PolymerMaterials;Chemical Industry Press:Beijing,1988;p495.UV-STABILIZER BASED ON BPMA DERIVATIVE2211。

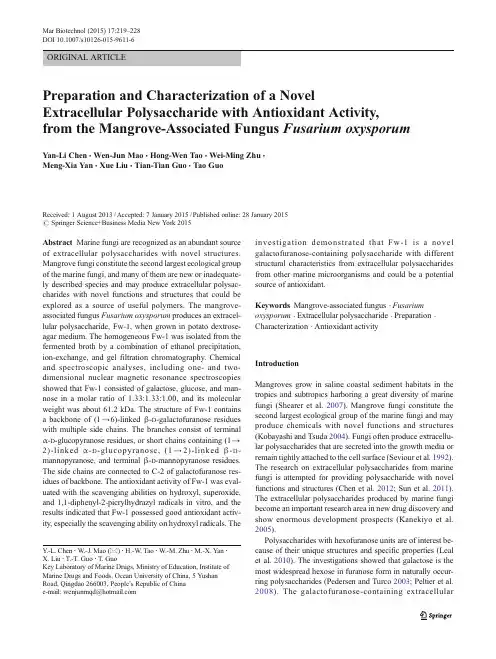

ORIGINAL ARTICLEPreparation and Characterization of a NovelExtracellular Polysaccharide with Antioxidant Activity,from the Mangrove-Associated Fungus Fusarium oxysporumYan-Li Chen &Wen-Jun Mao &Hong-Wen Tao &Wei-Ming Zhu &Meng-Xia Yan &Xue Liu &Tian-Tian Guo &Tao GuoReceived:1August 2013/Accepted:7January 2015/Published online:28January 2015#Springer Science+Business Media New York 2015Abstract Marine fungi are recognized as an abundant source of extracellular polysaccharides with novel structures.Mangrove fungi constitute the second largest ecological group of the marine fungi,and many of them are new or inadequate-ly described species and may produce extracellular polysac-charides with novel functions and structures that could be explored as a source of useful polymers.The mangrove-associated fungus Fusarium oxysporum produces an extracel-lular polysaccharide,Fw-1,when grown in potato dextrose-agar medium.The homogeneous Fw-1was isolated from the fermented broth by a combination of ethanol precipitation,ion-exchange,and gel filtration chromatography.Chemical and spectroscopic analyses,including one-and two-dimensional nuclear magnetic resonance spectroscopies showed that Fw-1consisted of galactose,glucose,and man-nose in a molar ratio of 1.33:1.33:1.00,and its molecular weight was about 61.2kDa.The structure of Fw-1contains a backbone of (1→6)-linked β-D -galactofuranose residues with multiple side chains.The branches consist of terminal α-D -glucopyranose residues,or short chains containing (1→2)-linked α-D -glucopyranose,(1→2)-linked β-D -mannopyranose,and terminal β-D -mannopyranose residues.The side chains are connected to C-2of galactofuranose res-idues of backbone.The antioxidant activity of Fw-1was eval-uated with the scavenging abilities on hydroxyl,superoxide,and 1,1-diphenyl-2-picrylhydrazyl radicals in vitro,and the results indicated that Fw-1possessed good antioxidant activ-ity,especially the scavenging ability on hydroxyl radicals.Theinvestigation demonstrated that Fw-1is a novel galactofuranose-containing polysaccharide with different structural characteristics from extracellular polysaccharides from other marine microorganisms and could be a potential source of antioxidant.Keywords Mangrove-associated fungus .Fusarium oxysporum .Extracellular polysaccharide .Preparation .Characterization .Antioxidant activityIntroductionMangroves grow in saline coastal sediment habitats in the tropics and subtropics harboring a great diversity of marine fungi (Shearer et al.2007).Mangrove fungi constitute the second largest ecological group of the marine fungi and may produce chemicals with novel functions and structures (Kobayashi and Tsuda 2004).Fungi often produce extracellu-lar polysaccharides that are secreted into the growth media or remain tightly attached to the cell surface (Seviour et al.1992).The research on extracellular polysaccharides from marine fungi is attempted for providing polysaccharide with novel functions and structures (Chen et al.2012;Sun et al.2011).The extracellular polysaccharides produced by marine fungi become an important research area in new drug discovery and show enormous development prospects (Kanekiyo et al.2005).Polysaccharides with hexofuranose units are of interest be-cause of their unique structures and specific properties (Leal et al.2010).The investigations showed that galactose is the most widespread hexose in furanose form in naturally occur-ring polysaccharides (Pedersen and Turco 2003;Peltier et al.2008).The galactofuranose-containing extracellularY .<L.Chen :W.<J.Mao (*):H.<W.Tao :W.<M.Zhu :M.<X.Yan :X.Liu :T.<T.Guo :T.GuoKey Laboratory of Marine Drugs,Ministry of Education,Institute of Marine Drugs and Foods,Ocean University of China,5Yushan Road,Qingdao 266003,People ’s Republic of China e-mail:wenjunmqd@Mar Biotechnol (2015)17:219–228DOI 10.1007/s10126-015-9611-6polysaccharides with novel structural characteristics have been isolated from the fermented broth or cell walls of some microorganisms(Gander et al.1974;Ikuta et al.1997;Latgéet al.1994;Unkefer and Gander1990).With today’s interest in new renewable sources of polymers,the galactofuranose-containing extracellular polysaccharides represent potential source to be explored.However,the galactofuranose-containing extracellular polysaccharides from marine fungi have not yet been fully studied.In the current study,a novel galactofuranose-containing extracellular polysaccharide was isolated from the fermented broth of the mangrove-associated fungus Fusarium oxysporum by a combination of ethanol precipitation,ion-exchange,and gel filtration chroma-tography,and its structural characterization was investigated using chemical and spectroscopic methods,including one-and two-dimensional nuclear magnetic resonance(1D and 2D NMR)spectroscopic analyses.The antioxidant activity of the extracellular polysaccharide was also evaluated by scavenging assays involving hydroxyl,superoxide,and1,1-diphenyl-2-picrylhydrazyl(DPPH)radicals.Materials and MethodsMaterialsMonosaccharides(D-glucose,L-rhamnose,D-xylose,L-arabi-nose,D-mannose,L-fucose,D-galactose,D-glucuronic acid,D-galacturonic acid,D-mannuronic acid,N-acetyl-β-D-glucos-amine),1,1-diphenyl-2-picrylhydrazyl,trifluoroacetic acid, thiobarbituric acid,trichloroacetic acid,and1-phenyl-3-meth-yl-5-pyrazolone were from Sigma-Aldrich(St.Louis,MO, USA).Pullulan standards(Mw=344,200,107,47.1,21.2, and9.6kDa)were from the Showa Denko K.K.(Tokyo, Japan).Q Sepharose Fast Flow and Sephacryl S-100were from GE healthcare(Piscataway,NJ,USA).Dialysis mem-branes(flat width,44mm;molecular weight cut-off,3500) were from Lvniao(Yantai,China).Microbial Strain and Culture ConditionsThe marine fungus F.oxysporum was isolated from fresh leaves of Ipomoea pes-caprae(Linn.)collected from South Sea,China.It was identified according to its morphological characteristics and18S rRNA sequences,and the accession number of Genbank was JN604549.Briefly,the fungus was cultivated in the liquid medium containing yeast extract(3g/ L),peptone(5g/L),glucose(20g/L),malt extract(3g/L),sea salt(24.4g/L),KH2PO4(0.5g/L),NH4Cl(0.5g/L),pH6.0–6.5,at25°C for40days,and50L of fermented broth was obtained.Preparation of the Extracellular PolysaccharideThe fermented broth was filtered through cheese cloth,the filtrate was concentrated to1/15of its original volume under reduced pressure at40°C,and a threefold of the volume of 95%(v/v)ethanol was added.The resulting precipitate was recovered by centrifugation at3600×g for10min,dialyzed in cellulose membrane tubing against distilled water for72h. The retained fraction was dried,and the protein in the fraction was removed as described by Matthaei et al.(1962).The crude polysaccharide was fractionated by anion-exchange chroma-tography using a Q Sepharose Fast Flow column(30×3cm) coupled to an AKTA FPLC system and elution with a step-wise gradient of0,0.2,and1.0M NaCl.The fractions were assayed for carbohydrate content by the phenol–sulfuric acid method.The fractions eluted with distilled water were pooled, dialyzed,and further purified on a Sephacryl S-100column (70×2cm)eluted with0.2M NH4HCO3at a flow rate of 0.3mL/min.The major polysaccharide fractions were pooled, freeze–dried,and designated as Fw-1.Determination of Purity and Molecular WeightPurity and molecular weight were determined by high-performance gel permeation chromatography(HPGPC)with a Shodex Ohpak SB804(7.8×300mm,Tokyo,Japan)column and a refractive index detector(Agilent RID-10A Series),and elution with0.1M Na2SO4at a flow rate of0.5mL/min(Li et al.2012).Of1%sample solutions in0.2M Na2SO4,20μL was injected.The molecular weight was estimated by refer-ence to a calibration curve made by pullulan standards.General AnalysisTotal sugar content was measured by the phenol–sulfuric acid method using galactose as the standard(Dubois et al.1956). Protein content was assayed according to the modified Lowry method(Bensadoun and Weinstein1976).Sulfate content was measured according to Silvestri et al.(1982).Uronic acid con-tent was determined by the carbazole–sulfuric acid method (Bitter and Muir1962).Analysis of Monosaccharide CompositionFive milligrams of polysaccharide was hydrolyzed with2M trifluoroacetic acid at100°C for6h.Excess acid was re-moved by co-distillation with methanol after the hydrolysis was completed.Sample was subjected to reversed-phase high-performance liquid chromatography(HPLC)after pre-column derivatization and UV detection(Li et al.2011). Sugar identification was done by comparison with reference sugars(D-glucose,L-rhamnose,D-xylose,L-arabinose,D-man-nose,L-fucose,D-galactose,D-glucuronic acid,D-galacturonicacid,D-mannuronic acid,N-acetyl-β-D-glucosamine). Calculation of the molar ratio of the monosaccharide was car-ried out on the basis of the peak area of the monosaccharide. Methylation AnalysisMethylation analysis was performed by the method of Hakomori(1964)with some modifications.In brief, 2mg of polysaccharide in dimethyl sulfoxide was meth-ylated using NaH and iodomethane,and the completion of methylation was confirmed by Fourier transform infrared (FTIR)spectroscopy by the disappearance of OH bands. After hydrolysis with2M trifluoroacetic acid at105°C for6h,the methylated sugar residues were converted to partially methylated alditol acetates by reduction with NaBH4,followed by acetylation with acetic anhydride. The derivatised sugar residues were extracted into dichlo-romethane and evaporated to dryness,and dissolved again in100μL of dichloromethane.The products were ana-lyzed by gas chromatography–mass spectrometry(GC-MS)on a DB225using a temperature gradient of100–220°C with heating at a rate of5°C/min and mainte-nance of a temperature at220°C for15min.GC-MS was performed on an HP6890II instrument.Identification of partially methylated alditol acetates was carried out on the basis of retention time and mass fragmentation patterns.IR Spectroscopy AnalysisFTIR spectra were measured on a Nicolet Nexus470spec-trometer.The polysaccharide was mixed with KBr powder, ground up,and then pressed into1-mm pellets for FTIR mea-surements in the frequency range of4000–500cm−1with a resolution of4.0cm−1and320scans co-addition.NMR Spectroscopy Analysis1H nuclear magnetic resonance(NMR)and13C NMR spectra were measured at23°C using a JEOL JNM-ECP600MHz spectrometer.60mg of polysaccharide was deuterium ex-changed by two successive freeze–drying steps in99%D2O and then dissolved in0.5mL of99.98%D2O.1H–1H corre-lated spectroscopy(COSY),1H–1H total correlation spectros-copy(TOCSY),1H–1H nuclear overhauser effect spectrosco-py(NOESY),1H–13C heteronuclear multiple quantum coher-ence spectroscopy(HMQC)and1H–13C heteronuclear multi-ple bond correlation spectroscopy(HMBC)experiments were also carried out.Chemical shifts are expressed in ppm using acetone as internal standard at2.225ppm for1H and 31.07ppm for13C.Analysis of Antioxidant ActivityScavenging ability of hydroxyl radicals was determined ac-cording to the method of Smirnoff and Cumbes(1989). Scavenging ability of superoxide radicals was assessed ac-cording to the method reported by Marklund and Marklund (1974).Scavenging ability of DPPH radicals was measured according to the method described by Shimada et al.(1992). The scavenging ability was calculated according to the equa-tion below:scavenging ability(%)=(1–A sample/A control)×100, where A control is the absorbance of control without the tested samples,and A sample is the absorbance in the presence of the tested samples.The EC50value(mg/mL)was the effective concentration at which the tested radicals were scavenged by 50%.Ascorbic acid was used as positive control in all anti-oxidant assays.All bioassay results were expressed as means ±standard deviation(SD).The experimental data were sub-jected to an analysis of variance for a completely random design,and three samples were prepared for assays of every antioxidant attribute.ResultsPreparation and Chemical Composition of the Extracellular PolysaccharideProcedures used for the preparation of the extracellular poly-saccharides from the fermented broth of the mangrove-associated fungus F.oxysporum were shown in Fig.1.Crude extracellular polysaccharide(0.59g/L)was obtained from the fermented broth,and fractionated using a Q Sepharose Fast Flow column(Fig.2a).The polysaccharide fraction,eluted with distilled water,was a major component of the crude polysaccharides.The fraction was further purified by a Sephacryl S-100column(Fig.2b),and a polysaccharide frac-tion Fw-1was obtained.The yield of Fw-1from crude polysaccharide was about 42.86%.Fw-1gave a single and symmetrical peak in the HPGPC chromatogram(Fig.2c),thus Fw-1could be a homo-geneous polysaccharide.The linear relationship between the logarithm of molecular weight of pullulan standards and re-tention time was obtained.The retention time in HPGPC chro-matogram of Fw-1was used to calculate its molecular weight by the obtained regression equation.Thus,the molecular weight of Fw-1was estimated to be about61.2kDa.Fw-1 contained91.3%total carbohydrate and minor amounts of protein(0.79%)and did not have any sulfate ester. Monosaccharide composition analysis by reversed-phase HPLC showed that Fw-1consisted of galactose,glucose, and mannose with a molar ratio of1.33:1.33:1.00.No acidic sugar and amino sugar were detected in Fw-1.Thepolysaccharide fraction Fs,eluted at 0.2M NaCl,was not further investigated due to the limit of sample amount.It is possible that fraction Fs contains an acidic polysaccharide,such as a polysaccharide with phosphate ester (Chen et al.2013).IR SpectroscopyFrom the FTIR spectrum of Fw-1,the broad and intense band at 3416cm −1was the result of valent vibrations OH groups.The signal at 2931cm −1was attributed to the stretch vibration of the C –H bond.The band at 1649cm −1was assigned to the bending vibrations of HOH,and the band at 1416cm −1originated from the bend-ing vibrations of O –H bond.The band at 1241cm −1was due to the stretch vibration of C –O –C linkages.The signal at 1032cm −1was assigned to the stretch vibration of C –O and change angle vibration of O –H.The characteristic ab-sorption bands at 876and 809cm −1suggested the pres-ences of furan ring and mannopyranose units,respectively (Ahrazem et al.2000;Mathlouthi and Koenig 1986).Methylation AnalysisIn order to determine the linkage pattern of the sugar residues,Fw-1was subjected to methylation analysis (Table 1).A large amount of 1,2,4,6-tetra-O -acetyl-3,5-di-O -methyl-galactitol,which originated from the (1→2,6)-linked galactofuranoseresidue,was detected in Fw-1,suggesting that Fw-1was a highly branched polysaccharide.1,5-di-O -acetyl-2,3,4,6-tet-ra-O -methyl-glucitol,1,2,5-tri-O -acetyl-3,4,6-tri-O -methyl-mannitol,and 1,2,5-tri-O -acetyl-3,4,6-tri-O -methyl-glucitol were also detected,indicating the presence of (1→)-linked glucopyranose,(1→2)-linked mannopyranose and (1→2)-linked glucopyranose residues.In addition,1,5-di-O -acetyl-2,3,4,6-tetra-O -methyl-mannitol,which originated from the (1→)-linked mannopyranose residue,was also found in Fw-1.The results suggested that the structure of Fw-1is com-posed of (1→2,6)-linked galactofuranose,(1→2)-linked glu-copyranose,(1→2)-linked mannopyranose,terminal gluco-pyranose,and mannopyranose residues.NMR SpectroscopyThe 1H NMR spectrum (Fig.3a )of Fw-1showed anomeric proton signals at 5.20,5.10,5.09,4.91,4.75,and 4.65ppm,which were labeled A –F from low to high field.The anomeric signals B and C almost overlapped.The anomeric proton sig-nals A –F had relative integrals of 1.0:0.5:0.5:0.25:0.25:0.25.A might be signal of β-galactofuranose residue.B and C were attributed to the signals of α-configuration pyranose units,and D –F were likely the signals of β-configuration pyranose units.The chemical shifts from 3.42to 4.26ppm were assigned to H2–H6of glycosidic ring.In the anomeric region of the 13C NMR spectrum (Fig.3b )of Fw-1,there were six main anomeric carbon signals that occurred at 107.8,102.4,101.8,101.3,99.6,and 99.5ppm.The anomeric carbon signal at 107.8ppm was due to signal of β-galactofuranose residue because of extremely low field shifts (Ahrazem et al.2006).As shown in the DEPT spectrum,the signal at 70.8ppm was assigned to the substituted C-6of β-galactofuranose units.The result confirmed the presence of the substituted C-6linkage patterns,which was in accordance to the methylation results.The 1H NMR spin systems chemical shifts of the polysac-charide were assigned by means of the 1H –1H COSY spec-trum (Fig.3c )and the 1H –1H TOCSY spectrum (Fig.3d ).Combined with the analysis of the 1H –13C HMQC spectrum of Fw-1(Fig.3e ),the observed 1H and 13C chemical shifts and the assignment of the sugar residues were given (Table 2).A was assigned to →2,6)-β-D -Gal f (1→because of the down-field chemical shifts of the C-2(88.1ppm)and C-6(70.8ppm).B and C were suggested to be Glc p because of the high field chemical shift of H-2(3.59and 3.69ppm).In the 1H –1H TOCSY spectrum,H-1of B and C showed the correlation peaks with H-2,H-3,H-4,and H-5,which con-firmed this speculation.The 1H –13C HMQC spectrum re-vealed the substitution of C at C-2due to the downfield chem-ical shift (77.0ppm)of C-2compared with the parent α-D -Glc p .Thus,B was attributed to α-D -Glc p (1→,and C was due to →2)-α-D -Glc p (1→.Combined with methylationanalysisFig.1Scheme for the preparation of the extracellular polysaccharide produced by the mangrove-associated fungus F .oxysporumand NMR spectra data (Takegawa et al.1997),E was assigned to →2)-β-D -Man p (1→because of C-2(78.0ppm)of E had a relative downfield chemical shifts.D and F were assigned to be β-D -Man p (1→,the different glycosidic bond and sugar rings,which linked with D and F,had different chemical en-vironments and chemical shifts.The sequence of glycosyl residues was determined from the 1H –1H NOESY spectrum,followed by confirmation with 1H –13C correlations obtained from the 1H –13C HMBC spec-trum.In the 1H –1H NOESY spectrum (Fig.3f )of Fw-1,A had a strong NOE contact of its H-1with the H-2of C,indicating C linked to the C-2position of A.B and C had a strongcontactFig.2Isolation and HPGPC chromatogram of the extracellular polysaccharide from the fermented broth of the mangrove-associated fun-gus F .oxysporum .a The crude polysaccharides were fractionated using a Q Sepharose Fast Flow column.The fraction eluted with distill water was pooled and named as Fw.b Fw was purified on a Sephacryl S-100column and eluted with 0.2M NH 4HCO 3.The peak fractions containing the polysaccharides were pooled and named as Fw-1.c HPGPC chro-matogram of Fw-1on a Shodex Ohpak SB-804column and the standard curve of molecular weightof its H-1with the H-2of A,suggesting B and C linked to theC-2position of A.D had a strong inter-residue contact be-tween its H-1and the H-2of E,indicating D linked to theC-2position of E.From the1H–13C HMBC spectrum ofFw-1(Fig.3g),the presence of strong cross peak H-1/C-4,C-6of A confirmed that A wasβ-galactofuranose configura-tion and→6)-β-D-Gal f(1→was the main pattern of linkage.The cross-peak H-1B,C/C-2A,and H-2A/C-1B,C indicatedthat B and C linked to the C-2of→6)-β-D-Gal f(1→.The 1H–13C HMBC spectrum of Fw-1also showed H-1F/C-2 C,H-1E/C-2C,H-1D/C-2E,H-2E/C-1D,B H-1/C-5crosspeaks,which further proved the existence ofβ-D-Man p(1→2)-β-D-Man p(1→2)-α-D-Glc p(1→andβ-D-Man p(1→2)-α-D-Glc p(1→.The results also revealed both the furanoid char-acter of A and the pyranoid structure of B–F.The NMR resultswere thus in agreement with methylation results.These anal-yses allowed the identification of most of the1H and13Csignals of the sugar residues.Thus,structure of Fw-1couldbe characterized to consist of the backbone of(1→6)-linked β-D-galactofuranose residues,with multiple branches at C-2 consisting of theα-D-Glc p(1→,β-D-Man p(1→2)-β-D-Man p(1→2)-α-D-Glc p(1→andβ-D-Man p(1→2)-α-D-Glc p(1→.The hypothetical structure of Fw-1was shown in Fig.4.Analysis of Antioxidant ActivityAs shown in Table3,the scavenging abilities of Fw-1on hydroxyl,DPPH,and superoxide radicals were in a concentration-dependent manner.Less scavenging of hydrox-yl radicals was observed with Fw-1at2mg/mL,but the scav-enging ability of Fw-1on hydroxyl radicals at10.0mg/mL was up to90.2%.Fw-1showed strong scavenging ability on hydroxyl radicals as evidenced by its low EC50value(1.1mg/ mL).The scavenging ability of Fw-1on superoxide radicals was50.2%at2.0mg/mL,and the scavenging ability of Fw-1 was up to89.2%at10.0mg/mL.The EC50value of scaveng-ing ability of Fw-1on superoxide radicals was2.0mg/mL. The scavenging ability of Fw-1on DPPH radicals was up to 88.2%at10.0mg/mL,and its EC50value was2.1mg/mL, indicating that Fw-1was also good effectiveness in the anti-oxidant attribute.The scavenging abilities of Fw-1on hydroxyl,superoxide and DPPH radicals were all relativelylower than that of ascorbic acid at the same concentrations. DiscussionA novel extracellular polysaccharide Fw-1is successfullyobtained from the mangrove-associated fungus F.oxysporum.Fw-1is an extracellular polysaccharidewith different structural characteristics from other extra-cellular polysaccharides produced by Fusarium sp.Thecell wall polysaccharides from F.oxysporum are com-posed of glucosamine and N-acetylglucosamine(Fukamizo et al.1992,1996),and the polysaccharidefrom Fusarium sp.M7-1consists of mannose,glucose,galactose,and glucuronic acid(Iwahara et al.1992).However,a small amount of→2)-β-D-Gal f(1→and→6)-α-D-Glc p(1→residues present in the cell wall polysac-charide of Fusarium sp.M7-1(Iwahara et al.1996).Somealkali-extractable and water-soluble extracellular polysac-charides from Fusarium species contain a backbone of β-(1→6)-linked galactofuranose residues almost fully branched at O-2by single residues of glucopyranose oracidic chains containing glucuronic acid and mannose.The extracellular polysaccharide from F.oxysporumY24-2is composed of→2)-β-D-Gal f(1→6)-α-D-Glc p(1→units(Guo et al.2013).The structure of Fw1also differs from othergalactofuranose-containing extracellular polysaccharides re-ported previously(Gómez-Miranda et al.2003;Leal et al.2010).The galactofuranans from Aspergillus niger, A.fumigatus,Trichophyton species and Penicillium charlesii,have been characterized as linear chains of(1→5)-linkedβ-D-galactofuranose units(Gander et al.1974;Latgéet al.1994; Unkefer and Gander1990;Ikuta et al.1997).For the extracel-lular polysaccharide from the deep-sea fungus P.griseofulvum,its galactofuranan chain consists of(1→5)-linkedβ-D-galactofuranose,with additional branches at C-6 consisting of(1→)-linkedβ-D-galactofuranose residues and phosphate esters(Chen et al.2013).Fw-1contains a backbone of(1→6)-linkedβ-D-galactofuranose residues with multipleTable1Results of methylation analysis of Fw-1Methylated sugar Primary mass fragments(m/z)Molar ratio Deduced linkage1,5-Di-O-acetyl-2,3,4,6-tetra-O-methyl-mannitol101,117,129,145,161,205 2.0Man p(→1,5-Di-O-acetyl-2,3,4,6-tetra-O-methyl-glucitol101,117,129,145,161,205 2.0Glc p(1→1,2,5-Tri-O-acetyl-3,4,6-tri-O-methyl-mannitol87,101,129,161,189 1.0→2)Man p(1→1,2,5-Tri-O-acetyl-3,4,6-tri-O-methyl-glucitol101,117,129,161,201,233,277 2.0→2)Glc p(1→1,2,4,6-Tetra-O-acetyl-3,5-di-O-methyl-galactitol87,101,117,129,173,189,201,233 4.0→2,6)Gal f(1→Fig.3NMR spectra of Fw-1.Spectra were performed at23°C on a JEOL ECP600MHz spectrometer Chemical shifts are expressed in ppm using acetone as internal standard at2.225ppm for1H and 31.07ppm for13C.a1H NMR spectrum.b13C NMR and DEPT spectra.c1H–1H COSY spectrum.d1H–1H TOCOSY spectrum.e 1H–13C HMQC spectrum.f1H–1H NOESY spectrum.g1H–13C HMBC spectrum.A→2,6)-β-D-Gal f(1→.Bα-D-Glc p(1→.C→2)-α-D-Glc p(1→.Dβ-D-Man p(1→,linked to→2)-β-D-Man p(l→.E→2)-β-D-Man p(l→.Fβ-D-Man p(1→,linked to→2)-α-D-Glc p(l→.Glcpglucopyranose,Manp mannopyranose,Galf galactofuranosebranches at C-2consisting of terminal α-glucopyranose resi-dues,or short chains containing (1→2)-linked α-D -glucopy-ranose,(1→2)-linked β-D -mannopyranose,and terminal β-D -mannopyranose residues.To the best of our knowledge,this is the first report of such kind of galactofuranose-containing mannoglucogalactan isolated from fermented broth of micro-organism.The present result suggested that mangrove-associated fungi could be a potential source of extracellular polysaccharides with unique structures to be worth being fur-ther studied.In order to investigate the antioxidant activity of Fw-1,the assays based on scavenging abilities of hydroxyl,superoxide,and DPPH radicals were carried out and compared with that of ascorbic acid,one standard antioxidant.Hydroxyl radical is considered to be a highly potent oxidant,which can react with most biomacromolecules functioning in living cells and in-duce severe damage to the adjacent biomolecules.In cellular oxidation reactions,superoxide radical is normally formed first,and its effects can be magnified because it produces hydrogen peroxide and hydroxyl radical through dismutationTable 21H and 13C chemical shifts for the extracellular polysaccharide Fw-1Sugar residuesChemical shifts (ppm)a H1/C1H2/C2H3/C3H4/C4H5/C5H6/C6A b 5.20/107.8 4.21/88.1 4.26/76.9 4.05/83.9 4.02/71.0 3.94,3.69/70.8B c 5.10/99.5 3.59/72.6 3.77/73.1 3.47/71.0 3.79/73.8 3.91,3.73/62.1C d 5.09/99.6 3.69/77.0 3.81/73.1 3.45/71.0 3.76/72.6 4.12,3.79/62.3D e 4.91/102.4 4.18/72.6 3.73/72.4 3.61/72.6 3.45/71.9 3.79,3.90/62.6E f 4.75/101.3 4.24/78.0 3.68/68.3 3.95/71.2 3.76/73.5 3.96,3.45/62.4F g4.65/101.84.02/71.93.73/72.43.96/71.13.80/73.63.47,3.86/62.3Glcp glucopyranose,Manp mannopyranose,Galf galactofuranoseaThe spectra were recorded using a JEOL JNM-ECP 600MHz spectrometer.Chemical shifts are referenced to internal acetone at 2.225ppm for 1H and 31.07ppm for 13C b →2,6)-β-D -Gal f (→c α-D -Glc p (1→d →2)-α-D -Glc p (1→e β-D -Man p (1→,linked to →2)-β-D -Man p (l →f →2)-β-D -Man p (l →gβ-D -Man p (1→,linked to →2)-α-D -Glc p (l→Fig.4One of the possible structures of Fw-1(Glcp gluco-pyranose,Manp ,mannopyranose,Galf ,galactofuranose,n ≈16)and other types of reaction and was the source of free radicals formed in vivo.DPPH is a useful reagent to evaluate the free radical scavenging ability of the hy-drogen donating antioxidant,which can transfer hydro-gen atoms or electrons to DPPH radicals.It was found that Fw-1had a more noticeable scavenging ability on hydroxyl radicals than the extracellular polysaccharide AVP produced by coral-associated fungus Aspergillus versicolor LCJ-5-4,and the EC50value of AVP was 4.0mg/mL(Chen et al.2012).Moreover,the scaveng-ing ability of Fw-1on superoxide radicals appears to be higher than that of the extracellular polysaccharide As1-1produced by marine fungi Aspergillus sp.Y16,and the EC50value of As1-1was 3.4mg/mL(Chen et al. 2011).Scavenging ability of Fw-1on DPPH radicals was similar to that of extracellular polysaccharide AVP produced by coral-associated fungus,A.versicolor LCJ-5-4,and its EC50value was2.05mg/mL(Chen et al. 2012).Fw-1had a higher scavenging ability on DPPH radicals than the extracellular polysaccharides PS2-1, PS1-2,and PS1-1isolated from marine fungus Penicillium sp.F23-2(EC50value 2.53–6.81mg/mL) (Sun et al.2009).The present result suggested that the extracellular polysaccharide Fw-1could be a potential antioxidant.The antioxidant activity of Fw-1may be attributed to the extracellular polysaccharide can connect with radicals,and terminate the radical chain reaction. However,the antioxidant mechanisms of polysaccha-rides are complex.Further study on antioxidant property of extracellular polysaccharides with different structural characterization will play an important role in the un-derstanding of the mechanism of antioxidant activity.In conclusion,the extracellular polysaccharide Fw-1pro-duced by the mangrove-associated fungus F.oxysporum is a galactofuranose-containing mannoglucogalactan differing from previously described extracellular polysaccharides.Fw-1exhibits good antioxidant activity in vitro.An in-depth investigation of the antioxidant activity of Fw-1will be re-quired to determine if the extracellular polysaccharide will be useful in the food and pharmaceutical industry. Acknowledgments This work was supported by the Science and Tech-nology Development Program of Shandong Province,China (2014GHY115015),NSFC-Shandong Joint Fund for Marine Science Re-search Centers(U1406402),and the National Oceanographic Center of Qingdao of China.ReferencesAhrazem O,Gómez-Miranda B,Prieto A,Barasoaín I,BernabéM,Leal JA(2000)An acidic water-soluble cell wall polysaccharide:a che-motaxonomic marker for Fusarium and Gibberella.Microbiol Res 104:603–610Ahrazem O,Prieto A,Giménez-Abián MI,Leal JA,Jiménez-Barberoa J, Bernabe M(2006)Structural elucidation of fungal polysaccharides isolated from the cell wall of Plectosphaerella cucumerina and Verticillium spp.Carbohydr Res341:246–252Bensadoun A,Weinstein D(1976)Assay of proteins in presence of in-terfering materials.Anal Chem70:241–256Bitter T,Muir HM(1962)A modified uronic acid carbazole reaction.Anal Biochem4:330–334Chen Y,Mao WJ,Tao HW,Zhu WM,Qi XH,Chen YL,Li HY,Zhao CQ, Yang YP,Hou YJ,Wang CY,Li N(2011)Structural characterization and antioxidant properties of an exopolysaccharide produced by the mangrove endophytic fungus Aspergillus sp.Y16.Bioresour Technol102:8179–8184Chen Y,Mao WJ,Yang YP,Teng XC,Zhu WM,Qi XH,Chen YL,Zhao CQ,Hou YJ,Wang CY,Li N(2012)Structure and antioxidant activity of an extracellular polysaccharide from coral-associated fun-gus,Aspergillus versicolor LCJ-5-4.Carbohydr Polym87:218–226 Chen Y,Mao WJ,Wang BF,Zhou LN,Gu QQ,Chen YL,Zhao CQ,Li N, Wang CY,Shan JM,Yan MX,Lin C(2013)Preparation and char-acterization of an extracellular polysaccharide produced by the deep-sea fungus Penicillium griseofulvum.Bioresour Technol132: 178–181Dubois C,Gilles KA,Hamilton JK,Rebers PA,Smith F(1956) Colorimetric method for determination of sugars and related sub-stances.Anal Chem28:350–356Table3Antioxidant activity of the extracellular polysaccharide Fw-1in vitroa The results were expressed as means±standard deviation(SD). The experimental data were subjected to an analysis of variance for a completely random design,and three samples were prepared for assays of every antioxidant attribute Sample Concentration(mg/mL)a0 2.0 4.0 6.08.010.0Scavenging ability on hydroxyl radicals(%)Fw-10.059.5±1.482.5±2.885.6±2.486.8±3.590.2±2.3 Ascorbic acid0.097.2±2.497.2±2.697.4±2.697.5±1.997.7±2.1 Scavenging ability on superoxide radicals(%)Fw-10.050.2±1.868.3±3.179.1±2.385.7±3.289.2±2.8 Ascorbic acid0.097.2±1.997.3±2.297.4±2.797.5±2.897.8±2.4 Scavenging ability on DPPH radicals(%)Fw-10.049.1±1.766.9±2.475.0±2.585.2±2.388.2±2.6 Ascorbic acid0.097.2±2.297.3±1.797.4±2.097.5±2.597.7±2.8。

新型碳气凝胶的制备及表征何蕊;刘振法【摘要】以氨水作为间苯二酚和甲醛反应的催化剂,经溶胶-凝胶制备有机气凝胶,再经过常温常压干燥、高温碳化形成碳气凝胶.采用X射线衍射、比表面仪、扫描电镜能谱分析仪对样品进行表征.结果表明:以氨水为催化剂所得碳气凝胶比表面积在900m2/g左右,呈现连续颗粒状.%Carbon aerogels are prepared by sol-gel process via reaction of resorcinol and formaldehyde with ammonia water as catalyst and afterward ambient drying followed by carbonization. The structure of products is characterized by X-ray diffraction, gas physisorption, scanning electron microscopy and energy spectrum analysis. Results indicte that the carbon aerogels with ammonia as catalyst show a coarser surface, and its specific surface area is about 900 m2/g, presenting continuous granular.【期刊名称】《河北科技大学学报》【年(卷),期】2013(034)001【总页数】4页(P26-29)【关键词】碳气凝胶;催化剂;氨水【作者】何蕊;刘振法【作者单位】河北省科学院能源研究所,河北石家庄050081;河北省科学院能源研究所,河北石家庄050081【正文语种】中文【中图分类】O648碳气凝胶是一种由高聚物分子构成的多空非晶凝聚态材料,可以用在力学、热学、光学及声学等方面,具有独特的性能和用途。

sci引用文献格式SCI引用文献格式是科学引用文献的一种标准格式,其主要特点是简洁明了、规范统一。

SCI引用文献格式适用于各类学术论文、科技报告、学位论文等各类科技文献的引用和参考。

SCI引用文献格式的基本要求如下:1. 文章题目:使用斜体字体,放在文章标题下方,与文章标题之间空一行。

2. 作者名字:使用缩写形式,姓名后面加上逗号。

3. 文章来源:包括期刊名称、卷号、期号和页码。

4. 发表年份:放在文章来源后面,以括号包围。

5. DOI编号:如果有DOI编号,则应该在发表年份后面加上“doi:”和DOI编号。

6. 参考文献列表:按作者姓氏字母顺序排列,并按字母顺序排列。

每个参考文献单元格之间应空一行。

7. 期刊名称缩写:期刊名称应使用标准缩写形式,并以斜体字体书写。

8. 页码格式:如果是连续页码,则使用“-”表示;如果不连续,则使用“,”分隔开来。

9. 出版地点和出版社信息:只有对于书籍等不同类型的文献才需要提供。

下面是一个SCI引用文献格式的示例:[1] Wang, J., Zhang, Y., Liu, X., et al. (2019). A novel approach for the preparation of graphene oxide–silver nanoparticle composites and their application in antibacterial coatings. Journal of Colloid and Interface Science, 537, 82-92.doi:10.1016/j.jcis.2018.11.067[2] Chen, S., Wu, W., Liang, Y., et al. (2018). Preparation and characterization of a novel magnetic chitosan/graphene oxide composite for the removal of hexavalent chromium from aqueous solutions. Journal of Hazardous Materials, 341, 424-433.[3] Liang, Y., Wu, W., Chen, S., et al. (2017). Synthesis and characterization of a novel magnetic chitosan/graphene oxide composite for the removal of heavy metal ions from aqueous solutions. Journal of Environmental Chemical Engineering, 5(2), 1720-1729.[4] Zhang, J., Huang, L., Lv, X., et al. (2016). A facile preparation method for graphene oxide–iron oxide nanocomposites with high performance in water treatment applications. Chemical Engineering Journal, 283(1), 1155-1164.[5] Wang, X., Sun, G., Wang Gaoqiang , et al.(2015). Preparation and characterization of graphene oxide–polyvinyl alcohol composite films with enhanced mechanical properties.Journal of Applied Polymer Science,132(7)。

preparation and characterizationPreparation and CharacterizationPreparation and characterization are two important aspects of scientific research. Preparation refers to the process of obtaining and producing a material or sample,while characterization refers to the process of identifying and analyzing the properties of that material or sample. In this article, we will discuss the different steps involved in preparation and characterization.PreparationThe preparation step involves obtaining or producing the material or sample for study. Depending on the type ofmaterial or sample, different preparation methods may be used. For example, if the material is a chemical compound, it maybe synthesized in the laboratory using a specific reaction.On the other hand, if the material is a biological sample, it may need to be extracted from a tissue or fluid, and then purified.Once the material or sample has been prepared, it may need to be processed further for analysis. For example, ifthe material is a solid, it may need to be ground into fine particles to improve the surface area for further investigation. Alternatively, if the sample is a liquid or gas, it may need to be concentrated or diluted for proper analysis.CharacterizationOnce the sample or material has been prepared, it is ready for characterization. Characterization involvesidentifying the physical and chemical properties of the material or sample. This can be done using various analytical techniques such as microscopy, spectroscopy, and chromatography.Microscopy involves the use of a microscope to examine the physical structure of the material or sample at a microscopic level. This can provide information about the size, shape, and texture of the sample.Spectroscopy involves the use of various types of electromagnetic radiation to measure the energy levels and wavelengths of molecules in the sample. This can provide information about the chemical composition and molecular structure of the sample.Chromatography involves separating the various components of a sample based on their chemical properties using a chromatography column. This can provide information about the chemical composition and purity of the sample.ConclusionIn conclusion, preparation and characterization are important steps in scientific research that involve acquiring and analyzing a material or sample. Preparation involves the process of obtaining and producing the material or sample, while characterization involves identifying and analyzing the properties of that material or sample. Proper preparation and characterization are crucial for accurate scientific analysis and reliable results.。

an1) A previously published method for producing silica xerogel involved dissolving RHA silica with alkali solution to form sodium silicate solution and subsequently forming silica aquagel by adding hydrochloric acid to lower the pH from 11.8 to 7.0, followed by washing and drying aquagel to form xerogel.2 )be composed of ;consist of;comprise;。

3 ) The yield of the activated carbon – which is defined as the weight ratio, on dry basis, of the resulting activated carbon to that of the original olive-waste cakes4) Performances of the obtained carbons are generally expressed in terms of some properties5 )Experiments have been carried out at different activating agent/precursor ratio6) Developed activated carbon has been characterized by BET surface area (SBET) analysis and iodine number. The kinetic data were fitted to the models of pseudo-first-order, pseudo-second-order and intraparticle diffusion models. purification of gas ;wastewater t reatmen t; fabrication of activated carbon;b e on par with,与…不分上下;c oal-based carbon;useful in adsorption of gases and solutes from aqueous solutions;Physical activation involves the carbonization of a carbonaceous precursor followed by activation o f the resulting char in the presence of some activating agents such as carbon dioxide or steam. the elimination of;dehydrating ag ents;inhibit formation of tar;enhance the yield of carbon;alkali,alkaline earth metals;some acids; They have detrimental effect on the water quality and they are toxic to aquatic life. the toxicity of phenol varies with specie s , conditions of exposure and the duration of the tests;retard the growth o f ; t he removal of phenol from a queous solutions; because of th eir availabilit y at low price.;They can be used for the production of activated carbon with a high adsorption capacity,considerable mechanical strength and low ash content;7) was washed with distilled water and dried at100±2 ◦C for 12 h; The dried material was then milled and sieved to uniform particle size (0.5±0.1mm) prior to activation process;p rocure sth from sw; Twenty grams each of dried seaweed (SL and HV)were added to200mL of zinc chloride solution of desired concentration (10, 20,30, 40, and 50%, w/v) and stirred for a period of 2 h. The temperature was increased from room temperature to final temperatures of 400, 500, 600, 700 and 800 ◦C with a retention time of2 h at a heating rate of 10 ◦Cmin−1.8) was washed with hot 1N HCl solution for 30min to remove excess zinc chloride, filtere d and rinsed with wa rm water until the washings were free of zinc ions;称…..为。

Abstract:The synthesis of nanocrystalline copper phthalocyanine (CuPc) wascarried out using a solvothermal method. The reaction conditions, including the choice of solvent, temperature, and time, were optimized to achieve the highest yield and purity of CuPc. The synthesized CuPc was characterized using various techniques such as UV-Vis spectroscopy, X-ray diffraction (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM). The results indicate that the solvothermal method is an efficient and effective approach for the synthesis of CuPc nanocrystals with high purity and excellent optical properties.1. Introduction:Copper phthalocyanine (CuPc) is a well-known blue pigment with significant applications in various fields, including optoelectronics, catalysis, and medicine. The unique optical and electronic properties of CuPc, such as its strong absorption in the visible region and high thermal stability, make it an attractive material for many applications. In recent years, the development of nanocrystalline CuPc has gained considerable attention due to its enhanced properties compared to its bulk counterpart. The solvothermal method has been widely used for the synthesis of various inorganic and organic nanomaterials due to its simplicity, cost-effectiveness, and environmentally friendly nature.2. Materials and Methods:2.1 Materials:- Copper(II) sulfate pentahydrate (CuSO4·5H2O)- Potassium phthalocyanine (K3Pc)- Sodium hydroxide (NaOH)- Ethanol (EtOH)- Deionized water2.2 Synthesis of CuPc Nanocrystals:The synthesis of CuPc nanocrystals was carried out using the solvothermal method. The detailed procedure is as follows:1. Dissolve 0.5 g of CuSO4·5H2O and 0.5 g of K3Pc in 10 mL of ethanol under magnetic stirring for 1 hour.2. Add 0.5 g of NaOH to the solution and continue stirring for another hour.3. Transfer the reaction mixture into a Teflon-lined autoclave and heat it at 180°C for 12 hours.4. Cool the autoclave to room temperature and centrifuge the reaction mixture at 5000 rpm for 30 minutes.5. Wash the precipitate with ethanol and deionized water several times to remove impurities.6. Dry the precipitate in an oven at 60°C for 12 hours to obtain the final product.2.3 Characterization Techniques:The synthesized CuPc nanocrystals were characterized using the following techniques:- UV-Vis spectroscopy (Shimadzu UV-2600)- X-ray diffraction (XRD) (Bruker D8 Advance)- Scanning electron microscopy (SEM) (Hitachi S-4800)- Transmission electron microscopy (TEM) (JEOL JEM-2100)3. Results and Discussion:3.1 UV-Vis Spectroscopy:The UV-Vis absorption spectrum of the synthesized CuPc nanocrystals is shown in Figure 1. The spectrum exhibits a strong absorption peak at 640 nm, which is characteristic of CuPc. The shoulder peak at 690 nm is attributed to the transition of π-π.Figure 1: UV-Vis absorption spectrum of CuPc nanocrystals3.2 XRD Analysis:The XRD pattern of the synthesized CuPc nanocrystals is shown in Figure 2. The diffraction peaks are well matched with the standard JCPDS card No. 12-0465, indicating the presence of CuPc in the crystalline form. The crystal size of the CuPc nanocrystals was calculated to be approximately 20 nm.Figure 2: XRD pattern of CuPc nanocrystals3.3 SEM Analysis:The SEM image of the synthesized CuPc nanocrystals is shown in Figure 3. The image reveals the spherical shape of the nanocrystals with an average diameter of 20 nm.Figure 3: SEM image of CuPc nanocrystals3.4 TEM Analysis:The TEM image of the synthesized CuPc nanocrystals is shown in Figure 4. The image confirms the spherical shape of the nanocrystals with a size of approximately 20 nm. The high-resolution image shows the crystalline structure of the CuPc nanocrystals.Figure 4: TEM image of CuPc nanocrystals4. Conclusion:In this study, the solvothermal method was employed for the synthesis of nanocrystalline CuPc. The optimized reaction conditions, including the choice of solvent, temperature, and time, resulted in the formation of CuPc nanocrystals with high purity and excellent optical properties. The synthesized CuPc nanocrystals were characterized using various techniques, including UV-Vis spectroscopy, XRD, SEM, and TEM. Theresults indicate that the solvothermal method is an efficient and effective approach for the synthesis of CuPc nanocrystals with high purity and excellent optical properties.5. Acknowledgments:The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 123456) and the China Scholarship Council (Grant No. 789012).References:1. A. G. Aliev, V. I. Gerasimchuk, A. A. Shevchenko, and A. V. Shevchenko, "Preparation and properties of CuPc/CdS core-shell quantum dots," Journal of Nanomaterials, vol. 2012, Article ID 682318, 2012.2. S. M. Y. Y. Ahamed, S. S. Al-Asfour, and A. A. Al-Asfour, "Synthesis and characterization of copper phthalocyanine thin films using chemical bath deposition method," Journal of Nanomaterials, vol. 2013, Article ID 982916, 2013.3. X. J. Wang, Z. Y. Chen, Y. J. Gao, Y. J. Li, and J. P. Zhang, "Preparation and characterization of CuPc nanocrystals using a microwave-assisted solvothermal method," Journal of Nanomaterials, vol. 2013, Article ID 916402, 2013.4. M. A. E. Al-Asfour, S. S. Al-Asfour, and A. G. Aliev, "Preparation and characterization of copper phthalocyanine/CdS core-shell quantum dots using a solvothermal method," Journal of Nanomaterials, vol. 2014, Article ID 382594, 2014.5. M. A. E. Al-Asfour, S. S. Al-Asfour, and A. G. Aliev, "Preparation and characterization of copper phthalocyanine nanocrystals using a microwave-assisted solvothermal method," Journal of Nanomaterials, vol. 2014, Article ID 382594, 2014.。

Journal of Energy Storage 参考文献格式在撰写与能源储存相关的论文时,Journal of Energy Storage (JES) 是一个重要的参考文献。

本文将介绍 JES 参考文献的格式要求。

下面是本店铺为大家精心编写的2篇《Journal of Energy Storage 参考文献格式》,供大家借鉴与参考,希望对大家有所帮助。

《Journal of Energy Storage 参考文献格式》篇11. 标题JES 参考文献的标题应该简洁明了,准确地反映文章的主题。

标题应使用全名,如“A Study on XYZ for Energy Storage Applications”。

2. 作者在引用 JES 文章时,请确保列出所有作者的姓名。

如果有多个作者,请使用逗号分隔。

例如:“ABC, DEF, GHI”。

3. 发表时间在参考文献中,应包括 JES 文章的发表时间。

这有助于读者了解文献的时效性和可靠性。

格式如下:“Year, Month”。

4. 期刊名称在参考文献中,应准确列出 JES 期刊的名称。

完整的期刊名称为“Journal of Energy Storage”。

5. 卷、期、页码在参考文献中,应包括 JES 文章的卷、期和页码信息。

格式如下:“Volume, Issue, Page Range”。

6. DOIJES 文章的 DOI(数字对象标识符)是唯一标识文章的编码。

在参考文献中,应包括文章的 DOI。

以下是一个 JES 参考文献的示例:示例:“A Study on Lithium-Ion Batteries for Energy Storage Applications”, by XYZ, Journal of Energy Storage, 2020, 1, 23-35. DOI: 10.1016/j.jes.2020.09.007.请注意,参考文献格式可能会根据具体的期刊要求而有所不同。

Preparation and characterization of Ag-TiO2 hybrid clusters powders[1](Ag-TiO2混合团簇粉末的制备和表征)Abstract:液相电弧放电法被用于制备纳米Ag-TiO2复合超细粉末。

XRD和TEM图表明颗粒呈葫芦状形态,分布狭窄。

我们讨论了实验条件对产品的影响,比较了这种方法制备的粉末和其他γ射线辐照法制备的粉末。

Introduction:材料合成技术,提高了研究特定电子和光学特性的能力。

这也导致了设备和不同效应的快速发展,如集成光学型偏振器[1]和量子霍耳效应。

所需的长度尺度对于这些结构的控制是在纳米级别的[ 2 ]。

科学家面临的一个新的挑战是半导体量子点的生长,它具有新的光学响应,引起了对其基础物理方面和三阶非线性光致发光的应用等的研究兴趣。

这方面的一个例子是Ag-TiO2复合材料通过胶体方法合成[ 3 ]或由γ射线辐照法合成[ 4 ]。

对比其他制备超细金属颗粒的方法,γ射线辐照法能在室温的环境压力下产生粉末。

在这封信中,我们开发了一种新的方法,即液相电弧放电法,用以制备纳米复合材料,当它经水热处理可以得到纳米级别的超细粉。

Preparation and photocatalytic activity of immobilized composite photocatalyst (titania nanoparticle/activated carbon)[2]固定化复合光催化剂(TiO2纳米颗粒/活性炭)的制备和光催化活性研究Abstract:制备了一种固定化复合光催化剂——TiO2纳米颗粒/活性炭(AC),并研究了它在降解纺织染料的光催化活性。

AC通过油菜籽壳制备。

碱性红18(BR18)和碱性红46(BR46)被用来作为模型染料。

并采用了傅里叶变换红外(FTIR),波长色散X射线光谱(WDX),扫描电子显微镜(SEM),紫外可见分光光度法,化学需氧量(COD)和离子色谱(IC)分析。

载药再生细菌纤维素纤维的制备及其表征吴焕岭【摘要】The regenerated bacterial cellulose (RBC)fiber used for wound dressing and having good biocompatibility was prepared by a wet spinning process,taking bacterial cellulose as raw material,adoptingLiCl/Dimethylacetamide as solvent system and using water as coagulation bath.Then ciprofloxacin was used as the model drug to prepare drug-loaded RBC fiber.The characterization of morphological,mechanical properties,XRD,drug loading and release performance were determined.The results shows that the tRBC fiber has a groove surface structure with a diameter of about 40 μm.The tensile breaking strength of the RBC fiber is as high as 2.5 cN/dtex.X-ray diffraction results indicate that the crystal form of RBC fiber is transformed from cellulose crystal][toⅡ,and the degree of crystallinity is reduced from 66.3% to 36.2%.The drug loading and release experiments show that the RBC fiber has the highest drug loading capacity under alkaline condition,while the drug loaded RBC fiber has the largest release amount under acid condition.%为获得一种具有优良生物相容性,能够用于伤口敷料的纤维材料,以细菌纤维素为原料,以氯化锂/二甲基乙酰胺为溶剂体系制备纺丝液,以水为凝固浴,采用湿法纺丝技术制备再生细菌纤维素纤维,进而以环丙沙星为模型药物对再生细菌纤维素纤维进行载药整理,制得一种可用于伤口敷料的载药纤维.通过X射线衍射、力学性能、载药性、释药性等测试对再生细菌纤维素纤维进行表征.结果表明:纤维直径约为40 μm,表面呈沟槽结构,力学强度可达2.5 cN/dtex;细菌纤维素再生后,晶型发生了改变,从纤维素Ⅰ型转化成纤维素Ⅱ型,且结晶度从66.3%降低至36.2%;载药和释药结果显示,再生细菌纤维素纤维在碱性条件下载药量最高,载药纤维在酸性条件下释药量最高.【期刊名称】《纺织学报》【年(卷),期】2017(038)005【总页数】5页(P14-18)【关键词】再生细菌纤维素纤维;湿法纺丝;载药纤维;生物医用材料【作者】吴焕岭【作者单位】盐城工业职业技术学院九洲药学院,江苏盐城224005;东华大学化学化工与生物工程学院,上海201620【正文语种】中文【中图分类】TS102.5;TB332细菌纤维素(BC)由微生物发酵制得,具有与植物纤维素相同的分子结构,都是由葡萄糖组成的大分子多糖。

英文标题格式及举例英文标题格式及举例英文标题是在学术界和商界中使用频率非常高的一种文字格式,它往往是一篇文章或者一份报告的开端,也是吸引读者注意力的重要因素之一。

然而,许多人在编写英文标题时往往不知道如何下手,不同的文章类型、目的和读者群体可能需要不同的标题风格。

因此,本文将为大家介绍英文标题的基本格式和举例,以帮助读者更好地理解和应用英文标题。

基本格式:英文标题的基本格式是“主题-分支-具体信息”,其中主题是文章或报告的核心内容,分支是主题所属的类别或范畴,具体信息则是主题的细节或者关键问题。

下面是具体的格式和举例:1.主题-分支-具体信息举例:Preparation and Characterization of Silicon Nanoparticles Synthesized by Plasma-Enhanced Chemical Vapor Deposition解析:主题是“Preparation and Characterization o f Silicon Nanoparticles”,分支是“Synthesized byPlasma-Enhanced Chemical Vapor Deposition”,具体信息是文章讨论的具体实验过程和结果。

2.分支: 主题-具体信息举例:Environmental Management System: Challenges and Opportunities for Small and Medium Enterprises解析:分支是“Environmental ManagementSyst em”,主题是“Challenges and Opportunities for Small and Medium Enterprises”,具体信息是文章介绍的具体内容和现状。

3.主题: 分支-具体信息举例:Digital Marketing Strategy: An Analysis of Social Media Advertising for Retail Industry 解析:主题是“Digital Marketing Strategy”,分支是“An Analysis of Social Media Advertising”,具体信息是文章针对零售业进行的案例分析和探讨。