Vacuum condensates, effective gluon mass and color confinement in a new reformulation of QC

- 格式:pdf

- 大小:467.73 KB

- 文档页数:39

专利名称:Vacuum consecutive processing device 发明人:江▲崎▼ 忍,神野 幸重,東海 正家申请号:JP特願平1-66213申请日:19890320公开号:JP第2691007号B2公开日:19971217专利内容由知识产权出版社提供摘要:PURPOSE:To enable vacuum continuous treatment without damaging, etc., the material to be treated by providing the devices for giving proper tension to the material to be treated to both a vacuum treatment chamber and the preliminary vacuum chambers provided fore and aft thereof. CONSTITUTION:The preliminary vacuum chambers 2, 3 are provided to the fore and aft sides of a vacuum treatment chamber 1, vacuumized and exhausted via the exhaust conduits 5, 7 so as to hold the prescribed degree of vacuum respectively. The material F to be treated is sent to the preliminary vacuum chamber 2 via a guide roll 9 for controlling tension, a tension cutter 27 and a tension detector 28 from a rewinding axis 8. In this preliminary vacuum chamber 2, a slit is formed by both a sealing block 15 guided and supported by an upper case 13 and a lower case 14. The material F to be treated is passed through this slit without being brought into contact therewith by a guide roll 25 and a tension imparting roll 26 and introduced into the vacuum treatment chamber 1. Therein proper tension is given to the material F to be treated by the tension cutters 29, 31 and a tension imparting guide roll 30 and plasma treatment is performed and the material F is sent to the preliminary vacuum chamber 3. The material to be treated is passed through this vacuum chamber 3 and thereafter wound around a winding axis 11 via a tension detector 33, a tension cutter32 and a guide roll 10.申请人:株式会社日立製作所地址:東京都千代田区神田駿河台4丁目6番地国籍:JP代理人:小川 勝男 (外1名)更多信息请下载全文后查看。

对四夸克凝聚的研究陈立安;许子斌;何龙庆【摘要】文章通过外场方法得到了四夸克凝聚的一般表达式.这个一般表达式中既包含夸克传播子又包含着衣顶点,分析了其因子化问题,结果发现,只有当所有的着衣顶点取裸顶点的时候,四夸克凝聚的因子化假定才成立.为了表明实际情况下因子化假定在多大程度上成立,该文利用一个简单的胶子传播子模型在DS方程的框架下对四夸克凝聚的值做了计算,结果发现,在这个胶子传播子模型下,着衣顶点对四夸克凝聚的效应不是很大,但是也不能忽略.【期刊名称】《南京晓庄学院学报》【年(卷),期】2011(027)003【总页数】4页(P30-33)【关键词】四夸克凝聚;真空饱和假定;因子化;DS方程【作者】陈立安;许子斌;何龙庆【作者单位】南京晓庄学院物理与电子工程学院,江苏南京211171;辽宁省葫芦岛市自来水公司,辽宁葫芦岛125001;南京晓庄学院物理与电子工程学院,江苏南京211171【正文语种】中文【中图分类】O572.243我们知道,量子色动力学(QCD)的真空结构相当复杂,QCD真空凝聚的计算对于QCD真空磁化率的研究是非常重要的.QCD真空凝聚的种类很多,有两夸克凝聚,四夸克凝聚,胶子凝聚,混合夸克-胶子凝聚等等,这些真空凝聚经常被用来研究QCD真空性质以及QCD的动力学手征自发对称性破缺.本文中我们主要关注四夸克凝聚,因为我们知道,在QCD求和规则方法的理论预言中,最大的不确定性体现在四夸克凝聚值的不确定[1,2].这个问题在过去的多年中一直存在很大的争论,其中争论的焦点就聚集在四夸克凝聚能否可以因子化成两夸克凝聚的乘积,如果可以,因子化在多大的近似程度下成立[3-6].因此,给出一般性的四夸克凝聚的处理就显得非常重要.我们首先来看QCD求和规则中,四夸克凝聚是如何定义的.QCD求和规则中,定义四夸克凝聚[7]:其中OΓ(x)=(x)Γq(x)表示具有不同的狄拉克以及味结构Γ的定域夸克流算符,这里我们只关心矢量流算符OV(x)=(x)Taγμq(x)以及轴矢量流算符OA(x)=(x)Taγ5γμq(x).其中Ta代表SU(Nf)群生成元,并且具有归一化形式tr(TaTb)=δab,这里只考虑(a,b=1,2).从上面四夸克凝聚的表达式(1)可以看出来,为了得到四夸克凝聚的数值,我们必须要知道如何计算〈0~|T[OΓ(x)OΓ(y)]|0~〉以及〈0|T[OΓ(x)OΓ (y)]|0〉,这里就牵扯到如何自洽定义四夸克算符的编时乘积的真空期待值问题,目前关于微扰真空的选择目前还具有很大的不确定性,虽然文献[8]中选择了“Wigner”真空作为微扰真空,因为“Wigner”真空和微扰真空在特征上相符,文中虽然得到了比较合理的混合夸克-胶子凝聚的值,但是这种微扰真空的选择具有很大的模型依赖性,反映到这里的四夸克凝聚的值,要想单独得到矢量或者轴矢量四夸克凝聚的值,都是依赖于微扰真空的选择的.但是,我们发现了一点,对于矢量和轴矢量四夸克凝聚,微扰的贡献是一样的.这个结果非常好,这样的话我们就可以重新定义一个新的四夸克凝聚,就是矢量和轴矢量四夸克凝聚的差,因此我们新定义的四夸克凝聚值在手征极限下是不依赖于微扰真空的选择的,根据文献[9,10]中对真空磁化率的对外场的线性响应理论推导过程,我们可以得到,其中类似的,其中上面式子中Γμ,Γ5μ分别指着衣矢量以及轴矢量顶点,求迹是对狄拉克、味道以及颜色空间求的,k±=k将方程(4)以及(5)带入到方程(2),我们可以得到我们所定义的四夸克凝聚,很明显,方程(7)形式上是一个模型无关的表达式,并且这个量的数值不依赖于微扰的减除.在利用QCD模型对上面的四夸克凝聚进行计算之前,我们首先来看看四夸克凝聚的因子化问题,因为之前我们提到过,关于四夸克凝聚问题争论的焦点就在于是否可以因子化以及多大程度上可以因子化问题.如果取真空饱和假定,就可得到,因此,也就是说,四夸克凝聚可以因子化成为两夸克凝聚的乘积.这里我们注意到,两夸克凝聚仅仅和两点格林函数,也就是夸克传播子有关,可是观察我们得到的四夸克凝聚公式(7)不仅和两点格林函数有关,还和三点格林函数(着衣顶点)有关.因此,我们可以说,对四夸克凝聚的因子化相当于忽略了三点格林函数(着衣顶点)的贡献.最简单的近似机制就是将着衣顶点用裸顶点代替.有趣的是,我们发现,只有在裸顶点假设下,四夸克凝聚的因子化才成立,也就是说,以往人们利用真空饱和假定来计算四夸克凝聚,实际上是忽略了着衣顶点的效应.为了获得着衣顶点的引入对四夸克凝聚的影响,我们选择在DS方程的框架下来研究这个问题.着衣矢量顶点Γaμ满足下面的非齐次的BS方程:其中K表示截腿的完全夸克-反夸克散射核.着衣轴矢量顶点Γa5μ满足类似的方程,只要把上面方程中的非齐次项换成-iγ5γμTa就行.着衣夸克传播子满足其自身的DS方程:其中Λv(q,p)表示着衣夸克-胶子顶点.由于DS方程是无穷阶的耦合方程,想要得到可以解的有限的方程的话,必须采取一定截断近似.多年来,人们最常用的截断近似就是彩虹-梯子近似,彩虹-梯子近似是DS方程的最低阶截断计算[11-13].所谓彩虹近似,就是用裸的夸克-胶子顶点γμ代替完全的夸克胶子顶点Λμ,而在BS方程中采用相应的梯近似,其中Dfμrvee(k)是指自由的胶子传播子,而C((k-q)2)表示有效耦合.由于采用一般的模型胶子传播子来解BS方程非常复杂,只是作为一个简单的练习,为求解的方便,我们首先选择一个非常简单的模型[14]其中η是表征该模型的质量标度,计算得到的物理量都与其有关.这个模型首先由Munczek和Nomirovsky~提出并使用,由于这个模型是红外有限的,因此我们可以不用做重整化,也就是说,所有的重整化常数都可以取为1.由于δ函数的缘故,夸克传播子方程(11)以及顶点方程(10)都可以化简为代数方程,并且很容易做数值计算.这个模型除了具备可以代数计算的优点之外,同时具备了动力学手征自发对称性破缺和夸克禁闭这样两个非微扰QCD的特征,所以可以用来简单讨论一些问题,但是这个模型表示的是动量空间的点相互作用,或者说只有夸克动量相等的时候才有相互作用,因此它没办法描述夸克传播子的紫外行为.将方程(13)代入方程(11),我们得到在这个胶子传播子模型下的夸克传播子也具备两个相:“Nambu-Goldstone相”(描述夸克色禁闭和手征对称性自发破缺)和“Wigner”相(夸克非禁闭和没有手征对称性破缺).对于着衣顶点方程,我们同样可以得到它们的解析形式的解,由于形式比较复杂我们这里就不列出.把夸克传播子以及着衣顶点全部带入到四夸克凝聚的表达式中,我们把方程(7)中的积分核∏V-∏A画在下图中,我们发现,积分核在大动量区域是趋于零的,所以方程(7)中的积分是自动收敛的.最终计算出我们获得的四夸克凝聚的值为:这个四夸克凝聚与因子化结果的比值为(方程(9)),注意这个模型下的两夸克凝聚的值为(0.11η)3[15].从计算结果来看,着衣顶点对四夸克凝聚的影响是稍微压低了一点四夸克凝聚的数值.本文定义了一种与截断无关的四夸克凝聚并且利用外场方法得到了其模型无关的表达式.在DS方程的彩虹-梯子近似框架下,利用一种简单的模型胶子传播子分别计算了因子化假定下以及考虑顶点效应的四夸克凝聚的值.通过研究发现,利用这种简单的胶子传播子得到的四夸克凝聚值比因子化假定得到的值稍微小一些,但是差别不大,也就是说,这种情况下着衣顶点的非微扰效应对四夸克凝聚的影响不大.但是我们必须指出,这种胶子传播子代表的相互作用形式太过简单,后面我们还必须利用实际一些的胶子传播子来计算才能够对这个问题分析得更加透彻一些.图1 方程(7)中的积分核∏V-∏A参考文献:【相关文献】[1]M.Shifman,A.Vainshtein,V.Zakharov.QCD and resonance physics:sum rules [J].Nucl.Phys.B,1979,(147):385-447.[2]L.Reinders,H.Rubinstein,S.Yazaki.Hadron properties from QCD sum rules [J].Phys.Rep,1985,127:1.[3]S.Narison,R.Tarrach.Higher dimensional renormalization group invariant vacuum condensates In Quantum Chromodynamics[J].Phys.Lett.B,1983,(125):217.[4]uner,S.Narison,R.Tarrach.Nonperturbative QCD vacuum from e+e-->I=1 hadron data[J].Z.Phys.C,1984,(26):433-439.[5]C.A.Dominguez,J.Sola.Determination of quark and gluon vacuum condensates from tau lepton decay data[J].Z.Phys.C,1988,(40):63.[6]V.Gimenez,J.Bordes,J.Penarrocha.A method to calculate ratios among QCD condensates[J].Nucl.Phys.B,1991,(357):3-31.[7]H.S.Zong and W.M.Sun,Modified approach for calculating four-quark condensates [J].Commun.Theor.Phys.,2007,(47):293-298.[8]H.S.Zong,J.L.Ping,H.T.Yang,X.F.Lv,and F.Wang.The calculation of vacuum properties from the global color symmetry model[J].Phys.Rev.D,2003,(67):074004. [9]H.S.Zong,F.Y.Hou,W.M.Sun,et al.New method for numerically solving the chemical potential dependence of the dressed quark propagator[J].Phys.Rev.C,2005,(72):034901.[10]H.S.Zong,Y.M.Shi,W.M.Sun,J.L.Ping.Modified approach for calculating axial vector vacuum susceptibility[J].Phys.Rev.C,2006,(73):035206.[11]C.D.Roberts,A.G.Williams.Dyson-Schwinger equations and their application to hadronic physics[J].Prog.Part.Nucl.Phys.,1993,(33):477-575.[12]P.Maris,C.D.Roberts.Dyson-Schwinger equations:A tool for hadron physics [J].Int.J.Mod.Phys.E,2003,(12): 297-365.[13]P.Maris,C.D.Roberts,P.C.Tandy.Pion mass and decay constant[J].Phys.Lett.B,1998,(420):267-273.[14]H.J.Munczek and A.M.Nemirovsky.The Ground State q anti-q Mass Spectrum in QCD[J].Phys.Rev.D,1983,(28):181.[15]P.Maris,C.D.Roberts,and S.Schmidt.Chemical potential dependence of pi and rho properties[J].Phys.Rev.C,1998,(57):R2821.。

Instruction ManualProBond TM Purification SystemFor purification of polyhistidine-containing recombinant proteinsCatalog nos. K850-01, K851-01, K852-01, K853-01, K854-01,R801-01, R801-15Version K2 September200425-0006iiTable of ContentsKit Contents and Storage (iv)Accessory Products (vi)Introduction (1)Overview (1)Methods (2)Preparing Cell Lysates (2)Purification Procedure—Native Conditions (7)Purification Procedure—Denaturing Conditions (11)Purification Procedure—Hybrid Conditions (13)Troubleshooting (15)Appendix (17)Additional Protocols (17)Recipes (18)Frequently Asked Questions (21)References (22)Technical Service (23)iiiKit Contents and StorageTypes of Products This manual is supplied with the following products:Product CatalogNo.ProBond™ Purification System K850-01ProBond™ Purification System with Antibodywith Anti-Xpress™ Antibody K851-01with Anti-myc-HRP Antibody K852-01with Anti-His(C-term)-HRP Antibody K853-01with Anti-V5-HRP Antibody K854-01ProBond™ Nickel-Chelating Resin (50 ml) R801-01ProBond™ Nickel Chelating Resin (150 ml) R801-15ProBond™Purification System Components The ProBond™ Purification System includes enough resin, reagents, and columns for six purifications. The components are listed below. See next page for resin specifications.Component Composition Quantity ProBond™ Resin 50% slurry in 20% ethanol 12 ml5X NativePurification Buffer250 mM NaH2PO4, pH 8.02.5 M NaCl1 × 125 ml bottleGuanidinium LysisBuffer6 M Guanidine HCl20 mM sodium phosphate, pH 7.8500 mM NaCl1 × 60 ml bottleDenaturingBinding Buffer8 M Urea20 mM sodium phosphate, pH 7.8500 mM NaCl2 × 125 ml bottlesDenaturing WashBuffer8 M Urea20 mM sodium phosphate, pH 6.0500 mM NaCl2 × 125 ml bottlesDenaturing ElutionBuffer8 M Urea20 mM NaH2PO4, pH 4.0500 mM NaCl1 × 60 ml bottleImidazole 3 M Imidazole,20 mM sodium phosphate, pH 6.0500 mM NaCl1 × 8 ml bottlePurificationColumns10 ml columns 6Continued on next pageivKit Contents and Storage, ContinuedProBond™Purification System with Antibody The ProBond™ Purification System with Antibody includes resin, reagents, and columns as described for the ProBond™ Purification System (previous page) and 50 µl of the appropriate purified mouse monoclonal antibody. Sufficient reagents are included to perform six purifications and 25 Western blots with the antibody.For more details on the antibody specificity, subclass, and protocols for using the antibody, refer to the antibody manual supplied with the system.Storage Store ProBond™ resin at +4°C. Store buffer and columns at room temperature.Store the antibody at 4°C. Avoid repeated freezing and thawing of theantibody as it may result in loss of activity.The product is guaranteed for 6 months when stored properly.All native purification buffers are prepared from the 5X Native PurificationBuffer and the 3 M Imidazole, as described on page 7.The Denaturing Wash Buffer pH 5.3 is prepared from the Denaturing WashBuffer (pH 6.0), as described on page 11.Resin and ColumnSpecificationsProBond™ resin is precharged with Ni2+ ions and appears blue in color. It isprovided as a 50% slurry in 20% ethanol.ProBond™ resin and purification columns have the following specifications:• Binding capacity of ProBond™ resin: 1–5 mg of protein per ml of resin• Average bead size: 45–165 microns• Pore size of purification columns: 30–35 microns• Recommended flow rate: 0.5 ml/min• Maximum flow rate: 2 ml/min• Maximum linear flow rate: 700 cm/h• Column material: Polypropylene• pH stability (long term): pH 3–13• pH stability (short term): pH 2–14ProductQualificationThe ProBond™ Purification System is qualified by purifying 2 mg of myoglobinprotein on a column and performing a Bradford assay. Protein recovery mustbe 75% or higher.vAccessory ProductsAdditionalProductsThe following products are also available for order from Invitrogen:Product QuantityCatalogNo.ProBond™ Nickel-Chelating Resin 50 ml150 mlR801-01R801-15Polypropylene columns(empty)50 R640-50Ni-NTA Agarose 10 ml25 ml R901-01 R901-15Ni-NTA Purification System 6 purifications K950-01 Ni-NTA Purification Systemwith Antibodywith Anti-Xpress™ Antibody with Anti-myc-HRP Antibody with Anti-His(C-term)-HRP Antibodywith Anti-V5-HRP Antibody 1 kit1 kit1 kit1 kitK951-01K952-01K953-01K954-01Anti-myc Antibody 50 µl R950-25 Anti-V5 Antibody 50 µl R960-25 Anti-Xpress™ Antibody 50 µl R910-25 Anti-His(C-term) Antibody 50 µl R930-25 InVision™ His-tag In-gel Stain 500 ml LC6030 InVision™ His-tag In-gelStaining Kit1 kit LC6033Pre-Cast Gels and Pre-made Buffers A large variety of pre-cast gels for SDS-PAGE and pre-made buffers for your convenience are available from Invitrogen. For details, visit our web site at or contact Technical Service (page 23).viIntroductionOverviewIntroduction The ProBond™ Purification System is designed for purification of 6xHis-tagged recombinant proteins expressed in bacteria, insect, and mammalian cells. Thesystem is designed around the high affinity and selectivity of ProBond™Nickel-Chelating Resin for recombinant fusion proteins containing six tandemhistidine residues.The ProBond™ Purification System is a complete system that includespurification buffers and resin for purifying proteins under native, denaturing,or hybrid conditions. The resulting proteins are ready for use in many targetapplications.This manual is designed to provide generic protocols that can be adapted foryour particular proteins. The optimal purification parameters will vary witheach protein being purified.ProBond™ Nickel-Chelating Resin ProBond™ Nickel-Chelating Resin is used for purification of recombinant proteins expressed in bacteria, insect, and mammalian cells from any 6xHis-tagged vector. ProBond™ Nickel-Chelating Resin exhibits high affinity and selectivity for 6xHis-tagged recombinant fusion proteins.Proteins can be purified under native, denaturing, or hybrid conditions using the ProBond™ Nickel-Chelating Resin. Proteins bound to the resin are eluted with low pH buffer or by competition with imidazole or histidine. The resulting proteins are ready for use in target applications.Binding Characteristics ProBond™ Nickel-Chelating Resin uses the chelating ligand iminodiacetic acid (IDA) in a highly cross-linked agarose matrix. IDA binds Ni2+ ions by three coordination sites.The protocols provided in this manual are generic, and may not result in 100%pure protein. These protocols should be optimized based on the bindingcharacteristics of your particular proteins.Native VersusDenaturingConditionsThe decision to purify your 6xHis-tagged fusion proteins under native ordenaturing conditions depends on the solubility of the protein and the need toretain biological activity for downstream applications.• Use native conditions if your protein is soluble (in the supernatant afterlysis) and you want to preserve protein activity.• Use denaturing conditions if the protein is insoluble (in the pellet afterlysis) or if your downstream application does not depend on proteinactivity.• Use hybrid protocol if your protein is insoluble but you want to preserveprotein activity. Using this protocol, you prepare the lysate and columnsunder denaturing conditions and then use native buffers during the washand elution steps to refold the protein. Note that this protocol may notrestore activity for all proteins. See page 14.1MethodsPreparing Cell LysatesIntroduction Instructions for preparing lysates from bacteria, insect, and mammalian cellsusing native or denaturing conditions are described below.Materials Needed You will need the following items:• Native Binding Buffer (recipe is on page 8) for preparing lysates undernative conditions• Sonicator• 10 µg/ml RNase and 5 µg/ml DNase I (optional)• Guanidinium Lysis Buffer (supplied with the system) for preparing lysatesunder denaturing conditions• 18-gauge needle• Centrifuge• Sterile, distilled water• SDS-PAGE sample buffer• Lysozyme for preparing bacterial cell lysates• Bestatin or Leupeptin, for preparing mammalian cell lysatesProcessing Higher Amount of Starting Material Instructions for preparing lysates from specific amount of starting material (bacteria, insect, and mammalian cells) and purification with 2 ml resin under native or denaturing conditions are described in this manual.If you wish to purify your protein of interest from higher amounts of starting material, you may need to optimize the lysis protocol and purification conditions (amount of resin used for binding). The optimization depends on the expected yield of your protein and amount of resin to use for purification. Perform a pilot experiment to optimize the purification conditions and then based on the pilot experiment results, scale-up accordingly.Continued on next page2Preparing Bacterial Cell Lysate—Native Conditions Follow the procedure below to prepare bacterial cell lysate under native conditions. Scale up or down as necessary.1. Harvest cells from a 50 ml culture by centrifugation (e.g., 5000 rpm for5 minutes in a Sorvall SS-34 rotor). Resuspend the cells in 8 ml NativeBinding Buffer (recipe on page 8).2. Add 8 mg lysozyme and incubate on ice for 30 minutes.3. Using a sonicator equipped with a microtip, sonicate the solution on iceusing six 10-second bursts at high intensity with a 10-second coolingperiod between each burst.Alternatively, sonicate the solution on ice using two or three 10-secondbursts at medium intensity, then flash freeze the lysate in liquid nitrogen or a methanol dry ice slurry. Quickly thaw the lysate at 37°C andperform two more rapid sonicate-freeze-thaw cycles.4. Optional: If the lysate is very viscous, add RNase A (10 µg/ml) andDNase I (5 µg/ml) and incubate on ice for 10–15 minutes. Alternatively,draw the lysate through a 18-gauge syringe needle several times.5. Centrifuge the lysate at 3,000 ×g for 15 minutes to pellet the cellulardebris. Transfer the supernatant to a fresh tube.Note: Some 6xHis-tagged protein may remain insoluble in the pellet, and can be recovered by preparing a denatured lysate (page 4) followed bythe denaturing purification protocol (page 12). To recover this insolubleprotein while preserving its biological activity, you can prepare thedenatured lysate and then follow the hybrid protocol on page 14. Notethat the hybrid protocol may not restore activity in all cases, and should be tested with your particular protein.6. Remove 5 µl of the lysate for SDS-PAGE analysis. Store the remaininglysate on ice or freeze at -20°C. When ready to use, proceed to theprotocol on page 7.Continued on next page3Preparing Bacterial Cell Lysate—Denaturing Conditions Follow the procedure below to prepare bacterial cell lysate under denaturing conditions:1. Equilibrate the Guanidinium Lysis Buffer, pH 7.8 (supplied with thesystem or see page 19 for recipe) to 37°C.2. Harvest cells from a 50 ml culture by centrifugation (e.g., 5000 rpm for5 minutes in a Sorvall SS-34 rotor).3. Resuspend the cell pellet in 8 ml Guanidinium Lysis Buffer from Step 1.4. Slowly rock the cells for 5–10 minutes at room temperature to ensurethorough cell lysis.5. Sonicate the cell lysate on ice with three 5-second pulses at high intensity.6. Centrifuge the lysate at 3,000 ×g for 15 minutes to pellet the cellulardebris.Transfer the supernatant to a fresh tube.7. Remove 5 µl of the lysate for SDS-PAGE analysis. Store the remaininglysate on ice or at -20°C. When ready to use, proceed to the denaturingprotocol on page 11 or hybrid protocol on page 13.Note: To perform SDS-PAGE with samples in Guanidinium Lysis Buffer, you need to dilute the samples, dialyze the samples, or perform TCAprecipitation prior to SDS-PAGE to prevent the precipitation of SDS.Harvesting Insect Cells For detailed protocols dealing with insect cell expression, consult the manual for your particular system. The following lysate protocols are for baculovirus-infected cells and are intended to be highly generic. They should be optimized for your cell lines.For baculovirus-infected insect cells, when the time point of maximal expression has been determined, large scale protein expression can be carried out. Generally, the large-scale expression is performed in 1 liter flasks seeded with cells at a density of 2 × 106 cells/ml in a total volume of 500 ml and infected with high titer viral stock at an MOI of 10 pfu/cell. At the point of maximal expression, harvest cells in 50 ml aliquots. Pellet the cells by centrifugation and store at -70°C until needed. Proceed to preparing cell lysates using native or denaturing conditions as described on the next page.Continued on next page4Preparing Insect Cell Lysate—Native Condition 1. Prepare 8 ml Native Binding Buffer (recipe on page 8) containingLeupeptin (a protease inhibitor) at a concentration of 0.5 µg/ml.2. After harvesting the cells (previous page), resuspend the cell pellet in8 ml Native Binding Buffer containing 0.5 µg/ml Leupeptin.3. Lyse the cells by two freeze-thaw cycles using a liquid nitrogen or dryice/ethanol bath and a 42°C water bath.4. Shear DNA by passing the preparation through an 18-gauge needle fourtimes.5. Centrifuge the lysate at 3,000 ×g for 15 minutes to pellet the cellulardebris.Transfer the supernatant to a fresh tube.6. Remove 5 µl of the lysate for SDS-PAGE analysis. Store remaining lysateon ice or freeze at -20°C. When ready to use, proceed to the protocol on page 7.Preparing Insect Cell Lysate—Denaturing Condition 1. After harvesting insect cells (previous page), resuspend the cell pellet in8 ml Guanidinium Lysis Buffer (supplied with the system or see page 19for recipe).2. Pass the preparation through an 18-gauge needle four times.3. Centrifuge the lysate at 3,000 ×g for 15 minutes to pellet the cellulardebris. Transfer the supernatant to a fresh tube.4. Remove 5 µl of the lysate for SDS-PAGE analysis. Store remaining lysateon ice or freeze at -20° C. When ready to use, proceed to the denaturingprotocol on page 11 or hybrid protocol on page 13.Note: To perform SDS-PAGE with samples in Guanidinium Lysis Buffer, you need to dilute the samples, dialyze the samples, or perform TCAprecipitation prior to SDS-PAGE to prevent the precipitation of SDS.Continued on next pagePreparing Mammalian Cell Lysate—Native Conditions For detailed protocols dealing with mammalian expression, consult the manual for your particular system. The following protocols are intended to be highly generic, and should be optimized for your cell lines.To produce recombinant protein, you need between 5 x 106and 1 x 107 cells. Seed cells and grow in the appropriate medium until they are 80–90% confluent. Harvest cells by trypsinization. You can freeze the cell pellet in liquid nitrogen and store at -70°C until use.1. Resuspend the cell pellet in 8 ml of Native Binding Buffer (page 8). Theaddition of protease inhibitors such as bestatin and leupeptin may benecessary depending on the cell line and expressed protein.2. Lyse the cells by two freeze-thaw cycles using a liquid nitrogen or dryice/ethanol bath and a 42°C water bath.3. Shear the DNA by passing the preparation through an 18-gauge needlefour times.4. Centrifuge the lysate at 3,000 ×g for 15 minutes to pellet the cellulardebris. Transfer the supernatant to a fresh tube.5. Remove 5 µl of the lysate for SDS-PAGE analysis. Store the remaininglysate on ice or freeze at -20° C. When ready to use, proceed to theprotocol on page 7.Preparing Mammalian Cell Lysates—Denaturing Conditions For detailed protocols dealing with mammalian expression, consult the manual for your particular system. The following protocols are intended to be highly generic, and should be optimized for your cell lines.To produce recombinant protein, you need between 5 x 106and 1 x 107 cells. Seed cells and grow in the appropriate medium until they are 80–90% confluent. Harvest cells by trypsinization. You can freeze the cell pellet in liquid nitrogen and store at -70°C until use.1. Resuspend the cell pellet in 8 ml Guanidinium Lysis Buffer (suppliedwith the system or see page 19 for recipe).2. Shear the DNA by passing the preparation through an 18-gauge needlefour times.3. Centrifuge the lysate at 3,000 ×g for 15 minutes to pellet the cellulardebris. Transfer the supernatant to a fresh tube.4. Remove 5 µl of the lysate for SDS-PAGE analysis. Store the remaininglysate on ice or freeze at -20° C until use. When ready to use, proceed to the denaturing protocol on page 11 or hybrid protocol on page 13.Note: To perform SDS-PAGE with samples in Guanidinium Lysis Buffer, you need to dilute the samples, dialyze the samples, or perform TCAprecipitation prior to SDS-PAGE to prevent the precipitation of SDS.Purification Procedure—Native ConditionsIntroduction In the following procedure, use the prepared Native Binding Buffer, NativeWash Buffer, and Native Elution Buffer, columns, and cell lysate preparedunder native conditions. Be sure to check the pH of your buffers before starting.Buffers for Native Purification All buffers for purification under native conditions are prepared from the5X Native Purification Buffer supplied with the system. Dilute and adjust the pH of the 5X Native Purification Buffer to create 1X Native Purification Buffer (page 8). From this, you can create the following buffers:• Native Binding Buffer• Native Wash Buffer• Native Elution BufferThe recipes described in this section will create sufficient buffers to perform one native purification using one kit-supplied purification column. Scale up accordingly.If you are preparing your own buffers, see page 18 for recipe.Materials Needed You will need the following items:• 5X Native Purification Buffer (supplied with the system or see page 18 forrecipe)• 3 M Imidazole (supplied with the system or see page 18 for recipe)• NaOH• HCl• Sterile distilled water• Prepared ProBond™ columns with native buffers (next page)• Lysate prepared under native conditions (page 2)Imidazole Concentration in Native Buffers Imidazole is included in the Native Wash and Elution Buffers to minimize the binding of untagged, contaminating proteins and increase the purity of the target protein with fewer wash steps. Note that, if your level of contaminating proteins is high, you may add imidazole to the Native Binding Buffer.If your protein does not bind well under these conditions, you can experiment with lowering or eliminating the imidazole in the buffers and increasing the number of wash and elution steps.Continued on next page1X Native Purification Buffer To prepare 100 ml 1X Native Purification Buffer, combine:• 80 ml of sterile distilled water• 20 ml of 5X Native Purification Buffer (supplied with the system or see page 18 for recipe)Mix well and adjust pH to 8.0 with NaOH or HCl.Native Binding Buffer Without ImidazoleUse 30 ml of the 1X Native Purification Buffer (see above for recipe) for use as the Native Binding Buffer (used for column preparation, cell lysis, and binding).With Imidazole (Optional):You can prepare the Native Binding Buffer with imidazole to reduce the binding of contaminating proteins. (Note that some His-tagged proteins may not bind under these conditions.).To prepare 30 ml Native Binding Buffer with 10 mM imidazole, combine: • 30 ml of 1X Native Purification Buffer• 100 µl of 3 M Imidazole, pH 6.0Mix well and adjust pH to 8.0 with NaOH or HCl.Native Wash Buffer To prepare 50 ml Native Wash Buffer with 20 mM imidazole, combine:• 50 ml of 1X Native Purification Buffer• 335 µl of 3 M Imidazole, pH 6.0Mix well and adjust pH to 8.0 with NaOH or HCl.Native Elution Buffer To prepare 15 ml Native Elution Buffer with 250 mM imidazole, combine:• 13.75 ml of 1X Native Purification Buffer• 1.25 ml of 3 M Imidazole, pH 6.0Mix well and adjust pH to 8.0 with NaOH or HCl.Continued on next pageDo not use strong reducing agents such as DTT with ProBond™ columns. DTTreduces the nickel ions in the resin. In addition, do not use strong chelatingagents such as EDTA or EGTA in the loading buffers or wash buffers, as thesewill strip the nickel from the columns.Be sure to check the pH of your buffers before starting.PreparingProBond™ ColumnWhen preparing a column as described below, make sure that the snap-off capat the bottom of the column remains intact. To prepare a column:1. Resuspend the ProBond™ resin in its bottle by inverting and gentlytapping the bottle repeatedly.2. Pipet or pour 2 ml of the resin into a 10-ml Purification Columnsupplied with the kit. Allow the resin to settle completely by gravity(5-10 minutes) or gently pellet it by low-speed centrifugation (1 minuteat 800 ×g). Gently aspirate the supernatant.3. Add 6 ml of sterile, distilled water and resuspend the resin byalternately inverting and gently tapping the column.4. Allow the resin to settle using gravity or centrifugation as described inStep 2, and gently aspirate the supernatant.5. For purification under Native Conditions, add 6 ml Native BindingBuffer (recipe on page 8).6. Resuspend the resin by alternately inverting and gently tapping thecolumn.7. Allow the resin to settle using gravity or centrifugation as described inStep 2, and gently aspirate the supernatant.8. Repeat Steps 5 through 7.Storing PreparedColumnsTo store a column containing resin, add 0.02% azide or 20% ethanol as apreservative and cap or parafilm the column. Store at room temperature.Continued on next pagePurification Under Native Conditions Using the native buffers, columns and cell lysate, follow the procedure below to purify proteins under native conditions:1. Add 8 ml of lysate prepared under native conditions to a preparedPurification Column (page 9).2. Bind for 30–60 minutes using gentle agitation to keep the resinsuspended in the lysate solution.3. Settle the resin by gravity or low speed centrifugation (800 ×g), andcarefully aspirate the supernatant. Save supernatant at 4°C forSDS-PAGE analysis.4. Wash with 8 ml Native Wash Buffer (page 8). Settle the resin by gravityor low speed centrifugation (800 ×g), and carefully aspirate thesupernatant. Save supernatant at 4°C for SDS-PAGE analysis.5. Repeat Step 4 three more times.6. Clamp the column in a vertical position and snap off the cap on thelower end. Elute the protein with 8–12 ml Native Elution Buffer (seepage 2). Collect 1 ml fractions and analyze with SDS-PAGE.Note: Store the eluted fractions at 4°C. If -20°C storage is required, addglycerol to the fractions. For long term storage, add protease inhibitors to the fractions.If you wish to reuse the resin to purify the same recombinant protein, wash the resin with 0.5 M NaOH for 30 minutes and equilibrate the resin in a suitable binding buffer. If you need to recharge the resin, see page 17.Purification Procedure—Denaturing ConditionsIntroduction Instructions to perform purification using denaturing conditions with prepareddenaturing buffers, columns, and cell lysate are described below.Materials Needed You will need the following items:• Denaturing Binding Buffer (supplied with the system or see page 19 forrecipe)• Denaturing Wash Buffer, pH 6.0 (supplied with the system or see page 19 forrecipe) and Denaturing Wash Buffer, pH 5.3 (see recipe below)• Denaturing Elution Buffer (supplied with the system or see page 20 forrecipe)• Prepared ProBond™ columns with Denaturing buffers (see below)• Lysate prepared under denaturing conditions (page 11)Preparing the Denaturing Wash Buffer pH 5.3 Using a 10 ml aliquot of the kit-supplied Denaturing Wash Buffer (pH 6.0), mix well, and adjust the pH to 5.3 using HCl. Use this for the Denaturing Wash Buffer pH 5.3 in Step 5 next page.Be sure to check the pH of your buffers before starting. Note that thedenaturing buffers containing urea will become more basic over time. PreparingProBond™ ColumnWhen preparing a column as described below, make sure that the snap-off capat the bottom of the column remains intact.If you are reusing the ProBond™ resin, see page 17 for recharging protocol.To prepare a column:1. Resuspend the ProBond™ resin in its bottle by inverting and gentlytapping the bottle repeatedly.2. Pipet or pour 2 ml of the resin into a 10-ml Purification Columnsupplied with the kit. Allow the resin to settle completely by gravity(5-10 minutes) or gently pellet it by low-speed centrifugation (1 minuteat 800 ×g). Gently aspirate the supernatant.3. Add 6 ml of sterile, distilled water and resuspend the resin byalternately inverting and gently tapping the column.4. Allow the resin to settle using gravity or centrifugation as described inStep 2, and gently aspirate the supernatant.5. For purification under Denaturing Conditions, add 6 ml of DenaturingBinding Buffer.6. Resuspend the resin by alternately inverting and gently tapping thecolumn.7. Allow the resin to settle using gravity or centrifugation as described inStep 2, and gently aspirate the supernatant. Repeat Steps 5 through 7.Continued on next pagePurification Procedure—Denaturing Conditions, ContinuedPurification Under Denaturing Conditions Using the denaturing buffers, columns, and cell lysate, follow the procedure below to purify proteins under denaturing conditions:1. Add 8 ml lysate prepared under denaturing conditions to a preparedPurification Column (page 11).2. Bind for 15–30 minutes at room temperature using gentle agitation (e.g.,using a rotating wheel) to keep the resin suspended in the lysatesolution. Settle the resin by gravity or low speed centrifugation (800 ×g), and carefully aspirate the supernatant.3. Wash the column with 4 ml Denaturing Binding Buffer supplied with thekit by resuspending the resin and rocking for two minutes. Settle theresin by gravity or low speed centrifugation (800 ×g), and carefullyaspirate the supernatant. Save supernatant at 4°C for SDS-PAGEanalysis. Repeat this step one more time.4. Wash the column with 4 ml Denaturing Wash Buffer, pH 6.0 supplied inthe kit by resuspending the resin and rocking for two minutes. Settle the resin by gravity or low speed centrifugation (800 ×g), and carefullyaspirate the supernatant. Save supernatant at 4°C for SDS-PAGEanalysis. Repeat this step one more time.5. Wash the column with 4 ml Denaturing Wash Buffer pH 5.3 (see recipeon previous page) by resuspending the resin and rocking for 2 minutes.Settle the resin by gravity or low speed centrifugation (800 ×g), andcarefully aspirate the supernatant. Save supernatant at 4°C for SDS-PAGE analysis. Repeat this step once more for a total of two washes with Denaturing Wash Buffer pH 5.3.6. Clamp the column in a vertical position and snap off the cap on thelower end. Elute the protein by adding 5 ml Denaturing Elution Buffersupplied with the kit. Collect 1 ml fractions and monitor the elution bytaking OD280readings of the fractions. Pool the fractions that contain the peak absorbance and dialyze against 10 mM Tris, pH 8.0, 0.1% Triton X-100 overnight at 4°C to remove the urea. Concentrate the dialyzedmaterial by any standard method (i.e., using 10,000 MW cut-off, low-protein binding centrifugal instruments or vacuum concentrationinstruments).If you wish to reuse the resin to purify the same recombinant protein, wash the resin with 0.5 M NaOH for 30 minutes and equilibrate the resin in a suitable binding buffer. If you need to recharge the resin, see page 17.。

饮料高压灭菌设备维护保养西语词汇本人在为西班牙饮料高压灭菌设备维护保养技师做口译时,积累了一些专业词汇。

在此,本人公布于众,贡献自己的一点微薄之力,以供有关人员参考。

Vasija, 处理舱Alineamiento entre la vasija y los tapones. 处理舱与柱塞之间的校准HPP, High Pressure Processing, 高压灭菌加工Clapeta, 提升阀Ciclo, 周期, 巡回Cuña, 楔块Émbolo (pistón), 活塞Transductor de presión, 压力传感器(测压力)Estirar, 拉伸Estiramiento, 拉伸Punto de referencia, 参照点Está roto. 断了,碎了Entrenamiento = training,培训(西班牙经常用这个英语词)Revisar, 检查Cuando la máquina empieza a subir la presión, coge el punto de referencia.当机器开始增加压力时,摄取参照点。

Configuración, 设置Raya, 划痕Corrosión, 锈蚀Yoke, 整体钢架Tapón, 柱塞Engrasador, 注油器Circuito, 回路Bomba de presión, 压力泵Válvula de descarga, 泄压阀Cal, 钙Intensificador, 增压器Mecanizado, 机械加工Mecanizado, es un proceso de fabricación por arranque de viruta.Viruta, (生产机械产品时产生的)碎屑Hay que mecanizar este eje en un torno.Taller de mecanizado, el taller donde se fabrican piezas.Válvula direccional, 比例双向阀Abrazadera, 卡箍Anillo seger, 卡簧Válvula neumática, 空气阀Válvula magnética, 电磁阀Una capa finita de grasa, 一层很薄的黄油Filo, 刀锋,锋口Lo más importante es ...,最重要的是......Punto de apoyo, 承重点Junta, o ring, 封闭圈Llave inglesa, 活扳手Estaría, 应该在Apretar poco a poco, 慢慢地旋紧Los tornillos estaban aflojados. 螺丝以前松了。

abnormal [æb'nɔ:məl] a. 反常的,不正常的,不规则的abnormalcy [æb'nɔ:məlsi] (=abnormality) n. 反常, 畸形absolute error 绝对误差absorbent [əb'sɔ:bənt] a. 能吸收的n. 吸收剂absorption [əb'sɔ:pʃən] n. 吸收aluminium tube extruding machine 铝管冲挤机ampoule filling an sealing machine 安瓿灌封机Accelerated testing 加速试验Acceptance criteria可接受标准accidental error 随机误差accuracy ['ækjurəsi] n. 准确(性),精确度acetaldehyde [,æsi'tældəhaid] n. 乙醛acetate buffer醋酸盐缓冲液acetic [ə'si:tik] adj.【化学】醋的,醋酸的,乙酸的;含醋的;似醋的;产醋的acetic acid 醋酸acetic anhydride n. [化]乙酸酐, 无水醋acetification [ə,setifi'keiʃən] n. 使变成醋,醋化acetone ['æsitəun] n. 丙酮acetonitrile [,æsitəu'naitril]n. 乙腈(氰甲烷) acetylcholine [ə,si:təl'kəulin] n. 乙酰胆碱acid solvent 酸性溶剂acid-base indicator 酸碱指示剂acid-base titrations 酸碱滴定acidification [ə,sidifi'keiʃɚn] n. 使发酸,酸化,成酸性Acid-Resistant Water Purifier抗酸化机能水制造装置action limit行动限度activated charcoal 活性炭Active Pharmaceutical Ingredient活性药用成分(原料药)=Drug SubstanceActual yield实际产量adapter 接液管ADE Adverse Drug Event 不良药品事件;药品不良事件ADR Adverse Drug Report 不良药品报告;药品不良反应报告ADR:Adverse Drug Reaction 药品不良反应adsorption [æd'sɔ:pʃən] n. 吸附adsorption chromaography 吸附色谱法adulterated [ə'dʌltəreitid] a. 掺入次级品的adverse ['ædvə:s] a. 不利的adversely affect反作用影响adverseness 不利AE:Adverse Event 不良事件aerosol cold-filling machine气雾剂冷灌装机aerosol drug filling-sealing machine气雾剂灌封机组aerosol drug machinery气雾剂机械AERS Adverse Events Reporting System 不良事件报告系统affecting factors testing 影响因素试验Aging Property Tester老化性能测定仪Agravic mixer无重力混合机AIDS Acquired immune deficiency syndrome获得性免疫缺陷综合症;艾滋病air condenser 空气冷凝管air driers手烘器air filtration空气过滤Air Lock气闸air pressure空气压力air stirring type fermenting equipment气流搅拌式发酵罐Airflow 气流airlift fermenting tank气升式发酵罐airlock n. 气锁vt 用气塞堵住Air-stream spraying drier气流喷雾干燥机alcohol ['ælkəhɔl] n. 酒精almost ['ɔ:lməust] adv. 几乎,差不多aluminium tube cap printing machine铝管旋盖机aluminium tube printing machine铝管印字机aluminium tube screwing machine铝管螺纹机ammonium chloride 氯化铵ammonium oxalate 草酸铵amphiprotic solvent 两性溶剂Sample Handling样品处理ampoule ['æmpu:l] 一次用量,安瓶ampoule cleaning and drawing-sealing machine安瓿洗灌封机ampoule cleaning machine安瓿清洗机ampoule cleaning-drying and filling-sealing interlocking machine安瓿洗、烘、灌、封联动机ampoule cutting machine安瓿割圆机ampoule marker安瓿色标机ampoule printing and boxing machine安瓿印字装盒机ampoule printing and packaging machine安瓿印字包装机ampoule printing machine安瓿印字机ampoule sterilization and leakage detector安瓿灭菌检漏设备ampoule tunnel sterilizing machine安瓿隧道式灭菌干燥机analytical [,ænə'litikl] adj. 分析的,解析的analytical methods分析方法Analyzer for Clinic Medicine Concentration临床药物浓度仪Analyzer,Particle Size Distribution Laser Diffraction Device回折/散乱式粒度分布测定装置anhydrous无水Anthracnose炭疽病anti-foaming agent 消泡剂anti-penetration equipment反渗透设备antisepsis [,ænti'sepsis] n. 防腐法,抗菌法API(Active Pharmaceutical Ingredient) 原料药appearance [ə'pirəns] n. 外表,出现,出场、外观application [,æpli'keiʃən] n. 申请n. 应用软件程序approval [ə'pru:vəl] n. 批准,认可,同意,赞同aprotic solvent 无质子溶剂Aqua水剂[拉]aqueous basic solution 碱性溶液Aqueous Ultrasonic Cleaning Systems大型超声波清洗机arrangement [ə'reindʒmənt] n. 安排Artificial Atmospheric Phenomena Simulator人工气候室ASE accelerated solvent extraction 加速溶剂萃取。

药物制剂常用设备名称词汇中英文翻译对照(Name of commonly used equipment for drug preparation, Vocabulary Translation inChinese and English)Name of commonly used equipment for drug preparation, Vocabulary Translation in Chinese and EnglishBoiling granulation dryer Fluid, bed, granulating, drierGranulating drier, with, high-speed, mixingFluidized granulation, coating dryer, Fluidizing, grain, coating, drierHot air circulation oven Hot, air, circulating, ovenHot air circulation oven Hot, air, circulating, ovenVacuum dryer Vacuum drierDouble cone rotary vacuum dryer Double, tapered, Vacuum, drierFluidized dryer (fluidized bed) Fluid, bed, drierEfficient boiling dryer High-efficient, Fluid, bed, drierHigh speed centrifugal spray dryer High-speed, centrifuging, and, spraying, drierSpray drier for Chinese traditional medicine extract for spray drying of Chinese herbal extractPressure spray dryer Pressure, spraying, drierAir jet dryer Air-stream spraying drierPulsed air dryer Pulse, air-streaming, drierVibration fluidized bed dryer Vibrating, fluid-bed, drierBundle drying machine Pipe, bundle, drierBelt dryer Belt drierRotary flash dryer Rotating, and, flash, streaming, drierGinkgo leaves drying unit Maidenhair, leaf, drierDrum scraper dryer Rolling, scratch, board, drierCoal burning hot blast stove Coal, hot, air, furnaceOil hot air furnace fuel hot blast stoveRotary tablet press Rotary, tablet, pressFully automatic 100 series tablet press Auto-100series, tablet, pressHigh speed rotary tablet press, High, -speed, rotary, tablet, pressBasket flower, of, tablet, pressSingle punch press Single punch tablet pressTablet press, vacuum cleaner, Vacuum, for, tablet, press Tablet polishing machine Tablet, polisher, tablet, press Tablet powder sifterPulse step filter dust filter Pulsing, cloth-screen, filterFull automatic capsule filling machine Auto-capsule, filling, machineSemi-automatic capsule filling machine Semi-capsule, filling, machineCapsule turning machine Capsule, orienting, U-turn, machineCapsule, tablet printer, Printing, machine, for, capsule, and, tabletCapsule, tablet polishing machine, Polishing, machine, for, capsule, and, tabletEfficient coating machine High, -efficent, coating, machineEfficient microporous coating machine High, -efficent, and, Micro-pore, coating, machineFull automatic icing film coating machine Automatic,sugar-film, coating, machineSugar coating machine Sugar-film, coating, machineAutomatic blister packing machine Auto-blister, packaging, machineAutomatic double aluminum loading machine, Auto, double,-aluminum, packaging, machineAutomatic filling machine Auto-filling packaging machineAutomatic pillow type packing machine Auto-horizontal, packaging, machineAutomatic assembly machine Automatic, packaging, box, machine Double-head counting tablet machineElectronic counting grain machine electronic counting machine Bottle machine Vial distributing machinePaper machine Paper inserting machinePaper inserting and cappingmachine自动旋盖机 car - capping machine电磁铝箔封口机 sealing machine with electromagnetism aluminumfoil自动上糊贴标机 labeling car paste machine不干胶贴标机 non dry sticker labeling machine多功能制药试验机 multi functions pharmaceutical trial machine 片剂小型试验机混合机 mixer颗粒机 granulator压片机 tablet press糖衣机 sugar coating machinegranulating drier 沸腾制粒干燥机 fluid bed高速混合制粒干燥机 granulating drier with high - speed mixing 流化造粒包衣干燥机 fluidizing grain coating driera hot air circulating oven 热风循环烘箱a hot air circulating oven 热风循环烘箱真空干燥机 vacuum drier双锥回转真空干燥机 double vacuum drier must be used沸腾干燥器 (流化床) fluid bed drier高效沸腾干燥机 high efficient fluid bed drierthe high - speed 高速离心喷雾干燥机 centrifuging and spraying drier中药浸膏用喷雾干燥机 spray drier for chinese traditional medicine extract压力喷雾干燥机 pressure spraying drier气流喷雾干燥机 air stream spraying drieran air - drier 脉冲气流干燥器 pulse振动流化床干燥机 drier vibrating fluid - bed管束式干燥机 pipe bundle drierdrier 带式干燥机 beltan drier 旋转闪蒸干燥机 bands and flash银杏叶干燥机组 drier maidenhair leaf滚筒刮板干燥机 drier rolling scratch board燃煤热风炉 coal hot air furnace燃油热风炉 oil hot air furnac。

<731>LOSS ON DRYINGThe procedure set forth in this chapter determines the amount of volatile matter of any kind that is driven off under the conditions specified.For substances appearing to contain water as the only volatile constituent, the procedure given in the chapter,Water Determination921,is appropriate,and is specified in the individual monograph.Mix and accurately weigh the substance to be tested,and,unless otherwise directed in the individual monograph,conduct the determination on1to 2g.If the test specimen is in the form of large crystals,reduce the particle size to about2mm by quickly crushing.Tare a glass-stoppered, shallow weighing bottle that has been dried for30minutes under the same conditions to be employed in the determination.Put the test specimen in the bottle,replace the cover,and accurately weigh the bottle and the contents.By gentle,sidewise shaking,distribute the test specimen as evenly as practicable to a depth of about5mm generally,and not more than10mm in the case of bulky materials.Place the loaded bottle in the drying chamber,removing the stopper and leaving it also in the chamber. Dry the test specimen at the temperature and for the time specified in the monograph.[NOTE—The temperature specified in the monograph is to be regarded as being within the range of±2of the stated figure.]Upon opening the chamber,close the bottle promptly,and allow it to come to room temperature in a desiccator before weighing.If the substance melts at a lower temperature than that specified for the determination of Loss on drying,maintain the bottle with its contents for1to2hours at a temperature5to10below the melting temperature, then dry at the specified temperature.Where the specimen under test is Capsules,use a portion of the mixed contents of not fewer than4capsules.Where the specimen under test is Tablets,use powder from not fewer than 4tablets ground to a fine powder.Where the individual monograph directs that loss on drying be determined by thermogravimetric analysis,a sensitive electrobalance is to be used.Where drying in vacuum over a desiccant is directed in the individual monograph,a vacuum desiccator or a vacuum drying pistol,or other suitable vacuum drying apparatus,is to be used.Where drying in a desiccator is specified,exercise particular care to ensure that the desiccant is kept fully effective by frequent replacement.Where drying in a capillary-stoppered bottle*in vacuum is directed in the individual monograph,use a bottle or tube fitted with a stopper having a225±25µm diameter capillary,and maintain the heating chamber at a pressure of5mm or less of mercury.At the end of the heating period, admit dry air to the heating chamber,remove the bottle,and with the capillary stopper still in place allow it to cool in a desiccator before weighing.本章中给出的方法阐述了在特定的条件下物质中的挥发性成分的测定。

生物实验室常用英文单词编辑整理:尊敬的读者朋友们:这里是精品文档编辑中心,本文档内容是由我和我的同事精心编辑整理后发布的,发布之前我们对文中内容进行仔细校对,但是难免会有疏漏的地方,但是任然希望(生物实验室常用英文单词)的内容能够给您的工作和学习带来便利。

同时也真诚的希望收到您的建议和反馈,这将是我们进步的源泉,前进的动力。

本文可编辑可修改,如果觉得对您有帮助请收藏以便随时查阅,最后祝您生活愉快业绩进步,以下为生物实验室常用英文单词的全部内容。

生物实验室常用英文单词一、化学试剂1、氨基酸alanine (Ala, A) 丙氨酸valine (Val, V) 缬氨酸leucine (Leu, L)亮氨酸isoleucine (Ile,I)异亮氨酸proline (Pro, P) 脯氨酸phenylalanine (Phe, F)苯丙氨酸tryptophan (Trp, W) 色氨酸methionine (Met, M) 蛋氨酸glycine (Gly, G)甘氨酸serine (Ser, S)丝氨酸threonine (Thr, T)苏氨酸cysteine (Cys, C)半胱氨酸tyrosine (Tyr, Y) 酪氨酸asparagines (Asn, N) 天冬氨酸glutamine (Gln, Q)谷氨酰胺lysine (Lys, K)赖氨酸arginine (Arg, R)精氨酸histidine (His, H) 组氨酸aspartic acid (Asp, D)天冬氨酸glutamic acid (Glu, E)谷氨酸2、核苷酸adenosine 阿糖腺苷guanosine 鸟嘌呤核苷cytidine 胞二磷胆碱thymidine胸腺嘧啶脱氧核苷uridine尿嘧啶核甙deoxy—脱氧3、其他化学试剂Acetic acid glacial 冰乙酸Boric acid (H3BO3,61。

专利名称:VACUUM COOLING DEVICE AND METHODFOR THE VACUUM COOLING OFFOODSTUFF发明人:Giger, Ulrich,Bäbler, Florian,Bäbler, Kasper申请号:EP16196000.0申请日:20161027公开号:EP3165859A1公开日:20170510专利内容由知识产权出版社提供专利附图:摘要:a vakuumk\u00fchlvorrichtung (1) for cooling of foodstuffs, in particular hotbaked goods includes a vacuum chamber (2, 102), a produktkammer (7, 107) for recordingthe food for its cooling and a container (10, 110) includes a vakuumquelle (3, 103) with the prod uktkammer (7, 107) and the container (10, 110) is connected, and a dampfkondensator (4)104) for condensation of the produktkammer (7, 107) during the abk\u00fchlvorgangs emerging dampfbeladener exhaust air. the dampfkondensator (4, 104) is below the produktammer (7, 107) arranged with the dampfkondensator in operating a coolant which may contain.the dampfkondensator (4, 104) contains ak\u00fchlmittelverteilvorrichtung (56, 156) for distribution of the coolant in the dampfkondensator (4, 104). the produktkammer (7, 107) includes at least one opening (31, 131) to start the dampfbeladenen exhaust air in the coolant.申请人:Giger, Ulrich,Bäbler, Florian,Bäbler, Kasper地址:Bürgstrasse 3a 8608 Bubikon CH,Zinggenstrasse 3 8753 Mollis CH,Seelmess 8 8753 Mollis CH国籍:CH,CH,CH代理机构:Herrmann, Johanna更多信息请下载全文后查看。

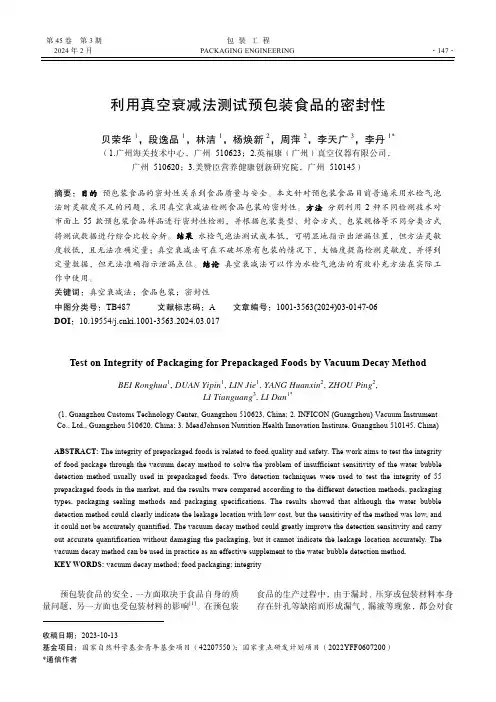

第45卷 第3期 包 装 工 程2024年2月PACKAGING ENGINEERING ·147·收稿日期:2023-10-13基金项目:国家自然科学基金青年基金项目(42207550);国家重点研发计划项目(2022YFF0607200) 利用真空衰减法测试预包装食品的密封性贝荣华1,段逸品1,林洁1,杨焕新2,周萍2,李天广3,李丹1*(1.广州海关技术中心,广州 510623;2.英福康(广州)真空仪器有限公司,广州 510620;3.美赞臣营养健康创新研究院,广州 510145)摘要:目的 预包装食品的密封性关系到食品质量与安全。

本文针对预包装食品目前普遍采用水检气泡法时灵敏度不足的问题,采用真空衰减法检测食品包装的密封性。

方法 分别利用2种不同检测技术对市面上55款预包装食品样品进行密封性检测,并根据包装类型、封合方式、包装规格等不同分类方式将测试数据进行综合比较分析。

结果 水检气泡法测试成本低,可明显地指示出泄漏位置,但方法灵敏度较低,且无法准确定量;真空衰减法可在不破坏原有包装的情况下,大幅度提高检测灵敏度,并得到定量数据,但无法准确指示泄漏点位。

结论 真空衰减法可以作为水检气泡法的有效补充方法在实际工作中使用。

关键词:真空衰减法;食品包装;密封性中图分类号:TB487 文献标志码:A 文章编号:1001-3563(2024)03-0147-06 DOI :10.19554/ki.1001-3563.2024.03.017Test on Integrity of Packaging for Prepackaged Foods by Vacuum Decay MethodBEI Ronghua 1, DUAN Yipin 1, LIN Jie 1, YANG Huanxin 2, ZHOU Ping 2,LI Tianguang 3, LI Dan 1*(1. Guangzhou Customs Technology Center, Guangzhou 510623, China; 2. INFICON (Guangzhou) Vacuum Instrument Co., Ltd., Guangzhou 510620, China; 3. MeadJohnson Nutrition Health Innovation Institute, Guangzhou 510145, China) ABSTRACT: The integrity of prepackaged foods is related to food quality and safety. The work aims to test the integrity of food package through the vacuum decay method to solve the problem of insufficient sensitivity of the water bubble detection method usually used in prepackaged foods. Two detection techniques were used to test the integrity of 55 prepackaged foods in the market, and the results were compared according to the different detection methods, packaging types, packaging sealing methods and packaging specifications. The results showed that although the water bubble detection method could clearly indicate the leakage location with low cost, but the sensitivity of the method was low, and it could not be accurately quantified. The vacuum decay method could greatly improve the detection sensitivity and carry out accurate quantification without damaging the packaging, but it cannot indicate the leakage location accurately. The vacuum decay method can be used in practice as an effective supplement to the water bubble detection method. KEY WORDS: vacuum decay method; food packaging; integrity预包装食品的安全,一方面取决于食品自身的质量问题,另一方面也受包装材料的影响[1]。

Vacuum Requirements for Steel DegassingDr Simon BruceApplications Technologist, BOC Edwards, Crawley UK+44 1293 603276simon.bruce@Metallurgical Plant and Technology International, June 2002, 44-46, ISBN0935-7254 SummaryVacuum degassing (VD) and vacuum oxygen decarburisation (VOD) are the main processes in secondary steel making. The large volumes of dissolved contaminant gases arising and the generation of metallic fines and oxide dust require robust, high-capacity pumping equipment. Today's advanced vacuum dry mechanical vacuum pumping systems are superior to previously-used systems in that they enable better dust handling, increased pumping speed, and reduced operational and maintenance costs.The need for advanced vacuum pump systemsInvestment in steel vacuum degassing processes, both in new plant and upgrades of existing plant, is continuing as steel companies see the opportunity to increase the value of their products by improving their quality and supplying more special steels. For reasons of economy these processes are usually conducted on large quantities of molten steel in very large plants, and consequently very large vacuum pumping capacities are usually required. These processes are potentially very dirty with large amounts of metallic fines and oxide dust being generated. Historically much vacuum degassing has been done using multiple steam ejector stages backed by hogging steam ejectors or large water ring pumps. These systems traditionally require a lot of maintenance, and consume extremely large and expensive amounts of steam, generated by substantial steam raising plant.Oil-sealed vacuum pumps have never been considered robust enough to offer a less expensive solution, but as pressure increases on steel companies to reduce both energy expenditure and plant maintenance they are now looking to dry mechanical vacuum pumping systems, with much better dust handling capabilities, to provide significant savings.Compared to steam ejector systems, dry mechanical vacuum systems offer clear savings in running costs, maintenance costs, and installation space, and also offer increased speed, flexibility, and overall productivity to steel degassing operations. Large Roots vacuum booster pumps designed for high dust tolerance are the major component of mechanical vacuum degassing systems.Steel degassing processesSteel degassing is an essential process in secondary steel-making. Its value is in its rapid and effective removal of dissolved contaminant gases from primary steel (principally hydrogen and carbon monoxide) and the reduction in dissolved carbon levels, resulting in higher quality, higher value steel product with more widespread applicability. The two main processes are vacuum degassing (VD) and vacuum oxygen decarburisation (VOD).Vacuum degassing (VD) The basic VD process usually lasts 15-20 minutes and is conducted at pressures in the region of 0.5torr/0.67mbar. Under these conditions much of the dissolved hydrogen and carbon monoxide gases in the liquid metal desorb into the atmosphere above the steel and are evacuated. This process can also assist with the removal of lighter, more volatile metal elements (Pb, Sn, As, Sb, Bi, etc.) and sulphur. Residual gas levels in the resulting steel can typically be as low as one ppm for hydrogen. Soft purging with argon at the end of the process can also reduce residual oxygen levels to below 15ppm.For VD, gas flows of many tens of kg/h air equivalent must be handled at 0.67mbar. This puts the pumping speed capacities required into the tens of thousands of m3/h as a minimum, and demands the use of very large, multi-stage pump sets based on Roots vacuum boosters.Vacuum oxygen decarburisation (VOD) The VOD process is used typically to reduce the carbon content of high chromium stainless steels while avoiding significant collateral losses of chromium by oxidation. It uses the injection of pure oxygen into the molten steel to ‘burn out’ dissolved carbon by high temperature conversion to carbon monoxide (CO) and carbon dioxide (CO2) which are then evacuated away. To avoid undue losses of chromium the process is usually conducted at pressures of around 60-150torr / 80-200mbar. Extremely large amounts of dust and fines can be generated by this process which may, or may not, be captured by large filtration systems. At these pressures the pumping speed capacities required are much less than for VD, however, large Roots vacuum boosters are still needed.Other Processes Similar vacuum processes requiring high capacity pumping are vacuum arc degassing (VAD) and vacuum induction degassing (VID) which use alternative forms of heating to achieve similar objectives.Pumping performance requirementsThe basic performance parameters and requirements in a typical steel degassing pump system are listed in Table 1.To meet these high speed vacuum pumping requirements, the system should use an adequate numbers of large high vacuum (HV) Roots booster pumps, staged correctly to achieve sufficient pumping speed while maintaining satisfactory pressure ratio across each stage. These should be backed by primary pumps of sufficient capacity.The selection of primary pumps for backing stages depends on the type and size of process, the available site facilities and any customer preferences as follows:Table 1process type VD & VOD or VD onlyheat mass (capacity) tonnes of liquid metalfurnace volume typ. 2-3m3 per tonnefurnace air leakage typ. up to 10kg/h (air@20o C)initial pump down time to VD typ. 5-7minsVD process pressure typ. 0.67mbar / 0.5torrVD suction capacity typ. 1-2 kg/h/tonne (air@20o C)typ. 1250-2500m3/h/tonneVD line diameter typ. 800-1000mmVD gas dust load to pump system typ. v. lowVD gas temperature to pump system should be <= 60o CVOD process pressure typ. 80-200mbar / 60-150torrVOD suction capacity variableVOD line diameter typ. 800-1000mmVOD gas dust load to pump system can be high if filtration is poorVOD gas temperature to pump system should be <= 60o CBacking pump optionsFor VD processes the general requirement for backing is to provide reliable and adequate pumping speed at pressures in the region 10-50mbar (7.5-37.5torr).For VOD processes the requirement for backing is to provide reliable, high pumping speed in the region 200-400mbar (150-300torr), and to be able to tolerate reasonable levels of dust and contaminants.Dry pump sets Dry pump sets such as medium sized Roots boosters and dry claw primary pumps provide good backing speed to HV booster stages for VD operation (i.e. provide good pumping speed in the 10-50mbar region) and will also have excellent abilities to handle abrasive dusts, even in the high amounts which can arise from the VOD process. Much positive operating experience has been achieved with claw pumps even with severe dust loads on steel degassing plants, demonstrating simplicity of operation with high reliability. However, for larger sized plants a larger set of dry backing pumps is clearly needed, and economics may dictate that other backing options may need to be considered.Liquid ring pumps (LRPs) Large LRPs (or WRPs - water ring pumps) are a very economic and reliable way to generate fast roughing and high capacity backing for large sets of HV boosters. They are well accepted in the steel industry as simple, reliable pumps for hogging and higher pressure processes (e.g. VOD), and have been a standard alternative for steam ejectors in these duties for many years. They are inherently quite tolerant of process dust and dirt since these are largely absorbed and flushed out with the seal water.LRPs have a vaned rotor eccentrically mounted (slightly high) in a partially flooded horizontal cylindrical stator, driven by a suitably large motor. On start-up, the centrifugal action of the rotor rapidly establishes a circular liquid ring around the shell of the stator, with more gas space on the low side than on the high side. Vents in the lower side plates allow gas to be drawn in by the circulating rotor, which is then compressed on the high side by the liquid ring and vented out via non-return flapper valves in the upper side plates. The exiting gas is separated from entrained seal liquid which can then be recycled.However, there are two major drawbacks associated with the use of water sealed LRPs for steel degassing.1) the seal water consumption is large:-A typical 4,200 m3/h LRP may consume up to 10m3/h water in standard operation (50% recycled) or 20m3/h water in ‘once-through’ mode (i.e. no water recycling) and this water will exit straight to the waste water treatment plant. The incoming seal water must be clean but the effluent can be very contaminated by steel degassing processes - potentially a significant environmental consequence. The manufacturer may recommend once-through mode for VOD processes to minimise abrasion and wear inside the pump.2) the seal water temperature limits the ultimate achievable:-Seal water temperature is critical to LRP performance. This is of special concern for VD backing where the LRP must achieve a good ultimate vacuum to avoid stressing the stage three HV boosters (i.e. causing excessive pressure ratio). LRP manufacturers' specifications are usually based on 15o C seal water temperature which can be quite unrealistic, and care must be taken to establish the expected performance with the actual water temperature limits for the application (consult manufacturer's charts or ask specifically). As the seal water temperature increases so does its vapour pressure which impairs the LRPs vacuum pumping speed and also begins to cause cavitation (vapour bubble ‘explosions’) within the LRP as the inlet pressure drops towards ultimate. Although many manufacturers incorporate anti-cavitation devices, the net result is significant loss of pumping speed, cavitation noise/vibration, and especially a poorer ultimate pressure. Where this would have a critical and unacceptable impact on VD performance this must be dealt with by one or more of the following:-use once-through water (a likely requirement anyway)-chill the seal water (high plant and energy cost - may not be economic)-add an air ejector stage in front of the LRP (can be fed from the exhaust - but not liked by some operators)-add a small Roots booster stage in front of the LRP (adds cost and complexity) Large dry exhausters Big roughing capacity at proportionately lower cost than with other dry pumps can also be provided using large dry exhausters, i.e. Roots blowers specifically designed to vent to atmosphere and provide very high pressure differentials safely. As single units, exhausters usually have a much poorer ultimate vacuum than LRPs (typically limited to 200mbar / 150torr) and so for steel degassingduties two stage exhauster sets are needed. The ultimates of these sets are better than those of LRPs.The big advantages of dry exhausters compared to LRPs are minimal water consumption (only small quantities needed for cooling) and no major waste water disposal problem, no performance dependence on water temperature, and a good, reliable ultimate pressure. However, they are more expensive than LRPs (may be double prime cost) and typically require more installation space. Noise levels of large exhauster sets can also be very high (e.g. up to 100dBa without muffling).Typical Steel Degassing ExampleA modern steel degassing plant of nominal 75tonne heat capacity is designed for vacuum degassing (VD) at 0.67mbar and vacuum oxygen decarburising (VOD) in the region of 200mbar. The vacuum system specification is 100,000m3/h at 0.67mbar for VD and also 12,000m3/h at 200 mbar. Specifically for the VOD process a large cyclone/bag filtration system is installed upstream of the vacuum system.To achieve approximately 100,000m3/h for VD may require four 30,000m3/h HV boosters on the front row (stage 1), backed by two 14,000m3/h HV boosters as stage 2. The third stage would be a pair of 11,000m3/h HV boosters, typically backed by two large LRPs.Using only the stage 3 HV boosters, plus the LRPs, a reasonably high pumping speed at 200mbar can be achieved for the VOD process. The typical system speed curve is shown in Figure 1.Vacuum systems for VD and VOD of this nature can be considered in a modular arrangement, with the number of "modules" required dependant on the size of the steel degassing plant. Figure 2 shows a basic standard steel degassing module conceptwhich provides approximately 50,000m3/h pumping speed at 0.67mbar for VD and approximately 6,500m3/h at 200mbar for VOD.Figure 2。

医用真空泵的用途Purpose of medical vacuum pumpThe medical vacuum pump, usually refers to the micro vacuum pump, has the advantages of small size, easy to carry, low noise, maintenance-free, and can operate continuously for 24 hours. Its working medium is mainly gas, and it can continuously form a vacuum or negative pressure at the inlet, while forming a slight positive pressure at the exhaust nozzle. Due to these characteristics, medical vacuum pumps are widely used in the medical field.During surgery, the medical vacuum pump can be used to suction blood and tissue debris in the surgical area, thereby cleaning the surgical area and improving the success rate of the surgery. In addition, in the treatment of respiratory diseases and infectious diseases, the endotracheal intubation negative pressure suction system also needs to use the medical vacuum pump to generate a negative pressure environment to help patients breathe and clear secretions in the respiratory tract.In addition to the medical field, medical vacuum pumps have also been widely used in scientific research, environmental protection and other fields. For example, in the field of scientific research, vacuum pumps are used to generate high vacuum environments required for material research. In the field of materials science, researchers need to perform high-temperature quenching experiments on new materials, generally placing the samples in a vacuum environment to avoid contamination of the material due to oxidation. At this time, the vacuum pump can pump out the air in the experimental box to establish a high vacuum environment, thereby protecting the sample from contamination and oxidation.Please note that when using the medical vacuum pump, relevant operational specifications and safety guidelines should be followed to ensure its effectiveness and safety. At the same time, for specific medical applications, it should be carried out under the guidance of professional doctors.医用真空泵,通常指的是微型真空泵,具有体积小、便于携带、噪音低、免维护、可以连续24小时运转等优点。

低温真空浓缩蜜渍工艺英文回答:Low-temperature vacuum concentration impregnation process.The low-temperature vacuum concentration impregnation process is a food processing technology that uses low-temperature and vacuum conditions to impregnate liquid materials into food products. This process can be used to improve the nutritional value, flavor, and shelf life of food products.The process begins by placing the food product in a vacuum chamber. The chamber is then sealed and the air is removed. This creates a vacuum that causes the food product to expand and the pores in the food product to open up.Once the vacuum is created, the liquid material is introduced into the chamber. The liquid material istypically a solution of water, sugar, and other ingredients. The liquid material is drawn into the pores of the food product by the vacuum.The vacuum is then released and the food product is removed from the chamber. The liquid material that has been impregnated into the food product will now be evenly distributed throughout the product.The low-temperature vacuum concentration impregnation process can be used to improve the nutritional value offood products. This process can be used to add vitamins, minerals, and other nutrients to food products. The process can also be used to improve the flavor of food products. By adding flavors and spices to the liquid material, theflavor of the food product can be enhanced.The low-temperature vacuum concentration impregnation process can also be used to extend the shelf life of food products. This process can be used to prevent the growth of bacteria and mold. By removing the air from the food product, the growth of bacteria and mold is inhibited.The low-temperature vacuum concentration impregnation process is a versatile food processing technology that can be used to improve the nutritional value, flavor, and shelf life of food products.中文回答:低温真空浓缩蜜渍工艺。

AvanceVacuum technology 1400 W35000 RPMHR3752/01Keep smoothies fresher throughout the day* Blending reinvented – with vacuumEnjoy a healthy smoothie throughout your day with our vacuum blender. If you’re on the go, use the blender to take healthy snacks with you that stay as fresh and tasty as when you made them.Smooth blending under vacuumVacuum technologyPreset program for vacuum and smoothie blendingStrong Tritan jarManual mode with variable speedUnlocks millions of nutrientsPowerful 1400 W motor for smoother blendsAdvanced ProBlend 6 3D blending technologyUp to 35,000 rpmEase of useDishwasher-safe blender jarDetachable blades for easy rinsingSingle press for preset programsQuality guaranteed2 year worldwide warrantyHighlightsVacuum technologyVacuum technology sucks the oxygen out of the jar before blending. Results are visible in the final blend: fewer bubbles, less foam, less juice separation. The smoothie stays fresh for longer.Program settingChoose from 3 programs: vacuum smoothie,pulse and ice crushing. Make any smoothie you like.Strong Tritan jarThe Tritan jar is made from copolyester and is lighter than a glass jar. It does not smell or stain. The ideal environment for your favourite smoothie.Choose your blending speedFrom gentle blending for soft fruits, to a burst of power for harder fruit and vegetables—it's up to you with our variable manual speed options.More power for smoother blendsFiner blending of fruit and vegetables, thanks to our 1400 W motor.Unlocks more nutrients We developed our ProBlend 6 3D technology to ensure that all of the ingredients in your smoothie are finely blended—so the nutrients in fruit, vegetables and nuts are unlocked from the cell structure and easily absorbed by your body.Up to 35,000 RPM35,000 RPM for excellent blending and even healthier smoothiesDishwasher safe, easy to cleanAll detachable parts of your Philips blender are dishwasher safe—except for the blade unit,which can be easily rinsed clean. The base can be wiped clean if needed.Detachable blender bladesTo clean the blender blades, simply detach them from the blender jar and rinse. Theblades cannot be cleaned in the dishwasher, topreserve their sharpness.Philips Green LogoPhilips Green Products can reduce costs,energy consumption and CO2 emissions. How?They offer a significant environmentalimprovement in one or more of the Philips Green Focal Areas — Energy efficiency,Packaging, Hazardous substances, Weight,Recycling and disposal and Lifetime reliability.SpecificationsAccessoriesIncluded: Jar, Measuring cup, Recipe booklet, Ice crush knifeCountry of originMade in: ChinaGeneral specificationsNumber of speed settings: VariablePrefix programs: 4Product features: Automatic shut-off, Cord storage, Dishwasher safe, Non-slip feet,On/off switch, Pulse, Variable speed,Removable lidVacuum Smoothies buttonKey Feature: ProBlend 6 3DService2-year worldwide guaranteeSustainabilityPackaging: > 90% recycled materialsUser manual: 100% recycled paperT echnical specificationsCapacity jar: 2.2 lWorking capacity jar: 1.8 lPower: 1400 WRPM blender (max): 35000 rpmCord length: 1 mDesignColour: MetallicFinishingMaterial blade: Stainless SteelMaterial jar: TritanMaterial of main body: SS* Compared to blending without the use of vacuumfunction in Philips HR3752. Test conducted by anindependent laboratory in Nov/Dec 2017.© 2019 Koninklijke Philips N.V.All Rights reserved.Specifications are subject to change without notice. Trademarks are the property of Koninklijke Philips N.V. or their respective owners.Issue date 2019‑03‑22 Version: 3.0.1EAN: 08 71010 38483 63 。

医学英语学习词汇如下:V (①vanadium ②volt) ①钒②伏特vacancy 空,空白vaccinating cl 种痘夹vaccinating b 种痘梳vaccinating lancet 种痘刀vaccinating pen 种痘笔vaccination knife 种痘刀vaccination needle 接种针,种痘针vaccinator 接种器,种痘器vaccine ①菌苗,疫苗②牛痘苗vaccinostyle 种痘针vac. pup. (Vacuum Pump) 真空泵vacreator 真空杀菌器vacuity 真空,空白vacuo 真空vacuometer 真空计,低压计vacustat 真空计vacuum 真空vacuum air pump 真空抽气泵vacuum bottle 保温瓶,热水瓶vacuum calorimeter 真空测热计vacuum chamber 真空腔,真空容器vacuum cleaner 真空吸尘器vacuum desiccator 真空干燥器vacuum drier 真空干燥器vacuum dryer 真空干燥器vacuum drying apparatus 真空干燥器vacuum drying oven 真空干燥箱,真空烘箱vacuum electric furnace 真空电炉vacuum equipment 真空装置vacuum evaporator 真空蒸发器vacuum e_pander 真空膨胀器vacuum e_siccator 真空干燥器vacuum e_tractor ①真空提取器②真空吸引器vacuum filter 真空抽滤器vacuum flask 真空瓶vacuum gauge 真空计vacuum hearing aid 真空管助听器vacuum investing machine 真空包埋机(牙科)vacuum ionization manometer 真空电离压力计vacuum meter 真空计,低压计vacuum mi_ing machine 真空混合机(牙科)vacuumometer 真空计,低压计vacuum oven 真空干燥箱vacuum pump 真空泵vacuum quantorecorder 真空光量计vacuum receiver 真空接受器vacuum still 真空蒸馏器vacuum suction massagelliut 真空抽吸按摩机vacuum tower 真空蒸馏塔vacuum tray dryer 真空盘架干燥器vacuum tube 真空管,电子管vacuum tube tester 真空管测试仪vagina 阴道vaginal 阴道的,鞘的vaginal applicator 阴道塞药器vaginal cl 阴道钳vaginal depressor 阴道压板vaginal dilator 阴道扩张器(扩阴器)vaginal forceps 阴道钳vaginal irrigating tube 阴道冲洗管vaginal plug 阴道塞vaginal retractor 阴道牵开器vaginal scrubber 阴道洗涤器vaginal smear 阴道涂片vaginal speculum 阴道窥器,窥阴器vaginal ton 阴道塞vaginal tractor 阴道拉钩vagino- 阴道vaginogram 阴道_ 射线(照)片vaginography 阴道_ 射线照像术vaginometer 阴道测量器vaginoscope 阴道镜,阴道窥器vaginoscopy 阴道镜检查vaginotome 阴道切开刀vago- 迷走神经vagogram 迷走神经电(流)图vagotomy retractor 断迷走神经术牵开器valency ①效价②化合价valency electron 价电子valid 有效的,确实的valid contract 有效合同validity 有效的,效力,有效期限valuable 有价值的,贵重的valuation 估价,评价value 价值,评价valve ①瓣膜②阈,活门③电子管valve generator 电子管振荡器valve radio set 电子管收音机valve receiver 电子管收音机valve scissors 瓣膜剪valve system for cerebrospinalfluid 脑积水引流装置valvoplasty 瓣膜成形术valvotome 瓣膜刀valvotomy 瓣膜切开术valvotomy knife 瓣膜切开刀valvula 瓣,瓣膜valvuloplasty 瓣膜成形术valvulotome 心瓣膜刀valvulotomy 瓣膜切开术vanadium (abbr. V) 钒vane 叶片,刀片,瓣vanguard 先锋,先驱vapor ①蒸汽②吸入剂vaporarium 蒸汽疗器vapor density apparatus 蒸汽密度测定仪vapor density bulb 蒸汽密度测定球vaporimeter ①蒸汽压力计②挥发度计vaporiser 蒸发器,喷雾器vaporium 蒸汽疗器vaporization 汽化,蒸汽疗法vaporizer 蒸发器,喷雾器vaporometer ①蒸汽压力计②挥发度计vapor pressure osmometer 蒸汽压渗透压计vapor pressure tester 蒸汽压力测试器vapor sterilization 蒸汽消毒vapotron 蒸发冷却器vapour 蒸汽vapourizer 蒸发器,喷雾器,汽化器variable ①易变的,可调的②变量variable angle retinal camera 广角眼底照像机variable filter 可调滤波器variable-note bu___er 变调蜂音器variable pacemaker 可调式心脏起搏器variable temperature unit 变温仪器variable-voltage regulator 可变电压调节器variance 变化,偏差,变量variation 变化,变更variator 变速器varico- 静脉曲张varicocele cl 精索静脉曲张夹varicography 曲张静脉照像术variety 多样性,变化,种类varifocal lens 变焦距镜头varifocal objective 变焦距物镜varimetric micropipettor 可调微量注射器variograph 变压计,变量计variohm 可变电阻器various 各式各样的,不同的varistor 变阻器,压敏电阻varnish 漆,清漆vasal 管的,脉管的vascular 血管的,导管的vascular bed 血管床vascular cl 血管夹vascular dilator 血管扩张器vascular endoscope 血管(内腔)镜vascular forceps 血管钳vascular grafts 人造血管vascular prosthesis 人造血管vascular retractor 血管牵开器vascular scissors 血管剪vascular suction tube 血管吸管vascular tissue forceps 血管组织镊vase 花瓶,瓶vaseline 凡士林vaso- 血管,管vasoconstriction 血管收缩vasodepression 血管减压vasodilatatioin 血管舒张vasography 血管造影术vasomotion 血管舒缩vasomotor apparatus 血管运动装置vasoscillator bed 血管振荡床(可以翻转,以恢复血管功能)vasotribe 血管压轧钳vasotripsy 血管压轧术vat 桶,槽,缸,箱VC (vital capacity) 肺活量VCG (vectorcardiogram) 心向量图VDR (video disc recorder) 圆盘录像机vectogram 向量图,矢量图vectograph 向量图描记器vector 向量,矢量vectorcardiogram (abbr. VCG) 心电向量图,矢量心电图vectorcardiograph (abbr. VCG) 心电向量仪,矢量心电图描记器vector diagram 矢量图,向量图vector-electrocardiograph 心电向量图机vector electro-oculograph 向量眼电计vectorgram 心电向量图,向量图vector loop 向量环vectorlyser 向量分析器vectormeter 矢量计vector quantity 向量vectorscope (色度)矢量显示器vectron 超高频频谱分析仪vehicle 车辆,运送装置vein 静脉vein dilator 静脉扩张器vein hook 静脉钩vein ocluder 静脉闭塞器veinogram 静脉造影片veinography 静脉造影术vein remaining needlleiv 留置针vein retractor 静脉牵开器vein scissors 静脉剪vein-seeker 静脉探索器vein spreader 静脉支摊开器vcin stretcher 静脉拉直器vein stripper 静脉支剥除器velocimeter 流速计,速度计velocitron 质谱仪velocity 速度,速率velocity gradient 速率梯度velograph 速度记录仪,速度计velometer 速度计venacaval cl 腔静脉夹venacavography 腔静脉照像术vendor ①售主,卖主②自动售货机veno- 静脉venoclysis needle 静脉输液针(小儿头皮针)venogram 静脉造影片,静脉描记图venography 静脉造影术,静脉搏描记法venostat 静脉郁阻器venous cannula 静脉套管venous retum catheter 静脉血流管venous valve 静脉瓣vent 孔,通风口ventilating fan 通风扇ventilation 通风,换气ventilation grate 通风栅(冰箱)ventilation installation 通风设备ventilation monitor 换气量监测仪ventilator ①呼吸器②通气机,空气调节器vent needle 孔针ventouse 吸杯,拔罐ventricle 室(如脑室,心室等)ventricle needle 脑室针ventricular 室的ventricular cannula 脑室套管ventricular catheter 心室导管ventricular casing pipe 脑室套管ventricularendoscope 脑室镜ventricular needle 脑室针ventricular puncture needle 脑室穿剌针ventriculo- ①心室②脑室ventriculocentesis 脑室穿刺术,心室穿刺术ventriculogram 脑室造影片,心室造影片ventriculography 脑室造影术,心室造影术ventriculometry 脑室内压测量法ventriculopuncture 脑室穿刺术,心室穿刺术ventriculoscope 脑室镜ventriculoscopy 脑到镜检查ventriculostium 脑室瘘ventro- 腹,腹侧ventroscope 腹腔镜ventroscopy 腹腔镜检查VEP (visual evoked potential) 视觉诱发电位VER (visual evoked response) 视觉诱发反应verdict 判定,判断,意见berge 环,边缘,界限verification 检验,核实verifier 检验机,取样器verify 证明,检验vermi_ 阑尾vermography 阑尾_ 射线造影术vernier 游标,游标尺vernier calliper 游标卡尺versatile 万能的,通用的,多方面的version ①翻译,译文②模型种类③胎位倒转术verso 背面,书的左页,书的反页vertebra 椎骨,脊椎vertebral arteriogram needle 椎骨动脉描记图针vertebral plate tractor 椎板牵引器vertebrated catheter 分节导管vertebrated probe 有节探子vertical ①垂直的②垂直面vertical dimension 垂直尺度vertical fluorescence illuminator 落射光荧光照明器vertical high pressure steam boiler 立式高压蒸汽锅vertical illuminator 垂直照明器vertical line 重直线vertical mercury column nanometer 立式汞柱血压计vertical microscope 立式显微镜vertical section 垂直切面vertical vacuum gauge 垂直式真空压力计vertigraphy 体层_ 射线照像术,断层_ 射线照像术vertometer 焦度计,屈度计vesical goniometer 膀胱测角计vesical stone 膀胱结石vesiculogram 精囊造影片vesiculography 精囊_ 射线造影术vessel ①血管,脉管②容器,器皿,罐,槽,瓶,桶vessel appro_imator 血管合拢器vessel cl 导管夹,动脉止血钳vessel dilator 血管扩张器vessel forceps 血管钳vessel irrigating needle 血管冲洗针vessel knife 血管刀vessel smooth forceps 无齿血管钳vessel spreader 微血管扩张器vessel supporter 血管支持器vessel suturing guide 血管缝合导子vest 背心,防护衣vestibular apparatus 前庭器官vestibule 前庭vest-pocket 袖珍的,小型的vest-pocket camera 袖珍照像机,小型照像机veterinary 兽医(的)veterinary instruments 兽医器械veterinary needle 兽用注射针veterinary station 兽医站veterinary thermometer 兽用温度计Vi (virginium)via 经过,经由,通路viability 生活力,生育力vial 小瓶,管形瓶vibra- 振动vibrameter 振动计,振动式计量器vibrating diaphragm 振动膜vibrating mirror 振动镜vibrating screen 摆动筛vibration 振动vibration frequency meter 振动频率计vibration meter 振动计vibration-proof 防震的vibratode 振动器极,振动器导子vibrator ①按摩器②振动器vibratormeter 振动计,振动式计量仪vibrocardiogram 心振动(描记)图vibrocarkkiograph 心振加速记录仪。