施工组织设计英文文献翻译

- 格式:doc

- 大小:43.00 KB

- 文档页数:9

同里时代花园住宅项目摘要本设计主要针对“同里时代花园住宅项目”。

在设计中,对该项工程的基础部分进行详细的手算工程量,内容包括挖土方、条基、独基、圈梁、砖基础,同时,抽样了基础中大部分独基、条基、圈梁及首层部分柱、梁中的钢筋进行计算,并运用广联达算量软件积极鲁班钢筋软件对本工程部分抽样。

上述工作完成后,即开始编写施工组织设计,编排施工进度计划、人员安排计划等。

最后进行上机,运用金天龙计价软件依据施工说明等进行套价。

所有完成后,即对所做的内容按要求整理、装订,准备答辩。

关键词:设计;工程量;施工组织Project Of Tongli’s Era Garden ResidentialAbstractThis design is aimed at the project of Tongli’s Era Garden Residential. In the design of the project, I had detailed calculation of the basis of the project on my hands, including based earthwork digging ,independent foundation , bar foundation ,DQL ,edc.At the same time, I also calculatied the part of the components on the first floor such as beams, columns and reinforcing steel bars . I used the software of Guang Lianda and luban to calculate the other components. When the work have done, I began to make up the construction organization design document schedule, personnel arrangement and so on. At last, I had to use the software of Jin Tianlong to reach a result of the engineering offer depending on the construction instructions. After completion of all, I shouid bind according to the requirements and be ready to plead.KEYWORDS: DESIGN; QUANTITY; CONSTRUCTION ORGANIZATION苏州科技学院天平学院本科生毕业设计目录第一篇设计总说明 (4)第一章工程总体概况 (4)第二章补充设定条件 (5)2.1 场地条件 (5)2.2 工程量计算及清单计价部分 (5)2.3 施工组织设计部分 (5)第三章主要完成的设计工作内容 (6)第四章心得体会 (7)第二篇施工组织设计 (8)第一章编制说明 (8)1.1 编制依据 (8)1.2 编制范围 (8)第二章工程概况 (9)第三章施工部署 (10)3.1 施工总体部署 (10)3.1.1 总体设想 (10)3.1.2 施工部署 (10)3.2 施工组织机构 (10)3.3施工准备 (10)3.3.1 施工现场准备 (10)3.3.2 技术准备 (11)3.3.3 物资准备 (11)3.3.4 劳动力组织准备 (13)第四章施工进度计划 (14)4.1 总工期控制 (14)4.2 施工进度计划 (14)第五章主要的施工方法 (15)5.1 施工测量 (15)5.2 土方工程 (16)5.3 基础工程 (17)5.4 框架结构工程 (19)5.5 砌体工程 (20)5.6 门窗工程 (21)5.7 楼地面工程 (22)5.8 装饰工程 (23)5.9 屋面工程 (24)5.10 脚手架工程 (25)第六章保证质量、安全、文明等技术措施 (26)6.1 质量保证的技术组织措施 (26)6.1.1 质量目标 (26)6.1.2 组织管理方面 (26)6.1.3 质量控制方面 (26)6.1.4 保证工程质量的措施 (27)6.2 保证工程质量的具体措施 (32)6.2.1 质量保证措施 (32)6.2.2 施工工期保证计划 (33)6.2.3 制度保证 (34)6.2.4 组织保证 (34)6.3 确保安全的技术组织措施 (35)6.3.1 突发事件应急措施 (35)6.3.2 安全施工过程控制措施 (35)6.3.3 安全管理内容 (36)6.4 确保工期的技术组织措施 (38)6.4.1 准备工作保证 (38)6.4.2 装备保证 (38)6.4.3 新技术保证 (38)6.4.4 作风保证 (39)6.4.5 经济手段保证 (39)6.5 文明标准化工地的技术组织措施 (39)6.5.1 环境保护措施 (39)6.5.2 确保文明施工的管理措施 (40)6.5.3 组织管理措施 (41)6.5.4 文明施工目标:创“文明现场标准化工地” (42)苏州科技学院天平学院本科生毕业设计6.6 季节性施工技术组织措施 (42)6.6.1 夜间施工技术措施 (42)6.6.2 冬季施工技术措施 (42)6.6.3 雨季施工技术措施 (43)6.6.4 总体要求 (43)致谢 (44)参考文献 (45)附录译文 (46)附录外文原文 (49)第一篇设计总说明第一章工程总体概况本工程位于苏州工业园区娄葑南区,主要结构类型为框架形式,建筑占地面积为1460.22m2,建筑总面积为2985.04m2。

CHINA HARBOUR ENGINEERING COMPANYLIMITEDConstruction SchemeRio Grande BridgeK0+150~K0+240soft foundationreplacement treatmentWriter:_______________ Chief: ____________Unit:_________________ Date:_________________Directory1.project profile ------------------------------------------------------------------ 32.Construction preparation ---------------------------------------------------- 33.Construction scheme --------------------------------------------------------- 43.1construction technology --------------------------------------------- 43.2construction process ------------------------------------------------- 43.3construction method ------------------------------------------------- 53.4 water ditch excavation ---------------------------------------------- 63.5 clearance and excavation ------------------------------------------- 63.6 backfill and rolling compaction ------------------------------------ 74. Personal and machine arrangement ------------------------------------- 84.1 labor arrangement --------------------------------------------------- 84.2 machine and equipment -------------------------------------------- 95.Quality control precautions ----------------------------------------- 106. safety and environmental protection precautions ------------------ 136.1 safety protection precautions ----------------------------------- 146.2Environment protection precaution ---------------------------- 171.project profileThe soft foundation of this project is K0+150-K0+340, the surface is plough soil, soft plastic sludge fine sands with the max thickness of 3.0m, and backfilled with min thickness 0.3m and width 70m and the final elevation should not lower than the original ground, the backfilling material should adopt water permeability material like gravel and roadbed should be filled directly after that with a thickness 2.3~7.5m.According to the engineer geology of soft layer and roadbed elevation in design, it should take a comprehensive dispose to soft section, including first excavation of vertically and horizontally drain ditch, surface water, and backfill the water permeability material.The main project quality is soft foundation excavation 5700m3 and water permeability material gravel 5700m3.2.Construction preparationIt should check the onsite or underground obstacles like underground cables, high-tension wire, communication cables and clear them out according to conditions.2.1“four supplies and one leveling ”Supply of water, electricity and road and leveled ground should be done on the construction site. The construction water, domestic water should adopt local well water; the construction and household power should be supplied by special line; the shortcut should be used as road and be sure that varies of cars and person can pass through with a regular maintenance to keep unblocked.2.2technology preparationThe construction drawings should be reviewed first and explained to the construction stuff after approval.2.3material preparationIt should investigate the backfilling material resources around and make storage to make sure the continual construction.3.Construction scheme3.1construction technologyReview the construction drawings design and relevant documents—construction preparation (store exchange fill water permeability material)—survey layout—drainage ditch set—soft soil and sludge removal—foundation check—exchange fill the water permeability material by layer—compact by layer3.2construction process3.3construction method53.1.1survey layoutThe control point should be retest and encrypted according to the design cross point to ensure the quantity of the lead wire point and level point, in that case the mutual check work will be more convenient during construction. The calculation of pile coordinates should be made according to the horizontal curve data in drawings, the layout will be made after checking the data and the location of roadbed mid-pile and side pile should be marked with a space 20m by lime.3.4 water ditch excavationFirst the drain water ditch should be excavated at the sides and middle of the roadbed to make sure that watering unblocked before soft foundation dispose and excavated at the soft section vertically and horizontally connecting with the geography elevation, as to some individual section, it should dewatering by the sumps in the soft foundation scope to make a advantage for subsequent soft foundation dispose.The location of soft foundation dispose and temporary drainage ditch layout please see below drawings:3.5 clearance and excavation3.5.1 The soft soil or sludge should be removed and bottom should be leveled. It should set a step or gentle slope if the bottom of the soft soil has a big curve. The excavation width should not less than the width of embankment and direct excavation and 50 cm wider than the side ditch border. After the soft foundation removed, the next process can only be carried on after the supervisor’s approval.3.5.2With the increment of the excavation depth, the drainage ditch should be deepened, the pit dewatering should be used for the sectionwhere has drainage difficult to protect the roadbed from soaking.3.5.3 It should be dewatered first when there’s a slope on the bottom, the foundation should be made as a counter-slope step with a more than 1m width after the soft soil removal.3.6 backfill and rolling compactionThe thickness of every backfilling layer should be less than 30cm and the process is as follow:After finish the soft bottom excavation and approved, the bottom should be leveled, back cover by qualified material with a thickness of 30~50cm and compacted by a degree above 85%.3.6.1 Layout: it should layout before the first layer backfill and marks the loose pavement thickness by lime and surveys elevation of every point for future use.3.6.2 Material transport: it should adopt the dumper car and excavator to transport the backfilling material and keep the construction road unblocked. Try to short the transport duration to ensure the excavator and roller can work continuity. It should level every layer backfilling material and set 2% transverse slope at both sides and roll timely especially in rain season. The roadbed should be backfilled by layer with a thickness of 30cm at one time.3.6.3 Spread, level and roll: the backfilling material should be leveled by bulldozer first and by person at difficult places. During compaction, it should notice the backfilling transverse slope and roll by vibroll after leveling. When rolling, it should along the longitudinal line from low to high level and fast followed by slow, from sides to middle at the straight section, from inside to outside at the curve section. First it should be rolled without vibration by 3.0~3.5km/h, then light vibrationby 2.0~2.5km/h and rolled with heavy vibration by 1.5~1.8km/h. The special person should be arranged to time, observe and control the rolling speed, track to ensure the overlap between 40~50cm. It should check the compaction degree and survey point elevation, record and calculate the compaction degree and loosen coefficient from the third time rolling compaction (The individual data should not be used in the loosen coefficient calculation). Take the followed measures to the backfilling materials in order to meet the requirements of every test standards: when the water content of backfilling materials is lower it can watering in the material site; when closer to the best content it should be spread with soil and rolled as soon as possible; when higher it can be rolled until dry enough. The rolling width should be 0.3m wider than the design roadbed width at both sides until meets the requirements of the specifications. Draw the compaction degree and rolling times relation schema. It should record the required rolling times, the speed and vibrating mode of rollers, compare the compacted thickness and loose pavement thickness, and compare the adopted pavement thickness to get the loose pavement coefficient and adopted loose pavement thickness.4. Personal and machine arrangementSoft foundation disposal roadbed construction team is responsible for the construction and the chief principle is in charge. The main management stuff includes roadbed engineer, QC engineer, safety man, material man, tester, and surveyor. The personal and machine arrangement details , please see the below tables.4.1 labor arrangementTable 4-1 roadbed labor arrangement table4.2 machine and equipmentTable 4-2 quantity list of main machines and equipments5. Quality control precautions5.1 According to the project requirement, construction explanation should be conducted prior to the commencement of work. After the completion of each construction section, we should request inspection and evaluation. We should strictly obey the quality management assurance system which is shown as followsQuality management assurance system112. Material quality control1) Material department should draw up the purchase plan according to the material supply application and relevant regulations. The supplier should be qualified for productivity and quality.2) Material should be with quality certification and sampled before using. If testing items are beyond the ability of testing lab, these should be sent to other qualified testing center.3. Construction control1) Key quality controlMaterial quality and critical procedure quality should be the key parts of quality control. Quality inspection document should be in on the basis of relevant standards and specifications.2) Three-grade inspection system should be conducted. The three- grade inspection refers to self-inspection, acceptance inspection and particular inspection.3) establish quality double check system to eliminate quality accident. Quality control seminar should be carried out frequently to promote the increasing of quality4) rewards and penalty system should be formed and implemented.4. testingTesting center should be with qualified test clerk and equipment.5. survey and concealed work acceptance1) Survey equipment should be checked by responsible survey engineer. Qualified equipment should get the acceptance letter before using.Survey equipment should accept frequent check to insure its measurement.Survey crew should include a survey engineer who is the responsible person for new-tech training.Constructor, survey engineer as well as chief engineer should check the measurement one by one.6. concealed work acceptanceConstructor should request inspection for the concealed work. After acceptance it should be moved to the next construction step.7. measuring equipment checkingTesting equipment and measuring equipment should accept checking weekly to insure its accuracy.8. professional personnelAll the construction personnel should be the qualified skilled person.Prior to the commencement of construction, all the stuff should acknowledge the construction technical documents, drawing as well as specifications.9. quality recording logQuality log should be the reflection of real construction quality. after the inspection, It should be filled in proper format on time and kept by responsible person and stored in reference room.Progress: constructor should record the construction progress and conduct quality inspection. Quality engineer should conduct the double check and make evaluation. Chief engineer should exam the record and then pass it to the recording management personnel to bookbind. When it get the acceptance of owner, quality supervision center and superior department, it can be stored in the reference room.6. safety and environmental protection precautions6.1 safety protection precautions1)Safety control group composed of project manager who are as the group leader), vice manager, chief engineer, dispatcher, site engineer, site forman who are as the group member.2)One full-time safety administrator (with the qualified safety management license), two on-site full-time safety inspector should occupy in safety control works.3)The leader of construction team should be part-time safety control administrator and construction engineer should be part-time safety inspectors4)Safety control management system shows as following tree diagramSafety control management system155) On-site safety precautions i(1) On-site safety control mandatory requirementsProject department safety control plan and progress should submit to owners and supervision engineers and acquire their approval. Project department should agree the additional regulations put forward by owners or supervision engineers and the following mandatory requirements should be implemented on site:①if people(including visitors, party representatives, materials, transportation workers) didn’t wear protective articles, they should not be allowed to enter the construction site.②all the moving parts of machinery, equipment or electrical tools must be installed protective cover to prevent contact with the body.③all the temporary distribution box should be grounded and installed earth-leakage circuit-breaker.④all the equipment should be operated by qualified licensed operator.⑤all special equipment should be operated by qualified licensed operator.⑥before the commencement ,all equipments should be tested by qualified inspector and the equipments should attach check tag .(2)Power supply management①construction, maintenance as well as remove of temporary power line should operate by professional electrician②electrician should acknowledges equipment property and safe use of electricity.③Operator should wear protective articles before the commencement of operation and check electric apparatus as well.Equipment should be confirmed running in good condition④Switch should be turn off to stop the equipment and switch box need to be locked.⑤Equipment load line, zero line and switch box need to be inspected by professional personnel. If any problem was found, it should be reported and solved immediately.⑥Before any remove, power supply should be cut off .(3)Hurricane precautions①during hurricane season , project department should have a persons on duty to listen to weather ,tropical storm and hurricane forecast everyday.②project department should accept and obey the instruction of superior department.③ According to the weather forecast of hurricane or tropical storm, the leadership group should hold a meeting to establish a emergency measures against hurricane.④project section should form an anti-hurricane rescue team, if hurricane visited ,rescue team should take positive action according to plan.⑤communication should be smooth. Any progress should report to relevant department. If necessary, project department should ask for proper assistance.6.2Environment protection precautionGuidelinesStuff should comply with environmental and occupational health management laws and regulations, standards and procedures and conduct the duty and commitment which is covered in the contract.During construction work stuff should save energy and reduce resource consumption and prevent environmental pollution incidents.Everyone should participate in the complementation of environment protection precaution and eliminate hidden risks to prevent the accident.Environmental and occupational management system should be constantly improved.1)Environmental management of construction equipmentconstruction equipment should be operate by qualified personnel .Equipment should be running, loading by the required ways and procedures. Operation time should be limited to prevent the noise and air pollution, waste gas should be tested before discharge and oil cotton or other toxic trashes should be central treated. All construction equipments are not free to discharge sewage, oil or other wastes to prevent pollution of nearby water sources.2)Environmental protection precaution and work site amenityConstruction design should include the content of environmental protection precaution of gas, sewage, sludge, dust, radioactive substances, noise and other environmental pollution hazards.The awareness of environment protection, resources conserving and ecology balancing should be raised to minimize the negative construction impaction.The environment safety condition should be evaluated to eliminate the safety hazards. Construction site should be leveled and project department should be safe, tidy and sanitary and greening. no sludge water. Road access should be hardened and sewage-free with a sprinkler to reduce the dust.Construction machineries and Vehicles Park tidily at specified place, maintain daily to keep them in good condition. Fixing machineries need temporary shed; working plot needs flat and solid with no sundries.Daily safety inspection, entrance registration and flare approval system should be implemented on construction site, living zone and auxiliary zone. Fire-prevention warning sign and fire fighting facilities should be shown at the construction site and living zone .3)According to the pollution hazards have been identified and environment control goals, the enterprise and inferior leadership, work team shall sign their letters of responsibility for environmental control to ensure that tall environmental control indicators are under control.4)According to the identified environmental factors, environmental protection precautions and management programs should be established. During the construction progress, major environmental pollution factors are as follows: noise of pile boring, vibrating and heavy trucks; Air pollution of sand, cement transportation, storage and the use and waste gas discharged by vehicle .water pollution of kitchen, toilet, bathroom sewage; solid waste of construction waste living waste.5)Stuff environmental educationNew labor should accept safety education as well as environmental protection education to raise their pollution control awareness Before the construction commencement, all construction stuff should accept environmental protection education to raise the self awareness of environmental protection. Technicians and environment inspector should acknowledge the environmental pollution factors and make a detailed explanation to construction workers and all workers should sign and implement the environmental precaution acceptancenotification or environmental protection agreement. Every technician is in charge of the establishment and supervising of the environmental protection precaution.Waste water, garbage should be discharged into the required location that local government permitted.Dust should be controlled according to requirement of the local government and the dust should be less than 250mg per cubic meter.Fire accident and explosion accidents should be prevented.。

Importance of construction organization design Summary:Construction work in the construction process, the construction organization scheme will not onl y directly affect project quality, duration and safety also has an important impact in the construct ion process。

Construction organization projects and mentoring inconstruction of key technical and economic documents。

Can regulate the construction people,machines, materials, environment, technology, equipment, construction, installation, manage ment, production and other conflicts , monitoring and control of the construction organization de sign , scientific and reasonable assurance the completion of project of high quality, low cost,low energy consumption。

Key words:Project management construction management programme the importance Construction organizat ion design is the idea of the whole construction process of engineering construction project ideas a nd specific arrangements, organization and management of construction work is the heart and so ul. Its aim is to enable high speed, high quality, efficiency。

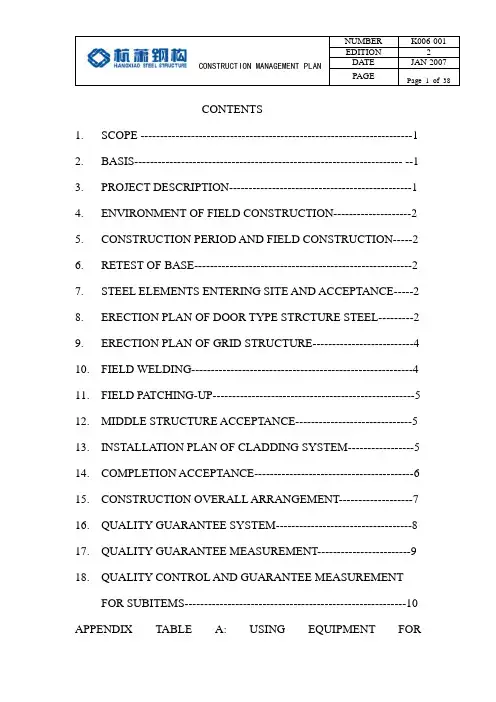

CONTENTS1.SCOPE ----------------------------------------------------------------------12.BASIS--------------------------------------------------------------------- --13.PROJECT DESCRIPTION-----------------------------------------------14.ENVIRONMENT OF FIELD CONSTRUCTION--------------------25.CONSTRUCTION PERIOD AND FIELD CONSTRUCTION-----26.RETEST OF BASE--------------------------------------------------------27.STEEL ELEMENTS ENTERING SITE AND ACCEPTANCE-----28.ERECTION PLAN OF DOOR TYPE STRCTURE STEEL---------29.ERECTION PLAN OF GRID STRUCTURE--------------------------410.FIELD WELDING---------------------------------------------------------411.FIELD PATCHING-UP----------------------------------------------------512.MIDDLE STRUCTURE ACCEPTANCE------------------------------513.INSTALLATION PLAN OF CLADDING SYSTEM-----------------5PLETION ACCEPTANCE-----------------------------------------615.CONSTRUCTION OVERALL ARRANGEMENT-------------------716.QUALITY GUARANTEE SYSTEM-----------------------------------817.QUALITY GUARANTEE MEASUREMENT------------------------918.QUALITY CONTROL AND GUARANTEE MEASUREMENTFOR SUBITEMS---------------------------------------------------------10 APPENDIX TABLE A: USING EQUIPMENT FORCONSTRUCTION--------------------------------------------------------------11 APPENDIX TABLE B: USING TOOL FOR CONSTRUCTION TABLEA--------------------------------------------------------------------------12 APPENDIX TABLE C:LABOR PLAN ARRANGEMENT TABLE----------------------------------------------------------------------------13 APPENDIX 1: FIELD GROUND PLANE DRAWING (WITH EXPLANATION)APPENDIX 2: CONSTRUCTION PROGRESS PLAN TABLE1.SCOPEThis construction management plan is written for the construction management of Yanbu petrochemical Complex U&O project plant building steel structure and it is the guiding document in the course of construction of this project.This construction management plan is only valid after being checked and approved.2.BASISContract2.1.1Buying contract for structure steel2.1.2Installment contract for structure steel2.2Drawing2.2.1Approved structure drawing by owner2.2.2Approved fabrication drawing by owner2.3References:2.3.1AWS D 1.1: 20002.3.2GB-50205-20012.3.3GB/T 50326-20062.3.4A01-S022.3.5B02-S012.3.6B02-S022.3.7ASTM2.3.8MANUAL OF HSE3Project Description3.1Introduction of Project3.1.1Project Name:YanBu petrochemical complex u&o project plantbuilding steel structure3.1.2 Project site: Yanbu of Saudi3.1.3 Project contents: light steel structure shop, grid3.1.4 Main structure: door type steel frame with part of second floor and grid3.1.5 Construction area: approximate 20600㎡3.2 Structure Description:3.2.1 Unit maintenance shop: axis:25m×25.6m;area:625㎡;cornice height:6m; roof panel:630㎡;wall panel:450㎡.3.2.2 Chemical warehouse: axis: 49.2m×92.4m;area:4546㎡;cornice height: 7.935; roof panel:4550㎡;wall panel:2200㎡.3.2.3 Central warehouse building(temporary dimension):axis:76.9m×64m; area:4921㎡;with high and low span(cornice of high span is 14.95m and cornice of low span is 7.95m); roof panel:4800㎡;wall panel:3100㎡3.2.4 Central maintenance building: projective axis of first floor:103m×64m; projective axis of second floor:103m×28.9m; area:6592㎡+2977㎡; cornice of primary shop:9.7m; cornice of secondary shop:7.95m; roof panel:6700㎡; wall panel:3100㎡3.2.5Grid 1(temporary): elevation of canopy top:9.2m; 42m×41m 1722㎡; top panel is polycarbonate lighting panel3.2.6 Grid 2(temporary): elevation of canopy top:8.2m; 26m×43m 1118㎡; top panel is polycarbonate lighting panel3.2.7 EPS sandwich panel will be used for the cladding of this project (temporary)4. Environment of field construction4.1 Field environment requirements:Jobsite is located in petrochemical industrial area of Yanbu economic and technical development district, residential area and office are separated from jobsite. Residential area is equipped with electricity and water facility, dormitory, office and canteen, jobsite is well equipped with safety facility.4.2 Requirements for construction condition:Base bolts of Unit maintenance shop, central maintenance shop and chemical warehouse will be completed before Feb.10,2007, backfilling is completed. Concrete cure will satisfy the strength requirement of erection and movement of 25T crane and 8T lift truck in jobsite. There should besufficient space to pile up steel elements.5. Construction period and field construction5.1 The overall construction period of this project is 60 days. If every shop is constructed separately, the construction period should be counted as 45 days for each shop.5.2 The construction order of each shop is: base retest→erection of steel column→erection of bea m→forming of frame uni t→installment of brace, purlin, wall beam and tie ro d→adjustment of structur e→acceptance of structur e→applying of claddin g→installment and adjustment of flashing plat e→complete acceptance6. Base Retest6.1 Base retest must be conveyed before the erection of structure.6.2 Base retest should be done after receiving of measuring data of base bolts.6.3 Base construction accuracy should the following requirements:6.3.1 Allowable tolerance for base top elevation is±3mm.6.3.2 Base flatness should be less than L/1000.6.3.3 Central deflection of anchor bolt should be less than 5mm.6.3.4 Central deflection of pre-punched hole is less than 10mm.7. Steel elements entering jobsite and Acceptance7.1 The first batch of steel elements are elements of chemical warehouse,central maintenance shop and unit maintenance shop; The second batch of steel elements are elements of central warehouse and grid. The erection and construction should conform to this plan.7.2 The steel elements of this project will be transported by sea so the long and big elements will be bulk and short and small members will be transported in container.7.3 Check the packing list when the steel members are transported to jobsite and check the number of members according to packing list and goods sending list. If there are any discrepancies in the number, check with goods-delivery company.7.4 convey visual inspection, if there are any problems such as paint dropping or deflection caused by transportation, report it in time.7.5 Apply for inspection for jobsite entering materials and provide relative test data and report. Full-scale acceptance should be done for configuration and dimension of steel members and submit handling plan for unqualified items.8 Erection plan of door type structure steel8.1 Requirements for jobsite equipmentsLift truck and truck crane will be used in this project. For central maintenance building, two 25T cranes will be used in the same time to promote efficiency and one 25T crane for the erection of other threebuilding. In erection, there should be good driving condition for crane and lift truck to move on jobsite. Assure that the ground is flat and has been tamped and the base is up to design strength before erection.8.2 Preparation before erection:Before erection, make sure that positioning axis, base axis and elevation, anchor bolt diameter and length have been checked and transfer acceptance has been conveyed. Check the number, diameter, bolt hole position and diameter and place of connection plate; mark erection central line of column top and bottom end and horizontal elevation in 1m high position of column; check all mark of steel column. Construction will be started only after it conforms to the requirements of design drawing and any rectifications such as incorrect horizontal position and incorrectly setting connection bolts should be submitted in written documents to owner and be approved by owner.8.3 Auxiliary preparation before the erection of steel column:Before the erection of steel column, rig, rope and falling-resistance machine should be fixed on the column and wind bracing rope should also be prepared according to specification.8.4 The erection and rectification of steel column:8.4.1 Use crane to erect the steel columns after they have been put in the right position. In order to promote the efficiency, in transportation, uselifting truck to put the steel column in the right position according to its axis. In laying the column, try to let the bundling point, central point of base column and foundation in the same circle.8.4.2 In erection, hoist should slowly erect the bundled column away from ground about 20cm and then stop; check the stability of cable and hoist, open rotating brake then put down column about 40-100mm from ground; aim at the base line, direct the hoist then insert the column into anchored bolt for temporary fixation. Hoist can only be removed from cable after the column has been preliminarily rectified and the verticality tolerance is within 20mm. The verticality of steel column should be checked by theodolites and rectify it if there is any tolerance. In rectification, notice whether there is any separation between the bottom of column and elevation backing plate and avoid any horizontal tolerance caused in the course of rectification.18.4.3 Two theodolites will be installed on the longitudinal and transverseaxis to vertically rectify and measure the column. First, aim at vertical flange of column base plate or central line then gradually aim above to the top of column, the deviation of central line from sight indicates that the column is not vertical and make it vertical by adjusting the tie rope or bracing as well as knocking the column. In the actual practice, rectification often happens after rows of columns have been erected and at that time install the two theodolites on one side of longitudinal and transverse axis, the deviation from central line should not be large than 2m. Re-rectification of steel column should be done in erecting roof frame or vertical steel elements.8.5 The erection and rectification of steel beam8.5.1 The main testing item in this project is verticality and it can be tested by hung ball. After test, the qualified roof frame should be fixed with high strength bolts.8.5.2 Moveable platform should be used in the connection of bolts and the installment of close joint plate to ensure the safety of working in high place.8.5.3 Moveable platform should be used to fixation and final tweak of high strength bolts.8.6 Installment of purlin and bracing system8.6.1 Purlin and bracing system should be helpful for the erection of steelstructure and cross operation should be taken.8.6.2 Pulley will be used in the installment of purlins and the installment requirements should be: bolts’hole should be aimed corrected and tweaking and fastening extent should be reasonable. According to the specification of purlin and using location, it should be put in the relative position of roof and wall by manual work using pulley and then be installed.8.6.3 Bracing should be installed in time according to relative requirements and installment location should be correct and up to design requirements; ensure the overall rigidity and stability of steel structure. 8.6.4 Wind bracing rope shall be installed to ensure the stability of frame and avoid instability caused by strong wind.8.7 Structure rectificationAfter erection, rectification of verticality and flatness between steel members should be conveyed in time. In order to ensure the installment position correctness of continuous steel members, column and horizontal bracing should be installed in time and these bracing also need rectification. When adjusting column bracing, lock one end and loose another and in the time column has been rectify to vertical, lock the bracing to a tense condition but avoid cause any damage to elements by locking too tensely. Adjust horizontal bracing using ridge point as thecentral point from eaves to roof ridge system and rectify roof beam to keep roof vertical. Anyway, lock the oblique bracing only after all elements have been rectified to vertical position.8.8 Set life lineSet life line in time after frame has been completed, for detail safety plan, see EHS.8.9 Installment of corner bracingOrdinary beam corner bracing should be connected from ground to roof beam and fixed to roof purlin with bolts after erection.8.10 The installment of tie rod and barAdjust the flatness of purlin in the time of installing tie rod and bar of wall and roof and rectify the deflection of purlin caused by transportation or piling up.8.11 The connection of high strength bolts8.11.1 Fastening order of joint bolt: fastening order in the same plane: fasten from middle to two ends.8.11.2 Construction order of high strength boltsUnless required by design, Inserting direction of high strength bolts should be based on the convenience of construction. Bolts around the frame should be fixed into the interior side of steel structure; bolts inside frame should be fixed according to specification. Fixing direction of highstrength bolts in the same joint should be uniform.8.12. Construction of high strength bolts8.12.1 The high strength bolts are large hex head high strength bolts and “torque method” will be taken as the construction method.8.12.2 Use torque wrench in the construction of high strength bolts and control torque strictly in the course of construction.8.12.3 Initial tweak and final tweak will be used in the tweaking of high strength bolts and the torque of initial tweak is 0.5 time of construction torque.8.12.4 The test for torque coefficient of high strength bolts should be taken before the construction of high strength bolts.8.12.5 Torque inspection of final tweak should be done within 48h after 1h later of the completion of final tweak of high strength heavy hex head bolts set.8.12.6 The calculation equation of torque value: construction torque value=torque coefficien t×standard construction pretension valu e×bolt nominal diameter8.12.7 Record in the course of tweaking9. Erection plan for grid structure9.1 construction preparation9.1.1 Scaffold shall be used in the erection of grid and the advantage of itis convenient and fast, the platform of scaffold can also be used for the materials piling platform.9.1.2 In order to control and rectify the coordinate position, four controlling point should be set for each grid.9.1.3 Tamp the area around temporary platform of spliced grid to ensure the stability of scaffold.9.1.4Scoring and positioning: position the scaffold according to dimension and upper and low chord of grid.9.2 Erection order of grid:Preparatio n→scoring and positionin g→organization of scaffol d→install upper chord, fastening central chord and rectify small unit gri d→initial installment of grid complete d→rectificatio n→weld pedesta l→acceptance9.3 Splicing order of grid9.3.1 The method of splicing triangular support is: first, find the ball and rod in this position and then one installing worker find out the ball hole position, butt connect two central rod separately, tweak sleeve bolt with wrench or pipe tongs, then another worker install upper chord, the third worker aim bolt to relative ball hole, fasten the upper chord with wrench or pipe tongs. In the course of fastening, central chord installing worker shake the rod member to tweak the rod member to ball as tight as possible.After above procedure is completed, install another upper chord.9.3.2 The working method of pushing triangular support in the course of grid construction: dispatch two workers on the upper joint of chord and another two workers on the lower joint of chord; these four workers find out ball holes correspondent with member bar and quickly fasten the bolt between member bar and ball. The four workers should work at the same time and cooperate dexterously and last two works install lower chord bar and ball.10. Field welding10.1 Groove weld shall be used for the field welding of this project and for the welding connection type, refer the construction drawing.10.2 For welding material and workmanship, refer general explanation of design drawing.10.3 weld rods should be baked before welding and keep in insulate bucket in the time of field welding.10.4 Check the mark of the steel members before welding and begin to weld after making sure there are no mistakes.10.5 Strictly control the quality of welds in the course of welding and operate in strict accordance with welding workmanship.10.6 Clear away slag after the completion of each weld; grind the welds and stamp the number of welder.10.7 Nondestructive flaw detection test will be used for welds.10.8 Weld the base plate after the rectification of steel structure.10.9 The welding of platform beam will be carried out only after it has been rectified and the final tweak of high strength bolt has been completed.10.10 For the welding of backing plate of crane beam, weld the surrounding area of backing plate after the crane beam has been erected and rectified. Safety measure such as “hung basket” shall be used in the process of welding.11. Field patching up11.1 Field patching up should be done if there is any damage to paint caused by delivery, loading, unloading, cutting or electric welding and patching up must conform to SES A01-02.11.2Sample areas of each finish shall be provided before proceeding with remainder of field painting.11.3 Sample areas shall be retained as project standard for the remainder of work.11.4 Areas used as project standard shall be one (1) square meter minimum surface area.11.5 Surrounding area of damaging place shall be grinded to smooth transitional layer to ensure the smooth transition of patching-up place.11.6 Evaluate the damaged paint film and make out a patching-up plan before the start of patching up.11.6 .1 Finish damaged(primer in good condition): grind with abrasive paper or grinding sheet and clean surface with thinner, patch up intermediate paint to design thickness then patch up finish paint.11.6.2 Primer damaged (without rust): grind with abrasive paper or grinding sheet, patch up primer to design film thickness then patch up intermediate and finish paint.11.6.3 Damage to plate and the place of burning out paint film rusted: grind to St 3 grade with grinding sheet, patch up the primer to design dry film thickness and then patch up intermediate and finish.12 Acceptance of intermediate structure12.1 Inform owner to check and accept the steel structure in written form after the erection and rectification has finished and the final tweak of high strength bolt has been completed.12.2 Provide relative structure acceptance data in the time of check and acceptance.13. Installment plan of cladding system13.1 Jobsite-entering inspectionCladding panel shall be transported in container and by sea. Check the cladding panel seriously according to goods-sending list and packing listafter it enters into the jobsite, the damage and deflection condition of plate is the focus of inspection.13.2 General requirements for installment13.2.1 The installment of cladding panel should take account of normal wind direction and lap connection of rib plate shall be against normal wind direction.13.2.2 Fix self drilling screw vertically to cladding panel and purlin, aim the center on purlin and make sure that the screws are drilled in one line.13.2.3 Check the flatness of two ends of plate after installing every 5-6 plates and rectify in time if tolerance occurs.13.3 Piling and delivery of material13.3.1 Handling: Professional shoulder pole and erecting band shall be used for the erection and delivery of bundled sandwich plate. Erection style such as triangle type formed by lifting hook and sandwich is forbidden. Begin to erect only after finding erecting balance point and erect one bundle after another, put on ground lightly. During erection, put plate on roof in the installment direction and avoid unnecessary turning of panel. For the handling of single panel, according to the length and weight of panel, use 3-5 workers to handle to avoid the deflection of panel. During handing, don’t drag panel on other panels or objects to avoid causing damage to finish.13.3.2 Field storage: Sleeper, foamed plastics or other materials shall be used to underlay panels and don’t put sandwich panels on the ground. 13.3.3 Piling up place of sandwich panels should be far away from other naked material to avoid the rusting materials of those steel materials float on the color panels and contaminate it.13.3.4 When sandwich panels are piled up, heavy objects are forbidden to put on panels and stomping on panels is forbidden to avoid any damage to finish. Roof panels should be put nearby the roof frame and piling up other materials on the installed panel is forbidden.13.3.5 Lighting panel should be placed separately and steel plate or other objects are forbidden to put on it.13.4 Installment of roof and wall panel13.4.1 Check the verticality and spacing of roof purlin and wall beam in accordance with dimensions on drawing.13.4.2 Be familiar with drawing and typeset according to the requirements of drawing.13.4.3 Self drilling screw shall be used in the fixation of roof and wall panels.13.5 Other notes13.5.1 Only nailless and flat soft shoes are permitted to wear when walking on the roof panel.13.5.2 The fixing order of screw should be in the same direction of panel installment and fixing screw in the opposite direction is forbidden.13.5.3 Field cutting or treating of plate ends is advised to be done on the ground and it is forbidden to cut adjacent to other plates. In the condition of operation on the roof, cutting on other roof panels is forbidden. When cutting, the face of panel should face to ground and clear away the swarf on the panel and neighboring panel in time. Electric scissor may be used to clear away the rusted swarf caused by cutting.13.5.4 Clear away all swarf and sundries on the roof and wall everyday after the finish of daily installment.13.5.5 The panel that has been erected to roof and waited to be installed next day needs to be bundled.13.6 The installment of flashing plateColorful plate shall be used for the flashing plate of roof and wall and it shall be fixed to the roof and wall panels with self drilling screw and rivet. For the specification, spacing and number of flashing plate and self drilling screw, see construction drawing.13.7 The installment of gutterDuring the installment of gutter hung outside of colorful plate, care should be taken for the connection between gutter and roof panel, waterproof treatment of lap joint between gutters.14. Completion acceptance14.1 Completion acceptance may be submitted in written form after the application of cladding panel has finished and local defects have been patched up.14.2 Completion acceptance of steel structure is the symbol of finish of steel structure.14.3 Whole steel structure data need to be submitted in the time of completion acceptance.15. Construction overall arrangement15.1 For Construction management institution, see following diagram15.2 The arrangement of field personnel:One project manager of jobsite project department, five managerial staff, 30 installment workers dispatched from China for field installment. If there is any need, Employ workers from local labor market at the busy time of construction.15.3 The responsibility of project managerial staff15.3.1 Project manager15.3.1.1 Responsible for organizing and directing the application of this project and responsible for owner.15.3.1.2 Responsible for establishing project management department; manage production factor needed for this project, such as talent, capital, material and equipment.15.3.1.3 Responsible for handling exterior relationship relative for this project.15.3.1.4 Responsible for the cooperation relationship between contractor and subcontract.15.3.1.5 Overall responsible for quality, safety, construction period, cost and civilized construction of project.15.3.2 Constructor and quality inspector15.3.2.1 responsible for field management and cooperation in the course of construction and handle other things under the leading of project manager.15.3.2.2 Responsible for labor management, civilized construction, equipment maintenance and the management of operator.15.3.2.3 Responsible for quality management and control in the course of construction.15.3.3 Technician who are also in charge of data:15.3.3.1 Responsible for the coordination and handling of technology in the whole course of construction.15.3.3.2 Responsible for compiling of construction plan, construction technology management data and statistics plan.15.3.3.3 Responsible for quality inspection and test data of all sub-items in the process of construction; collection and settling of all quality records data; collection, settling and package of construction completion data.15.3.4 People in charge of materials15.3.4.1 Responsible for buying and counting of steel members, the check of members’ mark and the management of piling up area.15.3.4.2 Responsible for summing up, counting and check of installmentproject volume.15.3.4.3 Responsible for the usage and management of jobsite materials and installment equipments.15.3.5 People in charge of safety15.3.5.1 Responsible for the safety inspection and control in the whole course of construction, check the reliability and effectiveness of safety technology measurements.15.3.5.2 Responsible for checking the hidden danger of jobsite and compiling and carrying out rectification measures.15.3.5.3 Supervise and control safety measures such as operation in high place, edge operation, power cut, providing electricity and sparking caused in operation and ensure the construction safety of this project. 16. Quality assurance system16.1 For the quality assurance system, see following diagram16.2 Quality responsibility of managerial staff:16.2.1 Quality responsibility of project manager:As the most senior leader of project, project manager should be responsible for the whole project and on the base of guaranteeing quality, project manager balance the completion situation of progress plan and economic effectiveness and urge all other managerial staff to bear the “quality first” idea in mind and ensure the implement of quality plan. 16.2.2 Quality responsibility of people in charge of project technology AS the executor of quality control and management of this project, the people who in charge of project technology should be responsible for the whole quality work of this project, such as compiling of quality plan, settlement and implement of quality assurance system, organize and convene technology analysis meeting, carrying out of quality responsibility of all managerial staff and he is also the quality assurance manager.16.2.3 Quality responsibility of constructorAs the project leader who is responsible for production, constructors should take construction quality of project as the primary task and should take account of the impact that construction difficulties bring to construction quality in arranging construction tasks. In normal production inspection, the constructor should carry out inspection according to planand guideline book and organize internal acceptance such as self check, mutual check, shifting check according to specification.16.2.4 Quality responsibility of quality inspector:As the main staff carrying out overall inspection of project construction quality, quality inspectors are required to have relative rich experience and should be hard working, they should have independent handling ability for the discovered quality problems and have relative foreseeing ability in the course of quality inspection. They should provide correct and whole check data, send rectification informing list for discovered hidden danger in time and supervise rectification to let it conform to relative quality requirements.16.2.5 Quality responsibility of construction foreman:As the jobsite director, construction foreman must himself bear in mind the idea “quality first” and carry out quality inspection for construction groups at any time and point out irregular operation. Supervise rectification if the quality can’t be up to grade. Construction foreman is the main compiler of all sub-item construction plan and operation guiding book and conduct the technology communication of every sub-item. 17. Quality assurance measures17.1 quality aim17.1.1 contract performing rate: 100℅。

CONSTRUCTION PLANNINGConstruction planning is a basic and challenging activity in the management and execution of project construction. It involves the choice of technology, the definition of work tasks, the estimation of resources and duration required for a single task, and the identification and definition of the interweaving of different work tasks. A good construction planning design is the basis for the budget and work plan. Even if the plan is not written or the plan is formally recorded in other ways, developing a construction planning design is a key task in construction management. In addition to these technical aspects of construction planning design, it may also be necessary to make organizational decisions about the relationships between project participants, and even the relationships between organizations to be included in the project. For example, the extent to which subcontractors are used on a project is often determined during the design of the construction planning.Developing a construction planning design is a very challenging task. The planner starts with the result (that is, the design of the facility) and must synthesize the steps needed toarrive at the result. The basic aspects of construction planning design include generating the required activities, analyzing the meaning of these activities, and choosing among various other ways of performing the activities. Construction planners are also faced with the normative issue of choosing the best of many alternatives. The planner must imagine the final facility described in the plan and specifications.When designing the construction planning, it usually focuses on cost control or schedule control, as shown in the figure below.Some projects are mainly divided into expense categories with associated costs.In these cases, the construction planning design is cost or expense oriented. In the expenditure category, a distinction is made between costs incurred directly in the execution of anactivity and costs indirectly used to complete the project. For example, borrowing costs for project financing and indirect projects are often considered as indirect costs. For other projects, it is important to schedule work activities over time and to emphasize this during the planning process. In this case, planners will ensure that proper priority is maintained between activities and that effective resources are effectively scheduled. Traditional schedulers emphasize maintaining task priorities (causing a critical path scheduler) or efficient use of resources over time (causing a job shop scheduler). Finally, most complex projects need to consider both cost and schedule, so planning, monitoring, and record keeping must consider both. In these cases, the integration of schedule and budget information is a major issue.施工组织设计施工组织设计是项目施工的管理和执行中的一项基本且具有挑战性的活动。

外文文献翻译(含:英文原文及中文译文)文献出处:Nuclear Instruments & Methods in Physics Research, 2015, 3(2):281-294.英文原文Importance of construction organization designG BaeckerAbstractDuring the construction process of a construction project, the advantages and disadvantages of the construction organization scheme not only directly affect the quality of the project, but also have an important impact on the duration and the safety of the personnel during the construction process. The construction organization is an important technical and economic document for the project construction and guidance of project construction. Can adjust the contradiction of personnel, machinery, raw materials, environment, process, equq)ment9 civil construction, installation, management, production, etc. in construction. It is necessary to supervise and control the construction organization design so as to ensure the project quality with high quality, low cost, and lessEnergy consumption is conpleted.Key words: Project Management, Construction Organization, Program ImportanceConstruction organization design is the conception and specific arrangement of the entire construction process of the engineering construction project. It is the core and soul of the construction organization management work. Its purpose is to make the project faster, better quality, and more efficient. Make the whole project get relatively optimal results in the construction.1.The reason for the importance of the design of construction organizationThe construction project and its construction have three characteristics: fixed and fluidity, diversity and individuality, large body and long construction period. Therefore, the construction of each construction project must be carried out. This is because: The production of other general industrial products has its own fixed, long-term factory. The construction of the building is fluid, and it is impossible to establish such a factory. It is only when each construction project is constructed that a corresponding, temporary construction site preparation like thenature of the plant is employed・The unique features of construction and the characteristics of construction mobility determine that each construction project must select the appropriate equipment and labor organization. The selection of construction methods, the formulation of construction technology plans, and the organization of workforces and implements are collectively referred to as construction work capacity allocation. The characteristics of the construction cycle have determined that the supply of various labors, equq)ment and many materials and materials technologies will take a long time・ This will result in the construction and design of materials and technologies that are compatible with the overall construction schedule・From this we can see that construction organization design is very important in project management.2.The importance of construction organization designAs a product, building products play an extremely important role in project management throughout the construction process. The construction organization of the engineering construction project has a close relationship with its engineering cost. The basic contents of the construction organization design include:project overview and construction condition analysis, construction plan, construction process, construction schedule plan, and general plan of construction. There are also economic analysis and construction preparation work plans. Among them, the determination of the construction plan and construction process is more important. For examp le, the selection of construction machinery, the selection of horizontal transportation methods, the construction methods of the earthwork, the construction methods of the main structure and the selection of the construction technology all directly affect the project budget. The price changes・ Under the premise of guaranteeing project quality and satisfying the owners use requirements and construction period requirements, optimizing the construction plan and construction process is an important measure and method to control investment and reduce construction project cost2.1The construction organization plan affects the quality of the project to a great extent. Therefore, a reasonable project organization plan is not only the basis for ensuring the successful completion of the project, but also the basis for project safety. The construction organization design is an important part of theconstruction engineering design documents・ It is the main basis for prq)aring the project investment budget and the main reference for the preparation of bidding documents・ Therefore, careful construction of the construction organization will have a very important role in determining the project cost and reducing the investment in the project, which will help control the construction cost.2.2The construction organization plan is an important means for scientific management of construction activities. It has the dual role of strategic deployment and tactical arrangements・ It embodies the requirements for realizing the basic construction plan and design, provides the contents of the construction preparation work in each phase, and coordinates the mutual relations between each construction work area, each construction work type, and each voluntary work in the construction process. The construction organization plan must be able to determine the basic combination of various factors of production based on the characteristics and requirements of the engineering product and the current and possible winning construction conditions. It is impossible to carry out any production without effectively solvingthe problem・・3.Index calculation and analysis of construction organizationdesignAt present, what indicators should be established in the construction organization design are not uniform and the calculation method is not standardized・ As it is a yardstick for evaluating the overall effect of construction organization design and evaluation of implementation status, it is also the basis for examining the level and effect of production, operation and management of the unit (project department) that undertakes construction. We should pay attention to the following suggestions ・3. 1 indicator system. The index system should be set up to reflect the level reached by the construction organization's design goals and provide convenience for evaluation, assessment, and implementation.3. 2 Index calculations・(1) Construction preparation period. From the start of site preparation to the full time of formal project start-up. (2) Unit project duration. The construction period arranged by the unit construction schedule・(3) Labor。

Abstract:This paper aims to explore the importance of construction organization and management in civil engineering projects. It emphasizes the significance of efficient planning and execution of constructionactivities to ensure the successful completion of projects within the allocated time, budget, and quality standards. The paper reviews various aspects of construction organization and management, including project planning, resource allocation, scheduling, and quality control. Furthermore, it discusses the challenges faced by construction organizations and proposes strategies to overcome them. This study is expected to provide insights for professionals involved in civil engineering projects to enhance their organizational and management skills.Introduction:Civil engineering projects are complex and involve multiple stakeholders, including contractors, designers, suppliers, and clients. Effective construction organization and management are crucial for the successful completion of these projects. This paper discusses the importance of construction organization and management in civil engineering projects, highlighting the key aspects and challenges associated with it.1. Project Planning:Project planning is the first step in construction organization and management. It involves defining project objectives, scope, and deliverables. This stage includes identifying project stakeholders, establishing project milestones, and allocating resources. Proper planning ensures that the project is executed efficiently and within the allocated budget.2. Resource Allocation:Resource allocation is an essential aspect of construction organization and management. It involves assigning resources, such as labor, materials, and equipment, to various tasks and activities. Efficient resource allocation ensures that the project is completed on time andwithin budget. This requires coordination among various stakeholders and continuous monitoring of resource usage.3. Scheduling:Scheduling is a critical aspect of construction organization and management. It involves developing a timeline for project activities and identifying dependencies between them. Effective scheduling helps in minimizing delays and ensuring the timely completion of the project. It also helps in managing project risks and identifying potential bottlenecks.4. Quality Control:Quality control is essential in construction projects to ensure that the final product meets the required standards. Construction organizations must implement quality management systems and establish processes to monitor and control the quality of work performed. Regular inspections, testing, and audits are necessary to ensure that the project is delivered with high-quality standards.5. Challenges in Construction Organization and Management:Construction organizations often face various challenges in managing projects effectively. Some of the common challenges include:- Coordination among various stakeholders- Managing project risks- Adapting to changing project requirements- Ensuring compliance with regulations and standards- Budget constraints6. Strategies to Overcome Challenges:To overcome the challenges in construction organization and management, construction organizations can adopt the following strategies:- Implementing effective communication channels among stakeholders- Developing robust risk management plans- Adopting flexible project management techniques- Ensuring compliance with regulations and standards- Investing in training and development for project managers and staff Conclusion:Construction organization and management play a vital role in the successful completion of civil engineering projects. Efficient planning, resource allocation, scheduling, and quality control are essential for achieving project objectives. This paper has discussed the importance of construction organization and management, highlighting key aspects and challenges. By adopting effective strategies, construction organizations can overcome challenges and deliver high-quality projects within the allocated time and budget.。

嘉兴学院本科毕业设计(论文)外文翻译题目:君山二期工程施工组织设计一、外文原文:1. Design project management1.1 Choosing the planning practiceChoosing a suitable planning practice is extremely important. Introducing a pre-qualification process provides essential insights about efficiency, specialist knowledge and quality: three to five applicants receive preliminary design documents and the building programme. Then interviews are held, reference evidence examined and the practices visited on the spot. But the key features are planning quality, knowledge of materials, degree of detail, and CAD and office equipment. The ability to coordinate building and technical planning is particularly relevant.1.2 Design and authorization planningCoordination and control of the planning process and content are particularly important in this planning phase. In no circumstances should planning in China be leftto the design institute alone. Regular planning and coordination meetings examine the planning process in its entirety to ensure that guidelines and standards are being met. It is important to coordinate routing and to check for collision points.1.3 Working plansRegular coordination, control and support are also required at the final planning stage. Coordinating building and technical workers within the planning team is often a weak point as well. Important details and technical specifications have to be demanded. It is not usual in China to present details on a scale of 1:20 to 1:5, and these planning features have to be insisted on; a great deal of convincing argument will be needed.1.4 Invitation to tender and tender awardsTender documents drawn up to Chinese standards are less detailed than comparable Western tender documents. Considerable importance should be attached to detailed working drawings. Drawings should be ranked before tender documents. It is not permissible to insist on specific product makes. Materials must be described neutrally in terms of product. This means that the building firm is able to use inferior materials without the client's agreement. This often results in buildings with serious deficiencies in quality and execution. To avoid these negative consequences, architects try to go beyond the standard guidelines to prevent the use of inferior quality materials. Also, Chinese planning and industrial standards are antiquated and do not yet meet national or international standards.As a rule, five to ten firms (general contractors or firms offering individual services) are invited to tender. Often foreign firms with branches in China are invited as well. Bids from such firms come out well above those of their Chinese competitors.After the bids have been evaluated, negotiations are conducted with the most reasonable bidders. Awards are decided on the basis of reference projects, quality of execution and evaluations of special proposals. Because the subsoil is so poor, the use of deep foundations on alluvial land is widespread. To gain time, the underground engineering work can be put out to earlier tender and award to specialist building firms.1.5 Building and completion phaseThe legislation requires using local site supervision and a quantity surveyor (see Chapter B 2.2). Site supervision requirements are not the same as the standard German site supervision requirements laid down in HOAI, Phase 8. Chinese site supervision practices offer the following service pattern under the headings "quality monitoring" and "safety management":- examining the working plans- quality control for building materials- quality control for building plant and equipment- building site safety- checking current building progress- examining the qualifications of the building site personnel- demanding and examining inventory documentsOnly building sites that also convey an impression of an orderly approach can produce quality and work effectively. This includes cleanliness and safety. Chinese building sites need pioneering work in this field. It does not make any sense to compel the contractor to adopt a particular working programme that runs counter to his own ideas. It is in fact advisable to make concessions in order to make best use of the available production and fitting methods. Quality control starts even in the planning phase. In the actual building phase, care should be taken to ensure that the required materials are really used, and that product-specific fitting requirements are met.The contractor can make alternative proposals to the tender standards. These are examined and approved on the basis of specimens and references. It has turned out to be worthwhile to build specimen rooms before the actual building phase starts, to test the guidelines for details and materials and introduce improvements to materials and details in good time. It is essential to check and approve the quality of finish in the form of mock-ups before production begins for facades, roof areas and other critical parts of the building.1.6 DocumentationThe quality control process ends with the correction of faults and the start-up phase. Buildings are officially accepted in China at the point of final acceptance. The quality bureau, the fire prevention department and the environmental health office have to approve in order to ensure successful acceptance. The as-complete plans should be drawn up by the planning practice, as the building firm usually delivers these too late,and in poor quality.1.7 CommunicationIt is a characteristic feature of Chinese building projects that a large number of participants have to work together, under pressure from deadlines and cost factors, on the basis of differing information from various locations. This creates the necessity for a "digital platform" that gives those involved in the project access to up-to-date documents and the ability to communicate with the same aims in mind and to keep up with the work as it needs to be done. But the project management team should have access to central scheduling and work monitoring, including reporting. These systems link those involved in the project, control the workflow, and distribute news, documents and information.2 Planning and building costs2.1 Quantity surveyingChinese quantity surveyors provide the same services as their English model. Quantity surveying is the generic term for cost planning and cost control. Quantity surveying includes tender award and contract management, both of which are part of the cost control process. The quantity surveyor is commissioned by the client directly and assists with planning and controlling project investment. He represents the client's financial interests throughout the entire course of the project. During the realization phase the quantity surveyor evaluates the level of work completed so that part payments and supplementary demands can be fixed, assists in warding off complaints, or evaluates and negotiates with the company over justifiable additional demands. Effective cost control is carried out within the project management framework. All the costings are noted in a cost monitoring system. Cost monitoring is not a passive system. Precise project control means that cost changes can be identified even in the initial phase. Causes and effects of measures affecting costs are conveyed to the project management team at an early stage so that counter-measures can be introduced where necessary.Cost reduction opportunities are largely exhausted by the end of the planning phase.The diagram makes it clear that realization decisions made in the early planning phases crucially influence fixing the cost framework. The importance of control increases when planning is concluded and during the realization phase.Despite the overwhelming volume of investment by Western standards, professional cost and schedule control rarely occurs in China. Moreover, clients who are commercially successful and put a great deal of money into building projects often have no knowledge of how to implement and control planning and building work, and often rely on their experience in other industries. Even though the predominant Chinese enterprise culture is not comparable with the Western world, professional project management will be indispensable in future if building investment is to accomplish its aims.二、外文译文:1.1选择一个切实可行的规划方式选择一个切实可行的规划方式是很重要的。