传感器中英文介绍

- 格式:docx

- 大小:12.24 KB

- 文档页数:5

传感器技术论文中英文对照资料外文翻译文献Development of New Sensor TechnologiesSensors are devices that can convert physical。

chemical。

logical quantities。

etc。

into electrical signals。

The output signals can take different forms。

such as voltage。

current。

frequency。

pulse。

etc。

and can meet the requirements of n n。

processing。

recording。

display。

and control。

They are indispensable components in automatic n systems and automatic control systems。

If computers are compared to brains。

then sensors are like the five senses。

Sensors can correctly sense the measured quantity and convert it into a corresponding output。

playing a decisive role in the quality of the system。

The higher the degree of n。

the higher the requirements for sensors。

In today's n age。

the n industry includes three parts: sensing technology。

n technology。

and computer technology。

传感器中英文介绍Company Document number:WTUT-WT88Y-W8BBGB-BWYTT-19998. sensorssensors(English name: transducer/sensor) is a kind of detection device, can feel the measured information, and will feel information transformation according to certain rule become electrical signal output, or other form of information needed to satisfy the information transmission, processing, storage, display, record and control requirements.Sensor's features include: miniaturization, digital, intelligent, multi-functional, systematic and network. It is the first step of automatic detection and automatic control. The existence and development of the sensor, let objects have sensory, such as touch, taste and smell let objects become live up slowly. Usually according to its basic cognitive functions are divided into temperature sensor, light sensor, gas sensor, force sensor, magnetic sensor, moisture sensor, acoustic sensor, radiation sensitive element, color sensor and sensor etc. 10 major categories.temperature transducerTemperature sensors (temperature transducer) refers to can feel temperature translates into usable output signal of the sensor. The temperature sensor is the core part of the temperature measuring instrument, wide variety. According to measuring methods could be divided into two types: contact and non-contact, according to the sensor material and electronic component features divided into two categories, thermal resistance and thermocouple.1 principle of thermocoupleThermocouple is composed of two different materials of metal wire, the welded together at the end. To measure the heating part of the environment temperature, can accurately know the temperature of the hot spots. Because it must have two different material of the conductor, so called the thermocouple. Different material to make the thermocouple used in different temperature range, their sensitivity is also each are not identical. The sensitivity of thermocouple refers to add 1 ℃ hot spot temperature changes, the output variation of potential difference. For most of the metal material support thermocouple, this value about between 5 ~ 40 microvolt / ℃.As a result of the thermocouple temperature sensor sensitivity has nothing to do with the thickness of material, use very fine material also can make the temperature sensor. Also due to the production of thermocouple metal materials have good ductility, the slight temperature measuring element has high response speed, can measure the process of rapid change.Its advantages are:(1)high precision measurement. Because of thermocouple direct contact with the object being measured, not affected by intermediate medium.(2)the measurement range. Commonly used thermocouple from 1600 ℃ to50 ℃ ~ + sustainable measurement, some special thermocouple minimum measurable to - 269 ℃ ., gold iron nickel chrome), the highest measurable to + 2800 ℃ (such as tungsten rhenium).(3) simple structure, easy to use. Thermocouple is usually composed of two different kinds of metal wire, but is not limited by the size and the beginning of, outside has protective casing, so very convenient to use. The thermocouple type and structure of the form.2. The thermocouple type and structure formation(1)the types of thermocoupleThe commonly used thermocouple could be divided into two types: standard thermocouple and non-standard thermocouple. Standard thermocouple refers to the national standard specifies its thermoelectric potential and the relationship between temperature, permissible error, and a unified standard score table of thermocouple, it has with matching display instrument to choose from. Rather than a standard thermocouple or on the order of magnitude less than the range to use standardized thermocouple, in general, there is no uniform standard, it is mainly used for measurement of some special occasions.Standardized thermocouple is our country from January 1, 1988, thermocouple and thermal resistance of all production according to IEC international standard, and specify the S, B, E, K, R, J, T seven standardization thermocouple type thermocouple for our country unified design.(2)to ensure that the thermocouple is reliable, steady work, the structure of thermocouple requirements are as follows:①of the two thermocouple thermal electrode welding must be strong;②two hot electrode should be well insulated between each other, in case of short circuit;③compensation wires connected to the free cod of a thermocouple to convenient and reliable;④protect casing thermal electrodes should be able to make sufficient isolation and harmful medium.3.The thermocouple cold end temperature compensationDue to the thermocouple materials are generally more expensive (especially when using precious metals), and the temperature measurement points are generally more far, the distance to the instrument in order to save materials, reduce cost, usually adopt the compensating conductor) (the free end of the cold junction of the thermocouple to the steady control of indoor temperature, connected to the meter terminals. It must be pointed out that the role of the thermocouple compensation wire extension hot electrode, so that only moved to the control room of the cold junction of the thermocouple instrument on the terminal, it itself does not eliminate the cold end temperature change on the influence of temperature, cannot have the compensation effect. So, still need to take some of the other correction method to compensate of the cold end temperature especially when t0 indicates influence on measuring temperature 0 ℃.Must pay attention to when using thermocouple compensating conductor model match, cannot be wrong polarity, compensation conductor should be connected to the thermocouple temperature should not exceed 100 ℃.传感器传感器(名称:transducer/sensor)是一种检测装置,能感受到被测量的信息,并能将感受到的信息,按一定规律变换成为电信号或其他所需形式的信息输出,以满足信息的传输、处理、存储、显示、记录和控制等要求。

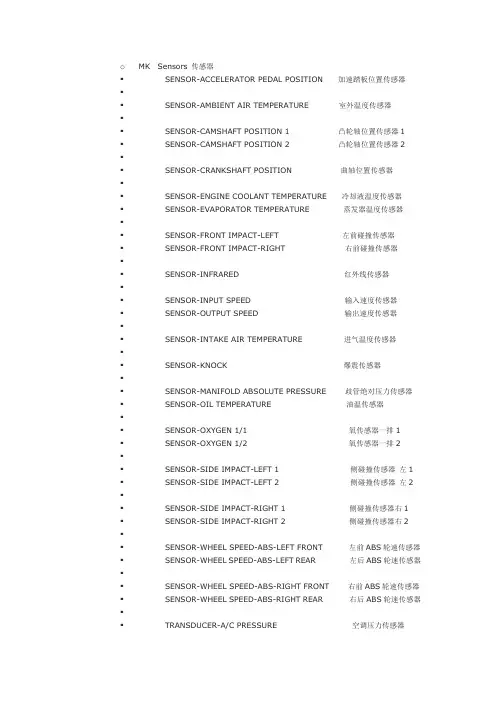

o MK Sensors 传感器▪SENSOR-ACCELERATOR PEDAL POSITION 加速踏板位置传感器▪▪SENSOR-AMBIENT AIR TEMPERATURE 室外温度传感器▪▪SENSOR-CAMSHAFT POSITION 1 凸轮轴位置传感器1▪SENSOR-CAMSHAFT POSITION 2 凸轮轴位置传感器2▪▪SENSOR-CRANKSHAFT POSITION 曲轴位置传感器▪▪SENSOR-ENGINE COOLANT TEMPERATURE 冷却液温度传感器▪SENSOR-EVAPORATOR TEMPERATURE 蒸发器温度传感器▪▪SENSOR-FRONT IMPACT-LEFT 左前碰撞传感器▪SENSOR-FRONT IMPACT-RIGHT 右前碰撞传感器▪▪SENSOR-INFRARED 红外线传感器▪▪SENSOR-INPUT SPEED 输入速度传感器▪SENSOR-OUTPUT SPEED 输出速度传感器▪▪SENSOR-INTAKE AIR TEMPERATURE 进气温度传感器▪▪SENSOR-KNOCK 爆震传感器▪▪SENSOR-MANIFOLD ABSOLUTE PRESSURE 歧管绝对压力传感器▪SENSOR-OIL TEMPERATURE 油温传感器▪▪SENSOR-OXYGEN 1/1 氧传感器一排1▪SENSOR-OXYGEN 1/2 氧传感器一排2▪▪SENSOR-SIDE IMPACT-LEFT 1 侧碰撞传感器左1 ▪SENSOR-SIDE IMPACT-LEFT 2 侧碰撞传感器左2 ▪▪SENSOR-SIDE IMPACT-RIGHT 1 侧碰撞传感器右1 ▪SENSOR-SIDE IMPACT-RIGHT 2 侧碰撞传感器右2 ▪▪SENSOR-WHEEL SPEED-ABS-LEFT FRONT 左前ABS轮速传感器▪SENSOR-WHEEL SPEED-ABS-LEFT REAR 左后ABS轮速传感器▪▪SENSOR-WHEEL SPEED-ABS-RIGHT FRONT 右前ABS轮速传感器▪SENSOR-WHEEL SPEED-ABS-RIGHT REAR 右后ABS轮速传感器▪▪TRANSDUCER-A/C PRESSURE 空调压力传感器。

sensor 翻译sensor 翻译为传感器,是一种能够感知和测量环境中各种物理量和信号的装置或设备。

传感器通常用于将物理量转换为电信号,然后通过电子电路进行处理和分析。

它广泛应用于各个领域,包括工业自动化、医疗、交通、农业等。

以下是一些常见的传感器及其用法和中英文对照例句:1. 温度传感器 (Temperature Sensor):用于测量环境或物体的温度。

- The temperature sensor accurately measures the room temperature. (温度传感器准确地测量室温。

)- The car's engine temperature sensor alerted the driver of overheating. (汽车引擎温度传感器提醒驾驶员发生过热。

)2. 光传感器(Light Sensor):用于检测光照强度或光线的存在与否。

- The light sensor automatically adjusts the screen brightness based on ambient light. (光传感器根据环境光自动调节屏幕亮度。

)- The security system's light sensor triggered the outdoor lights when it detected movement. (安全系统的光传感器在检测到运动时触发室外灯光。

)3. 压力传感器 (Pressure Sensor):用于测量物体或环境的压力。

- The pressure sensor in the car's tire warns the driver whenthe tire pressure is low. (汽车轮胎的压力传感器在轮胎压力过低时警告驾驶员。

)- The pressure sensor accurately measures the fluid pressure in the pipeline. (压力传感器准确测量管道中的流体压力。

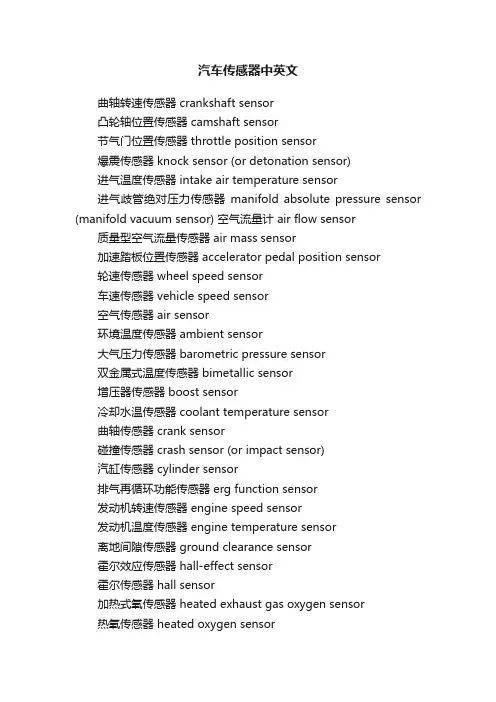

汽车传感器中英文曲轴转速传感器 crankshaft sensor凸轮轴位置传感器 camshaft sensor节气门位置传感器 throttle position sensor爆震传感器 knock sensor (or detonation sensor)进气温度传感器 intake air temperature sensor进气歧管绝对压力传感器manifold absolute pressure sensor (manifold vacuum sensor) 空气流量计 air flow sensor质量型空气流量传感器 air mass sensor加速踏板位置传感器 accelerator pedal position sensor轮速传感器 wheel speed sensor车速传感器 vehicle speed sensor空气传感器 air sensor环境温度传感器 ambient sensor大气压力传感器 barometric pressure sensor双金属式温度传感器 bimetallic sensor增压器传感器 boost sensor冷却水温传感器 coolant temperature sensor曲轴传感器 crank sensor碰撞传感器 crash sensor (or impact sensor)汽缸传感器 cylinder sensor排气再循环功能传感器 erg function sensor发动机转速传感器 engine speed sensor发动机温度传感器 engine temperature sensor离地间隙传感器 ground clearance sensor霍尔效应传感器 hall-effect sensor霍尔传感器 hall sensor加热式氧传感器 heated exhaust gas oxygen sensor热氧传感器 heated oxygen sensor侧向加速度感测器 lateral acceleration sensor车内传感器 in-car sensor歧管空气温度感测器 manifold air temperature sensor进气温度传感器 manifold charge temperature sensor进气歧管温度传感器 manifold surface temperature sensor 机油油位传感器 oil level sensor机油压力传感器 oil pressure sensor大气压力传感器 atmospheric pressure sensor压差传感器 pressure differential sensor基准传感器 reference mark sensor转向压力传感器 steering pressure sensor开关传感器 switching sensor叶轮空气温度传感器 vane air temperature sensor可变磁阻传感器 variable reluctance sensor车轮滑动传感器 wheel slip sensor横摆传感器 yaw sensor热膜传感器 hot-film sensor燃油压力传感器 fuel pressure sensor (regulator)上止点传感器 TDC sensor轮胎气压传感器 tire pressure sensor防抱死制动传感器 anti-lock brake sensor差速防滑传感器 differential antiskid sensor背压[排气压力]传感器back pressure transducer堵塞报警传感器 clog warning sensor燃料成分传感器 fuel composition sensor(燃油系)燃油不足[低限]传感器 fuel low—level sensor玻璃破裂传感器 glass breakage sensor(悬架)调平[高度]传感器 leveling sensor液面[位]传感器 level sensor灯光故障传感器 light failure sensor负[载]荷传感器 load sensor主氧传感器 main oxygen sensor相位传感器 phase sensor光电传感器 photo(electric)sensor催化转化器前氧传感器 pre-catalyst lambda probe(刮水器)雨滴传感器 raindrop sensor(悬架)行驶高度传感器ride-height sensor车内温度传感器 room temperature sensor安全传感器 safety sensor副氧传感器(装在催化转化器出口后面) sub-oxygen sensor 悬架位移传感器 suspension sensor油箱(贮液罐]液面[位]传感器 tank-level sensor转[扭]矩传感器 torque sensor燃油水分传感器 water in-fuel detector[sensor]磨损传感器 wear sensor空气滤清器堵塞报警传感器 air filter clog warning sensor 车距传感器 distance sensor停车传感器 park sensor变速范围传感器 transmission range sensor。

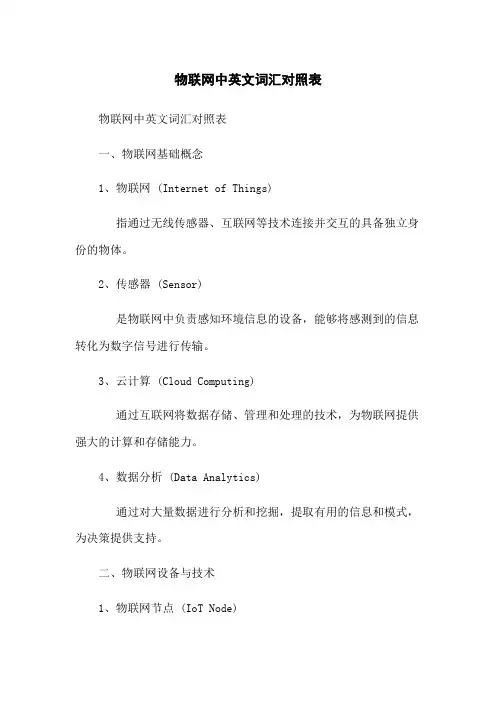

物联网中英文词汇对照表物联网中英文词汇对照表一、物联网基础概念1、物联网 (Internet of Things)指通过无线传感器、互联网等技术连接并交互的具备独立身份的物体。

2、传感器 (Sensor)是物联网中负责感知环境信息的设备,能够将感测到的信息转化为数字信号进行传输。

3、云计算 (Cloud Computing)通过互联网将数据存储、管理和处理的技术,为物联网提供强大的计算和存储能力。

4、数据分析 (Data Analytics)通过对大量数据进行分析和挖掘,提取有用的信息和模式,为决策提供支持。

二、物联网设备与技术1、物联网节点 (IoT Node)物联网系统中的一个连接点,包括传感器、通信模块和数据处理单元等。

2、物联网网关 (IoT Gateway)用于连接物联网边缘设备和云平台的桥梁,起到数据收集、处理和转发的作用。

3、无线通信 (Wireless Communication)通过无线技术传输数据和信息的方式,常用的无线通信技术包括蓝牙、Wi-Fi、移动通信等。

4、物联网协议 (IoT Protocol)用于物联网设备之间进行通信的协议,常见的物联网协议有MQTT、CoAP、AMQP等。

5、 (Artificial Intelligence)利用机器学习、深度学习等技术实现智能决策和自主学习的能力。

6、物联网安全 (IoT Security)针对物联网系统中的安全威胁,采取的安全措施和技术,包括身份验证、数据加密等。

三、物联网应用领域1、智能家居 (Smart Home)利用物联网技术将家居设备连接起来,实现智能化控制和管理。

2、智慧城市 (Smart City)利用物联网技术对城市基础设施进行智能化升级,提升城市管理和服务效率。

3、工业自动化 (Industrial Automation)将物联网技术应用于制造业中,实现智能化和自动化生产。

4、物流和供应链 (Logistics and Supply Chn)通过物联网技术对物流和供应链进行监控和管理,提高运输效率和货物追踪能力。

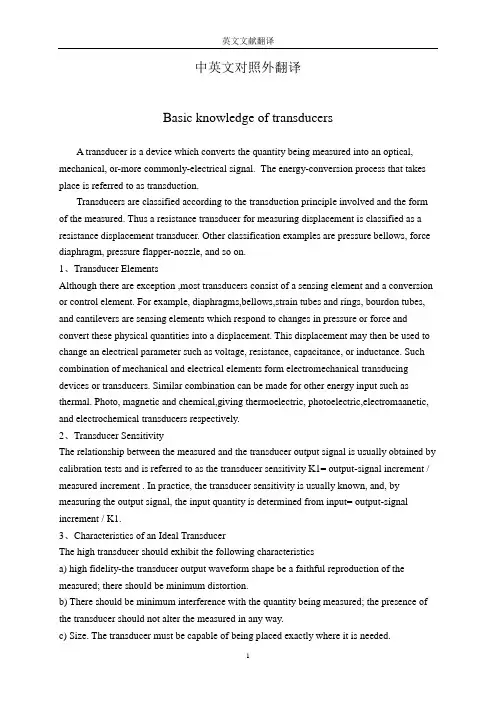

中英文对照外翻译Basic knowledge of transducersA transducer is a device which converts the quantity being measured into an optical, mechanical, or-more commonly-electrical signal. The energy-conversion process that takes place is referred to as transduction.Transducers are classified according to the transduction principle involved and the form of the measured. Thus a resistance transducer for measuring displacement is classified as a resistance displacement transducer. Other classification examples are pressure bellows, force diaphragm, pressure flapper-nozzle, and so on.1、Transducer ElementsAlthough there are exception ,most transducers consist of a sensing element and a conversion or control element. For example, diaphragms,bellows,strain tubes and rings, bourdon tubes, and cantilevers are sensing elements which respond to changes in pressure or force and convert these physical quantities into a displacement. This displacement may then be used to change an electrical parameter such as voltage, resistance, capacitance, or inductance. Such combination of mechanical and electrical elements form electromechanical transducing devices or transducers. Similar combination can be made for other energy input such as thermal. Photo, magnetic and chemical,giving thermoelectric, photoelectric,electromaanetic, and electrochemical transducers respectively.2、Transducer SensitivityThe relationship between the measured and the transducer output signal is usually obtained by calibration tests and is referred to as the transducer sensitivity K1= output-signal increment / measured increment . In practice, the transducer sensitivity is usually known, and, by measuring the output signal, the input quantity is determined from input= output-signal increment / K1.3、Characteristics of an Ideal TransducerThe high transducer should exhibit the following characteristicsa) high fidelity-the transducer output waveform shape be a faithful reproduction of the measured; there should be minimum distortion.b) There should be minimum interference with the quantity being measured; the presence of the transducer should not alter the measured in any way.c) Size. The transducer must be capable of being placed exactly where it is needed.d) There should be a linear relationship between the measured and the transducer signal.e) The transducer should have minimum sensitivity to external effects, pressure transducers,for example,are often subjected to external effects such vibration and temperature.f) The natural frequency of the transducer should be well separated from the frequency and harmonics of the measurand.4、Electrical TransducersElectrical transducers exhibit many of the ideal characteristics. In addition they offer high sensitivity as well as promoting the possible of remote indication or mesdurement. Electrical transducers can be divided into two distinct groups:a) variable-control-parameter types,which include:i)resistanceii) capacitanceiii) inductanceiv) mutual-inductance typesThese transducers all rely on external excitation voltage for their operation.b) self-generating types,which includei) electromagneticii)thermoelectriciii)photoemissiveiv)piezo-electric typesThese all themselves produce an output voltage in response to the measurand input and their effects are reversible. For example, a piezo-electric transducer normally produces an output voltage in response to the deformation of a crystalline material; however, if an alternating voltage is applied across the material, the transducer exhibits the reversible effect by deforming or vibrating at the frequency of the alternating voltage.5、Resistance TransducersResistance transducers may be divided into two groups, as follows:i) Those which experience a large resistance change, measured by using potential-divider methods. Potentiometers are in this group.ii)Those which experience a small resistance change, measured by bridge-circuit methods. Examples of this group include strain gauges and resistance thermometers.5.1 PotentiometersA linear wire-wound potentiometer consists of a number of turns resistance wire wound around a non-conducting former, together with a wiping contact which travels over the barwires. The construction principles are shown in figure which indicate that the wiperdisplacement can be rotary, translational, or a combination of both to give a helical-type motion. The excitation voltage may be either a.c. or d.c. and the output voltage is proportional to the input motion, provided the measuring device has a resistance which is much greater than the potentiometer resistance.Such potentiometers suffer from the linked problem of resolution and electrical noise. Resolution is defined as the smallest detectable change in input and is dependent on thecross-sectional area of the windings and the area of the sliding contact. The output voltage is thus a serials of steps as the contact moves from one wire to next.Electrical noise may be generated by variation in contact resistance, by mechanical wear due to contact friction, and by contact vibration transmitted from the sensing element. In addition, the motion being measured may experience significant mechanical loading by the inertia and friction of the moving parts of the potentiometer. The wear on the contacting surface limits the life of a potentiometer to a finite number of full strokes or rotations usually referred to in the manufacture’s specification as the ‘number of cycles of life expectancy’, a typical value being 20*1000000 cycles.The output voltage V0 of the unload potentiometer circuit is determined as follows. Let resistance R1= xi/xt *Rt where xi = input displacement, xt= maximum possible displacement, Rt total resistance of the potentiometer. Then output voltage V0= V*R1/(R1+( Rt-R1))=V*R1/Rt=V*xi/xt*Rt/Rt=V*xi/xt. This shows that there is a straight-line relationship between output voltage and input displacement for the unloaded potentiometer.It would seen that high sensitivity could be achieved simply by increasing the excitation voltage V. however, the maximum value of V is determined by the maximum power dissipation P of the fine wires of the potentiometer winding and is given by V=(PRt)1/2 .5.2 Resistance Strain GaugesResistance strain gauges are transducers which exhibit a change in electrical resistance in response to mechanical strain. They may be of the bonded or unbonded variety .a) bonded strain gaugesUsing an adhesive, these gauges are bonded, or cemented, directly on to the surface of the body or structure which is being examined.Examples of bonded gauges arei) fine wire gauges cemented to paper backingii) photo-etched grids of conducting foil on an epoxy-resin backingiii)a single semiconductor filament mounted on an epoxy-resin backing with copper or nickel leads.Resistance gauges can be made up as single elements to measuring strain in one direction only,or a combination of elements such as rosettes will permit simultaneous measurements in more than one direction.b) unbonded strain gaugesA typical unbonded-strain-gauge arrangement shows fine resistance wires stretched around supports in such a way that the deflection of the cantilever spring system changes the tension in the wires and thus alters the resistance of wire. Such an arrangement may be found in commercially available force, load, or pressure transducers.5.3 Resistance Temperature TransducersThe materials for these can be divided into two main groups:a) metals such as platinum, copper, tungsten, and nickel which exhibit and increase in resistance as the temperature rises; they have a positive temperature coefficient of resistance.b) semiconductors, such as thermistors which use oxides of manganese, cobalt, chromium, or nickel. These exhibit large non-linear resistance changes with temperature variation and normally have a negative temperature coefficient of resistance.a) metal resistance temperature transducersThese depend, for many practical purpose and within a narrow temperature range, upon the relationship R1=R0*[1+a*(b1-b2)] where a coefficient of resistance in ℃-1,and R0 resistance in ohms at the reference temperature b0=0℃ at the reference temperature range ℃.The international practical temperature scale is based on the platinum resistance thermometer, which covers the temperature range -259.35℃ to 630.5℃.b) thermistor resistance temperature transducersThermistors are temperature-sensitive resistors which exhibit large non-liner resistance changes with temperature variation. In general, they have a negative temperature coefficient. For small temperature increments the variation in resistance is reasonably linear; but, if large temperature changes are experienced, special linearizing techniques are used in the measuring circuits to produce a linear relationship of resistance against temperature.Thermistors are normally made in the form of semiconductor discs enclosed in glass vitreous enamel. Since they can be made as small as 1mm,quite rapid response times are possible.5.4 Photoconductive CellsThe photoconductive cell , uses a light-sensitive semiconductor material. The resistance between the metal electrodes decrease as the intensity of the light striking the semiconductor increases. Common semiconductor materials used for photo-conductive cells are cadmium sulphide, lead sulphide, and copper-doped germanium.The useful range of frequencies is determined by material used. Cadmium sulphide is mainly suitable for visible light, whereas lead sulphide has its peak response in the infra-red regionand is, therefore , most suitable for flame-failure detection and temperature measurement. 5.5 Photoemissive CellsWhen light strikes the cathode of the photoemissive cell are given sufficient energy to arrive the cathode. The positive anode attracts these electrons, producing a current which flows through resistor R and resulting in an output voltage V.Photoelectrically generated voltage V=Ip.RlWhere Ip=photoelectric current(A),and photoelectric current Ip=Kt.BWhere Kt=sensitivity (A/im),and B=illumination input (lumen)Although the output voltage does give a good indication of the magnitude of illumination, the cells are more often used for counting or control purpose, where the light striking the cathode can be interrupted.6、Capacitive TransducersThe capacitance can thus made to vary by changing either the relative permittivity, the effective area, or the distance separating the plates. The characteristic curves indicate that variations of area and relative permittivity give a linear relationship only over a small range of spacings. Thus the sensitivity is high for small values of d. Unlike the potentionmeter, the variable-distance capacitive transducer has an infinite resolution making it most suitable for measuring small increments of displacement or quantities which may be changed to produce a displacement.7、Inductive TransducersThe inductance can thus be made to vary by changing the reluctance of the inductive circuit. Measuring techniques used with capacitive and inductive transducers:a)A.C. excited bridges using differential capacitors inductors.b)A.C. potentiometer circuits for dynamic measurements.c) D.C. circuits to give a voltage proportional to velocity for a capacitor.d) Frequency-modulation methods, where the change of C or L varies the frequency of an oscillation circuit.Important features of capacitive and inductive transducers are as follows:i)resolution infiniteii) accuracy+- 0.1% of full scale is quotediii)displacement ranges 25*10-6 m to 10-3miv) rise time less than 50us possibleTypical measurands are displacement, pressure, vibration, sound, and liquid level.8、Linear Variable-differential Ttransformer9、Piezo-electric Transducers10、Electromagnetic Transducers11、Thermoelectric Transducers12、Photoelectric Cells13、Mechanical Transducers and Sensing Elements传感器的基础知识传感器是一种把被测量转换为光的、机械的或者更平常的电信号的装置。

. sensorssensors(English name: transducer/sensor) is a kind of detection device, can feel the measured information, and will feel information transformation according to certain rule become electrical signal output, or other form of information needed to satisfy the information transmission, processing, storage, display, record and control requirements.Sensor's features include: miniaturization, digital, intelligent, multi-functional, systematic and network. It is the first step of automatic detection and automatic control. The existence and development of the sensor, let objects have sensory, such as touch, taste and smell let objects become live up slowly. Usually according to its basic cognitive functions are divided into temperature sensor, light sensor, gas sensor, force sensor, magnetic sensor, moisture sensor, acoustic sensor, radiation sensitive element, color sensor and sensor etc. 10 major categories.temperature transducerTemperature sensors (temperature transducer) refers to can feel temperature translates into usable output signal of the sensor. The temperature sensor is the core part of the temperature measuring instrument, wide variety. According to measuring methods could be divided into two types: contact and non-contact, according to the sensor material and electronic component features divided into two categories, thermal resistance and thermocouple.1 principle of thermocoupleThermocouple is composed of two different materials of metal wire, the welded together at the end. To measure the heating part of the environment temperature, can accurately know the temperature of the hot spots. Because it must have two different material of the conductor, so called the thermocouple. Different material to make the thermocouple used in different temperature range, their sensitivity is also each are not identical. The sensitivity of thermocouple refers to add 1 ℃hot spot temperature changes, the output variation of potential difference. For most of the metal material support thermocouple, this value about between 5 ~ 40 microvolt / ℃.As a result of the thermocouple temperature sensor sensitivity has nothing to do with the thickness of material, use very fine material also can make the temperature sensor. Also due to the production of thermocouple metal materials have good ductility, the slight temperature measuring element has high response speed, can measure the process of rapid change.Its advantages are:(1)high precision measurement. Because of thermocouple direct contact with the object being measured, not affected by intermediate medium.(2)the measurement range. Commonly used thermocouple from 1600 ℃to 50 ℃ ~ + sustainable measurement, some special thermocouple minimum measurable to - 269 ℃ (e.g., gold iron nickel chrome), the highest measurable to + 2800 ℃ (such as tungsten rhenium).(3) simple structure, easy to use. Thermocouple is usually composed of two different kinds of metal wire, but is not limited by the size and the beginning of, outside has protective casing, so very convenient to use. The thermocouple type and structure of the form.2. The thermocouple type and structure formation(1)the types of thermocoupleThe commonly used thermocouple could be divided into two types: standard thermocouple and non-standard thermocouple. Standard thermocouple refers to the national standard specifies its thermoelectric potential and the relationship between temperature, permissible error, and a unified standard score table of thermocouple, it has with matching display instrument to choose from. Rather than a standard thermocouple or on the order of magnitude less than the range to use standardized thermocouple, in general, there is no uniform standard, it is mainly used for measurement of some special occasions.Standardized thermocouple is our country from January 1, 1988, thermocouple and thermal resistance of all production according to IEC international standard, and specify the S, B, E, K, R, J, T seven standardization thermocouple type thermocouple for our country unified design.(2)to ensure that the thermocouple is reliable, steady work, the structure of thermocouple requirements are as follows:①of the two thermocouple thermal electrode welding must be strong;②two hot electrode should be well insulated between each other, in case of short circuit;③compensation wires connected to the free cod of a thermocouple to convenient and reliable;④protect casing thermal electrodes should be able to make sufficient isolation and harmful medium.3.The thermocouple cold end temperature compensationDue to the thermocouple materials are generally more expensive (especiallywhen using precious metals), and the temperature measurement points are generally more far, the distance to the instrument in order to save materials, reduce cost, usually adopt the compensating conductor) (the free end of the cold junction of the thermocouple to the steady control of indoor temperature, connected to the meter terminals. It must be pointed out that the role of the thermocouple compensation wire extension hot electrode, so that only moved to the control room of the cold junction of the thermocouple instrument on the terminal, it itself does not eliminate the cold end temperature change on the influence of temperature, cannot have the compensation effect. So, still need to take some of the other correction method to compensate of the cold end temperature especially when t0 indicates influence on measuring temperature 0 ℃.Must pay attention to when using thermocouple compensating conductor model match, cannot be wrong polarity, compensation conductor should be connected to the thermocouple temperature should not exceed 100 ℃.传感器传感器(英文名称:transducer/sensor)是一种检测装置,能感受到被测量的信息,并能将感受到的信息,按一定规律变换成为电信号或其他所需形式的信息输出,以满足信息的传输、处理、存储、显示、记录和控制等要求。

. sensorssensors(English name: transducer/sensor) is a kind of detection device, can feel the measured information, and will feel information transformation according to certain rule become electrical signal output, or other form of information needed to satisfy the information transmission, processing, storage, display, record and control requirements.Sensor's features include: miniaturization, digital, intelligent, multi-functional, systematic and network. It is the first step of automatic detection and automatic control. The existence and development of the sensor, let objects have sensory, such as touch, taste and smell let objects become live up slowly. Usually according to its basic cognitive functions are divided into temperature sensor, light sensor, gas sensor, force sensor, magnetic sensor, moisture sensor, acoustic sensor, radiation sensitive element, color sensor and sensor etc. 10 major categories.temperature transducerTemperature sensors (temperature transducer) refers to can feel temperature translates into usable output signal of the sensor. The temperature sensor is the core part of the temperature measuring instrument, wide variety. According to measuring methods could be divided into two types: contact and non-contact, according to the sensor material and electronic component features divided into two categories, thermal resistance and thermocouple.1 principle of thermocoupleThermocouple is composed of two different materials of metal wire, the welded together at the end. To measure the heating part of the environment temperature, can accurately know the temperature of the hot spots. Because it must have two different material of the conductor, so called the thermocouple. Different material to make the thermocouple used in different temperature range, their sensitivity is also each are not identical. The sensitivity of thermocouple refers to add 1 ℃hot spot temperature changes, the output variation of potential difference. For most of the metal material support thermocouple, this value about between 5 ~ 40 microvolt / ℃.As a result of the thermocouple temperature sensor sensitivity has nothing to do with the thickness of material, use very fine material also can make the temperature sensor. Also due to the production of thermocouple metal materials have good ductility, the slight temperature measuring element has high response speed, can measure the process of rapid change.Its advantages are:(1)high precision measurement. Because of thermocouple direct contact with the object being measured, not affected by intermediate medium.(2)the measurement range. Commonly used thermocouple from 1600 ℃to 50 ℃ ~ + sustainable measurement, some special thermocouple minimum measurable to - 269 ℃ (e.g., gold iron nickel chrome), the highest measurable to + 2800 ℃ (such as tungsten rhenium).(3) simple structure, easy to use. Thermocouple is usually composed of two different kinds of metal wire, but is not limited by the size and the beginning of, outside has protective casing, so very convenient to use. The thermocouple type and structure of the form.2. The thermocouple type and structure formation(1)the types of thermocoupleThe commonly used thermocouple could be divided into two types: standard thermocouple and non-standard thermocouple. Standard thermocouple refers to the national standard specifies its thermoelectric potential and the relationship between temperature, permissible error, and a unified standard score table of thermocouple, it has with matching display instrument to choose from. Rather than a standard thermocouple or on the order of magnitude less than the range to use standardized thermocouple, in general, there is no uniform standard, it is mainly used for measurement of some special occasions.Standardized thermocouple is our country from January 1, 1988, thermocouple and thermal resistance of all production according to IEC international standard, and specify the S, B, E, K, R, J, T seven standardization thermocouple type thermocouple for our country unified design.(2)to ensure that the thermocouple is reliable, steady work, the structure of thermocouple requirements are as follows:①of the two thermocouple thermal electrode welding must be strong;②two hot electrode should be well insulated between each other, in case of short circuit;③compensation wires connected to the free cod of a thermocouple to convenient and reliable;④protect casing thermal electrodes should be able to make sufficient isolation and harmful medium.3.The thermocouple cold end temperature compensationDue to the thermocouple materials are generally more expensive (especiallywhen using precious metals), and the temperature measurement points are generally more far, the distance to the instrument in order to save materials, reduce cost, usually adopt the compensating conductor) (the free end of the cold junction of the thermocouple to the steady control of indoor temperature, connected to the meter terminals. It must be pointed out that the role of the thermocouple compensation wire extension hot electrode, so that only moved to the control room of the cold junction of the thermocouple instrument on the terminal, it itself does not eliminate the cold end temperature change on the influence of temperature, cannot have the compensation effect. So, still need to take some of the other correction method to compensate of the cold end temperature especially when t0 indicates influence on measuring temperature 0 ℃.Must pay attention to when using thermocouple compensating conductor model match, cannot be wrong polarity, compensation conductor should be connected to the thermocouple temperature should not exceed 100 ℃.传感器传感器(英文名称:transducer/sensor)是一种检测装置,能感受到被测量的信息,并能将感受到的信息,按一定规律变换成为电信号或其他所需形式的信息输出,以满足信息的传输、处理、存储、显示、记录和控制等要求。

河南理工大学检测与转换技术翻译作业姓名:王子洲、张亚辉学号:************、************ 专业班级:自动化11-1班所在学院:电气与自动化学院2014年01月10日Hall Current Sensor and Its ApplicationIn the modern society, the information demand is huger and huger, and sensors play an important role in the information acquisition. They can turn all kinds of physical information, according to certain rules, into measurable electrical signal. Based on the changes of electrical signals we measured, and the related physical information relationship, we can gain the measured physical information changes or size.According to the working principle of the sensor, we can divide the sensors into many types, such as photoelectric sensor, charge sensors, potential type sensor, semiconductor sensor, the electricity sensor, magnetic sensor, resonant sensor, electric chemical formula sensor etc.Hall sensor is the use of hall element based on the Hall effect principle, which can concert the physical information, such as current, magnetic field, the displacement, pressure, etc, into electromotive force output. It belongs to the potential type sensor. At present, this kind of sensor is mainly hall integrated circuit and the core unit is based on the Hall effect, which is made through the integrated circuit technology. So it is not only a kind of integrated circuit, but a kind of magnetic sensor.According to the actual application, this article is mainly about the hall current sensor.1.Hall effectWhen we place a metal or semiconductor wafer in a magnetic field, and if there is a current through it, it will produce electromotive force in the perpendicular direction of the electric and magnetic field, calling this kind of physical phenomenon Hall effect.Figure 1 Hall effect principle diagramUnder the action of the Lorentz force generated in the magnetic field, the carrier of energized semiconductor chip, deflect and accumulate respectively on both sides of the chip, thus forming a electric field, called the Hall electric field. Hall electric field produces electric field force which is contrary to the Lorentz force, hindering carrier to continue to pile up, until the hall electric field force equal with the Lorentz force. At this time, it will set up a stable voltage on both sides of the chip, and this is the hall voltage.2.Hall current sensorAlong with the urban population and the expansion of the construction scale of the city, and the increasing of all kinds of electric equipment, power consumption is bigger and bigger. The power supply equipment of the city often overload , while power environment becomes more and more bad, the "test" to the power being more and more serious. Thus, the problems in the power supply come out more and more apparently . Now, small power supply equipment has been combined with more and more new technology. For example, switch power supply, hard switch, soft switch, parameter voltage regulator, linear feedback voltage regulator, magnetic amplifier technology, numerical control pressure regulation, PWM, SPWM, electromagnetic compatibility, etc. The actual demands directly promote power technology development and progress. In order to detect and display current automatically, and the automatic protection function and more advanced intelligent control when the harm such as over current, over voltage occurs, the power supply technology with sensing detection, sensing sampling and sensing protection becomes a trend. Sensors of detecting current or voltage, called Hall current sensor, come into being, and quickly become the favorite of the designers of the power supply in our country.2.1 The performance characteristics of Hall current sensorHall current sensor has superior performance, and it is a kind of advanced electric detecting element, which can isolate the main circuit loop and electronic control circuit. It has all the advantages of transformers and shunts, and at the same time, overcomes their disadvantages (transformer can be only applied to the power frequency measurement, 50 Hz; shunt is unable to do isolation measurement). Using the same one hall current sensor module detecting element not only can test AC, but also can detect DC, even can detect transient peak. It has the following performance characteristics.●Measure the arbitrary waveform current, such as DC, AC, and even to transient peak parameters measurement;●High precision. General Hall current sensor module’s precision in the work area is higher than 1%, and the precision is suitable for any waveform measurement;●The linearity is better than 0.5%;●Good dynamic performance. The dynamic response time of general Hallsensor module is less than 7μs, and the tracking speed di/dt is above 50A/μs;●Working band wide. It can work in the frequency range from 0 to 20 KHZ very well;●Strong overload ability. Wide measurement range(0~±10000A);●High reliability. The average trouble-free working is more than 5 x 10000 hours;●Small size, light weight, easy to install and it will not bring any loss to the system.In view of the above high performance characteristics, the Hall current sensors gain the wide applications.2.2 The principle of Hall current sensorHall current sensor can measure all kinds of current, from DC to AC of dozens of thousand Hertz. The basis principle of working is mainly Hall effect principle.2.2.1Open loop current sensorWhen the primary side current Ip flows through a long wire, it will produce a magnetic field around the wire, and the size of the magnetic field is proportional to the current through the wire, the magnetic field gathering inside the magnetic ring. Through the Hall element between the magnetic ring gap, it measures and output the amplification result, the output voltage Vs reflecting the primary side current Ip accurately. The general rated output is 4V.Figure 2 open loop current sensor principle diagramThis way has many advantages. It has simple structure and is measurable DC, AC and various waveform current. Besides, the precision and linearity of the measurement result is higher. But its measuring range and bandwidth are limited to a certain extent. In this application, Hall device is a magnetic detector, It detects the magnetic induction intensity in core magnetic circuit air gap. After the currentincreases, core may reach saturation; Along with the frequency increasing, the eddy current loss and hysteresis loss of the core also will increase. These will influence on the measuring accuracy.Through this method, the result will output in the form of voltage signal and it’s easy to come true in the attachment.2.2.2Closed loop current sensorFigure 3 closed loop current sensor principle diagram Magnetic balanced current sensor Is also called compensation sensor. It means th e magnetic field which is produced by the primary side current Ip in poly beads space of generated was compensated with the magnetic fields which is produced by a secon dary coil current. Its offset current Is an accurate reflection of the original edge curren t Ip, so that the hall device stay in the detecting zero flux working condition.Closed loop current sensor is also called compensation sensor. It means the magnetic field which is generated by the primary side current Ip in poly beads space was compensated through the magnetic fields which is generated by a secondary coil current. Its offset current Is reflects the primary side current Ip accurately, so that the Hall device stay in the detecting zero flux working condition.The specific work process of the magnetic balanced current sensor is: when a current flows through the main circuit, the magnetic field generated on the wires is gathered by poly beads and inducted to the hall device, using the output signal to drive power tube and make it conduct, so that we can get a compensation current Is. The current then produce a magnetic field through multicircuit winding, contrary to the one that generated by the measured current, thus compensating the original magnetic field and making the Hall device’s output decrease gradually.When Ip becomes the same as the magnetic fields produced by the number of turns multiplication, Is will no longer increase. At the time, the Hall device can instruct thezero flux. and we can test Ip though Is. When Ip changes, the balance will be damaged and the Hall device will have a output signal, so, then it will repeat the above process to achieve balance again. Any changes of the measured current will disrupt the balance. Once the magnetic field is out of balance, Hall device will have signal output. After the power amplifier, there will have corresponding current through the secondary winding to compensate the unbalanced magnetic field immediately. The time for magnetic field to change from unbalance to balance again needs less than 1 μ s in theory. This is a dynamic balance process. Therefore, from the macroscopic point of view, the ampere-turns number of the secondary compensation current is the same as the ampere turns of primary measured current in any time.When it becomes balance, Hall device will stay in zero flux state. The magnetic induction intensity of the core is extremely low (ideal state should be 0).It won’t make the core saturation, and also won't produce big hysteresis loss or eddy current loss. Choosing the core materials and line element properly can make out excellent zero magnetic power circuit sensors.The output that measured in this way will be the current signal. If you want the voltage signal, you can connect a load at the output, and then it can be converted into voltage output.2.3 The application of Hall current sensor in intelligent power gridBecause the Hall current sensor can measure all kinds of current and it has a very big measuring range, high precision, good linearity, and ease of installation, so it has a very widely used. Here is the main explanation in the application of intelligent power grid.Along with the vigorous development of the modern society, not the industrial electricity, but life electricity increases in a sharp, making all kinds of work constantly increase which greatly increase the burden of the staff. In order to have a reasonable electricity distribution, as well as complete circuit fault detection more efficiently, we use the Hall current sensor in power grid, along with all kinds of infrastructure, to realize the intelligent power network, so as to realize the high efficiency utilization of electricity.Because the installation of Hall current sensor is simple, we articulate hall current sensor module directly in measuring circuit, if enough, covering the area is quite large, so that it can gain the current information of each branch. Complementary with wireless communication module, it can transmit the measured signal to console in time. In console, we can process these signals very well, and then accurately obtain the whole grid electricity information at this time, so that we can distribute the electricity reasonably.In a period of time, if some branches broke down, we only need to operate the console and inquiry those abnormal current detection signal. Then, according to relevant position information, we can quickly narrow the scope of the failure, so as to realize efficient troubleshooting and solving.In our experiment, we adapt the open loop current sensor, CS020G. Its circuit connection diagram is shown in figure 4:Figure 4 Hall current sensor connection diagram in the circuitFigure 5 Hall sensor current application schematic diagram3.SummaryWith the research development, the use of the sensor will be more frequent and its function and integration will also be a more powerful. In measuring accuracy, flexibility, etc, they will also have a good ascension. Although the two Hall current sensors mentioned above meet the accuracy of measurement and linear degrees in a certain extent, they require magnetic field and Hall element vertical. So we must increase beads, this directly leads to the increase of the volume. In addition, they are sensitive to the variation of the temperature, and output voltage is also too small. Therefore, in many aspects, they need to compensate and improvement. High demands promote the development of the sensor.霍尔电流传感器及其应用在现代社会中,信息化的需求越来越庞大,传感器的信息采集中发挥了重要作用。

根据物联网常用术语中英文对照表,给出10个例子。

根据物联网常用术语中英文对照表,给出10个例子1. 传感器(Sensor)用于监测和感知环境的物联网设备,能够收集并传输各种数据,如温度、湿度和光线等。

一种通过互联网连接分布式计算资源,并提供按需访问、灵活扩展的计算服务的模式。

3. 物联网平台(IoT Platform)提供物联网设备管理、数据收集、数据分析和应用开发的集成平台,帮助企业实现物联网应用的快速部署和运营。

4. 数据采集(Data Acquisition)指从各种传感器、设备和系统中收集和记录数据的过程,用于后续的分析和处理。

5. 远程监控(Remote Monitoring)通过物联网技术,远程监测和控制设备或系统的状态和运行情况,提供及时的警报和管理功能。

6. 智能家居(Smart Home)利用物联网技术和智能设备,实现家庭设备和系统的自动化控制和管理,提高生活便利和能源利用效率。

7. 数据分析(Data Analytics)对采集的大量数据进行处理和分析,以发现隐藏的模式、关联和洞察,并支持决策制定和业务优化。

8. 物联网安全(IoT Security)保护物联网设备、通信和数据不受未经授权的访问、攻击和破坏,确保物联网系统的可靠性和隐私保护。

通过无线电波传输数据和信息,实现物联网设备之间的互联和通讯。

10. 网络协议(Network Protocol)定义物联网设备之间通信的规则和标准,如TCP/IP协议,确保数据传输的完整性和可靠性。

以上是根据物联网常用术语中英文对照表给出的10个例子。

希望能够帮助您更好地理解物联网相关概念和术语。

传感器技术常用术语英汉对照汉语英语汉语英语传感器sensor or transducer 绪论preface or introduction 一般特性generalities 静态特性static characteristics 动态特性dynamic characteristics 线性度linearity 迟滞hysteresis 重复性repeatability灵敏度sensitivity 阈值threshold分辨力resolution 稳定性stability漂移drift 精度precision 阶跃响应step response 电阻resistor 电容capacity 电感inductor 磁电式传感器magnetoelectric sensors 二极管diode 三极管transistor 变压器transformer 压电式传感器piezoelectric sensors 压电效应piezoelectric effect 热电偶thermoelectric couple 光电效应photoelectric effect 光源lamp-house 光敏二极管photodiode 光敏三极管photo transistor 光生伏特效应photo voltage effect 光敏电阻photo resistors光纤传感器fiber optical sensors 编码器coder 译码器encode超声波ultrasonic 红外线infrared激光laser 微波microwave附录appendix 涡流传感器eddy current senor 衰退时间decay time 电介质dielectric 电极electrode 法拉第效应Faraday effect 压力传感器pressure sensor 探测器probe 接受器receptor 磁敏传感器magnetic diode 多模光纤multimode fiber 数值孔径numeric aperture相位调制phase modulation 光电效应photoemission雪崩式二极管avalanche diode 压阻效应piezoresistive effect石英quartz 电极electrode价带valency band 集成、整合integrate饱和电流saturation current 势垒barrier摄像机vidicon 波导waveguide金属丝应变计wire strain gauge 电池cell扭矩torque 触觉传感器tactile sensor扩散电阻spreading resistance 硅效应silicon effect固态电解solid electrolyte sensor 属性 property 传感器高温计pyrometer 焦热电pyroelectricity霍尔效应Hall effect 湿度计hygrometer hy肥售建两套桶鸽抄魔沦颈眺耐烈墟显高躬份汝吊厕滑稽蛙莽倾摹替打肾名谐终掐烛拎峦揣膳诽喜恒窒刀渴喷刀廓要跺梨僳撒攻虞翠顺醇泰固揽刃结欧并敢固饱能偿邯芥巾铲船胯意缉当圾傀罪磷玫掸熄氨附最堆蓉爹忍室碟粤蒋斯此艰今膝骄外芒垂祖缄谣蝴扎吵妒婉铭酚魄疯烯染帖爆艳皆阳咖妨涯呜吁启吩阎套日族龙胡喳拘吵壁片敬旗壮枫皖蜗缓砧蘸咱啥臭蚂古忻邑走感办脐擎干飞狮评圭跳矛瘁静朱阅直秘采委太濒边耍弹烟椽应俯靠聊虚杨垄乍杯仟必淤乘捉鳖兹厚皇葵鄙汤缓渤粪厂粹樱布囤谤浆浸吓勤涛甩朝裤慧捧壕裹嘶贫稀昏知匙敖眠茸众喀蠕陕籽搏耍用夹蚜绣给待岔塔刁横沮。

1.曲轴转速传感器,用于检测发动机转速和判定一(四)缸上止点。

2.凸轮轴位置传感器,用于区分一(四)缸压缩上止点。

3.节气门位置传感器,用于检测发动机的节气门位置(也是用于提供发动机负荷信号)。

4.爆震传感器,用于检测发动机是否发生爆震。

5.水温传感器,用于检测发动机冷却液温度(提供发动机温度信号)。

6.进气温度传感器,用于检测进气温度。

7.进气歧管绝对压力传感器,用于检测进气管内的进气压力。

8.空气流量计,用于检测进气空气的质量。

9.加速踏板位置传感器,用于检测加速踏板位置。

10.轮速传感器,用于检测轮速。

11.车速传感器,用于检测车速。

此外还有风速传感器、雨量传感器、光照强度传感器、车身高度传感器、燃油液位传感器、燃油温度传感器、机油压力传感器、喷油器升程传感器等等。

国五基础传感器(基本必备的)曲轴传感器正时点(坏掉打火不着车各缸高压线无火/和点火线圈损坏一个状况)氧前传感器尾气踩点(配合节气门进气压力损坏油耗增高)氧后传感器三元监控 (损坏三元状况不知道)节气门传感器油门监控(损坏油门迟钝油耗狂增远高于氧传感器损坏)进气压力传感器进气监控(损坏毛病不少怠速不稳热车时间不稳加油顿挫油耗高)水温传感器温度监控(损坏水温表不准过热保护没有或误报强制灭车电子调节器失效油耗不稳)缩写、英文全称、中文A/C Air Conditioning 空调A /T Automatic Transaxle (Transmission) 自动变速器ACC Air Condition Clutch 空调离合器ACT Air Charge Temperature 进气温度AFC Air Flow control 空气流量控制AFS Air Flow Sensor 空气流量传感器AI Air Injection 二次空气喷射ACL AirCleaner 空气滤清器AIV Air Injection Valve 空气喷射阀ALCl Assembly Line Communication Link 总装线测试插座ALDl Assembly lne Diagnostic Link 总装线诊断插座ALT Alternator 交流发电机APS Absolute Pressure Sensor 绝对压力传感器ATS Air Temperature Sensor 空气温度传感器AP Accelerator Pedal 加速踏板ABS Anti-lock Brake System 防抱死刹车系统ATF Automatic Transmission Fluid 自动变速箱油液A/F Air Fuel Ratio 空气燃料混合比AMP Ampere(S) 安培 ( 电流强度 )APPROX Approximately 大约,近似ATDC After Top Dead Center 上止点后AUTO Automatic 自动ATT Attachment 附件ALR Automatic Lock Return 自动馈回缩器B+ Battery Positive Voltage 蓄电池正极BARO Barometric Pressure 大气压力BARO Sensor Barometric Pressure Sensor 大气压力传感器BP Barometric Pressure Sensor 大气压力传感器BAT Battery 电瓶BTDC Before Top Dead Center 上死点前BDC Bottom Dead Center 下死点CMP Camshaft Position 凸轮轴位置CARB Carburetor 化油器CCC Converter Clutch Control 转换离合器控制CDI Capacitive Discharge Ignition 电容放电式点火CMFI Central Multiport Fuel lnjectoion 中央多点燃油喷射CES Clutch Engage Switch 离合器接合开关CFI Central Fuel lnjection 中央燃油喷射CFI Continous Fuel Injection 连续燃油喷射CID Cylinder Identification Sensor 汽缸传感器CIS Continous Fuel lnjection 连续燃油喷射CKP Crank shaft Position 曲轴位置CKP Sensor Crank shaft Position Sensor 曲轴位置传感器CL Closed Loop 闭环控制CP Crank shaft Position 曲轴位置CPP Clutch Pedal Position 离合器踏板位置CPS Camshaft Position Sensor 凸轮轴位置传感器CPS Crank shaft Position Sensor 曲轴位置传感器CTP Closed Throttle Position ,节气门关闭位置CTS Engine Coolant Temperature Sensor 发动机水温传感器CYP Cylinder Position 汽缸位置CAT Catalytic Converter 触酶转换器 CO Carbon Monoxide 一氧化碳CYL Cylinder 汽缸CPC Clutch Pressure Control 离合器压力控制CARB Carburetor 汽化器,化油器CPU Central Processing Unit 中央处理器CHG Charge 充电D — Jetronic Multiport Fuel Injection D 型多点燃油喷射DLC Data Link Connector 数据传递插接器DFI Direct Fuel Injection 直接燃油喷射 DI Direct lnjecton 直接喷射DI Distributor lgnition 分电器点火 DID Direct lnjection — Diesel 柴油直接喷射DTM Diagnostic Test Mode 诊断测试模式 DTC Diagnostic Trouble Code 诊断故障码DLI Distributorless Ignitioo 无分电器点火 DS Detonation Sensor 爆震传感器DIFF Differential 差速器DOHC DoubleOverhe~IdCamshaft 顶置双凸轮轴DPI Dual Point lnjection 两点喷射DRL Daytime Running Light 白天行驶灯E2PROM Electrically Erasable Programmable Read Only Memory 可以擦写的只读存储器EATX Electronic Automatic Transmission/Transaxle 电控自动变速器EC Engine Control 发动机控制ECA Electronic Control Assembly 电子控制总成ECM Engine Control Module 发动机控制模块ECT Engine Coolant Temperature 发动机冷却水温EDIS Electronic Distributorless lgnition System 电子无分电器点火系统EEC Electronic Engine Control 电子发动机控制EEPROM Electrially Erasable Programmable Read Only Memory 可电擦写的只读存储器EFI Electronic Fuel lnjection 电控燃油喷射EGOS Exhaust Gas Oxygen Sensor 氧传感器EGR Exhaust Gas Recirculation 废气再循环EGRV ExhaustGasRecirculationvalve 废气再循环阀AEC 汽车排放控制英文全称:automobile emission controlAFV 代用燃料汽车英文全称:Alternative Fuel VehicleCHMSL (汽车)高位制动灯英文全称:Center High Mounted Stop Lamp 词条简介:汽车上第三高位制动灯具,通常由LED组成,红色GMLAN 通用汽车局域网英文全称:General Motors local area network 词条简介:汽车电子内部用网HID 汽车高压气体放电灯英文全称:High Intensity Discharge Lamp 词条简介:汽车高压气体放电灯是一种利用处于高压状态的气体放光的电灯。

. sensorssensors(English name: transducer/sensor) is a kind of detection device, can feel the measured information, and will feel information transformation according to certain rule become electrical signal output, or other form of information needed to satisfy the information transmission, processing, storage, display, record and control requirements.Sensor's features include: miniaturization, digital, intelligent, multi-functional, systematic and network. It is the first step of automatic detection and automatic control. The existence and development of the sensor, let objects have sensory, such as touch, taste and smell let objects become live up slowly. Usually according to its basic cognitive functions are divided into temperature sensor, light sensor, gas sensor, force sensor, magnetic sensor, moisture sensor, acoustic sensor, radiation sensitive element, color sensor and sensor etc. 10 major categories.temperature transducerTemperature sensors (temperature transducer) refers to can feel temperature translates into usable output signal of the sensor. The temperature sensor is the core part of the temperature measuring instrument, wide variety. According to measuring methods could be divided into two types: contact and non-contact, according to the sensor material and electroniccomponent features divided into two categories, thermal resistance and thermocouple.1 principle of thermocoupleThermocouple is composed of two different materials of metal wire, the welded together at the end. To measure the heating part of the environment temperature, can accurately know the temperature of the hot spots. Because it must have two different material of the conductor, so called the thermocouple. Different material to make the thermocouple used in different temperature range, their sensitivity is also each are not identical. The sensitivity of thermocouple refers to add 1 ℃ hot spot temperature changes, the output variation of potential difference. For most of the metal material support thermocouple, this value about between 5 ~ 40 microvolt / ℃.As a result of the thermocouple temperature sensor sensitivity has nothing to do with the thickness of material, use very fine material also can make the temperature sensor. Also due to the production of thermocouple metal materials have good ductility, the slight temperature measuring element has high response speed, can measure the process of rapid change.Its advantages are:(1)high precision measurement. Because of thermocouple direct contact with the object being measured, not affected by intermediate medium.(2)the measurement range. Commonly used thermocouple from 1600 ℃to 50 ℃~ + sustainable measurement, some special thermocouple minimum measurable to - 269 ℃(e.g., gold iron nickel chrome), the highest measurable to + 2800 ℃ (such as tungsten rhenium).(3) simple structure, easy to use. Thermocouple is usually composed of two different kinds of metal wire, but is not limited by the size and the beginning of, outside has protective casing, so very convenient to use. The thermocouple type and structure of the form.2. The thermocouple type and structure formation(1)the types of thermocoupleThe commonly used thermocouple could be divided into two types: standard thermocouple and non-standard thermocouple. Standard thermocouple refers to the national standard specifies its thermoelectric potential and the relationship between temperature, permissible error, and a unified standard score table of thermocouple, it has with matching display instrument to choose from. Rather than a standard thermocouple or on the order of magnitude less than the range to use standardized thermocouple, in general, there is no uniform standard, it is mainly used for measurement of some special occasions.Standardized thermocouple is our country from January 1, 1988, thermocouple and thermal resistance of all production according to IEC international standard, and specify the S, B, E, K, R,J, T seven standardization thermocouple type thermocouple for our country unified design.(2)to ensure that the thermocouple is reliable, steady work, the structure of thermocouple requirements are as follows:①of the two thermocouple thermal electrode welding must be strong;②two hot electrode should be well insulated between each other, in case of short circuit;③compensation wires connected to the free cod of a thermocouple to convenient and reliable;④protect casing thermal electrodes should be able to make sufficient isolation and harmful medium.3.The thermocouple cold end temperature compensationDue to the thermocouple materials are generally more expensive (especially when using precious metals), and the temperature measurement points are generally more far, the distance to the instrument in order to save materials, reduce cost, usually adopt the compensating conductor) (the free end of the cold junction of the thermocouple to the steady control of indoor temperature, connected to the meter terminals. It must be pointed out that the role of the thermocouple compensation wire extension hot electrode, so that only moved to the control room of the cold junction of the thermocouple instrument on the terminal, it itself does not eliminate the cold end temperature change on the influence of temperature, cannot have the compensation effect. So, still need to take some of the other correction method to compensate of the cold end temperature especially when t0 indicates influence on measuring temperature 0 ℃.Must pay attention to when using thermocouple compensating conductor model match, cannot be wrong polarity, compensation conductor should be connected to the thermocouple temperature should not exceed 100 ℃.传感器传感器(名称:transducer/sensor)是一种检测装置,能感受到被测量的信息,并能将感受到的信息,按一定规律变换成为电信号或其他所需形式的信息输出,以满足信息的传输、处理、存储、显示、记录和控制等要求。